Page 1

SSTT11™™ aanndd SSTT11--XX™™ SSeerriieess SSttrreettcchheerr

MMaaiinntteennaannccee MMaannuuaall

6300

SK 6300 Rev 01

EN

2019/04

Page 2

Page 3

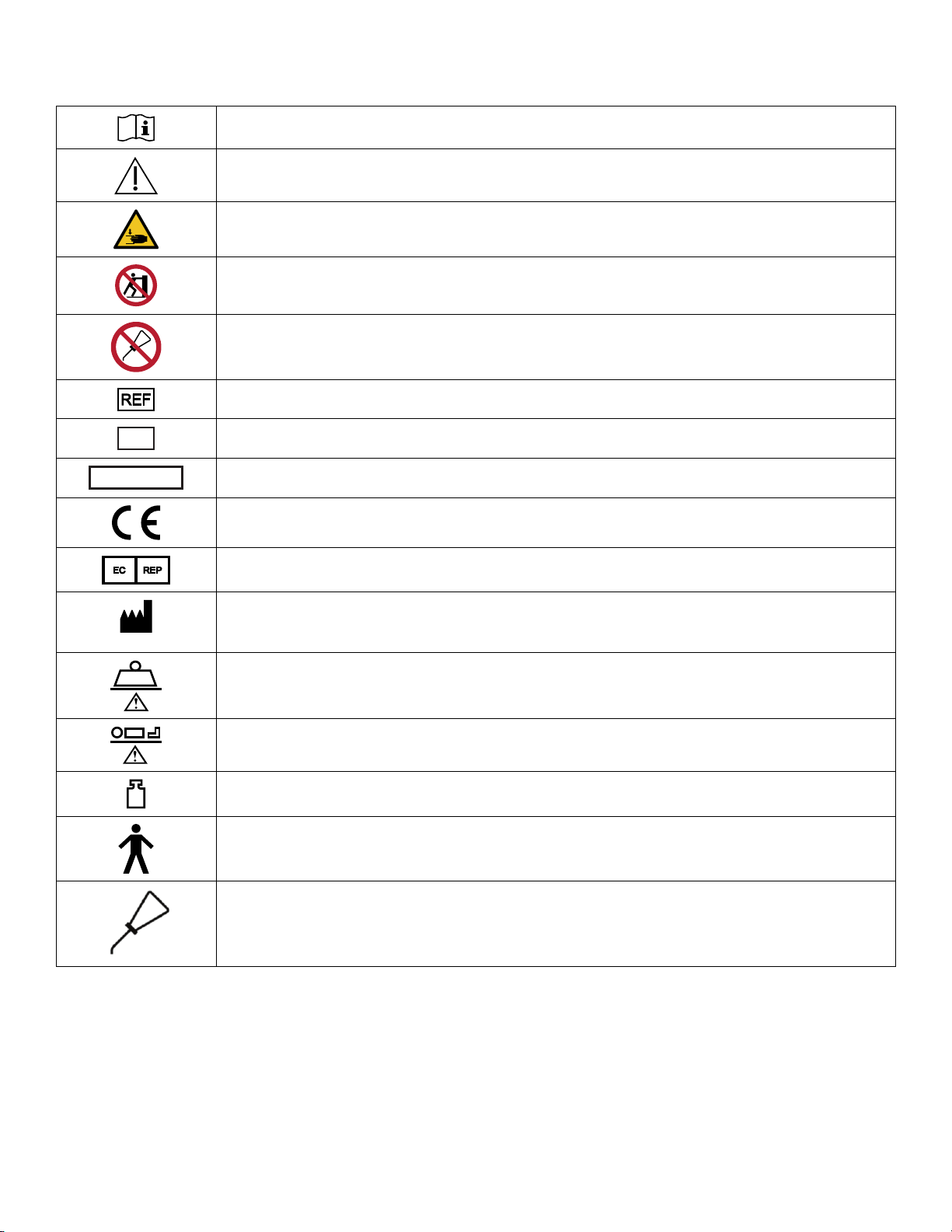

SSyymmbboollss

XXXX

Operating instructions/Consult instructions for use

Caution

Warning; crushing of hands

No pushing

Do not lubricate

Catalogue number

Serial number

For US Patents see www.stryker.com/patents

CE mark

EC REP

Manufacturer (XXXX indicates year of manufacture)

Safe working load

Maximum patient weight

Mass of equipment with safe working load

Type B applied part

Lubricate

SK 6300 Rev 01 EN

Page 4

Page 5

TTaabbllee ooff CCoonntteennttss

Warning/Caution/Note Definition ..............................................................................................................................3

Summary of safety precautions ................................................................................................................................4

Pinch points............................................................................................................................................................4

Introduction ...............................................................................................................................................................5

Product Description.................................................................................................................................................5

Indications for use...................................................................................................................................................5

Expected service life ...............................................................................................................................................5

Contraindications ....................................................................................................................................................6

Specifications .........................................................................................................................................................6

Product illustration ..................................................................................................................................................7

Applied parts ..........................................................................................................................................................8

Contact information .................................................................................................................................................8

Serial number location.............................................................................................................................................9

Preventive maintenance .........................................................................................................................................10

Retractable fifth wheel lubrication...........................................................................................................................12

Quick reference replacement parts ........................................................................................................................13

Service ....................................................................................................................................................................20

Raising the hood ................................................................................................................................................... 20

Replacing the hood ............................................................................................................................................... 20

Caster assembly replacement................................................................................................................................ 21

Brake rod replacement ..........................................................................................................................................22

Fifth wheel assembly replacement.......................................................................................................................... 23

Jack replacement.................................................................................................................................................. 24

Remove excess air from the hydraulic system .........................................................................................................26

Pump pedal replacement....................................................................................................................................... 26

Release pedal adjustment ..................................................................................................................................... 27

Release pedal replacement ................................................................................................................................... 28

Litter top removal .................................................................................................................................................. 29

Siderail latch replacement......................................................................................................................................30

X-ray cassette panel replacement - head end, ST1-X option..................................................................................... 30

X-ray cassette panel replacement - foot end, ST1-X option ...................................................................................... 31

Fowler gas cylinder replacement, ST1-X option .......................................................................................................32

Base assembly .......................................................................................................................................................34

Brake rod assembly - YM-660-320.........................................................................................................................40

Fifth wheel assembly - YM-660-123 .......................................................................................................................41

Lowering pedal assembly - YM-660-315................................................................................................................ 43

Pump pedal assembly - YM-660-037 ..................................................................................................................... 44

Litter frame assembly ............................................................................................................................................. 45

Litter mattress hook ................................................................................................................................................46

Litter assembly, ST1-X option ................................................................................................................................47

Fowler assembly, ST1-X option.............................................................................................................................. 49

Profile cap and Fowler guide part assembly........................................................................................................... 50

Left siderail assembly - YM-500-002 ...................................................................................................................... 51

Right siderail assembly - YM-500-003.................................................................................................................... 53

Left siderail latch assembly - YM-500-008 ............................................................................................................. 54

Right siderail latch assembly - YM-500-012...........................................................................................................55

Left spindle assembly - YM-500-006 ...................................................................................................................... 56

Right spindle assembly - YM-500-010.................................................................................................................... 57

Left latch spindle assembly - YM-500-007 ............................................................................................................. 58

SK 6300 Rev 01 1 EN

Page 6

Right latch spindle assembly - YM-500-009...........................................................................................................59

Corner cover assembly...........................................................................................................................................60

Covers assembly, no options, head end ................................................................................................................ 62

Covers assembly with IV pole and pop-up push handles, head end .....................................................................63

Defibrillator tray assembly ......................................................................................................................................64

Two-stage IV pole assembly .................................................................................................................................. 65

Push handle assembly, head end ..........................................................................................................................66

Mattresses .............................................................................................................................................................. 67

EN 2 SK 6300 Rev 01

Page 7

WWaarrnniinngg//CCaauuttiioonn//NNoottee DDeeffiinniittiioonn

The words WWAARRNNIINNGG, CCAAUUTTIIOONN, and NNOOTTEE carry special meanings and should be carefully reviewed.

WWAARRNNIINNGG -- Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also

describe potential serious adverse reactions and safety hazards.

CCAAUUTTIIOONN -- Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury to the user or patient or damage to the product or other property. This includes special care necessary for the safe

and effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

NNoottee -- Provides special information to make maintenance easier or important instructions clearer.

SK 6300 Rev 01 3 EN

Page 8

SSuummmmaarryy ooff ssaaffeettyy pprreeccaauuttiioonnss

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

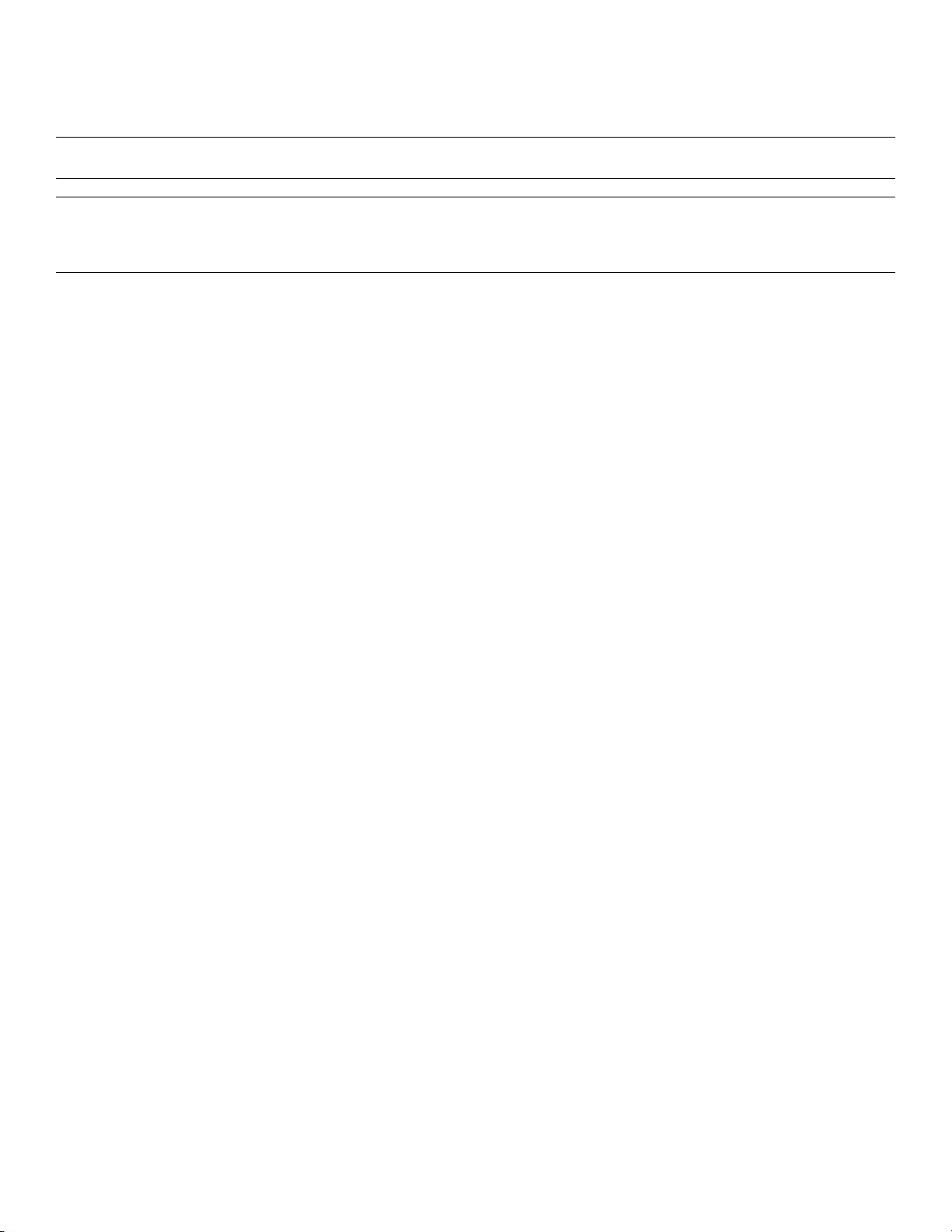

PPiinncchh ppooiinnttss

FFiigguurree 11 –– PPiinncchh ppooiinnttss ffoorr XX--rraayy ooppttiioonn oonnllyy

EN 4 SK 6300 Rev 01

Page 9

IInnttrroodduuccttiioonn

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating or

maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or maintenance

of this product.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

NNoottee

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current product

information available at the time of printing. There may be minor discrepancies between your product and this manual. If

you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

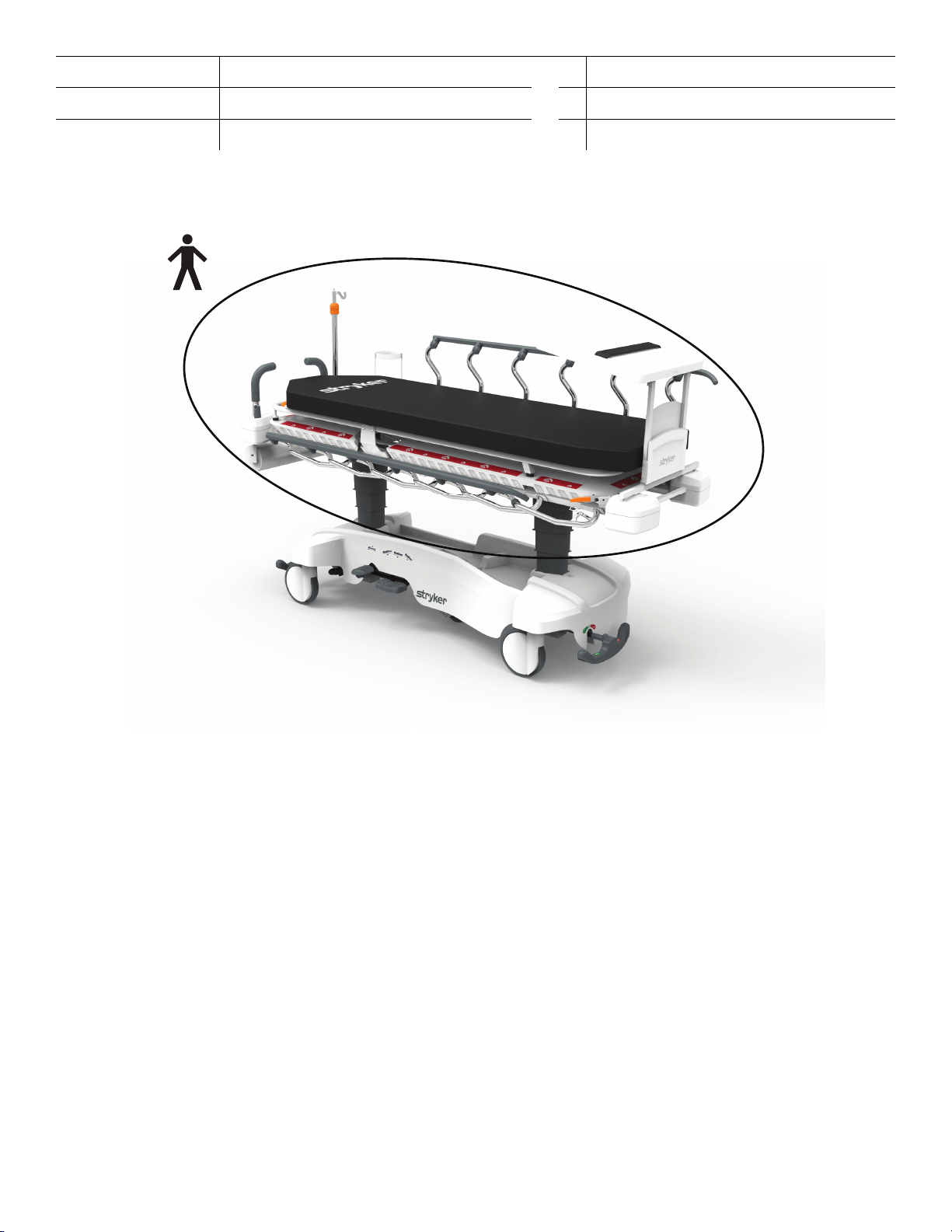

PPrroodduucctt DDeessccrriippttiioonn

The Stryker Model 6300 SSTT11 and SSTT11--XX Series stretcher is a wheeled device that consists of a platform mounted on a

wheeled frame to support patients in a horizontal position. The stretcher provides the operator with a method to transport

patients within the interior of a healthcare facility by health professionals or trained representatives of the facility. The

Stryker Model 6300 SSTT11 and SSTT11--XX Series stretcher with the retractable fifth wheel optimizes traction and cornering to

improve overall mobility.

IInnddiiccaattiioonnss ffoorr uussee

The stretcher is for use by human patients in a MedSurg setting, including those mildly to critically ill. The stretcher is for

use in hospitals, institutions, and clinics as a short-term outpatient clinical evaluation, treatment, minor procedure, and

short-term outpatient recovery platform. The stretcher may also be used to transport deceased patients within an enclosed

healthcare facility. Operators for the stretcher include healthcare professionals (nurses, nurse aides, and medical doctors)

and bystanders who can use bed motion functions (service or maintenance personnel).

The stretcher may include use in, but is not limited to:

• Emergency department (ED)

• Trauma area

• Post-anesthesia care unit (PACU)

The SSTT11 and SSTT11--XX Series stretcher is not for use for long-term (more than 24 hours) inpatient treatment and recovery.

The stretcher is not for use in a home healthcare environment.

The SSTT11 and SSTT11--XX Series stretcher frame, litter mounted accessories, mattresses, and siderails can contact human skin.

See the specifications table for the intended environmental conditions.

EExxppeecctteedd sseerrvviiccee lliiffee

The SSTT11 and SSTT11--XX Series stretcher with X-ray deck option has a 10 year expected service life under normal use,

conditions, and with appropriate periodic maintenance.

The casters have a minimum expected service life of 5 years dependent on normal use, conditions, and with appropriate

periodic maintenance.

SK 6300 Rev 01 5 EN

Page 10

CCoonnttrraaiinnddiiccaattiioonnss

100 °F

(38 °C)

50 °F

(10 °C)

122 °F

(50 °C)

14 °F

(-10 °C)

75%

30%

90 %

20 %

None known.

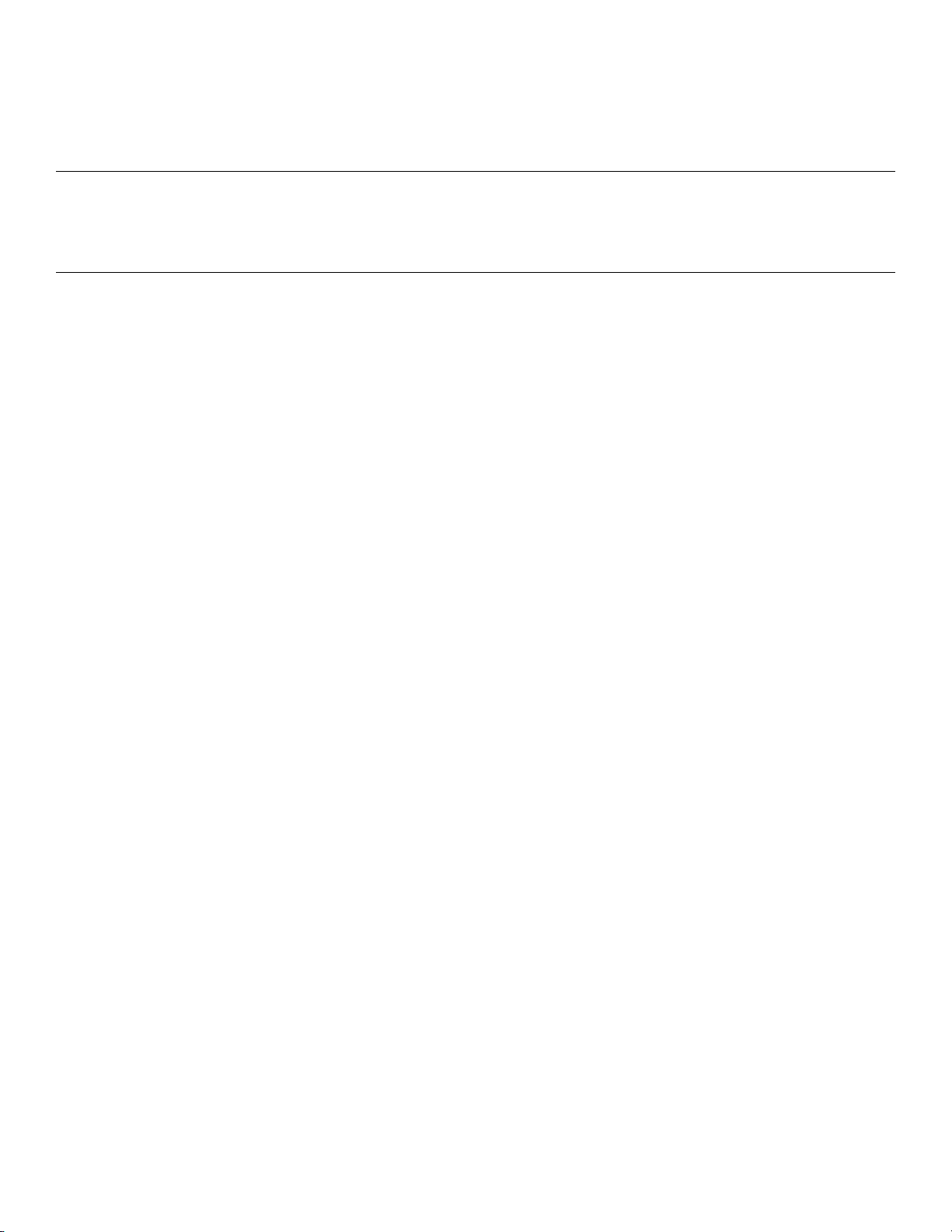

SSppeecciiffiiccaattiioonnss

Safe working load indicates the sum of the

patient, mattress and accessory weight

250 kg

Maximum patient weight

Overall length

Overall width (siderails up)

Overall width (siderails down)

215 kg

2170 mm ± 10 mm

790 mm ± 10 mm

735 mm

Height Non X-ray X-ray

Minimum height

Maximum height

560 mm + 15 mm, - 25

mm

860 ± 10 mm

610 + 15 mm, - 25 mm

910 ± 10 mm

Fowler angle 0° to 90° (± 5°)

Trendelenburg/Reverse Trendelenburg +16°/-16° (± 3°)

Nominal

15.4 cm ± 5 mm

Minimum

clearance

Under the hydraulic jacks

4.6 cm ± 5 mm

Stryker reserves the right to change specifications without notice.

NNoottee -- This product is not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or

nitrous oxide.

EEnnvviirroonnmmeennttaall ccoonnddiittiioonnss

OOppeerraattiioonn SSttoorraaggee aanndd ttrraannssppoorrttaattiioonn

Temperature

Relative humidity

Specifications listed are approximate and may vary slightly from product to product.

In accordance with the European REACH regulation and other environmental regulatory requirements, the components that

contain declarable substances are listed.

EN 6 SK 6300 Rev 01

Page 11

DDeessccrriippttiioonn NNuummbbeerr SSuubbssttaannccee ooff vveerryy hhiigghh ccoonncceerrnn

A

B

C

D

E

F

G

H

I

J

K

L

M

B

A

N

((SSVVHHCC)) cchheemmiiccaall nnaammee

2 stage IV pole assembly 0785-035-101 bis(2-ethyklhexyl) phthatlate (DEHP)

2 stage IV pole assembly HM-19-108 bis(2-ethyklhexyl) phthatlate (DEHP)

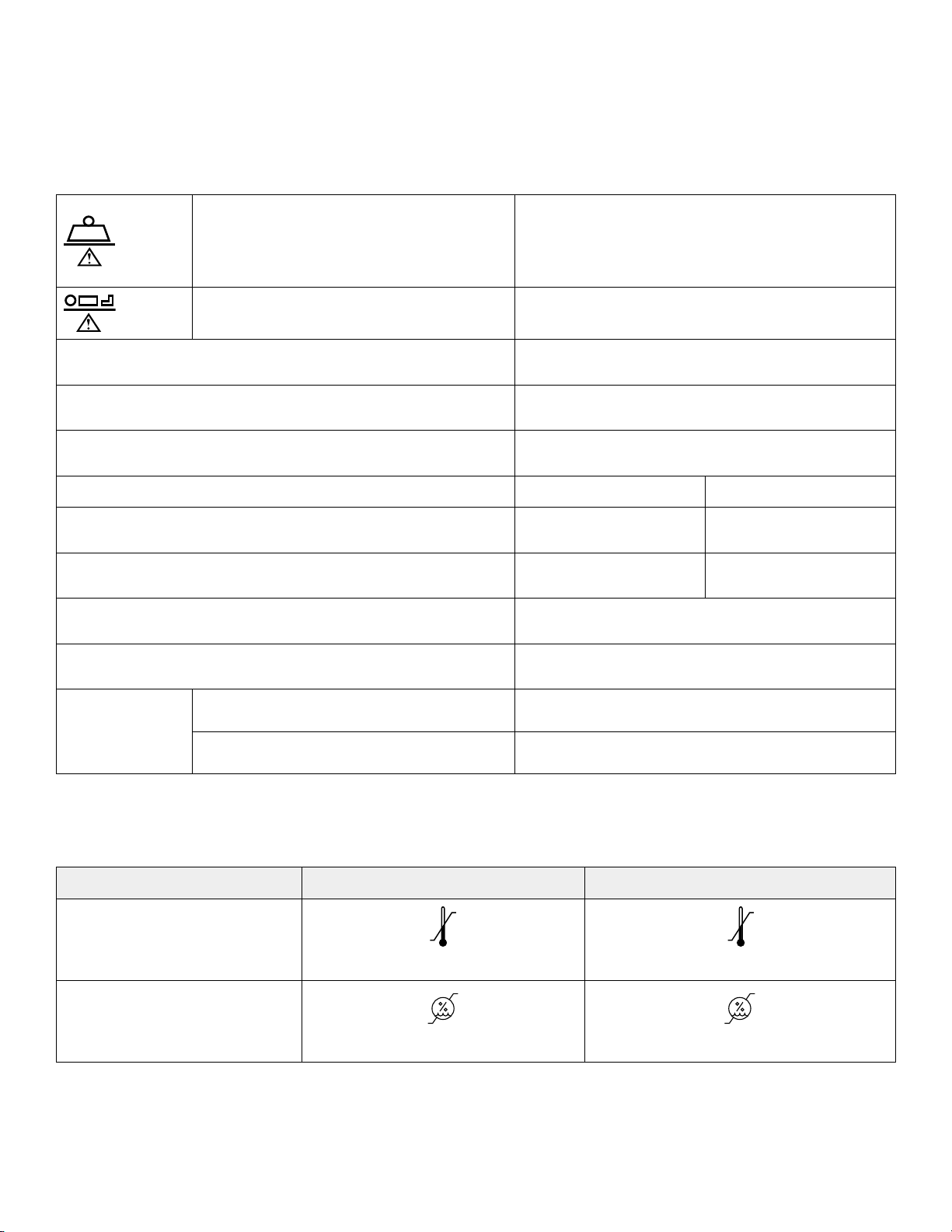

PPrroodduucctt iilllluussttrraattiioonn

A

B Caster I Siderail

C

D Fowler backrest release handle K

SK 6300 Rev 01 7 EN

Brake/steer control pedal

Defibrillator tray/chart holder

Pump pedal

H

J Siderail release handle

Uni-lower pedal

Page 12

E

IV pole

Upright oxygen bottle holder

L

F

G

AApppplliieedd ppaarrttss

Pop up push handle

Paper roll holder

X-ray deck

M

Antistatic caster

N

FFiigguurree 22 –– TTyyppee BB aapppplliieedd ppaarrttss

CCoonnttaacctt iinnffoorrmmaattiioonn

Contact Stryker Customer Service or Technical Support at: +1 800-327-0770.

Stryker Medical International

Kayseri Serbest Bölge Şubesi

2. Cad. No:17 38070

Kayseri, Turkey

Email: infosmi@stryker.com

Phone: + 90 (352) 321 43 00 (pbx)

Fax: + 90 (352) 321 43 03

Web: www.stryker.com

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

EN 8 SK 6300 Rev 01

Page 13

SSeerriiaall nnuummbbeerr llooccaattiioonn

A

FFiigguurree 33 –– SSeerriiaall nnuummbbeerr llooccaattiioonn

SK 6300 Rev 01 9 EN

Page 14

PPrreevveennttiivvee mmaaiinntteennaannccee

Remove product from service before you perform the preventive maintenance inspection. Check all items listed during

annual preventive maintenance for all Stryker Medical products. You may need to perform preventive maintenance checks

more often based on your level of product usage. Service only by qualified personnel.

NNoottee -- Clean and disinfect the exterior of the mattress before inspection, if applicable.

Inspect the following items:

All welds

All fasteners are secure

All product labels are in place and legible

All weldments (base frame, brake, litter, jack, carriage, IV pole pivot weldment, and push handle weldments) are not

damaged

Siderails move and latch

Siderail latches are secure

Siderail is not damaged

Siderail latch is not damaged, no burrs or debris in latch assembly

Antistatic caster is not worn or damaged

Casters lock with brake pedal applied

Casters are secure and swivel

Casters are free of wax and debris

Casters are not worn or damaged

Caster mounting joint is not damaged

Casters, brake mechanism, and brake rod are not damaged or cracked

Fowler raises, lowers, and latches in place

Fowler does not drift or drop unexpectedly

No leaks at the Fowler backrest cyclinders

Fowler gas cylinder pin is not stuck

Brake/steer pedals are not bent or damaged

Brake mechanism works

Steer function works

Fifth wheel is not worn or damaged and works

Fifth wheel linkage is not bent or overtraveled

No debris or wax buildup in fifth wheel

Carriage bolt is secure

Base frame is not damaged

Pump pedal is not loose, worn, or damaged

Hydraulic release pedals are not loose or damaged

Jack release valve is free of dust, debris, does not stick

Jack linkages are not out of adjustment or damaged

Jack adjustment valves and spring work

Jacks are not damaged

Head end and foot end jacks raise and lower at the same time

EN 10 SK 6300 Rev 01

Page 15

Litter raises and lowers from all locations

Litter components are in place and not damaged (fastener, holding pin, pin, bushing not backing out, loose, worn out,

or damaged)

Trendelenburg/Reverse Trendelenburg operates from all locations

Check skins for cracks

Hook and loop fastener is in place, intact, and secure

Fowler raises, lowers, and latches in place

Fowler subsystem (handle, wire, base weldment, cylinder, fasteners, etc. ) are not damaged

Hydraulic jacks are holding

No interference between wire and mechanical components on the Fowler backrest

No leaks at hydraulic connections

Lubricate where required

Push handles are not loose or damaged

Body restraints latch and are secure (optional)

IV pole is intact, is not damaged, and adjusts and latches in all positions (optional)

Oxygen bottle holder is intact and opens and closes (optional)

No rips or cracks in the mattress cover

Accessories and mounting hardware are in good condition

Product serial number:

Completed by:

Date:

SK 6300 Rev 01 11 EN

Page 16

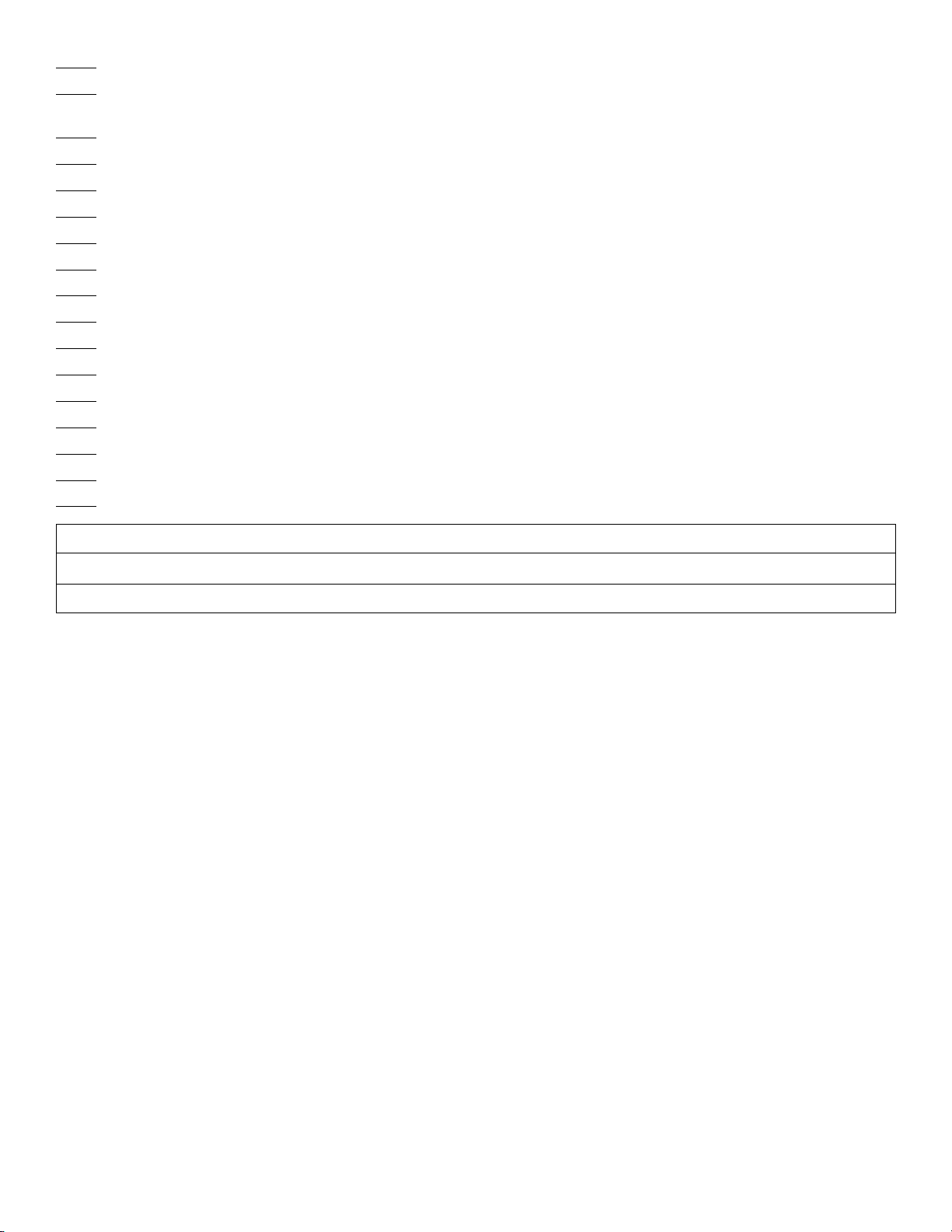

RReettrraaccttaabbllee ffiifftthh wwhheeeell lluubbrriiccaattiioonn

A

B

Tools required:

• MPG-3 grease

• Bungee cords

To lubricate the retractable fifth wheel:

1. Raise the product to the highest position.

FFiigguurree 44 –– RReettrraaccttaabbllee ffiifftthh wwhheeeell lluubbrriiccaattiioonn

2. Raise the base hood and support the hood with bungee cords.

3. Apply MPG-3 grease to the spring (A) and roller (B) (Figure 4).

4. Remove the bungee cords and lower the hood.

5. Verify proper operation before you return the product to service.

EN 12 SK 6300 Rev 01

Page 17

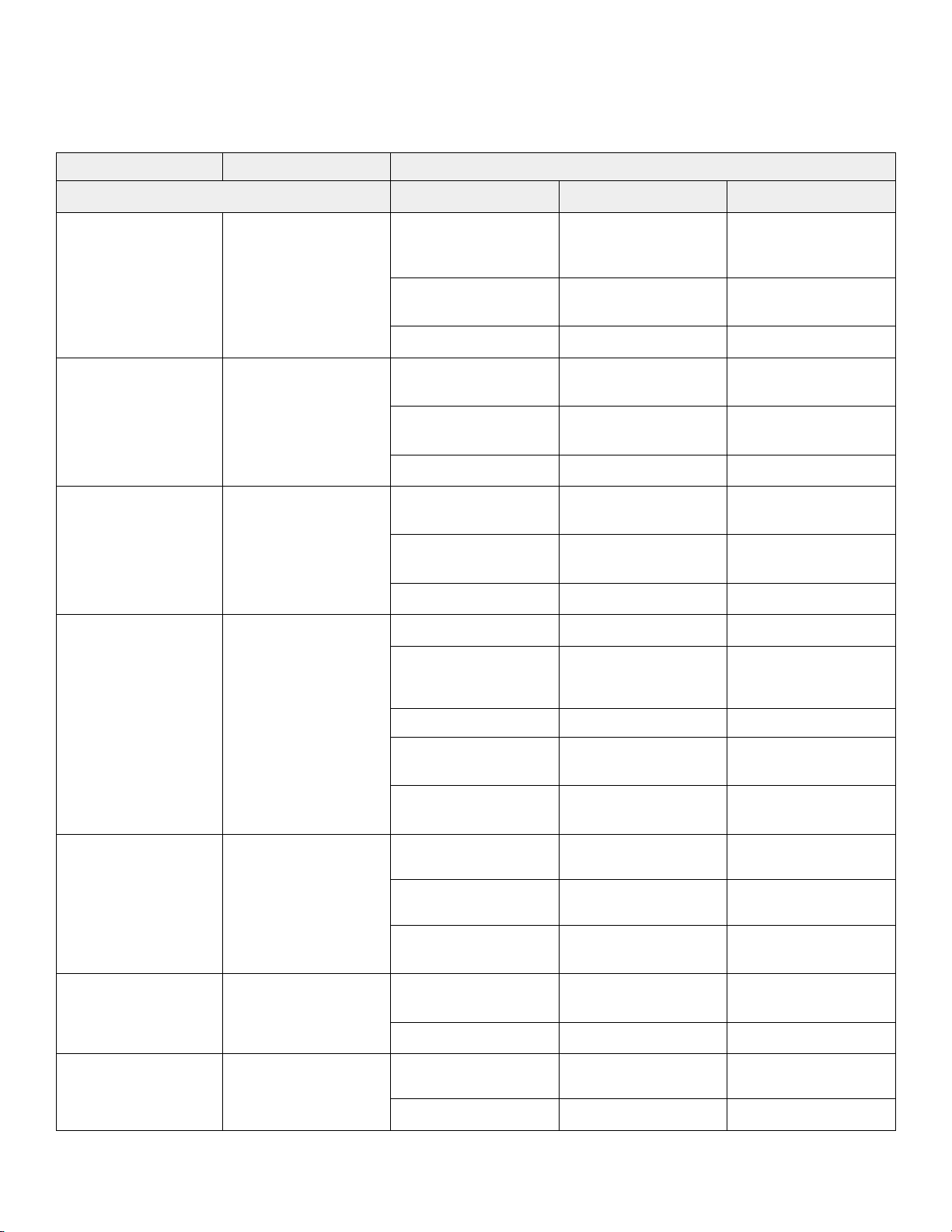

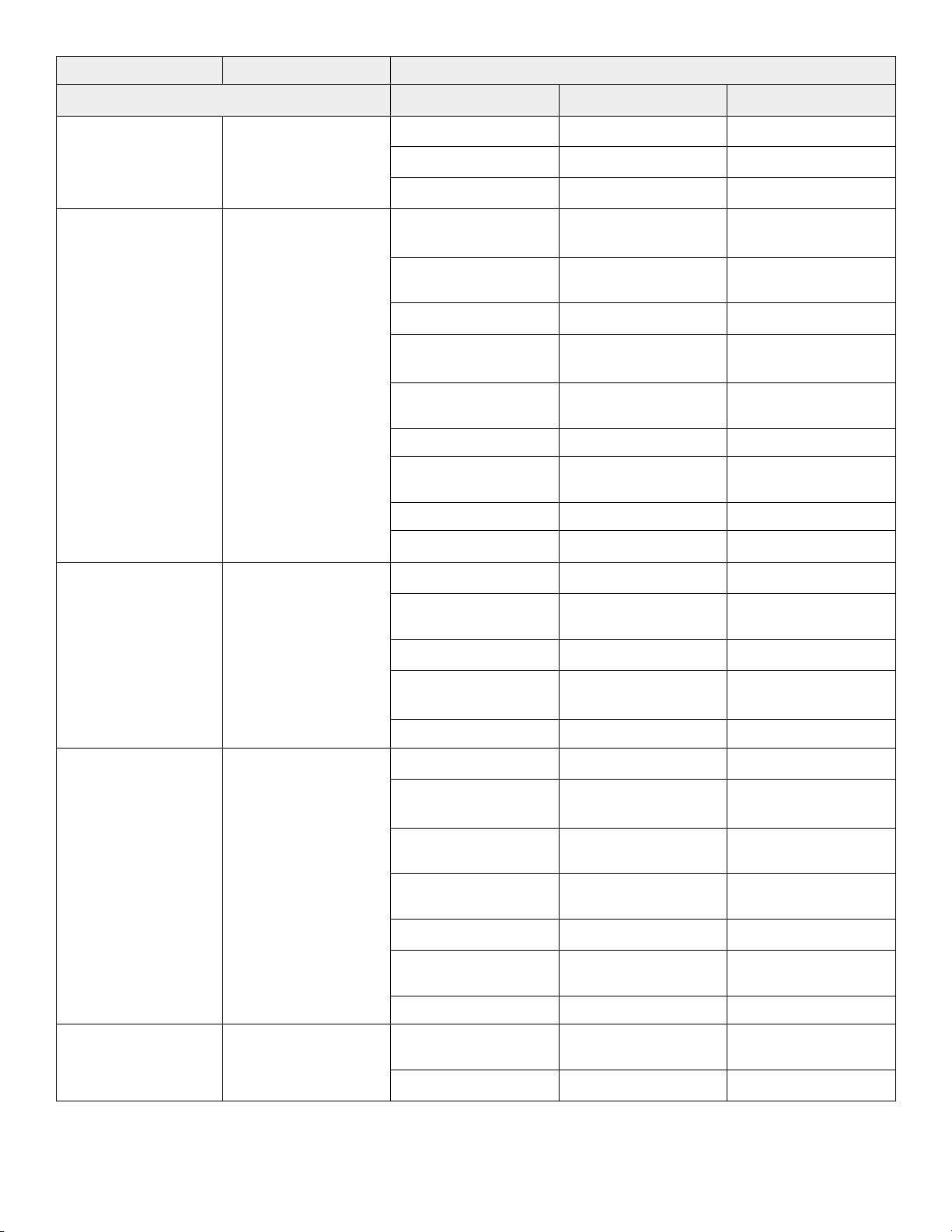

QQuuiicckk rreeffeerreennccee rreeppllaacceemmeenntt ppaarrttss

These parts are currently available for purchase. Call Stryker Customer Service: + 90 (352) 321 43 00 (pbx) for availability

and pricing.

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

Fifth wheel

replacement kit

Low mech, foot end

replacement kit

Low mech, head end

replacement kit

Caster replacement

kit

NNuummbbeerr NNaammee

YM-KIT-100095 HM-05-057 M8 x 25 hexagon

head flange adhesive

applied bolt

HM-07-06 M8 large washer -

special

YM-660-123 Fifth wheel assembly 1

YM-KIT-100096 YM-660-201 Low mech foot side

wire assembly

HM-16-122 Ø20 x 46 x 2 mm

spring

HM-11-33 Ø6 rue clip 2

YM-KIT-100097 YM-660-203 Low mech backrest

side wire assembly

HM-16-122 Ø20 x 46 x 2 mm

spring

HM-11-33 Ø6 rue clip 2

YM-KIT-100098 YM-660-045 Caster fixing part 2

HM-01-68 2046 UAX 200 R36-

32S35 D RAL9003 4 x

M6 Grauweiss wheel

QQuuaannttiittyy

3

1

1

2

1

2

1

Lowering pedal

replacement kit

Pump pedal

replacement kit

Brake-steer pedal

replacement kit

HM-08-06 M8 Fibered nut 1

HM-06-001 M6 x 25 mushroom

head square neck bolt

HM-12-905 Flanged bronze

bushing

YM-KIT-100099 HM-12-019 Ø5,15 x Ø10 x 3,5

washer

HM-09-27 Ø5 x 18 dome head

rivet

HM-02-245 Short uni-pedal, cool

grey

YM-KIT-100100 HM-02-240 Pump pedal plastic,

cool grey

HM-12-009 Groove pin 1

YM-KIT-100101 HM-12-097 Ø6 drilled pin flange

head

HM-11-33 Ø6 rue clip 1

1

1

2

2

1

1

1

SK 6300 Rev 01 13 EN

Page 18

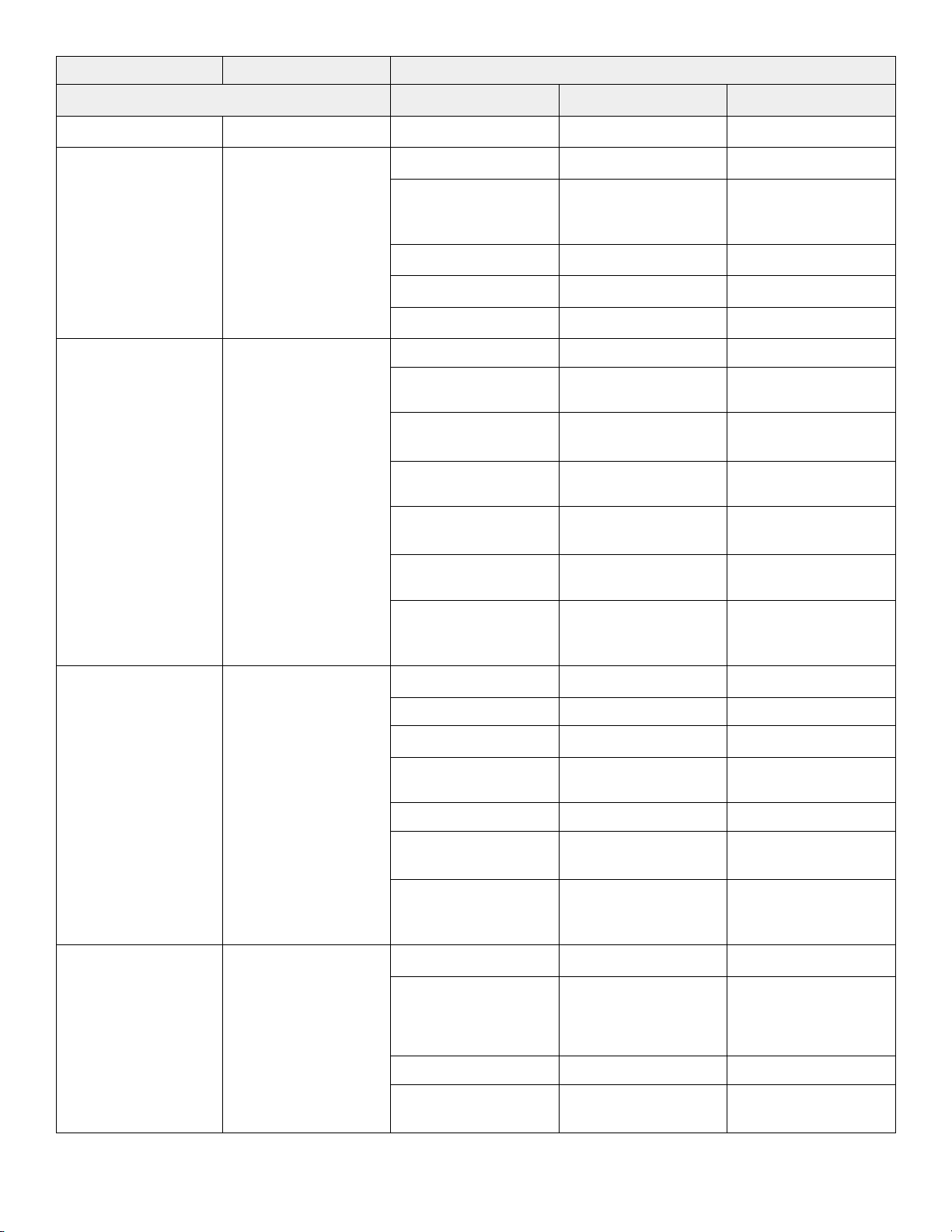

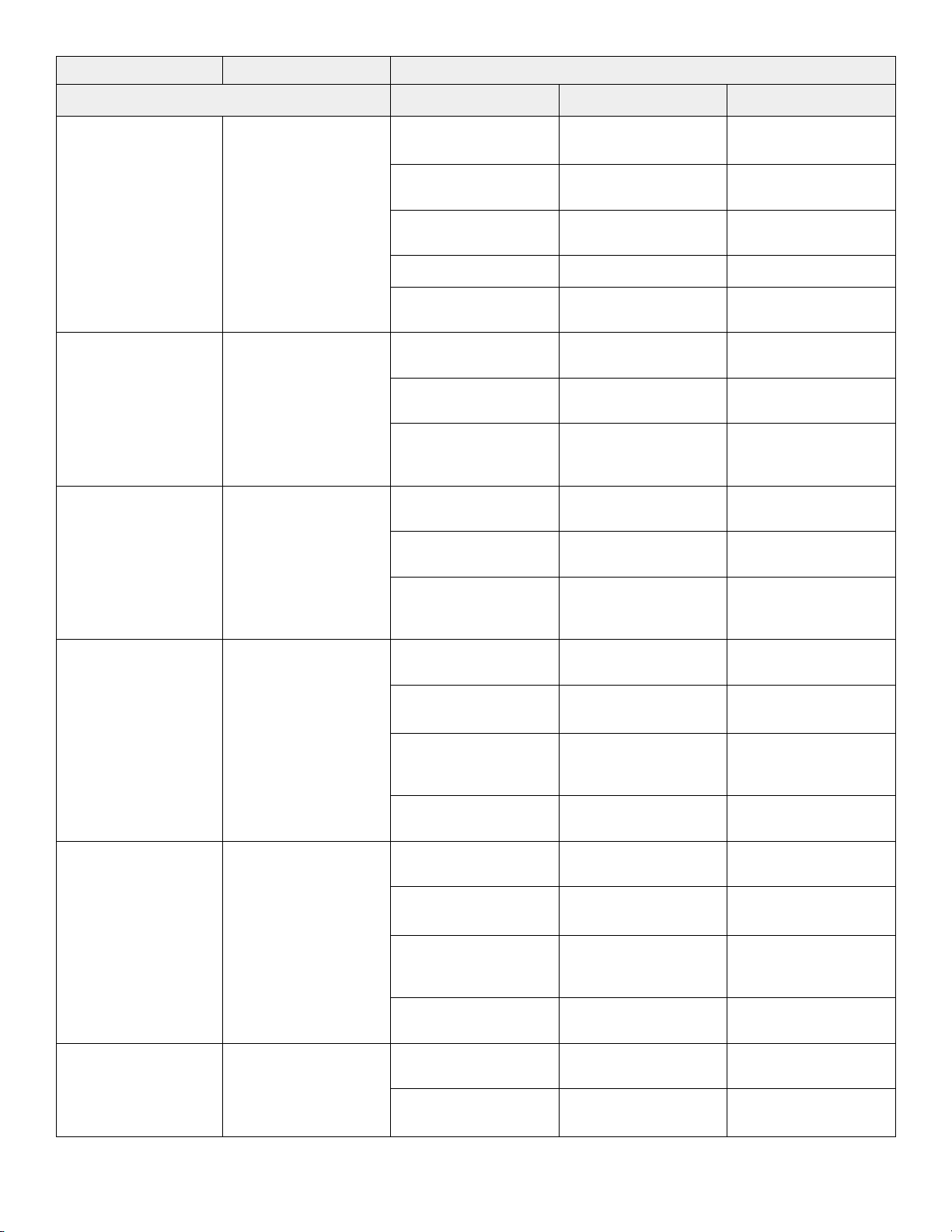

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

Brake-steer mech

replacement kit

Base hood

replacement kit

NNuummbbeerr NNaammee

HM-02-246 Butterfly ‘V’ pedal 1

YM-KIT-100102 YM-660-320 Brake rod assembly 1

HM-05-057 M8 x 25 hexagon

head flange adhesive

applied bolt

YM-660-195 Brake rod crank cap 3

HM-11-33 Ø6 rue clip 3

HM-12-027 Ø6 x 26 clevis pin 3

YM-KIT-100103 HM-02-247 Base hood ST1-X 1

YM-660-249 Base hood dual lock

25 mm

YM-660-257 Base hood support

single notched

YM-660-248 Base hood support

double notched

YM-660-251 SGS branded dual

sided EVA tape

QQuuaannttiittyy

6

8

2

2

4

HM-02-138 Flush head plastic

rivet

HM-05-057 M8 x 25 hexagon

head flange adhesive

applied bolt

Pump replacement kit YM-KIT-100104 HM-18-06 Jack assembly 1

HM-05-043 M5*20 imbus bolt 2

YM-660-086 Release rod bearing 1

HM-05-114 M6 x 30 hexagon

socket head screw

HM-08-05 M6 fibered nut 4

HM-07-22 M6 steel washer

(small)

HM-05-057 M8 x 25 hexagon

head flange adhesive

applied bolt

Anti-static caster

YM-KIT-100105 YM-660-046 Caster fixing part 2

replacement kit

HM-01-69 2046 XSX 200 R36-

32S35 D RAL9003 4 x

M6 Grauweiss

antistatic wheel

3

2

4

8

4

1

HM-08-06 M8 fibered nut 1

HM-06-001 M6 x 25 mushroom

1

head square neck bolt

EN 14 SK 6300 Rev 01

Page 19

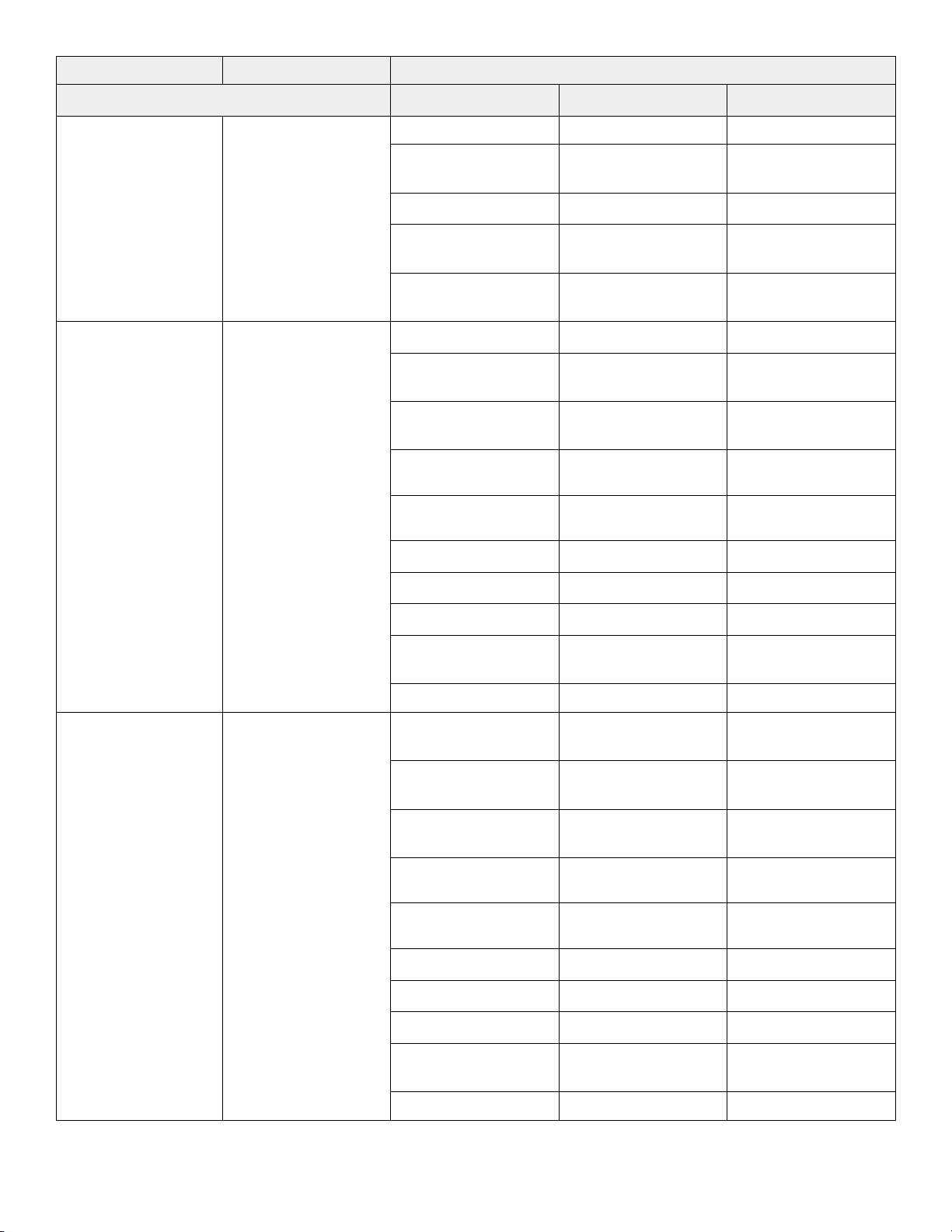

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

Left siderail assembly

replacement kit

NNuummbbeerr NNaammee

HM-08-05 M6 fibered nut 1

HM-12-905 Flanged bronze

bushing

YM-660-127 Caster fixing part 1

HM-07-06 M8 large washer -

special

HM-07-22 M6 steel washer

(small)

YM-KIT-100106 YM-500-006 Left spindle assembly 5

YM-500-007 Left latch spindle

assembly

HM-09-34 Ø6,6 x 32 tubular

component

HM-09-35 5 x 12 aluminum blind

rivet

HM-05-002 M8 x 30 torx head

machine screw

QQuuaannttiittyy

1

1

1

1

6

6

6

Right siderail

assembly

replacement kit

HM-12-033 Spindle bearing 6

HM-02-257 Left toprail 1

HM-02-253 Spindle plug 6

HM-07-22 M6 steel washer

(small)

HM-08-05 M6 fibered nut 2

YM-KIT-100107 YM-500-010 Right spindle

assembly

YM-500-009 Right latch spindle

assembly

HM-09-34 Ø6,6 x 32 tubular

component

HM-09-35 5 x 12 aluminum blind

rivet

HM-05-002 M8 x 30 torx head

machine screw

HM-12-033 Spindle bearing 6

HM-02-258 Right toprail 1

4

5

1

6

6

6

HM-02-253 Spindle plug 6

HM-07-22 M6 steel washer

4

(small)

HM-08-05 M6 fibered nut 2

SK 6300 Rev 01 15 EN

Page 20

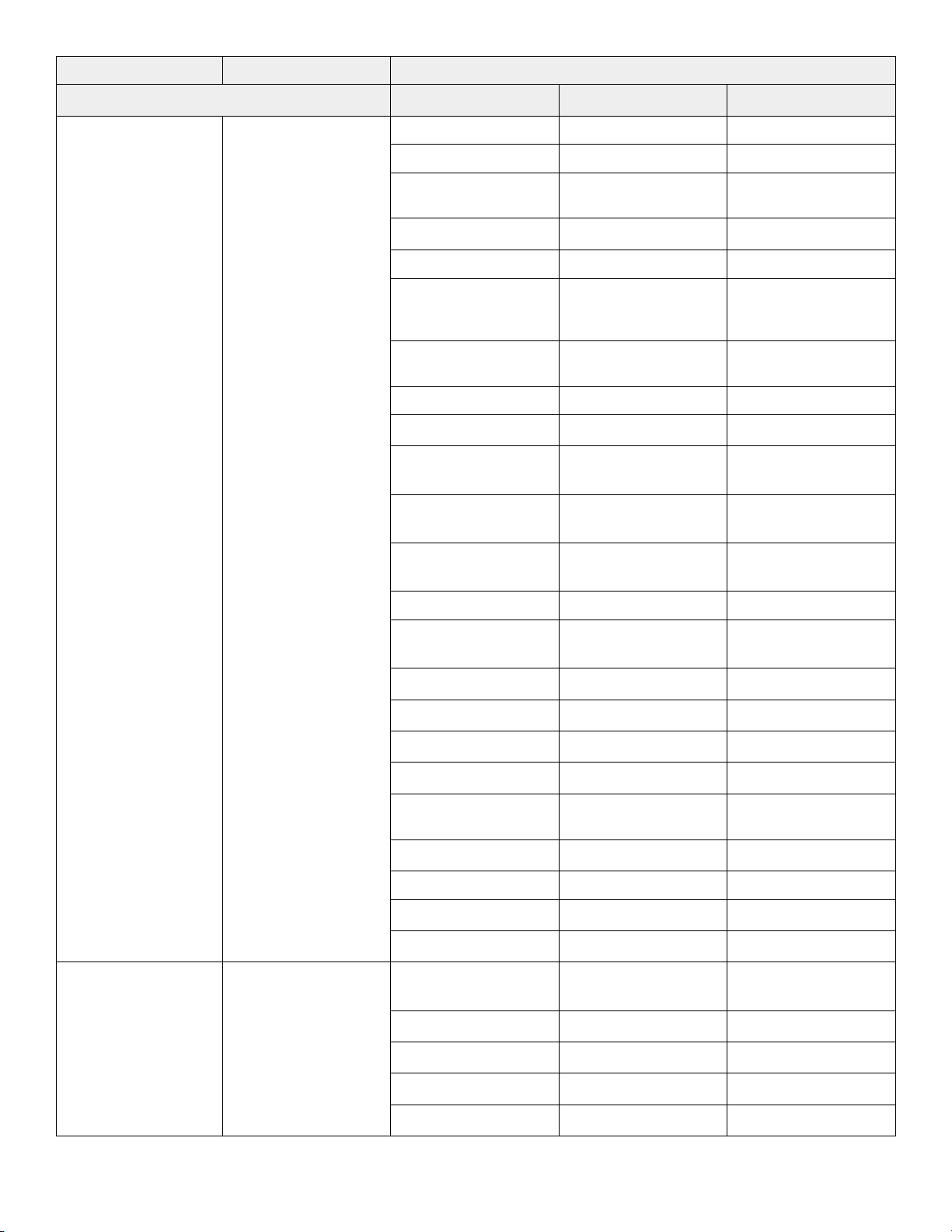

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

Fowler assembly

replacement kit

NNuummbbeerr NNaammee

YM-KIT-100108 YM-500-060-BY Fowler weldment 1

HM-02-255 Fowler release handle 2

YM-500-041 Fowler laminated

sheet

HM-12-035 Handle pivot bushing 4

HM-02-259 Inner cable roller 2

HM-09-33 6 x 20 steel large

flange open end pop

rivet

HM-09-35 5 x 12 aluminum blind

rivet

HM-02-260 Outer cable roller 2

HM-02-263 Recessed bumper 2

YM-HM-02-436 Laminated sheet

spacer handle

HM-09-34 Ø6,6 x 32 tubular

component

QQuuaannttiittyy

1

4

6

2

4

Fowler cylinder

replacement kit

HM-16-125 Fowler cable

assembly

YM-HM-02-438 7 x 10 x 4 washer 4

YM-HM-02-268 10,4 x 16 x 10,7

spacer

HM-12-040 Ø6 x 52 clevis pin 1

HM-11-33 Ø6 rue clip 1

HM-18-07 Cylinder - 420 N 1

HM-19-106 Gas spring trip 1

HM-05-002 M8 x 30 torx head

machine screw

HM-12-036 Pivot bushing 2

HM-08-09 M8 hex nut 4

HM-11-35 Ø8 rue clip 1

HM-12-039 Ø8 x 70 clevis pin 1

YM-KIT-100109 YM-HM-02–268 10,4 x 16 x 10,7

spacer

1

2

2

2

HM-12-040 Ø6 x 52 clevis pin 1

HM-11-33 Ø6 rue clip 1

HM-18-07 Cylinder - 420 N 1

HM-19-106 Gas spring trip 1

EN 16 SK 6300 Rev 01

Page 21

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

Foot end assembly

replacement kit

NNuummbbeerr NNaammee

HM-12-041 6,6 x 10 x 33 sleeve 1

HM-11-35 Ø8 rue clip 1

HM-12-039 Ø8 x 70 clevis pin 1

YM-KIT-100110 YM-500-062-BY Foot end weldment

assembly

YM-500-056 Footrest laminated

sheet

HM-02-263 Recessed bumper 2

HM-09-34 Ø6,6 x 32 tubular

component

HM-09-35 5 x 12 aluminum blind

rivet

YM-HM-02-438 7 x 10 x 4 washer 6

HM-05-002 M8 x 30 torx head

machine screw

HM-08-09 M8 hex nut 4

HM-12-036 Pivot bushing 2

QQuuaannttiittyy

1

1

6

8

2

Fowler tray

replacement kit

Foot end tray

replacement kit

YM-KIT-100111 YM-HM-02-434 Fowler tray 1

HM-20-1026 Right Fowler tray

label

HM-20-1027 Left Fowler tray label 1

HM-20-1028 Middle Fowler-foot

end tray label

HM-12-046 Hood latch 4

YM-KIT-100112 YM-HM-02-435 Foot end tray 1

HM-20-1028 Middle Fowler-foot

end tray label

HM-20-1029 Right foot end tray

label

HM-20-1030 Right foot end tray

short label

HM-20-1031 Left foot end tray label 1

HM-20-1032 Left foot end tray

short label

HM-12-046 Hood latch 4

1

1

1

1

1

1

Tray label

replacement kit

YM-KIT-100113 HM-20-1026 Right Fowler tray

label

1

HM-20-1027 Left Fowler tray label 1

SK 6300 Rev 01 17 EN

Page 22

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

NNuummbbeerr NNaammee

HM-20-1028 Middle Fowler-foot

end tray label

HM-20-1029 Right foot end tray

label

HM-20-1030 Right foot end tray

short label

HM-20-1031 Left foot end tray label 1

HM-20-1032 Left foot end tray

short label

Bumper A cover kit YM-KIT-100114 YM-501-039 Bumper A upper

cover

YM-501-025 Bumper A bottom

cover

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

Bumper B cover kit YM-KIT-100115 YM-501-024 Bumper B bottom

cover

YM-501-040 Bumper B upper

cover

QQuuaannttiittyy

2

1

1

1

1

1

3

1

1

Bumper A cover kit,

push handle

Bumper B cover kit,

push handle

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

YM-KIT-100116 YM-501-025 Bumper A bottom

cover

YM-501-043 Bumper A upper

cover, push handle

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

HM-05-002 M8 x 30 torx head

machine screw

YM-KIT-100117 YM-501-024 Bumper B bottom

cover

YM-501-044 Bumper B upper

cover, push handle

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

HM-05-002 M8 x 30 torx head

machine screw

3

1

1

3

1

1

1

3

1

Bumper A cover kit,

IV pole

YM-KIT-100118 YM-501-025 Bumper A bottom

cover

YM-501-041 Bumper A upper

1

1

cover, IV pole

EN 18 SK 6300 Rev 01

Page 23

KKiitt nnaammee NNuummbbeerr KKiitt ccoonntteennttss

Bumper B cover kit,

IV pole

Bumper A cover kit,

IV pole/push handle

NNuummbbeerr NNaammee

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

HM-05-002 M8 x 30 torx head

machine screw

YM-KIT-100119 YM-501-024 Bumper B bottom

cover

YM-501-042 Bumper B upper

cover, IV pole

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

HM-05-002 M8 x 30 torx head

machine screw

YM-KIT-100120 YM-501-025 Bumper A bottom

cover

YM-501-023 Bumper A upper

cover, IV pole/push

handle

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

QQuuaannttiittyy

3

2

1

1

3

2

1

1

3

Bumper B cover kit,

IV pole/push handle

HM-05-002 M8 x 30 torx head

machine screw

YM-KIT-100121 YM-501-024 Bumper B bottom

cover

YM-501-022 Bumper B upper

cover, IV pole/push

handle

HM-05-060 4,8*25 Torx pan head

tapping screw ANSI

B18.6.4

HM-05-002 M8 x 30 torx head

machine screw

3

1

1

3

3

SK 6300 Rev 01 19 EN

Page 24

SSeerrvviiccee

C

C

C

B

A

RRaaiissiinngg tthhee hhoooodd

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

• Bungee cords

PPrroocceedduurree::

1. Apply the brake. Push on the product to make sure that the brake is working.

2. Raise the product to the highest position.

3. Raise both siderails to the up and latched position.

4. Use a #2 Phillips screwdriver to remove the flush head plastic rivet (C) that secure the base hood (A) to the hood

retainer (Figure 5).

FFiigguurree 55 –– RRaaiissiinngg tthhee hhoooodd

5. Use bungee cords to raise and secure the base hood to the litter frame.

RReeppllaacciinngg tthhee hhoooodd

TToooollss rreeqquuiirreedd::

• #2 Phillips screwdriver

PPrroocceedduurree::

1. Remove the litter, see

2. Apply the brake. Push on the product to make sure that the brake is working.

EN 20 SK 6300 Rev 01

Litter top removal

(page 29).

Page 25

3. Raise the product to the highest position.

K

A

J

B

E

Torque item L to

15-18 Nm

Torque item D to

8-10 Nm

C

D

F

G

H

I

K

AP

L

4. Raise both siderails to the up and latched position.

5. Use a #2 Phillips screwdriver to remove the flush head plastic rivet (C) that secure the base hood (A) to the hood

retainer (Figure 5).

6. Remove and save the bellows (B), and discard the base hood (A) (Figure 5).

7. Reverse steps to reinstall.

8. Verify proper operation before you return the product to service.

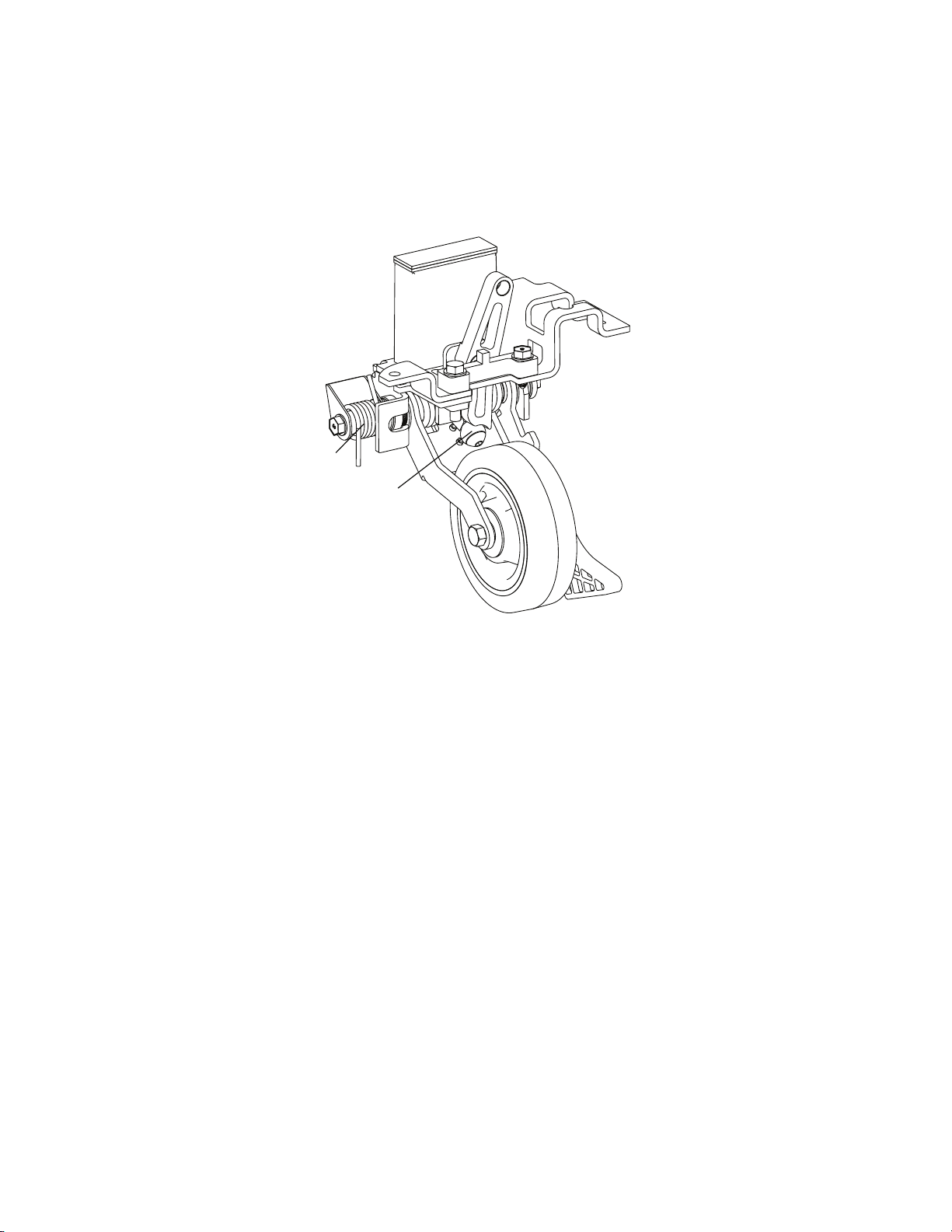

CCaasstteerr aasssseemmbbllyy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 10 mm socket wrench

• 13 mm socket wrench

• 3/8” drive ratchet

• 3/8” drive extension

• 3/8” drive torque wrench (Nm)

• Small jack

PPrroocceedduurree::

1. Raise the base hood, see

2. Put the brake/steer pedal in the neutral position.

3. Use a 13 mm socket wrench with a 3/8” drive ratchet to remove the M8 nut (L) (Figure 6).

Raising the hood

(page 20).

4. Use a 10 mm socket wrench with a 3/8” drive ratchet to remove the M6 nut (D).

SK 6300 Rev 01 21 EN

FFiigguurree 66 –– CCaasstteerr aasssseemmbbllyy rreeppllaacceemmeenntt

Page 26

5. Remove and save the caster lock link part weldment (C), washers (E, AP), caster fixing part (J), bearing (K), and

A

M

N

bushing (F).

6. Apply the brake. Push on the product to make sure that the brake is working.

7. Use a small jack to raise the product until the caster (H, I) falls out of the frame socket.

8. Position the supplied caster in the frame and lower the jack until the caster is in the base frame.

NNoottee -- Make sure that the read arrow on the top of the caster assembly points toward the foot end of the product.

9. Reverse steps to reinstall.

NNoottee -- Make sure to use a 3/8” drive torque wrench (Nm) to torque the M8 nut (L) to 15-18 Nm and the M6 nut (D) to 810 NM.

10.Verify proper operation before you return the product to service.

BBrraakkee rroodd rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 13 mm socket wrench

• 13 mm wrench

• 3/8” drive ratchet

• 3/8” drive torque wrench (Nm)

• Needle nose pliers

PPrroocceedduurree::

1. Raise the base hood, see

Raising the hood

(page 20).

2. Use needle nose pliers to remove and save the rue ring cotter (M) and clevis pin (N) that secure the brake link assembly

to the brake activation crank (Figure 7).

FFiigguurree 77 –– BBrraakkee rroodd rreeppllaacceemmeenntt

3. Remove and save the brake rod crank caps (R) (Figure 8).

EN 22 SK 6300 Rev 01

Page 27

Q

R

R

AO

A

Torque item Q to

15-18 Nm

FFiigguurree 88 –– BBrraakkee rroodd rreeppllaacceemmeenntt

PO

A

Torque item P to

15-18 Nm

4. Use a 13 mm wrench, 13 mm socket wrench, and a 3/8” drive ratchet to remove and save the hex head screw (P), hex

nut, and cam bearing (O) that secure the fifth wheel drive link assembly to the brake rod assembly (Figure 9).

NNoottee -- When you reinstall the hex head screw (P) make sure that you use a 3/8” drive torque wrench (Nm) to torque the

screw to 15-18 Nm.

FFiigguurree 99 –– BBrraakkee rroodd rreeppllaacceemmeenntt

5. Use a 13 mm socket wrench and a 3/8” drive ratchet to remove the five hex head bolts (Q) that secure the brake rod

supports to the brake rod assembly (Figure 8).

NNoottee -- When you reinstall the hex head bolts (Q) make sure that you use a 3/8” drive torque wrench (Nm) to torque the

bolts to 15–18 Nm.

6. Reverse steps to reinstall.

7. Verify proper operation before you return the product to service.

FFiifftthh wwhheeeell aasssseemmbbllyy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 13 mm socket wrench

• 13 mm wrench

• 3/8” drive ratchet

• 3/8” drive torque wrench (Nm)

• Needle nose pliers

PPrroocceedduurree::

1. Raise the base hood, see

Raising the hood

2. Use a 13 mm wrench, 13 mm socket wrench, and 3/8” drive ratchet to remove and save the hex head screw (P), hex nut

(page 20).

(T), and cam bearing (O) that secure the fifth wheel drive link assembly to the brake rod assembly (Figure 10).

SK 6300 Rev 01 23 EN

Page 28

NNoottee -- When you reinstall the hex head screw (P) make sure that you use a 3/8” drive torque wrench (Nm) to torque the

Q

O

AP

S

A

P

T

Torque item P to

15-18 Nm

screw to 15-18 Nm.

FFiigguurree 1100 –– FFiifftthh wwhheeeell aasssseemmbbllyy rreeppllaacceemmeenntt

3. Use a 13 mm socket wrench and 3/8” drive ratchet to remove and save the three hex head bolts (Q) and washer (AP)

that secure the fifth wheel assembly (S) to the base frame Figure 10.

4. Use needle nose pliers to remove the pump pedal return spring from the fifth wheel bracket.

5. Use needle nose pliers to remove the rue ring cotter that secures the foot end jack release rod to the release pedal

weldment.

6. Remove the foot end jack release rod.

7. Work from the patient left side to rotate the fifth wheel assembly counterclockwise. Lift the fifth wheel assembly up and

out.

8. Reverse steps to reinstall.

9. Verify proper operation before you return the product to service.

JJaacckk rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 13 mm socket wrench

• 13 mm wrench

• 3/8” drive ratchet

• 3/8” drive extension

• 3/8” drive torque wrench (Nm)

EN 24 SK 6300 Rev 01

Page 29

• 5 mm hex key

A

E

AR

AQ

D

E

Q

AD

Torque item Q to

15-18 Nm

Torque item AF to

8-10 Nm

AE

AF

• #2 Phillips screwdriver

PPrroocceedduurree::

1. Apply the brake. Push on the product to make sure that the brake is working.

2. Remove the litter from the product, see

3. Remove the base hood, see

Replacing the hood

Litter top removal

(page 20).

(page 29).

4. Use a 13 mm socket wrench with a 3/8” drive extension and a 3/8” drive ratchet to remove and save the two hex head

bolts (Q) that hold the jack to the base frame and remove the reservoir clamp (AE) (Figure 11).

NNoottee -- When you reinstall the hex head bolts (Q) make sure that you use a 3/8” drive torque wrench (Nm) to torque the

bolts to 15-18 Nm.

5. Lift up on the pump connecting rod and disconnect the pump piston from the connecting rod.

6. Disconnect the release pedal swivel from the pins on the release pedal weldment.

7. Remove the head end release rod from the release valve on the jack assembly.

8. Use a 10 mm socket wrench with a 3/8” drive extension and a 3/8” drive ratchet to remove and save the four M6 hex

9. Remove the jack assembly (AD) (Figure 11).

SK 6300 Rev 01 25 EN

FFiigguurree 1111 –– JJaacckk rreeppllaacceemmeenntt

nuts (D) while you hold the socket head screws (AF) from below with a 5 mm hex key (Figure 11).

NNoottee -- When you reinstall the jack assembly (AD), make sure that you install but do not tighten the hex head bolts (Q)

and reservoir clamp (AE) removed in step 4.

Page 30

10.Reinstall the pump connecting rod and release rod (removed in steps 5 and 7).

NNoottee -- The jack descent rate is set at the factory. Do not adjust the rate.

11.Press the pump pedal to the floor to position the jack on the base frame.

12.Use a 3/8” drive torque wrench to reinstall the hex head bolts (Q) to 15-18 Nm to secure the reservoir clamp (AE) to the

jack assembly (AD) (Figure 11).

13.Use a 3/8” drive torque wrench to reinstall the M6 hex nuts (D) (removed in step 8) to 8-10 Nm to secure the jack

assembly (AD) to the base frame (A) (Figure 11).

14.Reinstall the base hood, see

15.Reinstall the litter top, see

16.Raise the litter to the highest position. Apply weight to the litter to make sure that the jacks hold and do not drift.

17.Verify proper operation before you return the product to service.

Replacing the hood

Litter top removal

(page 20).

(page 29).

RReemmoovvee eexxcceessss aaiirr ffrroomm tthhee hhyyddrraauulliicc ssyysstteemm

TToooollss rreeqquuiirreedd::

• None

PPrroocceedduurree::

1. Raise the product to the highest position.

2. Push down on the pump pedal several times to force the air through the system.

3. Verify proper operation before you return the product to service.

PPuummpp ppeeddaall rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 13 mm socket wrench

• 3/8” drive ratchet

• 3/8” drive extension

• 3/8” drive torque wrench (Nm)

• Needle nose pliers

PPrroocceedduurree::

1. Raise the base hood, see

2. Use a 13 mm socket wrench with a 3/8” drive extension and a 3/8” drive ratchet to remove the hex head bolts (Q) that

secure the pump pedal link (AA) to the pump pedal (W) (Figure 12).

NNoottee -- When you reinstall the hex head bolts (Q) make sure that you use a 3/8” drive torque wrench (Nm) to torque the

screw to 15-18 Nm.

Raising the hood

(page 20).

EN 26 SK 6300 Rev 01

Page 31

AA

Y

U

X

A

V

V

W

Z

AB

AC

Q

FFiigguurree 1122 –– PPuummpp ppeeddaall rreeppllaacceemmeenntt

3. Use needle nose pliers to remove the hair pin cotter (X) from the pivot pin (Y).

4. Use needle nose pliers to remove the pump pedal return spring.

5. Remove and save the pivot pin (Y) from the base frame (A).

NNoottee -- The pump pedal assembly (W) will be loose and may fall when you remove the pivot pin (Y).

6. Remove the pump pedal assembly (W).

7. Reverse steps to reinstall.

8. Verify proper operation before you return the product to service.

RReelleeaassee ppeeddaall aaddjjuussttmmeenntt

TToooollss rreeqquuiirreedd::

• Needle nose pliers

PPrroocceedduurree::

1. Raise the base hood, see

2. Use needle nose pliers to remove the rue clips (M) from the release pedal assembly (AH) (Figure 13).

Raising the hood

(page 20).

SK 6300 Rev 01 27 EN

Page 32

Q

AH

AL

AK

A

Q

AJ

Q

AJ

W

U

AG

AG

AK

M

M

AL

AH

AQ

AQ

FFiigguurree 1133 –– RReelleeaassee ppeeddaall aaddjjuussttmmeenntt

3. Remove the clevis joint from the release pedal assembly (AH).

4. To increase the descent rate, increase the amount of the release rod (AK) thread in the clevis joint.

5. To decrease the descent rate, decrease the amount of the release rod (AK) thread in the clevis joint.

6. Reverse steps to reinstall.

7. Verify proper operation before you return the product to service.

NNoottee -- If you thread the clevis joint too far on the release rod (AK), it will trigger the release valve and the jack will drift.

RReelleeaassee ppeeddaall rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• 13 mm socket wrench

• 3/8” drive ratchet

• 3/8” drive extension

• Needle nose pliers

PPrroocceedduurree::

1. Raise the base hood, see

Raising the hood

(page 20).

EN 28 SK 6300 Rev 01

Page 33

2. Use needle nose pliers to remove the rue clips (M) and disconnect the release rods (AK, AL) from the release pedal

A

A

Torque item A to 15-18 Nm

assembly (AH) (Figure 13).

3. Use a 13 mm socket wrench with a 3/8” drive extension and a 3/8” drive ratchet to remove the hex head bolts (Q) that

secure the release pedal assembly (AH).

4. Reverse steps to reinstall.

5. Verify proper operation before you return the product to service.

LLiitttteerr ttoopp rreemmoovvaall

TToooollss rreeqquuiirreedd::

• 13 mm socket wrench

• 3/8” drive ratchet

• 3/8” drive extension

• 3/8” drive torque wrench (Nm)

• M8 hex head bolt

PPrroocceedduurree::

1. Apply the brake. Push on the product to make sure that the brake is working.

2. Raise the product to the highest position.

3. Raise the Fowler backrest.

4. At the head end and foot end of the product use a 13 mm socket wrench with a 3/8” drive extension and a 3/8” drive

ratchet to remove the two hex head bolts (A) that secure the jack support tubes to the jack shafts (Figure 14).

NNoottee -- When you reinstall the hex head bolts (A) make sure that you use a 3/8” drive torque wrench (Nm) to torque the

bolts to 15-18 Nm.

5. Insert an M8 hex head bolt into the top of the jack supports to separate the litter top from the jack shaft.

SK 6300 Rev 01 29 EN

FFiigguurree 1144 –– LLiitttteerr ttoopp rreemmoovvaall

Page 34

6. Lift the litter off of the jack shafts and set the litter aside.

AA

B

Torque item A

to 15-18 Nm

NNoottee -- Litter top removal requires two people.

7. Reverse steps to reinstall.

8. Verify proper operation before you return the product to service.

SSiiddeerraaiill llaattcchh rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T40 Torx driver

PPrroocceedduurree::

1. Apply the brake. Push on the product to make sure that the brake is working.

2. Raise the product to the highest position.

3. Use a T40 Torx driver to remove and discard the two torx head machine screws (A) that hold the siderail latch (B) to the

litter frame and remove the latch (Figure 15).

NNoottee -- When you install the torx head machine screws (A) make sure that you use a T40 Torx driver to torque the

screws to 15-18 Nm.

FFiigguurree 1155 –– SSiiddeerraaiill llaattcchh rreeppllaacceemmeenntt

4. Reverse steps to install.

5. Verify proper operation before you return the product to service.

XX--rraayy ccaasssseettttee ppaanneell rreeppllaacceemmeenntt -- hheeaadd eenndd,, SSTT11--XX ooppttiioonn

TToooollss rreeqquuiirreedd::

• None

PPrroocceedduurree::

1. Remove the mattress from the litter surface and set aside.

EN 30 SK 6300 Rev 01

Page 35

2. Raise the product to the highest position.

A

A A

AA

3. Raise the Fowler backrest to the highest position.

4. Raise both siderails to the up and latched position.

5. From below the litter frame, use your hand to unclip the four spring clips (A) that secure the head end X-ray cassette

panel to the litter frame (Figure 16).

6. Remove the head end X-ray cassette panel.

7. Reverse steps to reinstall.

NNoottee -- The head end panel and the foot end panel are interlocked.

8. Verify proper operation before you return the product to service.

XX--rraayy ccaasssseettttee ppaanneell rreeppllaacceemmeenntt -- ffoooott eenndd,, SSTT11--XX ooppttiioonn

TToooollss rreeqquuiirreedd::

• None

PPrroocceedduurree::

1. Remove the mattress from the litter surface and set aside.

2. Raise the product to the highest position.

3. Raise the Fowler backrest in the flat position (0 degrees).

4. Fold the foot section toward the Fowler backrest until the foot litter section rests on the Fowler backrest

5. Raise both siderails to the up and latched position.

6. From below the litter frame, use your hand to unclip the four spring clips (A) that secure the foot end X-ray cassette

panel to the litter frame (Figure 17).

FFiigguurree 1166 –– XX--rraayy ccaasssseettttee ppaanneell rreeppllaacceemmeenntt -- hheeaadd eenndd

SK 6300 Rev 01 31 EN

Page 36

A

A

A

A

A

A

FFiigguurree 1177 –– XX--rraayy ccaasssseettttee ppaanneell rreeppllaacceemmeenntt -- ffoooott eenndd

7. Remove the foot end X-ray cassette panel.

8. Reverse steps to reinstall.

NNoottee -- The head end panel and the foot end panel are interlocked.

9. Verify proper operation before you return the product to service.

FFoowwlleerr ggaass ccyylliinnddeerr rreeppllaacceemmeenntt,, SSTT11--XX ooppttiioonn

TToooollss rreeqquuiirreedd::

• 17 mm combination wrench

• Needle nose pliers

PPrroocceedduurree::

1. Remove the mattress and set aside.

2. Raise the product to the highest position.

3. Raise the Fowler backrest to about 30 degrees.

4. Fold the foot section toward the Fowler backrest until the foot section rests on the Fowler backrest.

5. Raise both siderails to the up and latched position.

6. From below the litter frame, use your hand to unclip the four spring clips (A) that secure the foot skin to the foot frame.

7. Lower the siderails to the lowest position.

8. Use needle nose pliers to remove the rue ring cotter (B) and clevis pin (C) that secure the cylinder (D) to the Fowler

backrest frame (Figure 18).

EN 32 SK 6300 Rev 01

Page 37

C

G

A

A

A

A

A

G

C

E

Torque item G

to 8-10 Nm

FFiigguurree 1188 –– FFoowwlleerr ggaass ccyylliinnddeerr rreeppllaacceemmeenntt

9. Raise the end of the cylinder (D) and remove the spacers (E) and the sleeve (F).

10.Use a 17 mm combination wrench to loosen the jam nut from the gas spring trip (G) and unthread the cylinder (D) from

the gas spring trip (G).

11.Discard the Fowler backrest cylinder.

12.Thread the supplied cylinder (D) into the gas spring trip (G) until the cylinder starts to release (extend). Turn the cylinder

back one full turn (360 degrees).

NNoottee -- If the gas cylinder threads are not aligned with the gas spring trip threads, damage may occur to the gas cylinder

or gas spring trip. Do not force threading together.

13.Use a 17 mm combination wrench to torque the jam nut to 8-10 Nm against the gas spring trip (G)

NNoottee -- Make sure that the gas cylinder shaft does not turn when you tighten the nut. If the cylinder turns, readjust the

Fowler backrest gas cylinder as instructed in step 10.

14.Reverse steps 1-9 to reinstall.

15.Verify proper operation before you return the product to service.

SK 6300 Rev 01 33 EN

Page 38

BBaassee aasssseemmbbllyy

A

M

N

K

A

J

B

E

Torque item L to

15-18 Nm

Torque item D to

8-10 Nm

C

D

F

G

H

I

K

AP

L

YM-600-000 (Reference only)

EN 34 SK 6300 Rev 01

Page 39

PO

A

Torque item P to

15-18 Nm

Q

R

R

AO

A

Torque item Q to

15-18 Nm

Q

O

AP

S

A

P

T

Torque item P to

15-18 Nm

SK 6300 Rev 01 35 EN

Page 40

AA

Y

U

X

A

Torque item Q to

15-18 Nm

V

V

W

Z

AB

AC

Q

A

E

AR

AS

D

E

Q

AD

Torque item Q to

15-18 Nm

Torque item AF to

8-10 Nm

AE

AF

EN 36 SK 6300 Rev 01

Page 41

U

AG

V

V

Q

AC

AB

AA

Z

W

AG

A

Q

AH

AL

AK

A

Q

AJ

Q

AJ

W

U

AG

AG

AK

M

M

AL

AH

Torque item Q to

8-10 Nm

Torque item Q to

15-18 Nm

AQ

AQ

SK 6300 Rev 01 37 EN

Page 42

AM

AM

A

AN

AN

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-660-047 Base weldment 1

B YM-660-160 Caster link weldment 2

C YM-660-116 Caster lock link part weldment 4

D HM-08-05 M6 fibered nut 12

E HM-07-22 M6 steel washer (small) 20

F HM-12-905 Flanged bronze bushing 4

G HM-06-001 M6 x 25 mushroom head square neck

bolt

H HM-01-69 2046XSXX200R36-32S35 D RAL9003

I HM-01-68 2046UAX200R36-32S35 D RAL9003

4XM6 signalwhite antistatic

4

1

3

4XM6 signalwhite

J YM-660-127 Caster fixing part 4

K YM-660-046 Caster fixing part 8

L HM-08-06 M8 fibered nut 4

M HM-11-33 Ø6 rue clip 4

N HM-12-027 Ø6 x 26 clevis pin 2

O HM-12-023 Cam bearing 1

P HM-05-015 M8 x 30 mm hexagonal head screw 1

Q HM-05-057 M8 x 25 hexagon head flange adhesive

applied bolt

12

R YM-660-195 Brake rod crank cap 2

S YM-660-123 Fifth wheel assembly (

assembly - YM-660-123

Fifth wheel

(page 41))

1

T HM-08-06 M8 self-lock hex nut 1

U YM-660-094 Pump connecting tube weldment 1

V YM-660-191 Pump ram plug 2

EN 38 SK 6300 Rev 01

Page 43

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

W YM-660-037 Pump pedal assembly (

assembly - YM-660-037

X HM-16-118 Cotter pin 1

Y HM-12-025 Pivot pin 1

Z YM-660-105 Ø16,3 x Ø31 x 2,5 mm washer 2

AA YM-660-083 Lifting pedal link arm 1

AB HM-12-026 Pump pedal bushing 4

AC YM-660-082 Ø8 laser washer 2

AD HM-18-06 Jack assembly 2

AE YM-660-092 Reservoir clamp 2

AF HM-05-114 M6 x 30 mm socket head cap bolt 8

AG HM-16-121 Return spring 2

AH YM-660-315 Lowering pedal assembly (

pedal assembly - YM-660-315

43))

AJ YM-660-040 Release rod bracket 2

AK YM-660-201 Low mech. footside wire assembly

(release rod)

AL YM-660-203 Low mech. backrest side wire assembly

(release rod)

AM YM-660-204 Hood support 2

AN HM-06-02 Bolt curved head screwdriver star

channel (Ø3.9 x 12)

AO YM-660-320 Brake rod assembly (

assembly - YM-660-320

AP HM-07-06 M8 large washer 5

AQ HM-16-122 Ø20 x 46 x 2 mm spring 2

AR HM-05-043 M5 x 20 mm hex socket cap screw 4

AS YM-660-086 Release rod bearing 2

Pump pedal

(page 44))

Lowering

Brake rod

(page 40))

1

1

(page

1

1

4

1

SK 6300 Rev 01 39 EN

Page 44

BBrraakkee rroodd aasssseemmbbllyy -- YYMM--666600--332200

G

IJK

L

D

C

F

B

C

D

A

F

H

E

D

C

D

C

B

F

D

C

I

J

G

L

K

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-660-322 Extension RH/rod brake tube 1

B HM-12-031 Brake activation crank 2

C HM-12-032 Brake rod support 5

D YM-660-098 Brake rod nyliner 5

E YM-660-064 Fifth wheel cam drive link 2

F HM-10-17 6 x 30 slotted spring pin 5

G HM-12-097 Ø6 drilled flange head pin 2

H HM-12-017 Brake rod drive link 1

I HM-20-425 Label, brake 2

J HM-20-425 Label, steer 2

K HM-02-246 Butterfly “V” pedal 2

L HM-11-33 Ø6 rue clip 2

EN 40 SK 6300 Rev 01

Page 45

FFiifftthh wwhheeeell aasssseemmbbllyy -- YYMM--666600--112233

AC

AD

AD

I

Y

S

T

U

AA

A

M

C

AB

J

Y

M

D

H

F

J

Y

W

X

Z

E

N

O

AE

L

E

B

R

Q

P

V

G

K

Torque item R to

15-18 Nm

Torque item Y to

15-18 Nm

Torque item AC to

8-10 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-660-325 Fifth wheel frame weldment 1

B YM-660-342 Fifth wheel holder part bracket 1

C YM-660-068 Drive shaft bearing (long) 1

D YM-660-165 Drive shaft bearing (short) 1

E YM-660-072 Ø25,4 x Ø31,75 x 1,5 mm 2

F YM-660-343 Return spring hook 1

G YM-660-074 Spring spacer 1

H YM-660-176 Ø16,3 x Ø25 x 2 washer 1

I YM-660-183 Fifth wheel support bracket 1

J HM-07-06 M8 large washer 2

K HM-16-119 Torsion spring 1

L HM-16-120 Torsion spring 1

M HM-12-014 Bearing race 2

N HM-02-242 Dampener 1

O HM-02-241 Bumper mounting pin 1

P HM-02-243 Fifth wheel ramp 1

Q HM-08-14 Nylon hex nut, 3/8” - 16 1

R HM-05-056 3/8” - 16 x 3” hex head cap screw 1

S HM-12-028 Fifth wheel cam 1

T HM-12-013 Cam bearing 1

SK 6300 Rev 01 41 EN

Page 46

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

U HM-12-030 Cam pivot block 1

V HM-01-67 Wheel 1

W HM-12-029 Drive pin 1

X HM-12-016 Roller 1

Y HM-05-057 M8 x 25 hexagon head flange adhesive

4

applied bolt

Z HM-05-055 Roller stem 1

AA HM-11-16 10 mm E clip DIN 6799 1

AB HM-12-015 Drive shaft 1

AC HM-05-022 M6 x 12 mm socket head cap screw DIN

2

912

AD HM-07-22 M6 steel washer (small) 2

AE HM-09-27 Ø5 x 18 dome head rivet 2

EN 42 SK 6300 Rev 01

Page 47

LLoowweerriinngg ppeeddaall aasssseemmbbllyy -- YYMM--666600--331155

D

C

E

A

A

E

A

A

E

A

A

C

D

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-12-019 Ø5,15 x Ø10 x 3,5 washer 6

B YM-660-316 Release pedal weldment, black 2

C HM-02-244 Release pedal support 2

D HM-02-245 Short uni-pedal, cool grey 2

E HM-09-27 Ø4,8 pop rivet 6

SK 6300 Rev 01 43 EN

Page 48

PPuummpp ppeeddaall aasssseemmbbllyy -- YYMM--666600--003377

D

C

B

B

A

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-660-130 Pump pedal weldment 1

B HM-02-240 Plastic pump pedal, cool grey 2

C YM-660-172 CLR vinyl tube 1

D HM-12-009 Groove pin 2

EN 44 SK 6300 Rev 01

Page 49

LLiitttteerr ffrraammee aasssseemmbbllyy

E

G

D

A

B

C

A

F

G

A

K

J

H

Torque item A

to 15-18 Nm

Torque item G

to 15-18 Nm

Torque item H

to 8-10 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-05-002 M8 x 30 torx head machine screw 12

B YM-500-087 Trend block - slide 2

C YM-500-153 Bumper weldment assembly 2

D YM-500-127 Frame tie weldment 1

E YM-500-003 Right siderail assembly (

assembly - YM-500-003

F YM-500-002 Left siderail assembly (

assembly - YM-500-002

G HM-05-057 M8 x 25 hexagon head flange adhesive

applied bolt

H HM-05-011 M6 x 60 mm hex bolt 4

J HM-07-22 M6 steel washer (small) 8

K HM-08-05 M6 fibered nut 4

L YM-500-113 Flange bearing 2

Right siderail

(page 53))

Left siderail

(page 51))

1

1

4

SK 6300 Rev 01 45 EN

Page 50

LLiitttteerr mmaattttrreessss hhooookk

B

A

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-500-215 Mattress VVeellccrroo®® hook, 610 x 5 mm 1

B YM-500-214 Mattress VVeellccrroo®® hook, 225 x 5 mm 3

EN 46 SK 6300 Rev 01

Page 51

LLiitttteerr aasssseemmbbllyy,, SSTT11--XX ooppttiioonn

B

A

C

D

E

DETAIL

B

K

L

DETAIL

A

C

A

B

F

G

BB

J

J

J

SECTION B-B

DETAIL

C

M

N

P

N

R

Torque item A

to 15-18 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-05-002 M8 x 30 torx head machine screw 4

B HM-12-036 Pivot bushing 4

C HM-08-09 Hex nut 8

D YM-500-004 Fowler assembly 1

E YM-500-005 Foot end assembly 1

F YM-500-143 Footboard receptacle 4

G YM-500-002 Left siderail assembly 1

J HM-20-557 Ø15 cable tie 4

K HM-12-039 Ø8 x 70 clevis pin 1

L HM-11-35 Ø8 rue clip 1

M HM-12-040 Ø6 x 52 clevis pin 1

N YM-HM-02-268 10,4 x 16 x 10,7 spacer 2

SK 6300 Rev 01 47 EN

Page 52

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

P HM-12-041 Sleeve 1

R HM-11-33 Ø6 rue clip 1

S YM-500-003 Right siderail assembly 1

EN 48 SK 6300 Rev 01

Page 53

FFoowwlleerr aasssseemmbbllyy,, SSTT11--XX ooppttiioonn

A

C

B

D

E

F

G

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-500-004 Fowler assembly 1

B HM-18-07 Cylinder - 420 N 1

C HM-19-106 Gas spring trip 1

D HM-12-041 Sleeve 1

E YM-HM-02-268 10,4 x 16 x 10,7 spacer 2

F HM-12-040 Ø6 x 52 clevis pin 1

G HM-11-33 Ø6 rue clip 1

H HM-16-125 Fowler cable assembly 1

SK 6300 Rev 01 49 EN

Page 54

PPrrooffiillee ccaapp aanndd FFoowwlleerr gguuiiddee ppaarrtt aasssseemmbbllyy

AA

B

B

CC

Torque item B

to 15-18 Nm

Torque item C

to 15-18 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-HM-02-033 Profile cap 2

B YM-500-085 Fowler guide part 2

C HM-05-002 M8 x 30 torx head machine screw 2

EN 50 SK 6300 Rev 01

Page 55

LLeefftt ssiiddeerraaiill aasssseemmbbllyy -- YYMM--550000--000022

A

K

J

F

GG

C

H

E

B

D

A

Torque item A

to 8-10 Nm

Torque item A

to 15-18 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-05-002 M8 x 30 torx head machine screw 8

B HM-09-35 Blind rivet, 5 x 12 aluminum 6

C HM-09-34 Tubular component 6

D YM-500-008 Left siderail latch assembly (

latch assembly - YM-500-008

E HM-12-033 Spindle bearing 6

F YM-500-013 Left siderail extension tube 1

G HM-02-257 Left toprail 1

H HM-02-253 Spindle plug 6

Left siderail

(page 54))

1

SK 6300 Rev 01 51 EN

Page 56

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

J YM-500-006 Left spindle assembly (

assembly - YM-500-006

K YM-500-007 Left latch spindle assembly (

spindle assembly - YM-500-007

58))

Left spindle

(page 56))

Left latch

(page

5

1

EN 52 SK 6300 Rev 01

Page 57

RRiigghhtt ssiiddeerraaiill aasssseemmbbllyy -- YYMM--550000--000033

F

A

J

K

C

G

B

H

E

D

AA

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-05-002 M8 x 30 torx head machine screw 8

B HM-09-35 Blind rivet, 5 x 12 aluminum 6

siderail latch assembly - YM-500-012

(page 55))

assembly - YM-500-010

latch spindle assembly - YM-500-009

(page 59))

Right

Right spindle

(page 57))

Right

C HM-09-34 Tubular component 6

D YM-500-012 Right siderail latch assembly (

E HM-12-033 Spindle bearing 6

F YM-500-014 Right siderail extension tube 1

G HM-02-258 Right toprail 1

H HM-02-253 Spindle plug 6

J YM-500-010 Right spindle assembly (

K YM-500-009 Right latch spindle assembly (

1

5

1

SK 6300 Rev 01 53 EN

Page 58

LLeefftt ssiiddeerraaiill llaattcchh aasssseemmbbllyy -- YYMM--550000--000088

D

C

F

B

G

E

AA

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-09-36 Dome head pop rivet 2

B HM-19-114 Ø8 x 25 mm slotted spring pin 1

C HM-19-112 Ø9 x 22 x 0,9 compression wire 1

D HM-19-113 Plunger 1

E YM-HM-02-232 Left latch handle 1

F HM-19-109 Left latch mounting block 1

G HM-19-111 Latch plate 1

EN 54 SK 6300 Rev 01

Page 59

RRiigghhtt ssiiddeerraaiill llaattcchh aasssseemmbbllyy -- YYMM--550000--001122

AA

E

G

B

F

C

D

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-09-36 Dome head pop rivet 2

B HM-19-114 Ø8 x 25 mm slotted spring pin 1

C HM-19-112 Ø9 x 22 x 0,9 compression wire 1

D HM-19-113 Plunger 1

E YM-HM-02-233 Right latch handle 1

F HM-19-110 Right latch mounting block 1

G HM-19-111 Latch plate 1

SK 6300 Rev 01 55 EN

Page 60

LLeefftt ssppiinnddllee aasssseemmbbllyy -- YYMM--550000--000066

A

B

D

E

C

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-09-36 Dome head pop rivet 1

B YM-HM-02-432 Left spindle spacer 1

C HM-19-102 Left spindle 1

D HM-16-123 Left siderail spring 1

E YM-HM-02-431 Spindle pivot block 1

EN 56 SK 6300 Rev 01

Page 61

RRiigghhtt ssppiinnddllee aasssseemmbbllyy -- YYMM--550000--001100

A

B

D

E

C

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-09-36 Dome head pop rivet 1

B YM-HM-02-437 Right spindle spacer 1

C HM-19-103 Right spindle 1

D HM-16-124 Right siderail spring 1

E YM-HM-02-431 Spindle pivot block 1

SK 6300 Rev 01 57 EN

Page 62

LLeefftt llaattcchh ssppiinnddllee aasssseemmbbllyy -- YYMM--550000--000077

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-09-36 Dome head pop rivet 1

B YM-HM-02-432 Left spindle spacer 1

C YM-HM-02-433 Rubber stop 1

D HM-16-123 Left siderail spring 1

E HM-19-105 Left latch spindle 1

F YM-500-017 Pivot block/nut assembly 1

EN 58 SK 6300 Rev 01

Page 63

RRiigghhtt llaattcchh ssppiinnddllee aasssseemmbbllyy -- YYMM--550000--000099

A

B

E

F

C

D

C

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-09-36 Dome head pop rivet 1

B YM-HM-02-437 Right spindle spacer 1

C YM-HM-02-433 Rubber stop 1

D HM-19-104 Right latch spindle 1

E HM-16-124 Right siderail spring 1

F YM-500-017 Pivot block/nut assembly 1

SK 6300 Rev 01 59 EN

Page 64

CCoorrnneerr ccoovveerr aasssseemmbbllyy

Torque item A

to 15-18 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-05-002 M8 x 30 torx head machine screw 4

B HM-05-060 4.8*25 Torx pan head tapping screw

ANSI B18.6.4

C YM-500-143 Footboard receptacle 2

D YM-501-023 Upper bumper cover A with IV pole,

push handle

E YM-501-025 Bottom bumper cover A 1

F YM-501-022 Upper bumper cover B with IV pole,

push handle

G YM-501-024 Bottom bumper cover B 1

EN 60 SK 6300 Rev 01

6

1

1

Page 65

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

H YM-500-153 Bumper weldment assembly 1

J HM-05-057 M8 x 25 hexagon head flange adhesive

applied bolt

2

SK 6300 Rev 01 61 EN

Page 66

CCoovveerrss aasssseemmbbllyy,, nnoo ooppttiioonnss,, hheeaadd eenndd

B

A

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-501-039 Bumper A upper cover 1

B YM-501-040 Bumper B upper cover 1

EN 62 SK 6300 Rev 01

Page 67

CCoovveerrss aasssseemmbbllyy wwiitthh IIVV ppoollee aanndd ppoopp--uupp ppuusshh hhaannddlleess,, hheeaadd eenndd

A

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-501-023 Bumper A upper cover, IV pole, push

handle

B YM-501-022 Bumper B upper cover, IV pole, push

handle

1

1

SK 6300 Rev 01 63 EN

Page 68

DDeeffiibbrriillllaattoorr ttrraayy aasssseemmbbllyy

E

H

A

L

G

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A YM-500-182-BY Weldment assembly 1

B HM-12-044 Connection socket 2

C HM-12-1066 15 x 25 x 1,5 mm inner support tube 2

D HM-09-36 Dome head pop rivet 13

E MM058 Strap 1

F HM-02-270 Upper hood 1

G HM-20-082 Label 1

H YM-500-174-BY Hood tray 1

J YM-660-249 Base hood dual lock 25 mm 12

K YM-DSPLK-0001 Chartholder sheet 1

L HM-DOSYALIK-03-01 Chartholder hood 1

EN 64 SK 6300 Rev 01

Page 69

TTwwoo--ssttaaggee IIVV ppoollee aasssseemmbbllyy

C

F

D

G

H

E

G

B

Torque item G

to 15-18 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

B HM-09-36 Dome head pop rivet 1

C HM-19-108 Two stage IV pole assembly 1

D HM-12-043 Handle pivot pin 1

E HM-02-267 Magnetic IV pole support assembly 1

F HM-12-042 IV pole socket 1

G HM-05-002 M8 x 30 torx head machine screw 2

H YM-500-145 IV pole lock profile 1

SK 6300 Rev 01 65 EN

Page 70

PPuusshh hhaannddllee aasssseemmbbllyy,, hheeaadd eenndd

D

C

E

A

B

Torque item A

to 15-18 Nm

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A HM-05-002 M8 x 30 torx head machine screw 1

B HM-12-043 Handle pivot pin 1

C HM-09-36 Dome head pop rivet 1

D HM-12-042 IV pole socket 1

E HM-19-107 Push handle 1

EN 66 SK 6300 Rev 01

Page 71

MMaattttrreesssseess

1930

620

80

NNuummbbeerr NNaammee QQuuaannttiittyy

6300-0-100 ST1 basic mattress 8 cm 1

SK 6300 Rev 01 67 EN

Page 72

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

SK 6300 Rev 01

WCR:

2019/04

Loading...

Loading...