Page 1

,*;y

T).^oW,*^q

r=-r=f-rr5r/

Service

manual

MNDBERG

Tape

modell

recorder

12

Page 2

Preface

This service manual covers

models

der

fully

playback

separate record and

power

rate

output

The model

model I

12-2 and

system and

We hope thot

will find

l2-4 and 12-2.fhe model

transistorised, three

unit

with

amplifiers

amplifiers are rated

-2

is the two-track

12

2-4 is the four-track version. The

)2-4

have exaclly

operating controls.

everyone concerned

this service manual

speed stereo,

two

heads. lt is equipped

playback preamplif

for

the

Tandberg tape recor-

series l2 is a

record

and

iers

each channel. The

for l0

the same mechanical

useful.

each.

watts

version while the

with our

products

April

arrd

with

sepa-

power

models

1967

1

1

Page 3

T'r

Contents

)

)

'l

,1

.t

t{

tI

tt

tope 34

. -

..

models

..

L2 '.

. .. ' 40

. . . . .

..

c/s

3t

3l

32

32

33

a?

33

33

33

33

34

34

35

JJ

JJ

AE

32

35

a5

35

35

36

36

35

36

36

36

36

35

36

36

1A

37

38

2a

Jd

39

39

39

41

4l

4l

4l

46

Technicol specificqlion,

1.0

l2-4 ond l2-2

The function

2.O

The

3.0

The mechonism, detoiled

4.O

instruciion

The operoling

1.1

4.I.1

1.1.2 lhe

4.1.3

4.1.4

4.1.5

The

4.2

^

r

4.2.1

4.2.2

4.2.3

of the

ond outpuf

inpuf

lever

moior

The

eccentric

pressure wheel ossembly

The

The tope broke

The

trip bor

turnfoble

ossemblies

lhe

supply turnfoble ossembly

lhe lope iight

The

toke-up turntoble

A.2.4 Horizontsl

1.3 Clulch

4.4

4.5

4.6 The lifting

1.7

1.9

O

4.9 The momenlqry stort-stop

4.10 The

4.l l The oulomotic

4.12

4.13

5.0

i

t

t

T

olignments

Generol

4.3.1

4.3.2 Fost

4.3.3 Fost

4.3.4 Normql forword

4.3.5 Neutrol

4.3.6 Free

fhe motor

4.4.1

The

The

4.7,1

The

The revolulion counler

Assembling the fop

The

instruction

5.1.1

5,'I .2

5.1.3

5.1.4

5.1.5

5.1.6

5.1,7

5.1.8

5.1.9

5,l.l0The

5.l,ll

rewind

wind

pulley

Threoding of

lronsfer

speed

mechonism .....

flywheel

speed

pressure pqd . .

electronic

with ihe copston

The broke

chonge mechonism

circuits,

lnpuls

The

record

The FM multiplex-filter

The equolizing

The equolizing

The equolizing

power

lhe

The ploybock

The record level

oscillotor,

The power

Tondberg

.

conlrols

lerminols

descripiion ond

.

.

switch

segment

lension .

ond veriicql

drive

the rubber drive

wheel

the flywheel

for

.

end sfop switch

.

cover

detoiled descriplion

pre-omplif

omplifier in

omplifier

omplifier in

oulput omplifier

pre-omplifier

indicotor

bios ond erose

supply

tope recorder

ossembly

olignments of

. .

.

. .

feoture

.

ier

record

ploybock position

in

omplifier

circuit ..

belt

circuit

models

odiusiment

the furntobles

. '.... '..

odiusfmenl

ond

posiiion . '... '

. .. . 26

posilion . .. . 27

't0

l0

12

t2

t2

IJ

l3

t4

l5

'15

't5

l6

l6

17

t7

l8

't8

l8

l8

19

20

21

2l

22

22

22

22

24

24

25

25

25

28

29

29

29

30

The f unclion selecior

5.2.1

lhe speoker selector

5.2.2

5.2.3 Monourol

5.2.4 Mixing

5.2.5 Stereo

e

9

9

5.2.5 Monourol

Stereo

5.2.7

5.2.8 Stereo

5.2.9 Add o

S.2,l0Sound

Heod

5.3

5.4

5.5

5.6

5.7

olignment

The

5.3.I

The model l2-2

5.3.2

Heod olignment

5.4.1 Demognetizing

The odlustoble

5.4.2

The record/ploybock

5.4.3

5.4.4 The erose

Trock

conlrol,

The

5.5,1

The erose

5.5.2

Trock conlrol,

The

5.6.1

The record/ploybock

5.6.2

Electrical

ond

12-4

5.7.1 Adiustment of

Adiusfment of the

5.7.2

5.7.3 The

Adiustment of the

5.7.4

Control

5.7.5

5.7.6 The boss

5.7.7 The ireble

,Adiusfment of

5.7.8

beqm indicotor

The electronic

5.7.9

5.7. r 0

.t I

5.7

5.7.12

5.7.13

4

5.7.1

5.7.15

5.7.16

5.7.17

5.7.18

5.7.19

Electricol

5.8

model

Modificolions

5,9

Modificofions

5.10

Ports list

6.0

6.0.1

Mechonicol

6.0.2 Elecrricol

recording

during

recording

ploybock, chonnel

ploybock

omplifier

irock .

on sound

ond frock

l2-4 and 12-2

Models

without Tqndberg

heod

model

record/ploybock

heqd

model

heod

erose

qdiustments

12-2

quiescent currenl

of

lhe frequency

conlrol

control

The

record

Adivstment

Dislortion

odiustment of lhe

Bolonce

Adiusiment of

of the recording

Control

of the

Control

of

Control

oulpul control

Power

test

Speed

modificotions introduced

12

from four-trock

from 220 volts 50

ports ' .

swilch

swilch .

on CHI or

monourol recording

conlrol

guides

tope

heod

without Tqndberg

l2-4

heod

without Tondberg

l2-2

heod . .

Tondberg tope

for

. .

ihe

the

circuits .

beqm

current.

of the

the

ploybock

the

lotol

outPuf

Power

outpui level

.

FM MX-filter

response

currenf

record

indicolors

osc, frequency

equolizoiion

curves

curves

frequency resPonse

.

to iwo-frock

c/s to ll0

ports

.

CH2 ,

or 2 .. '....,.

I

Tondberg test

with

topes

test

test lqPes

lesi topes

recorder

omplifier

in omp'

ond the eleclronic

ond the bios

pre-omP ouiPuts

coils Ll ond

.

.

tope recorder

to the

models .

volfs

..........

position

... ..

60

.'.....".

Page 4

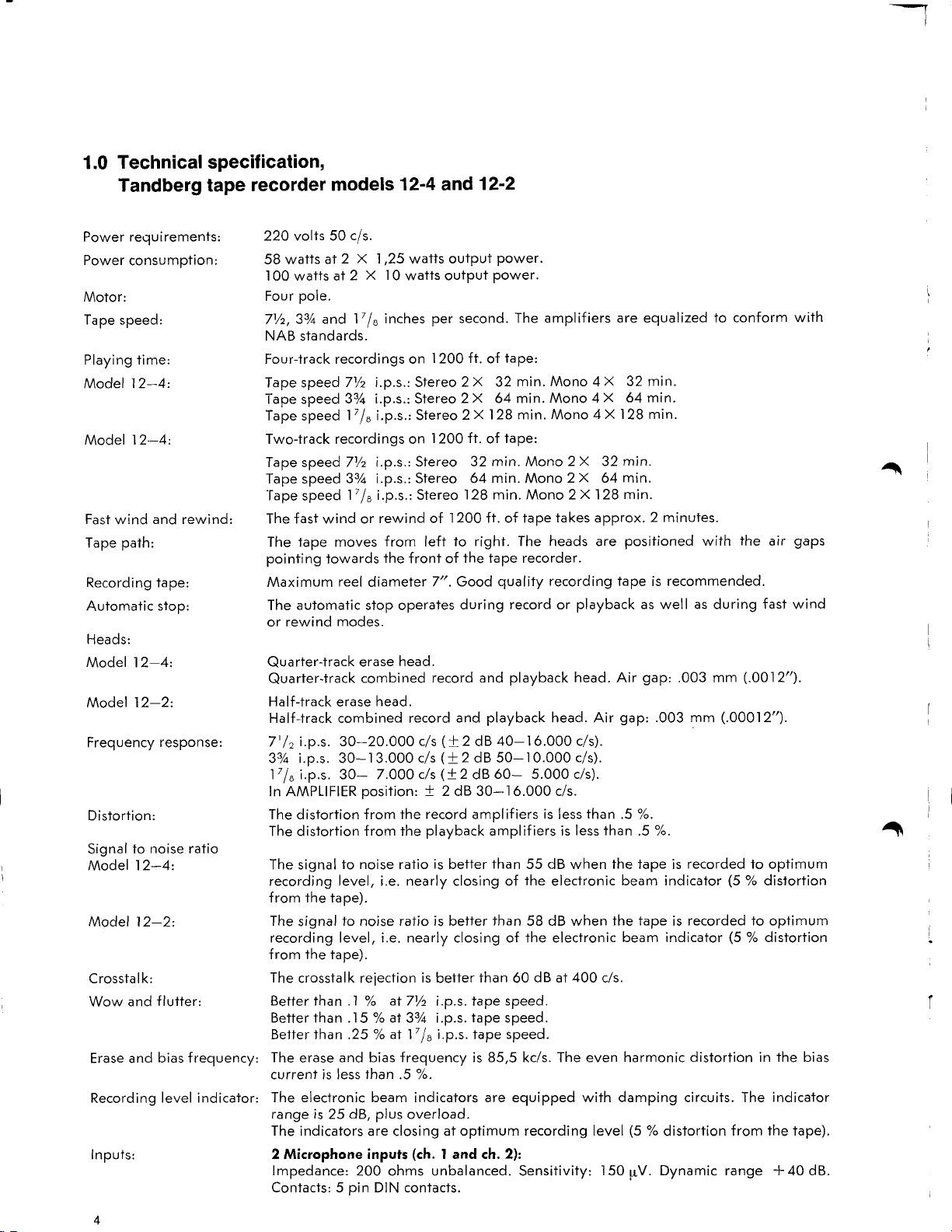

Technical specification,

1.0

Tandberg tape

recorder

models

12-4 and12'2

requirements:

Power

Power

consumption:

Motor:

Tapespeed:

Playing time:

Model

Model

l2-4'

l2-4:

Fast wind

Tape

Recording tape:

Automatic

Heads:

Model l2-4: Quarter-track

Model

Frequency

Distortion:

Signal

Model

Model 12-2'

Crosstalk:

Wow

Erase and

Recording

lnputs:

and rewind:

path: The tape moves

slop:

I2-2:

response:

noise ratio

to

l2-4:

f lulter:

and

bias frequency:

level indicaior'

220 volts 50

58 watts

i 00 watts aI

pole.

Four

71/2,33/t

NAB standards.

Four-track recordings on

Tape speed

Tapespeed

Tape speed

Two-track recordings on

Tape speed

Tape speed

Tape

speed

The fast wind or

pointing

Maximum

auiomatic

The

or rewind

Quarter-track

Half-track erase

Half-track combined record

i.p.s. 30-20.000

7'

l,

33/a i.p.s. 30- I 3.000

17/a i.p.s. 30- 2.000

ln AMPLIFIER oosition: t

The distortion from the

The distortion from the

The signal

recording level, i.e. nearly closing of

from the tape).

The

signal

recording level, i.e. nearly closing of the electronic

from the tape).

The

crosstalk reiection

Better ihan .I % at 7t/z

Better than

Belter than .25

The

erase

current is less than .5 %.

The electronic beam indicators are equipped with damping circuits. The

range is

The

indicators are closing

2

Microphone

lmpedance,200

Contacts: 5

c/s.

2 X 1

at

2

l7/e inches

and

7Vz i.p.s.: Stereo

37+ i.p.s.: Stereo

l7/o i.p.s.' Stereo

7t/z i.p.s.:

3% i.p.s.: Stereo

17/6

towards

reel

modes.

to noise ratio

io noise ratio is better

.15 %

and bias frequency is 85,5 kcls. The even harmonic distortion

dB, plus

25

pin

watts output

,25

.l

X

0 watts output

per

1200 ft.

1200 ft.

Stereo 32

Stereo

i.p.s.:

rewind of

from left to

the f ront of

diameter

stop operaies

head.

erase

combined

heao.

at

al

Y"

inpu?s

ohms unbalanced. Sensitivity:

DIN contacts.

.l200

7". Good

record and

('l

c/s

(-r

cls

(+2

c/s

2 dB 30-.l6.000 c/s.

record

playback

is

better

is

better

i.p.s. tape

33/+ i.p.s.

l'/o i.p.s. tape

overload.

at optimum recording level

(ch.

I and ch,2l:

power.

power.

amplifiers are equalized

second.

2 X 32 min.

2X 64 min. Mono

2x

.l28

the tape recorder.

during

and

2

2 dB 50- I 0.000

The

tape:

of

128 min. Mono

tape:

of

min.

Mono

64 min. Mono

min. Mono 2

ft. of tape

right. The heads are

quality recording tape

record

playback

playback

40- 16.000 c/s).

dB

60- 5.000 c/s).

dB

amplifiers

amplifiers is

than

ihan

than

tape speed.

is less

55 dB when the tape is

the

58 dB when

dB at

60

speed.

speed.

Mono 4

takes approx. 2 minutes.

or

head. Air

electronic

X 32 min'

4X 64min.

4 X i

2 X 32 min.

2 X 64 min.

.I28

X

playback

head. Air

c/s).

than

less than

400

c/s.

l50pV. Dynamic range *40d8.

min.

28

min.

positioned

is recommended.

as well as during

gap:

gap:

.5

%.

.5 %.

beam indicator

the

tape is

beam indicator

(5

% distortion

with

.003 mm

.003 mm

recorded to

recorded to optimum

to conform

the

air

fast

(.O012").

(.00012').

optimum

(5%

disloriion

(5

distortion

%

in the bias

indicator

from the tape).

with

A

gaps

wind

i

I

4

Page 5

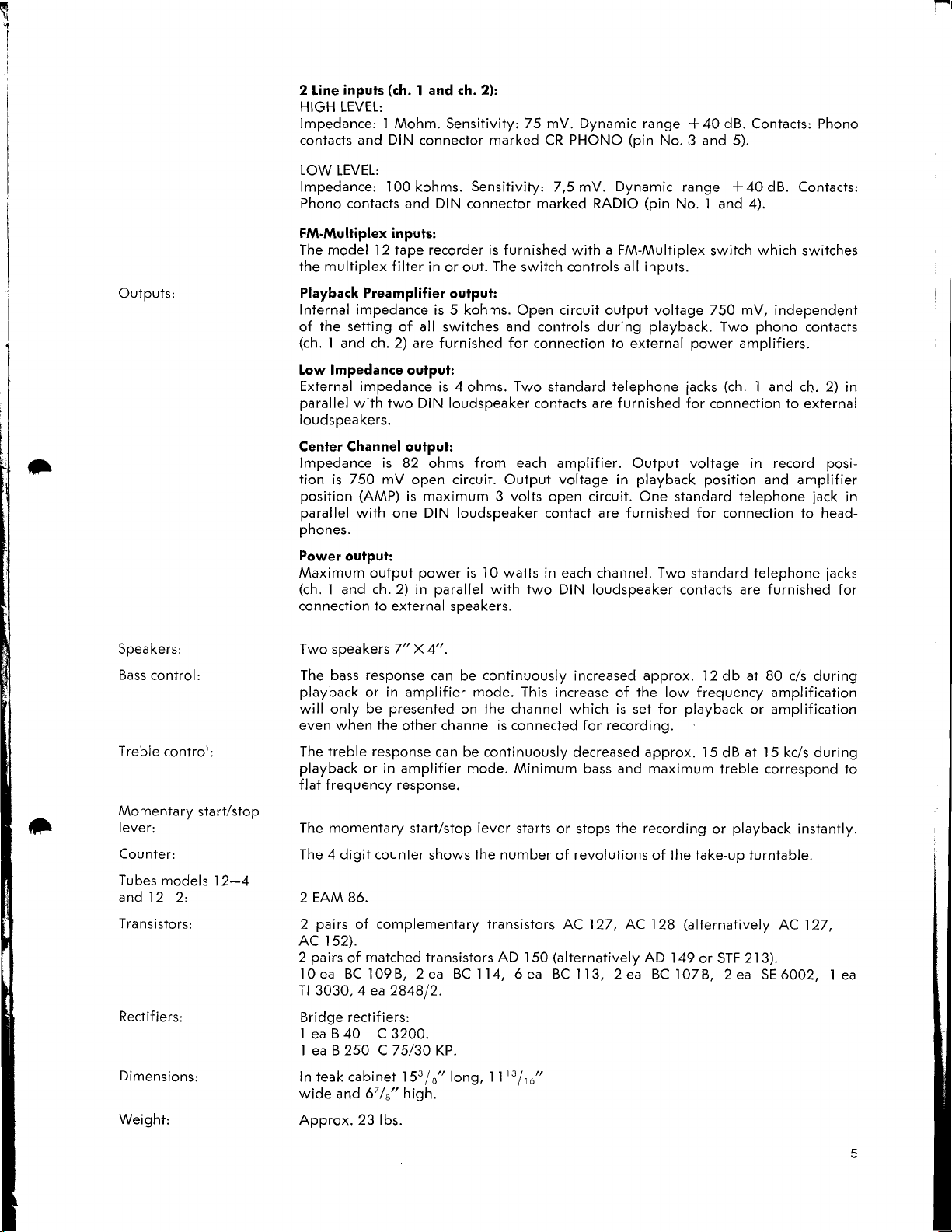

Oulputs:

2

line

HIGH LEVEL:

Impedance: I Mohm.

contacts

LOW

lmpedance:

Phono contacts and DIN

FM-Multiplex inpuls:

The model l2 tape recorder is furnished

the multiplex filter

Playback Preamplifier

lnternal impedance

of

(ch.

and DIN

LEVEL:

the setting

I

ch.2)

and

and

I

Sensitivity:

connector

.l00

kohms.

in

or oui.

oulpul:

is 5 kohms. Open circuit output voltage 750 mV, independent

of all

switches

are furnished

2):

ch.

marked

Sensitivity:

connector

The

switch controls

and controls during

for

75

mV. Dynamic range

CR PHONO

7,5 mV.

marked RADIO

connection

(ch.

inputs

(pin

Dynamic

a FM-Multiplex

with

all

to

external

+40

No. 3 and 5).

range *40 dB.

(pin

No. I and 4).

switch

inputs.

playback.

power

dB.

Contacts: Phono

which

phono

Two

amplifiers.

Contacts:

switches

contacts

Spea kers,

Bass

control:

Treble

control:

Momentary

tever:

Counter:

Tubes

and

l2-2:

Tra nsi

Rectif

Dimensions:

Weight:

start/stop

models

stors:

iers:

l2-4

low lmpedance

External impedance

parallel

loudspeakers.

Cenler

lmpedance

tion

position

parallel

pnones.

Power

Maximum output

(ch.

connection to external

Two

The bass response

playback

will only

even when

The treble

playback

f

lat f requency response.

The

The 4 digit counter

2 EAM 86.

2

AC

2

l0ea BC 1098, 2 ea BC

Tl

Bridge rectifiers:

I

I ea B 250 C 75/30 KP.

In teak cabinet l5'

wide and

Approx. 23 lbs.

with two DIN loudspeaker contacts

Channel

75O mY

is

(AMP)

with one DIN loudspeaker contact

ouipul:

I and

speakers

momeniary start/stop

pairs

of

r52).

pairs

of

4 ea

3030,

ea B 40 C 3200.

oulpul:

is 4

oulpul:

is

82 ohms

open circuit. Output voltage in

is maximum 3

power

ch.2)

in

7" X

or in amplifier mode. This

presented

be

the

other

response

or in amplifier

complementary lransistors

matched transistors AD

284812.

67/u" high.

is

parallel with two

speakers.

4".

can be

on

channel is connected for recording.

can be continuously

shows

long, I l"

u"

I

Two standard

ohms.

from each

I0 watts in

continuously

fhe

mode. Minimum bass and maximum

lever

the number

114, 6 ea BC 113, 2 ea BC

amplifier. Output voltage in record

volts

open circuit. One standard telephone

each channel. Two standard telephone

DIN loudspeaker contacts are furnished

increase of

channel

starts

or stops

of revolutions of the take-up turntable.

AC 127, AC 128

(alternatively

150

,u"

f

telephone

furnished

are

playback

furnished for

are

increased approx. l2db at 80 c/s

the

which

is set for playback

decreased approx. 1 5

the recording

iacks

for connection

position and

low frequency amplification

or

(alternatively

AD

149

or STF

1078, 2 ea SE6002,

(ch.

I and ch.

connection to head-

or amplification

at I 5 kc/s during

dB

treble correspond to

playback

AC

213).

2) in

to

external

posi-

amplifier

iack

iacks

during

instantly.

127,

i ea

in

for

Page 6

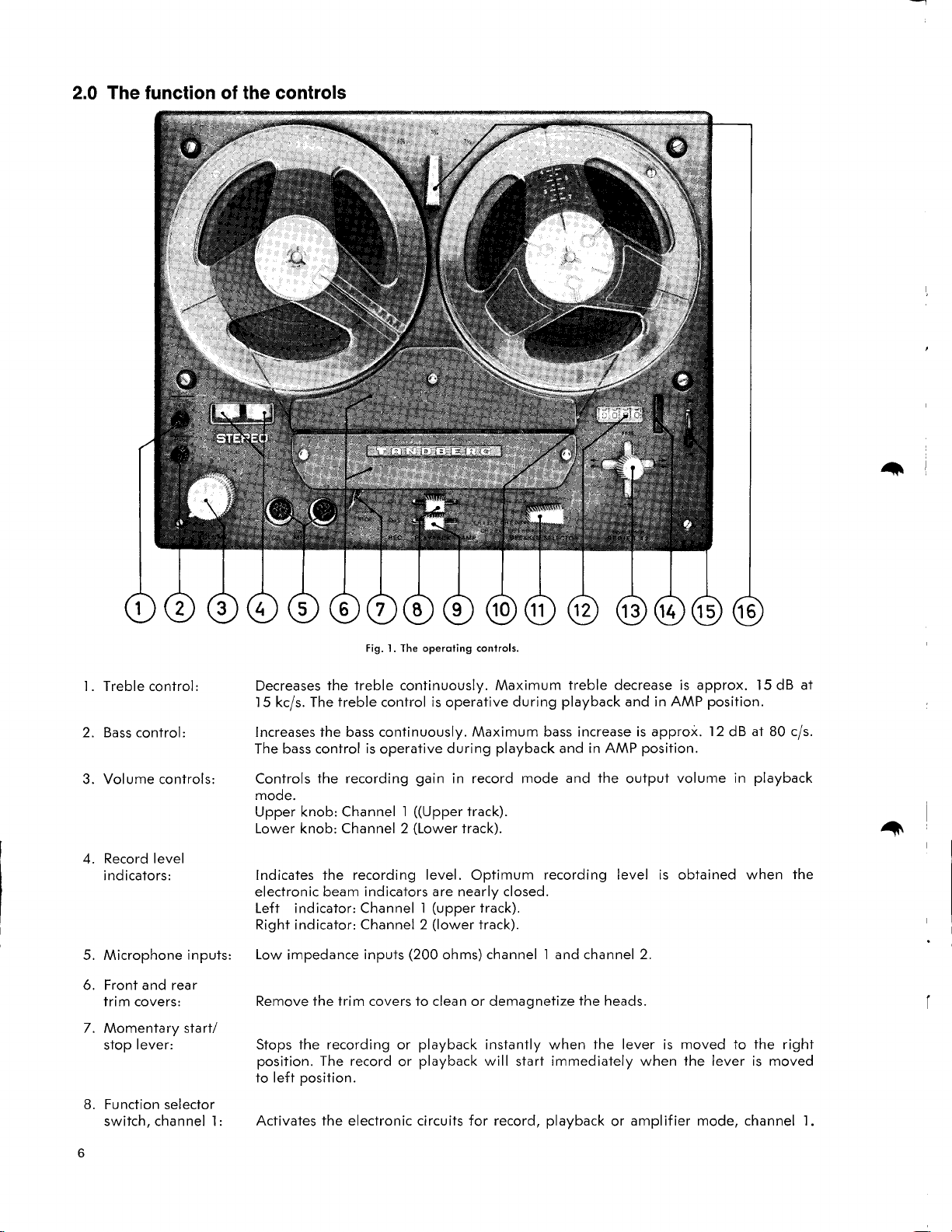

2.0 The function of the controls

,+1

l. Treble control:

2. Bass control:

3. Volume controls:

Record level

4.

ind icators:

Microphone

Front and rear

6.

trim covers:

7.

Momentary start/

lever:

stop

inputs:

Fig. l. The operoling conlrols.

Decreases

l5 kcis. The

lncreases the bass continuously. Maximum

The bass conirol

Conirols

mooe.

Upper knob: Channel

Lower

lndicates the recording level. Optimum

electronic beam

Left indicator: Channel i

Right

Low

Remove the trim covers to clean or demaqnetize

Stops the recording or

position. The record

to left

the treble continuously. Maximum

treble

the recording

Channel 2

knob:

indicator:

impedance

posiiion.

Channel 2

control

is

operative

indicators are nearly closed.

inputs

is

gain

((Upper

1

(Lower

(upper

(lower

(200

playback

playback

or

operative

during

in record mode and

track).

track).

track).

track).

ohms)

during

playback

channel I and channel 2.

instantly when

will

start

treble decrease is approx. l5 dB at

playback

bass increase is approi.

and

recording level is obtained when

immediately

and

the

position.

output

lever is

when

in AMP

the heads.

the

in AMP

position.

l2

at 80 c/s.

dB

volume in

moved to the right

the lever is moved

playback

4,

the

Function selector

8.

switch, channel l:

Activates the electronic circuits for record,

playback

amplifier mode, channel l.

or

Page 7

9. Funclion seleclor

channel 2:

switch

'l0.

Automatic

end

switch:

I

l. Speaker selector

switch.

12.

Tape counter:

stop

Activates

Stops the motor when

the electronic circuits for

the tape runs out or

EXT: External speakers only.

EXT* INT: External

and

internal

INT: Internal speakers only.

CHI EXT,

terminals. The output

CH2

terminals.

Indicates

CH2 INT: The output

CHI INT: The output

EXT,

The output from

position

the

from

the tape.

of

record,

if

playback

the tape

amplifier mode, channel

or

breaks.

speakers.

from CHI is connected to both external

CH2

is

connected

from CH2

to both

is connected

CHI is connected to both

internal

to

internal

speakers.

both

speakers.

external

2.

speaker

speaker

13.

Operating lever:

14. Re-set

;

15. Power

'I

6. Speed selector:

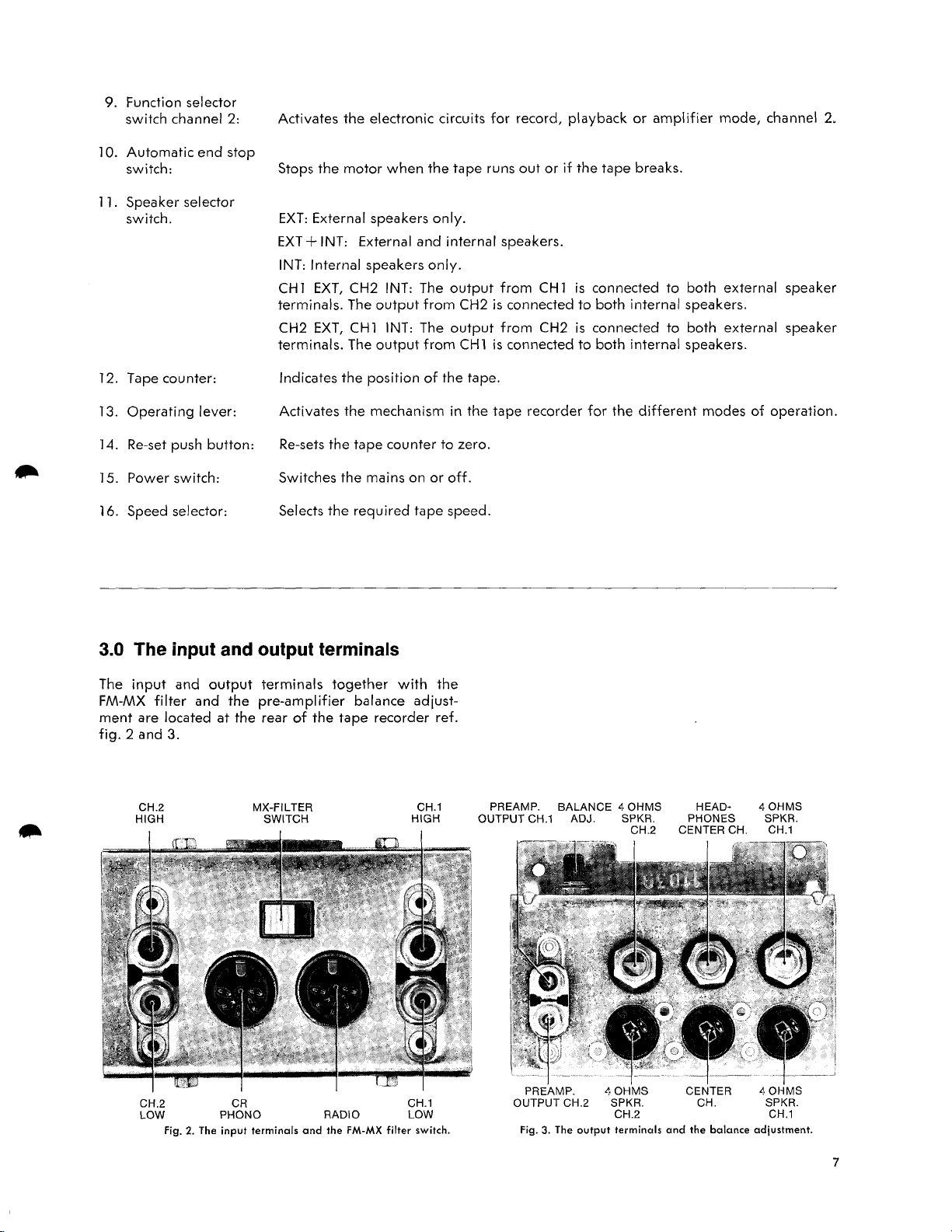

3.0

The

push

button:

switch:

The input

and

input and outpul terminals

FM-MX filter and the

are located

ment

fiq. 2 and

CH.2

HIGH

3.

at the rear

Activates

Re-sets the tape

Switches

Selects the

output terminals

pre-amplifier

of

MX-FILTER

SWITCH

the mechanism

counter fo zero.

the mains on or

required tape

together with the

balance

adiust-

the tape recorder

cH.1

HIGH

a

the lape recorder for the different modes of operalion.

in

.

off

speed.

ref.

PREAMP. BALANCE 4

OUTPUT CH.1

ADJ. SPKR.

OHMS

CH.2

HEAD. 4

PHONES

CENTER CH.

OHMS

SPKR.

CH.1

cH.z

LOW

Fig.

cR cH.1

PHONO

The

2.

input terminols

RADIO LOW

ond the

FM-MX

filter

$;r{ii

switcn.

iqi

:,1 i!

I

PREAMP. 4 OHMS CENTER 4.

OUTPUT

The

Fig.3.

CH.2 SPKR

cH.2

terminols ond the bolonce odiustment.

output

CH.

OHMS

SPKR

cH.1

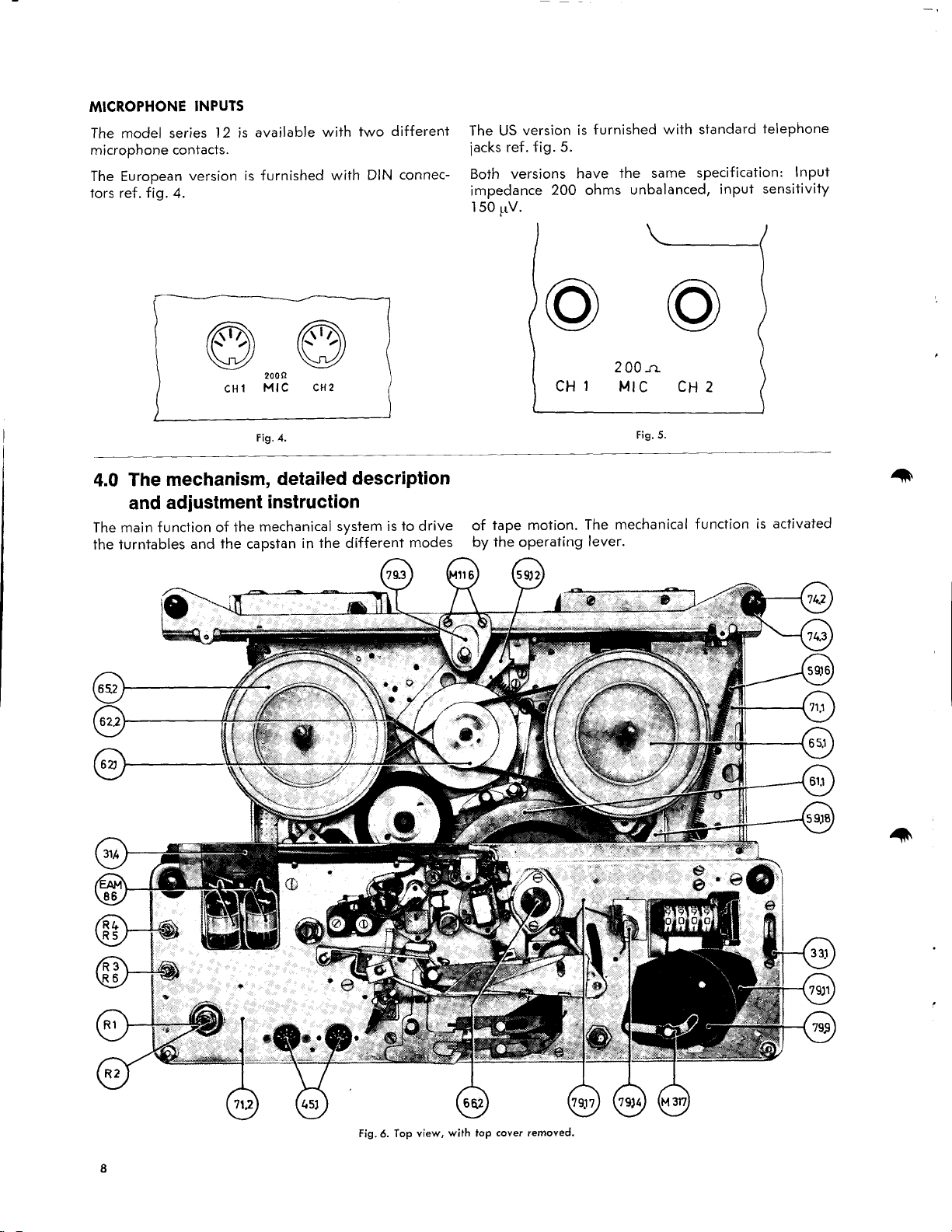

Page 8

MICROPHONE

model series

The

microphone contacts.

The European

tors ref . fig. 4.

INPUT5

l2 is

version is furnished

@)

V

cHt

available

A

((.t

\t/

n

200

Mtc

cH2

with

with

'))

two

DIN

different

connec-

The US

iacks

Both versions

impedance

150

version

ref .

trv.

fig. 5.

200 ohms

furnished

is

the same

have

with standard

specification:

unbalanced,

input

telephone

Inpul

sensitivity

mechanism,

The

4.0

adiustment

and

The main

the turntables

f unction of the

and

Fig. 4.

mechanical

the

capstan

detailed

description

instruction

system is

in the different

to

drive

modes

tape molion.

of

the operating

by

mechanical

The

lever.

Fig.5.

function

$

a

a

ss

+

is activated

{,

F

Fig.

Top view,

6.

wilh lop

cover removed.

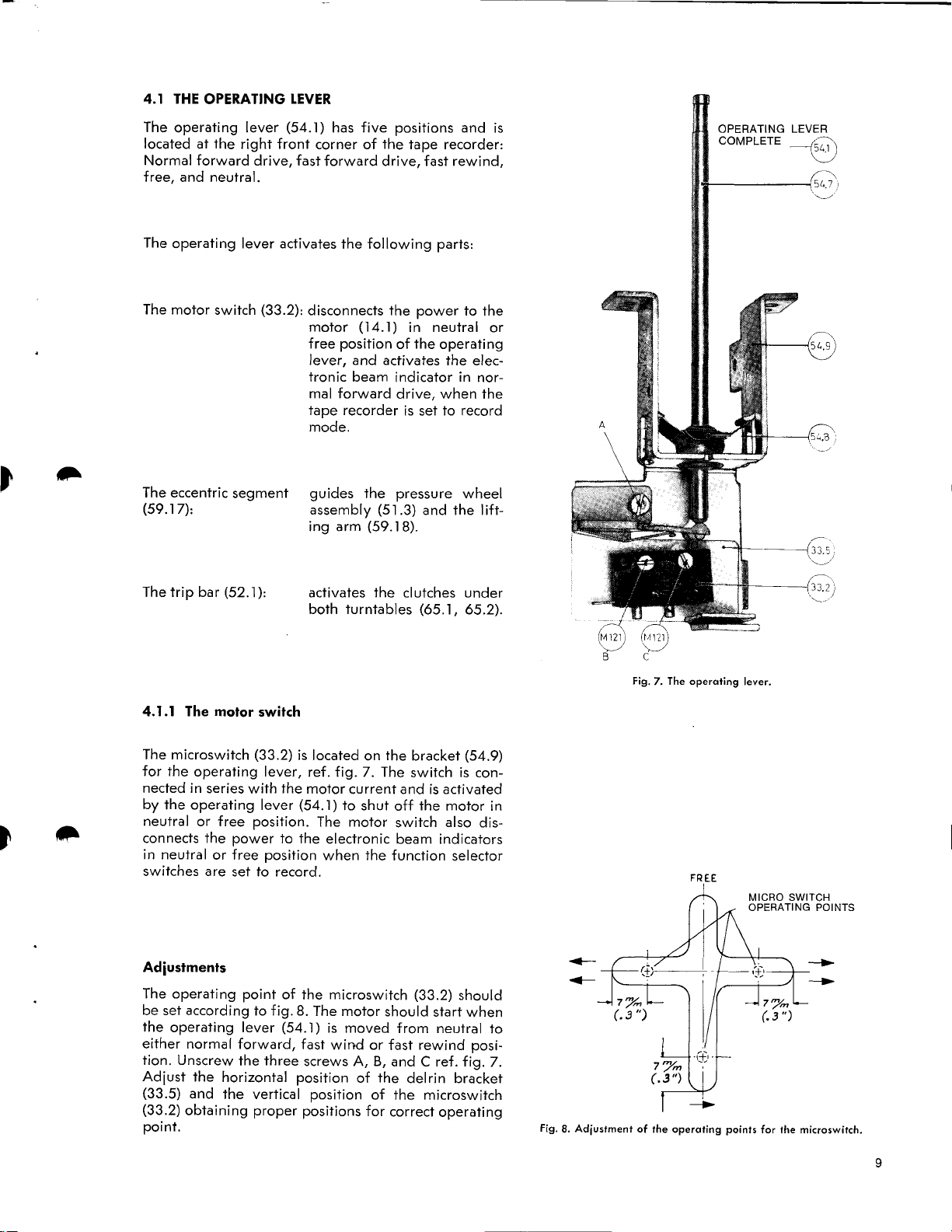

Page 9

4.I THE

OPERATING

LEVER

The

operating lever

located

at

fhe

Normal forward

(54.1)

right front

drive, fast

has five

corner of

positions

the

tape recorder:

and

forward drive, fast rewind,

is

OPERATING LEVER

free, and neutral.

The

operating lever activates

The motor

switch

(33.2):

the following

disconnects the power

motor

free

(14.1)

position

lever, and activates

tronic beam

mal forward

fape recorder

parts:

in neutral

the

of

operating

the elec-

indicator

when

drive,

is

to record

set

to the

in

nor-

the

or

mode.

)

;

The eccentric

(59.17)l

segment

guides

the

assembly

ing arm

(59.i8).

pressure

(5.l.3)

wheel

and the lift-

The trip bar

4.1.1 The motor

The microswitch

for the

nected in

by

the operating

neutral

)

iF

connects the

in neuiral

switches are

(52..I):

switch

(33.2)

is

operating lever,

series

or free

power

or free

lhe

with

lever

(54.i)to

position.

to the

position

set to record.

activafes

the

clutches under

both turntables

located

ref. fig. 7. The

motor

The motor

electronic

when the

the

on

switch

current and is activated

shut

off

switch

beam indicafors

function

(65.1

,

bracket

the

motor in

also

selector

65.2).

(54.9)

is

con-

dis-

Fig.7,

The operoling

IHLL

lever.

MICRO SWITCH

OPERATING POINTS

Adlustments

The operating

be set according

the

operating lever

either normal

tion. Unscrew

Adiust

(33.5)

(33.2)

lhe

and

obtaining

poinl.

point

of

to f i9.8.

(54..|)

forward,

three

the

horizonial

position

ihe vertical

proper

microswitch

the

The motor

is moved

fasl

wind or

screws A, B,

of

position

positions

of the microswitch

for

(33.2)

should

should

start

from neutral

rewind

fast

and C ref .fig.7.

the

delrin bracket

correct

operating

when

to

posi-

Fig.

Adiusimeni

8.

77-

(.

3'.)

of

the operoting

---l>

77^

/ z"\

points

for the microswitch.

Page 10

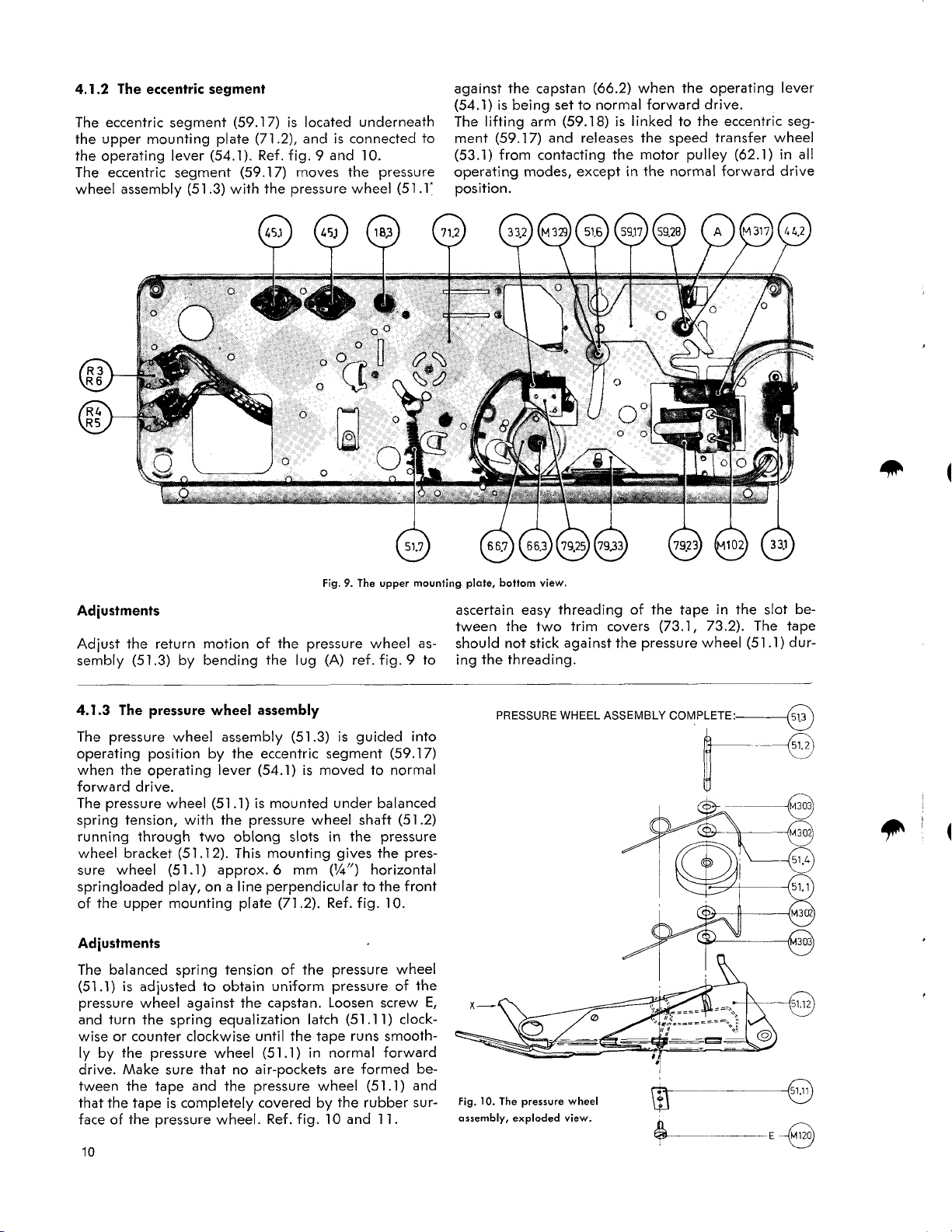

The

4.1.2

The

the upper mounting

the

The eccentric

wheel assembly

eccenlric segmenl

eccentric

operating

segment

lever

segment

(5.|.3)

(59.17)

plate

(54.1).

(59.17)

with

is located

(71.2),

Ref.

fig. 9

moves the

pressure

the

underneath

and is connected

and

10.

pressure

(5

wheel

l.l"

to

against

(54.'l)

The

ment

(53.1)

operating

position.

the

is being set

lifting arm

(59.17)

from

capstan

contacting

modes, except

(66.2)

to normal forward

(59..l8)

and releases the

is

the

when the operating

drive.

linked

moior pulley

in the normal forward drive

the eccentric seg-

to

transfer wheel

speed

(62.1)

lever

in all

+

Fig.9. The upper

Adiustments

Adiust the return

sembly

4.1.3 The

The

operating

when the

forward drive.

The pressure

spring tension, with the

running through two

wheel bracket

sure

springloaded

of the

Adiustments

The balanced

(51..|)

pressure

and

wise or counter clockwise until the tape

ly by

drive.

tween the tape and the

that

face of the

(51.3)

pressure

pressure

position

operating

wheel

upper

is

adjusted

wheel against the capstan. Loosen screw

turn

the

the pressure

Make

tape

the

pressure

motion

by

bending

wheel

by the eccentric segment

wheel

(5LI2).

(51.1)

play,

on

mounting

spring

to

spring

that no air-pockets

sure

is completely

of

assembly

wheel

assembly

(54.1)

lever

(51.1)

is mounted under balanced

pressure

oblong slots in

This

approx.6 mm

a line

plate

tension of the

obtain

equalization latch

wheel

pressure

covered by

wheel.

pressure

the

the

mouniing

perpendicular

uniform

(5

l.i)

Ref. fig.

(A)

lug

(51.3)

(71.2).

is

is moved to normal

wheel shaft

gives

(t/a")

Ref. fig. 10.

pressure

pressure

in normal

are formed be-

wheel

ihe rubber sur-

l0

wheel

ref.

fig.

guided

pressure

the

the

horizontal

to the

(51.1

l) clock-

runs

forward

(5

l.l)

and I1.

mounling plole, bollom

ascertain easy

tween

as-

should

9 to

(59.17)

(5

pres-

front

wheel

of

smooth-

ing

into

1.2)

the

E,

and

Fig.

ossembly, exploded view.

view.

threading of the

the

not

the threading.

I0.

The pressure wheel

two

stick

against the

trim covers

tape

(73.1

pressure

,

tr

in

the slot

73.2). The tape

(5

wheel

I .l

dur-

)

be-

--@

l(

t

10

Page 11

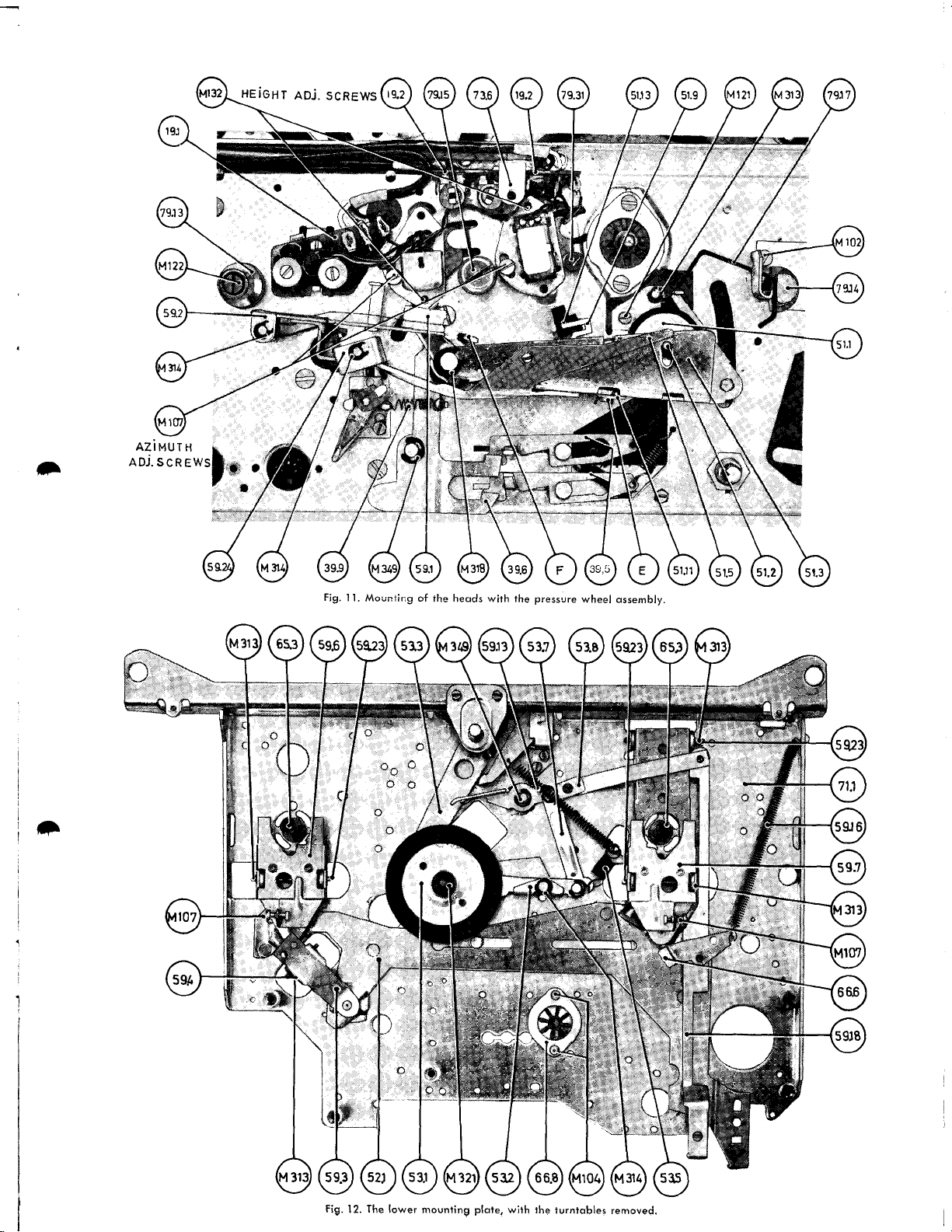

;

tr

AZIMUTH

oii'J'Jil*'),u.,

Fig.

Il.

Mounling of

the heods with the

pressure

wheel ossembly.

Fig.

12.

The

Lb"l

,,*3

xfx

&r

iatg

,4$

s

'?1't.:

lower

mounting plote, wi'lh

the

turntobles

removed,

E/

t

sriQ

uc

Page 12

brake

tape

The

4.1.4

(51.9)

brake

tape

The

assembly

wheel

lever

wheel

prevents

iever

mentary

tion).

Adlustments

Set

and the

tion, with

prevent

pad

Start

stop

should

until

the record/playback

the tape

(54.1)

start-stop

the operating

momentary

the tape

arm

fhe mechanism

lever

be completely

the spacing

(5

1 .3) and

(51.5).

is in normal

tape inserted.

(59.2)

to the

Ref.

from

lever

lever

from

pulled

is

left

between

is located

is activated

fig. I

creeping

forward

in stop

(54..|)

siart-stop

The

creeping

away

moving

by

position. The

disengaged.

head is approx.

inside

l. The tape

when

drive,

position

normal

to

lever

brake

tape

when

from

the

Adiust the

the tape

pressure

the

pressure

the

by

brake

the operating

the

with

(right

forward

to the stop

(51.9)

pressure

the

head.

erase

the

momentary

brake

tape

screw

(5.I.9)

brake

(.08").

2 mm

(51.9)

mo-

posi-

drive

posi-

should

+

start-

(5.|.9)

F

and

The trip

4.1.5

The trip bar

plate

ing

(54.1).

underneath

motion. The

determined

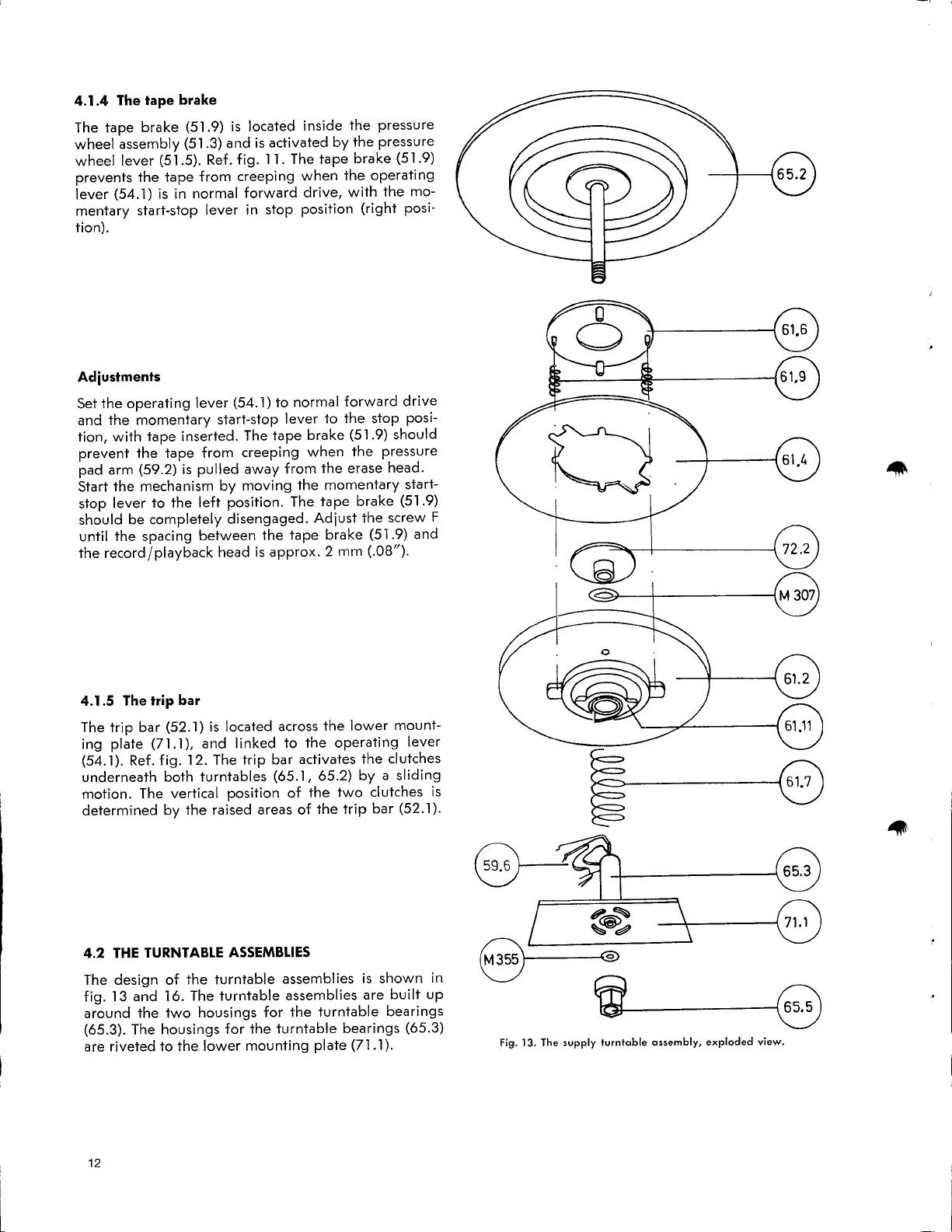

4.2 THE

The design of

fig. l3

around

(65.3).

riveted to the

are

(52.1)

(71.1),

Ref. fig. 12.

both

by the raised

TURNTABLE

and 16.

the two

housings

The

bar

is located

linked

and

trip bar

The

turntables

vertical

position

ASSEMBTIES

the turntable

The turntable

housings

for the

lower

across

to the operating

activates

(65.1

areas of

for the

mounting

65.2)

,

the two

of

the

assemblies

assemblies

turntable

turntable

plate

lower

the

the clutches

by

trip

is shown

are

bearings

(71.1)'

mount-

lever

a sliding

clutches

(52.1).

bar

built up

bearings

(65.3)

is

in

Fig. 13. The supply

@

lurntoble ossembly,

4s

exploded view.

12

Page 13

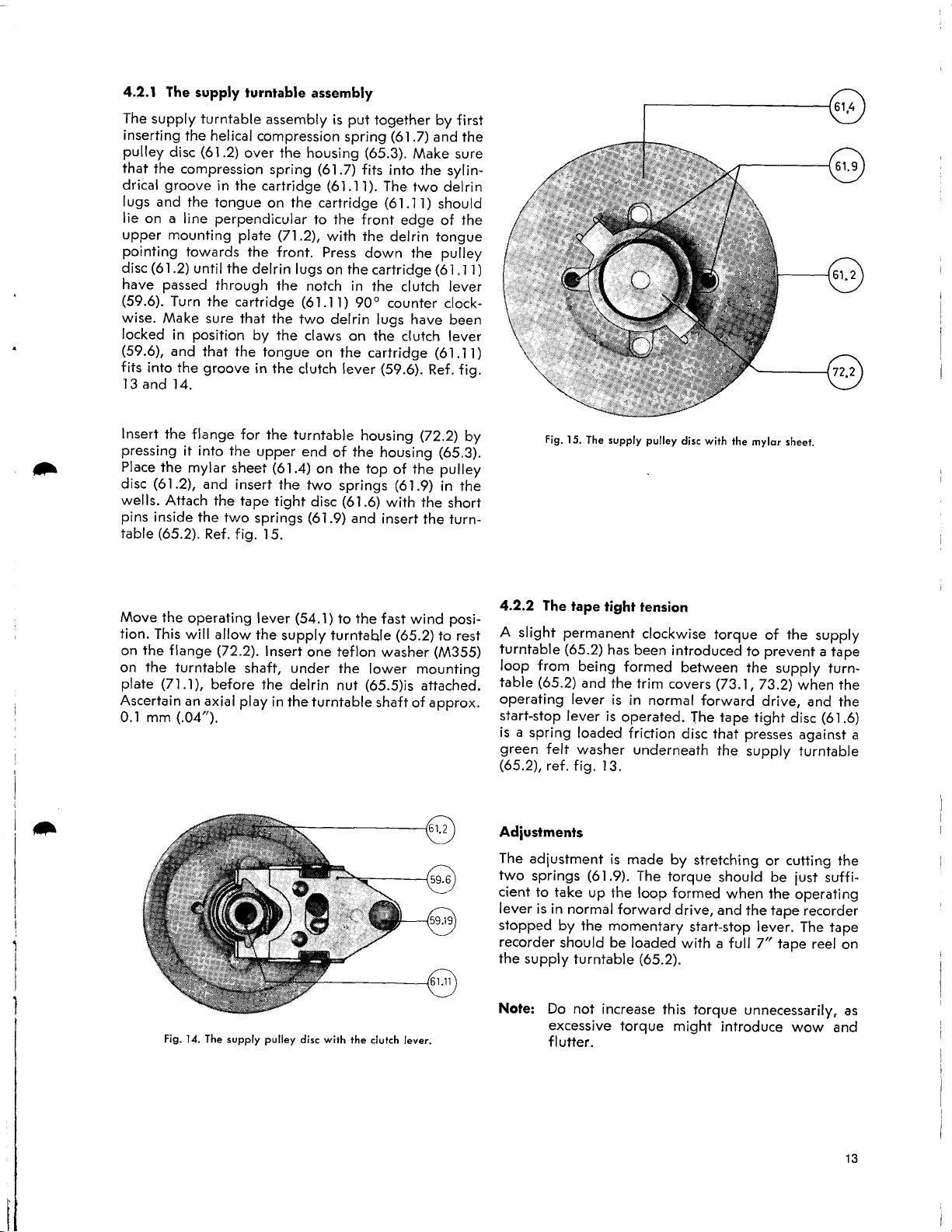

4.2.1 The

The

inserting

pulley

thaf

drical

lugs

lie

on a

upper mounting

pointing

disc

have passed

(59.6).

wise.

locked

(59.6),

fits

into

13 and

lnsert

pressing

-

Place

disc

wells.

pins

table

supply

turntable

supply turntable

the helical

(6.|.2)

disc

the

compression

groove

and

the tongue

line

compression

over the housing

in the cartridge

perpendicular

plate

towards

(61

.2) unfil the

the front.

delrin lugs

through

Turn the

Make

in

and

the

cartridge

sure that the

position

by the claws

that the

groove

in the

14.

the

flange

it into the

the

mylar

(61.2),

Attach

inside

(65.2).

for the turntable

upper

sheet

and

insert

the tape

the

two

springs

Ref.

fig. 15.

assembly

assembly

spring

on

(6i.7)

the cartridge

to the

(71.2),

Press

the

notch in

(61.1

two

tongue

on

clutch lever

end

(61.4)

on the top

the two

tight

disc

(61.9)

put

is

together

(61.7)

spring

(65.3).

fits

(6.|..l1).

into the

The

(61.11)

front

edge of the

with the

delrin

down the

on the

cartridge

the

clutch lever

l) 90o

delrin

counter clock-

lugs

on

the clutch lever

the cartridge

(59.6).

housing

the

of

housing

of the

and

(61.9)

with the

insert

springs

(61.6)

by first

and

the

Make sure

sylin-

two delrin

should

tongue

pulley

(6l

l

. l

have

been

(6l.l

l)

Ref.

fig.

(72.2)

by

(65.3).

pulley

in the

short

the turn-

)

Fig.

15.

The supply pulley

disc

wirh rhe

mylor

sheer.

a

Move

ihe

tion.

This

will allow

the

on

on

plate

Ascertain

0.1 mm

f lange

the

turntable

(71.1),

an axial play

(.0t"1.

Fig. 14. The

operating

(72.2).

shaft, under

before the

supply

(54.'l

lever

the

supply turntable

Insert

one

to

)

teflon

the

in

the

pulley

delrin

nut

turntable

disc wiih

the

fast

wind

(65.2)

washer

(M355)

lower mounting

(65.5)is

attached.

shaft of approx.

the clutch

lever.

posi-

ro rest

4.2.2 The

A

slight permanent

furntable

loop from

table

operating

sfarf-stop

is a

green

(65.2),

(65.2)

(65.2)

lever is

spring

felt

ref.

tape

being

and

lever

loaded

washer

f ig. 13.

Adiustments

The

adiustment

two

springs

cient

to take

lever

is in

stopped

recorder

the supply

Nofe:

(61.9).

up

normal forward

by ihe momenlary

should be

turntable

Do not

excessive

fl

utter.

tight

tension

clockwise

has

been

introduced

formed

the trim

is

in normal

between

covers

operated. The

friction

disc that presses

underneath

is

made

by stretching

The

torque

the loop formed

drive, and

start-stop lever.

loaded

with a full

(65.2).

increase

torque

this torque

might

torque

to

the

(73.1,73.2)

forward

drive,

tape tight

the

supply turntable

should be

when the

the tape recorder

7"

unnecessarily,

introduce

the

of

prevent

supply

when rhe

and the

disc

against

cutting

or

iust

operating

The tape

tape reel

wow

supply

a tape

turn-

(61.6)

a

the

suffi-

on

as

and

13

Page 14

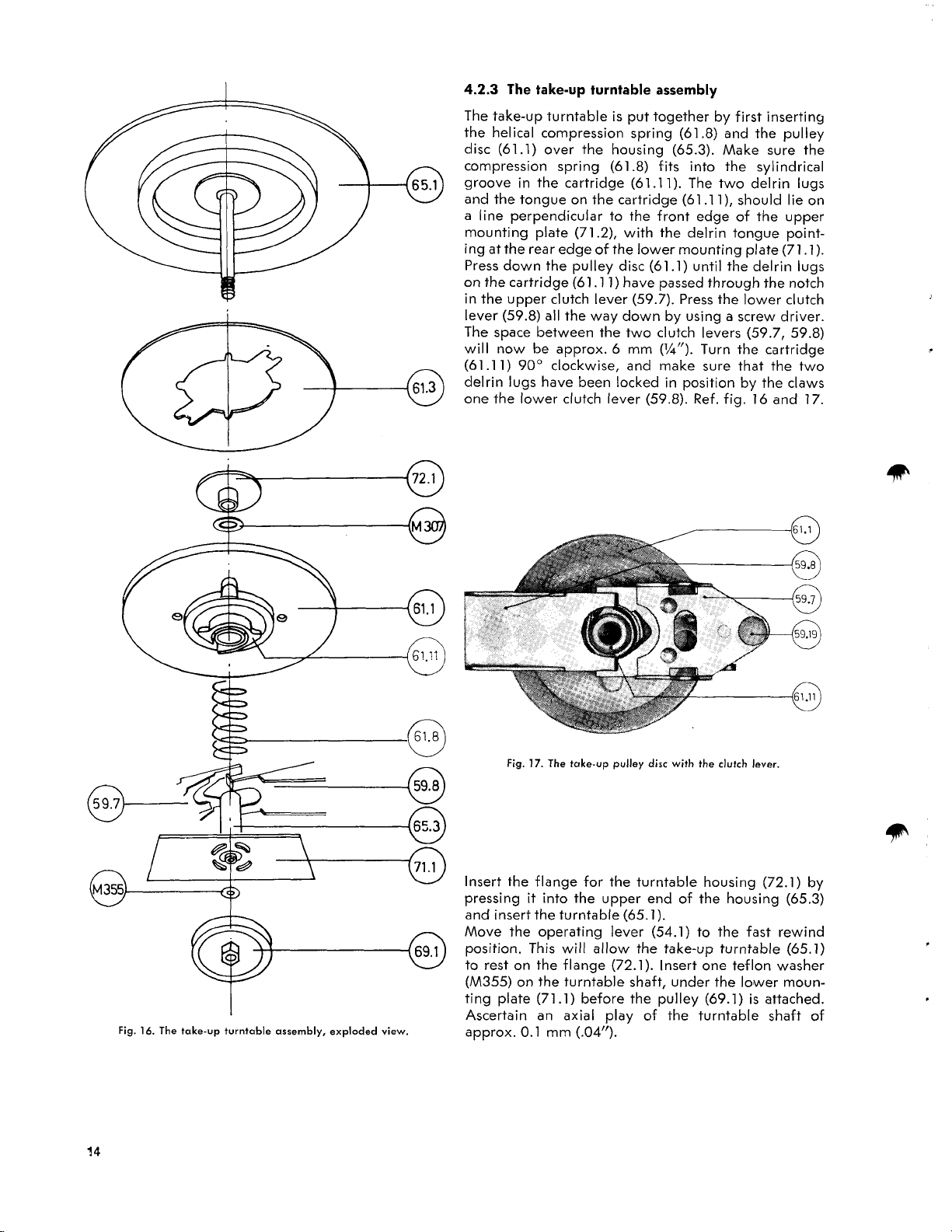

4.2.3 The take-up

The

take-up turntable

the helical

disc

compression

(61.1)

compression

groove

and

a

line

the

in

the tongue

perpendicular

mounting plate

ing

at the rear

Press

down the

on the cartridge

in

the upper

(59.8)

lever

The

space between

will now be

(61.1l)

90o

delrin lugs have

turntable assembly

is put together

spring

over the housing

spring

(61.8)

cartridge

(61.11).

on lhe cartridge

to the front

(71.2),

edge

pulley

(61

clutch lever

all the

with

the lower

of

disc

. I 1) have

(59.7).

way down by using a

the two clutch

approx. 6 mm

clockwise, and make

been locked

one the lower clutch lever

by f irst inserting

(6.l.8)

(65.3).

fits into the

The two

(6.l

I

.l

edge

the

delrin tongue

mounting

(61.1)

until the

passed

through

Press the

levers

Turn the cartridge

1t7o"'1.

sure that the two

position

in

(59.8).

Ref. fig. l6

the

pulley

and

Make sure the

sylindrical

delrin

should lie

),

of

lugs

on

the upper

point-

(71

plate

.l

).

delrin lugs

nofch

the

lower clutch

screw driver.

(59.7,

59.8)

by the claws

and 17.

f

14

Fig.

16. The toke-up

iurntoble ossembly,

exploded view.

Fig.

17. The toke-up

f

the

nsert

pressing

and

flange

into the

it

insert the turntable

pulley

the

for

upper end

(65.1).

turntable housing

Move the operating lever

position.

to rest

(M355)

ting

Ascertain an axial

approx.

This will allow the take-up turntable

the

on

the turntable

on

(71..|)

plate

flange

(72.1).

before

shaft, under the

the

play

0.1 mm

(.04").

disc with

the clufch

lever.

(72.1)

of the housing

(54.1)

to the fast

rewind

lnsert one teflon washer

moun-

lower

(69..I)

pulley

of the turniable

is attached.

shaft of

f

by

(65.3)

(65.i)

Page 15

G

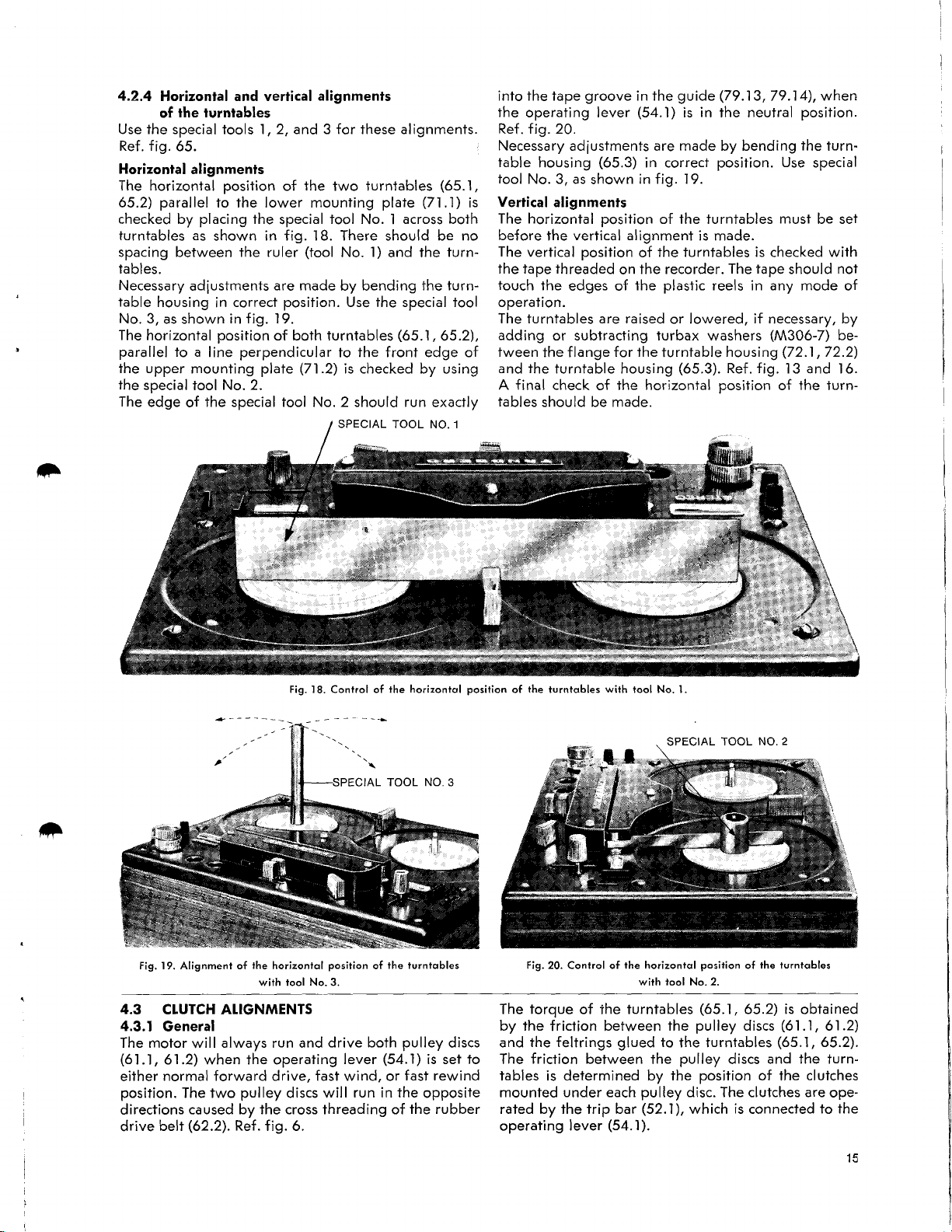

4.2.4

Horizontal and vertical

the turntables

of

alignmenls

Use the special tools I , 2, and 3 for these alignments.

Ref. fi9.

Horizontal

The horizontal

65.2)

checked by

turntables as

spacing between the ruler

65.

alignmenls

parallel

placing

position

of

the

two lurnlables

to the lower mounting

the

shown

special

in fig. lB. There should be no

tool

(tool

No. I

No.

plate

across both

i)

and the

(65..|,

(71..l)

turn-

is

tables.

Necessary

table

No. 3,

adiustments

housing

as shown

The horizonfal

parallel

the upper

the

The

to a

special

edge

of

line

mounting

tool

the special tool No. 2 should run

in

position

No. 2.

are made

correct

position.

in fig. 19.

of both turntables

perpendicular

(71.2)

plate

by bending

the turn-

Use the special tool

(65.1

,65.2),

to the front edge of

is checked by

using

exactly

into the tape

the

operating lever

groove

in the

(54..l)

Ref. fi9. 20.

Necessary

table

tool

Vertical

The horizontal position

before

The

the tape threaded

touch

adiustments are made by bending

housing

No. 3, as

(65.3)

shown

in correct

in fig. 19.

alignments

of the turntables

vertical alignment

lhe

the

position

on

edges of

the turntables is

of

the recorder.

plastic

the

vertical

operalion.

The turntables are raised

adding

tween

and the

A final check

tables

or subtracting turbax washers

the flange

for the

turntable

turntable housing

of the horizontal

should be made.

(79.13,79.1

guide

in

is

the neutral

position. Use

is made.

The tape

reels in any

or lowered,

housing

(65.3).

Ref. fig.

position

4),when

position.

the

special

must

checked

should

mode of

if

necessary,

(M306-7)

(72.1

13 and 16.

of the turn-

turn-

be set

with

not

by

be-

,72.2)

Fig.18. Control of the horizontol

position

of

the

turntobles

wilh

iool No. l.

SPECIAL TOOL NO,2

t

Fig. 19. Alignment of

4.3

CLUTCH ATIGNMENTS

4.3.1

General

The motor

(61..|,61.2)

either

position.

will

when the operating

normal forward drive, fast wind, or

The two

directions caused

(62.2).

belt

drive

the

horizontol

with fool No.3.

always run and

pulley

discs will

by the cross threading of

Ref .

fig. 6.

position

the turntobles

of

drive both

(54.1)

lever

run in the

pulley

discs

fo

is set

fast rewind

opposite

the rubber

Fig. 20. Control of the horizontol

wilh tool

torque

The

by the

the feltrings

and

friction between

The

of the turntables

fricfion between

glued

the

tables is determined by the

(54.

pulley

(52..l),

I

).

mounted

under each

rated by the trip bar

operating lever

position

No.2.

(65.1,

pulley

the

to

the turntables

pulley

position

lhe

of

65.2)

discs

and the turn-

discs

of fhe

disc. The clutches are

is

which

connecfed

turntqbles

is

obtained

(6i.1,61.2)

(65..I

65.2).

,

cluiches

ope-

to the

Page 16

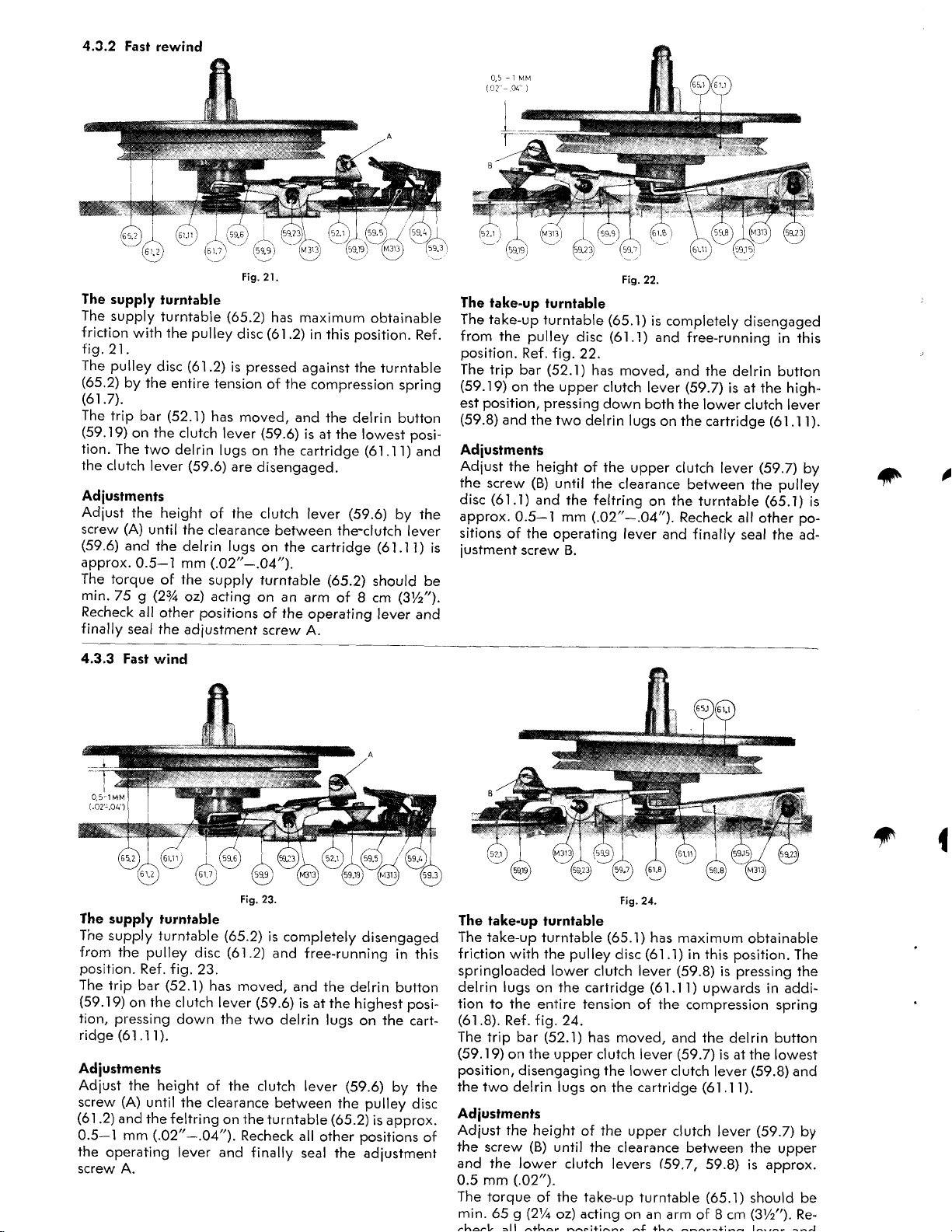

4.3.2 Fast

The supply

The

supply

friction

fi7.21.

The

(65.2)

(61.7).

The trip

(59..|9)

tion.

the clutch

Adiustments

Adiust

screw

(59.6)

approx.

The torque

min.

Recheck

finally

with

pulley

by

lhe

bar

on the clutch

The two

lever

the heighi

(A)

until

and

0.5-l

g

75

all

seal

rewind

turntable

turntable

the

pulley

(6.l.2)

disc

entire tension

(52..l)

has

lever

delrin

lugs

(59.6)

of

ihe clearance

the

delrin

(.02'

mm

the

of

(23/a

other

the

supply turntable

acting

oz)

positions

adiustment

.^.\

:'v

'-^1,

':':'

Fis.

2l

.

(65.2)

has maximum

(61.2)

disc

is pressed

of the

moved,

(59.6)

the

on

are

disengaged.

the

clutch

between

lugs

on

-.04").

on an

of

screw

the

the

obtainable

position.

in rhis

against the

compression

and

the delrin button

is

ai the lowest

cartridge

lever

cartridge

arm

operating

A.

(6.|.1l)

(59.6)

the-clutch

(65.2)

should be

of 8 cm

Ref.

turntable

spring

posi-

and

ihe

by

lever

(6l.l

i) is

(3y2").

lever and

The take-up

The take-up

from ihe

position.

The trip

(59.19)

position,

est

(59.8)

Adiustments

Adiust the

the screw

(61.1)

disc

approx.0.5-l

sitions

iustment

pulley

Ref.

bar

the upper

on

and

the two

height

(B)

and

the

of

screw B.

turntable

pressing

lurntable

disc

fig.

22.

(52.1)

has

delrin lugs

of the

until

the

feltring

the

(.02"-.04").

mm

operating

Fis.22.

(65.1)

is completely

(61.1)

and

moved,

clutch

lever

down both

on the

upper clufch

clearance

on

lever

and

disengaged

free-running

and

the delrin builon

(59.7)

is at the high-

the

lower clutch

cartridge

lever

between

the

turntable

Recheck

finally

all other

seal the ad-

(61.1l).

(59.7)

the

(65.1)

in this

lever

by

pulley

is

po-

f

,

4.3.3

Fast wind

The

supply turntable

The

supply turntable

{rom

the pulley

position.

The trip

(59.1

tion, pressing

ridge

Adiustments

Adiust

screw

(61.2)

0.5-l

the

screw A.

Ref . fi9.

(52..l)

bar

9)

the

on

clutch lever

(61..ll).

the

(A)

and the feltring

mm

operating lever and

down the

height of

until

the

(.02'-.04").

Fig. 23.

(65.2)

(61.2)

disc

23.

has moved,

two delrin

the clutch

clearance

the

on

Recheck

finally

is

completely

and free-running

and

the

lugs

lever

the

(65.2)

other

delrin button

highest

(59.6)

(59.6)

is at the

between

turntable

all

seal the

disengaged

in this

posi-

on the

positions

adiustment

cart-

by rhe

pulley

disc

is approx.

of

The

take-up turntable

The take-up

friction with the

springloaded

delrin lugs

tion to ihe

(61.8).

The trip bar

(59.19)

position,

the iwo delrin

Adiustments

Adiusf

the

screw

and

the lower

0.5 mm

The

torque

min.65

rhorlz

turntable

lower clutch lever

the cartridge

on

entire tension

Ref . fis.

(52.'l)

the

on

upper clutch lever

disengaging the

lugs

the height

(B)

until

(.02').

of the take-up

g(21/t

oz)

Fi1.24.

(65..l)

pulley

disc

24.

has

moved, and the

on the

of the upper

the clearance

clutch

levers

acting

on

has

maximum

(61.1)

in this

(59.8)

(61.1

l) upwards

of the compression

(59.7)

lower clutch

cartridge

clutch

befween the

(59.7,

turntable

an

arm

of 8 cm

obiainable

position.

is pressing

delrin button

is at

the

(59.8)

lever

(6.l.1l).

lever

59.8) is approx.

(65..l)

should be

(3t/2").Re-

The

in addi-

spring

lowest

and

(59.7)

upper

I

the

by

Page 17

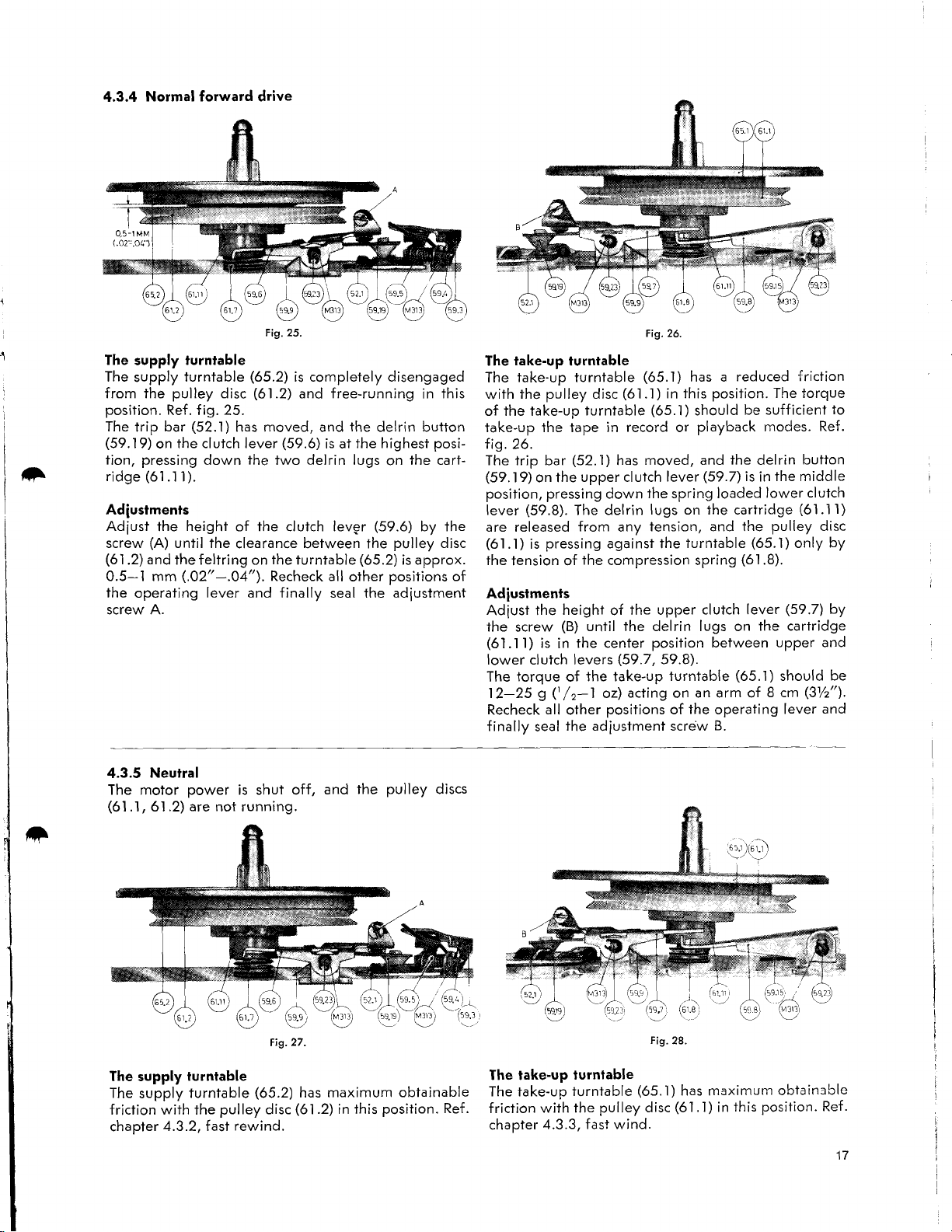

Normal forward drive

4.3.4

Fis.25.

The

supply

The

supply

from the

position.

The

trip

(59.19)

tion,

t

ridge

Adiustments

Adiust

screw

(61

.2)

0.5-l mm

the

operating

screw A.

4.3.5

The motor

(61.1,

turnfable

turntable

pulley

Ref . fig. 25.

(52.1)

bar

on the

pressing

(61.1i).

height

the

(A)

until the

and

the feltring on

(.02"-.O4").

Neutral

power

are

6.l.2)

(65.2)

is completely disengaged

(61.2)

disc

has moved, and

clutch lever

the

down

of the clutch levgr

clearance between the

lever and

and

(59.6)

delrin

two

the

turntable

Recheck all

finally seal the

is shut off,

not running.

free-running

the

delrin button

the highest

is at

lugs

on

(59.6)

pulley

(65.2)

is approx.

positions

other

adiustment

pulley

the

and

in this

posi-

the cart-

by the

disc

of

discs

take-up

The

take-up

The

the

with

of the take-up

take-up the tape in

fis.26.

The trip bar

(59.19)

posiiion, pressing

lever

are released

(61.1)

the

tension of

Adiustments

Adiust the

the

screw

(6.l.1l)

lower clutch levers

torque

The

12-25

Recheck

finally

turntable

turntable

pulley

disc

turntable

(52.1)

upper clutch

on the

(59.8).

The

from

pressing

is

the

height

(B)

until the delrin lugs on

is

the center

in

the take-up

of

(

/r-l

9

all

other

the adiustment screw

seal

Fi9.26.

(65.1)

(61..l)

record

has

down

delrin

any

against the

compression spring

the upper clutch

of

(59.7,

acting

oz)

positions

has a

position. The torque

this

in

(65..|)

should

playback modes.

or

moved, and

the spring loaded

lugs on the cartridge

tension, and the

position

(59.2)

lever

turntable

between upper

59.8).

iurntable

an arm of

on

the

of

operating

B.

reduced friction

suff icient

be

Ref.

the

is

(65.1)

(61.8).

lever

(65..I)

button

delrin

the middle

in

clutch

lower

(61..|l)

pulley

the cartridge

8 cm

disc

only

(59.7)

and

should

131/2").

and

lever

to

by

by

be

t

2l

Fis.

28.

(65.'l)

has maximum

(6

disc

I .l ) in

obtainable

position. Ref

this

.

17

supply

4.3.2, Iast

turnlable

turntable

The supply

The

friction with the

chapter

(65.2)

pulley

rewind.

Fis.27.

has maximum

(61.2)

disc

in this

obtainable

position. Ref .

The take-up

The take-up

f riction

chapter

with the

4.3.3, fast wind.

turnlable

turntable

pulley

Page 18

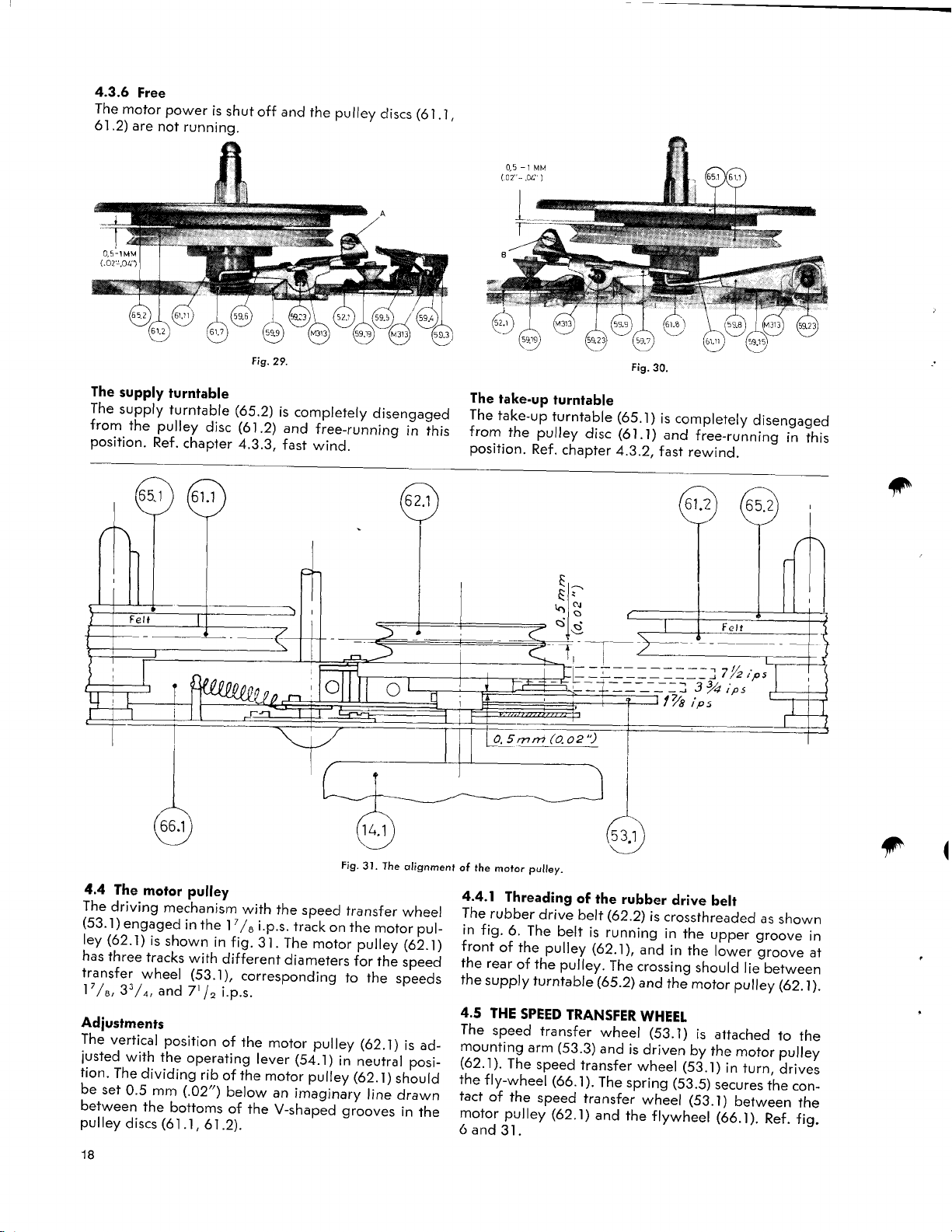

4.3.6

The

motor

6).2)

Free

are

power

not

running.

is

shut

off and

the pulley

(61.i,

discs

The

supply

The

supply

from.the

position.

turntable

turntable

pu-lley

Ref.

chapter

disc

Fig.29.

(65.2)

(6.l.2)

4,3.3,

is

complerely

and

fiee-running

fast

wind.

disengaged

in

rhis

The

take-up

The

take-up

from

the_pylley

position.

O,5mri

turntable

turntable

Ref.

chapter

(o.oz".

disc

Fig.

30.

(65.1)

(61.1)

4.3.2,

fast

is completely

and

fiee-running

rewind.

disengaged

in

ihls

'F

4.4

The

driving

engaged

(62.1)

three

wheel

3'/

u,

vertical

The

sef

0.5 mm

discs

motor

is

tracks

o,

dividing

the

Th-e

(53.1)

ley

has

lr.ultfgl

l'/

Adiustments

The

justed,with

tion.

be

between

pulley

18

pulley

mechanism

in

the

shown

and

position

the

(61

in

with

(53..l),

Zr/,

operating

rib

(.O2")

bottoms

.1

61

,

different

i.p.s.

of the

of the

.2).

with

the

speed

17

/ 6i.p.s.track

fig.3t.

below

of

The

diameters

corresponding

motor

lever

tS+.f

motor pulley

an imaginary

the

V-shapld

Fig.

transfer

on the

moror

to

pulley

in

l

grooves

31. The

olignment

wheel

motor

pul_

pulley (O).t)

ior

the

ipeej

the

speeds

(62.1)

is ad_

neutral

(62.1)

line

posi_

should

drawn

in

the

of

the

motor

pulley.

4.4.1

Threading

The

rubber

in

fig.

front

the

rear

lhe

supply

4.5

THE

The

mourting

\92 ).).

the

f ly-wheel (66.

tact

of

motor

6 and

drive

6.

The

of the.pulley (62.1),

of the pulley.

turntable

SPEED

speed

transfer

arm

The

speed

the

speed

pulley (62.1)

31.

of

the

rubber

(62.2)

belt

belt

is running

The

(65.2)

TRANSFER

wheel

(53.3)

and

rransfer

i

The

spring

).

transfer

and

rhe

drive

belt

is

crossthreaded

in

fhe

und

crossing

and

WHEET

(53.1)

is

driven

wheel

wheel

flywheel (66.1).

upper groove

in

the

should

the

motor

is

by

the

(5i.t)

(53.5)

(53.1)

lower groove

attached

secures

as

snown

liJbetween

pulley (62.1).

fo

the

moior

pulley

in

turn,

drives

the

con-

between

Ref.

the

fiq.

in

at

Page 19

IG

rt

Adiustments

The

speed

mounting

parallel

the

mounting

g1.l)

The

vertica.l

is_adiusted

between

mounting

ing.between

higher

be

approx.0.5

i.P.s. position.

The

vertical

should

of

th.e

flywheet

extra

bearing.

The

horizontal

(53.1)

(5S.2)

9er

(53.1)

4.6

THE

T.he

-design

fig.34.

The.

lifting

and

the

upper

selector

arm

to

the

two

screws

arm

should

be

flywheel

position

by

rhe

arm

speed

position

minimum

be

rransfer

the

track

(66.1)

thrust

washer

Ref.

chapter

is-adiusredLy

runs

adiustmenf

and

alignment

(tool

parailel

I.IFTING

of the

arm

the

lower

jfj']n'''.iT,ll?;t8)

/

\Jy.t

tween

holder (S3.2).

The

wheel (53.1)

anf

rating

Adiustments:

Ref.

Loosen

fer.

ylauatly

the

responding

The

t"nl

ward

before

switch (33.3).

The

the

be

is in

Set

the

justmeni

is

and

33/a

spacing_

adiust

wntte

)

the

lifting

lifting

thg

flywheel

lever

fis.

34.

screw

wheet (53.i)

adjusred

splirs

X,

lifring

is

the

?f.

drive

to

the

motor

clearance

speed

rransfer

minimum

neutral

the

speed

operaring

arm

obtained

the

.and.

between

flywheel

i'1,

is

min.

if

necessary

the

mechanism

from

(54.1)

A.

y

and

to

rhe

occasioned

operating

neufral.

between

3

mm

position.

selector

lever

(53.8)

i.p.t'.

0,5

bracket

for

the

lower

Ml

(53.3)

approx..

"t

adding

for

the

speed.rransfer

o.n

(.O2,'1

mm

of

f

(66.1)

is

titiea,

4.7.

bendins

No.

6)

to

MECHANISM

lifting

(59.18)

arm

mounting

is

linked

parallel

arm

conracrwirh

(66.1)

except

The

lifting

and

rhu

for

the,thruu'rpu"i.'-6y

Z

on

speeds

The

current

wheel (53.f

when

to

neutrli

unril

the

(66.1).

tape

mm

and

re_seal

(29.3)

speed

mounting

l3).

and

tne

or

transfer

rhe

the

rnnn

in

(66.g1)

until

rhe

(59.

transfer

fnu"riru.ing

the

I

mm

.p""j

subtracting-irru.-

wheel

ylt!

(53.g)

releases

holdei

wneet

.otor.

in,n"

speed

t.Oa

)

ti"

Z,'lr-i

ii

ne.J.r.ii,

in

of

the

th;-;;;r;";

rihe

ftywh"Jj-(-oZ.;;'

mechanism

the

is

plates

t".

*,"

arm (53.2)

lg)

and

tnurnorolp,lley

in

porir-ionsTt

ulf

normal

between

;;;,.

rhe

liftini

7,

1",

Uy

u'iufJi*ly"'Jmall

(54..1)

lever

lifting

,nortJ

is

siut

the

motor

ar

1

rh"

;p;r;;ffiJver

t/u

to

l

i.p.s.

piriii."Ii*n

a

.p..inl

speed

trJnsfer

irr"

rn"

speed

1.0),,1

and

for

tf.'r"

uJirrt,i"it

is

adiusted

plate (it.J)

".ounting

lo*"r.

(.O4,,).

tru*f"l,rn"el

(SC.Z)

(SS.Sl.

*n""fijg.rf

frtt-uy'iur..,) should

i;/.-i.p.s.

transfer

il"i"*

ps.

the'O*LI.

speed

transfer

,puJ'rr""nrter

\

parailel

rocateJ

(Zl

..i""iri.

is connected

the-tia-nsfer

the

speed

forward

the

;rii"vi#.U

until

rarheel

(53.3)

(unscrew

between

n"t.

f ig.

washers

and

The

and

and

wheel

in"

upper

position.

Ui

addins

flywheel

wheel

wheet

wheel

is

shown

(53.7)

arm

between

.2,71.1)-The

,esrn"nt

wheel

transfer

(62.1)

,h"

drive.

speed

trans_

is

indi_

U"naing

arm

i"lo

6,0.]A), .or-

unJ

t1u-'i.p.r.

move-

from

normal

["

.if-JV

pulley

afl

.ompleted

the

(62.1)

speJds

should

micro_

t5a.t)

tape

speed

and

rhe

ol

O,i'^^

1.92,1

wheet (S3.1)

,plej'."tu.tor.

check

that

Ool.,

pt.itlons.

the

Re_

r.rurar

the

the

plate

Sa.

(53..|)

the

spac-

rhe

33la

(53..1

rim

The

an

hot-

in

the

be_

opu_

for_

and

ad-

to

n.

is

)

Fi9.32.

flywheel

the

beorings,

exploded

The

with

view.

Page 20

THE CAPSTAN

4.7 THE FTYWHEEL

The flywheel shaft

mounted in two selflubricating

(66.3).

inss

Ref. fig. 32.

WITH

acts

as

the

capstan

and

selfadiusting

(66.2),

and

bear-

is

Adiustments

The vertical

the

with

as shown

stan

two

The

tion of

legs of

(71.2).

plate

4.7.1 The brake for

The brake spring

attached to the

wheel

The brake is engaged

(54.1)

lever

position of the capstan

special

screws

the capstan

the

(59..l8).

tool No. 5 inserted on

in f ig. 33.

(M.l25)

(66.2)

tool No. 5 touches

the

(66.6)

lifting arm for

Ref. fig. 6.

except

normal

are loosened,

is

obtained

the upper

flywheel

for

the

the

positions

in all

forward drive.

(66.2)

is

top of the cap-

and correct

when

mounting

flywheel

speed

the operating

of

aligned

posi-

all three

(66..l)

is

transfer

Fig.

Alignment

33.

of the copslon

wiih tool No. 5.

1

20

Fig.34. The speed

f

chonge mechonism.

Page 21

,t

4.8

THE SPEED

The

speed change

in fig.

34.

The

speed

lowest

mounting

pressed

disc

The

from

zontally

(53.4)

horizontal

arm

of

presses

fer

track

against

(59.1.l)

speed transfer

the

approx.

is

turned

(59.

12),

the

cam

against

wheel

@

\

\

CHANGE

mechanism

transfer

arm

in

motor pulley

movement

disc

(53.3)

wheel

on fhe

for the

the lowest

the 1?

/s

wheel

1",

when

towards Ihe

is accomplished

which

roller

(59.1l).

the mounting

point

in

MECHANISM

is

designed

(53.1)

is

engaged

motor pulley

speed

transfer

(level

level

posirion.

i.p.s.

(53.1)

(62.1),

rests

The cam

D.

will

and

the

speed

33/t i.p.s. position.

against the

arm

for

as shown

(62.1),

moved

by the

disc

the

with

and

(53.3)

wheel

a)

on the

be disengaged

out hori-

selector

cam

curvature

(59.12)

arm

speed trans-

the

the

is

cam

knob

This

disc

is adiusted

(59.12).

alignment.

4.9 THE

The

signed as

The

sure wheel

lever

wheel

(5.l.2)

capstan

Adiustments

Move

position

Remove

MOMENTARY

momentary

shown in fig.

delrin

(33.11)

lever

with the

(66.2)

the

and

by

bending the

the

start-stop

bushing

lever

operating

(33.9)

(5

1.5)

is moved

(51.5)

moves

pressure

and activates

set the

nose

of

motor pulley

START.STOP

35.

will

point

in

to

stop

the

wheel

lever to normal

momentary

(62.j)

mechanism

press

B when

position.

pressure

iSt.l)

the

tape

start-stop

the

cam

to make

FEATURE

(33.4)

against

brake

the

the

start-stop

The pressure

wheel

away

from

(51.9).

forward

disc

is

pres-

shaft

drive

lever

arm

this

de-

the

in

ttr

The

vertical

lransfer

the

cam

slope presses

fer

wheel

position)

rotation

Adiustments

The

spacing

(59.12)

wheel

lifting

wheel

disc

(53.3)

to

the

of the

and

the

(53.3)

(59.

at point

should

of

(53.3)

11)

the

mounting

upwards

Ievel

speed

mounting

be 0.5

the mounting

is accomplished

between

from the

(3,

b

/ o

selector

D between

arm

mm

arm

the

levels

arm

for the

level

i.p.s. position)

(53.4).

knob

the

for

ihe

(.02',)

Fig.35.

The

for

by the

a

speed transa

cam

speed

wiih the

momentory

the speed

slope

of

and b.

(lz,/6

during the

i.p.s.

disc

arm

transfer

operar-

The

stqrf-stop

mechonism.

ing

lever

<STOP>>

(5-1.5)

by

of approx.

(51.1)

approx.0.2

lever

Start the

the

(51.5)

approx.

shaft

point

sure wheel

is approx.

and

(5i.5)

left

by

(St.2)

D.

(54..l)

position.

bending

0.5

the

mechanism

posifion.

bending

I

mm

Make

lever

0.5

normal

in

mm

capstan

(.O12")

mm

and

the

Adiust

the

(.04")

and

the pressure

sure

(5

(.O2").

mm

forward

Adiust

the

(.02")

I .5)

the

f lat

between

(66.2).

between

transfer

by moving

lhe

tongue

between

that

the

and

pressure

part

B

Ascertain

bracket

the

pressure

C

to obtain

the

wheel

space

fhe

start-stop

drive.

The

wheel

to obtain

pressure

ihe

pressure

the

(59.24).

start-stop

wheel lever

a

pressuie

lever

between

lever

spacing

lever

a spacing

wheel

play

a

spacing of

the

wheel

lever

wheel

(5i.5)

pres-

(33.1

of

to

21

at

I

)

Page 22

4.IO THE

The

erase

erasure, and

when

drive.

(59.2)

and the transfer

(59.27)

in normal forward drive,

all

in

Adiustments

The

sionally, as

particles

tape movement.

Note: Do not soak the

The spring

signed

by bending

from

The tension of

erase head,

be 75-100

by

pressure pad.

PRESSURE

pressure pad

head and

to ensure constant

recorder is operating

the

fig. 11 and 35.

Ref.

is activated

pressing

is

positions

oiher

pressure

the accumulation

might seriously

with felt for

as a snap-on type,

the two tags on

the

slots

in normal

g

adiusting

the

PAD

(59.27)

is introduced

the

by

bracket

against

of

(59.27)

pad

pressure pad

the

in

pressure pad

the

forward drive

(25/e-3Vz

tension

is located

to

friciion

in

pressure

The

pressure wheel

(59.24).

the tape

and

the

operating

affect

pad

felt

the

and

the

oz).

of

and the

is completely

should

of dust

the

with

pressure

can easily

hard brass spring

arm

(59.27)

tension

This

the spring

front of

in

secure

The

be cleaned

maximum

for the

normal forward

pad arm

(5

lever

pressure

erase

disengaged

(54'1).

lever

iron oxide

and

erasure and

any liquid.

(59.1)

pad

pulled out

be

(59.2).

against

position,

(59.14)

should

is corrected

for

the

tape,

1.5)

pad

head

occa-

the

is

de-

away

the

the

actuating spring

The

guide

adiusted

point

The vertical

adlusted

spring

Misalignments

of

out

Ascertain

the actuating

of

cover

,

without sticking.

slot

to 2

Ref. fig. 36.

B.

position

shown in

as

should

the tape

sufficient

(73.1)

when

/D

shall run

(.08")

mm

of the

fig. 37. The

approx. 3

cover

cause the

could

guide.

clearance

spring marked

tape is

inserted.

free inside

widih of

The

by bending

vertical

mm

tape

D and

spring

('

/

actuating

between

the tape

slot

the

the bracket

(79.17)

part

of

of the

u")

to be

squeezed

the upper

the front

is

in

is

the

tape.

part

trim

rc

THE AUTOMATIC

4.I I

The actuating spring

located in the slot

is

The microswitch

mounting

The microswitch

runs out

tape

independent upon

(54.

r

).

(33.2)

(71

plate

.2)

(33.2)

if the tape breaks.

or

the

Adiustments

The

operating

bending the

ed by

Ref. fig. 36. The

in f ront of

(79.17)

spring

the front of

Fig.36.

point

actuating spring

operaling

the imaginary

is moved from

the upper mounting

Horizoniol

END STOP

(79.17)

of the right

is mounled

fig. 9 and 11.

ref .

shuts off

position of the operating

microswitch

of lhe

SWITCH

for the

iape

the

end stop

guide

under the

motor when

The swilch

(33.2)

(79.17)

point

is set 0.5

the actuating

line x-x,

odiustment of the

when

the rest

plate

end stop switch.

position lowards

(71.2).

switch

(79.14)'

works

adiust-

is

point A.

in

mm

upper

the

lever

(.02")

odiusfment

Verticol

Fig,37.

4.12 THE

The revoluiion

upper

hind the operating

driven

attached

Ref. fig. 9 and

Adiustmenls

The

mounted

(69..|)

(79.8)

vertical

belt

4.13 ASSEMBTING

The top cover

fig. 38.

Vertical alignment of

Two thick rubber washers

between

tightening lhe

will

adlustment of

The vertical

ed

tape

REVOTUTION

counter

the lower mounting

and

by a rubber

to the

pulley

is

for

position

(69.3)

be compressed

to ascertain

reels and the

shaft

53.

disc for

with the

flush

mounted tight

the take-up turntable.

of

to fall

off.

is

attached

the top cover

two screws

the top cover.

position of

sufficient

COUNIER

(79.23)

lever

(69.3)

belt

of

the revolution counter

counter shaft.

pullies might cause

the

THE TOP

the

and the mounting

and

the top cover should

fop cover in all

rhe

of

end stoP

is located

plates

(54.1).

The

and

the take-up turntable

up against the lock

Misalignment

COVER

to the recorder

lop cover

(74.5)

have been

(M.l30)

allow the

Ref. fig. 38.

spacing

switch'

between

(71

.2,71.1),be-

disc

pulley disc

The

the rubber

as shown