Page 1

BT-481 REV. B

Express fill 1500

Installation and Operation Manual

Do not attempt to use or maintain these units until you read and understand these instructions. Refer to the TaylorWharton’s Safety First

maintain this equipment. If you do not understand these instructions, contact your supplier for additional information.

booklet (TW-202) for handling cryogenic material. Do not permit untrained persons to use or

Page 2

BT-481 REV. B

Table of Contents

WARNING 3

Safety Precautions for Liquid Oxygen 3

Safety Precautions for Liquid Nitrogen 4

Safety Precautions for Liquid Carbon Dioxide 4

Safety Precautions for Liquid Nitrous Oxide 5

INTRODUCTION 6

System Description 6

Specifications 7

PIPING CIRCUITS 8

Fill and Vent Circuits 9

Express Fill Circuit 9

Pressure Building Circuit 10

Internal Vaporizer, External Vaporizer Inlet, and Economizer 13

Safety Devices 14

Instrumentation Circuits 15

INSTALLATION 16

Receiving Inspection 16

Handling 16

Vessel Installation Guidelines 16

Fill Box Installation Guidelines 16

OPERATION 19

Filling by Pressure Transfer 19

Filling by Pump Transfer 19

Withdrawing Product 20

Withdrawing Liquid 20

Changing Gas Service 20

MAINTENANCE 21

Leak Test 21

Globe Valves 21

Regulators 22

Instruments 23

Vacuum 23

Trouble-Remedy Guide 24

Replacement Parts 25

APPENDIXES 26

Appendix 1 – Express fill 1500 General Arrangement 26

Page 3

BT-481 REV. B

WARNING

The following safety precautions are for your protection. Before installing, operating, or maintaining this unit read and

follow all safety precautions in this section and in the reference publications. Failure to observe all safety precautions can

result in property damage, personal injury, or possibly death. It is the responsibility of the purchaser of this equipment to

adequately warn the user of the precautions and safe practices for the use of this equipment and the cryogenic fluid stored

in it.

CAUTION: When installing field fabricated piping, make certain a suitable safety valve is installed in each

section of piping between shut-off valves.

For more detailed information concerning safety precautions and safe practices to be observed when handling cryogenic

liquids consult CGA pamphlet P-12 "Handling Cryogenic Liquids" available from the Compressed Gas Association,

1235 Jefferson Davis Highway, Arlington, VA 22202.

Safety Precautions for Liquid Oxygen

Oxygen is a colorless, odorless, and tasteless gas that can be condensed into a liquid at the low temperature of 297

degrees below zero Fahrenheit (-183°C) under normal atmospheric pressure. Approximately one-fifth of normal air is

oxygen. As a liquid, oxygen is pale blue in color. Oxygen is non-flammable; however it vigorously accelerates the

burning of combustible materials.

Keep Combustibles Away from Oxygen and Eliminate Ignition Sources

Many substances that do not normally burn in air require only a slight spark or moderate heat to set them aflame in the

presence of concentrated oxygen. Other substances, which are only moderately combustible in air, can burn violently

when a high percentage of oxygen is present.

Do not permit smoking or open flame in any area where liquid oxygen is stored, handled, or used. Keep all organic

materials and other flammable substances away from possi bl e cont act wi t h li qui d oxy gen. Some of the materials that can

react violently with oxygen are oil, grease, kerosene, cloth, wood, paint, tat, and dirt that contains oil or grease. Under

certain conditions flammable materials that have become permeated with liquid oxygen are impact sensitive and can

detonate if subjected to shock.

Keep Area and Exterior Surfaces Clean to Prevent Ignition

As normal industrial soot and dirt can constitute a combustion hazard, all equipment surfaces must be kept very clean.

Do not place oxygen equipment on asphalt surfaces, or allow grease or oil deposits to remain on benches or concrete

surfaces in the vicinity of the oxygen equipment. Use cleaning agents, which will not leave organic deposits, on the

cleaned surfaces. Equipment to be used in contact with liquid oxygen should be handled only with clean gloves or hands

washed clean of oil.

Maintain Adequate Ventilation

Enclosed areas containing oxygen equipment should be ventilated to prevent accumulations of oxygen and thereby

minimize combustion hazards.

Extreme Cold - Cover Eyes and Exposed Skin

Accidental contact of liquid oxygen or cold issuing gas with the skin or eyes may cause a freezing injury similar to

frostbite. Handle the liquid so that it won't splash or spill. Protect your eyes and cover the skin where the possibility of

contact with the liquid, cold pipes and equipment, or the cold gas exists. Safety goggles or a face shield should be worn

if liquid ejection or splashing may occur or cold gas may issue forcefully from equipment. Clean, insulated gloves that

can be easily removed and long sleeves are recommended for arm protection. Cuffless trousers should be worn outside

boots or over the shoes to shed spilled liquid. If clothing should be splashed with liquid oxygen or otherwise saturated

with the gas, air out the clothing immediately, removing it if possible. Such clothing will be highly flammable and easily

ignited while the concentrated oxygen remains, and should not be consi dered safe for at least 30 m inutes.

Replacement Parts Must be Suitable for Oxygen Service

Many materials, especially some non-metallic gaskets and seals, constitute a combustion hazard when in oxygen service,

although they may be acceptable for use with other cryogenic liquids. Make no substitutions for recommended spare

3

Page 4

BT-481 REV. B

parts. Also, be sure all replacement parts are thoroughly "Cleaned For Oxygen Service" in accordance with Compressed

Gas Association (CGA) Pamphlet G-4.1 "Cleaning for Oxygen Service" or equivalent industrial cleaning specifications.

Observe Safety Codes When Locating Oxygen Equipment

Before locating oxygen equipment, become thoroughly familiar with National Fire Protection Association (NFPA)

Standard No. 50, "Bulk Oxygen Systems", and with all federal, state and local safety codes. The NFPA Standard covers

the general principles recommended for the installation of bulk oxygen systems on industrial and institutional consumer

premises.

Safety Precautions for Liquid Nitrogen

Nitrogen is an inert, colorless, odorless, and tasteless gas making up four-fifths of the air you breathe. Liquid nitrogen is

obtained by cooling air until it becomes a liquid and then removing the oxygen. Air is roughly one-fifth oxygen. Liquid

nitrogen is at a temperature of -320°F (-196°C) under norm al at mospheri c pressure.

Extreme Cold - Cover Eyes and Exposed Skin

Accidental contact of liquid nitrogen or cold issuing gas with the skin or eyes may cause a freezing injury similar to

frostbite. Handle the liquid so that it won't splash or spill. Protect your eyes and cover the skin where the possibility of

contact with the liquid, cold pipes and equipment, or the cold gas exists. Safety goggles or a face shield should be worn

if liquid ejection or splashing can occur or cold gas can issue forcefully from equipment. Insulated gloves that can be

easily removed and long sleeves are recommended for arm protection. Trousers without cuffs should be worn outside

boots or over the shoes to shed spilled liquid.

Keep Equipment Area Well Ventilated

Although nitrogen is non-toxic and non-flammable, it can cause asphyxiation in a confined area without adequate

ventilation. Any atmosphere not containing enough oxygen for breathing can cause dizziness, unconsciousness, or even

death. Nitrogen, a colorless, odorless, and tasteless gas, cannot be detected by the human senses and will be inhaled

normally as if it were air. Without adequate ventilation, the expanding nitrogen will displace the normal air resulting in a

non-life-supporting atmosphere.

Dispose of Waste Liquid Nitrogen Safely

Dispose of waste liquid nitrogen out-of-doors where its cold temperature cannot damage floors or driveway s and where it

will evaporate rapidly. An outdoor pit filled with clean sand or gravel will evaporate liquid nitrogen safely and quickly.

NOTE: Argon is an inert gas whose physical properties are very similar to those of nitrogen. For handling of liquid

argon, follow the safe practices described for the handling and use of liquid nitrogen.

Safety Precautions for Liquid Carbon Dioxide

WARNING: CARBON DIOXIDE CAN CAUSE ASPHYXIATION AND DEATH IN CONFINED, POORLY

VENTILATED AREAS.

COLD GAS CARBON DIOXIDE CAN CAUSE SEVERE FROSTBITE TO THE EYES OR SKIN. DO NOT

TOUCH FROSTED PIPES OR VALVES. IF ACCIDENTAL EXPOSURE TO THESE GASES OCCURS,

CONSULT A PHYSICIAN AT ONCE. IF A PHYSICIAN IS NOT READILY AVAILABLE, WARM THE AREAS

AFFECTED BY FROSTBITE WITH WATER THAT IS NEAR BODY TEMPERATURE.

Keep Equipment Area Well Ventilated.

Carbon dioxide affects the important acid-base balance in the body. Carbon dioxide is formed in normal functioning

within the body, but the body can tolerate increased amounts of carbon dioxide only in limited concentration. This is

recognized in OSHA standards where a Threshold Limit Value of 5,000 parts per million by volume (0.5 percent

concentration) has been adopted. For safety, concentrations above this level should not be permitted; increased

concentrations can

cause bodily harm or death. Additionally, carbon dioxide can cause asphyxiation by

displacing oxygen resulting in dizziness, unconsciousness or death.

4

Page 5

BT-481 REV. B

Ten percent carbon dioxide in air can be endured for only a few minutes; twelve to fifteen percent

soon cause unconsciousness; twenty five percent may cause death if exposure lasts for several hours.

Carbon dioxide cannot be detected by the human senses and will be inhaled like air. Carbon

dioxide is heavier than air and will accumulate in low lying areas. Carbon dioxide concentrations

will be greater in these areas. If adequate ventilation is not provided, carbon dioxide may displace

normal air without warning that a life-depriving atmosphere is developing.

COVER EYES AND SKIN.

If released to atmosphere, liquid carbon dioxide will turn to carbon dioxide snow. Accidental contact of carbon dioxide

snow or cold gas with the eyes or skin may cause severe frostbite. Handle liqu id so that it will no vent or spill. Protect

your eyes with safety goggles or a face shield, and cover the skin to prevent contact with snow or cold gas, or with cold

pipes and equipment. Protective gloves can be quickly and easily removed and long sleeves are recommended for

protection.

GROUND ALL PIPING.

The rapid discharge of liquid carbon dioxide through a line which is not electrically grounded will result in a buildup of

static electricity. Contact with this electrical charge could be startling and potentially dangerous to operating personnel.

Such lines should, therefore, be grounded before use.

NOTE: For additional information on properties of carbon dioxide and proper handling refer to CGA pamphlets G-6,

"Carbon Dioxide" and G-6.1, "Standard for Low Pressure Carbon Dioxide Systems at Consumer Sites". These

publications are available from the Compressed Gas Association, 1235 Jefferson Davis Hi ghway, Arlingt on, VA, 22202.

Safety Precautions for Liquid Nitrous Oxide

Nitrous oxide is a gas which has no color, no odor, and practically no taste. It is obtained by thermal decomposition of

ammonium, which yields nitrous oxide and water. Due to the toxic impurities produced in this process, the water is

condensed out and the gas is passed through scrubbing towers to remove impurities.

Due to the difficulty of detecting nitrous oxide's presence, there is imminent danger of loss of consciousness and physical

inability to function if exposed to low levels of this gas, and death by asphyxiation if exposed to medium or high levels.

Since nitrous oxide is a non-toxic gas, these hazards are created when life-supporting oxygen is displaced and diluted. It

is imperative to maintain a well-ventilated work environment to minimize the danger from a leaking system or activated

safety relief device.

Accidental exposure or contact with skin or eyes can cause severe frostbite. Avoid contact with cold piping and

equipment as this can also cause personal injury. Protect eyes with goggles or shield, especiall y i f there is a possibi l i t y of

liquid ejection or if cold gas may issue forcefully from equipm ent. Keep skin covered at all times.

Nitrous oxide is non-flammable but, as with oxygen, ignition of combustible materials may occur more readily in a

nitrous oxide-enriched atmosphere than in air with combustion proceeding at a faster rate. Open flame and smoking are

strictly prohibited.

For more detailed information concerning safety precautions and safe handling of nitrous oxide, consult CGA pamphlet

G-8.1, "Standard for Nitrous Oxide at Consumer Sites", and CGA pamphlet G-8.2 "Common Specification for Nitrous

Oxide". These publications are available from the Compressed Gas Association, 1235 Jefferson Davis Highway,

Arlington, VA 22202.

5

Page 6

BT-481 REV. B

INTRODUCTION

This manual provides information for the operation and maintenance of Taylor-Wharton's line of Express Fill 1,500

cryogenic gas supply systems. These products store cryogenic liquid and dispense it as a warm pressurized gas. The

Express Fill 1,500 is designed for applications requiring nitrogen, argon, or oxygen gas. These products are ideal for onsite filling with Taylor-Wharton’s Express cryogenic liquid d elivery vehicle. An external vaporizer (order separately)

may be used with this product.

Additional product specifications, flow diagram, views, and important dimensions are shown on the general arrangement

drawing provided in the appendix of this manual.

System Description

The Express Fill 1,500 consists of a cryogenic liquid vessel, piping, internal vaporizer, and external pressure builder.

The system vessel has an approximate gross capacity of 1,500 liters. The vessel consists of a pressure vessel suspended

inside a jacket. The space between the pressure vessel and the jacket is evacuated and insulated with a micro-fiberglass /

aluminum foil radiation shield. Both the inner pressure vessel and vacuum jacket are constructed of type 304 stainless

steel. All models are designed and constructed in accordance with ASME Section VIII.

Piping circuits allow the vessel to vent, fill, pressurize, and provide pressurized gas. Piping is type-304 stainless steel.

Valves are brass. Fittings are machined from forged brass and type-316 stainless steel.

Instrumentation consists of a pressure gauge and a differential pressure gauge. The pressure gauge allows the vessel

pressure to be monitored. Accurate measurement of the vessel cont ents is provi ded by the di fferential pressure gauge.

The Express Fill 1,500 automatically maintains pressure by vaporizing cryogenic liquid in a controlled fashion. All

energy for building pressure and vaporizing liquid is provided by heat from ambient air. The pressure building coil is an

external aluminum finned extrusion attached to the outer jacket.

6

Page 7

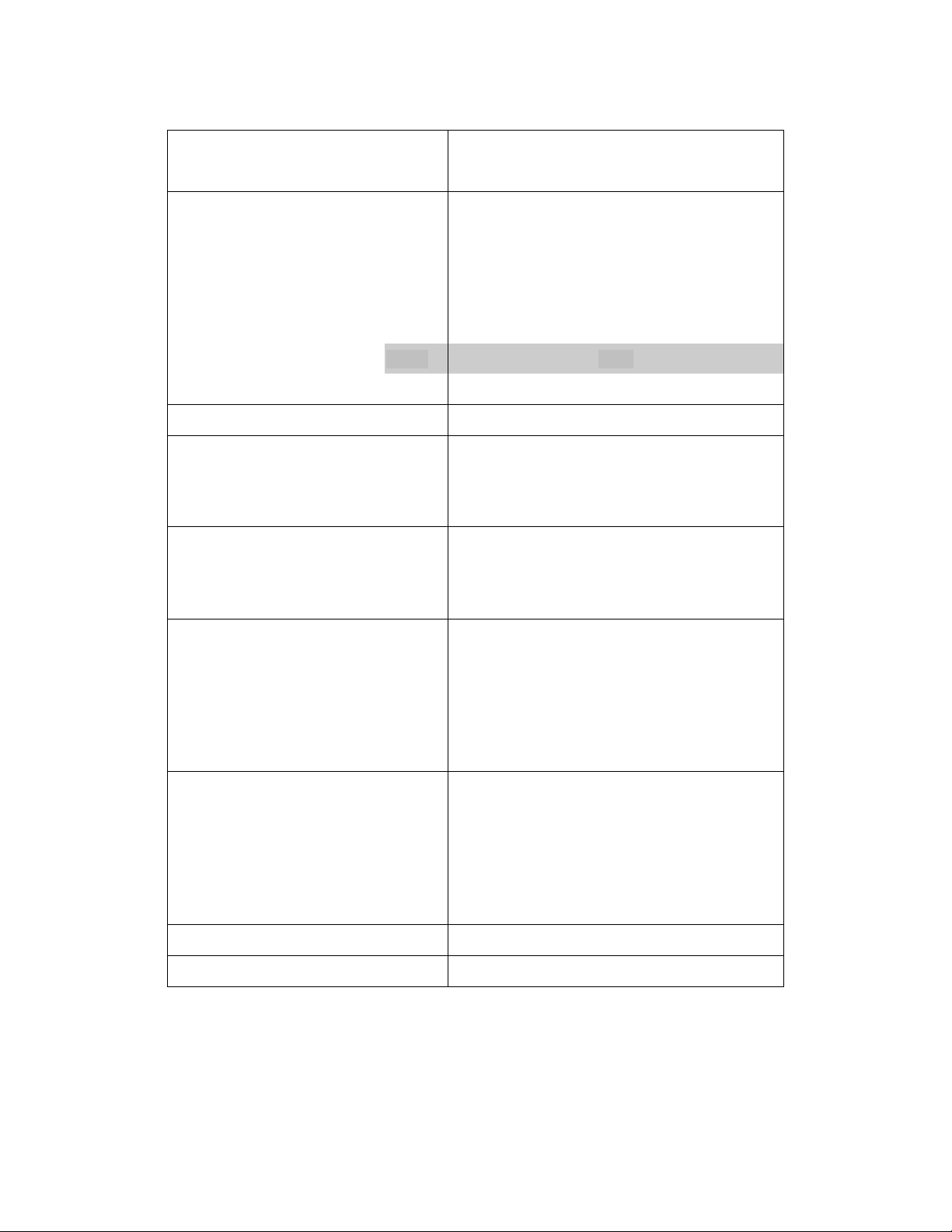

Specifications

Model EF-1500VHP

Part Number V15LOCO2-EZ/V15L0C03-EZ

Dimensions

Cylinder Diameter inches 48

Height inches 91

Empty Weight lbs 2,950

BT-481 REV. B

Capacity, Gross

gallons 414

(liters) 1,567

MAWP psig 500

Design Specification ASME Section VIII, Division I

Safety Devices

Pressure Relief Valve psig 500

Inner Container Bursting Disc psig 750

Pressure Control Devices

Economizer Setting psig 425

Pressure Building Setting psig 400

Gaseous Capacity NPT1

Nitrogen cu. ft. 31,400

Oxygen cu. ft. 39,500

Carbon Dioxide2 cu. Ft. 26,330

Argon cu. Ft. 38,700

Full Weight of Contents1

Nitrogen lbs 5,230

Oxygen lbs 6,220

Carbon Dioxide2 5,962

Argon lbs 6,950

Gas Delivery Rate scfh 1,350

NER (Percent of capacity per day O2) 1.0%

1

Based on liquid at full trycock saturated @ 0 psig.

2

Based on liquid at full trycock saturated @ operating pressure.

7

Page 8

BT-481 REV. B

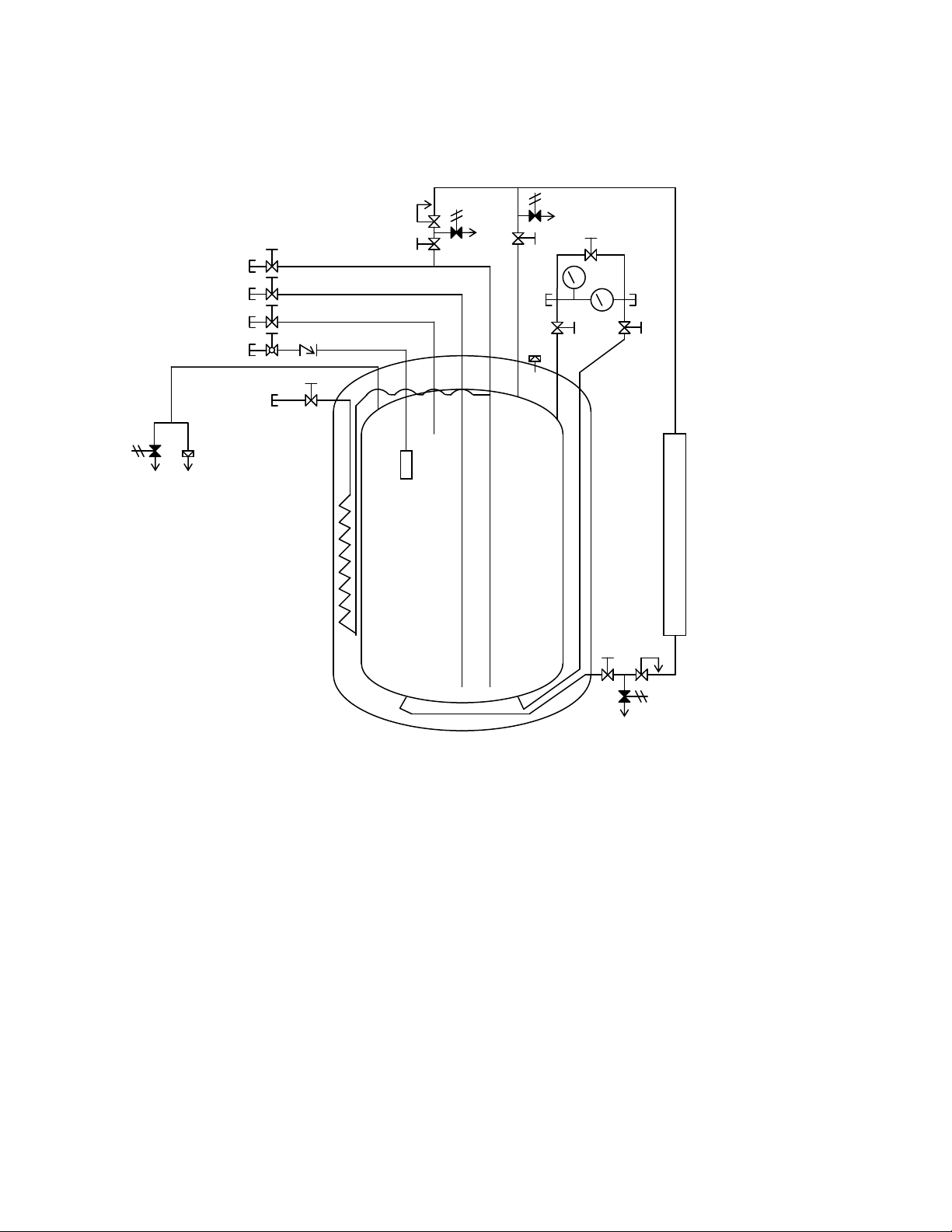

PIPING CIRCUITS

The following paragraphs describe the operation of the piping circuits of the system. The descriptions refer to the main

components of each circuit and are grouped by function. Reference the piping schematic below and in the general

arrangement drawing for the component designations. These component and circuit descriptions should be understood

before attempting operation.

CN-4

CN-3

CN-2

CN-1

V-3

V-2

-

CV-1

PCV-2

-

SV-2

SV-3

V-6

CN-6

R-2

V-9

PI-1

LI-1

V-8 V-10

CN-5

-

-

SV-1

FSV-1*

PBC-1

PCV-1

V-7

SV-4

Legend

CN-1 Connection, Pump / Top Fill V-10 Valve, Liquid Phase Isolation

CN-2 Connection, Full Trycock & Vent V-11 Valve, Gas Use

CN-3 Connection, Liquid Fill / Withdrawal CV-1 Check Valve, Pump / Top Fill

CN-4 Connection, Vaporizer Inlet (External) LI-1 Liquid Level Gauge

CN-5 Instrument Connection, Liquid Phase PI-1 Pressure Gauge

CN-6 Instrument Connection, Vapor Phase PBC-1 Pressure Building Coil

CN-7 Connection, Vaporizer Outlet (Internal) PCV-1 Pressure Building Regulator

V-1 Valve, Pump / Top Fill PCV-2 Economizer Regulator

V-2 Valve, Full Trycock / Vent SV-1** Safety Valve

V-3 Valve, Liquid Fill / Withdrawal SV-2 Relief Valve

V-4 Valve, Vaporizer Inlet SV-3 Relief Valve

V-5 Valve, Economizer Isolation SV-4 Relief Valve

V-6 Valve, Pressure Building Outlet R-1** Inner Container Safety Disc

V-7 Valve, Pressure Building Inlet R-2 Outer Casing Safety Disc

V-8 Valve, Vapor Phase Isolation FSV-1* Fill Stop Valve

V-9 Valve, Equalization

* Functions with delivery vehicle equipped with automatic filling system, i.e. Taylor-Wharton Express Cryogenic Delivery System.

** Option for Dual Safeties/Rupture Disc with Diverter Valve.

Figure 1: System Piping Schematic

8

Page 9

BT-481 REV. B

Fill and Vent Circuits

The liquid valve (V-3) communicates with the bottom of the vessel. Liquid is added or removed from the vessel through

this connection and valve.

The vent / trycock valve (V-2) is attached to a vertical tube in the upper portion of the vessel. Th e open end of the tube is

positioned at 90% liquid level based on the vessel volume. Opening the vent valve reduces pressure in the vessel during

filling. It also severs as a “full trycock”, venting liquid from the vessel when the liquid level exceeds 90%.

V-3

CN-3

Figure 2: Fill and vent circuits highlighted in blue.

V-2

CN-2

Express Fill Circuit

The Express Fill circuit may be used for filling from the Taylor-Wharton Exp ress Cryogenic Delivery System or for top

filling by a cryogenic pump. A ball valve (V-1) and a check valves (CV-1) prevent product from escaping the vessel.

A fill stop valve (FSV-1) within the vessel prevents over filling. This device functions when filled by the TaylorWharton Express Truck in automatic fill mode. The fill stop valve will not function when the vessel is filled by a typical

cryogenic pump.

CV-1

V-1

CN-1

Figure 3: Express Fill circuit highlighted in blue.

9

Page 10

BT-481 REV. B

Pressure Building Circuit

The pressure building circuit serves to build pressure after fillin g the vessel. The circuit is also used to ensure sufficient

driving pressure during high product withdrawal periods. Opening the pressure building outlet valve (V-6) and pressure

building inlet valve (V-7) permits the circuit to function. When the pressure inside the vessel drops below the pressure

builder setting, the pressure building regulator (PCV-1) opens. This creates a path from the liquid in the bottom of the

container to the gas space in the top. This path contains an external pressure building coil (PBC-1) to vaporize product as

it flows from the bottom to the top of the vessel. Liquid is expanded to a vapor and pressure is increased in the vessel.

HEATER INSTALLATION:

Make sure the container vessel is at 0

psi. Open the vent valve as a

precaution. Remove the ¾” plug in the

top flange and attach adapter then insert

the heater. Be sure to use tephlon tape

on all pipe threads and seal off well

assembly with a RTV sealant. Wire the

heater to the control box according to

the schematic provided on page 11. The

heater bracket will need to be welded to

the outer head in a suitable area.

V-6

PBC-1

V-7

PCV-1

SV-4

Figure 4: Pressure building circuit highlighted in blue.

When the EF cylinder is placed in Carbon Dioxide service and ambient temperatures are low, an electric heating system

may be required to assist in pressure building. The electric system consists of a heater in the container that is controlled

by a pressure switch in the top of the unit. The pressure switch responds to inner container pressure and turns the heater

current on and off as required to maintain a pressure greater than 125 psi (8.6 bar/862kPa). The following procedures

detail adjustment of the set points (high and low) of the pressure swit ch.

Field Adjustment Procedure: The set-point of the pressure switch that controls the heater elem ent can be adjusted from

inside the control box located on the top of the container. It is factory set to 125 psi . A ¼” open end wrench is required.

10

Page 11

BT-481 REV. B

Figure 4A: Pressure Switch Control Diagram

The switch should be set to close at pressure below 125 psi and open after a predetermined pressure rise. To check the

setting, vent the container from a pressure greater than 125 psi where the HEATER lamp is off indicating the switch is

open and the heater is not receiving power. As the container vents, observe the container pressure gauge. At

approximately 125 psi the switch should close and the HEATER lamp will light. Close the vent at this point and allow

the heater to cycle until the pressure rises and the HEATER lamp goes out. Note the pr essure rise on th e pressure g auge

as well as the time interval between ‘heater on’ and ‘heater off’.

Warning:

The pressure switch/control box contains live 120VAC or 240VAC connections. Always disconnect the power

from the wall receptacle before removing the cover from this box for adjustment or maintenance.

If adjustment is needed, unplug the unit and unscrew four Phillips-head screws on top of the pressure control box. The

clockwise movement of the adjusting screw will raise the ‘heater on’ setting; counterclockwise will lower it. The amount

of pressure rise (or the heater ‘off’ setting) will adjust automatically. Move the set point adjustment a small increment in

the desired direction and repeat the venting procedure to determine the new set point. Repeat the process as necessary

until the set point is 125 psi.

adjustment screw

Figure 4B: Pressure Switch Adjustment Screw

When the service application requires a higher flowrate than the product specification, an optional super pressure builder

can be purchased from Taylor Wharton. The replacement kit includes the super pressure builder and all necessary fittings

needed to perform the installation at the customer site without emptying the contents of the vessel. Follow the following

steps to replace the stock pressure builder:

11

Page 12

BT-481 REV. B

1. Close the pressure builder input (V-7) and output (V-6) Valves.

2. Allow the unit to vaporize the liquid that is in the pressure builder and closed off lines. It may require an hour

or longer to vaporize all the residual liquid and vent the gas through the safeties.

3. After all the liquid is vaporized, there will still be pressure on the lines that will not be vented through the safety.

Slowly loosen a fitting on both blocked lines a ¼ turn at a time until the line is able to bleed off the remaining

pressure.

4. Loosen the fittings connecting the pressure builder to the tubing.

5. Next, remove PCV-1 and associated tubing from the vessel by loosening the female connector that attaches the

tubing to the safety nipple.

6. Remove the Pressure Builder from the support brackets and install the Super Pressure Buil der.

7. Using the new fittings provided in the kit and the current PCV-1, assemble the components according to the

drawing supplied in the kit. Use Teflon tape or ano ther suitable thread sealant when threading the fittings into

the connections.

8. Open the pressure builder input (V-7) and output (V-6) Valves.

9. Follow the procedures for the Leak Test described on page 21.

12

Page 13

BT-481 REV. B

Internal Vaporizer, External Vaporizer Inlet, and Economizer Circuit

The Internal Vaporizer circuit vaporizes cryogenic liquid and warms it to ambient temperature for use in the final

application. Opening the gas use valve (V-11) allows liquid, driven by the pressure within t he vessel, t o flow t hrough the

vaporizer. The vaporizer uses heat from the ambient air to convert the liquid into a gas and warm it. The vaporizer is

attached to the inside surface of the vacuum jacket. .

The vaporizer inlet circuit provides pressurized cryogenic liquid to an external vaporizer. An external vaporizer is not

supplied with the Express Fill 1,500. Opening the gas withdrawal valve (V-4) allows liquid, driven by the pressure

within the vessel, to flow into the external vaporizer. The vaporizer uses heat from the ambient air to convert the liquid

into a gas and warm it.

The economizer circuit reduces product loss due to normal evaporation of the liquid within the vessel. The pressure

builder outlet valve (V-6) and the economizer circuit isolation valve (V-5) must be open for the circuit to function. The

economizer regulator (PCV-2) opens when the pressure within the vessel exceeds the economizer setpoint. This allows

gas from the top of the vessel to flow into the vaporizer circuit. Provided that gas from the vaporizer is being withdrawn

for use, the vessel pressure will be reduced. Th e primary safety valve (SV-1) will be prevented from opening, av oiding

product loss.

The economizer circuit may be isolated for maintenance without emptying or depressurizing the vessel. Closing the

pressure builder outlet valve (V-6) and the economizer circuit isolation valve (V-5) isolates the circuit. Two relief valves

(SV-2 and SV-3) prevent the circuit from over pressurizing in the event that the valves are closed while the circuit

contains cold gas or liquid.

SV-2

V-5

SV-3

V-11

PCV-2

V-6

CN-7

Figure 5: Internal Vaporizer, External Vaporizer inlet, and economizer circuit highlighted in red.

13

CN-4

V-4

Page 14

BT-481 REV. B

Safety Devices

The Express Fill 1,500 features a safety valve to prevent over pressurization of the vessel. The safety valve (SV-1)

relieves pressure when it exceeds the maximum operating pressure of the vessel. The valve reseats when pressure drops

below this point. In addition, the primary safety valve is supported by a secondary relief device consisting of a rupture

disc (R-1). The rupture disc requires replacement in the event a safety valve malfunctions and allows vessel pressure to

reach the burst pressure rating of the disc.

A diverter valve and dual relief valves along with rupture discs may also be ordered as an option.

SV-1

Figure 6: Safety circuit highlighted in blue.

R-1

14

Page 15

BT-481 REV. B

Instrumentation Circuits

The instrumentation consists of a pressure gauge and digital liquid level or differential pressure gauge. The pressure

gauge (PI-1) displays the inner vessel pressure in pounds-per-square-inch and kilopascals. The liquid level gauge (LI-1)

measures the difference in pressure between the top and bottom of the vessel. Product within the vessel creates a higher

pressure at the bottom of the vessel than at the top. Readings on the liquid level gauge are in inches of water. This

reading, when compared to the contents chart attached to the front of the vessel, allows accurate monitoring of the

amount of product within the vessel.

Isolation valves (V-10 and V-8) allow maintenance of the circuit without emptying and depressurizing the vessel. The

equalization valve (V-9) must be opened before the isolation valves are closed. Two ¼” female pipe thread connections

(CN-5 and CN-6) are provided to allow easy connection of telemetry devices or other differential pressure measurement

instruments. The connections are provided plugged.

V-10

CN-5

Figure 7: Instrumentation circuits highlighted in blue.

V-8

LI-1

PI-1

CN-6

V-9

15

Page 16

BT-481 REV. B

INSTALLATION

Dimensions and connection data for the Express Fill 1,500 can be found on the General Arrangement Drawing in the

appendix of the manual. System installation is the responsibility of the customer.

Receiving Inspection

Freight and damage claims are the customer’s responsibility. Take time to visually inspect each shipment in the

presence of the carrier’s agent before accepting delivery. If any damage is observed, make an appropriate notation on the

freight bill. Ask the driver to sign the notation before receiving the equipment. Do not accept equipment with damage

that may affect serviceability.

Handling

The Express Fill 1,500 should be handled only by a forklift or crane. Ensure that handling equipment has adequate rated

capacity for the system weight listed on the general arrangement drawing in the appendix. The Express Fill 1,500 is a

rugged product intended for years of industrial use. However, take care when moving the unit. Abuse (dropping

or careless handling by forklift) may affect the integrity of the insulation system or damage piping. Always

transport, operate, and store the unit in the vertical position. Never place the unit on its side.

Important: When lifting by crane, use the lift-eyes provided on the top of the jacket. Never lift the unit overhead.

Vessel Installation Guidelines

This section and the “Fill Box Installation Guidelines” section b elow provide general installation gu idelines. Complete

installation specifications, procedures, and applicable codes are beyond the scope of this manual. Designing and

installing a safe cryogenic system is the responsibility of the customer. Consultation, design, and installation services are

available from the factory or one of our authorized repair centers. Contact customer service at the location shown at the

back of the manual for additional information.

Important: Check the regulator codes and license requirements in your area before beginning an installation. When

installing piping, be sure to follow accepted design practices for cryogenic equipment. Use only components compatible

with cryogenic liquids. Be sure to include properly sized pressure relief valves in all piping where liquid product or cold

gas could be trapped between closed valves, regulators, etc. All components must be rated for the maximum operating

pressure of the vessel. If the vessel is in oxygen service, only use components compatible with and cleaned for oxygen

service.

The Express Fill 1,500 should be installed on a suitable concrete pad and secured with anchor bolts. The minimum

recommended pad is 4’ by 4’ by 6” thick. Concrete strength of 3 ksi (28 day strength) is recommended. In areas where

frost heaving is a concern, the pad perimeter should be 12” thick. Four 3/8” galvanized steel concret e expansion bol ts are

recommended. A heavy-duty rotary hammer will be required to drill the bolt holes in the concrete slab. The holes may

be drilled and the bolts installed with the vessel in place. Where seismic loads are a concern, 1/2” expansion bolts should

be used. When using 1/2” bolts, it is not practical to drill the bolt holes with the vessel in place.

For outdoor installations, the vessel should be installed in a location easily accessible to the delivery vehicle. A chainlink fence with a lockable gate should be installed around the vessel to prevent tam pering.

The unit may also be mounted on a steel pallet anchored with four ½” bolts to allow for easy maneuverability around the

customer site using a rated capacity fork lift. The pallet is available from Taylor Wharton.

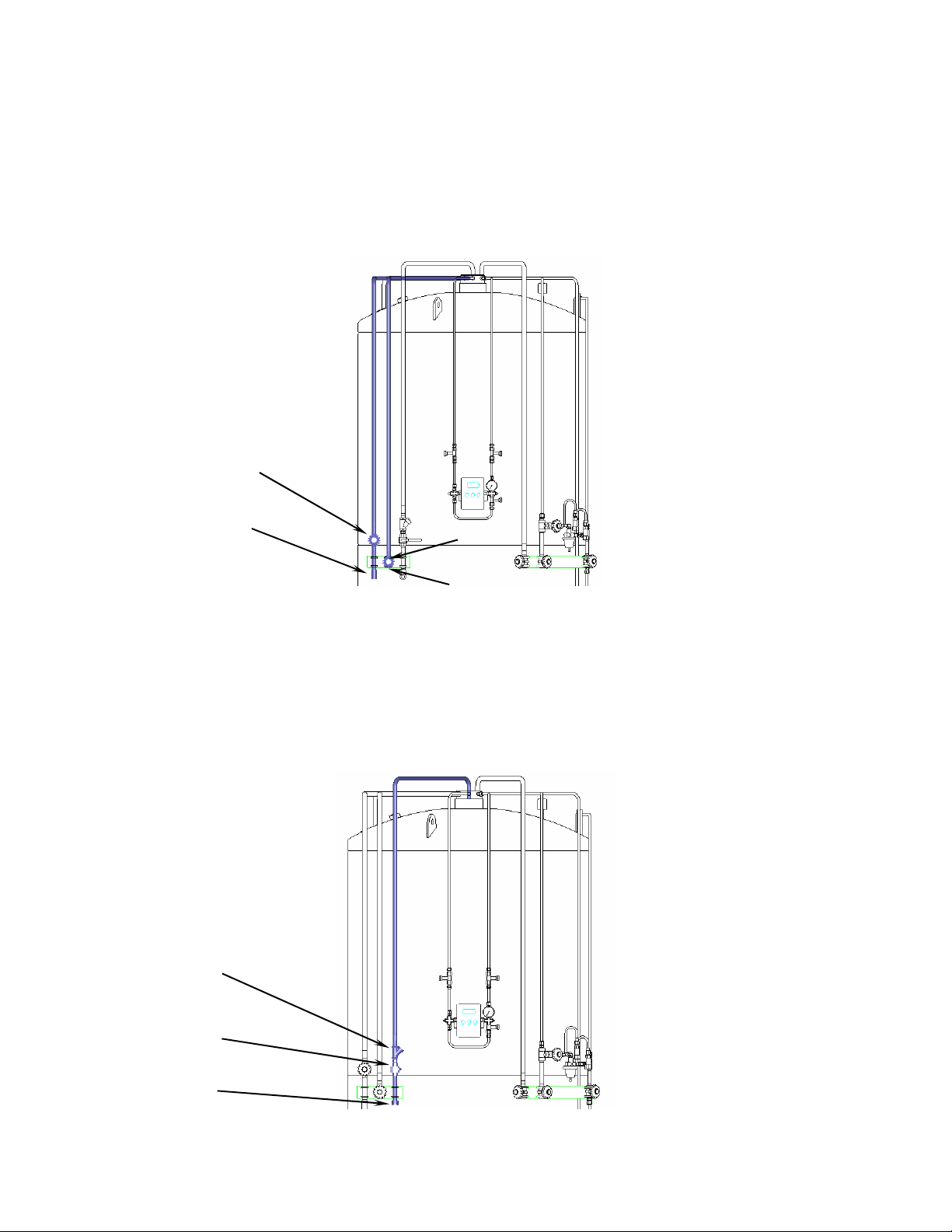

Fill Box Installation Guidelines

The Express Fill 1,500 may be installed inside a building or behind a wall and filled remotely through a fill box. Indoor

installations should only be considered for vessels in argon or nitrogen service. An Express Fill 1,500 in oxygen service

must never be installed indoors. The diagram below shows a typical installa tion with a fi ll box.

16

Page 17

BT-481 REV. B

Vent Line

Safety Line

Fill Line

Figure 8: Typical fill box installation diagram.

Recommended components for a typical fill box installation:

Fill and Vent Line

Vessel Fitting: Compression Fitting, 1/2” Male Pipe Thread x 7/8" O.D. Tube, Brass (2 required)

Tubing: Copper, 3/4" Size (7/8” Actual O.D.), Type K (.065” Wall), per ASTM B-88

Fill Box Fitting: Compression Fitting, 1/2” Female Pipe Thread x 7/8" O.D. Tube, Brass (2 required)

Safety Line

Vessel Fittings: Com pression Fitting, 3/4” Male Pipe Thread x 7/8" O.D. Tube, Brass

Compression Fitting, 1/2” Female Pipe Thread x 7/8" O.D. Tube, Brass

Safety Disc, 1/2" Inlet x 1/2” Outl et, (Consul t with fact ory for part.)

Compression Union Tee Fitting, 7/8” O.D. Tube, Brass

Tubing: Copper, 3/4" Size (7/8” Actual O.D.), Type K (.065” Wall), per ASTM B-88

Fill Box Fitting: Compression Fitting, 1/2” Female Pipe Thread x 7/8" O.D. Tube, Brass

Warning: It is essential that the lines be connected properly. If the vessel safety line were attached to the fill box fill line

or vent line, the vessel pressure relief devices could be prevented from functioning. This will cause a dangerous pressure

build-up in the vessel and in the lines. Never install a shut-off valve on the safety line.

The fill box should be located such that it is accessible for deliveries 24 hours a day. For safety and efficient filling, keep

the length of the lines as short as possible. Actual length of the lines must not exceed 20 feet. Consult with TaylorWharton when installing longer lines. Use large radius bends and minimize the number of bends. If wrought copper

fittings with slip joints are used in the lines, the joints should be silver brazed. Bag-7 silver braze rod is recommended.

Pipe insulation compatible with cryogenic temperatures (urethane based foam pipe insulation or a rigid cellular-glass pipe

insulation) is recommended. All of the lines (fill, vent, and safety) should be insulated.

Warning: Lines must not be installed such that they are susceptible to damage. A crushed safety line, for example,

could prevent the relief devices from functioning properly. This will cause a dangerous pressure build-up in the vessel

and in the lines.

Attach the lines to interior walls or secure them to overhead structural members as required by local codes. If damage to

the lines is a possibility, the damage prone sections should be placed inside protective jackets. Jackets may be

constructed from PCV pipe. For heavy-duty protection, construct the jackets from steel pipe.

17

Page 18

BT-481 REV. B

The vessel safety valve (SV-1) and inner container safety disc (R-1) must be piped to the single fill box safety line. The

existing safety disc must be removed and replaced with an equivalent device featuring outlets with pipe threads. Consult

the factory when specifying this component. Thread the compression fittings for the safety line of the vessel

(recommended above) into the safety valve and safety disc outlets. Connect the safety valve and safety disc fittings to a

compression union tee with the recommended tubing. Connect the compression union tee to the fill box with the same

tubing material.

The schematic below shows the components used in the wall mounted fill box. The fill box mounts on an exterior wall

with the pipe stub connections extending through the wall. Use silicone sealant to weather-tight the fill box against the

wall. Do not install the fill box at face height. Mount the fill box approximately 3 to 4 feet above the ground.

After the installation is complete, perform a pneumatic leak test on the lines (fill, vent, and safety) per ANSI/ASME

B31.3-345.5. Isolate the vent line from the vessel during the leak test by closing the vessel vent valve (V-2). It will be

necessary to test the safety and fill lines while disconnected from the vessel. The vessel connection ends of the lines

should be capped during testing. Check all line connections at reduced pressure with an oxygen compatible bubbleforming leak check solution.

11

10

1

9

2

8

4

Item # Description

1 Safety Line Connection, 1/2” Male Pipe Stub

2 Vent Line Connection, 1/2” Male Pipe Stub

3 Fill Line Connection, 1/2” Male Pipe Stub

4 Vent Line Relief Valve

5 Enclosure Vent

6 Vent Line Exhaust

7 Fill Line Ball Valve, 1/2” Female Pipe Thread, Fitted with proper CGA

8 Vent Line Shut-Off Valve, 1/2” Female Pipe Thread

9 Vent Line Pressure Gauge

10 Safety Line Baffle

11 Fill Box Enclosure

7

Figure 9: Fill box detail schematic (side-view).

Legend: Fill Box Detail Schematic

fitting (295 for argon or nitrogen, 440 for oxygen)

6

5

3

18

Page 19

BT-481 REV. B

OPERATION

These instructions are for operators experienced with cryogenic equipment. Before operating this product, become

familiar with the safety precautions in this manual and in reference publications. Study this manual and the general

arrangement drawing located in the back of this manual thoroughl y. Know the locat ion and function of al l com ponents.

Filling by Pressure Transfer

Filling by pressure transfer is accomplished by lowering the pressure in the Express Fill 1,500 below that of the source

vessel. Typically the source vessel is a truck-mounted vessel. The pressure is reduced in the Express Fill 1,500 by

venting gas through the vent valve (V-2). Liquid is pushed by pressure from the truck-mounted vessel and into the

Express Fill 1,500.

CAUTION: Follow the safety precautions at the beginning of this manual. Accidental contact with liquid or cold gas

can occur during filling.

A cryogenic transfer hose equipped with a relief valve and dump valve should be used to connect the Express Fill 1,500

to the liquid source. Follow the instructions below to fill by pressure transfer:

1. Visually inspect the Express Fill 1,500, transfer hose, and bulk tank piping. Do not attempt to fill the unit

if any components are broken or missing.

2. Connect a transfer hose from the source vessel to the liquid connection (CN-3).

3. Open the liquid valve (V-3) and vent valve (V-2) to begin the fill.

4. When liquid issues from the vent valve, the vessel is full. A 10% gas head space will remain above the

liquid. Close the liquid valve (V-3).

5. Once liquid stops issuing from the vent valve (V-2), close the vent valve.

6. Close the liquid source supply valve and open the transfer hose dump valve.

7. Disconnect the transfer hose from the liquid connection (CN-3).

Filling by Pump Transfer

When a pump is used to fill the container, the pump / top fill connection (CN-1) should be used. Open the ball Valve (V-

1) and closely monitor the vessel pressure during the fill. If the v essel pressure app roaches the relief valv e setting or the

pump pressure rating, shut down the pump. Open the vent valve (V-2) to reduce pressure as needed.

When filling using the Taylor-Wharton Express Cryogenic Delivery Vehicle in automatic mode, the fill is stopped at a

level providing an adequate gas head space. Refer to the Express Vehicle instruction manual for details.

When using a traditional pumping system, the vent valve (V-2) should remain open during the fill. Monitor the product

exiting the vent valve closely. When liquid issues from the vent valve (V-2) immediately stop the pump and close the

ball Valve (V-1). Once liquid stops issuing from the vent valve close the vent valve.

19

Page 20

BT-481 REV. B

Withdrawing Product

Internal Vaporizer

To withdraw gas from the Express Fill 1,500, connect a suitable line regulator to the gas withdrawal connection (CN-7).

Connect the outlet of the regulator to the application. Follow these steps:

1. Open the pressure building valve (V-6). Monitor the pressure gauge (PI-1). When the pressure exceeds

the desired delivery pressure, continue.

2. Open the gas withdrawal valve (V-11).

3. Adjust the line regulator to desired delivery pressure.

External Vaporizer

To withdraw product from the Express Fill 1,500, connect a suitable vaporizer to the vaporizer inlet connection (CN-4).

Equip the vaporizer with a relief valve sized in accordance with the vaporizer manufacturer’s recommendations. Install a

line regulator downstream of the vaporizer. Connect the outlet of the regulator to t he application. Foll ow these steps:

1. Open the pressure building valve (V-6). Monitor the pressure gauge (PI-1). When the pressure exceeds

the desired delivery pressure, continue.

2. Open the vapor izer inlet valve (V-4).

3. Adjust the line regulator to desired delivery pressure.

Withdrawing Liquid

Attach a transfer hose from the receiver vessel to the Express Fill 1,500 liquid connection (CN-3) and open the adjacent

liquid valve (V-3). The pressure in the container will drive liquid product out through the valve as long as the container

pressure exceeds that of the receiver.

Changing Gas Service

The Express Fill 1,500 may be used for argon, oxygen, or nitrogen service. Follow these steps to properly change gas

service:

1. Safely empty all liquid from the container.

2. Open the pressure building inlet and ou tlet valves (V-6 and V-7) and the vent valve (V-2) to vaporize any

residual liquid that may remain in the bottom of the vessel. It may require an hour or longer to vaporize all

the residual liquid.

3. To ensure purity, it is recommended that the Express Fill 1,500 be evacuated with a suitable vacuum pump.

The ultimate vacuum reading should be at least 20 inches of mercury.

4. Replace the fittings for the liquid, top fill, and use connections with the appropriate fittings shown in the

chart below. Use Teflon tape or another suitable thread sealant when threading the fittings into the

connections.

5. Remove any decals identifying the previous gas service. Attach new gas service identification decals.

Gas Service Valve Description TW Part Number

Oxygen

Nitrogen

Argon

Liquid & Top Fill Fitting CGA 440 x 1/2” NPT 6514-8990 (2 required)

NA Oxygen Service Decal GL55-9C52

Liquid & Top Fill Fitting CGA 295 x 1/2” NPT 7355-4698 (2 required)

NA Nitrogen Service Decal GL55-9C51

Liquid & Top Fill Fitting CGA 295 x 1/2” NPT 7355-4698 (2 required)

NA Argon Service Decal GL55-9C53

20

Page 21

BT-481 REV. B

MAINTENANCE

Routine inspections of the system are recommended. The need for maintenance usually becomes apparent from

inspection and indications of improper operation. Typical trouble indications include leakage from valves or piping

connections and excessive venting through relief valves. Keep a permanent log of all inspections and repairs performed.

Such a log can be valuable in evaluating performance and scheduling mainte nance.

Date Nature of Work (Describe in Full) Remarks Servicemen's Signature

Figure 11: Inspection and Repair Log (Sample Form)

Always observe the safety precautions at the front of this manual and follow the instructions given in this section. Before

working on the system, properly empty the vessel of liquid and relieve pressure on the vessel and piping. Do not allow

unqualified persons to attempt repairs on this equipment. Refer to the Trouble-Remedy Guide in this manual for

assistance in troubleshooting.

Leak Test

After making repairs requiring disassembly or replacement of components, leak test all valves or piping joints that were

taken apart and reconnected. Apply leak detector fluid to the test surface. Large leaks instantly form large bubble

clusters, while fine leaks produce white foam that builds up more slowly. All leaks must be repaired and retested before

the system is returned to service.

Globe Valves

All of the globe valves (V-2, V-3, V-4, V-5, V-6, & V-7) are easily removable. Tapered pipe thread connections are used

at the inlet and outlet. However, the valves may be rebuilt without removal from the system. All of the globe valves use

the same rebuild kit. The Taylor-Wharton part number for the rebuild kit is 1750-9C35. All valve components, except

the body, are provided in the kit.

21

Page 22

BT-481 REV. B

Regulators

The pressure building regulator may be adjusted without removal from the system. The following procedure describes

the process:

1. Fill the container with liquid product.

2. Open the pressure building valve and allow the container pressure to stabilize for about an hour. Note the

pressure.

3. Loosen the lock nut on the adjusting screw on the top of the regulator. Raise the setpoint by turning the

adjusting screw clockwise; lower the setpoint by turning the screw counterclockwise. When decreasing the

setting, the pressure building valve must be closed and the container vented to a lower pressure. Repeat

step two and observe the change.

For more accurate adjustment it is recommended that the pressure building regulator be removed from the system. A

regulator bench adjustment fixture should be used. The figure below shows a typical set up.

1. Leak test joints between the high pressure cylinder regulator and the dump valve. Joints must be leak free

2. Close the on/off valve and the dump valve.

3. Open the high pressure cylinder valve.

4. Set the high pressure regulator above the desired set point for the pressure builder.

5. Slowly open the on/off valve and observe the downstream pressure gauge.

6. When the regulator under adjustment closes, the P.B. set point is indicated on the downstream pressure

7. Close the on/off valve and open the dump valve.

8. To reset the regulator, loosen the lock nut on the adjusting screw. Raise the setpoint by turning the

9. When reinstalling the pressure building regulators on the system, orient the regulator so the flow arrow

Adjustment of the economizer regulator should be accomplished with the regulator removed from the system. The

regulator bench adjustment fixture shown above should be used.

High Pressure

Cylinder

before proceeding.

gauge.

adjusting screw clockwise; lower the setpoint by turning the screw counterclockwise. After adjustment,

repeat steps 5 and 6 to check the setting before reinstalling the regulator on the liquid container.

points away from the pressure building valve.

Pressure

Gauge

On/Off

Valve

Regulator

Figure 12: Regulator bench adjustment fixture.

Regulator to

be adjusted

Pressure

Gauge

Dump Valve

22

Page 23

BT-481 REV. B

1. Leak test joints between the high pressure cylinder regulator and the dump valve. Joints must be leak free

before proceeding.

2. Close the on/off valve. Open the dump valve.

3. Open the high pressure cylinder valve.

4. Set the high pressure regulator above the desired set point for the economizer.

5. Slowly open the on/off valve for a few seconds and then close it.

6. When the regulator under adjustment closes, the economizer set point is indicated on the upstream pressure

gauge.

7. To reset the regulator, loosen the lock nut on the adjusting screw. Raise the setpoint by turning the

adjusting screw clockwise; lower the setpoint by turning the screw counterclockwise. After adjustment,

repeat steps 5 and 6 to check the setting before reinstalling the regulator on the liquid container.

8. The economizer regulator should be reinstalled oriented horizontally with the tube compression fitting

threaded into the side port.

Instruments

User adjustment of the pressure gauge or liquid level gauge is not possible. If the gauges are malfunctioning, they must

be replaced. Close both isolation valves (V-8 and V-10) and immediately open the equalization valve (V-9). Loosen one

of the tube compression fitting nuts to red uce pressure. Wh en the pressure gaug e (PI-1) indicates zero it is safe to work

on the circuit.

Vacuum

Cryogenic containers are two containers, one within the other. The space between the containers acts as a highly efficient

thermal barrier including high technology insulation, a vacuum, and a vacuum maintenance system. Each serves a very

important part in the useful life of the container. The high technology insulation is very effective in preventing radiated

heat from entering the inner container. Unfortunately, the perfect vacuum cannot be achieved since trace gas molecules

begin to enter the vacuum space from the moment of manufacture. The vacuum maintenance system consists of

materials that gather trace gas molecules from the vacuum space. The maintenance system can perform its function for

years; however it has a limited capacity. When the vacuum maintenance system becomes saturated it can no longer

maintain the vacuum integrity of the container. The change will be very gradual and may go unnoticed for several years.

When the vacuum in the insulation space is no longer effective, the following symptoms may appear:

1. With liqu id in the container, the outer casing will be much colder than comparative containers.

2. Frost, indicating the liquid level, may be visible on the outer casing of the container.

3. Condensation may form on the container. Note that some icing or condensation is normal around the

piping connections of the vessel. Condensation may also occur on the vessel outer surface as a result of

high humidity.

4. The relief valve will open continuously until the container is empty.

If it has been determined that the vessel has a vacuum problem it will be necessary to repair and re-evacuate the vessel. A

skilled service technician should perform vessel repair. Contact Taylor-Wharton customer service at 1-800-898-2657 for

assistance in locating the closest service center.

23

Page 24

BT-481 REV. B

Trouble-Remedy Guide

Trouble Possible Cause Remedy

1. Low operating pressure.

2. Excessive system pressure.

3. Leaking relief valve.

4. Ruptured pressure vessel rupture

disc.

a. Safety valve leaking or frozen

open.

b. Safety disc ruptured. b. Replace disc.

c. Piping leaks to atmosphere. c. Leak test and repair piping.

d. Pressure building / economizer

regulator malfunction.

e. Excessive product withdrawal. e. Check for leaks downstream.

f. Pressure building valve closed. f. Open pressure building valve.

g. Malfunctioning pressure gauge. g. Replace pressure gauge.

h. Excessive frost on pressure

building coils.

a. Extensive shutdown time. a. No remedy.

b. Low withdrawal rate. b. No remedy.

c. Malfunction of pressure

building circuit.

d. Malfunction o f p r e s s u r e g auge. d. Replace gauge.

e. Bad vessel vacuum. e. Perform NER test. Have vessel

a. Dirt or ice in valve. a. Thaw out valve. Replace if

b. Damaged valve seat. b. Replace valve.

a. Excessive vessel pressure. a. Refer to Step 2, this section.

b. Defective rupture disc. b. Replace rupture disc.

c. Atmosphere corrosion and/or

disc fatigue.

d. Interior disc corrosion. d. Blow out safety device line.

e. Relief device failed. e. Replace relief device and rupture

a. Thaw out valve or replace if

necessary.

d. Adjust regulators. Replace if

necessary.

Reduce product use.

h. Thaw pressure building coils.

c. Adjust pressure building

regulators. Replace if necessary.

repaired and re-evacuated if

necessary.

necessary.

Replace rupture disc.

c. Replace rupture disc.

Replace rupture disc.

disc.

24

Page 25

BT-481 REV. B

Replacement Parts

Order replacement parts from Taylor-Wharton Customer Service at 1-800-898-2657. Refer to the piping circuits section

on Page 8 to identify the components.

ITEM PART NUMBER DESCRIPTION

V-1 6919-9075 Ball Valve, 1/2” FNPT

V-2 6914-4050 Glob e Valve, 1/2” F NPT

V-3 6914-4050 Globe Valve, 1/2” FNPT

V-4 6914-4050 Glob e Valve, 1/2” F NPT

V-5 2198262 Globe Valve, 1/2” FNPT

V-6 2198262 Globe Valve, 1/2” FNPT

V-7 6914-4050 Glob e Valve, 1/2” F NPT

V-8 85443725 Needle Valve, 1/4” FNPT

V-9 85443725 Needle Valve, 1/4” FNPT

V-10 85443725 Needle Valve, 1/4” FNPT

V-11 6914-4050 Globe V a lve, 1/ 2 ” FNPT

CV-1 6913-9365 Check V alve, Swing, 1/2” FNPT

LI-1 57143700 Digital Contents Gauge

PI-1 7702-6197 Pressure Gauge, 600 psig

PCV-1 85368044 Regulator, Pressure Builder, 400 psig

PCV-2 6999-9017 Regulator, Economizer, 425 psig

SV-1 85450299 Relief Valve, 1/2” MNPT, 500 psig

SV-2 6913-9079 Relief Valve, 1/4” MNPT, 600 psig

SV-3 6913-9079 Relief Valve, 1/4” MNPT, 600 psig

SV-4 6913-9079 Relief Valve, 1/4” MNPT, 600 psig

R-1 85163520 Safety Disc, 1/2” MNPT, 750 psig

R-2 BC04-6C66 Casing Safety Disc

N/A 85449402 Diverter Valve (Optional)

N/A BCO4-9C87 Heater, 208/240 (Optional)

N/A BCO4-9C86 Heater Control (Optional)

N/A BC06-9C71 Well Assembly (Optional)

N/A H4509C10 Adaptor, Heater (Optional)

N/A H4509C20 Bracket, Heater Control (Optional)

N/A Q15L9C36 Pallet, Steel (Optional)

N/A V15L9C13 Pressure Builder, Super (Optional)

25

Page 26

APPENDIXES

Appendix 1 – Express fill 1500 General Arrangement

BT-481 REV. B

26

Page 27

P/N 99187839

Publication # BT-481 REV. B

4075 Hamilton Blvd.

Theodore, Alabama 36582 U.S.A.

Telephone (251) 443-8680

Fax (251) 443-2250

In U.S. and Canada:

(800) TW TANKS (898-2657)

©2004 Taylor-Wharton International

Loading...

Loading...