Studer Vista 8

Digital Audio Console Information

29th July 2004

1 INTRODUCTION............................................................................................................ 3

2 GENERAL SYSTEM OVERVIEW ............................................................................... 3

2.1 S

YSTEM BLOCK DIAGRAM .......................................................................................... 3

2.1.1 Block Diagram showing system utlising D21m IO System ................................ 3

2.2 CONTROL SURFACE (VISTA 8)..................................................................................... 4

•

Momentary/Latching Activation of all Buttons .......................................................... 5

•

Ganging ...................................................................................................................... 5

•

Fast Copy/Paste and Half-Lit Keys............................................................................ 5

•

Banking with Scrolling Navigation ............................................................................ 5

2.3 DSP CORE................................................................................................................... 6

2.4 I

NPUT/OUTPUT SYSTEM .............................................................................................. 7

2.4.1 Available D21m Audio IO Cards ....................................................................... 7

2.4.2 D21m Stagebox System ...................................................................................... 7

2.5 MONITORING, TALKBACK AND SIGNALLING ............................................................... 8

2.5.1 Monitoring.......................................................................................................... 8

2.5.2 Talkback and Signalling..................................................................................... 8

2.6 EXTERNAL SYNCHRONISATION ................................................................................... 9

3 TROUBLESHOOTING................................................................................................... 9

3.1 SYSTEM SURVEYOR..................................................................................................... 9

3.2 SERVICE ISSUES......................................................................................................... 10

4 REDUNDANCY ............................................................................................................. 11

4.1.1 Power Supplies................................................................................................. 11

4.1.2 DSP Core.......................................................................................................... 11

4.1.3 MADI Links ...................................................................................................... 12

4.1.4 Control System ................................................................................................. 12

4.1.5 Control Surface ................................................................................................ 12

4.1.6 Mastersync Unit ............................................................................................... 13

4.2 N-1 DESCRIPTION ..................................................................................................... 13

5 TECHNICAL SPECS .................................................................................................... 14

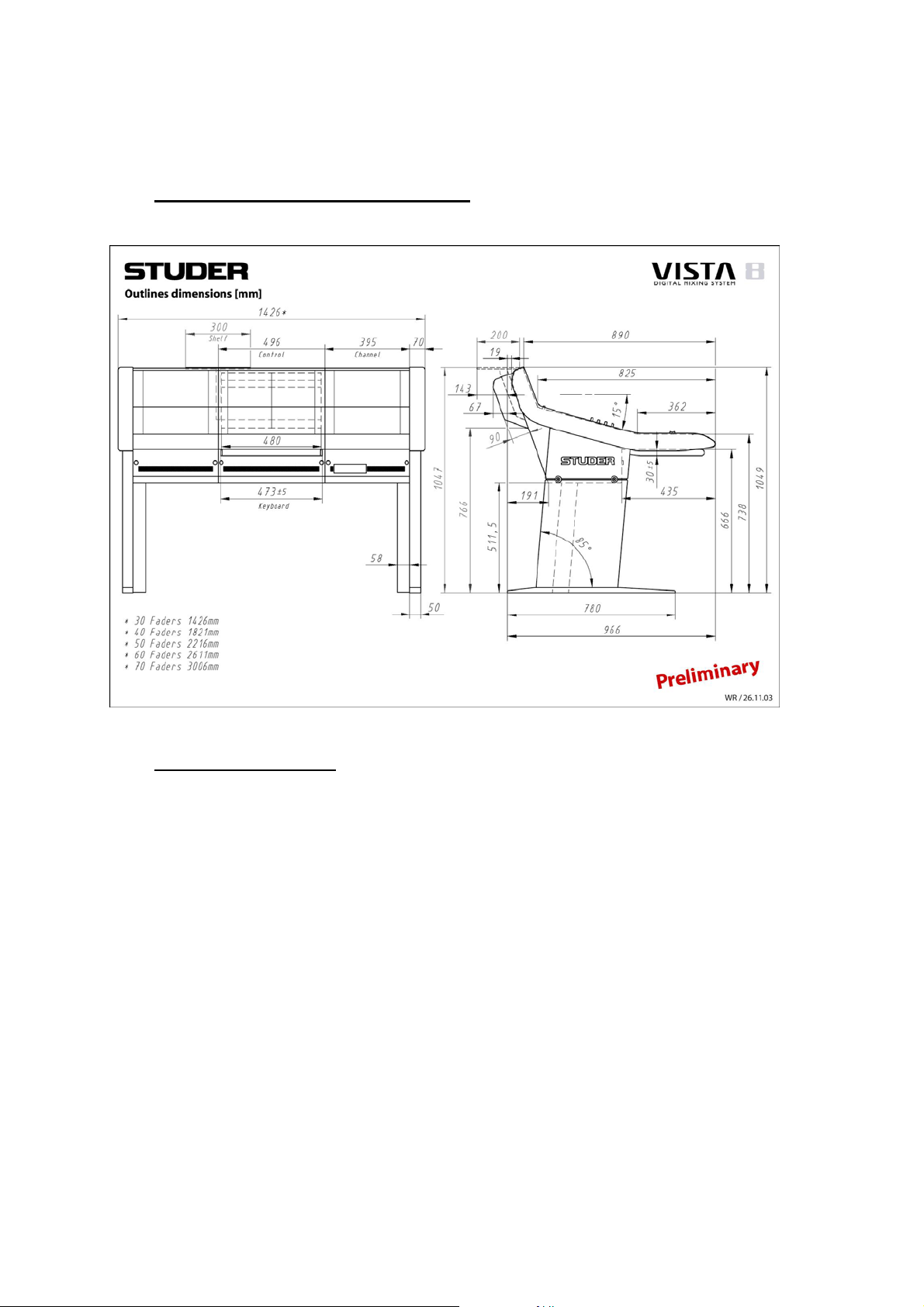

5.1 VISTA 8 CONTROL SURFACE DIMENSIONS ................................................................ 14

5.2 P

OWER CONSUMPTION .............................................................................................. 14

2

1 Introduction

This document outlines some of the key features of the Studer Vista 8 Digital Audio Console.

2 General System Overview

The system structure of the Vista 8 Digital Console can be separated into 5 main areas:

1. Control Surface

2. DSP Core

3. IO

4. Monitoring & Signalling

5. External Synchronisation

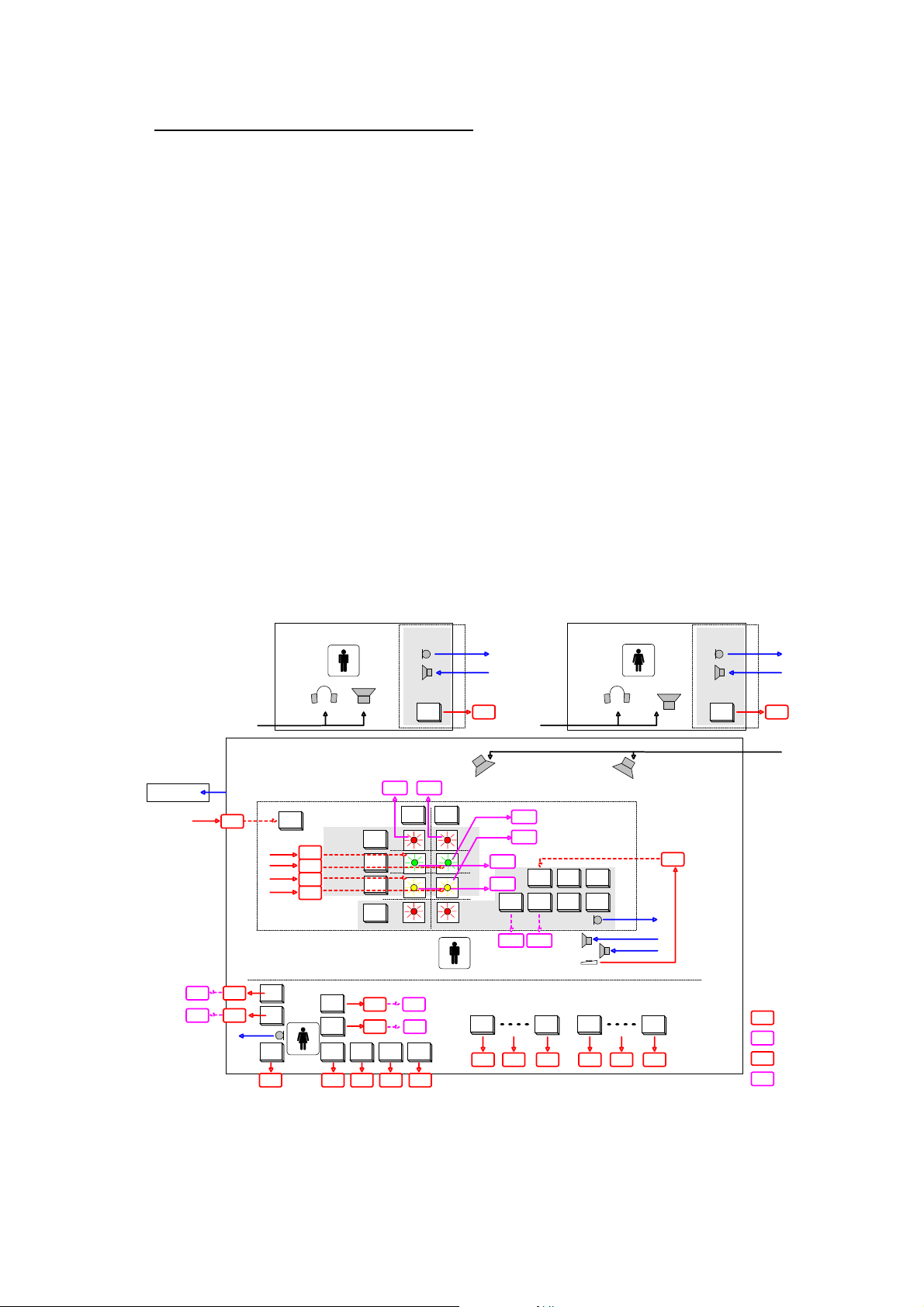

2.1 System Block Diagram

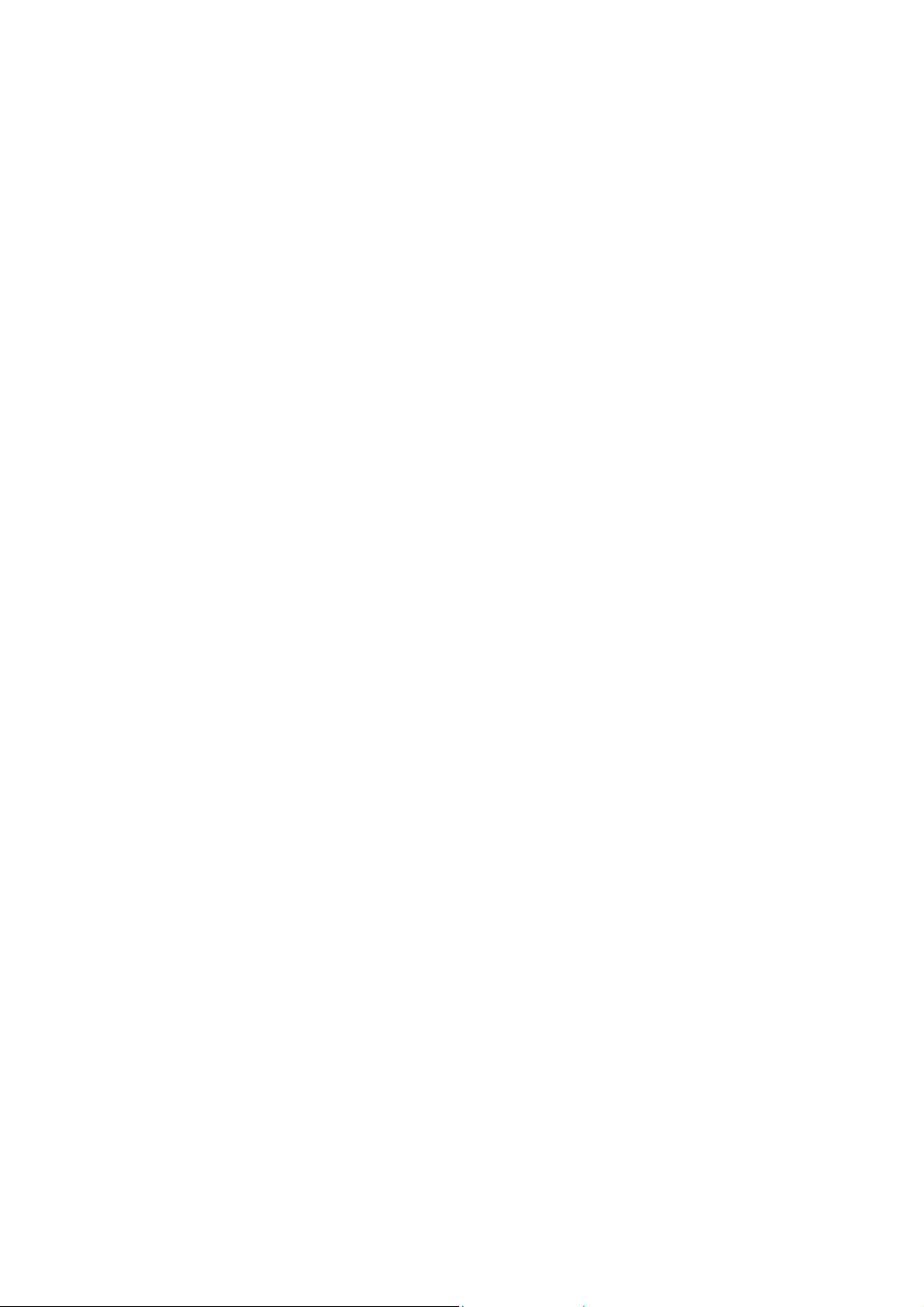

2.1.1 Block Diagram showing system utlising D21m IO System

Global Wiring Overview Vista 8 (with D21m I/O)

Vista 8 Desk (with built-in Cont rol System)

RS485/HP/TB

Optical Link

D21m Stagebox

Option: Outputs for Custom

Meters

Mic Control Data

AES/EBU Link

AES/EBU Link

Control Room

Monitoring 5.1

D21m Hub

TB Int

PFL/CR/ST

MADI (with embedded Mic Control)

LVDS (CAT 5)

DSP Core

Monitoring Frame

48 GPI

32 GPO

Studio A

Monitoring

2Ch

(optional)

Stagebox IO

Local IO

House Sync

(Video, Wordclock, etc)

(Option: Mastersync Unit)

Studio B

Monitoring

2Ch

(optional)

PLEASE NOTE: This is a general System Block Diagram. Actual number of D21 IO frames

will depend on customer requirements.

3

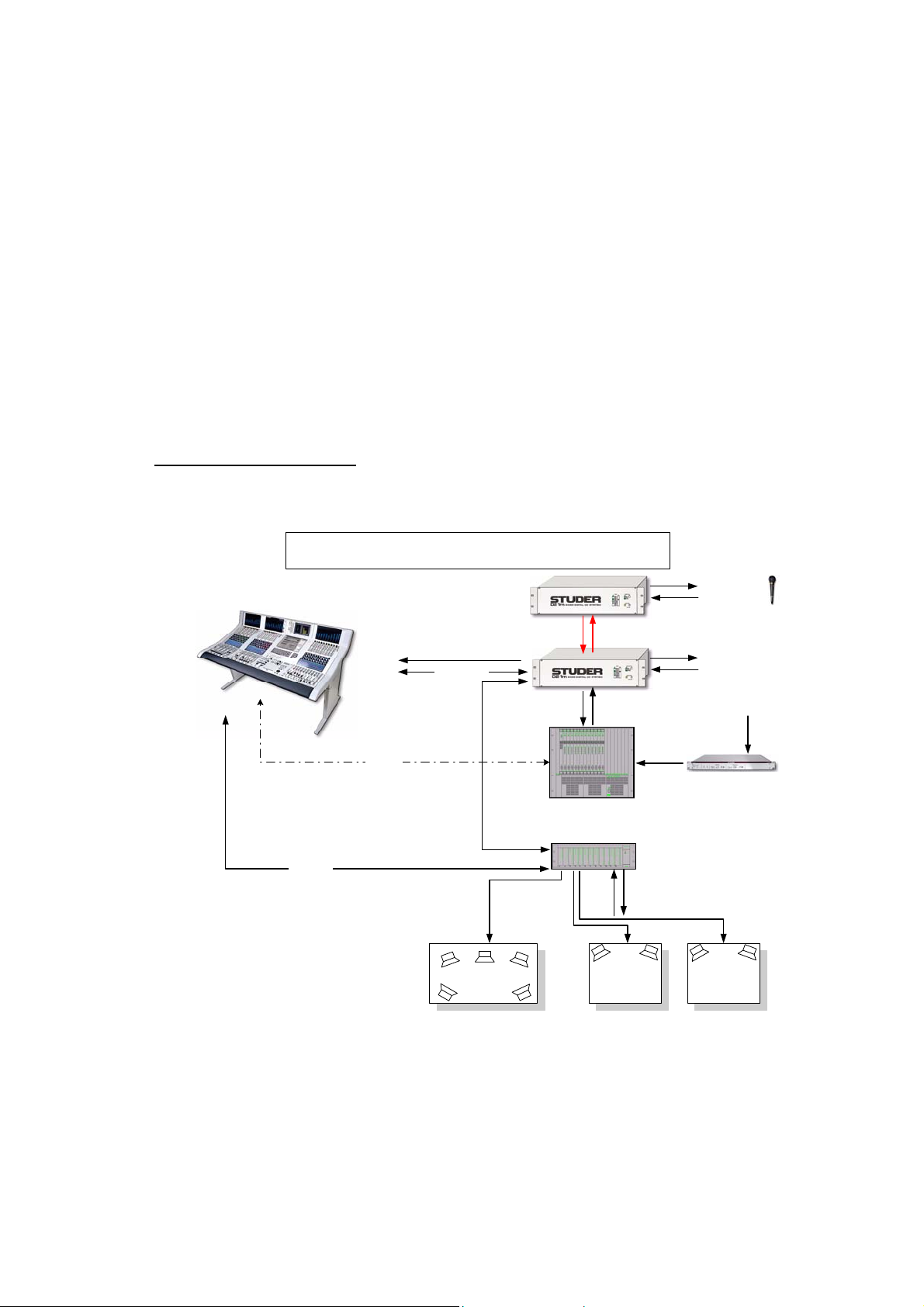

2.2 Control Surface (Vista 8)

The Control Surface of the Vista 8 is shown below (only 1 fader bay shown):

The control surface features the industry acclaimed Vistonics User Interface which offers a

“where you look is where you control” philosophy. The Studer developed Vistonics

technology mounts rotary controls and switches on TFT Screens. This then offers the user the

benefits of screen technology (Touchscreen, colour, icons and text) without the limitations of

having to access physical controls away from the where the control is displayed. A touch and

access philosophy combined with Channel strip orientated operation offers a friendly and

intuitive operating concept.

4

This extremely intuitive and fast to learn operational concept is further enhanced by 4 other

key operational features that frees the users mind from working on the console and allows

more thought to be placed on the work at hand. These key features are:

• Momentary/Latching Activation of all Buttons

The console recognizes and senses the button-push duration and responds accordingly. The

buttons therefore act momentarily or latchingly depending on how they were pressed (pressedand-held or briefly tapped). In addition to Talkback, PFL, EQ on/off, etc., the functions affected

include those accessed by the touch-screen - such as viewing of audio function - as well as the

monitoring source selectors and the machine control.

• Ganging

The ganging function in the mixer allows the operator to quickly apply functions to multiple

channel strips because channels within the gang act as one. This can be used, for example, for

Mute, Automation mode changes, faders, Bus assign and much more to increase speed and

comfort in operation. Creating a gang over the console makes the set-up quick and easy.

• Fast Copy/Paste and Half-Lit Keys

The console incorporates dedicated copy/paste keys for each audio function including EQ,

dynamics, panorama and delay. A simple button-press in the original channel and another in

the target channel copies the settings across. Copy/Paste is guided up by the half-lit buttons: if

one button has been pressed and the desk is awaiting a second button-press, all available

target buttons illuminate at half brightness until one of them has been selected. Also, complete

channels can be cloned to one or many target channels. Setting up the Studer Vista 7 for a

production becomes a quick and easy task. Non-productive time is reduced considerably.

• Banking with Scrolling Navigation

DSP channels not visible on the physical desk are accessed by scrolling the channels available in the

DSP core. The channel order is freely assignable: channels can be grouped or even shown repeatedly

on the surface. This ensures physical orientation on the desk so that the operator is always clearly

informed as to what is happening. Channel Bays with, for example, the master channels can also be

locked in place.

The Vista 8 also includes a completely redesigned Control Bay. While talkback and monitoring

functionality, trackball and a motorized joystick have been maintained from the previous Vista

consoles, dedicated control elements have been introduced for operation of outputs. 12 motorized

5

faders and a Vistonics™ screen with 40 rotaries have been added. Multiple user definable assignments

of these 12 faders and Vistonics™ controls are possible to be recalled by one button press, giving up

to 52 directly accessible level controls for controlling all sorts of outputs such as master, groups or

matrix outputs. Two of the faders will act as “grand masters” without alternate pages, allowing instant

influence on all console outputs if needed. The other 10 fader strips as well as all 40 rotaries with their

pushbuttons will allow also SOLO/PFL, MUTE as well as TALKING to each masters individually.

Metering has also been extended: 40 meters are visible on the Vistonics and the corresponding level

controls are immediately available on the rotary controls next to them. Looking at levels and

correcting them therefore is just a fraction of a second away.

Another major improvement is the “reverse operation” of masters and their busses. Vista 8 can show

all channels contributing to a specific master bus on the Vistonics™ screen and allows level

adjustment of all those channels instantly - without physically accessing the contributing channels

themselves on the fader bay.

Furthermore the control group functionality (VCA style) will be extended to form control groups with

different levels of control (hierarchical control groups). Each channel strip allows the possibility to flip

a single fader to a second layer without flipping the whole console. Dynamic Automation is also a

feature of the desk. You can boot the desk in one of two modes; Snapshot automation for live on-air or

dynamic automation for production use. New dual colour metering is provided on each channel to give

better headroom indication which is definable.

2.3 DSP Core

The DSP core of the Studer Vista 8 builds on Studer‘s well-proven digital technology. It incorporates

an excellent reliability record and inspires a high degree of confidence enjoyed by the numerous users

operating systems in mission-critical applications. The DSP core uses parallel processing architecture

with integrated floating point circuitry and an internal word length of 40 bits. No overloads will ever

occur within the console, since floating point architecture is even used in the summing busses. The

system can be used in 48 kHz or 96 kHz mode.

The DSP Core is based on modular cards and the more DSP cards that have been fitted in the core, the

more DSP power is available. DSP Boards can have 8 AES IO incorporated per board.

An offline Configuration Editor tool is also available which allows the available DSP Power to be

reconfigured by the customer. This includes changing the number of channels, audio processing and

bussing structure of the console for a particular project. Extensive import functions allows the user to

adapt existing configurations to meet changing needs. In addition, the combination of modular DSP

cards and the configuration editor means that future console expansion is as simple as adding more

DSP cards and making new larger configurations with the configuration editor.

6

2.4 Input/Output System

The D21m high-density audio interface system is like a hub to the Vista 8 DSP Core. The 19” Frame

can hold up to 12 interface cards where audio is collected from or distributed to all standard

professional industry audio formats.

Up to 384 inputs and outputs from 12 audio card slots are collected in the center of the 3U D21m

Frame where one or two High Density Cards can be placed. These cards provide the link to the DSP

Core of the console using standard CAT 5 cable connections. Each connection carries up to 96

channels into the Performa DSP Core and 48 channels out in 24 bit 96Khz quality. The system

automatically detects newly inserted cards and assigns the appropriate number of Input/Output

channels to it. A status display on the front panel informs the user if a card is present or if the card has

failed or been removed. The Frame may also be ordered with redundant power supplies. In addition,

all D21m audio cards are hot-pluggable.

2.4.1 Available D21m Audio IO Cards

• Microphone Card: 4 x microphone Preamp with 24 bit Converter (split output available as

standard)

• AES/EBU Card: 8 x AES/EBU in and 8 x AES/EBU Out

• AES/EBU Card with Input and Output SFC: Same as above but with asynchronous

sampling Frequency converters on both inputs and outputs.

• Line In Card: 8 channel D/A Converter Board (Specs?)

• Line Out Card: 8 channel A/D Converter Board (Specs?)

• ADAT Card: 2 optical input and 2 optical output interfaces

• TDIF Board: 2 TDIF Interfaces

• MADI IO Board: 1 x 56 or 64 channel MADI Input and Output. A Second input and output

is available and can be used as a redundant MADI or to provide a split MADI signal of Output

1.

2.4.2 D21m Stagebox System

The D21m Stagebox system utilises a D21m Hub which sits local (10m) to the DSP Core and

stageboxes which collect all the remote IO signals and convert them to a single 56 or 64 channel

MADI signal. The Hub then receives the MADI signals from the stageboxes and sends them to the

DSP core via a single CAT 5 cable. The hub can handle up to a maximum of 6 stageboxes. A D21m

Hub can also handle any of the local IO. Any stageboxes with Microphone Preamp cards will require

some control data from the Vista Control Surface. This control data is first sent to the D21m Hub

where the control data is merged with the MADI stream. The system can automatically detect

stageboxes with microphones and send the correct Control Data from the desk making operational

handling incredibly simple. This auto detection mechanism means that sharing stageboxes between

different Consoles is extremely easy requiring no user administration.

7

2.5 Monitoring, Talkback and Signalling

A single 3U rack unit is utilised for housing all of the Monitoring and Signaling cards of the system.

2.5.1 Monitoring

The monitoring is controlled in the analogue domain. Some fixed AES/EBU outputs are utilized from

the Vista 8 DSP Core and are fed to converters built into the monitoring frame. 5.1 monitoring is

standard on the Vista 8 with Dolby EX Monitoring as an option. The Control Room monitoring

section on the control surface provides control of up to three different speaker systems (Two multichannel and one stereo) and 76 source selectors. All internal digital sources can be assigned to any of

the source selector keys as mono, stereo or multichannel sources. The 2 Studio Monitors are

configurable in the same way as the CR Monitor section, although as standard only stereo studio

loudspeaker feeds are supported. Surround studio feeds are available with a custom monitoring frame.

A headphone socket is also available on the control surface for use in the control room.

2.5.2 Talkback and Signalling

An extensive talkback system is implemented within the Vista. The talkback source can either be the

built in desk operator microphone or an external producer microphone. Several destinations, such as

buses, direct outs, auxillaries, groups and master outputs are available on block. The block diagram

below shows the talkback and signaling possibilities of the Vista 8.

Talkback and signaling blockdiagram

e.g.Intercom

GPO 5

GPO X

Studio MonitorA

Control Room

Ext 3

(always on)

GPI X

Talk to

GPI11

EXT1

Talk to

GPI12

EXT2

Mic "TB2"

Talk to

preselected

GPI 6 GPI 7 GPI 8 GPI 9 GPI 10

On Air

Vista6 Desk

GPI 3

GPI X

GPI 4

GPI X

Producer

e.g.Speaker

Signaling Keys

Talk to

Studio

A

Talk to

Studio

B

Talk to

Aux1

Studio A

Talk to

GPI 5

GPI X

Talk to

Aux2

SIG1

SIG2

Studio

Ext Location 1

Ret 1

(Line level)

Ext 1

Talk to

CR

(-> to PFL Speaker)

GPO 0

GPO X

Selector

StudioA

Red

Light

GPO 3

GPO X

Talk to

Talk to

Aux3

Aux4

GPI 1

Selector

StudioB

Desk

Operator

Producer area (either in control room or in another room)

GPO 1

GPO 2

Talk to

Ext1

TB Keys

GPO 4

Talk to

ChanOut

Grp01

GPI X GPI X GPI X GPI XGPI XGPI X

GPO X

GPO X

GPO X

Talk to

preselected

Talk to

Ext2

CR Monitor

Talk to

ChanOut

Grp N

Talk to

Aux1

Talk to

Aux3

Studio Monitor B

Talk to

Aux2

Talk to

Aux4

PFL/TB Out

Footswitch

Channel

Mute

Grp01

TB only

TB Mic

e.g.Speaker

Studio B

Channel

Mute

Grp N

GPI 0

Ext Location 2

Ret 2

Talk to

CR

(-> to PFL Speaker)

Ext 2

GPI 2

Legend :

= GPI already configured in .ini files

GPI 1

= GPO already configured in .ini files

GPO 2

= GPI prepared to use, but not

assigned to signaling card.

GPI X

This can be configured in .ini files

= GPO prepared to use, but not

assigned to signaling card.

GPO X

This can be configured in .ini files

8

2.6 External Synchronisation

External digital synchronization of the console is provided by a Studer Mastersync Unit. This

single 19 inch 1U unit will allow the console to be synchronized to an external video black

burst, wordclock or AES signal.

A second mastersync unit may be used as a redundant unit with an automatic switchover

should a problem occur with the first unit.

3 Troubleshooting

3.1 System Surveyor

The software graphical controller has a built in real/time system surveyor. This surveyor

monitors the status of all of the communication between the various parts of the system and

provides a visual indication to the user of the status. This is extremely re-assuring for the user

who not only has a continuous visual performance indication, but if there is a problem,

clicking on the icon will show the user where problems have occurred. See the screenshot of

the surveyor window below. It also surveys all of the IO racks and displays the status of each

individual IO Card and Power supply in the D21m Frames.

9

This is also extremely useful for service issues. A log file is also kept which logs any system

errors. In some instances, this can then be sent to the factory (via e-mail) for fault finding

assistance.

3.2 Service Issues

As far as the control surface is concerned, each bay is a single module which opens up like a

car bonnet to access inside the console (See picture). All cable connections to the control

surface are on the front of the console for easy access.

The DSP, IO and monitoring are all made up of have modular cards.

10

4 Redundancy

There are 5 areas where redundancy is available:

Power supplies

DSP Core

MADI Links

Complete Control System

Control Surface

Mastersync Unit

4.1.1 Power Supplies

Without exception, throughout all parts of the system redundant power supplies that

automatically switch in case of failure of the primary supply are provided. This includes:

Control Surface

DSP Core

Monitoring

All I/O Frames

Control System (Installed as standard)

4.1.2 DSP Core

The DSP Core is the audio heart of any Digital Mixing Console and therefore if a problem is

to occur in this part of the system, it will usually result in some audible problems. It is

therefore essential that some redundancy is available to ensure continuous and seemless audio

even in the event of failure of part of the DSP Core.

The Studer Vista 8 DSP core is based on mature technology with over 250 broadcast consoles

worldwide utilising the DSP core in round the clock use. The design of the Vista 8 DSP Core

provides seemless audio flow with no disruption to the operator in the case of a DSP Card

failure. Both the physical design and DSP architecture mean that, assuming a redundant card

is available in the DSP Core, the redundant card will instantly take the role of a failed card

with a worse case scenario of a small mute in audio. A failed card may then be physically

replaced with a new card in a hot pluggable manner, again once installed assuming the role of

a redundant card. The replaced DSP card is auto detected in the system with no need for

reboot of any part of the system. If a DSP card is to fail, the worst case scenario in terms of

audio is a small mute (less than 1 sec) and the operator is simply informed of the failure by a

pop up window in the Graphic Controller. In terms of operation, the user is not affected and

can continue undisturbed.

The amount of redundancy is dependent on the number of ‘idle’ cards that are available in the

DSP core and this in turn is dependent on the configuration

1

that is currently loaded. If two

DSP cards lay idle, then this gives the possibility for two cards to fail without interruption.

11

It should be mentioned that if a DSP Card with AES inputs and outputs fails, the processing

will automatically switch but the 8 AES IO for that card, however will still be hardwired to

the failed card. This would mean the loss of the IO signals which were connected to the failed

card although the DSP processing will still swap to the redundant card.

It should also be noted, the DSP Core configuration is stored within the DSP Core itself. This

means that in the rare event of a problem with the Control System, audio will pass through the

DSP Core. In fact, the control system need not be running at all for audio to pass through the

DSP Core. The other advantage of this is that audio passes through the DSP Core in a matter

of seconds from DSP Core Power up.

4.1.3 MADI Links

Every IO frame with a MADI Link can have a second redundant MADI link which would

switch automatically if an invalid MADI signal is received.

4.1.4 Control System

The Control System is central to the communication and control of the different parts of the

system. For this reason, redundant Power Supplies and Raid 0 removable hard drives are

fitted as standard.

A second, fully equipped Control System housed underneath the console is available as an

option offering full 100 % redundancy and peace of mind. The user has the ability to switch to

the redundant Control System for emergency reasons. The data is backed up with an

adjustable time interval and automatically accessed by the redundant System when the

emergency switch is activated. Both Systems can be accessed from the same keyboard. It is

possible to switch GC screen and keyboard/trackball easily back and forth between both

Control Systems. If the emergency switch is activated, the keyboard/trackball/GC is

automatically switched to redundant Control Systems as well. The emergency switch is

located in the meterbridge and must be pressed several seconds in order to activate the

emergency switch. After switching, the user must boot the application from the redundant PC

before he has control. This takes approx 20 seconds. Both Control Systems may be switched

on and off separately, but are normally linked together by a jumper, located within the

meterbridge.

4.1.5 Control Surface

The Control Surface is made up of a number of modular Fader bays. Should one of these bays

fail, all other bays will continue as normal. The concept of navigation allows totally free

allocation of DSP Channels to physical channel strips. In this instance, the user can quickly

and easily re-arrange the strip layout in the Graphical Controller of the control system to reassign the channels that were represented on the failed bay. In addition, the navigation

philosophy allows scrolling of the virtual desk in front of the user. This also provides very fast

navigation in such events.

12

4.1.6 Mastersync Unit

The Mastersync unit provides the clock reference for all parts of the system. The unit can

either synchronise to an external clock or generate it’s own clock. The unit can have two

separate and different clock sources connected to it and will automatically switch to the

redundant input should there be a problem with the primary clock source.

A complete standby mastersync unit is available as an option that will instantly take over

should the main unit have a failure.

4.2 N-1 Description

The N-1 System for the Vista 8 is based on a bussing system. Any number of N-1 busses can

be configured which means that each outside source or telephone hybrid can be assigned to be

the owner of one bus. Any channel on the console can be routed to these n-1 busses (except

the owner to the relevant bus) and assignment is typically pre setup. By using the quick bus

assign functionality, a channel can be quickly de-assigned from a particular bus. All control of

overall level, N-1 On/Off and talkback are provided on the channel itself. In addition it is

possible to adjust the send level of a particular source to all of the n-1 busses. This is

particularly useful for 2 track sources which the outside source wants to hear but at a lower

level. In addition, a bus owner splits its’ input meter for the left hand side of the meter to

show the return level and the right hand side of the meter the N-1 Send.

One further feature of the N-1 system is the ability to send the outside source an off-air signal

whilst waiting to go live. This is achieved by the simple activation of the ‘Alt N-1’ button on

the relevant N-1 owner channel. When the operator opens the fader of the outside source, the

appropriate N-1 bus output is then automatically sent to the outside source without the user

having to manually de-select the off-air signal.

An off-air conferencing (MPX) function is also available allowing any number of outside

sources to talk together whilst off air. When one of the outside sources is put on-air, they are

automatically removed from the conference and fed their correct N-1 bus without operator

intervention.

13

5 Technical Specs

5.1 Vista 8 Control Surface Dimensions

5.2 Power Consumption

Approximate figures

Control Surface:

150W for Control System and Control Bay. 60 Watts in addition per fader bay.

Example: 40 faders (3 fader bays and 1 Control Bay) = 150 + (3x60) = 330W

DSP Core:

20 Processing cards = 800 Watts

Monitoring Frame = 100 Watts

D21m IO Frames = 150W per frame

14

Loading...

Loading...