Superior 500, 800, 600 User Manual

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

This appliance may be installed in an aftermarket permanently located, manufactured home (USA only) or mobile home, where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use with other gases, unless a certified kit is used.

INSTALLATION

INSTRUCTIONS

DIRECT VENT

500/600/800 SERIES

VENTED GAS FIREPLACE HEATERS - DIRECT VENT MODELS P/N 700,005M REV. X 11/2004

MODELS

Millivolt Models |

Electronic Models |

D-500CMN D-500CMP DT-500CMN DT-500CMP DR-500CMN DR-500CMP D-600CMN D-600CMP DT-600CMN

DT-600CMP DR-600CMN DR-600CMP D-800CMN D-800CMP DT-800CMN DT-800CMP DR-800CMN DR-800CMP

D-500CEN DT-600CEP D-500CEP DR-600CEN DT-500CEN DR-600CEP DT-500CEP D-800CEN DR-500CEN D-800CEP DR-500CEP DT-800CEN D-600CEN DT-800CEP D-600CEP DR-800CEN DT-600CEN DR-800CEP

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING:IFTHEINFORMATIONINTHISMANUAL |

|

|

|

|

AVERTISSEMENT: ASSUREZ-VOUS DE BIEN SUIVRE |

|

|

||||

|

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLO- |

|

|

|

|

LESINSTRUCTIONSDONNÉDANSCETTENOTICEPOUR |

|

|

||||

|

SION MAY RESULT CAUSING PROPERTY DAM- |

|

|

|

|

RÉDUIRE AU MINIMUM LE RISQUE D'INCENDIE OU |

|

|

||||

|

AGE, PERSONAL INJURY OR LOSS OF LIFE. |

|

|

|

|

POUR ÉVITER TOUT DOMMAGE MATÉRIEL, TOUTE |

|

|

||||

|

|

|

|

|

|

|

|

|

BLESSURE OU LA MORT. |

|

|

|

|

FOR YOUR SAFETY: Do not store or use gasoline |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||||||

|

or other flammable vapors or liquids in the vicin- |

|

|

POUR VOTRE SÉCURITÉ: Ne pas entreposer ni utiliser |

|

|||||||

|

ity of this or any other appliance. |

|

|

d'essence ni d'autre vapeurs ou liquides inflammables |

|

|||||||

|

FOR YOUR SAFETY: What to do if you smell gas: |

|

|

dans le voisinage de cet appareil ou de tout autre |

|

|||||||

|

|

|

appareil. |

|

|

|

||||||

|

• DO NOT light any appliance. |

|

|

POUR VOTRE SÉCURITÉ: Que faire si vous sentez une |

|

|||||||

|

• DO NOT touch any electrical switches. |

|

|

odeur de gaz: |

|

|

|

|||||

|

• DO NOT use any phone in your building. |

|

|

|

|

|

|

|

||||

|

• Immediately call your gas supplier from a |

|

|

• Ne pas tenter d'allumer d'appareil. |

|

|

|

|||||

|

neighbor’s phone. Follow your gas suppliers |

|

|

• Ne touchez à aucun interrupteur. Ne pas vous servir |

|

|||||||

|

instructions. |

|

|

|

des téléphones se trouvant dans le batiment où |

|

||||||

|

• If your gas supplier cannot be reached, call the |

|

|

|

vous vous trouvez. |

|

|

|

||||

|

fire department. |

|

|

• Evacuez la piéce, le bâtiment ou la zone. |

|

|

|

|||||

|

Installation and service must be performed by a |

|

|

• Appelez immédiatement votre fournisseur de gaz |

|

|||||||

|

|

|

|

depuis un voisin. Suivez les instructions |

du |

|

||||||

|

qualified installer, service agency or the gas |

|

|

|

fournisseur. |

|

|

|

||||

|

supplier. |

|

|

• Si vous ne pouvez rejoindre le fournisseur de gaz, |

|

|||||||

|

|

|

|

|

|

|

|

|

appelez le service dos incendies. |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

L'installation et service doit être exécuté par un qualifié |

|

|||

|

|

|

|

OTL Report No. 116-F-13-4 |

|

|

|

|

||||

|

|

|

|

|

|

|

installeur, agence de service ou le fournisseur de gaz. |

|

||||

|

|

|

|

NOTE: DIAGRAMS & |

|

ILLUSTRATIONS NOT TO SCALE. |

|

|

1 |

|||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

||||||

TABLE OF CONTENTS |

|

|

|

Packaging ........................................ |

page |

2 |

|

Introduction ..................................... |

page |

2 |

|

General Information ......................... |

page |

2 |

|

Location |

.......................................... |

page |

3 |

Appliance and Vent Clearances ....... |

page |

4 |

|

Vent Termination Clearances ........... |

page |

5 |

|

Typical Installation Sequence .......... |

page |

5 |

|

Detailed Installation Steps ............... |

page |

5 |

|

Step 1. |

Framing ............................. |

page |

5 |

Step 2. Routing Gas Line ............... |

page |

5 |

|

Fireplace Specifications ................... |

page |

8 |

|

Step 3. Install the Vent System ...... |

page |

9 |

|

Vertical Termination Systems .......... |

page |

10 |

|

Vent Section Length Chart ............... |

page |

10 |

|

Vertical Vent Tables and Figures ...... |

page |

13 |

|

Horizontal Termination System ........ |

page |

15 |

|

Horizontal Vent Tables and Figures . page |

17 |

||

Venting Using Flexible Vent Pipe ..... |

page |

20 |

|

Step 4. |

Field Wiring ....................... |

page |

21 |

Step 5. Optional Blower Kit Wiring |

page |

21 |

|

Step 6. Connecting Gas Line .......... |

page |

22 |

|

Step 7. |

Installing Logs ................... |

page |

22 |

Step 8. |

Checking Unit Operation ..... |

page |

22 |

Step 9. Installing Glass Door ......... |

page |

23 |

|

Step 10. Burner Adjustments ........... |

page |

23 |

|

Step 11. Hood Installation ............... |

page |

23 |

|

Finishing Requirements ................... |

page |

23 |

|

Cold Climate Insulation .................... |

page |

24 |

|

Installation Accessories ................... |

page |

25 |

|

Gas Conversion Kits .................. |

page 26 |

||

This installation manual will help you obtain a safe, efficient, dependable installation for your appliance and vent system.

Please read and understand these instructions before beginning your installation.

2

PACKAGING

The assembled vented gas fireplace heater is packaged with:

1 - one log set located in firebox area.

2 - one envelope containing the literature package which consists of the homeowner's manual, installation instructions, log set supplement and warranty; envelope is located in the control area.

3- one vent restrictor to be applied as shown on page 9; restrictor is taped to the envelope.

4 - one hood located behind the top panel.

5 - one bag of decorative volcanic stone located in the control area.

6 - one bag of glowing embers located in the control area.

INTRODUCTION

These vented gas fireplace heaters are sealed combustion, air circulating gas fireplaces designed for residential applications. These appliances must be installed with the Secure Vent™ and /or Secure Flex™ vent systems routed to the outside atmosphere.

Millivolt appliances are designed to operate on natural or propane gas. A millivolt gas control valve with piezo ignition system provides safe, efficient operation. External electrical power is required to operate the optional blower if installed in these units.

Electronic appliances are designed to operate on natural or propane gas. An electronic intermittent pilot ignition system provides safe, efficient operation. External electrical power is required to operate these units.

These appliances comply with National Safety Standards and are tested and listed by OmniTest Laboratories (Report No. 116-F-13-4) to ANSI Z21.88-2002 (in Canada, CSA-2.33-2002), and CAN/CGA-2.17-M91 in both USA and Canada, as vented gas fireplace heaters.

Both millivolt and electronic versions of these appliances are listed by Omni-Test Laboratories for installation in bedrooms and mobile homes.

Installation must conform to local codes. In the absence of local codes, installation must comply with the current National Fuel Gas Code, ANSI Z223.1. (In Canada, the current CAN-1 B149 installation code.) Electrical wiring must comply with the National Electrical Code ANSI/ NFPA 70 - (latest edition). (In Canada, the current CSA C22-1 Canadian Electrical Code.)

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

DO NOT ATTEMPT TO ALTER OR MODIFY THE CONSTRUCTION OF THE APPLIANCE OR ITS COMPONENTS. ANY MODIFICATION OR ALTERATION MAY VOID THE WARRANTY, CERTIFICATION AND LISTINGS OF THIS UNIT.

GENERAL INFORMATION

Note: Installation and repair should be performed by a qualified service person. The appliance should be inspected annually by a qualified professional service technician. More frequent inspections and cleanings may be required due to excessive lint from carpeting, bedding material, etc. It is imperative that the control compartment, burners and circulating air passage ways of the appliance be kept clean.

S'assurer que le brùleur et le compartiment des commandes sont propres. Voir les instructions d'installation et d'utilisation qui accompagnent l'appareil.

Provide adequate clearances around air openings and adequate accessibility clearance for service and proper operation. Never obstruct the front openings of the appliance.

These appliances are designed to operate on natural or propane gas only.

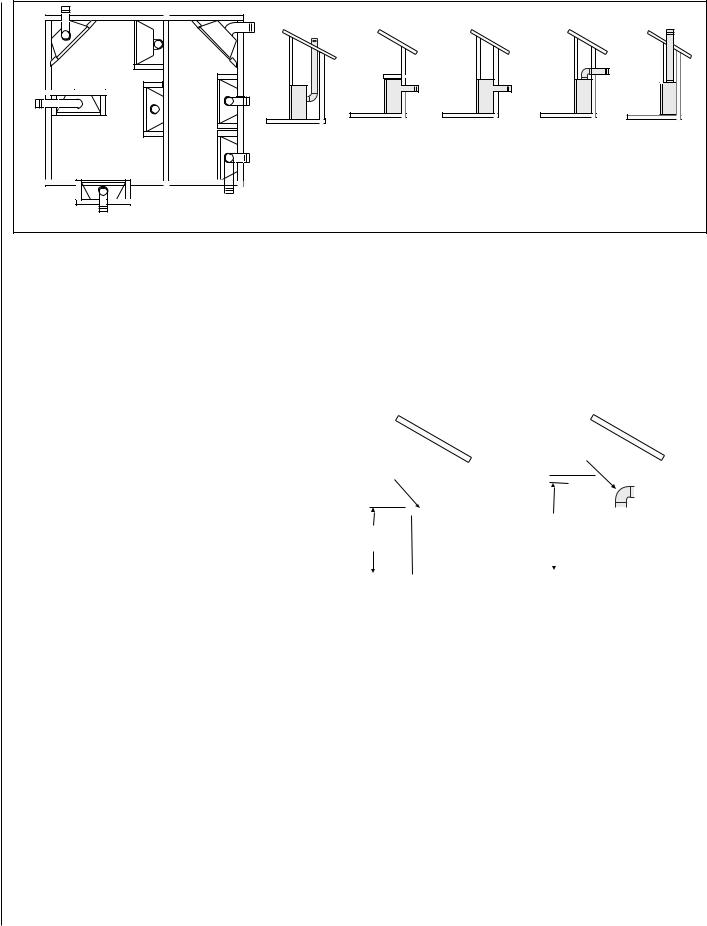

TYPICAL INSTALLATION

Figure 1

Millivolt Models -

Millivolt models come standard with the manually-modulated gas valve; flame appearance and heat output can be controlled at the gas valve.

Input of millivolt models is shown in the following table:

Millivolt Models with

Manually-Modulated Gas Valve

Natural Gas |

Propane Gas |

|||

D, DT, |

Input rate |

D, DT, |

Input rate |

|

DR |

DR |

|||

(BTU/H) |

(BTU/H) |

|||

Series |

Series |

|||

|

|

|||

500 |

17,500 to |

500 |

17,500 to |

|

23,000 |

23,000 |

|||

|

|

|||

600 |

21,500 to |

600 |

22,500 to |

|

29,000 |

29,000 |

|||

|

|

|||

800 |

24,000 to |

800 |

25,500 to |

|

32,000 |

32,000 |

|||

|

|

|||

Electronic Models -

Electronic models have a fixed rate gas valve. Input of electronic models is shown in the following table:

Electronic Models with Fixed-Rate Gas Valve

Natural and Propane Gas

D, DT, DR Series |

Input rate (BTU/H) |

500 |

23,000 |

600 |

29,000 |

800 |

32,000 |

All Models -

Maximum manifold pressure is 3.5 in. w.c. (0.87 kPa) for natural gas and 10 in. w.c. (2.49 kPa) for LP/Propane gas.

Installations at Altitudes of 0 to 4500 ft.- Units are tested and approved for elevations of 0 to 4500 feet (0 to 1372 meters).

Installations at Altitudes above 4500 ft.- For elevations above 4500 feet (1372 meters), install the unit according to the regulations of the local authorities having jurisdiction and, in the USA, the latest edition of the National Fuel Gas Code (ANSI Z223.1) or, in Canada, the latest edition of the CAN1-B149.1 and .2 codes.

Table 1 shows the units' gas orifice size for the elevations indicated.

D, DT, |

Orifice size |

Elevation |

||

DR |

|

|

Feet |

|

Series |

Nat. |

Prop. |

(meters) |

|

|

|

|||

|

|

|

|

|

500 |

0.090 in. |

#54 |

|

|

|

|

|

0-4500 |

|

600 |

#36 |

#52 |

||

(0-1370) |

||||

|

|

|

||

800 |

#33 |

0.065 in. |

|

|

|

|

|

|

|

Table 1

The millivolt appliances are manually controlled and feature a spark ignitor (piezo) that allows the appliance's pilot gas to be lit without the use of matches or batteries. This system provides continued service in the event of a power outage.

Do not use these appliances if any part has been under water. Immediately call a qualified, professional service technician to inspect the appliance and to replace any parts of the control system and any gas control which have been under water.

Ne pas se servir de cet appareil s'il a été plongé dans l'eau, complètement ou en partie. Appeler un technicien qualifié pour inspecter l'appareil et remplacer toute partie du système de contrôle et toute commande qui ont été plongés dans l'eau.

This appliance may be installed in an aftermarket permanently located, manufactured home (USA only) or mobile home, where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use with other gases, unless a certified kit is used.

Cet appareil peut être installé dans un maison préfabriquée (É.-U. seulement) ou mobile déjà installée à demeure si les réglements locaux le permettent.

Cet appareil doit être utilisé uniquement avec les types de gaz indiqués sur la plaque signalétique. Ne pas l'utiliser avec d'autres gaz sauf si un kit de conversion certifié est installé.

Test gage connections are provided on the front of the millivolt gas control valve (identified IN for the inlet and OUT for the manifold side). A ¹⁄ " NPT test gage connection is provided at the inlet and outlet side of the electronic gas control valve.

Minimum inlet gas pressure to these appliances is 5.0 inches water column (1.24 kPa) for natural gas and 11 inches water column (2.74 kPa) for propane for the purpose of input adjustment.

Maximum inlet gas supply pressure to these appliances is 10.5 inches water column (2.61 kPa) for natural gas and 13.0 inches water column (3.23 kPa) for propane.

These appliances must be isolated from the gas supply piping system (by closing their individual manual shut-off valve) during any pressure testing of the gas supply piping system at test pressures equal to or less than ¹⁄ psig (3.5 kPa).

These appliances and their individual shut-off valves must be disconnected from the gas supply piping system during any pressure testing of that system at pressures in excess of ¹⁄ psig (3.5 kPa).

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

These appliances must not be connected to a chimney or flue serving a separate solid fuel burning appliance.

Carbon Monoxide Poisoning: Early signs of carbon monoxide poisoning are similar to the flu with headaches, dizziness and/or nausea. If you have these signs, obtain fresh air immediately. Turn off the gas supply to the appliance and have it serviced by a qualified professional, as it may not be operating correctly.

WARNING: FAILURE TO COMPLY WITH THE INSTALLATION AND OPERATING INSTRUCTIONS PROVIDED IN THIS DOCUMENT WILL RESULT IN AN IMPROPERLY INSTALLED AND OPERATING APPLIANCE, VOIDING ITS WARRANTY. ANY CHANGE TO THIS APPLIANCE AND/OR ITS OPERATING CONTROLS IS DANGEROUS. IMPROPER INSTALLATION OR USE OF THIS APPLIANCE CAN CAUSE SERIOUS INJURY OR DEATH FROM FIRE, BURNS, EXPLOSION OR CARBON MONOXIDE POISONING.

WARNING: CHILDREN AND ADULTS SHOULD BE ALERTED TO THE HAZARDS OF HIGH SURFACE TEMPERATURES. USE CAUTION AROUND THE APPLIANCE TO AVOID BURNS OR CLOTHING IGNITION. YOUNG CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME ROOM AS THE APPLIANCE.

WARNING: DO NOT PLACE CLOTHING OR OTHER FLAMMABLE MATERIALS ON OR NEAR THIS APPLIANCE.

AVERTISSEMENT: SURVEILLER LES ENFANTS. GARDER LES VÊTEMENTS, LES MEUBLES, L'ESSENCE OU AUTRES LIQUIDES À VAPEUR INFLAMMABLES À COTE DE L'APPAREIL.

LOCATION

In selecting the location, the aesthetic and functional use of the appliance are primary concerns. However, vent system routing to the exterior and access to the fuel supply are also important. Consideration should be given to traffic ways, furniture, draperies, etc., due to elevated surface temperatures (see Figure 2 ).

3

TOP |

|

VENTREAR |

APPLICATION |

|

REAR |

|

|

|

|

|

|

VENT |

|

|

|

APPLICATION |

|

|

|

|

|

||

APPLICATION |

|

|

|

|

VENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOP VENT |

APPLICATION |

VENTTOP TOP VENT |

APPLICATION |

|

HORIZONTAL VENT |

HORIZONTAL VENT |

HORIZONTAL VENT |

VERTICAL VENT |

|

INSTALLATION |

APPLICATION |

|

|

|

|

|

||||

APPLICATION |

|

|

|

|

|

VERTICAL VENT |

|

|

|

|

|

TOP VENT |

|

|

|

|

|

(Rear Vent Application |

(Rear Vent Application |

(Top Vent |

(Top Vent |

||

|

|

|

|

|

|

|

(Rear Vent |

without a chase) |

With a chase) |

Application) |

Application) |

|

|

|

|

|

|

|

Application) |

||||

|

RECESSED |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

TOP VENT |

|

|

|

|

|

|

|

|

|

|

|

APPLICATION |

|

Typical Locations |

|

|

|

||

Figure 2 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

The location should also be free of electrical, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

plumbing or other heating/air conditioning duct- |

|

|

|

|

Model No. |

|

|

|

|

|

|

|

Shelf Height inches (mm) |

|

|

|

|

|

||||||||

ing. These direct vent appliances are uniquely |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

Top Vent - with One 90 Degree Elbow |

|

Rear Vent - Straight Out the Back |

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||

suited for installations requiring a utility shelf |

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Secure Vent |

|

|

Secure Flex |

|

|

|

Secure Vent |

Secure Flex |

|

||||||||||

positioned directly above the fireplace. Utility |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

D-500 |

|

|

46 1/8 (1172) |

|

|

47 7/8 (1216) |

|

|

35 1/4 (895) |

|

35 1/4 (895) |

|

||||||||||

shelves like these are commonly used for locat- |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

ing television sets and decorative plants. |

|

|

|

|

DT-500 |

46 1/8 (1172) |

|

|

47 7/8 (1216) |

|

|

|

|

N/A |

|

N/A |

|

|||||||||

|

|

|

|

|

DR-500 |

N/A |

|

|

|

N/A |

|

|

35 1/4 (895) |

|

35 1/4 (895) |

|

||||||||||

To provide for the lowest possible shelf surface |

|

|

|

|

D-600, D-800 |

51 1/8 (1298) |

|

|

52 7/8 (1343) |

|

|

40 1/4 (1022) |

|

40 1/4 (1022) |

|

|||||||||||

use the alternate rear vent outlet with attached |

|

|

|

|

DT-600, DT-800 |

51 1/8 (1298) |

|

|

52 7/8 (1343) |

|

|

|

|

N/A |

|

N/A |

|

|||||||||

venting routed in a way to minimize obstructions |

|

|

|

|

DR-600, DR-800 |

N/A |

|

|

|

N/A |

|

|

40 1/4 (1022) |

|

40 1/4 (1022) |

|

||||||||||

to the use of the space above the appliance. Do |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

not insulate the space between the appliance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Do not insulate the |

|

|

|

|

|

|||||

and the area above it. See Figure 3. The |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

minimum height from the base of the appliance |

|

|

|

|

|

Do not insulate the |

|

|

|

|

space between the |

|

|

|

|

|

||||||||||

|

|

|

|

|

space between the |

|

|

|

|

appliance and the |

|

|

|

|

|

|||||||||||

to the underside of combustible materials used |

|

|

|

|

|

appliance and the |

|

|

|

|

|

|

area above it. |

|

|

|

|

|

||||||||

to construct a utility shelf in this fashion is shown |

|

|

|

|

|

|

area above it. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

in the table in Figure 3. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The appliance should be mounted on a fully |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shelf Height |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

supported base extending the full width and |

|

|

|

|

|

|

|

Shelf Height |

|

|

|

|

|

|

|

(see table) |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

(see table) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

depth of the unit. The appliance may be located |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

on or near conventional construction materi- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

als. However, if installed on combustible ma- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

terials, such as carpeting, vinyl tile, etc., a |

|

|

Figure 3 |

Shelf Above Fireplace With Rear Venting |

Shelf Above Fireplace With Top Venting |

|||||||||||||||||||||

metal or wood barrier covering the entire bot- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tom surface must be used. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

APPLIANCE AND VENT CLEARANCES |

|

|

|

|

BACK |

|

|

1/2 in. (13 mm) |

|

*Note: |

|

3 in. (75 mm) above any horizontal/ |

||||||||||||||

|

|

|

|

|

|

0 in. (0 mm) spacers |

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

inclined vent component. |

|

|

|

|

|

|||||||||||||

These appliances are approved with zero clear- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

SIDES |

|

|

1/2 in. (13 mm)** |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

ance from spacers to combustible materials on |

|

|

|

|

|

|

0 in. (0 mm) spacers |

**Note: |

|

The nailing flange and the cabinet |

||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||

all sides (as detailed in Table 2 ), with the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

surfaces directly adjacent to the framing mem- |

|||||||||||

|

|

|

|

TOP SPACERS |

0 in. (0 mm) |

|

||||||||||||||||||||

following exception: When the unit is installed |

|

|

|

|

|

ber attached to the nailing flange, are exempt |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

with one side flush with a perpendictular side |

|

|

|

|

FLOOR |

|

|

0 in. (0 mm) |

|

from the 1/2" clearance to combustibles de- |

||||||||||||||||

wall, the wall perpendicular to the opposite side |

|

|

|

|

|

|

|

fined for the rest of the cabinet sides and back. |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

of the appliance front face must not extend |

|

|

|

From Bottom of |

64 in. (1626 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

more than five inches beyond the front edge of |

|

|

|

|

Unit to Ceiling |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

the unit. In addition, when the unit is recessed, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VENT |

|

|

1 in. (25.4 mm)* |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

the side walls surrounding the unit must not |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

extend more than five inches beyond the front |

|

|

|

|

SERVICE CLEARANCES |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

edge of the unit. Refer to Figure 2. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FRONT |

|

|

3 Feet. (0.9 meters) |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

VENT TERMINATION CLEARANCES

These instructions should be used as a guideline and do not supersede local codes in any way. Install vent according to local codes, these instructions, the current National Fuel Gas Code (ANSI-Z223.1) in the USA or the current standards of CAN/CGA-B149.1 and - B149.2 in Canada.

Vertical Vent Termination Clearances

Terminate single vent caps relative to building components according to figure 4.

TERMINATION HEIGHTS FOR VENTS ABOVE FLAT OR SLOPED ROOFS

Horizontal Overhang

2 FT MIN.

Vent

Termination

Storm Collar

Flashing

Concentric

Vent Pipe

2 FT |

Vertical |

MIN. |

Wall |

|

|

Lowest |

|

Discharge |

|

Opening |

|

H* |

|

|

X |

|

12 |

Roof Pitch is X/12 |

|

1 inch (25.4 mm) Minimum Clearance to Combustibles

1 inch (25.4 mm) Minimum Clearance to Combustibles

*H = MINIMUM HEIGHT FROM ROOF TO LOWEST DISCHARGE OPENING OF VENT

Roof Pitch |

H (feet) |

|

Flat to 6/12 |

1.0 |

|

Over 6/12 to 7/12 |

1.25 |

|

Over 7/12 to 8/12 |

1.5 |

|

Over 8/12 to 9/12 |

2.0 |

|

Over 9/12 to 10/12 |

2.5 |

|

Over10/12 to 11/12 |

3.25 |

|

Over 11/12 to |

4.0 |

|

12/12 |

||

|

Figure 4

Terminate multiple vent terminations according to the installation codes listed at the top of this page.

Horizontal Vent Termination Clearances

The horizontal vent termination must have a minimum of 3" (76 mm) clearance to any overhead combustible projection of 2 ¹⁄ " (64 mm) or less. See Figure 5. For projections exceeding 2 ¹⁄ " (64 mm), see Figure 5. For additional vent location restrictions refer to

Figure 8 on page 6.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation follows, however, each installation is unique resulting in variations to those described.

See the page numbers references in the following steps for detailed procedures.

Step 1. (page 5) Construct the appliance framing. Position the appliance within the framing and secure with nailing brackets.

Step 2. (page 5) Route gas supply line to appliance location.

Horizontal Vent Termination Clearances

Combustible Projection 2¹⁄ inches or less in length

Combustible Projection greater than 2¹⁄ inches in length

Ventilated

Soffit Unventilated

Soffit

|

|

3" |

18" |

12" |

(76 mm) |

(457 mm) |

(305 mm) |

|

Termination Kit

Note - See Figure 34 on page 16 for the recess allowances, into exterior walls, of the round, square and small square horizontal terminations.

Figure 5 |

Side Elevation View |

Step 3. (page 9) Install the vent system and exterior termination.

Step 4. (page 21) Field Wiring

a.Millivolt Appliances – Install the operating control switch (not factory provided) and bring in electrical service line for forced air circulating blower (optional equipment).

b.Electronic Appliances – Field wire and install operating control switch.

Step 5. (page 21) Install blower kit (optional equipment).

Step 6. (page 22) Make connection to gas supply. Step 7. (page 22) Install the logs, decorative volcanic stone and glowing embers.

Step 8. (page 22) Checkout appliance operation. Step9. (page23)Installglassdoorframeassembly. Step 10. (page 23) Adjust burner to ensure proper flame appearance.

Step 11. (page 23) Install the hoods.

DETAILED INSTALLATION STEPS

The appliance is shipped with all gas controls and components installed and pre-wired. Remove the shipping carton, exposing the front glass door. Remove the top panel. Remove the cardboard from underneath the pressure relief plates. Gently depress the outer top corners of the access panel until the catches "pop" the panel free, allowing it to swing out and down to open. Open the two latches (located under the firebox floor) securing the glass door. Remove the door by tilting it outward at the bottom and lifting it up. Set the door aside protecting it from inadvertent damage. See

Figure 55 on page 23.

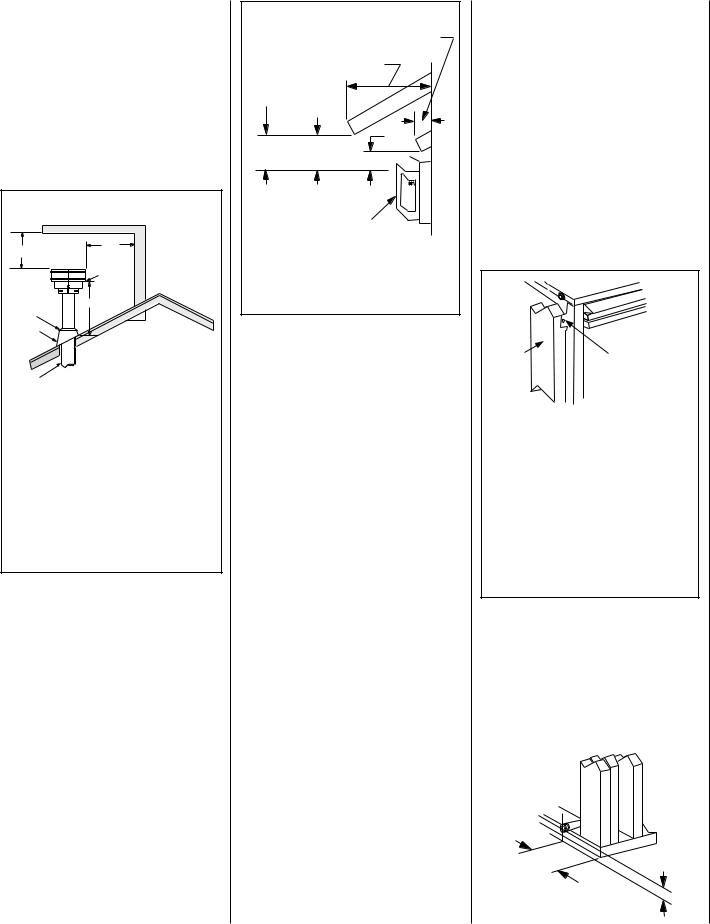

Step 1. FRAMING

Frame these appliances as illustrated in Figure 9 on page 7, unless the appliance is to be installed in a corner.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

See Figure 10 on page 7 or Figure 11 on page 8 for corner framing installations. All framing details must allow for a minimum clearance to combustible framing members as shown in

Table 2.

If the appliance is to be elevated above floor level, a solid continuous platform must be constructed.

Headers may be in direct contact with the appliance top spacers but must not be supported by them or notched to fit around them. All construction above the appliance must be self supporting. DO NOT use the appliance for structural support.

The fireplace should be secured to the side framing members using the unit's nailing flanges - one top and bottom on each side of the fireplace front. See Figure 6. Use 8d nails or their equivalent.

Side |

Unit Nailing Flange |

|

(No clearance to |

||

Framing |

||

combustible |

||

|

framing is required) |

|

Left Side Front Corner of Fireplace Shown |

||

(Right Side Requirements the Same) |

||

Unit Being Secured By Its Nailing Flanges |

||

|

To The Framing |

|

Note: The nailing flanges, combustible members |

||

and screw heads located in areas directly adjacent |

||

to the nailing flanges, are EXEMPT from the 1/2” |

||

clearance to combustible requirements for the |

||

firebox outer wrapper. Combustible framing may be |

||

in direct contact with the nailing flanges and may |

||

be located closer than 1/2” from screw heads and |

||

the firebox wrapper in areas adjacent to the nailing |

||

flanges. Frame the opening to the exact dimensions |

||

specified in the framing details of this manual. |

||

Figure 6

Step 2. ROUTING GAS LINE

Route a ¹⁄ " (13 mm) gas line along the inside of the right side framing as shown in Figure 7. Gas lines must be routed, constructed and made of materials that are in strict accordance with local codes and regulations.

All appliances are factory-equipped with a flexible gas line connector and ¹⁄ inch shutoff valve. (See step 6 on page 22).

Right Side

Front Corner of

Fireplace Framing

|

3" |

|

(76 mm) |

|

6 ¹⁄" |

|

(152 mm) |

Figure 7 |

5 |

|

EXTERIOR HORIZONTAL VENT TERMINATION CLEARANCE REQUIREMENTS

* See Item D in the Text Below.

Exterior Wall |

Center Line |

|

of Termination |

*18” |

|

Horizontal |

|

Termination |

|

18” |

|

|

Ventilated Soffit |

Inside Corner |

|

Detail D |

|

B |

|

|

C |

V |

|

V |

|

|

|

||

L |

|

Fixed |

|

|

|

||

|

|

|

Closed |

|

F |

V |

Window |

|

|

||

|

|

C |

|

|

V |

|

|

|

C |

C |

|

|

|

||

|

|

A |

|

X = Air Supply Inlet |

|

V = Vent Terminal |

|

Inside

Corner Detail

G

V

A

|

|

A |

= 9” in U.S. |

|

|

|

|

|

= 12” in Canada |

|

|

||

|

|

|

|

|

H |

|

|

|

|

|

3 ft. |

|

|

B |

|

|

|

X |

D |

E |

|

|

|

A |

|

|

|

|

|

|

A |

|

V |

|

V |

Operable |

|

|

|

|

|

|

Window |

|

|

3 ft. |

|

|

|

|

|

|

|

|

|

B |

|

|

J |

|

M |

|

|

B |

B |

|

|

|

|

|

|

|

V |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

= Area where Terminal is not Permitted |

|

|

|

|||

|

Canadian Installation* |

US Installation** |

|

|

|

A = Clearance above grade, veranda, porch, |

12 inches (30cm)* |

12 inches (30cm)** |

deck, or balcony. |

|

|

|

|

|

B = Clearance to window or door that may be |

6 in (15cm) for appliances |

6 in (15cm) for appliances |

opened. |

< 10,000 Btuh (3kW), 12 in (30cm) |

< 10,000 Btuh (3kW), 9 in (23cm) |

|

for appliances > 10,000 Btuh (3kW) and |

for appliances > 10,000 Btuh (3kW) and |

|

< 100,000 Btuh (30kW), 36 inches (91cm) |

< 50,000 Btuh (15kW), 12 inches (30cm) |

|

for appliances > 100,000 Btuh (30kW)* |

for appliances > 50,000 Btuh (15kW)** |

C = Clearance to permanently closed window |

12" (305mm) recommended to prevent |

9" (229mm) recommended to prevent |

|

window condensation |

window condensation |

|

|

|

D = Vertical clearance to ventilated soffit |

18" (458mm) |

18" (458mm) |

located above the terminal within a horizontal |

|

|

distance of 18 inches (458mm) from the center |

|

|

line of the terminal |

|

|

E = Clearance to unventilated soffit |

12" (305mm) |

12" (305mm) |

|

|

|

F = Clearance to outside corner |

5" (12.7cm) minimum |

5" (12.7cm) minimum |

G = Clearance to inside corner |

6" (15.2cm) minimum |

6" (15.2cm) minimum |

H = Clearance to each inside of center line |

3 feet (91cm) within a height of 15 feet |

3 feet (91cm) within a height of 15 feet |

extended above meter/regulator assembly |

above the meter/regulator assembly* |

above the meter/regulator assembly** |

I = Clearance to service regulator vent outlet |

3 feet (91cm)* |

3 feet (91cm)** |

|

|

|

J = Clearance to nonmechanical air supply inlet |

6 in (15cm) for appliances |

6 in (15cm) for appliances |

to building or the combustion air inlet to any |

< 10,000 Btuh (3kW), 12 in (30cm) |

< 10,000 Btuh (3kW), 9 in (23cm) |

other appliance |

for appliances > 10,000 Btuh (3kW) and |

for appliances > 10,000 Btuh (3kW) and |

|

< 100,000 Btuh (30kW), 36 inches (91cm) |

< 50,000 Btuh (15kW), 12 inches (30cm) |

|

for appliances > 100,000 Btuh (30kW)* |

for appliances > 50,000 Btuh (15kW)** |

K = Clearance to a mechanical air supply inlet |

6 feet (1.83m)* |

3 feet (91cm) above if within 10 feet (3m) |

|

|

horizontally** |

L = Clearance above paved sidewalk or paved |

7 feet (2.13m)‡ |

7 feet (2.13m)‡ |

diveway located on public property |

|

|

M = Clearance under veranda, porch, deck or |

12 inches (30cm)*‡ |

12 inches (30cm)‡ |

balcony |

|

|

*In accordance with the current CSA-B149.1 National Gas And Propane Installation Code.

**In accordance with the curent ANSI SZ223.1/NFPA 54 National Fuel Gas Codes.

‡A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings.

*‡ Only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the floor:

Figure 8

6 |

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE. |

FIREPLACE FRAMING SPECIFICATIONS

**FRAMING WITH SQUARE HORIZONTAL TERMINATIONS (SV4.5HTSS or SV4.5HTS) AND ROUND HORIZONTAL TERMINATION (SV4.5HTR)

|

Framing should be constructed |

||

VENT FRAMING - |

|

of |

2x4 or larger lumber. |

10¹⁄ |

|

|

|

TOP VENT WITH ONE |

|

|

|

90° ELBOW |

(267) |

|

|

VENT FRAMING - |

|

|

|

REAR VENT WITH |

|

|

|

NO ELBOWS |

|

7 |

|

|

|

|

|

|

5¹⁄ |

(178) |

|

|

|

12¹⁄ |

|

|

(130) |

|

|

|

|

|

(308) |

|

|

7 |

|

|

5¹⁄ |

(178) |

|

D |

|

12¹⁄ |

|

(130) |

|

||

B |

|

|

(308) |

C

16

(406)

¹⁄ A

Inches (mm) |

A |

|

16” (406mm) is the required framing depth dimension when the finish material (drywall) thickness is 1/2 in. (13mm).

** See the horizontal venting Figures 33 and 34 on page 16 for restrictions on the use of the round termination (SV4.5HTR).

Framing Dimensions

Model No. |

|

A |

B |

|

C |

D |

|

|

|

|

|

|

|

|

|

D-500 |

in. |

35 1/4 |

35 1/4 |

21 |

11/16 |

39 1/8 |

|

mm |

895 |

895 |

|

551 |

994 |

||

|

|

||||||

DT-500 |

in. |

35 1/4 |

35 1/4 |

- - - - |

39 1/8 |

||

|

|

|

|

|

|

||

mm |

895 |

895 |

- - - - |

994 |

|||

|

|||||||

|

|

|

|

|

|

||

DR-500 |

in. |

35 1/4 |

35 1/4 |

21 11/16 |

- - - - |

||

|

|

|

|

|

|

||

mm |

895 |

895 |

|

551 |

- - - - |

||

|

|

||||||

|

|

|

|

|

|

||

D-600 |

in. |

40 1/4 |

40 1/4 |

26 11/16 |

44 1/8 |

||

|

|

|

|

|

|

||

mm |

1022 |

1022 |

|

678 |

1121 |

||

|

|

||||||

|

|

|

|

|

|

||

DT-600 |

in. |

40 1/4 |

40 1/4 |

- - - - |

44 1/8 |

||

|

|

|

|

|

|

||

mm |

1022 |

1022 |

- - - - |

1121 |

|||

|

|||||||

|

|

|

|

|

|

||

DR-600 |

in. |

40 1/4 |

40 1/4 |

26 11/16 |

- - - - |

||

|

|

|

|

|

|

||

mm |

1022 |

1022 |

|

678 |

- - - - |

||

|

|

||||||

|

|

|

|

|

|

||

D-800 |

in. |

45 1/4 |

40 1/4 |

26 11/16 |

44 1/8 |

||

|

|

|

|

|

|

||

mm |

1149 |

1022 |

|

678 |

1121 |

||

|

|

||||||

DT-800 |

in. |

45 1/4 |

40 1/4 |

- - - - |

44 1/8 |

||

|

|

|

|

|

|

||

mm |

1149 |

1022 |

- - - - |

1121 |

|||

|

|||||||

DR-800 |

in. |

45 1/4 |

40 1/4 |

26 11/16 |

- - - - |

||

mm |

1149 |

1022 |

|

678 |

- - - - |

||

|

|

||||||

Figure 9

Model |

|

|

A |

B |

C |

|

D |

E |

|

F |

|

No. |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||

D-500 |

in. |

35 |

1/8 |

57 1/2 |

40 5/8 |

19 |

3/16 |

28 3/4 |

6 |

1/8 |

|

DT-500 |

|

|

|

|

|

|

|

|

|

|

|

mm |

892 |

1461 |

1032 |

487 |

730 |

156 |

|||||

DR-500 |

|||||||||||

D-600 |

in. |

40 |

1/8 |

61 3/16 |

43 1/32 |

19 |

3/16 |

30 11/16 |

7 |

7/8 |

|

DT-600 |

|

|

|

|

|

|

|

|

|

|

|

mm |

1019 |

1554 |

1101 |

487 |

779 |

200 |

|||||

DR-600 |

|||||||||||

D-800 |

in. |

45 |

1/8 |

66 3/8 |

46 15/16 |

19 |

3/16 |

33 3/16 |

9 |

3/4 |

|

DT-800 |

|

|

|

|

|

|

|

|

|

|

|

mm |

1146 |

1686 |

1192 |

487 |

843 |

248 |

|||||

DR-800 |

|||||||||||

Note-

Venting requirements for rear vent applications in corner installations -

-the the round termination (SV4.5HTR) may not be used

-the horizontal vent length “a” to “b,” must not exceed 28 inches (711 mm)

*These dimensions occur when one 45 |

|

degree elbow is connected directly to the |

|

appliance collar. |

b |

*F |

|

D and DR units |

7 (178) |

|

|

D and DT units |

|

Inches (millimeters)

E

C

*D

a

A

B

Back wall of chase/enclosure (including any finishing materials)

Figure 10 Corner Framing with Square Termination (SV4.5HTS)

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE. |

7 |

FIREPLACE FRAMING SPECIFICATIONS |

|

|

|

|

|

*These dimensions occur when one 45 |

|

b |

|

|

degree elbow is connected directly to the |

|

||

|

|

|

||

|

|

appliance collar. |

|

|

Note- |

|

|

*6¹⁄ |

|

Venting requirements for rear vent applications in corner |

(156) |

8³⁄ (208) |

||

installations for D-500, DT-500 AND DR-500 models only - |

|

|||

- the round termination (SV4.5HTR) may not be used |

|

|

||

- the horizontal vent length “a” to “b,” must not exceed 28 |

|

|

||

inches (711 mm) |

|

|

|

|

|

|

40 ⁄ |

|

28³⁄ |

|

|

(1032) |

|

|

|

|

|

(730) |

|

|

|

|

|

|

|

|

|

a |

*19³⁄ |

|

|

|

(487) |

|

Back wall of chase/enclosure |

|

|

|

|

(including any finishing materials) |

|

|

|

|

|

|

|

35¹⁄ |

|

|

|

|

(892) |

|

|

Inches |

|

57¹⁄ |

|

|

(millimeters) |

|

(1461) |

|

|

CORNER FRAMING WITH SMALL SQUARE HORIZONTAL TERMINATION(SV4.5HTSS) |

|||

Figure 11 |

|

|

FOR D-500, DT-500 AND DR500 MODELS ONLY) |

|

FIREPLACE SPECIFICATIONS |

|

|

|

|

FRAMING |

G |

(Louvered Front Model Shown) |

|

|

SPACERS |

H |

*CONCENTRIC FLUE |

|

|

(Top and Sides |

|

|

||

and Rear) |

|

FLUE - 4¹⁄ (114) |

|

|

|

COMBUSTION AIR - 7¹⁄ (190) |

|

||

|

|

|

||

* D models have a top and rear vent DR models have only a rear vent

9 DT models have only a top vent

(229)

Top View |

NOTE - Hood shown as |

|

|

|

|

|

positioned in louvered |

|

3 (76) |

front model. |

¹⁄ (13) |

E |

|

|

|

16 |

|

|

GAS INLET |

(406) |

|

|

|

|

(Either Side |

|

|

and bottom) |

|

|

|

OPTIONAL ELECTRICAL |

5¹⁄ |

|

|

|

INLET KNOCKOUT |

(140) |

|

A |

|

REQUIRING A FIELD |

|

|

|

PROVIDED JUNCTION |

9³⁄ |

|

|

C |

B |

BOX (Either Side) |

(238) |

F** |

D |

|

|

2 |

|

|

|

3 (76) |

|

|

|

|

(53) |

ELECTRICAL INLET |

|

|

|

1³⁄ |

|

|

|

|

(35) |

|

2³⁄ x 2 (70 x 51) COVER |

|

|

|

|

PLATE with KNOCKOUT) |

|

|

|

Front View |

|

|

|

|

|

Right Side View |

**Rear vent models only |

||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

A |

B |

C |

D |

E |

|

**F |

G |

|

H |

|

|

|

No. |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D-500 |

in. |

35 1/8 |

32 1/8 |

19 |

29 1/2 |

35 1/8 |

21 11/16 |

24 7/8 |

|

12 7/16 |

|

|

|

|

DT-500 |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mm |

892 |

816 |

483 |

749 |

892 |

551 |

632 |

|

316 |

|

||

|

|

DR-500 |

|

|

||||||||||

|

|

D-600 |

in. |

40 1/8 |

37 1/8 |

24 |

34 1/2 |

40 1/8 |

26 11/16 |

29 7/8 |

14 15/16 |

|

||

|

|

DT-600 |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mm |

1019 |

943 |

610 |

876 |

1019 |

678 |

759 |

|

379 |

|

||

|

|

DR-600 |

|

|

||||||||||

|

|

D-800 |

in. |

40 1/8 |

37 1/8 |

24 |

39 1/2 |

45 1/8 |

26 11/16 |

34 7/8 |

|

17 7/16 |

|

|

|

|

DT-800 |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

**Rear Vent Units Only. |

|

|

|

mm |

1146 |

943 |

610 |

1003 |

1146 |

678 |

886 |

|

443 |

|||

|

Figure 12 |

DR-800 |

|

|||||||||||

|

|

|

||||||||||||

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE. |

|

|

|

|

||||||

Step 3. INSTALL THE VENT SYSTEM

General Information

These instructions should be used as a guideline and do not supersede local codes in any way. Install vent according to local codes, these instructions, the current National Fuel Gas Code (ANSI-Z223.1) in the USA or the current standards of CAN/CGA-B149.1 and - B149.2 in Canada.

These fireplaces are designed, tested and listed for operation and installation with, andonlywith,SecureVent™ (SV4.5)Direct Vent System Components, Secure Flex™

Flexible Vent Components manufactured by Security Chimneys International. These approved vent system components are labeled for identification. DO NOT use any other manufacturer's vent components with these appliances. These fireplaces must be vented directly to the outside.

The vent system may not service multiple appliances, and must never be connected to a flue serving a solid fuel burning appliance. The vent pipe is tested to be run inside an enclosing wall (such as a chase). There is no requirement for inspection openings in the enclosing wall at any of the joints in the vent pipe.

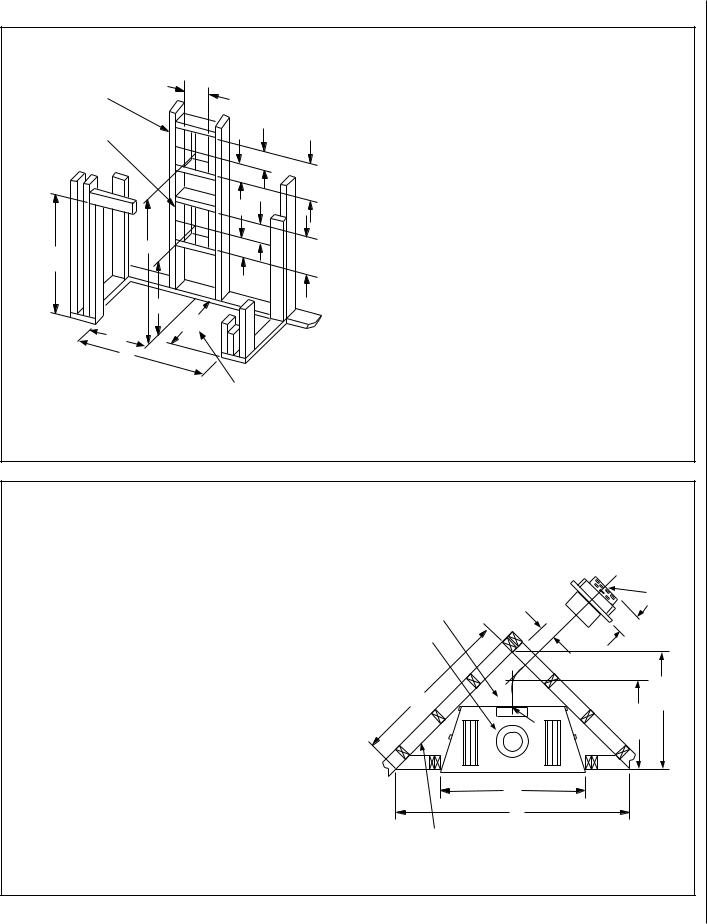

Preparing the Appliance Vent Collar on D-500/600/800 Series (Combined Top and Rear Vent) Models

Each of the unit's two vent collars are sealed with a cover plate and a seal plate and gasket. The cover, and seal plate and gasket must be removed from the vent collar being used. Refer to Figure 13 for top vent usage and Figure 14 for rear, and the following steps to prepare the appropriate collar for use.

From the vent collar being used, remove the four screws securing the vent seal plate and gasket. Remove and discard the seal plate and gasket.

When the top vent collar is being used, from inside the firebox, loosen the two screws in the keyhole slots of the cover plate and remove the remaining two cover plate securing screws. Remove and discard the cover plate. Reinstall and securely tighten all four screws.

When the rear vent collar is being used, from inside the firebox, remove the two screws securing the lintel to the rear wall of the firebox, then remove the lintel. Remove the four cover plate securing screws.

Remove and discard the cover plate. Reinstall and securely tighten all four cover plate screws. Re-secure the lintel to the rear wall of the firebox.

WARNING: FAILURE TO REINSTALL AND SECURELY TIGHTEN COVER PLATE SCREWS COULD RESULT IN LEAKAGE OF FLUEPRODUCTSINTOTHELIVINGSPACE. VENTCOVERPLATEANDVENTSEALPLATE MUST REMAIN SECURELY INSTALLED ON UNUSED VENT COLLAR. FAILURE TO DO SO COULD RESULT IN LEAKAGE OF FLUE PRODUCTS INTO LIVING SPACE.

ON D-500/600/800 SERIES MODELS (COMBINED TOP AND REAR VENT UNITS)

TOP VENT SEAL & COVER PLATE

REMOVAL WHEN USING THE TOP VENT

(OUTSIDE UNIT) |

VENT SEAL PLATE |

|

GASKET |

|

SECURING |

CABINET TOP |

SCREWS |

TOP VENT

FIREBOX TOP

VENT

COVER PLATE  COVER PLATE SECURING SCREWS

COVER PLATE SECURING SCREWS

(INSIDE UNIT)

CROSS SECTION

Figure 13

ON D-500/600/800 SERIES MODELS (COMBINED TOP AND REAR VENT UNITS)

REAR VENT SEAL & COVER PLATE REMOVAL

WHEN USING THE REAR VENT

COVER PLATE |

VENT SEAL PLATE |

SECURING SCREWS |

GASKET |

|

|

LINTEL |

SECURING |

SECURING |

|

SCREWS |

SCREWS |

|

REAR VENT |

LINTEL |

|

|

CABINET BACK |

(INSIDE UNIT) |

(OUTSIDE UNIT) |

CROSS SECTION

Figure 14

Installation of Vent Restrictor

A vent restrictor may be needed with this appliance, install the vent restrictor (provided) in the appliance top flue outlet as shown in Figure 15 or rear flue outlet as shown in Figure 16. It is held in place by friction, only.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

VENT RESTRICTOR INSTALLATION |

|

|

(TOP VENT) |

A vent restrictor may be needed when |

|

vertically terminating the vent system above |

|

the roof (when using the appliance top |

|

vent), install vent restrictor in the top vent |

|

of the fireplace outlet on D-500/600/800 and |

|

DT-500/600/800 series models. |

|

If needed, install the restrictor orientated as |

|

shown, either from inside or outside the unit, |

|

in the inner fireplace collar. |

|

RESTRICTOR |

|

INNER |

|

FIREPLACE |

|

COLLAR |

APPLIANCE TOP |

|

|

|

VENT OUTLET |

Figure 15 |

|

VENT RESTRICTOR INSTALLATION

(REAR VENT)

A vent restrictor may be needed when horzontally terminating the vent system from the rear of the appliance (when using the applliance rear vent), install vent restrictor in the rear vent of the fireplace outlet on D-500/600/800 and DR-500/600/800 series models, in any installation that has a vertical vent run in excess of three feet (0.914 meters).

If needed, install the restrictor orientated as shown, either from inside or outside the unit, in the inner fireplace collar.

INNER FIREPLACE |

APPLIANCE REAR |

|

COLLAR |

||

VENT OUTLET |

||

|

||

|

RESTRICTOR |

Figure 16

Select Venting System - Horizontal or Vertical

With the appliance secured in framing, determine vent routing and identify the exterior termination location. The following sections describe vertical (roof) and horizontal (exterior wall) vent applications. Refer to the section relating to your installation. A list of approved venting components is shown in the two tables on page 24 and the two tables on page 25.

9

Loading...

Loading...