Page 1

Instructions for

XL-160 and XL-180

TW-72

Do not attempt to use or maintain this

unit until you read and understand these

instructions. Do not permit untrained

persons to use or maintain this unit. If

you do not fully understand these instructions, contact your supplier for further

information.

Page 2

Contents

Container Safety ....................................................................... 1

General Information .................................................................. 2

Specifications ............................................................................ 2

Operation...................................................................................4

Component Descriptions............................................. 4

Withdraw Liquid from the Container ........................... 5

Filling the Container .................................................... 5

Fill Hose Kits ............................................................... 6

Maintenance .............................................................................. 8

Checking Container Performance ................................ 8

Hand V alve Repair ....................................................... 9

Shock Mount Foot Ring .............................................. 9

Full V iew Contents Gauge Maintenance...................... 1 0

T r oubleshooting ........................................................................ 13

Replacement Parts .................................................................... 14

Accessories 14

Page 3

Pressure Hazard – The containers covered by this literature contain liquefied gas

under pressure. Sudden release of this pressure may cause personal injury by

issuing cold gas or liquid, or by expelling parts during servicing. Do not attempt any

repairs on these containers until all pressure is released, and the contents have

been allowed to vaporize to ensure no pressure buildup can occur.

Extreme Cold – Cover Eyes and Exposed Skin – Accidental contact of the skin or

eyes with any cryogenic liquid or cold issuing gas may cause a freezing injury

similar to frostbite. Protect your eyes and cover your skin when handling the container or transferring liquid, or in any instance where the possibility of contact with

liquid, cold pipes, and cold gas may exist. Safety goggles or a face shield should be

worn when withdrawing liquid or gas. Long-sleeved clothing and gloves that can be

easily removed are recommended for skin protection. Cryogenic liquid is extremely

cold and will be at temperatures below -300° F (-184°C) under normal atmospheric

pressure.

Keep Equipment Well Ventilated – Although the gases used in these containers

are non-toxic and non-flammable, they can cause asphyxiation in a confined area

without adequate ventilation. An atmosphere that does not contain enough oxygen

for breathing can cause dizziness, unconsciousness, or even death. These gases

cannot be detected by the human senses and will be inhaled normally as if they

were air. Ensure there is adequate ventilation where these gases are used and store

liquid containers outdoors or only in a well ventilated area.

Replacement Parts Must be Clean to Prevent Contamination – Use only TaylorWharton recommended spare parts, and be certain parts used are properly cleaned

to prevent contamination of stored product. For information on cleaning, consult the

Compressed Gas Association (CGA) pamphlet1 G-4.1, “Cleaning for Oxygen

Service” or equivalent industrial cleaning specifications.

Container

Safety

NOTE:

For detailed information on teh

handling of cryogenic liquids, refer

to the Compressed Gas Association

publication(1): P-12 “Safe Handling

of Cryogenic Liquids.”

Install Relief Valves in Cryogenic Liquid Lines – When installing or fill hose

assemblies, make certain a suitable safety relief valves is installed in each section

of plumbing between shut-off valves. Trapped liquefied gas will expand as it warms

and may burst hoses or piping causing damage or personal injury.

1

Available from the Compress Gas Association, 1235 Jefferson Davis Highway,

Arlington, VA 22202.

Page 4

q

y

General

Information

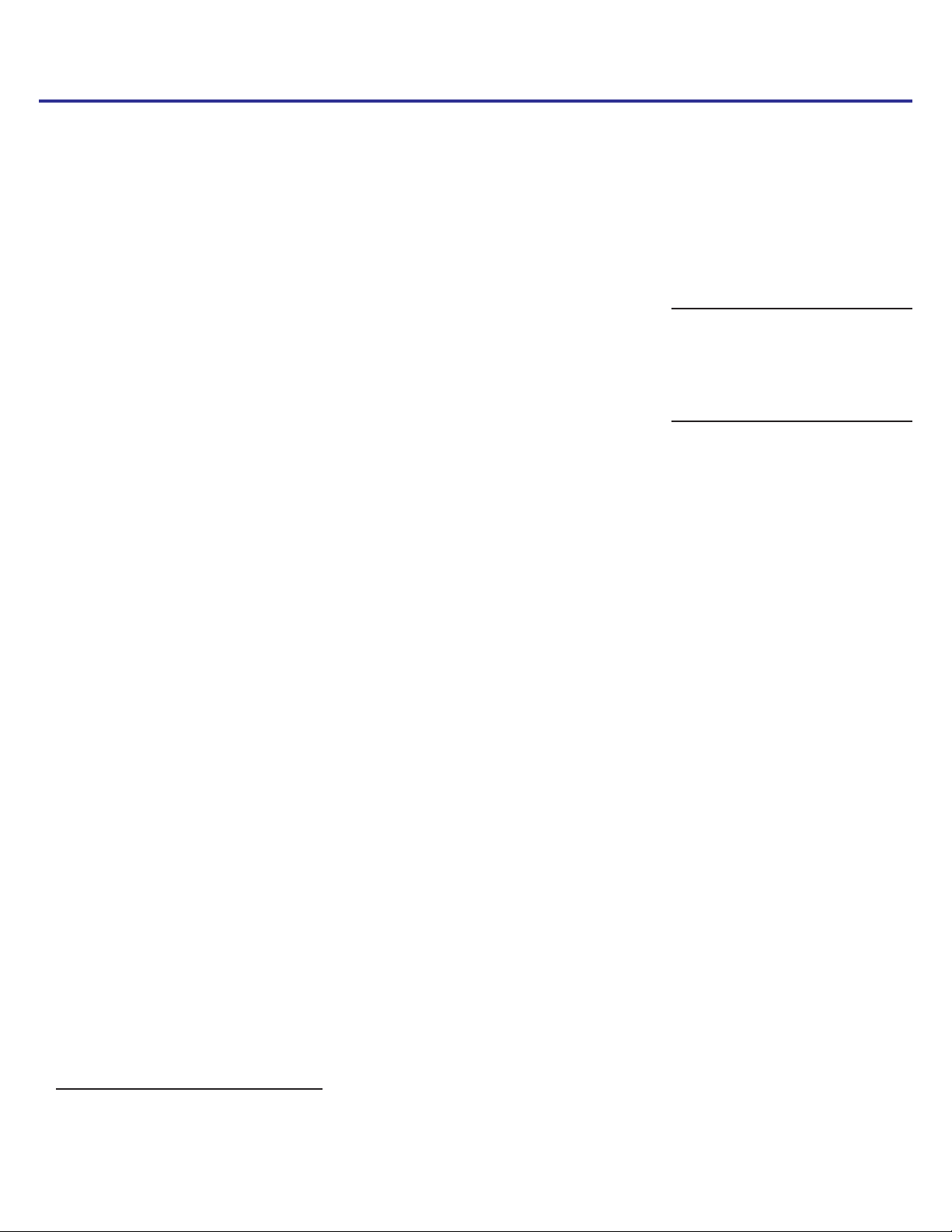

Specifications

The XL-160 and XL-180 are vacuum insulated, stainless steel containers designed to

store, transport, and dispense cryogenic liquid nitrogen. Built to DOT 4L standards,

these containers may be used for over-the-road transportation, as well as on-site

storage and supply.

Dimensions (Nominal)

Diameter

Height

Weight

Empty 197 lb. (89 kg) 205 lb. (93 kg)

Approximate Weight of Contents

(Nitrogen) in 22 psig (1.5 bar/152

kPa) Service

Capacity, Gross 163 liters 186 liters

Capacity, Useable Liquid 160 liters 180 liters

Normal Evaporation Rate* (%

Capacity per Day)

Nitrogen 1.3% 1.25%

Relief Valve Setting 22 psig

Inner Container Bursting Disc 176 psig

Design Specifications

T/DOT

Rated Service Pressure

Specifications are subject to change without notice.

*Vented N.E.R. based on Useable Li

20 in. (508 mm)

57 5/8 (1464 mm)

259 lb. (117 kg) 296 lb. (134 kg)

(1.5 bar/152 kPa)

(12 bar/ 1214 kPa)

4LM/4L

100 psig

(6.9 bar/ 690 kPa)

uid Capacit

XL-160 XL-180

20 in. (508 mm)

64 3/8 in. (1635 mm)

22 psig

(12 bar/1214 kPa)

176 psig

(12 bar/1214 kPa)

4LM/4L

100 psig

(6.9 bar/690 kPa)

Page 5

Handling the Container

XL Series containers are very rugged liquid cylinders. All cryogenic liquid containers

have an inner container and on outer container with an insulated vacuum space

between them; any abuse (dents, dropping, tip-over, etc.) can affect the integrity of

the container’s insulation system.

When fully loaded, the XL-180 in nitrogen service will contain up to 296 lb. (134 kg)

of product. While moving a full container, you may be handling up to 501 lb. (227 kg),

and you should treat the load accordingly. The attachment points provided on the Xl160/XL-180 will allow you to use a hand truck, or a hoist, to handle these loads

properly. Do not attempt to move these cylinders by any other means. When moving

the cylinder, the following precautions should be observed:

Never lay the container on its side. Always ship, operate, and store the

unit in a vertical or upright position.

When loading or unloading the container from a truck, use a lift gate, a

crane, or a parallel loading dock. Never attempt to manually lift from the

unit.

To move the container over rough surfaces or to life the container, attach

an appropriate sling to the lifting points cut into the welded support posts,

and use a portable lifting device that will handle the weight of the container.

Freight Damage Precautions

XL-160 and XL-180 Liquid Cylinders

Any Freight Damage claims are

your responsibility. Cryogenic

liquid containers are delivered to

your carrier from Taylor-Wharton’s

dock in new condition. When you

receive our product you may

expect it to be in that same

condition. For your own protection, take time to visually inspect

each shipment in the presence of

the carrier’s agent before you

accept delivery. If any damage is

observed, make an appropriate

notation on the freight bill. Then

ask the driver to sign the notation

before you receive the equipment.

You should decline to accept

containers that show damage

which may affect service ability.

Page 6

Operation

The model numbers of XL-160/XL-180 indicate their respective liquid storage capacities

in liters of product. Both cylinders are designed for liquid nitrogen service only. The

following component and circuit descriptions are pertinent to either container and should

be read before attempting operation. The components may be identified on the Component Location illustration.

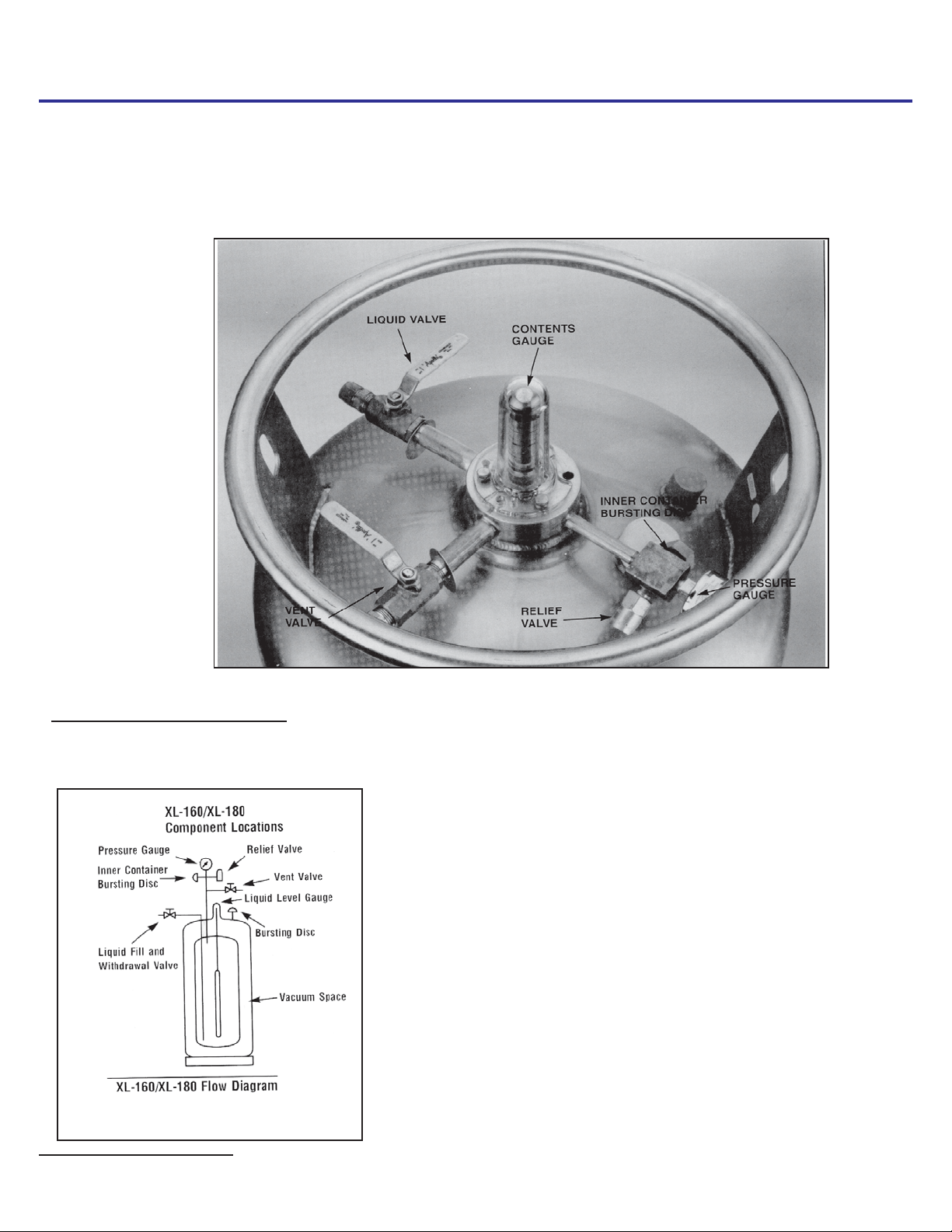

XL-160/XL-180 Component Locations

The Liquid Valve - Liquid product is added or withdrawn from the container through the connection controlled by this valve. It has the CGA

fitting that is required for liquid connections.. The valve is opened for fill

or liquid withdrawl after connecting a transfer hose with compatible fittings

to the LIQUID line connection.

The Pressure Gauge - Thepressure gauge dsplays teh internal container

pressure in pounds per-square-inch, bar or in kiloPascals.

The VENT Valve - This valve controls a line into the head space of the

container. It is used during thet fill process. the VENT valve is opened to

vent the head space area while liquid is entering the inner container

during a pressure transfer fill through the LIQUID valve.

The Full View Contents Gauge - The container contents gauge is a float

type liquid level sensor that indicates container liquid content through a

magnetic coupling to a yellow indicator band. This gauge is an indication

of approximate container contents only and should not be used for filling.

Relief Devices - These cylinders have inner container relief valves set at

22 psig (1.5 bar/152kPa) and inner container bursting disc that will rupture

at 176 psig (12 bar/1213)

XL-160/XL-180 Flow Diagram

Page 7

Withdrawing Liquid From The Container

To use the container in liquid delivery service, attach a transfer hose to the LIQUID

connection and open the adjacent LIQUID valve. The pressure in the container will

drive liquid product out through the valve as long as the container pressure exceeds

trhat of the receiver.

CAUTION:

To avoid contamination, close

the LIQUID valve before disconnecting the transfer line.

The rate of liquid withdrawal from these containers is variable depending on teh

container pressure and the saturation temperature of the liquid. With liquid saturated

at 22 psig (1.5 bar/152 kPa) withdrawal rate of up to 6 liters/min can be obtained.

WITHDRAWING LIQUID FROM THE CONTAINER

To use the container in liquid delivery service, attach a transfer hose to the LIQUID

connection and open the adjacent LIQUID valve. The pressure in the container will

drive liquid product out through the valve as long as the container pressure exceeds

that of the receiver.

The rate of liquid withdrawal from these containers is variable depending on the

container pressure and the saturation temperature of the liquid. With liquid saturated

at 22 psig (1.5 bar/152 kPa) withdrawal rate of up to 6 liters/min can be obtained.

Filling the Container

Cryogenic liquid containers that operate below 25 psig (1.7 bar/172 kPa) may be filled

by weight or by volume. The latter method depends on the filler observing liquid

product exiting the vent valve as an indication that the container is full. Both methods

are listed here. Be certain to observe all safety precautions associated with the

handling of cryogenic liquids.

Filling the Container by Weight of Contents

Using the procedures below, first determine the proper filled weight of each container.

The weight derived is then used in the filling procedure that follows.

WARNING:

Filling operations should take

place only in well ventilated

areas. Accumulations of

product gas can be very dangerous (refer to the safety precautions in the front of these

instructions). Maintain adequate ventilation at all times.

1. Visually inspect the container. Do not attempt to fill containers that have broken or

missing components.

2. Move the container to a filling station scale and weigh it both with, and without,

the fill hose attached to determine the weight of the fill line assembly. The difference is the fill line weight.

3. To determine the weight at which the fill should be stopped, add the desired filling

weight, the transfer line weight, and the Tare Weight from the container’s data

plate.

4. Once you have determined the proper fill weight for the container, connect a

transfer hose to the LIQUID fitting from a low pressure sources of liquid.

5. Open the supply valve. Then, on the XL-160/XL-180, open the LIQUID and VENT

valves to begin the fill.

6. During the fill, monitor the container pressure and maintain a pressure of 10-15

psig (0.7 bar/69-103 kPa) by throttling the VENT valve.

7. When full weight is reached, close both the LIQUID and the VENT valves.

8. Close the liquid supply valve and open the dump valve on the fill line assembly.

9. Disconnect the fill line from the container and remove the container from the scale.

Liquid Withdrawal

NOTE:

The fill weight calculation

inlcudes the weight of residual

liquid. the weights shown in the

Specifications are for liquid

saturated at atmospheric pressure. The actual fill weight for

your applaction depends on the

saturation temperature of liquid

in your storage tank, and mayh

be determined by weighing

cylinders that have been filled by

volume.

Page 8

Pressure Transfer Filling

Filling the Container by Volume

1. Visually inspect the container. Do not attempt to fill containers that have broken or

missing components.

2. Connect a transfer hose to the LIQUID fittings from a low-pressure source of liquid.

3. Open the supply valve. Then, on the XL-160/XL-180, open the LIQUID and VENT

valves to begin the fill.

4. When liquid begins to spit from the VENT valve, quickly close the LIQUID valve

and then the VENT valve. Both valves must be closed before the container relief

valve opens.

5. Open the dump valve on fills line assembly to vent the fill line assembly.

6. Disconnect the fill line from the container.

Fill Hose Kits

Taylor-Wharton fill hose kits for the XL-160/XL-180 are designed to transfer liquefied

gases to, or from the containers. These accessories are comprised of a Fill Tee Assembly and a Fill Hose. Cryogenic transfer hoses are constructed of stainless steel suitable

for cryogenic liquids, and are available in 4 or 6-ft. (1.2 or 1.8 m) lengths with a 3/8 in.

NPT fitting on one end and CGA service specific female fittings on the other. A Fill Tee

Assembly consists of a cross fitting with a CGA end fitting, relief valve and manual

dump vave.

Fill Hose Kits

Page 9

In use, the CGA end fitting on the Fill/Vent Tee Assembly couples to the fill connection

to be filled. The Relief Valve vents pressure over 350 psig (24-bar/2413 kPa) that builds

up in the fill line due to trapped liquid. The Dump Valve is used to allow the operator to

blow-down in the receiving container during a pump fill, or to relieve residual pressure

from expanding liquid trapped before disconnecting the fill line.

Fill kits are available with different combinations of hose length. The following chart

identifies the available transfer hoses and the Fill/Vent Tee assemblies that are appropriate for use with the XL-160/XL-180.

Transfer Hoses & FILL/VENT Tee Assemblies

The Fill/Vent Tee connects to a transfer hose to complete a fill line kit. Each assembly

includes a 3/8-in. pipe connector to CGA fitting with a 350-psig (24-bar/2413-kPa) relief

valve, and a ball-type dump valve.

Description Cylinder

Connections

Hose, 4 ft. (1.2 m) SS LIQUID or VENT valve CGA 295 to 3/8 in NPT 1700-9C65

Hose, 6 ft. (1.8 m) SS LIQUID or VENT valve CGA 295 to 3/8 in NPT 1600-9C66

Fill/Vent Tee Assemb. LIQUID or VENT valve CGA 295 GL50-8C60

End

Fittings

Part

Number

Page 10

Maintenance Read the Safety Precautions in the front of this manual before attempting any repairs

on these containers. Also, follow these additional safety guidelines while performing

container maintenance.

Never work on a pressurized container. Open the vent valve as a standard

practice during maintenance to guard against pressure build-up from residual

liquid.

Use only repair parts for oxygen service. Be certain your tools are free of oil and

grease. This is a good maintenance practice and helps ensure you do not introduce

any contaminants to the plumbing of the container.

Leak test connections after every repair. Pressurize the container with an appro

priate inert gas for leak testing. Use only approved leak test solutions and follow the

manufacturers recommendations. “Snoop” Liquid Leak Detector is one approved

solution. It is available from Nupro Co., 4800 E. 345

USA.

CHECKING CONTAINER PERFORMANCE

Cryogenic containers are two containers, one within the other. The space between the

containers acts as a highly efficient thermal barrier including high technology insulation,

and a vacuum maintenance system. Each serves a very important part in the useful life

of the container. The high technology insulation is very effective in preventing radiated

heat or solid conduction from entering the container; the vacuum prevents heat convection from reaching the stored product. Unfortunately, the perfect vacuum cannot be

achieved since trace gas molecules begin to enter the vacuum space from the moment

of manufacture. The vacuum maintenance system consists of materials which gather

gas molecules from the vacuum space. The maintenance system can perform its

function for years, but has a limited capacity. When the vacuum maintenance system is

saturated, it can no longer maintain the vacuum integrity of the container. The change

will be very gradual and may go unnoticed for several years. When the vacuum in the

insulation space is no longer effective, the following symptoms may appear.

th

St., Willoughby, Ohio 44094

1. When the container is filled with liquid, the outer casing will be much colder than

normal.

2. The container may appear to “sweat” if the air surrounding the container is hot and

humid.

3. The relief valve will open continuously until the container is empty.

4. The container will hold pressure for several days, but will not hold liquid.

NER TESTING

If a loss of vacuum integrity is suspected, the container’s Normal Evaporation Rate

(NER) should be checked. The test measures the actual product lost over time so you

can compare the results obtained to the NER value in the SPECIFICATIONS table. A

test period of 48 hours is recommended, after the container is allowed to stabilize, but

the formula given produces a Daily NER over any time period.

1. Fill the container with 150 pounds (68 kg) of liquid nitrogen.

2. Close the LIQUID valve, open the VENT valve and allow it to remain open during

the test.

Page 11

3. Allow the container to stabilize for 24 hours, then weigh it. Record the weight, time

and date.

4. Reweigh after the recommended 48 hours. The test if most effective if the

container is not moved during this period, and if conducted in an area where

ambient temperatures are consistent.

The following calculation will provide the actual Normal Evaporation Rate.

NOTE:

Fill through the LIQUID valve with

VENT valve open

.

Daily NER =

Weight Loss (Step 3-Step4) x 24 hours

Elapsed Time (Hrs.)

Compare the results of your test to the “as manufactured” NER value in the SPECIFICATIONS section of this manual. A container in service should maintain an NER value

of less than two times the new specification. Any test result greater than two times the

listed value is indicative of a failed, or failing, vacuum. If NER is found to be high,

contact Taylor-Wharton Customer Service at (334) 443-8680 for disposition.

HAND V ALVE REPAIR

The ball valves used on the XL-160/XL-180 may be replaced by removing fittings

and unscrewing the valve body from the container plumbing. When installing a new

valve, it is important to close the valve, and observe the presence of a small hole in the

ball that is visible through only one of the threaded openings in the valve body. This

hole is a vent that allows the valve to prevent pressure buildup due to liquid trapped in

the ball chamber when the valve is closed. When installing a replacement valve,

always check to ensure the hole faces the container when the valve is closed.

SHOCK MOUNT FOOT RING

Item No. Description Part. No. Qty.

1 Rubber Shock Ring XL50-4C18 1

2 Foot Ring XL50-4C19 1

3 Hex Nut 6310-0135 4

4 Washer 6430-0125 4

5 Carriage Bolt 6620-0401 4

NOTE:

IF the original Shock Mount Ring is

badly damaged we recommend that an

NER test is performed to ensure that no

internal damage has resulted from the

impact of teh shock mount ring.

Replacement of Shock Mount Foot Ring

1. Empty or transfer all contents of tank. Vent to atmospheric pressure.

2. Gently lay the tank on its side and unbolt the four (4) carriage bolts that attach

the foot ring and rubber shock ring to the tank.

3. Slide off the damaged foot ring and rubber shock ring.

4. Assemble rubber shock ring into new foot ring and force over shock mount ring on

vessel. Use a rubber hammer to drive the rubber shock ring into place.

5. Using a ½ in. drill bit, drill holes through the rubber so that the carriage bolt slides

in smoothly.

6. The holes in foot ring must be positioned in alignment with hole in shock mount

ring. Using the 4 bolts, washers and nuts, fasten the new parts of the cylinder.

7. After securing the shock mount ring to the tank, gently life the tank to the upright

position and inspect your work.

Shock Mount Foot Ring -

Exploded View

Page 12

WARNING:

Cold surfaces should never be handled

with bare skin. Use gloves and other

protective clothing when performing

this procedure.

FULL VIEW CONTENTS GAUGE MAINTENANCE

The contents of these containers is measured with the Full View Contents Gauge. The

device consists of the gauge assembly beneath a clear plastic protective cover. When

the gauge is assembled, a level indicator ring is magnetically coupled to the top of a

float rod and moves up or down with the changing level of liquid in the container. The

clear cover over the gauge body and level indicator is sealed at assembly to resist

fogging of the gauge. This seal should never need to be broken.

If the level indicator does not move when container is filled, it may indicate that the

magnetic field between the level indicator and the gauge has been uncoupled. The

level indicator should recouple itself as the container is emptied. However, a reengagement tool (ring) is available to correct the problem immediately. To reestablish

the correct relationship, slip the re-engagement ring over the contents gauge and its

protective cover. The magnetic field of this tool will allow you to lift the yellow level

indicator until it recouples with the magnetic field on the gauge rod.

Fill Dwawing

Full V iew Contents Gauge

Removing the Full View Contents Gauge

1. Vent all pressure from the container.

2. Remove the protective cover by removing three bolts from the base cover.

3. Unscrew the gauge body using a wrench on hex fittings at base of the indicator.

4. Lift the entire gauge assembly free of the container. The gauge assembly is long

and my be very cold. Gloves should be used to protect your skin.

Calibration Procedure for Liquid Level Contents Gauge

1. You will need a column of water approximately 4-ft. (1.2 m) tall. A clear plastic

tube 2.0-in. (51 mm) with a cap glued to one end of perfect.

2. Support the gauge assembly by holding the base of the indicator tube. Care must

be taken to prevent interference with the spring action. Partially immerse the

aluminum float road in the water. The water level should be 3.0 in. (76 mm) below

the top of the rod as illustrated. The gauge assembly must be held vertically and

the rod must not touch the side or bottom of the tube. The yellow level indicator of

the gauge should indicate a full reading with the scale.

If the gauge fails to indicate a full liquid level, the assembly is to be removed from the

water, calibrated and retested.

To change calibration, loosen locking nut away from brass calibration nut and turn the

threaded rod with respect to the calibration nut.

Page 13

If the rod is turned clockwise (to the left) with respect to calibration nut, the exposed

portion of rod becomes longer and the gauge yellow band will be lowered.

To raise the yellow band, turn rod counter clockwise. The exposed portion of rod becomes shorter. Once you had adjusted calibration, recheck for proper setting. (See

illustration.) After proper setting has been obtained, lock down nut against calibration

unit.

1. Once the gauge assembly has been calibrated to read in full water, it must be

verified that it reads empty when the aluminum float rod is suspended in the air. The

yellow indicator must be as close to the bottom as possible (inner rod will be firmly

bottomed out.)

If calibration is required to make the gauge read empty in air, it must be rechecked in

water.

2. After calibration, you will need to follow contents gauge installation to reinsert gauge.

Be sure to dry the assembly before reinserting into the cylinder to prevent ice build

up that could restrict movement or catch on the guide ring inside the cylinder.

NOTE:

The yellow band will move approximately1/4 in. (6.4 mm) to each 10

turns of the rod.

NOTE:

Remember this procedure is

performed with gauge in an upright

(vertical) position.

NOTE:

Make sure that the Gauge Assembly

is not bent or out of line gefore

reinserting teh gauge into the

container.

Calibration drawing

Contents Gauge Installation

Before installing a new or repaired gauge, inspect the gasket seals. If any damage is

apparent, replace the gasket. (See following page for illustration.)

1. When inserting the gauge assembly, lower the float rod through the gauge opening

until about 8 in. (203 mm) of the float rod remains above the container.

2. Grasp the clear cover portion of the gauge assembly with two fingers so that the

assembly hangs free and “plumb.”

Calibration for XL-160/XL-180

Page 14

CAUTION:

When installing the gauge assembly, care must be taken to ensure

that the float rod is inserted through

“guide ring” located on the liquid

withdrawal line inside container. IF

gauge does not engage this ring, the

contents indication will be inaccurate, or the gauge may be damaged

in use.

Contents Gauge Insertion

Lower the assembly about 4 in. (102 mm) slowly and try to keep the rod in the center of

the threaded entrance hole as you do. If you are careful during this portion of the insertion, you will drop the float rod straight though the guide ring inside the cylinder.

1. To confirm that the rod is correctly positioned in the cylinder, stop where you can

still grasp the top of the rod (see illustration) and try to swing the lower end from

side to side.

2. When the rod is engaged in the guide ring, the rod will be restricted to lower end

movement of about ½ in. (12.7 mm); if you can feel greater movement, withdraw

the rod to the point where its top is 8 in. (203 mm) above the gauge opening and try

again.

3. When you are satisfied that the float rod is correctly installed, lower the rest of the

way into the container until the top portion threads can be engaged.

4. Screw the gauge in place and hand torque to about 20 ft. lbf (2.8 kgf m). Leak check

the connection of gauge body to the flange.

Page 15

Sym ptom Possible Cause Corrective Action

Consistently low operating

pressure.

Very low or no pressure

show on gauge

C o n ta in e r is c o ld a n d m a y

have ice or frost on outer

casing. W ill not hold liquid

overnight. Relief valve is

venting gas.

Container vents after fill but

quits after a short tim e.

Float-type level indicator at

bottom of gauge. C ontainer

full of product.

1. Relief valve open at low

pressure.

2. Cold liquid.

1. Bad pressure gauge.

2. Ope n in ner container

sa fe ty h e a d .

3. Leaks in valves or

plumbing.

4. Liquid too cold.

5. Possible leak in VEN T

valve.

6. Faulty relief valve.

Vacuum loss. Check

vacuum burstin g disc.

This ma y be caused by

residual heat vaporizing

liquid inside container and

is a normal condition.

Indicator disengage d from

gauge rod magnetic field.

Caused by dropping the

container.

1. Rem ove and replace

re lief va lve .

2. Container pressure will

build over tim e, or an

external pressure

source can be used to

pressurize con tainer.

1. Rem ove and replace

bad gauge.

2. Rem ove and replace

safety head. Pressurize

container and check

relief valve operation .

3. Leak test and repair

leaks.

4. Allow contain er to stand

and build pressure.

5. Replace valve.

6. Replace valve.

C o n s u lt w ith T a y lo rW harton for course of

a c tion . D o n o t a tte m pt to

put additional liquid into

container.

Sym ptom should stop when

container reaches operating

temperature and the liqu id

reaches its saturation point

at container operating

pressure.

Re-couple indicator using

re-engage m ent ring.

Troubleshooting

Page 16

Replacement Parts

XL-160/XL-180

Component Locations

Accessories

Accessories available for use with Taylor-Wharton XL Series containers include:

· Manifolds, Automatic and Manual

· Transfer Hoses

· Fill/Vent Tee Assemblies

· Container Hand Trucks

· Cryogenic Phase Separators

For additional information concerning the accessory of your choice, please consult the separate manual on accesso-

ries or call Taylor-Wharton at (334) 443-8680.

Page 17

Index

No.

1. Gasket, Glass Filled Teflon 7701-0083 5 each

2. Float, Contents Gauge 1604-9C60 1 each

3. Contents Gauge Assembly

4. Screw, Contents Gauge Cover 6114-1087 3 each

5. Cover, Contents Gauge, Protective GL50-9C04 4 each

6. Gauge, Pressure 0-60 (4.1 bar/414 kPa) 7702-6192 2 each

7. Safety Head, 176 psig (12 bar/1213 kPa) L240-9C20 2 each

8. Relief Valve, 22 psig (1.5 bar/152 kPa) 6913-6223 5 each

9. Ball Valve ½ in. 6916-7114 3 each

10. Cross, Brass ¼ in. NPT GL55-9C30 2 each

11.

*

*

*

*

*

Description

(Includes Gauge and Spring)

End Fitting, CGA 295, Vent/Liquid

Decal Nitrogen

Decal, XL-160

Decal, XL-180

Decal, UN Number, Nitrogen

Decal, Warning

Part No. Recommended for 10

Units

GL50-9C42 1 each

7355-4698

GL55-9C51

1604-9C50

L180-9C50

GL55-9C63

1700-9C07

5 each

A/R

A/R

A/R

A/R

A/R

Page 18

Warranty

TAYLOR-WHARTON

XL Series Liquid Cylinders

Taylor-Wharton Gas Equipment Division, Harsco Corporation warrants that

each of its Refrigerator and Dewars will be free from defects in material and workmanship, in the normal service for which the product was manufactured, for a period

of ninety (90) days from date of shipment to the original purchaser. The product is

further warranted to maintain a Normal Evaporation Rate (NER) within 10% of TaylorWharton’s published specifications for the product, on date of shipment. This warranty is in effect for all XT, HC, LS, CX and LD Series products for a period of three

(3) years from date of shipment to the original purchaser, and for all Series products

for a period of two (2) years from date of shipment to original purchaser, if the

product is used and maintained according to Taylor-Wharton’’ instructions.

To make a claim under this warranty, the purchaser must: 1) give TaylorWharton written notice with ten (10) days after discovery of claimed defect, 2)

immediately discontinue use of the product, and 3) return such product freight paid to

the location specified by Taylor-Wharton for evaluation to validate warranty claim. If

the claimed defect is confirmed by Taylor-Wharton’s inspection, Taylor-Wharton will,

at its option and as the purchaser’s sole remedy, repair or replace such product or

any component part thereof, or refund the original purchase price.

This warranty is voided by alterations or by repairs by others. Taylor-Wharton

shall not be liable under this warranty, or otherwise, for defects caused by negligence,

abuses, or misuse of the product, corrosion, fire, heat, or the effects of normal wear.

Any related components or other equipment manufactured by other which may be

sold with Taylor-Wharton’s product are not covered y this warranty.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

THE REMEDIES SET FORTH HEREIN ARE EXCLUSIVE TAYLOR-WHARTON

SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, SPECIAL OR INCIDENTAL

DAMAGES RESULTING FROM THE DELIVERY, USE OR FAILURE OF THE

PRODUCT (INCLUDING LOSS OF ANY MATERIAL STORED IN THE PRODUCT),

OR FROM ANY OTHER CAUSE WHATSOEVER. BY ACCEPTING DELIVERY OF

THE PRODUCT SOLD HEREUNDER, THE PURCHASER ACKNOWLEDGES THAT

THIS LIMITATION REMEDIES IS REASONABLE AND ENFORCEABLE. IN NO

EVENT SHALL TAYLOR-WHARTON’S LIABILITY EXCEED THE PURCHASE

PRICE FOR THE PRODUCT.

Taylor-Wharton

4075 Hamilton Blvd.

Theodore, AL 36590-0568

Phone: (334) 443-8680

(800) TW TANKS (898-2657)

Fax: (334) 443-2209

Loading...

Loading...