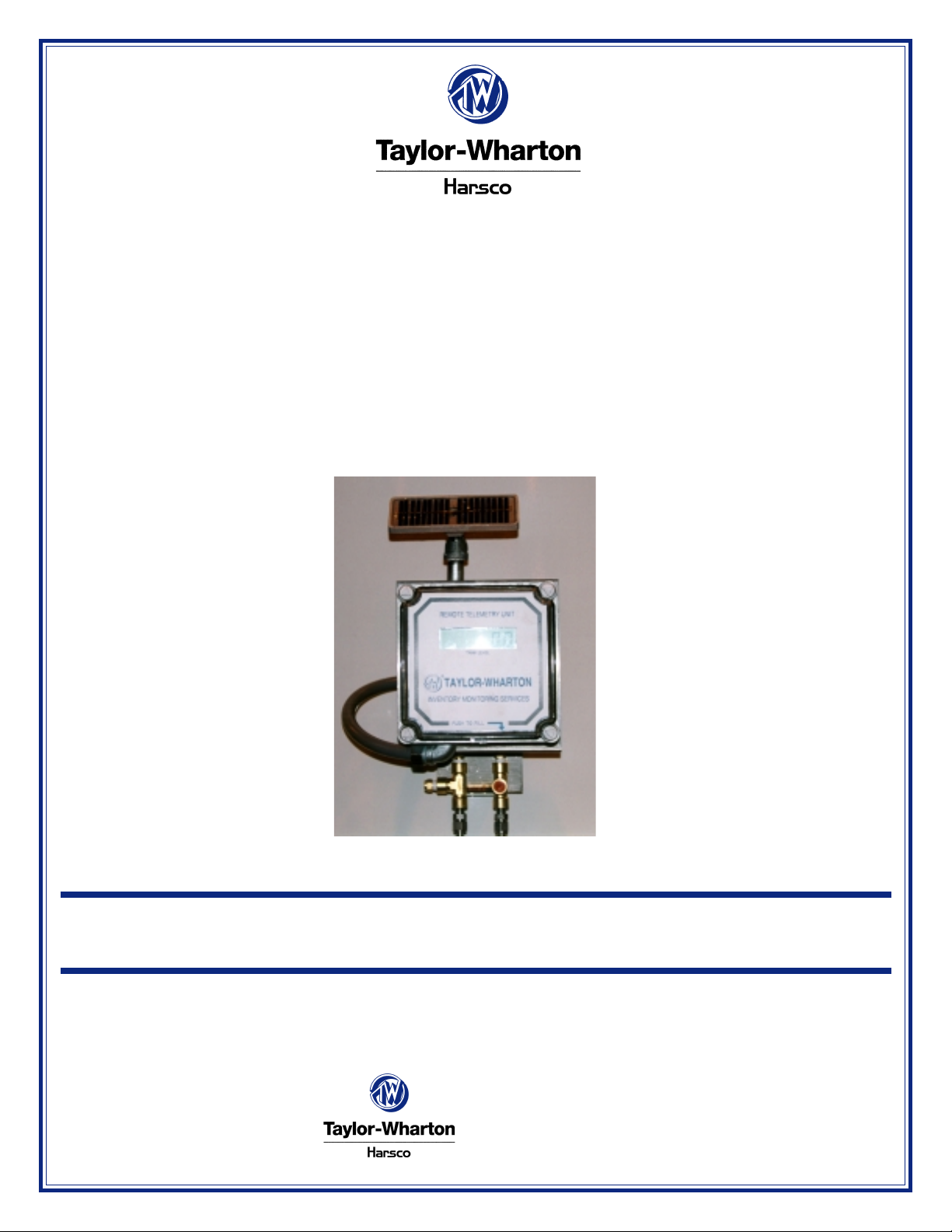

Page 1

Instructions

for

KeepFull Wireless/Internet Bulk Tank Liquid Level Monitoring System

PART NUMBERS 5740-8800 & 5740-8825

Do not attempt to use or maintain these units until you read and understand these instructions. Refer to Taylor -Wharton’ s

Safety First booklet (TW-202) for handling cryogenic material. Do not permit untrained persons to maintain this equip-

ment. If you do not understand these instructions, contact your supplier for additional information.

Taylor-Wharton

4075 Hamilton Blvd.

Theodore, AL 36582

Phone: (251) 443-8680

Fax: (251) 443-2250

BT-826

Page 2

Table of Contents

Table of Contents .................................................................................................. 2

Safety ..................................................................................................................3-4

Introduction .......................................................................................................... 5

Installation............................................................................................................. 6

System Activation ................................................................................................. 7

Web site.............................................................................................................7-10

A) Explanation of User Menus ............................................................... 10

B) Alarms.................................................................................................. 10

Part Numbers ...................................................................................................... 10

Troubleshooting .................................................................................................. 10

Warranty Service................................................................................................ 10

Bulk Vessel Registration Form.......................................................................... 11

Appendix A: Example of Bulk Vessel Registration Form.................................12

Appendix B: Example of Schedule 1 - Customer Information Form..............13

2

Page 3

The following safety precautions are for your protection. Before performing installation, operating, or maintenance procedures read and follow all safety precautions in this section and in reference publications. Failure to observe all safety precautions can result in property damage, personal injury, or possible death. It is

the responsibility of the purchasers of this equipment

to adequately warn the user of the precautions and safe

practices for the use of this equipment and cryogenic

fluids.

SAFETY PRECAUTIONS FOR LIQUID OXYGEN

Oxygen is a colorless, odorless, and tasteless gas that can

be condensed into a liquid at the low temperature of -297°F

(-183°C) under normal atmospheric pressure. Approximately

one-fifth of normal air is oxygen. As a liquid, oxygen is pale

blue in color. Oxygen is non-flammable but vigorously accelerates the burning of combustible materials.

Keep Combustibles Away from

Oxygen and Eliminate Ignition Sources

Many substances which do not normally burn in air require

only a slight spark or moderate heat to set them aflame in

the presence of concentrated oxygen. Other substances

which are only moderately combustible in air can burn violently when a high percentage of oxygen is present.

Do not permit smoking or open flame in any area where

liquid oxygen is stored, handled, or used. Keep all organic

materials and other flammable substances away from possible contact with liquid oxygen. Some of the materials that

can react violently with oxygen are oil, grease, kerosene,

cloth, wood, paint, tar , and dirt which contains oil or grease.

Under certain conditions flammable materials which have

become permeated with liquid oxygen are impact sensitive

and can detonate if subjected to shock.

Keep Area and Exterior Surfaces Clean

to Prevent Ignition

As normal industrial soot and dirt can constitute a combustion hazard, all equipment surfaces must be kept very clean.

Do not place oxygen equipment on asphalt surfaces, or allow grease or oil deposits to remain on benches or concrete

surfaces in the vicinity of the oxygen equipment. Use cleaning agents which will not leave organic deposits on the

cleaned surfaces. Equipment to be used in contact with

liquid oxygen should be handled only with clean gloves or

hands washed clean of oil.

Maintain Adequate Ventilation

Enclosed areas containing oxygen equipment should be ventilated to prevent accumulations of oxygen and thereby minimize combustion hazards.

Extreme Cold - Cover Eyes and Exposed Skin

Accidental contact of liquid oxygen or cold issuing gas with

the skin or eyes may cause a freezing injury similar to frostbite. Handle the liquid so that it won’t splash or spill. Protect

your eyes and cover the skin where the possibility of contact

with the liquid, cold pipes and cold equipment, or the cold

gas exists. Safety goggles or a face shield should be worn if

liquid ejection or splashing may occur or cold gas may issue

forcefully from equipment. Clean, insulated gloves that can

be easily removed and long sleeves are recommended for

arm protection. Cuffless trousers should be worn outside

boots or over the shoes to shed spilled liquid. If clothing

should be splashed with liquid oxygen or otherwise saturated

with the gas, air out the clothing immediately, removing it if

possible. Such clothing will be highly flammable and easily

ignited while the concentrated oxygen remains, and should

not be considered safe for at least 30 minutes.

Replacement Parts

Must be Suitable for Oxygen Service

Many materials, especially some non-metallic gaskets and

seals, constitute a combustion hazard when in oxygen service, although they may be acceptable for use with other cryogenic liquids. Make no substitutions for recommended spare

parts. Also, be sure all replacement parts are thoroughly

“Cleaned For Oxygen Service” in accordance with Compressed Gas Association (CGA) Pamphlet G-4.1 “Cleaning

for Oxygen Service” or equivalent industrial cleaning specifications.

Observe Safety Codes When

Locating Oxygen Equipment

Before locating oxygen equipment, become thoroughly familiar with National Fire Protection Association (NFP A) S tandard No. 50, “Bulk Oxygen Systems”, and with all federal,

state and local safety codes. The NFP A S tandard covers the

general principles recommended for the installation of bulk

oxygen systems on industrial and institutional consumer premises.

CAUTION: When installing field fabricated piping,

make certain a suitable safety valve is installed in each section of piping between

shut-off valves.

For more detailed information concerning safety precautions

and safe practices to be observed when handling cryogenic

liquids consult CGA pamphlet P-12 “Handling Cryogenic Liquids” available from the Compressed Gas Association, 1235

Jefferson Davis Highway , Arlington, Va. 22202.

3

Page 4

SAFETY PRECAUTIONS FOR LIQUID NITROGEN

Nitrogen is an inert, colorless, odorless, and tasteless gas

which makes up four-fifths of the air you breathe. Liquid nitrogen is obtained by cooling air until it becomes a liquid and

then removing the oxygen which makes up the other fifth of

the air. Liquid nitrogen is at a temperature of -320°F (-196°C)

under normal atmospheric pressure.

Extreme Cold - Cover Eyes and Exposed Skin

Accidental contact of liquid nitrogen or cold issuing gas with

the skin or eyes may cause a freezing injury similar to frostbite. Handle the liquid so that it won’t splash or spill. Protect

your eyes and cover the skin where the possibility of contact

with the liquid, cold pipes and cold equipment, or the cold

gas exists. Safety goggles or a face shield should be worn if

liquid ejection or splashing may occur or cold gas may issue

forcefully from equipment. Clean insulated gloves that can

be easily removed and long sleeves are recommended for

arm protection. Cuffless trousers should be worn outside

boots or over the shoes to shed spilled liquid.

Keep Equipment Area W ell Ventilated

Although nitrogen is non-toxic and non-flammable, it can

cause asphyxiation in a confined area without adequate ventilation. Any atmosphere which does not contain enough oxygen for breathing can cause dizziness, unconsciousness, or

even death. Nitrogen being colorless, odorless, and tasteless cannot be detected by the human senses and will be

inhaled normally as if it were air Without adequate ventilation, the expanding nitrogen will displace the normal air without warning that a non-life-supporting atmosphere is present.

Store liquid containers outdoors or in other well ventilated

areas.

Dispose of Waste Liquid Nitrogen Safely

Dispose of waste liquid nitrogen out-of-doors where its cold

temperature cannot damage floors or driveways and where

it will evaporate rapidly . An out door pit filled with clean sand

or gravel will evaporate liquid nitrogen safely and quickly .

CAUTION: When installing field fabricated piping,

make certain a suitable safety valve is

installed in each section of piping between shut-off valves.

For more detailed information concerning safety precautions and safe practices to be observed when

handling cryogenic liquids consult CGA pamphlet

P-12 “Handling Cryogenic Liquids” available from

the Compressed Gas Association, 1235 Jefferson

Davis Highway , Arlington, VA 22202.

NOTE: Argon is an inert gas whose physical prop-

erties are very similar to those of nitrogen.

For handling of liquid argon, follow the safe

practices described for the handling and

use of liquid nitrogen.

4

Page 5

Introduction

The bulk tank liquid level monitoring system provided by

Taylor Wharton provides the latest technology for local as

well as remote observation of a bulk tank’s contents. This

system enables an operator to check tank liquid level

from any computer that has Internet access as well as at

the tank site. With its local digital display it is a direct

replacement for the analog differential pressure “Contents Gauge” commonly being used. Because wireless

transmission is used and the unit is battery powered, no

external wiring is required. Therefore installation is as

easy as the replacement of the “Contents Gauge.”

The system consists of a differential pressure transmitter,

a local digital display , a cellular transmitter/receiver, and a

database service that is accessed through an Internet

Web site. Solar assisted batteries supply power for long

life. The differential pressure transmitter connects to the

same tank instrument lines as the “Contents Gauge.”

This component comes with 0-325” and 0-600” water

column spans. Every hour the pressure transmitter

senses the tank liquid level by measuring the differential

pressure produced by liquid in the tank. T ransmitter

output is communicated to the tank mounted telemetry

device in the form of a 4 to 20 mA electrical signal. The

hourly readings are locally stored and at least one time

per day they are all transmitted to the database. For local

observation of the current liquid level, a button is depressed causing a tank reading to be taken. The tank will

be sampled every 10 seconds for 15 minutes. During a

fill the same button is used and the tank will be sampled

at the same rate for 1 hour.

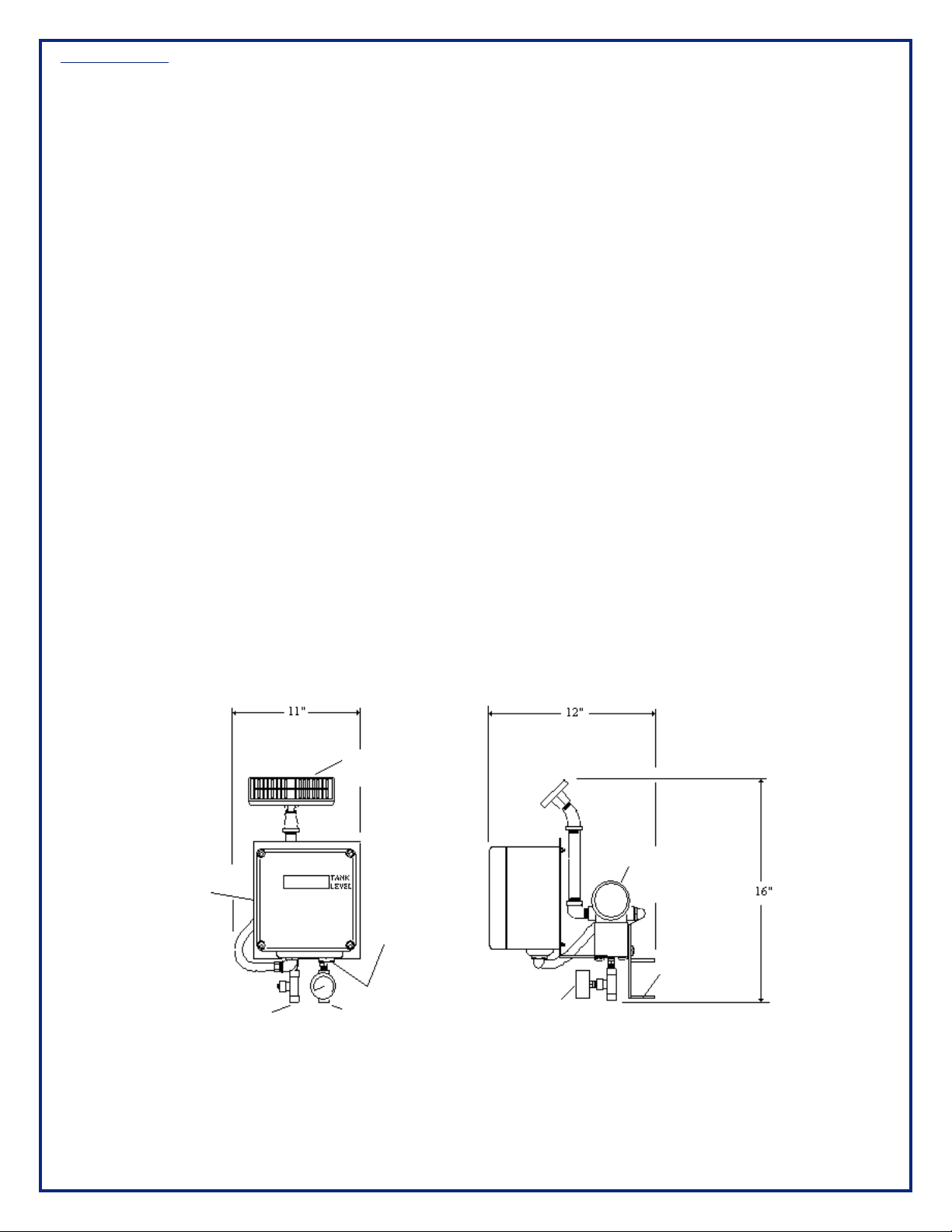

Figure 1 below shows the general layout of the telemetry

device.

Telemetry

Unit

High

Pressure

Tap

Solar

Panel

Button

For Local

Display

Low

Pressure

Tap

Figure 1: General Layout and dimensions

5

Tank

Pressure

Gauge

Differential

Pressure

Transmitter

Mounting

Bracket

Page 6

Installation

Before installing the telemetry unit inspect it carefully .

Report any damage to the carrier and Taylor Wharton

Customer Service. As shipped, the unit is operational and

ready to be installed on the tank. For installation on a

typical tank with an existing Contents Gauge follow these

steps.

1) Fill out the Bulk Vessel Registration Form supplied with

this manual and fax it to Taylor Wharton Customer

Service. This form, along with the Customer Information Form, filled out at the time of purchase is used to

prepare your Internet Web Site.

2) Verify that the dif ferential pressure transmitter sp an

(inches of water) covers the range required for the

tank.

3) Record the present liquid level and tank pressure as

indicated on the existing Contents Gauge Assembly.

Also, label the high and low-pressure instrument lines.

4) Close both instrument valves to isolate the existing

Contents Gauge Assembly from the t ank. Open the

Instrument Bypass valve to equalize the pressure

between the high-pressure and low-pressure side of

the Contents Gauge Assembly.

5) Carefully loosen the connections at the Contents

Gauge Assembly to relieve any pressure and then

remove the assembly .

6) Identify the high (H) and low-pressure (L) sides of the

Differential Pressure T ransmitter on the Telemetry Unit.

7) Mount the Telemetry Unit on the tank using the supplied bolts. See figure 2. The Telemetry Unit bracket

is designed to mate to a typical bracket supplied with

the tank. If there is a mismatch some field adaptation

may be required.

8) Solar panel must be directed to maximize southern sun

exposure. Turn the solar p anel by rot ating the 45°

elbow as much as one-quarter turn to direct the panel

to a maximized southern sun exposure. Caution, only

apply torque to 45° elbow using appropriate

wrenches.

9) Install an appropriate pressure gauge in the tee at the

low-pressure side of the telemetry unit. See figure 2.

10) Connect the instrument lines and then open the

instrument valves.

11) Leak test all connections using a suitable liquid leak

detector.

12) To obtain the current reading momentarily hold the “Fill

Button” until you see “FILL” on the display . The screen

will blink with the current reading. If “ERROR” is

displayed the high and low-pressure connections are

most likely reversed.

13) Activate your website.

Figure 2: T ypical Installation

Notes: All supplied pressure parts are

suitable and have been cleaned for

oxygen service. All field installed

parts must have a pressure rating

equal to or higher than the tank

MA WP, be suitable for oxygen service

and likewise cleaned. See the safety

precautions in the front of this

manual.

Seal all pipe threads using Teflon tape.

Telemetry

Unit

High

Pressure

Tap

Figure 2: Typical Installation

Low

Pressure

Tap

Solar Panel

45-degree Elbow

Existing Tank Bracket

Tank

Pressure

Gauge

Tube Adapter From

Instrument Tube Size

Connecting to 0.25” FNPT

Screw and Locknut

Supplied With Unit

4 Places

6

Page 7

System Activation

Y our Internet service provider is Dat aQwest Inc. Please

call their technical service group at (908) 464-2646 ext. 12

to commission your telemetry system. Units may be

commissioned Monday through Friday from 7:30 AM to

5:00 PM EST.

Y ou will be instructed to hold the “Fill Button” depressed

for about 20 seconds. “LOG ON” and then “CALL” should

appear on the display . The unit will log on to the network.

Expect this to take about 5 minutes. If “ERROR” is

displayed a failure to connect with the network is indicated.

In this event, please call DataQwest. Upon successful

transmission the Telemetry unit will receive its alarm points

and begin to log data. It is now on-line and ready to report

liquid level information.

Web site

After the telemetry unit is activated wait at least 3 business

days for the unit to collect and transmit the first readings

before accessing the DataQwest Web site for your tank.

You may access your telemetry Web site at http://

www.dataqwestinc.com. The following screen should

appear.

Click on “DATA ONLINE” at the left of the screen. A log on box like shown below will appear.

Type your Dat aQwest assigned user name and password and click “OK”. You should have received this information via telephone or letter from DA TAQWEST. If you have not received your user name and password, contact DATAQWEST’s Technical

Service Group at (908) 464-2646 ext. 12. A screen that shows a list of states where your telemetry equipped tanks are located

will appear.

7

Page 8

Click on the state to access a screen that will direct you to cities.

Clicking on the city of interest will produce a screen listing individual sites.

8

Page 9

Click on the site for a listing of tanks.

Clicking on the tank of interest will allow you to see its data.

9

Page 10

Explanation of User Menus

Alarms

At the bottom of this screen there are six choices for

viewing tank information and making changes to system

parameters. Click on each to view its features and

functions.

Change Request: This screen allows changes to tank

and sensor parameters. Upon receipt of a change request

“DataQwest” technicians will change the parameters.

Configuration: As shown above this screen gives

general tank and sensor information.

Events: Product deliveries and other important events are

displayed, with information about the time of their occur-

rence and the tank level afterwards.

Historical Data: Historical data showing product usage

and replenishment is display along with fill levels and

alarm points.

Site Summary: As shown above this screen list s the t anks

that are located at a particular site.

Site Directory: As shown above this screen lists the

St ates where tank sites are located.

When product level falls below a “critical point” the telemetry unit will within the hour transmit an alarm to the Web

site. A predetermined contact in your organization will

immediately be notified by E-mail or Fax.

Part Numbers

Two dif ferent telemetry units cover a dif ferential pressure

range from 0 to 600 inches of water. Order Taylor

Wharton’s part number 5740-8800 to receive a unit that

spans the range from 0 to 325 inches of water . For 0 to

600 inches of water order part number 5740-8825.

Trouble Shooting

If erratic or erroneous readings are indicated check all

pressure connections for leakage. Repair any leaks. If the

unit still is displaying false readings or no leaks are found,

call Taylor Wharton Customer Service.

Warranty and Service

For warranty and service call Taylor Wharton Customer

Service: 1-800-TW-TANKS.

10

Page 11

Bulk Vessel Registration Form

Please fax this completed form Attention: Taylor Wharton Technical Response Group (334) 443-2250 for each telemetry

device to be installed. This information should agree with that provided on “Schedule One: Customer Information form” that

was provided when your telemetry unit was ordered.

Contact for Website User Name and Password

Customer Name: Contact: Date:

Street: City: State: Zip:

Phone: Service Agreement Number:

T ank Site Information

Site Name: Installed by:

Streeet: City: State: ZIP:

Phone:

Please sketch the overall tank area, noting South and solar panel direction.

Building

Note any power sources:

Tank Information

Tank identification at tank site: (Serial # preferred) (Nominal size/model)

Product: Full Reading: (inches of H2O)

Reorder Reading: (inches of H2O) Low Level Alarm Reading (inches of H2O)

Please circle one:

Tank Orientation: Vertical or Horizontal Unit installed on: Tank or Instrument Stand

Original D.P. Gauge: Removed or Retained Are Extra Alarms to Customer Required? Yes or No

Tank liquid level and pressure prior to disconnection of existing gauges: Pressure: (psig)

Building

S

Note any obstructions:

Liquid level (inches)

T elemetry Device Information

Device I.D. Sensor span:

Comments:

11

Page 12

Appendix A: Example of Bulk Vessel Registration Form

Bulk Vessel Registration Form

Please fax this completed form Attention: Taylor Wharton Technical Response Group (334) 443-2250 for each telemetry

device to be installed. This information should agree with that provided on “Schedule One: Customer Information form” that

was provided when your telemetry unit was ordered.

Contact for Website User Name and Password

Customer Name: Contact: Date:

Street: City: State: Zip:

Phone: Service Agreement Number:

(000) 000-0000

JL Welding Company Jane Doe

123 Any Street XX 00000

Someville

TWRB-123

T ank Site Information

Site Name: Installed by:

Streeet: City: State: Zip:

Phone:

Ace Metal Works Inc.

78 Ginger Rd.

(000) 000-0000

Someville

Please sketch the overall tank area, noting South and solar panel direction.

Note any power sources:

Note any obstructions:

Jack Doe

Building

XX

S

00/00/00

00000

Building

Tank Information

Tank identification at tank site: (Serial # preferred) (Nominal size/model)

Product: Full Reading: (inches of H2O)

Reorder Reading: (inches of H2O) Low Level Alarm Reading (inches of H2O)

Please circle one:

Tank Orientation: Vertical or Horizontal Unit installed on: Tank or Instrument Stand

Original D.P. Gauge: Removed or Retained Are Extra Alarms to Customer Required? Yes or No

T elemetry Device Information

Device I.D. Sensor span:

Comments

Nitrogen

100

S/N-XXXX

311

FGD123P4 0-400

12

VT-6,000-250

85

108

152

Page 13

Appendix B: Example of Schedule 1- Customer Information Form

Schedule 1: Customer Information Form

Customer Billing & Notice Information for Monthly Web Service

Customer Name: Contact:

Street: City: State: Zip: Phone:

Service Agreement Number: Effective Date:

Fees

Monthly Fee: $ 1x Activation Fee: $

T ank Site Information

Site Name: Contact (if any):

Street: City: State: Zip: Phone:

Transmission Coverage Checked: Y or N Transmission Frequency: Every 12/24/ hrs.

T ank Information

123 West Street

7878 Ginger Road

ABC Gas Distributor

ACE Metal Works Inc.

John Williams

Someville

TWRB-123 00/00/00

Someville

XX 00000 (000) 000-0000

Jack Doe

XX

00000

(000) 000-0000

Tank Identification at Tank Site (Serial Number if possible):

Nominal Size & Model: Product:

Full Reading: (inches of H20)

Reorder Reading: (inches of H20)

Low Level Alarm Reading: (inches of H20)

Please Circle One:

Tank Orientation: Vertical or Horizontal Unit installed on: Tank or Instrument St and

Are Extra Alarms to Customer Required: Y or N Original D.P. Gauge: Removed or Retained

Contact for Web Site User name and Passwork

Customer Name: Contact:

Street: City: State: Zip: Phone:

Current DataQwest Web Site Username (if any):

77 Hickory Lane Someville XX 00000

VT-6,000-250

311

100

85

JL Welding Company

S/N-XXXX

Nitrogen

Jane Doe

(000) 000-0000

JLWelding

Alarm Method: Email Address:

Fax Number:

Name of Contact:

JLWelding@JLWelding.com

(000) 000-0000

Jack Smith

13

Page 14

Taylor-Wharton

4075 Hamilton Blvd.

Theodore, AL 36582

Phone: (334) 443-8680

Fax: (334) 443-2250

www.taylorwharton.com

Part # 99187826 © 2001 Harsco Corporation BT-826

Loading...

Loading...