Page 1

Power-PRO™ XT

Model 6500

Operations/Maintenance Manual

For Parts or Technical Assistance:

USA: 1-800-327-0770 (option 2)

Canada: 1-888-233-6888

2008/11 6500-309-001 REV A www.stryker.com

Page 2

Page 3

Table of Contents

Introduction...............................................................................6

Specifications .........................................................................6

WARNING / CAUTION / NOTE DEFINITION ....................................................8

Symbols .................................................................................9

Warranty................................................................................10

Stryker EMS Return Policy ...............................................................11

Return Authorization....................................................................11

Damaged Merchandise..................................................................11

International Warranty Clause .............................................................11

Patent Information .....................................................................11

Summary of Safety Precautions...............................................................12

Component Identification.................................................................... 17

Product Inspection ........................................................................18

General Inspection .....................................................................18

Setup Procedures .........................................................................20

Cot Load Height and “Jog” Function ........................................................21

Cot Fastener Installation ....................................................................22

In-Fastener Shut-Off....................................................................24

Vehicle Safety Hook Installation ...............................................................25

Ambulance Configuration ................................................................25

Required Hardware for Installation of the Safety Hook (Not Supplied) ................................25

Positioning and Installing the Safety Hook ....................................................26

Cot Features.............................................................................28

Using Restraint Straps ..................................................................28

Using The Restraint Belt Extension (Optional) .................................................30

Pedi-Mate™ Infant Restraint System (Optional) Attachment Instructions...............................31

Operating The Optional Wheel Lock(s) ......................................................33

Adjusting The Wheel Locking Force.........................................................34

Adjusting the Cot Retaining Post ...........................................................34

Adjusting the Footrest ...................................................................35

Operating the Backrest..................................................................36

Operating the Siderails ..................................................................36

Battery Power Indicator..................................................................37

Hour Meter ..........................................................................38

Installing the Optional Head End Storage Flat..................................................39

Installing the Optional Backrest Storage Pouch.................................................40

Using the Optional Equipment Hook ........................................................41

Operating the 2-Stage I.V. Pole (Optional Equipment) ............................................42

Operating the 3-Stage I.V. Pole (Optional Equipment) ............................................43

Cot Operation............................................................................44

Operating Guidelines ...................................................................44

Proper Lifting Techniques ................................................................44

Transferring the Patient to the Cot..........................................................45

www.stryker.com 650 0- 309 -0 01 REV A 3

Page 4

Table of Contents

Cot Operation (Continued)

Using the Optional Transfer Flat ...........................................................45

Ambulance Cot Motion ..................................................................45

Loading the Cot into a Vehicle with Two Operators - Powered Method ...............................46

High Speed Retract/Extend...............................................................47

Loading the Cot into a Vehicle with Two Operators at the Foot End..................................47

Loading an Empty Cot into a Vehicle with One Operator - Powered Method............................48

Unloading the Cot from a Vehicle with Two Operators - Powered Method .............................49

Unloading the Cot from a Vehicle With One Operator - Powered Method..............................50

Manual Override Operation...............................................................51

Loading the Cot into a Vehicle with Two Operators - Manual Method ................................52

Unloading the Cot from a Vehicle with Two Operators - Manual Method..............................53

Unloading an Empty Cot from a Vehicle with One Operator - Manual Method ..........................54

Adjusting Cot Height ....................................................................55

Using Additional Assistance ..............................................................55

Operating the Retractable Head Section .....................................................56

Battery Operation ......................................................................57

Cleaning................................................................................58

Washing Procedure ....................................................................58

Washing Limitations ....................................................................58

Removal of Iodine Compounds ............................................................59

Preventative Maintenance ...................................................................60

Base Lubrication ......................................................................61

Regular Inspection and Adjustments ........................................................62

Maintenance Record .......................................................................65

Training Record...........................................................................66

Cot Assembly ............................................................................67

Base Assembly...........................................................................75

Outer Lift Tube Assembly, Base Pivot - 6500-301-021 ...............................................80

Inner Lift Tube Assembly, Base Pivot - 6500-301-022 ...............................................81

Inner Lift Tube, Litter Pivot - 6500-001-034 ......................................................82

Inner Lift Tube, Litter Pivot - 6500-001-035 ......................................................83

Outer Rail, Patient Right Assembly .............................................................84

Outer Rail, Patient Left Assembly..............................................................86

Hall Sensor Assembly ......................................................................88

Sensor Housing Assembly...................................................................89

Powerplant Assembly ......................................................................90

Hydraulic Sub-Assembly - 6500-001-030 ........................................................92

Foot End Assembly ........................................................................93

Switch Assembly - 6500-001-016..............................................................97

Fowler Assembly..........................................................................98

Trend Assembly ..........................................................................99

Head Section Assembly - 6500-001-020........................................................ 100

4 650 0- 309 -0 01 REV A www.stryker.com

Page 5

Table of Contents

Assembly Drawings (Continued)

Head Section Lock Assembly - 6500-001-026 ...................................................102

In-Fastener Shut-Off Assembly - 6500-001-027 .................................................. 103

Optional Oxygen Bottle Holder - 6500-140-000 ................................................... 104

Optional Oxygen Bottle Holder Assembly - 6500-001-040 ...........................................10 5

Optional Head End Oxygen Bottle Holder - 6500-141-000 ...........................................106

Removable Oxygen Bottle Holder Assembly - 6080-140-010 .........................................107

Two-Stage I.V. Pole Assembly Patient Right - 6500-210-000..........................................108

Three-Stage I.V. Pole Assembly Patient Right - 6500-215-000......................................... 10 8

Three-Stage I.V. Pole Assembly Patient Right - 6500-001-043 ........................................ 110

Two-Stage I.V. Pole Assembly Patient Left - 6500-211-000 ..........................................111

Three-Stage I.V. Pole Assembly Patient Left - 6500-216-000 .........................................111

Two-Stage I.V. Pole Assembly Patient Left - 6500-001-042........................................... 112

Three-Stage I.V. Pole Assembly Patient Left - 6500-001-044 ......................................... 113

Two-Stage I.V. Pole Assembly, Dual - 6500-212-000 .......................................114

Three Stage I.V. Pole Assembly, Dual - 6500-217-000 .............................................. 114

Optional Defibrillator Platform - 6500-170-000.................................................... 115

Optional Head Extension - 6100-044-000 .......................................................116

Optional Head Extension Assembly - 6100-044-012 ............................................... 117

Troubleshooting Guide..................................................................... 118

Electronics and Hydraulics Locator ........................................................ 118

Hydraulic Manifold Components Locator .................................................... 119

Electronics Assembly Wiring Schematics.................................................... 120

Electrical System Block Diagram .........................................................121

Troubleshooting Guide .................................................................123

Recycling Passport .......................................................................12 7

Product: 6500-700-006 ................................................................12 7

Product: 6500-001-016 ................................................................. 12 8

Product: 6500-001-028 ................................................................. 12 9

Product: 6500-001-015 ................................................................. 13 0

Product: 6500-001-014 .................................................................13 0

Product: 6500-001-030 ................................................................ 13 1

Product: 6500-001-159 ................................................................. 13 2

Quick Reference Replacement Part List ........................................................ 13 3

www.stryker.com 650 0- 309 -0 01 REV A 5

Page 6

Introduction

INTRODUCTION

This manual is designed to assist you with the operation and maintenance of the Power-PRO™ XT

Ambulance Cot. Read it thoroughly before using the equipment or beginning any maintenance on it.

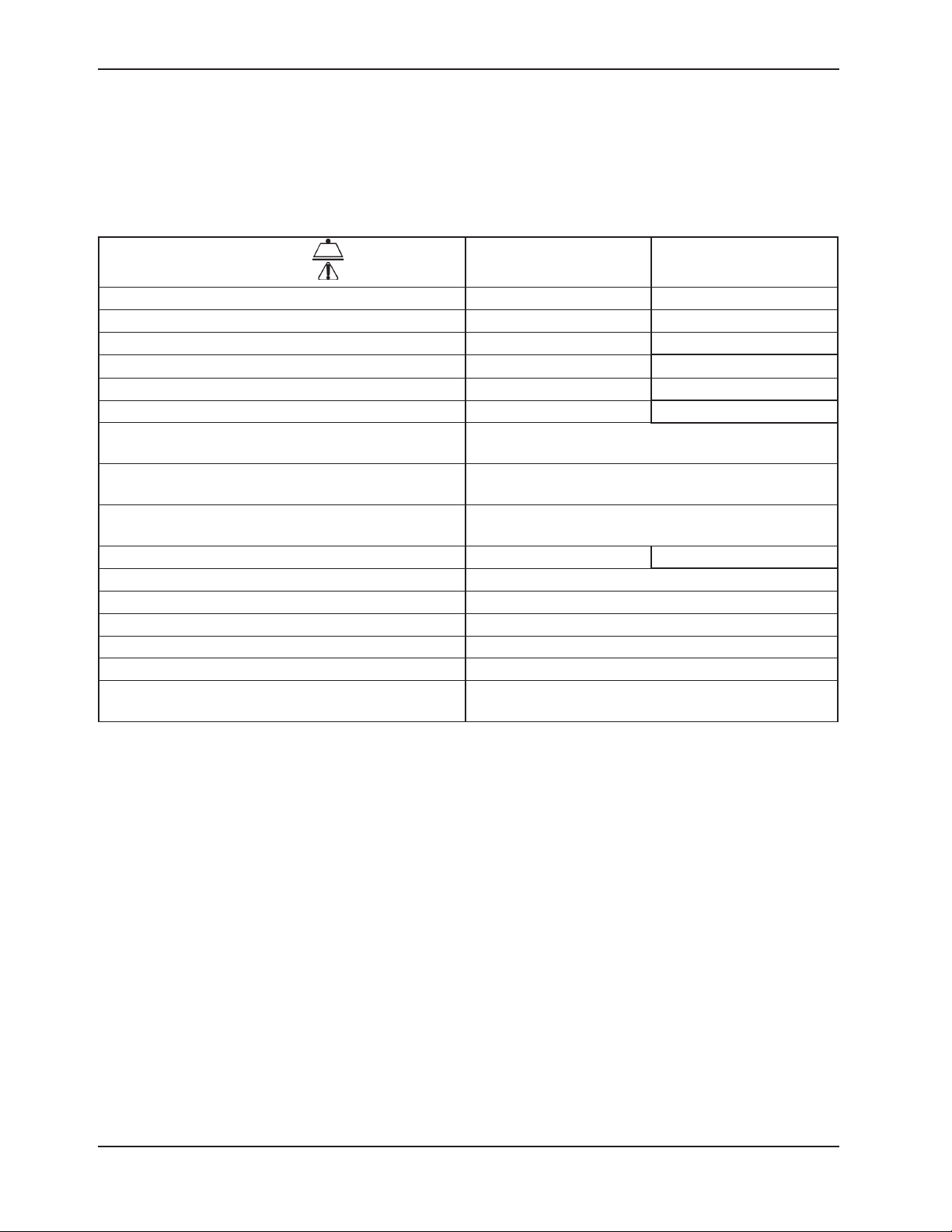

SPECIFICATIONS

Maximum Cot Load Capacity 700 pounds 315 kg

Maximum Unassisted Lift Capacity 500 pounds 225 kg

Backrest Articulation/Shock Position 2° to 73° / +15°

Overall Length/Minimum Length/Width 81" / 63" / 23" 206 cm / 160 cm / 58,5 cm

1

Height

2

Weight

Caster Diameter/Width 6" / 2" 15,2 cm / 5,1 cm

Minimum Operators Required for Loading/

Unloading an Occupied Cot

Minimum Operators Required for Loading/

Unloading an Unoccupied Cot

Recommended Fastener Systems Model 6370 or 6377 Floor Mount Type

Recommended Loading Height

3

Roll-In Style Yes

Single Wheel Lock / Double Wheel Lock Optional

Hydraulic Oil Stryker Part Number 6500-001-293

Battery System DeWA LT® 24 Volt NiCd Battery

- Battery Stryker Part Number 6500-700-006

- Charger Stryker Part Number 6500-070-000 (120 Volt)

1

Adjustable from 14" to 41.5" 35,5 cm to 105 cm

122 pounds 55,3 kg

2

1

Model 6371 Wall Mount Type

Adjustable up to 36" 91 cm

Part Number 6500-072-000 (12/24 Volt)

1

Height measured from bottom of mattress at seat section to ground level.

2

Cot is weighed with 1 battery and without mattress and restraints.

3

Cot may be set to any ambulance deck height ranging from 26" to 36" (66 cm to 91 cm).

Stryker reserves the right to change specifications without notice.

The Power-PRO™ XT is designed to conform to the Federal Specification for the Star-of-Life Ambulance (KKK-A-1822).

The Power-PRO™ XT is designed to be compatible with competitive cot fastener systems.

DeWA LT® is a registered trademark of Black & Decker Inc.

Patents pending.

The yellow and black color scheme is a proprietary trademark of Stryker Corporation.

Return To Table of Contents

6 650 0- 309 -0 01 REV A www.stryker.com

Page 7

Introduction

Contact Stryker Customer Service or Technical

Support at: (800) 327-0770 or (269) 324-6500.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

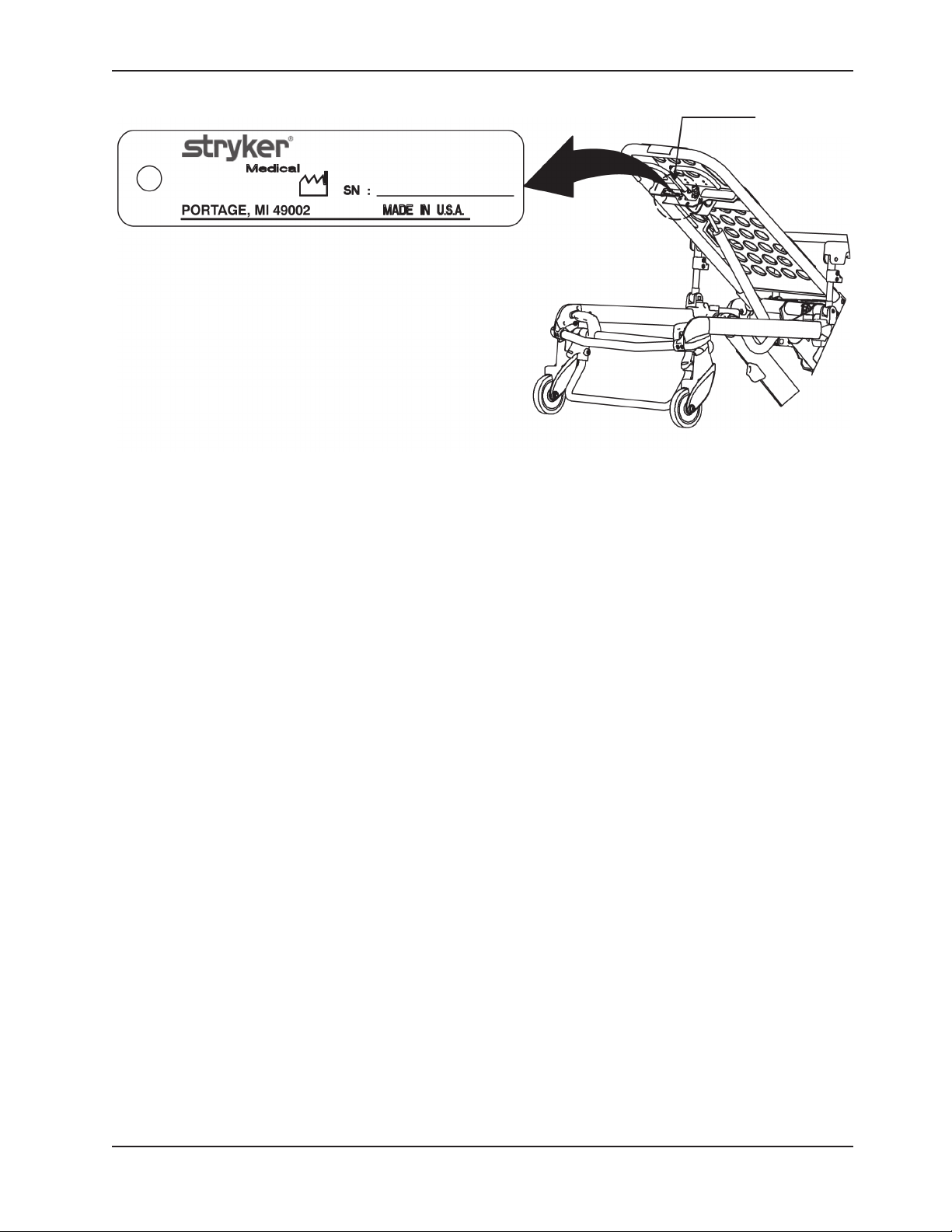

Please have the serial number of your Stryker product when

calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

Figure 1 - Cot Serial Number & Location

Serial Number

HEAD END

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 7

Page 8

Introduction

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation, which if not avoided, could result in death or serious injury. It may also describe potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation, which if not avoided, may result in minor or moderate injury to

the user or patient or damage to the equipment or other property. This includes special care necessary for the safe

and effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use

or misuse.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

Return To Table of Contents

8 650 0- 309 -0 01 REV A www.stryker.com

Page 9

Symbols

Warning, consult accompanying documentation

Dangerous Voltage Symbol

Pinch Point

Extend

Retract

IPX6

Type B Equipment: equipment providing a particular degree of protection against electric shock,

particularly regarding allowable leakage current and reliability of the protective earth connection.

Internally Powered Equipment: Equipment able to operate from an internal (removable) electric power

source.

Mode of Operation: 10% (1 Min. On / 5 Min. Off)

Protection from powerful jets.

Medical Equipment Classified by Underwriters Laboratories Inc. With Respect to Electric Shock, Fire, and

Mechanical Hazards Only in Accordance with UL 60601−1, and CAN/CSA C22.2 No. 601.1.

Safe Working Load Symbol

In accordance with European Directive 2002/96/EC on Waste Electrical and Electronic Equipment, this

symbol indicates that the product must not be disposed of as unsorted municipal waste, but should be

collected separately. Refer to your local distributor for return and/or collection systems available in your

country.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 9

Page 10

Warranty

Stryker EMS, a division of the Stryker Corporation, offers one warranty option in the United States:

Two (2) year parts and labor. Stryker EMS warrants to the original purchaser that its products

should be free from manufacturing non-conformances that affect product performance and

customer satisfaction for a period of two (2) years after date of delivery. Stryker’s obligation

under this warranty is expressly limited to supplying replacement parts and labor for, or

replacing, at its option, any product that is, in the sole discretion of Stryker, found to be

defective. Expendable components, i.e. mattresses, restraints, I.V. poles, storage nets, storage

pouches, O2 straps, and other soft goods, have a one (1) year limited warranty.

Stryker Medical EMS products are designed for a 7 year expected service life under normal

use, conditions, and with appropriate periodic maintenance as described in the maintenance

manual for each device. Stryker warrants to the original purchaser that the welds on its EMS

products will be free from structural defects for the expected 7 year life of the EMS product as

long as the original purchaser owns the product. Original purchasers will also obtain a three

(3) year limited parts warranty for the X-frame components of the POWER PRO cot and a three

(3) year limited power train warranty covering the motor pump assembly and hydraulic cylinder

assembly. Stryker’s obligation under this three (3) year limited warranty is expressly limited to

supplying replacement parts and labor for, or replacing, at its option, any part that is, in the sole

discretion of Stryker, found to be defective.

If Stryker requests, products or parts for which an original purchaser makes a warranty claim,

the purchaser shall return the product or part prepaid freight to Stryker’s factory.

Any improper use or alteration or repair by unauthorized service providers in such a manner

as in Stryker’s judgment affects the product materially and adversely, shall void this warranty.

Any repair of Stryker products using parts not provided or authorized by Stryker shall void this

warranty. No employee or representative of Stryker is authorized to change this warranty in

any way.

This statement constitutes Stryker EMS’s entire warranty with respect to the aforesaid

equipment. STRYKER MAKES NO OTHER WARRANTY OR REPRESENTATION EITHER

EXPRESSED OR IMPLIED, EXCEPT AS SET FORTH HEREIN. THERE IS NO WARRANTY OF

MERCHANTABILITY AND THERE ARE NO WARRANTIES OF FITNESS FOR ANY PARTICULAR

PURPOSE. IN NO EVENT SHALL STRYKER BE LIABLE HEREUNDER FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING FROM OR IN ANY MANNER RELATED TO SALES OR

USE OF ANY SUCH EQUIPMENT.

DeWALT® Product Warranty

Any DeWA LT® product purchased from Stryker EMS is covered for a period of one (1) year

after date of delivery. Stryker’s obligation under this warranty is expressly limited to supplying

replacement parts and labor for, or replacing, at its option, any product that is, in the sole

discretion of Stryker, found to be defective.

Return To Table of Contents

10 650 0- 309 -0 01 REV A www.stryker.com

Page 11

Warranty

STRYKER EMS RETURN POLICY

Cots, Stair Chairs, Evacuation Chairs, Cot Fasteners and Aftermarket Accessories may be

returned up to 180 days of receipt if they meet the following guidelines:

Prior to 30 Days

• 30daymoneybackguaranteeineffect

• StrykerEMSisresponsibleforallcharges

• Returnswillnotbeapprovedonmodifieditems

Prior to 90 Days

• Productmustbeunused, undamaged and in the original packaging

• Customerisresponsiblefora10%restockingfee

Prior to 180 Days

• Productmustbeunused, undamaged and in the original packaging

• Customerisresponsiblefora25%restockingfee

RETURN AUTHORIZATION

Merchandise cannot be returned without approval from the Stryker Customer Service

Department. An authorization number will be provided which must be printed on the returned

merchandise. Stryker reserves the right to charge shipping and restocking fees on returned

items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

DAMAGED MERCHANDISE

ICC Regulations require that claims for damaged merchandise must be made with the carrier

within fifteen (15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS

UNLESS SUCH DAMAGE IS NOTED ON THE DELIVERY RECEIPT AT THE TIME OF RECEIPT.

Upon prompt notification, Stryker will file a freight claim with the appropriate carrier for damages

incurred. Claim will be limited in amount to the actual replacement cost. In the event that this

information is not received by Stryker within the fifteen (15) day period following the delivery of

the merchandise, or the damage was not noted on the delivery receipt at the time of receipt,

the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

INTERNATIONAL WARRANTY CLAUSE

This warranty reflects U.S. domestic policy. Warranty outside the U.S. may vary by country.

Please contact your local Stryker Medical representative for additional information.

PATENT INFORMATION

products are covered by one or more of the following patents:

United States 5,575,026 6,276,010 6,648,343 6,908,133 6,796,757

5,537,700 6,125,485 6,735,794 7,100,224 7,398,571

D527,10 3

Other Patents Pending

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 11

Page 12

Summary of Safety Precautions

The following is a list of safety precautions that must be observed when operating or servicing this unit. The precautions

are repeated throughout the manual, where applicable. Carefully read this list before using or servicing the unit.

WARNINGS

Do not modify the ambulance cot or any components of the cot, including the hydraulic unit. Modifying the product •

can cause unpredictable operation resulting in injury to the patient or operator. Modifying the product will also void

its warranty.

The in-fastener shut-off module must be positioned properly before placing the ambulance cot into EMS service. •

Failure to install the in-fastener shut-off module may cause injury to the patient or operator and/or damage to the

vehicle.

It is the responsibility of the cot operator to ensure the ambulance cot being used in the Stryker cot fastener •

system meets the installation specifications listed on page 23. Injury may result if a non-compatible ambulance cot

is used in the Stryker cot fastener system.

Have the vehicle safety hook installed by a certified mechanic. Improper safety hook installation can result in injury •

to the patient or operator and/or damage to the cot.

Failure to install the vehicle safety hook can result in injury to the patient or operator. Install and use the safety •

hook as described in this manual. To avoid injury, verify the safety bar has engaged the safety hook before

removing the ambulance cot from the patient compartment.

Install the vehicle safety hook at least 1/8" (3 mm) from the edge of the rear ambulance door. After installation, •

verify that the undercarriage locks in the load position without contacting the emergency vehicle bumper.

The ambulance cot must have at least 5/8" (1,6 mm) of clearance between the emergency vehicle bumper and •

the ambulance cot to disengage the safety bar when unloading the product from the ambulance. Verify that the

product is locked in a rolling position before disengaging the safety bar from the safety hook (if equipped).

To avoid accidental release of the Pedi-Mate™, and possible injury to the infant, ensure that the restraint buckle •

is located away from obstructions on the ambulance cot or accessories.

Never apply the optional wheel lock(s) while a patient is on the ambulance cot. Tipping could occur if the •

ambulance cot is moved while wheel locks are applied, resulting in injury to the patient or operator and/or damage

to the product.

Never install or use wheel locks on an ambulance cot with excessively worn wheels. Installing or using wheel locks •

on wheels with less than a 6" (16 cm) diameter could compromise the holding ability of the wheel lock, resulting

in injury to the patient or operator and/or damage to the product or other equipment.

To avoid risk of electric shock, never attempt to open the battery pack for any reason. If the battery pack case •

is cracked or damaged, do not insert it into the charger. Return damaged battery packs to a service center for

recycling.

Do not remove the battery when the ambulance cot is activated.•

Avoid contact with a wet battery or battery enclosure. Contact may cause injury to the patient or operator.•

When the optional head-end storage flat is being used, ensure it does not interfere with the operation of the •

retractable head section, safety bar and safety hook. Injury to the patient or operator could result.

Improper usage of the ambulance cot can cause injury to the patient or operator. Operate the ambulance cot only •

as described in this manual.

Entanglement in powered ambulance cot mechanisms can cause serious injury. Operate the ambulance cot only •

when all persons are clear of the mechanisms.

Practice changing height positions and loading and unloading the ambulance cot until operation of the product is •

fully understood. Improper use can cause injury.

Do not allow untrained assistants to assist in the operation of the ambulance cot. Untrained technicians/assistants •

can cause injury to the patient or themselves.

Ensure proper hand placement on hand grips. Hands should be clear of red safety bar pivots while loading and •

unloading the cot.

Do not ride on the base of the ambulance cot. Damage to the product could occur, resulting in injury to the patient •

or operator.

Grasping the ambulance cot improperly can cause injury. Keep hands, fingers and feet away from moving parts. •

Return To Table of Contents

12 6500- 309- 001 REV A ww w.stryker.com

Page 13

Summary of Safety Precautions

WARNINGS (CONTINUED)

Transporting the cot sideways can cause the cot to tip, resulting in possible damage to the product and/or injury to •

the patient or operator. Transporting the cot in a lowered position, head or foot end first, will minimize the potential

of a cot tip.

Any emergency vehicle to be used with this ambulance cot • must have the in-fastener shut-off system installed.

Always use all restraint straps to secure the patient to the ambulance cot. An unrestrained patient may fall from •

the ambulance cot and be injured.

Do not attach restraints to the base or cross tubes, improper restraint attachment could result in damage to the •

cot further resulting in injury to the patient or operator.

Never leave a patient unattended on the ambulance cot or injury could result. Hold the ambulance cot securely •

while a patient is on the cot.

Siderails are not intended to serve as a patient restraint device. Refer to • pages 28 and 30 for proper restraint strap

usage. Failure to utilize the siderails properly could result in patient injury.

High obstacles such as curbing, steps or rough terrain can cause the ambulance cot to tip, possibly causing injury •

to the patient or operator. Transporting the cot in lower positions can reduce the potential of a cot tip. If possible,

obtain additional assistance (see page 55 for a reference chart) or take an alternate route.

Whenever the weight of the ambulance cot and patient is off the wheels, the ambulance cot will • automatically

enter the high speed retract mode if the retract button is pressed.

Once the weight is off the ground, the operator(s) must support the load of the patient, ambulance cot and any •

accessories. Failure to support the load properly may cause injury to the patient or operator.

To avoid injury, verify the safety bar has engaged the safety hook before removing the ambulance cot from the •

patient compartment.

Do not pull or lift on the safety bar when unloading the ambulance cot. Damage to the safety bar could result and •

injury to the patient or operator could occur.

Do not press the extend (+) button until the safety bar engages the safety hook.•

To avoid injury, always verify that the head section is locked into place prior to operating the ambulance cot (see •

page 54). The head section must be extended and locked into position before loading/unloading the ambulance

cot.

When using a standard ambulance cot fastener, do not load the cot into the vehicle with the head section retracted. •

Loading the cot with the head section retracted may cause the product to tip or not engage properly in the cot

fastener, possibly causing injury to the patient or operator and/or damage to the cot.

The one person loading and unloading procedures are for use only with an empty ambulance cot. Do not use the •

procedures when loading/unloading a patient. Injury to the patient or operator could result.

Do not attempt to operate the ambulance cot when loaded into a cot fastener. The in-fastener shut-off is • only a

means for disabling the electronic functionality. Damage to the product or injury to the patient or operator may

occur.

In-fastener shut-off must be installed in all ambulances in which the cot will be used.•

Use any appropriate personal safety equipment (goggles, respirator, etc.) to avoid the risk of inhaling contagion. •

Use of power washing equipment can aerate contamination collected during the use of the ambulance cot.

Failure to properly clean or dispose of contaminated mattress or other ambulance cot components will increase •

the risk of bloodborne pathogens and may cause injury to the patient or operator.

Hydraulically raising or lowering the cot may temporarily affect electronic patient monitoring equipment. For best •

results, patient monitoring should be conducted when the cot is idle.

SOME CLEANING PRODUCTS ARE CORROSIVE IN NATURE AND MAY CAUSE DAMAGE TO THE PRODUCT IF •

USED IMPROPERLY. If the products described above are used to clean Stryker patient care equipment, measures

must be taken to insure the cots are wiped with clean water and thoroughly dried following cleaning. Failure to

properly rinse and dry the cots will leave a corrosive residue on the surface of the cots, possibly causing premature

corrosion of critical components.

Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by relieving pressure •

before disconnecting hydraulic or other lines. Tighten all connections before applying pressure. If an accident

occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours

or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical

source.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 13

Page 14

Summary of Safety Precautions

CAUTIONS

Set the cot height limit to the proper stop height prior to operation.•

Installation of the safety hook should be done by a certified mechanic familiar with ambulance construction. •

Consult the vehicle manufacturer before installing the safety hook and be sure the installation of the safety hook

does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank or electrical wiring of the

vehicle.

Ensure that restraints are not entangled in the base frame when raising and lowering the cot. •

Wheel locks are only intended to help prevent the ambulance cot from rolling while unattended. Wheel locks may •

not provide sufficient resistance on all surfaces or under loads.

The ambulance cot fastener comes preconfigured for an X-Frame cot, if the fastener has been configured for an •

H-frame style cot, the cot retaining post must be adjusted to accommodate the fastener.

Only use the battery and charger as specified.•

The Power-PRO™ XT is not for use with an AC adaptor.•

Ensure that the battery is charged prior to placing into service. An uncharged or depleted battery may cause poor •

ambulance cot performance.

A preventative maintenance program should be established for all Stryker EMS equipment. Preventative maintenance •

may need to be performed more frequently based on the usage level of the product. Close attention should be

given to safety features including, but not limited to:

Hydraulic power mechanism•

All electrical controls return to off or neutral position when released•

For additional maintenance information, refer to the preventative maintenance section.•

Do not store items under the ambulance cot mattress. Storing items under the mattress can interfere with the •

operation of the ambulance cot.

The weight of the equipment in the head end storage flat (if equipped) must not exceed 40 pounds (18 kg). •

The weight of the equipment in the pocketed backrest storage pouch (if equipped) must not exceed 20 pounds •

(9 kg).

To avoid damage to the equipment hook, the weight of the accessories or equipment must not exceed 20 pounds •

(9 kg).

The weight of the I.V. bags or equipment must not exceed 40 pounds (18 kg) for usage on the I.V. poles •

(if equipped).

The weight of the oxygen bottle cylinder and/or other equipment must not exceed 40 pounds (18 kg) with the •

permanent foot-end oxygen bottle holder (if equipped). Oxygen bottle cylinder should not be stored on the cot or

on the oxygen holder when in the ambulance vehicle.

The weight of the removable oxygen bottle holder and/or other equipment must not exceed 25 pounds (11.3 kg) •

Before operating the cot, clear any obstacles that may interfere and cause injury to the operator or patient.•

The ambulance cot can be set at any height position. Establish the required load height for the ambulance cot •

prior to placing the unit into service.

Loading, unloading or changing the position of a loaded ambulance cot requires a minimum of• two trained

operators. The operator(s) must be able to lift the total weight of the patient, cot and any other items on the cot

(if additional assistance is needed, see page 53 for a reference chart).

When unloading the ambulance cot from the patient compartment, ensure the caster wheels are safely set on the •

ground or damage to the product may occur.

Do not “jog” the ambulance cot past the established load height of the product when the safety bar engages the •

vehicle safety hook or damage may occur to the product.

Remove the battery if the cot is not going to be used for an extended period of time (over 24 hours).•

Remove the battery before washing the cot.•

Do not steam clean or ultrasonically clean this ambulance cot. Maximum water temperature should not exceed •

180 °F/82 °C. Maximum air dry temperature (cart washers) is 240 °F/115 °C. Maximum water pressure should not

exceed 1500 psi/130.5 bar. If a hand held wand is being used to wash the unit, the pressure nozzle must be kept

a minimum of 61 centimeters from the unit. Towel dry all casters and interface points. Failure to comply with these

instructions may invalidate any/all warranties.

Return To Table of Contents

14 6500 -309- 001 REV A w ww.stryker.com

Page 15

Summary of Safety Precautions

CAUTIONS (CONTINUED)

Improper maintenance can cause injury or damage to the product. Maintain the ambulance cot as described in this •

manual. Use only Stryker approved parts and maintenance procedures. Using unapproved parts and procedures

could cause unpredictable operation and/or injury and will void the product warranty.

Failure to use authorized parts, lubricants, etc. could cause damage to the ambulance cot and will void the •

warranty of the product.

Hydraulic hose connections and lines can fail due to physical damage, kinks, age, and exposure. Check hoses and •

lines regularly to avoid damage to the cot. Check and tighten loose connections.

Hydraulic fluid connections can loosen due to physical damage and vibration. Check and tighten loose •

connections.

When charging batteries in an ambulance vehicle, locate the charger either in the forward cab or an enclosed •

compartment (i.e. cabinet).

Do not lubricate the bearings in the X-frame as it will degrade the performance of the Power-PRO™ XT ambulance •

cot and may void its warranty.

NOTES

This manual should be considered a permanent part of the ambulance cot and should remain with the product •

even if the cot is subsequently sold.

Adjustment of the rail clamp assembly may be required in order to compensate for any variation in the cot retaining •

post position depending on the ambulance cot manufacturer and model number.

These are general instructions for installation of the Pedi-Mate™. Safe and proper use of the Pedi-Mate™ is solely •

at the discretion of the user. Stryker recommends all users be trained on the proper use of the Pedi-Mate™ before

using it in an actual situation.

If the arrow on the bottom bracket of the retaining post points toward the head end of the cot, the retaining post •

is set for an X-frame style cot. If the arrow points toward the foot end of the cot the post is set for an H-frame

style cot.

If the push button switch remains activated, the motor will remain halted until the operator releases the button. •

Once the push button is released, depress the appropriate button to “jog” the cot height in either direction.

Add an additional 1/2" (1,3 cm) inch to your deck height measurement to allow for variations with patient weight •

and equipment added to the cot.

The operators must lift the cot slightly off the ground to use the manual extend or retract while a patient is on the •

cot.

Batteries slowly lose power when not on the charger.•

Failure to follow the cleaning directions when using the specified types of cleaners may void this product’s •

warranty.

Activation of the manual release may cause the ambulance cot to drop slowly if less than 40 pounds (18 kg) are •

on the cot.

When operating the manual release, avoid rapid lifting or lowering of the base or movement may appear sluggish; •

lift with a slow constant motion.

In order to achieve the optimal performance of the Power-PRO™ XT, center the patient weight within the width of •

the cot.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 15

Page 16

Summary of Safety Precautions

Figure 2 - Potential Pinch Points

WARNING: Pinch Points

Return To Table of Contents

16 650 0- 309 -001 REV A www.stryker.com

Page 17

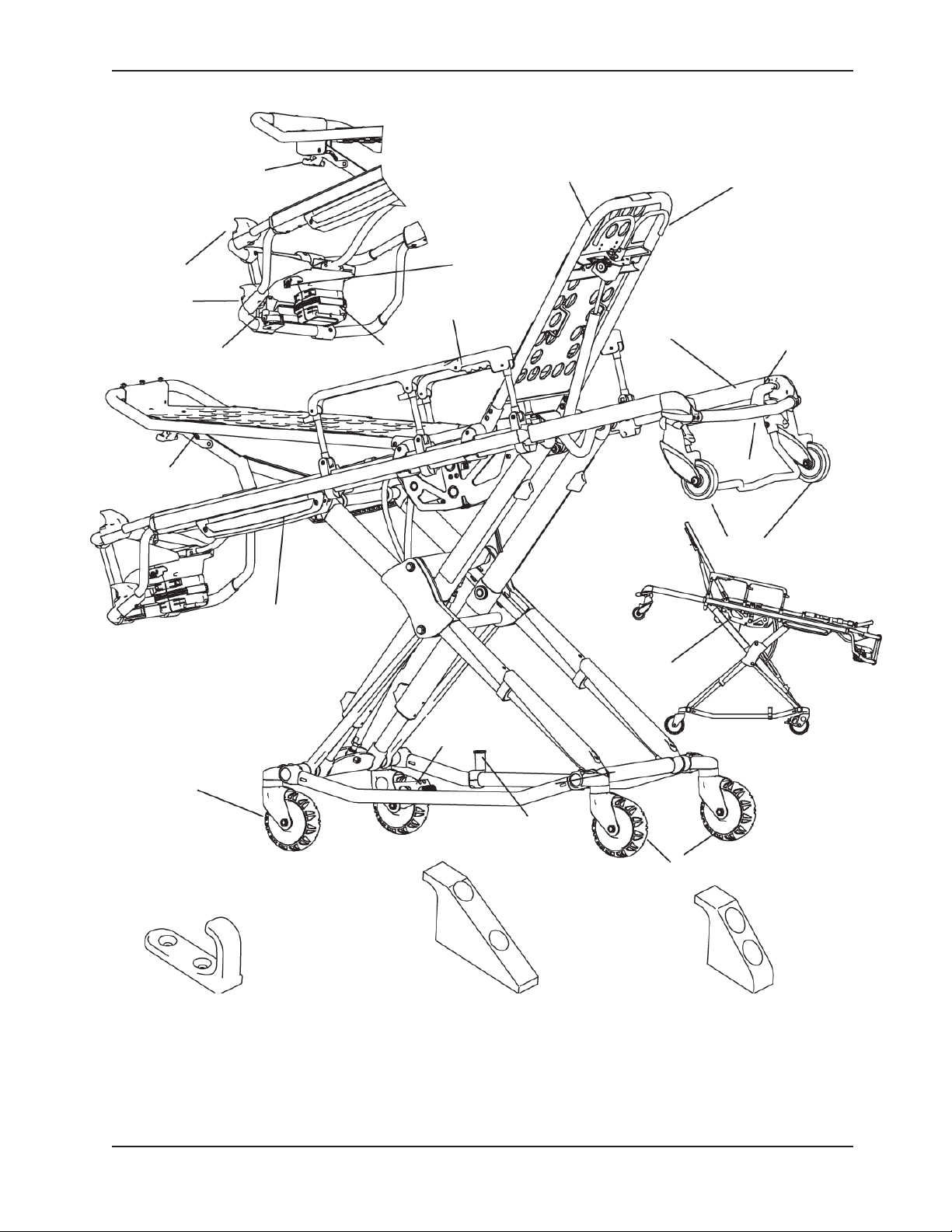

Component Identification

Foot Rest Release

Handle

Height Adjustment

Switches

Manual Release

Leg Rest

Battery

Battery Release

Siderail Release

Backrest

Backrest Adjustment Handle

HEAD END

Retractable

Head Section

Lifting Bar

Loading Wheels

Head Section

Release

Transport Wheels

Height

Sensor

Housing

J Safety Hook

Stryker part number

6092-036-018

Wheel Lock

(Optional)

Cot Retaining Post

Long Safety Hook

Stryker part number

6060-036-018

Figure 3 - Cot Components

Hydraulic Unit

Transport Wheels

Short Safety Hook

Stryker part number

6060-036-017

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 17

Page 18

Product Inspection

GENERAL INSPECTION

The condition of the ambulance cot is the responsibility of the owner. It is important that the ambulance cot is working

properly before the product is put into service. Have a qualified service person use the following list and the operation

instructions to check the ambulance cot before the product is put into service.

Unpack the cartons and check all items for proper operation.

Item Routine Page(s)

Battery Unpack batteries and charger

Charge battery according to DeWA LT® instructions

CAUTION

When charging batteries in an ambulance vehicle, locate the charger either in the forward cab or an enclosed

compartment (i.e. cabinet).

Prior to checking the features and condition of the cot, the battery must be charged until the red LED lights continuously

to ensure a full charge. Refer to the DeWA LT® instructions for further charging information.

Once the battery is fully charged, inspect the ambulance cot for the following points:

P/N 6500-001-206

Item Routine Page(s)

Battery Charge spare battery (if necessary) according to DeWALT®

instructions.

Install battery into foot-end enclosure, battery indicator operates. 57

Ensure the battery remains firmly secured. 57

Release and remove battery from foot-end enclosure. 57

Reinstall battery into foot-end enclosure. 57

Hydraulics Inspect motor mount, all fasteners secure. 118

Check cylinder attachments at both ends, all fasteners secure. 118

Inspect main cable, all connections secure. 118

Inspect hoses and cylinder seal for leaks. 118

Electronic

Controls

Manual Release Verify the manual release lever functions properly, adjust accordingly. 51

Check battery indicator, charged. 37

Extend cot to raised position. 55

Verify ”jog” function operating smoothly. 55

Lower to retracted position, cot secures in a mid-height position

(motor does not operate).

Determine and set ambulance vehicle load height 21

Check high speed retract. 47

Extend cot to full height, no drift. 55

With the cot empty, check the raise/lower function. 51

With the cot loaded with a minimum of 45 kg, check the raise/lower

function.

With the cot loaded with a minimum of 45 kg, check the load/unload

function.

P/N 6500-001-206

55

51

48

Return To Table of Contents

18 650 0- 309 -001 REV A www.stryker.com

Page 19

Product Inspection

Item Routine Page(s)

Litter All fasteners secure (reference all assembly drawings).

All welds intact, not cracked or broken.

No bent, broken, or damaged components.

Inspect hand grips, no defects or tears.

Verify siderails operate and latch properly. 36

Verify backrest cylinder operates properly through range of motion. 36

Verify the leg rest operates properly. 35

Install body restraints. Restraints intact and operating properly. 28 - 30

No rips or tears in mattress cover.

Head Section All fasteners secure (reference all assembly drawings).

No bent or broken tubing or sheet metal.

Verify the head section extends and retracts properly. 56

Inspect grip on lift bar, no defects or tears.

Load wheels are secure and roll freely.

Verify the safety bar operates properly. 24

Base All fasteners secure (reference all assembly drawings).

All welds intact, not cracked or broken.

No bent, broken, or damaged components.

Wheels and Tires No debris in wheels.

All wheels secure, rolling and swiveling properly.

Operate wheel locks (if equipped) - wheel secure when engaged,

rolls freely when disengaged.

Cot Fastener Inspect the cot retaining post, fasteners secure. 34

Install in-fastener shut-off module.

Determine and set in-fastener shut-off position.

Verify the ambulance cot and cot fastener fit and function properly.

Install vehicle safety hook. 25 - 27

Verify the safety bar engages the vehicle safety hook properly. 24

Accessories Verify I.V. pole (if equipped) operates properly. 42 - 43

Verify foot-end oxygen bottle holder (if equipped) operates properly.

Verify removable oxygen bottle holder (if equipped) operates properly.

Verify Pedi-Mate™ restraint package (if equipped) operates properly. 31 - 32

Verify accessory hook (if equipped) is installed properly. 41

Verify head extension with pillow (if equipped) installed properly.

Verify pocketed backrest storage pouch (if equipped) installed properly. 40

Head-end storage flat (if equipped) installed properly. 39

Verify pillow (if equipped) included.

Verify 36" restraint extender (if equipped) is included. 30

Verify the Bariatric transfer flat (if equipped) is included. 45

33 - 34

24

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 19

Page 20

Setup Procedures

Ensure that all shipping and packaging materials have been removed from the product(s) prior to use.

The patient compartment of the vehicle in which the ambulance cot will be used must have:

• Asmoothrearedgeforcotloading.

• Alevelfloorlargeenoughforthefoldedcot.

• Stryker6370/6374/6377/6378/6379or6371/6375crashstablecotfastener(notincluded).

• In-fastenershut-offmoduleinstalledandpositionedproperly.

• Spacetoinstallthesafetyhook.

When necessary, modify the vehicle to fit the cot. Do not modify the cot.

WARNING

Do not modify the Power-PRO™ XT ambulance cot or any components of the cot, including the hydraulic unit. •

Modifying the product can cause unpredictable operation resulting in injury to the patient or operator. Modifying

the product will also void its warranty.

Any emergency vehicle to be used with this ambulance cot • must have the in-fastener shut-off system installed.

Refer to DeWA LT® manual (Stryker part number 6500-001-206) for battery and charger operation.

NOTE

This manual should be considered a permanent part of the ambulance cot and should remain with the product •

even if the cot is subsequently sold.

Stryker continually seeks advancements in product design and quality. Therefore, while this manual contains the •

most current product information available at the time of printing, there may be minor discrepancies between your

ambulance cot and this manual. If you have any questions, please contact Stryker Customer Service or Technical

Support at (800) 327-0770 or (269) 324-6500.

Return To Table of Contents

20 6500 -309- 001 REV A www.stryker.com

Page 21

Setup Procedures

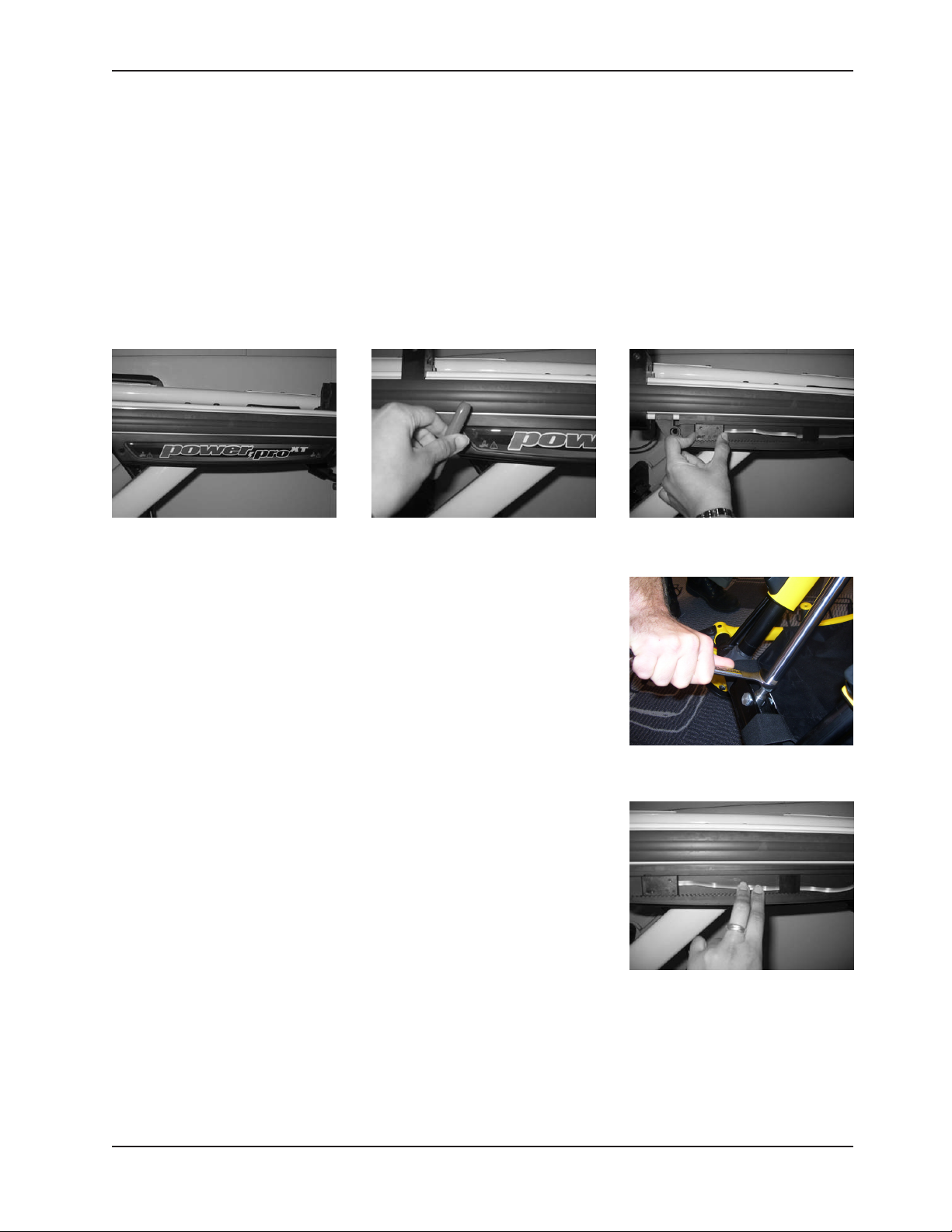

COT LOAD HEIGHT AND “JOG” FUNCTION

The control mechanism of the ambulance cot utilizes height sensors to set the load height stop for the cot. The sensors

are used to match the load wheel height for a specific ambulance deck height.

The ambulance cot load height can be set from 26" to 36" (66 cm to 91,4 cm), measured from the ground to the bottom

of the load wheel. Establish the height for the cot prior to placing the unit into service. The load height of the ambulance

cot can be modified at anytime, but must be determined and set before the cot is placed into service.

To Set Cot Load Height:

1. Locate the sensor housing on the patient right side of the ambulance cot (Figure 4a), using a T27 Torx wrench,

remove the sensor housing cover by loosening the two (2) screws (one on each end) (Figure 4b).

Figure 4a - Sensor Housing

2. Adjust only the left height sensor (Figure 4c).

a. Move the sensor to the far left, then push the plus (+) button to

move the cot to its highest position.

b. Measure the cot height from the bottom of the load wheels to the

floor.

c. To reach the desired cot height you will need to adjust the cylinder

shaft. Loosen the nut at the end of the shaft (Figure 4d).

i. To increase the height, rotate the shaft clockwise.

Note: Do not exceed 36”

ii. To decrease cot height, rotate the shaft counter-clockwise.

Note: Add an additional 1/2" (1,3 cm) to your deck height

measurement to allow for variations with patient weight

and other equipment added to the cot.

3. After the proper load wheel height is set, ensure all the height sensor

cables are secured and are lying flat in the housing between the sensors

(Figure 4e). Replace the sensor housing cover using the screws removed

in step 1.

4. Following completion of the sensor height adjustment, verify the cot

properly engages the safety hook.

Figure 4b - Loosening Screws

Figure 4c - Adjusting Height

Figure 4d - Adjusting Shaft

Figure 4e - Securing Cables

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 21

Page 22

Cot Fastener Installation

The Stryker Cot Fastener systems are designed to be compatible only with cots which conform to the installation

specifications listed on page 23.

WARNING

It is the responsibility of the cot operator to ensure that the cot being used in the Stryker Cot Fastener System meets

the installation specifications listed on page 20. Injury may result if a non-compatible cot is used in the Stryker Fastener

System.

NOTE

Adjustment of the rail clamp assembly may be required in order to compensate for any variation in the cot retaining

post position depending on the ambulance cot manufacturer and model number.

For more detailed instruction and operation instructions for the Stryker Cot Fastener systems, refer to part number

6370-090-010 Cot Fastener Installation/Operation Instructions.

Return To Table of Contents

22 6500 -309- 001 REV A www.stryker.com

Page 23

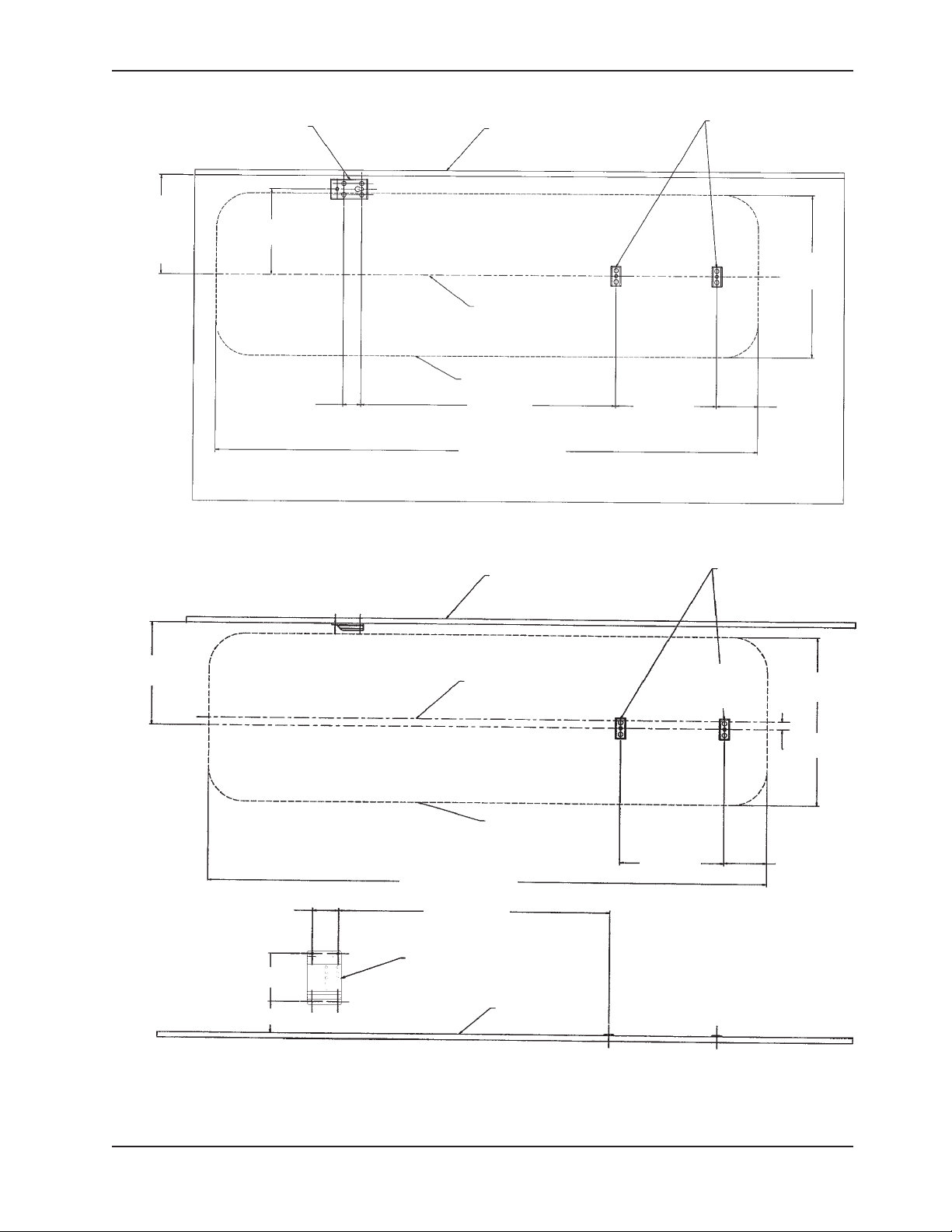

Cot Fastener Installation

RAIL SUPPORT BRACKET

14 5/8 (REF.)

(37,1 cm)

OR DESIRED

POSITION FROM

WALL

REAR OF

AMBULANCE

(REF.)

FLOOR PLATE

12 5/8

WALL OF VEHICLE

(32 cm)

ANTLER FLOOR

PLATES

COT

HEAD

END

COT CENTERLINE

COT PERIMETER

2 5/8

(6,6 cm) (95,6 cm) (37,9 cm) (15,6 cm)

37 5/8

14 15/16

80.000 (REF.)

Figure 5 - Installation Specifications - Floor Mount Fastener

WALL OF VEHICLE

ANTLER FLOOR PLATES

24.000

(REF.)

(61 cm)

6 1/8

14 5/8

(37,1 cm)

REAR OF

AMBULANCE

(REF.)

3 5/8

(9,2 cm)

6 1/2

4 5/16

COT CENTERLINE

COT PERIMETER

14 15/16

80.000 (REF.)

(203 cm)

(37,9 cm) (15,6 cm)

37 3/8

(94,9 cm)

WALL MOUNTING BRACKET

(16,5 cm)

FLOOR OF

(10,9 cm)

VEHICLE

Figure 6 - Installation Specifications - Wall Mount Fastener

COT

HEAD

END

24.000 (REF.)

(61 cm)

1 1/8

(2,9 cm)

6 1/8

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 23

Page 24

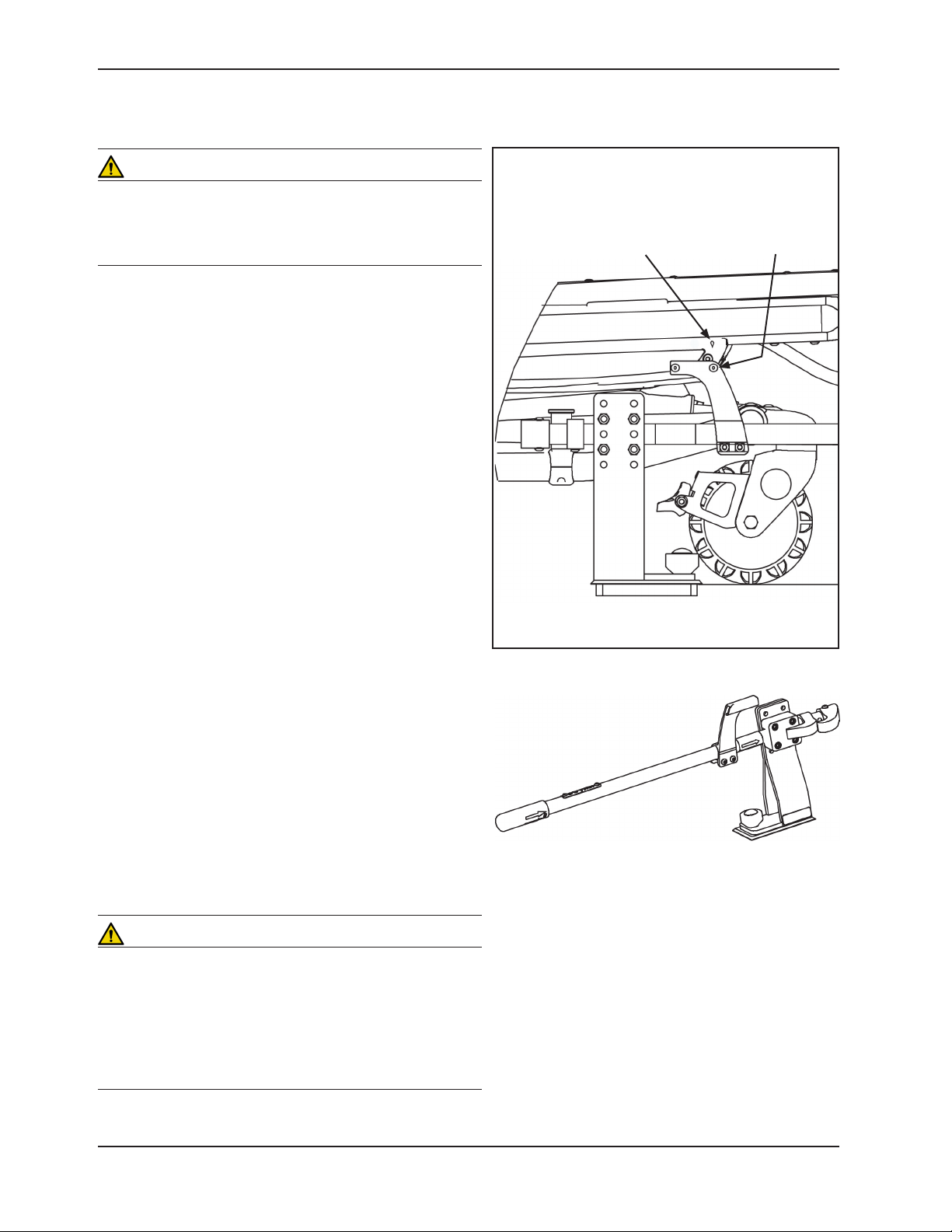

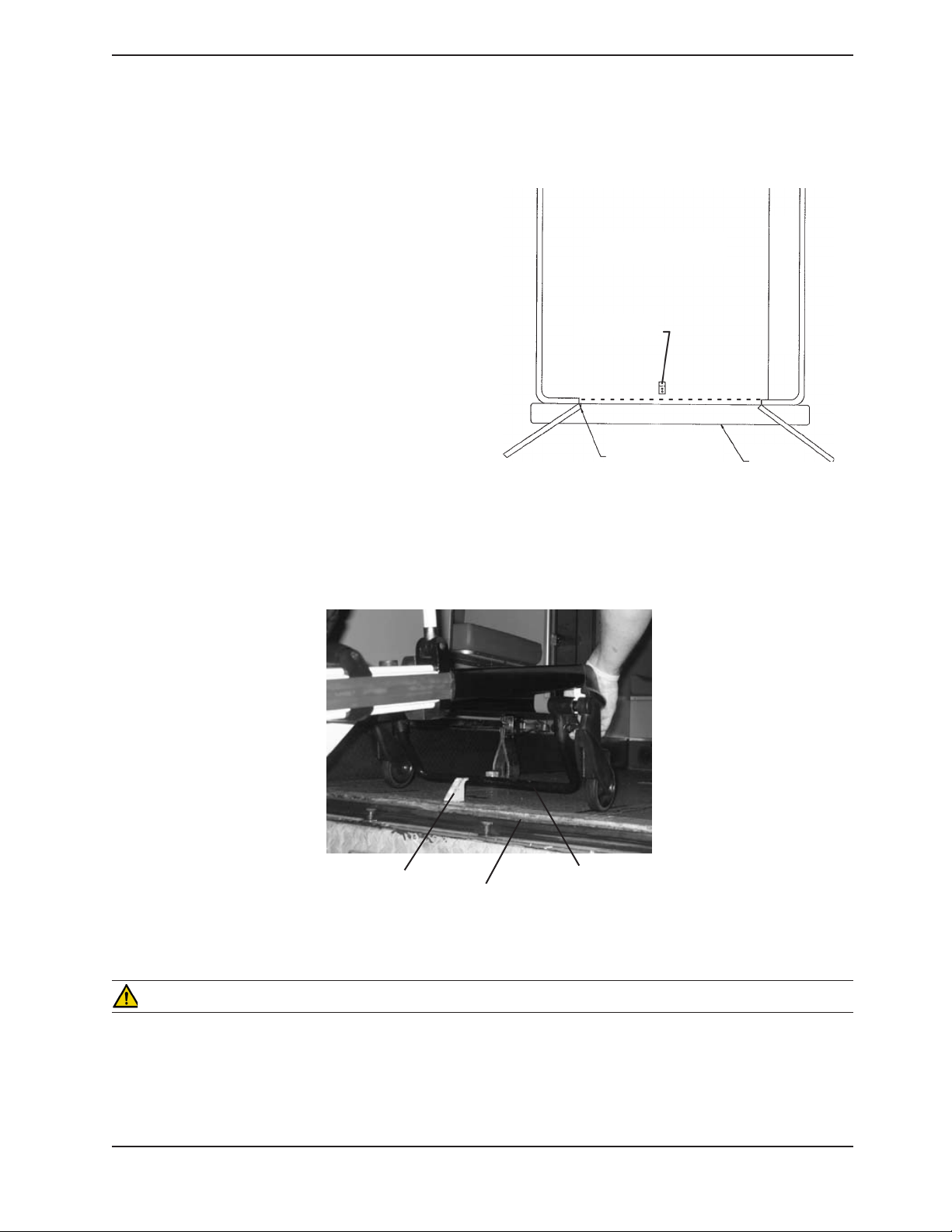

IN-FASTENER SHUT-OFF

Cot Fastener Installation

WARNING

The in-fastener shut-off must be positioned properly before

placing the cot into service. Failure to install the in-fastener

shut-off may cause injury to the patient or operator and/or

damage to the vehicle.

The ambulance cot and fastener system have an integrated

in-fastener shut-off function that disables the cot motor when

the cot is secured in the ambulance cot fastener. Be sure

the bolts on the fastener are tightened before installing the

shut-off bracket. The shut-off magnet must be installed on

the rail clamp assembly before putting the ambulance cot

into service.

1. Place the ambulance cot into a loading position (any

position where the load wheels of the head section meet

the vehicle floor height). Roll the ambulance cot to the

open door of the patient compartment. Lift the vehicle

bumper to the raised position (if possible).

2. Push the ambulance cot forward until the load wheels

are on the patient compartment floor and the safety bar

passes the safety hook.

3. For maximum clearance to lift the base, pull the

ambulance cot until the safety bar engages the safety

hook.

4. Raise the base and push the ambulance cot into the

patient compartment following loading instructions.

5. Engage the extended head section of the cot into the cot

fastener antler and secure the cot post into the fastener

rail clamp.

6. Adjust the magnet assembly along the rail clamp until the

arrow on the sensor housing is lined up with the fastener

as shown in Figure 7.

7. Using a T27 Torx wrench, securely fasten the bolts

attaching the magnet assembly to the rail clamp

assembly.

8. Press the retract (–) button to ensure the motor does

not turn on while the cot is in the fastener. The battery

indictor will still light. If the cot moves, readjust the cot

fastener.

Note: Align the ‘diamond’ on the sensor housing

cover with the pop rivet head on the in-ambulance

shut-off.

Pop Rivet Head“Diamond”

Figure 7 - Cot Engaging Cot Fastener

Figure 8 - In-Fastener Shut-Off Module

WARNING

Do not attempt to operate the ambulance cot when loaded

into a cot fastener. The in-fastener shut-off is only a means

for disabling the electronic functionality.

Damage to the product or injury to the patient or operator

may occur.

In-fastener shut-off must be installed in all ambulances in

which the cot will be used.

Return To Table of Contents

24 650 0- 309 -0 01 REV A www.stryker.com

Page 25

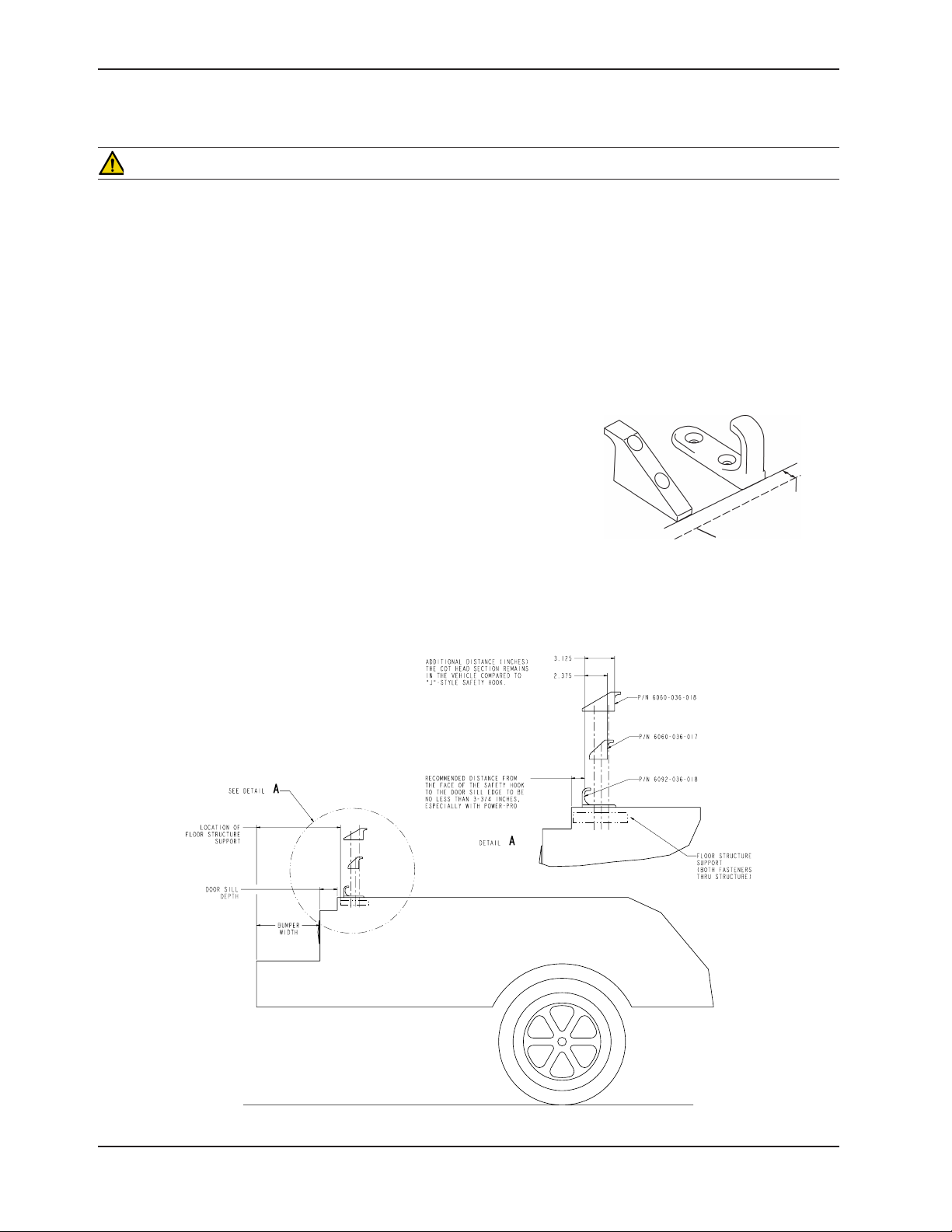

Vehicle Safety Hook Installation

DH

2

2

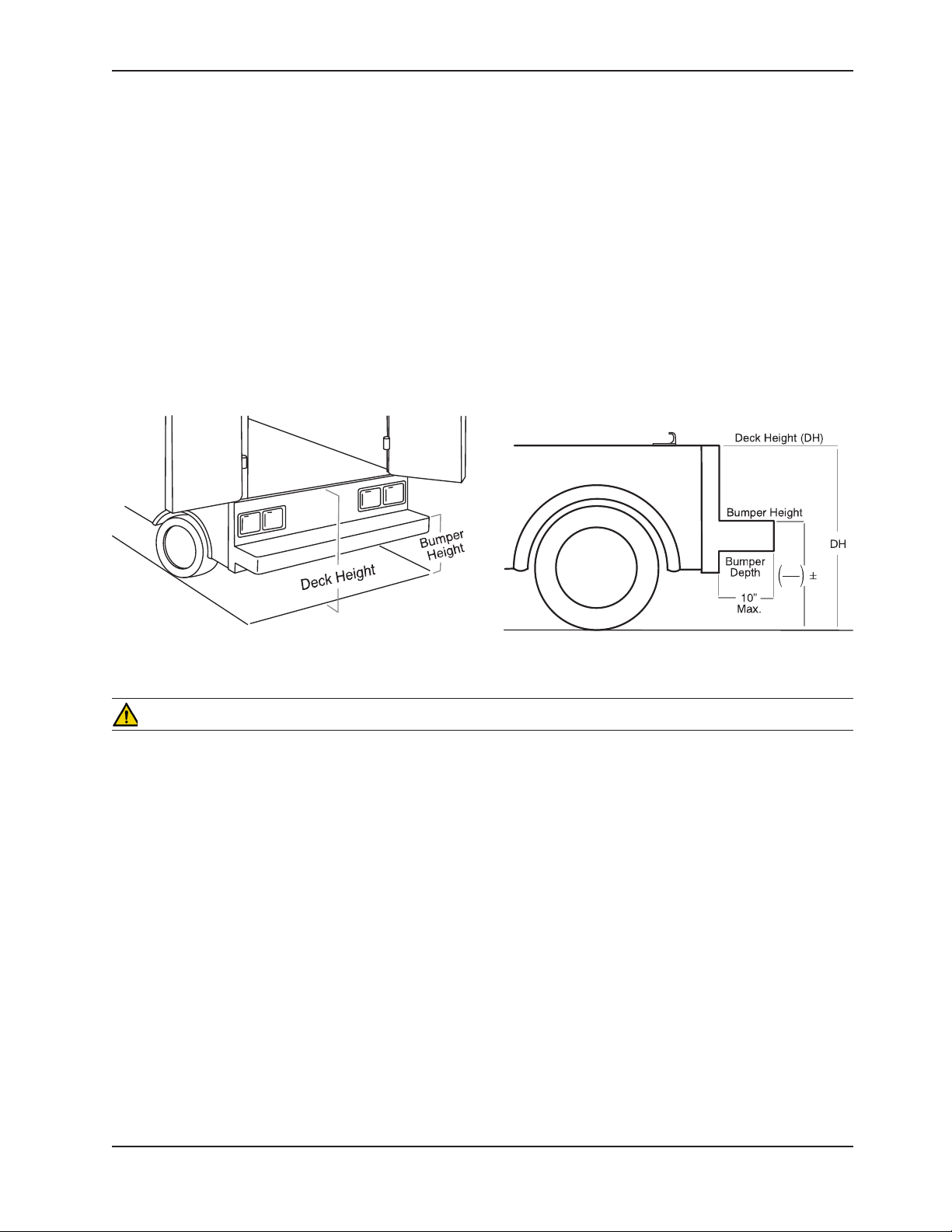

AMBULANCE CONFIGURATION

The vehicle safety hook is a device shipped with the cot. The safety hook activates the safety bar and prevents the

cot from being removed from the vehicle accidently. The vehicle safety hook was designed to ensure compatibility and

proper operation of the cot during unloading when used in an ambulance vehicle compliant with Federal Regulation

KKK-A-1822.

According to federal regulations (reference KKK-A-1822), the bumper height of the ambulance shall be installed

equidistant ± 5 cm (2 inches) from the ambulance floor to the ground level, defined as the ambulance deck height

(Figure 9a). The bumper step shall have a minimum depth of 13 cm (5 inches) and a maximum depth of 25 cm (10

inches). If the bumper depth is greater than 18 cm (7 inches), then the bumper must be able to fold. Installation of the

safety hook into any ambulance vehicle compliant with this federal specification will provide adequate clearance for

the cot base to lower to its fully extended position (Figure 9b). The cot is compatible with all ambulance deck heights

up to 36 inches (91 cm) as long as the ambulance meets the federal specifications outlined in KKK-A-1822.

Figure 9a - Ambulance Deck Height

Figure 9b - Ambulance Deck Height

CAUTION

Set cot height limit to the proper stop height (see • page 21) prior to operation.

Installat• ion of the safety hook should be done by a certified mechanic familiar with ambulance construction.

Consult the vehicle manufacturer before installing the safety hook and be sure the installation of the safety hook

does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank or electrical wiring of the

vehicle.

REQUIRED HARDWARE FOR INSTALLATION OF THE SAFETY HOOK (NOT SUPPLIED)

(2) Grade 5, 1/4”-20 Socket Head Cap Screws*

(2) Grade 5, 1/4”-20 Flat Socket Head Cap Screws*

(2) Flat Washers

(2) Lock Washers

(2) 1/4”-20 Nuts

* The length of the socket head cap screws depends on the thickness of the vehicle floor. Use screws long enough to

go completely through the patient compartment floor, washer and nut by at least two full threads.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 25

Page 26

Vehicle Safety Hook Installation

1/8 inch

(reference only)

Inside Edge of Rear

Doors (When Closed)

POSITIONING AND INSTALLING THE SAFETY HOOK

WARNING

Have the vehicle safety hook installed by a certified mechanic. Improper safety hook installation can cause injury •

to the patient and/or operator or damage to the cot.

Failure to install the safety hook can cause injury to the patient or operator. Install and use the safety hook as •

described in this manual.

Install the safety hook at least 1/8 inch from the edge of the rear ambulance door. After installation, verify the cot •

legs lock into the load position without contacting the ambulance bumper.

To avoid injury, verify the safety bar has engaged the safety hook before removing the cot from the patient •

compartment.

Note:

Stryker EMS recommends that, prior to installation, the certified mechanic plan the placement of the safety hook in

the rear of the vehicle.

Procedure:

Remove the cot from the fastener and unload it from the vehicle.1.

While the cot is being removed, not the position of the load wheels and 2.

the safety bar.

Center the safety hook on the cot safety bar, with the hook facing the 3.

front of the vehicle (Figure 10). For best results, the face of the safety

hook which engages the safety bar should be at least 3-3/4” from the

leading edge of the door sill (Figure 11).

Figure 10 - Safety Hook Placement

Figure 11 - Safety Hook Placement

Return To Table of Contents

26 6 500 -309- 001 REV A www.stryker.com

Page 27

Vehicle Safety Hook Installation

POSITIONING AND INSTALLING THE SAFETY HOOK (CONTINUED)

Mark the position of the safety hook on the patient 4.

compartment floor. The safety hook should be

installed as close as possible to the rear of the vehicle

while allowing the vehicle doors to close and checking

that the load wheels always remain on the patient

compartment floor (i.e., wheels do not roll off the door

sill when the cot safety bar engages the safety hook)

when the cot is loaded and unloaded from road and/or

curb height (Figure 12).

Ensure the bumper and bumper step do not interfere 5.

with the operation of the cot.

Drill the holes for the socket head cap screws.6.

Fasten the safety hook to the patient compartment 7.

floor and verify that the safety hook always engages

the cot safety bar when the cot is unloaded from the

vehicle (Figure 13).

Note

If the ambulance cot can be removed by rolling to one

side of the vehicle and not engaging the safety hook,

an additional safety hook should be installed.

Safety Hook

Figure 12 - Safety Hook Placement

Top View of Vehicle

Door Frame

Squad Bench

Bumper

Safety Hook

Floor Edge

Safety Bar

Figure 13 - Safety Bar Engaging Safety Hook

WARNING

The cot must have at least 5/8” of clearance between the ambulance bumper and the cot to disengage the safety •

bar when unloading the cot from the ambulance. Verify the cot legs lock into the load position before disengaging

the safety bar from the safety hook. Failure to properly lock the cot into position can cause injury to the patient or

operator and/or damage to the cot.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 27

Page 28

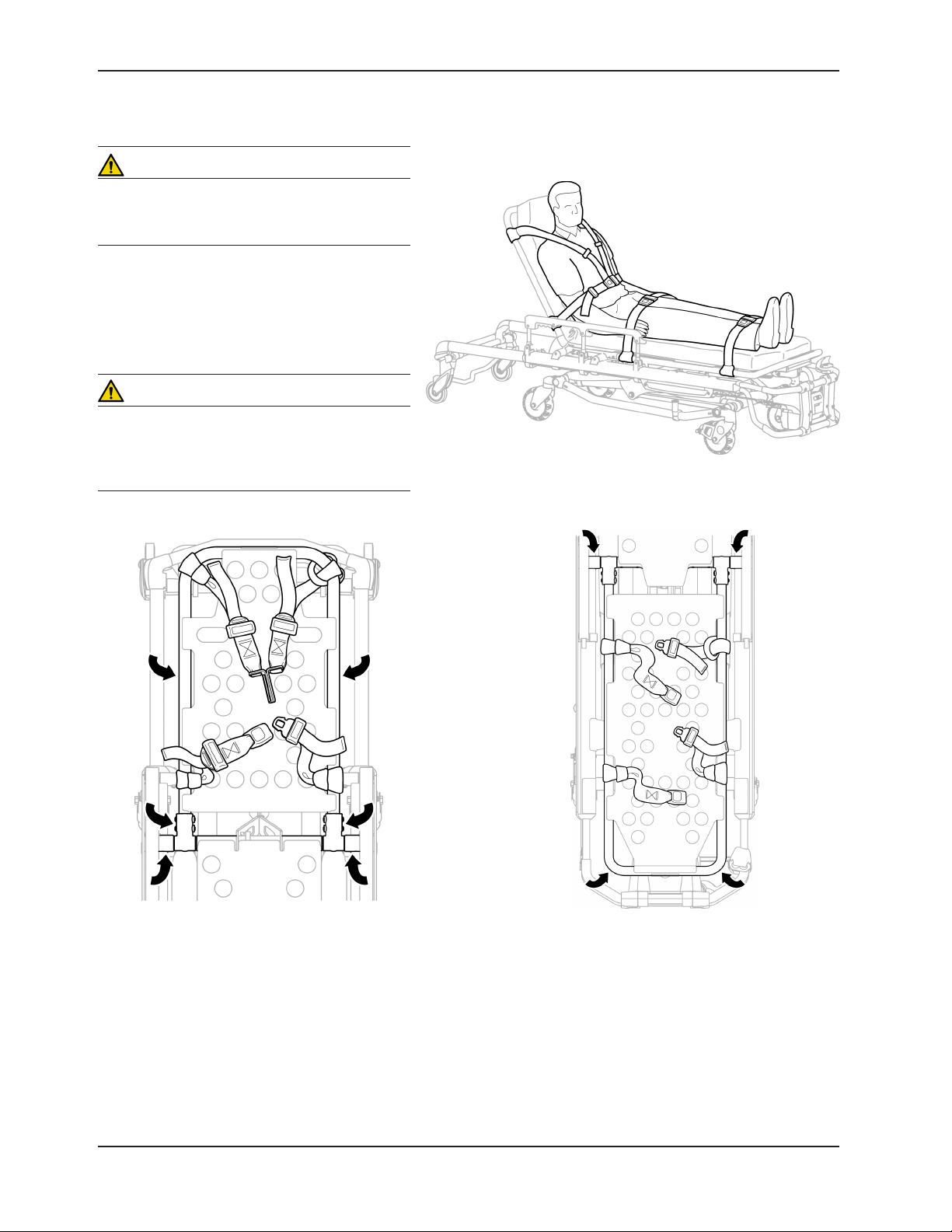

Cot Features

USING RESTRAINT STRAPS

WARNING

Always use all restraint straps to secure the patient

on the cot. An unrestrained patient may fall from

the cot and be injured.

Always secure the patient on the cot with all the

restraint straps. Buckle the restraints across the

patient’s chest/shoulders, waist and legs (Figure

14). Keep the restraint straps buckled when the

cot is not being used with a patient to avoid damage to the buckles and straps.

WARNING

Do not attach restraints to the base or crosstubes, improper restraint attachment could result

in damage to the cot further resulting in injury to

the patient or operator.

Figure 14 - Safety Restraints

Figure 15 - Head Section Restraints

Wrap the strap around the cot frame and back through the loop on the end of the strap as shown in Figures 15 and 16.

The arrows indicate alternate attachment areas.

When attaching the restraint straps to the cot, remember the attachment points should provide both strong anchorage

and proper restraint position while not interfering with equipment and accessories.

Return To Table of Contents

28 6 500 -3 09-001 REV A www.stryker.com

Figure 16 - Foot Section Restraints

Page 29

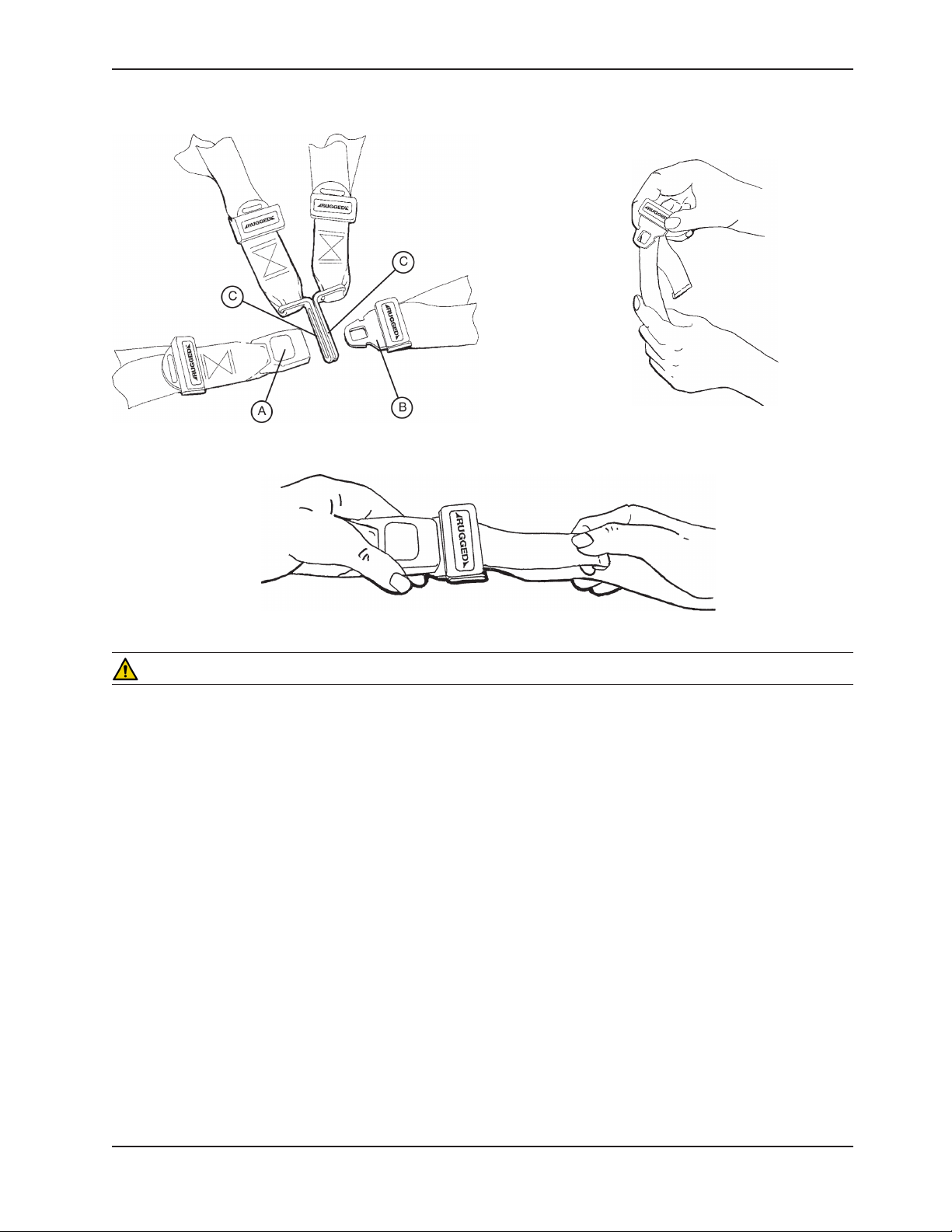

USING RESTRAINT STRAPS (CONTINUED)

Cot Features

Figure 17 - Buckling the Safety Restraints

Figure 19 - Shortening the Safety Restraint

Figure 18 - Lengthening the Safety Restraint

CAUTION

Ensure that restraints are not entangled in the base frame when raising and lowering the cot.

When the cot is put into service, open the restraints and place them at either side of the cot until the patient is

positioned on the cot mattress. Lengthen the restraints, buckle them around the patient and shorten them until the

required tightness is achieved.

• Toopentherestraint,presstheredbutton(A)onthefrontofthebuckle“receiver”.Thisreleasesthebuckle“tang”

(B) which can then be pulled out of the receiver (Figure 17).

• Toclosetherestraint,pushthetangintothereceiveruntila“click”isheard.Whenfasteningthechestrestraint

ensure the tang passes through both links (C) on the shoulder strap (Figure 17).

• Tolengthentherestraint,graspthebuckletang,turnitatanangletothewebbing,thenpullitout(Figure18).A

hemmed tab at the end of the webbing prevents the tang from coming off the strap.

• Toshorten the restraint,graspthehemmed tab and pull the webbing backthroughthetanguntil the required

tightness is achieved (Figure 19).

Whenever a restraint is buckled on a patient, verify the tang is fully engaged and any extra webbing is not tangled in

the cot or hanging loose.

Inspection of the restraints should be done at least once a month (more frequently if used heavily). Inspection should

include checking for a bent or broken receiver or tang, torn or frayed webbing, etc. Any restraint showing wear or not

operating properly must be replaced immediately.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 29

Page 30

Cot Features

USING THE RESTRAINT BELT EXTENSION (OPTIONAL)

Figure 20 - Attaching the Restraint Belt Extension

Use the restraint belt extension for extra length when buckling the lap belt around large patients.

Return To Table of Contents

30 65 00-30 9- 001 RE V A www.stryker.com

Page 31

Cot Features

PEDI-MATE™ INFANT RESTRAINT SYSTEM (OPTIONAL) ATTACHMENT INSTRUCTIONS

Refer to the Pedi-Mate™ users manual for the manufacturer’s recommendations for the use, operation and care of the

Pedi-Mate™ Infant Restraint System.

Securing the Pedi-Mate™ to the cot:

1. Remove any restraints already attached to the cot.

2. Raise the cot backrest to the full upright position.

3. Position the Pedi-Mate™ pad flat on the backrest with the black backrest straps out (see Figure 21).

Figure 21 - Positioning the Pedi-Mate™

4. Wrap the straps around the backrest and insert the ends of the straps through the brackets. Securely fasten the

buckle (see Figure 22).

Figure 22 - Fastening the Pedi-Mate™ Buckle

WARNING

To avoid accidental release of the Pedi-Mate™, and possible injury to the infant, ensure the buckle is located away from

obstructions on the cot or accessories.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 31

Page 32

Cot Features

PEDI-MATE™ INFANT RESTRAINT SYSTEM ATTACHMENT INSTRUCTIONS (CONTINUED)

5. Pull firmly on the end of the adjustable backrest strap and tighten it securely.

6. Insert the mainframe straps between the cot frame and the mattress. To ensure the release button is toward

the foot end of the cot, insert the buckle behind the litter cross brace and bring it up in front of the cross brace.

Figure 23 - Securing the Safety Restraints on a Cot

Secure the buckle around the crossbrace, leaving a little slack in the strap for final adjustment (see Figure 23).

WARNING

To avoid accidental release of the Pedi-Mate™, and possible injury to the infant, ensure the buckle is located away

from obstructions on the cot.

Figure 24- Pedi-Mate™ Strapped to a Cot

7. Verify all the straps are snug and fastened securely (see Figure 24).

NOTE

These are general instructions for installation of the Pedi-Mate™. Safe and proper use of the Pedi-Mate™ is solely at

the discretion of the user. Stryker recommends all users be trained on the proper use of the Pedi-Mate™ before using

it in an actual situation.

Retain these instructions for future reference. Include them with the product in the event of transfer to new users.

Pedi-Mate™ is a trademark of Ferno-Washington Inc.

Return To Table of Contents

32 6 500 -309-001 REV A www.stryker.com

Page 33

Cot Features

OPERATING THE OPTIONAL WHEEL LOCK(S)

Figure 25 - Wheel Lock

1. To activate the optional wheel lock(s), press fully down on the pedal (A) until it stops and is resting firmly against

the surface of the wheel.

2. To release the optional wheel lock(s), depress the upper face of the pedal with your foot or lift up with your

toe under the pedal. The upper portion of the pedal will rest against the caster frame when the wheel lock is

released.

WARNING

Never apply the optional wheel lock(s) while a patient is on the cot. Tipping could occur if the cot is moved while a

wheel lock is applied, resulting in injury to the patient or operator and/or damage to the cot.

Never leave a patient unattended on the cot or injury could result. Hold the cot securely while a patient is on the cot.

Never install or use a wheel lock on a cot with excessively worn wheels. Installing or using a wheel lock on a wheel with

less than a 6" diameter could compromise the holding ability of the wheel lock, possibly resulting in injury to the patient

or operator and/or damage to the cot or other equipment.

CAUTION

Wheel lock(s) are only intended to help prevent the cot from rolling while unattended. A wheel lock may not provide

sufficient resistance on all surfaces or under loads.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 33

Page 34

Cot Features

ADJUSTING THE WHEEL LOCKING FORCE

MINIMUM

1. To adjust the wheel locking force, remove the socket screw from the center of the lock pedal. The wheel lock is

initially assembled with the pedal set at the minimum locking force. The marker on the pedal (item A) is aligned

with the marker on the octagonal sleeve (item B).

2. Remove the sleeve (B). Rotate the sleeve counterclockwise to increase the pedal locking force and clockwise to

decrease the locking force. Insert the sleeve into the pedal. Reinstall the socket screw.

3. Test the pedal locking force and verify the pedal holds properly before returning the cot to service.

Figure 26 - Wheel Locking Force Adjustment

MAXIMUM

ADJUSTING THE COT RETAINING POST

Retaining Post

Arrow

Bottom Bracket

Figure 27 - Cot Retaining Post

Bottom View

CAUTION

The ambulance cot fastener comes preconfigured for an X-Frame cot, if the fastener has been configured for an Hframe style cot, the cot retaining post must be adjusted to accommodate the fastener.

1. Remove the bolts holding the two retaining post brackets to the base frame.

2. Turn the bottom bracket 180˚.

3. Reinstall the bolts.

NOTE

If the arrow on the bottom bracket of the retaining post points toward the head end of the cot, the retaining post is

set for an X-frame style cot. If the arrow points toward the foot end of the cot the post is set for an H-frame style cot.

Return To Table of Contents

34 6500 -309- 001 REV A www.stryker.com

Page 35

ADJUSTING THE FOOTREST

Cot Features

FOOT END

Figure 28 - Footrest Elevated

The footrest is adjustable to allow for elevation of the patient’s legs.

To raise the footrest, lift the foot rest frame (A) as high as possible. The support bracket will engage automatically

when released.

To lower the footrest, lift the foot rest frame (A) and, while holding the frame, lift up on the release handle (B) until the

bracket disengages. Lower the footrest until flat.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 35

Page 36

HEAD END

Cot Features

Figure 29 - Backrest Elevated and Siderails Raised

OPERATING THE BACKREST

To raise, squeeze handle (A) for pneumatic assist in lifting the backrest to the desired height.

To lower, squeeze handle (A) and push down on the backrest frame until the backrest has reached the desired

height.

OPERATING THE SIDERAILS

To raise, lift up until the latch clicks and the siderail locks into place. When a patient is on the cot, always keep the

siderails in the raised position unless the patient is being transferred.

To lower, squeeze handle (B) to release the siderail latch. Guide the siderail down toward the foot end until flat.

WARNING

Siderails are not intended to serve as a patient restraint device. Refer to pages 24 and 25 for proper restraint strap

usage. Failure to utilize the siderails properly could result in patient injury.

Return To Table of Contents

36 6500 -30 9- 001 RE V A w ww.stryker.com

Page 37

BATTERY POWER INDICATOR

Cot Features

Figure 30a - Battery Power Indicator

To check the battery power level, depress lightly on the retract (–) switch (A) to activate the battery power indicator

light (B). The battery power indicator is located at the foot-end control enclosure, represented by a battery icon.

• The indicator lights GREEN when the battery is fully charged or has adequately charged battery power.

• TheindicatordisplaysREDwhenthebatteryneedstoberechargedorreplaced.

Figure 30b - Retract Switches

WARNING

To avoid risk of electric shock, never attempt to open the battery pack for any reason. If the battery pack case •

is cracked or damaged, do not insert it into the charger. Return damaged battery packs to a service center for

recycling.

Do • not remove the battery when the ambulance cot is activated.

Avo• id contact with a wet battery or battery enclosure. Contact may cause injury to the patient or operator.

CAUTION

Only use the battery and charger as specified.•

The • Power-PRO™ XT ambulance cot is not for use with an AC adapter.

Wh• en charging batteries in an ambulance vehicle, locate the charger either in the forward cab or an enclosed

compartment (i.e. cabinet).

E• nsure that the battery is fully charged prior to placing into service. An uncharged or depleted battery may cause

poor ambulance cot performance.

Ref• er to the DeWA LT® manual (Stryker part number 6500-001-206) for battery and charger information.

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 37

Page 38

HOUR METER

Cot Features

Figure 31 - Usage Meter

The cot has an hour meter on the foot-end control enclosure that indicates the amount of time (HHH.H hours) that

the hydraulics have been activated. The hour meter can be used to help determine the frequency for preventative

maintenance procedures found on pages 58-61.

CAUTION

A preventative maintenance program should be established for all Stryker EMS equipment. Preventative maintenance •

may need to be performed more frequently based on the usage level of the product. Close attention should be

given to safety features including, but not limited to:

Hydraulic power mechanism•

All electrical controls return to off or neutral position when released•

For additional maintenance information, refer to the preventative maintenance section (pages 58-61).•

Return To Table of Contents

38 65 00-30 9- 001 RE V A www.stryker.com

Page 39

Cot Features

INSTALLING THE OPTIONAL HEAD END STORAGE FLAT

Crossbar

V-Tube

Figure 32 - Head End Storage Flat

1. Install the Velcro® straps (A) across the V-Tube near the pneumatic cylinder and around the crossbar of the retractable head section.

2. Buckle the restraint straps (B) around the outer rails of the retractable head section.

WARNING

When the optional head-end storage flat is being used, ensure it does not interfere with the operation of the retractable

head section, safety bar and safety hook. Injury to the patient or operator could result.

CAUTION

Do not store items under the ambulance cot mattress. Storing items under the mattress can interfere with the operation

of the ambulance cot.

The weight of the equipment in the head end storage flat (if equipped) must not exceed 40 pounds (18 kg).

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 39

Page 40

Cot Features

INSTALLING THE OPTIONAL BACKREST STORAGE POUCH

Figure 33 - Backrest Storage Pouch

Install the optional backrest storage pouch using the Velcro® straps. Insert each strap through a hole in the backrest

skin and mount the pouch flat against the backrest.

CAUTION

Do not store items under the ambulance cot mattress. Storing items under the mattress can interfere with the •

operation of the ambulance cot.

The• weight of the equipment in the pocketed backrest storage pouch (if equipped) must not exceed 20 pounds

(9 kilograms).

Return To Table of Contents

40 6500-309- 001 REV A www.stryker.com

Page 41

Cot Features

USING THE OPTIONAL EQUIPMENT HOOK

Equipment Hook

Figure 34 - Equipment Hook

The equipment hook is used to hang additional accessories or equipment such as defibrillators or monitors.

CAUTION

To avoid damage to the equipment hook, the weight of the accessories or equipment must not exceed 20 pounds

(9 kilograms).

Return To Table of Contents

www.stryker.com 650 0- 309 -0 01 REV A 41

Page 42

Cot Features

OPERATING THE 2-STAGE I.V. POLE (OPTIONAL EQUIPMENT)

Figure 35 - 2-Stage I.V. Pole Storage Position

C

D

B

A

Figure 36 - 2-Stage I.V. Pole

1. Lift and pivot the pole from the storage position and push down until it is locked into receptacle (A).

2. To raise the height of the pole, turn the lock actuator (B) counterclockwise and pull up on the telescoping portion

(C) of the pole to raise it to the desired height.

3. Turn the lock actuator (B) clockwise to lock the telescoping portion in place.

4. Hang the I.V. bags on the I.V. hook (D).

CAUTION

To avoid damage to the I.V. pole, the weight of the I.V. bags or equipment must not exceed 40 pounds (18kg).

5. Turn the lock actuator (B) counterclockwise and slide section (C) into the bottom tube.

6. Lift up and pivot the pole down into the storage position.

Return To Table of Contents

42 6500 -309- 001 REV A www.stryker.com

Page 43

Cot Features

A

B

C

D

E

F

OPERATING THE 3-STAGE I.V. POLE (OPTIONAL EQUIPMENT)

1. Lift and pivot the pole from the storage position and push down

until it is locked into receptacle (A).

2. To raise the height of the pole, turn the lock actuator (B)

counterclockwise and pull up on the bottom telescoping portion

(C) of the pole to raise it to the desired height.

3. Turn the lock actuator (B) clockwise to lock the bottom telescoping

portion in place.