Page 1

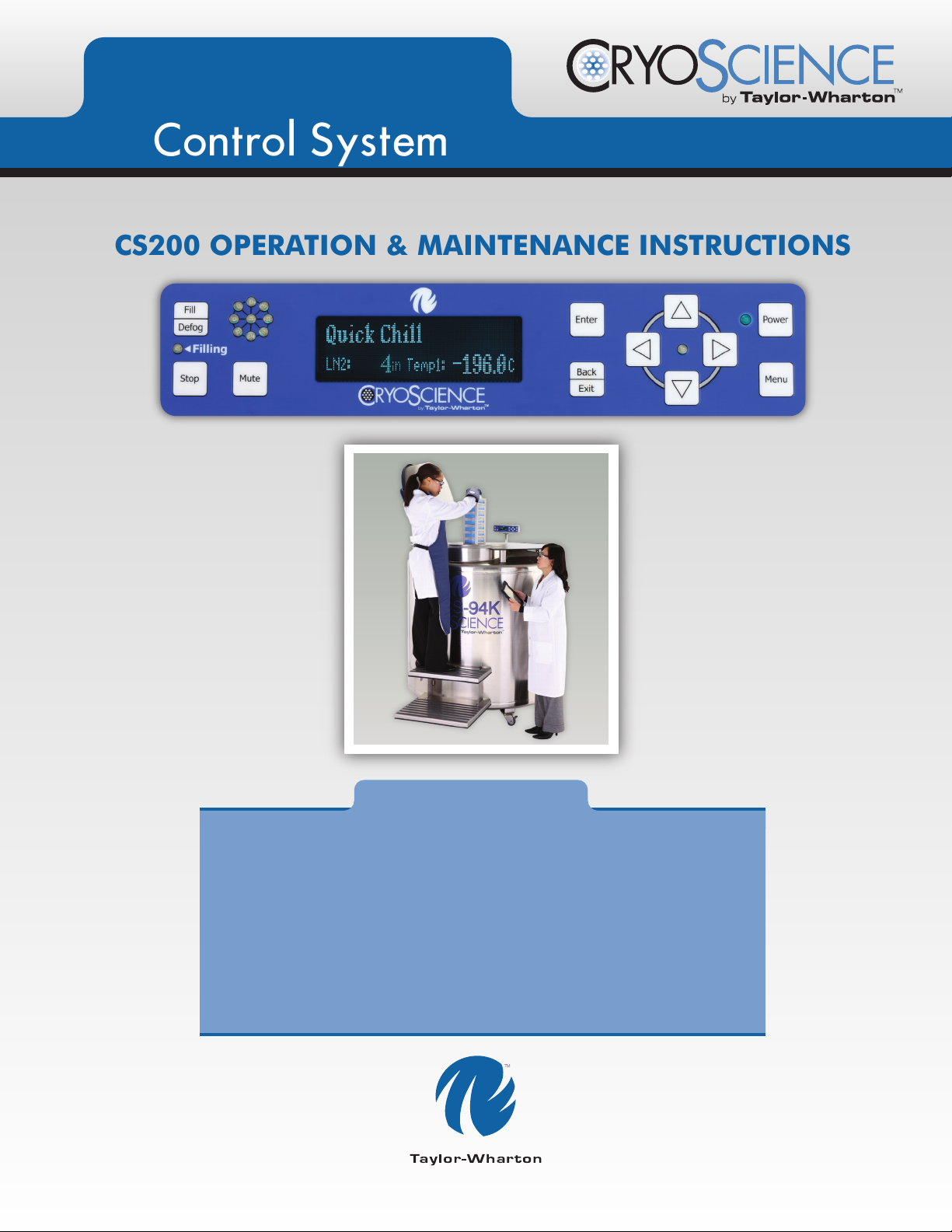

CS SERIES

Control System

CS200 OPERATION & MAINTENANCE INSTRUCTIONS

CAUTION - SAFETY FIRST!

• REVIEW AND UNDERSTAND ALL SAFETY PROCEDURES IN THE “HANDLE WITH CARE”

BOOKLET FORM # TW-10 P/N 7950-8052 BEFORE ATTEMPTING TO INSTALL, OPERATE

OR PERFORM MAINTENANCE ON THIS LN

• DO NOT ATTEMPT TO USE OR MAINTAIN ANY LIQUID NITROGEN FREEZER UNTIL YOU

READ AND UNDERSTAND THESE INSTRUCTIONS.

• DO NOT PERMIT UNTRAINED PERSONS TO USE OR MAINTAIN THIS UNIT.

• IF YOU DO NOT FULLY UNDERSTAND THESE INSTRUCTIONS, CONTACT YOUR SUPPLIER

FOR FURTHER INFORMATION.

• BEFORE ATTEMPTING TO OPERATE THIS CONTROLLER WITH ANY CRYOSCIENCE BY

TAYLOR-WHARTON™ LABS & K SERIES UNITS, YOU MUST READ THE SEPARATE

OPERATING AND SAFETY MANUAL PROVIDED WITH THAT TAYLOR-WHARTON UNIT.

*CS SERIES Control Systems are used on all Taylor-Wharton LABS units.

The unit featured is only one of the cryostorage systems available in the CryoScience by Taylor-Wharton™ lines.

CONTROLLER.

2

Page 2

Page 3

TABLE OF CONTENTS

SAFETY PRECAUTIONS ................................................................................. 3

Liquid Nitrogen ...................................................................................................... 3

Extreme Cold - Cautionary Statement ...................................................................3

Keep Equipment Area Well Ventilated ...................................................................3

Liquid Nitrogen System .......................................................................................... 3

Electrical .................................................................................................................3

GENERAL INFORMATION ............................................................................ 4

CS SERIES Control System Specifications ................................................................. 5

DELIVERY AND RETURNS.............................................................................. 7

Unpacking and Inspection ......................................................................................7

Freight Damage Procedures ..................................................................................7

Repackaging for Shipment ..................................................................................... 7

INSTALLATION ............................................................................................. 8

Getting Unit into Service ........................................................................................8

Electrical ................................................................................................................8

Electromagnetic Compatibility (EMC) ....................................................................8

Power Supply Connection .....................................................................................9

Validation ..............................................................................................................9

CS SERIES

OPERATION ................................................................................................. 9

Initial Fill ................................................................................................................ 9

Control Components ............................................................................................ 10

CS200 Controller Display Guide ........................................................................... 10

Operational Theory ..............................................................................................11

Operating Parameters .........................................................................................14

Temperature Monitoring .......................................................................................15

Liquid Phase Storage ............................................................................................15

Maintenance ......................................................................................................... 15

CONTROLLER OPERATION ......................................................................... 16

Introduction .........................................................................................................16

Operation Data .....................................................................................................16

Communications ................................................................................................... 16

Normal Fill Cycle .................................................................................................16

Control Setting Adjustments .................................................................................17

Temperature .........................................................................................................20

Battery Operation ................................................................................................ 21

Lid Switch ..............................................................................................................21

Interconnection Block Diagram .............................................................................25

Wiring Diagram ....................................................................................................26

Installation & Setup...............................................................................................27

Diagnostic Menu .................................................................................................. 29

External Connector Ratings ..................................................................................29

LED Status Wheel Flash Patterns ........................................................................... 29

Temperature Thermocouple Select ....................................................................... 30

Temperature Calibration ..................................................................................... 30

Test Temperature System .......................................................................................31

Test Level Sensors .................................................................................................31

Alarms and Error Conditions ...............................................................................32

System Alarms ......................................................................................................32

Test Alarms ..........................................................................................................32

Logging ................................................................................................................. 33

Dump Logs ............................................................................................................ 33

Page 4

CS SERIES

TABLE OF CONTENTS (continued...)

Error Logs .............................................................................................................34

System Logs ..........................................................................................................34

Temperature Logs ................................................................................................34

Erase Logs ............................................................................................................. 35

Display Brightness ................................................................................................35

Making Adjustments to the CS SERIES Control System Sensor Assembly .............35

Removing/Installing the Solenoid Valve ...............................................................36

Controller Electrical Tests ...................................................................................... 36

Plumbing Assembly ............................................................................................... 37

TROUBLESHOOTING .................................................................................. 37

Symptoms .............................................................................................................37

Controller Will Not Turn ON ................................................................................37

Indicates High Liquid Level .................................................................................. 38

Indicates Low LN2 Supply ...................................................................................... 39

Indicates Open Sensor .......................................................................................... 39

Temperature Reading 10 to 20 Degrees Warm .....................................................39

Fill Solenoid Cycles On and Off ............................................................................ 40

Fill Solenoid Makes Excessive Humming Noise ..................................................... 40

Display = “Check” ............................................................................................... 40

Lid Open Alarm ....................................................................................................40

QCF (Quick Chill Feature) Will Not Operate .......................................................41

Defog Feature Will Not Operate .......................................................................... 41

Push Buttons Will Not Respond ............................................................................ 41

Liquid Level Readout is Incorrect .........................................................................41

Power Failure Alarm ............................................................................................41

REPLACEMENT PARTS ................................................................................ 41

SERVICE AND MAINTENANCE HISTORY LOG ............................................. 42

Appedix ...................................................................................................... 43

EN Compliance Tables ..........................................................................................43

Declaration of Conformity ....................................................................................47

Warranty ............................................................................................................... 47

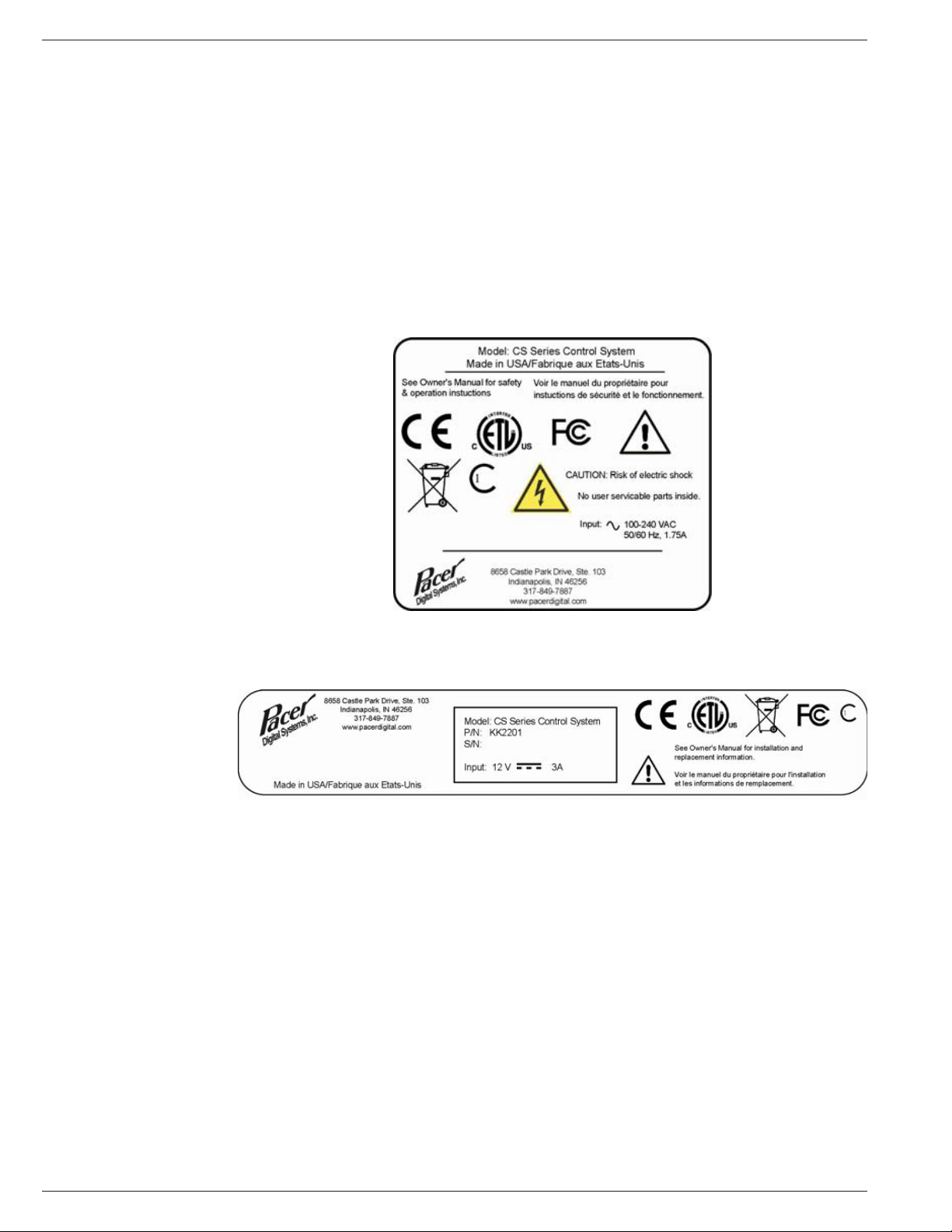

Labels ...................................................................................................................48

Page 5

CS SERIES

SAFETY PRECAUTIONS

Liquid Nitrogen

Nitrogen is an inert, colorless, odorless, and tasteless gas making up four-fifths of

the air you breathe – and can be very dangerous. Air is roughly one-fifth oxygen.

Liquid nitrogen is at a temperature of -196°C (-320°F) under normal atmospheric

pressure. Cryogenic freezers are used in LN2 service only.

Extreme Cold - Cautionary Statement

Accidental contact of liquid nitrogen or cold issuing gas with the skin or eyes may

cause a freezing injury similar to frostbite. Handle the liquid so it won’t splash or

spill. Protect your eyes and cover the skin where the possibility of contact with the

liquid, cold pipes and equipment, or cold gas exists. Safety goggles or a face shield

should be worn when operating this equipment. Insulated gloves that can be easily

removed and long sleeves are recommended for arm protection. Trousers without

cuffs should be worn outside boots or over the shoes to shed spilled liquid.

Keep Equipment Area Well Ventilated

Although nitrogen is non-toxic and non-flammable, it can cause asphyxiation in

a confined area without adequate ventilation. Any atmosphere not containing

enough oxygen for breathing can cause dizziness, unconsciousness, or even death.

Nitrogen, a colorless, odorless, and tasteless gas that cannot be detected by the

human senses, will be inhaled normally as if it were air. One (1) liter of liquid

nitrogen is equivalent to 696 liters of nitrogen gas. Without adequate ventilation, the

expanding nitrogen will displace the normal air resulting in death.

WARNING:

The following safety

precautions are for

your protection.

Before installing,

operating, or

maintaining this unit

read and follow all

safety precautions

in this section

and in reference

publications. Failure

to observe all safety

precautions can

result in property

damage, personal

injury, or possibly

death.

WARNING:

Maintain adequate

ventilation to

prevent asphyxiation

hazard (see Safety

Precautions).

Liquid Nitrogen System

The liquid nitrogen supply pressure at the inlet to the refrigerator should be in

the range of 10 psig (0.7 bar/69 kPa) to 20 psig (1.4 bar/138 kPa) for optimum

performance. Higher operating pressures will increase transfer losses and create

excessive turbulence of the liquid in the refrigerator, which can generate false signals

to the liquid level controller causing the refrigerator to under-fill. In “liquid phase”

storage applications, excessive turbulence can cause splashing which could result in

personal injury and/or damage to the refrigerator. When installing piping or fill hose

assemblies, make certain a suitable safety relief valve is installed in each section

of plumbing between any two isolation points. Trapped liquefied gas will expand

greatly as it warms and may burst hoses or piping causing damage or personal

injury. A relief valve is installed in the refrigerator plumbing to protect the line

between the customer supplied shut-off valve and the refrigerator solenoid valve.

Relief valves can be piped to the outside of the building.

Electrical

• This product is not intended for a life support function.

• This product is intended to be used in hospitals and clinics.

• This product has no Radio Transmitter (Intentional Radiator) functions.

• This product is not intended for electromagnetic shielded rooms only.

• This product does not intentionally apply RF energy for its function.

• This product does not intentionally receive RF energy for its function.

Caution:

When installing field

fabricated piping,

make certain a

suitable safety relief

valve is installed

in each section of

piping between any

two isolation points.

WARNING:

Inlet pressure should

not exceed 22 psig

(1.5 bar/152 kPa).

Higher pressures

could result

in damage to

equipment.

WARNING:

Electrical shock can

kill. Do not attempt

any service on these

units without first

disconnecting the

electrical power cord.

The liquid level controllers used with these refrigerators operate from 12 VDC.

Disconnect the electrical power cord from the outlet before attempting any service.

3

Page 6

CS SERIES

For more detailed information concerning safety precautions and safe practices to

be observed when handling cryogenic liquids consult CGA publication P-12 “Safe

Handling of Cryogenic Liquids” available from the Compressed Gas Association:

CGA website: www.cganet.com; CGA customer service +1.703.788.2700; or email

customerservice@cganet.com.

GENERAL INFORMATION

The CS SERIES Control System can monitor and control both the liquid nitrogen

level and the vapor temperature range in the cryostorage unit you have selected. CS

SERIES Control Systems are designed to work with Taylor-Wharton LABS Cryostorage

Systems. The features are designed to provide a safe environment for samples while

at the same time tracking all relevant information associated with the freezer. This

control provides a complete historical record of the environment in your unit and

therefore, the environment in which your samples have been stored in this system.

This controller features a vacuum fluorescent display. The addition of a liquid

nitrogen supply and inventory control racks for systematic retrieval of stored product

completes the total Cryostorage System.

Taylor-Wharton LABS Cryostorage Systems are designed for applications where

extremely low temperature storage of biological products is required. They are also

appropriate for industrial or other applications where liquid nitrogen temperatures

and high capacity are needed.

Before beginning installation or operation of this CS SERIES Control System, make

sure that you read and understand this manual as well as the operating and safety

instructions for the cryostorage unit you will be using with this controller.

4

Page 7

CS SERIES Control System Specifications

Control Type: LN2 Level Control & Temperature Control

Level Measurement Sensor Type: 8-Thermistor Fixed

4-Thermistor Adjustable

Range: 8 inch range (8-Thermistor)

Low, Normal, High (4-Thermistor)

Redundancy Multiple discrete points

CS SERIES

Temperature Measurement: Sensor Type:

Accuracy of 1.5% with Resolution of 0.1°c

Number of Channels: 2

Temperature Display Units: °C, F, K, R

Electrical: Input Voltage: 100-240 VAC

Input Current (max: 1.75 A

Input Current (continuous): 0.5 A

Power Consumption (max): 21 W

Power Consumption (continuous): 6 W Input

Frequency: 50/60 Hz

Output: 12 VDC

Control Input Voltage: 12 VDC

Power Cord: Available for all countries

Battery: Rating: 12 Volt, 18Ah

Type: Absorbent Glass Mat (AGM) Sealed Non-

Spillable

Short Protection: Installed PCB with thermal fuse

Battery Cover: Vinyl

Solenoid Valve Input Voltage: 12 VDC

Input Current 0.96 amps

Type T Thermocouples

Communications: Protocol: Connectivity Access Network (CAN)

Number of Communication Ports: 3

User Interface: Display Type Vacuum Fluorescent

Display: (VFD)

Buttons:11

Level, Temperature and Alarm

Information

“At a Glance” Status LED status wheel

Filling 1 LED

Menu Access 1 LED

Power LED

Control Tests: Power Up Self Test Control System Check

Thermistor Status

Battery voltage

Control voltages

Temperature Circuit

Alarms: Low Level Alarm: Always enabled

High Level Alarm: Always enabled

Sensor Error Alarm: Always enabled

High Temperature Alarm: (T/C #1, T/C #2)

Programmable

5

Page 8

CS SERIES

Alarms (continued...): Low Temperature Alarm: (T/C #1, T/C#2)

Programmable

Thermocouple Calibration: Alarm Always enabled

Thermocouple Open Alarm: Always enabled

Power Failure (Remote only): Always enabled

Low LN2 Supply Alarm: Programmable

Battery Mode Warning: Always enabled

Lid Open Too Long Alarm: Programmable

Valve Stuck Open Alarm: Programmable

Unauthorized Access Warning: Programmable

LN2 Usage Warning: Programmable

Low Battery Voltage: Always enabled

Temperature Alarm Delay: Programmable

Audible Alarm: Always enabled

Audible Alarm Re-trigger: Programmable

Visual Alarm Indicator: Always enabled

Remote Alarm Delay: Programmable

Buttons: Power: Turns power on/off

Fill/Defog: Open Solenoid Valve

Stop: Close Solenoid Valve

Menu: Access Menu

Mute: Silence audible

Enter: Save a setting or select a menu choice

Back/Exit: Leave a setting unchanged or back out

of menu

Up Arrow: Scroll the menu system or increase a

value

Down Arrow: Scroll the menu system or decrease

a value

Left Arrow: Scroll horizontal menu

Right Arrow: Scroll horizontal menu

Data Collection: Temperature

Level

Alarms

Memory: 4 Mb

Dimensions: Display Width: 9.5 in. (241 mm)

Display Height: 2.0 in. (50.8 mm)

Display Depth: 1.31 in. (33.3 mm)

Display Weight: 0.625 lbs (.28 kg)

Main Control Width: 8.875 in. (225.4 mm)

Main Control Height: 6.688 in. (169.9 mm)

Main Control Depth: 1 in. (25.4 mm)

Main Control Weight: 1.0 lbs (.45 kg)

Battery Width: 7.25 in. (184.2 mm)

Battery Height: 6.375 in. (161.9 mm)

Battery Depth: 3.25 in. (82.6 mm)

Battery Weight: 12.4 lbs (5.6 kg)

6

Page 9

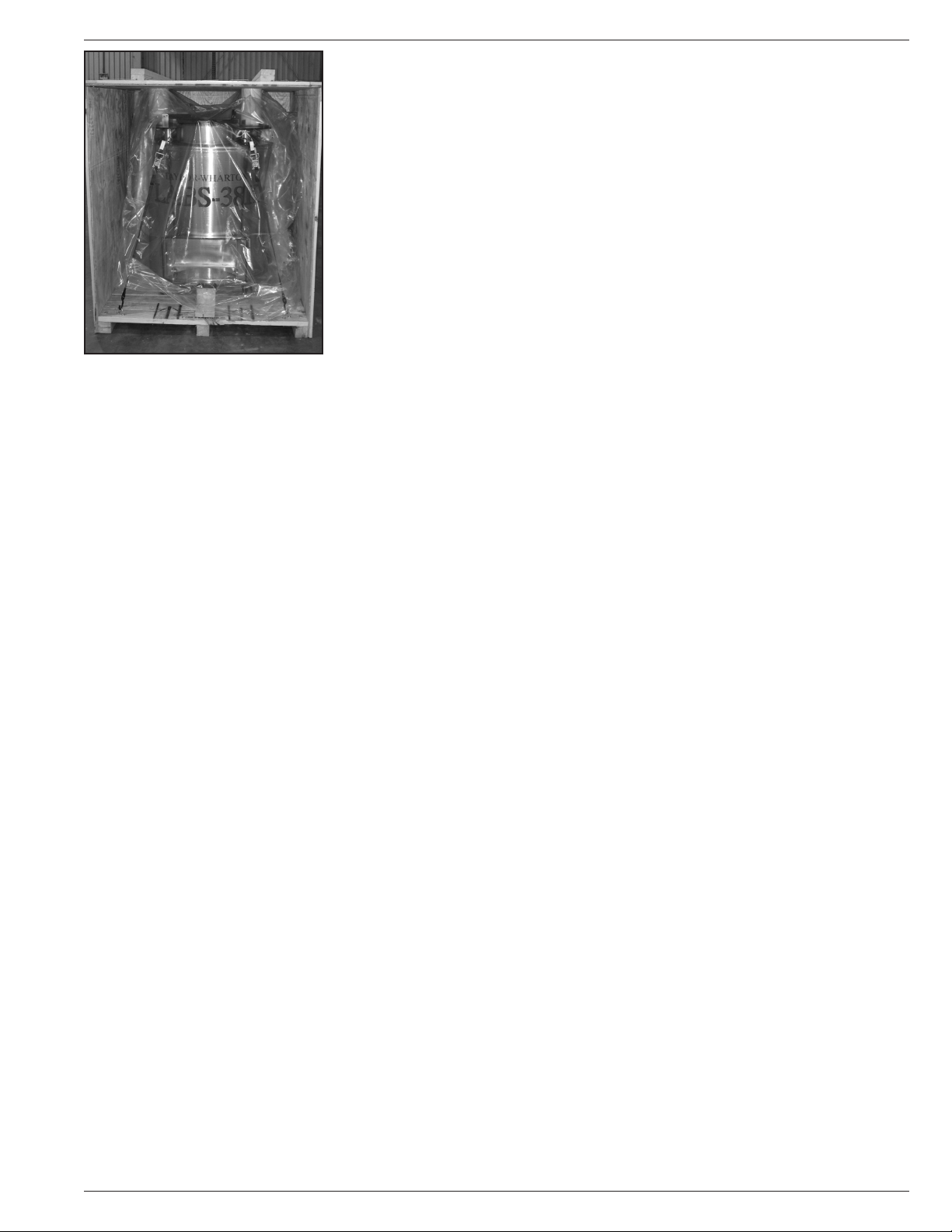

DELIVERY AND RETURNS

Unpacking and Inspection

Inspect shipping containers for external damage.

All claims for damage (apparent or concealed)

or partial loss of shipment must be made in

writing within five (5) days from receipt of goods.

If damage or loss is apparent, please notify the

appropriate parties as indicated below:

Domestic LTL Shipments – The customer

should notify and file the appropriate damage

claims with the carrier. All products are shipped

FOB Origin.

CS SERIES

Figure 1.0 Crated LABS 38K

delivery, and Taylor-Wharton must also be notified. Confirm with Taylor-Wharton

Customer Service the filing procedures for any UPS damage claims.

International Shipments – Any damage and/or claims are to be filed with the

carrier. Insurance agent(s) and customs’ brokers should also be notified.

In all cases, Taylor-Wharton should be notified so we can assist if needed

in filing damage claims.

Open the shipping containers; a packing list is included with the system to simplify

checking that all components, cables, accessories, and manuals were received.

Please use the packing list to check off each item as the system is unpacked. Inspect

for damage. Be sure to inventory all components supplied before discarding any

shipping materials. If there is damage to the system during transit, be sure to file

proper claims promptly. Please advise Taylor-Wharton of such filings. In case of parts

or accessory shortages, advise Taylor-Wharton immediately. Taylor-Wharton cannot

be responsible for any missing parts unless notified within 10 days of shipment.

Domestic UPS Shipments – Any damage

should be noted and reported to shipper upon

Freight Damage Procedures

Any freight damage claims are your responsibility. Cryostorage Systems

are delivered to your carrier from Taylor-Wharton’s dock in new

condition; when you receive our product you may expect it to be in that

same condition. For your own protection, take time to visually inspect each

shipment in the presence of the carrier’s agent before you accept delivery. If any

damage is observed, make an appropriate notation on the freight bill. Then, ask the

driver to sign the notation before you receive the equipment. You should decline to

accept containers that show damage which might affect serviceability.

Repackaging for Shipment

If it is necessary to return any part of the system for repair or replacement, a

Material Return Authorization (MRA) number must be obtained from an authorized

factory representative before returning the equipment to our service department.

Contact your distributor for return authorization. When returning equipment for

service, the following information must be provided before obtaining an MRA:

A. System model and serial number, and controller model and unit, if available.

B. User’s name, company, address, and phone number

C. Malfunction symptoms

7

Page 10

CS SERIES

CAUTION:

If using a power

source other than

North American

110/220 VAC,

contact TaylorWharton Customer

Service to make

sure you are using

the appropriate

converter. Use of an

unapproved power

source converter may

cause permanent

damage to the unit.

If possible, the original packing material should be retained for reshipment. If not

available, consult Taylor-Wharton for shipping and packing instructions. It is the

responsibility of the customer to assure that the goods are adequately packaged for

return to the factory. All refrigerators returned to Taylor-Wharton must be clean and

sterile before return. Refer to the operating manual of the freezer you are using for

cleaning instructions.

INSTALLATION

Getting Unit into Service

Your Cryostorage System comes with complete instructions for how you should

remove the unit from the crate and put it into service. Read both this manual and

your Cryostorage System’s manual before beginning any installation. Make sure to

follow any required procedures and safety guidelines when you are connecting your

Liquid Nitrogen source.

The CS SERIES Control System is designed to be operated at normal room

temperatures 15° C to 27° C (60° F to 80° F) at a relative humidity level below 50%.

The humidity level should be maintained such that the electronics are not exposed to

condensation.

The Taylor-Wharton Cryostorage freezer should be positioned such that the all sides

of the unit are easily accessible and the user can easily connect/disconnect the

power cord from the wall socket.

Proper ventilation MUST BE adequate to sustain life for those working with or

maintaining this equipment.

Electrical

WARNING:

Electrical shock can

kill. Do not attempt

any service on these

units without first

disconnecting the

electrical power cord.

WARNING:

Maintain adequate

ventilation to

prevent asphyxiation

hazard (see Safety

Precautions).

WARNING:

If the fill fails to

stop for any reason,

quickly close the

liquid supply valve

to prevent overfilling

until the cause of

the problem can be

determined.

The liquid level controllers used with these refrigerators operate at 12 VDC. The

external transformer has a 100/240 VAC primary. Disconnect the electrical power

cord from the outlet before attempting any service.

Electromagnetic Compatibility (EMC)

Although this equipment conforms to the intent of the 2004/108/EC EMC Directive,

all medical equipment may produce electromagnetic interference or be susceptible

to electromagnetic interference. The following are guidance and manufacturer’s

declarations regarding EMC for the CS SERIES Control System.

The CS SERIES Control System needs special precautions regarding EMC and needs

to be installed and put into service according to the EMC information provided in

the following pages.

Portable and Mobile RF communications equipment can affect the performance

of the CS SERIES Control System. Please use the guidelines and recommendations

specified in the EN Compliance tables found on pages 43-46.

Other Medical Equipment or Systems can produce electromagnetic emissions and

therefore can interfere with the functionality of the CS SERIES Control System. Care

should be used when operating the CS SERIES Control System adjacent to or stacked

with other equipment. If adjacent or stacked use is necessary, the CS SERIES Control

System should initially be observed to verify normal operation in the configuration in

which it will be used.

The electrical cables, external power supplies and accessories listed or referenced

in this manual have been shown to comply with the test requirements listed in the

8

Page 11

CS SERIES

EN Compliance tables found on pages 43-46. Care should be taken to use only

manufacturer-recommended cables, power supplies and electrical accessories

with the CS SERIES Control System. If a third-party supplier offers cables, external

power supplies and electrical accessories for use with the CS SERIES Control System

and they are not listed or referenced in this manual, it is the responsibility of that

third-party supplier to determine compliance with the standards and tests in the EN

Compliance tables found on pages 43-46.

The use of electrical cables and accessories other than those specified in this manual

or referenced documents may result in increased electromagnetic emissions from

the CS SERIES Control System or decreased electromagnetic immunity of the CS

SERIES Control System.

Power Supply Connection

Connect the power supply to your LABS Cryostorage System and then plug the

power supply into a surge-protected 110/220 VAC outlet.

Validation

Some organizations require that equipment be validated periodically. If information

is needed on the proper techniques to validate this equipment, please contact your

supplier.

WARNING:

This equipment

is intended for

use by healthcare

professionals. As

with all electrical

medical equipment,

this equipment

may cause radio

interference or

may disrupt the

operation of nearby

equipment. It may

be necessary to take

mitigation measures

such as re-orienting

or relocating the

CS SERIES Control

System unit or

shielding the

location.

OPERATION

These instructions are for operators experienced with cryogenic equipment. Before

operating the system, become familiar with the safety precautions in this manual

and in reference publications. Make certain all applicable provisions set forth in the

Installation Section have been followed before placing a system in operation. Study

this manual thoroughly. Know the location and function of all system components.

Initial Fill

The Cryostorage System, using the CS SERIES Controller, comes preset from the

factory. The liquid nitrogen supply pressure at the inlet to the refrigerator should be

in the range of 10 psig (0.7 bar/69 kPa) to 20 psig (1.4 bar/138 kPa) for optimum

performance. Higher operating pressures will increase transfer losses and create

excessive turbulence of the liquid in the refrigerator which can generate false signals

to the liquid level controller causing the refrigerator to under fill. In “liquid phase”

storage applications, excessive turbulence can cause splashing which could result in

personal injury.

For complete instructions for the initial fill refer the Quick Start Guide that comes

with your cryogenic freezer model.

9

Page 12

CS SERIES

Control Components

CS SERIES Control System Components

The CS SERIES Control System for the Taylor-Wharton Cryostorage freezer consists of

the following components:

• Main Control Module

• VFD (Vacuum Florescent Display) Module

• Shielded Display Cable

• Wiring Harness Assembly

• Power Supply

• Thermocouple Assembly (Optional Second Thermocouple)

• Sensor Assembly

• Cryogenic Solenoid Valve

• Remote Alarm Plug

• Lid Switch Assembly

• 12 Volt, 18aH battery

• Solenoid Valve Assembly with Freezeguard

• Strainer

The CS SERIES Control System is assembled onto the freezer at the factory and

completely tested. Refer to the Quick Start Guide for freezer set-up. Start operation

of the control system by plugging the power cord into the wall outlet. Press and hold

the POWER button for 2 seconds. The CS SERIES Control System will go through

a short startup routine and then start operation. Refer to Figure 2.0 below CS200

Controller Display for a description of the controller’s navigation buttons.

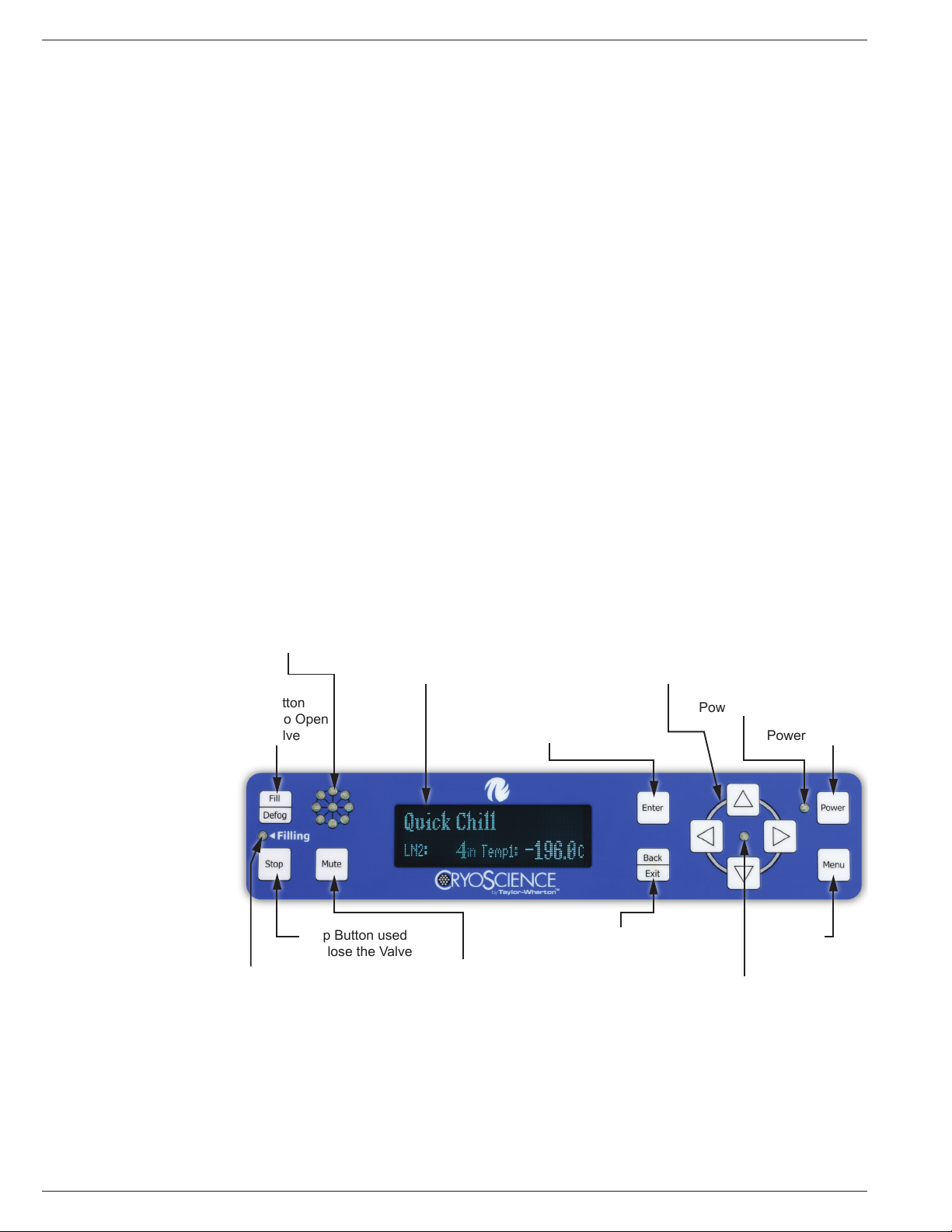

CS200 Controller Display Guide

Status Wheel VFD Graphics Display

Shows information

about the Freezer

Fill Button

Used to Open

the Valve

Stop Button used

to Close the Valve

Valve Indicator lights

if the Valve is Open

Figure 2.0 CS200 Controller Display

Enter button “selects”

a Menu choice or setting

Mutes the

Audible Alarm

Directional Buttons

Increment/decrement values or allow

movement through the menu system

Power Indicator

Power On/Off

Back Button moves

out of Menu System

or leaves current

Setting unchanged

Enter/Exit

Menu System

Menu Indicator

10

Page 13

Operational Theory

The CS SERIES Control System automatically maintains the Liquid Nitrogen (LN2)

level and monitors temperature in the Cryogenic freezer. Operational conditions

are monitored and any alarm is triggered if necessary. Operations data is stored in

memory on the control board.

#8

#7

High Level Alarm #6

CS SERIES

#5Stop Fill

#4

#3Start Fill

#2Low Level Alarm

#1

Figure 3.0 Thermister LN2 Level

The CS CONTROL SYSTEM uses thermistors to measure the LN2 level within

the vessel. A thermistor is a thermal resistor and its resistance changes as the

temperature changes. When a thermistor is submerged in LN2, its resistance will be

significantly greater than its resistance at room temperature. The control can detect

this resistance change and determine the level of the LN2 within the freezer. The CS

CONTROL SYSTEM is designed to work with an 8 thermistor assembly. There are

four thermistors that can be selected that will maintain the LN2 level. These selected

thermistors correspond to Low Alarm, Start Fill, Stop Fill and High Alarm. When

the LN2 level drops below the Start Fill thermistor, the control opens a solenoid

valve allowing LN2 to enter the vessel. This continues until the Stop Fill thermistor is

submerged in LN2 at which point the solenoid valve is closed preventing the flow of

additional LN2 into the vessel. The Low Alarm, Start Fill, Stop Fill and High Alarm

settings can all be changed by the user through the menu system.

11

Page 14

CS SERIES

The LN2 level is indicated on the display and is determined by the number of

thermistors submerged in LN2 according to the table below:

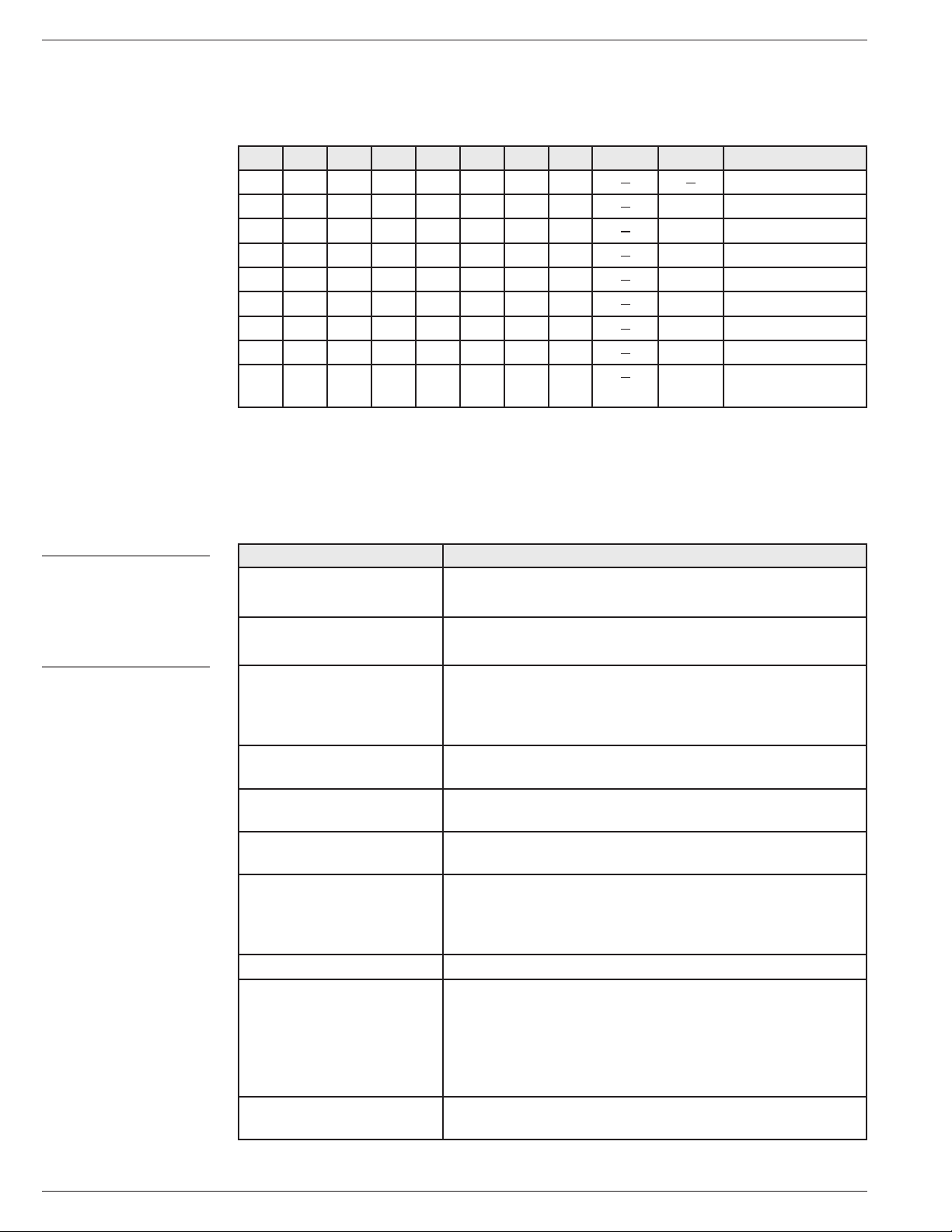

Table 1.0 8-Thermistor Sensor (G=NORMAL, L=LN2 Flow)

#1 #2 #3 #4 #5 #6 #7 #8 Offset Display Actions

G G G G G G G G 0 0 Low Alarm, Filling

L G G G G G G G 0 1 Low Alarm, Filling

L L G G G G G G 0 2 Filling

L L L G G G G G 0 3 Normal

L L L L G G G G 0 4 Normal

L L L L L G G G 0 5 Stop Fill

L L L L L L G G 0 6 High Alarm

L L L L L L L G 0 7 High Alarm

L L L L L L L L 0 8 High Alarm, Valve

stuck Open Alarm

Alarm Conditions

The CS SERIES Control System monitors a number of conditions and provides an

alarm if a problem is detected. The alarms are listed below:

Note: Please see

description of the offset.

Level displayed may vary

depending on the offset

setting.

Table 2.0 Alarm Conditions

ALARM PROBLEM DETECTED

Low Level Alarm

High Level Alarm LN2 level is too high. Thermistor #6 on the sensor assembly

Sensor Error Alarm A problem exists with the level sensor. The control detects an

High Temperature Alarm The temperature detected is warmer than the high

Low Temperature Alarm The temperature detected is colder than the low temperature

Thermocouple Calibration

Alarm

Thermocouple Open Alarm A problem exists with the temperature sensor

Power Failure No Power.

Low LN2 Supply Alarm A problem may exist with the LN2 supply connected to the

LN2 Use Warning The consumption of LN2 has increased and should be

LN2 level is too low. Thermistor #2 on the sensor assembly is

not submerged in LN2.

is submerged in LN2.

open sensor circuit meaning that the sensor is unplugged or

the sensor assembly has been damaged. A faulty sensor is

denoted as “O” for open.

temperature alarm setting.

alarm setting.

The calibration data is incorrect.

(thermocouple). The control detects an open circuit meaning

that the sensor is unplugged or the sensor assembly has

been damaged.

freezer. This alarm occurs if the freezer does not fill within

the designated amount of time determined by the setting

on the control. Possible reasons include an empty supply

cylinder, low head pressure in the supply cylinder or a closed

shut off valve.

checked.

12

Page 15

Table 2.0 Alarm Conditions

ALARM PROBLEM DETECTED

Operating in Battery Mode

Alarm Warning

Low Battery Voltage The voltage on the battery is low.

Lid Open Too Long Alarm The lid has been opened for a period which is longer than

Valve Stuck Open Alarm The valve is stuck open.

Unauthorized Access

Warning

Temp Alarm Delay This is the amount of time after a warm temperature is

Audible Alarm Retrigger The audible alarm is retriggered if the error condition that

Remote Alarm Relay The control provides a relay to provide an external signal

The power from the power supply has been disrupted and

the control system is operating on battery power.

the designated alarm setting.

The lid has been opened and an incorrect or no

identification has been entered.

detected before the control goes into alarm.

caused it is not corrected. The retrigger time can be adjusted

by the user.

that an alarm condition has occurred. The user can set the

remote alarm timer that determines the amount of time an

error must be active before the relay is triggered.

CS SERIES

All alarms include the following:

• The flashing status wheel flashes to signal an error condition

• An audible tone sounds

• The error detected is displayed and scrolled on the screen

• The remote alarm relay changes state to provide a dry contact output signal

Lid Switch

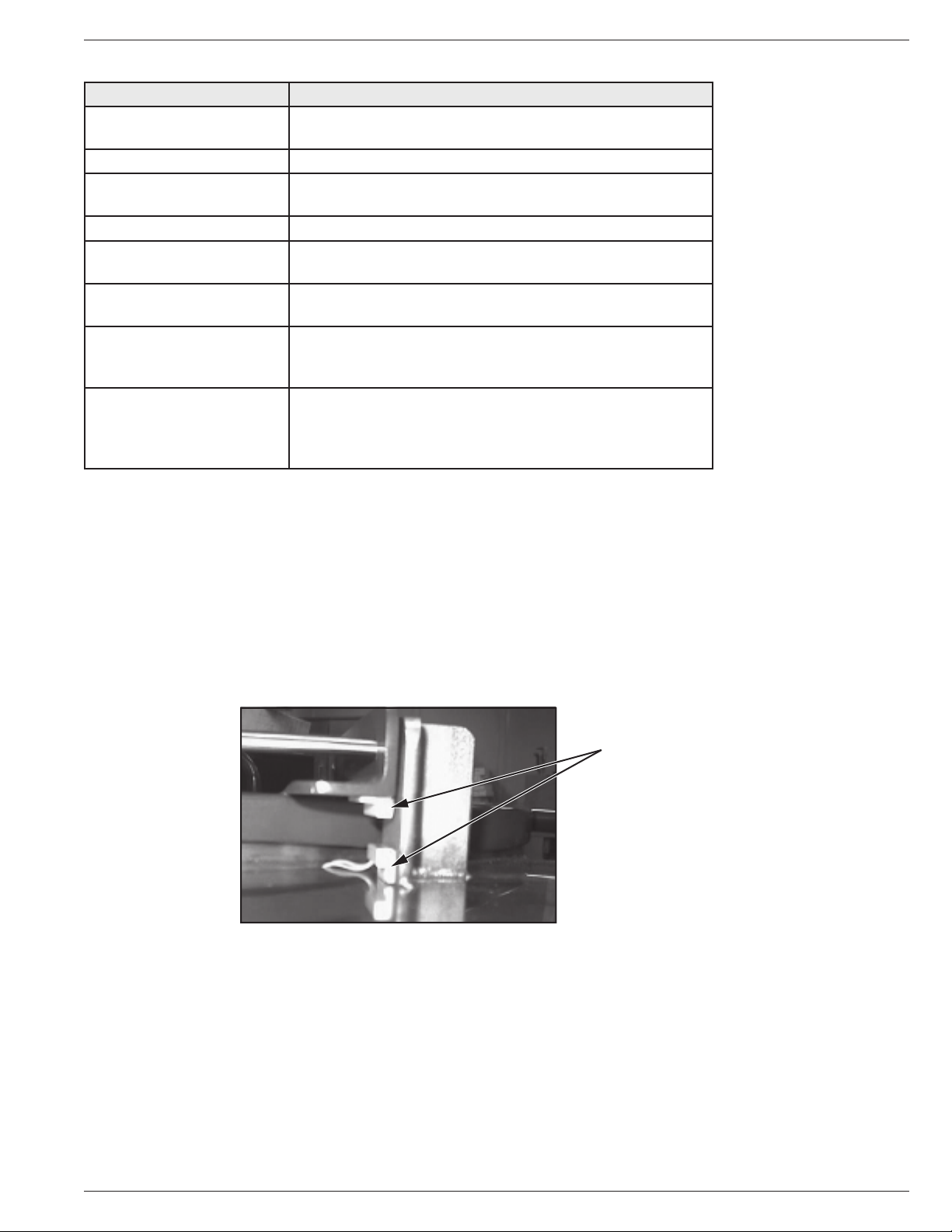

The LABS Lid Switch (Figure 4.0) is attached to the hinge and determines whether or

not the lid is open on the freezer. This also allows the control to determine whether

to activate the Auto Defog, Quick Chill or Lid Alarm features.

Lid Switch

Figure 4.0 LABS Lid Switch

Solenoid Valve

These units are designed to work with 12 VDC solenoid valve (see Figure 17.0 LABS

Plumbing Assembly on page 37).

Thermocouples

Type T thermocouples monitor the temperature in the freezer. The user may choose

to use NONE, 1 or 2 thermocouples with this control at any time. (The unit comes

complete with one Thermocouple)

13

Page 16

CS SERIES

Remote Alarm Connector

Power Supply

A 12 VDC power supply is supplied for the CS SERIES Control System. The system is

supplied with a transformer compatible with common household (North American)

100/240 VAC. (For other power outlets contact Taylor-Wharton Customer Service.)

UL approval for the system as a whole is not required since the control operates on

low voltage. If your power source differs, or is subject to disruption or line surges

due to other equipment on line, consult your Taylor-Wharton representative.

Remote Alarm

If an error condition occurs after a user defined period of time, a remote alarm

can be initiated. This is accomplished by connecting a remote device to the remote

alarm jack on the rear electrical panel. The 3-pin jack on the back of the unit

provides continuity between pin #2 (common) and pin #3 in the normal condition.

Continuity between pin #1 and pin #2 is provided in an error condition.

Figure 5.0 Remote Alarm Plug Connection

Operating Parameters

When materials are immersed in liquid nitrogen, they will assume the temperature

of the liquid (-196°C/-320°F). When material is stored in the vapor phase over the

liquid, the liquid nitrogen is still a very cold refrigerant, but the refrigerator’s interior

temperature increases as product is stored higher over the liquid. This temperature

differential is not significant for many biological storage applications, and is affected

by the amount of product stored in the refrigerator, the type size and material of

inventory control system, and the liquid level in the unit.

The liquid level in the refrigerator is determined by the position of the of the

Thermistor Assembly in the sensor tube. These sensors are set at installation to

maintain a specific liquid level. A filling cycle is initiated when the level falls below

the Start Fill sensor and is completed when the Stop Fill sensor is reached. This

filling cycle repeats when the level fall below the Start Fill sensor. Sensor Probe

assignments may be changed on the controller keypad to define new start and stop

levels, and these levels may be set independently to vary the liquid level deference

between fills. Prior to the initial fill of the refrigerator, a determination should be

made whether vapor phase or liquid phase storage will be utilized.

All units are supplied with an eight thermistor assembly and a freeze-guard sensor

unless otherwise specified. The LABS factory setting positions will maintain liquid

level within a distance of 2 in. (50.8 mm) from the bottom of the operating tray on

the LABS 20K, 38K, 40K, 80K units, and 3 in. (76.2 mm) from the bottom of the

operating tray on the LABS 94K.

14

Page 17

Temperature Monitoring

The CS SERIES Control System uses a type T thermocouple to monitor the

temperature in the vessel. The thermocouple is factory-installed near the top of

the Taylor-Wharton Cryostorage freezer vapor chamber and the temperatures are

measured at that point.

The CS SERIES Control System accommodates a second user-installed thermocouple

for temperature measurement at a secondary location. This is also a Type T

thermocouple.

The control provides a High Temperature Alarm for each thermocouple which can

be selected by the user. If the temperature exceeds the temperature alarm set point,

the status wheel flashes and an audible alarm is triggered.

Liquid Phase Storage

Liquid phase storage is normally utilized when -196 is required to maintain stored

product viability and the storage medium is adequate for storage in liquid nitrogen.

In a typical liquid phase storage system, the liquid level sensors are positioned to

maintain the liquid level at or below the top level of the inventory control system.

During operation, the upper levels of the inventory control system will at times

become exposed as the liquid level fluctuates.

CS SERIES

Care must be taken to ensure that the liquid level remains below the bottom of the

refrigerator lid. Exposure to liquid nitrogen may result in physical damage to the lid.

Additionally, operating the refrigerator with high liquid levels characteristic of liquid

phase storage may result in turbulence during fill cycles. Caution must be exercised

if the refrigerator lid is opened during a fill, and appropriate safety equipment

should always be worn.

The Taylor-Wharton Cryostorage Systems are set at factory for vapor phase storage.

Maintenance

To insure proper operation and maintain excellent performance of the TaylorWharton Cryostorage freezer, an annual maintenance schedule should be followed

for the CS SERIES Control System. This would include the following:

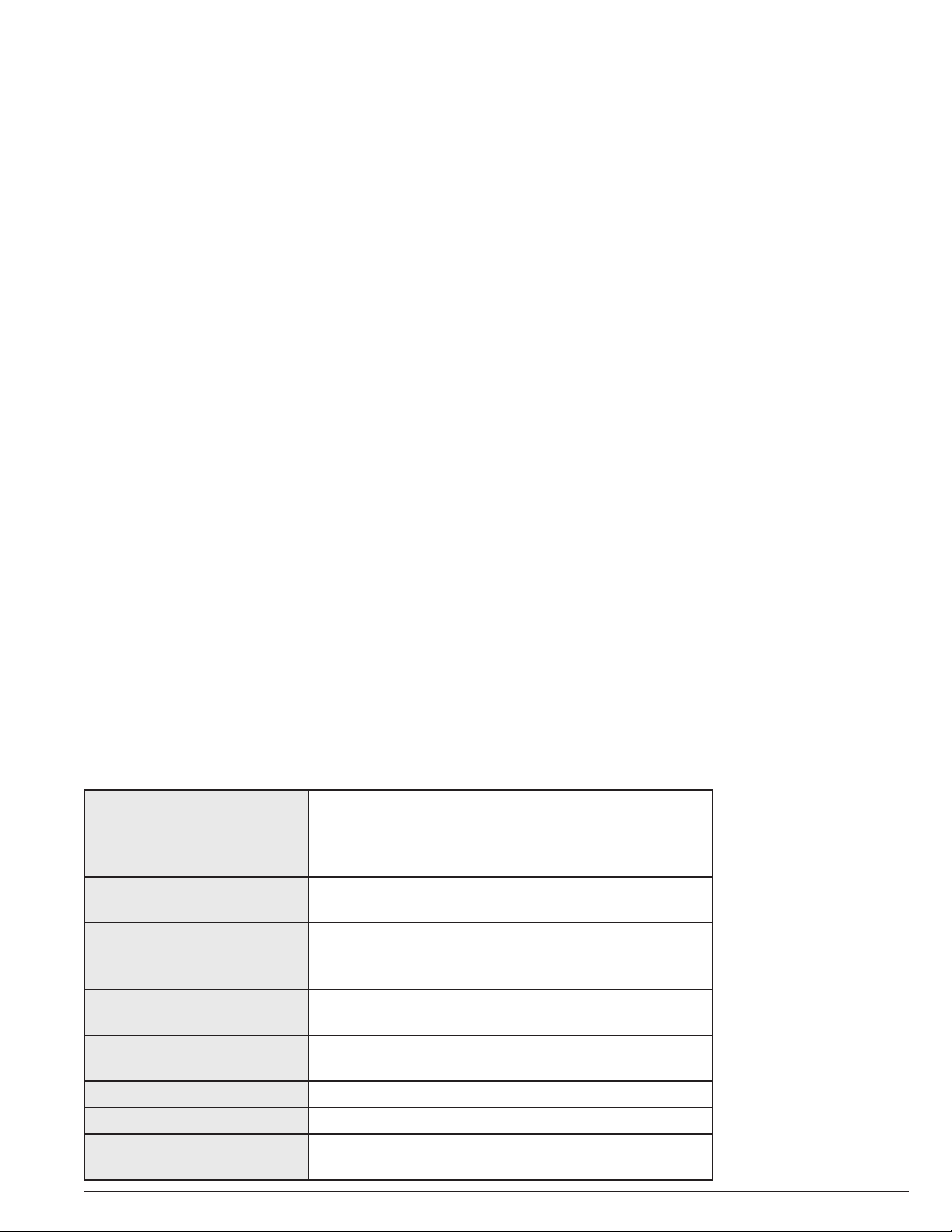

Table 3.0 Annual Maintenance Schedule

CS SERIES Control

System

Harness Assembly

Battery

Solenoid Valve

Lid Switch

Level Sensor Assembly

Thermocouple Assembly

Power Supply

Examine for exposure to moisture, wear and tear,

connector problems, and cracks or other damages

to the faceplate or buttons. In addition, periodic

firmware updates may be important.

Examine for damage to the cable and damage to

connectors.

Examine connection cable and connector for

damage.Examine vinyl cover for damage.

Replace every 2 years.

Examine wires and connector for damage.

Replace every 3 years.

Examine lid switch pickup and wires for damage.

Replace if necessary.

Examine for damage to wires and connector.

Examine for damage to wires and connector.

Examine for damage to power supply and power

cords.

15

Page 18

CS SERIES

In addition, inspection and preventive maintenance should also be performed on

the freezer and its mechanical parts. Refer to owner’s manual for details.

If any intermittent alarm or defect with the Cryo-Storage System is observed or

suspected, it should be investigated and remedied immediately even if this falls

outside of the normal maintenance schedule.

CONTROLLER OPERATION

This section of the operating manual is for Taylor-Wharton approved equipment that

uses the CS SERIES Control System.

Introduction

The CS200 Control System, temperature and LN2 level controller is designed for

easy operation and uninterrupted reliable service. This controller will maintain the

selected liquid level range of LN2 in your refrigerator as well as provide audible

and visual alarms for any non conforming conditions that may occur. An Alarm

is any condition outside the activated preset limits on the control, such as an

open sensor circuit or temperature alarm. “System Events” are lid openings and

closings, solenoid valve openings and closing, and operation of the controller’s

relay for remote alarm indication. System Events, Alarms and Temperature “Data”

can be downloaded.

The System should require no additional attention to maintain liquid level if an

adequate supply source of liquid nitrogen is maintained. If your protocol calls for

you to “top-off” the Cryostorage System at the end of a workday or workweek,

press the FILL button. The unit will fill to the upper allowable liquid level and stop

automatically. You may choose to manually stop the fill by pressing the STOP

button at anytime during the fill.

Operation Data

The CS200 CONTROL SYSTEM stores data related to the operation of the TaylorWharton Cryo-Storage freezer. This data includes date, time, LN2 level, temperature,

system events and error conditions. This can be useful for audit purposes, operation

analysis and preventive maintenance.

Communications

The CONTROL SYSTEM has been designed with advanced communications

capabilities. This allows for the transfer of data out of the control where the data

can more easily be used. Please check with your supplier for available protocols and

compatible products.

Normal Fill Cycle

When the refrigerator is filled and the controller is operating, the START FILL and

LOW ALARM sensors are immersed in liquid nitrogen. Their resistance values

are interpreted by the controller as “in liquid”. At the same time, the STOP FILL

and the HIGH ALARM sensors are above the liquid pool, informing the control

that these sensors are in vapor. As liquid nitrogen evaporates, the liquid level

in the refrigerator drops slowly until the START FILL sensor is above the liquid

and sends a different signal to the controller. After a delay sufficient to ensure

the signal, the controller interprets this condition as low liquid and opens the fill

solenoid, admitting more liquid nitrogen from the supply source.

16

The refrigerator will fill slowly. The fill continues until the STOP FILL sensor sends

the controller a signal that it is now in liquid. The controller will close the liquid

supply valve to stop the fill. As liquid evaporates, the display will indicate the

liquid is at a normal level as the cycle begins again.

Page 19

Control Setting Adjustments

Level

The standard sensor assembly that is installed on a freezer consists of a circuit

board with thermistors installed. The assembly has a maximum range of 6 inches

(150mm). Thermistor assignments can be changed through the menu system and

the operating range can be changed by either raising or lowering the circuit board

(offset) within the freezer.

If a wider range is needed between the start fill and stop fill thermistor, please

contact your supplier for an alternate sensor assembly.

Features & Settings

Some control settings can be changed through the menu system.

Enter and Exit the menu system by pressing:

Move down through the menu system by pressing:

CS SERIES

Move up through the menu system by pressing:

Select a menu choice or lock in a setting by pressing:

Back out of the menu system by pressing:

When changing settings, single button presses will increment/decrement a value

one step at a time. Pressing and holding a button will allow for rapid change of a

setting.

The menu system incorporates icons to show the user settings which can be changed

and which are locked.

Locked menu choice:

Accessible menu choice:

Also, the menu system includes a scroll bar on the right side of the display. The

scroll bar will indicate the current location in the menu system and will indicate if

additional menu choices are available with the display of up and down arrows on

the scroll bar.

The control will continue to monitor all sensors and conditions while the user

accesses the menu system. If no activity is detected for 30 seconds, the control will

automatically return to the main operational screen.

17

Page 20

CS SERIES

View Only

The View Only menu selection allows the user to view settings but will not allow

changes to any settings. This restriction is designated with a lock symbol. Refer to

Figure 8.1 Menu System - View Only on page 22 to navigate the “View Only” menu.

Change Settings

The Change Settings menu selection allows the user to change operational settings

for the control system. Refer to Figure 8.2 Menu System - Change Settings on page

23 to navigate through any changes you need to make.

Below are the Menu Settings that are available in both the “View

Only” and “Change Settings” modes.

•TEMPERATURE

– Thermocouple Select: Allows the user to turn on/off thermocouples for

temperature measurement.

– Calibrate

•Calibrate Thermocouple 1: Allows the user to calibrate the control for use

with thermocouple #1.

•Calibrate Thermocouple 2: Allows the user to calibrate the control for use

with thermocouple #2.

•Restore Calibration: Resets the calibration to the data stored during factory

calibration.

•Set Ambient: Ambient temperature is set at the factory and should not be

changed in the field.

– Test Temperature System

•Check Thermocouples: Gives status of temperature sensors.

•Test Temp Alarms: Allows the user to manually test temperature alarms for

the thermocouples.

– Control by Temperature

•Temp Control On/Off: Enables/Disables temperature control.

•Temp Control Range: Allows the user to set the range for temperature control.

– Temperature Alarms

•High Temperature Alarm: Allows the user to set the high temperature

alarm for both thermocouples. Settings [00° C to -1900° C]

•Low Temperature Alarm: Allows the user to set the low temperature alarm

for both thermocouples. Settings [00° C to -1900° C]

•Time with no Temp alarm: Displays the time since the last high or low

temperature alarm.

18

– Temperature Units: Allows the user to choose the units of measure for

temperature.

•LEVEL

– Thermistor Status: Gives the user the status for the 8 thermistors on the level

sensor assembly and the freezeguard sensor installed at the valve.

– Sensor Positions: Allows the user to assign the thermistors for low level alarm,

start fill, stop fill, high level alarm and the sensor offset.

– Valve Open Duration: Allows the user to set the fixed times for valve open

and valve closed durations.

Page 21

– Sensor Type: Allows the user to set the sensor type as a 4 thermistor sensor or

an 8 thermistor sensor. Also allows the user to disable the freezeguard sensor.

– Level Sensor Alarm

•Sensor Error Mute: Allows the user to mute the audible alarm for a sensor

error.

•Freezeguard Error Mute: Allows the user to mute the audible alarm for a

freezeguard sensor error.

•SYSTEM

– Inch/Metric: Allow the user to switch between English and Metric level

measurement systems.

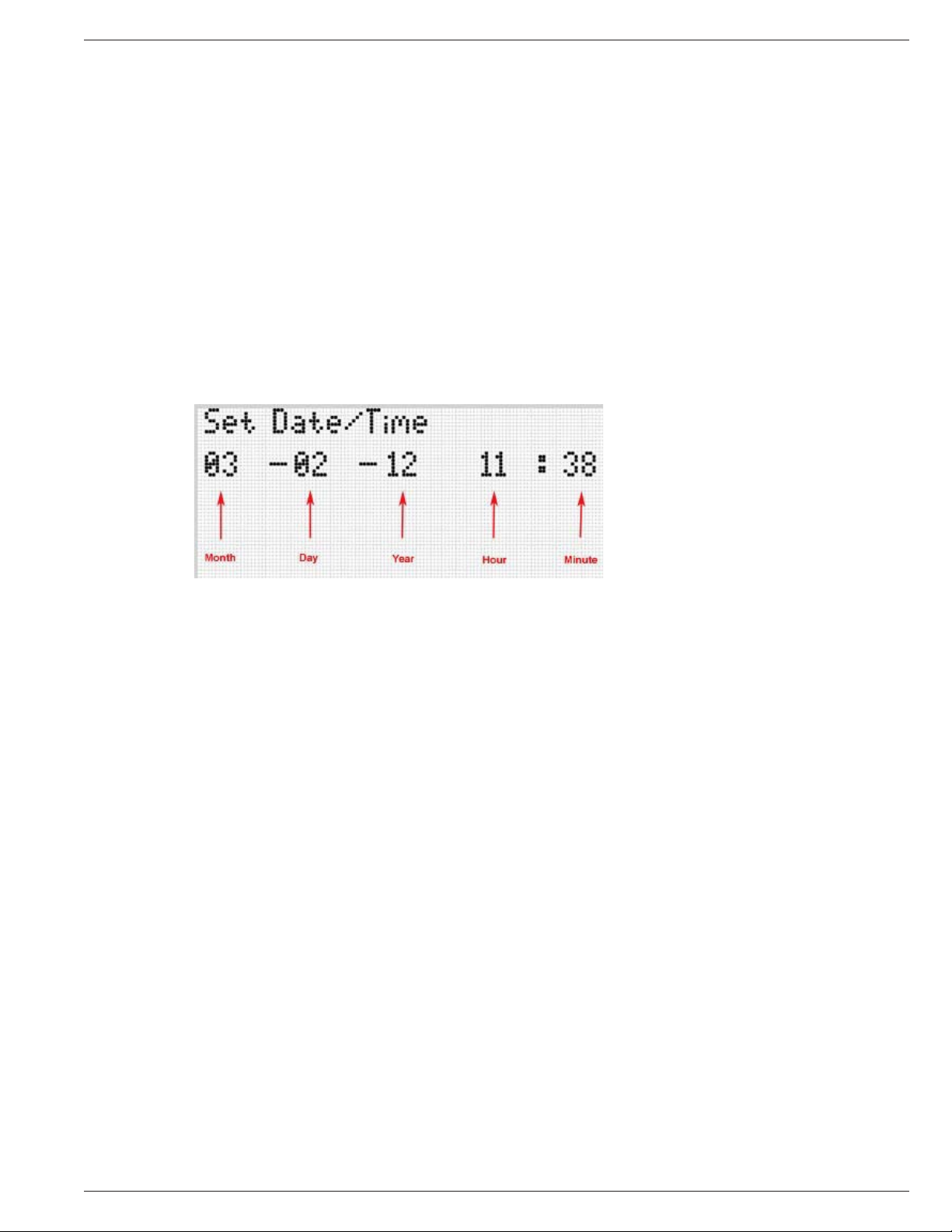

– Date/Time:

•Set Date/Time: Allows the user to set the date and the time. Use the up/

down arrows to change settings. Use the left/right arrows to move between the

date and time fields.

CS SERIES

Figure 6.0 Set Date/Time Menu

•Date Format: Allows the user to change between U.S. and International format.

– Lid Functions

•Lid Switch: Permits the user to enable/disable the lid switch feature.

•Quickchill Timer: Enables the user to set the amount of time that the valve

will stay open after the lid is closed.

•Manual Defog Timer: Allows the user to set the amount of time that the

valve stays open when the Fill/Defog button is pressed and the LN2 level is

within normal range.

•Auto Defog Timer: Allows the user to set the amount of time that the valve

stays open. Triggered by the lid switch when the lid is opened and the LN2 level

is within normal range.

•User Access On/Off: Allows the user to enable/disable this feature.

– User ID’s: Allows the user to set user identification for freezer access.

•Lid Open Valve Off: Allows the user to enable this feature which insures that

solenoid is closed when the lid is opened.

– System Alarms

•Test Alarm: Allows the user to manually check the audible, visual and remote alarm.

•LN2 Supply Alarm Delay: Allows the user to set the time to wait before

an error condition occurs if the freezer does not fill in a timely manner. If this

alarm occurs the supply should be checked to insure that the supply valve on

turned on, a sufficient supply of LN2 (at least 10 psi) is available in the supply

cylinder. Settings [30, 45, 60, 75, 90 min] or [2, 3, 4 hours]

19

Page 22

CS SERIES

•Remote Alarm Delay: Allows the user to set the time before the remote

alarm relay is triggered after an error condition occurs. Settings [Immediate,

30, 60, 90 min] or [2,3, 4, 6 hours]

•Lid Open Alarm Delay: Allow the user to set the time before an alarm

condition occurs if the lid is opened too long.

•Valve Stuck Alarm: Allow the user to enable/disable this feature.

•Audible Re-trigger: Allows the user to set the time before the audible alarm

is re-triggered after an alarm has been acknowledged. Settings [15, 30, 60,

120, 240, 480 min] or [1 day]

– Display

•Display Brightness: Allows the user to adjust brightness for the display.

Settings [1 to 15]

•Screen Saver Time: Allows the user to adjust the time before the screen

saver starts working. Settings [0 to 60 min]

– Freezer ID: Allows the user the capability to change the freezer identification.

•SCHEDULED EVENTS

– Scheduled Fills

•Set Time: Allows the user to set the day and time for the next filling operation.

•Next Fill: Displays the next scheduled fill.

– LN2 Supply Reminder

•Set Reminder: Allows the user to set the day which the control will display a

reminder to check the supply of LN2.

•Clear Reminder: Allows the user to acknowledge that the LN2 supply has

been checked.

•Next Reminder: Displays the next scheduled reminder.

Below are the Menu Settings that are available only in the “Change

Settings” mode.

•SECURITY

– Settings Password: Allows the user to set a password to allow setting changes.

– Power Password: Allows the user to set the password which secures power

button operation.

•CONTACT SUPPORT

– Distributor: Contact information for the distributor.

– Taylor-Wharton: Contact information for Taylor-Wharton.

•SYSTEM INFORMATION

– Displays the control serial number, the firmware version and the freezer

identification.

20

Temperature

The temperature in the Cryostorage freezer is measured at the location of the

thermocouple. The installation location is different depending on the model of

the freezer but usually the thermocouple is positioned level with the top storage

box. This may mean that temperatures displayed may be slightly warmer than the

temperature experienced by the samples or product stored in the freezer.

Page 23

Temperature Control

The CS SERIES Control System has the capability to control the vapor temperature

at the top of the freezer. The temperature is controlled at the location of

thermocouple 1.

To maintain temperature, the CS200 SERIES Control System bubbles N2 gas

through the pool of LN2 in the bottom of the freezer. The nitrogen gas evaporates

some of the LN2 causing a cooling effect reducing the temperature in the freezer.

Since a pool of LN2 is important in the process of temperature control, an adequate

level is always maintained by the control systems and the level control always takes

precedence over temperature control. Temperature control will not work if the LN2

level is above High Level Alarm.

Enabling the temperature control feature will always increase the use of LN2.

The increased consumption will depend on a number of factors including the

temperature to be maintained, the range of the controlled temperature, the ambient

temperature and the length of supply hose connected to the freezer and the

frequency which users open the lid or otherwise introduce heat.

Battery Operation

The CS200 SERIES Control System is designed to operate with or without an optional

battery backup system if required. Simply plug the battery into the appropriate

connector. The control will recognize that the battery has been connected and will

activate the battery backup mode.

CS SERIES

LED Status Wheel

The CS SERIES Control System offers an innovative concept called a status wheel. In

normal operation, the LED’s on the status wheel light to show a slow rotation of the

wheel. If an error condition occurs, the control will alert the user with an additional

visual alarm from the status wheel. The rotation can be accelerated, flashed or even

illuminated in the opposite direction.

Condition LED Flash Property

Normal Clockwise pattern, 1 LED per second

General Error Clockwise pattern, rapid rotation, flash

Figure 7.0 LED Status Wheel Flash Patterns

Lid Switch

The lid switch consists of a magnet and a pickup installed on the lid. The control can

determine when the lid is opened because the magnet moves out of range of the

pickup and the circuit becomes open. A number of features are associated with the

lid switch such as Auto Defog, Quickchill and the Lid Open Too Long Alarm. If the

lid switch is deactivated, these features are also disabled.

21

Page 24

CS SERIES

MENU

VIEW ONLY

TEMPERATURE

LEVEL

SYSTEM

SCHEDULED EVENTS

THERMOCOUPLE SELECT

TEST TEMPERATURE SYSTEM

CONTROL BY TEMPERATURE

TEMPERATURE ALARMS

TEMPERATURE UNITS

THERMISTOR STATUS

SENSOR POSITIONS

VALVE OPEN DURATION

SENSOR TYPE

LEVEL SENSOR ALARM

INCH/METRIC

DATE/TIME

LID FUNCTIONS

SYSTEM ALARMS

DISPLAY

FREEZER ID

SCHEDULED FILLS

LN2 SUPPLY REMINDER

T/C 1 ON/OFF T/C ON/OFF

CHECK THERMOCOUPLES

VALIDATE CALIBRATION

TEST TEMP ALARMS

TEMP CONTROL ON/OFF

TEMP CONTROL RANGE

HIGH TEMPERATURE ALARM

LOW TEMPERATURE ALARM

TIME WITH NO TEMP ALARM

CELCIUS FAHRENHEIT

KELVIN RANKINE

123456789 LID SWITCH

123456789 0

02 03 04 05

SENSOR OFFSET 0 INCH

OPEN 0 CLOSE 0

NUMBER OF THERMISTORS

FREEZEGUARD

SENSOR ERROR MUTE

FREEZEGUARD ERRROR MUTE

INCH METRIC

SET DATE/TIME

DATE FORMAT

LID SWITCH

QUICKCHILL TIMER

MANUAL DEFOG TIMER

AUTO DEFOG TIMER

USER ACCESS

LID OPEN VALVE OFF

TEST ALARMS

LN2 SUPPLY ALARM DELAY

REMOTE ALARM DELAY

LID OPEN ALARM DELAY

VALVE STUCK ALARM

AUDIBLE RE-TRIGGER

DISPLAY BRIGHTNESS

SCREEN SAVER TIME

FREEZER 1

SET TIME

NEXT FILL

SET REMINDER

CLEAR REMINDER

NEXT REMINDER

T/C 1 OK T/C

2 OFF

OFF

OFF ON

-150C -165C

THERMOCOUPLE 1

THERMOCOUPLE 2

THERMOCOUPLE 1

THERMOCOUPLE 2

TEMP 1: 0

4 8

OFF ON

ON OFF

ON OFF

03 -03 -12 15 06

U.S. INTERNATIONAL US

MM/DD/YY INT: DD/MM/YY

OFF ON

20

20

20

USER ACCESS ON/OFF

USER IDs

USER ID ON/OFF

OFF ON

AUDIBLE

VISUAL

REMOTE

30 45 60 75 90 MIN 2 3

4 HOURS

IMMEDIATE 30 60 90 MIN 2

3 4 5 HOURS

10 MIN

OFF ON

15 30 60 120 240 480 MIN 1

DAY

0

20

SET DAY SET TIME

DAILY 17:00

03-12-12 14:37

OFF SUN MON TUES WED

THRS FRI SAT

YES

3/3/2012

-100

-100

-180

-180

OFF ON

USER 1

USER 2

USER 3

OFF ON

OFF ON

OFF ON

OFF ON

22

Figure 8.1 Menu System - View Only

Page 25

CS SERIES

CHANGE SETTINGS

CONTACT SUPPORT

SYSTEM INFORMATION

TEMPERATURE

LEVEL

SYSTEM

SCHEDULED EVENTS

SECURITY

DISTRIBUTOR

PAGER DIGITAL

TAYLOR-WHARTON

SERIAL # 12345

VERSION 1.00

FREEZER ID FRZ01

THERMOCOUPLE SELECT

CALIBRATE

TEST TEMPERATURE SYSTEM

CONTROL BY TEMPERATURE

TEMPERATURE ALARMS

TEMPERATURE UNITS

THERMISTOR STATUS

SENSOR POSITIONS

VALVE OPEN DURATION

SENSOR TYPE

LEVEL SENSOR ALARM

INCH/METRIC

DATE/TIME

LID FUNCTIONS

SYSTEM ALARMS

DISPLAY

FREEZER ID

SCHEDULED FILLS

LN2 SUPPLY REMINDER

SETTINGS PASSWORD

POWER PASSWORD

CONTACT INFO

CONTACT INFO

CONTACT INFO

T/C 1 ON/OFF T/C ON/OFF

CALIBRATE THERMOCOUPLE 1

CALIBRATE THERMOCOUPLE 2

RESTORE CALIBRATION

SET AMOUNT

CHECK THERMOCOUPLES

VALIDATE CALIBRATION

TEST TEMP ALARMS

TEMP CONTROL ON/OFF

TEMP CONTROL RANGE

HIGH TEMPERATURE ALARM

LOW TEMPERATURE ALARM

TIME WITH NO TEMP ALARM

CELCIUS FAHRENHEIT

KELVIN RANKINE

123456789 LID SWITCH

123456789 0

02 03 04 05

SENSOR OFFSET 0 INCH

OPEN 0 CLOSE 0

NUMBER OF THERMISTORS

FREEZEGUARD

SENSOR ERROR MUTE

FREEZEGUARD ERROR MUTE

INCH METRIC

SET DATE/TIME

DATE FORMAT

LID SWITCH

QUICKCHILL TIMER

MANUAL DEFOG TIMER

AUTO DEFOG TIMER

USER ACCESS

LID OPEN VALVUE OFF

TEST ALARMS

LN2 SUPPLY ALARM DELAY

REMOTE ALARM DELAY

LID OPEN ALARM DELAY

VALVE STUCK ALARM

AUDIBLE RE-TRIGGER

DISPLAY BRIGHTNESS

SCREEN SAVER TIME

FREEZER ID #1

SET TIME

NEXT FILL

SET REMINDER

CLEAR REMINDER

NEXT REMINDER

0 0 0 0

0 0 0 0

PUT T/C 1 IN ICE WATER (0C)

PUT T/C 1 IN LN2 (-196C)

DONE

PUT T/C 2 IN ICE WATER (0C)

PUT T/C 2 IN LN2 (-196C)

DONE

ABORT LOAD

35.3

T/C 1 OK T/C 2

OFF

OFF

OFF ON

-150C -155C

THERMOCOUPLE 1

THERMOCOUPLE 2

THERMOCOUPLE 1

THERMOCOUPLE 2

TEMP1: 0

4 0

OFF ON

ON OFF

ON OFF

00 -00 -12 15:00

US INTERNATIONAL

US: MM/DD/YY INTL: DD/MM/YY

OFF ON

30

30

33

USER ACCESS ON/OFF

USER IDs

USER ID ON/OFF

OFF ON

AUDIBLE

VISUAL

REMOTE

30 45 60 75 90 MIN 2

3 4 HOURS

IMMEDIATE 30 60 90 MIN 2

3 4 5 HOURS

10 MIN

OFF ON

15 30 60 120 240 480 MIN 1

DAY

0

30

SET DAY SET TIME

DAILY 17:00

03-13-12 14:37

OFF SUN MON TUES WED

THURS FRI SA

YES

10-13-12T

-100

-100

-130

-130

OFF ON

USER 1

USER 2

USER 3

OFF ON

OFF ON

OFF ON

OFF ON

Figure 8.2 Menu System - Change Settings

23

Page 26

CS SERIES

Factory Defaults

Thermocouple #1 On

Thermocouple #2 Off

Control by Temperature Off

High Temperature Alarm #1 -100C

High Temperature Alarm #2 -100C

Low Temperature Alarm #1 Off

Low Temperature Alarm #2 Off

Temperature Units Celsius

Sensor Position Freezer dependant

Valve Open Duration Off

Sensor Type 8 thermistor sensor

Freezeguard feature On

Sensor Error Mute Off

Freezeguard Error Mute Off

Level Units of Measure inch

Date/Time Factory Set for Eastern Standard Time

Lid Switch On

Quickchill Timer 30 seconds

Manual Defog Timer 30 seconds

Auto Defog Timer 30 seconds

User Access Off

Lid Open-Valve Off Off

LN2 Supply Alarm Delay 30 minutes

Remote Alarm Delay 30 minutes

Lid Open Alarm Delay 10 minutes

Valve Stuck Alarm On

Audible Retrigger 30 minutes

Display Brightness 10

Screen Saver Time 30 minutes

Freezer ID Not set

Scheduled Fills Off

LN2 Supply Reminder Off

Settings Password Off

Power Password Off

24

Page 27

Troubleshooting

If the Taylor-Wharton Cryostorage freezer with the CS200 SERIES Control System

installed experiences problems or appears that it is not operating at optimum

efficiency, please contact your distributor for assistance. The CS SERIES Control

System has incorporated state of the art diagnostic tools to assist in the identification

and correction of any issues that may arise.

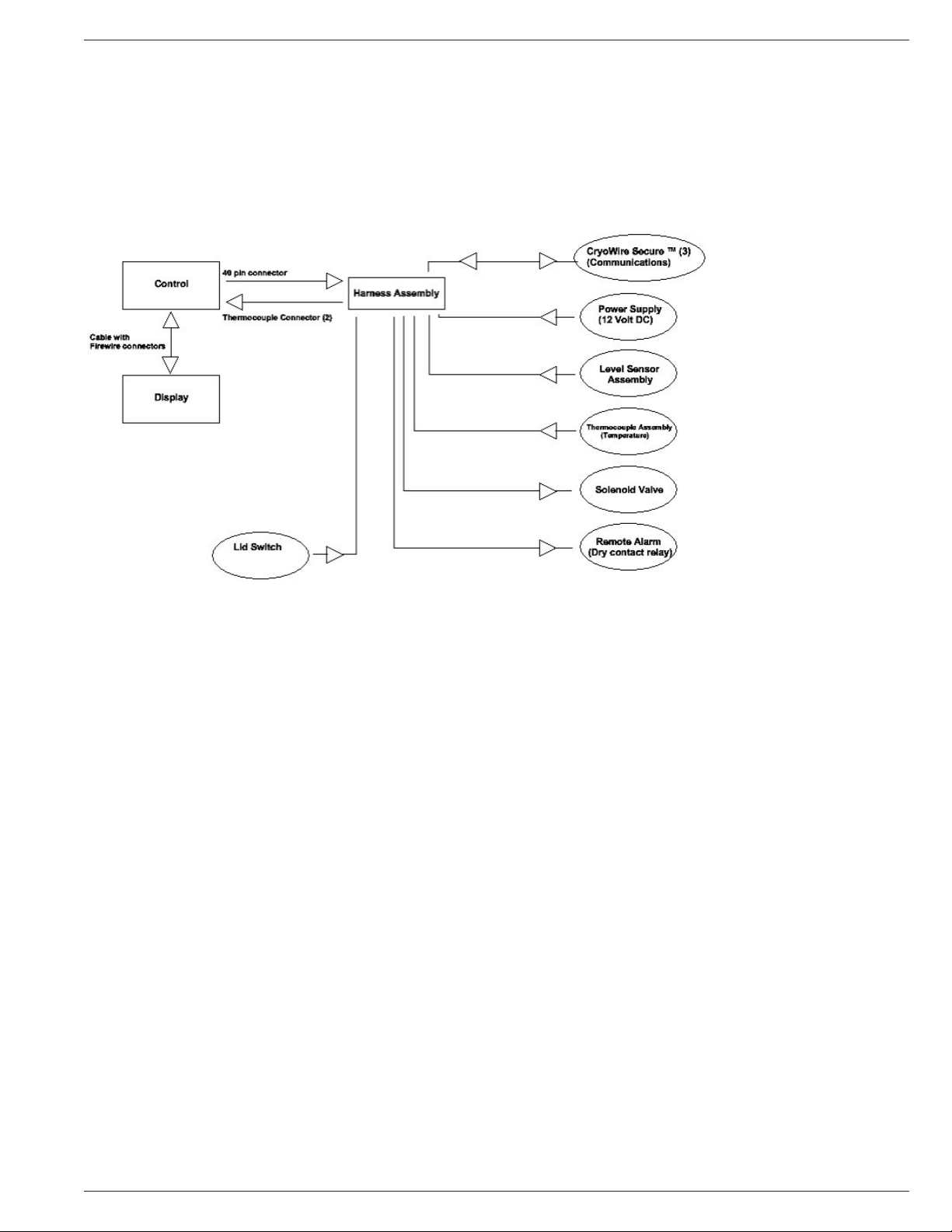

Interconnection Block Diagram

CS SERIES

Figure 9.0 Interconnection Block Diagram

25

Page 28

CS SERIES

4 wires position 1 P1P1

4 wires position 2 P1P2

10 wires position 1 P2P1

10 wires position 2 P2P2

Blue P1P1 Valve

Red P1P1

Yellow + White/ Yellow P2P1 Remote A larm

Orange + Whit e/Orange P2P1 Remote Alarm

Brown + White/B rown P2P 1 Remote Alarm

Yellow/Green P1P1 Power

White P1P1 Power

Harness Control End

White/Blac k P2P1

Red + Black P2P1 RS-232

White/Red P2P1

Black P 2P2

Brown P2P2

Red P2P2 Sens or

Orange P2P2

Yellow P2P2

P2P2

white Power Connector

Yellow/Green

Valve Connector

Red

Blue

White/Bla

ck P2P1 DB-9 Connector

Connector Box End White/Red P2P1

Red + Black P2P1

White/Yellow + Yellow P2P1

White/Orange + Orange P2P1 Remote Alarm Connector

White/Brown + B rown P2P 1

Black P2P2

Brown P 2P2

Red P2P2 Sensor Assembly

Orange P2P2

Yellow P2P2

Pod 1

Pod 2

2

1

5

4

3

2

1

3

2

1

6

5

4

3

2

1

P1P1

P1P1

P1P1

P1P1

2

3

5

1

2

3

1

2

3

4

5

Wiring Diagram

Figure 10.0 CS Series Control System Harness Wiring Diagram

26

Page 29

Installation & Setup

Main Harness Connector

Connection to Main Control

The CS SERIES Control System consists of the following components.

• Main Control

• VFD Display Module

• Wiring Harness Assembly

• Power Supply

• Thermocouple Assembly

• Lid Switch Assembly

• Sensor Assembly

• Cryogenic Solenoid Valve

• Remote Alarm Plug

CS SERIES

• LN

2

• Plumbing

Connect the wiring harness assembly to the main control. The connector is keyed

and can only be plugged in one way.

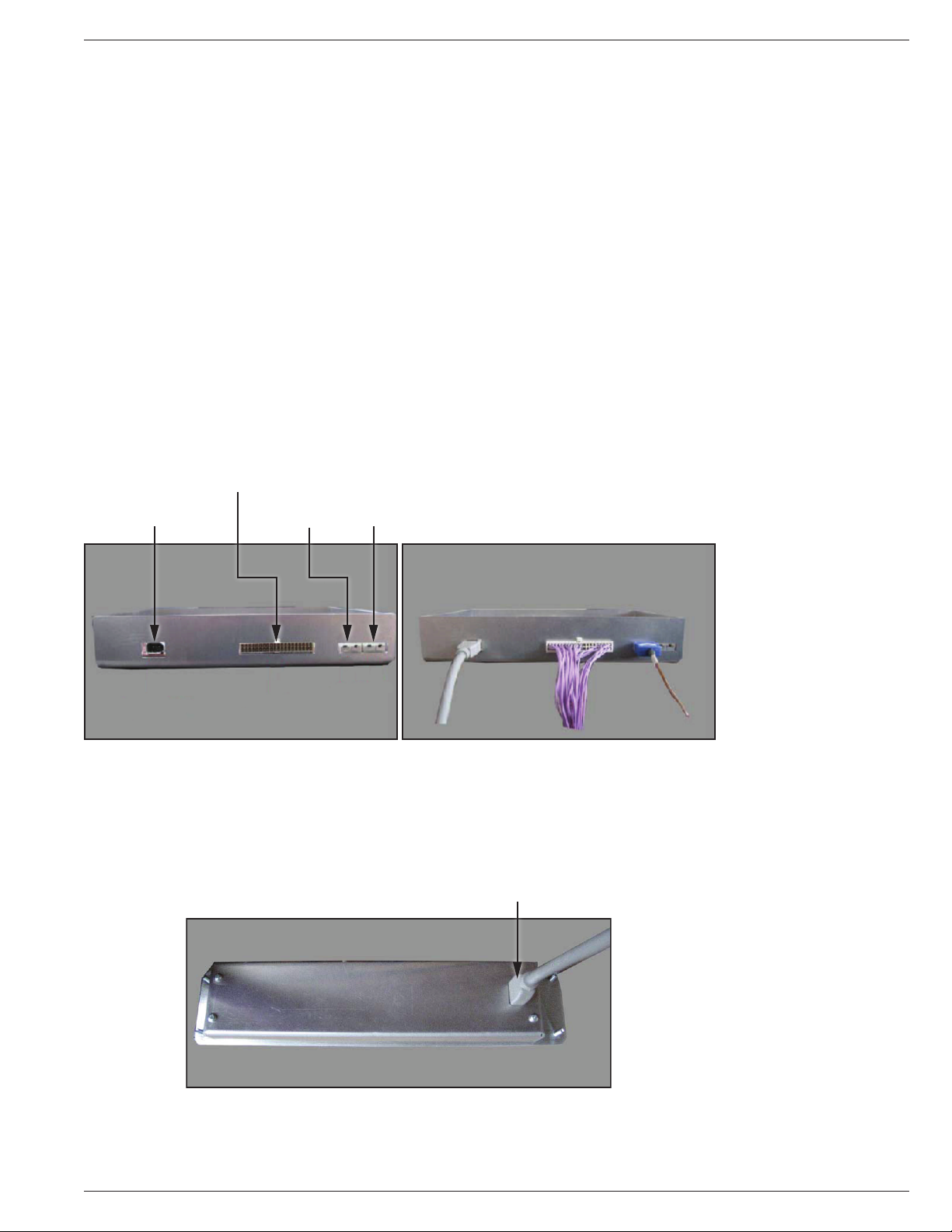

Display Connector T/C #1 T/C #2

Figure 11.0 Main Control Back Panel

Connect the thermocouple plug of the harness assembly into the control at the

thermocouple plug labeled T/C #1. One of the blades on the plug is slightly wider

insuring that it is plugged in correctly. The copper blade should plug into copper

colored plug. Finally, connect the display cable into the main control and the display.

Figure 12.0 Connection to Main Control

27

Page 30

CS SERIES

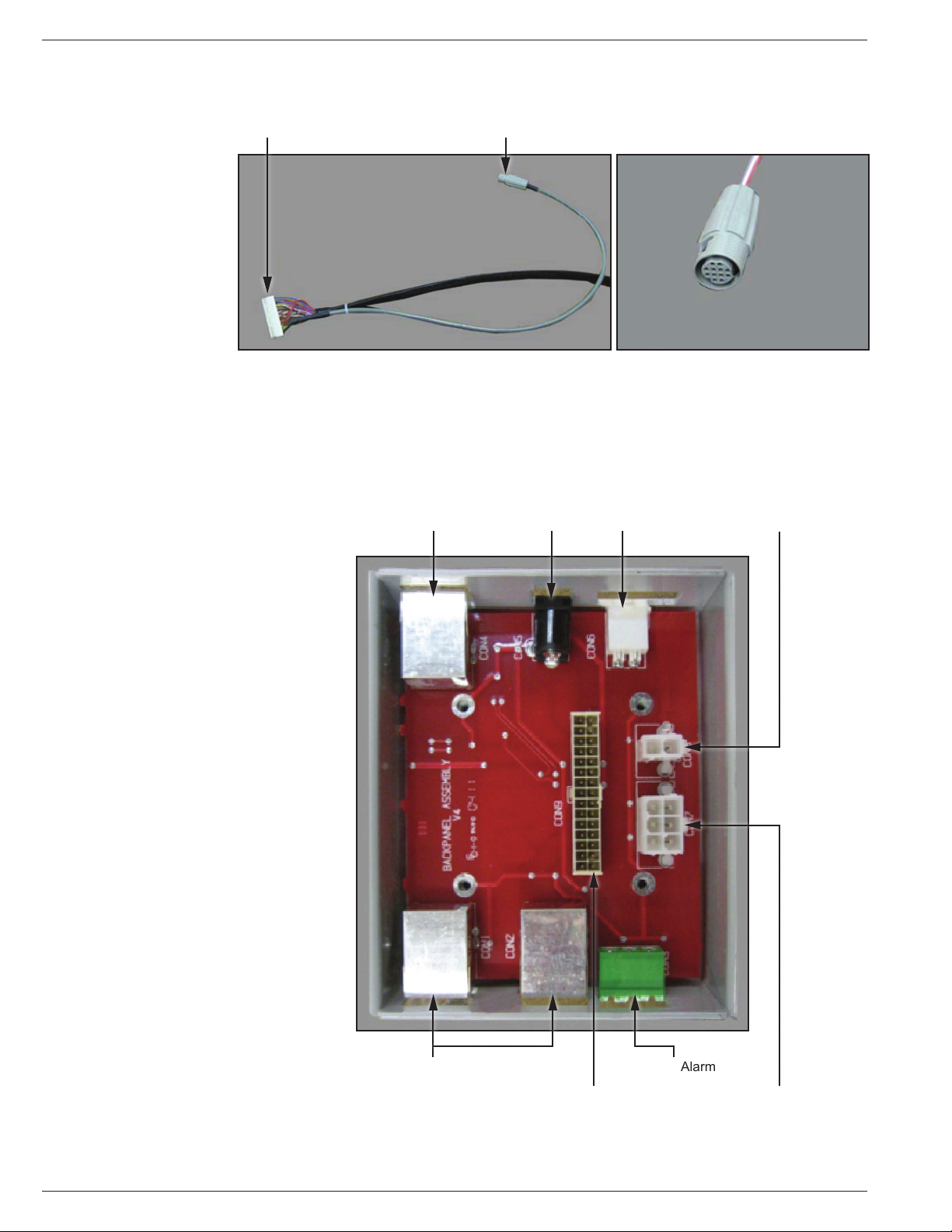

Connector to Main Control Connector for Level Sensor

Valve and Freeze Guard

Connect the level sensor assembly into the pigtail with the round connector

terminating at the control end of the harness assembly. The connector is a round

locking connector that is keyed so it can only be plugged in one way.

Figure 13.1 Harness Assembly Figure 13.2

Senor Assembly Connector

Connect the solenoid valve and the lid switch into the appropriate connectors on

the connector box. These are located on the circuit board inside the box and are

labeled. The solenoid connector is a 6 pin locking connector and the lid switch is a

2 pin locking connector. Each is keyed so they can only be plugged in one way.

Cryowire Port Power

Battery

Lid Switch Connector

28

Cryowire Port

Harness Connector

to Main Control

Remote Alarm

Figure 14.0 Harness Assembly & Back Panel

Sensor Connector

Page 31

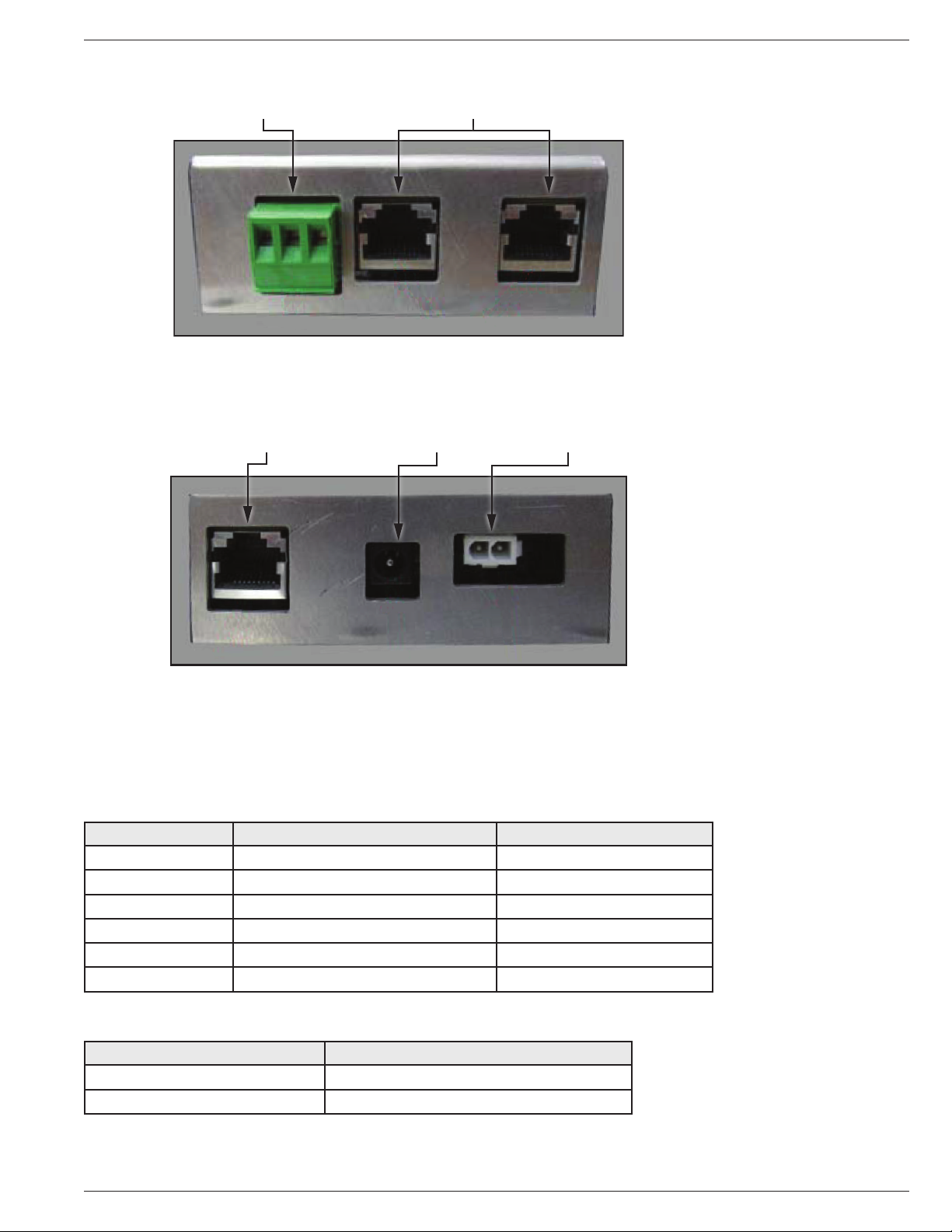

Connect the Remote Alarm plug into the panel at the end of the wiring harness

Remote Alarm Connector Cryowire Dual Communication Ports

Power Connector Battery ConnectorCryowire Communication Port

assembly. This is keyed so that it can only be plugged in one way.

Figure 15.0

Finally, connect the barrel plug of the power supply and the battery into the

appropriate receptacles in the connector box.

CS SERIES

Figure 16.0

Diagnostic Menu

Need diagnostic menu

External Connector Ratings

Designated Use Max rated voltage/current ratings Connector type

Power 36 VDC 2.5mm barrel connector

CAN N/A Modular shielded jack

Remote Alarm 300 volts 5mm terminal block

Solenoid Valve 600 volts 4.2mm header

Thermocouple N/A 2 pin thermocouple

Level Sensor 5 amps / contact Sealed circular connector

LED Status Wheel Flash Patterns

Normal Clockwise pattern, 1 LED per second

General Error Clockwise pattern, rapid rotation, flash

Condition LED Flash Pattery

29

Page 32

CS SERIES

Temperature Thermocouple Select

The chamber temperature is monitored with 1 or 2 Type T thermocouples. The

thermocouple is placed in the chamber to monitor temperature level at the top

of the inventory system. Factory installation includes one thermocouple inside of

the LABS thermocouple tube or inside of the thermocouple tube at an elevation to

match the height of standard racks. A second Type T thermocouple may be added to

monitor another location inside the chamber. Both thermocouples can be activated/

deactivated through the menu system.

Temperature Calibration

The CS SERIES Control System uses a type T thermocouple to measure temperature

within the CryoStorage freezer. The temperature curve for a thermocouple is

nonlinear so it is important that the CS SERIES Control System have a good

calibration to provide accurate temperature readings. The temperature is traceable

to the National Institute of Standards and Technology (NIST) ITS-90 Thermocouple

Database.

There are three important reference points needed for calibration:

Ambient Temperature:

Ice Water: 0°C

Liquid Nitrogen (LN2): -196°C

The ambient temperature is the temperature measured inside the control box and

is used to provide temperature compensation adjustment. This is calibrated at the

factory and should not be adjusted in the field.

Ice water and LN2 provide the reference points on the temperature curve. If these

two points are calibrated correctly then all other points (temperatures) on the curve

are correct.

The accuracy of a thermocouple is +/- 1°C or +/- 1.5% of the reading, whichever is

greater.

To check a calibration, submerge the thermocouple in ice water slurry and then LN2.

If readings are within accuracy specifications noted above, then the temperature

circuit on the control is properly calibrated. If not, follow the steps below to calibrate

the temperature.

30

Page 33

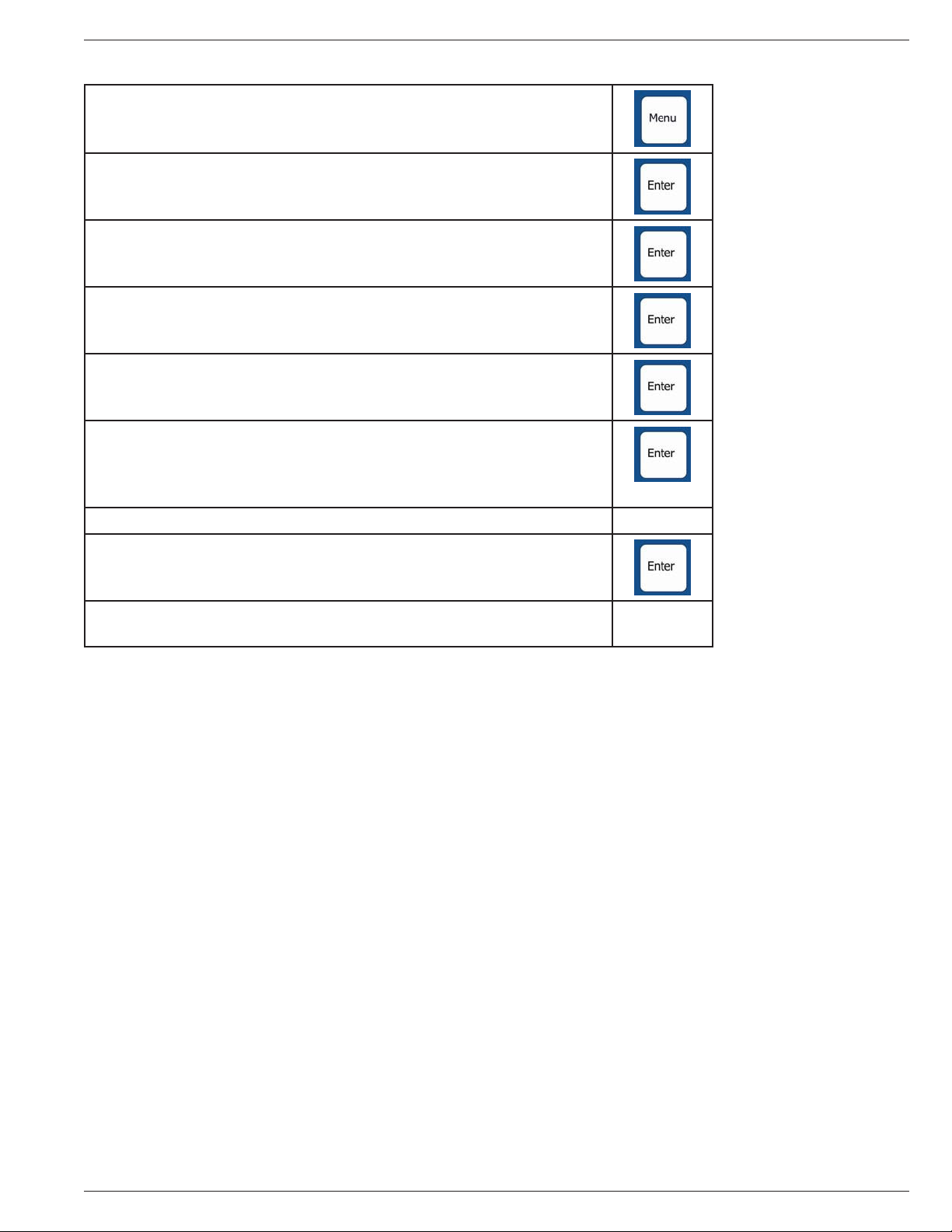

Table 4.0 Temperature Calibration Instruction

Access the menu by pressing

Highlight CHANGE SETTINGS and press

Highlight TEMPERATURE and press

Highlight CALIBRATE and press

Highlight CALIBRATE THERMOCOUPLE 1. The display will read Dip

the thermocouple into ice water.

Submerge the thermocouple into an ice water bath. The bar graph

will fluctuate. When a good stable reading in obtained, the bar

graph will decrease to 1 or 2 bars. At this point, press to lock in the

value

The display will read Dip the thermocouple into LN2.

Submerge the thermocouple into LN2. The bar graph will fluctuate.

When a good stable reading in obtained, the bar graph will

decrease to 1 or 2 bars. At this point, press to lock in the value.

If the calibration values fall within the expected range, DONE! Will

be displayed on the screen.

CS SERIES

Test Temperature System

The temperature circuitry can be checked at any time through the menu system.

This check will tell if the thermocouples are working or if they are “open” (broken

or unplugged). If a thermocouple is not connected to the control it will check as

“open.” If a thermocouple is “Disabled” through the menu system, it will not show

up on the check.

Test Level Sensors

The sensor assembly can be tested through the menu system. The sensor diagnostics

indicates the sensor number and the status (whether in liquid or gas). If the control

is set for an eight-thermistor it will indicate 9 sensors in the diagnostics. If it is set

for a four-sensor assembly, it will indicate 4 sensors. The status is indicated with

either an “O” for open, a “G” for gas or an “L” for liquid. This is an easy means to

tell if sensors are in or out of liquid or if a new sensor assembly is needed (open or

defective sensors).

The sensor type can be set through the menu system. The sensor type selection

should match the sensor type that is being used in the system. This is a 4-sensor, a

8-sensor (Freeze-Guard) or an 8-sensor array. If the sensor assembly is unplugged

and the main control is still on, the display will indicate that a sensor error has

occurred. In addition the level indicated would be 8” on an 8-sensor assembly,

or “High Alarm” on a 4-sensor assembly. This occurs because the control cannot

differentiate between a very high resistance (when a thermistor is in LN2) and an

infinite resistance (when an open circuit appears in the level sensing circuitry).

31

Page 34

CS SERIES

Alarms and Error Conditions

The CS SERIES Control System control tracks many different conditions in the freezer

and therefore, has a full complement of alarms associated with these different

conditions. As alarms occur, they cause an audible beep as well as a flashing red

light on the same wheel. A remote alarm relay is also triggered following a userdesignated period of time, after the error condition occurs, if it is not corrected. In

addition, the error condition is displayed on the top line until the error condition is

corrected. When an error does occur, the audible alarm may be muted by pressing

the designated button. The audible alarm will then be silent until activated by a new

error condition. A red light will continue to flash until all errors are corrected. The

remote alarm will be activated if the power is interrupted.

The High Temperature Alarm for Thermocouple #1 can be set through the menu

system. This alarm is activated if the temperature rises above the designated

temperature. The alarm temperature can range from 0ºC to -190ºC. It can also be

disabled.

High Temperature Alarm for Thermocouple #2 can be set through the menu system.

This alarm is activated if the temperature rises above the designated temperature.