Page 1

Studer Vista 9

Digital Mixing System, SW V4.5

1. Introduction, Operating Principles

2. Vista Desk Operation

3. Parameter Description

4. Graphic Controller Operation

5. AutoTouch+ Dynamic Automation

6. Configuration Tool (Option)

7. DAW Control / Studer RELINK

8. SCore Live

9. Application Notes

10. Update Information: (currently empty)

Operating Instructions

Page 2

Prepared and edited by Copyright by Studer Professional Audio GmbH

Studer Professional Audio GmbH Printed in Switzerland

Technical Documentation Order no. BD10.275270 (Ed. 1010)

Althardstrasse 30

CH-8105 Regensdorf --- Switzerland

http://www.studer.ch Subject to change

Studer is a registered trade mark of Studer Professional Audio GmbH, Regensdorf

Page 3

I

For Your Own Safety and to Avoid Invalidation of the Warranty

Please Read This Section Carefully

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do not use this apparatus near water.

• Clean only with a dry cloth.

• Do not block any ventilation openings. Install in accordance with the

manufacturer's instructions.

• Do not install near any heat sources such as radiators, heat registers,

stoves, or other apparatus (including amplifiers) that produce heat.

• Do not defeat the safety purpose of a polarised or grounding type plug. A

polarised plug has two blades with one wider than the other. A grounding

type plug has two blades and a third grounding prong. The wide blade or

the third prong are provided for your safety. If the provided plug does not

fit into your outlet, consult an electrician for replacement of the obsolete

outlet

• Protect the power cord from being walked on or pinched particularly

at plugs, convenience receptacles and the point where they exit from the

apparatus.

• Only use attachments/accessories specified by the manufacturer.

• Use only with the cart, stand, tripod, bracket or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use cau

tion when moving the cart/apparatus combination to avoid injury from

tip-over.

• Refer all servicing to qualified service personnel. Servicing is required

when the apparatus has been damaged in any way, such as power-supply

cord or plug is damaged, liquid has been spilled or objects fallen into the

apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

Note: It is recommended that all maintenance and service on the product

should be carried out by Studer or its authorised agents. Studer cannot

accept any liability whatsoever for any loss or damage caused by service,

maintenance or repair by unauthorised personnel.

• WARNING: To reduce the risk of fire or electric shock, do not expose this

apparatus to rain or moisture. Do not expose the apparatus to dripping

or splashing and do not place objects filled with liquids, such as vases,

on the apparatus.

• No naked flame sources, such as lighted candles, should be placed on the

apparatus.

• Ventilation should not be impeded by covering the ventilation openings

with items such as newspapers, table cloths, curtains etc.

Warning: Do not use this apparatus in very dusty atmospheres, or in atmospheres

containing flammable gases or chemicals.

• THIS APPARATUS MUST BE EARTHED. Under no circumstances

should the safety earth be disconnected from the mains lead.

Safety Information

Page 4

II

• The mains supply disconnect device is the mains plug. It must remain

accessible so as to be readily operable when the apparatus is in use.

• If any part of the mains cord set is damaged, the complete cord set should

be replaced. The following information is for reference only. The wires

in the mains lead are coloured in accordance with the following code:

• Protective Earth (Ground): Green/Yellow (US: Green or Green/

Yellow)

• Neutral: Blue (US: White)

• Live (Hot): Brown (US: Black)

As the colours of the wires in the mains lead may not correspond with

the coloured markings identifying the terminals in your plug, proceed

as follows:

• The wire which is coloured Green and Yellow must be connected to

the terminal in the plug which is marked with the letter E or by the

earth symbol.

• The wire which is coloured Blue must be connected to the terminal in

the plug which is marked with the letter N

• The wire which is coloured Brown must be connected to the terminal

in the plug which is marked with the letter L

Ensure that these colour codes are followed carefully in the event of the

plug being changed

• This unit is capable of operating over a range of mains voltages, as

marked on the rear panel.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

This

Class A digital apparatus meets the requirements of the Canadian Inter-

ference-Causing Equipment Regulations.

C

et appareil numérique de la Classe A respecte toutes les exigences du Règle-

ment sur le matériel brouilleur du Canada.

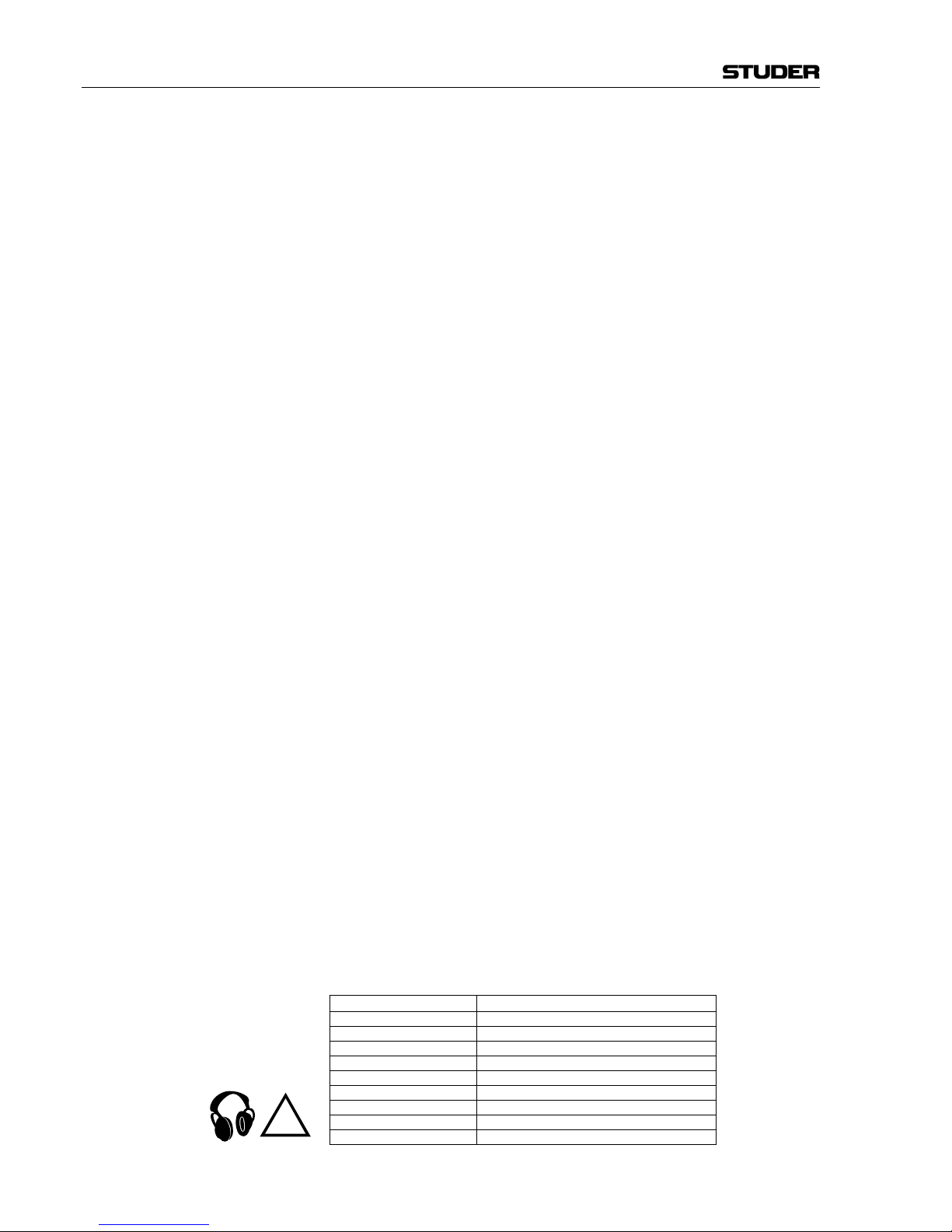

W

orking Safely With Sound Although your new console will not make any noise until you feed it signals,

it has the capability to produce sounds that, when monitored through a monitor system or headphones can damage hearing over time.The table below is

taken from the Occupational Safety & Health Administration directive on

occupational noise exposure (1926.52):

Permissible Noise Exposure:

Duration per day [h] Sound level [dBA, slow response]

8 90

6 92

4 95

3 97

2 100

1.5 102

1 105

0.5 110

<0.25 115

!

Safety Information

Page 5

III

Conforming to this directive will minimise the risk of hearing damage caused

by long listening periods. A simple rule to follow is: The longer you listen, the

lower the average volume should be. Please take care when working with your

audio system – if you are manipulating controls which you don’t understand

(which we all do when we are learning), make sure your monitoring level is

turned down. Remember that your ears are the most important tool of your

trade. Look after them, and they will look after you. Most importantly: Don’t

be afraid to experiment to find out how each parameter affects the sound;

this will extend your creativity and help you to get the best results.

A1 Safety Symbol Guide

For your own safety and to avoid invalidation of the warranty, all text marked

with these symbols should be read carefully.

T

o reduce the risk of electric shock, do not remove covers. No user-serviceable parts inside. Refer servicing to qualified service personnel (i.e., persons

having appropriate technical training and experience necessary to be aware

of hazards to which they are exposed in performing a repair action, and of

measures to minimize the danger of themselves).

The

lightning flash with arrowhead symbol is intended to alert the user to the

presence of un-insulated “dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute a risk of electric shock to

persons.

The

exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

Headphones

safety warnings contain important information and useful tips

on headphone outputs and monitoring levels.

A

ssemblies or sub-assemblies of this product can contain opto-electronic

devices. As long as these devices comply with Class I of laser or LED products according to EN 60825-1:1994, they will not be expressly marked on

the product. If a special design should be covered by a higher class of this

standard, the device concerned will be marked directly on the assembly or

sub-assembly in accordance with the above standard.

A2 Fir

st Aid

In Case of Electric Shock: Separate the person as quickly as possible from the electric power source:

• By switching the equipment off,

• By unplugging or disconnecting the mains cable, or

• By pushing the person away from the power source, using dry insulating

material (such as wood or plastic).

• After ha

ving suffered an electric shock, always consult a doctor.

W

arning! Do not touch the person or his clothing before the power is turned off,

otherwise you stand the risk of suffering an electric shock as well!

If the Person is Unconscious: • Lay the person down

• Turn him to one side

• Check the pulse

• Reanimate the person if respiration is poor

• Call for a doctor immediately.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

ACHTUNG

GEFAHR: ELEKTRISCHER SCHLAG

NICHT ÖFFNEN

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

!

CLASS 1

LASER PRODUCT

CLASS 1

LED PRODUCT

!

Safety Information

Page 6

IV

B General Installation Instructions

Please consider besides these general instructions also any product-specific

instructions in the “Installation” chapter of this manual.

B1 Unpacking

Check the equipment for any transport damage. If the unit is mechanically

damaged, if liquids have been spilled or if objects have fallen into the unit,

it must not be connected to the AC power outlet, or it must be immediately

disconnected by unplugging the power cable. Repair must only be performed

by trained personnel in accordance with the applicable regulations.

B2 Installa

tion Site

Install the unit in a place where the following conditions are met:

• T

he temperature and the relative humidity of the environment must be

within the specified limits during operation of the unit. Relevant values

are the ones at the air inlets of the unit (refer to Appendix 1).

• Condensation

must be avoided. If the unit is installed in a location with

large variation of ambient temperature (e.g. in an OB-van), appropriate

precautions must be taken before and after operation (refer to Appendix

1).

• Unobstructed air flow is essential for proper operation. Air vents of the

unit are a functional part of the design and must not be blocked in any

way during operation (e.g. by objects placed upon them, placement of the

unit on a soft surface, or installation of the unit within a rack or piece of

furniture).

• The unit must not be heated up by external sources of heat radiation (sunlight, spotlights).

B3 Earthing and Power Supply

Earthing of units with mains supply (class I equipment) is performed via

the protective earth (PE) conductor integrated in the mains cable. Units with

battery operation (< 60 V

, class III equipment) must be earthed separately.

Earthing the unit is one of the measures for protection against electrical shock

hazard (dangerous body currents). Hazardous voltage may not only be caused

by a defective power supply insulation, but may also be introduced by the

connected audio or control cables.

If the unit is installed with one or several external connections, its earthing

must be provided during operation as well as while the unit is not operated.

If the earthing connection can be interrupted, for example, by unplugging

the mains plug of an external power supply unit, an additional, permanent

earthing connection must be installed using the provided earth terminal.

Avoid ground loops (hum loops) by keeping the loop surface as small as

possible (by consequently guiding the earth conductors in a narrow, parallel

way), and reduce the noise current flowing through the loop by inserting an

additional impedance (common-mode choke).

Installation

Page 7

V

Installation / EMC

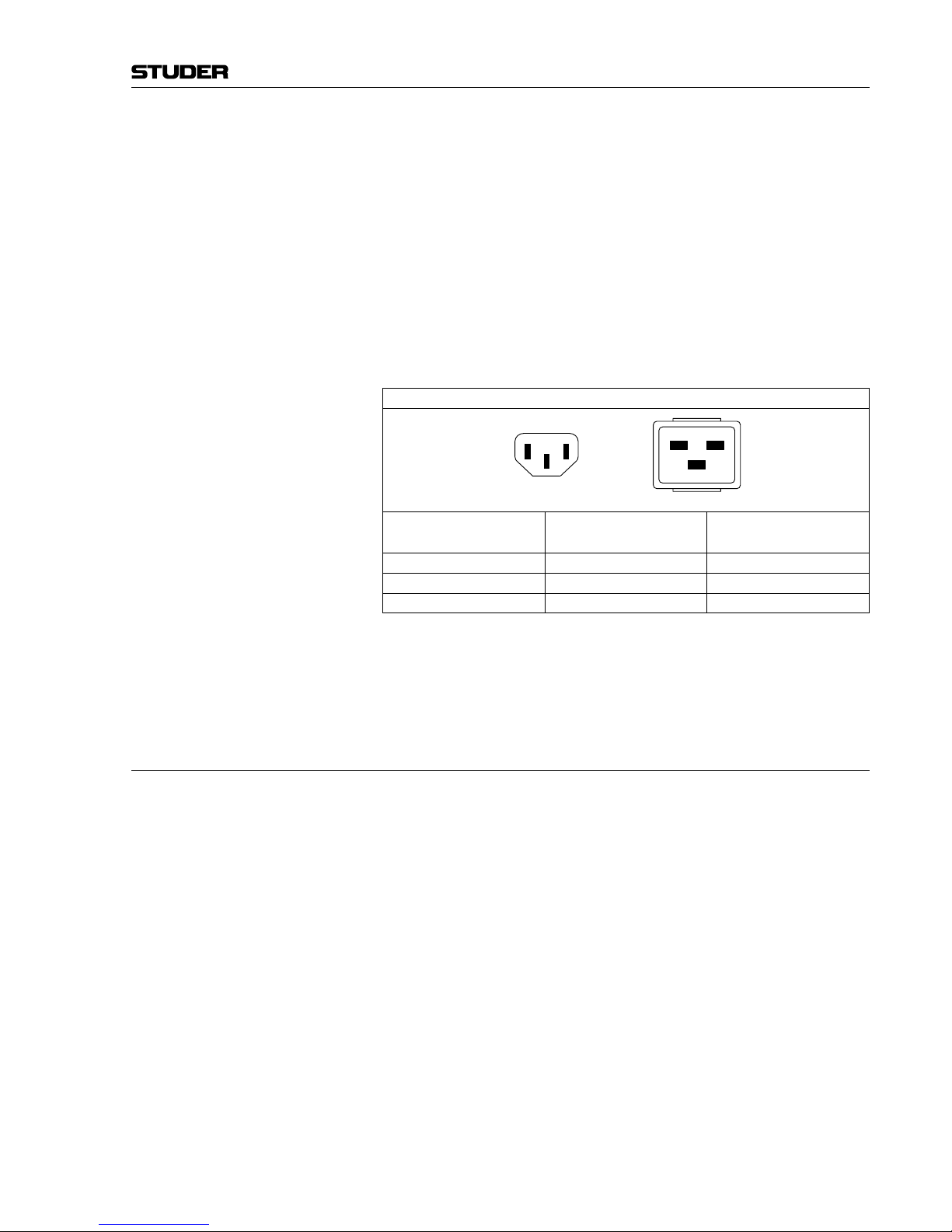

Class I Equipment (Mains Operation)

Should the equipment be delivered without a matching mains cable, the

latter has to be prepared by a trained person using the attached female plug

(IEC 320 / C13 or IEC 320 / C19) with respect to the applicable regulations

in your country.

Before

connecting the equipment to the AC power outlet, check that the local

line voltage matches the equipment rating (voltage, frequency) within the

admissible tolerance. The equipment fuses must be rated in accordance with

the specifications on the equipment.

Equipment

supplied with a 3-pole appliance inlet (protection conforming to

class I equipment) must be

connected to a 3-pole AC power outlet in such a

way that the equipment cabinet is connected to the protective earth.

For information on mains cable strain relief, please refer to Appendix 2.

Female Plugs (IEC320), Front-Side View:

European Standard

(CENELEC)

North American Standard

(NAS)

Brown

L (Live)

Black

Blue

N (Neutral)

White

Green/Yellow

PE (Protective Earth)

Green (or Green/Yellow)

Class III Equipment (Battery Operation up to 60 VDC)

Equipment of this protection class must be earthed using the provided earth

terminal if one or more external signals are connected to the unit (see explanation at the beginning of this paragraph).

B4 Electromagnetic Compatibility (EMC)

The unit conforms to the protection requirements relevant to electromagnetic

phenomena that are listed in guidelines 89/336/EC and FCC, part 15.

• The

electromagnetic interference generated by the unit is limited in such

a way that other equipment and systems can be operated normally.

• The unit is adequately protected against electromagnetic interference so

that it can operate properly.

The unit has been tested and conforms to the EMC standards of the speci-

fied electromagnetic environment, as listed in the following declaration.

The limits of these standards ensure protection of the environment and corresponding noise immunity of the equipment with appropriate probability.

However, a professional installation and integration within the system are

imperative prerequisites for operation without EMC problems.

For this purpose, the following measures must be followed:

• Install the equipment in accordance with the operating instructions. Use

the supplied accessories.

• In the system and in the vicinity where the equipment is installed, use only

components (systems, equipment) that also fulfill the EMC standards for

the given environment.

PE

L N

IEC 320 / C19IEC 320 / C13

PE

L N

Page 8

VI

• Use a system grounding concept that satisfies the safety requirements

(class I equipment must be connected with a protective ground conductor) and that also takes into consideration the EMC requirements. When

deciding between radial, surface, or combined grounding, the advantages

and disadvantages should be carefully evaluated in each case.

• Use

shielded cables where shielding is specified. The connection of the

shield to the corresponding connector terminal or housing should have a

large surface and be corrosion-proof. Please note that a cable shield connected only single-ended can act as a transmitting or receiving antenna

within the corresponding frequency range.

• Avoid ground loops or reduce their adverse effects by keeping the loop surface as small as possible, and reduce the noise current flowing through the

loop by inserting an additional impedance (e.g. common-mode choke).

• Reduce electrostatic discharge (ESD) of persons by installing an appropriate floor covering (e.g. a carpet with permanent electrostatic filaments) and

by keeping the relative humidity above 30%. Further measures (e.g. conducting floor) are usually unnecessary and only effective if used together

with corresponding personal equipment.

• When using equipment with touch-sensitive operator controls, please take

care that the surrounding building structure allows for sufficient capacitive

coupling of the operator. This coupling can be improved by an additional,

conducting surface in the operator’s area, connected to the equipment

housing (e.g. metal foil underneath the floor covering, carpet with conductive backing).

C Maintenance

All air vents and openings for operating elements (faders, rotary knobs) must

be checked on a regular basis, and cleaned in case of dust accumulation. For

cleaning, a soft paint-brush or a vacuum cleaner is recommended.

Cleaning the surfaces of the unit is performed with a soft, dry cloth or a soft

brush.

Persistent

contamination can be treated with a cloth that is slightly humidified

with a mild cleaning solution, such as dishwashing detergent.

For cleaning display windows, commercially available computer/TV screen

cleaners are suited. Use only a slightly damp (never wet) cloth.

Never use any solvents for cleaning the exterior of the unit! Liquids must

never be sprayed or poured on directly!

F

or equipment-specific maintenance information please refer to the corre-

sponding chapter in the operating and service manuals.

D Electrostatic Discharge during Maintenance and Repair

Caution: Observe the precautions for handling devices sensitive to electrostatic dis-

charge!

Many semiconductor components are sensitive to electrostatic discharge

(ESD). The lifespan of assemblies containing such components can be drastically reduced by improper handling during maintenance and repair. Please

observe the following rules when handling ESD sensitive components:

• ESD sensitive components should only be stored and transported in the

packing material specifically provided for this purpose.

EMC / Maintenance / ESD

Page 9

VII

ESD / Repair

• When performing a repair by replacing complete assemblies, the removed

assembly must be sent back to the supplier in the same packing material

in which the replacement assembly was shipped. If this should not be the

case, any claim for a possible refund will be null and void.

• U

npacked ESD sensitive components should only be handled in ESD

protected areas (EPA, e.g. area for field service, repair or service bench)

and only be touched by persons wearing a wristlet connected to the ground

potential of the repair or service bench by a series resistor. The equipment

to be repaired or serviced as well as all tools and electrically semi-conducting work, storage, and floor mats should also be connected to this ground

potential.

• T

he terminals of ESD sensitive components must not come in uncontrolled

contact with electrostatically chargeable or metallic surfaces (voltage

puncture, discharge shock hazard).

• T

o prevent the components from undefined transient stress and possible

damage due to inadmissible voltages or compensation currents, electrical

connections should only be established or separated when the equipment

is switched off and after any capacitor charges have decayed.

E Repair

By removing housing parts or shields, energized parts may be exposed. For

this reason the following precautions must be observed:

• Maintenance may only be performed by trained personnel in accordance

with the applicable regulations.

• The equipment must be switched off and disconnected from the AC power

outlet before any housing parts are removed.

• Even if the equipment is disconnected from the power outlet, parts with

hazardous charges (e.g. capacitors, picture tubes) must not be touched until

they have been properly discharged. Do not touch hot components (power

semiconductors, heat sinks, etc.) before they have cooled off.

• If maintenance is performed on a unit that is opened while being switched

on, no un-insulated circuit components and metallic semiconductor housings must be touched, neither with bare hands nor with un-insulated

tools.

Certain components pose additional hazards:

• Explosion hazard from lithium batteries, electrolytic capacitors and power

semiconductors (Observe the component’s polarity. Do not short battery

terminals. Replace batteries only by the same type).

• Implosion hazard from evacuated display units.

• Radiation hazard from laser units (non-ionizing), picture tubes (ionizing).

• Caustic effect of display units (LCD) and components containing liquid

electrolyte.

Such components should only be handled by trained personnel who are prop-

erly protected (e.g. protection glasses, gloves).

Page 10

VIII

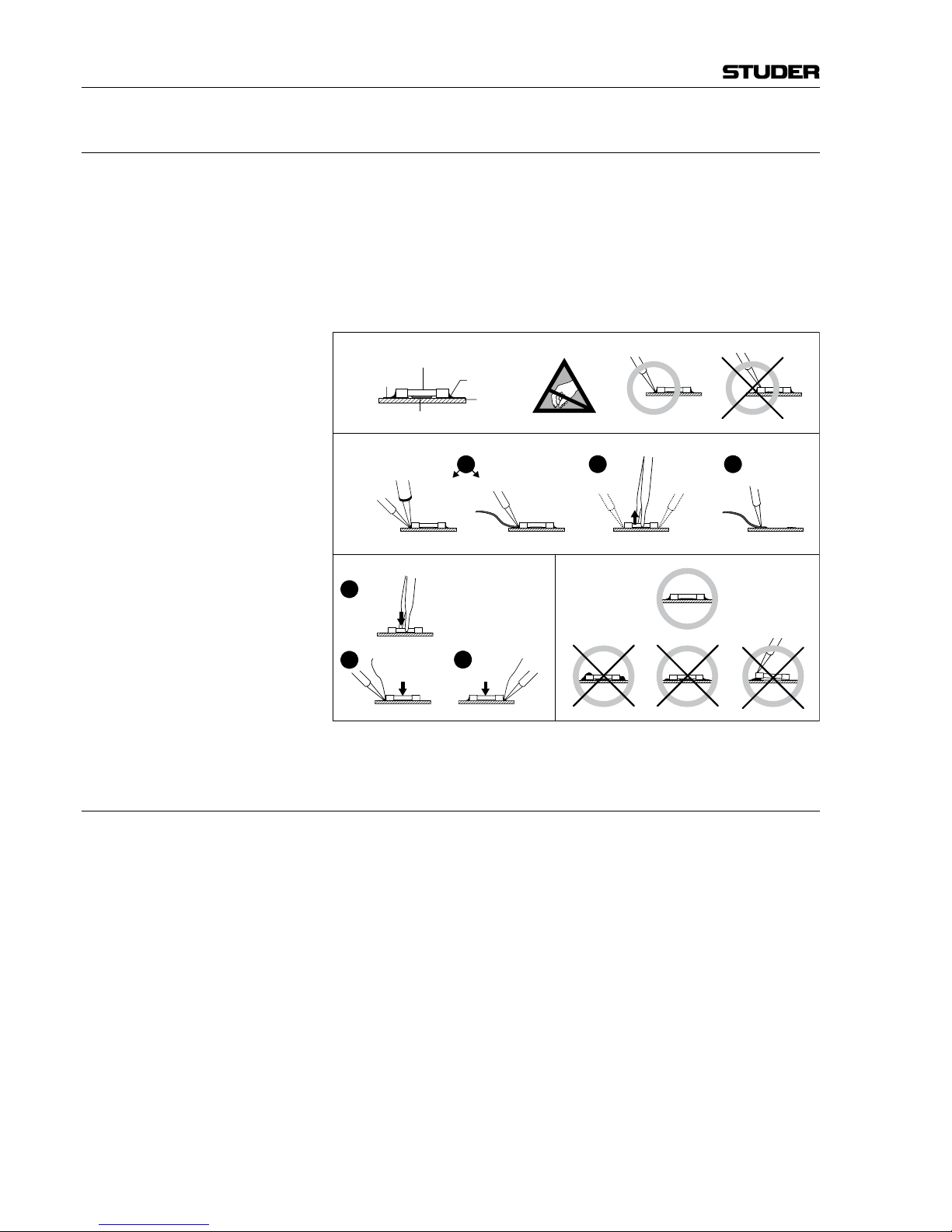

E1 SMD Components

Studer has no commercially available SMD components in stock for ser-

vice purposes. For repair, the corresponding devices have to be purchased

locally. The specifications of special components can be found in the service

manual.

SMD

components should only be replaced by skilled specialists using appropriate tools. No warranty claims will be accepted for circuit boards that have

been damaged. Proper and improper SMD soldering joints are illustrated

below.

F Disposal

Packing Materials The packing materials have been selected with environmental and disposal

issues in mind. All packing material can be recycled. Recycling packing saves

raw materials and reduces the volume of waste.

If you need to dispose of the transport packing materials, please try to use

recyclable means.

Used Equipment Used equipment contains valuable raw materials as well as materials that

must be disposed of professionally. Please return your used equipment via an

authorized specialist dealer or via the public waste disposal system, ensuring

any material that can be recycled is.

Please take care that your used equipment cannot be abused. To avoid abuse,

delete sensitive data from any data storage media. After having disconnected

your used equipment from the mains supply, make sure that the mains connector and the mains cable are made useless.

Repair / Disposal

Dismounting

Mounting Examples

Solder

SMD

Component

Copper

Track

Adhesive

Soldering Iron

Desoldering

Iron

Desolder

Wick

Heat and Remove Cleaning

Solder

Ø 0.5...0.8 mm

Heating Time < 3 s per Side

Soldering

Iron

Desolder

Wick

PCB

3

2

1

3

2

1

Page 11

IX

G Declarations of Conformity

G1 Class A Equipment - FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide a reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

This Class A digital apparatus meets the requirements of the Canadian Inter-

ference-Causing Equipment Regulations.

C

et appareil numérique de la Classe A respecte toutes les exigences du Règle-

ment sur le matériel brouilleur du Canada.

Caution: Any changes or modifications not expressly approved by the manufacturer

could void the user’s authority to operate the equipment. Also refer to relevant

information in this manual.

Conformity

Page 12

X

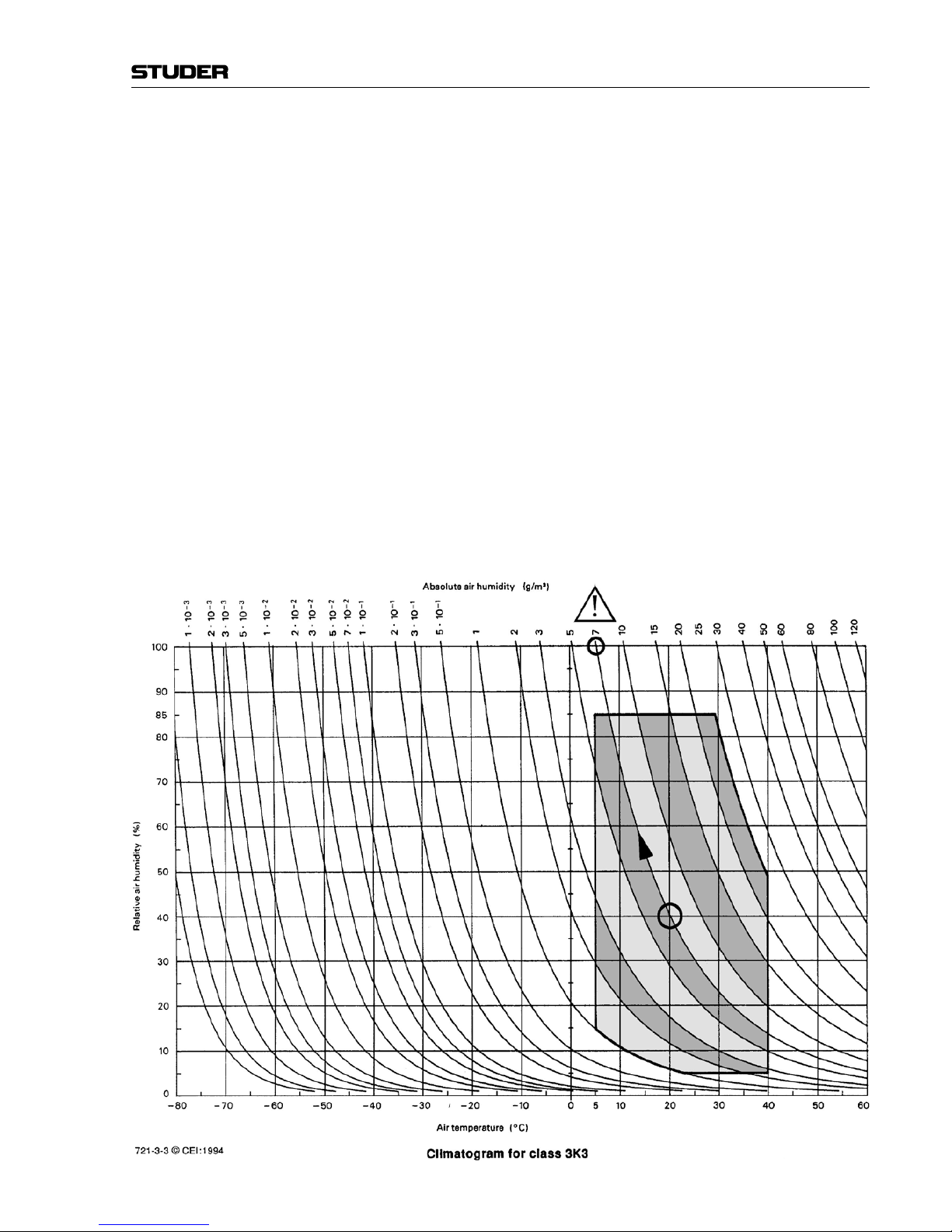

Appendix 1: Air Temperature and Humidity

General

Normal operation of the unit or system is warranted under the ambient condi-

tions defined by EN 60721-3-3, set IE32, value 3K3.

T

his standard consists of an extensive catalogue of parameters, the most

important of which are: ambient temperature +5...+40 °C, relative humidity 5...85% (i.e., no formation of condensation or ice); absolute humidity

1...25 g/m³; rate of temperature change < 0.5 °C/min. These parameters are

dealt with in the following paragraphs.

Under these conditions the unit or system starts and works without any prob-

lem. Beyond these specifications, possible problems are described below.

Ambient Temperature

Units and systems by Studer are generally designed for an ambient tempera-

ture

range (i.e. temperature of the incoming air) of +5 °C to +40 °C. When

rack mounting the units, the intended air flow and herewith adequate cooling

must be provided. The following facts must be considered:

• The admissible ambient temperature range for operation of the semiconductor components is 0 °C to +70 °C (commercial temperature range for

operation).

• The air flow through the installation must provide that the outgoing air is

always cooler than 70 °C.

• Average heat increase of the cooling air shall be about 20 K, allowing for

an additional maximum 10 K increase at the hot components.

• In order to dissipate 1 kW with this admissible average heat increase, an

air flow of 2.65 m³/min is required.

Example: A rack dissipating P = 800 W requires an air flow of 0.8 * 2.65 m³/min which

corresponds to 2.12 m³/min.

• If the cooling function of the installation must be monitored (e.g. for fan

failure or illumination with spot lamps), the outgoing air temperature must

be measured directly above the modules at several places within the rack.

The trigger temperature of the sensors should be 65 °C to 70 °C.

Frost and Dew

The unsealed system parts (connector areas and semiconductor pins) allow

for a minute formation of ice or frost. However, formation of dew visible to

the naked eye will already lead to malfunctions. In practice, reliable operation

can be expected in a temperature range above –15 °C, if the following

general rule is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it

reaches 100%, condensation will arise, usually in the boundary layer between

the air and a cooler surface, together with formation of ice or dew at sensitive areas of the system (contacts, IC pins, etc.). Once internal condensation

occurs, trouble-free operation cannot be guaranteed, independent of temperature.

Before putting into operation, the system must be checked for internal for-

mation of condensation or ice. Only with a minute formation of ice, direct

Appendix

Page 13

XI

evaporation (sublimation) may be expected; otherwise the system must be

heated and dried while switched off.

A system without visible internal formation of ice or condensation should be

heated up with its own heat dissipation, as homogeneously (and subsequently

as slow) as possible; the ambient temperature should then always be lower

than the one of the outgoing air.

If it is absolutely necessary to operate the cold system immediately within

warm ambient air, this air must be dehydrated. In such a case, the absolute

humidity must be so low that the relative humidity, related to the coldest

system surface, always remains below 100%.

E

nsure that the enclosed air is as dry as possible when powering off (i.e. before

switching off in winter, aerate the room with cold, dry air, and remove humid

objects such as clothes from the room).

These

relationships are visible from the following climatogram. For a controlled procedure, thermometer and hygrometer as well as a thermometer

within the system will be required.

Example 1: An OB-van having an internal temperature of 20 °C and a relative humidity of

40% is switched off in the evening. If the temperature falls below +5 °C, the

relative humidity will rise to 100% (7 g/m³); dew or ice will be forming.

Example 2: An OB-van is heated up in the morning with air of 20 °C and a relative

humidity of 40%. On all parts being cooler than +5 °C, dew or ice will be

forming.

Appendix

Page 14

XII

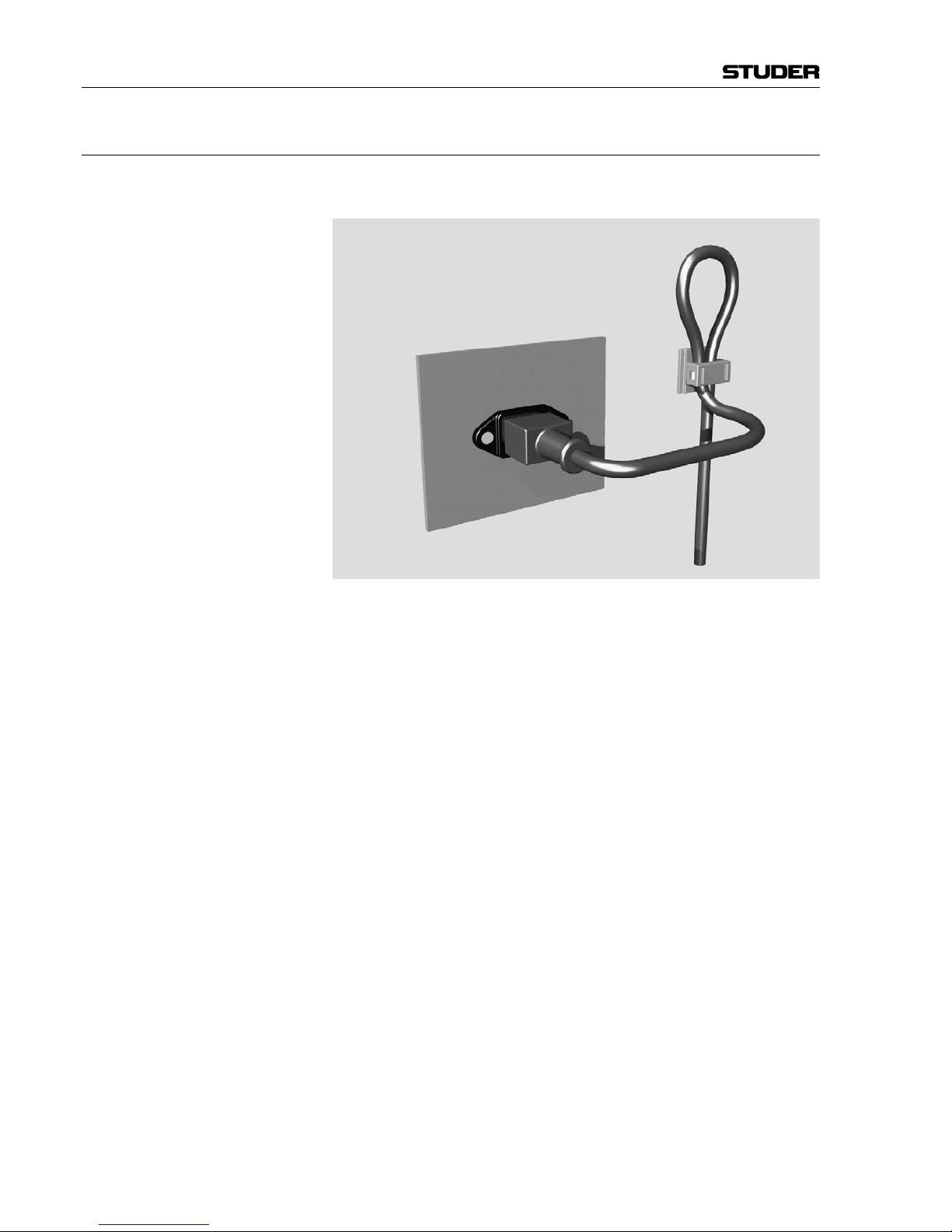

Appendix 2: Mains Connector Strain Relief

For anchoring connectors without a mechanical lock (e.g. IEC mains connec-

tors), we recommend the following arrangement:

Pr

ocedure: The cable clamp shipped with your unit is auto-adhesive. For mounting please

follow the rules below:

• The surface to be adhered to must be clean, dry, and free from grease, oil,

or other contaminants. Recommended application temperature range is

+20 °C to +40 °C.

• Remove the plastic protective backing from the rear side of the clamp

and apply it firmly to the surface at the desired position. Allow as much

time as possible for curing. The bond continues to develop for as long as

24 hours.

• For improved stability, the clamp should be fixed with a screw. For this

purpose, a self-tapping screw and an M4 bolt and nut are included.

• Place the cable into the clamp as shown in the illustration above and firmly

press down the internal top cover until the cable is fixed.

Appendix

Page 15

XIII

Appendix

Appendix 3: Software License

Use of the software is subject to the Studer Professional Audio Software

License Agreement set forth below. Using the software indicates your acceptance of this license agreement. If you do not accept these license terms, you

are not authorized to use this software.

Under the condition and within the scope of the following Terms and Con-

ditions, Studer Professional Audio GmbH (hereinafter “Studer”) grants the

right to use programs developed by Studer as well as those of third parties

which have been installed by Studer on or within its products. References

to the license programs shall be references to the newest release of a license

program installed at the Customer’s site.

Programs Covered by the Agreement

License Programs of Studer The following Terms and Conditions grant the right to use all programs of

Studer that are part of the System and/or its options at the time of its delivery

to the Customer, as well as the installation software on the original data disk

and the accompanying documentation (“License Material”). In this Agreement the word “Programs” shall have the meaning of programs and data

written in machine code.

Using

the software indicates your acceptance of this license agreement. If

you do not accept these license terms, you are not authorized to use this software.

Programs of Third Parties Programs of third parties are all programs which constitute part of the System

and/or its options at the time of delivery to the Customer but have not been

developed by Studer. The following conditions are applicable to programs of

third parties:

• The

right to use third parties’ programs is governed by the License Agreement attached hereto (if applicable), which is an integral part of this Agreement. The Customer shall sign any and all License Agreements for all

further programs of third parties installed on the system. The Customer

shall be deemed to have received all License Agreements upon delivery

of the system and/or its options.

• Studer shall accept no responsibility or liability for, and gives no warranties (express or implied) as to the programs of third parties. The Customer

waives any and all claims versus Studer for any consequential damages,

which might occur due to defects of these programs.

Right of Use

Principle Studer grants the Customer the non-exclusive right to use the License Ma-

terial in one copy on the system and/or its options as laid down by the Sales

Agreement concluded between the parties and all Terms and Conditions

which shall be deemed to form and be read and construed as part of the

Sales Agreement. This right is assignable according to the “Assignability”

paragraph hereinafter.

Customized Configurations The Customer is not entitled to alter or develop further the License Material

except within the expressly permitted configuration possibilities given by the

software installed on the system or elsewhere. All altered programs, includ-

Page 16

XIV

ing but not limited to the products altered within the permitted configuration

possibilities, are covered by this License Agreement.

Re

verse Engineering Reverse engineering is only permitted with the express consent of Studer.

The consent of Studer can be obtained but is not limited to the case in which

the interface software can not be provided by Studer. In any case Studer has

to be informed immediately upon complete or partial reverse engineering.

Copying the License Material The Customer is entitled to make one copy of all or parts of the License

Material as is necessary for the use according to this Agreement, namely for

backup purposes. The Customer shall apply the copyright of Studer found on

the License Material onto all copies made by him. Records shall be kept by

the Customer regarding the amount of copies made and their place of keeping.

The responsibility for the original program and all copies made lies with the

Customer. Studer is entitled to check these records on first request. Copies

not needed anymore have to be destroyed immediately.

Disclosure of License Material The License Material is a business secret of Studer. The Customer shall not

hand out or in any way give access to parts of or the complete License Material

to third parties nor to publish any part of the License Material without prior

written consent of Studer. The Customer shall protect the License Material

and any copies made according to the paragraph above by appropriate defense

measures against unauthorized access. This obligation of non-disclosure is a

perpetual obligation.

Third parties are entitled to have access to the License Material if they use the

License Material at the Customer’s site in compliance with this Agreement.

Under no circumstance are third parties entitled to have access to the instal-

lation software on the original data media. The Customer shall safeguard the

original data media accordingly.

Assignability The rights granted to the Customer according to this License Agreement shall

only be assignable to a third party together with the transfer of the system

and/or its options and after the prior written consent of Studer.

Rights to License Material

With the exception of the right of use granted by this License Agreement all

proprietary rights to the License Material, especially the ownership and the

intellectual property rights (such as but not limited to patents and copyright)

remain with Studer even if alterations, customized changes or amendments

have been made to the License Material.

Studer’

s proprietary rights are acknowledged by the Customer. The Customer

shall undertake no infringements and make no claims of any patent, registered

design, copyright, trade mark or trade name, or other intellectual property

right.

Warranty, Disclaimer, and Liability

F

or all issues not covered herewithin, refer to the “General Terms and Condi-

tions of Sales and Delivery” being part of the sales contract.

Appendix

Page 17

Vista 9 Digital Mixing System

Introduction 1-1

Date printed: 26.10.10

SW V4.5

CHAPTER 1

1 Introduction ..................................................................................................................................................................... 3

1.1 Operating Features ...................................................................................................................................................... 3

1.1.1 Vistonics™ .............................................................................................................................................................4

1.1.2 Momentary/Latching Keys .............................................................................................................................. 7

1.1.3 Ganging ................................................................................................................................................................. 8

1.1.4 Copy/Paste ............................................................................................................................................................. 9

1.1.5 Scrolling .............................................................................................................................................................. 10

1.1.6 FaderGlow™ ........................................................................................................................................................ 12

1.1.7 TFT Level Meters ............................................................................................................................................... 13

1.2 The Graphical Controller (GC) ................................................................................................................................. 14

1.2.1 GC Screen Examples........................................................................................................................................... 15

1.3 Channels, Routing, and Buses ..................................................................................................................................18

1.4 Processing Blocks ..................................................................................................................................................... 19

1.5 Monitoring and Communication ............................................................................................................................... 19

1.6 Automation ...............................................................................................................................................................21

1.7 Input Channel Block Diagrams................................................................................................................................. 22

Page 18

Vista 9 Digital Mixing System

1-2 Introduction

Date printed: 26.10.10

SW V4.5

Page 19

Vista 9 Digital Mixing System

Introduction 1-3

Date printed: 26.10.10

SW V4.5

1 INTRODUCTION

1.1 Operating Features

Studer Vista 9 incorporates operating features that are applicable throughout

nearly the whole console operation:

• Vistonics

™

• Momentary/Latching Key Activation

• Ganging

• Copy/paste

• Scrolling

• FaderGlow

™

• TFT screens for level metering

These operating principles are described below, they are freely combinable.

Some exceptions may occur where the combination of functions is not practical. The real speed and easiness of operation will become obvious to a sound

engineer by using and combining these operating principles in every day

life.

Page 20

Vista 9 Digital Mixing System

1-4 Introduction

Date printed: 26.10.10

SW V4.5

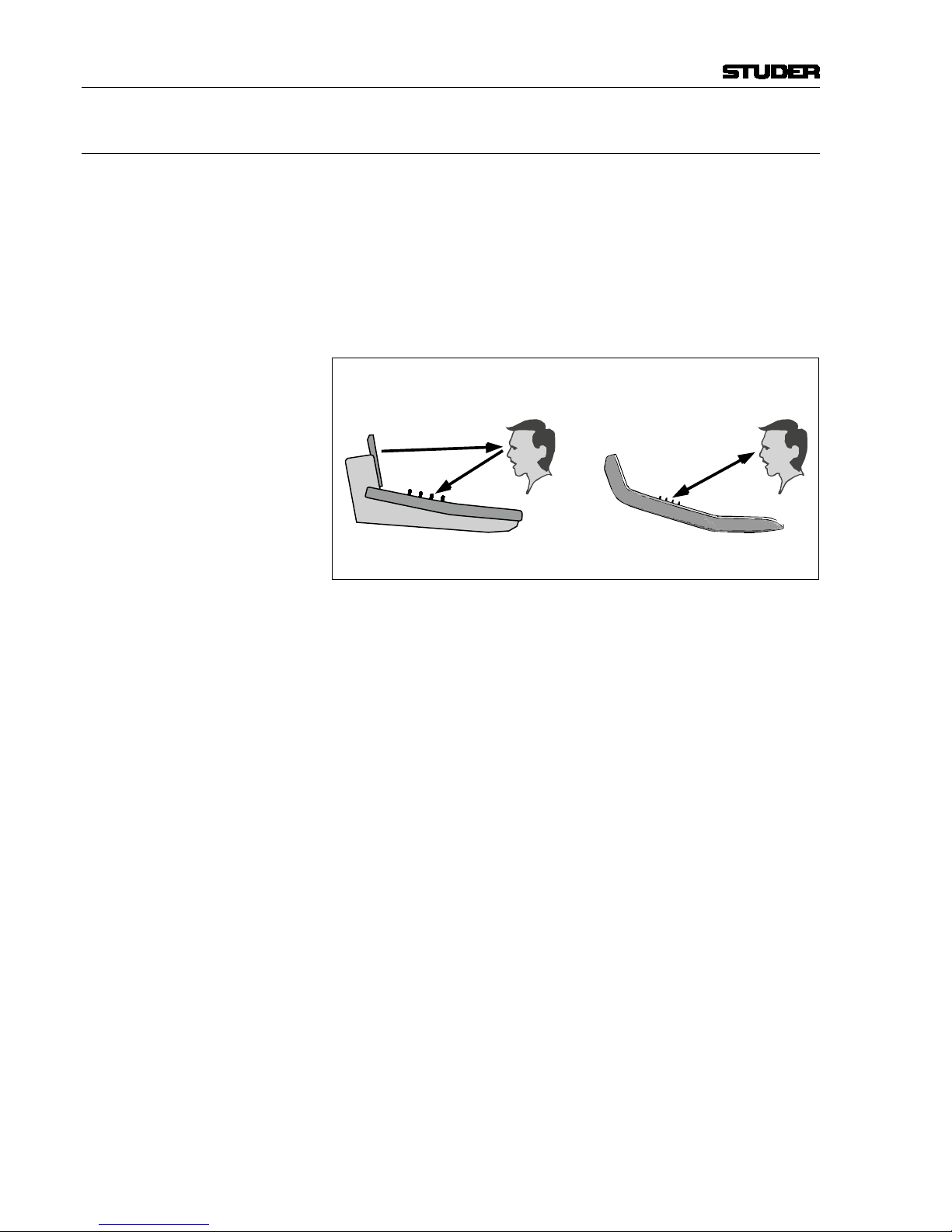

1.1.1 Vistonics™

Vistonics™ allows color and shape of controls to be varied according to good

ergonomic practice. A given audio function is always associated with the same

color, and a parameter is always associated with the same icon displaying

values graphically – just as or even more intuitive than an analog console.

Vistonics™ makes it possible to bring the location where you can see a value to

exactly the place where you control it. Therefore, tiring translation processes

between looking at a screen and finding the corresponding hardware control

somewhere else are not existing anymore, saving just a little time and energy

a few hundred times a day!

View = Control Location View = Control Location

Display

+ Controls

Conventional TFT Approach Vistonics Technology

Controls

Display

/

Great attention has been paid in order to make the current association clearly

visible. Color coding has been used to indicate families of audio functions

such as EQ, dynamics, etc. Consistent icons make the physical meaning of

an audio function obvious – e.g. bar graph-like icons indicate levels, time

adjustments are indicated by clock dials, etc. This way, it is easy to identify

the currently associated function even from a distance.

The Vistonics™ module consists of two main parts: 40 rotary controls with

push buttons next to each of them, as well as a touch screen area, showing

graphically the most important settings of each channel: Dynamics, EQ and

panning information. It is possible to change the association of a rotary control to audio functions either globally or locally.

Page 21

Vista 9 Digital Mixing System

Introduction 1-5

Date printed: 26.10.10

SW V4.5

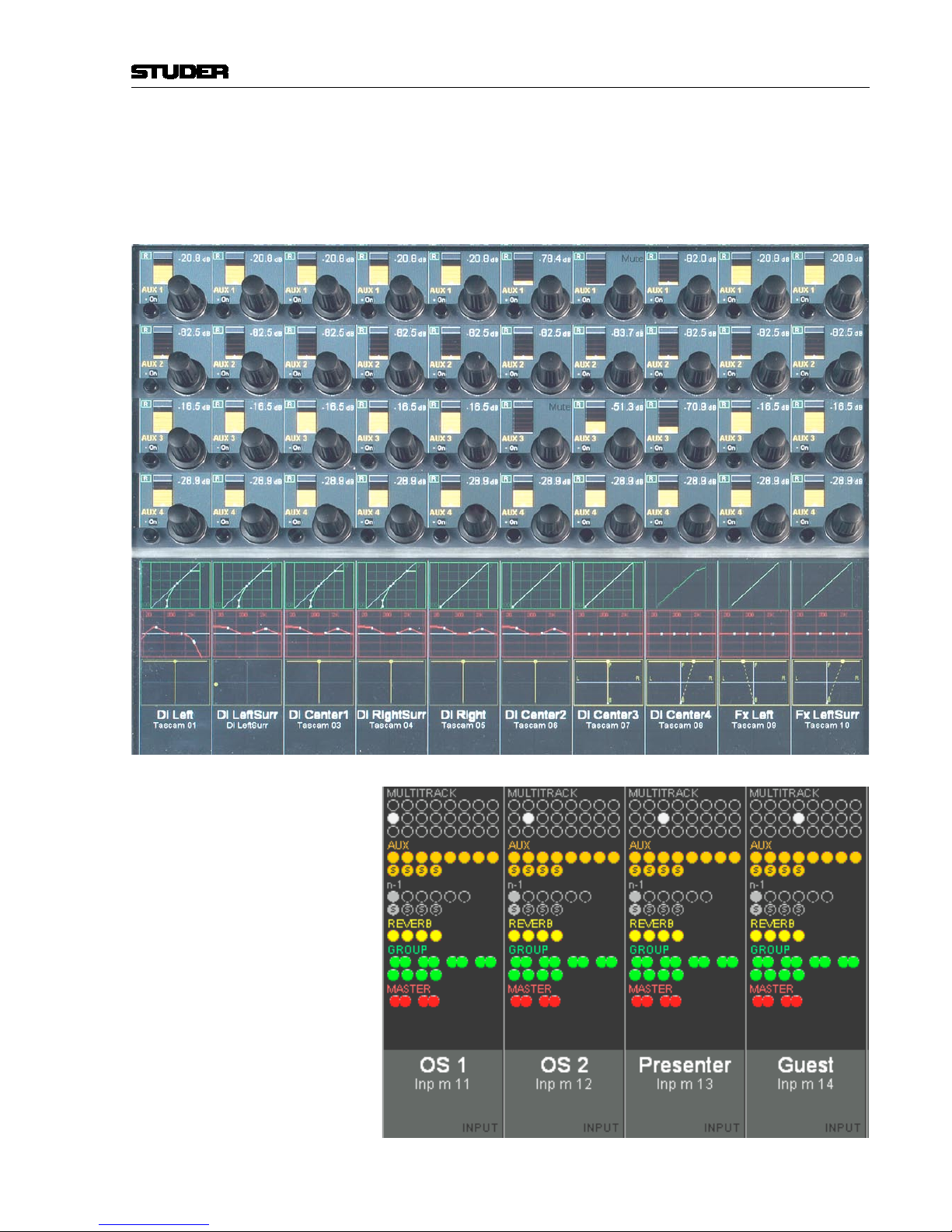

Global Views Up to four different parameters are shown in each channel strip. The same

four parameters will be shown globally on the whole console. This mode is

meant to be the ‘horizontal way of operation’, mostly used for e.g. operating

auxiliaries or input settings. The picture below shows a global AUX 1...4

view.

Global Bus Assign Overview

Page 22

Vista 9 Digital Mixing System

1-6 Introduction

Date printed: 26.10.10

SW V4.5

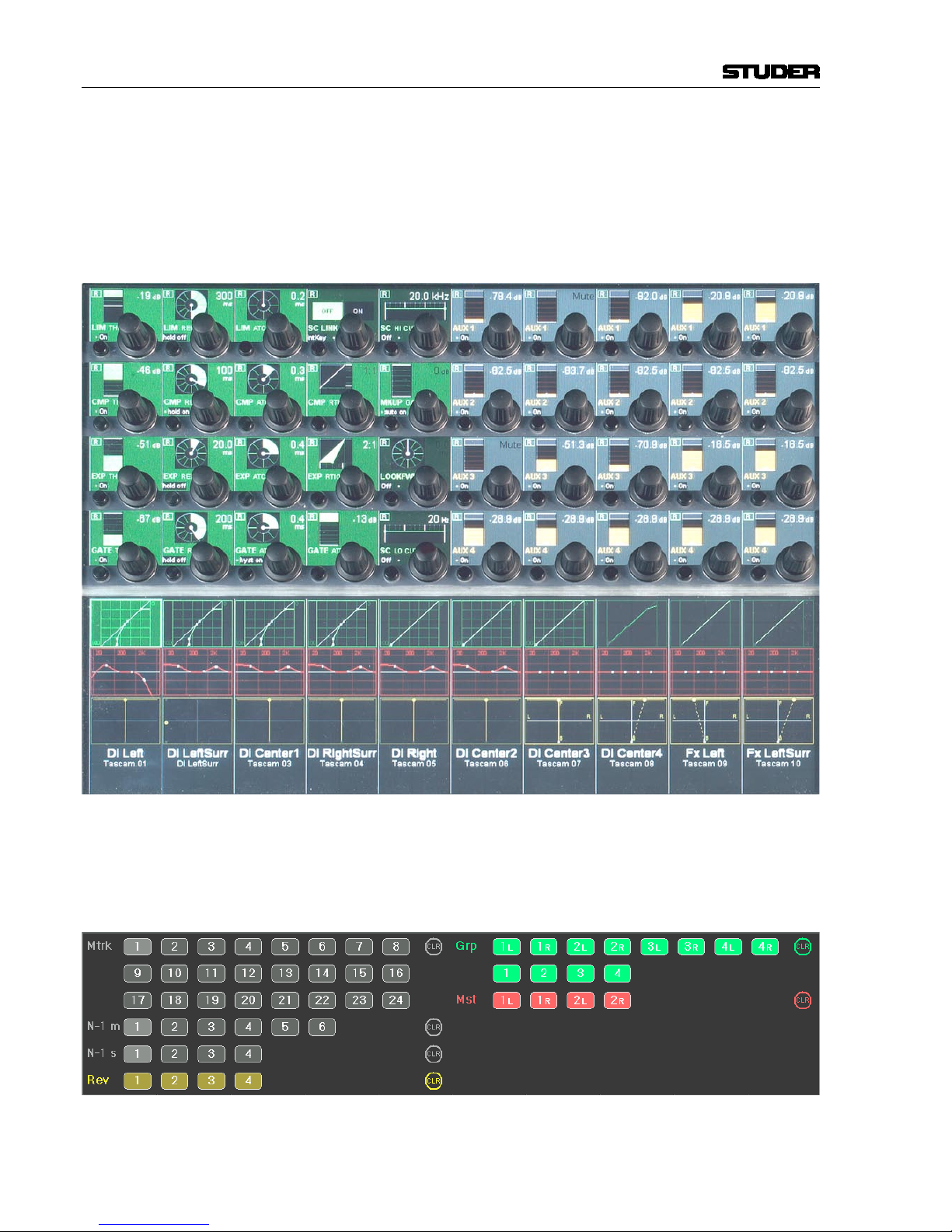

Local Views By touching the graphics shown below the Vistonics™ rotary controls, the

whole parameter set of that specific curve is displayed, also covering some

of the neighboring channel strips. It is also possible to touch any two curves

in one bay in order to display both at the same time.

The example below shows the complete dynamics section of the leftmost

channel (the small dynamics view is highlighted), overlaid to a global AUX

view.

This philosophy is completed by three hardware keys underneath the Viston-

ics

™

display, showing different combinations of parameters as well as the bus

assignment of that specific channel, covering the whole Vistonics

™

area.

Local Bus Assign View (here, channels can directly be assigned to a bus)

Page 23

Vista 9 Digital Mixing System

Introduction 1-7

Date printed: 26.10.10

SW V4.5

1.1.2 Momentary/Latching Keys

A lot of key presses during console operation are repetitive in order to com-

pare settings or to make quick checks for monitoring purposes. The Studer

Vista console has reduced the amount of needed key presses tremendously by

incorporating a special logic for these cases: The Studer Vista control surface

distinguishes long and short key presses and reacts differently in both cases:

Pressing and holding a key will automatically reverse its activation upon

release of the key – this is, however, applied only where appropriate. All

keys featuring momentary/latching activation are labeled with a symbol

throughout this manual.

For example, holding down a MUTE key for one second will automatically un-

mute the signal again upon release. Further examples are ON/OFF switching

of audio functions (EQ, filters, dynamics), PFL/SOLO as well as most of the

monitoring functions: soloing different loudspeakers, muting loudspeakers,

selecting alternate loudspeaker sets, etc. Keeping a monitoring source key or

loudspeaker set key pressed will automatically go back to the previous selection upon key release. If you want a switch to be activated continuously, just

press the key and release it immediately, without holding.

This automatism also works on view changes: Pressing and holding an EQ

graphic will make all its parameters accessible for as long as the graphic on

the screen is being touched. However, it will disappear immediately when

the graphic is untouched. The same thing is possible for global view changes:

Quick checks of bus assignments or auxiliary levels are as fast as never

before.

This philosophy has also the advantage of not having to remember the last

settings or views. The console remembers it automatically.

Note The threshold time for the momentary/latching distinction is adjustable in the

Graphical Controller’s ‘Vista Desk Settings’ screen.

Page 24

Vista 9 Digital Mixing System

1-8 Introduction

Date printed: 26.10.10

SW V4.5

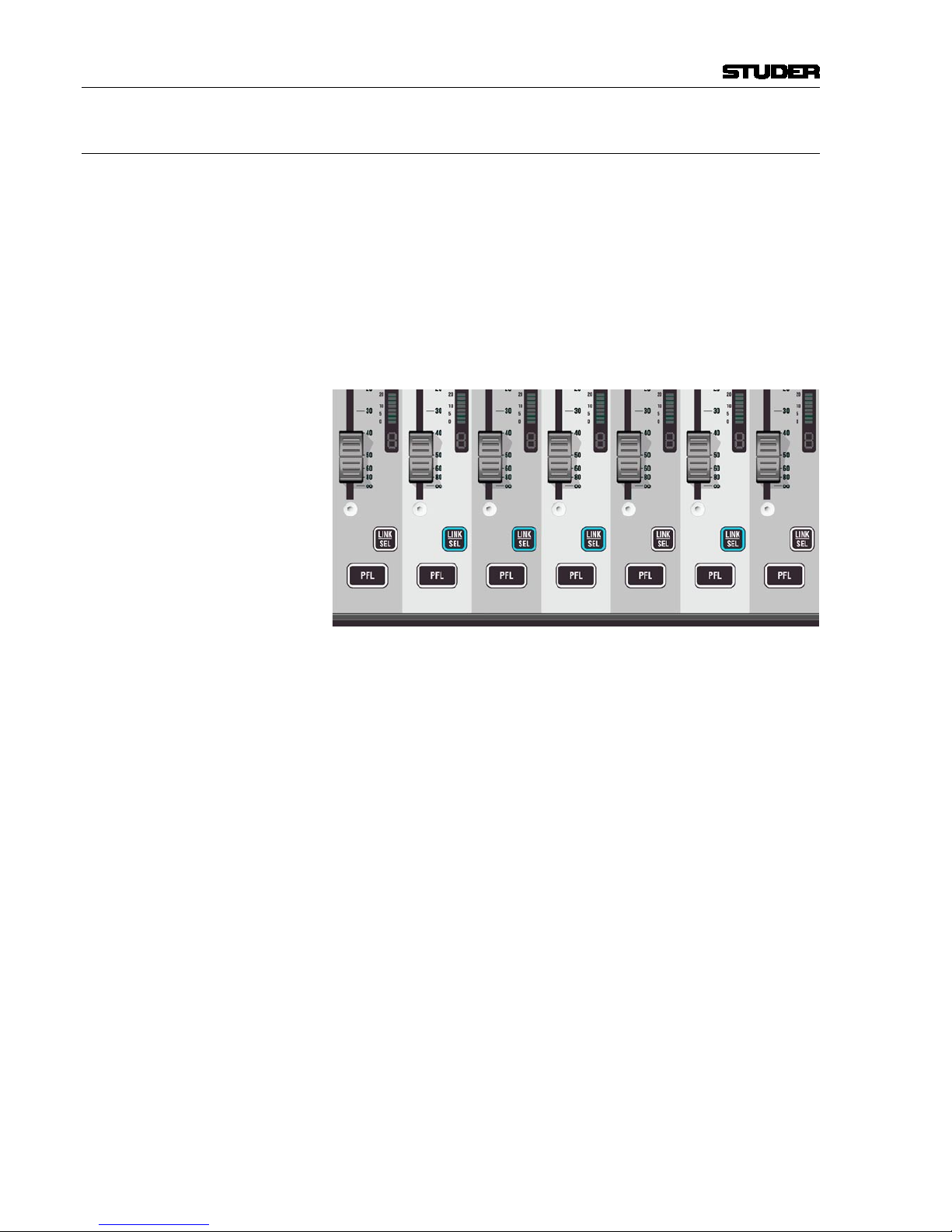

1.1.3 Ganging

On top of grouping certain channels together in a way commonly known as

VCA groups, Studer Vista has the ability to link multiple channels temporarily together and let them behave like one single channel. Such a link is called

a Gang. It co-exists with VCA style groups (Control Groups) and is only a

momentary help to influence multiple channels at the same time. A gang is

created by pressing and holding one LINK / SEL key on one channel while

the same key on a second channel gets pressed. This will link all channels

between the two. By using the MULTI SEL key it is possible to select or deselect any channels on the surface without having them next to each other.

The MULTI SEL key acts much the same as the Ctrl key on a standard PC

keyboard.

A gang is simply canceled by pressing any LINK / SEL key on the console

again. Please note that always one channel is selected.

Temporary de-activation of a gang is done by simultaneously touching identi-

cal control elements (e.g. f

ader or rotary encoder) of two channels within a

gang.

Typical Applications • Trimming of some faders or auxiliaries by changing the corresponding

control on any of the channels

• Cop

ying a certain setting to multiple channels by pasting the value to any

of the ganged channels

• Changing a bus assignment on all the ganged channels by changing it on

one of them

• Changing dynamic automation modes on the whole gang.

Basically any operation on one of the ganged channels will influence all of

them. Changing switches will overwrite the same switch on the other channels, while adjusting a audio function with a certain range will adjust all

other channels in a relative manner. Setting all channels to the same value is

accomplished by a copy/paste operation on one of the ganged channels.

Setting Up the Console

For setup application there is a fast way to link all channels of the same type

together. Pressing LINK ALL followed by pressing the LINK/SEL key of one

channel will gang all channels of that very same type together (e.g. all input

channels). The gang may exceed the visible channels and may also contain

channels in other sections. While having that gang active, you may setup your

console within seconds: Changing bus assignment, clearing one channel or

copy/paste certain values to any of these channels.

Page 25

Vista 9 Digital Mixing System

Introduction 1-9

Date printed: 26.10.10

SW V4.5

1.1.4 Copy/Paste

Copying certain audio settings across the console is made very fast and easy:

Each channel strip hosts copy/paste keys dedicated to a certain audio function, as EQ, dynamics, etc. Pressing one of these keys will make it fully lit,

while all possible destination channels (channels that also have this same

audio function) will show up half-lit. Selecting anyone of them will paste the

value into that channel. It is possible to paste a value to multiple channels

with the help of the MULTI SEL key or by creating a gang. However, there is

a shortcut to paste a value to multiple channels located next to each other:

Press and hold the (Cop

y/Paste) key of the first channel while pressing

the (Cop

y/Paste) key on the last channel. This will paste the value to all

channels in between.

There is also a special A (Copy/Paste All) key to copy a whole channel

including bus assignment, as well as a

(Undo/Redo) key to undo the last

paste or clear function on each channel separately. Pressing this key after an

undo operation again will redo the last copy.

Note The

(Undo/Redo) key can be used momentarily (long press) in order to

compare settings on a channel:

1 Press the (Copy/Paste) key twice in order to ‘memorize’ the current

setting (i.e., by pasting it to itself)

2 Adjust the audio function to an alternative setting

3 Press (Undo/Redo) multiple times (either short or long) in order to

compare the two settings.

Half-Lit Keys Whenever the console is waiting for a key press in order to finish a function,

it will illuminate all possible keys by half. This is a guide for the user – so

he can select one of these keys, or reverse the function by pressing the first

(fully lit) key again. A timeout applies if none of the half-lit keys are pressed

within a given time frame. Timeout duration is adjustable in the “Vista Desk

Settings” menu on the GC.

Examples:

(Copy/Paste) > (Copy/Paste),

LINK ALL

> LINK/SEL,

Setup of control groups, etc.

Page 26

Vista 9 Digital Mixing System

1-10 Introduction

Date printed: 26.10.10

SW V4.5

1.1.5 Scrolling

Most Vista installations will have more channels available in the DSP core

than there are physical faders on the console surface. Most manufacturers deal

with that fact by introducing ‘layers’. The console surface can be switched

in order to show the different layers, all of which making all DSP channels

available to the user. The Vista operating philosophy has modified this concept: Rather than thinking of layers sitting on top of each other, we think

of the layers being arranged on a horizontal line. The ‘Layer’ is now called

‘Section’. The six sections are next to each other on an imaginary horizontal

line, as indicated by the ‘Section Navigator’ keys in the control bay.

As long as the user wants to switch to a specific section, there is no difference

in operation to the ‘layer’ concept. Changing to another section is accomplished by pressing one of the corresponding keys in the SEcTIoN NAvIgATor

area of the control bay (belo

w right), or by pressing the arrow keys located

in each fader bay with ScroLL: SEcTIoN set to ON (below left).

Information on which section is currently displayed is given by the lit keys

(Control Bay) or the LEDs representing the different sections (Fader Bay).

Looking at the Graphical Controller with the ‘strip setup’ screen in the foreground will also indicate the currently displayed section by putting a dark

background to the displayed channels.

The Difference from the Layer Concept

Rather than just switching to another section, it is possible to scroll through

the sections by pressing any arrow key (for this purpose, ScroLL: SEcTIoN

has to be OFF on the fader bays). This will make the physical surface scroll

through all sections with a step size of one bay (10 channels). It is therefore

possible to move any channels close to the position of the operator, allowing

him to stay in the ‘sweet spot’ at all times. This concept can also be imagined

like moving a chair in front of an analog console. On Studer Vista, you move

the surface of an imaginary console six times larger than the physical console.

Page 27

Vista 9 Digital Mixing System

Introduction 1-11

Date printed: 26.10.10

SW V4.5

Which DSP channel is shown where is defined in the ‘strip setup’ dialog in

the Graphical Controller (refer to chapter 4.4.7).

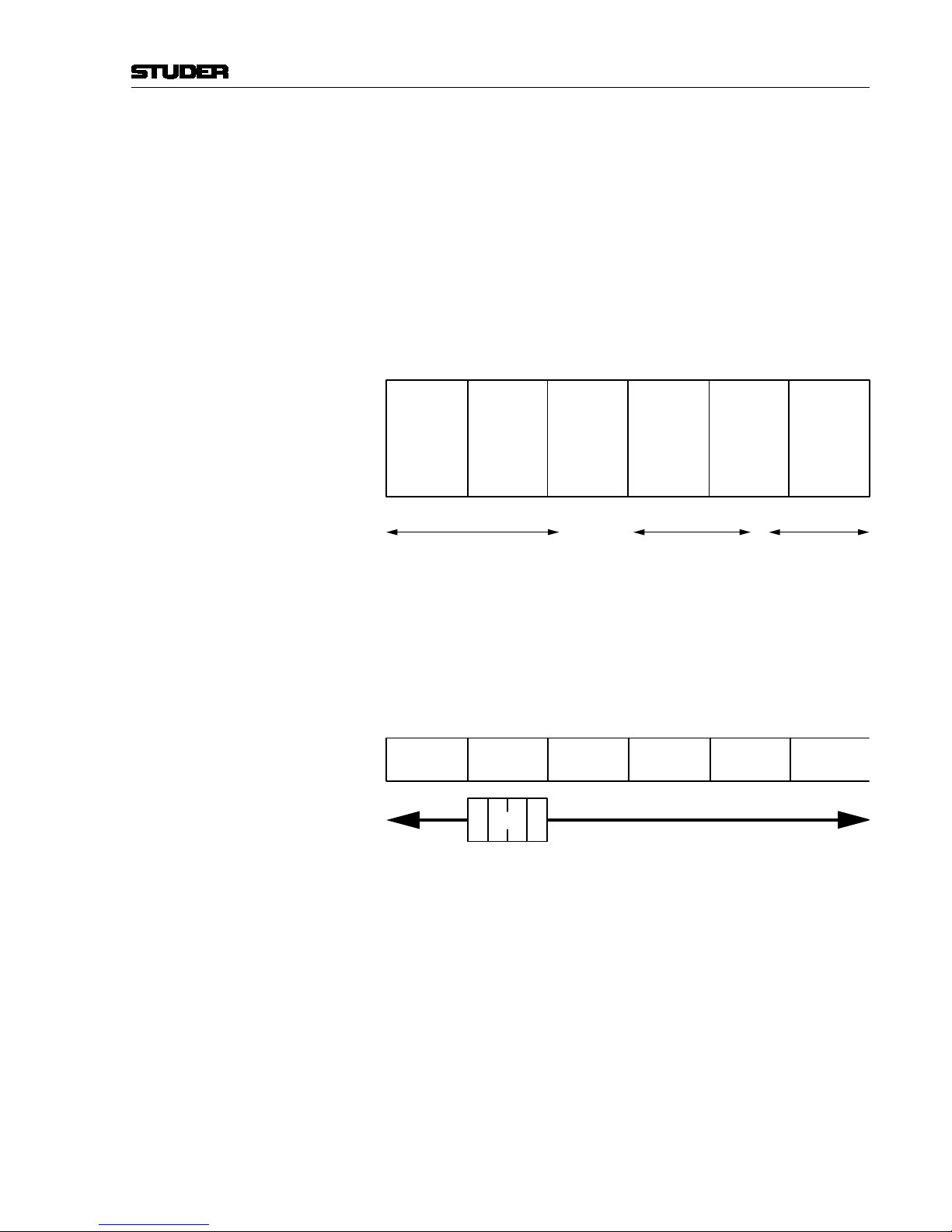

Desk Navigation Example Let’s assume a desk with 30 faders (between 20 and 70 possible in steps of

10). Since the desk can jump to six sections, this user can operate up to 6 × 30

DSP channels. Please note that it is possible to have the same DSP channel

visible in multiple places within the six sections.

Step 1 The user defines the order of the 180 DSP channels in the strip setup dialog

box in the GC. There he will find six empty sections with 30 placeholders,

each for a channel assignment.

The definition will most likely be made in such a way that the user starts with

a new section when he starts with new channel type (as shown below).

Section

1

(30 Channel Strips

to Occupy)

Section

2

Section

3

Section

4

Section

5

Section

6

(30 Channel Strips

to Occupy)

(30 Channel Strips

to Occupy)

(30 Channel Strips

to Occupy)

(30 Channel Strips

to Occupy)

(30 Channel Strips

to Occupy)

User occupies 70 Placeholders

with DSP Channels

‘Input Mono 1...70’

User occupies 48 Placeholders

with DSP Channels

‘Track Return 1...48’

42 Places with

DSP Channels

‘AUX Send’, ‘CGM’,

‘Master Outputs’

Step 2 The user can now navigate through the ‘virtual surface’ (6 sections wide) in

two ways: Either he jumps to a specific section by pressing the corresponding

key in the control bay, or he scrolls from the present position to the destination

by pressing one of the arrow keys (< and >) in any of the bays. Pressing one

of these arrow keys will virtually move the physical surface in front of the

total console (6 sections) by one bay (10 faders) at a time in the corresponding

direction (like moving a chair in front of a huge console).

Section

1

Section

2

Section

3

Section

4

Section

5

Section

6

Desk

The arrow keys are located in every bay, and they all have the same function-

ality. This prevents the user from having to move to the center of the console

for navigation.

Locking a Bay It is possible to prevent one or more bays from scrolling by switching the

ScroLL: LocK BAY key on the corresponding bay ON. This will make that

bay isolated from the remaining sections. It doesn’t only lock from scroll-

ing, but also all global view changes on the surface will not influence locked

bays. However, it is possible to change views on a locked bay by operating its

gLoBAL vIEW keys. These will now only influence the locked bay. A locked

bay is strictly isolated from view changes and will operate independently.

Please note that it is also possible to scroll a locked bay independently by

using the arrow keys on that specific bay.

It is possible as well to lock multiple bays at a time by pressing and holding

the first ScroLL: LocK BAY key and pressing a second ScroLL: LocK BAY

Page 28

Vista 9 Digital Mixing System

1-12 Introduction

Date printed: 26.10.10

SW V4.5

key on a different bay; this will lock all bays in between and form a ‘lock

group’. Multiple bays within a lock group will scroll at a time and perform

common global view changes. In this way it is easy to split the desk for twooperator use.

Scrolling a Locked Bay by One Section

When both the ScroLL: SEcTIoN and the ScroLL: LocK BAY keys are ON

on a fader bay, this is a special case. When pressing one of the arrow keys on

that specific bay, the display of channels will jump by exactly one section.

This function becomes very obvious when looking at the dark background

indication on the Graphical Controller. This operation mode might be useful

for operators who want to change to a different section with a locked bay.

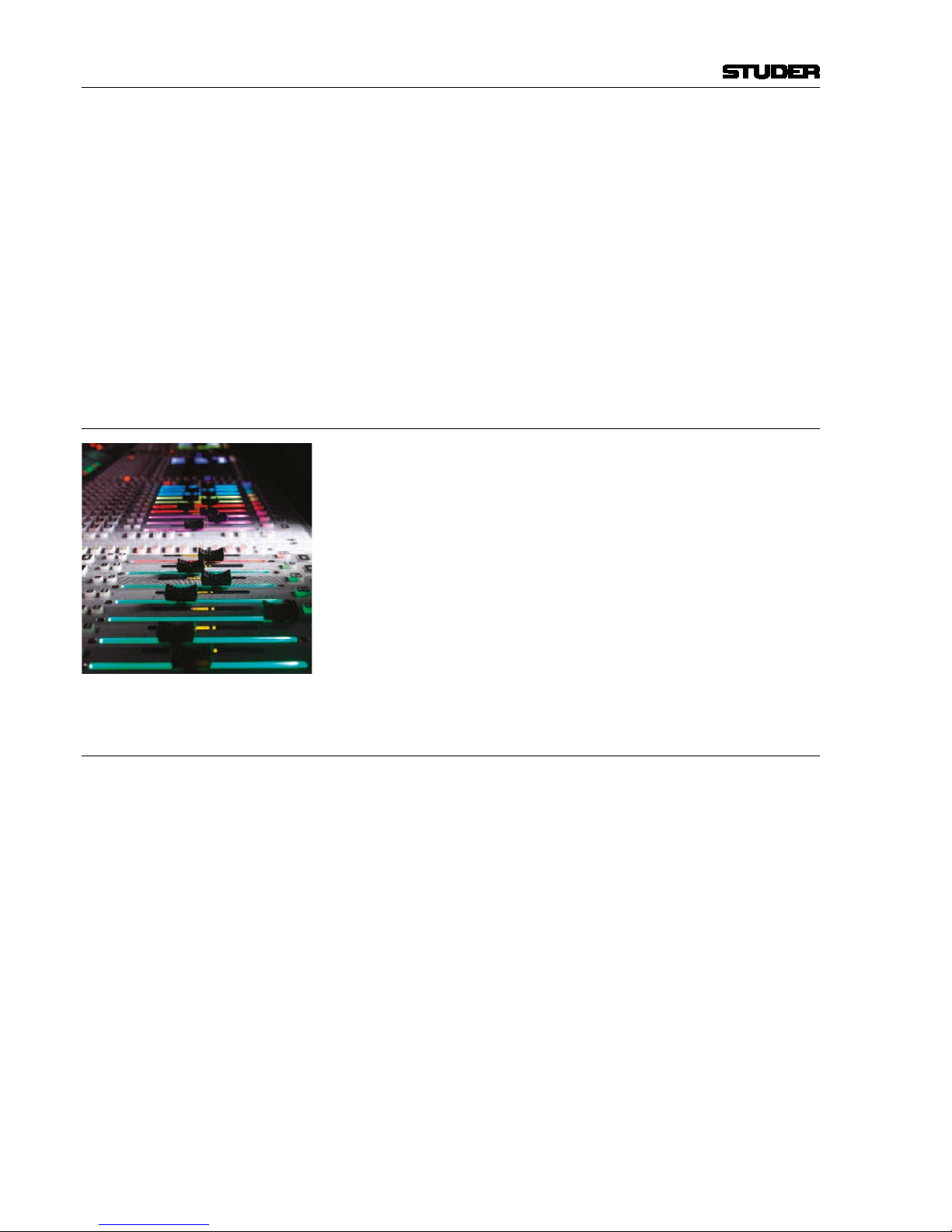

1.1.6 FaderGlow

™

During a hectic live production, FaderGlow™ provides the operator with an

instant overview of the console status by illuminating each fader in one of

eight freely-assignable colours.

Now the operator can mark individual, important channels such as present-

ers, main talents and other ‘must-never-lose-their-signal’ channels. Once the

important channel is colored, it can be found within a fraction of a second,

even after mixing on a different layer and coming back to a channel layout

that may not have been on the surface for some time. Moreover, FaderGlow

™

allows the operator colouring entire channel groups (such as ‘band’, ‘guest’,

‘ambience’, ‘string section’, ‘rhythm section’ channels), in order to distinguish them easier and locate them faster. One of eight different colours can

be assigned to any channel strip.

1.1.7 TFT Level Meters

TFT screens allow displaying all sorts of data, for example the metering.

For all possible channel types the metering has to go with it – from mono

over stereo and 5.1 to 7.1, always in the same space. Priority was to have as

large a bar graph meter as possible. In order to bring in more information, a

lower area is configurable and enables different options, depending on the

channel type. It can bring a surround image view or what is called the history

diagram of incoming or outgoing signal waveforms. This shows the history

of the signal and makes it easy to spot anomalies in the audio signal, such

as overloads or signal loss. When focusing on some important channels, one

might miss what’s going on somewhere else. If suddenly hearing something

strange, with the history feature a quick look across the console is sufficient

to see what has happened. Another option in the lower portion of the TFTs is a

bus assignment view, giving an overview of the channel’s current bus assignment, e.g. on a single channel where bus assignment is changed frequently.

The control bay metering differs from the meter screen on the fader bays; it is

mainly made to show output channels. Different meter views are available for

this screen. It can be switched to a predefined meter view to see all auxiliary

outputs. Or to all groups, or all programme masters, direct outs, bus outputs,

N–1s, matrix channels, etc. In addition there are user pages assignable to

Page 29

Vista 9 Digital Mixing System

Introduction 1-13

Date printed: 26.10.10

SW V4.5

whatever is desired via the strip set-up. There are four configurable user page

pages, one with ten slots in one row, one with 20 slots in two rows, and two

with 40 half-width slots in two rows. So if calling up page four, there are 40

meters, and they can be virtually anything. The two meter slots at the right

of the control bay TFT screen continuously show PFL and CR levels.

The illustration above is an example of a meter screen, with mono, stereo and

surround channels and different views in the lower area – such as metering of

the L2 channel, history, bus assignment and surround view. Further information is displayed as well, such as fader glow color, gain reduction, correlation

(for stereo signals) or surround signal type.

Page 30

Vista 9 Digital Mixing System

1-14 Introduction

Date printed: 26.10.10

SW V4.5

1.2 The Graphical Controller (GC)

An important feature of the Vista Digital Mixing System is the Graphical Con-

troller, also referred to as ‘GC’. The Graphical Controller program is used for

operating all mixing console functions that extend console’s functionality.

Specifically, the Graphical Controller’s extended functions include:

• General and channel-specific router control (defining the order of processing elements, e.g. EQ or dynamics libraries, within a channel)

• Recall and management of snapshots and cue points

• Saving of desk clipboards

• Assignment of the DSP channels to the fader strips

• Tone generator and metering control

• Control group and linkage control

• Production and Title management

• System administration

Various display windows and dialog boxes logically group the individual

functions. Visual elements are optimized for simple and intuitive operation.

With the help of an easy-to-understand General Patch page, the setup of

router cross points is dramatically simplified, even for large mixing console

configurations. Via a Snapshot window, all mixing console parameters can be

stored and recalled using mouse clicks. Some of the most important functions

are also available as dedicated keys on Vista’s control bay.

The concept of overall system configurability has been also adopted within

the Graphical Controller application. Since most functions are arranged in

overlapping windows of changeable sizes, users can set up their work environment to suit their specific requirements for each recording or production

session. These settings can be saved and recalled at any time, allowing for

fast and application-oriented operation of the Vista system.

Page 31

Vista 9 Digital Mixing System

Introduction 1-15

Date printed: 26.10.10

SW V4.5

1.2.1 GC Screen Examples

Internal Routing Matrix Control The Channel Patch screen is an audio path-oriented view for controlling the

routing of a particular channel, and is used to set up the sequence of channel

processing blocks (EQ, Insert, Delay, etc.) and metering locations within the

signal path, as well as defining the direct out signal. This screen also displays

the connections made to the channel’s various inputs and outputs. By double

clicking on one of these display boxes the system will go directly to the

associated connection in the General Patch. The Channel Patch also includes

labeling and dynamics link facilities.

Page 32

Vista 9 Digital Mixing System

1-16 Introduction

Date printed: 26.10.10

SW V4.5

Within the General Patch window, the various cross point routing of sources

and targets (destinations) is displayed. For example, it will show which audio

signals (AES/EBU in, Direct outs, etc.) connected to the DSP sections are

assigned to the corresponding channels and outputs (Input channel, MADI out

etc.). These connections are stored within Snapshots and Presets. The sources

and targets can be identified by Fixed, Device, Inherited, or User labels.

Page 33

Vista 9 Digital Mixing System

Introduction 1-17

Date printed: 26.10.10

SW V4.5

Snapshot Functions Display and control of snapshot settings (in other words, complete ‘pictures’

of the operating desk’s controls and of the console’s internal settings) and

factory/user presets provide basic working templates.

Control of snapshot/preset filters and channel protection is achieved via

separate windows:

Page 34

Vista 9 Digital Mixing System

1-18 Introduction

Date printed: 26.10.10

SW V4.5

1.3 Channels, Routing, and Buses

Processing blocks, such as equalizer, dynamics, delay, etc., can be configured

for all channel types.

Input Channels Vista’s digital routing matrix is located between the console’s physical inputs

and the actual DSP channels. This topology means that the physical analog

and digital inputs can be assigned to any console channel via the General

Patch page on the Graphical Controller. The patch setup forms part of each

individual snapshot, and can be saved, updated and recalled within the Snapshot/Preset system.

Output Channels This also applies to the outputs. On the General Patch page, each channel’s

output can be selected and sent to any analog or digital output destination.

Auxiliaries The number of stereo or mono AUX sends is fully configurable. The users

can establish the number and type of AUX sends they would like to use. The

AUX master channel can be equipped with the same selection of processing

blocks such as equalizer, dynamics, delay, and more.

Clean-Feeds/Mix-Minus (N–1/N–X) Clean-Feeds/Mix-Minus or N–1/N–X buses can be set up in stereo or mono,

and are configurable in number.

Multi-track and Group Routing Full multi-track and group routing can be configured.

Solo Modes Each channel features a Solo and a PFL Switch. Depending upon the mode

selected within the Control Bay the SOLO key is active as SOLO or Solo-InPlace. Clearing these buttons can be achieved by opening the corresponding

fader in case ‘PFL BC’ (Broadcast) is active. A very handy PFL/Solo Reset

is provided to disengage any solos regardless of where they are engaged on

the console. This eliminates the need to ‘search’ for solos with large console

configurations. A key to define certain channels to be safe from being muted

in ‘Solo-In-Place’ mode is also provided. This set will be stored with each

title.

Page 35

Vista 9 Digital Mixing System

Introduction 1-19

Date printed: 26.10.10

SW V4.5

1.4 Processing Blocks

Equalizer Four fully parametric bands are provided on the Vista. Each band, which

can be switched in and out independently, extends from 20 Hz to 20 kHz,

with a ±18 dB gain range. The EQ features a psycho-acoustically corrected

frequency response for high frequencies, similar to well-known analog EQ

designs. The two mid-bands can be switched between constant-Q and constant-range modes. The high and low frequency bands can be switched to

shelving mode. A second EQ type is available (defined in the Configuration

Tool), which features an additional Notch filter.

Filter Low-cut and high-cut filters are provided, with cutoff frequencies that are

variable between 20 Hz and 20 kHz, and slope selections of 12, 18, or 24 dB/

octave.

In addition, an analog low-cut filter with a cutoff frequency of 75 Hz and a

slope of 12 dB/octave is available in the D21m Mic/Line preamplifier.

Dynamics The Vista standard dynamics processing consists of four parts:

Limiter, Compressor, Expander, and Gate.

To avoid pumping and modulation, the dynamics processing sections feature

high sampling rate transient detection. Distortion artifacts are minimized

through selectable, program-dependent attack and release times. The Vista’s

dynamics feature a side-chain input that can be used with or without HP/LP

filters. A unique ‘look forward’ function is also featured. If desired, this

allows the entire transient portion of a waveform to be affected when using

the limiter/compressor or to be passed when the expander/gate is used.

Sometimes the dynamics processing can be utilized in a more pronounced

way, i.e., as an effect itself. For this purpose the ‘vintage dynamics’ was created. It is targeted to be flexible enough for different types of sound coloration

including extreme and unusual settings, but does not feature a dedicated

limiter.

Selection between the standard or vintage dynamics section can be made per

input channel during configuration of the console.

Soft Clip In addition, a soft clip function can be activated in the D21m Mic/Line pre-

amplifier.

1.5 Monitoring and Communication

Monitoring The Control Room (CR) monitoring section provides control of up to three

different speaker systems (two multi-channel and one two-channel stereo)

and 32 source selectors. All internal digital sources can be assigned to any of

the source selector keys. A headphone socket is also supplied for use within

the control room.

The Studio Monitor is configurable in the same way as the CR monitor sec-

tion. T

wo stereo loudspeaker pairs are supported.

Talkback An extensive talkback system is implemented within the Vista. The talkback

source can be either the desk-operator microphone or an external producer

microphone. Several destinations, such as buses, direct outputs, auxiliaries,

groups, and master outputs are available block.

Page 36

Vista 9 Digital Mixing System

1-20 Introduction

Date printed: 26.10.10

SW V4.5

Each channel is fitted with a talkback key that activates talkback to the direct

output of the corresponding channel and, if the channel is an N–1 owner, to

the N–1 output.

For details see the talkback and signaling block diagram below.

Control Room

Studio A

Talk to

CR

Ret 1

Ext 1

Studio MonitorA

TB only

PFL/TB Out

CR Monitor

Signaling Keys

Talk to

Aux1

Talk to

Aux2

Talk to

Aux3

Talk to

Aux4

Talk to

Aux1

Talk to

Aux2

Talk to

Ext1

Talk to

Ext2

Talk to

Aux3

Talk to

Aux4

Talk to

preselected

Talk to

preselected

Talk to

Studio

B

e.g.Speaker

GPI 2

GPI 4

GPI 5

GPO 3

GPO 2

GPI 1

Foot Switch

GPI 7 GPI 8 GPI 9 GPI 10 GPI 11

e.g.Intercom

Ext 3

(Line level) (Line level)

(always on)

Vista9 Desk

Mic "TB2"

TB Mic

GPO 1

Ext Location 1

Producer

( to PFL Speaker)

Studio B

Talk to

CR

Ret 2

Ext 2

Studio Monitor B

GPI 3

Ext Location 2

( to PFL Speaker)

Talk to

Studio

A

GPI 6

GPI X

Talk

to

ChanOut

Grp01

Talk

to

ChanOut

Grp N

Channel

Mute

Grp01

Channel

Mute

Grp N

Talk to

EXT1

Talk to

EXT2

GPI13

GPI12

GPI X

GPI X

GPI X GPI X

GPI X

GPI X

Live

GPI X

GPO 4

GPO X

GPO X

GPI X

GPI X

GPO X

GPO X

e.g.Speaker

GPO 6

GPO X

TB Keys

GPO 5

Legend :

GPI 1

GPO 2

GPI X

= GPI already configured in .ini files

= GPO already configured in .ini files

= GPI prepared to use, but not

assigned to signaling card.

This can be configured in .ini files

GPO X

= GPO prepared to use, but not

assigned to signaling card.

This can be configured in .ini files

Desk Operator

GPO X

Producer Area (either in control room or in another room)

Studio A Studio B

Red

Light

SIG1

SIG2

Talk

Red

Light

SIG1

SIG2

Talk

20.09.2010 wp

Talkback and signaling blockdiagram using D21m GPIO cards

Relations :

Dim CR and PFL if: Anytalk in Desk OR ( )Anytalk Producer AND Producer located in CR [DimLock is activated]

Dim StudioA if: Ret1 Talk to CR AND Ret1 located in Studio [DimLock is activated]

Dim StudioB if: Ret2 Talk to CR AND Ret2 located in Studio [DimLock is activated]

Cut StudioA if: (Faderstart of source which is assigned to StudioA) OR (StudioA is OnAir)

Cut StudioB if: (Faderstart of source which is assigned to StudioB) OR (StudioB is OnAir)

Cut Ext1 if: StudioA Cut AND Ret1 located in Studio

Cut Ext2 if: StudioB Cut AND Ret2 located in Studio

Sig1 LED StudioA = Sig1OutStudioA OR Sig1InStudioA

Sig2 LED StudioA = Sig2OutStudioA OR Sig2InStudioA

RedLight StudioA

=

StudioA Cut OR Red lightStudioA manual

TalkLED StudioA = DeskTalktoStudioA OR Ret1TalktoCR

Sig1 LED StudioB = Sig1OutStudioB OR Sig1InStudioB

Sig2 LED StudioB = Sig2OutStudioB OR Sig2InStudioB

RedLight StudioB = StudioB Cut OR RedlightStudioB manual

TalkLED StudioB = DeskTalktoStudioB OR Ret2TalktoCR

OnAirMode = OnAirKey OR GPI

Page 37

Vista 9 Digital Mixing System

Introduction 1-21

Date printed: 26.10.10

SW V4.5

1.6 Automation

Static Automation Snapshots An unlimited number of snapshots can be captured, stored, and recalled

for each Project Title. All control parameters of the console are stored in

the snapshots. When a snapshot is recalled, the console typically requires

120 ms to fully reset itself. Snapshots recalls can be done with snapshot filters active, protecting certain console parameters from being changed by the

recall. Extensive editing functions allow modifying snapshots after or during

a live show. Besides absolute protection of certain parameters it is possible to

trim parameters relative to their stored values rather then letting them totally

unmodified. Recalling a preset however, will ignore any snapshot filters

which may be active and bring the console into a defined audio state.

Copy & Paste Clipboard The Vista System supports copy and paste of some or all channel settings to

one or more other channels. This ability streamlines the set-up of the console

when an operator is starting from scratch with a new layout. However, if starting from a clean slate is desired, clearing all or some of the parameters

Dynamic Automation Each audio parameter of the Vista mixing console can be stored and recalled

dynamically against timecode information.

Such enormous versatility can be accompanied, of course, by a certain op-

eration complexity. For this reason, all operator controls capable of being

automated are touch-sensitive.

Please refer to chapter 5 for a complete description.

Page 38

Vista 9 Digital Mixing System

1-22 Introduction

Date printed: 26.10.10

SW V4.5

1.7 Input Channel Block Diagrams

Block Diagram of a Typical Mono Input Channel:

Please note that,

essentially, all

channel types

have the same

structure,

regardless

of the type

(input, AUX,

group, master,

etc.)

VSP

L/R PAN

TALKBACK

PREAMP

CTRL

EQ / +

NOTCH

INSERT

PHASE

(Mono)

IN 1

IN 2

GEN (Generator)

INSERT RETURN

INP

SEL

INPUTS

GR Meter

SC LINK INPUT

Input Mode Section

FILTER

DC

REJECT

GAIN

Input Process Section

SIDECHAIN IN

DIGITAL

PATCH

DIGITAL

PATCH

DIGITAL

PATCH

DIGITAL

PATCH

DIGITAL

PATCH

DYN /

V. DYN

FADER

MUTE

DELAY

PF AF

CHANNEL PATCH MATRIX

PF AF

PATCH

DIGITAL

DIGITAL

PATCH

MULTI-TRACK

Buses

MULTI-TRACK

Enh. Buses

DIR OUT

AF

PF

AINP

TB

DIRECT OUTPUT

TB

METER

SELECT

DO

AF

AINP

METER

DATA

N–X

Buses

N–1

Buses

PFL

1-8

1-8

1-8

1-8

1-8

1-8

1-8

STEREO AUX

Buses

GROUP

Buses

MASTER

Buses

MONO AUX

Buses

MPX

Buses

INSERT SEND

CHANNEL

OUTPUTS

PFL Bus

SOLO Bus

SC LINK OUTPUT

L

R

PAN

PF

AF

PF

AF

PF

AF

MONO AUX

MPX

PF

AF

MTR ENH.

STEREO AUX

MULTI-

FMT

PAN

Page 39

Vista 9 Digital Mixing System

Introduction 1-23

Date printed: 26.10.10

SW V4.5

Block Diagram of a Typical Stereo Input Channel:

Please note that,

essentially, all

channel types

have the same

structure,

regardless

of the type

(input, AUX,

group, master, etc.)

TALKBACK

PREAMP

CTRL

EQ / +

NOTCH

INSERT

MS / XY PHASE

MATRIX (Stereo)

STEREO

BAL

MODE

IN 1

IN 2

GEN (Generator)

INSERT RETURN

INP