Page 1

SuperLoader

™

For more information about Tandberg Data´s

quality products, visit www.tandberg.com

Tandberg Data publications can be requested from a Tandberg Data Sales Representative or ordered directly from

For the latest information about Super DLTtape™ and DLTtape™ products and accessories, visit the Tandberg Data

web site at www.tandberg.com or the Technical Support site at www.dlttape.com.

Tandberg Data reserves the right to make changes and improvements to its products, without incurring

any obligation to incorporate such changes or improvements in units previously sold or shipped.

Publication Number: 432549-01

© 2002 Tandberg Data. All rights reserved. Tandberg Data and the Tandberg Data logo are trademarks of Tandberg

Data ASA. The DLTtape logo and the Super DLTtape logo are trademarks of Quantum Corporation, registered

in the U.S.A. and other countries. DLTtape, Super DLTtape, SuperLoader, and the SuperLoader logo are

trademarks of Quantum Corporation. Products mentioned herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies. All other trademarks are the property of their

Tandberg Data.

respective owners.

Quick Start Guide

432549-01

Page 2

Caution

Do not rest the autoloader on the

unpacked side. The weight of the unit

could bend the metal flange on the

front end.

While one unpacker steadies the

autoloader, the other unpacker should

remove the foam packaging from the

other side of the unit and set down the

unit.

Remove the foam inserts from the front

of the unit.

• Power cord

• Quick Start Guide

Each unpacker should:

1. Position him/herself along a lengthwise side of the carton, facing the

other unpacker.

2. Reach in through the openings in

the foam packaging and grip the

autoloader securely.

3. In a coordinated motion with the

other unpacker, lift the autoloader

out of the box and place it on a flat,

stable surface.

While one unpacker steadies one side

of the autoloader, the other unpacker

should grip the front of the autoloader

with one hand and remove the foam

packaging from the other side of the

unit.

d

e

f

g

3

!

1

Unpack the

autoloader

This guide contains

a sequence of steps

recommended for

unpacking, installing,

and setting up your

autoloader.

For additional information:

Refer to the enclosed CD-ROM,

visit www.tandberg.com

Tandberg Data recommends that two

people unpack the autoloader and that

you practice good ergonomic techniques

to lessen the risk of personal injury and

damage to the unit.

Look for markings on the carton that indicate the top. If necessary, re-position the

carton so that it is upright according to

the markings.

Use a utility knife or scissors to cut the

packing tape along the length and ends

of the carton.

Remove the accessories box from the carton. The accessories box contains the following items:

• Cable(s)

• Documentation CD

• Mounting hardware (brackets and

screws)

a

b

c

2

Page 3

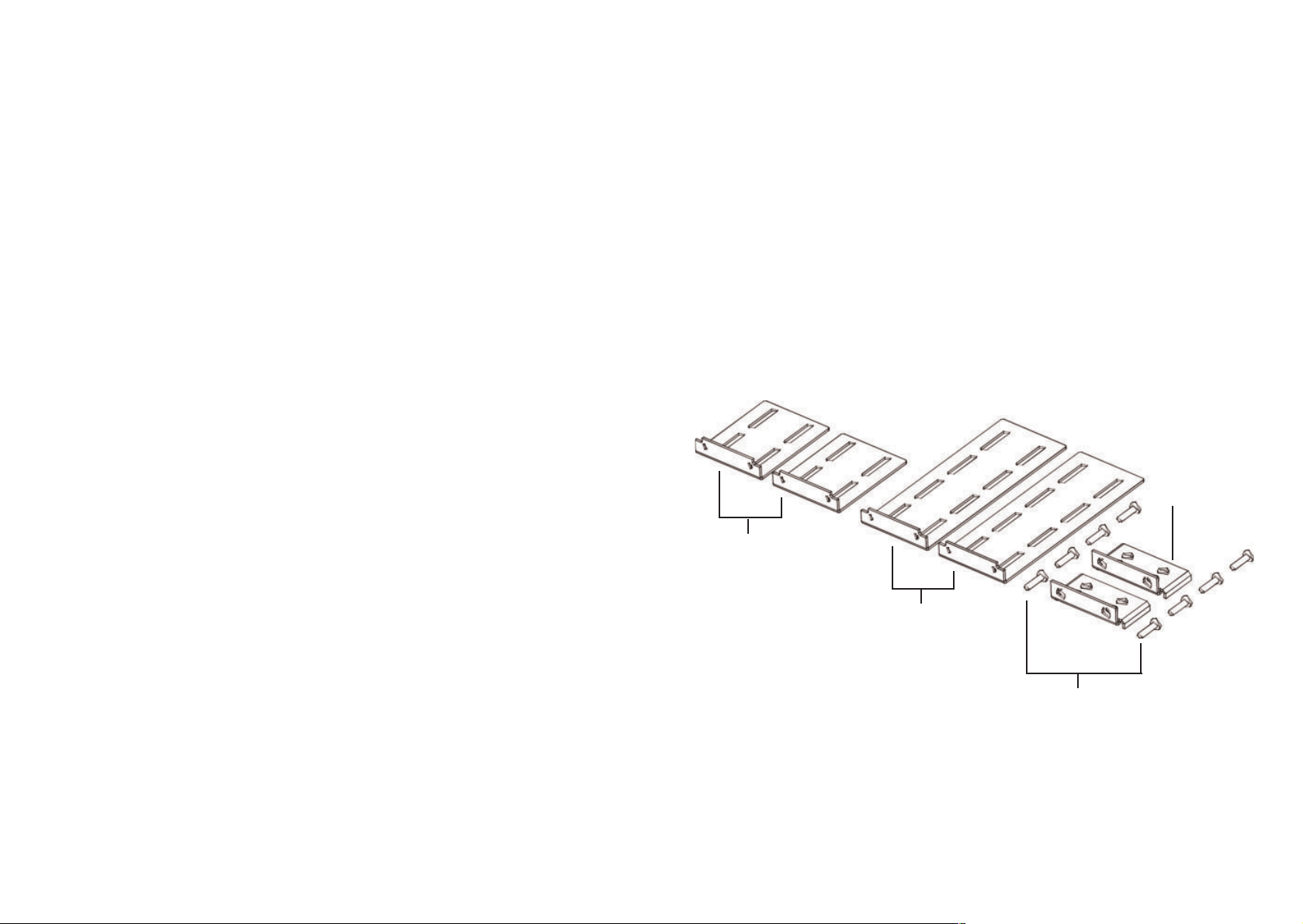

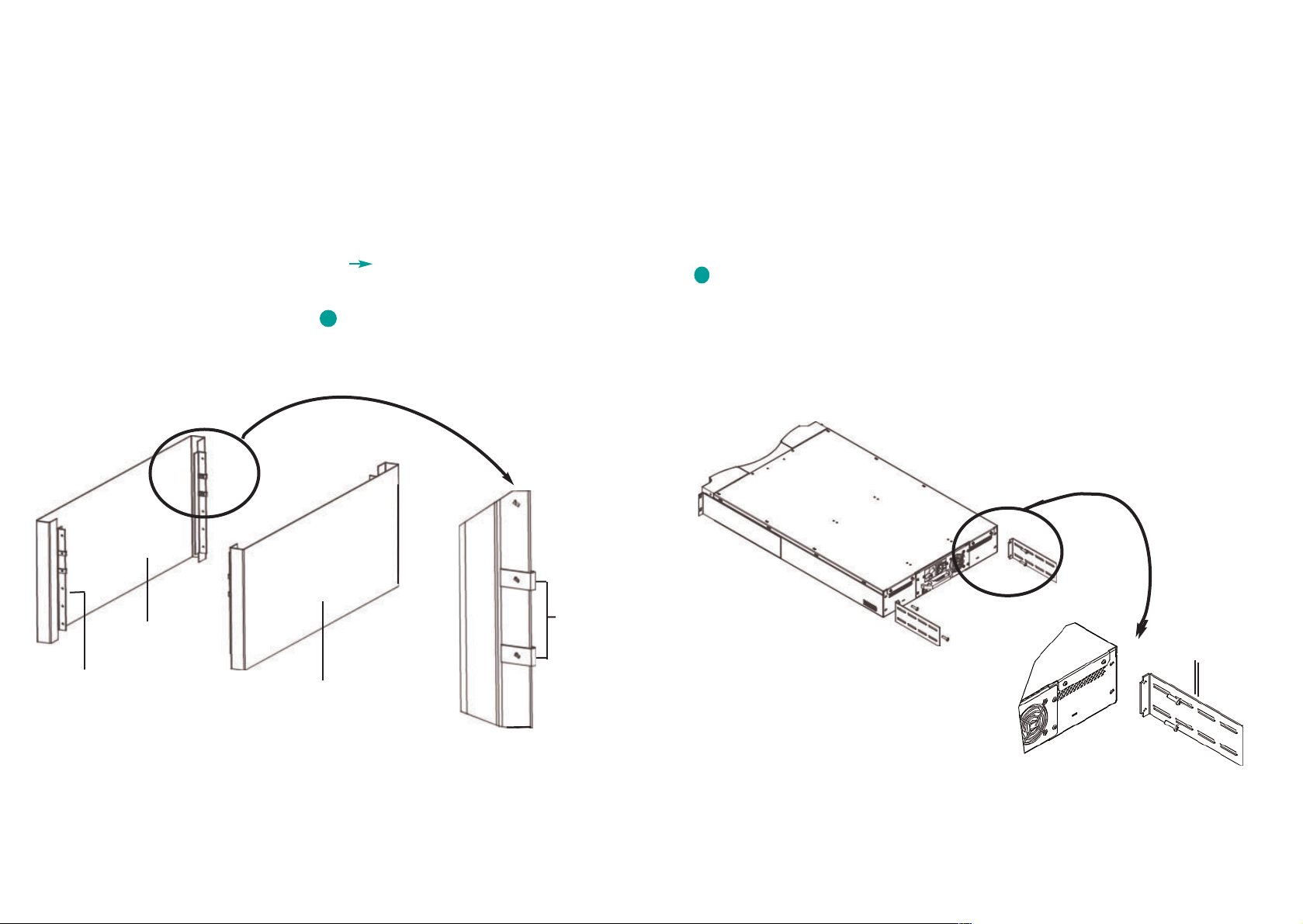

Short autoloader

brackets (part number

74-60604-02)

Long autoloader

brackets (part number

74-60604-01)

8 support bracket

screws

Support brackets

5

Tools

•#2 Phillips screwdriver

Parts

• 4 autoloader brackets (2 long and 2

short, to accommodate different rack

depths)

• 2 support brackets

• 8 10-32 x 1/4 inch button head screws

for the support brackets (4 per support

bracket)

Note: You also need 8 clip nuts and 8

screws, which are not included with your

autoloader but should be included with

your cabinet.

Prepare parts

and tools

2

Sections 2-4 explain

how to prepare and

install the autoloader.

4

Page 4

It takes two people to safely rackmount

your autoloader.

Warning

Before you begin, lower the rack’s leveler

feet and extend the rack’s anti-tip device.

Failure to extend the anti-tip device could

result in personal injury or damage to the

tape autoloader if the rack tips over.

Caution

Do not remove the top cover of the

autoloader during the installation process.

Removing the top cover could result in

damage to the autoloader.

Caution

Ensure that the rack and all equipment

mounted in the rack have a reliable

ground connection. Verify that the total

current of the rack components does not

exceed the current rating of the power

distribution unit or outlet receptacles.

!

!

!

Rackmount the

autoloader

4

7

Choose a

location

3

Choose a location to install the

autoloader.

Caution

Position the autoloader so that no cooling

vents or exhaust from other devices are

located directly in front of the unit; this

helps minimize the amount of foreign

debris entering the tape path. Excessive

dust and debris can damage tapes and

tape drives.

For details about accessing

cartridges and removing magazines,

see the User Manual.

!

6

Page 5

Select the long or short autoloader brackets and attach them to the rear of the

autoloader. (Procedure continues.)

Autoloader

bracket

b

9

Rail in rack

Outer cover

of rack

Outer cover

of rack

Clip nuts

Rackmount the

autoloader,

continued

For details about this procedure, see

the User Manual.

Install two clip nuts, 1.75 inches apart,

onto each of the four rails of the rack,

making sure that you install each pair of

clip nuts at exactly the same level.

a

8

Page 6

Put the autoloader into the rack and do

the following:

1. Position the autoloader in the rack so

that each autoloader bracket rests on a

support bracket. Each autoloader

bracket should slide along the lip of the

support bracket. (Procedure continues.)

Autoloader bracket

Support bracket

d

11

Rackmount the

autoloader,

continued

c

Attach one support bracket to each rear

rail, loosely installing the screws through

the clip nuts. Make sure that you attach

the side of the support bracket that has

only two holes, and do not tighten the

screws yet. You will tighten the screws in

Step h.

Outer cover of rack

Rear rail in rack

Support bracket

10

Page 7

Loosely install the four screws that

connect the support brackets (two

screws per support bracket) to the

autoloader brackets.

e

Verify that the autoloader is level.

Adjust as needed.

Tighten the four screws that attach the

two front ears to the front rails.

Tighten the four screws that connect

the two support brackets to the two

autoloader brackets.

Tighten the four screws that connect

the two support brackets to the two

rear rails.

f

g

h

i

Autoloader bracket

Support bracket

13

Rackmount the

autoloader,

continued

2. Slide the autoloader in place so that

the front ears of the autoloader align

with the front clip nuts. Then loosely

install the four screws that connect the

two support brackets to the two front

rails.

Front rail

Front ear

12

Page 8

e

f

g

If the autoloader will be the last device

on the SCSI bus, install the supplied

SCSI terminator to the remaining port

that is on the autoloader/DCA and then

tighten the screws.

Attach the other end of the SCSI cable

to the SCSI host adapter card.

Power back on any peripheral devices

that you powered off in Step b.

Double-stacked SCSI connector

Note: Do not power on the host computer at this time. You must configure the

autoloader for SCSI and Ethernet prior to

powering on the host.

15

5

Make the SCSI

connection

Caution

When installing cables, be careful not to

damage the SCSI pins on the connectors.

Damaged pins will cause the connection

to fail.

If the host computer is connected to a

network, check with the system administrator before turning off power.

Properly power off all peripheral devices

connected to the host computer.

Power off the host computer.

Install the supplied 68-pin SCSI cable to

the double-stacked SCSI connector that is

on the back of the autoloader/DCA and

tighten the screws. You can install the

SCSI cable in either port.

Note: Notice that the connector on the

end of the cable is offset. Make sure that

you install it with the correct orientation

so that you can fit a terminator or another cable in the other port.

!

d

a

b

c

Sections 5-9 explain

how to set up the

autoloader.

14

Page 9

7

Power on the

autoloader

Push the power switch on the back

of the autoloader to the on position

(the 1 is pressed).

When you first power on the

autoloader, it automatically runs a

Power On Self Test (POST). During

the POST, the left (green) LED flashes. After the POST, the left (green)

and right (amber) LED flash alternately.

Wait while the autoloader performs

its power-on sequence. During this

time, the following activities occur:

• The LCD displays the model and

firmware.

• The LCD displays the tests being

performed as part of the internal

power-on.

Note: If the autoloader displays a

warning message, press Escape to

clear the message.

• The autoloader performs a calibration and magazine element status.

The Ready LED flashes green. A +

appears in the upper right corner

of the LCD while calibration is in

progress.

When the power-on sequence completes and the autoloader is ready,

the LCD displays a list of the

autoloader options that are present

and the Ready LED is steady green.

Note: If there is a warning message

indicating a change, you may need to

press Escape to clear the message.

Note: After the first time you power

on the autoloader, you should use

the switch on the front to power on

and off the autoloader.

a

b

17

6

Connect the

power cord

Note: The first time you power on the

autoloader, do not power on the host.

Make sure that the power switch on the

back of the autoloader is off (the 0 is

pressed).

Connect the female end of the power

cord to the power connector on the back

of the autoloader.

Plug the male end of the power cord into

the power source.

a

b

c

16

Page 10

9

Set the

Ethernet

Ethernet is the method that the

autoloader uses to access a network.

The Ethernet connection is how you

access the Web Administration to

modify the SuperLoader configurations, such as the IP address. Each

Ethernet device must have a unique IP

address.

Use the front panel to determine and

modify the static IP address or set the

SuperLoader to a dynamic address.

If you are not using a dynamic address,

you must set the IP address and

Subnet mask.

For more details, see the User

Manual.

19

8

Set the SCSI ID

Each SCSI device that is attached to a

server or workstation must have a unique

SCSI ID. The SuperLoader is set to a

default SCSI ID of 5. Use the front panel

or Web Administration to change the SCSI

ID if necessary.

For details about setting the SCSI ID,

see the User Manual.

18

Page 11

Scroll to Right Magazine or Left

Magazine and press Enter to eject that

magazine.

If the front panel requests a password,

the default password is 000000. If you

are using the Web Administration, the

default passwords are

Username = guest

password = guest

The magazine selected will be released

and can be removed.

Caution

To prevent damage to the autoloader or

the magazine, use both hands when

removing the magazine from the

autoloader, supporting the entire length

of the magazine.

Grasp the magazine by the handle with

one hand and slide it out, supporting it

underneath with the other hand.

!

d

c

Note: When you eject a magazine, you

must fully remove it or fully re-install it

before powering off the autoloader.

21

Use magazines

and magazine

blanks

This section explains

how to correctly

handle magazines

and cartridges.

The Autoloader will not run unless both

magazine openings are properly closed.

One way that you can close the openings

is to use two magazines. If you use only

one magazine, then you must fill the

other magazine opening with a magazine

blank for the unit to become operational.

For instructions about how to

assemble a magazine blank, provided the one you received is not

assembled, see the User Manual.

Eject a magazine

When you want to remove several

cartridges at once, eject the magazine(s)

first.

On the LCD, press Enter and then scroll to

Commands. Press Enter again to select

Commands.

Scroll to Eject and press Enter.

a

b

20

Page 12

Load and unload cartridges

from a fully ejected magazine

There are two handles located on both

ends of the magazine. Move the slots

within the magazine by using these two

handles. You can use the two openings

along the top of the magazine and the

four openings along the bottom of the

magazine to load and unload cartridges

from the eight slots within each magazine.

Handle

Handle

View of right side of right magazine

23

Use magazines

and magazine

blanks,

continued

Install a magazine

For detailed instructions, see the

User Manual.

Grasp the magazine by the handle with

one hand and support it underneath with

the other hand.

Push the magazine in until it clicks and

locks into place. Make sure that you position the magazine correctly; it should slide

smoothly. If the magazine does not slide

all the way in, verify that the magazine is

properly oriented to the autoloader. If the

magazine is backwards or upside down, it

will not slide and lock into place.

a

b

22

Page 13

b

Properly orient the cartridge.

Note: There is a keying feature in each

slot that only allows you to fully insert the

cartridge one way.

25

Fully insert the cartridge into the slot.

When pushing the cartridge into the slot,

you will feel a small resistance until the

cartridge is properly latched into the slot.

All forward progress stops when the cartridge is fully inserted.

You can remove a cartridge in the same

manner as you insert it. Use the handles

to center the desired slot(s) in the openings on the side of the magazine. Using

your thumb and index finger, pull out the

cartridge. You will feel a small resistance

but continue to pull the cartridge until it

frees.

c

Identify a slot

Each slot has an identification mark that

is exposed when the slots are on the

upper section of the magazine. You can

see the identification mark on the top side

of the magazine.

Each slot has a unique identification number that corresponds to the side on which

the magazine is operating. If the magazine is operating on the left side, the slots

are numbered L1 through L8. If the magazine is operating on the right side, the

slots are numbered R9 through R16.

For a visual representation, see the

User Manual.

Use magazines

and magazine

blanks,

continued

Caution

To load and unload cartridges, it is recommended that you fully remove the magazine. If the magazine is not fully removed,

do not rotate the magazine.

!

To load cartridges in the magazine, center

a slot within one of the six openings

located on the side of the magazine.

a

Orientation mark that

shows which way is up

Correct orientation of cartridge

relative to the magazine

24

Page 14

Loading...

Loading...