Symmons S-3500 Service Manual

Dia™

Dia™

Tub-Shower Systems S-3500, S-3501, S-3502 Series

Installation and Service Instructions

Model Number Series

S-3502.......... Tub-Shower System S-3502-X....... Valve includes stops S-3502-TRM. Trim only

S-3501.......... Shower System S-3501-X....... Valve includes stops S-3501-TRM. Trim only

S-3500.......... Shower Valve System S-3500-X....... Valve includes stops S-3500-TRM. Trim only

S-3500TS...... Tub-Shower Valve Sys. S-3500TS-X.. Valve includes stops

Need Help?

Symmons customer service: (800) 796-6667, (781) 848-2250

customerservice@symmons.com Mon - Fri 7:30 am - 7:00 pm EST

www.symmons.com/service

•Technical help

•Product information

•Warranty policy

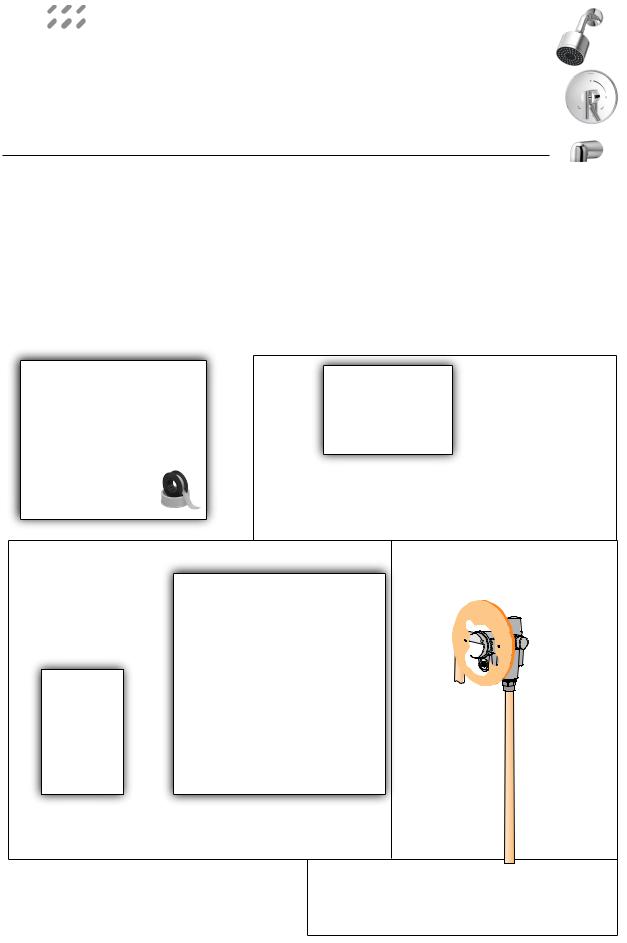

Visual Guide Dia Tub-Shower Systems, S-3500, S-3501, S-3502 Series

Tools & Materials |

Arm and ange |

|

300S |

3/32"

1 |

2 |

3 |

4 |

Model Series

S-3500 S-3502 S-3500-X S-3502-X S-3500-TRM S-3502-TRM

S-3501 S-3500TS S-3501-X S-3500TS-X S-3501-TRM

|

Showerhead |

|

352SH |

|

Mounting |

|

plate, T-177 |

Screwless escutcheon kit |

Temp Limit |

RTS-011, brass |

stop screw |

RTS-012, plastic |

|

Handle kit |

|

|

HOT |

|

T-242A |

|

|

||

|

|

|

supply inlet |

|

|

Dome |

Escutcheon |

Escutcheon |

|

3/32" |

cover |

|

mounting plate |

|

|

|

|

||

Volume control handle |

|

|

|

|

or diverter handle |

|

|

|

|

RTS-013, brass |

|

|

|

|

RTS-014, plastic |

|

|

|

|

Note: Piping, ttings and tools are not included. |

Tub spout |

|||

Actual plumbing should be determined and |

||||

067 |

||||

installed by a licensed plumber. |

|

|

||

|

|

|

||

Protective valve shield (not shown) T-176 |

|

|||

Model Series

S-3501

S-3501-X S-3501-TRM

S-3502

S-3502-X S-3502-TRM

Temptrol® Control Valve

S-4001-BODY S-4001-X-BODY S-4002-BODY S-4002-X-BODY

COLD supply inlet

Model Series S-3500 S-3500-X

S-3500TS S-3500TS-X

S-3501

S-3501-X

S-3502

S-3502-X

Model Series S-3502 S-3502-X S-3502-TRM

Installation Instructions

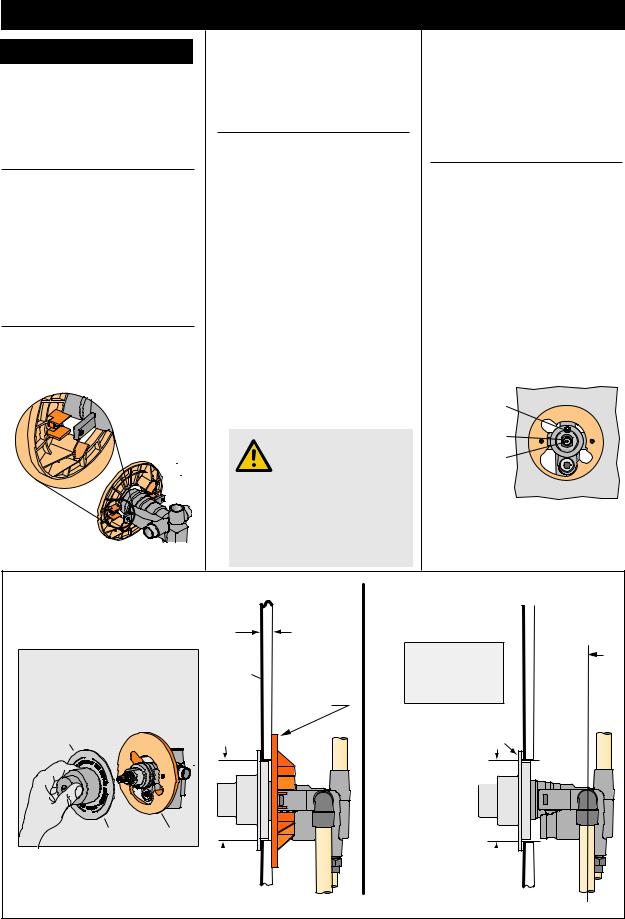

Rough-in Installation

Control valve assembly, piping and fittings (Note: Illustrations below show valve model without stops)

Reference as required: |

Page |

Visual guide.................................... |

1 |

Dimensions illustration................. |

4 |

1)Determine wall thickness

■■Determine type of wall and wall thickness where valve will be mounted.

■■Consider whether to use mounting plate by reviewing figure 2 below.

■■Skip ahead to Step 3 if mounting plate is not used.

2)Attach valve mounting plate

Seat mounting plate against valve assembly as illustrated in figure 1.

Figure 1 Mounting plate

3)Attach protective shield

■■Reference figure 2 to determine whether shield is required.

■■Attach protective shield by snap fitting over end of valve spindle.

4)Install piping, fittings and control valve

Piping and fittings not supplied

■■Control Valve

Install through cutout hole in wall as specified in figure 2 below and dimension illustration on page 4.

■■Showerhead (S on valve)

Pipe from outlet port on valve marked S to showerhead mounting arm location.

■■Hot & Cold Supply (H & C)

Pipe hot water supply to valve inlet marked H and cold water supply to valve inlet marked C.

■■Tub Spout (T on valve)

Pipe from outlet port on valve marked T to tub spout.

Important! Do not substitute Tub Spout with restrictive fittings such as

PEX, CPVC or outlet accessories such as a ledge spout, hose and spray that would subject the valve to excessive internal back pressure, otherwise operation will be compromised.

5)Remove protective shield

If protective shield was attached in Step 3 then remove shield snap fitted over the end of valve spindle once valve is securely installed and wall finish work has been completed.

6)Adjust valve packing nut

Reference figure 3 below

■■Turn hot & cold supplies on. Valve will not operate unless both hot and cold water supply pressures are turned on.

■■Place handle over end of control spindle stem.

■■Adjust packing nut for positive frictional resistance as handle is rotated from shutoff position across adjustment range.

Temp Limit |

|

stop screw |

|

packing nut |

|

control |

|

spindle |

|

stem |

wall |

Figure 3 Valve adjustments

Walls for using T-177 mounting plate

Fiberglass or acrylic walls (required)

Plaster or other type walls (optional) 1/16" (2 mm) min 1/2" (13 mm) max

Protective shield |

nished |

When mounting plate is used, |

|

then shield is optional for |

wall |

protecting end of valve during |

|

installation. |

|

"snap on-off" |

|

p/n T-176 p/n T-177

wall cutout hole size  3-1/2" (95 mm) min

3-1/2" (95 mm) min

4" (101 mm) max

Ensure valve’s mounting plate is ush against inner wall

Dry wall, plaster or other type wall

1/2" (13 mm) or greater

nished wall

nished wall

2-3/8" ± 1/2"

(60 mm ±13 mm) pipe centerline to nished wall

Finished wall must beush with back side of protective shield surface

Protective shield

"snap on-off"

(required when mounting plate is not used)

wall cutout hole size  3-1/2" (89 mm) min

3-1/2" (89 mm) min

4" (101 mm) max

Figure 2 Mounting valve

Page 2

Loading...

Loading...