Page 1

Operating Instructions

SAFETY

Before using any cryogenic refrigerator, read

the Handle with Care booklet provided with the

unit. It details safety precautions that must be

understood before using the equipment. If a

replacement booklet is needed, order publication TW-10 Handle with Care from your sup-

plier.

Following are a few of the safety precautions

described in the Handle with Care booklet.

Please be sure to read the entire booklet.

Store and use these containers only in well

ventilated areas. In a confined area, nitrogen

gas from these units may cause suffocation by

displacing air needed for breathing. Install a

suitable oxygen monitor.

Do not touch liquid or cold metal surfaces

with your bare skin. The liquid nitrogen

refrigerant is extremely cold: -196°C (-320°F).

Exposure to skin or eyes to liquid, cold gas or

frosted parts could result in a severe frostbitelike injury. Because of the extremely low

temperature, a face shield and gloves must be

worn when transferring liquid nitrogen and

material into or out of these containers.

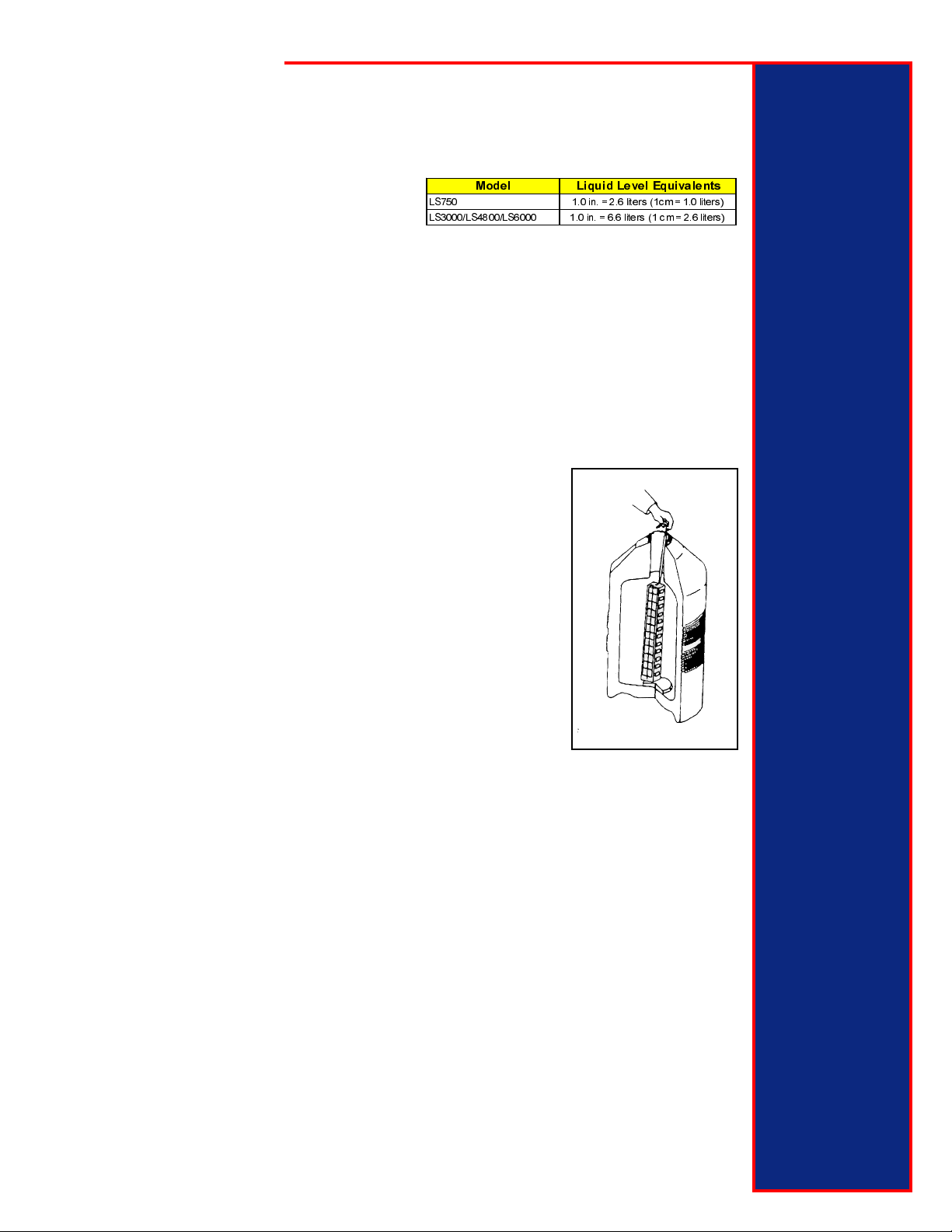

These values are approximate and are based

on a standard condition with no stored material

in the container. With store material, the liquid

volume will be slightly less than the value of

the chart.

/6

0RGHO

/6/6/6

/LTXLG/HYHO(TXLYDOHQWV

LQ OL WHUVFP O L WHUV

LQ O LWHUVFP O L WHUV

INSERTING OR REMOVING RACKS

To prevent unnecessary loss of liquid nitrogen

and accumulation of ice, the necktube core

(the stopper) should remain in the container

when the stored material is not being accessed. When accessing stored material, the

necktube should be removed as briefly as

possible.

When removing material from the racks,

withdraw the rack just far enough to remove

contents. Completely withdrawing the rack will

unnecessarily

expose the stored

material to warm

room temperature

conditions.

TW-348

Laboratory

Systems

Use only the necktube covers supplied with

this unit or a listed replacement part. A tight

fitting plug or stopper will cause a pressure

increase in the container that may damage the

container and/or cause personal injury.

OPERATION

Filling: Adding liquid nitrogen to a warm

container may cause splashing and will generate a significant volume of nitrogen gas as cold

liquid contacts warm refrigerator surfaces. Add

liquid slowly to minimize these effects. Be sure

there is adequate ventilation. Keep your head

clear of the heavy volume of vapor that may be

produced. It is extremely cold and could cause

personal injury.

WARNING:

DO NOT OVERFILL. Over-filling may result in personal

injury due to liquid spillage.

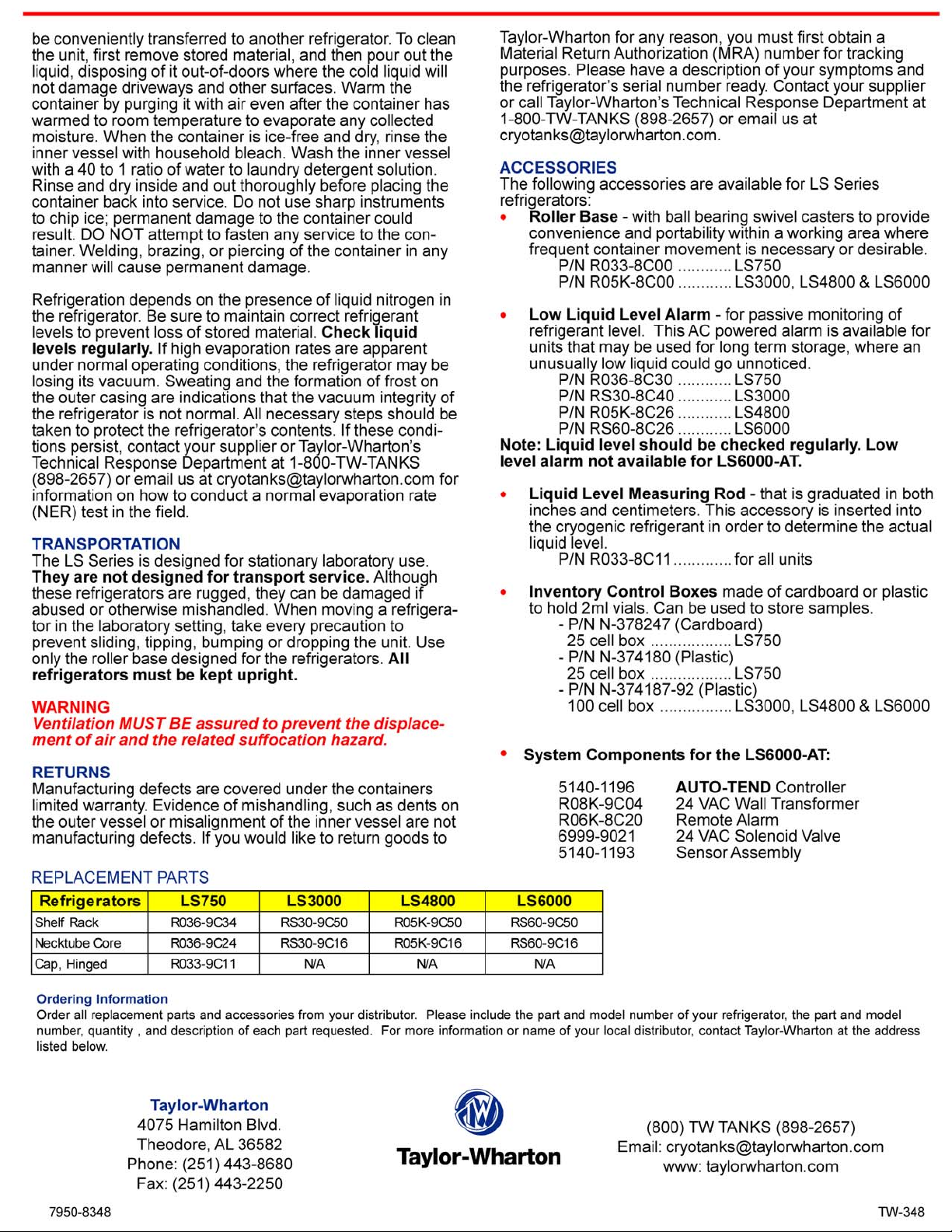

DETERMINING LIQUID LEVEL

Liquid level must be checked at regular intervals refrigeration depends on the pressure of

liquid nitrogen. The liquid level in the container

can be determined with a dipstick. Insert the

dipstick straight into the container so that it rests

on the rack positioning fixture on the bottom of

the unit. After 5 to 10 seconds, withdraw the

dipstick and wave it back and forth in the air. A

frosted section will form representing the depth

of the liquid in the container.

WARNING

Never use hollow rods or tubes as dipsticks. When a

warm tube is inserted into liquid nitrogen, liquid will

spout from the top of the tube and may cause personal

injury.

The liquid level chart shows volume of liquid

nitrogen vs. depth for LS Series refrigerators.

WARNING

Some boxes have

liquid drain openings,

some do not. If racks

are completely

removed from the

container, liquid

nitrogen may remain

in the either rack and

boxes, or simply drain

from the bottom. When

removing racks, stop

briefly at the necktube

to allow liquid to drain

completely, then

handle the rack carefully to prevent personal injury.

Avoid direct rack contact with bare skin. The use of

proper personal protective gear is strongly urged

cryogenic gloves, face shield and gown to protect

against splashing.

When room temperature is added, slowly lower

the rack into the refrigerator to reduce the

boiling of refrigerant and the surge of cold

nitrogen gas. When inserting the rack, tilt the

bottom of the rack in the direction of the index

ring notch. The numbers and colors on the

rack handles are a convenient aid to inventory

control.

SECURING CONTENTS

The contents of all models may be secured

with a seal or lock through tabs on the edge of

the lid opposite the hinge.

ROUTINE CARE AND MAINTENANCE

If ice accumulates inside the necktube, a

general cleaning of the refrigerator should be

scheduled as soon as the stored material can

LS SERIES

Page 2

Page 3

AUTO FILL OPERATION

WARNING: In order to prevent the

relief device on nitrogen

refrigerator(s) from opening when

the system is in operation,

liquid nitrogen supply system must

be protected by a pressure relief

device that will open when the

pressure at the inlet to the

refrigerator(s) is approximately 22

psig (1.5 bar/152 kPa). Never install

the supply system pressure relief

device into a liquid service line.

Filling the Refrigerator (Initial Fill)

The LS6000-AT uses the AutoTend controller that comes

preset from the factory to operate.

The liquid nitrogen supply pressure at the inlet to the unit

should be in the range of 10 psig (0.7 bar/69 kPa) to 20

psig (1.4 bar/138 kPa) for optimum performance. Higher

operating pressures will increase transfer losses and

create excessive turbulence of the liquid in the unit which

can generate false signals to the liquid level controller

causing the unit to underfill. In liquid phase storage

applications, excessive turbulence can cause splashing

which could result in personal injury and/or damage to the

unit.

If the liquid nitrogen supply pressure at the inlet to the unit

rises above the opening pressure of the relief valve on the

unit, liquid nitrogen will be discharged into surrounding

area which can cause rapid and very dangerous depletion

of oxygen in the atmosphere. Once this pressure relief

device has opened and cooled to liquid nitrogen temperature, it will not reset until it has warmed to near ambient

temperature. THIS COULD PERMIT THE ENTIRE CONTENTS OF THE LIQUID NITROGEN SUPPLY SYSTEM

TO BE DISCHARGED INTO THE IMMEDIATE AREA OF

THE REFRIGERATOR(S).

the

Operating Parameters

When materials are immersed in liquid nitrogen, they will

assume the temperature of the liquid -320° F (-196° C).

When material is stored in the vapor phase of the liquid, the

liquid nitrogen is still a very cold refrigerant, but the units

interior temperature increases somewhat as product is

stored higher above the liquid. This temperature differential is

not significant in many biological storage applications, and is

affected by the amount of product stored in the unit, the type

and size of inventory control system, and the liquid level in

the unit.

The liquid level in the unit is determined by the position of the

sensor probes in the tube located next to the fill tube. These

probes are set at installation to maintain a specific liquid

level. (See Figure 4) The cycle repeats when the liquid level

drops to the low level sensor over time. Sensor probes may

be moved to define new high and low levels, and these levels

may be set independently to vary the liquid level differential

between fills. For adjusting the temperature probes see

Changing Liquid Level section in this manual.

Vapor Phase Storage

Vapor phase storage is normally utilized when stored product

is unable to withstand liquid nitrogen temperatures, or when

the storage medium (vials, ampules, etc.) is not designed for

liquid phase storage.

In a typical vapor phase storage system, the liquid level

sensors are positioned to maintain the liquid level at or below

the top of the spider. This positioning allows stored product to

be kept at cryogenic temperatures without being exposed to

liquid nitrogen, reducing the possibility of leakage or crosscontamination. Care must be taken in the positioning of the

level of refrigerant in the event of power outages, which may

disable the controller for an extended period of time. Consideration must also be given to liquid nitrogen availability and

delivery schedules.

WARNING: Maintain adequate ventilation to

prevent asphyxiation hazard. (See Safety Precautions)

Power Supply Connection

Connect the 24 Volt AC power supply to the rear of the

cryostorage system; then plug the power supply into a 110/

120 VAC outlet. (See Figure 5 for the Electrical Supply

Connections.) Turn on the AutoTend by turning the key on

the front panel (see Figure 5) to the on position. The

audible alarm may sound during setup; silence the alarm

by pressing the button labeled MUTE.

WARNING: If the fill fails to stop for

any reason, quickly close the liquid

supply valve to prevent overfilling

until the cause of the problem can

be determined.

The unit is now under automatic fill control. Liquid will be

added by the controller as long as the liquid supply and

electrical power are maintained.

Liquid Phase Storage

Liquid phase storage is normally utilized when liquid nitrogen

temperatures are required to maintain stored product viability

and the storage mediums are adequate for storage in liquid

nitrogen.

In a typical liquid phase storage system, the liquid level

sensors are positioned to maintain the liquid level at or below

the top level of the inventory control system. During operation, the upper levels of the inventory control system will at

times become exposed as the liquid level fluctuates.

Care must be taken to ensure that the liquid level remains

below the bottom of the lid. Operating the refrigerator with

high liquid levels characteristic of liquid phase storage may

result in turbulence during fill cycles. Caution must be

exercised if the unit lid is opened during a fill, and appropriated safety equipment should always be worn.

Sensor Positioning for the AutoTend Controller

The longer sensor probe (orange/yellow wires) contains the

Low Level sensor in a pod. The shorter probe (red/black

wires) contains the High Level sensor. The factory sensor

positions will maintain a liquid level between 2.0 in. to 4.0 in.

The dimensions used for the factory sensor installation are

shown in Figure 2.

Page 4

Start Fill

Stop Fill

2.0 inches

CONTROLLER OPERATION

Introduction

The AUTO-TEND Control System is designed to provide

simple, reliable liquid level control in your LN

operates on 24 Volts AC and uses a two-sensor system to

freezer. It

2

open and close a solenoid valve. The liquid level, the sensor

condition, the valve condition, and the LN2 supply condition

are indicated by lights on the front panel.

Installation:

The AUTO-TEND Control System is designed to mount

onto your Taylor-Wharton Cryogenic refrigerator. The

components plug into the back of the control panel as

follows: The Solenoid Valve has a 2-pin connector. The

sensor assembly has a 4-pin connector. These plug into the

mates on the back of the control panel.

The sensor assembly should be installed with the yellow

and orange wires at the High Level and the black and red

wires at the Low Level. These are labeled for easy reference.

The Auto-Tend controller should not require additional

attention to maintain liquid level if an adequate supply of

liquid nitrogen is maintained. If your protocol calls for you to

top off the cryostorage system at the end of a work day or

work week, press the Start button. The unit will fill to the

upper allowable liquid level and stop automatically. You may

choose to manually stop the fill by pressing the STOP

button at anytime during the fill.

.25 inches

Figure 2. Sensor Positioning for the AutoTend

Normal Fill Cycle

When the unit is filled and the controller is operating, the low

level sensor is immersed in liquid nitrogen (see Figure 4.)

Its resistance value is interpreted by the controller as in

liquid. At the same time, the high level sensor is above the

liquid pool sending the controller an in-gas signal. In this

condition, the control panel will read Normal. As liquid

nitrogen evaporates, the liquid level in the refrigerator drops

slowly until the low level sensor is above the liquid and

sends a different signal to the controller. The controller

interprets this condition as low liquid and opens

the fill solenoid valve admitting more refrigerant.

The unit fills slowly, the control panel will read

LOW when the liquid level is above the low

level sensor. It will continue to display the green

filling light until the high level sensor is immersed

in liquid. Once the level of the liquid reaches the

point of the high level sensor, the Solenoid Valve

will close. Figure 4 illustrates this cycle in graph

form where liquid level is plotted against time,

and display graphics are shown as they appear

at key points in the cycle.

Figure 4. Normal Fill/Evaporation Cycle Chart

Page 5

Controller Features Level LN2 Controllers

The controller is designed to maintain the LN2 level in the

unit within a user-defined range. The LN2 level will be

maintained between the low level sensor and the high level

sensor. When the liquid level reaches the low level sensor,

LN2 will be added to the refrigerator until it reaches the high

level sensor.

Basic Operation

1.) Automatic Fill: The control will open the solenoid

valve automatically when the liquid level falls below the

Low Level Sensor. It will continue filling until the High

Level Sensor is covered by liquid.

Manual Fill: The Start Fill button can be pressed at

any time and the solenoid valve will open. If the liquid

level is between High Level Sensor and the Low Level

Sensor, the solenoid will stay open until the Stop Fill

button is pressed or until the liquid level covers the

High Level Sensor. If the liquid level is above the High

Level Sensor, the solenoid valve will stay open while

the user presses the Start Fill Button but will close

when the user releases the button.

Please Note: The maximum time that the

valve will stay open when the liquid level is

above the High Level sensor is one

minute. The user can open the valve again

by simply releasing and then pressing the

Start Fill button again.

Remote Alarm Jack: The remote alarm relay has a

set of dry contacts capable of carrying 5 amperes

current at 30 volts D.C. The relay is normal during

any alarm condition. The remote alarm is triggered 30

minutes after an error condition occurs. The remote

alarm will be reset when the error condition is corrected. Pins 1 and 2 are closed in normal operating

condition while pins 2 and 3 are open in a remote

alarm condition. See Figure 8.

DESCRIPTION OF FRONT PANEL

Key Lock: This turns the control On/Off. Turning the Key to

the 3 oclock position provides power to the control while

rotating the key 12 oclock position turns the control off.

Start Fill: This button opens the solenoid valve and allows

LN2 to flow into the freezer.

Stop Fill & Mute: This button closes the solenoid valve and

stops the flow of LN2 into the freezer. This button also

silences the audible alarm.

Filling LED: Lights green to indicate that the solenoid valve

is open.

LN2 Level LED: Lights red to indicate that the liquid level is

above the high level sensor. Lights green to indicate that

the liquid level is between the low level sensor and the high

level sensor. Lights yellow to indicate that the liquid level is

below the low level sensor.

Alarm Conditions: An alarm condition occurs when

a sensor problem develops or the supply tank runs

low on LN2. When an alarm condition does occur, the

appropriate light on the front panel flashes and an

audible alarm is activated.

Testing the front panel lights: To test all the lights on

the control except the Filling LED, press the Stop Fill &

Mute button and hold for 8 seconds.

Testing the Remote Alarm: To test the remote alarm,

press the Stop Fill & Mute button and hold for 13

seconds (5 additional seconds after testing the lights,

or unplug the power supply from the wall.)

Sensor Assembly

Please note: The LED will not light if the high level

sensor is submerged in LN2 while the low level

sensor is located in gas. The only time that this can

occur is if the sensors are installed backwards.

Sensor Fault LED: Lights red to indicate that a sensor fault

has occurred. A sensor fault can be either an open circuit or

a short circuit in the sensor assembly.

Low LN2 Supply LED: Lights red to indicate that the LN

supply is low. This is triggered when the liquid level does

2

not reach the high level sensor within 1 hour of opening the

solenoid valve.

Remote Alarm24VAC Solenoid Valve

24VAC Power

Electrical Supply Connections For LS6000

Page 6

Changing Liquid Level

The liquid level in the unit is determined by the position of

the sensor probes in the sensor tube next to the fill tube.

These probes have been set at installation to maintain a

specific liquid level. The controller operates a fill cycle that

adds liquid at low level, fills to a predetermined high level,

then stops the fill. The cycle repeats when liquid drops to

the low level over time.

Sensor probe positions may be changed to define new high

and low liquid levels, and these levels may be set independently to vary the liquid level differential between fills. If a

higher liquid level is desired, withdraw the sensor tube; for a

low level, the sensors must be moved further into (down)

the sensor tube.

CAUTION: Ice or frost in the sensor

tube may restrict movement of

sensor probes in the tube. Do not

pull excessively on sensor wiring

while attempting to change sensor

position. It may be necessary to

remove the sensor from the container and allow it to thaw before the

sensor can be repositioned.

Increasing the distance between low and high sensor

probes allows greater liquid level fluctuation, less frequent

filling and reduced fill loses; decreasing the distance has

the opposite effect.

To set the liquid level to a different point, or to change the

level differential, the sensors must be repositioned. Their

position within the sensor tube is held in place by the

sensor tube plug, which is split to allow the sensor leads to

pass through. The sensor tube plug holds the sensors at

the position necessary to maintain a specific liquid levels.

Two different sensor heights are specified by their position

within the sensor tube. The low and high sensor pods are

separately positioned to set the liquid levels at which the

controller will start or terminate each fill cycle. Insert the

sensor leads into the perforated sensor tube to the desired

height. Mark the sensor leads at the top of the sensor tube.

Pull the leads out just enough to install the sensor tube plug

around the marks on the sensor leads. Insert sensor plug

securely into the mouth of the tube. Perform this operation

carefully, so the sensor leads are not damaged.

Remote Alarm Connection on Taylor-Wharton Freezers

Back panelson most Taylor-Wharton freezers are equipped

with a 3 point electrical socket. The socket connects to a

control board mounted, SPDT (single pole double throw)

relay, rated at 10 amps, 125 VAC.

1

1

3

2

2

3

1

(NC)

3 (NO)

A Switchcraft plug (#05GM3M) connects to the above

socket. It is available with leads as Taylor-Wharton part

#R06K-8C20. Approximately 9 of wire extend from the

plug. The gray wire connects to Pin #1, orange wire to Pin

#2 and the purple wire to Pin #3.

3

1

2

To connect an AC load, such as an alarm light or buzzer,

connect as shown below:

AC Line

AC Line

~

~

orange

Alarm

gray

For automatic dialers and other alarm systems that are

alarmed on either a contact make or break, connect as

shown below:

orange

purple

Alarm on break

2

3

orange

gray

Alarm on make

2

1

MAINTENANCE

LS Series CryoStorage Maintenance

Defrosting your K Series CryoStorage System

NOTE: The high level sensors must be at least

1.75 in. (5.1 cm) above the low level

sensor pod.

After repositioning sensors, check to be sure the sensor

tube is secured to the fill tube and the sensor wires are

dressed and clear of rack operation, and turn the controller

on. The controller should fill the refrigerator to the new

liquid level. After sensors are repositioned, the controller

should maintain the liquid pool at the new operating level.

Remote Alarm Connection

Relay connections are provided on an external for user

installation of a remote alarm circuit (see Figure 8.) Wiring

external power supply and alarm devices must be supplied

by the user. During an alarm condition, contacts 1 & 2 are

closed and contacts 2 & 3 are open.

All liquid nitrogen storage systems are subject to ice and

frost buildup over time. Regular preventive maintenance

programs should be instituted to remove ice and frost from

the sensor and fill tubes and from the refrigerator lid.

Ice and frost build up in the sensor tube may result in false

readings being relayed to the controller from the sensors.

Ice can form a thermal barrier around a level sensor,

rendering it insensitive to the temperature differences

between vapor and liquid. Sensors and thermocouple

should be removed regularly and inspected for ice and frost

build up.

NOTE: Ice or frost in the sensor tube may restrict

the movement of sensor probes in the

tube. Do not pull excessively on the sensor

wiring while attempting to change sensor

position. It may be necessary to remove

the fill tube and tube from the container

and allow it to thaw before the sensors can

be repositioned.

Page 7

Loading...

Loading...