Symmons 4-10A Service Manual

Mechanical

Mixing Valve

4-10 Series

INSTALLATION, OPERATION AND SERVICE INSTRUC-

TIONS

4-10C

Same as 4-10A except with 1/2” IPS tempered outlet connection

Temperature Selection

The temperature of 4-10 Mechanical Mixing Valve is adjusted by inserting a 1/4” hex key (not supplied) into the temperature adjustment slot in mixing valve and turning the key either clockwise or counter-clockwise. Turning the handle clockwise decreases the output temperature of the unit and turning the handle counterclockwise increases output temperature.

4-10A

The 4-10A Mechanical Mixing Valve is furnished with all ferrule fittings attached. To install, remove the three (3) nuts and ferrules from the unit and install 3/8” copper tubing into compression fitting nipple. Flexible braided stainless steel hose will also fasten to the 9/16 – 24 thread of the compression nipple once the nuts and ferrules are removed. Slide the nut and then the ferrule over the copper tubing in preparation for tightening. Torque the nut onto the compression nipple so as to compress the ferrule around the tubing. The nut should be tightened so as to prevent any leaks by the ferrule. HOT water is supplied to the left side of the valve (when looking at the adjustment handle) and COLD water is supplied to the right side.

System Cleaning

The integral checks installed in the 4-10 mixing valve should be kept clean to insure proper operation of the unit. Unwanted debris may cause the checks to remain open and allow a cross connection of hot and cold water. To clean checks, shut off water supply to the unit. Remove mixing valve from piping assembly and prepare for check removal. Unthread the threaded nipple from the body using a 5/16” HEX key. Dislodge the rubber washer from the threaded hole using a small flat blade screwdriver. Insert the screw driver or needle nose pliers into the small hole in the plastic insert and gently remove. The duckbill check will remove with insert. Clean checks or replace with MV-107 repair kit as needed. Reverse instructions to re-install checks into main body.

4-10B

The 4-10B is installed similar to the 4-10A valve, except a 3/8” compression tee is supplied to deliver COLD water both to the mixing valve and to the cold side of a fixture. The ferrule fittings of the compression tee are secured exactly like those of the mixing valve.

Compliance:

-ASME A112.18.1/CSA B125.1

-NSF 372 (CA 116875)

-NSF 61.9

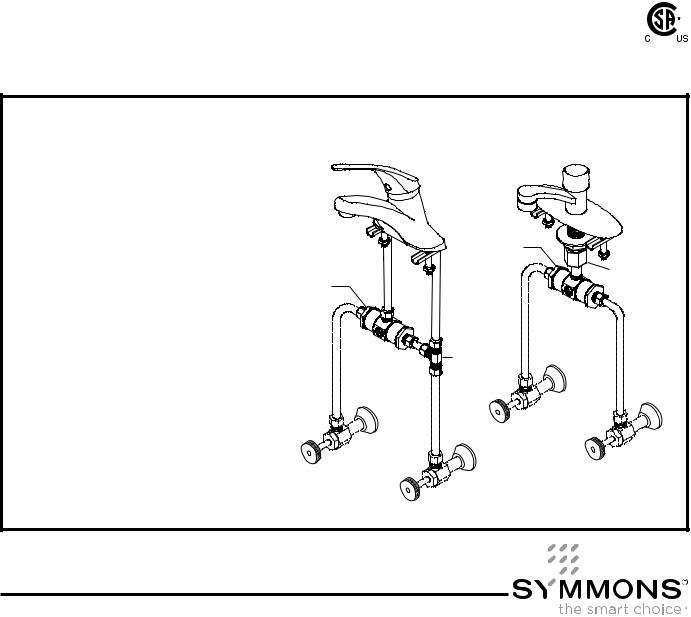

4-10A Mechanical Mixing Valve with 3/8” compression connections and (2) integral checks (piping not supplied)

4-10B Mechanical Mixing Valve with 3/8” compression connections, (2) integral checks and 3/8” compression tee (piping not supplied).

Symmons Single Lever Faucet |

Symmons Metering Faucet |

Typical |

Typical |

(faucet not included) |

(faucet not included) |

4-10C

(2) 3/8” compression connections

4-10B |

1 |

/2 |

” |

3/8” compression |

|

||

connections |

IPS connection |

||

|

|

|

|

4-10C Mechanical Mixing Valve with (2) 3/8” compression connections and (1) 1/2” IPS connection.

Note 1/4” Hex Key (not supplied) used to adjust temperature

3/8”

compression tee

Symmons Industries, Inc. 31 Brooks Drive Braintree, MA 02184 (800) 796-6667, (781) 848-2250 Fax (800) 961-9621, (781) 843-3849

Website: www.symmons.com Email: customerservice@symmons.com

©2013 Symmons Industries, Inc. Printed in U.S.A. ZV-353 111813

Loading...

Loading...