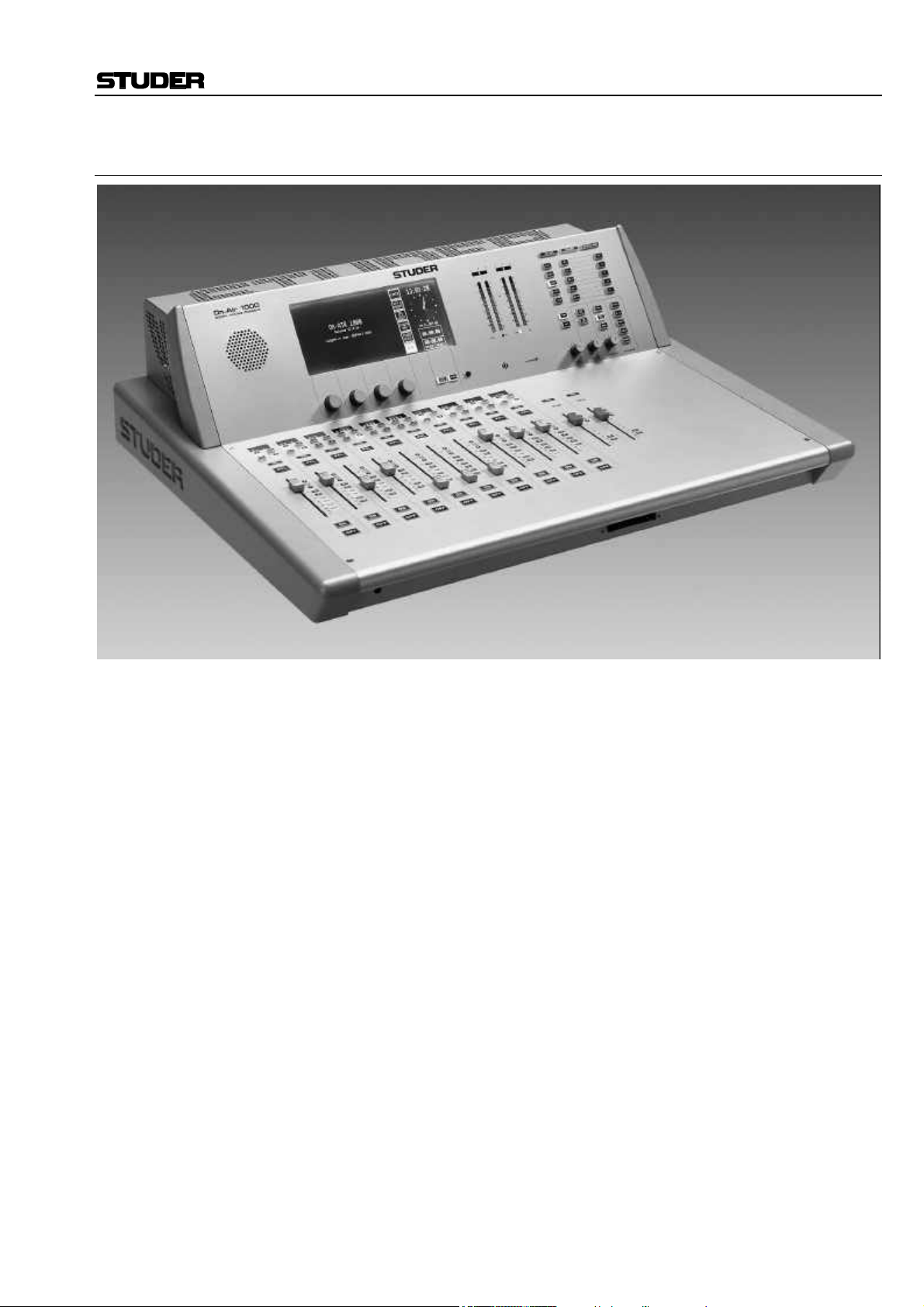

Studer OnAir 1000

Digital Mixing Console

SW Version 4.0/4.03

Operating Instructions

Prepared and edited by Copyright by Studer Professional Audio GmbH

Studer Professional Audio GmbH Printed in Switzerland

Technical Documentation Order no. 10.27.4872 (Ed. 0405)

Althardstrasse 30

CH-8105 Regensdorf – Switzerland

http://www.studer.ch Subject to change

Studer is a registered trade mark of Studer Professional Audio GmbH, Regensdorf

A Safety Information

To reduce the risk of electric shock, do not remove covers. No userserviceable parts inside. Refer servicing to qualified service personnel

(i.e., persons having appropriate technical training and experience necessary to be aware of hazards to which they are exposed in performing a

repair action, and of measures to minimize the danger of themselves).

This symbol alerts the user to the presence of un-insulated dangerous

voltage within the equipment that may be of sufficient magnitude to constitute a risk of electric shock to a person.

This symbol alerts the user to important instructions for operating and

maintenance in this documentation.

Safety Information

CLASS I

LED PRODUCT

CLASS I

LASER PRODUCT

A1 First Aid

Assemblies or sub-assemblies of this product can contain opto-electronic

devices. As long as these devices comply with Class I of laser or LED

products according to EN 60825-1:1994, they will not be expressly

marked on the product. If a special design should be covered by a higher

class of this standard, the device concerned will be marked directly on

the assembly or sub-assembly in accordance with the above standard.

In Case of Electric Shock: Separate the person as quickly as possible from the electric power

source:

• By switching off the equipment,

• By unplugging or disconnecting the mains cable, or

• By pushing the person away from the power source, using dry,

insulating material (such as wood or plastic).

• After having suffered an electric shock, always consult a doctor.

Warning! Do not touch the person or his clothing before the power is turned

off, otherwise you stand the risk of suffering an electric shock as

well!

If the Person is Unconscious: • Lay the person down

• Turn him to one side

• Check the pulse

• Reanimate the person if respiration is poor

• Call for a doctor immediately.

I

Installation/Maintenance/ESD

B General Installation Instructions

Please consider besides these general instructions also any product-specific

instructions in the “Installation” chapter of this manual.

B1 Unpacking

Check the equipment for any transport damage. If the unit is mechanically

damaged, if liquids have been spilled or if objects have fallen into the unit,

it must not be connected to the AC power outlet, or it must be immediately

disconnected by unplugging the power cable. Repair must only be per-

formed by trained personnel in accordance with the applicable regulations.

B2 Installation Site

Install the unit in a place where the following conditions are met:

• The temperature and the relative humidity of the environment must be

within the specified limits during operation of the unit. Relevant values

are the ones at the air inlets of the unit.

• Condensation must be avoided. If the unit is installed in a location with

large variation of ambient temperature (e.g. in an OB-van), appropriate

precautions must be taken before and after operation (for details on this

subject, refer to Appendix 1).

• Unobstructed air flow is essential for proper operation. Air vents of the

unit are a functional part of the design and must not be blocked in any

way during operation (e.g. by objects placed upon them, placement of

the unit on a soft surface, or installation of the unit within a rack or

piece of furniture).

• The unit must not be heated up by external sources of heat radiation

(sunlight, spot lights).

B3 Earthing and Power Supply

Earthing of units with mains supply (class I equipment) is performed via

the protective earth (PE) conductor integrated in the mains cable. Units

with battery operation (< 60 V, class III equipment) must be earthed separately.

Earthing the unit is one of the measures for protection against electrical

shock hazard (dangerous body currents). Hazardous voltage may not only

be caused by a defective power supply insulation, but may also be introduced by the connected audio or control cables.

If the unit is installed with one or several external connections, its earthing

must be provided during operation as well as while the unit is not operated.

If the earthing connection can be interrupted, for example, by unplugging

the mains plug of an external power supply unit, an additional, permanent

earthing connection must be installed using the provided earth terminal.

Avoid ground loops (hum loops) by keeping the loop surface as small as

possible (by consequently guiding the earth conductors in a narrow, parallel way), and reduce the noise current flowing through the loop by inserting

an additional impedance (common-mode choke).

II

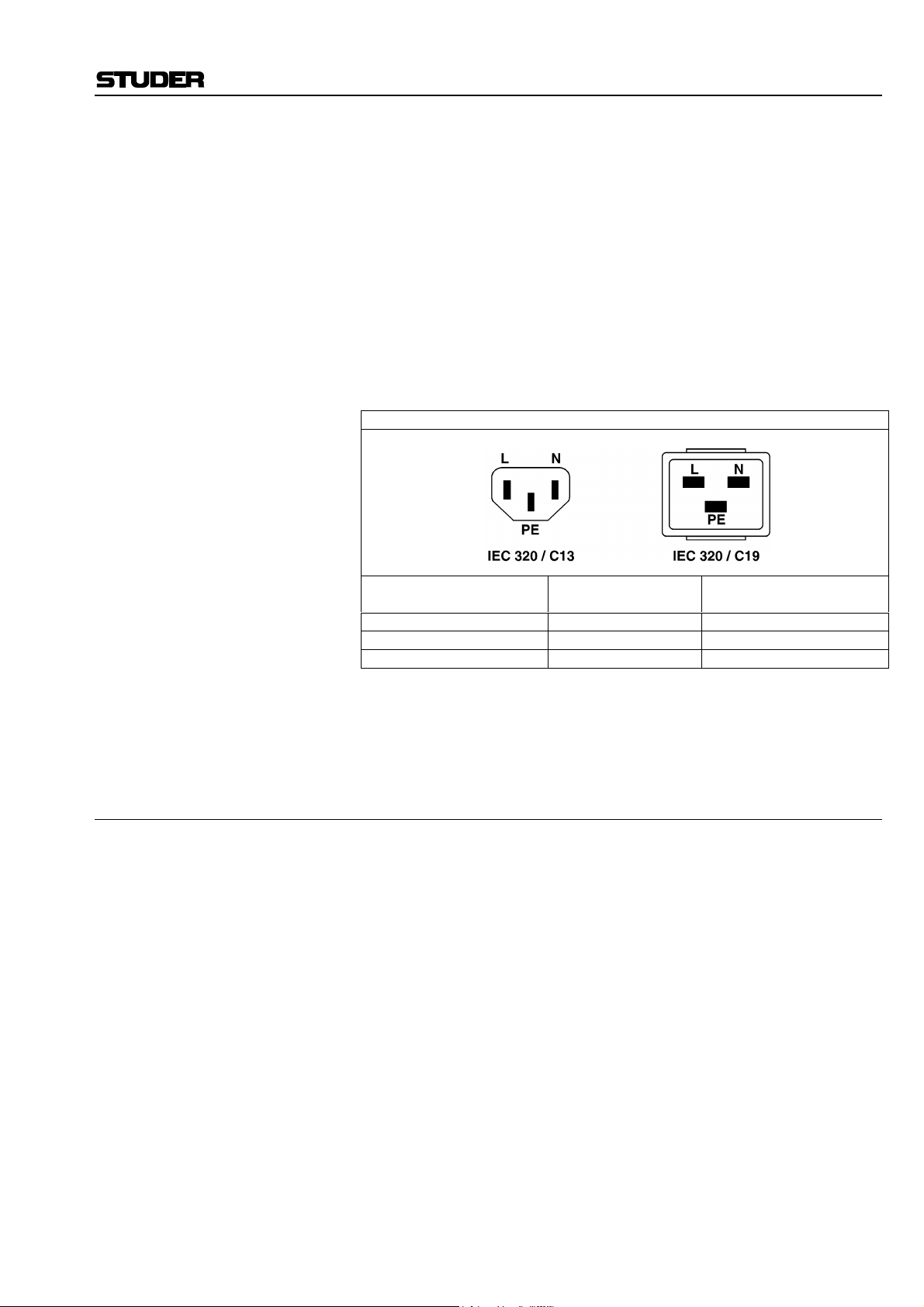

Class I Equipment (Mains Operation)

ESD/Repair

Should the equipment be delivered without a matching mains cable, the

latter has to be prepared by a trained person using the attached female plug

(IEC320/C13 or IEC320/C19) with respect to the applicable regulations in

your country.

Before connecting the equipment to the AC power outlet, check that the

local line voltage matches the equipment rating (voltage, frequency) within

the admissible tolerance. The equipment fuses must be rated in accordance

with the specifications on the equipment.

Equipment supplied with a 3-pole appliance inlet (protection conforming to

class I equipment) must be connected to a 3-pole AC power outlet so that

the equipment cabinet is connected to the protective earth.

For information on mains cable strain relief please refer to Appendix 2.

Female Plugs (IEC320), Front-Side View:

European Standard

(CENELEC)

Brown L (Live) Black

Blue N (Neutral) White

Green/Yellow PE (Protective Earth) Green (or Green/Yellow)

Class III Equipment (Battery Operation up to 60 VDC)

Equipment of this protection class must be earthed using the provided earth

terminal, if one or more external signals are connected to the unit (see explanation at the beginning of this paragraph).

B4 Electromagnetic Compatibility (EMC)

The unit conforms to the protection requirements relevant to electromagnetic phenomena that are listed in guidelines 89/336/EC and FCC, part 15.

• The electromagnetic interference generated by the unit is limited in such

a way that other equipment and systems can be operated normally.

• The unit is adequately protected against electromagnetic interference so

that it can operate properly.

The unit has been tested and conforms to the EMC standards of the specified electromagnetic environment, as listed in the following declaration.

The limits of these standards ensure protection of the environment and corresponding noise immunity of the equipment with appropriate probability.

However, a professional installation and integration within the system are

imperative prerequisites for operation without EMC problems.

For this purpose, the following measures must be followed:

• Install the equipment in accordance with the operating instructions. Use

the supplied accessories.

• In the system and in the vicinity where the equipment is installed, use

only components (systems, equipment) that also fulfill the EMC standards for the given environment.

• Use a system grounding concept that satisfies the safety requirements

(class I equipment must be connected with a protective ground conduc-

North American Standard

(NAS)

III

Installation/Maintenance/ESD

tor) and that also takes into consideration the EMC requirements. When

deciding between radial, surface, or combined grounding, the advantages and disadvantages should be carefully evaluated in each case.

• Use shielded cables where shielding is specified. The connection of the

shield to the corresponding connector terminal or housing should have a

large surface and be corrosion-proof. Please note that a cable shield

connected only single-ended can act as a transmitting or receiving antenna within the corresponding frequency range.

• Avoid ground loops or reduce their adverse effects by keeping the loop

surface as small as possible, and reduce the noise current flowing

through the loop by inserting an additional impedance (e.g. commonmode choke).

• Reduce electrostatic discharge (ESD) of persons by installing an appropriate floor covering (e.g. a carpet with permanent electrostatic filaments) and by keeping the relative humidity above 30%. Further measures (e.g. conducting floor) are usually unnecessary and only effective if

used together with corresponding personal equipment.

• When using equipment with touch-sensitive operator controls, please

take care that the surrounding building structure allows for sufficient

capacitive coupling of the operator. This coupling can be improved by

an additional, conducting surface in the operator’s area, connected to the

equipment housing (e.g. metal foil underneath the floor covering, carpet

with conductive backing).

C Maintenance

All air vents and openings for operating elements (faders, rotary knobs)

must be checked on a regular basis, and cleaned in case of dust accumulation. For cleaning, a soft paint-brush or a vacuum cleaner is recommended.

Cleaning the surfaces of the unit is performed with a soft, dry cloth or a

soft brush.

Persistent contamination can be treated with a cloth that is slightly humidified with a mild cleaning solution (soap-suds).

For cleaning display windows, commercially available computer/TV

screen cleaners are suited. Use only a slightly damp (never wet) cloth.

Never use any solvents for cleaning the exterior of the unit! Liquids must

never be sprayed or poured on directly!

For equipment-specific maintenance information please refer to the corresponding chapter in the Operating and Service Instructions manuals.

D Electrostatic Discharge during Maintenance and Repair

Caution: Observe the precautions for handling devices sensitive to electrostatic dis-

charge!

Many semiconductor components are sensitive to electrostatic discharge

(ESD). The life-span of assemblies containing such components can be

drastically reduced by improper handling during maintenance and repair

work. Please observe the following rules when handling ESD sensitive

components:

• ESD sensitive components should only be stored and transported in the

packing material specifically provided for this purpose.

• When performing a repair by replacing complete assemblies, the removed assembly must be sent back to the supplier in the same packing

IV

E Repair

ESD/Repair

material in which the replacement assembly was shipped. If this should

not be the case, any claim for a possible refund will be null and void.

• Unpacked ESD sensitive components should only be handled in ESD

protected areas (EPA, e.g. area for field service, repair or service bench)

and only be touched by persons who wear a wristlet that is connected to

the ground potential of the repair or service bench by a series resistor.

The equipment to be repaired or serviced as well as all tools and electrically semi-conducting work, storage, and floor mats should also be connected to this ground potential.

• The terminals of ESD sensitive components must not come in uncontrolled contact with electrostatically chargeable (voltage puncture) or

metallic surfaces (discharge shock hazard).

• To prevent undefined transient stress of the components and possible

damage due to inadmissible voltages or compensation currents, electrical connections should only be established or separated when the

equipment is switched off and after any capacitor charges have decayed.

Removal of housing parts, shields, etc. exposes energized parts. For this

reason the following precautions must be observed:

• Maintenance may only be performed by trained personnel in accordance

with the applicable regulations.

• The equipment must be switched off and disconnected from the AC

power outlet before any housing parts are removed.

• Even if the equipment is disconnected from the power outlet, parts with

hazardous charges (e.g. capacitors, picture tubes) must not be touched

until they have been properly discharged. Do not touch hot components

(power semiconductors, heat sinks, etc.) before they have cooled off.

• If maintenance is performed on a unit that is opened and switched on, no

un-insulated circuit components and metallic semiconductor housings

must be touched, neither with your bare hands nor with un-insulated

tools.

Certain components pose additional hazards:

• Explosion hazard from lithium batteries, electrolytic capacitors and

power semiconductors (watch the component’s polarity. Do not short

battery terminals. Replace batteries only by the same type).

• Implosion hazard from evacuated display units.

• Radiation hazard from laser units (non-ionizing), picture tubes (ionizing).

• Caustic effect of display units (LCD) and components containing liquid

electrolyte.

Such components should only be handled by trained personnel who are

properly protected (e.g. safety goggles, gloves).

V

Repair/Disposal

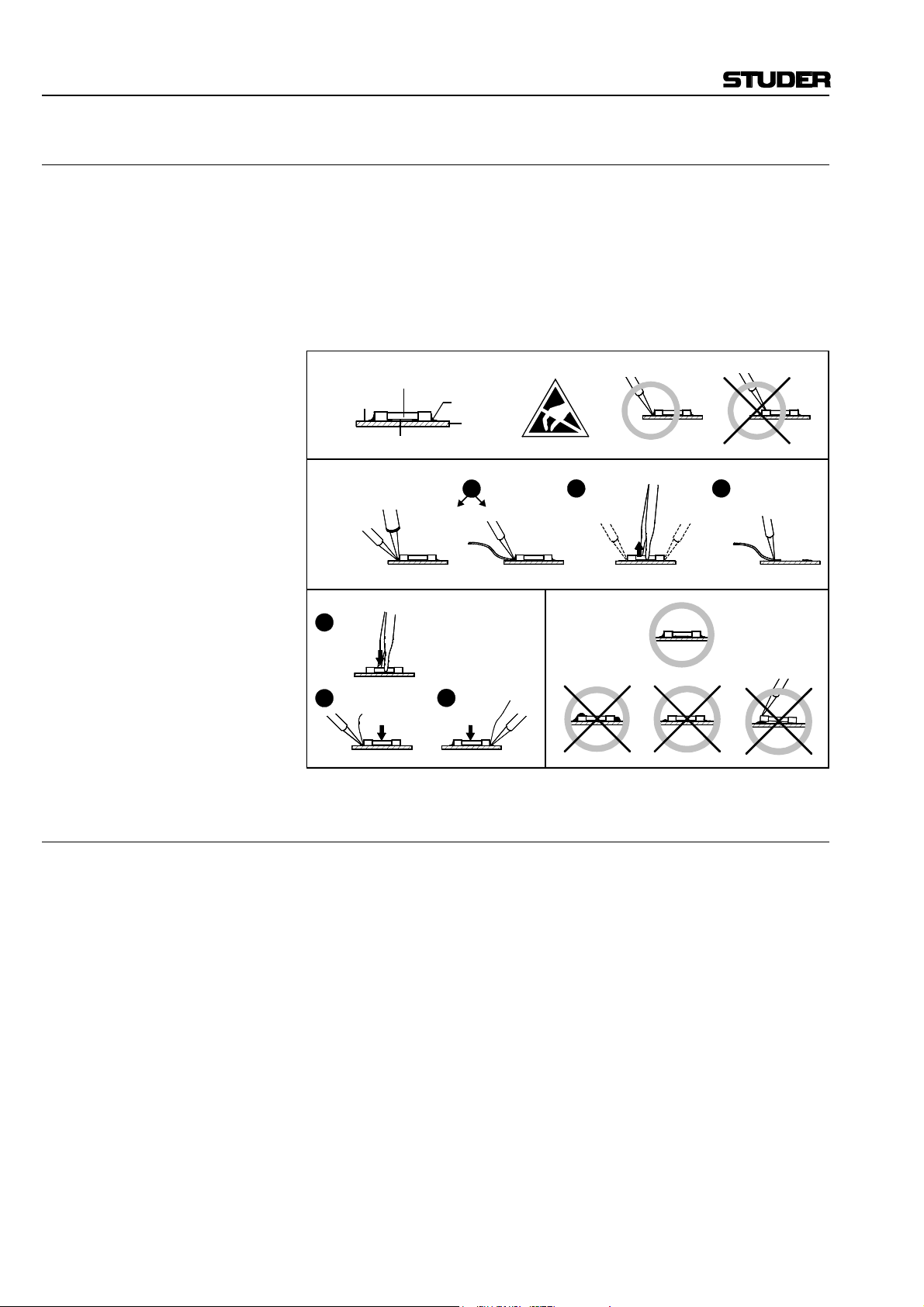

E1 SMD Components

Studer has no commercially available SMD components in stock for service purposes. For repair, the corresponding devices have to be purchased

locally. The specifications of special components can be found in the service manual.

SMD components should only be replaced by skilled specialists using appropriate tools. No warranty claims will be accepted for circuit boards that

have been damaged. Proper and improper SMD soldering joints are illustrated below.

Copper

Track

Dismounting

Soldering

Iron

Mounting

1

Solder

2

Ø 0.5...0.8 mm

SMD

Component

Solder

Adhesive

Desoldering

Iron

Desolder

Wick

3

Heating Time < 3 s per Side

PCB

1

Soldering Iron

32

Desolder

Wick

Heat and Remove Cleaning

Examples

F Disposal

Disposal of Packing Materials The packing materials have been selected with environmental and disposal

issues in mind. All packing material can be recycled. Recycling packing

saves raw materials and reduces the volume of waste.

If you need to dispose of the transport packing materials, please try to use

recyclable means.

Disposal of Used Equipment Used equipment contains valuable raw materials as well as materials that

must be disposed of professionally. Please return your used equipment via

an authorized specialist dealer or via the public waste disposal system, ensuring any material that can be recycled is.

Please take care that your used equipment cannot be abused. To avoid

abuse, delete sensitive data from any data storage media. After having disconnected your used equipment from the mains supply, make sure that the

mains connector and the mains cable are made useless.

VI

G Declarations of Conformity

G1 Class A Equipment - FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide a reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in

which case the user will be required to correct the interference at his own

expense.

Caution: Any changes or modifications not expressly approved by the manufacturer

could void the user's authority to operate the equipment. Also refer to relevant information in this manual.

G2 CE Declaration of Conformity

Conformity

We,

Studer Professional Audio GmbH,

CH-8105 Regensdorf,

declare under our sole responsibility that the product

Studer OnAir 1000, Digital Mixing Console,

(starting with serial no. 1000)

to which this declaration relates, according to following regulations of EU

directives and amendments

• Low Voltage (LVD):

73/23/EEC + 93/68/EEC

• Electromagnetic Compatibility (EMC):

89/336/EEC + 92/31/EEC + 93/68/EEC

is in conformity with the following standards or normative documents:

• Safety:

EN 60950:2000 (Class I equipment)

• Safety of laser products:

EN 60825-1:1994 + A11 + A2, EN60825-2:2000

• EMC:

EN 55103-1/-2:1996, electromagnetic environments E2 and E4.

Regensdorf, December 18, 2000

B. Hochstrasser, President P. Fiala, Manager QA

VII

Appendix

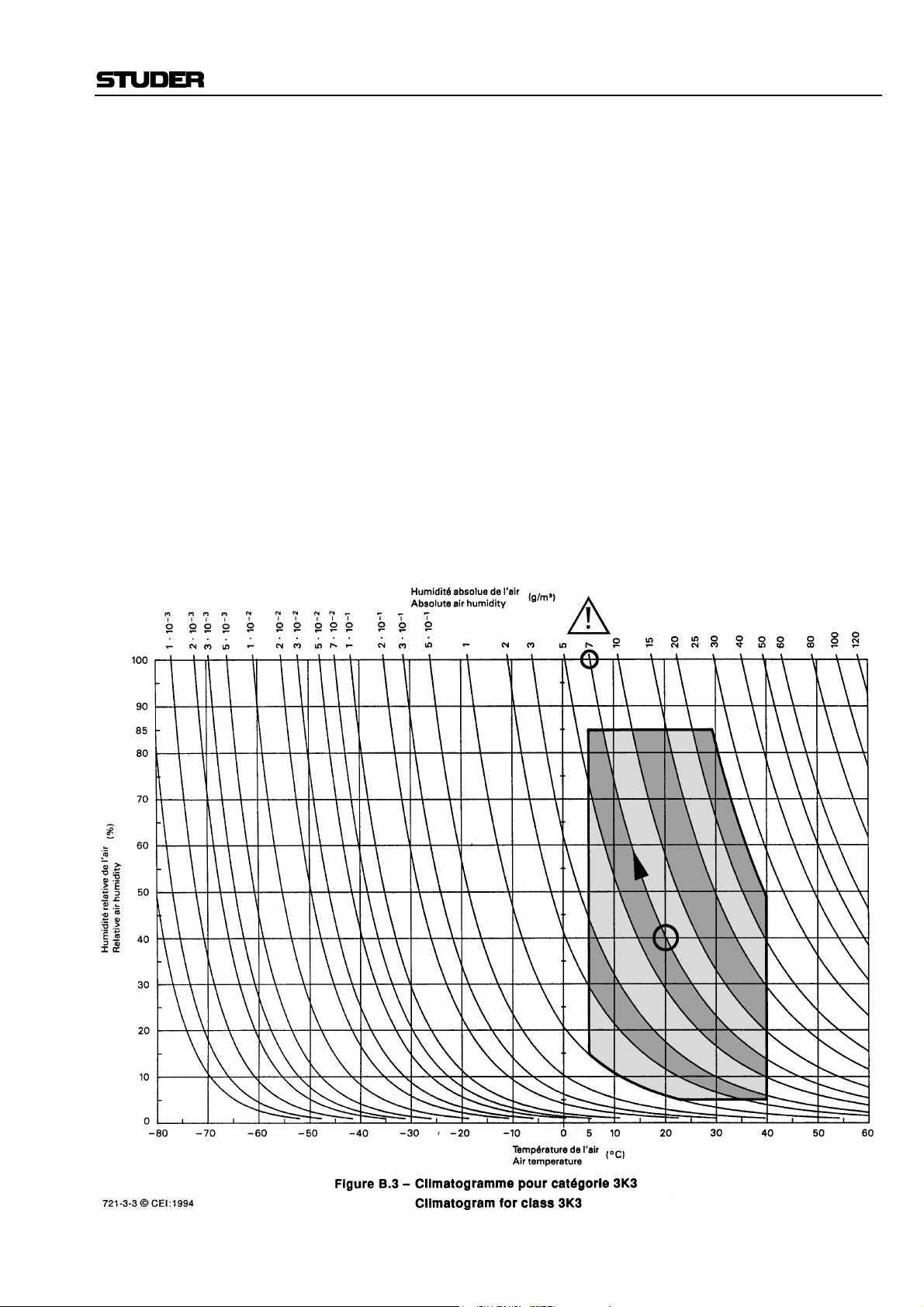

Appendix 1: Air Temperature and Humidity

General

Normal operation of the unit or system is warranted under the following

ambient conditions defined by EN 60721-3-3, set IE32, value 3K3.

This standard consists of an extensive catalogue of parameters, the most

important of which are: ambient temperature +5...+40 °C, relative humidity

5...85% (i.e., no formation of condensation or ice); absolute humidity

1...25 g/m³; rate of temperature change < 0.5 °C/min. These parameters are

dealt with in the following paragraphs.

Under these conditions the unit or system starts and works without any

problem. Beyond these specifications, possible problems are described in

the following paragraphs.

Ambient Temperature

Units and systems by Studer are generally designed for an ambient temperature range (i.e. temperature of the incoming air) of +5...+40 °C. When

rack mounting the units, the intended air flow and herewith adequate cooling must be provided. The following facts must be considered:

• The admissible ambient temperature range for operation of the semiconductor components is 0 °C to +70 °C (commercial temperature range

for operation).

• The air flow through the installation must provide that the outgoing air

is always cooler than 70 °C.

• Average heat increase of the cooling air shall be about 20 K, allowing

for an additional maximum 10 K increase at the hot components.

• In order to dissipate 1 kW with this admissible average heat increase, an

air flow of 2.65 m³/min is required.

Example: A rack dissipating P = 800 W requires an air flow of 0.8 * 2.65 m³/min

which corresponds to 2.12 m³/min.

• If the cooling function of the installation must be monitored (e.g. for fan

failure or illumination with spot lamps), the outgoing air temperature

must be measured directly above the modules at several places within

the rack. The trigger temperature of the sensors should be 65 to 70 °C.

Frost and Dew

VIII

The unsealed system parts (connector areas and semiconductor pins) allow

for a minute formation of ice or frost. However, formation of dew visible

with the naked eye will already lead to malfunctions. In practice, reliable

operation can be expected in a temperature range above –15 °C, if the following general rule is considered for putting the cold system into operation:

If the air within the system is cooled down, the relative humidity rises. If it

reaches 100%, condensation will arise, usually in the boundary layer between the air and a cooler surface, together with formation of ice or dew at

sensitive areas of the system (contacts, IC pins, etc.). Once internal condensation occurs, trouble-free operation cannot be guaranteed, independent

of temperature.

Before putting into operation, the system must be checked for internal formation of condensation or ice. Only with a minute formation of ice, direct

Appendix

evaporation (sublimation) may be expected; otherwise the system must be

heated and dried while switched off.

A system without visible internal formation of ice or condensation should

be heated up with its own heat dissipation, as homogeneously (and subsequently as slow) as possible; the ambient temperature should then always

be lower than the one of the outgoing air.

If it is absolutely necessary to operate the cold system immediately within

warm ambient air, this air must be dehydrated. In such a case, the absolute

humidity must be so low that the relative humidity, related to the coldest

system surface, always remains below 100%.

Ensure that the enclosed air is as dry as possible when powering off (i.e.

before switching off in winter, aerate the room with cold, dry air, and remove humid objects as clothes from the room).

These relationships are visible from the following climatogram. For a controlled procedure, thermometer and hygrometer as well as a thermometer

within the system will be required.

Example 1: An OB-van having an internal temperature of 20 °C and relative humidity

of 40% is switched off in the evening. If temperature falls below +5 °C,

dew or ice will be forming.

Example 2: An OB-van is heated up in the morning with air of 20 °C and a relative

humidity of 40%. On all parts being cooler than +5 °C, dew or ice will be

forming.

IX

Appendix

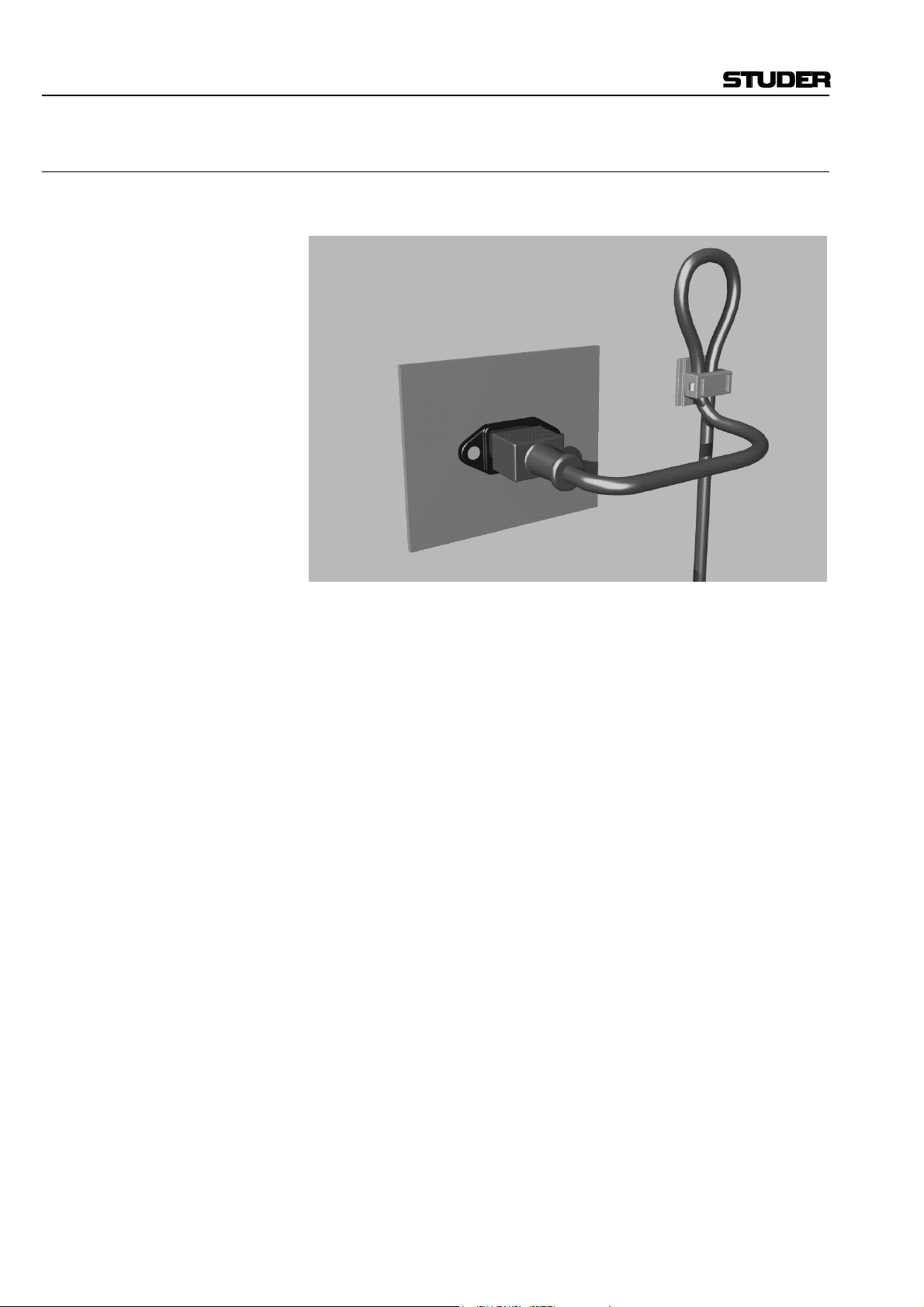

Appendix 2: Mains Connector Strain Relief

For anchoring connectors without a mechanical lock (e.g. IEC mains connectors), we recommend the following arrangement:

Procedure: The cable clamp shipped with your unit is auto-adhesive. For mounting

please follow the rules below:

• The surface to be adhered to must be clean, dry, and free from grease,

oil, or other contaminants. Recommended application temperature range

is +20...+40 °C.

• Remove the plastic protective backing from the rear side of the clamp

and apply it firmly to the surface at the desired position. Allow as much

time as possible for curing. The bond continues to develop for as long as

24 hours.

• For improved stability, the clamp should be fixed with a screw. For this

purpose, a self-tapping screw and an M4 bolt and nut are included.

• Place the cable into the clamp as shown in the illustration above and

firmly press down the internal top cover until the cable is fixed.

X

Appendix 3: Software License

Use of the software is subject to the Studer Professional Audio Software

License Agreement set forth below. Using the software indicates your acceptance of this license agreement. If you do not accept these license terms,

you are not authorized to use this software.

Under the condition and within the scope of the following Terms and Conditions, Studer Professional Audio GmbH (hereinafter “Studer”) grants the

right to use programs developed by Studer as well as those of third parties

which have been installed by Studer on or within its products. References

to the license programs shall be references to the newest release of a license program installed at the Customer’s site.

Programs Covered by the Agreement

License Programs of Studer The following Terms and Conditions grant the right to use all programs of

Studer that are part of the System and/or its options at the time of its delivery to the Customer, as well as the installation software on the original data

disk and the accompanying documentation (“License Material”). In this

Agreement the word “Programs” shall have the meaning of programs and

data written in machine code.

Using the software indicates your acceptance of this license agreement. If

you do not accept these license terms, you are not authorized to use this

software.

Appendix

Programs of Third Parties Programs of third parties are all programs which constitute part of the

Right of Use

System and/or its options at the time of delivery to the Customer but have

not been developed by Studer. The following conditions are applicable to

programs of third parties:

• The right to use third parties’ programs is governed by the License

Agreement attached hereto (if applicable), which is an integral part of

this Agreement. The Customer shall sign any and all License Agreements for all further programs of third parties installed on the system.

The Customer shall be deemed to have received all License Agreements

upon delivery of the system and/or its options.

• Studer shall accept no responsibility or liability for, and gives no warranties (express or implied) as to the programs of third parties. The

Customer waives any and all claims versus Studer for any consequential

damages, which might occur due to defects of these programs.

Principle Studer grants the Customer the non-exclusive right to use the License Ma-

terial in one copy on the system and/or its options as laid down by the

Sales Agreement concluded between the parties and all Terms and Conditions which shall be deemed to form and be read and construed as part of

the Sales Agreement. This right is assignable according to the “Assignability” paragraph hereinafter.

Customized Configurations The Customer is not entitled to alter or develop further the License Mate-

rial except within the expressly permitted configuration possibilities given

by the software installed on the system or elsewhere. All altered programs,

including but not limited to the products altered within the permitted configuration possibilities, are covered by this License Agreement.

XI

Appendix

Reverse Engineering Reverse engineering is only permitted with the express consent of Studer.

The consent of Studer can be obtained but is not limited to the case in

which the interface-software can not be provided by Studer. In any case

Studer has to be informed immediately upon complete or partial reverse

engineering.

Copying the License Material The Customer is entitled to make one copy of all or parts of the License

Material as is necessary for the use according to this Agreement, namely

for backup purposes. The Customer shall apply the copyright of Studer

found on the License Material onto all copies made by him. Records shall

be kept by the Customer regarding the amount of copies made and their

place of keeping. The responsibility for the original program and all copies

made lies with the Customer. Studer is entitled to check these records on

first request. Copies not needed anymore have to be destroyed immediately.

Disclosure of License Material The License Material is a business secret of Studer. The Customer shall not

hand out or in any way give access to parts or the complete License Material to third parties nor to publish any part of the License Material without

prior written consent of Studer. The Customer shall protect the License

Material and any copies made according to the paragraph above by appropriate defense measures against unauthorized access. This obligation of

non-disclosure is a perpetual obligation.

Third parties are entitled to have access to the License Material if they use

the License Material at the Customer’s site in compliance with this Agreement.

Under no circumstance are third parties entitled to have access to the installation software on the original data media. The Customer shall safeguard the original data media accordingly.

Assignability The rights granted to the Customer according to this License Agreement

shall only be assignable to a third party together with the transfer of the

system and/or its options and after the prior written consent of Studer.

Rights to License Material

With the exception of the right of use granted by this License Agreement

all proprietary rights to the License Material, especially the ownership and

the intellectual property rights (such as but not limited to patents and copyright) remain with Studer even if alterations, customized changes or

amendments have been made to the License Material.

Studer’s proprietary rights are acknowledged by the Customer. The Customer shall undertake no infringements and make no claims of any patent,

registered design, copyright, trade mark or trade name, or other intellectual

property right.

Warranty, Disclaimer, and Liability

For all issues not covered herewithin, refer to the “General Terms and

Conditions of Sales and Delivery” being part of the sales contract.

XII

NEW FEATURES WITH SW V4.02/V4.03

1 Momentary/Latching Key Functions

1.1 PFL and Talkback Keys

Latching: If a PFL key or one of the talkback keys (N–1 A, N–1 B, AUX 1, AUX 2,

or STUDIO) is pressed for less than 0.2 s, the function is now latching, and

the key is illuminated. To release the function, an other short press of the

key is required.

The same functionality applies for the F1...F5 keys if configured as additional talkback keys. For this purpose, please refer to the “MONITOR

EXPANDER page, Talkback Functions” paragraph below.

Momentary: When pressing a PFL or TB key longer than 0.2 s, it acts as a momentary

key, i.e., the function is automatically canceled upon releasing the key.

Basic information on this subject to be found in chapters: 3.1.4 / 6.1 / 6.3

OnAir 1000 Digital Mixing Console

1.2 Monitoring Keys

Mutually Releasing / Latching: If one of the Monitoring Selector keys is pressed for less than 0.2 s, the

former monitoring source selection is canceled, and the new monitoring

source selection becomes active. The selection is latching and the key is illuminated until any other Monitoring Selector key is pressed.

Mutually Releasing / Momentary:If one of the Monitoring Selector keys is pressed for longer than 0.2 s, it acts as

a momentary key. The former monitoring source selection is canceled, and

the new monitoring source selection becomes active. Upon releasing the key,

the former monitoring source selection is reactivated.

Uhm... This may sound a bit confusing, but in everyday use it is a very convenient

feature – just give it a try!

2 Talkback and PFL Signaling

2.1 Talkback Signaling from CR to Studio, and Vice Versa

CR to Studio: When talkback from the control room (CR) to the studio is activated, pin 23

of the STUDIO MON CTRL connector is activated (i.e. pulled to ground).

This pin was formerly labeled as “Spare OUT 1”. Now it can be used for

illuminating the CR lamp on an external talkback box.

Please refer to the pin assignment diagram and table on the next page.

Studio to CR: When talkback from the studio to the CR is activated (e.g. when using the

external talkback box), the TALK BACK STUDIO key in the console’s

central section is illuminated.

Basic information on this subject to be found in chapters: 3.1.4 / 6.3 /

14.11

Date printed: 12.07.04 SW V 4.02/V4.03 New Features 1

OnAir 1000 Digital Mixing Console

2.2 PFL Signaling

When a PFL key is activated, pin 11 of the STUDIO MON CTRL connec-

tor is activated (i.e. pulled to ground). This pin was formerly labeled as

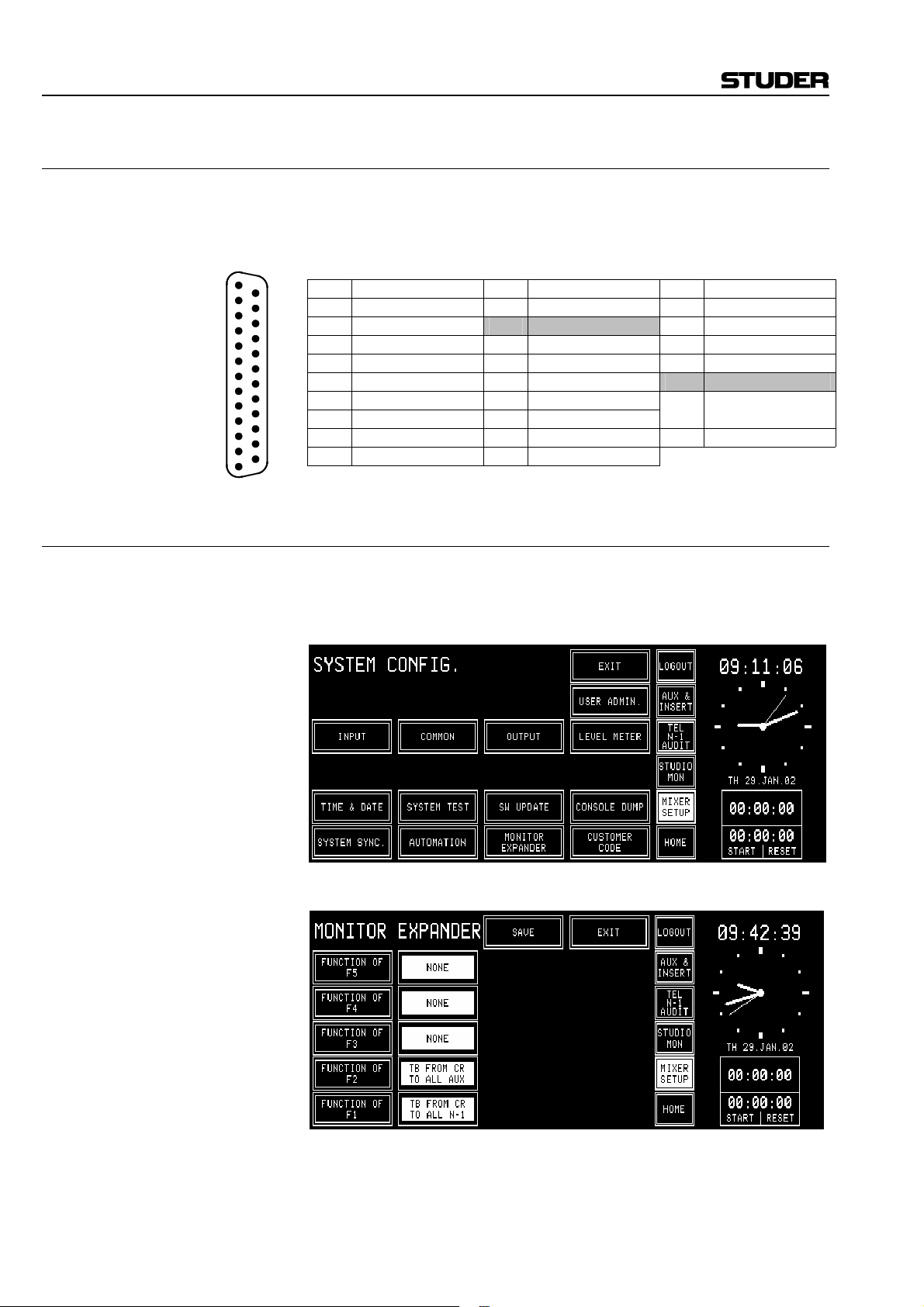

STUDIO MON CTRL (D-type, 25 pin, male):

Pin Signal Pin Signal Pin Signal

1 +5 V SUPPLY 10 Lamp EXTERN 19 Switch TB TO TEL2

2 COMMON 11 Lamp PFL SIGN. 20 Lamp PGM

3 Switch AUX1 12 n.c. 21 Lamp AUX2

4 Switch OFF AIR 13 GND 22 Lamp PFL

5 Switch EXTERN 14 +5 V SUPPLY 23 Lamp TB T O S T U D I O

6 Switch TB TO TEL1 15 Switch PGM

7 n.c. 16 Switch AUX2

8 Lamp AUX1 17 Switch PFL 25 GND

9 Lamp OFF AIR 18 Switch TB TO CR

13

12

11

10

9

8

7

6

5

4

3

2

1

“Spare OUT 2”.

25

24

23

22

21

20

19

18

17

16

15

14

24 Lamp STUDIO MIC

ON

3 MONITOR EXPANDER Page, Talkback Functions

The MONITOR EXPANDER page, possibly known from your experience

with OnAir 2000M2 consoles, can now be opened on the OnAir 1000 consoles as well. For this purpose, the SYSTEM CONFIG. Page has an additional “MONITOR EXPANDER” button, as shown below:

When touching this button, the MONITOR EXPANDER page opens and

allows to assign three different functions to any of the F1...F5 buttons:

TB FROM CR TO ALL AUX, TO ALL N–1, or TO ALL (meaning all

AUX and all N–1), or NONE (no function at all).

However, no Monitor Extension module can be installed in an OnAir 1000

console, which means that no other functions (as known from OnAir

2000M2 consoles) can be configured.

2 New Features

SW V 4.02/V4.03 Date printed: 13.04.2005

OnAir 1000 Digital Mixing Console

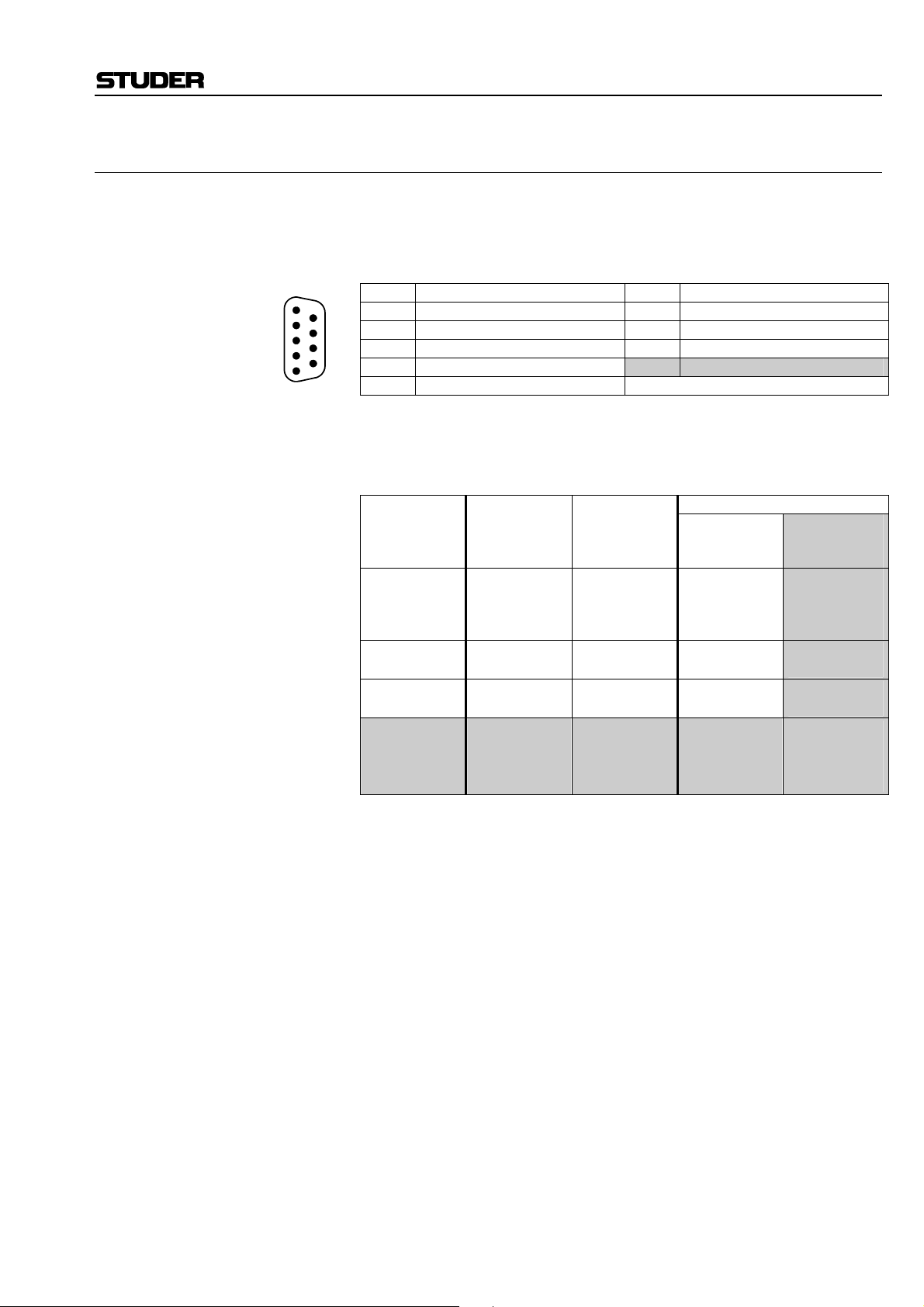

4 Additional REC Signaling Output

An additional REC signaling output has been provided on pin 9 of the

SIGN. connector (formerly labeled as “Spare OUT”) to extend the on-air

SIGN. (D-type, 9 pin, male):

Pin Signal Pin Signal

1 +5 V SUPPLY 6 COMMON

2 ON AIR IN – 7 Spare IN – or Ext. CR DIM IN – *

3 CR MIC OUT 8 STUDIO MIC OUT

4 PGM OUT 9 REC OUT

5 GND

5

4

3

2

1

For the ON AIR INDICATION setting on the COMMON SETTINGS

In other words:

• For the 1

• For the 2

• For the 3

• For the 4

Basic information on this subject to be found in chapter 11.2.2

signaling features.

9

8

7

6

* depending on Customer Code setting

page, a fourth selection item ( PROGRAM/ REC) was created. Depending

on this setting, the two signaling outputs are active according to the following table:

ON AIR

INDICATION

setting

1)

PROGRAM

AND REC

2)

PROGRAM

3)

REC

4)

PROGRAM

/ REC

(new setting)

st

setting, both signaling outputs are active whenever any audio

signal is routed either to the program or the record output (or both).

nd

setting, only the PGM OUT signaling output is active while an

PROGRAM

output on-air

0

1

0

1

0

1

x

x

0

1

0

1

REC

output on-air

0

0

1

1

x

x

0

1

0

0

1

1

(PGM OUT)

SIGN output:

Pin 4

0

1

1

1

0

1

0

0

0

1

0

1

(REC OUT)

(new output)

audio signal is routed to the program output. An audio signal routed to the

record output has no effect.

rd

setting, only the REC OUT signaling output is active while an

audio signal is routed to the record output. An audio signal routed to the

program output has no effect.

th

(new) setting, only the PGM OUT signaling output is active

while an audio signal is routed to the program output, and only the REC

OUT signaling output is active while an audio signal is routed to the record

output. If audio signals are routed to both the program and the record outputs, both the PGM OUT and REC OUT signaling outputs are active.

Pin 9

0

1

1

1

0

0

0

1

0

0

1

1

Date printed: 13.04.2005 SW V 4.02/V4.03 New Features 3

OnAir 1000 Digital Mixing Console

5 Additional Customer Codes

Code 0x00000800: Used to disable dimming of the CR monitor speakers during talkback from

the studio to the control room.

Code 0x00001000: Used to disable dimming of the studio monitor speakers during talkback

from the control room to the studio.

Code 0x00002000: Used to swap the functions of the PFL and the OFF keys next to the faders,

regardless whether they are used for the standard PFL and OFF functions,

or whether other functions are configured for any of these keys.

Basic information on this subject to be found in chapter 9

Code 0x00004000: If this code is active, whenever a channel is activated by moving its fader up

from its lower stop while it is switched ON (or the other way round, by

switching the channel ON while its fader is positioned above the lower stop),

this channel’s Channel Control page pops up automatically and allows for

immediate changes of the channel settings. This Channel Control page remains displayed until another channel is activated, or until another page is

selected using one of the five buttons next to the clock dial.

Code 0x00008000: If this code is active, the status of the channel ON/OFF switch of channels

currently not routed to the console surface will be saved in the flash memory

when powering the console off. At power on, the ON or OFF status of these

channels will automatically be re-established.

If this code is inactive, the channels not routed to the console surface will

always be set to OFF at power on.

Basic information on Customer Code to be found in chapter 11.2.11

4 New Features SW V 4.02/V4.03 Date printed: 12.07.04

OnAir 1000 Digital Mixing Console

CONTENTS

1 Introduction.................................................................................................................................................................... 1-1

1.1 Block Diagram OnAir 1000, SW V4.0.....................................................................................................................1-2

1.2 Definition of Terms ..................................................................................................................................................1-4

2 General ............................................................................................................................................................................2-1

2.1 Utilization for the Purpose Intended ......................................................................................................................... 2-1

2.2 First Steps ................................................................................................................................................................. 2-1

2.2.1 Unpacking and Inspection.................................................................................................................................2-1

2.2.2 Installation ........................................................................................................................................................2-1

2.2.3 Adjustments, Repair.......................................................................................................................................... 2-2

2.2.4 PC-Card ............................................................................................................................................................ 2-2

2.3 Technical Specifications ........................................................................................................................................... 2-3

3 Operating Concept .........................................................................................................................................................3-1

3.1 Operating Elements................................................................................................................................................... 3-1

3.1.1 Power Switch .................................................................................................................................................... 3-1

3.1.2 Touch-Screen Unit ............................................................................................................................................3-2

3.1.3 Metering Section............................................................................................................................................... 3-3

3.1.4 Monitoring and Talkback Section ..................................................................................................................... 3-4

3.1.5 Fader Section .................................................................................................................................................... 3-6

3.2 Connector Panels ...................................................................................................................................................... 3-8

4 Channel Functions..........................................................................................................................................................4-1

4.1 Keys ..........................................................................................................................................................................4-1

4.2 Faders........................................................................................................................................................................4-2

4.3 LED Indicators .........................................................................................................................................................4-2

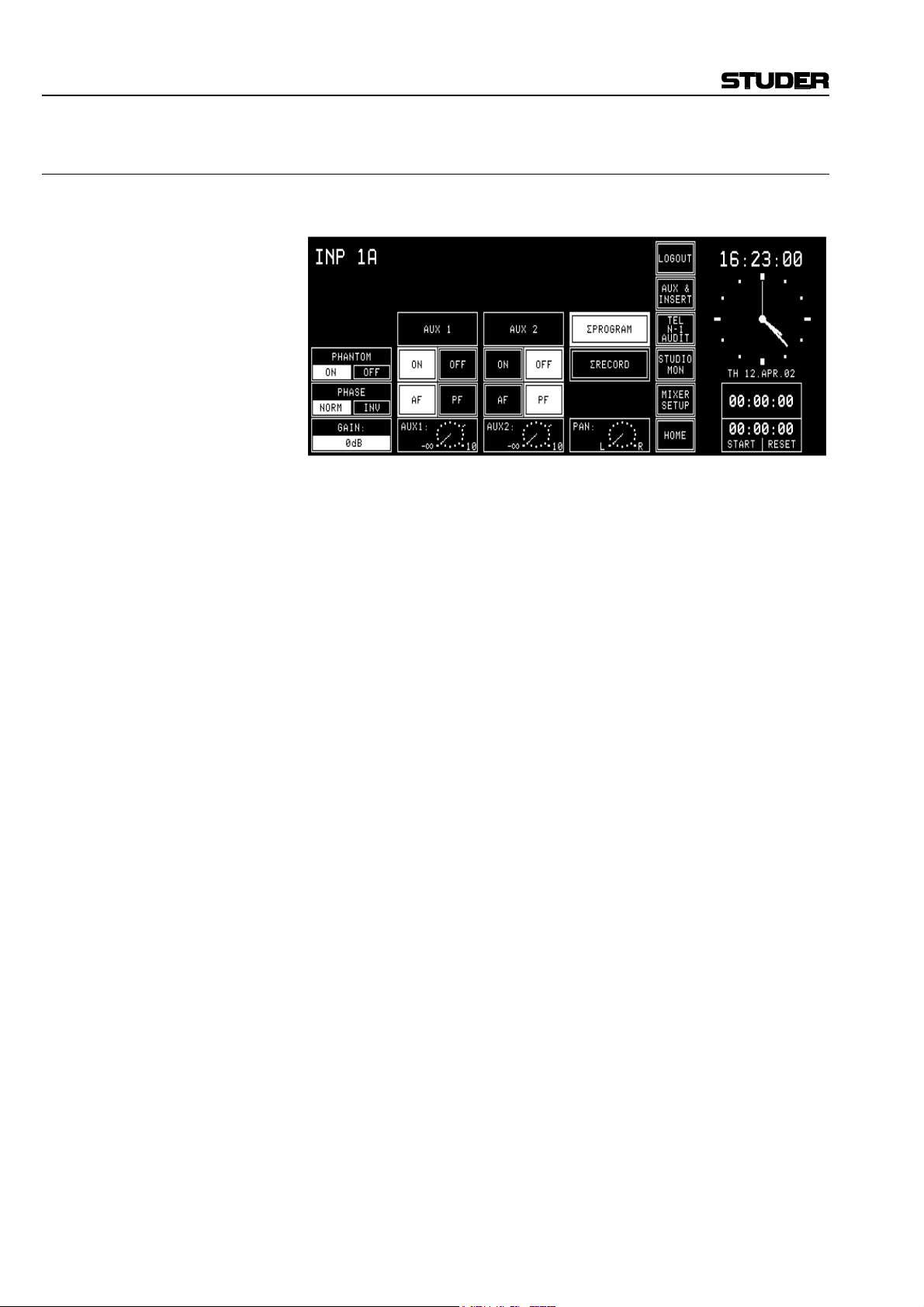

4.4 Channel Control Page, Microphone Input ................................................................................................................4-4

4.5 Channel Control Page, Line Input............................................................................................................................. 4-5

4.6 EQ/Filter Page, Microphone Input............................................................................................................................ 4-7

4.7 EQ/Filter Page, Analog Line/Digital Input ............................................................................................................... 4-8

Date printed: 23.10.03 SW V 4.0 Contents Part 1 0-1

OnAir 1000 Digital Mixing Console

5 Master Functions............................................................................................................................................................ 5-1

5.1 Login/Logout............................................................................................................................................................ 5-1

5.2 AUX and Insert Control ........................................................................................................................................... 5-2

5.3 N–1/Audition Bus and Telephone Hybrid Control................................................................................................... 5-3

5.3.1 N–1 and Audition Bus Routing ........................................................................................................................ 5-4

5.4 Studio Monitoring .................................................................................................................................................... 5-5

5.5 Mixer Setup.............................................................................................................................................................. 5-6

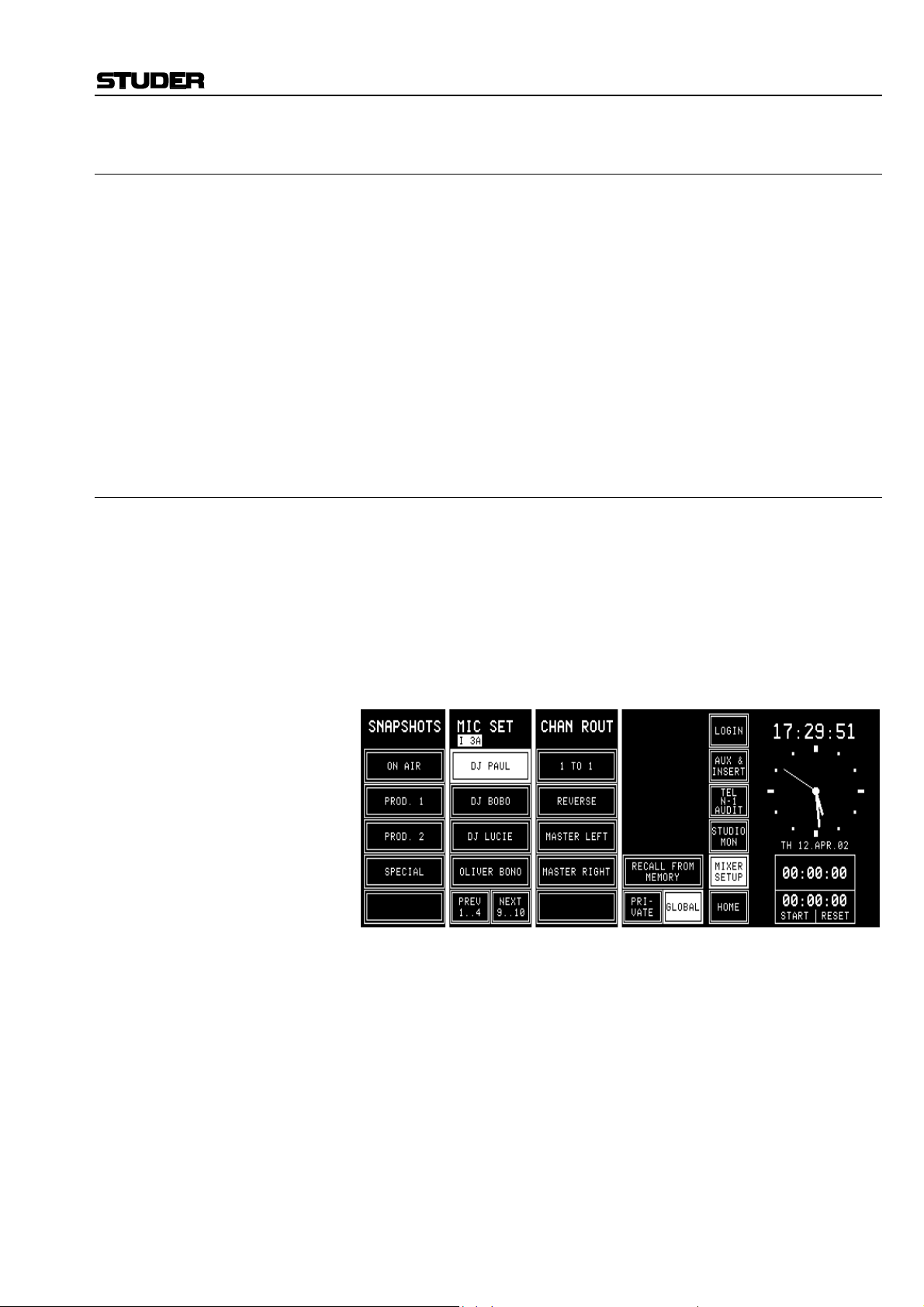

5.6 Snapshots.................................................................................................................................................................. 5-7

5.6.1 Recall a Snapshot from Memory ...................................................................................................................... 5-7

5.6.2 Save a Snapshot to Memory............................................................................................................................. 5-8

5.6.3 Delete a Snapshot from Memory...................................................................................................................... 5-8

5.7 Mic Settings ............................................................................................................................................................. 5-9

5.7.1 Recall a Mic Setting from Memory.................................................................................................................. 5-9

5.7.2 Save a Mic Setting to Memory....................................................................................................................... 5-10

5.7.3 Delete a Mic Setting from Memory................................................................................................................ 5-10

5.8 Routing................................................................................................................................................................... 5-11

5.8.1 Channel Routing............................................................................................................................................. 5-11

5.8.2 Recall a Channel Routing from Memory........................................................................................................ 5-14

5.8.3 Save a Channel Routing to Memory............................................................................................................... 5-14

5.8.4 Delete a Channel Routing from Memory (Administrator Only) ..................................................................... 5-15

5.8.5 Channel Routing Administration.................................................................................................................... 5-15

5.9 Using PC-Cards...................................................................................................................................................... 5-16

5.9.1 Load a Snapshot/Mic Setting/Channel Routing from PC-Card ...................................................................... 5-16

5.9.2 Save a Snapshot/Mic Setting/Channel Routing to PC-Card ........................................................................... 5-17

5.9.3 Delete a Snapshot/Mic Setting/Channel Routing from PC-Card .................................................................... 5-17

5.10 Administrator ......................................................................................................................................................... 5-18

5.10.1 Features .......................................................................................................................................................... 5-18

5.10.2 Admin Selection of Snapshots/Mic Settings/Channel Routings ..................................................................... 5-19

5.10.3 Users with and without a Password ................................................................................................................ 5-20

5.11 User Administration ............................................................................................................................................... 5-21

5.12 System Configuration............................................................................................................................................. 5-21

5.13 Watch and Stopwatch............................................................................................................................................. 5-22

5.13.1 Watch ............................................................................................................................................................. 5-22

5.13.2 Fader Stopwatch ............................................................................................................................................. 5-23

5.13.3 User Stopwatch .............................................................................................................................................. 5-23

5.14 PGM and REC Master Faders................................................................................................................................ 5-24

5.14.1 Fixed Master Levels ....................................................................................................................................... 5-24

6 Monitoring ...................................................................................................................................................................... 6-1

6.1 Control Room Monitoring........................................................................................................................................ 6-1

6.2 Studio Monitoring .................................................................................................................................................... 6-3

6.3 Talkback................................................................................................................................................................... 6-4

6.3.1 Talkback Settings ............................................................................................................................................. 6-5

6.4 External PFL ............................................................................................................................................................ 6-6

7 Signaling.......................................................................................................................................................................... 7-1

0-2 Contents Part 1 SW V 4.0 Date printed: 23.10.03

OnAir 1000 Digital Mixing Console

8 Machine Control.............................................................................................................................................................8-1

8.1 Keys and LEDs ......................................................................................................................................................... 8-1

8.2 Control Outputs ........................................................................................................................................................8-3

8.2.1 CTRL OUT1..................................................................................................................................................... 8-3

8.2.2 CTRL OUT2..................................................................................................................................................... 8-3

8.3 Control Inputs ........................................................................................................................................................... 8-4

8.3.1 CTRL IN........................................................................................................................................................... 8-4

8.3.2 EXT PFL Input ................................................................................................................................................. 8-4

8.4 CTRL OUT1/2 & CTRL IN Application Examples ................................................................................................. 8-5

9 Automation...................................................................................................................................................................... 9-1

9.1 Introduction ..............................................................................................................................................................9-1

9.2 Features of the OnAir 1000 CAB Support................................................................................................................ 9-1

9.3 Application Handling................................................................................................................................................ 9-2

9.3.1 Configuration for Automation Control .............................................................................................................9-2

9.3.2 Communication Time-Out ................................................................................................................................9-2

9.3.3 Output Selection ...............................................................................................................................................9-3

9.3.4 Start a New Title from Schedule.......................................................................................................................9-3

9.3.5 Indication of the Currently Playing Input Line .................................................................................................9-4

9.3.6 Pre-Listening..................................................................................................................................................... 9-4

9.3.7 Time Synchronization.......................................................................................................................................9-4

10 User Modes................................................................................................................................................................10-1

10.1 Purpose of User Modes........................................................................................................................................... 10-1

10.2 Access to Configurable Functions of the Console ..................................................................................................10-2

10.3 User Administration................................................................................................................................................ 10-4

10.4 Administration Functions........................................................................................................................................ 10-5

10.5 Log-in Procedure and Defaults ............................................................................................................................... 10-7

11 Configuration............................................................................................................................................................11-1

11.1 Configuration Handling ..........................................................................................................................................11-1

11.2 Configuration Procedure......................................................................................................................................... 11-1

11.2.1 Input................................................................................................................................................................11-3

11.2.2 Common Settings ............................................................................................................................................ 11-6

11.2.3 Output .............................................................................................................................................................11-7

11.2.4 Level Meter.....................................................................................................................................................11-7

11.2.5 Time and Date................................................................................................................................................. 11-8

11.2.6 System Test.....................................................................................................................................................11-9

11.2.7 Software Update ........................................................................................................................................... 11-10

11.2.8 Console Dump .............................................................................................................................................. 11-10

11.2.9 System Synchronization................................................................................................................................11-11

11.2.10 Automation.................................................................................................................................................... 11-12

11.2.11 Customer Code..............................................................................................................................................11-13

Date printed: 23.10.03 SW V 4.0 Contents Part 1 0-3

OnAir 1000 Digital Mixing Console

12 SW Update.................................................................................................................................................................12-1

12.1 Software Structure ..................................................................................................................................................12-1

12.1.1 CPU Software Package...................................................................................................................................12-1

12.1.2 DSP Software Package ...................................................................................................................................12-1

12.1.3 Important Information for Software Update to V4.0......................................................................................12-1

12.2 SW Update Procedure.............................................................................................................................................12-2

12.2.1 Error Handling................................................................................................................................................12-4

13 System Diagnostics and Error Handling ................................................................................................................13-1

13.1 Error, Warning, and Information Messages............................................................................................................13-1

13.1.1 System Diagnostics.........................................................................................................................................13-2

13.2 Indication on Failure of Restricted Functions.........................................................................................................13-6

13.3 System Test.............................................................................................................................................................13-7

13.3.1 Buttons/Faders Test.........................................................................................................................................13-7

13.3.2 Display Test....................................................................................................................................................13-8

13.3.3 PC-Card Test...................................................................................................................................................13-9

13.3.4 SW Versions Display......................................................................................................................................13-9

14 Wiring and Hardware information.........................................................................................................................14-1

14.1 DC Supply...............................................................................................................................................................14-1

14.2 Redundant Power Supply........................................................................................................................................14-3

14.3 Mic Input.................................................................................................................................................................14-6

14.4 Analog Line Input...................................................................................................................................................14-8

14.5 Digital Input............................................................................................................................................................14-8

14.6 TB Mic Input ..........................................................................................................................................................14-9

14.7 Telephone Hybrid Interface ..................................................................................................................................14-10

14.8 Analog Output.......................................................................................................................................................14-11

14.9 Digital Output .......................................................................................................................................................14-11

14.10 Analog Insert.........................................................................................................................................................14-12

14.11 Monitoring............................................................................................................................................................14-13

14.12 Serial Interface......................................................................................................................................................14-19

14.13 Clock Sync Interface.............................................................................................................................................14-19

14.14 Time Sync Interface..............................................................................................................................................14-20

System Wiring, Standard Version.....................................................................................................................................14-21

System Wiring, Redundant Supply Version.....................................................................................................................14-22

0-4 Contents

SW V 4.0 Date printed: 14.04.2005

OnAir 1000 Digital Mixing Console

15 Dip Switches and Jumpers ....................................................................................................................................... 15-1

15.1 Input Units .............................................................................................................................................................. 15-1

15.2 TB Mic Input Units................................................................................................................................................. 15-2

15.3 Telephone Hybrid Interface .................................................................................................................................... 15-3

15.4 Analog Output Units...............................................................................................................................................15-4

15.5 Digital Output Units................................................................................................................................................ 15-5

15.6 Insert Unit ............................................................................................................................................................... 15-5

15.7 Clock Sync Interface............................................................................................................................................... 15-5

15.8 Time Sync Interface................................................................................................................................................15-6

15.9 Monitoring Controller PCB ....................................................................................................................................15-7

15.10 Level Meter PCB .................................................................................................................................................... 15-7

15.11 PSU Sub Board.......................................................................................................................................................15-7

15.12 DSP PCB ................................................................................................................................................................15-8

15.13 Control Front Board I .............................................................................................................................................15-8

16 Index ..........................................................................................................................................................................16-1

Date printed: 23.10.03 SW V 4.0 Contents Part 1 0-5

OnAir 1000 Digital Mixing Console

0-6 Contents Part 1 SW V 4.0 Date printed: 23.10.03

1 INTRODUCTION

OnAir 1000 Digital Mixing Console

The OnAir 1000 is a smart but yet powerful digital mixing console for

“on-air” and small recording and editing studio applications. It has ten input channels, each with two physical inputs, and two master faders.

There are two different basic versions available:

• An analog-biased version with five analog stereo line and two digital

input channels, and

• A digital-biased version with two analog stereo line and five digital

input channels.

Both versions feature three mono microphone input channels with

switchable high-pass filter and phantom power. Both versions can be ordered with double, redundant mains power supply. For more information

on this subject, please refer to chapter 14.2.

The OnAir 1000 can be integrated seamlessly with a broadcast automation

system (CAB) like Studer’s DigiMedia.

The OnAir 1000 is based on a touch-screen user interface. Only the most

important functions have hardware control elements, making it very easy

to use. It has everything integrated in a single, lightweight console and

does not need any external racks or power supplies (except the Redundant

Supply versions, refer to chapter 14.2).

Since it is fully digital, it can individually be adapted to the current user

using snapshot automation. Extensive configuration possibilities allow the

OnAir 1000 to be integrated into almost any broadcast studio environment.

For an overview, please refer to the OnAir 1000 block diagram located on

the following two pages.

Date printed: 23.10.03 SW V 4.0 Intro 1-1

OnAir 1000 Digital Mixing Console

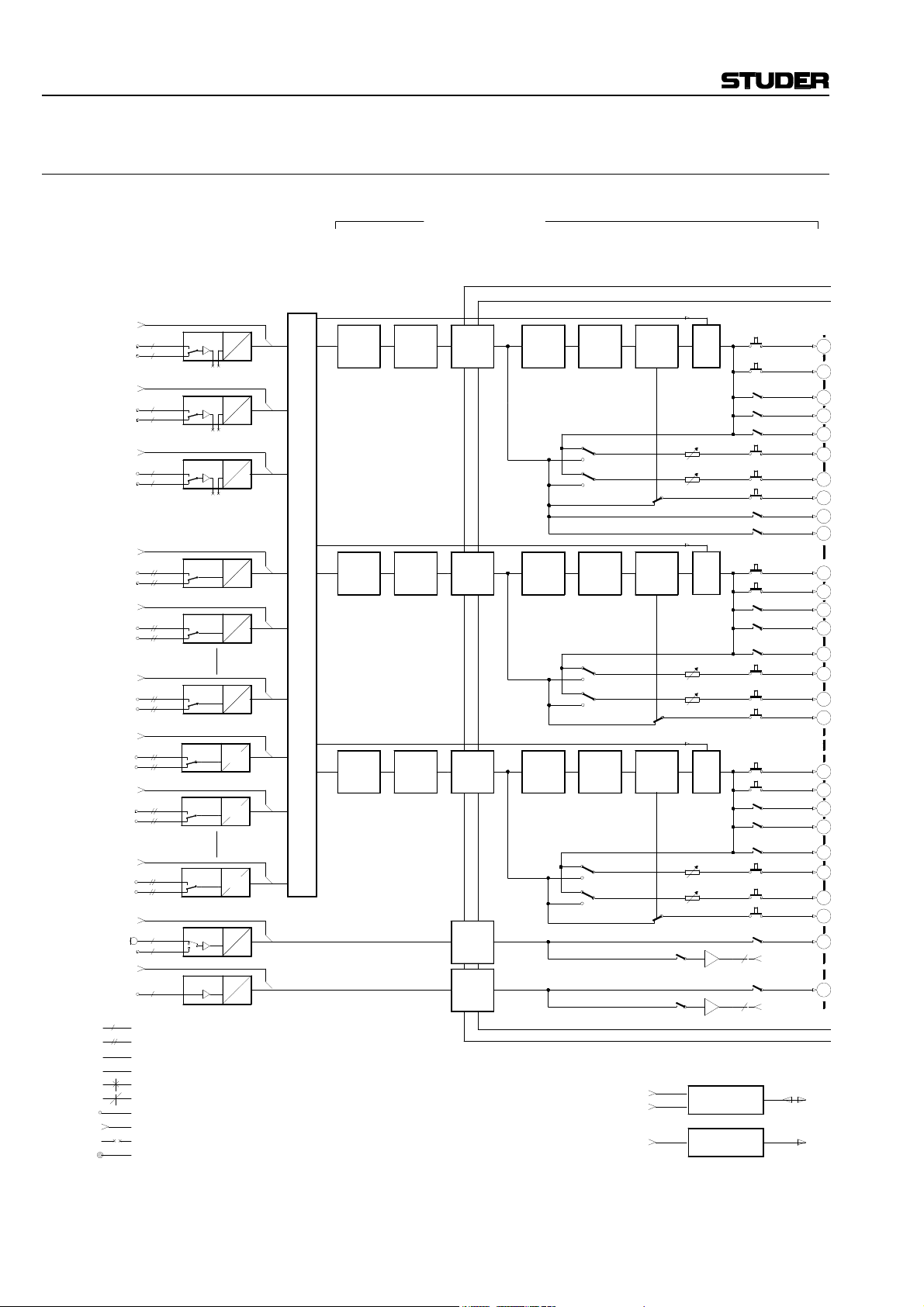

1.1 Block Diagram OnAir 1000, SW V4.0

INPUTS

CTRL I/O

DJ MIC 1

CTRL I/O

GUEST MIC.1

STUDIO MIC.1

CTRL I/O

GUEST MIC.2

STUDIO MIC.2

CTRL I/O

ANALOG STEREO INP 1

ANALOG STEREO INP 2

CTRL I/O

ANALOG STEREO INP 3

ANALOG STEREO INP 4

CTRL I/O

* ANALOG STEREO INP 9

* ANALOG STEREO INP 10

CTRL I/O

DIGITAL STEREO INP 1

DIGITAL STEREO INP 2

CTRL I/O

DIGITAL STEREO INP 3

DIGITAL STEREO INP 4

CTRL I/O

# DIGITAL STEREO INP 9

# DIGITAL STEREO INP 10

CTRL I/O

TB MIC

CTRL I/O

TB MIC

STUDIO

a

d

a

a

a

a

a

a

a

a

a

a

a

a

d

d

d

d

d

d

a

a

CR

a

MONO LINE

STEREO LINE

ANALOG SIGNAL

DIGITAL SIGNAL (AES/EBU)

CONFIG SELECTION

MONITOR SELECTOR

XLR CONNECTOR

D-TYPE CONNECTOR

BANTAM JACK

HEADPHONE JACK SOCKET

INPUT

PCBs

INSERT

PREAMP 2

INSERT

PREAMP 3

INSERT

HL INP 1

HL INP 2

APREAMP 1

D

A

D

A

D

A

D

A

D

INPUT CHANNEL 1

DC REJ

PHASE

INPUT CHANNEL 4

DIG PAD

PHASE

INPUT ROUTER

A

HL INP 5

AES INP 1

AES INP 2

AES INP 5

D

*

INPUT CHANNEL 10

D

SFC

D

D

SFC

D

D

SFC

D

APREAMP

D

APREAMP

D

* ANALOG-BIASED VERSION (6 mic, 10 analog, and 4 digital inputs)

# DIGITAL-BIASED VERSION (6 mic, 4 analog, and 10 digital inputs)

*** IF "PFL CUT ON CHANNEL ACTIVE" IS YES

DC REJ

DIG PAD

PHASE

TB INPUT CHANNELS

INPUT CHANNELS

FILTER/

EQU.DIG PAD

FILTER/DC REJ

FILTER/

EQU.

INSERT

INSERT

INSERT

INSERT

BALANCEFADERINSERT

AF

PF

AF

PF

FADER BALANCEEQU.

AF

PF

AF

PF

FADER BALANCE

AF

PF

AF

PF

COMMUNICATION I/O

TIME SYNC INP

RS 232

RS 422

CHANNEL

ON

CHANNEL

ON

CHANNEL

ON

***

***

CHANNEL ON

***

CHANNEL ON

CHANNEL ON

AUX1

AUX2

AUX1

AUX2

AUX1

AUX2

MUTE

MUTE

MUTE

RS 232/422

INTERFACE

TIME SYNC

INTERFACE

Σ PROGRAM

Σ RECORD

AUDITION

Σ

N–1 A

N–1 B

AUX 1

AUX 2

PFL

TB TO STUDIO

TB TO CR

PROGRAM

Σ

RECORD

Σ

AUDITION

Σ

N–1 A

N–1 B

AUX 1

AUX 2

PFL

PROGRAM

Σ

Σ RECORD

AUDITION

Σ

N–1 A

N–1 B

AUX 1

AUX 2

PFL

TB TO STUDIO

TB TO EXT

TB TO CR

TB TO EXT

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

BUS

+

+

+

+

+

+

+

+

+

+

1-2 Intro SW V 4.0 Date printed: 23.10.03

OnAir 1000 Digital Mixing Console

MASTER AND MONITORING

MAIN OUTPUTS

METER 1 METER 2

PPM / VU

BARGRAPH BARGRAPH

RETURNSEND

PROGRAM

+

+

+

+

+

Σ FADER PGM

Σ

Σ AUDITION

Σ N–1 A

Σ N–1 B

FADER REC

INSERT

INSERT

DIM

DIM

+

+

LIMITER

LIMITER

+

+

C+S TALK

C+S TALK

INSERT

INSERT

Σ

Σ RECORD

Σ AUDITION

N–1 A

N–1 B

+

+

+

+

+

+

+

+

+

+

+

BUS

+

+

+

+

+

+

+

+

+

RET 1

+

RET 2

a

a

AUX1 MASTER

AUX2 MASTER

2 x INSERTS

A

D

A

+

+

C TALK

C TALK

EXT. PFL

OFF AIR

EXT. 1

EXT. 2

EXT. 3

DIM

DIM

EXT. PFL CONTROL

EXTERN MONITORING

EXT TB TO STUDIO

EXT. TB INPUT

EXT TB TO CR

EXTERN TB INPUT

D

A

LIM

LIM

LIMITER

LIMITER

DAD

+

a

a

a

a

a

a

D

A

D

AD

EXT. TO PFL

a

SEND 1

a

SEND 2

D

A A

+

TB TO C.R.MON

MONO

MONO

A

D

DIM

STUDIO CUT

C.R.MON.

CR/PFL

PFL

C.R. CUT + DIM

D

TB TO STUDIO

A

DIM

A

D D

+

PPM / VU

A

C.R./ DJ MONITOR

VOL CONTR

+

VOL CONTR

+

VOL CONTR

d

D

D

D

A

D

D

D

A

D

A

D

A

D

A

D

D

D

A

D

D

d

a

d

d

a

a

a

a

a

a

d

d

a

d

d

Σ PROGRAM D

(Σ ON AIR / D)

Σ PROGRAM A

(Σ ON AIR / A)

Σ RECORD / D

Σ RECORD / A

N–1 A

N–1 A

N–1 B

N–1 B

AUX 1

AUX 1

AUX 2

AUX 2

STUDIO MONITOR

VCA

VCA

MONITOR SELECT

TB TO C.R.MON

PFL/TB

VCA

CR.LOUDSPEAKER

STUDIO

STUDIO LSP

TB TO TEL

MIC SIGN.STUDIO MIC SIGN.

DJ

GUESTS

SYNC INP

WORD CLOCK

AES/EBU

VIDEO

CLOCK

GENERATOR

REGENSDORF

SWITZERLAND

ON AIR 1000M2 V4

BLOCK DIAGRAM AUDIO

Date printed: 23.10.03 SW V 4.0 Intro 1-3

OnAir 1000 Digital Mixing Console

1.2 Definition of Terms

Terms used in this manual:

Inputs: The physical inputs of the input unit; all input units have mono or stereo

inputs with A/B selection.

Analog inputs are equipped with 3-pin XLR connectors.

Digital inputs are equipped with AES/EBU inputs on XLR connectors, and

S/PDIF inputs on Cinch/RCA and optical (TOSlink) connectors.

Input Unit: An input unit is a hardware assembly installed within the console. All in-

put units contain two selectable mono or stereo inputs; all input signals to

the input units are connected to the input connectors at the rear of the console.

Microphone input units have transformer-balanced mono inputs on XLRs,

with selectable 48 V phantom supply and A/B selection.

Analog Line input units have two electronically balanced stereo inputs on

XLRs, with A/B selection.

On Digital Line input units, there is a selection of AES/EBU inputs on

XLR connectors, and S/PDIF inputs on Cinch/RCA and optical (TOSlink)

connectors available.

Each (A or B) input of every input unit is equipped with general-purpose

control inputs and outputs (GPIO) that can be used for fader start, mute,

signaling, etc.; these control inputs and outputs are available on D-type

connectors.

Input Channel: An input channel is the combination of all signal processing functions that

can be assigned to a fader strip, as A/B input selection, gain, filter, EQ,

pan/balance etc.; each input channel can be routed to any fader strip thanks

to the input channel routing performed in the DSP section of the console.

Fader Strip: A fader strip contains the operating elements for an input channel, as a

linear fader and a few keys and LEDs (e.g. ON, OFF, and PFL keys, and

OVL and AUTO TAKEOVER LEDs).

As the number of operating elements is reduced to a minimum, the adjustment of some less often used input channel functions, as e.g. EQ setting, is

performed on the center touch-screen and the rotary encoders located next

to this screen.

1-4 Intro SW V 4.0 Date printed: 23.10.03

2 GENERAL

2.1 Utilization for the Purpose Intended

The OnAir 1000 mixing console is intended for professional use.

It is presumed that the unit is operated only by trained personnel. Servicing

is reserved to skilled technicians.

The electrical connections may be connected only to the voltages and signals designated in this manual.

2.2 First Steps

2.2.1 Unpacking and Inspection

Your new mixing console is shipped in a special packing that protects the

unit against mechanical shock during transit. Care should be exercised

when unpacking so that the surfaces do not get marred.

Verify that the content of the packing agrees with the items listed on the

enclosed shipping list.

Check the condition of the equipment for signs of shipping damage. If

there should be any complaints you should immediately notify the forwarding agent and your nearest Studer distributor.

Please retain the original packing material because it offers the best protection in case your equipment ever needs to be transported.

OnAir 1000 Digital Mixing Console

2.2.2 Installation

Primary Voltage: The power supply unit is auto-ranging; it can be used for mains voltages in

a range of 100 to 240 VAC, 50 to 60 Hz.

DC Operation: The console can be operated from a 24 VDC source through the respective

24 VDC connector provided on the rear panel.

For DC operation it is mandatory that a UL approved, external fuse is

connected in series with one of the supply lines (T 10 A H 250 V UL/CSA).

The power switch next to the power inlet only switches the mains voltage;

for DC operation, an external power switch has to be foreseen by the installer.

Dual (Redundant) Power Supply: For information on the Dual Power Supply versions refer to chapter 14.2.

General Precautions: Do not use the unit in conditions of excessive heat or cold, near any source

of moisture, in excessively humid environments, or in positions where it is