Page 1

Auto-Fill Laser Pak

Installation and Operation Manual

Product Part Number AF55-0C00

Revision A, May 8, 2006

Do not attempt to use or maintain these units until you read and understand these instructions. Refer to the TaylorWharton’s Safety First

maintain this equipment. If you do not understand these instructions, contact your supplier for additional information.

booklet (TW-202) for handling cryogenic material. Do not permit untrained persons to use or

Page 2

______ Table of Contents

WARNING 3

Safety Precautions for Liquid Nitrogen 3

INTRODUCTION 4

System Description 4

Operation Sequence: Brief Overview 4

PIPING CIRCUITS 6

Vent to Bulk Circuits 7

Fill and Vent to Atmosphere Circuits 8

Pressure Building Circuits 9

Use Circuits 10

Safety Devices 11

Instrumentation Circuits 12

INSTALLATION 13

Handling 13

Pre-Installation Checks 13

Customer Installed Equipment/Piping 14

Electrical 15

Power 15

Error Alarm 15

Bulk Tank Pressure Line 16

OPERATION 17

Controller Operation 17

Graphic Terminal Operation 17

First Fill 19

Normal Operation 20

Long Duration Shutdowns 20

Restart 21

Error Conditions 21

Taking the Auto-Fill Laser Pak Out of Service 22

MAINTENANCE 23

Leak Test 23

Solenoid Valves 23

Safety Device Replacement 24

Instruments 24

Controller 24

Checking Vacuum 25

Trouble-Remedy Guide 26

Replacement Parts 28

APPENDIXES 29

Auto-Fill Laser Pak General Arrangement

Contoller, Auto-Fill Laser Pak

Page 3

WARNING

The following safety precautions are for your protection. Before installing, operating, or maintaining this unit

read and follow all safety precautions in this section and in reference publications. Failure to observe all

safety precautions can result in property damage, personal injury, or possibly death. It is the responsibility of

the purchaser of this equipment to adequately warn the user of the precautions and safe practices for the use of

this equipment and the cryogenic fluid stored in it.

Safety Precautions for Liquid Nitrogen

Nitrogen is an inert, colorless, odorless, and tasteless gas making up four-fifths of the air you breathe. Liquid

nitrogen is obtained by cooling air until it becomes a liquid and then removing the oxygen. Air is roughly

one-fifth oxygen. Liquid nitrogen is at a temperature of -320°F (-196°C) under normal atmospheric pressure.

Extreme Cold - Cover Eyes and Exposed Skin

Accidental contact of liquid nitrogen or cold issuing gas with the skin or eyes may cause a freezing injury

similar to frostbite. Handle the liquid so that it won't splash or spill. Protect your eyes and cover the skin

where the possibility of contact with the liquid, cold pipes and cold equipment, or the cold gas exists. Safety

goggles or a face shield should be worn if liquid ejection or splashing can occur or cold gas can issue

forcefully from equipment. Insulated gloves that can be easily removed and long sleeves are recommended

for arm protection. Trousers without cuffs should be worn outside boots or over the shoes to shed spilled

liquid.

Keep Equipment Area Well Ventilated

Although nitrogen is non-toxic and non-flammable, it can cause asphyxiation in a confined area without

adequate ventilation. Any atmosphere not containing enough oxygen for breathing can cause dizziness,

unconsciousness, or even death. Nitrogen, a colorless, odorless, and tasteless gas, cannot be detected by the

human senses and will be inhaled normally as if it were air. Without adequate ventilation, the expanding

nitrogen will displace the normal air resulting in a non-life-supporting atmosphere.

Dispose of Waste Liquid Nitrogen Safely

Dispose of waste liquid nitrogen out-of-doors where its cold temperature cannot damage floors or driveways

and where it will evaporate rapidly. An outdoor pit filled with clean sand or gravel will evaporate liquid

nitrogen safely and quickly.

For more detailed information concerning safety precautions and safe practices to be observed when handling

cryogenic liquids consult CGA pamphlet P-12 "Handling Cryogenic Liquids" available from the Compressed

Gas Association, 1235 Jefferson Davis Highway, Arlington, VA 22202.

NOTE: Argon is an inert gas whose physical properties are very similar to those of nitrogen. For

handling of liquid argon, follow the safe practices described for the handling and use of liquid nitrogen.

CAUTION: The Auto-Fill Laser Pak is not designed for use in oxygen service.

3

Page 4

INTRODUCTION

This manual provides information for the operation and maintenance of Taylor-Wharton's Auto-Fill Laser Pak

cryogenic liquid pressurization system. The Auto-Fill Laser Pak is intended for use in applications requiring

nitrogen or argon at pressures higher than possible from standard 175 or 250 psig cryogenic bulk tanks.

Cryogenic liquid is supplied to the Auto-Fill Laser Pak from a standard bulk tank. The Auto-Fill Laser Pak

“boosts” the liquid up to pressures as high as 450 psig. Once the pressure of the cryogenic fluid is raised to the

desired level, the Auto-Fill Laser Pak is capable of delivering liquid to a downstream vaporizer at gas

equivalent rates as high as 15,000 standard cubic feet per hour. The supply of product out of the Auto-Fill

Laser Pak is continuous even when the bulk tank is being filled.

Product specifications, flow diagram, views, and important dimensions are shown on the general arrangement

drawing, AF55-0C00_GA, provided in this manual.

System Description

The Auto-Fill Laser Pak consists of three groups of components: vessels, piping circuits, and

control/instrumentation. These components are assembled to a stainless steel frame for easy installation.

Two 196-liter vessels are included in the system. Each vessel consists of a pressure vessel suspended inside a

jacket. The space between the pressure vessel and the jacket is evacuated and insulated with a microfiberglass / aluminum foil radiation shield. The pressure vessel is designed and constructed in accordance

with the ASME Boiler and Pressure Vessel Code Section VIII, Division 1. Both the inner pressure vessel and

vacuum jacket are constructed of type 304 stainless steel.

The piping circuits allow the vessels to vent, fill, pressurize, and deliver cryogenic liquid to the vaporizer.

Eight solenoid valves, four for each vessel, control flow. Two high capacity pressure builders, one for each

vessel, use heat from ambient air to maintain pressure in the vessels. Piping is type-304 stainless steel. Valves

are brass. Weld and compression type fittings are type-316 stainless steel. Compression fittings are double

ferrule type. Screwed fittings are machined from forged brass. The pressure builders are constructed of

aluminum.

The controller is housed inside a NEMA 4X fiberglass enclosure. Instrumentation consists of two differential

pressure transmitters and three pressure transmitters. A differential pressure transmitter is piped to each of the

vessels in order to measure liquid level. Gauge pressure transmitters monitor pressure in each of the vessels

and the bulk tank. The bulk tank pressure transmitter is provided with the system. All wiring is in accordance

with the National Electrical Code.

The Auto-Fill Laser Pak pressurizes cryogenic liquid by adding heat to the liquid in a controlled fashion. All

energy for building pressure is provided by heat from ambient air. Electrical power is required only to operate

the controller, instruments, and solenoid valves.

Operation Sequence: Brief Overview

Consider the following starting conditions: vessel A is empty of liquid and filled with high-pressure gas;

vessel B is filled with liquid and pressurized. (See piping schematic on page 6.)

1. Liquid from vessel B is supplied at pressure to the vaporizer. Vessel B is in SUPPLY mode.

2. High-pressure gas from vessel A is vented back to the bulk tank. Vessel A is in VENTING TO

BULK mode. This feature minimizes product loss during filling.

4

Page 5

3. Once the pressure in vessel A and the bulk tank are nearly equal, gas from vessel A is vented to the

atmosphere. Driven by the higher pressure in the bulk tank, liquid from the bulk tank flows into

vessel A. Vessel A is in FILLING mode.

4. When vessel A is full, venting to atmosphere stops. Pressure in vessel A is increased by boiling

liquid in the pressure builder and returning it to the top of the vessel as gas. Vessel A is in

PRESSURIZING mode.

5. Once pressure in vessel A reaches set point, flow through the pressure builder stops. Vessel A is in

STAND-BY mode.

6. During the filling and pressurization process of vessel A, vessel B has been supplying an

uninterrupted flow of high-pressure liquid to the vaporizer. Pressure in vessel B is increased as

necessary by the pressure builder.

7. When vessel B becomes empty of liquid, the system places vessel A in SUPPLY mode. Vessel B

begins the venting to bulk, filling, and pressurizing steps.

A more detailed explanation of the system operation is described in the next section, “Piping Circuits.”

5

Page 6

PIPING CIRCUITS

b

The following paragraphs describe the operation of the piping circuits of the system. The descriptions refer to

the main components of each circuit and are grouped by function. Reference the piping schematic below and

in the general arrangement drawing for the component designations. Round stainless steel tags attached to the

system identify the components. Component tags ending with “A” identify components associated to vessel

A; tags ending with “B” identify components associated to vessel B. These component and circuit

descriptions should be understood before attempting operation.

PT-1A

PI-A

PT-2A

CN-1

PT-1B

BD-A RV-1A

PI-B

AF55-0C00 has a

strainer following the

ulk connection

PT-2B

RV-1B BD-B

V-7A

V-5A

V-6A

CV-3A

V-7B

V-5B

V-6B

CV-3B

CV-1A

V-1A

V-1B

CV-1B

V-2A

CV-2A

V-2B

CV-2B

V-3A

V-3B

Vessel “A”

V-4A

PB-A

CN-2

V-4B

Vessel “B”

PB-B

Legend

CN-1 Bulk Tank Connection PB Pressure Builder

CN-2 Vaporizer Connection V-1 Liquid Use Solenoid Valve

CV-1 Liquid Use Check Valve V-2 Vent to Bulk Tank Solenoid Valve

CV-2 Vent to Bulk Tank Check Valve V-3 Vent Solenoid Valve

CV-3 Fill Check Valve V-4 Pressure Building Solenoid Valve

BD Rupture Disc V-5 Liquid Phase Isolation Valve

PI Vessel Pressure Gauge V-6 Vapor Phase Isolation Valve

PT-1 Liquid Level Transmitter V-7 Equalization Valve

PT-2 Vessel Pressure Transmitter RV-1 ASME Relief Valve

PT-3 Bulk Tank Pressure Transmitter

Figure 1: System Piping Schematic

6

Page 7

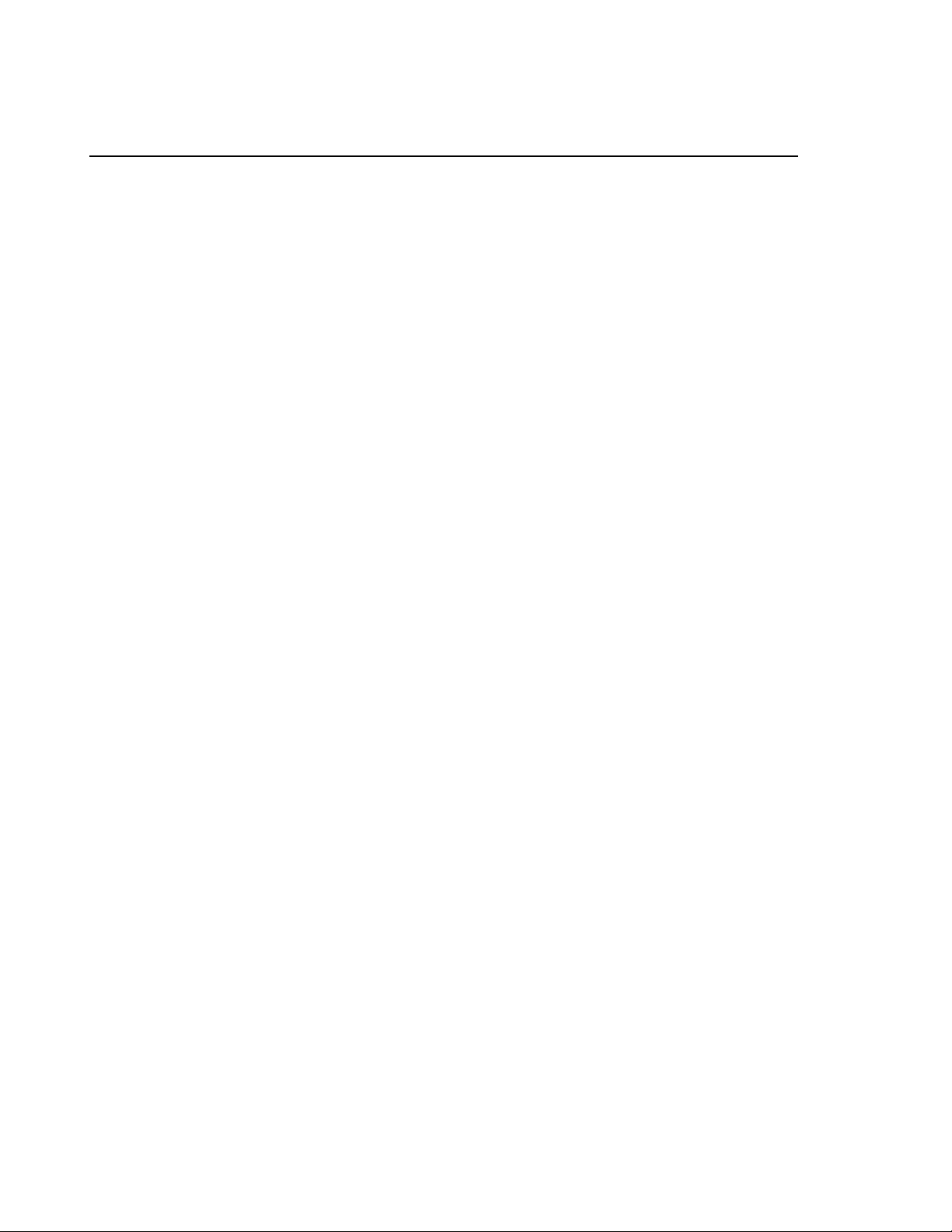

Vent to Bulk Circuits

Before filling occurs, the Auto-Fill Laser Pak recovers high-pressure gas in the vessels by returning it to the

bulk tank. The gas is vented from the top of the vessel through the vent to bulk solenoid valve (V-2). Gas

exits the system through the bulk tank connection (CN-1) and enters the bulk tank through the liquid

withdrawal line. The gas is recondensed as it bubbles through the liquid in the bulk tank. Venting to the bulk

tank occurs until the pressure in the vessels is less than the bulk tank pressure plus 25 psi.

Venting to the bulk tank also occurs during periods of little or no usage. Gas is generated over time due to

heat input to the inner vessel through the supports, piping, and insulation. This gas is recovered by venting it

back to the bulk tank through the same circuit described above. This occurs when the pressure in the vessels

exceeds a user adjustable set point. This is similar to the “economizer” feature found on bulk cryogenic

vessels.

The user can deactivate these features by setting a controller parameter. This is described in the controller

operation section of this manual.

V-2A

CV-2A

CN-1

Figure 2: Vent to bulk circuit for vessel A highlighted in blue.

(Frame and wiring omitted from view for clarity.)

7

Page 8

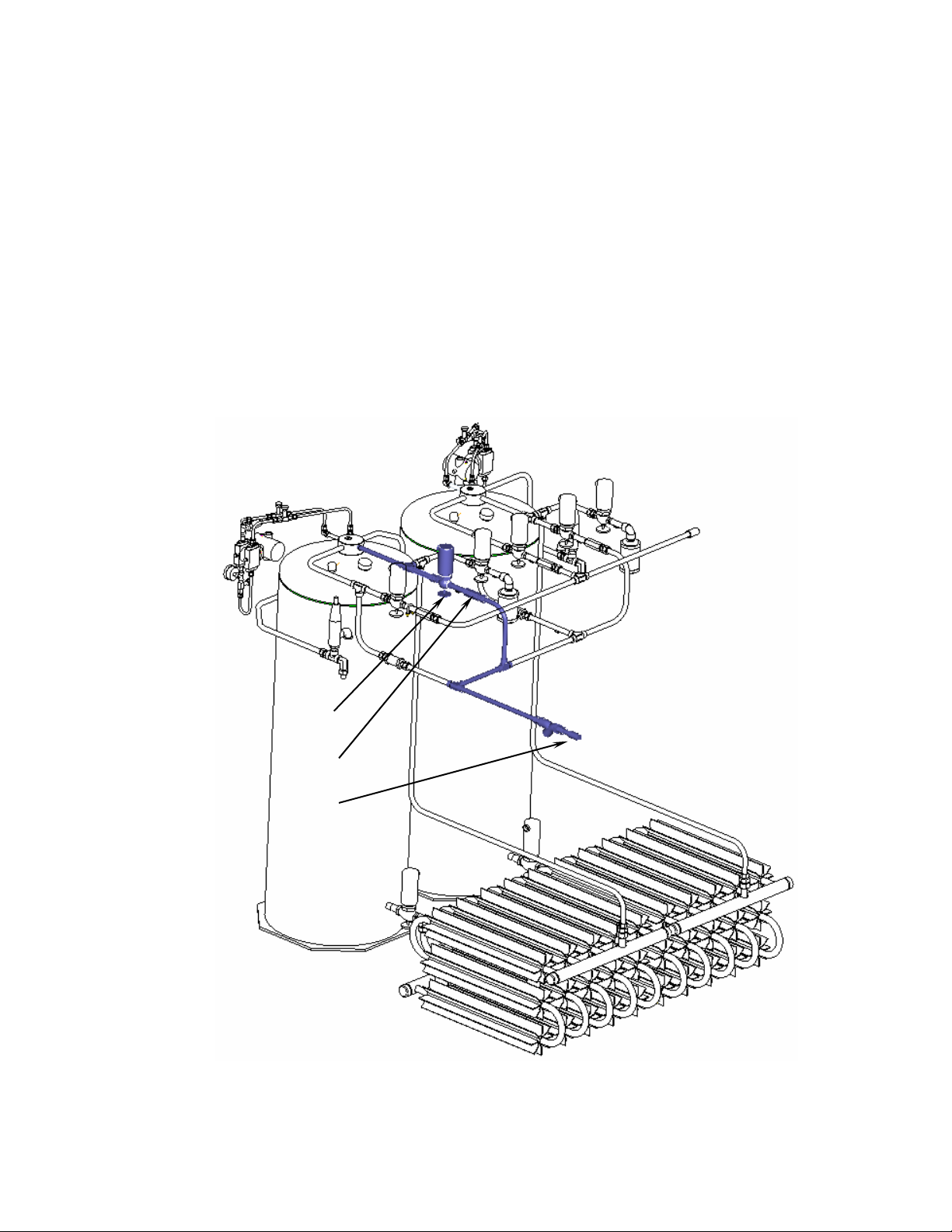

Fill and Vent to Atmosphere Circuits

Filling a vessel with liquid from the bulk tank occurs by pressure transfer. The pressure in a vessel is reduced

by venting gas from the top of the vessel to the atmosphere through the vent solenoid valve (V-3). A muffler

connected to the vent valve outlet keeps noise to a comfortable level. Liquid flows from the bulk tank,

through the liquid withdrawal line, and into the system through the bulk tank connection (CN-1). Liquid

flows through the fill check valve (CV-3) and into the vessel.

Note that filling occurs anytime the pressure in a vessel is less than that of the bulk tank.

V-3A

Muffler

CV-3A

CN-1

Figure 3: Fill and vent to atmosphere circuit for vessel A highlighted in blue.

(Frame and wiring omitted from view for clarity.)

8

Page 9

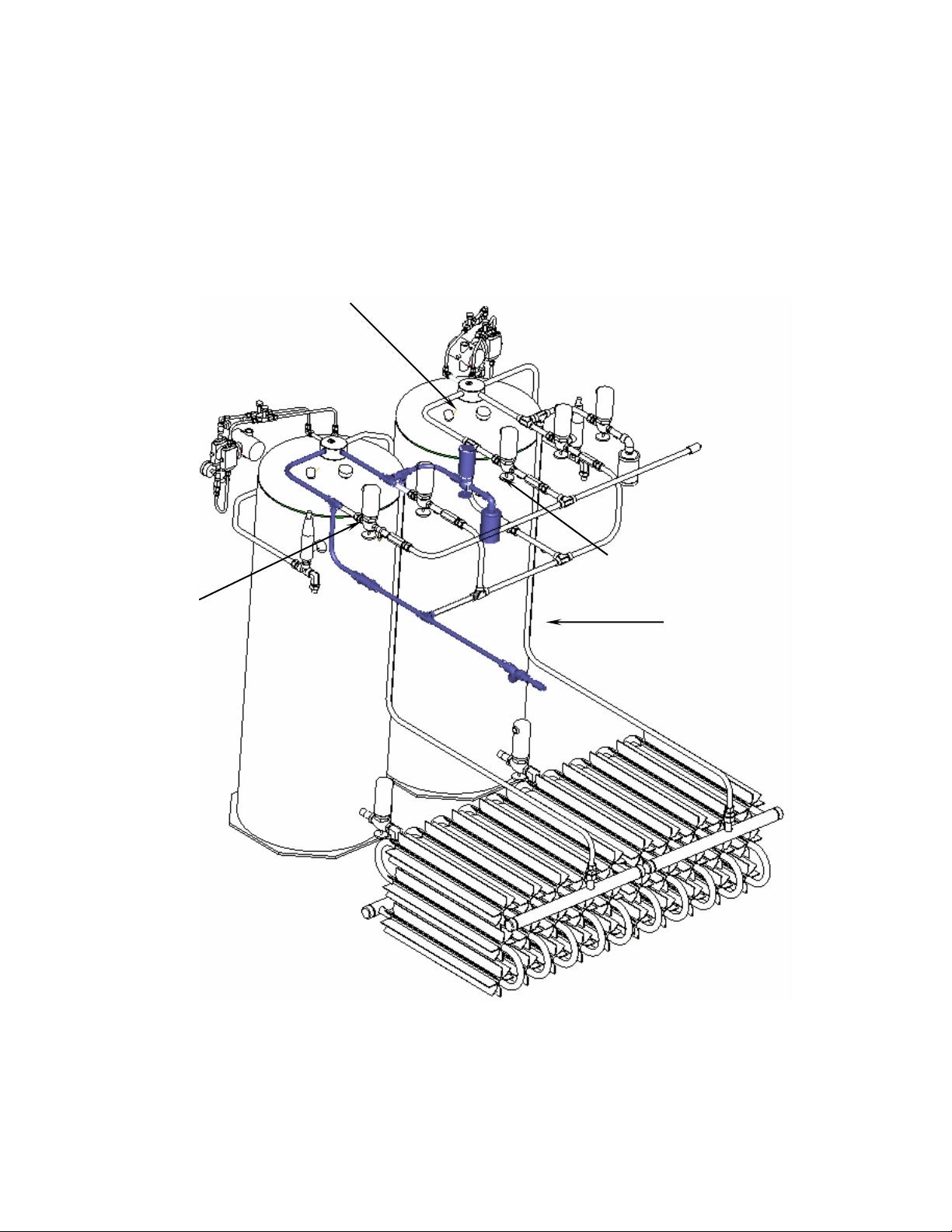

Pressure Building Circuits

A pressure building circuit serves to build pressure after filling a vessel. The circuit is also used to ensure

sufficient driving pressure during product withdrawal periods. The controller opens the pressure building

solenoid valve (V-4) that creates a path from the liquid in the bottom of the container to the gas space in the

top. This path contains a pressure-building coil (PB) to vaporize product as it flows from the bottom to the top

of the vessel. Liquid is expanded to a vapor and pressure is increased in the vessel.

V-4B

PB-B

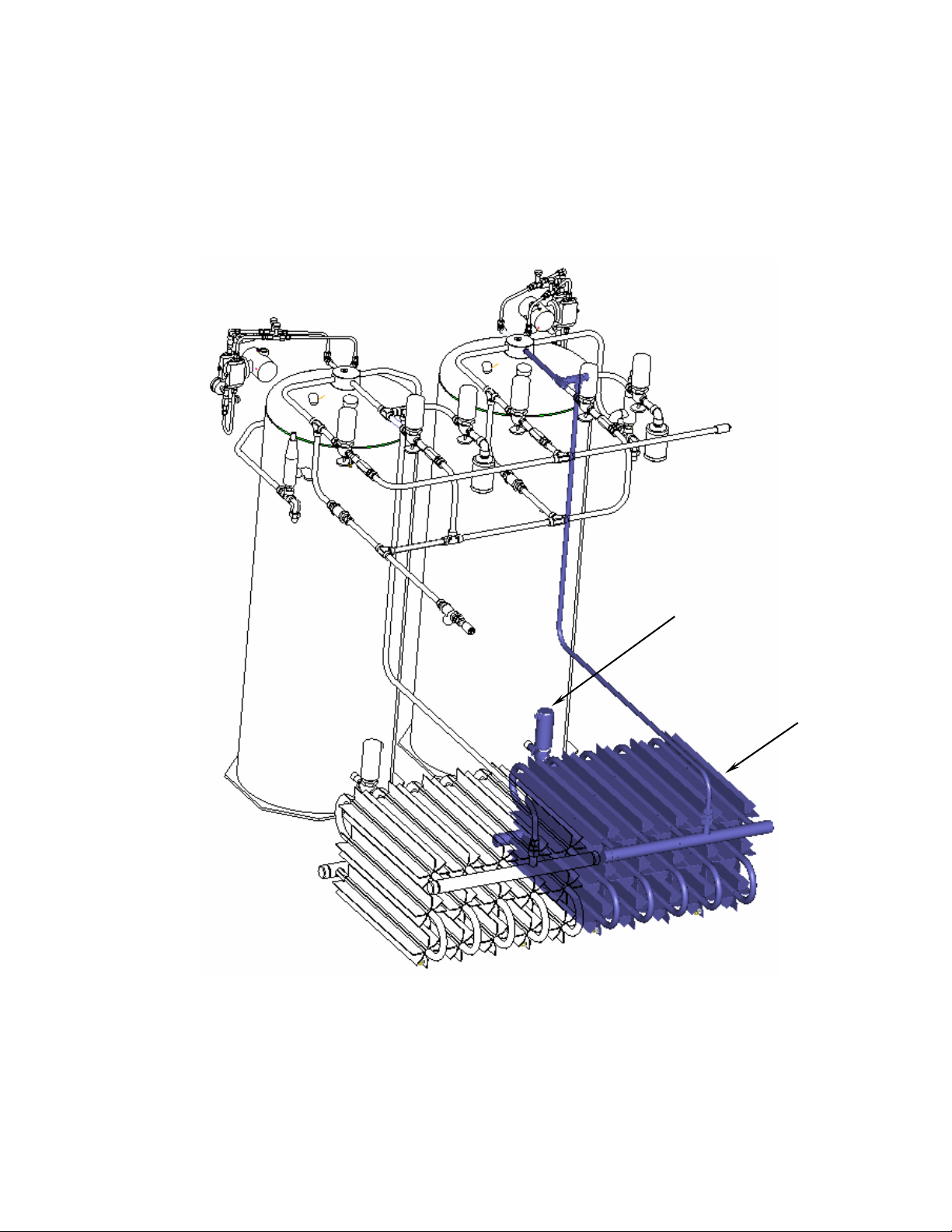

Figure 4: Pressure building circuit for vessel B highlighted in blue.

(Frame and wiring omitted from view for clarity.)

9

Page 10

Use Circuits

The use circuit delivers pressurized liquid to an external vaporizer for use in the final application. The liquid

use solenoid valve (V-1) is opened. Liquid flows out of the vessel, through the liquid use solenoid valve and

liquid use check valve (CV-1), and exits the system through the vaporizer connection (CN-2).

V-1A

CN-2

CV-1A

Figure 5: Use circuit for vessel A highlighted in blue.

(Frame and wiring omitted from view for clarity.)

10

Page 11

Safety Devices

The system has independent inner container relief devices piped to each of the vessels. Each set consists of a

primary relief valve (RV-1) to relieve pressure when it exceeds 600 psig. The valve reseats when pressure

drops below this point. In addition, each primary relief valve is supported by a secondary relief device

consisting of a rupture disc (BD). The rupture disc will burst at a pressure of approximately 875 psig. The

rupture discs require replacement in the event a safety valve malfunctions and allows vessel pressure to reach

the burst pressure rating.

RV-1B

BD-B

Figure 6: Safety circuit for vessel B highlighted in blue.

(Frame and wiring omitted from view for clarity.)

11

Page 12

Instrumentation Circuits

The system instrumentation consists of liquid level transmitter, pressure transmitter, pressure gauges, and

isolation valves. The vessel pressure gauges (PI) display the inner container pressure in pounds-per-squareinch and kilopascals. A pressure gauge is piped to each of the vessels.

The liquid level transmitters (PT-1) measure the liquid level in the vessels. This instrument is a differential

pressure transmitter. Liquid inside the vessel creates slightly greater pressure at the bottom of the vessel than

at the top. The pressure differential increases with increasing liquid content. By measuring this differential

pressure, the liquid level is determined. One of these instruments is supplied for each of the vessels.

Three pressure transmitters monitor pressure in each of the vessels (PT-2) and the bulk tank (PT-3). The bulk

tank pressure transmitter is located inside the Auto-Fill Laser Pak control panel. The controller uses these

inputs to control supply pressure and venting to the bulk tank.

Isolation valves allow the instruments to be replaced without emptying and depressurizing the system.

The vapor phase isolation valve (V-6) isolates the liquid level transmitters, pressure gauges, and pressure

transmitters from the line (low pressure) connected to top of the inner vessel. The liquid phase isolation

valve (V-5) isolates the same instruments from the line (high pressure) connected to the bottom of the

inner vessel. The equalization valve (V-7) is used to equalize the pressure between the high and lowpressure sides of the liquid level transmitter.

V-5B

V-6B

PT-2B

PI-B

PT-1B

V-7B

Figure 7: Instrumentation circuit for vessel B highlighted in blue.

(Frame and wiring omitted from view for clarity.)

12

Page 13

INSTALLATION

Dimension and connection data for the Auto-Fill Laser Pak can be found on the General Arrangement

Drawing in the appendix of this manual. System installation is the responsibility of the customer.

Handling

Employ experienced personnel to move and install the system. Ensure that rigging equipment, if used, has

adequate rated capacity to handle the system weight listed in the specifications. This system must be

shipped and lifted empty.

Important: The system may be handled by forklift from the side with the cylinders only. Lifting by forklift

from other sides may cause the system to be unstable and tip. When lifting by crane, use all four lift-eyes.

Lift-Eye

Forklift on

this side only

Figure 8: Handling

Pre-Installation Checks

Before installing the system, inspect it carefully for possible shipping damage. Report any damage to the

carrier and the factory. In addition, check system pressure as follows:

The system is shipped pressurized with nitrogen gas at 20 psig (1.38 bar/138 kPa). Record the "as received"

pressure for both vessels.

System pressure may change due to temperature variations, accidental opening of valves, or packing leaks. If

a positive pressure is not indicated on the vessel pressure gauges (PI) and no repairable leaks are found,

contact the factory. This pressure reading is essential to complete a “first fill” warranty claim.

13

Page 14

Customer Installed Equipment/Piping

Designing safe and effective cryogenic systems requires extensive knowledge and experience. Persons

lacking the necessary skills are urged to seek competent advice before attempting to design cryogenic systems.

Design and consultation services are available from the factory. Contact information is provided at end of the

manual.

Important: When installing the vaporizer and piping be sure to follow accepted design practices for cryogenic

equipment. Use only components compatible with cryogenic liquids. Be sure to include pressure relief valves

in all piping where liquid product could be trapped between closed valves, regulators, etc. Any components

installed downstream of the bulk tank, including the bulk liquid withdrawal valve, must be rated for 500 psig

service pressure or higher.

Install the cryogenic bulk tank per the manufacturer’s instructions. It is recommended that a bulk tank with a

gross capacity of at least 500 gallons be used. Maximum operating pressure of the bulk tank should be 175 or

250 psig. Set the bulk tank pressure-building regulator to at least 100 psig.

If the bulk tank liquid withdrawal valve is not rated for service to 500 psig, it should be replaced. If this is not

possible, install a valve with an adequate pressure rating immediately downstream. Disable the upstream

valve by opening it and removing the valve handle. Wire tie a permanent tag to the valve reading, “DO NOT

CLOSE.”

It is recommended that a strainer, the same size as the bulk liquid withdrawal line, be installed downstream of

the bulk liquid withdrawal shut-off valve. The strainer will prevent particulate contamination from entering

the system and interfering with the function of the solenoid and relief valves. A strainer of mesh size 20 or

finer is recommended.

Install the Auto-Fill Laser Pak outdoors as close as possible to the bulk tank. This will minimize filling times

and allow maximum flow performance. If it is not possible to install the Auto-Fill Laser Pak reasonably close

to the bulk tank, the customer should consider the use of insulated piping. The line connecting the bulk tank

to the Auto-Fill Laser Pak should be pipe size ¾” or larger. Use a reducer immediately before the Auto-Fill

Laser Pak bulk connection (CN-1) to adapt to the ½” FNPT connection fitting.

The Auto-Fill Laser Pak vents gas while filling. In an area where this may cause risk of asphyxiation, the vent

valve outlets should be piped away to a safe location. Piping size and length should be designed to prevent

excessive pressure drop. Excessive pressure drop will cause extended filling times. When in doubt, monitor

the area with an oxygen level detector.

The vaporizer must have a maximum operating pressure of at least 500 psig. An operating pressure of 600

psig or greater is recommended. This allows the vaporizer relief valve to have a greater opening pressure than

the Auto-Fill Laser Pak relief valves. This reduces the possibility of product loss due to the vaporizer relief

valve opening prematurely. A vaporizer with adequate capacity must be specified. It is recommended that a

vaporizer rated for 15,000 SCFH be selected. The piping connection on the Auto-Fill Laser Pak for the

vaporizer (CN-2) is ½” female tapered pipe thread. Adapt the piping size to the vaporizer inlet as necessary.

Important: Ensure that the vaporizer is equipped with a relief valve with adequate flow capacity and proper

opening pressure. Follow the vaporizer manufacturer’s recommendations on selecting and installing the

proper relief valve.

14

Page 15

Bulk Tank

Bulk Liquid

Withdrawal Valve

Vaporizer

Auto-Fill

Laser Pak

CN-2 CN-1

Control

Panel

Vaporizer

Relief Valve

Relief

Valve

Final Line

Regulator

Strainer

Bulk Tank

Pressure Line

Figure 9: Piping schematic for typical installation

Vaporizer Shut-

Off Valve

System

Drain Valve

To

Atmosphere

To

Application

Electrical

Only persons experienced with industrial wiring should perform the electrical installation. The installation

should conform to the National Electrical Code and any applicable local requirements. The control panel,

instruments, and solenoid valves are preinstalled and wired. Power and alarm (if used) are to be installed and

wired by the customer.

Two 1/2” female conduit hubs are provided pre-installed in the bottom of the control panel. See sheet 2 of the

general arrangement drawing in the appendix. The hub on the left (when facing the panel door) is intended for

power wiring. The hub on the right is for the alarm.

Power

Power electrical requirements are 20 amps, 120 volts alternating current at 60 Hz. It is recommended that the

power wiring be enclosed in rigid metal conduit.

Important: Before wiring power, turn the power switch on the front of the panel, to the “Off” position. Push

the “Start/Stop” button to the inward position.

A 20-amp breaker is provided inside the control panel in the lower left corner. This is the hot power

connection. The neutral power wire may be attached to any of the neutral power terminals. They are located

immediately to the right of the 20-amp breaker and are labeled “N”. A ground lug is mounted on the

enclosure sub-panel. The ground power wire should be attached to the lug.

Error Alarm

The customer may install an error alarm. This is not required for operation. Note that an error indicator light

is pre-installed on the front of the control panel. The customer provides the alarm horn, buzzer, or light. The

alarm must be powered by 120 volts alternating current. Connect the hot power wire of the alarm to the

terminal labeled R1-1. Connect the neutral power wire to any of the neutral power terminals labeled “N”.

The ground wire, if required, should be attached to the ground lug mounted on the enclosure sub-panel. The

Auto-Fill Laser Pak controller will activate the alarm when an error has been detected. A selector switch on

15

Page 16

the front of the control panel disables the alarm. The panel error indictor light will continue to function if the

alarm is disabled. A table of alarm conditions is provided in the operation section of the manual.

Bulk Tank Pressure Line

Installation of a bulk tank pressure line is required for the Auto-Fill Laser Pak to operate. The bulk tank

pressure line should be connected to the bulk tank vapor (low pressure) instrument line. This line is also

commonly used for the bulk tank pressure gauge. Follow the bulk tank manufacturer’s instructions for

removing the pressure gauge. A convenient piping installation is to thread a 1/4" pipe nipple into the open

port. Thread a female tee fitting on to the nipple. Thread a stainless steel compression fitting for 3/8” OD

tube into the branch of the tee. Thread the pressure gauge into the tee. Connect a 3/8” OD stainless steel tube

to the compression fitting. Stainless steel is recommended over copper to reduce the possibility of damage to

the tube. Run the tube to the bulkhead compression fitting located on the bottom of the Auto-Fill Laser Pak

control panel. Teflon tape should be used on all piping connections except tube compression connections.

Use leak check fluid on all connections. Be sure to open the bulk tank instrument isolation valves and close

the equalization valve after the installation is complete.

16

Page 17

OPERATION

These instructions are for operators experienced with cryogenic equipment. Before operating the Auto-Fill

Laser Pak, become familiar with the safety precautions in this manual and in the referenced publications.

Make certain all applicable provisions set forth in the Installation Section have been followed before placing

an Auto-Fill Laser Pak into operation. Study this manual and the general arrangement drawing located in the

back of this manual thoroughly. Know the location and function of all system components.

Controller Operation

The controller, located in the larger fiberglass enclosure, automates the operation of the Auto-Fill Laser Pak.

The controller inputs include: two liquid level transmitters (PT-1A & PT-1B), three pressure transmitters (PT2A, PT-2B, and the transmitter for the bulk tank), and the “Start/Stop” push button. Controller outputs

include the eight solenoid valves and the four lights on the front of the enclosure. A graphic terminal user

interface, located inside the enclosure, allows the operator to monitor the system and change settings. A

diagram showing the front of the enclosure, indicator lights, and switches is shown on page 2 of the drawing

titled “Controller, Auto-Fill Laser Pak” in the appendix.

The “Power” selector switch controls all power to the system. It should be in the “Off” position during system

installation and maintenance. If power is turned off or lost, all controller settings will be retained in the

memory. When power is reapplied the controller will automatically restart provided the “Start/Stop” button

remains in the inward position.

The “Start/Stop” button begins and stops the automatic operation sequence described in the Operation

Sequence Section. When the inward position is selected, power to the controller and transmitters remains

active and all the solenoid valves are deactivated. Solenoid valves are closed when deactivated unless

operated by manual override. This allows the operator to adjust the controller settings without running the

system. When the Start/Stop button is pulled outward, the controller begins the operation sequence.

The “Alarm” selector switch controls the user-installed alarm. In the “Off” position the alarm will not

function. In the “On” position the alarm will activate when the controller determines that an error has

occurred.

The “System Running” light indicates that the system is at the correct pressure and operating normally. The

“System Start” light becomes illuminated after pressing the “Start/Stop” button. It remains lit while the

system is filling or pressurizing at the beginning of the operation sequence. The “System Stop” light indicates

that the “Start/Stop” button has been pushed inward. It also becomes lit when the controller has stopped the

operation sequence due to an error condition.

The “Error” light indicates that the controller has detected an error condition. The controller activates the

user-installed alarm and the “Error” light simultaneously. Read the Error Conditions section for an

explanation of controller detectable errors.

Graphic Terminal Operation

System operation can be monitored or adjusted using the graphic terminal. It is located inside the panel in the

upper-right corner. Function keys, labeled F1 through F8, allow the operator to select the various screens.

Scroll through the settings displayed on the screen by pressing the left or right arrow keys. Change a setting

by scrolling to it and pressing the Enter key. Type the new value using the keypad. Pressing the Backspace

key deletes the last character entered. If all characters are deleted, pressing the Backspace key returns to the

previous screen without changing the value. Pressing the Enter key sets the value and returns to the previous

screen.

17

Page 18

F1 F2 F3 F4

F5 F6 F7 F8

1 2 3

4 7 5 6

8 9

. 0 -

Figure 10: Graphic Terminal

Display

Scroll

Enter

Backspace

TAYLOR-WHARTON

Vessel A B

Pressure, PSIG 425 410

Percent Full 80 50

Mode View

F1

Alarm

History

F2

Bulk

155

Setting

Adj

F3

Figure 11: Default display screen

Six settings are user adjustable through the Graphic Terminal. The initial settings should be used in most

cases. However, the settings may be adjusted to better suit a particular installation. The Auto-Fill Laser Pak

should not be operated at pressures exceeding 500 psig. It is possible to cause the system to malfunction by

improperly setting these values. However, the system is designed to be inherently safe regardless of the

controller output. An explanation of each of the settings follows:

Pressure Builder Open – The pressure building solenoid valve (V4) will open when the pressure is less than

this setting. The valve will not open if the vessel is in Venting to Bulk or Filling mode. It is not

recommended to set this value above 450 psig.

Pressure Builder Range – If open, the pressure building solenoid valve (V4) will close when the pressure

exceeds this value plus the Pressure Builder Open setting.

Vent to Bulk – When a vessel pressure exceeds this value, the vent to bulk solenoid valve (V2) will open.

This is true for vessels in Stand-By mode or Supply mode. This feature allows gas that would otherwise be

lost through the relief valves to be recovered.

Bulk Pressure High – If the bulk tank pressure exceeds this value the system will not vent back to the bulk

tank.

18

Page 19

Low Pressure Alarm – If the pressure of the vessel in Supply mode drops below this value the error alarm

and error indicator light will be activated.

System Vent to Bulk – The system will not vent back to the bulk tank if this parameter is turned off.

Setting Initial Setting Unit

Pressure Builder Open 450 psig

Pressure Builder Range 30 psi

Vent to Bulk 510 psig

Bulk Pressure High 230 psig

Low Pressure Alarm 370 psig

System Vent to Bulk On On/Off

Figure 12: Initial Settings

First Fill

The first fill should be performed manually. This is necessary to properly purge and control cooling of the

inner vessels. Calibration of the level transmitters is also covered in this procedure. It is recommended that

this procedure be performed once a year to recalibrate the level transmitters.

CAUTION: Follow the safety precautions at the beginning of this manual. Accidental contact with liquid or

cold gas can occur when operating the solenoid valve manual overrides.

1. Press the start/stop button on the control panel inward. Turn the power switch to the “On” position.

Open the control panel door. With power on and the start/stop button pressed inward settings may be

adjusted on the graphic interface (Panel View) without running the system.

CAUTION: Do not touch the wiring inside the control panel while power is activated. The

operator should touch only the graphic interface located in the upper right corner.

2. Make sure that the manual override handles of all eight of solenoid valves are in the closed position.

The override is closed when the handle is turned counterclockwise fully. When closing the override,

the handle will move downward, away from the valve body.

3. Slowly open the bulk liquid withdrawal valve. Open the valve completely.

4. Turn the manual override handles of the vent solenoid valves (V-3A & V-3B) until venting begins.

Turn the handles two additional turns. The vessels are now being filled. First fill should be

performed slowly. The rate of filling can be adjusted by throttling the vent solenoid valves.

5. While the vessels are filling, go to the control panel. On the graphic interface, from the default

screen, press “F3” to enter the setting adjustment screen. Press “F1” to enter the level scale screen.

The row labeled “Vessel Level” indicates the liquid level, in inches of water, for each of the vessels.

The vessel level reading will update continuously.

19

Page 20

Level Scale

Vessel A B

Vessel Level 5 8

Scaled Min. 0 0

Scaled Max. 30 30

Exit F1

Figure 13: Level Scale Screen

6. Each of the vessels should be filled until liquid exits the muffler. When this occurs, note the level

displayed on the screen and the vessel letter, A or B. Close the manual override of the vent

solenoid valve (V3) for the full vessel. Repeat this step for the other vessel.

7. After the vent valves are closed, the vessel liquid levels will increase slightly until the vessel

pressure equalizes with the bulk tank. This is normal. Set the Scaled Max parameter for each of

the vessels to the readings noted in step 6. For nitrogen service the Scaled Max parameter is

typically 28; for argon service 39 is typical.

8. Press the “F1” button to exit to the default screen. The controller now recognizes when the

vessels are liquid full. The level readings on the default screen are indicated by percent full;

100% meaning that the liquid level has reached the vent tube extending into the inner vessel. The

vessels are designed to allow a gas space above the liquid, even when the controller indicates

100% full.

9. Press “F3” to enter the setting adjustment screen. The settings are set at the factory as indicated

in the Graphic Terminal Section of this manual. Verify that these parameters have been set to the

proper values. The user may change these settings to better suit a particular application.

10. The system is now ready for operation. Pull the “Start/Stop” button outward to activate the

system.

Normal Operation

Once the Auto-Fill Laser Pak is started, it will run automatically. The user only needs to ensure that the bulk

tank does not run empty. The controller maintains liquid level in the vessels between 30 and 80 percent full.

You may notice that the liquid level reading displayed on the graphic terminal reads slightly erratic when the

relief valves open momentarily. This is normal and will not interfere with proper operation.

For shutdowns of a short duration, over-night and weekends, leave the power switch in the “On” position.

The “Start/Stop” button should remain in the outward position. Stop gas flow from the system by shutting off

valves at the application or by closing the vaporizer shut-off valve (see figure 9). The controller will

automatically minimize product loses by venting gas back to the bulk tank as necessary.

Long Duration Shutdowns

For shutdowns of a longer duration, exceeding three days, it is recommended that the Auto-Fill Laser Pak be

deactivated.

1. Push the “Start/Stop” button inward.

2. Turn the power switch to the “Off” position.

20

Page 21

3. Close the bulk liquid withdrawal valve.

Restart

When restarting after a long duration shutdown or if the bulk tank should run empty, the following procedure

is recommended.

CAUTION: Follow the safety precautions at the beginning of this manual. Accidental contact with liquid or

cold gas can occur when operating the solenoid valve manual overrides.

1. Press the start/stop button on the control panel inward. Turn the power switch to the “On” position.

Open the control panel door. With power on and the start/stop button pressed inward settings may be

adjusted on the graphic interface (Panel View) without running the system.

CAUTION: Do not touch the wiring inside the control panel while power is activated. The operator

should touch only the graphic interface located in the upper right corner.

2. Make sure that the manual override handles of all eight of solenoid valves are in the closed position.

The override is closed when the handle is turned counterclockwise fully. When closing the override,

the handle will move downward, away from the valve body.

3. If the bulk liquid withdrawal valve is closed, slowly open it. Open the valve completely.

4. Turn the manual override handles of the vent solenoid valves (V-3A & V-3B) until venting begins.

Turn the handles two additional turns. The vessels are now being filled. Filling should be performed

slowly. The rate of filling can be adjusted by throttling the vent solenoid valves.

5. While the vessels are filling, go to the control panel. On the graphic interface, go to the default

setting screen. The first line of the default screen reads “TAYLOR-WHARTON”. Monitor the

liquid level of the vessels in this screen.

6. Each of the vessels should be filled to approximately 70 percent full. When this liquid level is

reached for one of the vessels, close the manual override of the vent solenoid valve (V3) for the

vessel. Repeat this step when the other vessel reaches approximately 70 percent full.

7. After the vent valves are closed, the vessel liquid levels will increase slightly until the vessel

pressure equalizes with the bulk tank. This is normal.

8. The system is now ready for operation. Pull the “Start/Stop” button outward to activate the

system.

Error Conditions

In the event of an error, the controller will activate the error alarm and error panel light. The Auto-Fill Laser

Pak will continue to supply product until the vessel in “Supply” mode becomes empty. Some errors will

cause the controller to immediately stop operation. The reason for the error will be indicated on the graphic

terminal by a text message. The error will also be recorded in the Error Log along with the date and time.

View the error log by pressing F3 from the default screen. A list of controller detectable errors follows:

21

Page 22

Message Meaning

Vessel “X” Pressure Low Vessel pressure dropped below alarm setting. No

Transmitter “X” Error No signal from transmitter. Yes

Vent to Bulk Time Out Vent to Bulk time exceeded 10 minutes. No

Fill Time Out Fill time exceeded 10 m inutes. No

Filling Error

Pressurization Time Out Pressurization time exceeded 10 minutes. No

Once the error has been resolved, the controller must be restarted. Restart the controller by pressing the

“Start/Stop” button inward and pulling it back outward. If the Auto-Fill Laser Pak has been emptied for

maintenance or remained in error mode for an extended period of time it will be necessary to follow the

“Restart” procedure above.

Supply vessel emptied before filling cycle

completed for other vessel.

Figure 14: Error Messages

Immediate System

Stop

No

Taking the Auto-Fill Laser Pak Out of Service

In order to empty and depressurize the Auto-Fill Laser Pak, perform the following steps:

1. Deactivate the system by pressing the “Start/Stop” button inward. Turn the alarm switch to the

“Off” position.

2. Close the bulk tank liquid withdrawal valve.

3. Close the vaporizer shut-off valve and open the system drain valve. (These valves are shown in

figure 9.) The system drain valve may be throttled as necessary to control noise.

4. Open the liquid use solenoid valves (V-1A and V-1B).

5. Monitor the liquid level in the vessels on the gr aphic interface. The vessels are empty when the

liquid level and pressure are zero. Note that the system may be empty and indicate a small

positive or negative value. This is normal transmitter error.

6. Close the liquid use solenoid valves (V-1A and V-1B). Make sure that the manual overrides on

all solenoid valves are in the closed position.

7. Crack open the bulk tank liquid withdrawal valve for a second to slightly pressurize the Auto-Fill

Laser Pak. Bleed the pressure down on both vessels to approximately 20 psi using the vent

solenoid valve (V3) manual override handles.

8. Turn the power switch to the “Off” position.

22

Page 23

MAINTENANCE

Routine inspections of the system are recommended. The need for maintenance usually becomes apparent

from inspection and indications of improper operation. Typical trouble indications would be error alarms,

leakage from valves or piping connections, and excessive venting through relief valves. Keep a permanent log

of all inspections and repairs performed. Such a log can be valuable in evaluating performance and scheduling

maintenance.

Date Nature of Work (Describe in Full) Remarks Servicemen's Signature

Figure 15: Inspection and Repair Log (Sample Form)

Always observe the safety precautions at the front of this manual and follow the instructions given in this

section. Before working on piping, isolate the piping section to be repaired from the vessels, and relieve

pressure on the component or piping.

Do not allow unqualified persons to attempt repairs on this equipment. Field repairs to instruments and

controls must be made by a qualified electrician. Refer to the Trouble-Remedy Guide in this manual for

assistance in troubleshooting.

Leak Test

After making repairs requiring disassembly or replacement, leak test all valves or piping joints that were taken

apart and reconnected. Apply leak detector fluid to the test surface. Large leaks instantly form large bubble

clusters, while fine leaks produce white foam that builds up more slowly. All leaks must be repaired and

retested before the system is returned to service.

Solenoid Valves

The most common trouble with a solenoid valve will be leakage at the stem packing. Packing leaks are

usually indicated by ice emerging from the packing gland or retainer threads. If tightening cannot stop

packing leakage, replace the packing. Use preformed packing ordered from the valve manufacturer.

The solenoid valves may be rebuilt without removing the valve body from the system. Rebuild kits are

available from the solenoid valve manufacturer. If necessary the valve may be completely replaced.

Compression type fittings make valve replacement relatively easy. It is not necessary to cut, weld, or braze

the piping in order to remove the valves.

23

Page 24

Order replacement parts from the valve manufacturer. Be sure to give all information on the valve nameplate,

including the factory part number, to ensure receiving the correct parts for these valves.

Atkomatic – Circle Seal Controls Inc.

P.O. Box 3300

Corona, California 92878 U.S.A.

Phone: 951-270-6200

Fax: 951-270-6201

Web: www.circle-seal.com/atkomatic/

Safety Device Replacement

In order to replace the safety devices the system pressure must reduced to zero gauge pressure. It is not

necessary to empty the system of liquid. Push the start/stop button on the control panel and turn the power

switch off. Close the liquid auxiliary valve on the bulk tank. Manually open both of the vent valves (V3-A &

V3-B). Be sure that the vapor phase isolation valves (V6-A & V6-B) are open. Once the vessel pressure

gauges (PI-A & PI-B) indicate zero and flow through the vent valves has stopped, the safety devices may be

replaced.

If a rupture disc (BD) bursts, determine and correct the cause of the rupture before replacing the device. These

devices should be replaced annually as a preventive maintenance procedure. The rupture discs on this tank are

sealed assemblies that must be replaced as a unit.

Vessel relief valves (RV) that leak or fail to operate at the set pressure should be replaced immediately. Do

not attempt to repair these components.

Instruments

The major cause of a malfunctioning level transmitter (PT-1) is an open equalization valve (V-7). Closed

liquid or vapor phase isolation valves (V-5 & V-6) are another likely cause of malfunction. Leakage in the

gauge lines may also cause the instrument to read incorrectly. Instructions for recalibrating the level

transmitters are included in the section titled “First Fill”. If the problem is not readily corrected, replace the

transmitter with a spare.

A malfunctioning vessel pressure gauge (PI) or vessel pressure transmitter (PT2) may be caused by a closed

liquid or vapor phase isolation valve (V-5 or V-6). If the problem is not readily corrected, replace the gauge

or pressure transmitter with a spare.

Controller

A qualified electrician should perform controller maintenance. Most controller components are readily

available Allen-Bradley parts. The controller wiring drawing, included in the appendix of this manual,

contains a detailed wiring schematic and bill of materials. The most likely problem on the controller is a

failed fuse. Should it be necessary, the programmable logic controller (PLC) may be sent to Taylor-Wharton

for reprogramming. Contact the Taylor-Wharton Customer Service Department at 1-800-898-2657.

24

Page 25

Checking Vacuum

This product is carefully designed, manufactured, and tested with every effort made to eliminate vacuum

space leakage. An absorbent material (molecular sieve) and a reactive chemical (palladium oxide) are sealed

inside the vessel casing to help maintain the vacuum over a long period of time. However, some vacuum

deterioration may be experienced after years of service due to out-gassing of materials inside the vacuum

space. To determine if vacuum deterioration has occurred perform an evaporation rate test:

1. Press the Start/Stop button on the control panel inward while leaving the power switch in the

“On” position.

2. Close the liquid auxiliary valve on the bulk tank.

3. Slowly open the vent valve (V3) of the vessel with the suspect vacuum using the manual

override. Use a face shield and insulated gloves to protect against possible contact with liquid.

Allow the vessel to vent down to atmospheric pressure. This may require an hour or more.

4. Check the liquid level reading of the vessel on the display inside the control panel. If it is less

than 50 percent it will be necessary to add more liquid. Slowly open the liquid auxiliary valve on

the bulk tank. Fill the vessel to greater than 50 percent full and close the valve.

5. Leave the vent valve (V3) open. After 24 hours, note the liquid level reading of the vessel. Take

a second reading after another 24-hour interval. Compare the two readings.

A liquid level decrease exceeding 15% over a 24-hour period may indicate a vacuum problem. Condensation

or even ice on the vessel jacket is another indication of a vacuum problem. Note that some icing or

condensation is normal around the piping connections of the vessel. Condensation may also occur on the

vessel’s outer surface as a result of high humidity.

If it has been determined that the vessel has a vacuum problem, it will be necessary to repair or replace the

vessel. A skilled service technician should perform vessel replacement or repair. Contact Taylor-Wharton

customer service at 1-800-898-2657 for assistance in locating the closest service center.

25

Page 26

Trouble-Remedy Guide

Trouble Possible Cause Remedy

1. Pressure low, controller error text

“Vessel Pressure Low” or

“Pressurization Time Out”.

2. Excessive system pressure.

3. Erratic or erroneous liquid level

readings.

4. Leaking relief valve (RV).

5. Ruptured pressure vessel rupture

disc (BD).

a. Safety valve (RV-1) leaking or

frozen open.

b. Rupture disc (BD) rupture. b. Replace rupture disc.

c. Piping leaks to atmosphere. c. Leak test and repair piping.

d. Pressure building solenoid (V-4)

failure.

e. Excessive product withdrawal. e. Check for leaks downstream.

f. Controller off or not started. f. Turn on controller and pull start

g. Excessive frost on pressure

building coils.

a. Extensive shutdown time. a. No remedy.

b. Low withdrawal rate. b. No remedy.

c. Malfunction of pressure

building circuit.

d. Malfunction of pressure gauge

(PI) or pressure transmitter (PT-

2).

e. Bad vessel vacuum. e. Have vessel repaired and re-

a. Leaking gauge lines. a. Test and repair leaks.

b. By-pass valve open. b. Close by-pass valve.

c. Blown fuse. c. Check for electrical short; replace

d. Liquid level transmitter (PT-1)

damaged or faulty.

e. Gauge lines reversed. e. Connect properly.

f. Wiring fault. f. Check and fix transmitter wiring.

g. Plugged gauge lines. g. Disconnect lines at liquid level

a. Dirt or ice in valve. a. Thaw out valve. Replace if

b. Improper valve set point. b. Replace valve.

c. Damaged valve seat. c. Replace valve.

a. Excessive vessel pressure. a. Refer to Step 2, this section.

b. Defective rupture disc. b. Replace rupture disc.

c. Atmosphere corrosion and/or

disc fatigue.

d. Interior disc corrosion. d. Blow out safety device line.

e. Improper rupture disc. e. Install correct rupture disc.

f. Relief device failed. f. Replace relief device and rupture

a. Thaw out valve or replace if

necessary.

d. Check fuse and wiri ng. Clean,

seat, rebuild, or replace solenoid

valve if necessary.

Reduce product use.

button.

g. Thaw pressure buil ding coils.

c. Clean, rebuild, or replace

pressure building solenoid valve

(V-4).

d. Compare gauge to transmitter

reading. Replace defective unit.

evacuated.

fuse.

d. Replace liquid level transmitter

(PT-1).

transmitter (PT-1) and test for

flow.

necessary.

Replace rupture disc.

c. Replace rupture disc.

Replace rupture disc.

disc.

26

Page 27

6. Controller error text, “Transmitter

Error”.

7. Controller error text, “Vent to

Bulk Time Out”.

8. Controller error text, “Fill Time

Out”.

9. Controller error text, “Filling

Error”.

a. Blown fuse. a. Check for electrical short; replace

fuse.

d. Transmitter damaged or faulty. d. Replace transmitter indicated by

controller.

c. Wiring fault. c. Check and fix transmitter wiring.

a. Bulk liquid withdrawal valve

closed.

d. Bulk liquid withdrawal line

strainer clogged.

c. Vent to bulk solenoid valve (V-

2) failure.

d. Pressure transmitter (PT-2) or

bulk tank pressure transmitter

malfunctioning.

a. Bulk liquid withdrawal valve

closed.

d. Bulk liquid withdrawal line

strainer clogged.

c. Bulk tank empty or pressure low. c. Refill or repair bulk tank.

d. Vent solenoid valve (V-3)

failure.

e. Level transmitter (PT-1) requires

calibration or is malfunctioning.

a. Bulk liquid withdrawal valve

closed.

d. Bulk liquid withdrawal line

strainer clogged.

c. Excessive product withdrawal. c. Check for leaks downstream.

a. Open valve.

d. Clean strainer.

c. Check fuse and wiring. Rebuild or

replace solenoid valve if

necessary.

d. Check against accurate pressure

gauge. Replace if necessary.

a. Open valve.

d. Clean strainer.

d. Check fuse and wiring. Rebuild or

replace solenoid valve if

necessary.

e. Calibrate level transmitter per

“First Fill” section of manual.

Replace level transmitter if

necessary.

a. Open valve.

d. Clean strainer.

Reduce product use.

27

Page 28

Replacement Parts

Order replacement parts from Taylor-Wharton Customer Service (1-800-898-2657). Refer to system piping

schematic on the general arrangement drawing.

Replacement Parts List

ITEM PART NUMBER DESCRIPTION

CV-1, C V-2 85441390 Valve , Check, 1/ 2 " F NPT

CV-3 85441395 Valve, Check, 1/2" FNPT, 5 psi C r ack Pressu re

BD 85088188 Rupture D i sc, ASME, 811 PSI, 1/2" MNPT

PI 7702-6197 Pressure Gauge, 600 PSIG, 1/4” MNPT

PT-1 57408750 Differen t i al Pressure Transm itter, 100” H2O

PT-2 57408626 Pressure Transmitter, 500 PSIG

PT-3 57408627 Pressure Transmitter, 1000 PSIG

PB AF55-9C28 Pressure Builder

V-1, V - 2, V-3 85456547 Valve, Sol enoid, 1/2" F NPT

V-4 85456552 Valve, Solenoid, 3 /4" FNPT

V-5, V - 6, V-7 85443725 Valve, Glo be, 1/4” MN P T

RV 2198235 Safet y V alve, ASME , 500 PSI, 1/2" Inlet X 3/4" Outlet

AF55-9C02 Complete Controller in Enclosure

AF55-6C00 Complete Vessel without Piping

AF55-9C12 Flow Schematic Decal

28

Page 29

APPENDIXES

Appendix 1 - Auto-Fill Laser Pak General Arrangement

Appendix 2 - Controller, Auto-Fill Laser Pak

29

Page 30

Manual P/N 99187847

4075 Hamilton Blvd.

Theodore, Alabama 36582 U.S.A.

Telephone (251) 443-8680

Fax (251) 443-2250

In U.S. and Canada:

(800) TW TANKS (898-2657)

Loading...

Loading...