SUZUKI GSX-R 600 User Manual

GSX-R600

FOREWORD

This manual contains an introductory description on the SUZUKI GSX-R600 and procedures for its inspection/service and overhaul of its main components.

Other information considered as generally known is not included.

Read the GENERAL INFORMATION section to familiarize yourself with the motorcycle and its maintenance. Use

this section as well as other sections to use as a guide for proper inspection and service.

This manual will help you know the motorcycle better so that you can assure your customers of fast and reliable

service.

* This manual has been prepared on the basis of the latest specifications at the time of publication. If modifi-

cations have been made since then, differences may exist between the content of this manual and the

actual motorcycle.

* Illustrations in this manual are used to show the basic principles of operation and work procedures. They

may not represent the actual motorcycle exactly in detail.

* This manual is written for persons who have enough knowledge, skills and tools, including special tools, for

servicing SUZUKI motorcycles. If you do not have the proper knowledge and tools, ask your authorized

SUZUKI motorcycle dealer to help you.

!

WARNING

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the motorcycle unsafe for the

rider and passenger.

© COPYRIGHT SUZUKI MOTOR CORPORATION 2008

TABLE OF CONTENTS

Precautions............................................................... 00-i

Precautions ............................................................ 00-1

General Information ................................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubrication ................................. 0B-1

Service Data........................................................... 0C-1

Engine ......................................................................... 1-i

Precautions .............................................................. 1-1

Engine General Information and Diagnosis ...........1A-1

Emission Control Devices ...................................... 1B-1

Engine Electrical Devices.......................................1C-1

Engine Mechanical.................................................1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System.......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension................................................................. 2-i

Precautions .............................................................. 2-1

Suspension General Diagnosis.............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension....................................................2C-1

Wheels and Tires ...................................................2D-1

00

0

1

2

3

4

5

6

Driveline / Axle ........................................................... 3-i

Precautions .............................................................. 3-1

Drive Chain / Drive Train / Drive Shaft ................... 3A-1

Brake ........................................................................... 4-i

Precautions .............................................................. 4-1

Brake Control System and Diagnosis ....................4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ...........................................................4C-1

Transmission / Transaxle .......................................... 5-i

Precautions .............................................................. 5-1

Manual Transmission ............................................. 5B-1

Clutch .....................................................................5C-1

Steering....................................................................... 6-i

Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering / Handlebar .............................................. 6B-1

Body and Accessories............................................... 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems.................................................... 9B-1

Combination Meter / Fuel Meter / Horn..................9C-1

Exterior Parts .........................................................9D-1

Body Structure ....................................................... 9E-1

9

Section 00

Precautions

CONTENTS

Table of Contents 00- i

00

Precautions ...............................................00-1

Precautions........................................................... 00-1

Warning / Caution / Note..................................... 00-1

General Precautions ........................................... 00-1

Precautions for Electrical Circuit Service ............ 00-2

00-1 Precautions:

Precautions

Precautions

Precautions

Warning / Caution / Note

B837H10000001

Please read this manual and follow its instructions

carefully. To emphasize special information, the symbol

and the words WARNING, CAUTION and NOTE have

special meanings. Pay special attention to the messages

highlighted by these signal words.

!

WARNING

Indicates a potential hazard that could result

in death or injury.

!

CAUTION

Indicates a potential hazard that could result

in motorcycle damage.

NOTE

Indicates special information to make

maintenance easier or instructions clearer.

Please note, however, that the warnings and cautions

contained in this manual cannot possibly cover all

potential hazards relating to the servicing, or lack of

servicing, of the motorcycle. In addition to the

WARNINGS and CAUTIONS stated, you must use good

judgement and basic mechanical safety principles. If you

are unsure about how to perform a particular service

operation, ask a more experienced mechanic for advice.

General Precautions

!

WARNING

• Proper service and repair procedures are

important for the safety of the service

mechanic and the safety and reliability of

the motorcycle.

• When 2 or more persons work together,

pay attention to the safety of each other.

• When it is necessary to run the engine

indoors, make sure that exhaust gas is

forced outdoors.

• When working with toxic or flammable

materials, make sure that the area you

work in is well ventilated and that you

follow all of the material manufacturer’s

instructions.

• Never use gasoline as cleaning solvent.

B837H10000002

• To avoid getting burned, do not touch the

engine, engine oil, radiator and exhaust

system until they have cooled.

• After servicing the fuel, oil, water, exhaust

or brake systems, check all lines and

fittings related to the system for leaks.

!

CAUTION

• If parts replacement is necessary, replace

the parts with Suzuki Genuine Parts or

their equivalent.

• When removing parts that are to be reused,

keep them arranged in an orderly manner

so that they may be reinstalled in the

proper order and orientation.

• Be sure to use special tools when

instructed.

• Make sure that all parts used in

reassembly are clean. Lubricate them

when specified.

• Use the specified lubricant, bond or

sealant.

• When removing the battery, disconnect the

negative (–) cable first and then the

positive (+) cable.

• When reconnecting the battery, connect

the positive (+) cable first and then the

negative (–) cable, and replace the terminal

cover on the positive (+) terminal.

• When performing service to electrical

parts, if the service procedures do not

require use of battery power, disconnect

the negative (–) cable the battery.

• When tightening the cylinder head or case

bolts and nuts, tighten the larger sizes

first. Always tighten the bolts and nuts

diagonally from the inside toward outside

and to the specified tightening torque.

• Whenever you remove oil seals, gaskets,

packing, O-rings, locking washers, selflocking nuts, cotter pins, circlips and

certain other parts as specified, be sure to

replace them with new ones. Also, before

installing these new parts, be sure to

remove any left over material from the

mating surfaces.

Precautions: 00-2

• Never reuse a circlip. When installing a

new circlip, take care not to expand the

end gap larger than required to slip the

circlip over the shaft. After installing a

circlip, always ensure that it is completely

seated in its groove and securely fitted.

• Use a torque wrench to tighten fasteners

to the specified torque. Wipe off grease

and oil if a thread is smeared with them.

• After reassembling, check parts for

tightness and proper operation.

• To protect the environment, do not

unlawfully dispose of used motor oil,

engine coolant and other fluids: batteries,

and tires.

• To protect Earth’s natural resources,

properly dispose of used motorcycle and

parts.

Precautions for Electrical Circuit Service

B837H10000003

When handling the electrical parts or servicing FI

system, observe the following points for the safety of the

systems.

• Inspect each terminal for corrosion and

contamination. The terminals must be clean and free

of any foreign material which could impede proper

terminal contact.

• Before refitting the sealed coupler, make sure its seal

rubber is positioned properly. The seal rubber may

possibly come off the position during disconnecting

work and if the coupler is refitted with the seal rubber

improperly positioned, it may result in poor water

sealing.

I310G1000002-01

• Inspect each lead wire circuit for poor connection by

shaking it by hand lightly. If any abnormal condition is

found, repair or replace.

Electrical Parts

Connector / Coupler

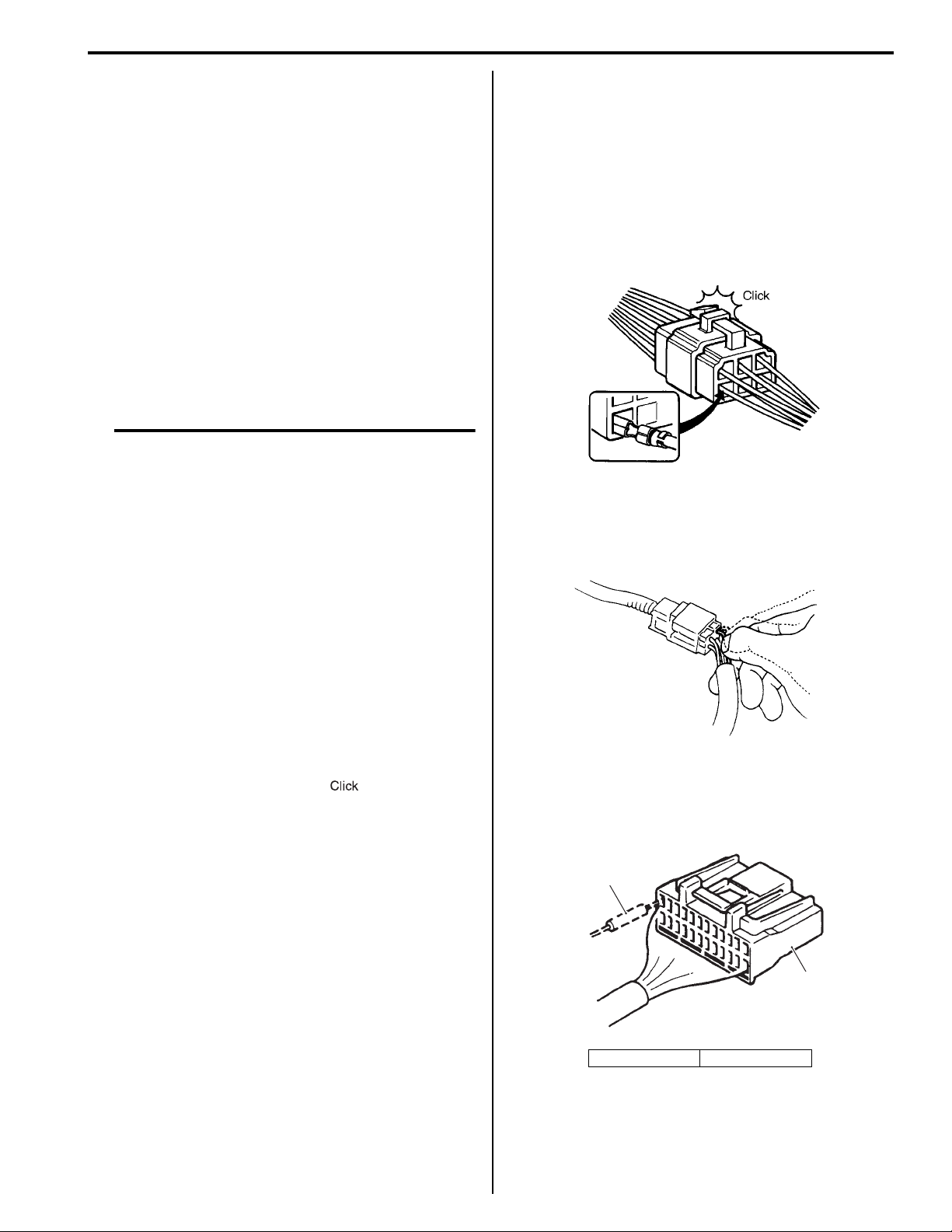

• Faulty FI system is often related to poor electrical

contact of connector/coupler. Before servicing

individual electronic part, check electrical contact of

the connector/coupler.

• When connecting a connector, be sure to push it in

until a click is felt.

I823H1000002-01

• With a lock type coupler, be sure to release the lock

when disconnecting, and push it in fully to engage the

lock when connecting.

• When disconnecting the coupler, be sure to hold the

coupler body and do not pull the lead wires.

• Inspect each terminal on the connector/coupler for

looseness or bending.

• Push in the coupler straightly. An angled or skewed

insertion may cause the terminal to be deformed,

possibly resulting in poor electrical contact.

I310G1000003-02

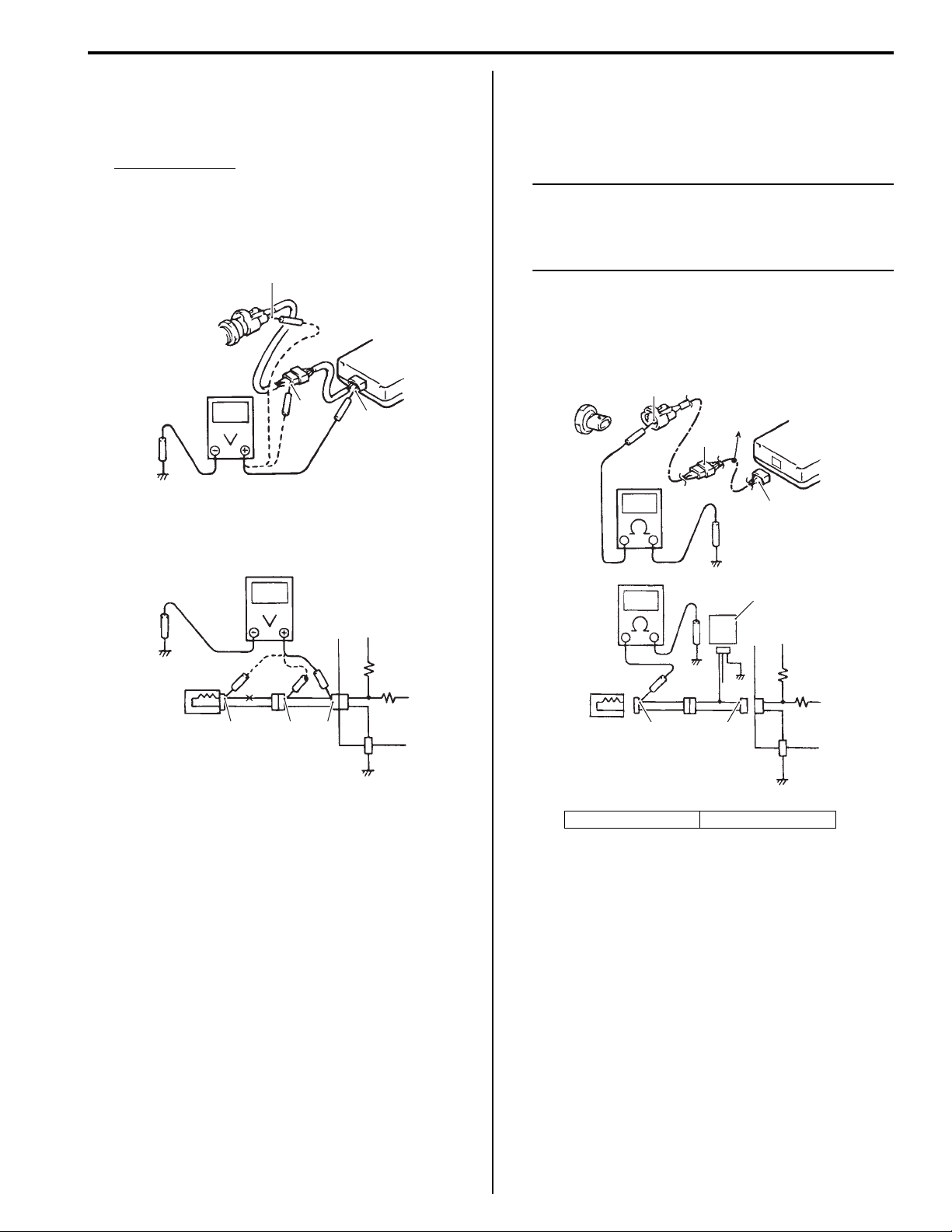

• When taking measurements at electrical connectors

using a tester probe, be sure to insert the probe from

the wire harness side (rear) of the connector/coupler.

2

1

I649G1000013-02

1. Coupler 2. Probe

00-3 Precautions:

• When connecting meter probe from the terminal side

of the coupler (where connection from harness side

not being possible), use extra care not to force and

cause the male terminal to bend or the female

terminal to open. Connect the probe as shown to

avoid opening of female terminal. Never push in the

probe where male terminal is supposed to fit.

• Check the male connector for bend and female

connector for excessive opening. Also check the

coupler for locking (looseness), corrosion, dust, etc.

4

“A”

3

4

I649G1000030-02

3. Coupler 4. Probe “A”: Where male terminal fits

• Avoid applying grease or other similar material to

connector/coupler terminals to prevent electric

trouble.

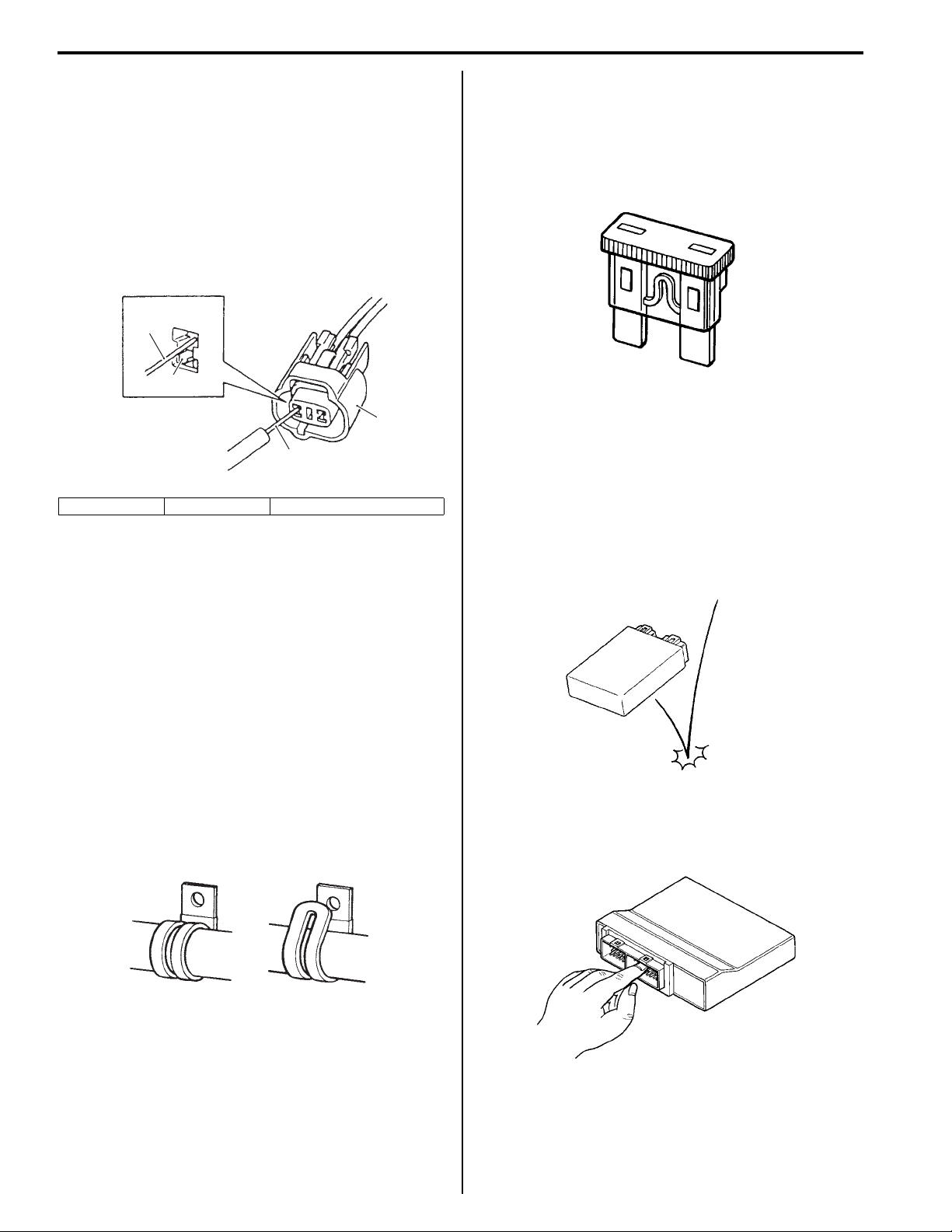

Fuse

• When a fuse is blown, always investigate the cause to

correct it and then replace the fuse.

• Do not use a fuse of different capacity.

• Do not use wire or any other substitute for the fuse.

I649G1000001-02

Switch

Never apply grease material to switch contact points to

prevent damage.

ECM / Various sensors

• Since each component is a high-precision part, great

care should be taken not to apply any severe impacts

during removal and installation.

Clamp

• Clamp the wire harness at such positions as indicated

in “Wiring Harness Routing Diagram in Section 9A

(Page 9A-5)”.

• Bend the clamp properly so that the wire harness is

clamped securely.

• In clamping the wire harness, use care not to allow it

to hang down.

• Do not use wire or any other substitute for the band

type clamp.

CORRECT INCORRECT

I718H1000001-02

I310G1000007-01

• Be careful not to touch the electrical terminals of the

electronic parts (ECM, etc.). The static electricity from

your body may damage them.

I310G1000008-01

Precautions: 00-4

• When disconnecting and connecting the coupler,

make sure to turn OFF the ignition switch, or

electronic parts may get damaged.

1

I837H1000001-01

1. Ignition switch

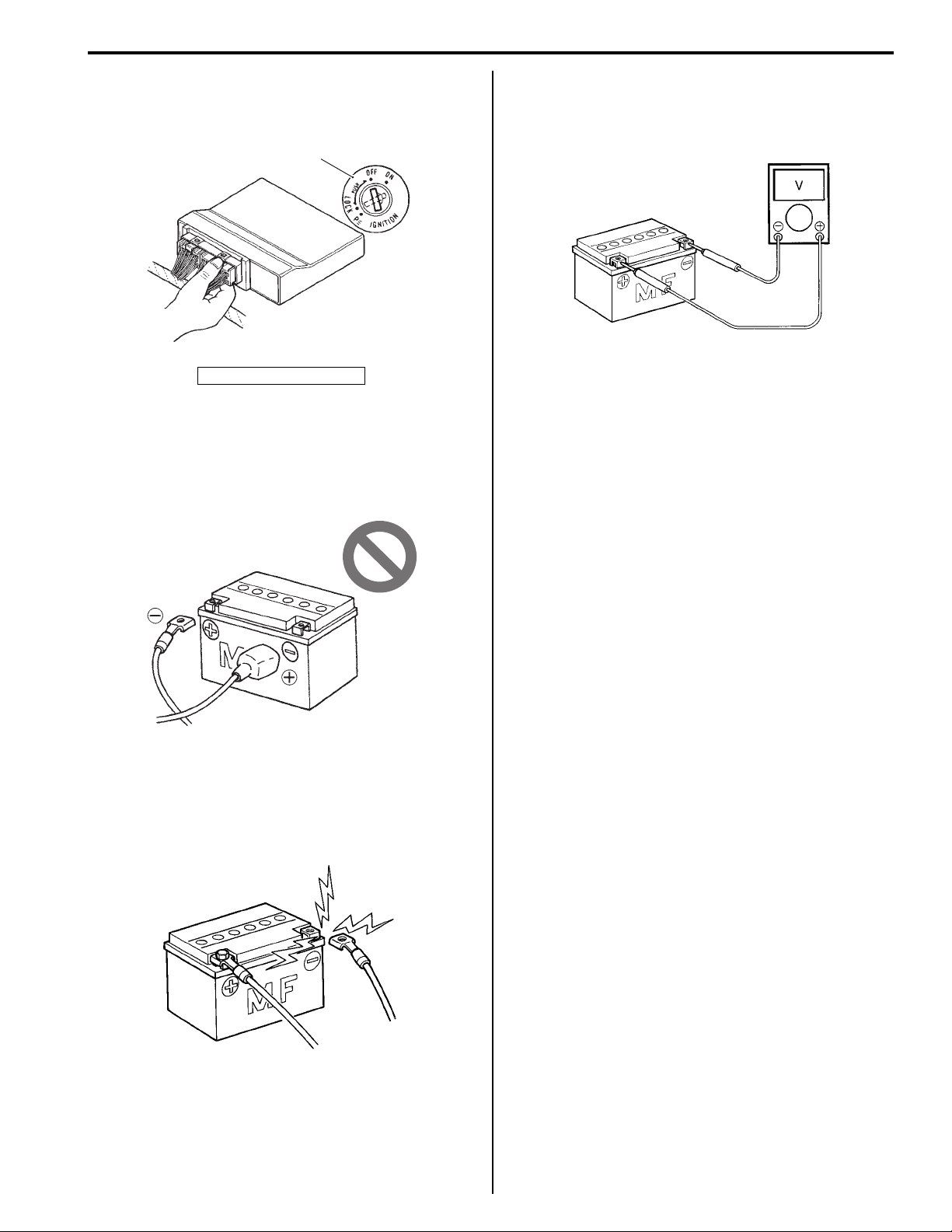

Battery

• Battery connection in reverse polarity is strictly

prohibited. Such a wrong connection will damage the

components of the FI and ABS systems instantly

when reverse power is applied.

• Before measuring voltage at each terminal, check to

make sure that battery voltage is 11 V or higher.

Terminal voltage check with a low battery voltage will

lead to erroneous diagnosis.

I310G1000012-02

• Never connect any tester (voltmeter, ohmmeter, or

whatever) to the electronic unit when its coupler is

disconnected. Otherwise, damage to electronic unit

may result.

• Never connect an ohmmeter to the electronic unit with

its coupler connected. If attempted, damage to ECM

or sensors may result.

• Be sure to use a specified voltmeter/ohmmeter.

Otherwise, accurate measurements may not be

obtained and personal injury may result.

I718H1000004-01

• Removing any battery terminal of a running engine is

strictly prohibited. The moment such removal is made,

damaging counter electromotive force will be applied

to the electronic unit which may result in serious

damage.

Electrical Circuit Inspection Procedure

While there are various methods for electrical circuit

inspection, described here is a general method to check

for open and short circuit using an ohmmeter and a

voltmeter.

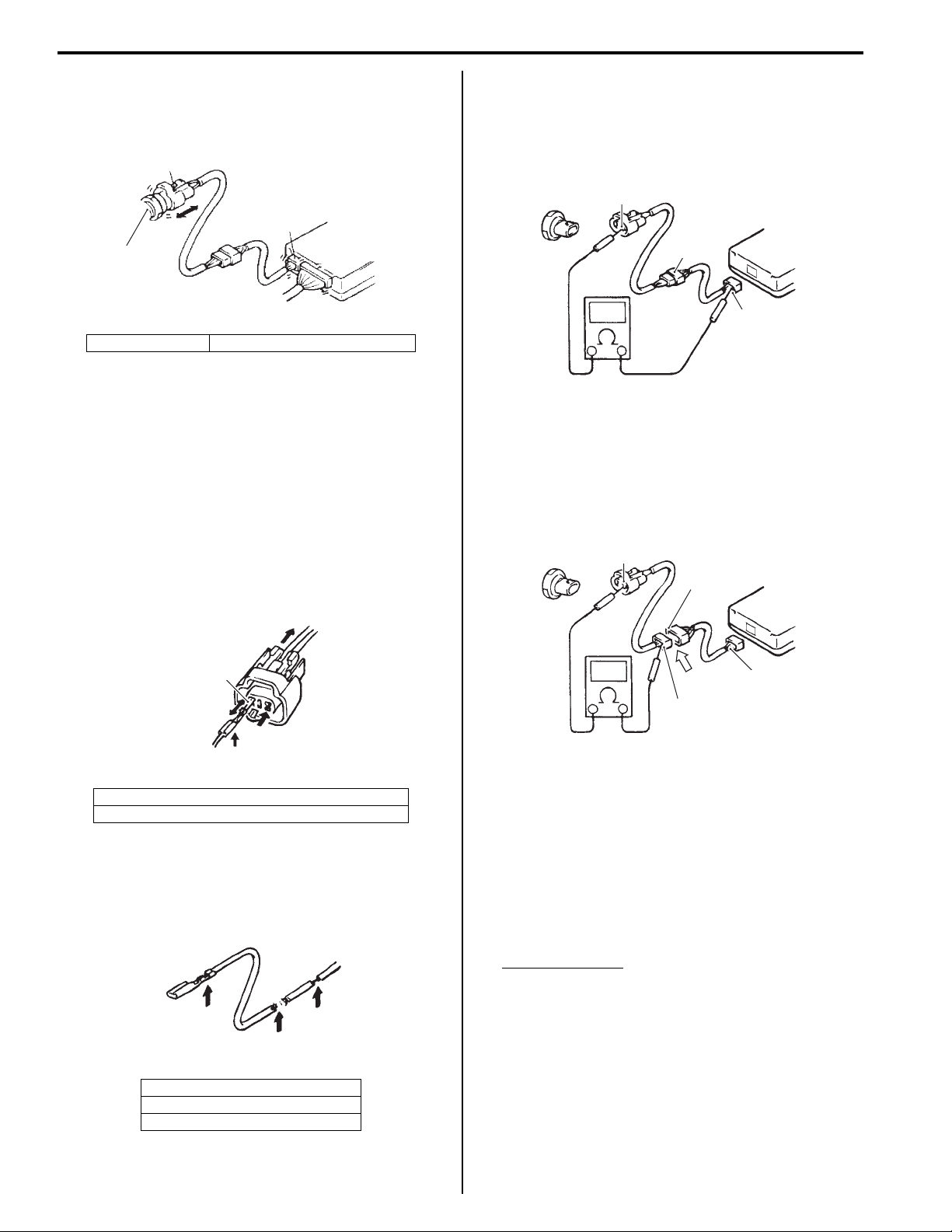

Open circuit check

Possible causes for the open circuit are as follows. As

the cause can exist in the connector/coupler or terminal,

they need to be checked carefully.

• Loose connection of connector/coupler.

• Poor contact of terminal (due to dirt, corrosion or rust,

poor contact tension, entry of foreign object etc.).

• Wire harness being open.

• Poor terminal-to-wire connection.

When checking system circuits including an electronic

control unit such as ECM, ABS control unit/HU, etc., it is

important to perform careful check, starting with items

which are easier to check.

1) Disconnect the negative (–) cable from the battery.

I310G1000011-01

00-5 Precautions:

2) Check each connector/coupler at both ends of the

circuit being checked for loose connection. Also

check for condition of the coupler lock if equipped.

“A”

“A”

1

1. Sensor “A”: Check for loose connection

ECM

I718H1000005-02

3) Using a test male terminal, check the female

terminals of the circuit being checked for contact

tension.

Check each terminal visually for poor contact

(possibly caused by dirt, corrosion, rust, entry of

foreign object, etc.). At the same time, check to

make sure that each terminal is fully inserted in the

coupler and locked.

If contact tension is not enough, rectify the contact to

increase tension or replace. The terminals must be

clean and free of any foreign material which could

impede proper terminal contact.

Continuity check

1) Measure resistance across coupler “B” (between “A”

and “C” in figure).

If no continuity is indicated (infinity or over limit), the

circuit is open between terminals “A” and “C”.

“A”

“B”

ECM

“C”

I705H1000006-02

2) Disconnect the coupler “B” and measure resistance

between couplers “A” and “B-1”.

If no continuity is indicated, the circuit is open

between couplers “A” and “B-1”. If continuity is

indicated, there is an open circuit between couplers

“B-2” and “C” or an abnormality in coupler “B-2” or

coupler “C”.

“A”

“B-2”

ECM

“B”

“C”

I649G1000027-02

“B”: Check contact tension by inserting and removing.

“C”: Check each terminal for bend and proper alignment.

4) Using continuity inspect or voltage check procedure

as described below, inspect the wire harness

terminals for open circuit and poor connection.

Locate abnormality, if any.

“D”

”D”: Looseness of crimping

“E”: Open

“F”: Thin wire (A few strands left)

“F”

“E”

I649G1000028-02

“B”

“B-1”

“C”

I705H1000010-02

Voltage check

If voltage is supplied to the circuit being checked, voltage

check can be used as circuit check.

1) With all connectors/couplers connected and voltage

applied to the circuit being checked, measure

voltage between each terminal and body ground.

2) If measurements were taken as shown in the figure

and results were listed in the following, it means that

the circuit is open between terminals “A” and “B”.

Voltage between

“A” and body ground: Approx. 5 V

“B” and body ground: Approx. 5 V

“C” and body ground: 0 V

Precautions: 00-6

3) Also, if measured values are as listed following, a

resistance (abnormality) exists which causes the

voltage drop in the circuit between terminals “A” and

“B”.

Voltage between

“A” and body ground: Approx. 5 V

“B” and body ground: Approx. 5 V – 2 V voltage

drop

“C” and body ground: 3 V – 2 V voltage drop

“A”

ECM

“B”

“C”

Short circuit check (Wire harness to ground)

1) Disconnect the negative (–) cable from the battery.

2) Disconnect the connectors/couplers at both ends of

the circuit to be checked.

NOTE

If the circuit to be checked branches to other

parts as shown, disconnect all connectors/

couplers of those parts. Otherwise, diagnosis

will be wrong.

3) Measure resistance between terminal at one end of

circuit (“A” terminal in figure) and body ground. If

continuity is indicated, there is a short circuit to

ground between terminals “A” and “C”.

“A”

“D”

“B”

ECM

“C”

5V

0V

“A” “B” “C”

5V

5V

I705H1000007-01

“E”

5V

“A” “C”

I705H1000008-01

“D”: To other parts “E”: Other parts

00-7 Precautions:

4) Disconnect the connector/coupler included in circuit

(coupler “B”) and measure resistance between

terminal “A” and body ground. If continuity is

indicated, the circuit is shorted to ground between

terminals “A” and “B”.

“A”

“D”

ECM

“B”

“D”: To other parts

“C”

I705H1000009-02

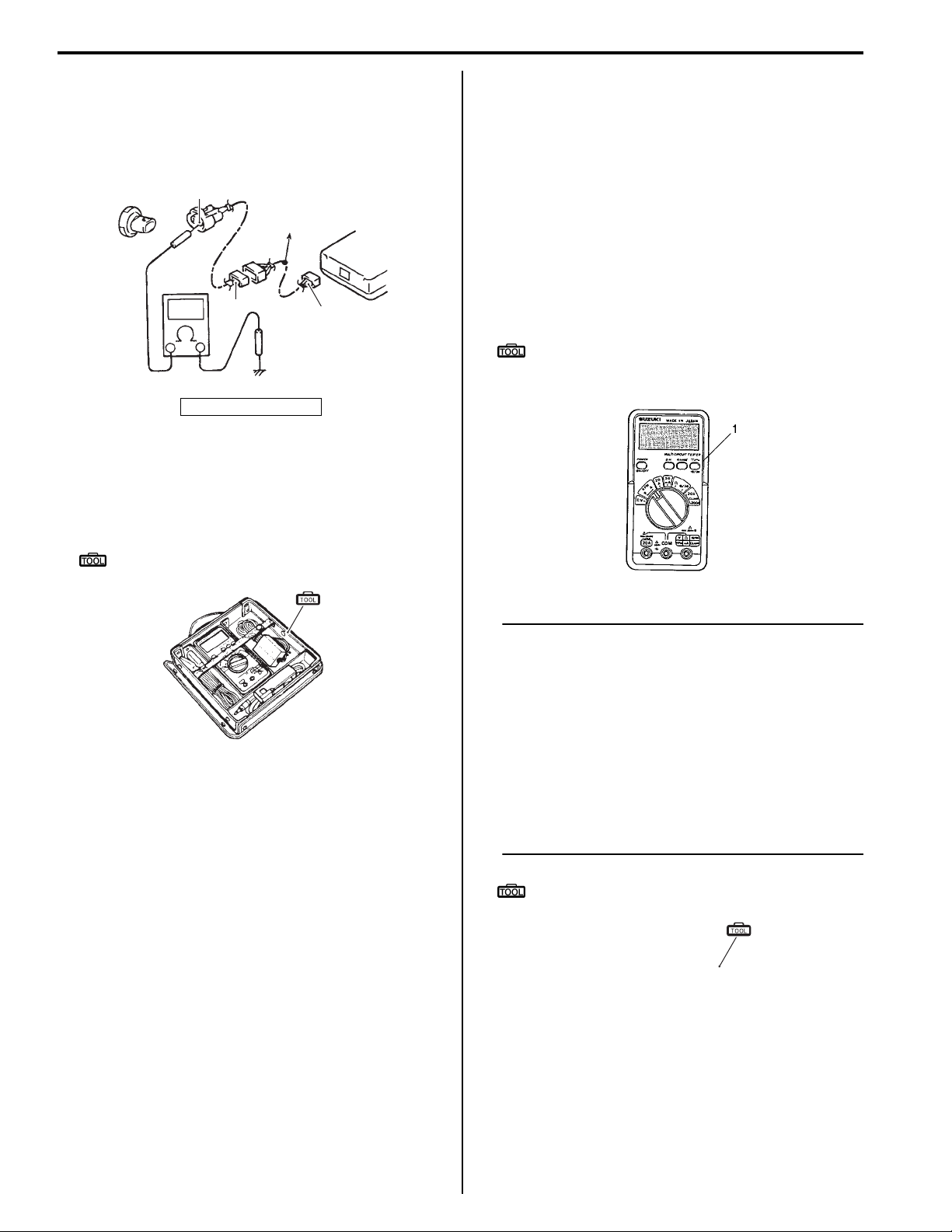

Using The Multi-Circuit Testers

• Use the Suzuki multi-circuit tester set.

• Use well-charged batteries in the tester.

• Be sure to set the tester to the correct testing range.

Using the testers

• Incorrectly connecting the (+) and (–) probes may

cause the inside of the tester to be burned.

• If the voltage and current are not known, make

measurements using the highest range.

• When measuring the resistance with the multi-circuit

tester (1), ∞ will be shown as 10.00 MΩ and “1”

flashes in the display.

• Check that no voltage is applied before making the

measurement. If voltage is applied the tester may be

damaged.

• After using the tester, turn the power off.

Special tool

: 09900–25008 (Multi-circuit tester set)

Special tool

(A): 09900–25008 (Multi-circuit tester set)

(A)

I649G1000024-03

I649G1000002-02

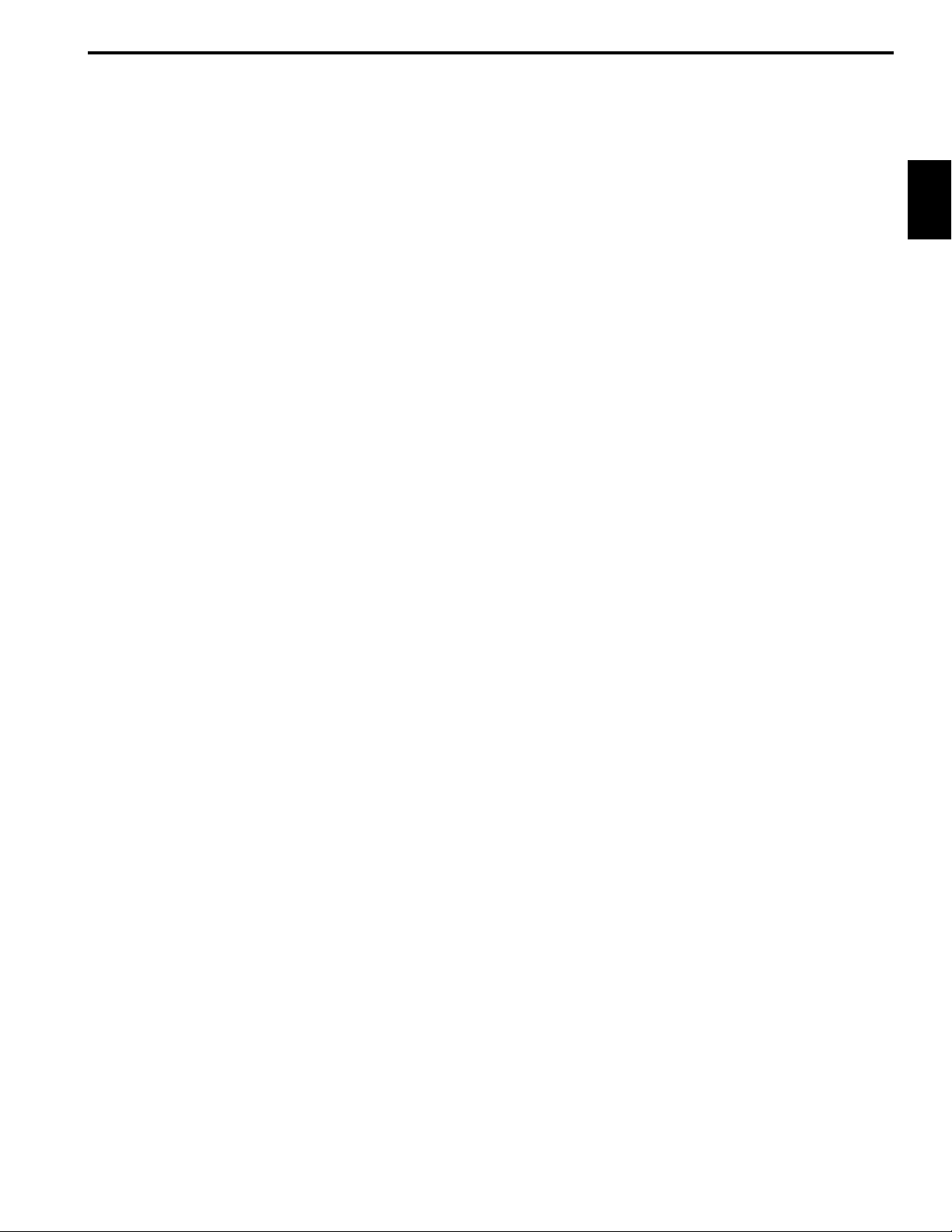

NOTE

• When connecting the multi-circuit tester,

use the needle pointed probe to the back

side of the lead wire coupler and connect

the probes of tester to them.

• Use the needle pointed probe to prevent

the rubber of the water proof coupler from

damage.

• When using the multi-circuit tester, do not

strongly touch the terminal of the ECM

coupler with a needle pointed tester probe

to prevent terminal damage.

Special tool

(A): 09900–25009 (Needle pointed probe set)

(A)

I649G1000025-03

Section 0

General Information

CONTENTS

Table of Contents 0- i

0

General Information ................................ 0A-1

General Description .............................................0A-1

Symbols .............................................................. 0A-1

Abbreviations ...................................................... 0A-1

Vehicle Side View ............................................... 0A-2

Vehicle Identification Number ............................. 0A-3

Fuel and Oil Recommendation ........................... 0A-3

Engine Coolant Recommendation ...................... 0A-4

BREAK-IN Procedures........................................ 0A-4

Cylinder Identification.......................................... 0A-4

Country and Area Codes .................................... 0A-5

Wire Color Symbols ............................................ 0A-5

Warning, Caution and Information Labels

Location ............................................................ 0A-6

Component Location ...........................................0A-7

Electrical Components Location ......................... 0A-7

Specifications.......................................................0A-9

Specifications ...................................................... 0A-9

Special Tools and Equipment ........................... 0A-11

Special Tool ...................................................... 0A-11

Maintenance and Lubrication................. 0B-1

Precautions...........................................................0B-1

Precautions for Maintenance ..............................0B-1

General Description .............................................0B-1

Recommended Fluids and Lubricants................. 0B-1

Scheduled Maintenance ......................................0B-1

Periodic Maintenance Schedule Chart................ 0B-1

Lubrication Points ............................................... 0B-2

Repair Instructions ..............................................0B-3

Air Cleaner Element Replacement...................... 0B-3

Air Cleaner Element Inspection .......................... 0B-3

Exhaust Pipe Bolt and Muffler Bolt Inspection ....0B-3

Exhaust Control Valve Inspection ....................... 0B-4

Valve Clearance Inspection and Adjustment ......0B-4

Spark Plug Replacement .................................... 0B-9

Spark Plug Inspection and Cleaning ...................0B-9

Fuel Line Inspection ..........................................0B-10

Evaporative Emission Control System

Inspection (E-33 only) ..................................... 0B-10

Engine Oil and Filter Replacement ...................0B-10

Throttle Cable Play Inspection and

Adjustment ......................................................0B-12

PAIR System Inspection ...................................0B-12

Throttle Valve Synchronization .........................0B-12

Cooling System Inspection................................0B-12

Clutch Cable Play Inspection and Adjustment ..0B-14

Drive Chain Inspection and Adjustment ............0B-15

Drive Chain Cleaning and Lubricating...............0B-16

Brake System Inspection .................................. 0B-17

Tire Inspection................................................... 0B-19

Steering System Inspection .............................. 0B-19

Front Fork Inspection ........................................ 0B-20

Rear Suspension Inspection .............................0B-20

Chassis Bolt and Nut Inspection ....................... 0B-20

Compression Pressure Check .......................... 0B-22

Oil Pressure Check ...........................................0B-22

SDS Check........................................................0B-22

Specifications.....................................................0B-22

Tightening Torque Specifications...................... 0B-22

Special Tools and Equipment ...........................0B-23

Recommended Service Material .......................0B-23

Special Tool ......................................................0B-23

Service Data ............................................. 0C-1

Specifications.......................................................0C-1

Service Data........................................................0C-1

Tightening Torque List ........................................0C-9

0A-1 General Information:

General Information

General Information

General Description

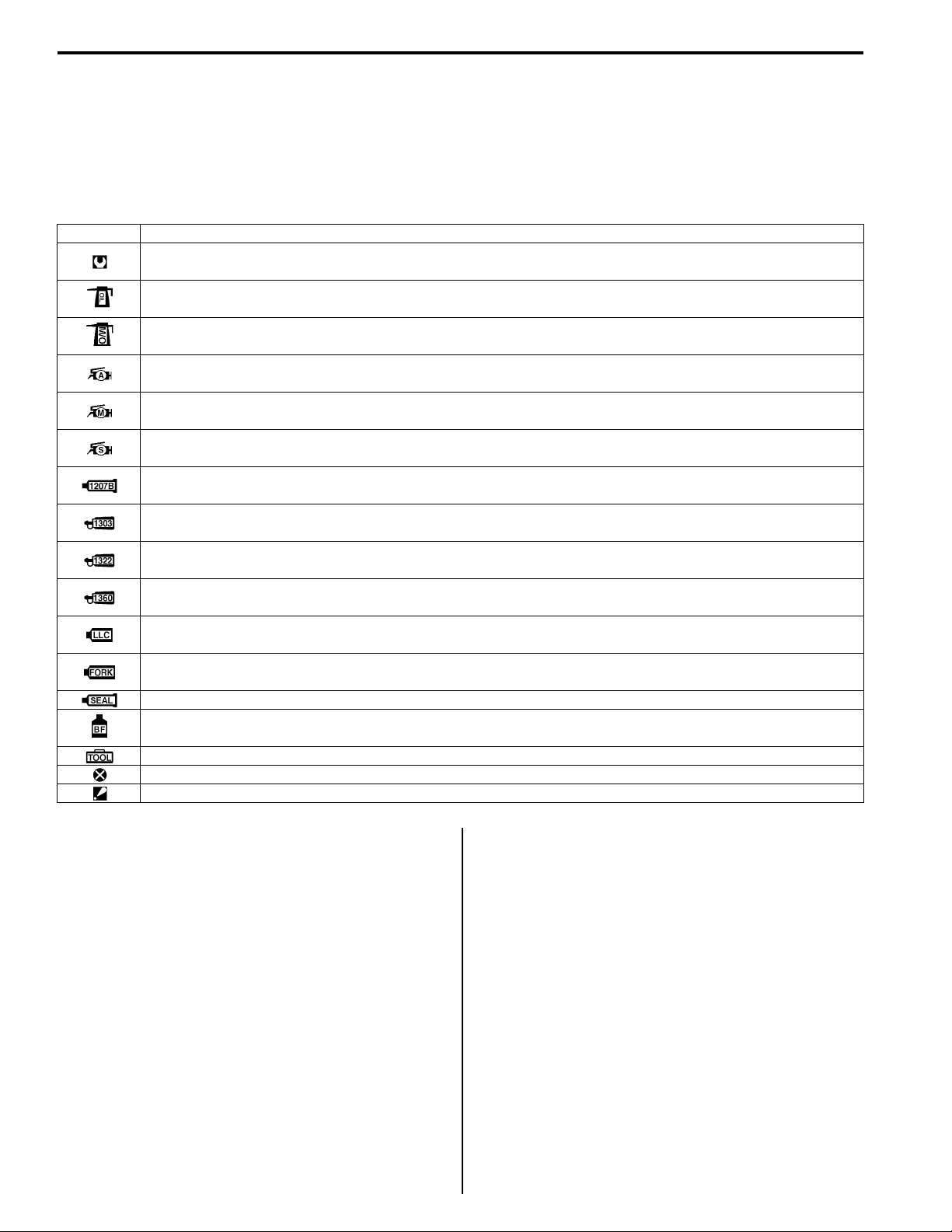

Symbols

B837H10101001

Listed in the table below are the symbols indicating instructions and other information necessary for servicing.

The meaning of each symbol is also included in the table.

Symbol Definition

Torque control required.

Data beside it indicate specified torque.

Apply oil.

Use engine oil unless otherwise specified.

Apply molybdenum oil solution.

(Mixture of engine oil and SUZUKl MOLY PASTE in a ratio of 1:1).

Apply SUZUKI SUPER GREASE “A” or equivalent.

99000-25010

Apply SUZUKI MOLY PASTE or equivalent.

99000-25140

Apply SUZUKI SILICONE GREASE or equivalent.

99000-25100

Apply SUZUKI BOND “1207B” or equivalent.

99000-31140

Apply THREAD LOCK SUPER “1303” or equivalent.

99000-32030

Apply THREAD LOCK SUPER “1322” or equivalent.

99000-32110

Apply THREAD LOCK SUPER “1360” or equivalent.

99000-32130

Use engine coolant or equivalent.

99000-99032-11X

Use fork oil or equivalent.

99000-99001-SS5

Apply MUFFLER SEAL LOCTITE “5920” (commercially available) or equivalent.

Apply or use brake fluid.

Use special tool.

Do not reuse.

Note on reassembly.

Abbreviations

B837H10101002

A:

ABDC: After Bottom Dead Center

AC: Alternating Current

ACL: Air Cleaner, Air Cleaner Box

API: American Petroleum Institute

ATDC: After Top Dead Center

ATM Pressure: Atmospheric Pressure, Atmospheric

Pressure Sensor (APS, AP Sensor)

A/F: Air Fuel Mixture

B:

BARO: Barometric pressure (Atmospheric pressure)

BBDC: Before Bottom Dead Center

BTDC: Before Top Dead Center

B+: Battery Positive Voltage

C:

CKP Sensor: Crankshaft Position Sensor (CKPS)

CKT: Circuit

CLP Switch: Clutch Lever Position Switch (Clutch

Switch)

CMP Sensor: Camshaft Position Sensor (CMPS)

CO: Carbon Monoxide

CPU: Central Processing Unit

D:

DC: Direct Current

DMC: Dealer Mode Coupler

DOHC: Double Over Head Camshaft

DRL: Daytime Running Light

DTC: Diagnostic Trouble code

General Information: 0A-2

E:

ECM: Engine Control Module Engine Control Unit

(ECU) (FI Control Unit)

ECT Sensor: Engine Coolant Temperature Sensor

(ECTS)

Water Temp. Sensor (WTS)

EVAP: Evaporative Emission

EVAP Canister: Evaporative Emission Canister

(EVAPC)

EXC System: Exhaust Control System (EXCS)

EXC Valve: Exhaust Control Valve (EXCV)

EXCV Actuator: Exhaust Control Valve Actuator

(EXCVA)

F:

FI: Fuel Injection, Fuel Injector

FP: Fuel pump

FPR: Fuel Pressure Regulator

FP Relay: Fuel Pump Relay

G:

GEN: Generator

GND: Ground

GP Switch: Gear Position Switch

H:

HC: Hydrocarbons

HO2 sensor: Heated Oxygen Sensor (HO2S)

I:

IAP Sensor: Intake Air Pressure Sensor (IAPS)

IAT Sensor: Intake Air Temperature Sensor (IATS)

IG: Ignition

ISC Valve: Idle Speed Control Valve (ISCV)

J:

JASO: Japanese Automobile Standards Organization

L:

LCD: Liquid Crystal Display

LED: Light Emitting Diode (Malfunction Indicator Lamp)

LH: Left Hand

M:

MAL-CODE: Malfunction Code (Diagnostic Code)

Max: Maximum

MIL: Malfunction Indicator Lamp (LED)

Min: Minimum

N:

NOx: Nitrogen Oxides

O:

OHC: Over Head Camshaft

OPS: Oil Pressure Switch

P:

PAIR: Pulsed Secondary Air Injection

PCM: Power Control Module

PCV: Positive Crankcase Ventilation (Crankcase

Breather)

R:

RH: Right Hand

ROM: Read Only Memory

S:

SAE: Society of Automotive Engineers

SDS: Suzuki Diagnosis System

SRAD: Suzuki Ram Air Direct

STC System: Secondary Throttle Control System

(STCS)

STP Sensor: Secondary Throttle Position Sensor

(STPS)

ST Valve: Secondary Throttle Valve (STV)

STV Actuator: Secondary Throttle Valve Actuator

(STVA)

T:

TO Sensor: Tip-over Sensor (TOS)

TP Sensor: Throttle Pos

ition Sensor (TPS)

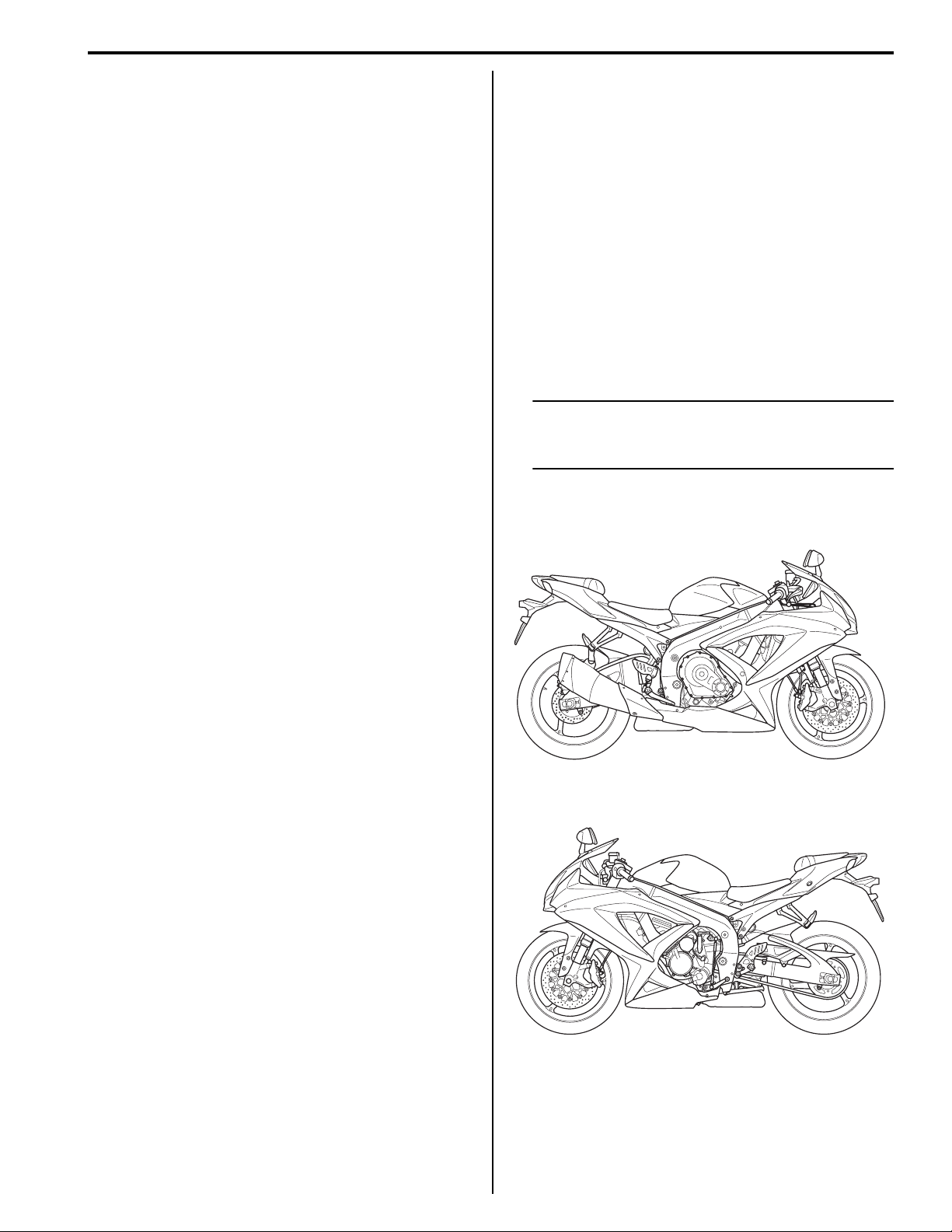

Vehicle Side View

B837H10101003

NOTE

Difference between illustrations and actual

motorcycles may exist depending on the

markets.

SUZUKI GSX-R600 (2008-model)

Right Side

I837H1010001-01

Left Side

I837H1010002-01

0A-3 General Information:

Vehicle Identification Number

B837H10101004

The frame serial number or V.I.N. (Vehicle Identification

Number) “A” is stamped on the right side of the steering

head tube. The engine serial number “B” is located on

the lower crankcase. These numbers are required

especially for registering the machine and ordering

spare parts.

“A”

I837H1010003-02

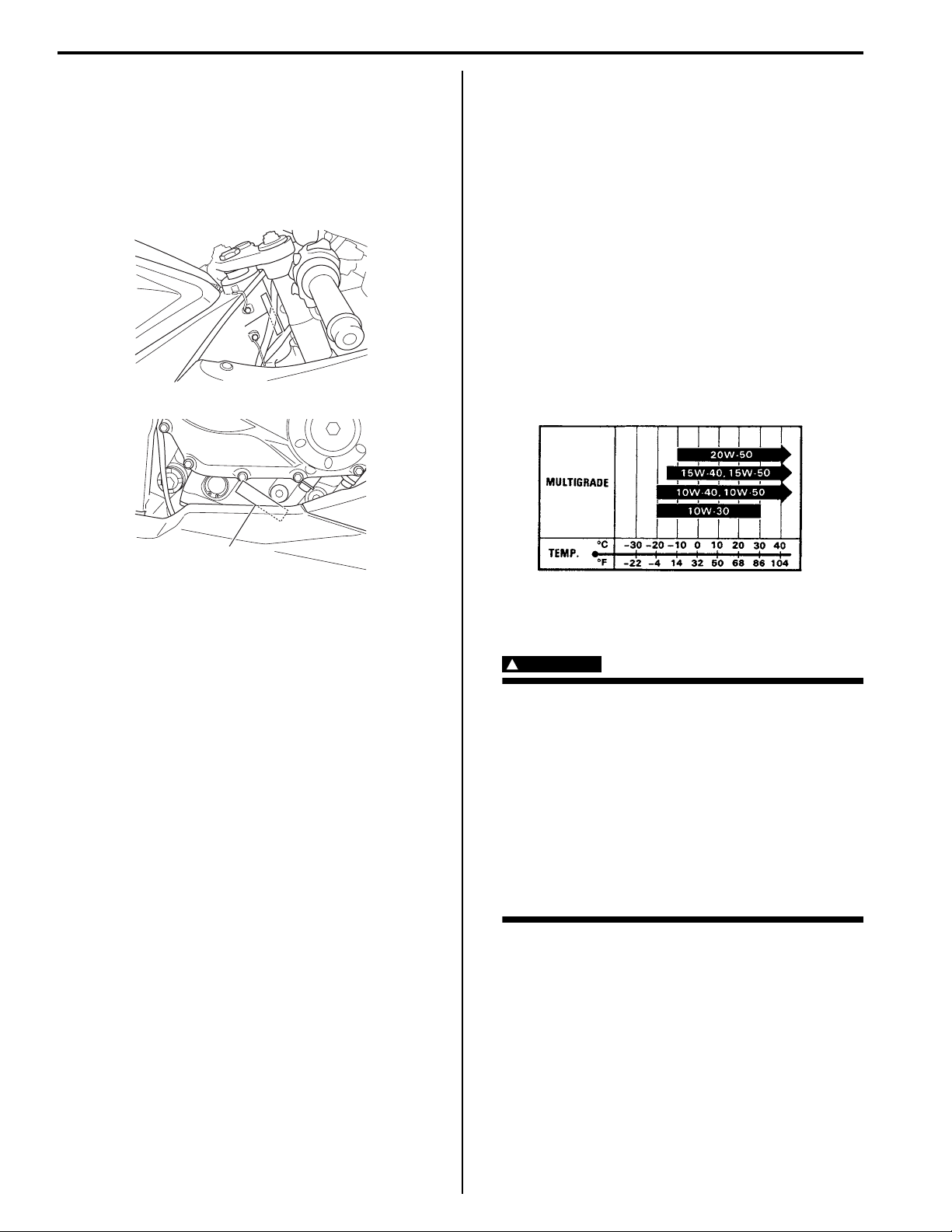

Engine Oil (For USA)

Oil quality is a major contributor to your engine’s

performance and life. Always select good quality engine

oil.

Suzuki recommends the use of SUZUKI

PERFORMANCE 4 MOTOR OIL or equivalent engine

oil. Use of SF/SG or SH/SJ in API with MA in JASO.

Suzuki recommends the use of SAE 10W-40 engine oil.

If SAE 10W-40 engine oil is not available, select and

alternative according to the chart.

Engine Oil (For Other Countries)

Oil quality is a major contributor to your engine’s

performance and life. Always select good quality engine

oil. Use of SF/SG or SH/SJ in API with MA in JASO.

Suzuki recommends the use of SAE 10W-40 engine oil.

If SAE 10W-40 engine oil is not available, select an

alternative according to the chart.

“B”

I837H1010004-01

Fuel and Oil Recommendation

B837H10101005

Fuel (For USA and Canada)

Use only unleaded gasoline of at least 87 pump octane

(R/2 + M/2).

Gasoline containing MTBE (Meltyl Tertiary Butyl Ether),

less than 10% ethanol, or less than 5% methanol with

appropriate cosolvents and corrosion inhibitor is

permissible.

Fuel (For Other Countries)

Gasoline used should be graded 91 octane (Research

Method) or higher. Unleaded gasoline is recommended.

Brake Fluid

Specification and classification: DOT 4

!

WARNING

Since the brake system of this motorcycle is

filled with a glycol-based brake fluid by the

manufacturer, do not use or mix different

types of fluid such as silicone-based and

petroleum-based fluid for refilling the

system, otherwise serious damage will

result.

Do not use any brake fluid taken from old or

used or unsealed containers.

Never reuse brake fluid left over from a

previous servicing, which has been stored

for a long period.

Front Fork Oil

Use fork oil SS-05 or equivalent fork oil.

I310G1010005-01

General Information: 0A-4

Engine Coolant Recommendation

B837H10101006

Engine Coolant

Use an anti-freeze/engine coolant compatible with an

aluminum radiator, mixed with distilled water only.

Water for mixing

Use distilled water only. Water other than distilled water

can corrode and clog the aluminum radiator.

Anti-freeze / Engine coolant

The engine coolant perform as a corrosion and rust

inhibitor as well as anti-freeze. Therefore, the engine

coolant should be used at all times even though the

atmospheric temperature in your area does not go down

to freezing point.

Suzuki recommends the use of SUZUKI COOLANT antifreeze/engine coolant. If this is not available, use an

equivalent which is compatible with an aluminum

radiator.

Liquid amount of water / Engine coolant

Solution capacity (total)

2 650 ml (2.8/2.3 US/Imp qt)

For engine coolant mixture information, refer to “Engine

Coolant Description in Section 1F (Page 1F-1)”.

!

CAUTION

Mixing of anti-freeze/engine coolant should

be limited to 60%. Mixing beyond it would

reduce its efficiency. If the anti-freeze/engine

coolant mixing ratio is below 50%, rust

inhabiting performance is greatly reduced.

Be sure to mix it above 50% even though the

atmospheric temperature does not go down

to the freezing point.

BREAK-IN Procedures

B837H10101007

During manufacture only the best possible materials are

used and all machined parts are finished to a very high

standard but it is still necessary to allow the moving parts

to “BREAK-IN” before subjecting the engine to maximum

stresses. The future performance and reliability of the

engine depends on the care and restraint exercised

during its early life. The general rules are as follows.

1) Keep to these break-in engine speed limits:

Speed limits

Initial 800 km (500 miles): Below 8 000 r/min

Up to 1 600 km (1 000 miles): Below 12 000 r/min

Over 1 600 km (1 000 miles): Below 16 000 r/min

2) Upon reaching an odometer reading of 1 600 km (1

000 miles) you can subject the motorcycle to full

throttle operation. However, do not exceed 16 000 r/

min at any time.

Cylinder Identification

B837H10101008

The four cylinders of this engine are identified as #1, 2, 3

and #4 cylinder, as counted from left to right (as viewed

by the rider on the seat).

#1

#2

#3

#4

I837H1010008-01

0A-5 General Information:

Country and Area Codes

The following codes stand for the applicable country(-ies) and area(-s).

Code Country or Area Effective Frame No.

GSX-R600 K8 (E-02) U.K. JS1CV111100100001 –

GSX-R600 K8 (E-19) E.U. JS1CV111100100001 –

GSX-R600U2 K8 (E-19) E.U. JS1CV211100100001 –

GSX-R600U3 K8 (E-19) E.U. JS1CV311100100001 –

GSX-R600 K8 (E-03) U.S.A (Except for California) JS1GN7EA 82100001 –

GSX-R600 K8 (E-24) Australia JS1CV111200100001 –

GSX-R600 K8 (E-28) Canada JS1GN7EA 82100001 –

GSX-R600 K8 (E-33) California (U.S.A) JS1GN7EA 82100001 –

Wire Color Symbols

Symbol Wire Color Symbol Wire Color

B Black G/W Green with White tracer

Bl Blue G/Y Green with Yellow tracer

Br Brown Gr/B Gray with Black tracer

Dbr Dark brown Gr/R Gray with Red tracer

Dg Dark green Gr/W Gray with White tracer

G Green Gr/Y Gray with Yellow tracer

Gr Gray Lg/Bl Light green with Blue tracer

Lbl Light blue Lg/G Light green with Green tracer

Lg Light green Lg/W Light green with White tracer

O Orange O/B Orange with Black tracer

P Pink O/Bl Orange with Blue tracer

R Red O/G Orange with Green tracer

W White O/R Orange with Red tracer

Y Yellow O/W Orange with White tracer

B/Bl Black with Blue tracer O/Y Orange with Yellow tracer

B/Br Black with Brown tracer P/B Pink with Black tracer

B/G Black with Green tracer P/W Pink with White tracer

B/Lg Black with Light green tracer R/B Red with Black tracer

B/O Black with Orange tracer R/Bl Red with Blue tracer

B/R Black with Red tracer R/Y Red with Yellow tracer

B/W Black with White tracer W/B White with Black tracer

B/Y Black with Yellow tracer W/Bl White with Blue tracer

Bl/B Blue with Black tracer W/G White with Green tracer

Bl/G Blue with Green tracer W/R White with Red tracer

Bl/W Blue with White tracer W/Y White with Yellow tracer

Bl/Y Blue with Yellow tracer Y/B Yellow with Black tracer

Br/B Brown with Black tracer Y/Bl Yellow with Blue tracer

Br/Y Brown with Yellow tracer Y/G Yellow with Green tracer

G/B Green with Black tracer Y/R Yellow with Red tracer

G/Bl Green with Blue tracer Y/W Yellow with White tracer

G/R Green with Red tracer

B837H10101009

B837H10101010

General Information: 0A-6

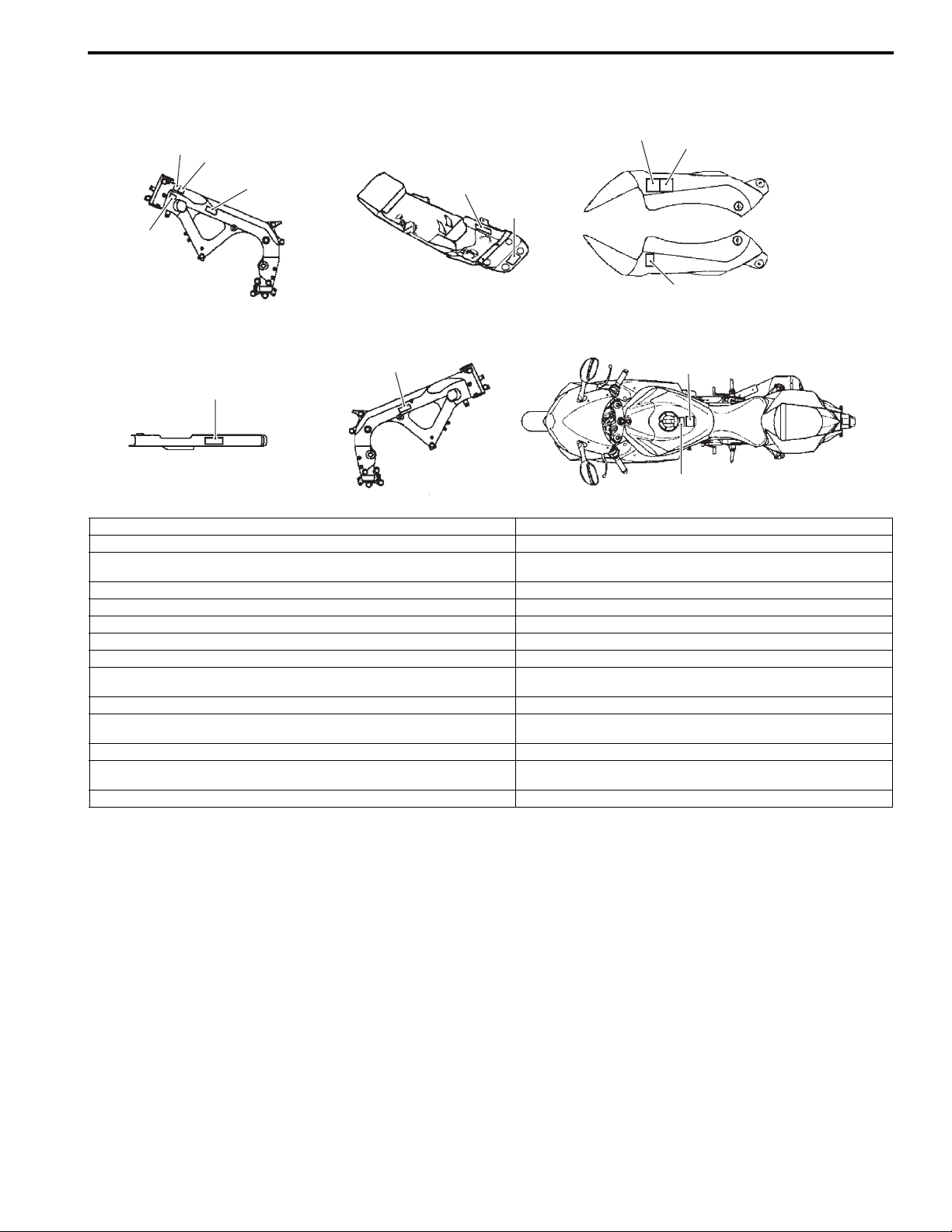

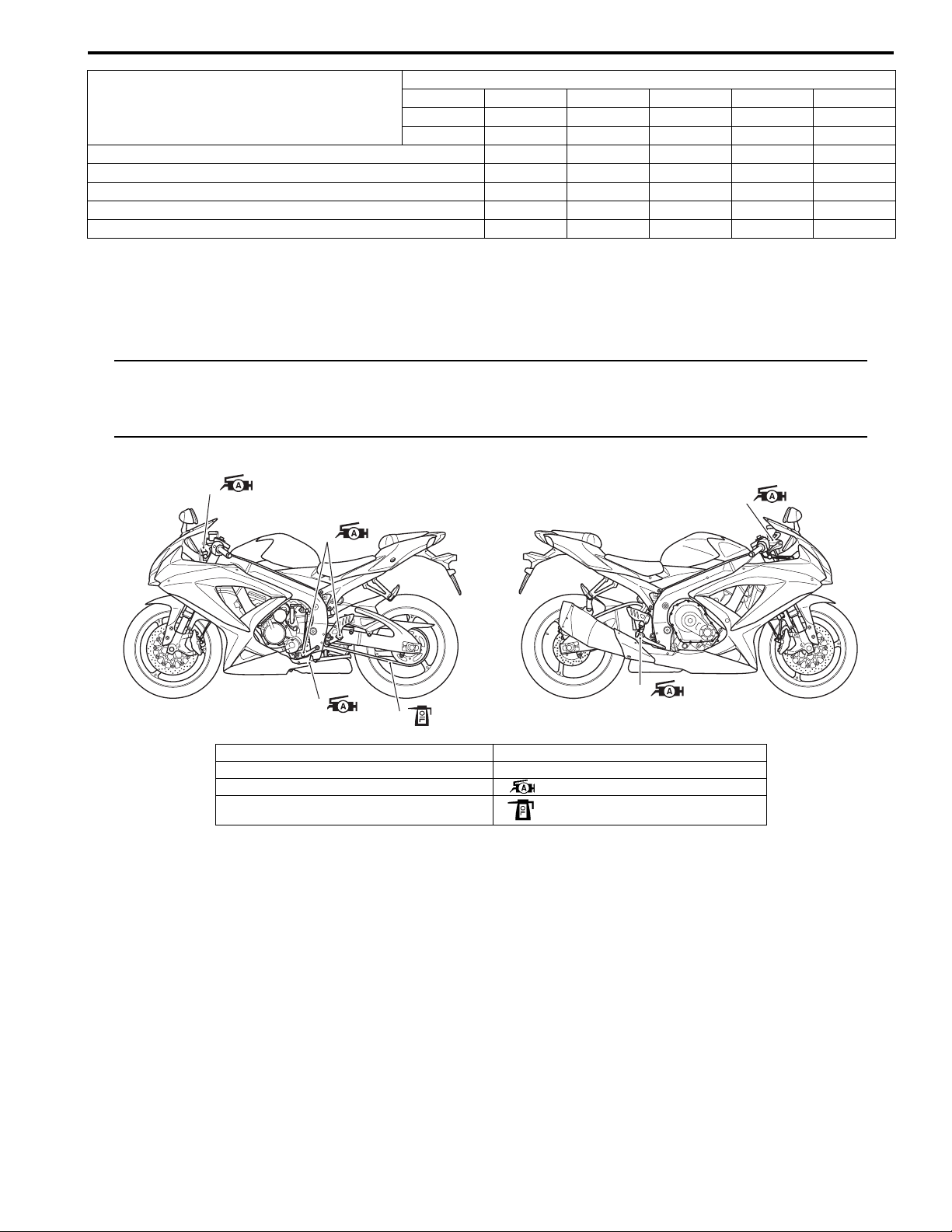

Warning, Caution and Information Labels Location

B837H10101011

7, 9

[A] [B]

1

2, 3

19, 21

4

6

18

[D] [E]

20

12, 13

1. Noise label (For E-03, 33) 15. General warning label (French) (For GSX-R600U2 E-19)

2. Noise label (For E-24) 16. General warning label (English/French) (For E-28)

3. Information label (For E-03, 28, 33) 17. General warning label (French/German/Italian/Swedish) (For E-19,

4. Vacuum hose routing label (For E-33) 18. ICES Canada label (For E-28)

5. Fuel caution label (For E-24) 19. I.D. plate (For E-02, 19, 24, GSX-R600U2 E-19, GSX-R600U3 E-19)

6. Manual notice label (For E-03, 33) 20. I.D. label (For GSX-R600U2 E-19)

7. Screen label (English) (For E-02, 03, 24, 28, 33) 21. Safety plate (For E-03, 28, 33)

8. Screen label (French) (For E-28) [A]: Frame (LH)

9. Screen label (French/German/Italian/Swedish) (For E-19, GSX-R600U2 E-19,

GSX-R600U3 E-19)

10. Steering warning label (English) (For E-03, 33) [C]: Intake cover

11. Steering warning label (French/German/English) (For E-02, 19, 24, 28, GSXR600U2 E-19, GSX-R600U3 E-19)

12. Tire information label (English) (For E-03, 33) [E]: Frame (RH)

13. Tire information label (French/German/English) (For E-02, 19, 24, 28, GSXR600U2 E-19, GSX-R600U3 E-19)

14. General warning label (English) (For E-02, 03, 24, 33)

[B]: Rear fender, front

[D]: Chain case

[C]

GSX-R600U3 E-19)

8

10, 11

14, 15, 16, 17

5

I837H1010005-01

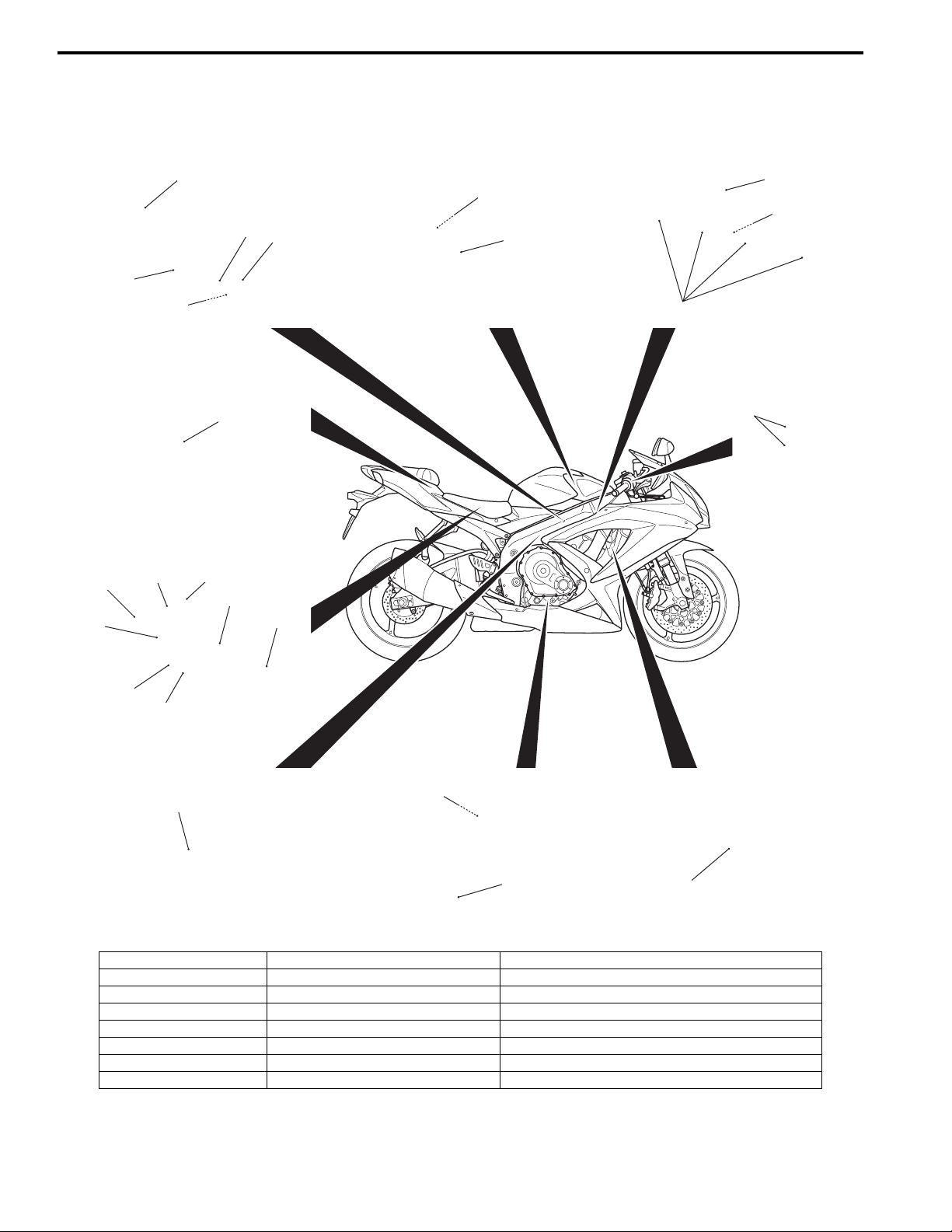

0A-7 General Information:

Component Location

Electrical Components Location

1

4

5

2

3

11

B837H10103001

10

7

9

6

8

12

16

17

18

19

15

20

14

13

22

21

23

1. EXCV actuator 9. CMP sensor 17. Fuel pump relay

2. IAP sensor 10. PAIR control solenoid valve 18. Cooling fan relay

3. TP sensor 11. Starter relay/Main fuse 19. AP sensor

4. STP sensor 12. Drive mode selector 20. Battery

5. STV actuator 13. Fuse box 21. EVAP system purge control solenoid valve (E-33 only)

6. Fuel pump 14. ECM 22. CKP sensor

7. Fuel level gauge 15. TO sensor 23. HO2 sensor

8. Ignition coil 16. Mode select switch coupler 24. Cooling fan

24

I837H1010006-03

27

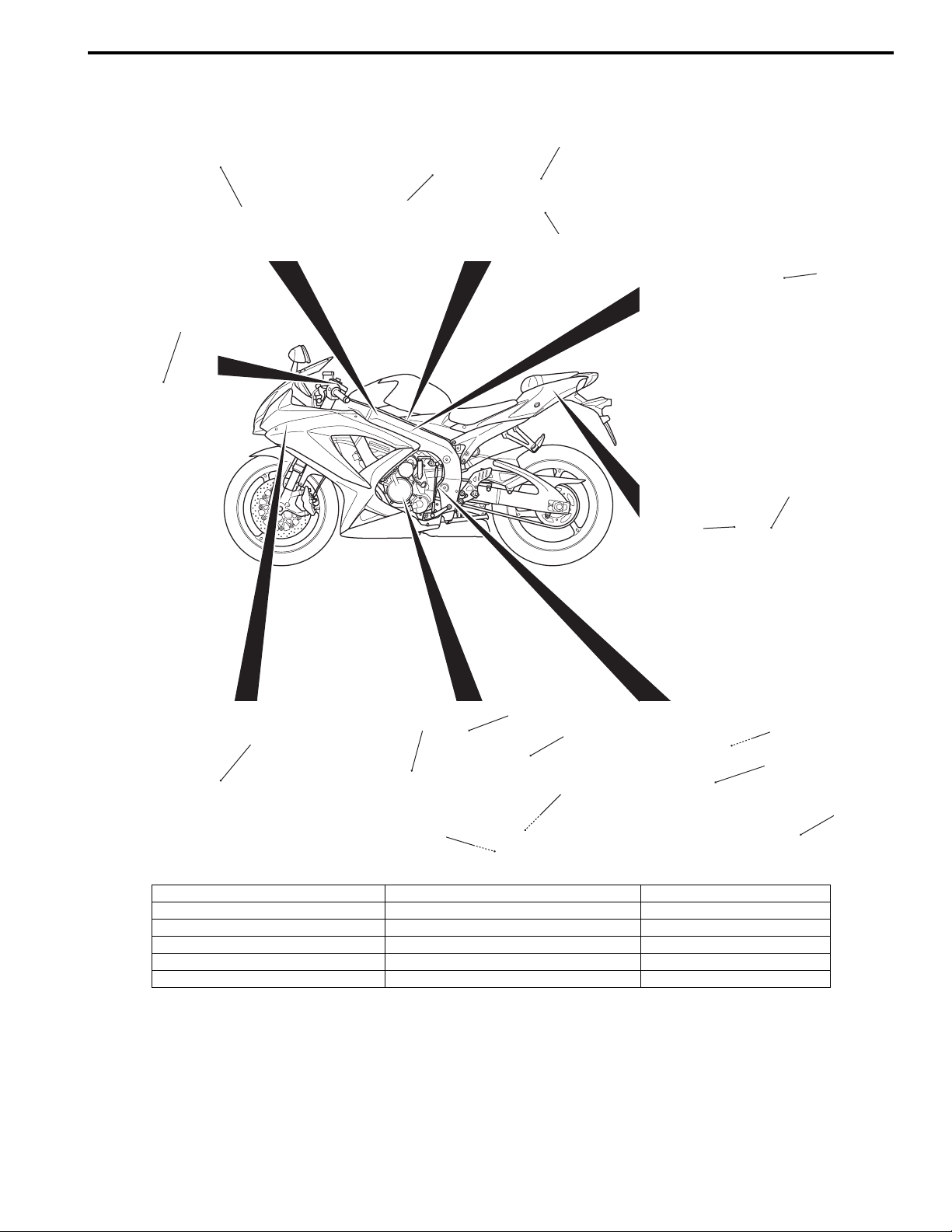

General Information: 0A-8

29

25

26

28

30

31

32

33

34

35

36

38

37

25. IAT sensor 31. Head light relay 37. Oil pressure switch

26. ISC valve 32. Turn signal/Side-stand relay 38. Generator

27. Secondary fuel injector 33. Steering damper solenoid valve 39. GP switch

28. Primary fuel injector 34. Horn 40. Speed sensor

29. Ignition switch 35. Regulator/Rectifier 41. Side-stand switch

30. ECT sensor 36. Starter motor

39

40

41

I837H1010007-03

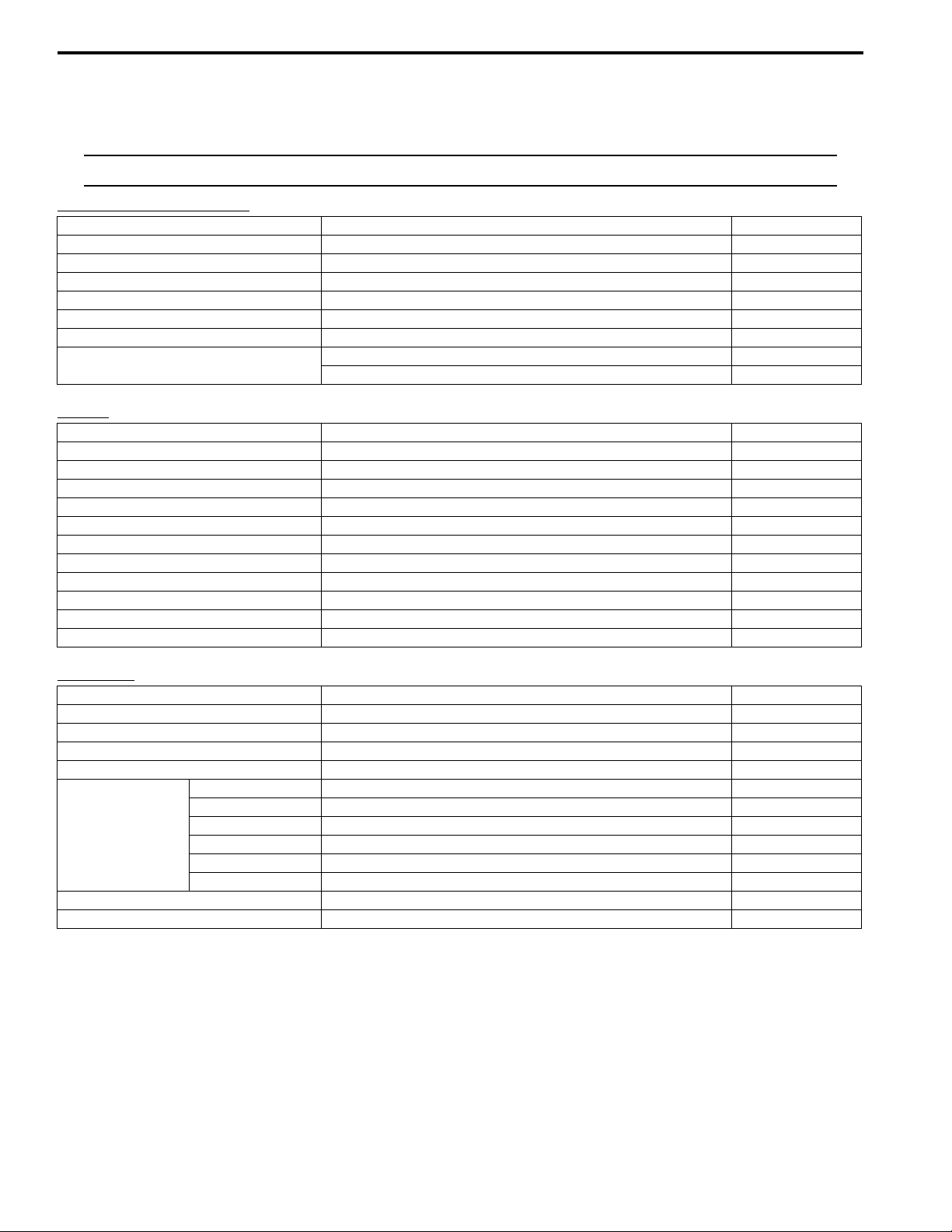

0A-9 General Information:

Specifications

Specifications

NOTE

These specifications are subject to change without notice.

Dimensions and dry mass

Item Specification Remark

Overall length 2 040 mm (80.3 in)

Overall width 715 mm (28.1 in)

Overall height 1 125 mm (44.3 in)

Wheelbase 1 400 mm (55.1 in)

Ground clearance 130 mm (5.1 in)

Seat height 810 mm (31.9 in)

Dry mass

Engine

Item Specification Remark

Type 4-stroke, Liquid-cooled, DOHC

Number of cylinders 4

Bore 67.0 mm (2.638 in)

Stroke 42.5 mm (1.673 in)

Displacement 599 cm

Compression ratio 12.8 : 1

Fuel system Fuel injection system

Air cleaner Paper element

Starter system Electric

Lubrication system Wet sump

Idle speed 1 300 ± 100 r/min

166 kg (365 lbs) E-33

165 kg (363 lbs) Others

3

(36.5 cu. in)

B837H10107001

Drive train

Item Specification Remark

Clutch Wet multi-plate type

Transmission 6-speed constant mesh

Gearshift pattern 1-down, 5-up

Primary reduction ratio 1.974 (77/39)

Low 2.785 (39/14)

2nd 2.052 (39/19)

Gear ratios

3rd 1.714 (36/21)

4th 1.500 (36/24)

5th 1.347 (31/23)

Top 1.208 (29/24)

Final reduction ratio 2.687 (43/16)

Drive chain RK 525SMOZ8, 114 links

General Information: 0A-10

Chassis

Item Specification Remark

Front suspension Inverted telescopic, coil spring, oil damped

Rear suspension Link type, coil spring, oil damped

Front suspension stroke 120 mm (4.7 in)

Rear wheel travel 130 mm (5.1 in)

Caster 23° 45’

Tail 97 mm (3.8 in)

Steering angle 27° (right & left)

Turning radius 3.4 m (11.2 ft)

Front brake Disc brake, twin

Rear brake Disc brake

Front tire size 120/70ZR17M/C (58W), tubeless

Rear tire size 180/55ZR17M/C (73W), tubeless

Electrical

Item Specification Remark

Ignition type Electronic ignition (Transistorized)

Ignition timing 6° B.T.D.C. at 1 300 r/min

Spark plug NGK CR9EIA-9 or DENSO IU27D

Battery 12 V 28.8 kC (8 Ah)/10 HR

Generator Three-phase A.C. generator

Main fuse 30 A

Fuse 15/10/15/15/10/10 A

Headlight

Position 12 V 5 W

Brake light/Taillight LED

License plate light 12 V 5 W

Turn signal light 12 V 21 W

Speedometer light LED

Tachometer light LED

Fuel level indicator light LED

Turn signal indicator light LED

Neutral indicator light LED

High beam indicator light LED

Oil pressure/Coolant temperature/

FI indicator light

Engine R.P.M. indicator light LED

Immobilizer indicator light LED E-02, 19, 24

High 12 V 60 W (HB3) x 2

Low 12 V 55 W (H11)

LED

Capacities

Item Specification Remark

Fuel tank

Oil change 2 200 ml (2.3/1.9 US/lmp qt)

Engine oil

Engine coolant 2.65 L (2.8/2.3 US/lmp qt)

With filter change 2 500 ml (2.6/2.2 US/lmp qt)

Overhaul 2 900 ml (3.1/2.6 US/lmp qt)

16 L (4.2/3.5 US/lmp gal) E-33

17 L (4.5/3.7 US/lmp gal) Others

0A-11 General Information:

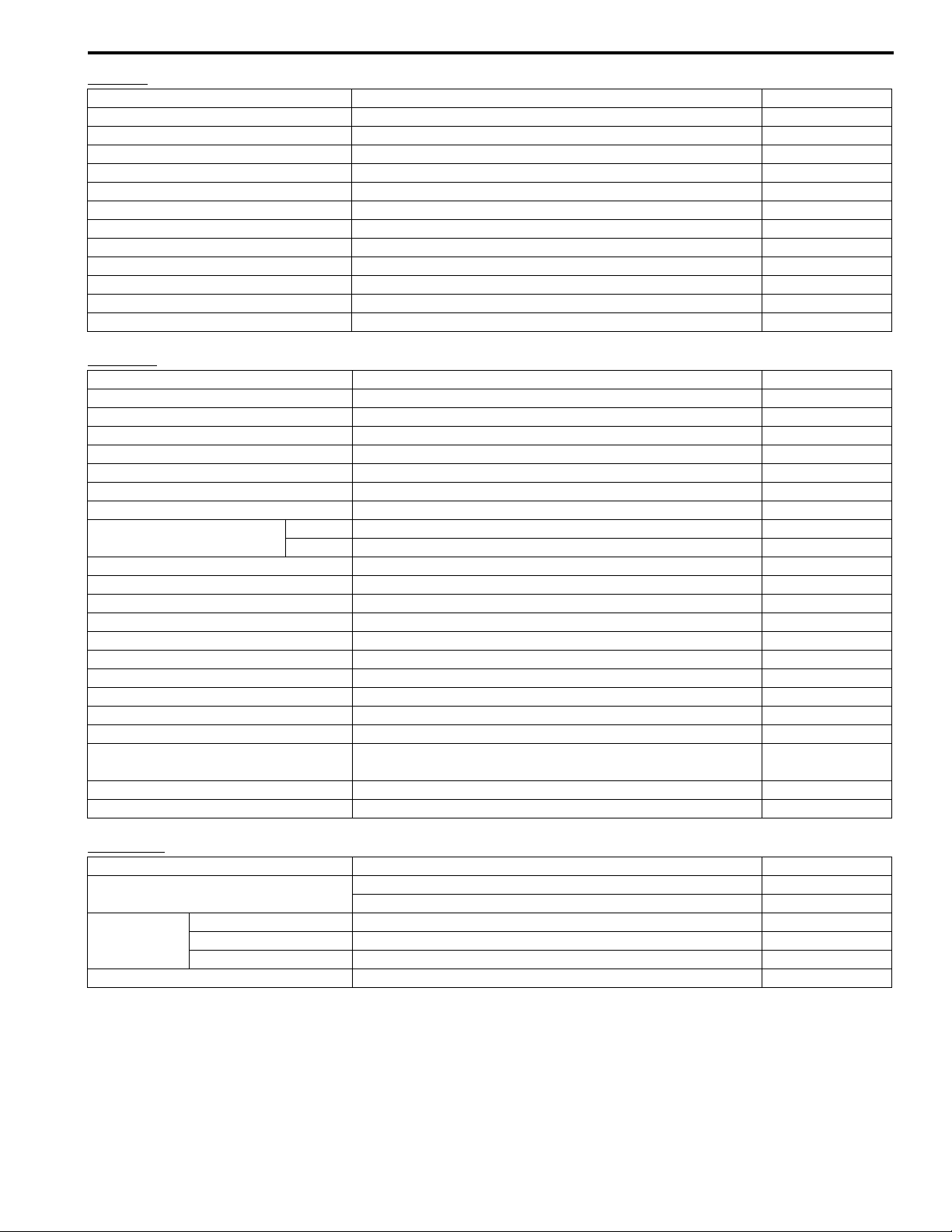

Special Tools and Equipment

Special Tool

09900–06104

Snap ring pliers

09900–20202

Micrometer (1/100

mm, 25 – 50 mm)

09900–06107

Snap ring pliers

09900–20203

Micrometer (1/100

mm, 50 – 75 mm)

09900–06108

Snap ring pliers

09900–20205

Micrometer (0 – 25

mm)

09900–18740

Hexagon socket (24

mm)

09900–20530

Cylinder gauge set

B837H10108002

09900–20102

Vernier calipers (1/20

mm, 200 mm)

09900–20602

Dial gauge (1/1000

mm, 1 mm)

09900–20605

Dial calipers (1/100

mm, 10 – 34 mm)

09900–21304

V-block (100 mm)

09900–25008

Multi-circuit tester set

09900–20607

Dial gauge (1/100 mm,

10 mm)

09900–22301

Plastigauge (0.025 –

0.076 mm)

09900–25009

Needle pointed probe

set

09900–20701

Magnetic stand

09900–22302

Plastigauge (0.051 –

0.152 mm)

09900–28630

TPS test wire harness

09900–20803

Thickness gauge

09900–22401

Small bore gauge (10

– 18 mm)

09904–41010

SDS set

09900–20805

Tire depth gauge

09900–22403

Small bore gauge (18

– 35 mm)

09913–10750

Compression gauge

adapter

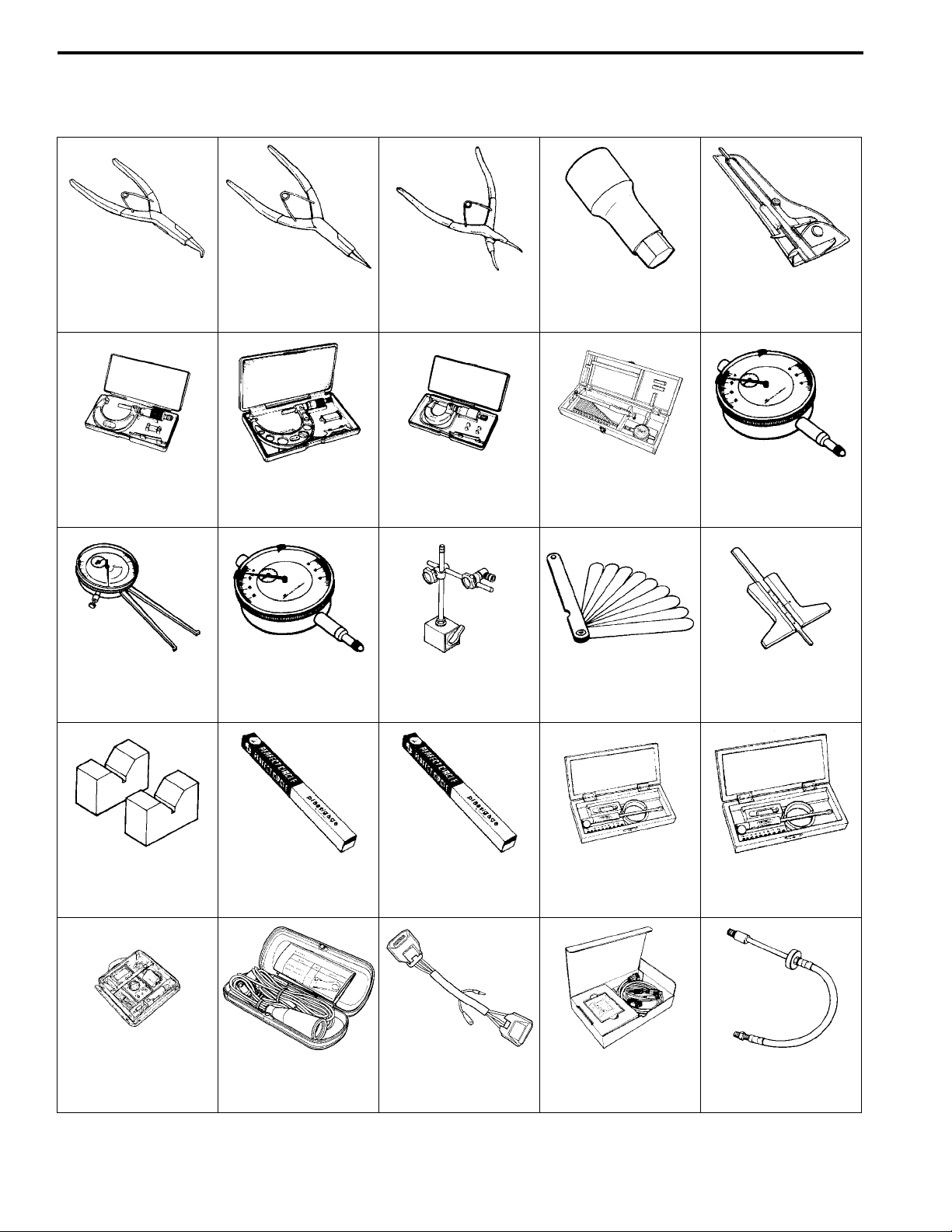

General Information: 0A-12

09913–50121

Oil seal remover

09915–74540

Oil pressure gauge

attachment

09916–33210

Valve guide reamer

(4.5 mm)

09913–70210

Bearing installer set

09915–77331

Meter (for high

pressure)

09916–33320

Valve guide reamer

(9.8 mm)

09915–40610

Oil filter wrench

09916–10911

Valve lapper set

09916–34542

Reamer handle

09915–64512

Compression gauge

09916–14510

Valve spring

compressor

09916–43211

Valve guide remover/

installer

09915–74521

Oil pressure gauge

hose

09916–14522

Valve s p r ing

compressor

attachment

09916–57370

Attachment

09916–77310

Piston ring

compressor

09921–20210

Bearing remover

09916–84511

Tweezers

09921–20240

Bearing remover set

09917–47011

Vacuum pump gauge

09922–22711

Drive chain cutting

and joining tool

09919–28620

Sleeve protector

09923–74511

Bearing remover

09920–53740

Clutch sleeve hub

holder

09924–84510

Bearing installer set

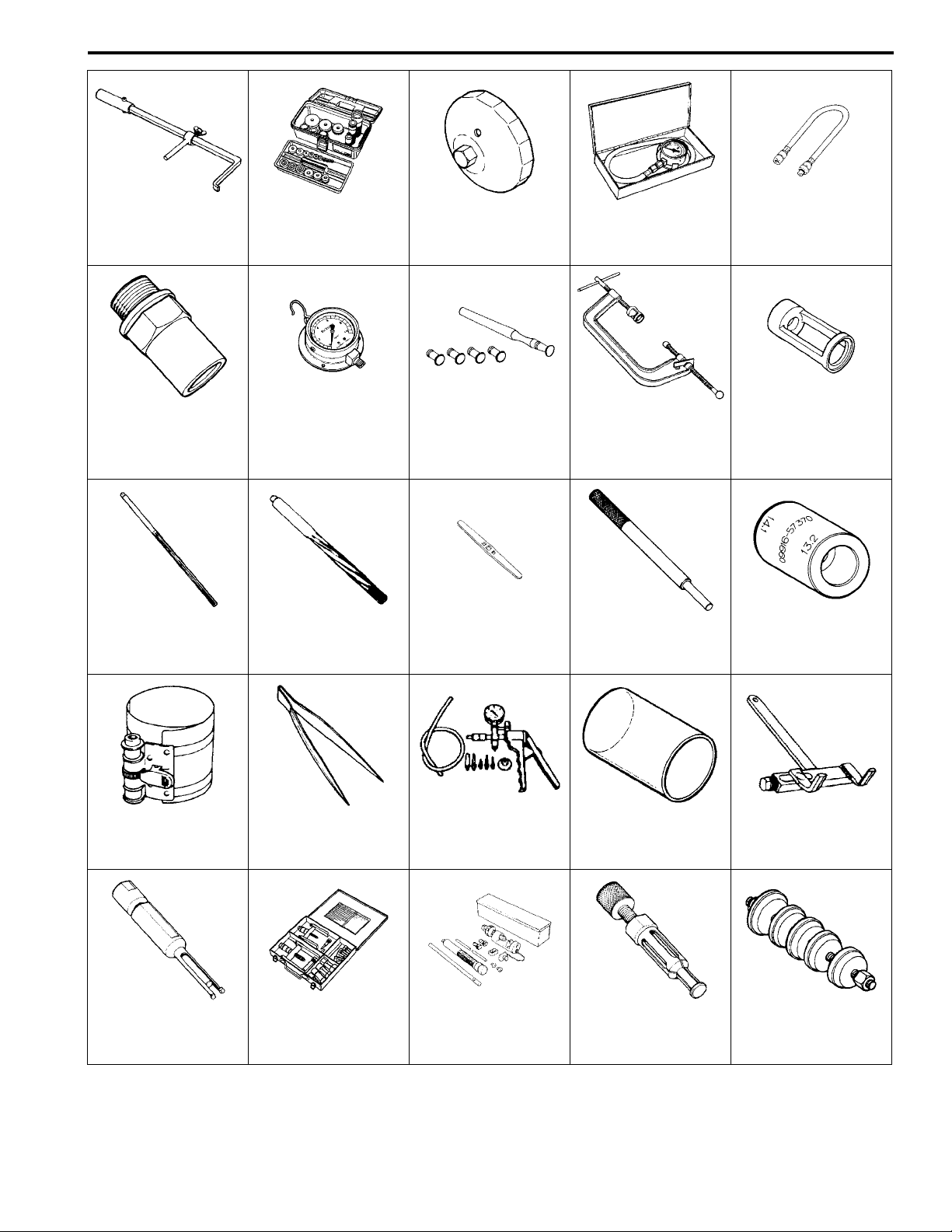

0A-13 General Information:

09924–84521

Bearing installer set

09930–11950

Torx wrench

09930–82720

Mode select switch

09925–18011

Steering bearing

installer

09930–30104

Rotor remover slide

shaft

09940–14911

Steering stem nut

wrench

09930–10121

Spark plug wrench set

09930–34980

Rotor remover

09940–14940

Swingarm pivot thrust

adjuster socket

wrench

09930–11920

Torx bit (JT40H)

09930–44520

Rotor holder

09940–14960

Steering nut wrench

socket

09930–11940

Bit holder

09930–44530

Rotor holder

09940–14980

Rotor remover

09940–30221

Front fork assembling

tool

09940–92720

Spring scale

09940–40211

Fuel pressure gauge

adapter

09940–94922

Front fork spring

stopper plate

09940–40220

Fuel pressure gauge

hose attachment

09940–94930

Front fork spacer

holder

09940–52841

Inner rod holder

09941–34513

Steering race installer

09940–52861

Front fork oil seal

installer

09943–74111

Fork oil level gauge

General Information: 0A-14

09944–28320

Hexagon socket (19

mm)

99565–01010–015

CD-ROM Ver.15

0B-1 Maintenance and Lubrication:

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance

B837H10200001

The “Periodic Maintenance Schedule Chart” lists the recommended intervals for all the required periodic service work

necessary to keep the motorcycle operating at peak performance and economy. Maintenance intervals are expressed

in terms of kilometers, miles and months for your convenience.

NOTE

More frequent servicing may be required on motorcycles that are used under severe conditions.

General Description

Recommended Fluids and Lubricants

Refer to “Fuel and Oil Recommendation in Section 0A (Page 0A-3)” and “Engine Coolant Recommendation in Section

0A (Page 0A-4)”.

B837H10201001

Scheduled Maintenance

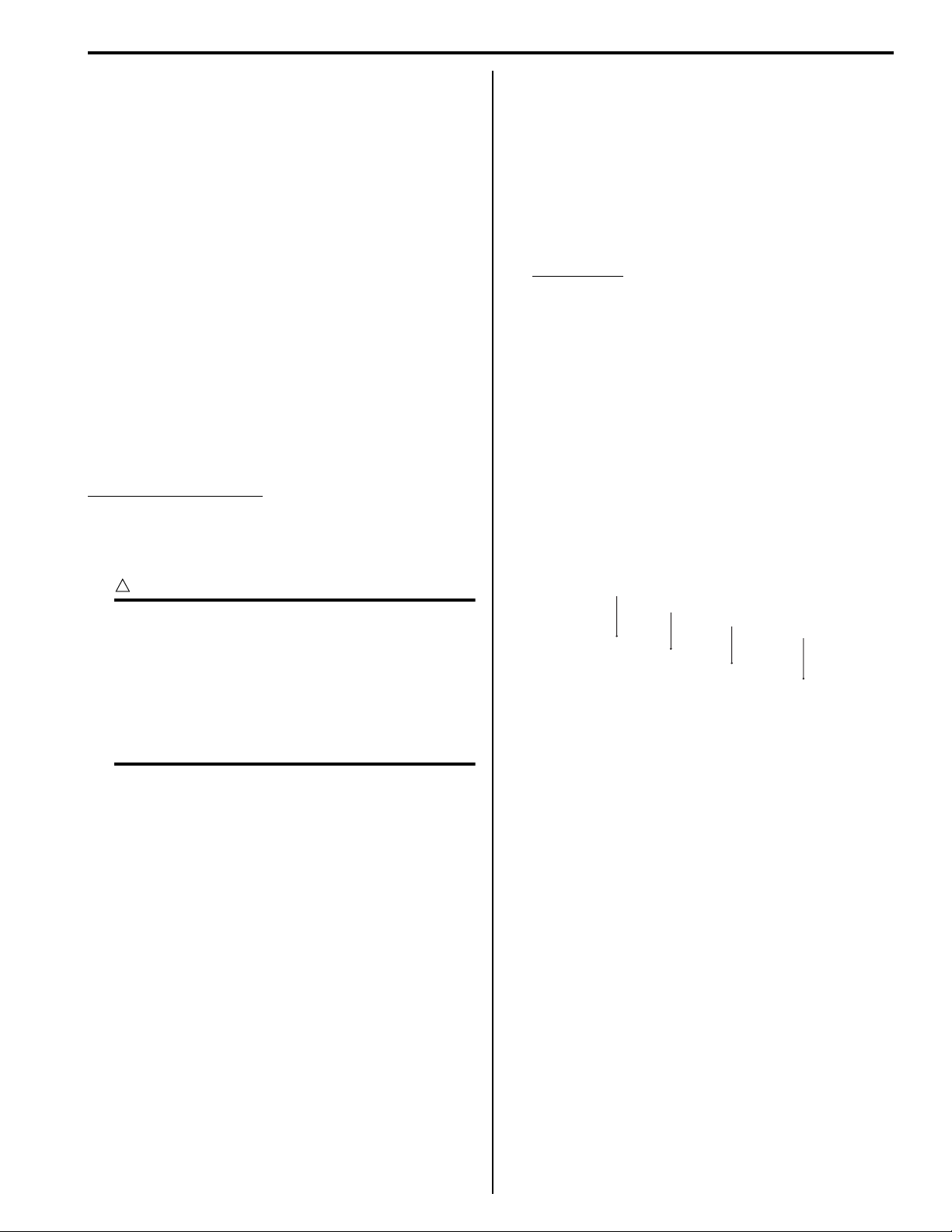

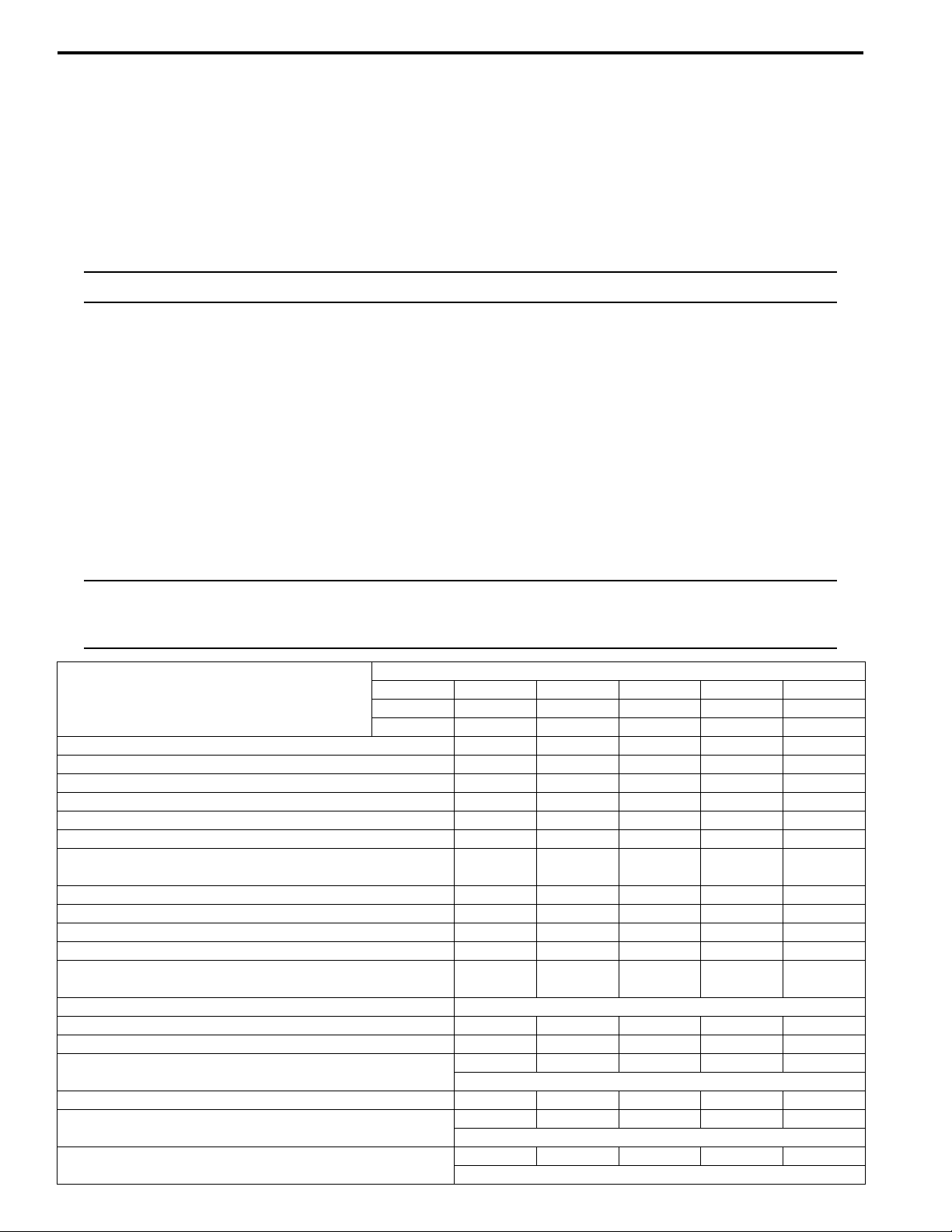

Periodic Maintenance Schedule Chart

NOTE

I = Inspect and clean, adjust, replace or lubricate as necessary.

R = Replace.

T = Tighten.

Interval

Item

Air cleaner element — I I R I

Exhaust pipe bolts and muffler bolts T — T — T

Exhaust control valve I — I — I

Valve clearance ———— I

Spark plugs — I R I R

Fuel line —IIII

Evaporative emission control system

(E-33 only)

Engine oil RRRRR

Engine oil filter R — — R —

Throttle cable play IIIII

PAIR (air supply) system — — I — I

Throttle valve synchronization

Engine coolant Replace every 2 years.

Radiator hose —IIII

Clutch cable play —IIII

Drive chain

Brakes IIIII

Brake fluid

Brake hoses

km 1 000 6 000 12 000 18 000 24 000

miles 600 4 000 7 500 11 000 14 500

months2 12243648

—— I — I

I

(E-33 only)

—I—I

IIIII

Clean and lubricate every 1 000 km (600 miles).

—IIII

Replace every 2 years.

—IIII

Replace every 4 years.

B837H10205001

Maintenance and Lubrication: 0B-2

Interval

Item

km 1 000 6 000 12 000 18 000 24 000

miles 600 4 000 7 500 11 000 14 500

months2 12243648

Tires —IIII

Steering I—I—I

Front fork — — I — I

Rear suspension — — I — I

Chassis bolts and nuts TTTTT

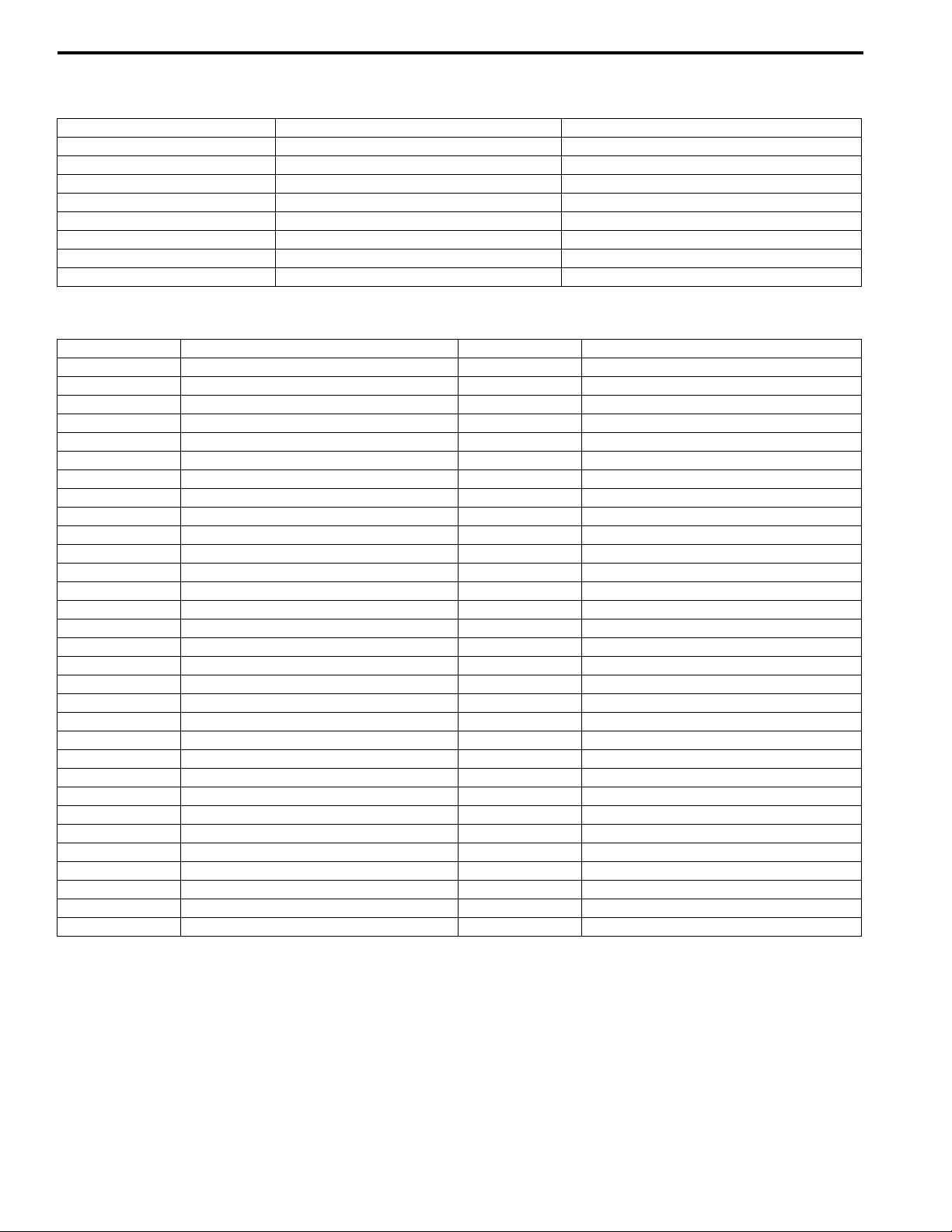

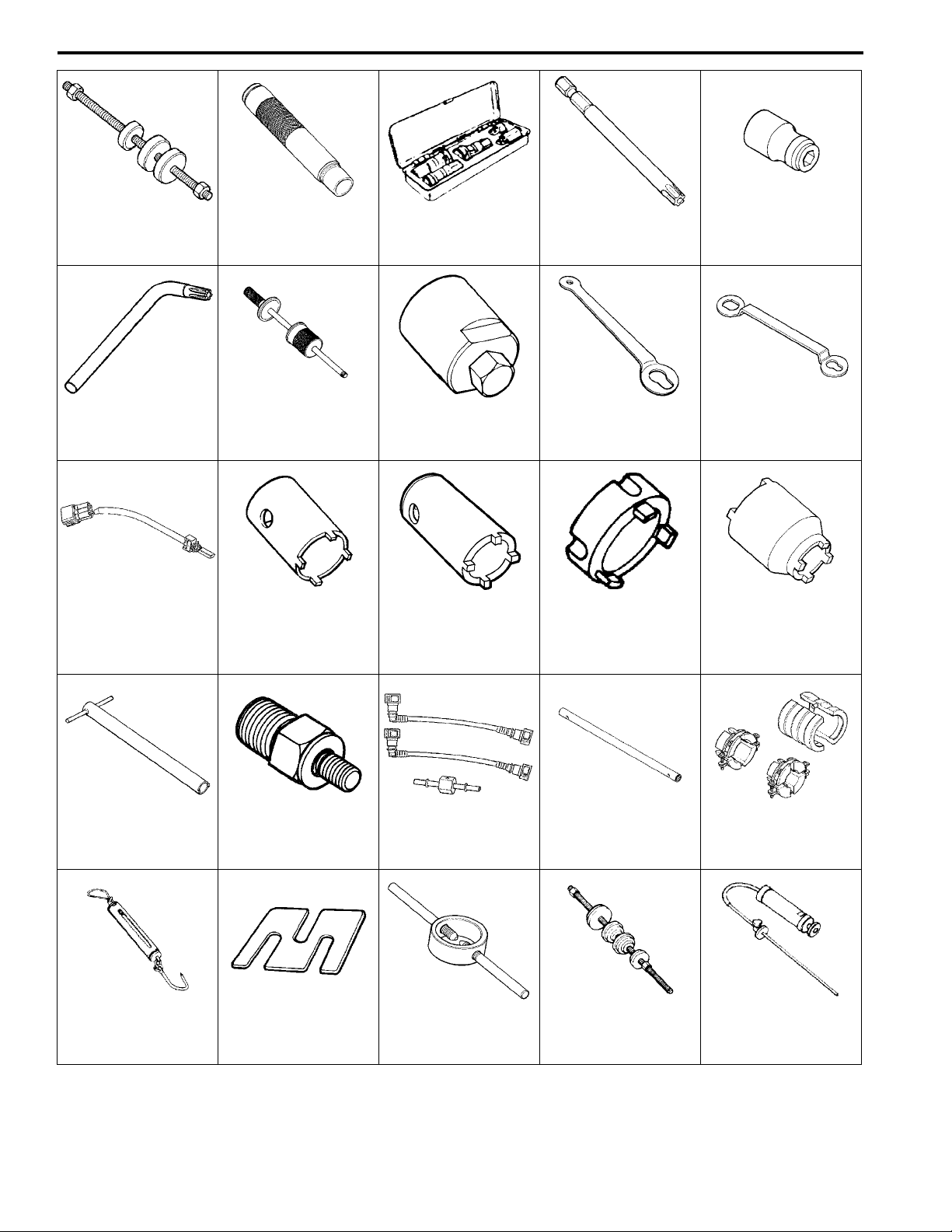

Lubrication Points

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle.

Major lubrication points are indicated as follows.

NOTE

• Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or grime.

• Lubricate exposed parts which are subject to rust, with a rust preventative spray whenever the

motorcycle has been operated under wet or rainy conditions.

1

3

2

1. Clutch lever holder 5. Brake lever holder

2. Side stand pivot and spring hook 6. Brake pedal pivot and footrest pivot

3. Gearshift lever pivot and footrest pivot : Apply grease.

4. Drive chain : Apply oil.

4

6

5

B837H10205002

I837H1020001-01

0B-3 Maintenance and Lubrication:

FWD

Repair Instructions

Air Cleaner Element Replacement

B837H10206001

Replace air cleaner element

Every 18 000 km (11 000 miles, 36 months)

Refer to “Air Cleaner Element Removal and Installation

in Section 1D (Page 1D-6)”.

Air Cleaner Element Inspection

B837H10206002

Inspect air cleaner element

Every 6 000 km (4 000 miles, 12 months)

Inspection

1) Remove the air cleaner element. Refer to “Air

Cleaner Element Removal and Installation in Section

1D (Page 1D-6)”.

2) Inspect the air cleaner element for clogging. If it is

clogged with dirt, replace it with a new one.

!

CAUTION

Do not blow the air cleaner element with

compressed air.

NOTE

If driving under dusty conditions, replace the

air cleaner element more frequently. Make

sure that the air cleaner is in good condition

at all times. The life of the engine depends

largely on this component.

3) Drain water from the air cleaner box by removing the

drain plug (1).

1

I837H1020003-01

4) Reinstall the removed parts.

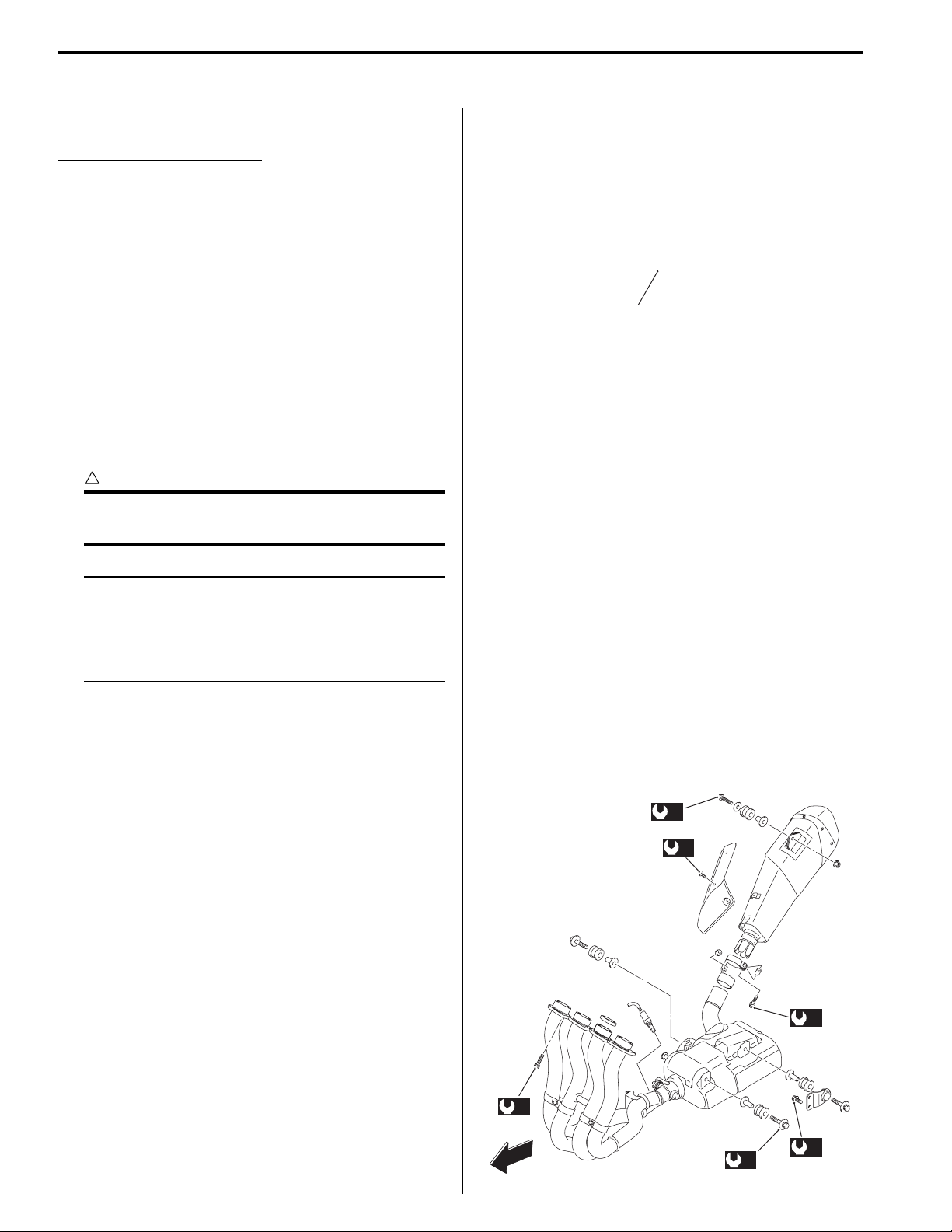

Exhaust Pipe Bolt and Muffler Bolt Inspection

B837H10206003

Tighten exhaust pipe bolts and muffler bolts

Initially at 1 000 km (600 miles, 2 months) and every

12 000 km (7 500 miles, 24 months) thereafter

Check the exhaust pipe bolts and muffler bolts to the

specified torque.

Tightening torque

Exhaust pipe bolt (a): 23 N·m (2.3 kgf-m, 16.5 lb-ft)

Exhaust pipe mounting bolt (b): 23 N·m (2.3 kgf-m,

16.5 lb-ft)

Exhaust pipe bracket bolt (c): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Muffler connecting bolt (d): 23 N·m (2.3 kgf-m, 16.5

lb-ft)

Muffler cover bolt (e): 5.5 N·m (0.55 kgf-m, 4.0 lb-ft)

Muffler mounting bolt (f): 25 N·m (2.5 kgf-m, 18.0 lbft)

I837H1020002-01

(a)

FWD

(f)

(e)

(d)

(c)

(b)

I837H1020004-03

Loading...

Loading...