Page 1

Instructions For

Instructions for

TW-287

XL-45, XL-50 and XL-55

XL-45, XL-50 and XL-55

with Dual Regulator

with Dual Regulator

Do not attempt to use or maintain this

unit until you read and understand these

instructions. Do not permit untrained

persons to use or maintain this unit. If

you do not fully understand these

instructions, contact your supplier for

further information.

Page 2

CONTAINER

SAFETY

NOTE:

For detailed

information on the

handling of cryogenic

liquids, refer to the

Compressed Gas

Association

publication: P-12

“Safe Handling of

Cryogenic Liquids”

available from the

Compressed Gas

Association, Inc., 1235

Jefferson Davis

Highway , Arlington,

V A 22202.

Pressure Hazard - The containers covered by this literature may contain pressures up

to 230 psig (16 bar/1586 kPa.) Sudden release of this pressure may cause personal injury

by issuing cold gas or liquid, or by expelling parts during servicing. Do not attempt any

repairs on these containers until all pressure is released, and the contents have been

allowed to vaporize to ensure no pressure build-up can occur.

Extreme Cold – Cover Eyes and Exposed Skin – Accidental contact of the skin or

eyes with any cryogenic liquid or cold issuing gas may cause a freezing injury similar to

frostbite. Protect your eyes and cover your skin when handling the container or transferring liquid, or in any instance where the possibility of contact with liquid, cold pipes, and

cold gas may exist. Safety goggles or a face shield should be worn when withdrawing

liquid or gas. Long-sleeved clothing and gloves that can be easily removed are recommended for skin protection. Cryogenic liquids are extremely cold and will be at temperatures below -300° F (-184°C) under normal atmospheric pressure.

Keep Equipment Well V entilated – Although some of the gases used in these containers are non-toxic and non-flammable, they can cause asphyxiation in a confined area

without adequate ventilation. An atmosphere that does not contain enough oxygen for

breathing will cause dizziness, unconsciousness, or even death. These gases cannot be

detected by the human senses and will be inhaled normally as if they were air. Ensure

there is adequate ventilation where these gases are used and store liquid containers or

only in a well ventilated area.

Replacement Parts Must be “Cleaned for Oxygen Use” – Some materials, especially non-metallic gaskets and seals, can be a combustion hazard if used in oxygen or

nitrous oxide service, although they may be acceptable for use with other cryogenic

liquids. Use only T aylor-Wharton recommended spare p arts, and be certain part s used on

oxygen or nitrous oxide are marked “cleaned for oxygen service.” For information on

cleaning, consult the Compressed Gas Association (CGA) pamphlet G-4.1, “Cleaning for

Oxygen Service” or equivalent industrial cleaning specifications.

GENERAL

INFORMATION

Install Relief Valves in Cryogenic Liquid Lines – When installing piping or fill hose

assembly, make cert ain a suitable safety relief valve is installed in each section of plumbing between shut off valves. Trapped liquefied gas will expand as it warms and may burst

hoses or piping causing damage or personal injury .

The XL-45, XL-50 and XL-55 are vacuum insulated, stainless steel containers designed to

store and transport cryogenic liquid oxygen, nitrogen or argon. Built to DOT 4L standards,

these containers may be used for over the road transportation of cryogenic fluids, as well

as on-site storage and supply in a wide range of applications.

As rugged, long holding time, self-contained gas supply systems, these cylinders are

capable of providing continuous flow rates of up to 350 cfh (9.2 cu.m/h) with a delivery

pressure of approximately 100 psig (6.9 bar/690 kPa).

Page 3

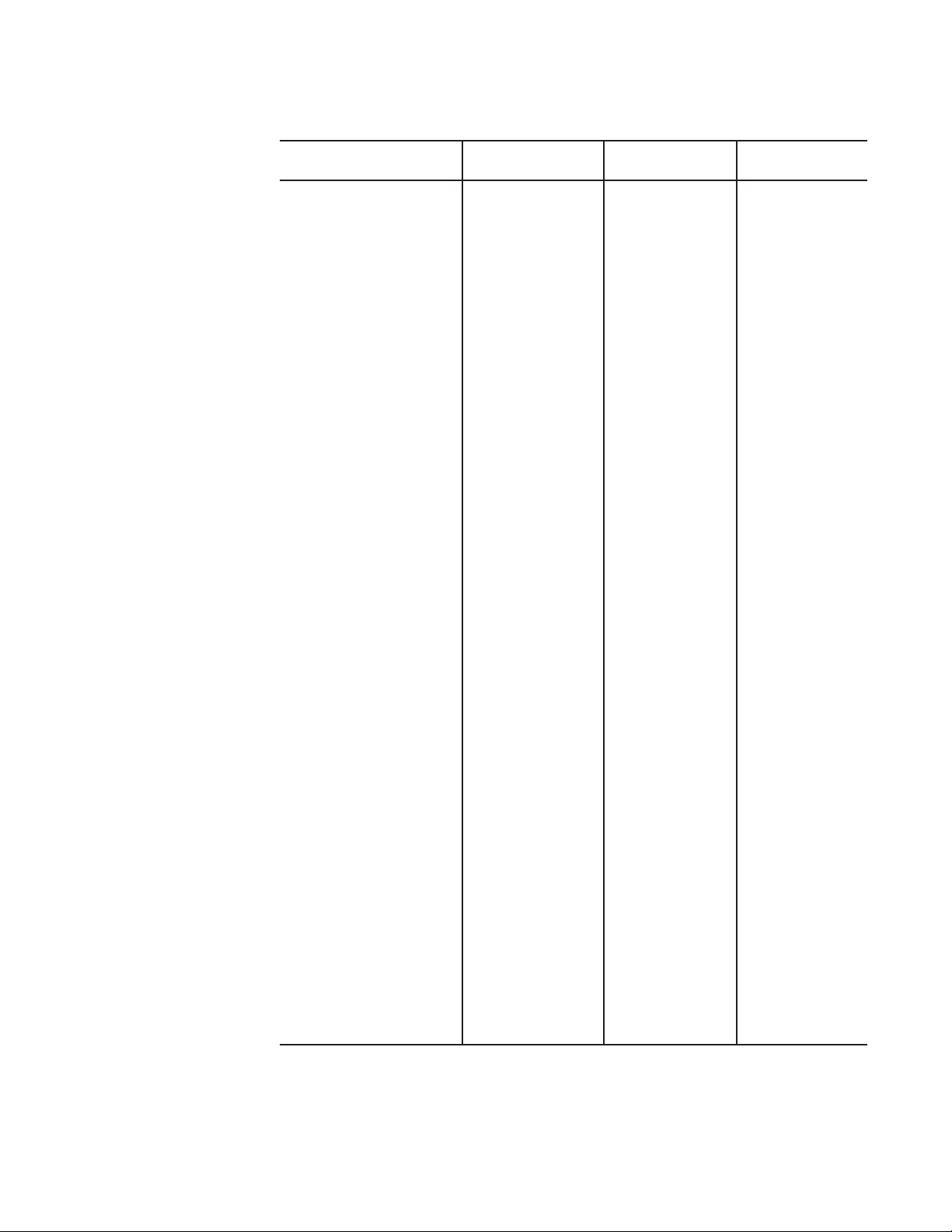

SPECIFICATIONS

XL-45 XL-50 XL-55

Dimensions

Diameter 20 in. (508 mm) 20 in. (508 mm) 20 in. (508 mm)

Height 61 ½ in. (1562 mm) 64 5/8 in. (1641 mm) 69 7/8 in. (1764 mm)

Weight

Empty (Nominal) 255 lb. (1 16 kg) 270 lb. (122 kg) 270 lb. (122 kg)

Capacity, Gross 180 liters 193 liters 210 liters

Capacity, Usable Liquid 169 liters 181 liters 200 liters

Weight on Contents Max.

Based on DOT Rated Service Pressure

Oxygen 388 lb. (176 kg) 416 lb. (189 kg) 454 lb. (206 kg)

Nitrogen 273 lb. (124 kg) 293 lb. (133 kg) 319 lb. (145 kg)

Argon 471 lb. (214 kg) 505 lb. (229 kg) 551 lb. (250 kg)

Normal Evaporation Rate*

(% Capacity per Day)

Oxygen/Argon 1.2% 1.1% 1.1%

Nitrogen 1.9% 1.8% 1.7%

Gas Flow Rate @ NTP (STP**)

Oxygen, Nitrogen, Argon 350 cfh (9.2 cu.m/h) 350 cfh (9.2 cu.m/h) 350 cfh (9.2 cu.m/h)

Relief V alve Setting 230 psig 230 psig 230 psig

(16 bar/1586 kPa) (16 bar/1586 kPa) (16 bar/1586 kPa)

Inner Container Bursting Disc 380 psig 380 psig 380 psig

(26 bar/2620 kPa) (26 bar/2620 kPa) (26 bar/2620 kPa)

Dual Pressure Building/

Economizer Regulator***

Pressure Building Setting 125 psig 125 psig 125 psig

(8.6 bar/862 kPa) (8.6 bar/862 kPa) (8.6 bar/862 kPa)

Economizer Setting 145 psig 145 psig 145 psig

(10 bar/1000 kPa) (10 bar/1000 kPa) (10 bar/1000 kPa)

Design Specifications

TC 4LM 4LM 4LM

DOT 4L 4L 4L

Gaseous Capacity

Based on DOT Rated Service Pressure

@ NTP (STP)

Oxygen 4688 cu. ft (123 cu.m) 5025 cu.ft (132 cu.m) 5484 cu.ft.(144 cu.m)

Nitrogen 3771 cu. ft (99 cu.m) 4043 cu. ft(106 cu.m) 4402 cu. ft(116 cu.m)

Argon 4558 cu. ft(120 cu. m) 4884 cu. ft(128 cu. m) 5331 cu. ft(140 cu.m)

Specifications are subject to change without notice

* Vented N.E.R. based on Usable Liquid Capacity

** Container pressure at or above factory Dual Pressure Building/Economizer Regulator setting

*** Regulator has a pressure delta of 20 psig (1.4 bar/138 kPa)

Page 4

XL-45, XL-50, XL-55

Containers

Handling the Container

The XL Series containers are very rugged liquid cylinders. All cryogenic liquid cylinders

have an inner container and an outer container with an insulated vacuum space between

them. Any abuse (dents, dropping, tip-over , etc.) can af fect the integrity of the containers

insulation system.

When fully loaded, the XL-55 in argon service will contain 551 lb. (250 kg) of product.

While moving a full container, you may be handling 821 lb. (372 kg) and you should treat

the load accordingly . The attachment points provided on the XL-45/50/55 will allow you to

use a hand truck or a hoist to handle these loads properly . Do not attempt to move these

cylinders by any other means. While moving the cylinder, the following precautions should

be observed.

q Never lay the cylinder on its side. Always ship, operate and store the unit in a vertical

or upright position.

q When loading or unloading the container from a truck, use a hand truck, lift gate, crane

or parallel loading dock. Never attempt to manually lift the unit.

q T o move the container over rough surfaces, or to lif t the container, att ach an appropri-

ated sling to the lifting points cut into the welded support posts, and use a portable

lifting device that will handle the weight of the container and its contents.

FREIGHT DAMAG E

PRECAUTIONS

ANY FREIGHT DAMAGE CLAIMS ARE

YOUR RESPONSIBILITY . Cryogenic

liquid containers are delivered to your

carrier from T aylor-Wharton’ s dock in new

condition. When you receive our product

you may expect it to be in that same

condition. For your own protection, take

time to visually inspect each shipment in

the presence of the carrier’s agent before

you accept delivery . If any damage is

observed, make an appropriate notation

on the freight bill. Then ask the driver to

sign the notation before you receive the

equipment. Y ou should decline to accept

containers that show damage which may

affect serviceability .

Page 5

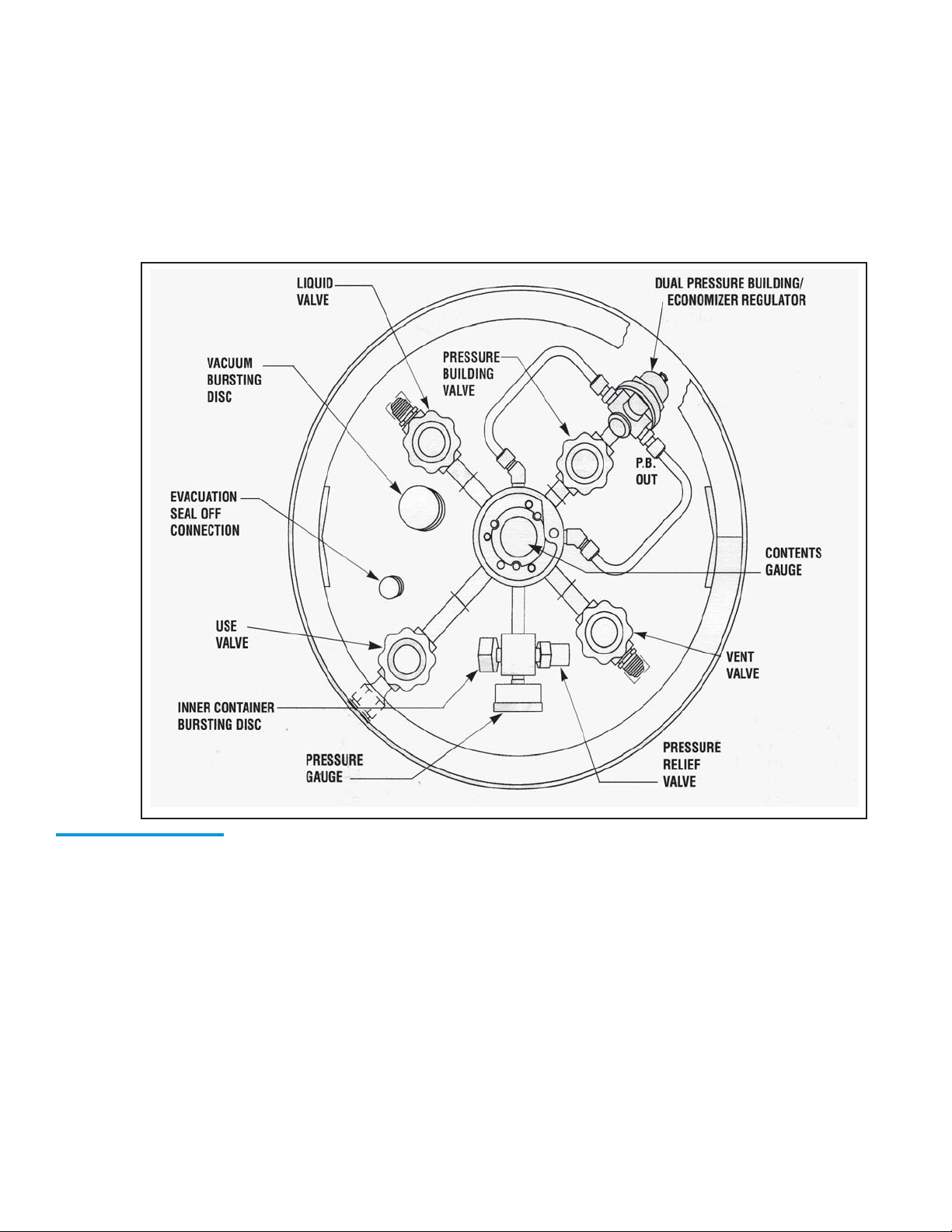

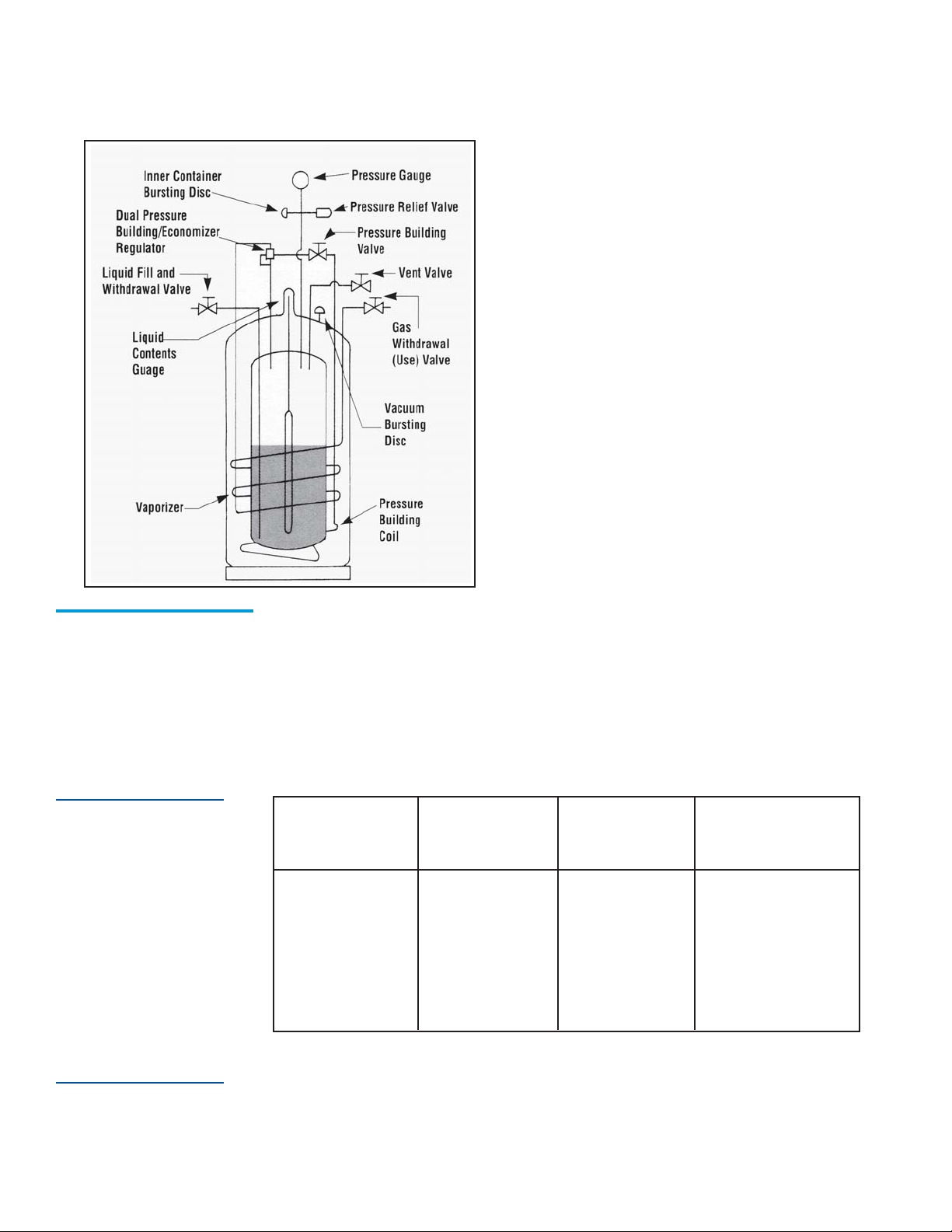

OPERATION

The XL-45 will store up to 169 liters of product, the XL-50 up to 181 liters and 200 liters

for the XL-55. All three cylinders can deliver either liquid or gas. The following component and circuit descriptions are pertinent to the operation of all the containers and

should be read before attempting operation. The components may be identified on the

Component Location Illustration.

XL-45/50/55

Component

Locations

Internal Vaporizer – A liquid container for gas service must have an internal heat exchanger that functions as a gas vaporizer coil to convert liquid product to gas continuously during withdrawal. The XL-45/50/55 utilizes an internal heat exchanger that is inside

the vacuum space attached to the container’s outer casing. It provides a means of introducing heat from outside the container’s insulated jacket, to vaporize liquid as gaseous

product is withdrawn. The capacity of this circuit is sufficient to vaporize liquid as gaseous

product is withdrawn. The capacity of this circuit is sufficient to vaporize product at flow

rates up to 350 cfh @ NTP (9.2 cu. m/h @ STP). If a greater continuous demand is put on

the vaporizer, an external vaporizer should be added to properly warm the gas and avoid

malfunction, or damage, to gas regulators, hoses, and other downstream components.

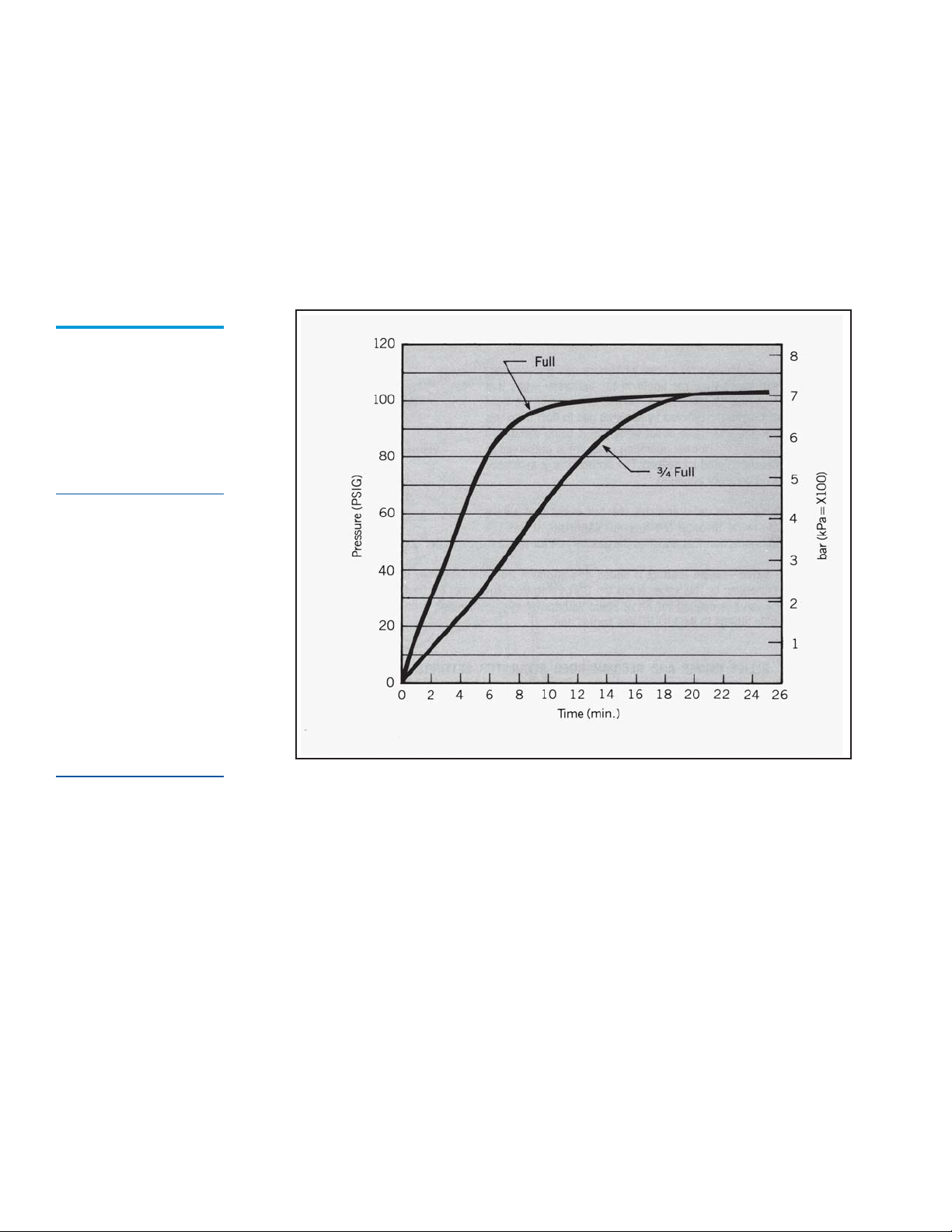

Pressure Building – A Pressure Building circuit is used to ensure sufficient driving pressure during high withdrawal periods. This function is actuated by opening a hand valve that

creates a path from the liquid in the bottom of the container , through the Pressure Building

Regulator, to the gas space in the top. When the pressure building valve is open, and the

container pressure is below the pressure building regulator setting, liquid taken from the

Page 6

XL-45/XL-50-XL-55

Flow Diagram

inner container is vaporized in a heat exchanger which

is inside the outer casing. The expanding gas is fed into

the upper section of the container to build pressure. The

resulting pressure will drive either the liquid or gas delivery system.

Pressure Building is not normally required unless container pressure drops below the gas output pressure desired. If, for example, the container pressure gauge reads

75 psig (5 bar/517 kPa), and your gas pressure requirement is 100 psig (6.9 bar/690 kPa), the pressure

building valve may be opened to build container pressure to 125 psig (8.6 bar/862 kPa).

Economizer – An economizer circuit withdraws gas preferentially from the head space over the liquid in the container – gas that would otherwise be lost to venting. Excess pressure in the head space of the container is

relieved by allowing gas to flow from this area directly to

the USE valve outlet while gas is being withdrawn from

the container; yet normal operating pressure is preserved

to ensure uninterrupted product delivery. The economizer is automatic and requires no operator attention.

The USE Valve - This valve controls the gas outlet that

allows product withdrawal through the internal vaporizer. It has the CGA connection that

matches the gas service for which the container is configured.

The LIQUID Valve – Liquid product is added or withdrawn from the container through

the connection controlled by this valve. It has the CGA fitting that is required for liquid

line connections. The valve is open for fill or liquid withdrawal after connecting a transfer

hose with compatible fittings to the LIQUID line connection.

NOTE:

The economizer and

pressure building

functions are

controlled by a single

dual action regulator.

The pressure delta

between the pressure

building setpoint and

the economizer

setpoint is

approximately 20 psig

(1.4 bar/138 kPa). This

delta cannot be

altered.

RELIEF VALVES AND RECOMMENDED REGULATOR SETTINGS

Relief Pressure Normal

Valve Building Economizer Operating

Setting Setting Setting Range

22 psig N/A N/ A 0-22 psig

1.5 bar N/A N/A 0-1.5 bar

152 kPa N/A N/A 0-152 kPa

230 psig 125 psig 145 psig 75-175 psig

16 bar 8.6 bar 10 bar 5-12 bar

1586 kPa 862 kPa 1000 kPa 517-1207 kPa

The PRESSURE BUILDING V alve – This valve isolates the liquid in the bottom of the

container to the Dual Pressure Building/Economizer Regulator. This valve must

be open to build pressure inside the container .

Page 7

Pressure

Building Rates

Graph

CAUTION:

When withdrawing

gas from the cylinder,

the capacity of the

internal vaporizer can

be exceeded. If gas is

withdrawn at rates

greater than the

vaporizer capacity,

liquid or very cold gas

will be discharged.

Severe damage to

external equipment

could result from the

extreme cold.

The VENT Valve – This valve controls a line into the head space of the container. It is

used during the fill process. The VENT valve acts as a fill point during a pump transfer , or

to vent the head space area while liquid is filling the inner container during a pressure

transfer fill through the LIQUID valve.

The Pressure Gauge – The pressure gauge displays the internal container pressure in

pounds-per-square-inch or in kilo Pascals.

The Full View Contents Gauge – The container contents gauge is a float type liquid

level sensor that indicates container liquid through a magnetic coupling to a yellow indicator band. This gauge is an indication of approximate container contents only and should

not be used for filling; liquid cylinders should be filled by weight.

Relief Devices – These cylinders have a gas service relief valve and inner container

bursting disc with settings of 230 psig (16 bar/1586 kPa) and 380 psig (26 bar/2620 kPa)

respectively. A 22 psig (1.5 bar/152 kPa) relief valve is available for liquid delivery applications.

WITHDRAWING GAS FROM THE CONTAINER

T o withdraw gas from the XL-45/50/55 connect a suitable pressure regulator to the USE

connection, and the output of the regulator to your external equipment. Then open the

USE and the PRESSURE BUILDING valves. When the container pressure reaches 125

psig (8.6 bar/862 kPa), set the pressure regulator for the desired delivery pressure.

Page 8

Vaporizer

Performance

Graph

Increasing Gas Supply Capacity – T wo or more liquid cont ainers may be manifolded

together. Accessory manifolds are available for use in creating a higher capacity gas

supply system. The XL-45/50/55 can supply gas at flow rates 1 up to 350 cfh @ NTP (9.2

cu.m/h @ STP) using only its internal vaporizer . At low flow rates, the gas supplied will be

at near ambient temperature. As the flow demand is increased, the gas will become

proportionately colder. If greater vaporizing capacity is required, an accessory external

vaporizer is available. When an external vaporizer is used, it must be connected to the

USE valve and the regulator moved to the output of the external vaporizer.

WITHDRAWING LIQUID FROM THE CONTAINER

Attach a transfer hose to the LIQUID connection and open the adjacent LIQUID valve.

The pressure in the container will drive liquid product out through the valve as long as the

container pressure exceeds that of the receiver.

Liquid

Withdrawal

CAUTION:

To avoid

contamination, close

the LIQUID valve on

an empty container

before disconnecting

the transfer line.

The rate of liquid withdrawal from these containers is variable depending on the gas phase and

the saturation temperature of the liquid.

FILLING THE CONTAINER

Cryogenic liquid containers must always be filled

by weight to ensure there is enough gas head

space (ullage) for liquid to expand as it warms.

Using the procedure below, first determine the

proper filled weight of each container. The weight

derived is then used in either the Pump Transfer

of Pressure Transfer filling procedures that follow.

Page 9

Determine Proper Fill Weight

1. Visually inspect the container . Do not attempt to fill containers with broken or missing

components.

NOTE:

The weight calculation

includes the weight of

residual liquid and is

applicable to both

Pressure Transfer and

Pump Transfer filling

methods.

WARNING:

Filling operations

should take place only

in well ventilated

areas. Accumulations

of product gas can be

very dangerous (refer

to the safety

precautions in the

front of these

instructions.) Maintain

adequate ventilation

at all times.

2. Move the container to a filling station scale and weight it both with and without the fill

hose attached to determine the weight of the fill line assembly . The difference is the fill

line weight.

3. To determine the weight at which the fill should be stopped, add the desired filling

weight (from the table below), the transfer line weight, and the Tare W eight from the

container’s data plate.

FILLING WEIGHTS

XL-45 XL-50 XL-55

ARGON 471 lb. (214 kg) 505 lb. (229 kg) 551 lb. (250 kg)

NITROGEN 273 lb. (124 kg) 293 lb. (133 kg) 319 lb. (145 kg)

OXYGEN 388 lb. (176 kg) 416 lb. (189 kg) 454 lb. (206 kg)

Pressure Transfer Filling Method

Filling a liquid cylinder using the pressure transfer method is common for 22 psig (1.5 bar/

152 kPa) service where the product is used for refrigerant purposes. This method may

also be used for higher pressure cylinders to increase liquid holding time. A fill is accomplished by first establishing a pressure difference between the source vessel and the XL45/50/55 (higher pressure at the bulk vessel). The pressure differential will then push the

liquid from the storage vessel to the container being filled. This method is employed when

no transfer pump system is available, or if a greater control over liquid temperature is

desired.

Filling the container is accomplished through the LIQUID valve while the VENT valve is

open or partially open to control product pressure. Careful control of pressure will control

the amount of heat retained in the liquid. Lower pressure results in colder liquid transferred to the container and increases, or lengthens, product holding time.

Pressure Transfer Filling Procedure (Low Pressure Source) - Once you have determined the proper full weight for a container , connect a transfer hose to the LIQUID fitting

from a low pressure source of liquid.

1. Open the supply valve. Then, on the XL-45/50/55, open the LIQUID and VENT valves to

begin the fill.

Page 10

Pressure Transfer

Filling From a Low

Pressure Source

2. During the fill, monitor the container pressure and maintain a pressure of 10-15 psig

(0.7-1 bar/69-103 kPa) by throtting the VENT valve.

3. When the full weight is reached, close both the LIQUID and VENT valves.

4. Close the liquid supply valve and open the dump valve on the fill line assembly .

5. Disconnect the fill line from the container and remove the container from the scale.

Pump Transfer Filling Method

When a pump is used for filling liquid containers, the fill may be accomplished through

either the VENT valve or the LIQUID valve. Filling through the VENT valve recondenses

gas in the area over the liquid in the cylinder and reduces product loss during the fill. This

method will also result in liquid near the saturation temperature of the supply vessel.

Filling through the LIQUID valve may provide colder liquid and longer holding time before

the liquid warms to the point where venting beings, but will require more frequent venting

and greater product loss.

Pump Transfer Filling Procedure - This method applies only to containers in gas

service that are equipped with a 230 psig (16 bar/ 1586 kPa) relief valve. Liquid is admitted

through the VENT valve and recondenses gas in the head space during the fill. The fill line

is connected from the liquid supply to the VENT valve on the cylinder . Both the fill line and

the container should be pre-cooled prior to beginning the fill process. Proper full weight is

determined by the previously explained method.

1. Open the supply valve. Then, on the container being filled, open only the VENT valve to

begin the fill. Start the pump at this time.

2. Observe the container pressure closely. If the pressure approaches the relief valve

setting (or the dump pressure rating) stop the fill process at the supply and open the fill

line dump valve to vent excess pressure. As soon as the pressure has dropped to a

level that will allow you to resume the fill, close the dump valve and restart the pump (or

reopen the supply valve.)

3. When full weight is reached, close the VENT valve. Stop pump (where applicable),

close liquid supply valve and open the dump valve on fill line assembly to vent trapped

liquid.

4. Disconnect the fill line from the container and remove the container from the scale.

Fill Hose Kits

T aylor-Wharton fill hose kits for the XL-45/50/55 are designed to transfer specific liquefied

gases to, or from, the containers. These accessories are comprised of a Fill Tee Assembly and a Fill Hose. Cryogenic transfer hoses are constructed of stainless steel for the

transfer of cryogenic liquids and are available in four or six feet (1.2 or 1.8 m) lengths with

a 3/8 in. NPT fitting on one end and CGA service-specific female fitting on the other . A Fill

Tee Assembly consists of a cross fitting with a CGA end fitting, relief valve and manual

dump valve.

Pump Transfer Liquid

Fill Through Vent

Valve

In use, the CGA T ailpiece couples to the fill connection on the container being filled. The

Relief V alve vents pressure over 350 psig (24 bar/2413 kPa) that builds up in the fill line

due to trapped liquid. The Dump Valve is used to allow the operator to blow-down the

receiving container during a pump fill, or to relieve residual pressure from expanding liquid

trapped in the line before disconnecting the fill line.

Page 11

Fill Hose Kits

Fill kits are available with different combinations of hose length and fittings for a specific

gas service. The following chart identifies the available transfer hoses and fill tee assemblies.

TRANSFER HOSE CHART

Description Cylinder End Part

(Service/Hose Length) Connections(s) Fittings Number

Inert (N2,Ar) Service

4 ft. (1.2 m) Stainless Steel LIQUID or VENT Valve CGA 295 to 3/8 in. NPT 1700-9C65

6 ft. (1.8 m) Stainless Steel LIQUID or VENT Valve CGA 295 to 3/8 in. NPT 1600-9C66

6 ft. (1.8 m) Stainless Steel USE Valve CGA 580 to 3/8 in. NPT GL50-8C51

Oxygen Service

6 ft. (1.8 m) Stainless Steel LIQUID or VENT V alve CGA 440 to 3/8 in. NPT GL-8C53

6 ft. (1.8 m) Stainless Steel USE Valve CGA 540 to 3/8 in. NPT GL50-8C56

VENT TEE CHART

The vent tee connects to transfer hose to complete a fill line kit. Each assembly includes

a 3/8 in. pipe connector to CGA fitting with a 350 psig (24 bar/2413 kPa) relief valve, and

a ball-type dump valve.

Page 12

MAINTENANCE

PROCEDURES

Service CGA Connection Part Number

Inert (N2, Ar) CGA 295 GL50-8C60

Read the Safety Precautions in the front of this manual before attempting any repairs on

these containers. Also follow these additional safety guidelines while performing container maintenance.

Never work on a pressurized container. Open the vent valve as a standard practice

during maintenance to guard against pressure build-up from residual liquid.

Use only repair parts cleaned for oxygen service. Be certain your tools are free of oil

and grease. This is a good maintenance practice, and helps ensure you do not create a

combustion hazard when working on containers for oxygen or nitrous oxide service.

Leak test connections after every repair . Pressurize the container with an appropriate

inert gas or leak testing. Use only approved leak test solutions and follow the manufacturer’s

recommendations. “Snoop” Liquid Leak Detector is one approved solution, it is available

from: Nupro Co. 4800 E. 345th St. Willoughby , Ohio 44094 U.S.A.

WARNING:

For the O2 System

Users: Residue of leak

detectors solutions

can be flammable. All

surfaces to which the

leak detector solutions

have been applied

must be adequately

rinsed with potable

water to remove all

traces of residue.

Reference CGA G-4.

Section 4.9.

CONVERTING A CONT AINER TO A DIFFERENT GAS SERVICE

XL-45/50/55 cylinders may be converted from one service to another within the confines of

the argon, nitrogen, and oxygen service for which the containers are designed. Conversion consists of changing the end connections at the USE, LIQUID, and VENT valves;

then changing the liquid level gauge scale by changing its plastic cover; and revising

product decals. Parts are available in kit from for each gas service as illustrated in the

following table.

Service Change Procedure

Before removing any parts, empty the container and open the vent valve to prevent any

pressure build-up in the unit.

1. Remove the LIQUID, VENT , and USE end fittings, one at a time, with standard wrenches.

Install new fittings from the Gas Service Change Kit, using Teflon tape or another

oxygen-compatible thread sealant.

2. Remove the protective cover over the liquid level gauge. Replace the contents scale

with the scale for the new gas service from the service change kit, then replace the

protective cover.

3. Install new fittings for the USE, VENT , and LIQUID connections from the Gas Service

Change Kit. Leak test the fittings you just replaced, and change the gas service decals to complete the conversion.

Page 13

CAUTION:

When changing gas

service, install the

proper fittings – DO

NOT use adapters. The

following procedures

address the physical

changes to the

container only. For

detailed procedures

on the

decontamination of

the container itself,

refer to CGA pamphlet

C-10 “Changes of

Service for Cylinders

Including Procedures

for Inspection and

Contaminant

Removal.”

GAS SERVICE CHANGE KITS

Kit Valve Connection

Part No. Gas Service Name Designation

GL50-8C35 Oxygen LIQUID CGA 440

VENT CGA 440

USE CGA 540

GL50-8C30 Nitrogen LIQUID CGA 295

VENT CGA 295

VENT CGA 295

USE CGA 580

GL50-8C31 Argon LIQUID CGA 295

VENT CGA 295

USE CGA 580

REGULA TOR MAINTENANCE

A dual stage, spring-loaded regulator is employed for the pressure building/economizer

circuit. This regulator can be adjusted on the container, replaced, or checked and adjusted off the container in a readily fabricated bench adjustment fixture.

NOTE:

One clockwise turn of

the adjustment will

raise the setpoint by

approximately 30 psig

(2 bar/207 kPa). See

the chart below to

determine the range

of adjustment for the

regulator you are

servicing. Do not

attempt to set the

regulator to a pressure

outside of its design

range.

Regulator Adjustment – On Container

1. Fill the container with the appropriate liquid product.

2. Open the Pressure Building Valve and allow the container pressure to stabilize for

about an hour. Note the point where the pressure stabilizes.

3. Adjust the screw on the top of the regulator to raise or lower the pressure to the

desired point. When decreasing the setting, the pressure building valve must be closed

and the container vented to a lower pressure. Then repeat step 2 in order to observe

the change.

Part No. Normal Setting Range Delta

6999-9015 125 psig 75 to 175 psig 2 0 psig

8.6 bar 5 to 12 bar 1.4 bar

86 2 kPa 517 to 1207 kPa 1 38 kPa

Page 14

Regulator Removal or Replacement Procedure

1. Close manual Pressure Building V alve.

2. V ent the container to atmospheric pressure.

3. Loosen and remove both the tube connections on the pressure building and economizer output sides of the regulator.

4. Remove the regulator from the container by unscrewing the valve body and elbow from

the output of the Pressure Building V alve.

5. Repair the regulator and readjust its setpoint using the bench test setup.

6. T o install a replacement or readjusted regulator , apply Teflon tape to the elbow on the

container and thread the valve body onto the elbow .

7. Reconnect the tube connections to the regulator and tighten.

8. Pressurize the container and check it for leaks.

Regulator Adjustment – Bench Procedure

NOTE:

The regulator has

directional gas flow.

The arrow on the

regulator body must

point in direction

indicated in the Bench

Adjustment Fixture

illustration.

Regulator

Bench

Adjustment

Fixture

Assemble the regulator adjustment fixture, and the regulator to be adjusted, as shown in

the accompanying illustration.

1. Leak test joints between the high pressure cylinder and the dump valve. Joints must

be leak free before proceeding.

2. Close the on/off valve and the Dump valve.

3. Slightly open the high pressure cylinder valve.

4. Set the high pressure regulator above the desired set point for the Pressure Building

setpoint.

5. Slowly open the on/off valve and observe the downstream pressure gauge.

NOTE:

The economizer

portion of the

regulator has already

opened approximately

20 psig (1.4 /138 kPa)

below the pressure

building setpoint.

6. When the regulator under test closes, the P.B. set point may be read on the downstream pressure gauge.

7. Close the on/off valve, and open the Dump valve.

8. To reset the regulator, loosen the lock nut on the adjusting screw . Raise the setpoint

by turning the adjusting screw clockwise; lower the setpoint by turning the screw

counter-clockwise. Af ter adjustment, repeat steps 5 and 6 to check the setting before

reinstalling the regulator on the liquid container .

Page 15

NOTE:

Fill through the

LIQUID valve with the

VENT valve open. The

Pressure Building

valve must be closed

during the NER test or

P.B. operation will

increase evaporation

and invalidate test

results.

CHECKING CONTAINER PERFORMANCE

Cryogenic containers are two container, one within the other. The space between the

containers acts as a highly efficient thermal barrier including high technology insulation, a

vacuum, and a vacuum maintenance system. Each serves a very important part in the

useful life of the container . The high technology insulation is very effective in preventing

radiated heat from entering the inner container . Unfortunately, the perfect vacuum cannot be achieved since trace gas molecules begin to enter the vacuum space from the

moment of manufacture. The vacuum maintenance systems consists of materials which

gather trace molecules from the vacuum space. The maintenance system can perform

its function for years, but it has a limited capacity. When the vacuum maintenance

system is saturated it and no long maintains the vacuum integrity of the container. The

change will be very gradual and my go unnoticed for several years. When the vacuum in

the insulation space is no longer effective, the following symptoms may appear:

1. With liquid in the container and pressure building/vaporizer coil not in use, the outer

casing will be much colder than comparative containers.

2. Frost, indicating the liquid level, may be visible on the outer casing of the container .

3. The container may appear to “sweat” if the air surrounding the container is hot and

humid.

4. The relief valve will open continuously until the container is empty .

5. The container will hold pressure for several days but will not hold liquid.

NER T esting

If a loss of vacuum integrity is suspected, the container’s Normal Evaporation Rate (NER)

should be checked. The test measures the actual product lost over time so you can

compare the results obtained to the NER value in the SPECIFICATIONS table. A test

period of 48 hours is recommended, after the container is allowed to stabilize, but the

formula given produces a Daily NER over any time period.

1. Fill the container with 150 pounds (68 kg) of liquid nitrogen.

2. Close the LIQUID valve and the PRESSURE BUILDING valve, leave the VENT valve

open and allow it to remain open during the test.

3. Allow the container to stabilize for 24 hours, then reweigh it. Record the weight, time

and date.

4. Reweigh 48 hours later. The test is more effective if container is not moved during this

period. Record the second date, time and weight.

The following calculation will provide the actual Normal Evaporation Rate in pounds-perday . Daily normal evaporation is simply half the lost over 48 hours.

Daily NER =

Compare the results of your test to the “as manufactured” NER value in the SPECIFICATIONS section of this manual. A container in service should maintain an NER value of less

than two time the new specification. Any test result greater than two times the listed value

is indicative of a failed, or failing vacuum. If NER is found to be high, contact Taylor-

Weight (Step 3) – Weight (Step 4)

Time between S tep 3 and 4 in hours x 24

Page 16

WARNING:

Cold surfaces should

never be handled with

bare skin. Use gloves

and other protective

clothing when

performing this

procedure.

Wharton Customer Service at (334)443-8680 for disposition.

FULL VIEW CONTENTS GAUGE MAINTENANCE

The content of these containers is measured with the Full View Contents Gauge. The

device consists of the gauge assembly beneath a clear plastic protective cover. When the

gauges is assembled, a level indicator ring is magnetically coupled to the top of a float

road and moves up or down with the changing level of liquid in the container . The clear

cover over the gauge body and level indicator is sealed at assembly to resist fogging of the

gauge. This seal should never need to be broken.

REMOVING THE FULL VIEW CONTENTS GAUGES

1. Vent all pressure from cont ainer .

2. Remove the protective coating by removing three bolts from the base of the cover.

3. Unscrew the gauge body using a wrench on hex fitting at base of the indicator.

4. Lift the entire gauge assembly free of the container. The gauge assembly is long and

may be very cold. Gloves should be used to protect your skin.

Calibration Procedure for Liquid Level Contents Gauges

1. You will need a column of water approximately 4 ft. (1.2 m) tall. A clear plastic tube 2.0

in. (51 mm) dia. with a cap glued to one end is perfect. Place an oxygen service

contents scale sleeve (P/N GL50-9C43) over the sight tube.

2. Support the gauge assembly by holding the base of the indicator tube. Care must be

taken to prevent interference with the spring action or from misaligning the scale sleeve.

Immerse teh aluminum float rod below the water level as illustrated. The gauge assembly must be held vertically and the rod must not touch the side or bottom of the tube.

The yellow level indicator of the gauge should indicate a full level reading with the

oxygen scale.

If the gauge fails to indicate a full liquid level, the assemlby is to be removed from the

water, calibrated and retested.

T o change calibration, loosen locking nut away from the brass calibration nut, the exposed

portion of rod becomes longer and the gauge yellow band will be lowered.

T o raise the yellow band, turn rod counterclockwise. The exposed portion becomes shorter .

Once you have adjusted calibration, recheck for proper setting. (See illustration.) After

proper setting has been obtained, lock down nut against calibration nut.

3. Once the gauge assembly has been calibrated and to read full in water, it must be

verified that it reads empy when the aluminum floating rod is suspended in air. The

yellow indicator must be as cloase to the bottom as possible (inner rod will be firmly

bottomed out.)

If calibration is required to make the gauge read empty in air, it must be rechecked in

water.

4. Af ter calibration, you will need to follow content s gauge inst allation to reinsert gauge.

Be sure to dry the assembly before reinserting into the cylinder to prevent ice build-up

that could restrict movement or catch on teh guide ring inside the cylinder.

Full View Contents

Gauge

Page 17

NOTE:

The yellow band will

move approximately

¼ in. (6.4 mm) to each

10 turns of the rod.

NOTE:

Make sure that the

Gauge Assembly is not

bent or out of line

before reinserting that

gauge into the

container.

Calibration For

XL-45, XL-50, XL-55

Contents Gauge Installation

Before installing a new or repaired gauge, inspect the gasket seals. If any damage is

apparent, replace the gasket. (See following page for illustration.)

1. When inserting the gauge assembly, lower the float rod through the gauge opening

until about 8 in. (203 mm) of the float rod remains above the container .

2. Grasp the clear cover portion of the gauge assembly with two fingers so that the

assembly hangs free and “plumb.”

3. Lower the assembly about 4 in. (102 mm) slowly and try to keep the rod in the center

of the threaded entrance hole as you do. If you are careful during this portion of insertion, you will drop the float rod straight though the guide ring inside the cylinder.

4. To confirm that the rod is correctly positioned in the cylinder, stop where you can still

grasp the top of the rod (See illustration.) and try to swing the lower end from side to

side.

5. When the rod is engaged in the guide ring, the rod will be restricted to lower end

movement of about ½ in. (12.7 mm); if you can feel greater movement, withdraw the

rode to the point where its top is 8 in. (203 mm) above the gauge opening and try

Page 18

CAUTION:

When installing the

gauge assembly, care

must be taken to

ensure that the float

rod is inserted through

the “guide ring”

located on the liquid

withdrawal line inside

the container. If the

gauge does not

engage this ring, the

contents indication

will be inaccurate, or

the gauge may be

damaged in use.

Contents Gauge

Insertion

again.

6. When you are satisfied that the float rod is correctly installed, lower the assembly the

rest of the way into the container until the top portion threads can be engaged.

7. Screw the gauge in place and hand torque to about 20 ft lbf (2.8 kgf m). Leak check the

connection of gauge body to the flange.

Page 19

HAND VALVE REPAIR

Hand valve are an integral part of the container, and the valve bodies rarely need replacement. However, the handwheel and internal p arts of the valves are renewable. The

illustration below are exploded views of the valves replaceable parts used on TaylorWharton liquid containers.

Valve Repair Kit

Fits: 3/8 in. or 1/2 in. Rego Globe or 3/8 in. Sherwood valves.

KIT P ARTS - KIT P/N 1750-9C35

Item No. Description Qty.

1 Screw and Washer 1

2 Spring Retainer 1

3 Retainer Washer 1

4 Spring 1

5 Seal Washer 1

6 Seal 1

7 Handwheel 1

8 Bonnet Washer 2

9 Bonnet 1

1 0 Stem Gasket 1

11 Stem 1

1 2 Seat Assembly 1

13 Bushing 1

14 Body *

T Q T orque 80 ft. lbf (1 1 kgf m) 1

Hand ValveExploded View

*Not available as a repair part

Valve Disassembly Instructions

1. Open valve by turning handwheel counterclockwise as far as it will go to release any

trapped gas in the system.

2. Using a screwdriver, remove Handwheel Screw and W asher by turning counterclockwise to allow removal of Spring Retainer , Washer , Spring, Seal W asher, Seal, Handwheel

and Bonnet Washers. Discard these parts.

3. Using a large adjustable wrench to hold valve body , remove Bonnet by turned counterclockwise with a 15/16 in. socket wrench that is capable of developing at least 80 ft. lbf

(1 1 kgf m) torque.

4. Remove the following parts from the valve body and discard – Stem, Stem Gasket,

Seat Assembly and Bushing.

5. Inspect body and clean if necessary; be sure interior and seal areas are free from dirt,

Page 20

residue and foreign particles.

Valv e Replacement Instructions

1. Partially thread Seat Assembly (12) (seat disc first) into large end of Bushing (13)

leaving a tang of nipple assembly exposed about 1/8 in. beyond top of Bushing.

2. Insert Seat Assembly (seat disc first) with attached Bushing, into valve body until

properly seated.

3. Place Stem Gasket (10) carefully over S tem (1 1) convex side facing downward.

4. Insert slotted end of S tem into valve body , making sure that slot fully engages tang of

Seat Assembly .

5. Place Bonnet over Steam and while holding square end of S tem to keep it from turning,

thread Bonnet (9) into valve body . Hold body with one wrench and using another wrench

(15/16 in. socket), tighten Bonnet to 80 ft lbf (1 1 kgf m) torque.

6. Install Bonnet W ashers over Stem on Bonnet.

7. Place Handwheel over Stem and on Bonnet.

8. Install Seal (6) over S team into recess of Handwheel.

9. Install Seal Washer (5) over Seal at the bottom of Handwheel recess shown.

10. With the flat side facing downward, place Retainer Washer (3) on top of Seal.

1 1. Align the holes of these parts and place Spring (4) over Seal.

12. Place Spring Retainer (2) over assembly as shown, keeping center hole aligned with

parts installed in steps 6-11.

13. Install Screw and Washer (1) over retainer. Tighten firmly with a screwdriver , turning

clockwise.

14. Turn Handwheel completely clockwise to close valve. Re-pressurize container and

leak check valve.

Page 21

SHOCK MOUNT FOOT RING

Item No. Description Part No. (XL-55 Only) Qty.

1 Rubber Shock Ring XL50-4C18 (GL55-4C21) 1

2 Foot Ring XL50-4C19 (GL55-4C19) 1

3 Hex Nut 6310-0135 4

4 Washer 6430-0125 4

5 Carriage Bolt 6620-0401 4

Replacement of Shock Mount Foot Ring

1. Empty or transfer all contents of tank. Vent to atmospheric pressure.

2. Gently lay the container on its side and unbolt the four (4) carriage bolts that attach the

foot ring and rubber shock ring to the tank.

Shock Mount

Foot Ring Exploded View

3. Slide off the damaged foot ring and rubber shock ring.

4. Assemble rubber shock ring into new foot ring and force over shock mount ring on

container . Use a rubber hammer to drive the rubber shock ring into place.

5. Using a 1/2 in. drill bit, drill holes through the rubber so that the carriage bolt slides in

smoothly.

6. The holes in foot ring must be positioned in alignment with holes in shock mount ring.

Using the 4 bolts, washers and nuts, fasten the new parts to the cont ainer .

7. After securing the shock mount ring, gently lift the container to the upright position and

Page 22

TROUBLESHOOTING

The following chart is provided to give you some guidance in determining the probable

cause and suggested corrective action for some problems that may occur with cryogenic

liquid containers. This chart is specifically tailored to your XL-45, XL-50, or XL-55.

Symptom Possible Cause Corrective Action

Consistently low 1. Relief valve open at low 1. Remove and replace relief

operating pressure. pressure. valve.

then inspect your work.

TROUBLESHOOTING CHART

2. Economizer side of 2. Remove and replace

P .B./Economizer Regulator re gulator.

stuck open.

3. Cold liquid. 3. Open pressure building valve.

With P .B. inoperative, the

container will build pressure

over time, or an external

pressure source can be used

to pressurize container.

No pressure shown 1. Bad container pressure 1. Remove and replace bad

on container gauge. gauge.

pressure gauge. 2. Open inner container 2. Remove and replace bursting

bursting disc. disc. Pressurize container

and check relief valve

operation.

3. Leaks in valves or 3. Leak test and repair leaks.

plumbing. For valve repairs, see

Maintenance section.

4. Cold liquid. 4. Open pressure building

circuit.

No pressure showing 1. Broken pressure gauge. 1. Replace pressure gauge.

but container is full 2. V ent valve open/P.B. 2. Close vent valve, open P .B.

by weight. valve closed. valve.

3. Faulty relief valve. 3. Replace relief valve.

Container full by 1. Liquid too cold. 1. Open P .B. valve or allow

weight and Liquid to stand.

Level Gauge but very 2. Possible leak in vent valve. 2. Rebu ild val ve.

low pressure 3. Faulty relief valve. 3. Replace valve.

Page 23

TROUBLESHOOTING CHART

Symptom Possible Cause Corrective Action

Container is cold and 1. Vacuum loss. Check NER. 1. Consult with T aylor-Wharton

may have ice or frost for course of action. Do not

on outer casing. Will attempt to put additional

not hold liquid over- liquid in container.

night. Relief valve is 2. Defective P .B./Economizer 2. Look for P.B. coil pattern in

venting gas. regulator. ice. Close P .B. valve.

Replace or reset regulator.

Ice formation on 1. Pressure building valve 1. Replace or rebuild valve.

bottom of container not closing properly.

when P .B. valve is 2. Leak in pressure 2. Leak test piping

closed. building system connections and tighten

topworks. fittings if needed.

Container vents Pressure Building/ Remove and reset or replace

through relief valve Economizer Regulator set regulator .

when in use. above relief valve setting.

Economizer side of

regulator clogged or

stuck open.

Container vents after This may be caused by Symptom should go away

fill but quits after residual heat vaporizing once container reaches

awhile. some liquid inside operating temperature and

container and is a normal the liquid reaches its

condition. saturation point at container

operating pressure.

Container vents gas Heat leak may be too Perform container

continuously through great. performance evaluation test

relief valve. per Maintenance section to

determine if container

vacuum is adequate.

Level indicator stuck Float rod stuck on or in Reinstall. See Contents

1/2 full. Y ellow float rod guide. Gauge Installation.

indicator ring will not

move.

Level indicator at Indicator disengaged from Recouple indicator using

bottom of gauge. gauge rod. Caused by engagement ring.

Container full of dropping the container .

product.

Page 24

REPLACEMENT

PARTS

XL-45/50/55

Component

Locations

This replacement part list include a recommended inventory quantity which allows you to

order part on a timely basis to keep all your XL-45/50/55 containers in service. When

placing orders, please use the nomenclature and part numbers in this section and send

written orders to:

T aylor-Wharton Fax: 1-334-443-2209

ACCESSORIES

4075 Hamilton Blvd. Call: 1-334-443-8680

Theodore, AL 36590-0568 1-800-898-2657 in USA and Canada

Accessories available for use with Taylor-Wharton XL Series containers are:

-

Manifolds, Automatic and Manual

-

V aporizers adding up to 250 cfh

(6.6 cu.m/h) each

-

Transfer Hoses (O2, N2, and AR)

-

Fill T ee Assemblies

For additional information concerning the accessory of your choice, please consult the

separate manuals on accessories or call Taylor-Wharton.

-

Container Hand Trucks

-

Gas Service Changeover Kits

-

Cryogenic Phase Separators

Page 25

Index Recommended

No. Description Part No. For 10 Units

1. Dual Regulator, Pressure Building/Economizer 69999-9015 2 Each

125 psig (8.6 bar/862 kPa)

* 2. Gasket, Glass Filled Teflon, Contents Gauge 7701-0083 5 Each

3. Contents Gauge Assembly (Includes Gauge and Spring) GL45-9C65 1 Each

* Float Rod (45/50) GL45-9C96 1 Each

(55) GL45-9C97 1 Each

4. Contents Gauge Cover, Protective Clear GL50-9C54 4 Each

Snap-on indicator, Nitrogen GL45-9C75 4 Each

Snap-on indicator, Oxygen GL45-9C77 4 Each

Snap-on indicator, Argon GL45-9C76 4 Each

5. Screw, Brass, 1/4 in. - 20 UNC x 5/8 in. 6114-1088 10 Each

5a. Washer, Lock, 1/4 in., Stainless Steel 6460-2025 10 Each

6. Gauge, Pressure 0-400 psig (0-28 bar/0-2758 kPa) 7702-6196 2 Each

7. Safety Head 380 psig (26 bar/2620 kPa) 1 190-9C21 2 Each

8. Relief V alve

**22 psig (1.5 bar/152 kPa) 6913-9069 5 Each

230 psig (16 bar/1586 kPa) 6913-9070 5 Each

9. Valve Repair Kit 1750-9C35 3 Each

10. Elbow, Male, Brass 45

1 1. Connector, Lake, Brass, 3/8 in. ODT -comp x 1/4 in. NPT -EXT 4570-1960 2 Each

12. Tube, P.B./Economizer Line GL45-9C20 2 Each

14. Elbow, Male, 3/8 in. NPT x 1/4 in. NPT 45° 6814-9241 2 Each

° 3/8 in. ODT-comp x 1/4 in. 6814-9233 2 Each

End Fittings for Hand Valves

15.

-

USE (CGA 540)-oxygen 7114-0163 5 Each

-

USE (CGA 580)-argon/nitrogen 7114-0164 5 Each

-

USE (CGA 320)-carbon dioxide 71 14-0181 5 Each

-

USE (CGA 326)-nitrous oxide 71 14-0195 5 Each

16.

-

LIQUID (CGA 440)-oxygen 6514-8992 5 Each

-

LIQUID (CGA 295)-argon/nitrogen 7355-4712 5 Each

-

LIQUID (CGA 320)-carbon dioxide 71 14-0181 10 Each

-

LIQUID (CGA 326)-nitrous oxide 71 14-0195 10 Each

17.

-

VENT (CGA 440)-oxygen 6514-8992 5 Each

-

VENT (CGA 295)-argon/nitrogen 7355-4712 5 Each

-

VENT (CGA 295)-carbon dioxide 7355-4712 5 Each

-

VENT (CGA 295)-nitrous oxide 7355-4712 5 Each

* Decal, Warning 1700-9C07 4 Each

* Decal, Nitrogen GL55-9C51 A/R

* Decal, Oxygen GL55-9C52 A/R

* Decal, Argon GL55-9C53 A/R

* Decal, UN Number, Nitrogen GL55-9C63 A/R

* Decal, UN Number, Oxygen GL55-9C64 A/R

* Decal, UN Number, Argon GL55-9C65 A/R

* Not illustrated.

** Optional/Not Illustrated.

Loading...

Loading...