Page 1

TW-43

LIQUID

WITHDRAWAL DEVICE

The Liquid Withdrawal Device (L WD) provides convenient

pressure transfer to liquid nitrogen from LD25,LD35, and

50LD Dewars. The device clamps directly to the special

neck flange that is found under the plastic trim collar

around the neck of these containers.

Flow rates up to 8 liters per minutes are possible at

operating pressures up to 10 psig (0.7 bar/69 kPa). Liquid

can be dispensed directly from the L WD via the spout

provided, or through a standard cryogenic hose connected

to the liquid outlet.

Filling a Dewar is accomplished by pressure transfer

through the withdrawal device. (See Filling Instructions.) This filling method allows replenishment of the

liquid supply in the Dewar without removing the L WD,

while keeping the liquid saturated at a pressure sufficient

to sustain liquid withdrawal.

For Liquid Nitrogen

LD25, LD35, and

50LD Dewars

Safety

Before using this equipment, read these instructions

carefully. Also, read and understand the instructions sup-

plied with your Dewar and the Handle with Care booklet

packed with all Liquid Nitrogen Dewars. The Handle with

Care booklet (Form TW-10) gives detailed information on

the safe handling of liquid nitrogen. Additional copies of

these publications can be obtained from your supplier. Do

not modify LWD or Dewar or use in a manner other than that

described in accompanying instructions and documentation.

Contact with liquid nitrogen or cold gas may cause

serious freezing (frostbite) injury . Do not touch liquid or

cold metal surfaces with your bare skin. Always wear a face

shield and gloves when transferring liquid nitrogen.

Nitrogen gas can cause suffocation without warning.

In a confined area, nitrogen gas from this equipment may

displace air required for breathing. Store and use this

equipment only in well-ventilated areas.

Use only containers designed for low-temperature

liquids. Cryogenic containers should be filled SLOWLY to

minimize stresses which can damage the container .

Vent all pressure from a Dewar before attempting to

remove the Liquid Withdrawal Device. If the band clamp

securing the L WD to a dewar is loosened while there is

pressure in the Dewar, cold gas or liquid could be expelled

causing personal injury .

Liquid Withdrawal Device is for use with liquid nitrogen

only . LWD is for use on specific model Taylor-Wharton

Dewars listed above.

Pressure in Dewar with LWD installed should never

exceed 10 psi. Fill dewar from supply source at 22 psi or

less. Do not pressurize using compressed air.

Page 2

Installation

1. Remove the necktube cap/core from the Dewar.

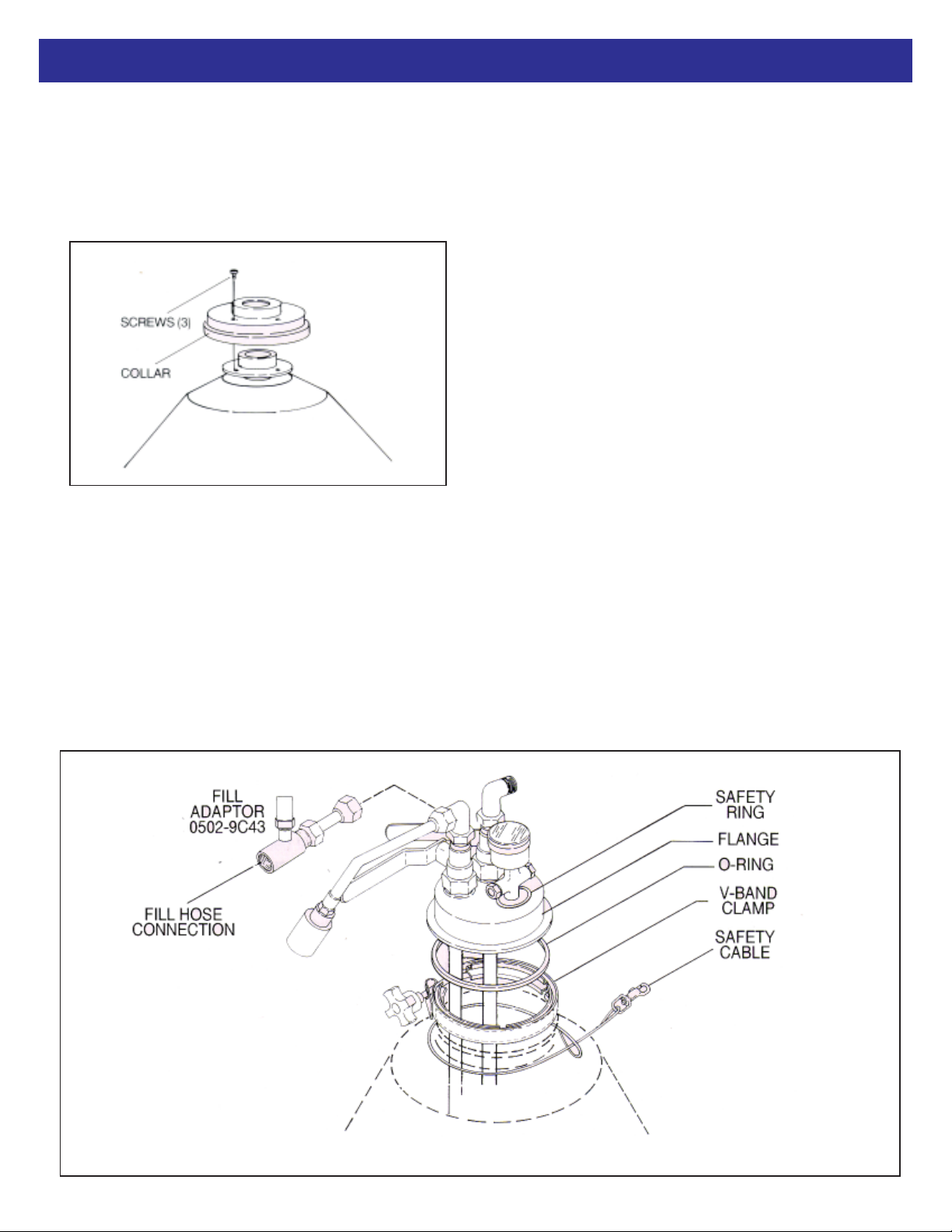

2. Remove 3 flat-head mounting screws in the base of

the plastic trim collar around the neck of the Dewar,

remove the collar and discard or save for later. It is not

used while the LWD is installed.

3. The liquid withdrawal tube (the longer of the two plastic

tubes) is scored approximately 6 in. (152 mm) from the

end. This tube must be shortened for use with a LD25

or LD35 Dewar by breaking off the 6 in. (152 mm)

section. Discard the 6 in. (152 mm) piece. The tube is

used as supplied with the LD50.

valve. Tighten the compression nut s with a wrench to

secure.

5. Position the safety cable assembly around the top of the

Dewar, underneath the flange. Loosen V-Band Clamp

until the clamp is large enough to remove from the

L WD. Drop the band clamp around the flange on the

Dewar (see Figure 2).

6. Clean the flange O-ring and apply a thin layer of silicone

grease before placing it on the grooved flange.

NOTE: Be sure flanges surfaces are warm, clean and

dry . The O-ring must be cleaned and lightly lubricated

before installing the LWD.

7. Carefully lower the LWD unit into the Dewar. The LWD

should rest firmly centered on the neck flange of the

Dewar; the liquid withdrawal tube should not touch the

bottom of the Dewar.

8. Place the band clamp around the flanges of both the

L WD unit and the Dewar. Be sure that the clamp is

properly engaged on both flanges. Tighten the clamp –

hand tighten only .

9. Attach the snap of the safety cable to the ring on the

LWD (see figure 2).

4. Insert the longer plastic tube into the underside of the

flange assembly , beneath the LIQUID valve. Insert the

shorter plastic tube into the threaded fitting on the

underside of the flange assembly , beneath the VENT

10. If the spout assembly is to be used, install it on the

outlet fitting above the LIQUID valve. The phase separator will ensure a controlled flow of liquid.

Page 3

Installation (cont.)

11. To remove the L WD, first open the VENT valve to

release all pressure in the Dewar. Then loosen the band

clamp enough to allow it to pass over the Dewar flange,

disengage the cable snap from the ring on the L WD and

lift the withdrawal unit out of the Dewar .

Operation

Filling – It is not necessary to remove the L WD unit from

the Dewar for filling. You may fill the Dewar by pressuretransfer of liquid nitrogen through the LIQUID valve of the

LWD.

WARNING: Over pressurization of the Dewar could

result in serious bodily injury or property damage.

Never exceed the 10 psig (0.7 bar/69kPa) relief valve

pressure setting of the LWD.

To fill, remove the spout assembly and connect a 22 psig

(1.52 bar/152kPa) or lower pressure liquid supply cylinder

to the withdrawal device using a liquid nitrogen transfer

hose and the fill adapter with the L WD.

WARNING: The transfer hose must be used with a

pressure relief valve to prevent excessive pressure

buildup in the hose when the valves are closed at both

ends of the hose. If liquid nitrogen is trapped between

the valves of the liquid cylinder and the LWD, it has no

escape path as it warms and expands. The resulting

pressure can cause the hose to rupture and may cause

personal injury . The current model LWD is equipped

with a pressure relief valve. Previous versions of the

LWD must be used with a transfer hose equipped with

a pressure relief valve.

secondary relief valve, set at 15 psig (1.0 bar/103 kPa),

prevents hazardous pressure rise in the event of primary

relief valve malfunction or if its capacity is exceeded. Never

replace either of these parts with higher value relief valves;

increasing the pressure in the Dewar beyond 15 psig (1.0

bar/103 kPa) may burst the Dewar and cause personal

injury/property damage.

To fill the Dewar by pouring liquid from another container,

(This is not the recommended filling method) first open

the VENT valve to release pressure. Then, loosen the band

clamp, unsnap the safety cable, and remove the L WD unit.

When replacing the L WD on the filled Dewar, leave the

VENT valve open until the flanges are securely clamped. To

pressurize the Dewar for liquid withdrawal, refer to “Pressure Building” below.

Note: Be sure flanges surfaces are warm, clean and dry .

The o-ring must be cleaned and lightly lubricated before

replacing the L WD.

Liquid Withdrawal – When the liquid valve is opened,

pressure in the Dewar forces liquid to go up through the

withdrawal tube and out through the valve. The liquid

nitrogen can be dispensed through the spot or through

plumbing connected to the liquid outlet.

Once the transfer hose is connected, open the L WD VENT

valve first and then open the L WD LIQUID valve. Then

slowly open the liquid valve on the supply cylinder until

liquid flow is established. Adjust the VENT valve to maint ain

a back pressure of 8 to 10 psig (0.6 bar/55 kPa to 0.7 bar/

69 kPa) in the Dewar. When liquid sputters from the VENT

valve, quickly close the liquid vavle on the supply cylinder,

next the LWD LIQUID valve and then the LWD VENT valve.

WARNING: Closely monitor Dewar pressure

througout the fill process. Never let the pressure

exceed 10 psig (0.7 bar/69 kPa). If the pressure approaches 10 psig, immediately fully open the LWD

VENT valve and/or close the LWD LIQUID valve as

necessary to control the pressure in the Dewar.

Loosen the hose connection slowly and allow all pressure

and any remaining liquid to be verified before completely

disconnecting the hose.

The primary relief valve, set at 10 psig (0.7 bar/69 kPa),

maintains the normal operating pressure of the LWD. A

Pressure Building – If the Dewar is filled properly , liquid

nitrogen evaporation will normally maintain a pressure

sufficient to sustain liquid withdrawal. However , if pressure is

lost, bubbling dry nitrogen gas through the liquid may restore

proper operating pressure. This adds heat to the liquid,

causes evaporation, and increases pressure. Connect a

pressure-regulated – 8 to 10 psig (0.6 bar/55 kPa to 0.7 bar/

69 kPa) – source of dry nitrogen gas to the LIQUID connection. Open the LIQUID valve and adjust the VENT valve to

maintain a back pressure of 8 to 10 psig (0.6 bar/55 kPa to

0.7 bar/69 kPa) while the gas bubbles up through the liquid.

After several minutes, close the valves and read the pressure gauge. If the pressure does not remain above the 5

psig (0.3 bar/34 kPa), resume the gas flow until the liquid

has warmed enough to provide normal operating pressure.

External pressurization can be applied while withdrawing

liquid from the Dewar by connecting a supply of nitrogen

gas, regulated to a pressure of 8 to 10 psig (0.6 ba/55 kPa

to 0.7 bar/69 kPa), to the vent valve connection.

Page 4

Replacement Parts

Item Desc ript ion Part No.

1 Elb ow, Liquid 6814-9222

2 Elb ow, V ent 6814-9225

3 Va lve (Liquid/ V ent ) 6986-9004

4 Valve Handle Cover, Liquid D050-8C18

5 Valve Handle Cover, Vent D050-8C19

6 O-Ring for valve 8830-6142

7 Press ure Gauge

0-30 psig (0-2 bar/207 k P a) 7702-6091

8 Relief Valve

10 psi g (0.7 bar/69 k P a) 6913-9044

9 Cross, 1/8" NP T 6817-5056

10 Relief Valve

15 psig (1.0 bar/103 kP a) 6913-9046

11 O -Ring for flange 8830-6135

12 V -B and Cl am p 7342-1119

13 Warning Label D050-8C21

14 Ring for Safety Cable 8830-6311

15 S afety Cabl e A s s em bly D050-8C20

16 S pout A ssem bly D050-8C14

17 P h as e S eperat or 1193-8C80

(part of Spout A s s e m bly )

18 Tube, Liqu id Withdrawal D050-8C22

19 Tube, V ent D050-8C23

20 Loc k nut , Com pres s ion D050-8C25

21 A d aptor, Fill D050-9C43

22 Relief Valve

22 psig (2.4 bar/241 kP a) 6913-9069

23 Hex Bushing, 1/ 2" X 1/4", B ras s 6810-8998

24 S treet Tee, 1/2" NPT 6816-9210

25 V -B and Cl am p Tightening K nob 7342-1125

26 V a lve Replacement Handle 7801-5051

Ordering Information – Order all replacement parts and

accessories from your distributor. Please include the part

and model number of your refrigerator, quantity, and

description of each part requested. For more information

or the name of your local distributor, cont act Taylor-

Wharton at the address listed.

Taylor-Wharton

4075 Hamilton Boulevard

Theodore, AL 36582

Phone (334) 443-8680

Fax: (334) 443-2250

In U.S. and Canada: (800) TW TANKS (898-2657)

Loading...

Loading...