Page 1

Operating Instructions

SAFETY

Before using any cryogenic refrigerator, read

the Handle with Care booklet provided with the

unit. It details safety precautions that must be

understood before using the equipment. If a

replacement booklet is needed, order publication TW-10 Handle with Care from your supplier.

Following are a few of the safety precautions

described in the Handle with Care booklet.

Please be sure to read the entire booklet.

Store and use these containers only in well

ventilated areas. In a confined area, nitrogen

gas from these units may cause suffocation by

displacing air needed for breathing. Install a

suitable oxygen monitor .

Do not touch liquid or cold metal surfaces

with your bare skin. The liquid nitrogen

refrigerant in these containers is extremely

cold: -196°C (-320°F). Exposure of skin or eyes

to liquid, cold gas or frosted parts could result in

a severe frostbite-like injury . Because of the

extremely low temperature, a face shield and

gloves must be worn when transferring liquid

nitrogen and material into or out of these

containers.

Use only the necktube core supplied with

this unit or a listed replacement part. A tight

fitting plug of stopper will cause a pressure

increase in the container that may damage the

container and/or cause personal injury .

Dispose of liquid nitrogen only in areas

specifically designed for that purpose.

Disposal of liquid nitrogen should be done

outdoors in a safe place. Pour the liquid

slowly on gravel or bare earth where it can

evaporate without causing damage.

OPERATION

Important note: Before filling the CX for the

first time, record the tare weight and serial

number of each container . Recording the

“as received” tare weight on the container

itself is recommended.

Filling: Adding liquid nitrogen to a warm

container may cause splashing and will generate a significant volume of nitrogen gas as cold

liquid contacts warm refrigerator surfaces. Add

liquid slowly to minimize these effects. Be sure

there is adequate ventilation. Keep your head

clear of the heavy volume of vapor that may be

produced. It is extremely cold and could cause

personal injury.

moisture will displace nitrogen in the absorbent materials on the subsequent filling and

effect the overall holding time.

CAUTION: When filling the Cryogenic Refrigerator,

avoid liquid nitrogen coming in contact with the

vacuum plug. In order to accomplish this, the CryoExchange must be removed from its shipping carton

during the “fill” operation.

Remove the unit from its shipping enclosure. Set the unit on a scale and fill the

refrigerator with liquid to the bottom of the

necktube. Then allow the unit to stand undisturbed while the refrigerant is being absorbed.

About every five minutes, add liquid to maintain the refrigerant level as the liquid is

absorbed by the filler. This procedure can t ake

ten to fifteen cycles. When the liquid levels

remains at the bottom of the necktube, the

shipper is full. At this point, the quantity of

liquid standing in the central cavity of the

refrigerator must be poured out to prevent

spillage during shipment. To assure a complete fill, the dry CX100 weight should increase by approximately 7.9 lb. (3.7 kg) and

the dry CX500 weight should increase by

approximately 1 1.5 lb. (5.2 kg).

The material to be stored in the Cryo-Exchange Refrigerator, as well as the canister or

rack, should be pre-cooled before being

placed in the shipper. When the refrigerator is

fully charged, place the pre-cooled material to

be stored in the pre-cooled canister and lower

it into the necktube. Install the necktube core

and cap to hold the canister in place.

CAUTION: When the Cryo-Exchange is in use, it must

be kept upright. When properly filled, there is no

concern for liquid refrigerant spills. However, holding

time will be drastically reduced when the refrigerant

is on its side.

Securing contents: The contents of all

models may be secured with a seal or lock

through tabs on the edge of the lid.

ROUTINE CARE AND MAINTENANCE

Do not attempt to fasten any device to the

container . Welding, brazing, or piercing of the

container in any manner will cause permanent

damage.

TW-347

Cryo-Exchange

Vapor Shippers

WARNING

DO NOT OVERFILL. Over-filling may result in personal

injury due to liquid spillage.

With regular usage, moisture can accumulate in

the refrigerator as a result of lowering a frosted

canister back into the shipping cavity . This

CX SERIES

Page 2

Refrigeration depends on the presence of cryogenic

nitrogen refrigerant in the refrigerator. Be sure to maintain a full charge of refrigerant to prevent loss of stored

materials. Please refer to the “Operations” section of

this document for instructions on the filling procedure. If

you are not able to fully charge the Cryo-Exchange by

weight, it is possible that more moisture has accumulated in the filler material over time with normal usage.

This accumulation will result in the displacement of

refrigerant. Allow the refrigerant to warm to room

temperature. The warming procedure may take as long

as four weeks. Then direct dry heat not to exceed 150°F

(65°C) from hair dryer to other source, into the refrigerator. The unit is accept ably dry when the tare weight is

within 1 lb. (0.45 kg) of the “as received from the

manufacturer” tare weight.

If high evaporation rates are apparent under normal

operating conditions, the dewar may be losing its

vacuum. Sweating and the formation of frost on the

outer casing are indications the refrigerator may be

losing its vacuum. All necessary step s should be taken

to protect the refrigerator’s contents. If these conditions

persist, contact your supplier or Taylor-Wharton’s

Technical Response Team (1-800-TW-TANKS or email

us at

cryotanks@taylorwharton.com) for information on

how to conduct a normal evaporation rate (NER) test in

the field.

TRANSPORT ATION

Although these refrigerators are rugged, they can be

damaged or abused or otherwise mishandled. A

specially designed hard-shell shipping container (refer to

the parts section for ordering information) should be

used anytime the refrigerator is transported. This

container will help prolong the life of the unit and should

be replaced if damaged during use. When moving or

transporting a refrigerator, t ake every precaution to prevent

sliding, tipping, bumping or dropping the unit. Keep the unit

upright. Although there is no safety hazard if the properly

filled refrigerator is on its side, the refrigerant consumption is

much greater with the unit in this position and holding time

will be significantly reduced.

RETURNS

Manufacturing defects are covered under the containers

limited warranty . Evidence of mishandling, such as dents on

the outer vessel, or misalignment of the inner vessel, are not

manufacturing defects. If you would like to return goods to

Taylor-Wharton for any reason, you must first obtain a

Material Return Authorization (MRA) number for tracking

purposes.

ACCESSORIES

The following accessories are available for CX Series

Refrigerators:

• Roller Base - will ball-bearing swivel casters to provide

convenience and portability within a working area where

frequent container movement is necessary or desirable.

P/N R018-8C00 ...............................CX500

• Inventory Control Boxes - made of cardboard or

plastic to hold 2ml vials. Can be used to store samples.

(Plastic) 100 cell box

P/N N-374187-92.............................CX500

• Rugged Shipping Enclosures - for easy transport.

P/N 3701-9277(padded carton)..........CX100

P/N CX10-8C00 (Hard shell)............CX100

P/N CP19-8C00 (Hard shell)............CX500

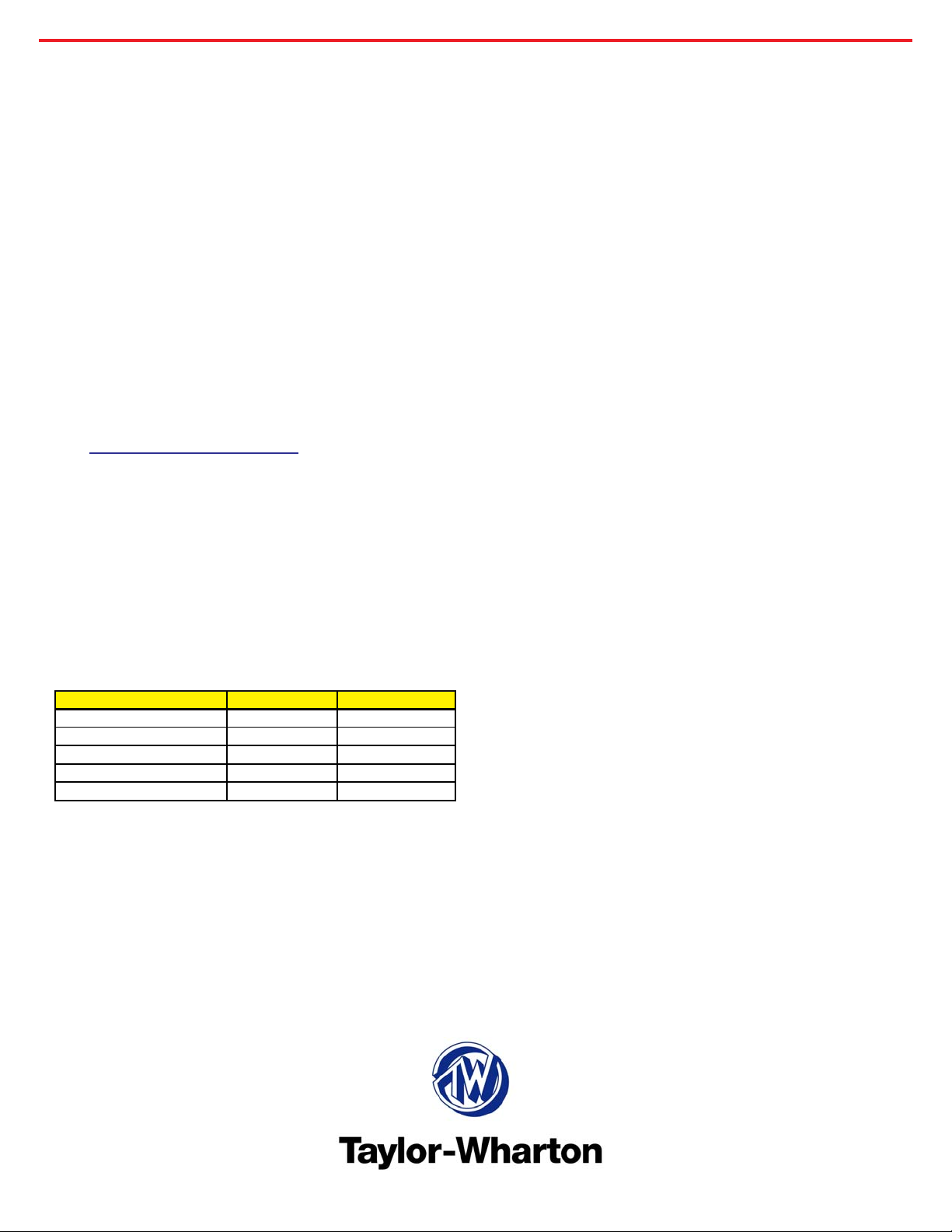

REPLACEMENT P ARTS

Description CX100 CX500

Handle R005-5C11 N/A

Handle Pin 8631-5000 N/A

Canister R005-9C24 Note*

Necktu be Core R005-9C21 CP70-9C 18

Hard Shell Shipping Enclosure CX10-8C 0 0 CP19-8C 00

Note*: Five shelf rack (for TW plastic box).........RS30-9C40

Blood Bag Rack……………………………….......CP70-9C44

ORDERING INFORMA TION

Order all replacement parts and accessories from your distributor . Please include the p art and model number of your

refrigerator, the p art number, quantity, and description of each part requested. for more information cont act Taylor-Wharton

at the address listed.

Taylor-Wharton

4075 Hamilton Blvd.

Theodore, AL 36582

Phone: (251) 443-8680

(800) TW TANKS (898-2657)

Email: cryotanks@taylorwharton.com

www.taylorwharton.com

Fax: (251) 443-2250

7950-8347 TW-347

Loading...

Loading...