Page 1

Surgery Platform

Model 1034

Maintenance Manual

For Parts or Technical Assistance

800-327-0770

Page 2

INTRODUCTION

Introduction page 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications page 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning/Caution/Note Information page 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning and Caution Statements page 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty page 1-3, 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREVENTIVE MAINTENANCE

Preventive Maintenance Checklist page 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning page 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE PROCEDURES

Brake Adjustment page 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Cover Replacement page 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Hood Removal page 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Hydraulic Fluid Level page 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Assembly Removal and Replacement page 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constant Flow Jack Descent Rate Adjustment page 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustable P.C. Valve Replacement page 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Removal page 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Crank Assembly Removal page 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Tilt Assembly Removal page 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Box Removal page 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Gear Replacement page 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic Fowler Adjustment page 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Section Latch Adjustment page 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

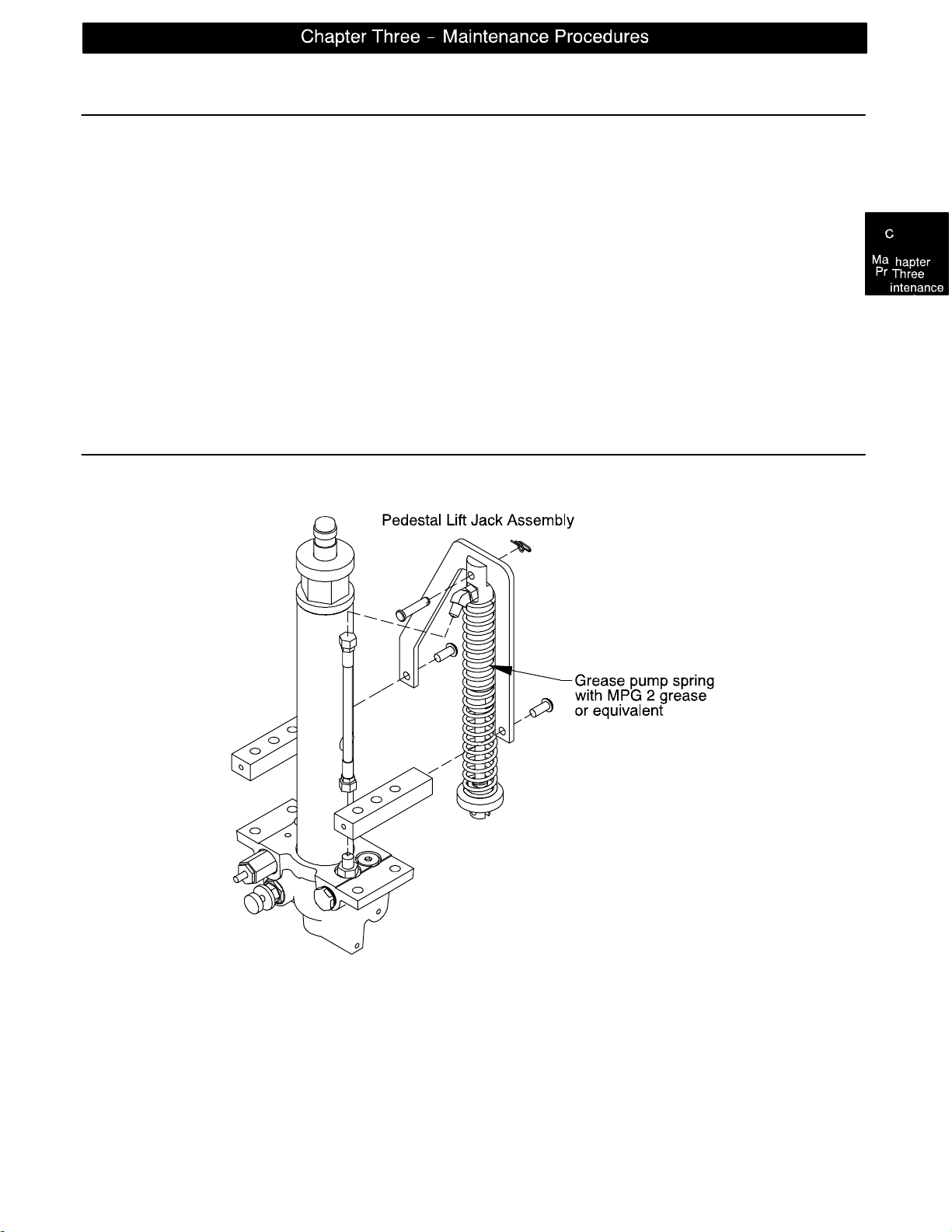

Lubrication Points page 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

QUICK REFERENCE REPLACEMENT PARTS LIST

Quick Reference Replacement Parts List page 4-1, 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

ASSEMBLY DRAWINGS AND PARTS LISTS

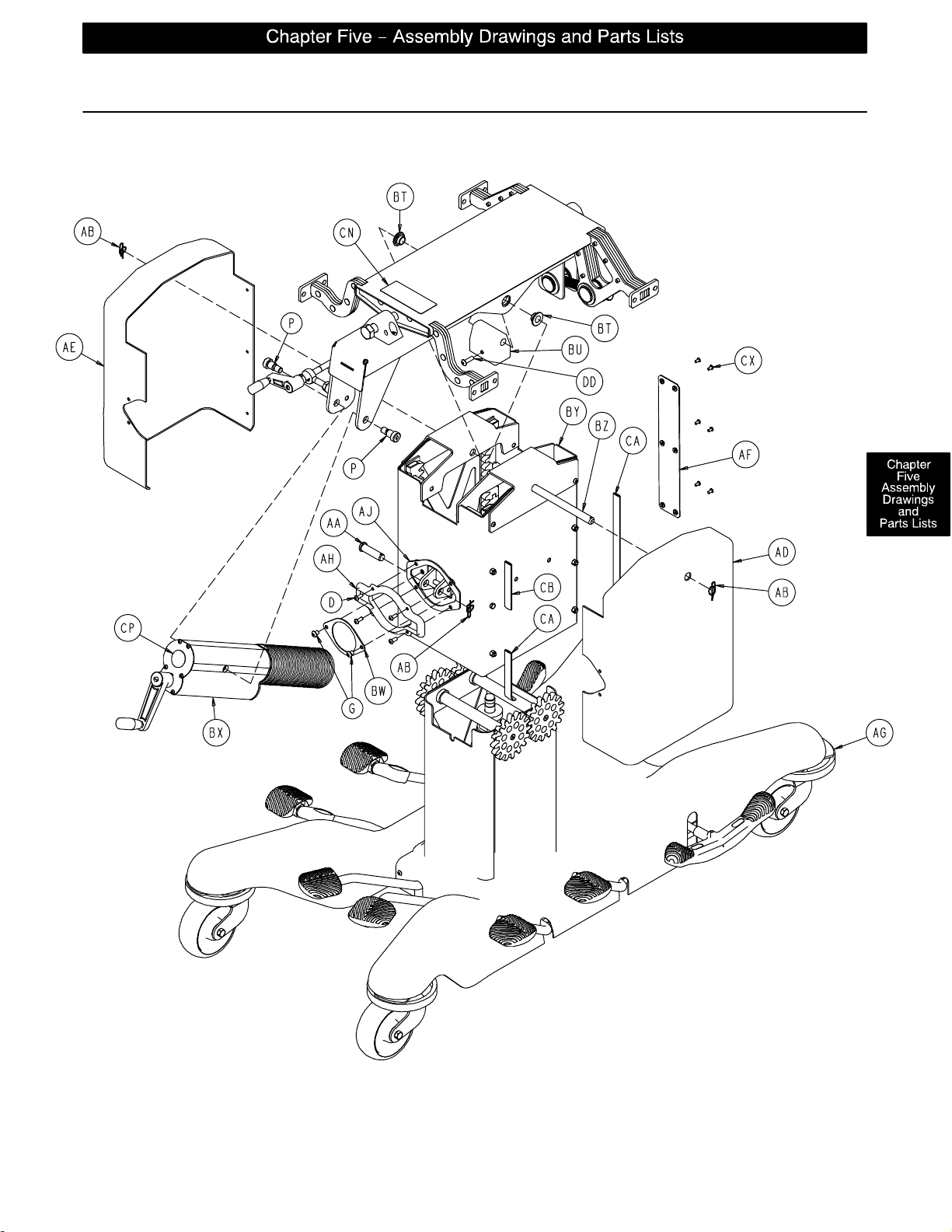

Trio Common Components page 5-3 - 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

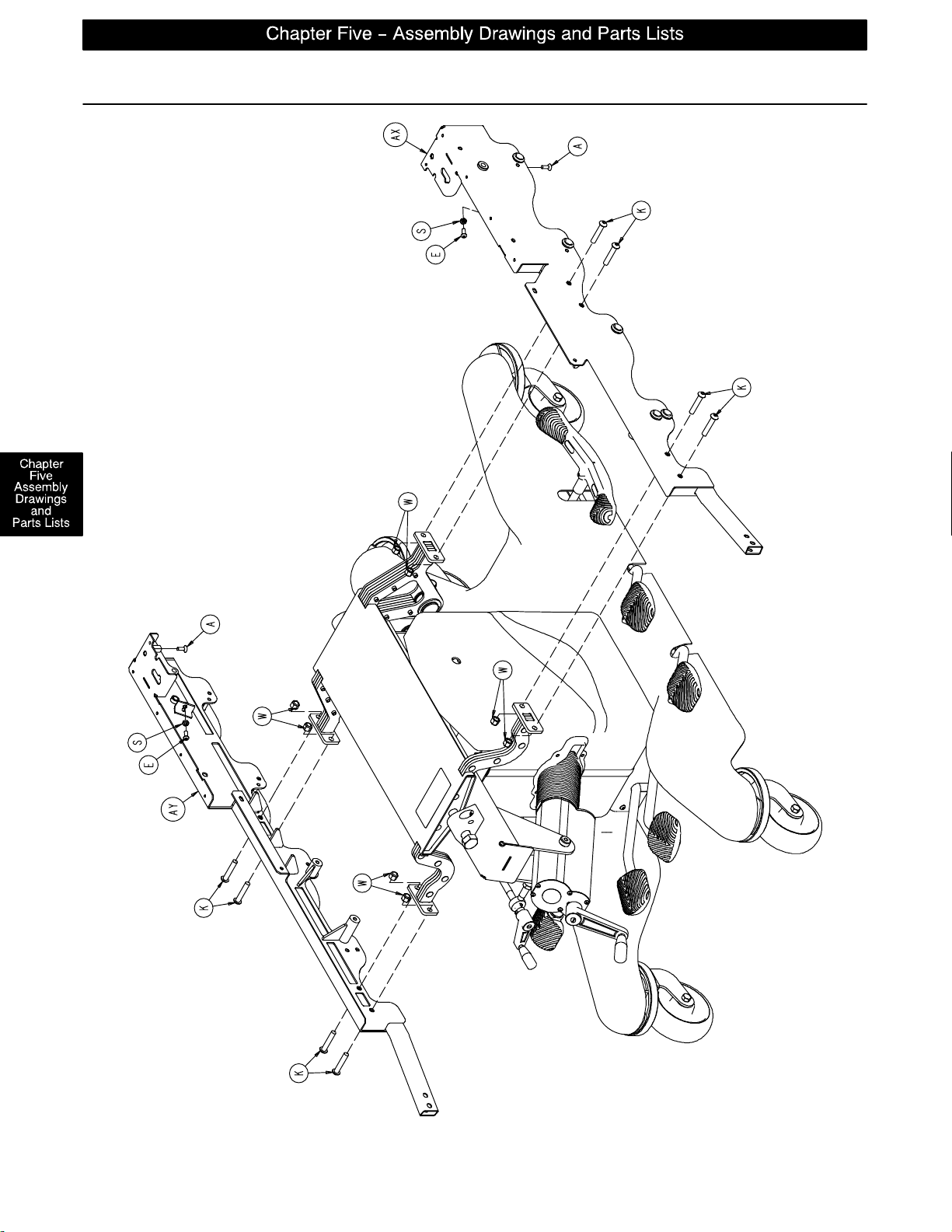

Base Assembly page 5-11 - 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Pan Assembly page 5-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedestal Lift Jack Assembly page 5-22 - 5-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedestal Lift Jack Pump Assembly page 5-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Assembly page 5-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Assembly page 5-27 - 5-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Section Receptacle Assembly page 5-30, 5-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Assembly page 5-32, 5-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Box Assembly page 5-34, 5-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Actuator Assembly page 5-36, 5-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Inner Screw Assembly page 5-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Tilt Assembly page 5-40, 5-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Tilt Hinge Gear Assembly page 5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Standard I.V. Pole Receptacles page 5-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Standard I.V. Pole Assembly page 5-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Heavy-Duty I.V. Pole Receptacles page 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Heavy-Duty I.V. Pole Assembly page 5-46, 5-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Oxygen Bottle Holder Assembly page 5-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Drape Support Assembly page 5-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Direct Clamp page 5-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Perineal Pad Assembly page 5-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Foot Board/Foot Extender Assembly page 5-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot/Fowler Option Assembly page 5-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Foot/Fowler Assembly page 5-54, 5-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Pre-Op/Post-Op Pad Assembly page 5-56, 5-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Head Piece Assembly page 5-58 - 5-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Foot End Siderail Assembly page 5-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Cysto Pan Assembly page 5-63 - 5-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattresses page 5-66, 5-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

INTRODUCTION

This manual is designed to assist you with the operation of the Model 1034 Solo Surgery Platform. Read it

thoroughly before using the equipment.

The Solo product is designed to be a stationary patient support surface for use in a hospital or outpatient surgery room. It is designed for patients up to 500 pounds. This patient support surface can be used in a variety

of positions: level, Trendelenburg, Reverse Trendelenburg, Fowler up, foot section down, foot section removed, lateral tilt or a combination of these positions.

SPECIFICATIONS

Maximum Weight Capacity 500 pounds

Patient Surface Length / Width 78”/27”

Overall Length / Width 80” / 30” (rails down) 33” (rails up)

Minimum / Maximum Height 26”/40”

Fowler Angle 1_ to 80_

Foot Section Angle 0_ to 50_

Trendelenburg / Reverse Trendelenburg +20_ to -15_

Lateral Tilt +15_ to -15_

Stryker reserves the right to change specifications without notice.

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

The personal safety of the patient or user may be involved. Disregarding this information could result in injury

to the patient or user.

CAUTION

These instructions point out special procedures or precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

1034 Surgery Platform 1034-009-002 REV A page 1-1

Page 5

Before operating this unit, it is important to read and understand all information in this manual. Carefully read

and strictly follow the warnings and cautions listed on this page.

WARNING

The decision to use the Solo patient support surface for an individual surgical patient must be made by a

healthcare professional. The use of the Solo product should be based on patients’ assessed medical needs.

Individual patient assessment and proper patient screening in selection of a surgical support surface is needed to mitigate patient safety issues. All traditional surgical protocols should be followed per AORN guidelines.

Injury could result if the table moves during procedures or examinations or while a patient is getting on or off

the table. Always engage the brakes and push on the table to ensure the brakes are securely locked.

Do not rest your feet on the cover of the surgery table base. Injury may occur, especially if the litter is lowered

while in a non-horizontal position.

To avoid injury, keep hands/fingers clear of area between the litter frame and the Fowler when lowering the

Fowler.

To avoid injury, keep hands/fingers clear of the area between the litter frame and the foot section when lowering the foot section.

Always hold the foot section when adjusting it. The foot section may rise too quickly and injury may result.

To avoid injury, always support the patient’s feet and legs when removing the foot section.

Do not sit on the foot section. Sitting on the foot section may result in a fall and injury. When the load on the

foot section exceeds 150 pounds, the foot section will lower to prevent the unit from tipping.

To avoid patient falls and injury, always use proper patient restraints when positioning the surgery table litter

in Trendelenburg or reverse Trendelenburg or in lateral tilt.

To avoid injury or damage to the equipment, do not allow the siderail to lower on its own.

To avoid patient injury or damage to the unit, remove equipment from the foot end accessory rail before chang-

ing the position of the foot section and from the Fowler accessory rail before changing the position of the Fowler.

To avoid patient injury or damage to the unit, remove I.V. poles from the foot end receptacles before lowering

the foot section.

Do not sit on the Foot End Back Rest. Excessive weight on the Foot End Back Rest could cause the unit

to tip, resulting in injury.

The weight of the patient’s head is resting on the head piece and must be supported by the operator when

the latches are released and the head piece is being positioned. Failure to adequately support the head piece

while positioning the head could result in patient injury.

To avoid possible pinch points when adjusting the head piece, keep your fingers away from the jointed areas.

Do not reach between the side of the head extension and the articulating head piece to pull the release handle.

Finger injury could result.

CAUTION

To avoid damage, move any equipment that may hinder motion before raising or lowering the table height

and positioning the table.

If the unit is positioned in reverse Trendelenburg with the foot section lowered, the foot section may contact

the floor. To avoid damaging the unit, raise the litter or raise the foot section to the flat position before positioning the unit in reverse Trendelenburg.

The weight of the I.V. bags should not exceed 40 pounds.

1034 Surgery Platform 1033-009-002 REV Apage 1-2

Page 6

Warranty

Limited Warranty:

Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser that its products

should be free from defects in material and workmanship for a period of one (1) year after date of delivery.

Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or

replacing, at its option, any product which is, in the sole discretion of Stryker, found to be defective. Stryker

warrants to the original purchaser that the frame and welds on its beds will be free from structural defects

for as long as the original purchaser owns the bed. If requested by Stryker, products or parts for which a

warranty claim is made shall be returned prepaid to Stryker’s factory. Any improper use or any alteration or

repair by others in such manner as in Stryker’s judgement affects the product materially and adversely shall

void this warranty. Any repair of Stryker products using parts not provided or authorized by Stryker shall void

this warranty. No employee or representative of Stryker is authorized to change this warranty in any way.

Stryker Medical stretchers are designed for a 10 year expected life under normal use conditions and appropriate periodic maintenance as described in the maintenance manual for each device.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. STRYKER

MAKES NO OTHER WARRANTY OR REPRESENTATION, EITHER EXPRESSED OR IMPLIED, EXCEPT

AS SET FORTH HEREIN. THERE IS NO WARRANTY OF MERCHANTABILITY AND THERE ARE NO

WARRANTIES OF FITNESS FOR ANY PARTICULAR PURPOSE. IN NO EVENT SHALL STRYKER BE

LIABLE HEREUNDER FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM OR IN ANY

MANNER RELATED TO SALES OR USE OF ANY SUCH EQUIPMENT.

To Obtain Parts and Service:

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives.

These representatives are factory trained, available locally, and carry a substantial spare parts inventory to

minimize repair time. Simply call your local representative, or call Stryker Customer Service at (800)

327-0770.

Service Contract Coverage:

Stryker has developed a comprehensive program of service contract options designed to keep your equipment operating at peak performance at the same time it eliminates unexpected costs. We recommend that

these programs be activated before the expiration of the new product warranty to eliminate the potential of

additional equipment upgrade charges.

A SERVICE CONTRACT HELPS TO:

S Ensure equipment reliability

S Stabilize maintenance budgets

S Diminish downtime

S Establish documentation for JCAHO

S Increase product life

S Enhance trade-in value

S Address risk management and safety

1034 Surgery Platform 1034-009-002 REV A page 1-3

Page 7

Warranty

Stryker offers the following service contract programs:

SPECIFICATIONS GOLD SILVER PM* ONLY

Annually scheduled preventative maintenance X X

All parts,** labor, and travel X X

Unlimited emergency service calls X X

Priority one contact; two hour phone response X X X

Most repairs will be completed within 3 business days X X

JCAHO documentation X X X

On-site log book w/ preventative maintenance & emergency service records X

Factory-trained Stryker Service Technicians X X X

Stryker authorized parts X X X

End of year summary X

Stryker will perform all service during regular business hours (9-5) X X X

* Replacement parts and labor for products under PM contract will be discounted.

** Does not include any disposable items, I.V. poles (except for Stryker HD permanent poles), mattresses, or damage re-

sulting from abuse.

Stryker Medical also offers personalized service contracts.

Pricing is determined by age, location, model and condition of product.

For more information on our service contracts,

please call your local representative or call (800) 327-0770 (option #2).

Return Authorization:

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An authorization number will be provided which must be printed on the returned merchandise. Stryker reserves the

right to charge shipping and restocking fees on returned items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

Damaged Merchandise:

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifteen

(15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE

IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT. Upon prompt notification, Stryker

will file a freight claim with the appropriate carrier for damages incurred. Claim will be limited in amount to

the actual replacement cost. In the event that this information is not received by Stryker within the fifteen

(15) day period following the delivery of the merchandise, or the damage was not noted on the delivery receipt

at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

International Warranty Clause:

This warranty reflects U.S. domestic policy. W arranty outside the U.S. may vary by country. Please contact

your local Stryker Medical representative for additional information.

1034 Surgery Platform 1033-009-002 REV Apage 1-4

Page 8

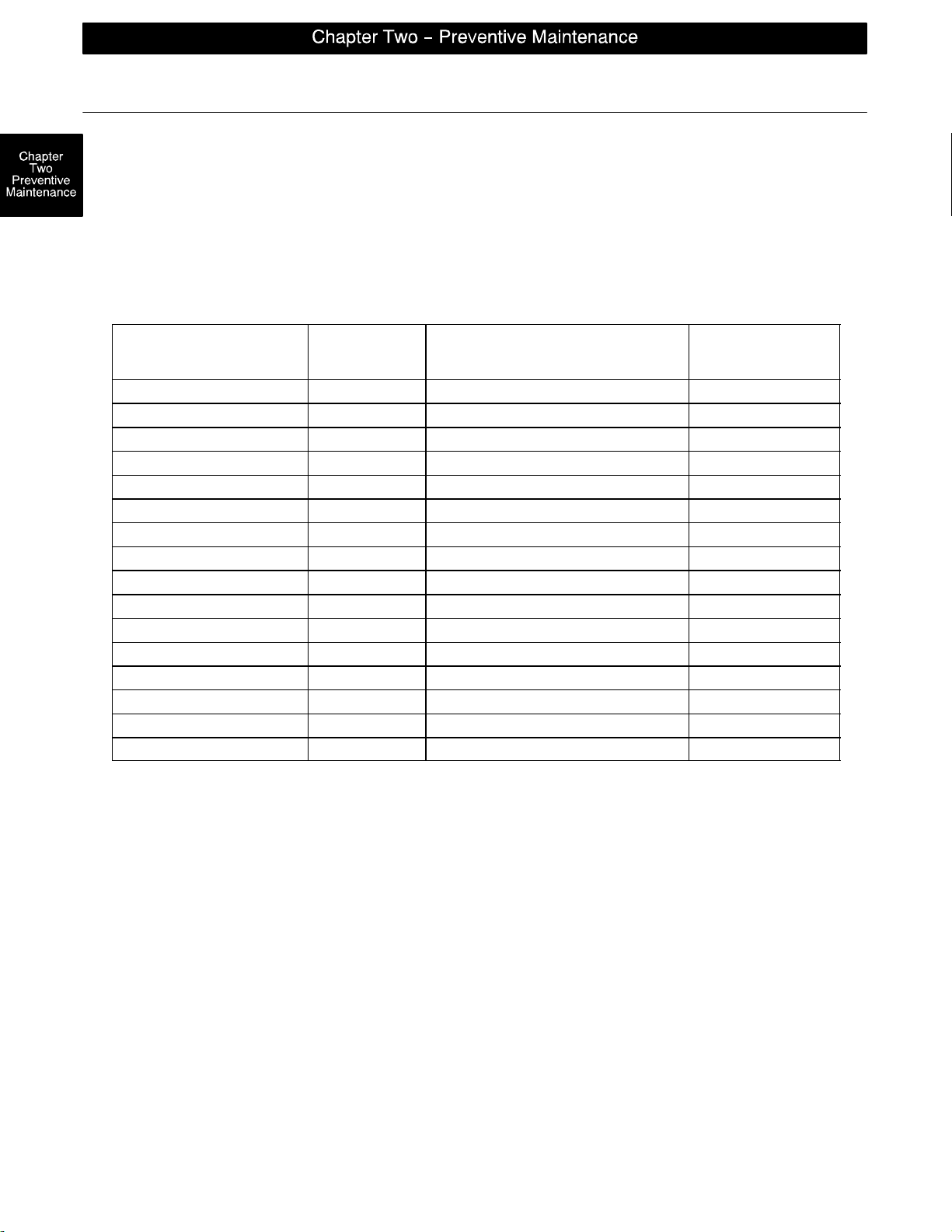

Checklist

All fasteners secure

Siderails move and latch properly

Engage brake pedal and push on the stretcher to ensure all casters lock securely

Brake pedal adjusted properly (see page 3-2)

Base release linkage functions properly with weight on unit

All casters secure and swivel properly

Body restraints work properly

I.V. pole intact and operates properly

I.V. pole receptacle weldments secure

Fowler operates properly

Fowler trip bar adjusted properly

Foot section raises, lowers and latches properly

Foot section level

Trendelenburg/Reverse Trendelenburg operates properly

Lateral tilt operates properly

No rips or cracks in mattresses/Velcro attachments

Ground chain intact

No leaks at hydraulic connections

Hydraulic lift jack holds properly

Hydraulic drop rate set properly

Hydraulic oil level sufficient

Lubricate as required (see page 3-9)

Tighten surgery accessory rails on Fowler and seat section

Accessories and mounting hardware in good condition and working properly

Serial No.

Completed By:_________________________________ Date:_____________

NOTE

Preventative maintenance should be performed at a minimum of annually. A preventative maintenance program should be established for all Stryker Medical equipment. Preventative maintenance may need to be

performed more frequently based on the usage level of the product.

1034 Surgery Platform 1034-009-002 REV A page 2-1

Page 9

Cleaning

Hand wash all surfaces of the table with warm water and mild detergent. Dry thoroughly. DO NOT STEAM

CLEAN, PRESSURE WASH, HOSE OFF OR ULTRASONICALLY CLEAN. Using these methods of cleaning

is not recommended and may void this product’s warranty.

Clean Velcro AFTER EACH USE. Saturate Velcro with disinfectant and allow disinfectant to evaporate. (Appropriate disinfectant for nylon Velcro should be determined by the hospital.)

In general, when used in those concentrations recommended by the manufacturer, either phenolic type or

quaternary type disinfectants can be used. Iodophor type disinfectants are not recommended for use because staining may result. The following products have been tested and have been found not to have a harmful effect WHEN USED IN ACCORDANCE WITH MANUFACTURERS RECOMMENDED DILUTION.*

*MANUFACTURER’S

TRADE NAME DISINFECTANT

TYPE

A33 Quaternary Airwick (Professional Products Division) 2 ounces/gallon

A33 (dry) Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Beaucoup Phenolic Huntington Laboratories 1 ounce/gallon

Blue Chip Quaternary S.C. Johnson 2 ounces/gallon

Elimstaph Quaternary Walter G. Legge 1 ounce/gallon

Franklin Phenomysan F2500 Phenolic Purex Corporation 1 1/4 ounce/gallon

Franklin Sentinel Quaternary Purex Corporation 2 ounces/gallon

Galahad Phenolic Puritan Churchill Chemical Company 1 ounce/gallon

Hi-Tor Quaternary Huntington Laboratories 1/2 ounce/gallon

LPH Phenolic Vestal Laboratories 1/2 ounce/gallon

Matar Phenolic Huntington Laboratories 1/2 ounce/gallon

Omega Quaternary Airwick (Professional Products Division) 1/2 ounce/gallon

Quanto Quaternary Huntington Laboratories 1 ounce/gallon

Sanikleen Quaternary West Chemical Products 2 ounces/ gallon

Sanimaster II Quaternary Service Master 1 ounce/gallon

Vesphene Phenolic Vestal Laboratories 1 1/4 ounce/ gallon

MANUFACTURER

RECOMMENDED

DILUTION

Quaternary Germicidal Disinfectants, used as directed, and/or Chlorine Bleach products, typically 5.25% So dium Hypochlorite in dilutions ranging between 1 part bleach to 100 parts water, and 2 parts bleach

to 100 parts water are not considered mild detergents. These products are corrosive in nature and

may cause damage to your table if used improperly. If these types of products are used to clean Stryker

equipment, measures must be taken to insure the equipment is rinsed with clean water and thoroughly dried

following cleaning. Failure to properly rinse and dry the equipment will leave a corrosive residue on the surface

of the equipment, possibly causing premature corrosion of critical components.

NOTE

Failure to follow the above directions when using these types of cleaners may void this product’s warranty.

REMOVAL OF IODINE COMPOUNDS

This solution may be used to remove iodine stains from mattress cover surfaces.

1. Use a solution of 1-2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area.

Clean as soon as possible after staining occurs. If stains are not immediately removed, allow solution to

soak or stand on the surface.

2. Rinse surfaces which have been exposed to the solution in clear water before returning bed to service.

1034 Surgery Platform 1033-009-002 REV Apage 2-2

Page 10

GENERAL INFORMATION

This section contains tool lists and step-by-step procedures to assist with the maintenance and servicing

of your equipment.

In the text, the words “right” and “left” refer to the right and left sides of a patient lying face up on the bed.

MAINTENANCE CONTENTS

Brake Adjustment page 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caster Cover Replacement page 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Hood Removal page 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Hydraulic Fluid Level page 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Assembly Removal and Replacement page 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Constant Flow Jack Descent Rate Adjustment page 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustable P.C. Valve Replacement page 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Litter Removal page 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Crank Assembly Removal page 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Tilt Assembly Removal page 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Box Removal page 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift Gear Replacement page 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic Fowler Adjustment page 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Section Latch Adjustment page 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication Points page 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1034 Surgery Platform 1034-009-002 REV A page 3-1

Page 11

Brake Adjustment

Required Tools:

3/16” Allen Wrench 7/16” Wrench

Procedure:

1. Locate the brake ring assembly.

2. To increase the brake force, loosen the 7/16” nut and use a 3/16” Allen wrench to tighten the set screw

toward the tie rod until enough brake force to keep the casters from rolling or pivoting is attained.

3. To decrease the brake force, use a 3/16” Allen wrench to turn the set screw away from the tie rod.

4. Tighten the 7/16” nut.

7/16”

2 places

FOOT END BRAKE ADJUSTMENT HEAD END BRAKE ADJUSTMENT

1.5” 2 places

Caster Cover Replacement

Required Tools:

1/8” Allen Wrench

3/8”

2 places

Procedure:

1. Using a 1 / 8 ” Allen wrench, remove the screw and washer holding the caster cover to the wheel assembly .

2. Reuse the screw and washer to install the new caster cover.

1034 Surgery Platform 1033-009-002 REV Apage 3-2

Page 12

Base Hood Removal

Required Tools:

Phillips Screwdriver

Procedure:

1. Engage the wheel brakes.

2. Raise the litter to the full up position.

3. Using a Phillips screwdriver, remove the four screws and 4 U-nuts holding the hood cover plate to the

base frame at the head end of the unit.

4. Remove the black hood grommet around the column cover.

5. Remove the base hood.

6. Reverse the above steps to reinstall the hood.

Checking Hydraulic Fluid Level

Required Tools:

Standard Screwdriver Phillips Screwdriver 1/8” Allen Wrench

3/4” Open End Wrench 3/8” Open End Wrench 3/16” Allen Wrench

Needle Nose Pliers 7/16” Wrench

Procedure:

1. Using a standard screwdriver, remove the screw and handle on the Trend crank at the head end of the

surgery platform (see page 5-36 for part reference).

2. Remove the base hood assembly (see procedure above).

3. Remove the jack (see page 3-4).

4. Be sure there are no hydraulic leaks. If there are, jack replacement will be necessary.

5. Lower the jack to the full down position.

6. Using a 3/4” open end wrench, slowly turn the fill plug located on the side of the reservoir counterclock-

wise to allow excess system pressure to vent. Remove the fill plug.

7. The hydraulic fluid should be visible at the bottom of the fill hole. If it is not, add Mobil Aero HFA hydraulic

fluid (Stryker part number 2020-70-475) until the fluid is visible at the bottom of the fill hole. Replace

the fill plug.

CAUTION

Use of other types of oil may damage hydraulic units.

8. Replace the jack.

9. Reinstall the base hood.

1034 Surgery Platform 1034-009-002 REV A page 3-3

Page 13

Jack Assembly Removal and Replacement

Required Tools:

Standard Screwdriver 1/8” Allen Wrench 3/8” Wrench

3/16” Allen Wrench Needle Nose Pliers 7/16” Wrench

Phillips Screwdriver

Procedure:

1. Engage the wheel brakes.

2. Using a standard screwdriver, remove the screw and handle on the Trend crank at the head end of the

surgery platform (see page 5-36 for part reference).

3. To gain access to the bottom of the unit, lift the base at the foot end of the surgery platform and tip up

the unit until it rests on its head end.

4. Remove the base hood (see page 3-3).

5. Using needle nose pliers, remove the two extension springs on the head end pump/release pedal actua-

tors.

6. Remove the two roll pins on the inner side of the base frame for the side pump pedal assembly.

7. Using a 7/16” wrench, remove the pump pedal linkage and release mechanism.

8. Remove the 3/16” Allen screw at the top of the jack actuator on the jack cradle support.

9. Using a 7/16” wrench, remove the two sets of nuts and bolts holding the jack assembly to the base.

10. Reverse the above procedure to install the new jack assembly.

1 1. T o test the jack operation before returning the unit to service, pump the lift pedal to raise the jack all the

way up and depress the release pedal to lower the jack fully down. Repeat several times.

1034 Surgery Platform 1033-009-002 REV Apage 3-4

Page 14

Constant Flow Jack Descent Rate Adjustment

Adjustment Procedure:

1. Engage the wheel brakes.

2. Pump the litter up to full height.

3. The adjustable jack descent valve has a blue knob on the end and is located on the base of the jack (see

page 5-24 for part reference). To adjust the jack descent rate, turn the silver locking ring counterclockwise to loosen it. T urn the blue knob clockwise to increase the litter descent rate. Turn it counterclockwise

to decrease the litter descent rate.

4. Adjust the valve so that the jack at the foot end of the stretcher will descend slightly faster than the jack

at the head end.

Adjustable Pressure Compensated (P.C.) Valve Replacement

Required Tools:

Standard Screwdriver Phillips Screwdriver 1/8” Allen Wrench

13/16” Wrench 3/8” Wrench

Replacement Procedure:

1. Using a standard screwdriver, remove the screw and handle on the Trend crank at the head end of the

surgery platform (see page 5-36 for part reference).

2. Remove the base hood assembly (see page 3-3).

3. Remove the jack assembly (see page 3-4)

4. Push down on the jack actuator to put the jack in the full down position.

5. Using a 13/16” wrench, remove the adjustable P.C. valve.

6. Check for any contaminants in the valve and in the jack base.

7. Install a new P.C. valve. Moisten the O-ring seal with hydraulic fluid to ensure a good seal.

8. Tighten the valve manually and then an additional 1/8-1/4 turn with 13/16” wrench. Do not over -tighten

or damage may occur to the O-ring seal.

9. Reinstall the jack assembly

10. To test the jack operation before returning the unit to service, pump the lift pedal to raise the jack all the

way up and depress the release pedal to lower the jack fully down. Repeat several times.

11. Adjust the jack descent rate, if necessary (reference procedure above).

12. Check for any hydraulic fluid leaks before replacing the base hood.

1034 Surgery Platform 1034-009-002 REV A page 3-5

Page 15

Litter Removal

Required Tools:

7/32” Hex Allen Wrench 9/16” Open End Wrench

Procedure:

1. Engage the wheel brakes.

2. Lower the litter to the full down position.

3. Using a 7/32” hex Allen wrench and a 9/16” open end wrench, remove the eight Allen bolts and Nylock

nuts holding the litter frame to the lateral tilt assembly.

4. With the assistance of another person, lift the litter off the lateral tilt assembly and carefully set it aside.

5. Reverse the above procedure to reinstall the litter.

T rend Actuator Assembly Removal

Required Tools:

5/8” Hex Allen Wrench Needle Nose Pliers

Procedure:

1. Engage the wheel brakes.

2. Using needle nose pliers, remove the rue ring and clevis pin holding the Trend actuator assembly to the

outer box assembly.

3. Using a 5/8” hex Allen wrench, remove the two Allen bolts holding the Trend actuator assembly to the

lateral tilt assembly.

4. Reverse the above procedure to reinstall.

1034 Surgery Platform 1033-009-002 REV Apage 3-6

Page 16

Lateral Tilt Assembly Removal

Required Tools:

Needle Nose Pliers 7/32” Hex Allen Wrench 9/16” Open End Wrench

Procedure:

1. Engage the wheel brakes.

2. Lower the litter to the full down position.

3. Remove the litter (see page 3-6).

4. Using needle nose pliers, remove the rue ring from the left or right side of the outer box assembly and

pull out the trend pivot shaft.

5. Lift the lateral tilt assembly off the base assembly.

6. Reverse the above procedure for reassembly.

Outer Box Assembly Removal

Required Tools:

Needle Nose Pliers 7/32” Hex Allen Wrench 9/16” Open End Wrench

5/32” Hex Allen Wrench 7/16” Wrench

Procedure:

1. Engage the wheel brakes.

2. Lower the litter to the full down position.

3. Remove the litter (see page 3-6).

4. Remove the lateral tilt assembly (see procedure above).

5. Using a 5/32” hex Allen wrench and a 7/16” wrench, loosen but do not completely remove the ten

Nylock nuts and six Allen screws holding the gear racks on the outer box assembly.

6. Lift the outer box assembly off the base assembly.

7. Reverse the above procedure for reassembly.

1034 Surgery Platform 1034-009-002 REV A page 3-7

Page 17

Lift Gear Replacement

Required Tools:

Needle Nose Pliers 7/32” Hex Allen Wrench 9/16” Open End Wrench

5/32” Hex Allen Wrench 7/16” Wrench T27 Torx Wrench

Procedure:

1. Engage the wheel brakes.

2. Remove the litter (see page 3-6).

3. Remove the lateral tilt assembly (see page 3-7)

4. Remove the outer box assembly (see page 3-7)

5. Remove the T27 Torx head screw holding the lift gear on the gear shaft.

6. Reverse the above steps to install the new gear.

Pneumatic Fowler Adjustment

Required Tools:

5/32” Hex Allen Wrench 1/2” Open End Wrench

Adjustment Procedure:

1. Engage the wheel brakes.

2. For easier access, move the Fowler to 75_ or higher.

3. Using a 1/2” open end wrench, loosen the nuts in the actuator arms on the end of the trip bar.

4. To adjust the Fowler, use a 5/32” hex Allen wrench to turn the Allen set screws 1 to 2 turns counterclock-

wise if the Fowler will not move or 1 to 2 turns clockwise if the Fowler will not hold its position.

5. Retighten the nuts. Be sure the Fowler will travel from flat to 90_ and down again and will hold its position

when weight is applied before returning the unit to service.

1034 Surgery Platform 1033-009-002 REV Apage 3-8

Page 18

Foot Section Latch Adjustment

Required Tools:

3/32” Hex Allen Wrench

Adjustment Procedure:

1. Engage the wheel brakes.

2. Remove the foot section from the unit and turn it over.

3. Using a 3/32” hex Allen wrench, loosen the Allen screw on the red release handle.

4. Move the handle until the desired locking force is achieved.

5. Tighten the Allen screw.

Lubrication Points

1034 Surgery Platform 1034-009-002 REV A page 3-9

Page 19

Notes

1034 Surgery Platform 1033-009-002 REV Apage 3-10

Page 20

PART NAME PART NUMBER

Air Delivery/Drape Support Assembly 1068-168-000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direct Clamp 1068-054-010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Board/Foot Extender Assembly 1033-130-010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Spring, Fifth Wheel 5010-040-010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Spring, Fowler & Foot Section 0360-031-077. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Oil, Mobil Aero HFA - 1 Quart 2020-070-475. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Pole Assembly, Standard, Removable 0721-047-006. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Pole Assembly, 3-Stage, Heavy-Duty 1033-110-110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Pole Receptacles, Standard I.V. 1033-110-030. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.V. Pole Receptacles, 3-Stage Heavy-Duty I.V. 1033-110-130. . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Assembly, Pedestal Lift 1033-001-050. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Pressure Control (P.C.) Valve 5050-070-050. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jack Pump Assembly 1033-001-070. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Brake Pedal, Left Side 1034-090-025. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Brake Pedal, Right Side 1034-090-026. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Descent Pedal, Left Side 1033-090-030. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Descent Pedal, Right Side 1033-090-028. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, “Do Not Sit on Foot Section” 1033-090-034. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Pump Pedal, Left Side 1033-090-029. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Pump Pedal, Right Side 1033-090-027. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Label, Trendelenburg 1033-090-031. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattress Assembly, 3” Ultra-Comfort, Foot Section 1034-041-020. . . . . . . . . . . . . . . . . . . . . . . .

Mattress Assembly, 3” Ultra-Comfort, Fowler/Seat Section 1034-041-010. . . . . . . . . . . . . . . . .

Mattress Assembly, 3” Ultra-Comfort Set 1034-041-001. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oxygen Bottle Holder Assembly, Upright 1010-030-000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedal, “Butterfly” Brake 1033-001-233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedal, Pump, Plastic 1033-001-240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perineal Pad Assembly 1034-041-201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perineal Pad, 3” Cushion 1034-041-030. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1034 Surgery Platform 1034-009-002 REV A page 4-1

Page 21

PART NAME PART NUMBER

Restraint Strap, Ankle 0946-043-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restraint Strap, Body 0390-019-000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restraint Strap, Chest 1010-058-000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restraint Strap, Wrist 0946-044-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restraint Straps, Full Patient Security Package 1010-077-000. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Assembly 1033-001-225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Covers (set of 4) 1033-001-301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1034 Surgery Platform 1033-009-002 REV Apage 4-2

Page 22

GENERAL INFORMATION

This section contains assembly drawings and parts lists to assist with the identification of individual components of the equipment and accessories.

In the parts lists, the words “right” and “left” refer to the right and left sides of a patient lying face up on the

stretcher.

ASSEMBLY DRAWINGS AND PARTS LISTS CONTENTS

Trio Common Components page 5-3 - 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Assembly page 5-11 - 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Pan Assembly page 5-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedestal Lift Jack Assembly page 5-22 - 5-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pedestal Lift Jack Pump Assembly page 5-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Assembly page 5-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fowler Assembly page 5-27 - 5-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Section Receptacle Assembly page 5-30, 5-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Assembly page 5-32, 5-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Box Assembly page 5-34, 5-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Actuator Assembly page 5-36, 5-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Inner Screw Assembly page 5-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Tilt Assembly page 5-40, 5-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Tilt Hinge Gear Assembly page 5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Standard I.V. Pole Receptacles page 5-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Standard I.V. Pole Assembly page 5-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Heavy-Duty I.V. Pole Receptacles page 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Heavy-Duty I.V. Pole Assembly page 5-46, 5-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Oxygen Bottle Holder Assembly page 5-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Drape Support Assembly page 5-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Direct Clamp page 5-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Perineal Pad Assembly page 5-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Foot Board/Foot Extender Assembly page 5-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1034 Surgery Platform 1034-009-002 REV A page 5-1

Page 23

ASSEMBLY DRAWINGS AND PARTS LISTS CONTENTS (CONTINUED)

Foot/Fowler Option Assembly page 5-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Foot/Fowler Assembly page 5-54, 5-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Pre-Op/Post-Op Pad Assembly page 5-56, 5-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Head Piece Assembly page 5-58 - 5-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Foot End Siderail Assembly page 5-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Cysto Pan Assembly page 5-63 - 5-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mattresses page 5-66, 5-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1034 Surgery Platform 1033-009-002 REV Apage 5-2

Page 24

Surgery Platform Common Components

Assembly part number 1034-026-010

(reference only)

1034 Surgery Platform 1034-009-002 REV A page 5-3

Page 25

Surgery Platform Common Components

1034 Surgery Platform 1033-009-002 REV Apage 5-4

Page 26

Surgery Platform Common Components

1034 Surgery Platform 1034-009-002 REV A page 5-5

Page 27

Surgery Platform Common Components

1034 Surgery Platform 1033-009-002 REV Apage 5-6

Page 28

Surgery Platform Common Components

SURGERY ACCESSORY RAIL AND

FOWLER ROLLER CHANNEL

(TYPICAL BOTH SIDES)

1034 Surgery Platform 1034-009-002 REV A page 5-7

Page 29

Surgery Platform Common Components

1034 Surgery Platform 1033-009-002 REV Apage 5-8

Page 30

Surgery Platform Common Components

1034 Surgery Platform 1034-009-002 REV A page 5-9

Page 31

Surgery Platform Common Components

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0001-001-000 Flat Hd. Socket Screw 2 BC 1033-031-071 Fowler Link Bushing 4

C 0004-356-000 But. Hd. Cap Screw 2 BD 1033-032-420 Foot Release Link 2

D 0004-156-000 But. Hd. Cap Screw 6 BE 1033-032-430 Ft. Cylinder Rel. Block, Rt. 1

E 0004-358-000 But. Hd. Cap Screw 6 BF 1033-032-435 Ft. Cylinder Rel. Block, Lt. 1

F 0004-359-000 But. Hd. Cap Screw 2 BG 1033-032-436 Ft. Rel Handle. Cross Rod 1

G 0004-479-000 But. Hd. Cap Screw 2 BH 1033-032-540 Ft.Hand. Rel. Timing, Rt. 1

H 0004-363-000 But. Hd. Cap Screw 4 BJ 1033-032-545 Ft.Hand. Rel. Timing, Lt. 1

J 0004-366-000 But. Hd. Cap Screw 2 BK 1033-032-140 Foot Release Handle, Rt. 1

K 0004-145-000 But. Hd. Cap Screw 8 BL 1033-032-145 Foot Release Handle, Lt. 1

L 0004-369-000 But. Hd. Cap Screw 2 BM (page 5-30) Foot Receptacle Ass’y, Rt. 1

M 0004-371-000 Low Soc. Hd. Cap Scr. 4 (page 5-31) Foot/Fowler Recept., Rt. 1

P 0008-059-000 Soc. Hd. Shoulder Screw 2 BN (page 5-30) Foot Receptacle Ass’y, Lt. 1

R 0052-815-000 Nyliner 2 (page 5-31) Foot/Fowler Recept., Lt. 1

S 0015-066-000 Hex Jam Nut 2 BP 1033-032-560 Foot Release Adjust 2

T 0016-122-000 Nylock Nut 4 BS 1033-032-580 GS Lever 2

U 0016-123-000 Nylock Nut 10 BT 1033-033-026 Trend Flange Bearing 2

W 0016-124-000 Nylock Nut 10 BU 1033-033-031 Jack Trend Pivot Block 1

X 0016-126-000 Hex Nylock Nut 2 BW 1033-033-038 Tr. Bellows Outer Box Plate 1

Y 0017-023-000 Acorn Nut 2 BX (page 5-36) Trend Actuator Assembly 1

Z 0026-314-000 Slotted Spring Pin 4 BY (page 5-34) Outer Box Assembly 1

AA 0026-317-000 Clevis Pin 1 BZ 1033-034-021 Trend Pivot Shaft 1

AB 0027-024-000 Rue Ring Cotter 3 CA 1033-001-232 15.5” Extrusion Profile 1

AC 0360-031-077 Gas Cylinder 2 CB 1033-001-232 5.50” Extrusion Profile 1

AD 1033-001-004 Outer Box Cover, Right 1 CC 1033-001-232 4.75” Extrusion Profile 1

AE 1033-001-005 Outer Box Cover, Left 1 CD 0026-006-000 Spring Pin 2

AF 1033-001-009 O. B. Cov. Attach. Strip 1 CE 0011-447-000 Washer 2

AG (page 5-11) Base Assembly 1 CF 0081-327-000 Flange Bearing 2

AH 1033-001-045 Cover/Interface Bellows 1 CG 0025-133-000 Blind Rivet 2

AJ 1033-001-046 Bellows/Cover Plate 1 CH 0081-229-000 Bearing 8

AN 8839-793-700 Cap Screw 10 CJ 0081-293-000 Flange Bearing 2

AR 1033-030-031 Seat Surgery Acc. Rail, Rt. 1 CK 7900-001-102 12” Velcro Pile 2

1033-630-031 Int. Surgery Acc. Rail, Rt. 1 CN 1034-090-021 Specification Label 1

AS 1033-030-032 Seat Surgery Acc. Rail, Lt. 1 CP 1033-090-031 Trend Label 1

1033-630-032 Int. Surgery Acc. Rail, Lt. 1 1033-090-131 International Trend Label 1

AT 1033-030-033 Surgery Acc. Rail Spacer 4 CR 1034-090-024 Solo Logo Label 2

AU 1033-030-434 Seat Skin 1 CW 1033-032-571 Relay Bracket 2

AW 1033-030-035 Barrel Nut 4 CX 0004-073-000 But. Hd. Cap Screw 6

AX 1033-030-400 Litter Frame Weldment, Rt. 1 CY 1033-032-440 Shaft Pivot Bracket 2

A Y 1033-030-405 Litter Frame Weldment, Lt. 1 DB 0026-334-000 Clevis Pin 4

AZ (page 5-27) Fowler Assembly 1 DC 0027-020-000 Rue Ring Cotter 4

BA 1033-031-029 Fowler Roller Rub Strip 2 DD 0004-484-000 But. Hd. Cap Screw 1

BB 1033-031-031 Fowler Roller Channel 2

1034 Surgery Platform 1033-009-002 REV Apage 5-10

Page 32

6.

BRAKE RING ASSEMBLY

(TYPICAL 4 PLACES)

Base Assembly

Assembly part number 1034-001-010 (reference only)

1034 Surgery Platform 1034-009-002 REV A page 5-11

Page 33

Base Assembly

CASTER ASSEMBLY

(TYPICAL 4 PLACES)

1034 Surgery Platform 1033-009-002 REV Apage 5-12

Page 34

Base Assembly

1034 Surgery Platform 1034-009-002 REV A page 5-13

Page 35

Base Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-14

Page 36

Base Assembly

1034 Surgery Platform 1034-009-002 REV A page 5-15

Page 37

Base Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-16

Page 38

Base Assembly

1034 Surgery Platform 1034-009-002 REV A page 5-17

Page 39

Base Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-18

Page 40

Base Assembly

SECTION A-A

1034 Surgery Platform 1034-009-002 REV A page 5-19

Page 41

Base Assembly

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0715-001-333 Rel. Valve Stop Sleeve 1 CF 1033-001-270 Pump Pedal, Head End 1

C 1210-201-401 Bushing 4 CG 1033-001-175 Release Pedal, Head End 1

D 1033-001-251 Eyebolt 4 CH 1033-001-180 Side Pedal 4

E 2025-032-068 Flange Bearing 2 CJ 1033-001-490 Release Driver 1

F 5050-001-232 Rod End Bearing 5 CK 1033-001-200 Fifth Wheel Drive Arm 1

G 0001-001-000 Flat Hd. Soc. Screw 4 CL 1033-001-210 Brake Shaft Arm, Right 1

H 0003-362-000 Hex Hd. Cap Screw 4 CM 1033-001-215 Brake Shaft Arm, Left 1

J 0004-500-000 Soc. Hd. Cap Screw 2 CP (page 5-26) Wheel Assembly 4

K 0004-358-000 But. Hd. Cap Screw 6 CR 1033-001-233 Butterfly “V” Pedal 2

L 0004-359-000 But. Hd. Cap Screw 5 CS 1033-001-240 Plastic Pump Pedal 6

M 0004-361-000 But. Hd. Cap Screw 3 CU 0011-077-000 Washer 1

P 0004-145-000 But. Hd. Cap Screw 4 CW 0011-310-000 Flat Washer 4

R 0004-306-000 Soc. Hd. Cap Screw 12 CY 0015-037-000 Hex Jam Nut 5

T 0004-492-000 Soc. Hd. Cap Screw 2 CZ 0016-014-000 Dynalock Nut 4

U 0004-129-000 But. Hd. Cap Screw 2 DA 0016-060-000 Torque Lock Nut 4

W 0015-066-000 Hex Jam Nut 6 DB 0016-078-000 Center Lock Nut 25

X 0016-122-000 Nylock Nut 24 DD 0026-014-000 Roll Pin 2

Z 0016-125-000 Nylock Nut 4 DE 0026-143-000 Groove Pin 6

AA 0026-316-000 Clevis Pin 1 DF 0026-239-000 Groove Pin 14

AB 1033-001-31 1 Flange Bearing Bushing 4 DG 0026-251-000 Clevis Pin 3

AC 1033-001-322 Flange Bearing 4 DH 0027-020-000 Rue Ring Cotter 2

AD 1033-001-001 Base Hood 1 DJ 0027-022-000 Rue Ring Cotter 2

AE 1033-001-002 Hood Cover Plate 1 DK 0003-342-000 Hex Hd. Cap Screw 4

AF (page 5-21) Base Pan 1 DM 0004-028-000 Soc. Hd. Cap Screw 2

AG 1033-001-006 Hood Grommet 1 DN 0004-102-000 Soc. Hd. Cap Screw 8

AJ 1033-001-012 Lift Gear 4 DR 0052-702-000 U-Nut 4

AK 1033-001-013 Gear Shaft 2 DS 0081-240-000 Flange Bushing 2

AL 1033-001-414 Jack Nut Plate 1 DT 0081-268-000 Flange Bushing 32

AM 1033-001-017 Pillow Block 2 DW 0081-293-000 Flange Bearing 11

AN 1033-001-418 Release Cross Shaft 1 DY 1033-090-027 Pump Pedal Label, Rt. 1

AP 1033-001-019 Main Release Drive Arm 1 DZ 1033-090-028 Descent Pedal Label, Rt. 2

AR 1033-001-320 Short Release Link 1 EA 1033-090-029 Pump Pedal Label, Lt. 2

AT 1033-001-323 Long Release Link 1 EB 1033-090-030 Descent Pedal Label, Lt. 1

AU 1033-001-024 Release Drive Pivot Pin 1 EC 0946-201-060 Stryker Logo Label 1

AW 1033-001-025 Pump Cross Shaft 1 ED 0004-142-000 Hex Soc. Hd. Screw 6

AX 1033-001-026 Jack Pump Coupler 4 EE 0014-021-000 Washer 2

AY 1033-001-028 Brake Ring Link 16 EG 0023-025-000 Hex Washer Hd. Screw 1

AZ 1033-001-029 Brake Spring, Right 2 EH 1033-001-256 Ground Chain 1

BA 1033-001-030 Brake Spring, Left 2 EK 1034-090-025 Brake Label, Left 1

BE 1033-001-035 Brake/Steer Shaft 1 EL 1034-090-026 Brake Label, Right 1

BH 1033-001-038 Bell Crank Link 2 EM 1210-201-335 Red Brake Label 2

BJ 1033-001-039 Slide Link 2 EN 1210-201-336 Green Steer Label 2

BK 1033-001-040 Pump Cross Shaft Spacer 1 EP 0004-156-000 But. Hd. Cap Screw 2

BL 1033-001-041 Pump Pedal Plug 2 ER 1033-001-126 Jack Pump Coupler 5

BM 1033-001-043 Brake Ring Stabilizer Bshg. 4 ES 0029-010-000 Dual Lock 4

BP 1033-001-147 Hd. End Pedal Stop Plate 1 ET 0029-008-000 Dual Lock 4

BR (page 5-22) Pedestal Lift Jack Ass’y 1 EU 0004-163-000 But. Hd. Cap Screw 2

BS 1033-001-081 Brake Wldmt. Ret. Spring 4 EW 1033-001-478 Pivot Link 1

BT 1033-001-082 Side Lower Ped. Ret. Spr. 2 EX 1033-001-470 Roller Pivot Weldment 1

BU 1033-001-083 Front Pedal Return Spring 3 EY 1033-001-475 Jack Release Roller 1

BW 1033-001-400 Base Weldment 1 EZ 0081-328-000 Plane Bearing 1

BX 1033-001-129 Caster Horn w/Bearing 4 FA 1033-001-477 Plane Bearing 2

BY 1033-001-130 Brake Ring Weldment 4 FB 0081-327-000 Flange Bearing 1

BZ 1033-001-140 Short Brake Link, Right 1 FC 1033-001-480 Jack Release Link 1

CA 1033-001-145 Long Brake Link, Right 1 FD 1033-001-321 Aligner Bearing 2

CB 1033-001-150 Short Brake Link, Left 1 FE 0025-099-000 Blind Rivet 4

CC 1033-001-155 Long Brake Link, Left 1 FF 0004-491-000 Soc. Hd. Cap Screw 1

CD 1033-001-260 Pump Link Weldment 1 FG 0003-041-000 Hex Hd. Cap Screw 1

CE 1033-001-465 Release Arm Weldment 1

1034 Surgery Platform 1033-009-002 REV Apage 5-20

Page 42

1033-001-065 Base Pan Assembly

Item Part No. Part Name Qty.

A 0025-133-000 Blind Rivet 2

B 1033-001-066 Base Pan 1

C 1033-001-067 Base Pan Filler Plate 1

D 1033-001-068 Base Pan Felt Pad 1

E 0044-039-000 2” x 6” Acrylic Tape 2

1034 Surgery Platform 1034-009-002 REV A page 5-21

Page 43

1033-001-050 Pedestal Lift Jack Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-22

Page 44

1033-001-050 Pedestal Lift Jack Assembly

1034 Surgery Platform 1034-009-002 REV A page 5-23

Page 45

1033-001-050 Pedestal Lift Jack Assembly

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0388-100-038 Plug 1 AC 0004-469-000 Soc. Hd. Cap Screw 2

B 0390-001-238 Actuator Gasket 1 AD 0027-025-000 Rue Ring Cotter 1

C 0390-001-243 Gasket 1 AE 0026-270-000 Clevis Pin 1

D 0390-001-244 Base Gasket 1 AF 0048-147-000 Hex Hd. O-Ring Plug 1

E 0390-002-139 Retaining Ring 2 AG 0390-002-134 Conical Comp. Spring 1

F 0660-001-031 Piston 1 AH 0715-001-309 Valve Plug 1

G 1033-001-052 Actuator Cylinder 1 AJ 0715-001-329 Pump Seal 1

H 0715-001-320 Jack Screen 1 AK 0715-001-341 Poppet 1

J 0715-001-340 Jack Cap 1 AL 0715-270-001 Pin 1

K 0715-001-422 Reservoir 1 AM 0926-020-153 Check Valve 1

L 0715-101-325 Parker Packing 1 AN 0926-020-154 Seal 1

M 0926-020-161 Parker Packing 1 AP 1210-170-013 Base Plug 1

N 0926-020-162 Wear Ring 1 AR 2025-075-087 Pin Housing 1

P 0048-174-000 Pump Hose 1 AS 5050-070-050 Adj. P.C. Valve Cartridge 1

R (page 5-25) Jack Pump Assembly 1 AT 1033-001-055 Machined Jack Base 1

S 0004-014-000 Soc. Hd. Cap Screw 1 AU 0048-173-000 Jack Base Fitting 1

T 0045-014-000 O-Ring 1 AW 1033-001-061 Jack Base Plug 1

U 0045-110-000 O-Ring 1 AX 0038-311-000 Compression Spring 1

W 0045-904-000 O-Ring 1 AY 0045-006-000 O-Ring 2

X 0045-978-000 O-Ring 1 AZ 0045-966-000 O-Ring 1

Y 0921-001-252 Serial Number Label 1 BA 0045-967-000 O-Ring 1

Z 1033-001-051 Jack Assembly Label 1 BB 0715-001-321 Check Valve Screen 2

AA 1033-001-015 Jack Spacer Block 2 BC 2025-700-026 Relief Valve Assembly 1

AB 1033-001-027 Jack Pump Supt Arm. 1

1034 Surgery Platform 1033-009-002 REV Apage 5-24

Page 46

1033-001-070 Pedestal Lift Jack Pump Assembly

Item Part No. Part Name Qty.

A 715-001-133 Collar 1

B 0052-704-000 External Retaining Ring 1

C 1033-001-063 Washer 1

E 0028-188-000 Spiral Retaining Ring 1

F 0045-242-000 O-Ring 1

G 0047-021-000 Seal 1

H 0048-175-000 45_ Straight Thread Elbow 1

K 1033-001-071 Pump Body 1

L 1033-001-072 Pump Brass End Cap 1

M 1033-001-073 Pump Shaft 1

N 1033-001-074 Pump Shaft Clevis 1

P 0026-318-000 Dowel Pin 1

Q 1033-001-080 Pump Cylinder Spring 1

S 1033-001-090 Spring Seat 1

1034 Surgery Platform 1034-009-002 REV A page 5-25

Page 47

1033-001-225 Wheel Assembly

Item Part No. Part Name Qty.

A 0715-001-255 Wheel Bushing 2

B 6060-002-046 Bearing Spacer 1

C 1033-001-231 Molded Wheel 1

D 0081-226-000 Bearing 2

1034 Surgery Platform 1033-009-002 REV Apage 5-26

Page 48

Fowler Assembly

Assembly part number 1033-031-010 (reference only)

1034 Surgery Platform 1034-009-002 REV A page 5-27

Page 49

Fowler Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-28

Page 50

Fowler Assembly

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0360-031-077 Gas Cylinder 2 Z 1033-031-014 Fowler Handle Brkt, Right 1

B 1069-031-012 Barrel Nut 6 AA 1033-031-015 Fowler Handle Brkt, Left 1

C 1210-31-103 Pivot Tab 2 AB 1033-031-016 Fowler Roller Spacer 2

D 0004-358-000 Button Hd. Cap Screw 10 AC 1033-031-017 Fowler Skin 1

E 0004-363-000 Button Hd. Cap Screw 2 AD 1033-031-018 Fowler Acc. Rail, Domestic 2

F 0004-364-000 Button Hd. Cap Screw 2 1033-631-018 Fowler Acc. Rail, Int. 2

G 0004-370-000 Button Hd. Cap Screw 2 AF 1033-031-020 Fowler Bumper Barrel Nut 2

H 0004-558-000 Socket Hd. Cap Screw 6 AG 1033-031-021 Cylinder Shoulder Rivet 2

J 0015-060-000 Metric Hex Nut 4 AH 1033-031-035 Fowler Trip Bar Weldment 1

K 0015-067-000 Hex Jam Nut 4 AJ 1033-031-041 Fowler Trip Bar Stop Cover 2

L 0016-122-000 Nylock Nut 12 AK 1033-031-050 Fowler Link Wldmt, Right 1

M 0016-123-000 Nylock Nut 2 AL 1033-031-055 Fowler Link Wldmt, Left 1

N 0016-126-000 Nylock Hex Nut 2 AM 1033-031-071 Fowler Link Bushing 2

P 0021-078-000 Set Screw 2 AN 0011-159-000 Washer 2

S 3000-300-003 Adjustable Bumper 2 AP 0014-002-000 Washer 4

T 0081-307-000 Ball Bearing 4 AR 0014-020-000 Washer 4

U 1033-031-008 Fowler Tube Plug 2 AS 0025-133-000 Blind Rivet 7

W 1033-031-1 11 Fowler Tube 1 AT 0007-058-000 Truss Hd. Machine Screw 8

X 1033-031-012 Fowler Roller Brkt, Right 1 AU 0008-056-000 Soc. Hd. Shoulder Screw 2

Y 1033-031-013 Fowler Roller Brkt, Left 1 AW 0015-066-000 Hex Jam Nut 2

1034 Surgery Platform 1034-009-002 REV A page 5-29

Page 51

1033-031-1 10/115 Foot Section Receptacle Ass’y, Right & Left

Item Part No. Part Name Qty.

A 0004-360-000 Button Hd. Cap Screw 3

B 0026-299-000 Clevis Pin 1

C 0016-122-000 Nylock Nut 3

D 1033-032-088 Foot Receptacle Plate, Left 1

E 1033-032-089 Foot Receptacle Plate, Right 1

F 1033-032-090 Foot Section Insert Guide 1

G 0027-025-000 Rue Ring Cotter 1

1034 Surgery Platform 1033-009-002 REV Apage 5-30

Page 52

Foot/Fowler Receptacle Assembly, Right and Left

1033-032-590 Foot/Fowler Receptacle, Right 1033-032-595 Foot/Fowler Receptacle, Left

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0026-330-000 Clevis Pin 1 A 0026-330-000 Clevis Pin 1

B 0004-359-000 But. Hd. Cap Screw 1 B 0004-359-000 But. Hd. Cap Screw 1

C 0004-176-000 But. Hd. Cap Screw 2 C 0004-176-000 But. Hd. Cap Screw 2

E 0026-299-000 Clevis Pin 1 E 0026-299-000 Clevis Pin 1

F 0027-025-000 Rue Ring Cotter 1 F 0027-025-000 Rue Ring Cotter 1

G 1033-032-090 Guide Insert 1 G 1033-032-090 Guide Insert 1

H 1033-032-480 Receptacle, Right 1 H 1033-032-485 Receptacle, Left 1

L 1033-032-489 Outside Plate 1 L 1033-032-489 Outside Plate 1

M 0027-020-000 Rue Ring Cotter 1 M 0027-020-000 Rue Ring Cotter 1

1034 Surgery Platform 1034-009-002 REV A page 5-31

Page 53

Foot Assembly

Assembly part number 1034-032-050 (reference only)

FOOT RELEASE HANDLE ASSEMBLY

(TYPICAL BOTH SIDES)

1034 Surgery Platform 1033-009-002 REV Apage 5-32

Page 54

Foot Assembly

Item Part No. Part Name Qty.

A 1010-032-066 Hole Plug 2

B 0004-355-000 But. Hd. Cap Screw 2

C 0004-356-000 But. Hd. Cap Screw 2

D 0004-359-000 But. Hd. Cap Screw 2

E 0004-306-000 Soc. Hd. Cap Screw 10

F 0016-122-000 Nylock Nut 8

G 0017-023-000 Acorn Nut 2

H 0027-025-000 Rue Ring Cotter 2

J 1033-032-052 Foot Section Skin 1

K 1033-032-059 Foot Latch Spring 2

L 1033-032-060 Outer Frame Weldment 1

M 1033-032-068 Foot Section Backer Plate 2

R 1033-032-080 Siderail Latch Spacer 2

T 1033-032-082 Ft. Sect. Opt. Rail Standoff 4

U 1033-032-084 Foot Acc. Rail, Rt., Domestic 1

1033-632-084 Foot Acc. Rail, Rt., International 1

W 1033-032-085 Foot Acc. Rail, Lt., Domestic 1

1033-632-85 Foot Acc. Rail, Lt., International 1

X 1033-032-086 Ft. Sect. Insert Cover 4

Y 1033-032-092 Ft. Sect. Release Handle 2

Z 1033-032-193 Ft. Sect. Release End Pivot 2

AA 1033-032-095 Foot Sect. Handle Support 2

AB 1033-032-096 Foot Section Latch, Left 1

AC 1033-032-097 Foot Section Latch, Right 1

AF 0011-077-000 Washer 2

AG 0025-126-000 Semi-T ubular Rivet 6

AH 0025-133-000 Rivet 15

AJ 0052-245-000 Nyliner Bearing 4

AK 0007-058-000 Phillips Truss Hd. Screw 4

AL 0081-293-000 Flange Bearing 2

AM 7900-001-102 Velcro Adhesive Pile 2

AN 0025-038-000 Blind Rivet 2

AU 1033-090-034 Label, “Do Not Sit”, Domestic 1

1061-600-040 Label, “Do Not Sit”, International 1

1034 Surgery Platform 1034-009-002 REV A page 5-33

Page 55

Outer Box Assembly

Assembly part number 1033-034-001

(reference only)

1034 Surgery Platform 1033-009-002 REV Apage 5-34

Page 56

Outer Box Assembly

Item Part No. Part Name Qty.

A 0003-074-000 Hex Hd. Cap Screw 2

B 0004-361-000 Button Hd. Cap Screw 4

C 0005-035-000 Carriage Bolt 4

D 0005-036-000 Carriage Bolt 6

E 0021-025-000 Set Screw 8

F 1033-034-031 Outer Box Top Rack 4

G 1033-034-032 Outer Box Bottom Rack 4

H 1033-034-036 Outer Box Rack Spacer 4

J 1033-034-050 Outer Box Lower Trend Pivot 1

K 1033-034-061 Outer Box Foot Box 1

L 1033-034-062 Outer Box Head Box 1

M 1033-034-070 Outer Box Trend Pivot Cap, Rt. 1

N 1033-034-075 Outer Box Trend Pivot Cap, Lt. 1

P 0016-122-000 Nylock Nut 10

1034 Surgery Platform 1034-009-002 REV A page 5-35

Page 57

1033-033-130 Trend Actuator Assembly

TREND SCREW

1034 Surgery Platform 1033-009-002 REV Apage 5-36

Page 58

1033-033-130 Trend Actuator Assembly

TREND FLANGE BEARING

TREND DRIVER SPUR GEAR

TREND NUT

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0004-304-000 But Hd. Cap Screw 12 L 1033-033-043 Trend Acme Nut 1

B 0011-464-000 Thrust Washer 4 M 1033-033-044 Trend Back Plate 1

C 0011-465-000 Thrust Washer 2 N 1033-033-046 Trend Front Plate 1

D 0004-222-000 But. Hd. Cap Screw 1 P 1033-033-047 Trend Drive Shaft 1

E 0081-314-000 Thrust Bearing 2 R 1033-033-048 Trend Flanged Bearing 1

F 0081-315-000 Thrust Bearing 1 S 1033-033-049 Trend Crank Handle 1

G 0081-316-000 Radial Bearing 1 T (page 5-38) Trend Inner Screw Ass’y1

H 1033-033-036 Trend Driver Spur Gear 1 U 1033-33-35 Crank Bellows 1

J 1033-033-037 Trend Driver Spur Gear 1 W 0081-226-000 Bearing 2

K 1033-033-042 Trend Housing 1 X 1033-033-033 Trend Glide Bearing 1

SECTION A-A

TREND HOUSING BEARING

1034 Surgery Platform 1034-009-002 REV A page 5-37

Page 59

1033-033-135 Trend Inner Screw Assembly

Item Part No. Part Name Qty.

A 0026-114-000 Spring Pin 1

B 1033-033-032 Trend Screw 1

C 1033-033-034 Trend Screw Pivot 1

1034 Surgery Platform 1033-009-002 REV Apage 5-38

Page 60

Notes

1034 Surgery Platform 1034-009-002 REV A page 5-39

Page 61

Assembly part number 1033-033-001

(reference only)

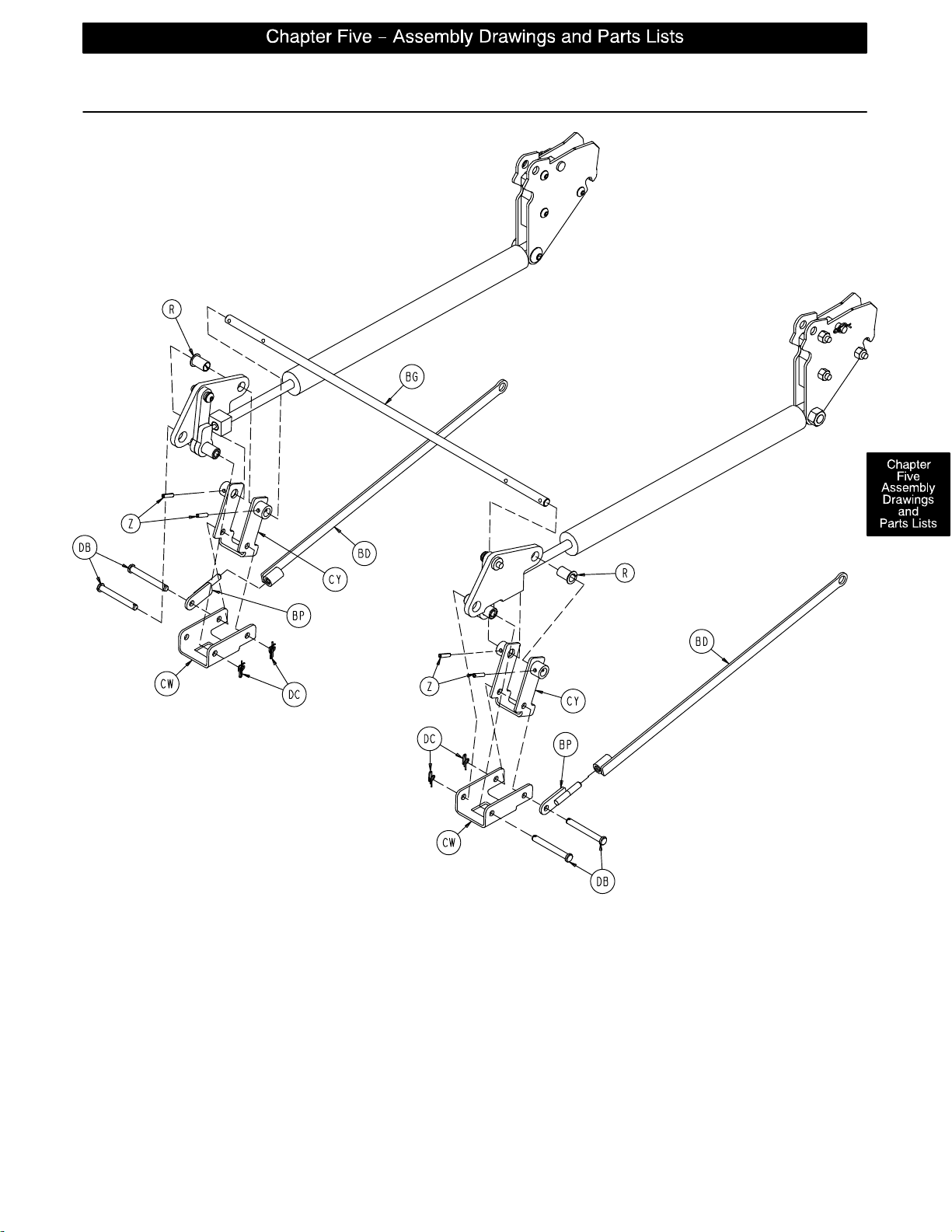

Lateral Tilt Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-40

Page 62

Lateral Tilt Assembly

Item Part No. Part Name Qty.

A 0003-363-000 Hex Hd. Cap Screw 1

B 0004-357-000 But. Hd. Cap Screw 1

C 0004-365-000 But. Hd. Cap Screw 4

D 0015-068-000 Hex Jam Nut 2

E 0016-125-000 Nylock Nut 1

F 0016-127-000 Nylock Nut 1

G 0028-302-000 External Retaining Ring 2

H 0052-703-000 Bronze Bearing Sleeve 1

J 0052-825-000 Rod End Ball Joint 1

K 0081-308-000 Thrust Bearing 2

L 0081-309-000 Axial Bearing Washer 2

M 0081-226-000 Single Row Radial Ball Bearing 2

N (page 5-42) Lateral Tilt Hinged Gear Ass’y1

P 1033-033-021 Lateral Tilt Nut 1

R 1033-033-022 Lateral Tilt Screw Pivot 1

S 1033-033-023 Lateral Tilt Screw 1

T 1033-033-024 Lateral Tilt Flange Bearing 4

U 1033-033-027 Lateral Tilt Bearing Plate 2

W 1033-033-030 Lateral Tilt Crank Handle 1

X 1033-033-050 Lateral Tilt Frame Wldmt. 1

Y 1033-033-1 10 Trend Frame Weldment 1

Z 1033-034-022 Trend Pivot Shaft 1

AA 1033-034-1 11 Lateral Tilt Foot Pillow Block 1

AB 1033-034-1 12 Lateral Tilt Head Pillow Block 1

AC 1033-034-1 13 Lateral Tilt Pivot Spacer 2

AD 1033-034-1 14 Lat. Tilt Brg. Adjustment Spacer 1

AE 0004-456-000 But. Hd. Cap Screw 1

1034 Surgery Platform 1034-009-002 REV A page 5-41

Page 63

Lateral Tilt Hinged Gear Assembly

Assembly part number

1033-033-018 (reference only)

Item Part No. Part Name Qty.

A 0026-118-000 Spring Pin 3

B 0052-826-000 Hinged Gear Joint 1

C 1033-033-019 Acme Screw Hinge Gear Coupler 1

D 1033-033-016 Crank Shaft Hinge Gear Coupler 1

E 1033-033-029 Lateral Tilt Crank Shaft 1

F 1033-033-028 Hinge Gear Cover 1

G 3000-300-1 14 4” Cable Tie 2

1034 Surgery Platform 1033-009-002 REV Apage 5-42

Page 64

1033-110-030 Optional Standard I.V. Pole Receptacles

Item Part No. Part Name Qty.

A 0028-187-000 Spiral Retaining Ring 2

B 1033-030-038 Barrel Nut 4

C 1033-030-040 I.V. Pole Receptacle 2

D 1033-030-050 Bumper Roller 2

E 0007-058-000 Phillips Truss Hd. Screw 4

1034 Surgery Platform 1034-009-002 REV A page 5-43

Page 65

0721-047-006 Standard, Removable I.V. Pole Assembly

Item Part No. Part Name Qty.

A 0938-001-305 Pole Socket Assembly 1

B 0938-001-308 Pole Assembly 1

C 0004-495-000 Soc. Hd. Cap Screw 1

D 1211-117-016 Knob 1

1034 Surgery Platform 1034-009-002 REV A page 5-44

Page 66

1033-1 10-130 Optional Heavy-Duty I.V. Pole Receptacles

Item Part No. Part Name Qty.

A 0028-191-000 Spiral Retaining Ring 2

B 1033-030-038 Barrel Nut 4

C 1033-110-125 Bumper Roller 2

D 1033-110-140 I.V. Pole Receptacle, Right 1

E 1033-110-145 I.V. Pole Receptacle, Left 1

F 0007-058-000 Phillips Truss Hd. Mach. Screw 4

1034 Surgery Platform 1034-009-002 REV A page 5-45

Page 67

1033-110-110 Optional Heavy-Duty I.V. Pole Assembly

Item Part No. Part Name Qty.

A 0926-400-162 Spacer 1

B 1001-359-013 Dampener 1

C 1010-061-014 Collar 1

D 1010-259-016 I.V. Hook 2

E 0026-076-000 Spring Pin 1

F 1033-110-111 H.D.I.V. Pole Tube 1

G 1033-110-112 H.D.I.V. Pole Insert 1

H 1033-110-113 H.D.I.V. Pole Tube Adapter 1

J (page 5-47) H.D.I.V. Pole Extension 1

K 0052-017-000 Spacer 2

L 0007-004-000 Truss Hd. Mach. Screw 1

1034 Surgery Platform 1033-009-002 REV Apage 5-46

Page 68

1033-110-120 Heavy-Duty I.V. Pole Extension Assembly

Item Part No. Part Name Qty.

A 0031-021-000 Ball Bearing 6

B 1010-061-013 Ball Retainer 1

C 1010-061-016 Retaining Shaft 1

D 1010-061-017 Thumb Knob 1

E 1010-061-018 Hand Guard 1

F 1033-110-017 Nut 1

G 1033-110-121 Extension Rod 1

H 0038-303-000 Compression Spring 1

1034 Surgery Platform 1034-009-002 REV A page 5-47

Page 69

1010-030-000 Optional Upright Oxygen Bottle Holder Assembly

Item Part No. Part Name Qty.

A 1010-030-0 11 Upright Bottle Holder 1

B 0027-012-000 Cotter Pin 1

C 0741-030-024 Nylon Stand-Off 1

D 1010-030-017 Specification Label 1

1034 Surgery Platform 1033-009-002 REV Apage 5-48

Page 70

1068-168-000 Optional Drape Support Assembly

Item Part No. Part Name Qty.

A 1068-168-050 Drape Support Weldment 1

B 1068-068-043 Oxygen Tube Cap 1

C 1068-268-042 Oxygen Tube Receptacle 1

D 1068-068-041 Oxygen Supply Line 1

E 1068-090-068 Specification Label 1

F 1066-085-013 Goose Neck 1

G 1068-168-015 O@ Latch 1

H 0026-172-000 Roll Pin 1

I 0014-007-000 Nylon Washer 1

1034 Surgery Platform 1034-009-002 REV A page 5-49

Page 71

1068-054-010 Optional Direct Clamp

1034 Surgery Platform 1033-009-002 REV Apage 5-50

Page 72

1034-041-201 Optional Perineal Pad Assembly

Item Part No. Part Name Qty.

A 1034-041-030 Perineal Pad Cushion 1

B 1033-041-034 Perineal Pad Plate 1

C 1034-041-039 Perineal Pad Label 1

1034 Surgery Platform 1034-009-002 REV A page 5-51

Page 73

1033-130-010 Optional Foot Board/Foot Extender Assembly

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 1010-050-050 Knob 1 J 1033-130-030 Extender Pivot Frame 1

B 1010-050-248 Lower Pin Lock 1 K 1033-130-045 Extender Mount 1

C 1010-050-250 Lock Adjuster 1 L 1033-130-050 Foot Extender Cushion 1

D 0008-056-000 Soc. Hd. Shoulder Screw 2 M 0014-002-000 Nylon Washer 2

E 0016-122-000 Nylock Nut 2 N 0014-020-000 Nylon Washer 2

F 1033-130-021 Specification Label 1 P 0038-133-000 Compression Spring 1

G 1033-130-022 Maximum Weight Label 2 R 1033-090-034 “Do Not Sit” Label 1

H 1033-130-023 Push/Pull Label 1

1034 Surgery Platform 1033-009-002 REV Apage 5-52

Page 74

1033-132-000 Foot/Fowler Option Assembly

Item Part No. Part Name Qty.

A (page 5-54) Foot Fowler Assembly 1

B (page 5-56) Pre-Op/Post-Op Head Pad, Rt. 1

C (page 5-56) Pre-Op/Post-Op Head Pad, Lt. 1

D (page 5-62) Foot End Siderail Assembly, Rt. 1

E (page 5-62) Foot End Siderail Assembly, Lt. 1

Refer to page 5-10 for the part numbers of the Foot/Fowler mounting receptacles.

1034 Surgery Platform 1034-009-002 REV A page 5-53

Page 75

1033-132-010 Optional Foot/Fowler Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-54

Page 76

1033-132-010 Optional Foot/Fowler Assembly

Item Part No. Part Name Qty.

A 0004-018-000 Soc. Hd. Cap Screw 2

B 0004-360-000 But. Hd. Cap Screw 4

C 0025-133-000 Blind Rivet 11

D 0026-149-000 Slotted Spring Pin 4

F 0052-815-000 Nyliner 2

G 1033-132-015 Foot/Fowler Skin 1

H 1033-132-020 Prong Insert 2

K 1033-132-030 Pre-Op Pad Insert 2

L 1033-132-040 Release Rod 1

M 1033-132-045 Release Rod Hanger Plate 2

N 1033-132-047 Release Torsion Spring 2

P 1033-132-100 Foot/Fowler Weldment 1

R 0037-200-000 Vinyl Cap 2

S 7900-001-102 6” Velcro Pile 2.67 Ft.

T 0007-080-000 Truss Hd. Mach. Screw 2

W (page 5-58) Head Piece Assembly 1

1034 Surgery Platform 1034-009-002 REV A page 5-55

Page 77

Optional Pre-Op/Post-Op Pad Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-56

Page 78

Optional Pre-Op/Post-Op Pad Assembly

1033-132-050 Pre-Op/Post-Op Pad, Right 1033-132-055 Pre-Op/Post-Op Pad, Left

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

B 0004-371-000 Low Soc. Hd. Cap Screw 2 B 0004-371-000 Low Soc. Hd. Cap Screw 2

C 0004-325-000 But. Hd. Cap Screw 3 C 0004-325-000 But. Hd. Cap Screw 3

D 0011-456-000 Washer 1 D 0011-456-000 Washer 1

F 0038-499-000 Compression Spring 1 F 0038-499-000 Compression Spring 1

G 0052-795-000 Weld Nut 2 G 0052-795-000 Weld Nut 2

H 0081-293-000 Flange Bearing 1 H 0081-293-000 Flange Bearing 1

J 1033-031-019 Spacer 2 J 1033-031-019 Spacer 2

L 1033-132-060 Slider Tube 1 L 1033-132-060 Slider Tube 1

M 1033-132-070 Slider Pin 1 M 1033-132-070 Slider Pin 1

N 1033-132-081 Pre-Op Lever, Right 1 N 1033-132-080 Pre-Op Lever, Left 1

P 1033-132-090 Pre-Op Surgery Acc. Rail 1 P 1033-132-090 Pre-Op Surgery Acc. Rail 1

R 1033-132-151 Pre-Op Frame, Right 1 R 1033-132-150 Pre-Op Frame, Left 1

S 0037-200-000 Handle Grip 1 S 0037-200-000 Handle Grip 1

T 7900-001-102 11.5” Velcro Pile .96’ T 7900-001-102 11.5” Velcro Pile .96’

W 0011-286-000 Washer 1 W 0011-286-000 Washer 1

1034 Surgery Platform 1034-009-002 REV A page 5-57

Page 79

1069-133-020 Optional Head Piece Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-58

Page 80

1069-133-020 Optional Head Piece Assembly

1034 Surgery Platform 1034-009-002 REV A page 5-59

Page 81

1069-133-020 Optional Head Piece Assembly

1034 Surgery Platform 1033-009-002 REV Apage 5-60

Page 82

1069-133-020 Optional Head Piece Assembly

Item Part No. Part Name Qty.

B 0007-080-000 Truss Hd. Mach. Screw 14

C 0011-304-000 Washer 2

D 0016-123-000 Hex Nut 2

F 0037-200-000 Vinyl Cap 2

G 0038-474-000 Compression Spring 2

H 0052-086-000 Nyliner 2

J 0052-815-000 Nyliner 4

K 0058-056-000 Edge Trim 2

L 1068-091-021 40 Pounds Max. Label 2

M 1069-133-030 Neck Weldment 1

N 1069-133-040 Head Weldment 1

P 1069-133-057 Head Bracket Weldment, Rt. 1

R 1069-133-058 Head Bracket Weldment, Lt. 1

S 1069-133-073 Shaft Gear 2

T 1069-133-075 Head Piece Cover 1

V 1069-133-076 Gear Housing 2

W 1069-133-083 Head Shaft 1

X 1069-133-084 Neck Shaft 1

Y 1069-133-085 Neck Spacer 1

Z 1069-133-088 Head Spacer 1

AA 1069-133-100 Link Weldment 1

AB 1069-133- 110 Handle Weldment, Right 1

AC 1069-133--115 Handle Weldment, Left 1

AD 7900-001-102 4.25” Velcro Pile .71 Ft.

AE 1069-133-121 Handle Torsion Spring 2

1034 Surgery Platform 1034-009-002 REV A page 5-61

Page 83

1033-132-201 Optional Foot End Siderail Assembly

1033-132-200 Siderail Assembly, Right 1033-132-205 Siderail Assembly, Left

Item Part No. Part Name Qty. Item Part No. Part Name Qty.

A 0004-074-000 But. Hd. Cap Screw 4 A 0004-074-000 But. Hd. Cap Screw 4

B 0026-332-000 Dowel Pin 1 B 0026-332-000 Dowel Pin 1

C 0026-172-000 Slotted Spring Pin 1 C 0026-172-000 Slotted Spring Pin 1

D 0026-209-000 Slotted Spring Pin 1 D 0026-209-000 Slotted Spring Pin 1

E 1033-132-210 Siderail Brkt. Wldmt., Rt. 1 E 1033-132-215 Siderail Brkt. Wldmt., Lt. 1