Superior SLO-SYN SS2000MD4 User Manual

www.DanaherMotion.com

Installation Instructions for SLO-SYN ® MODEL SS2000MD4 Translator Drive

400030-043 Rev G

Danaher Motion Superior Electric

Record of Manual Revisions

ISSUE |

Date |

Description of Revision |

G |

09/12/2003 |

Updated corporate information |

Copyright Information

ã Copyright 1992 - 2003 Danaher Motion - All rights reserved. Printed in the United States of America.

NOTICE:

Not for use or disclosure outside of Danaher Motion except under written agreement. All rights are reserved. No part of this book shall be reproduced, stored in retrieval form, or transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise without the written permission from the publisher. While every precaution has been taken in the preparation of the book, the publisher assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein.

This document is proprietary information of Danaher Motion that is furnished for customer use ONLY. No other uses are authorized without written permission of Danaher Motion. Information in this document is subject to change without notice and does not represent a commitment on the part of Danaher Motion. Therefore, information contained in this manual may be updated from time-to-time due to product improvements, etc., and may not conform in every respect to former issues.

SS2000MD4 |

2 |

400030-043 Rev G |

Danaher Motion Superior Electric

Safety

Safety symbols used in this manual are:

Warning Alerts users to potential physical danger or harm. Failure to follow warning notices could result in personal injury or death.

Caution Directs attention to general precautions, which if not followed, could result in personal injury and/or equipment damage.

Note Highlights information critical to your understanding or use of the product.

Instructions

Only qualified personnel should install or perform servicing procedures on this equipment. Do not operate the unit without the enclosures in place as voltage present in this unit can cause serious or fatal injury.

Before performing any work on the unit, allow at least five minutes for the capacitors to discharge fully.

Voltage is present on unprotected pins when unit is operational.

The "PWR ON" LED must be off for approximately 30 seconds before making or breaking the motor connections.

Motors powered by these drives may develop extremely high torque. Disconnect AC power to these drive before doing any mechanical work.

This unit is designed for 115 VAC input only (see Section 4.2,

Electrical Specifications).

Warranty And Limitation Of Liability

Danaher Motion (the "Company") warrants to the first end user purchaser (the "purchaser") of equipment manufactured by the Company that such equipment, if new, unused and in original unopened cartons at the time of purchase, is free from defects in material and workmanship under normal use and service for a period of one year from date of shipment from the Company's factory or a warehouse of the Company in the event that the equipment is purchased from the Company or for a period of one year from the date of shipment from the business establishment of an authorized distributor of the Company in the event that the equipment is purchased from an authorized distributor.

THE COMPANY'S OBLIGATION UNDER THIS WARRANTY SHALL BE STRICTLY AND EXCLUSIVELY LIMITED TO REPAIRING OR REPLACING, AT THE FACTORY OR A SERVICE CENTER OF THE COMPANY, ANY SUCH EQUIPMENT OR PARTS THEREOF WHICH AN AUTHORIZED REPRESENTATIVE OF THE COMPANY FINDS TO BE DEFECTIVE IN MATERIAL OR WORKMANSHIP UNDER NORMAL USE AND SERVICE WITHIN SUCH PERIOD OF ONE YEAR. THE COMPANY RESERVES THE RIGHT TO SATISFY SUCH OBLIGATION IN FULL BY REFUNDING THE FULL PURCHASE PRICE OF ANY SUCH DEFECTIVE EQUIPMENT. This warranty does not apply to any equipment which has been tampered with or altered in any way, improperly installed or has been subject to misuse, neglect or accident.

SS2000MD4 |

3 |

400030-043 Rev G |

Danaher Motion Superior Electric

THE FOREGOING WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, and of any other obligations or liabilities on the part of the Company; and no person is authorized to assume for the Company any other liability with respect to equipment manufactured by the Company. The Company shall have no liability with respect to equipment not of its manufacture. THE COMPANY SHALL HAVE NO

LIABILITY WHATSOEVER IN ANY EVENT FOR PAYMENT OF ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, DAMAGES FOR INJURY TO ANY PERSON OR PROPERTY.

Written authorization to return any equipment or parts thereof must be obtained from the Company. The Company shall not be responsible for any transportation charges.

IF FOR ANY REASON ANY OF THE FOREGOING PROVISIONS SHALL BE INEFFECTIVE, THE COMPANY'S LIABILITY FOR DAMAGES ARISING OUT OF ITS MANUFACTURE OR SALE OF EQUIPMENT, OR USE THEREOF, WHETHER SUCH LIABILITY IS BASED ON WARRANTY, CONTRACT, NEGLIGENCE, STRICT LIABILITY IN TORT OR OTHERWISE, SHALL NOT IN ANY EVENT EXCEED THE FULL PURCHASE PRICE OF SUCH EQUIPMENT.

Any action against the Company based upon any liability or obligation arising hereunder or under any law applicable to the sale of equipment, or the use thereof, must be commenced within one year after the cause of such action arises.

The right to make engineering refinements on all products is reserved. Dimensions and other details are subject to change.

SS2000MD4 |

4 |

400030-043 Rev G |

|

Danaher Motion Superior Electric |

|

Table of Contents |

|

|

SECTION 1: INTRODUCTION.................................................................................... |

6 |

|

1.1 USING THIS MANUAL.............................................................................................. |

6 |

|

1.2 PRODUCT FEATURES............................................................................................... |

6 |

|

SECTION 2: EXPRESS START UP ............................................................................ |

7 |

|

SECTION 3: INSTALLATION GUIDELINES ........................................................... |

8 |

|

3.1 |

MOUNTING............................................................................................................. |

8 |

3.2 |

TERMINAL LOCATIONS AND ASSIGNMENTS........................................................... |

9 |

3.3.1 MOTOR CONNECTIONS................................................................................... |

10 |

|

3.3.2 POWER INPUT ................................................................................................ |

12 |

|

SECTION 4: SPECIFICATIONS ................................................................................ |

13 |

|

4.1 |

MECHANICAL....................................................................................................... |

13 |

4.2 |

ELECTRICAL ........................................................................................................ |

13 |

4.3 |

ENVIRONMENTAL................................................................................................. |

13 |

4.4 |

MOTOR COMPATIBILITY ..................................................................................... |

13 |

4.5 |

CURRENT SETTINGS............................................................................................. |

15 |

4.6 |

STEP RESOLUTION ............................................................................................... |

15 |

4.7 |

SIGNAL SPECIFICATIONS...................................................................................... |

16 |

4.7.1 CONNECTOR PIN ASSIGNMENTS..................................................................... |

16 |

|

4.7.2 SIGNAL DESCRIPTIONS .................................................................................. |

16 |

|

4.7.3 LEVEL REQUIREMENTS.................................................................................. |

16 |

|

4.7.4 TIMING REQUIREMENTS ................................................................................ |

17 |

|

4.8 |

INDICATOR LIGHTS.............................................................................................. |

17 |

SECTION 5: TORQUE VERSUS SPEED CHARACTERISTICS........................... |

18 |

|

5.1 |

MOTOR PERFORMANCE ....................................................................................... |

18 |

5.2 |

TYPICAL TORQUE VERSUS SPEED CURVES ......................................................... |

19 |

SECTION 6: SYSTEM CHECKING ......................................................................... |

35 |

|

APPENDIX A: TROUBLESHOOTING ........................................................................ |

36 |

|

A.1 ELECTRICAL INTERFERENCE PROBLEMS ........................................................... |

36 |

|

A.2 CUSTOMER SUPPORT .......................................................................................... |

36 |

|

SS2000MD4 |

5 |

400030-043 Rev G |

Danaher Motion Superior Electric

SECTION 1: INTRODUCTION

1.1 USING THIS MANUAL

It is important that you understand how this SLO-SYN® 2000MD4 Translator/Drive is installed and operated before you attempt to use it. Read this manual completely before proceeding with the installation of this unit.

This manual is an installation and operating guide to the SLO-SYN 2000MD4 Translator/Drive. Section 1 gives an overview of the Drive and its features. Section 2 describes the steps necessary to place the drive into operation. General wiring guidelines as well as the physical mounting of the unit and connections to the drive portion are covered in Section 3.

Complete specifications, listed in Section 4, provide electrical, mechanical and performance specifications. The procedure for setting the motor current level is also covered in this section.

Torque versus speed characteristics with all appropriate SLO-SYN Stepper Motors are given in Section 5. Section 6, System Checking, gives procedures to follow if the SLOSYN 2000 drive fails to operate properly.

Appendix A provides procedures for troubleshooting electrical interference problems.

1.2 PRODUCT FEATURES

SLO-SYN 2000MD4 Translator/Drive is a bipolar, adjustable speed, two-phase PWM drive that uses hybrid power devices. It can be set to operate a step motor in full steps or half steps. The maximum running speed is 3,000 rpm. To reduce the chances of electrical noise problems, the control signals are optically isolated from the drive circuit. Features include:

Switch selectable current levels of 0.5 through 3.5 amperes

Full short circuit protection (phase-to-phase and phase-to-ground)

Undervoltage and transient overvoltage protection

Efficient thermal design

Optically isolated inputs

Windings Off capability

Switch selectable step resolution

Compact size

Sturdy all-aluminum mounting base

SS2000MD4 |

6 |

400030-043 Rev G |

Danaher Motion Superior Electric

SECTION 2: EXPRESS START UP

The following instructions define the minimum steps necessary to make your Drive operational.

Always disconnect the AC power to the unit and be certain the "PWR

ON" LED is OFF before connecting or disconnecting the motor leads.

FAILURE TO DO THIS RESULTS IN A SHOCK HAZARD.

Always operate the Motor and the Drive GROUNDED. Be sure to twist together the wires for each motor phase. Six twists per foot is a good guideline.

1.Check to see that the motor used is compatible with the drive. Refer to Section 4.4 for a list of compatible motors.

2.Set the correct current level for the motor being used per the instructions in Section 4.5.

Heat sinking may be required to maintain case temperature below +70° C (+158° F).

3.Select the appropriate step resolution and set the front panel switches as described in Section 4.6.

4.Wire the motor per the "Motor Connections" description in Section 3.2.

5.Connect the power source to the DC input terminal strip. Be sure to follow the instructions for connecting the filter capacitor as described in Section 3.2, under Power Input.

If the motor operates erratically, refer to Section 5, "Torque Versus Speed Characteristics". Clockwise and counter-clockwise directions are properly oriented when viewing the motor from the end opposite the mounting flange.

SS2000MD4 |

7 |

400030-043 Rev G |

Danaher Motion Superior Electric

Section 3: Installation Guidelines

3.1 MOUNTING

The SLO-SYN Drive is mounted by fastening its mounting brackets to a flat surface as shown in Figure 3.1. If the drive assembly is mounted against a bulkhead, be sure to apply a thin coating of thermal compound between the drive and the mounting surface before fastening the unit in place. Do not use too much thermal compound. It is better to use too little than too much.

Figure 3.1 Mounting Diagram

Case temperature should not exceed +70° C (+158° F). Forced air cooling may be required to maintain temperature within the stated limits.

When selecting a mounting location, it is important to leave at least two inches (51mm) of space around the top, bottom and sides of the unit to allow proper airflow for cooling.

It is also important to keep the drive away from obvious noise sources. If possible, locate the drive in its own metal enclosure to shield it and its wiring from electrical noise sources. If this cannot be done, keep the drive at least three feet from any noise sources.

SS2000MD4 |

8 |

400030-043 Rev G |

Danaher Motion Superior Electric

3.2 TERMINAL LOCATIONS AND ASSIGNMENTS

Figure 3.2 shows the terminal locations for the SLO-SYN SS2000MD4 Translator/Drive.

I/O Connector (J2)

Motor And Power Supply Connector (J1)

Figure 3.2, Terminal Locations

SS2000MD4 |

9 |

400030-043 Rev G |

Danaher Motion Superior Electric

3.3.1 Motor Connections

All motor connections are made via the 6-terminal strip (J1). Terminal assignments are given below. Motor connections are shown in Figure 3.3.

J1 Pin Assignment

1M1 (Phase A+)

2M3 (Phase A-)

3M4 (Phase B+)

4M5 (Phase B-)

Motor phase A is M1 and M3 and motor phase B is M4 and M5. The motor frame must be grounded.

Cabling from the drive to the motor should be done with a shielded, twisted pair cable. As a guideline, the wires for each motor phase should be twisted about six times per foot.

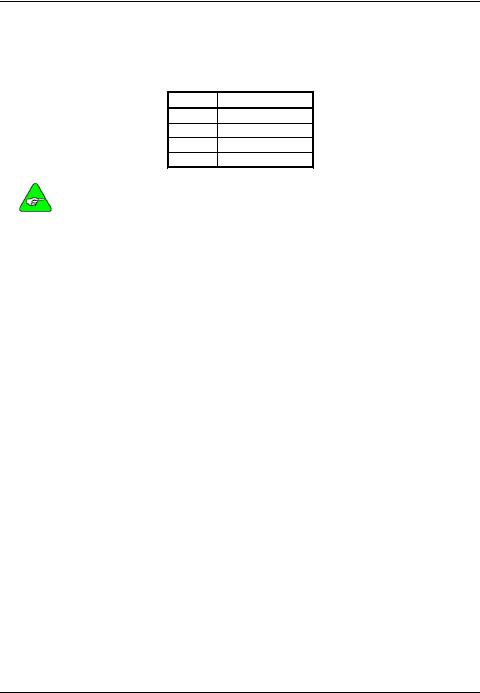

Danaher Motion offers the following motor cable configurations. These cables have unterminated leads on both ends.

Length |

Part Number |

10 ft (3 m) |

216022-031 |

25 ft (7.6 m) |

216022-032 |

50 ft (15.2 m) |

216022-033 |

75 ft (22.8 m) |

216022-034 |

Figure 3.3 shows the possible motor wiring configurations.

SS2000MD4 |

10 |

400030-043 Rev G |

|

|

|

|

|

|

|

Danaher Motion Superior Electric |

|

|

MOTOR |

MOTOR TERMINAL "M" NUMBERS |

MOTOR |

|

||||

CONNECTOR PIN |

|

|

|

|

CONNECTOR PIN |

|||

DRIVE PIN 1 |

RED |

B |

1 |

5 |

|

D |

WHITE/ |

DRIVE PIN 4 |

|

BLACK |

|||||||

|

|

|

|

|

|

|

|

|

DRIVE PIN 2 |

WHITE/ |

H |

3 |

4 |

|

F |

BLACK |

DRIVE PIN 3 |

RED |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

4-LEAD MOTORS |

|

GREEN |

|

||

|

|

|

|

|

|

|||

DRIVE PIN 1 |

RED |

B |

1 |

5 |

|

D |

GREEN |

DRIVE PIN 4 |

* N.C. |

BLACK |

G |

6 |

|

2 |

E |

WHITE |

N.C.* |

DRIVE PIN 2 |

WHITE/ |

H |

3 |

4 |

|

F |

WHITE/ |

DRIVE PIN 3 |

RED |

|

GREEN |

||||||

|

|

|

|

|

|

|

||

|

|

|

6-LEAD MOTORS |

|

|

|

||

DRIVE PIN 1 |

RED |

B |

1 |

5 |

|

D |

GREEN |

DRIVE PIN 4 |

* |

BLACK |

G |

6 |

|

7 |

E |

ORANGE |

* |

WHITE |

A |

2 |

|

8 |

C |

WHITE/ |

||

|

|

|

|

BLACK |

|

|||

|

WHITE/ |

|

|

|

|

|

|

|

DRIVE PIN 2 |

H |

3 |

4 |

|

F |

WHITE/ |

DRIVE PIN 3 |

|

RED |

|

GREEN |

||||||

|

|

|

|

|

|

|

||

|

8-LEAD MOTORS, SERIES CONNECTIONS |

|

||||||

DRIVE PIN 1 |

RED |

B |

1 |

5 |

|

D |

GREEN |

DRIVE PIN 4 |

|

BLACK |

G |

6 |

|

7 |

E |

ORANGE |

|

|

WHITE |

A |

2 |

|

8 |

C |

WHITE/ |

|

|

|

BLACK |

|

|||||

|

|

|

|

|

||||

DRIVE PIN 2 |

WHITE/ |

H |

3 |

4 |

|

F |

WHITE/ |

DRIVE PIN 3 |

RED |

|

|||||||

|

|

|

|

|

|

GREEN |

|

|

8-LEAD MOTORS, PARALLEL CONNECTIONS

*These leads must be insulated and isolated from other leads or ground.

Circled letters identify terminals for connector motors, numbers identify those for terminal box motors.

Figure 3.3 Motor Wiring Configurations

SS2000MD4 |

11 |

400030-043 Rev G |

Loading...

Loading...