Suzuki SV1000 2003-2005 Service Manual 2 Periodic Maintenance

PERIODIC MAINTENANCE

CONTENTS

PERIODIC MAINTENANCE

2-1

0

PERIODIC MAINTENANCE SCHEDULE

PERIODIC MAINTENANCE CHART

LUBRICATION POINTS

MAINTENANCE AND TUNE-UP PROCEDURES

AIR CLEANER

SPARK PLUG

TAPPET CLEARANCE

FUEL HOSE

ENGINE OIL AND OIL FILTER

ENGINE IDLE SPEED

THROTTLE CABLE PLAY

THROTTLE VALVE SYNCHRONIZATION

EVAPORATIVE EMISSION CONTROL SYSTEM (FOR E-33 ONLY)

PAIR (AIR SUPPLY) SYSTEM

CLUTCH

COOLING SYSTEM

DRIVE CHAIN

BRAKE

TIRE

STEERING

FRONT FORK

REAR SUSPENSION

EXHAUST PIPE BOLT

CHASSIS BOLT AND NUT

COMPRESSION PRESSURE CHECK

COMPRESSION TEST PROCEDURE

OIL PRESSURE CHECK

OIL PRESSURE TEST

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

PROCEDURE

~

~

~

~

~

~

~

~

~

2- 2

2- 2

2- 4

2- 5

2- 5

2- 6

2- 8

2-14

2-14

2-16

2-16

2-17

.

.2-17

2-17

2-18

2-19

2-21

2-23

2-27

2-27

2-28

2-28

2-28

2-29

2-31

2-31

2-32

2-32

2

2

-2 PERIODIC MAINTENANCE

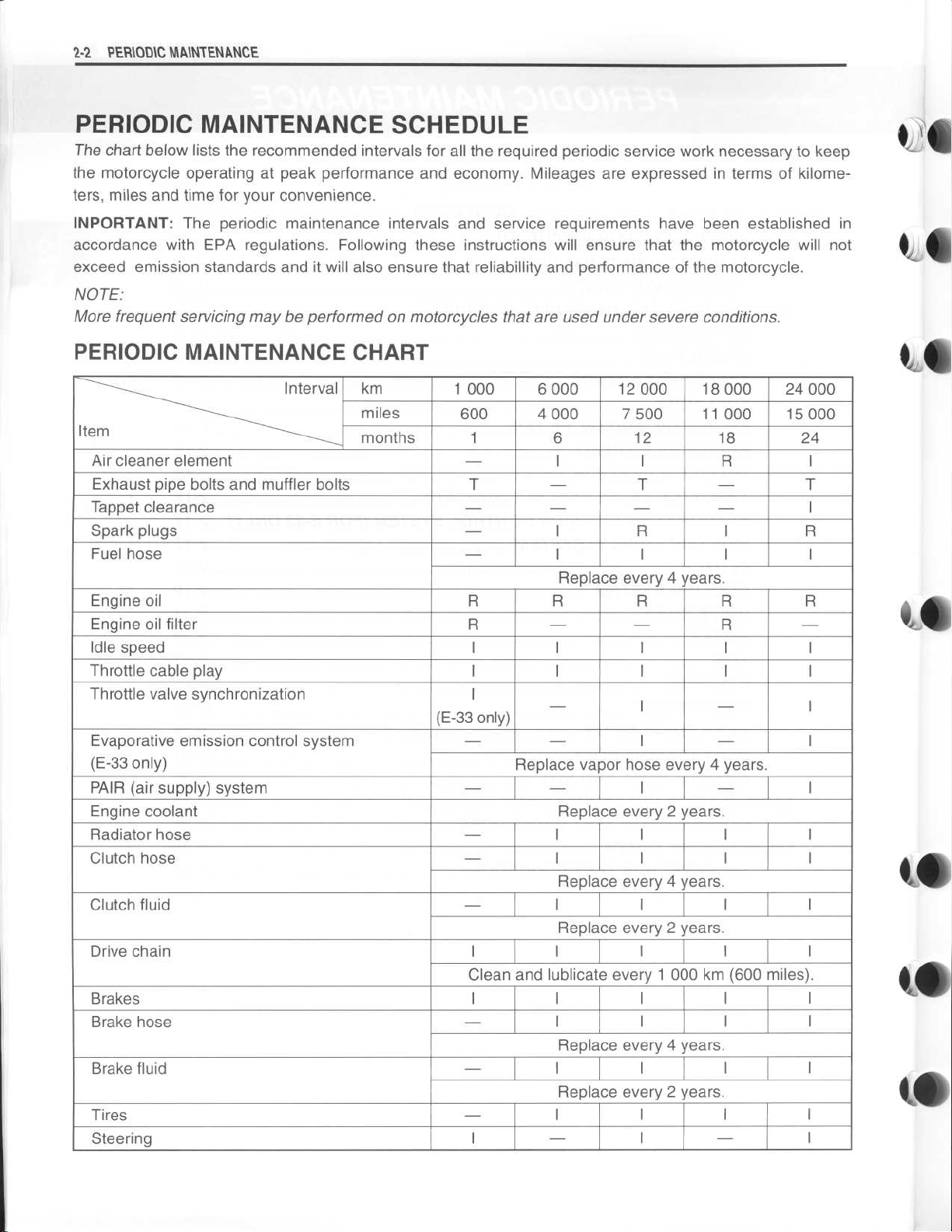

PERIODIC MAINTENANCE SCHEDULE

The chart below lists the recommended intervals for all the required periodic service work necessary to keep

the motorcycle operating at peak performance and economy

ters, miles and time for your convenience

INPORTANT:The periodic maintenance intervals and service requirements have been established in

accordance with EPA regulations

exceed emission standards and it will also ensure that reliabillity and performance of the motorcycle

NOTE

:

More frequent servicing may be performed on motorcycles that are used under severe conditions

.

. Following these instructions will ensure that the motorcycle will not

PERIODIC MAINTENANCE CHART

. Mileages are expressed in terms of kilome-

.

.

Interval

Item

Air cleaner element

Exhaust pipe bolts and muffler bolts

Tappet clearance

Spark plugs

Fuel hose

Engine oil

Engine oil filter

Idle speed

Throttle cable play

Throttle valve synchronization

Evaporative emission control system

(E-33 only)

PAIR (air supply) system

Engine coolant

Radiator hose

Clutch hose

Clutch fluid

Drive chain

Brakes

Brake hose

Brake fluid

Tires

Steering

km

miles

months

1 000

600

1

T

- - - -

-

-

R R R R R

R

I I I I I

I I I I I

I

(E-33 only)

-

-

-

-

I I I I I

Clean

I I I I I

-

-

I

6 000 12 000 18 000 24 000

4 000 7 500 11 000 15 000

6 12 18

I I

-

I

I I I I

Replace

- -

Replace vapor

Replace every 2 years

I I I I

I I I I

Replace

I I I I

Replace

and lublicate

I I I

Replace

I I I I

Replace

I I I I

-

T

R

every 4

I

I

hose every

I

every 4

every 2

every 1 000

every 4

every 2

I

years

4 years

years

years

km (600

years

years

R

-

I

.

R

-

-

.

.

.

.

.

-

24

-

.

miles)

I

T

I

R

I

I

I

.

I

I

PERIODIC MAINTENANCE 2-

3

k )'

Interval

Item

Front fork

Rear suspension

Chassis bolts and nuts

NOTE

: l=Inspect and clean, adjust, replace or lubricate as necessary

km

miles

months

1 000

600

1

T

6 000 12 000 18 000

4 000 7 500 11 000

6 12 18

-

T

; R=Replace

24 000

15 000

I

I

T T T

; T=Tighten

-

-

24

I

I

0J

2-4PERIODIC MAINTENANCE

LUBRICATION POINTS

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle

Major lubrication points are indicated below

.

.

1is

,

1,0

NOTE

:

* Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or grime

* Lubricate exposed parts which are subject to rust, with a rust preventative spray whenever the motorcycle

has been operated under wet or rainy conditions

.

.

4

G

•

.0

~

~

~

~

~

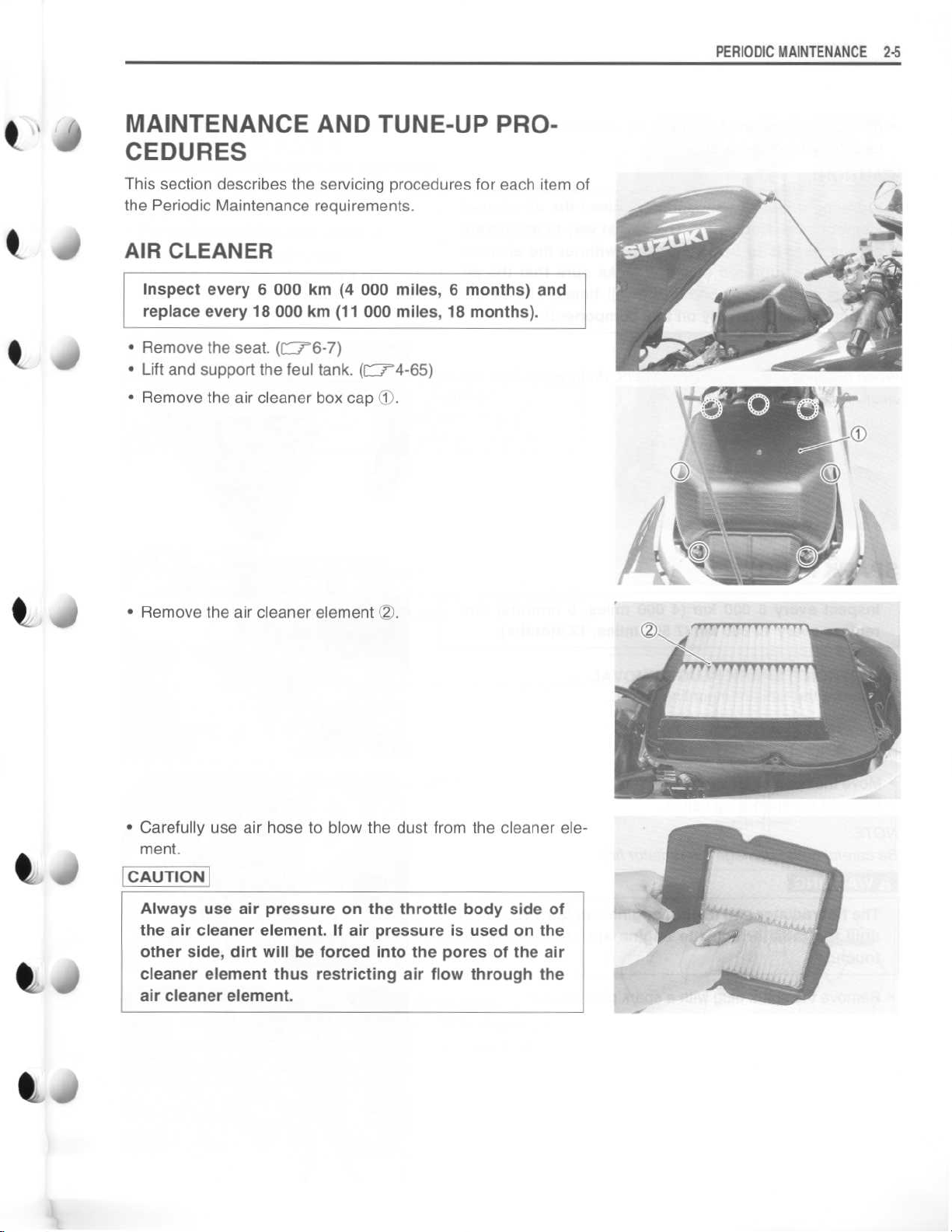

MAINTENANCE AND TUNE-UP PRO-

CEDURES

This section describes the servicing procedures for each item of

the Periodic Maintenance requirements

.

AIR CLEANER

Inspect every 6 000 km (4 000 miles, 6 months) and

replace every 18 000 km (11 000 miles, 18 months)

•

Remove the seat . (LF6-7)

•

Lift and support the feul tank

•

Remove the air cleaner box cap

.(C-74-65)

O

.

.

PERIODIC

MAINTENANCE

2 -5

f

0

4 r

I

•

Remove the air cleaner element

•

Carefully use air hose to blow the dust from the cleaner element

.

CAUTION

Always use air pressure on the throttle body side of

the air cleaner element

other side, dirt will be forced into the pores of the air

cleaner element thus restricting air flow through the

air cleaner element

. If air pressure is used on the

.

O

.

~

~

~

~

~

2-6PERIODIC MAINTENANCE

•

Reinstall the cleaned or new air cleaner element in the

reverse order of removal

CAUTION

If driving under dusty condition, clean the air cleaner

element more frequently

engine wear is to use the engine without the element

or to use a ruptured element

cleaner is in good condition at all times

engine depends largely on this component!

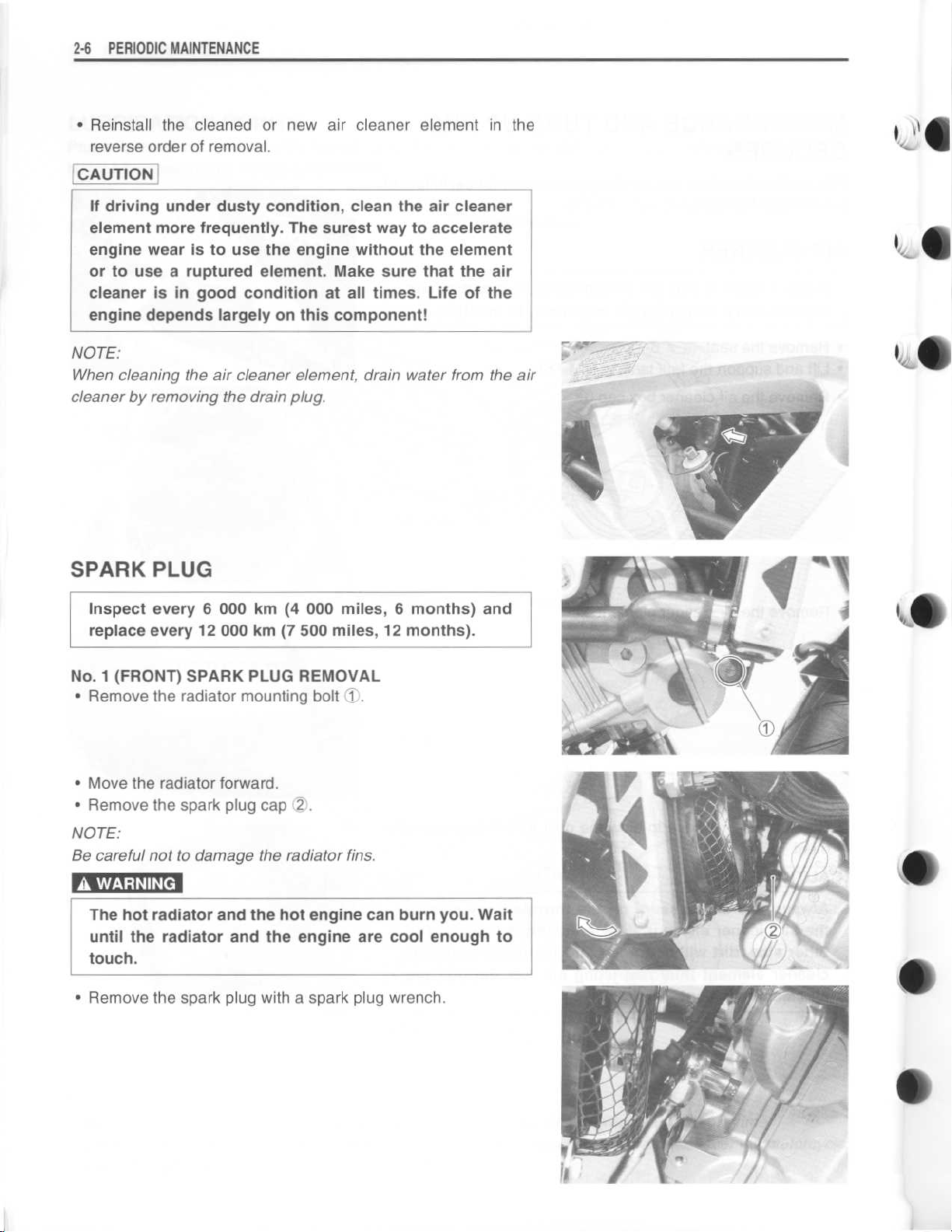

NOTE

:

When cleaning the air cleaner element, drain water from the air

cleaner by removing the drain plug

.

. The surest way to accelerate

1

. Make sure that the air

. Life of the

.

SPARK PLUG

Inspect every 6 000 km (4 000 miles, 6 months) and

replace every 12 000 km (7 500 miles, 12 months)

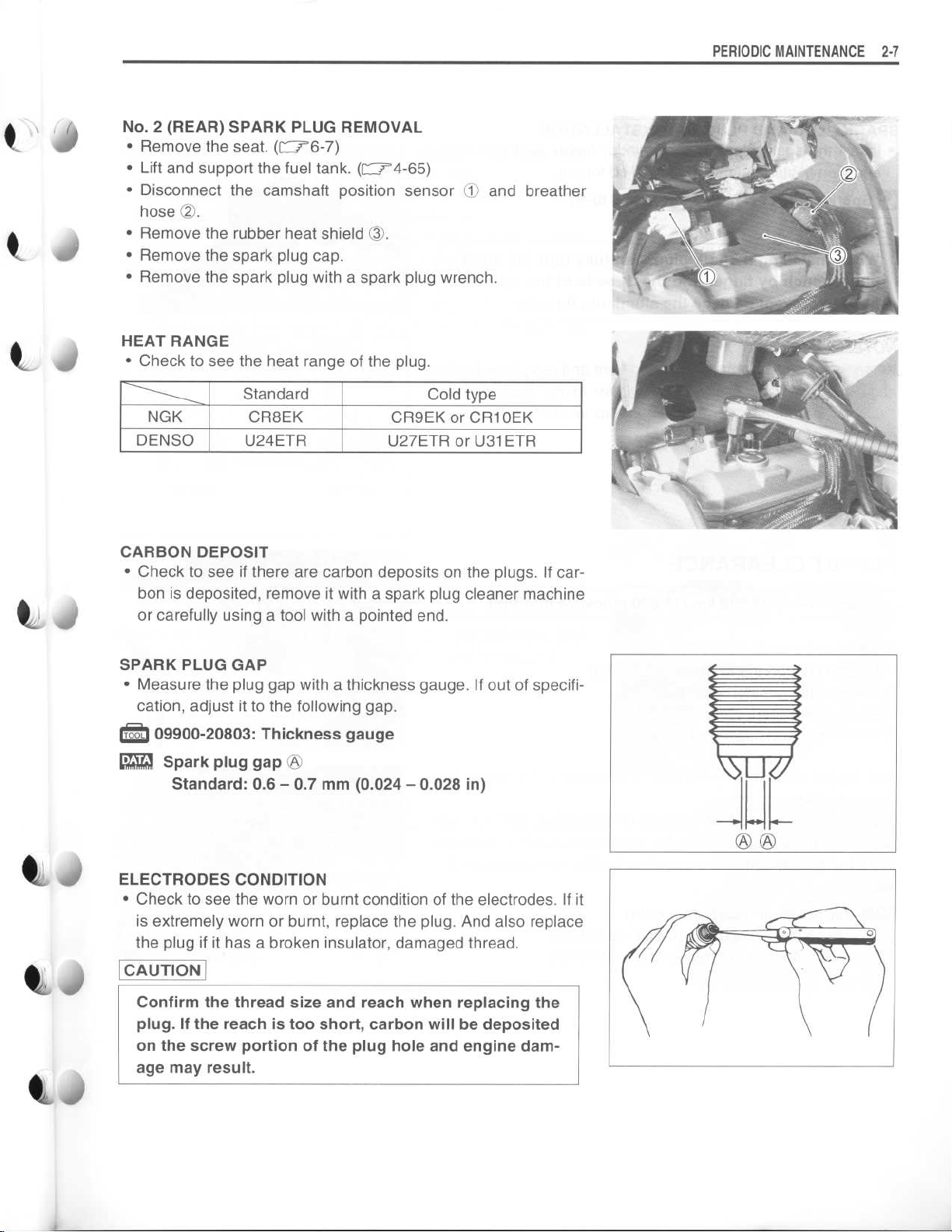

No

. 1 (FRONT) SPARK PLUG REMOVAL

•

Remove the radiator mounting bolt

•

Move the radiator forward

•

Remove the spark plug cap

NOTE

:

Be careful not to damage the radiator fins

A WARNING

The hot radiator and the hot engine can burn you

until the radiator and the engine are cool enough to

.

touch

•

Remove the spark plug with a spark plug wrench

.

O

O

.

.

.

.

.

6

. Wait

~

~

~

~

~

~

~

~

PERIODIC MAINTENANCE2-7

No

. 2 (REAR) SPARK PLUG REMOVAL

•

Remove the seat

•

Lift and support the fuel tank

•

Disconnect the camshaft position sensor 1O and breather

hose

(Z

.

•

Remove the rubber heat shield ®

•

Remove the spark plug cap

•

Remove the spark plug with a spark plug wrench

HEAT RANGE

•

Check to see the heat range of the plug

.

(r--,-6-7)

. (=4-65)

4-65)

.

.

.

.

Standard

NGK

DENSO

CARBON DEPOSIT

•

Check to see if there are carbon deposits on the plugs

bon is deposited, remove it with a spark plug cleaner machine

or carefully using a tool with a pointed end

SPARK PLUG GAP

•

Measure the plug gap with a thickness gauge

cation, adjust it to the following gap

09900-20803

Spark plug gap

Standard

CR8EK

U24ETR

: Thickness gauge

OA

: 0

.6 - 0

.7 mm (0

.024 -0.028 in)

Cold type

CR9EK or CR1 OEK

U27ETR or U31 ETR

. If car-

.

. If out of specifi-

.

I

It

ELECTRODES CONDITION

•

Check to see the worn or burnt condition of the electrodes

is extremely worn or burnt, replace the plug

the plug if it has a broken insulator, damaged thread

CAUTION

Confirm the thread size and reach when replacing the

plug

. If the reach is too short, carbon will be deposited

on the screw portion of the plug hole and engine damage may result

.

. And also replace

. If it

.

~

~

~

~

~

~

2-8PERIODIC MAINTENANCE

SPARK PLUG AND PLUG CAP INSTALLATION

•

Install the spark plugs to the cylinder heads by finger tight,

and then tighten them to the specified torque

.

Spark plug

CAUTION

When installing a spark plug, carefully turn the spark

plug wrench by finger into the threads of the cylinder

head to prevent damage the aluminum threads

NOTE

:

When installing the spark plug caps, front and rear, face the tri-

angle mark

exhaust side

end

.

: 11 N

.m (1 .1 kgf-m, 8

on the water-proof cover to the each cylinder

OA

. Insert the spark plaug cap securely to the dead

.0 lb-ft)

.

TAPPET CLEARANCE

Inspect every 24 000 km (15 000 miles, 24 months)

•

Remove the seat.(f"

•

Lift and support the fuel tank

•

Remove the radiator

•

Remove the spark plugs

•

Remove the cylinder head covers

r'6-7)

. (=5-5)

.(f"

4-65)

. (=4-65)

7'2-6)

.

.

4

0

klb

The tappet clearance specification is different for intake and

exhaust valves

Tappet clearance must be checked and adjusted, 1) at the time

of periodic inspection, 2) when the valve mechanism is serviced,

and 3) when the camshafts are disturbed by removing them for

servicing

Tappet clearance (when cold)

IN.:0.10-0

EX

.

.

. :0.20-0

.20 mm (0

.30 mm (0

.004-0

.008-0

.008 in)

.012 in)

I'16

~

~

~

~

~

~

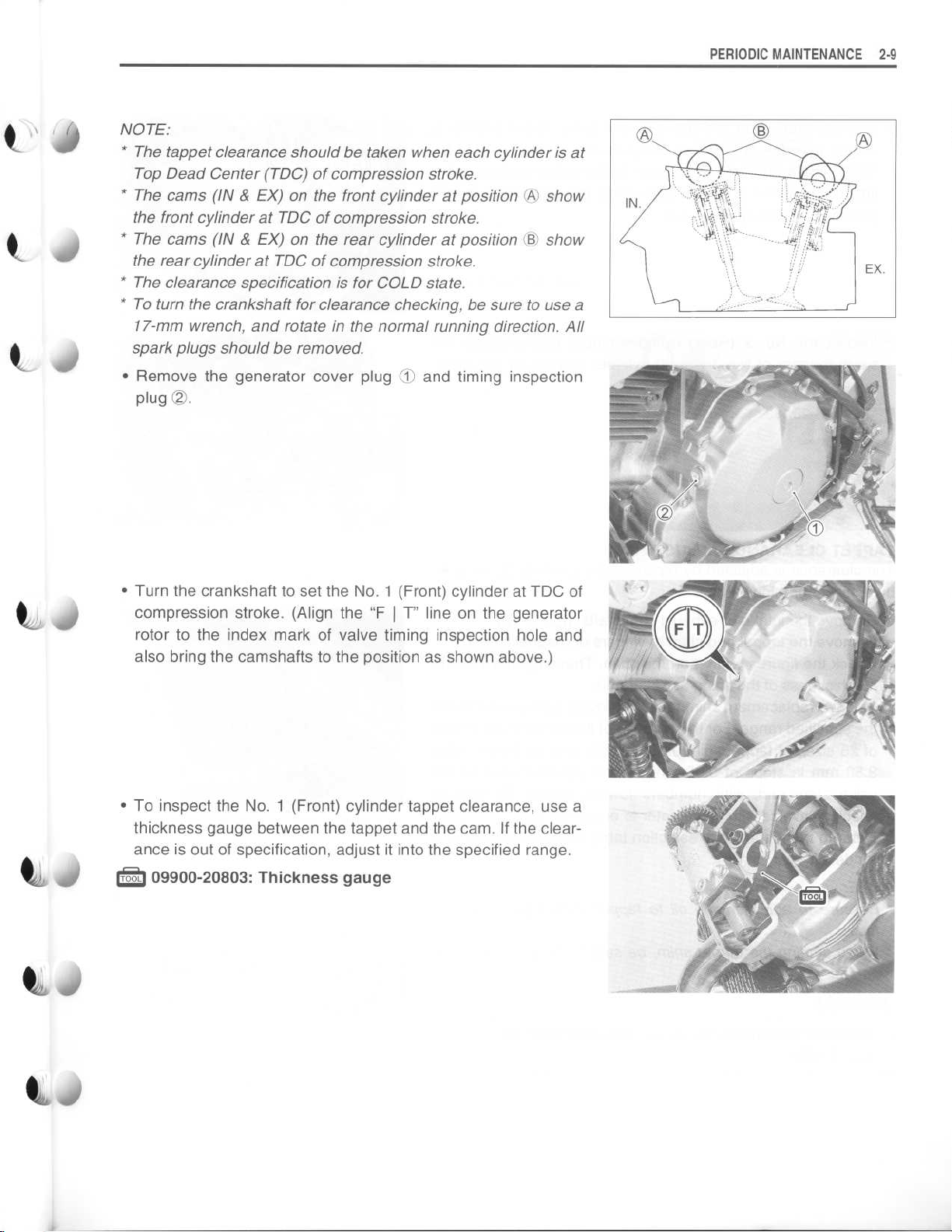

NOTE

:

•

The tappet clearance should be taken when each cylinder is at

Top Dead Center (TDC) of compression stroke

•

The cams (IN & EX) on the front cylinder at position ~~ show

the front cylinder at TDC of compression stroke

•

The cams (IN & EX) on the rear cylinder at position © show

the rear cylinder at TDC of compression stroke

•

The clearance specification is for COLD state

•

To turn the crankshaft for clearance checking, be sure to use a

17-mm wrench, and rotate in the normal running direction

spark plugs should be removed

•

Remove the generator cover plug

plug

OO

.

.

0

and timing inspection

.

.

.

.

. All

PERIODIC MAINTENANCE 2-

9

•

Turn the crankshaft to set the No

compression stroke

rotor to the index mark of valve timing inspection hole and

also bring the camshafts to the position as shown above

•

To inspect the No

thickness gauge between the tappet and the cam

ance is out of specification, adjust it into the specified range

.

.

09900-20803

. (Align the "F

. 1 (Front) cylinder tappet clearance, use a

: Thickness gauge

. 1 (Front) cylinder at TDC of

I

T" line on the generator

.)

. If the clear-

.

~

~

~

~

2- 10PERIODIC MAINTENANCE

•

Turn the crankshaft 270 degrees (3/4 turns) to set the No

(Rear) cylinder at TDC of compression stroke

"RIT" line on the generator rotor to the index mark of valve

timing inspection hole and also bring the camshafts to the

position as shown in page

•

Inspect the No

same manner of No

ance if necessary

.

.

09900-20803

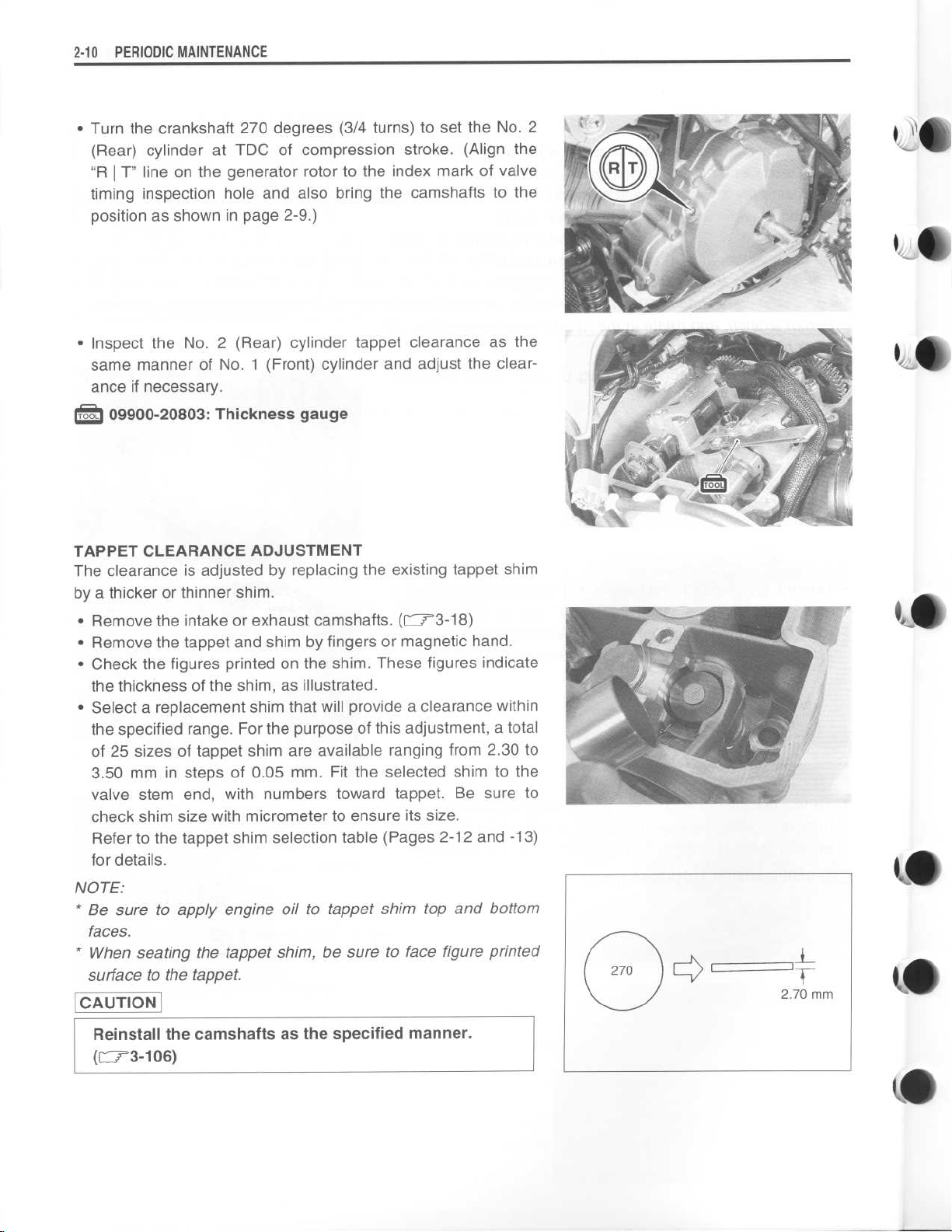

TAPPET CLEARANCE ADJUSTMENT

The clearance is adjusted by replacing the existing tappet shim

by a thicker or thinner shim

. 2 (Rear) cylinder tappet clearance as the

.

: Thickness gauge

2-9

.)

. 1 (Front) cylinder and adjust the clear-

.

. (Align the

. 2

$

Remove the intake or exhaust camshafts

•

Remove the tappet and shim by fingers or magnetic hand

•

Check the figures printed on the shim

•

the thickness of the shim, as illustrated

Select a replacement shim that will provide a clearance within

•

the specified range

of 25 sizes of tappet shim are available ranging from 2

.50 mm in steps of 0

3

valve stem end, with numbers toward tappet

check shim size with micrometer to ensure its size

Refer to the tappet shim selection table (Pages 2-12 and -13)

for details

NOTE

.

:

. For the purpose of this adjustment, a total

.05 mm

. Fit the selected shim to the

. (=3-18)

3-18)

.

. These figures indicate

.

.30 to

. Be sure to

.

* Be sure to apply engine oil to tappet shim top and bottom

faces

.

* When seating the tappet shim, be sure to face figure printed

surface to the tappet

.

CAUTION

Reinstall the camshafts as the specified manner

(CI3-106)

.

I

0

Loading...

Loading...