Page 1

PPoowweerr--PPRROO™™ XXTT CCoott

MMaaiinntteennaannccee MMaannuuaall

6506

6506-109-002 Rev G.1

EN

2019/07

Page 2

Page 3

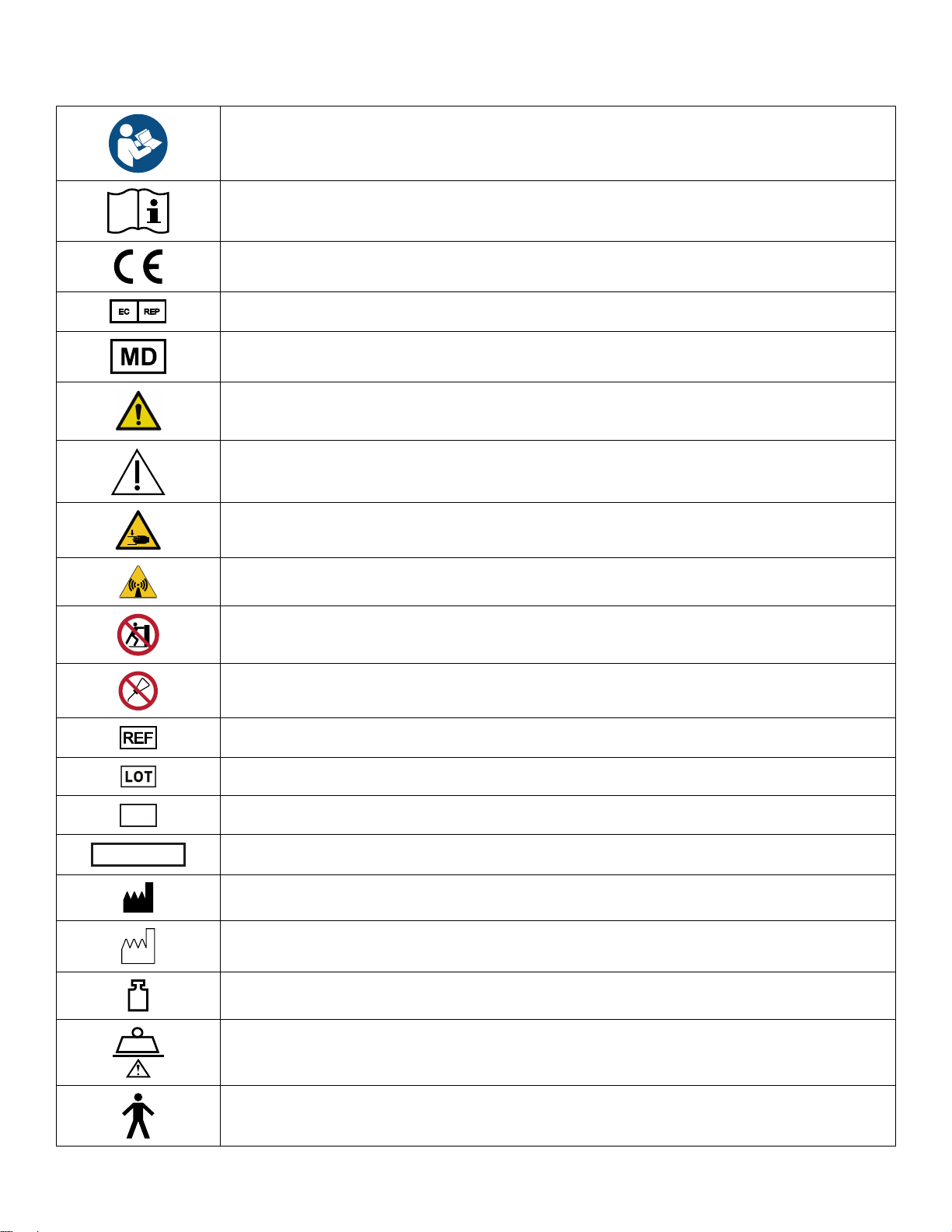

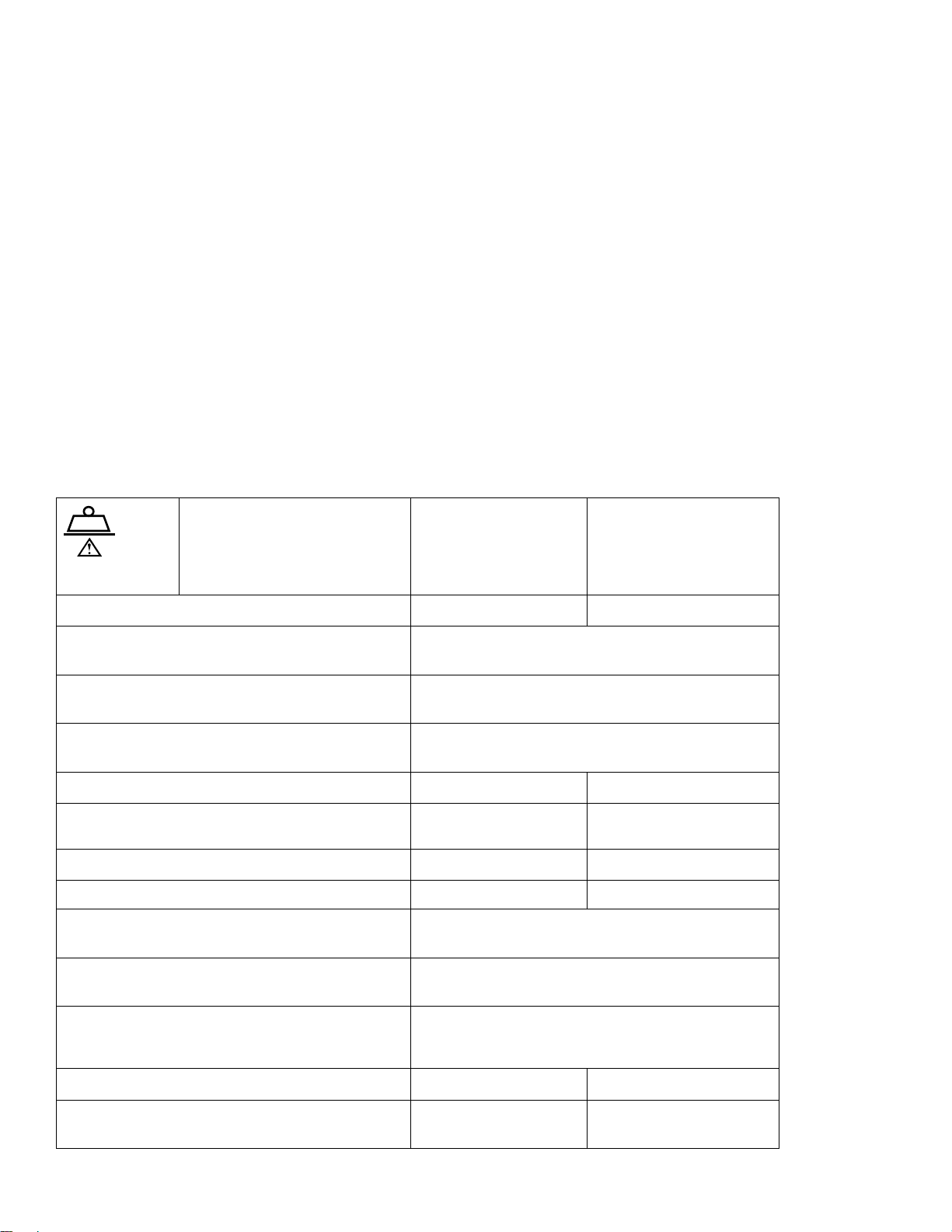

SSyymmbboollss

Refer to instruction manual/booklet

Operating instructions

CE mark

Authorized representative in the European Community

European medical device

General warning

Caution

Warning; crushing of hands

Warning; non-ionizing radiation

No pushing

Do not lubricate

Catalogue number

Lot (batch) code

Serial number

For US Patents see www.stryker.com/patents

Manufacturer

Date of manufacture

6506-109-002 Rev G.1 EN

Mass of equipment with safe working load

Safe working load

Type B applied part

Page 4

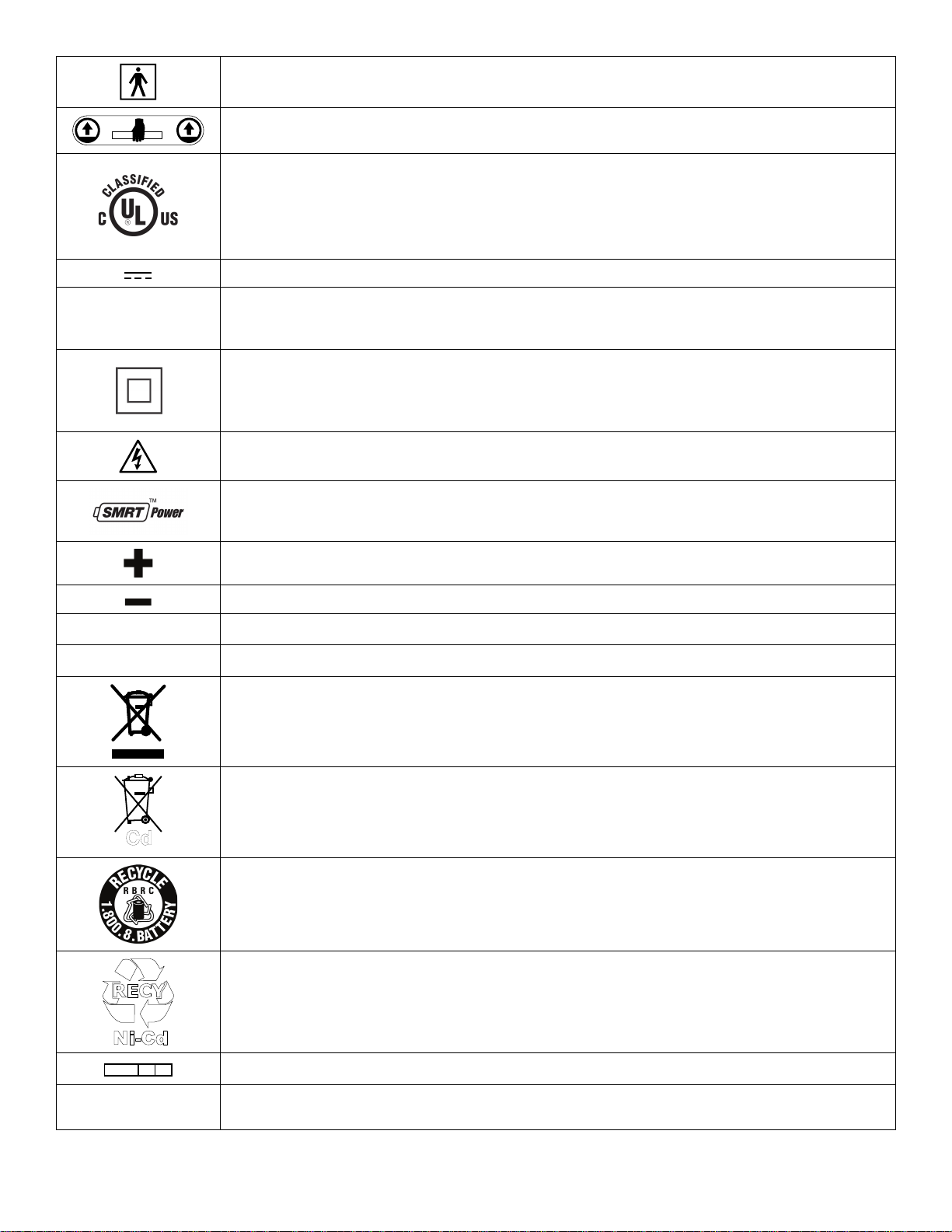

Type BF applied part

87VL

~

Cd

DATA

_

+

Lift here

Medical Equipment Classified by Underwriters Laboratories Inc. With Respect to Electric Shock,

Fire, and Mechanical Hazards Only in Accordance with ANSI/AAMI ES60601-1:2012 and CAN/

CSA-C22.2 No. 60601-1:14.

Direct current

Alternating current

Class II electrical equipment: equipment in which protection against electric shock does not rely

on basic insulation only, but in which additional safety precautions such as double insulation or

reinforced insulation are provided, there being no provision for protective earthing or reliance

upon installation conditions.

Dangerous voltage

SSMMRRTT power system

IIPPXX00

IIPPXX66

Extend

Retract

Non-protected

Protection from powerful water jets

In accordance with European Directive 2012/19/EU on Waste Electrical and Electronic

Equipment (WEEE) as amended, this symbol indicates that the product should be collected

separately for recycling. Do not dispose of as unsorted municipal waste. Contact local distributor

for disposal information. Ensure infected equipment is decontaminated prior to recycling.

WEEE Directive (2012/96/EC). Contains cadmium.

The Rechargeable Battery Recycling Corporation (RBRC) is a non-profit, public service

organization that promotes the recycling of portable rechargeable batteries. Batteries must be

delivered to a battery collection site. Visit the RBRC website (www.rbrc.org) to find a nearby

collection site or call the phone number shown on the recycling symbol.

Contains nickel cadmium cells and should be recycled accordingly

Battery terminal identification (data line, negative, and positive)

KRX

23/44

EN 6506-109-002 Rev G.1

Ni-Cd cell identification per IEC 61951-1:2003

Page 5

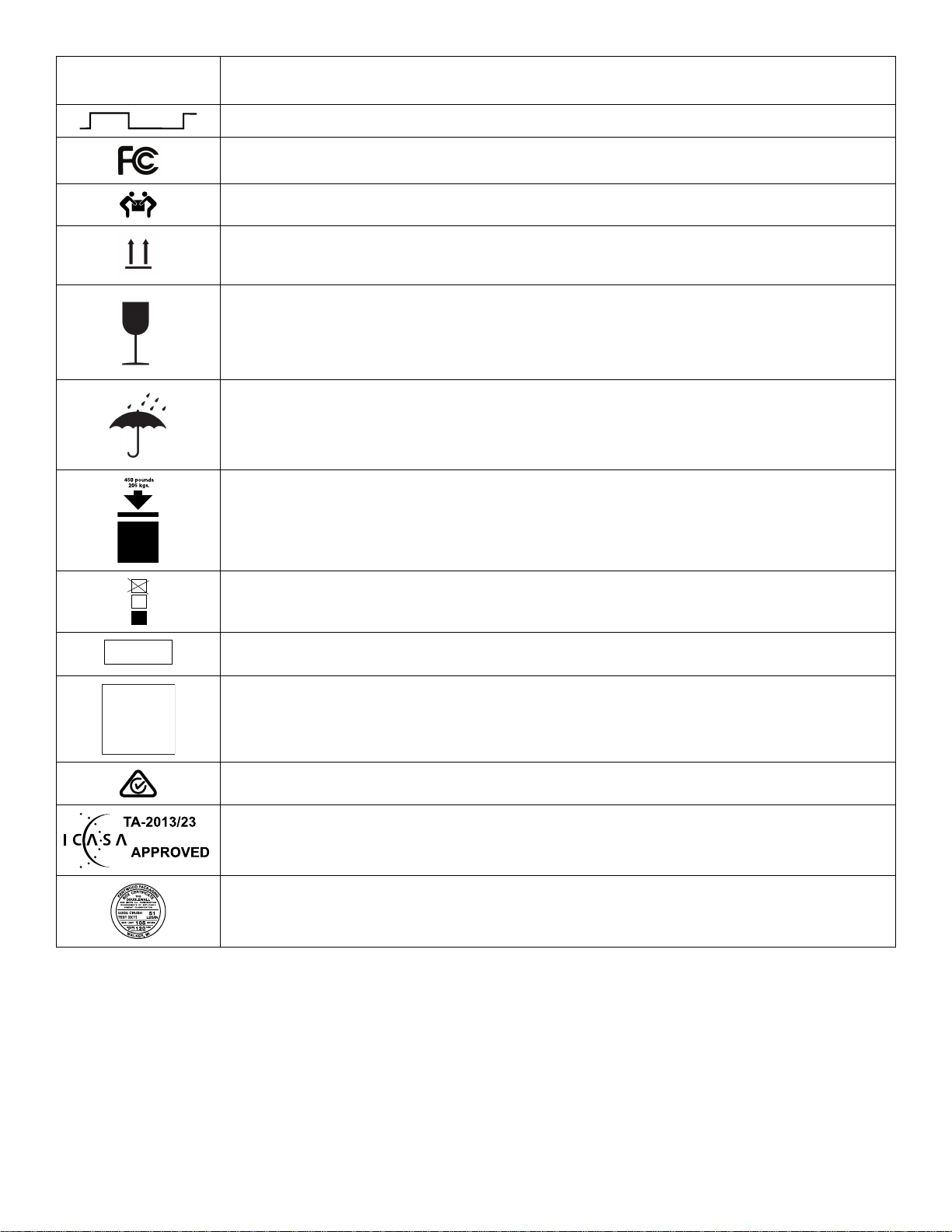

2300 mAh

<60s >300s

3

U.S.A.

TRA

Registered No:

ER35122/14

Dealer No:

DA35173/14

50

(1.2A/2h)

Battery capacity, typical charge, and duration

Cot duty cycle: 16.7% (less than 60 seconds on, more than 300 seconds off)

This device complies with Part 18 of the FCC rules

Two person lift

This way up

Fragile, handle with care

Keep dry

450 lb /205 kg weight capacity

Do not stack more than three high

English text below this symbol is intended for USA audiences only

Registered in United Arab Emirates by the Telecommunications Regulatory Authorities

Product complies with applicable EMC standards in Australia/New Zealand

Approved by independent communications authority of South Africa

Box manufacturer’s certificate - this packaging box has a minimum test value of 500 lb per sq. in

6506-109-002 Rev G.1 EN

Page 6

Page 7

TTaabbllee ooff CCoonntteennttss

Warning/Caution/Note Definition ..............................................................................................................................5

Summary of safety precautions ................................................................................................................................5

Pinch points .......................................................................................................................................................6

Mechanical stability ............................................................................................................................................6

Introduction ...............................................................................................................................................................8

Product description .................................................................................................................................................8

Indications for use...................................................................................................................................................8

Expected service life ...............................................................................................................................................9

Disposal/recycle .....................................................................................................................................................9

Contraindications ....................................................................................................................................................9

Specifications - Power-PRO.....................................................................................................................................9

Standards with required options .............................................................................................................................11

Specifications - SMRT ........................................................................................................................................... 11

Product illustration - Power-PRO............................................................................................................................ 13

Product illustration - SMRT ....................................................................................................................................14

Contact information............................................................................................................................................... 14

Serial number location - Power-PRO ...................................................................................................................... 15

Serial number location - SMRT ..............................................................................................................................15

Date of manufacture.............................................................................................................................................. 15

Preventive maintenance .........................................................................................................................................16

Lubrication ........................................................................................................................................................... 16

Regular inspection and adjustments .......................................................................................................................16

Every month or two hours ................................................................................................................................. 16

Every three months or six hours.........................................................................................................................17

Every six months or 12 hours ............................................................................................................................18

Every 12 months or 24 hours.............................................................................................................................18

Foot end fastener part replacement schedule .....................................................................................................19

Maintenance record ..............................................................................................................................................19

Training record .....................................................................................................................................................20

Troubleshooting ...................................................................................................................................................... 21

Electronics and hydraulics locator ..........................................................................................................................21

Hydraulic assembly............................................................................................................................................... 22

Hydraulic assembly wiring schematics....................................................................................................................22

Electrical system block diagram – unload ................................................................................................................23

Electrical system block diagram – load....................................................................................................................23

Litter drifts (without patient weight) .........................................................................................................................24

Base drifts (without patient weight) .........................................................................................................................25

Litter does not lower in the powered mode ..............................................................................................................25

Litter does not extend in the powered mode - check motor .......................................................................................25

Litter does not extend in powered mode - check the power indicator LED ..................................................................25

Base does not retract in the powered mode............................................................................................................. 26

Base does not extend in the manual mode ..............................................................................................................26

Base does not retract in the manual mode ..............................................................................................................26

Litter does not retract in the manual mode (with patient weight) ................................................................................26

Litter does not extend in the manual mode .............................................................................................................. 26

High speed retract does not engage .......................................................................................................................26

LCD error codes - main micro ................................................................................................................................26

LCD error codes - safety micro............................................................................................................................... 27

Main cable assembly............................................................................................................................................. 28

Main cable assembly wiring schematics..................................................................................................................29

Control board assembly......................................................................................................................................... 29

Control board assembly wiring schematics.............................................................................................................. 30

SMRT charger power LED is NOT illuminated .........................................................................................................30

SMRT charger will not charge the SMRT Pak .......................................................................................................... 30

SMRT charger indicator LEDs are NOT illuminated when the Pak is inserted.............................................................31

6506-109-002 Rev G.1 1 EN

Page 8

12 VDC automotive cable fuse replacement ............................................................................................................31

A fully charged SMRT Pak does not provide sufficient power for cot operation ...........................................................32

SMRT charger indicates a SMRT Pak error (amber LED), but the Pak performs well on the cot...................................32

Charger indicates a temperature delay (flashing amber LED), but the Pak is within the normal operating temperature

range ................................................................................................................................................................... 32

Service ....................................................................................................................................................................33

Backrest adjustment..............................................................................................................................................33

Head section replacement .....................................................................................................................................34

Backrest gas cylinder replacement ......................................................................................................................... 34

Manual release cable adjustment ...........................................................................................................................35

Filling the hydraulics assembly reservoir ................................................................................................................. 36

Wheel locking force adjustment.............................................................................................................................. 36

Steer-Lock mechanism adjustment.........................................................................................................................37

Cot retaining post adjustment.................................................................................................................................37

Cot retaining post replacement............................................................................................................................... 38

Cot retaining post screw replacement .....................................................................................................................39

Hydraulic A valve or B valve replacement ............................................................................................................... 39

Hydraulic manual release valve replacement ..........................................................................................................40

Hydraulic cylinder replacement ..............................................................................................................................41

Hydraulic hose replacement................................................................................................................................... 42

Terminal block replacement ...................................................................................................................................43

Siderail assembly replacement (standard) .............................................................................................................. 45

Siderail assembly replacement (XPS option) ........................................................................................................... 45

Ratchet assembly replacement (XPS option) ..........................................................................................................47

Release handle assembly replacement (XPS option) ...............................................................................................48

Spring handle assembly replacement (XPS option) .................................................................................................49

Cot assembly .......................................................................................................................................................... 50

Base assembly .......................................................................................................................................................56

No wheel lock option...............................................................................................................................................60

Single wheel lock option ......................................................................................................................................... 61

Dual wheel lock option............................................................................................................................................62

Caster horn assembly - 6082-002-012 ...................................................................................................................63

Adjustable caster lock assembly ............................................................................................................................64

No Steer-Lock option .............................................................................................................................................. 65

Steer-Lock, optional - 6506-038-000...................................................................................................................... 66

Steer-Lock sub assembly, head end ......................................................................................................................67

6 in. molded wheel assembly - 6060-002-010........................................................................................................ 68

Cot retaining post, right - 6085-033-000................................................................................................................. 69

Optional kickstand assembly - 6085-102-000 ........................................................................................................70

Kickstand sub assembly - 6085-002-016 ............................................................................................................... 71

Outer lift tube assembly, base pivot - 6500-301-021.............................................................................................. 72

Inner lift tube assembly, base pivot - 6500-301-022 .............................................................................................. 73

Inner lift tube, litter pivot, patient right assembly - 6500-001-034 .......................................................................... 74

Inner lift tube, litter pivot, patient left assembly - 6500-001-035.............................................................................75

Standard siderail.....................................................................................................................................................76

Siderail assembly....................................................................................................................................................77

Outer rail sub assembly, right .................................................................................................................................78

Outer rail sub assembly, left ................................................................................................................................... 79

Hall sensor assembly..............................................................................................................................................80

Sensor housing assembly ...................................................................................................................................... 81

XPS option siderail .................................................................................................................................................82

EN 2 6506-109-002 Rev G.1

Page 9

XPS main assembly, right - 6500-003-034............................................................................................................. 83

XPS main assembly, left - 6500-003-044 ...............................................................................................................84

Power assembly ..................................................................................................................................................... 85

Hydraulic sub assembly - 6500-101-030 ................................................................................................................87

Foot end assembly .................................................................................................................................................88

Button assembly - 650600010016..........................................................................................................................92

Trend - 6085-031-000 ............................................................................................................................................. 93

Trend assembly ......................................................................................................................................................94

Gatch, optional - 6500-082-000..............................................................................................................................95

Gatch assembly, optional .......................................................................................................................................96

Gatch support assembly, optional .......................................................................................................................... 99

Fowler assembly................................................................................................................................................... 100

Standard Fowler ................................................................................................................................................... 101

1865 Fowler option ...............................................................................................................................................102

Antler only head section option............................................................................................................................. 103

Head section (non-Power-LOAD compatible) - 6506-001-020 ............................................................................105

Head section (Power-LOAD compatible) - 6506-001-021 ................................................................................... 106

Head section - 6500-002-020 ............................................................................................................................... 107

Head section lock assembly - 6500-001-026 .......................................................................................................109

Bent, antler only head section - 650600020020...................................................................................................110

In-fastener shut-off assembly, optional - 6500-001-027....................................................................................... 113

No head section oxygen bottle holder option - 6506-036-000 ............................................................................. 114

Power-LOAD compatible option - 6506-127-000 ................................................................................................. 115

Performance-LOAD option - 6506-034-001 .........................................................................................................118

Power-LOAD and Performance-LOAD option - 6506-034-002............................................................................ 120

Foot end fastener assembly (Power-LOAD compatible option)...........................................................................123

G-rated restraint package - 6500-002-030 ........................................................................................................... 126

X-restraint package - 6500-001-430..................................................................................................................... 127

X-restraint package, cobalt blue - 6500-001-431 ................................................................................................. 128

RRUUGGGGEEDD™-X restraint package - 6506-001-430 ...............................................................................................129

Belt extension - 6082-160-050 ............................................................................................................................. 130

Battery pack, SMRT - 6500-033-000.................................................................................................................... 131

Defibrillator platform - 6506-170-000.................................................................................................................... 132

Defibrillator platform common components..........................................................................................................134

Equipment hook option ......................................................................................................................................... 136

Head extension option - 6100-044-000 ................................................................................................................ 137

Head extension assembly ....................................................................................................................................138

Pillow - 6100-041-030 ...........................................................................................................................................139

Load wheel, hard - 6500-101-086 ........................................................................................................................ 140

Wheel, front - 6500-001-086................................................................................................................................. 141

IV pole assembly, two-stage, right - 6500-310-000.............................................................................................. 142

IV pole assembly, three-stage, right - 6500-315-000 ...........................................................................................143

IV pole assembly, two-stage, right - 6500-101-041.............................................................................................. 144

IV pole assembly, three-stage, right - 6500-101-043 ...........................................................................................145

IV pole assembly, two-stage, left - 6500-311-000 ................................................................................................ 146

IV pole assembly, three-stage, left - 6500-316-000 ............................................................................................. 147

6506-109-002 Rev G.1 3 EN

Page 10

IV pole assembly, two-stage, left - 6500-101-042 ................................................................................................ 148

IV pole assembly, three-stage, left - 6500-101-044 ............................................................................................. 149

IV pole assembly, two-stage, dual - 6500-312-000 .............................................................................................. 150

IV pole assembly, three-stage, dual - 6500-317-000 ........................................................................................... 151

Oxygen bottle holder, foot end - 6500-240-000.................................................................................................... 152

Oxygen bottle holder assembly - 6500-101-040 .................................................................................................. 153

Oxygen bottle holder, Fowler - 6500-241-000...................................................................................................... 154

Removable oxygen bottle holder - 6080-140-000 ................................................................................................ 155

Retractable head section oxygen bottle holder - 6085-046-000 .......................................................................... 156

Base storage net - 6500-160-000 ......................................................................................................................... 157

Backrest pouch - 6500-130-000 ...........................................................................................................................158

Head end storage flat - 6500-128-000.................................................................................................................. 159

Transfer flat........................................................................................................................................................... 160

Knee Gatch bolster mattress - 6500-002-150 ...................................................................................................... 161

Knee Gatch bolster mattress, gray - 6506-002-150 ............................................................................................. 162

Knee Gatch bolster mattress, XPS - 6500-003-130 ............................................................................................. 163

Knee Gatch bolster mattress grey, XPS - 6506-003-130..................................................................................... 164

Safety hook, short - 6060-036-017 / Safety hook, long - 6060-036-018 / Safety hook, J - 6092-036018

........................................................................................................................................................................ 165

Recycling passport ...............................................................................................................................................166

650600010016 ................................................................................................................................................... 166

6500-201-010 ....................................................................................................................................................... 167

6500-201-148 ....................................................................................................................................................... 168

6500-101-010 ....................................................................................................................................................... 169

6500-002-159 ....................................................................................................................................................... 170

6500-001-214 ....................................................................................................................................................... 171

6500-002-028 ....................................................................................................................................................... 172

6500-102-015 ....................................................................................................................................................... 173

EMC information ................................................................................................................................................... 174

EN 4 6506-109-002 Rev G.1

Page 11

WWaarrnniinngg//CCaauuttiioonn//NNoottee DDeeffiinniittiioonn

The words WWAARRNNIINNGG, CCAAUUTTIIOONN, and NNOOTTEE carry special meanings and should be carefully reviewed.

WWAARRNNIINNGG

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CCAAUUTTIIOONN

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and effective

use of the device and the care necessary to avoid damage to a device that may occur as a result of use or misuse.

NNoottee -- Provides special information to make maintenance easier or important instructions clearer.

SSuummmmaarryy ooff ssaaffeettyy pprreeccaauuttiioonnss

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WWAARRNNIINNGG

• Always keep your hands clear of the red safety bar pivots when you load, unload, or change the height position of the

cot.

• Always use both hands when you transport the cot.

• PPoowweerr--PPRROO with the PPoowweerr--LLOOAADD compatibility option operates primarily at these frequencies: 70 - 85 kHz for

inductive charging and 13.56 MHz±7 kHz, Amplitude Modulated (OOK), ERP: -82.37 dBm. The inductive charging can

operate between these frequencies: 70 - 125 kHz. Other equipment may interfere with the PPoowweerr--LLOOAADD system, even

if that other equipment complies with CISPR emission requirements.

• Always relieve pressure before you disconnect hydraulic or other lines. Escaping fluid under pressure can penetrate the

skin and cause serious injury. Tighten all connections before you apply pressure. If an accident occurs, see a doctor

immediately.

• Do not use bare hands to check for hydraulic leaks.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

• This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at their expense.

• Always use authorized parts to avoid the risk of product damage.

• Always check hoses and lines regularly to avoid damage to the cot. Check and tighten loose connections. Hydraulic

lines, hoses, and connections can fail or loosen due to physical damage, kinks, age, and environment exposure.

• Do not tip the cot onto its load wheels and actuate the product as this will allow air to enter the hydraulic system.

• Do not lubricate the bearings in the X-frame as it will degrade the performance of the cot and may void its warranty.

• The cot retaining post is shipped pre-configured for an X-frame cot. If the fastener has been configured for an H-frame

cot, you must adjust the retaining post to accommodate the fastener.

• The use of accessories, transducers, and cables, other than those specified or provided by the manufacturer, could

result in increased electromagnetic emissions or decreased electromagnetic immunity and result in improper operation.

6506-109-002 Rev G.1 5 EN

Page 12

• The emissions characteristics of this equipment make it suitable for use in industrial areas and hospitals (CISPR 11

class A). If it is used in a residential environment, for which CISPR 11 class B is normally required, this equipment might

not offer adequate protection to radio frequency communication services. The user might need to take mitigation

measures, such as relocating or reorienting the equipment.

• Portable RF communications equipment, including peripherals such as antenna cables and external antennas, should

be used no closer than 12 inches (30 cm) to any part of PPoowweerr--PPRROO and SSMMRRTT charger, including cables specified by

the manufacturer.

• Avoid stacking or placing other equipment adjacent to PPoowweerr--PPRROO and SSMMRRTT charger to prevent improper operation of

the products. If such use is necessary, carefully observe PPoowweerr--PPRROO and SSMMRRTT charger and the other equipment to

make sure that they are operating properly.

PPiinncchh ppooiinnttss

WWAARRNNIINNGG -- Always keep your hands clear of the red safety bar pivots when you load, unload, or change the height

position of the cot.

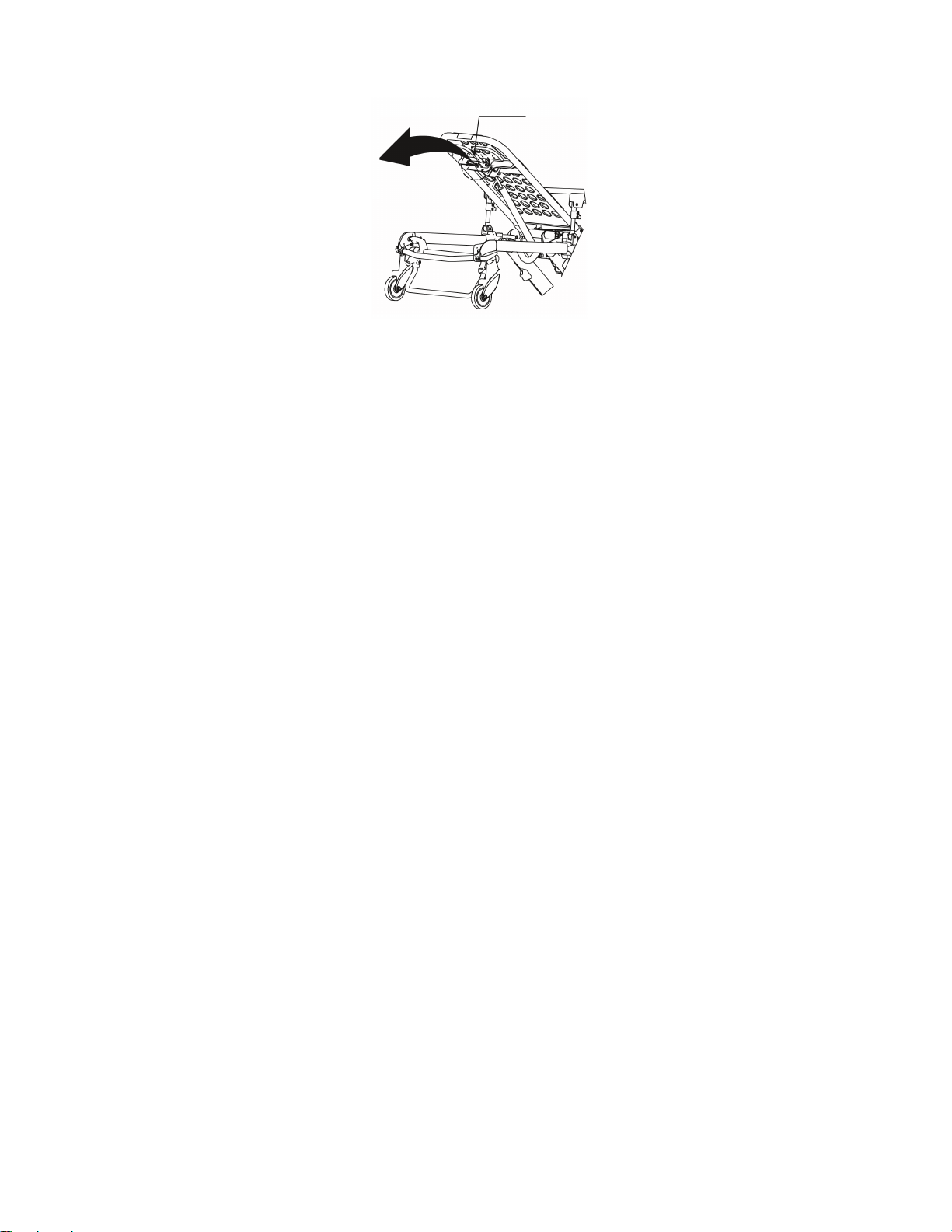

FFiigguurree 11 –– PPiinncchh ppooiinnttss

MMeecchhaanniiccaall ssttaabbiilliittyy

WWAARRNNIINNGG -- Always use both hands when you transport the cot.

EN 6 6506-109-002 Rev G.1

Page 13

FFiigguurree 22 –– MMeecchhaanniiccaall ssttaabbiilliittyy

NNoottee

• If the cot is on a plane steeper than five degrees, place the cot in the lowest position.

• Do not use the defibrillator option and the foot end oxygen bottle holder option at the same time.

6506-109-002 Rev G.1 7 EN

Page 14

IInnttrroodduuccttiioonn

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating or

maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or maintenance

of this product.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

NNoottee

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current product

information available at the time of printing. There may be minor discrepancies between your product and this manual. If

you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

PPrroodduucctt ddeessccrriippttiioonn

The Stryker Model 6506 PPoowweerr--PPRROO™ XT cot is a powered ambulance cot that consists of a platform mounted on a

wheeled X-frame designed to support and transport a maximum weight of 700 lb (318 kg) in pre-hospital and hospital

environments.

The device is collapsible for use in emergency vehicles and has an adjustable load height feature to allow the device to be

set to different ambulance deck heights for proper body mechanics during loading and unloading. The NiCd batterypowered hydraulic lift system allows operators to raise and lower the cot using the powered controls, while duplicate foot

end controls on the upper and lower lift bars accommodate different operator positions or sizes. The cot is equipped with a

manual back-up release handle to allow the operation of cot functions in the event of power loss. The device is equipped

with a retractable head section for 360-degree mobility in any height position, siderails, patient securement straps, an

adjustable pneumatic backrest, and various optional accessories that assist with the transport of a patient. Maximum

patient comfort is attainable with the three different litter positions of shock, flat leg, and optional knee Gatch positioning.

The SSMMRRTT™ power system consists of a SSMMRRTT charger and a SSMMRRTT Pak. The SSMMRRTT Pak powers the hydraulic lift

system of the Stryker powered ambulance cots.

IInnddiiccaattiioonnss ffoorr uussee

The Stryker PPoowweerr--PPRROO XT is a powered wheeled stretcher, which is intended to support and transport the entire body of

a traumatized, ambulatory, or non-ambulatory human patient (includes infants and adults).

The battery-powered hydraulic lift system is intended to help reduce the effort required by the operator to raise and lower

the cot. The device is designed to support patients in a supine (horizontal) or sitting position and facilitate the transportation

of associated medical equipment (such as oxygen bottles, monitors, or pumps) in emergency or transport vehicles. This

ambulance cot is intended to be used in pre-hospital and hospital environments, and in emergency and non-emergency

applications. It is rated to a maximum capacity of 700 lb (318 kg) (sum of the patient, mattress, and accessory weight) and

the intended operators of the device are trained professionals including emergency medical service and medical care

center personnel, as well as medical first responders.

PPoowweerr--PPRROO XT is not intended for extended stay or use as a hospital bed or in devices that modify air pressure, such as

hyperbaric chambers.

EN 8 6506-109-002 Rev G.1

Page 15

EExxppeecctteedd sseerrvviiccee lliiffee

PPoowweerr--PPRROO has a seven year expected service life under normal use conditions and with appropriate periodic

maintenance.

The SSMMRRTT charger has a seven year expected service life under normal use conditions and with appropriate periodic

maintenance.

The SSMMRRTT Pak battery has a two year expected service life under normal use conditions.

DDiissppoossaall//rreeccyyccllee

Always follow the current local recommendations and/or regulations governing environmental protection and the risks

associated with recycling or disposing of the equipment at the end of its useful life.

CCoonnttrraaiinnddiiccaattiioonnss

None known.

SSppeecciiffiiccaattiioonnss -- PPoowweerr--PPRROO

NNoottee -- Safe working load

indicates the sum of the

patient, mattress, and

accessory weight.

Maximum unassisted lift capacity

Backrest articulation/shock position (standard

Fowler - 6506-012-003)

Backrest articulation/shock position (1865 Fowler

option - 6506-012-004)

Backrest articulation/shock position (6506-700-

013)

Overall length/minimum length/width 81 in./63 in./23 in. 206 cm/160 cm/58 cm

Height

Weight

Caster diameter/width 6 in./2 in. 15 cm/5 cm

Minimum operators required for loading/

unloading an occupied cot

2

3

1

700 lb 318 kg

500 lb 227 kg

0° to 73°/+15°

0° to 75°/+15°

6° to 73°/+15°

Adjustable from 14 in.

to 41.5 in.

125 lb 57 kg

2

Adjustable from 36 cm to

105 cm

Minimum operators required for loading/

unloading an unoccupied cot

Recommended fastener systems Model 6370 or 6377 Floor mount type, Model 6371

Recommended loading height

Recommended working height (excluding

mattress)

6506-109-002 Rev G.1 9 EN

4

1

Wall mount type, Model 6390 PPoowweerr--LLOOAADD, Model

6392 PPeerrffoorrmmaannccee--LLOOAADD

Up to 36 in. Up to 91 cm

15.75 in. 40 cm

Page 16

Hydraulic oil Stryker part number 6500-001-293

130 °F

(54 °C)

-30 °F

(-34 °C)

130 °F

(54 °C)

-30 °F

(-34 °C)

93%0%93%

0%

1060 hPa

700

1060 hPa

700

Power system

Battery 24 VDC NiCd - SSMMRRTT power system

Charger 100-240 VAC 1.20 A,

50/60 Hz or 12 VAC 4.16 A - SSMMRRTT power system

Cot duty cycle 16.7% (less than 60 seconds on, more than 300

seconds off)

Standards (cots and chargers) ANSI/AAMI ES60601-1:2012, CAN/CSA-C22.2 No.

60601-1:14, KKK-A-1822

For standards that require specific options, see

Standards with required options

1

Cot loads over 300 lb (136 kg) may require additional assistance to meet the set cot load height.

2

Height measured from bottom of mattress at seat section to ground level.

3

Cot is weighed with one battery and without mattress and restraints.

4

Set the cot height to any ambulance deck height that ranges from 26 in. to 36 in. (66 cm to 91 cm).

(page 11).

Stryker reserves the right to change specifications without notice.

PPoowweerr--PPRROO XT is designed to conform to the Federal Specification for the Star-of-Life Ambulance (KKK-A-1822).

PPoowweerr--PPRROO XT is designed to be compatible with some competitive cot fastener systems.

The yellow and black color scheme is a proprietary trademark of Stryker Corporation.

Hereby, Stryker declares that the radio equipment type short range device is in compliance with Directive 2014/53/EU. The

full text of the EU declaration of conformity is available at the following internet address: http://techweb.med.strykercorp.

com/EMS/EU%20Declaration%20of%20Conformity/index.html.

Labels may be unreadable from a viewing distance greater than 12 inches.

WWAARRNNIINNGG -- PPoowweerr--PPRROO with the PPoowweerr--LLOOAADD compatibility option operates primarily at these frequencies: 70 - 85 kHz

for inductive charging and 13.56 MHz±7 kHz, Amplitude Modulated (OOK), ERP: -82.37 dBm. The inductive charging can

operate between these frequencies: 70 - 125 kHz. Other equipment may interfere with the PPoowweerr--LLOOAADD system, even if

that other equipment complies with CISPR emission requirements.

EEnnvviirroonnmmeennttaall ccoonnddiittiioonnss

OOppeerraattiioonn SSttoorraaggee aanndd ttrraannssppoorrttaattiioonn

Temperature

Relative humidity

Atmospheric pressure

CCAAUUTTIIOONN -- This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at their expense.

EN 10 6506-109-002 Rev G.1

Page 17

NNoottee -- In accordance with the European REACH regulation and other environmental regulatory requirements, the 6500001-210 and 6500-001-211 hydraulic hoses contain dibutyl phthalate (DBP).

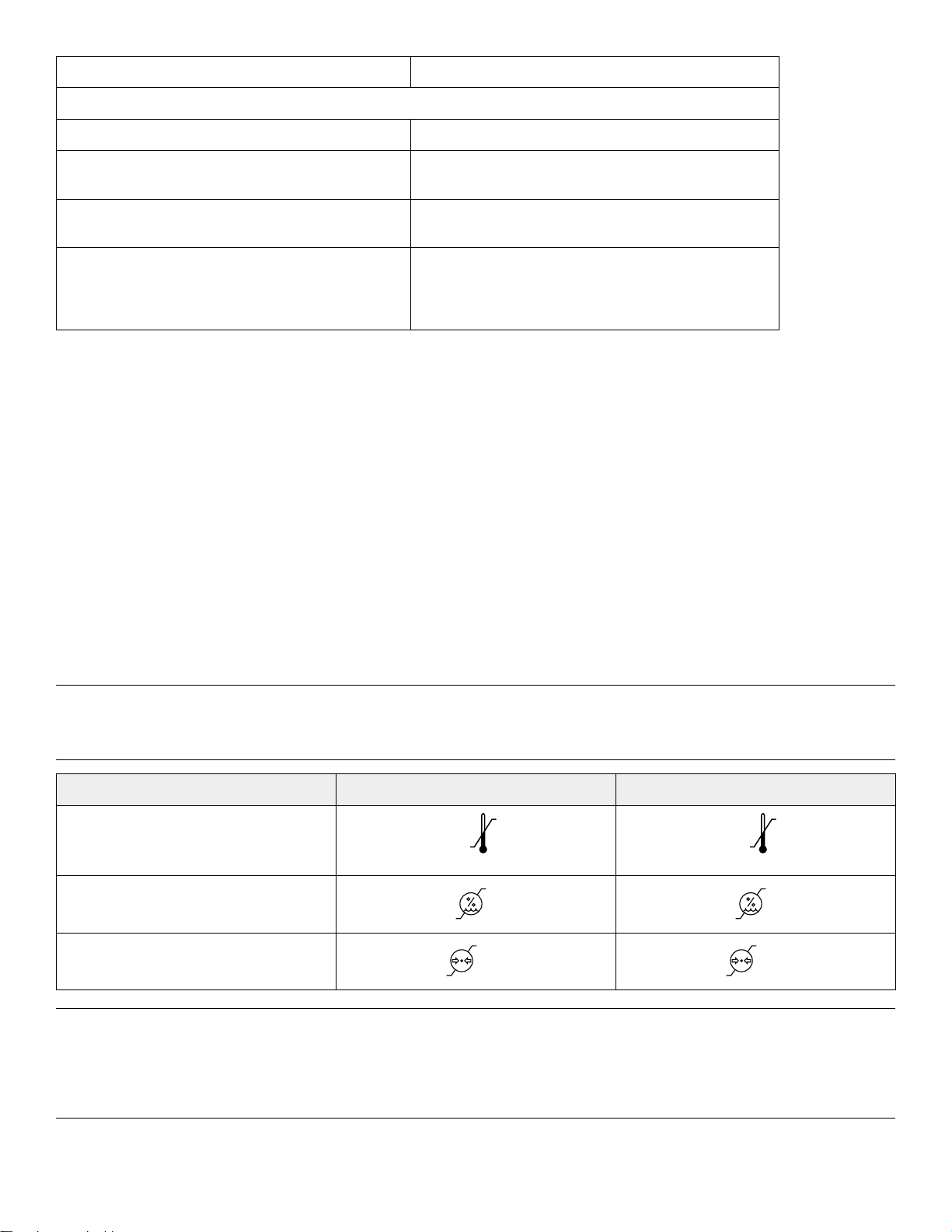

SSttaannddaarrddss wwiitthh rreeqquuiirreedd ooppttiioonnss

To be compliant with the standards, you must install the following required options on your cot.

NNoottee -- Compatible cot is loaded into PPoowweerr--LLOOAADD in powered mode for crash testing.

OOppttiioonn sseelleeccttiioonn

SSttaannddaarrdd

SAE J3027 crash-test

standards with the use of a

crash-rated fastener

AS/NZS-4535 crash-test

standards with the use of a

crash-rated fastener

BS EN 1789:2007+A2:2014

crash-test standards with

the use of a crash-rated

fastener

BS EN 1865-3:2012

+A1:2015

BS EN 1865-2:2010

+A1:2015

RReessttrraaiinntt ppaacckkaaggee MMaattttrreessss OOppttiioonn

X-restraint package (6500001-430) or RUGGED-X

restraint package (6506001-430)

X-restraint package (6500001-430)

G-rated restraint package

(6500-002-030), X-restraint

package (6500-001-430), or

RUGGED-X restraint

package (6506-001-430)

Knee Gatch bolster

mattress (6500-002-150/

6506-002-150) or XPS

mattress (6500-003-130/

6506-003-130) (depending

on cot siderail)

Knee Gatch bolster

mattress (6500-002-150/

6506-002-150) or XPS

mattress (6500-003-130/

6506-003-130) (depending

on cot siderail)

Knee Gatch bolster

mattress (6500-002-150/

6506-002-150) or XPS

mattress (6500-003-130/

6506-003-130) (depending

on cot siderail)

XPS option (6506-040-000)

1865 Fowler option (6506012-004)

The Britax Meridian SICT Series No. 7200/A/2010 Convertible Child Restraint with the X-restraint package (6500-001-430)

has been dynamically crash tested with a 10 kg crash dummy to 18.2 G forward and 10 G sideward per AS/NZS-4535:

1999 crash-test standards.

SSppeecciiffiiccaattiioonnss -- SSMMRRTT

SSMMRRTT cchhaarrggeerr SSMMRRTT PPaakk AACC ppoowweerr ssuuppppllyy XXPP ppoowweerr MMeeaannWWeellll

Electrical input 13.9 VDC 4.16 A Not applicable 100-240 VAC

1.20 A 50/60 Hz

Electrical output Open circuit 40

VDC 1.20 A

Height

Width 5.125 in. (130.175

6506-109-002 Rev G.1 11 EN

2.375 in. (60.325

mm)

mm)

24 VDC NiCd 12 VDC 4.16 A 12 V 5.4 A 12 V 5.0 A

3.25 in. (82.55

mm)

4 in. (101.6 mm) 2.56 in. (65.02

1.61 in. (40.89

mm)

mm)

100-240 VAC

~1.4 A 50/60 Hz

1.32 in. (33.5 mm) 1.24 in. (31.5 mm)

2.19 in. (55.5 mm) 1.97 in. (50 mm)

100-240 VAC

~1.4 A 50/60 Hz

Page 18

SSMMRRTT cchhaarrggeerr SSMMRRTT PPaakk AACC ppoowweerr ssuuppppllyy XXPP ppoowweerr MMeeaannWWeellll

88 °F

(31 °C)

43 °F

(6 °C)

88 °F

(31 °C)

43 °F

(6 °C)

104 °F

(40 °C)

-4 °F

(-20 °C)

93%0%75%

30%

93%

0%

1060 hPa

700

1060 hPa

700

1060 hPa

500

Length 7 in. (177.8 mm) 5.75 in. (146.05

mm)

4.72 in. (119.89

mm)

4.94 in. (119.89

mm)

4.72 in. (125 mm)

Weight 1.3 lb (.59 kg) 3.8 lb (1.7 kg) .61 lb (.28 kg) .68 lb (.308 kg) .71 lb (.32 kg)

Enclosure

IPX0 IPX6 IPX0 IPX0 IPX0

protection

Equipment type Not applicable Not applicable Class II Not applicable Not applicable

Approvals ANSI/AAMI

Not applicable Not applicable Not applicable Not applicable

ES60601-1:

2012, CAN/CSAC22.2 No. 606011:14

EEnnvviirroonnmmeennttaall ccoonnddiittiioonnss OOppeerraattiioonn CChhaarrggiinngg SSttoorraaggee aanndd

ttrraannssppoorrttaattiioonn

Temperature

Relative

Atmospheric pressure

Specifications are approximate and may vary from unit to unit or as a result of power supply fluctuations.

Stryker reserves the right to change specifications without notice.

EN 12 6506-109-002 Rev G.1

Page 19

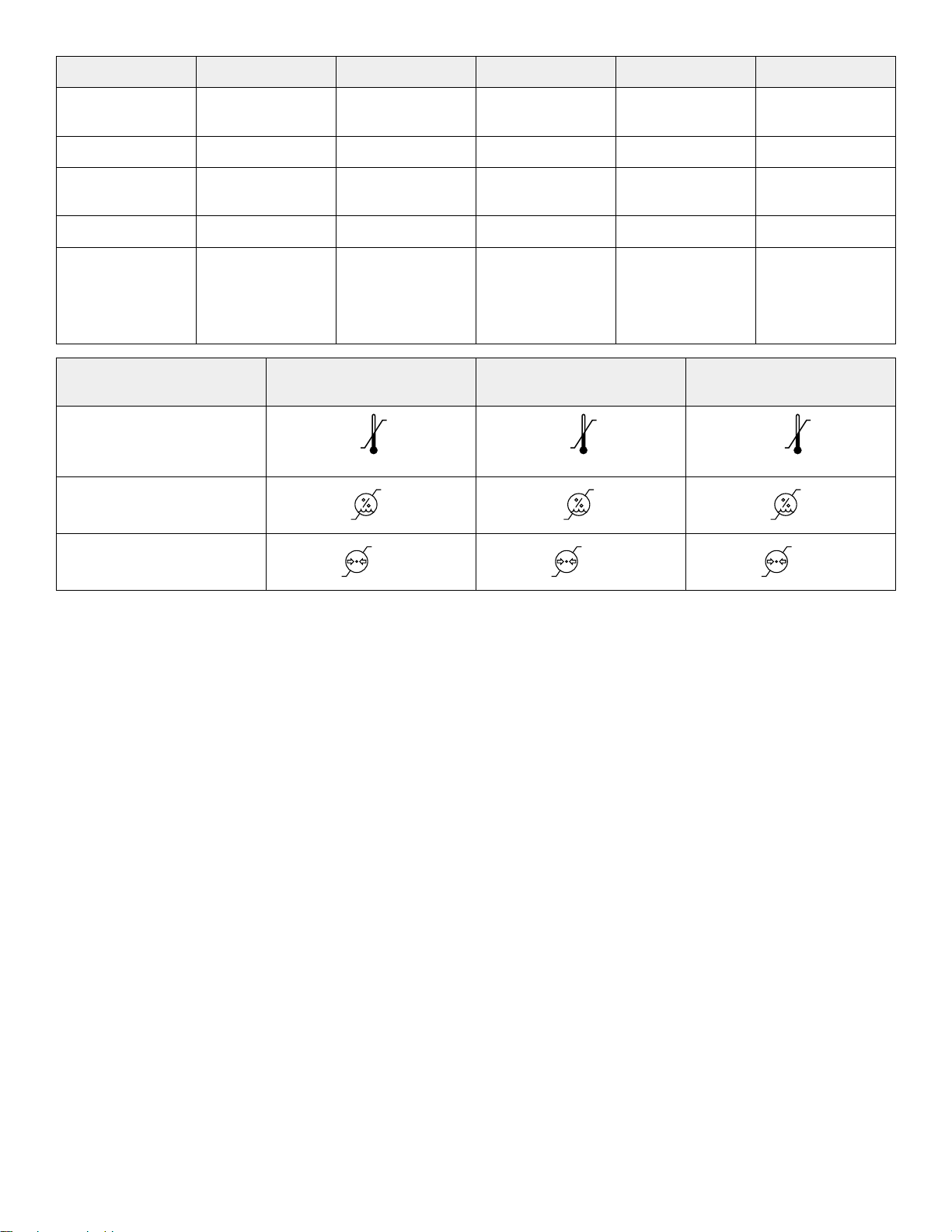

PPrroodduucctt iilllluussttrraattiioonn -- PPoowweerr--PPRROO

A

B

C

D

E

F

G

H

I

K

L

M

N

O

P

Q

R

J

FFiigguurree 33 –– PPoowweerr--PPRROO XXTT

A Footrest release handle J Siderail release handle

B

C

D Footrest M

E

F Wheel lock O Head section release handle

G

H

I

Height adjustment switches

Manual back-up release handle

Height sensor housing (on other side)

Cot retaining post

Battery release

Battery

K

L Backrest

N Retractable head section

P

Q

R

Transport wheels

Backrest adjustment handle

Safety bar

Load wheel

Hydraulic unit

6506-109-002 Rev G.1 13 EN

Page 20

PPrroodduucctt iilllluussttrraattiioonn -- SSMMRRTT

A

C

D

E

F

H

I

G

B

FFiigguurree 44 –– SSMMRRTT ppoowweerr ssyysstteemm

A

B SSMMRRTT Pak G Data

C DC cable H

D

E

SSMMRRTT charger

AC power supply

AC power cord

F

I

Output cord

Power (-)

Power (+)

CCoonnttaacctt iinnffoorrmmaattiioonn

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

NNoottee -- The user and/or the patient should report any serious product-related incident to both the manufacturer and the

Competent authority of the European Member State where the user and/or patient is established.

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

EN 14 6506-109-002 Rev G.1

Page 21

SSeerriiaall nnuummbbeerr llooccaattiioonn -- PPoowweerr--PPRROO

A

FFiigguurree 55 –– SSeerriiaall nnuummbbeerr llooccaattiioonn

SSeerriiaall nnuummbbeerr llooccaattiioonn -- SSMMRRTT

The serial number for the SSMMRRTT charger is located on the bottom of the unit. The lot number for the SSMMRRTT Pak is located

on the top of the SSMMRRTT Pak above the red release button.

DDaattee ooff mmaannuuffaaccttuurree

The year of manufacture is the first 2 digits of the serial number for PPoowweerr--PPRROO.

6506-109-002 Rev G.1 15 EN

Page 22

PPrreevveennttiivvee mmaaiinntteennaannccee

WWAARRNNIINNGG

• Always relieve pressure before you disconnect hydraulic or other lines. Escaping fluid under pressure can penetrate the

skin and cause serious injury. Tighten all connections before you apply pressure. If an accident occurs, see a doctor

immediately.

• Do not use bare hands to check for hydraulic leaks.

CCAAUUTTIIOONN

• Always use authorized parts to avoid the risk of product damage.

• Always check hoses and lines regularly to avoid damage to the cot. Check and tighten loose connections. Hydraulic

lines, hoses, and connections can fail or loosen due to physical damage, kinks, age, and environment exposure.

• Do not tip the cot onto its load wheels and actuate the product as this will allow air to enter the hydraulic system.

Establish and follow a maintenance schedule and keep records of the maintenance activity. Remove product from service

before you perform the preventive maintenance inspection. You may need to perform preventive maintenance checks more

often based on your level of product usage. Service only by qualified personnel.

When using maintenance products, follow the directions of the manufacturer and reference all material safety data sheets

(MSDS).

LLuubbrriiccaattiioonn

The cot has been designed to operate without the need for lubrication.

CCAAUUTTIIOONN -- Do not lubricate the bearings in the X-frame as it will degrade the performance of the cot and may void its

warranty.

RReegguullaarr iinnssppeeccttiioonn aanndd aaddjjuussttmmeennttss

The following schedule is a general guide to maintenance. Factors such as weather, terrain, geographical location, and

individual usage will alter the required maintenance schedule. If you are unsure how to perform these checks, contact your

Stryker service technician. If you are in doubt as to what intervals to follow to maintain your product, consult your Stryker

service technician. Check each routine and replace worn parts if necessary.

EEvveerryy mmoonntthh oorr ttwwoo hhoouurrss

Inspect these items every month or two hours, whichever comes first.

IItteemm IInnssppeecctt

Settings In-fastener shutoff configuration

Cylinder Extend cylinder rod. Wipe the cylinder rod with a soft cloth

and household cleaner.

Cables and wires No hanging wires from routings or connections

Manual backup release handle Manual backup release handle functions

Litter Frame and litter

Base Frame and base

Wheels All wheels are secure, roll, and swivel

EN 16 6506-109-002 Rev G.1

Page 23

IItteemm IInnssppeecctt

Head section Safety bar operates. Pull toward the head section to make

sure that the safety bar swings and rotates freely and pulls

back to the home position

Restraint Restraints function with no excessive wear (such as a bent

or broken receiver or latch plate or torn or frayed webbing)

Battery SSMMRRTT Pak housing and terminal area for cracks or

damage before first and every use

Charger SSMMRRTT charger and parts for cuts in the cord, bent pins or

contacts, or cracks in the housing before first and every

use

EEvveerryy tthhrreeee mmoonntthhss oorr ssiixx hhoouurrss

Inspect these items every three months or six hours, whichever comes first.

IItteemm IInnssppeecctt

Cylinder All fasteners are secure

No hydraulic fluid (red) leaks

Loose fittings - tighten, if needed

Hydraulics Motor mount fasteners are secure

No hydraulic fluid leaks

No leaks from reservoir

Cables and wires No damage or pinching of wiring harness, cable, or lines

No damaged connectors

Manual backup release handle Base extends and retracts when you pull the manual

backup release handle

Cot does not lower when you pull the manual backup

release handle with 100 lb (45 kg) or more on the cot

Litter All fasteners are secure

Backrest cylinder operates

Adjust pneumatic cylinder for full range of motion, if

required

Base All fasteners are secure

X-frame X-frame expands and retracts

Kickstand (optional) Retracts fully to the transport position

Bolts are tightened

Head section All fasteners are secure

Head section extends and locks

Accessories and parts (optional) All accessories and parts operate (such as IV pole, head

extension and pillow, oxygen bottle holder, and restraint

extender)

6506-109-002 Rev G.1 17 EN

Page 24

EEvveerryy ssiixx mmoonntthhss oorr 1122 hhoouurrss

Inspect these items every six months or 12 hours, whichever comes first.

IItteemm IInnssppeecctt

Hydraulics Hoses and fittings for damage or wear

Hydraulic velocity fuse - place a weight of approximately 50

lb (23 kg) on the cot, raise the cot, lift the cot with two

operators, pull the manual backup release handle, rapidly

set the cot down, and make sure that the cot does not drop

Electronic controls Extend cot to raised position, measure and check load

height

Jog function operates

High speed retract works

Switches No damage or wear to either switch

Both switches operate

Litter No bent, broken, or damaged components

No damage or tears on cot grips

Siderails operate and latch

Foot rest operates

Mattress No cracks or tears

Base No bent, broken, or damaged components

Cot retaining post is secure. If not, replace the screw

No excessive damage to X-frame guards

Wheels Free of debris

Head section No bent, broken, or damaged components

Grip bar has no excessive damage or tears

Load wheels are secure and roll

Kickstand (optional) Lubricate the kickstand spring and internal spring housing

(optional) using TTrrii--FFllooww® lubrication.

EEvveerryy 1122 mmoonntthhss oorr 2244 hhoouurrss

Inspect these items every 12 months or 24 hours, whichever comes first.

IItteemm IInnssppeecctt

Settings Cot and fastener fit and function

Safety bar connects to the vehicle safety hook

Cylinder Cylinder is adjusted - lock nut is tight and the cot stops

moving when it hits the dead stops

Manual backup release handle Returns to the stowed position

EN 18 6506-109-002 Rev G.1

Page 25

IItteemm IInnssppeecctt

Litter All welds are intact, not cracked, or broken

Warning labels present, legible

Base All welds are intact, not cracked, or broken

Wheels Check and adjust wheel locks

Retractable head section oxygen bottle holder (optional) Straps and clips for wear

Defibrillator platform (optional) Straps not frayed or torn

Latch hooks are intact and secure

FFoooott eenndd ffaasstteenneerr ppaarrtt rreeppllaacceemmeenntt sscchheedduullee

For PPeerrffoorrmmaannccee--LLOOAADD compatible cots, you must replace the foot end fastener parts every 18,078 calls. This is to make

sure that the PPeerrffoorrmmaannccee--LLOOAADD remains functional. Follow this call volume time table to remain compliant with this

requirement.

CCaallllss ppeerr ddaayy MMoonntthhss

≤ 7 Not applicable

8 77

9 67

10 59

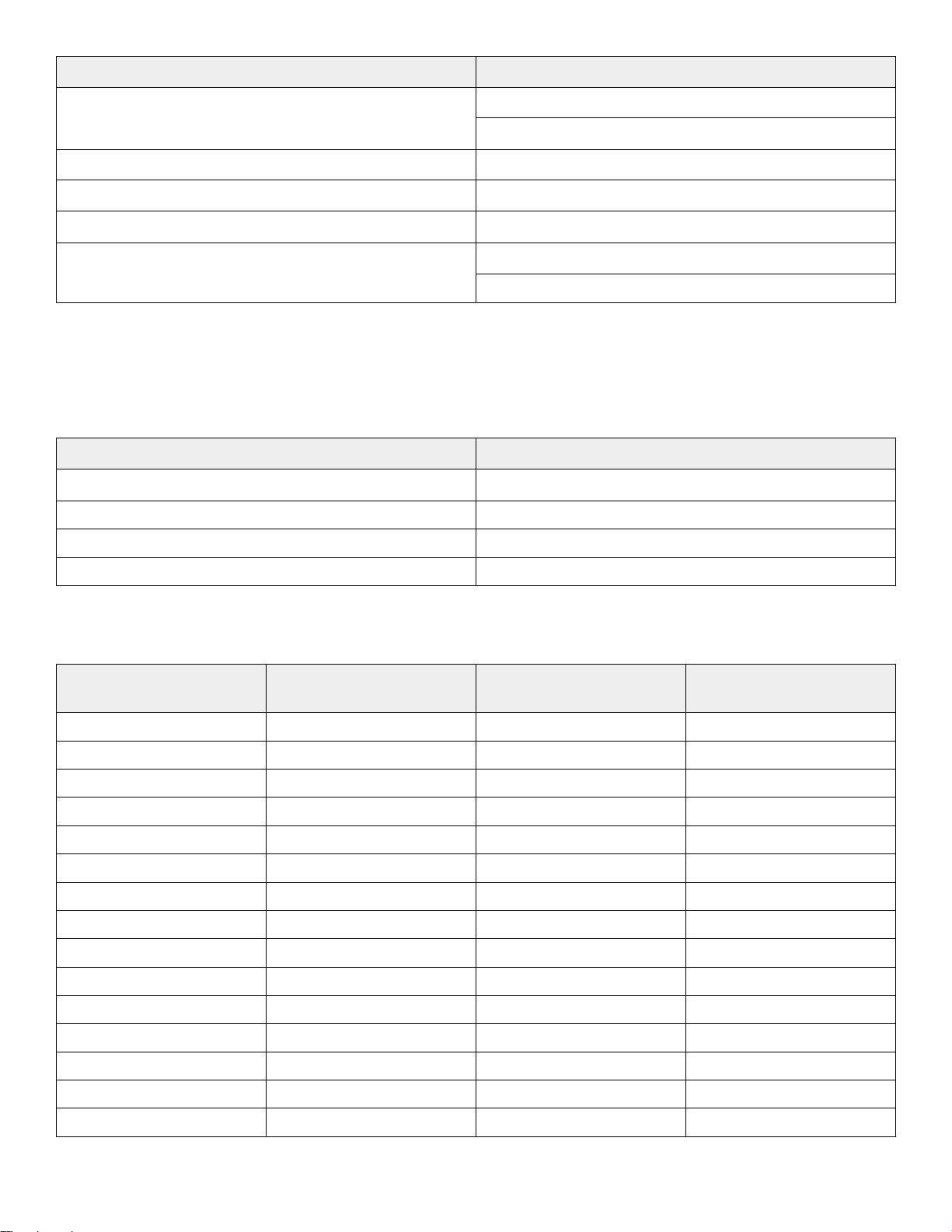

MMaaiinntteennaannccee rreeccoorrdd

DDaattee MMaaiinntteennaannccee ooppeerraattiioonn

ppeerrffoorrmmeedd

BByy HHoouurrss

6506-109-002 Rev G.1 19 EN

Page 26

DDaattee MMaaiinntteennaannccee ooppeerraattiioonn

ppeerrffoorrmmeedd

BByy HHoouurrss

TTrraaiinniinngg rreeccoorrdd

TTrraaiinniinngg ddaattee

TTrraaiinneeee nnaammee BBaassiicc ttrraaiinniinngg RReeffrreesshheerr uuppddaattee OOwwnneerr’’ss mmaannuuaall,, iinn--

sseerrvviiccee,, ffoorrmmaall ccllaassss,, eettcc..

EN 20 6506-109-002 Rev G.1

Page 27

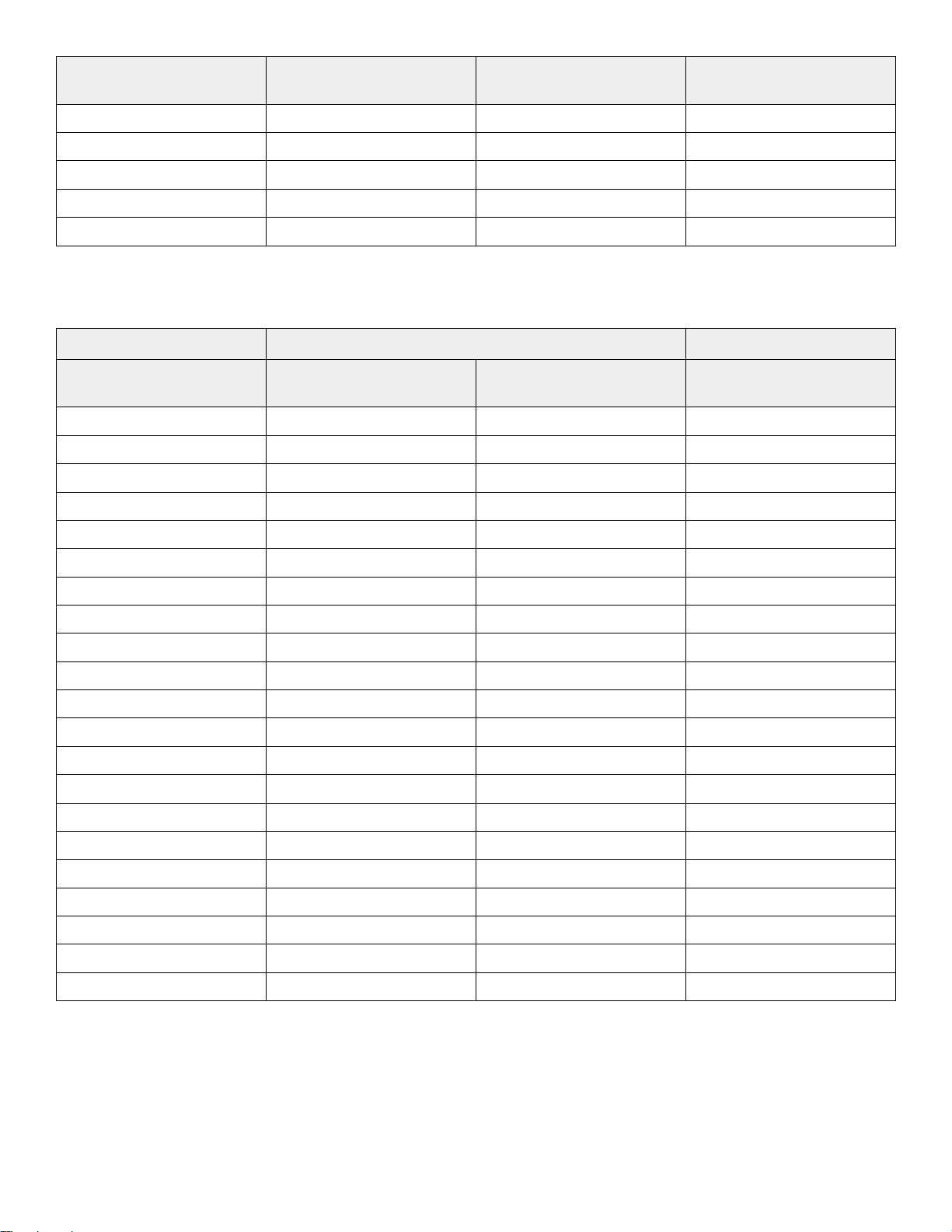

TTrroouubblleesshhoooottiinngg

A

B

C

D

E

F

G

H

I

K

L

J

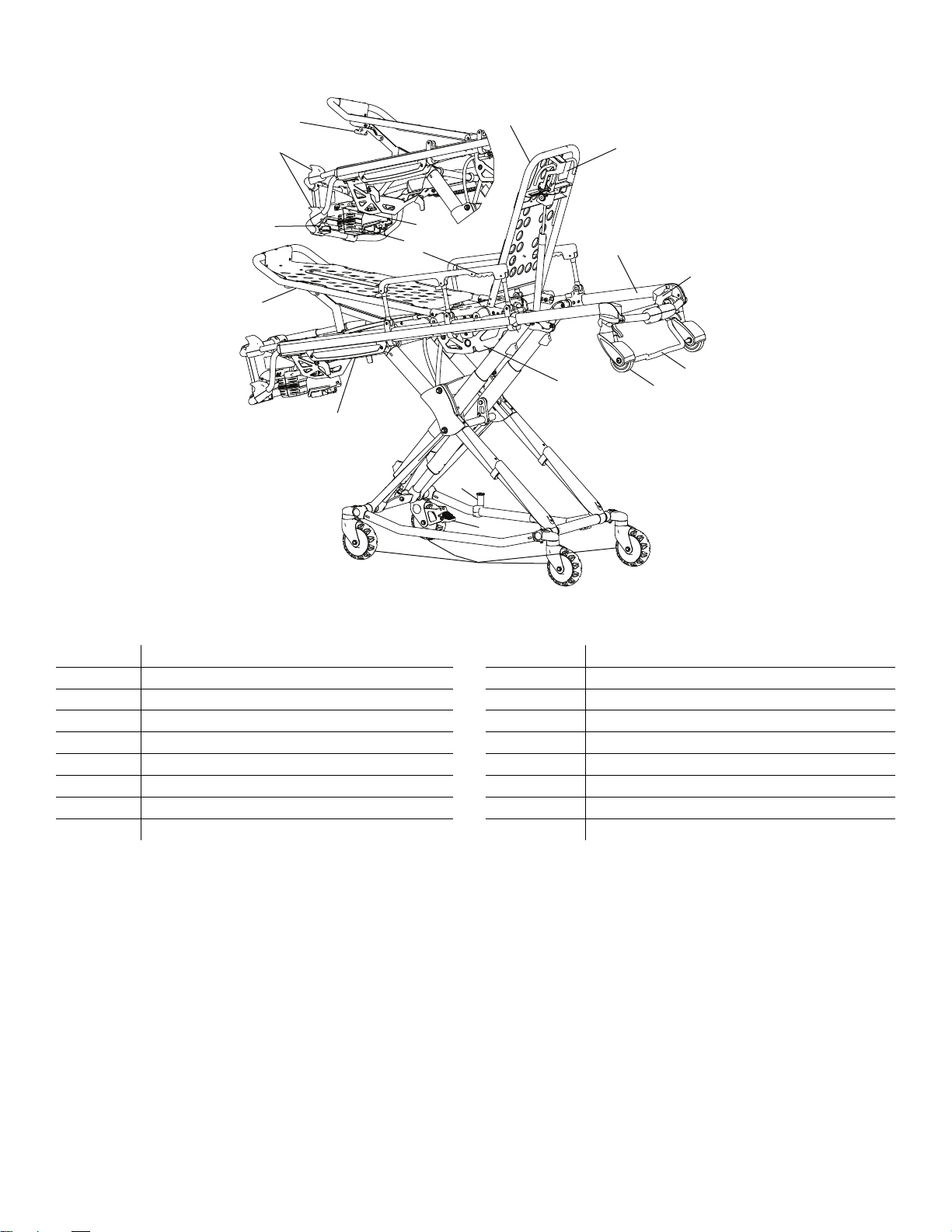

EElleeccttrroonniiccss aanndd hhyyddrraauulliiccss llooccaattoorr

NNoottee -- Some components have been removed for clarity.

A Cap-side hydraulic hose G Manual backup release

B Electronic housing (control

C Hydraulic cylinder I Power indicator LED

D Hydraulic manifold

E LCD screen K Sensor housing (hall effects

F Main cable L Switches, height adjustment

board inside)

assembly

handle

H Manual release cable

J Rod-side hydraulic hose

sensor inside)

6506-109-002 Rev G.1 21 EN

Page 28

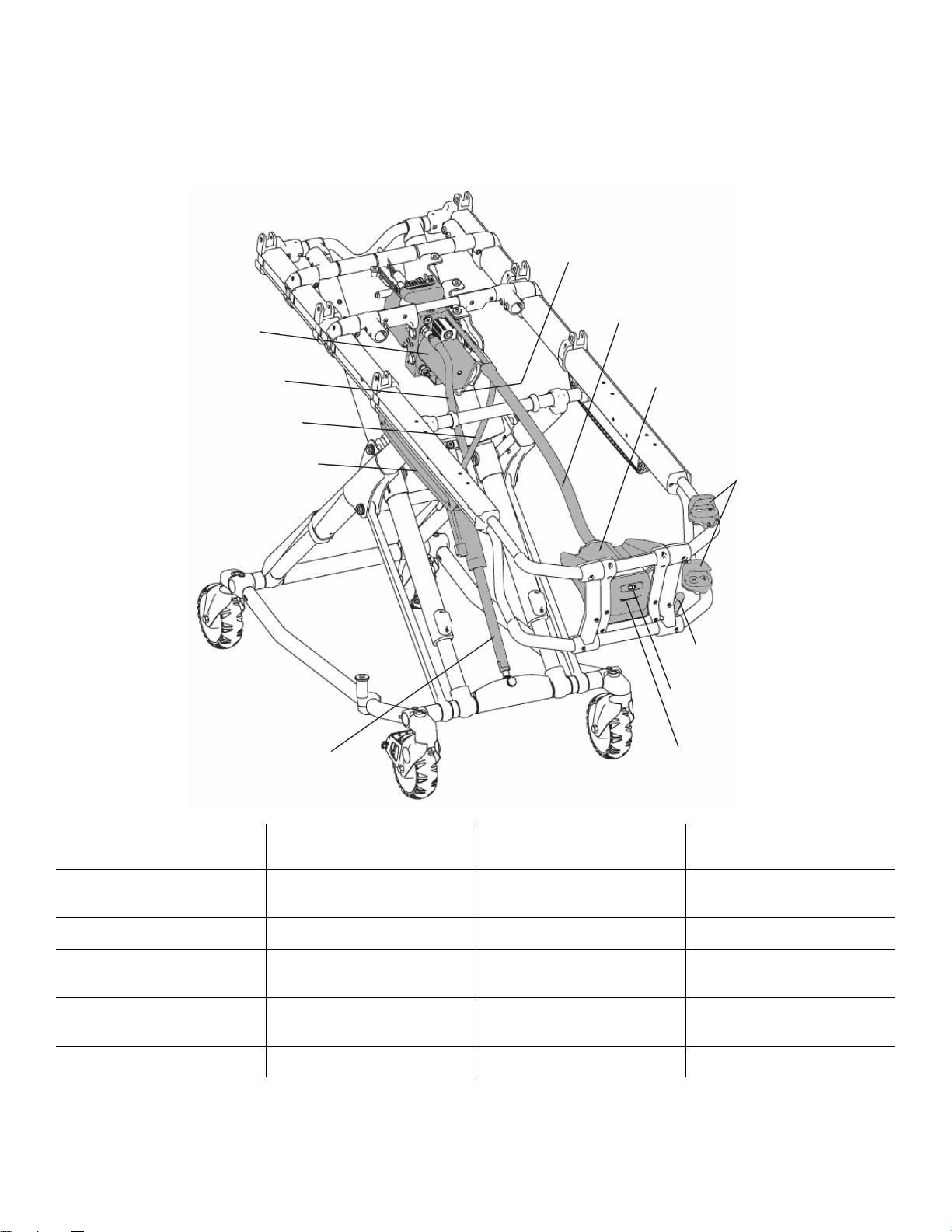

HHyyddrraauulliicc aasssseemmbbllyy

A

B

C

D

E

F

Item Item

ConnectionConnection

Pressure

switch

Pressure

switch

connector

A-valve

solenoid

A-valve

connector

B-valve

solenoid

B-valve

connector

Motor

Motor

connector

Blue

Black

Green

A A-valve connector D Motor connector

B B-valve connector E Pressure switch

C

Hydraulic manifold

F Pressure switch connector

HHyyddrraauulliicc aasssseemmbbllyy wwiirriinngg sscchheemmaattiiccss

EN 22 6506-109-002 Rev G.1

Page 29

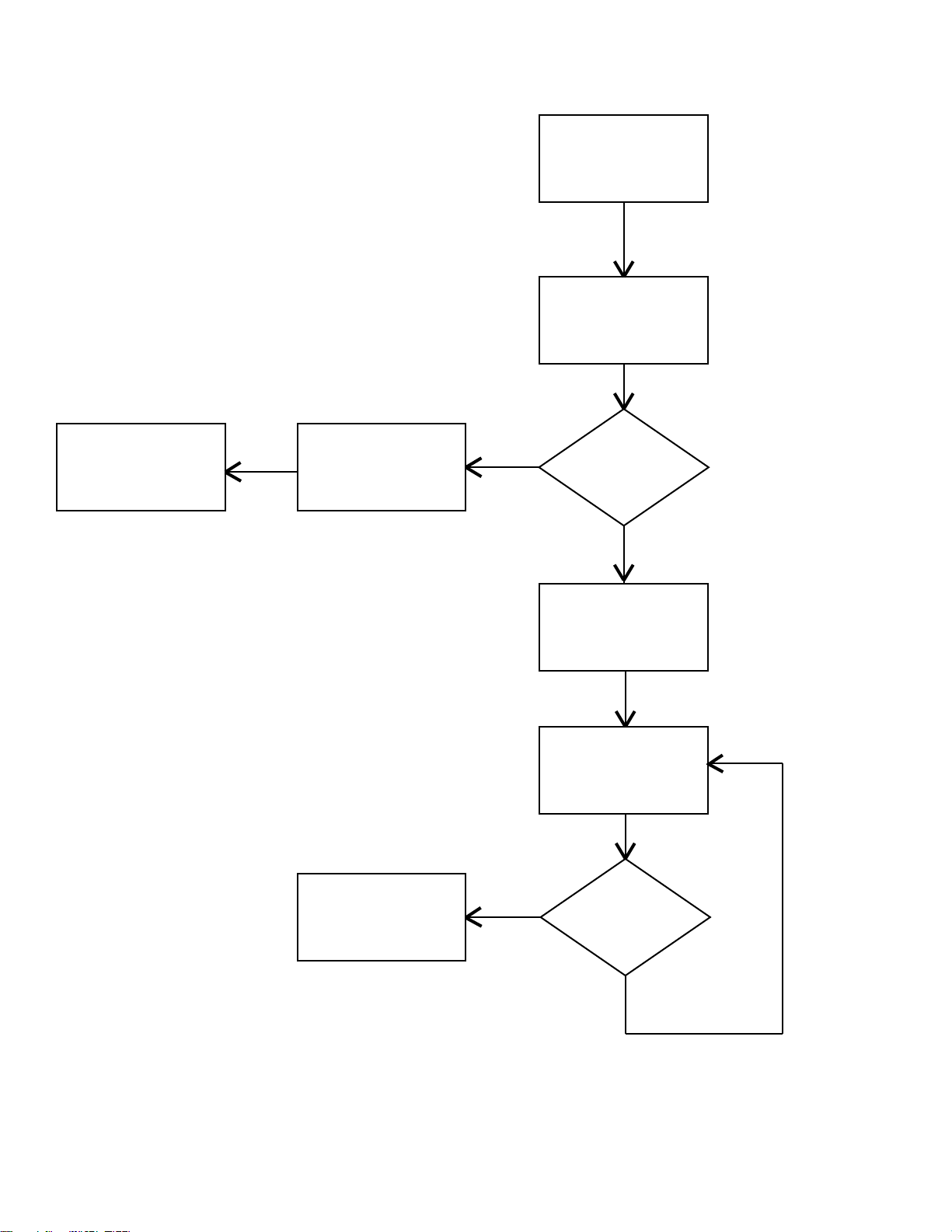

EElleeccttrriiccaall ssyysstteemm bblloocckk ddiiaaggrraamm –– uunnllooaadd

Press Extend (+) Button

Open A-Valve

Top Hall Effects

Sensor Detected?

Stop until button is pressed Jog Up

Ramp in motor (Up)

Ramp out motor and stop

Top Hall Effects

Sensor Detected?

Run motor at max speed

No

Yes

No

Yes

Lift and extend functions

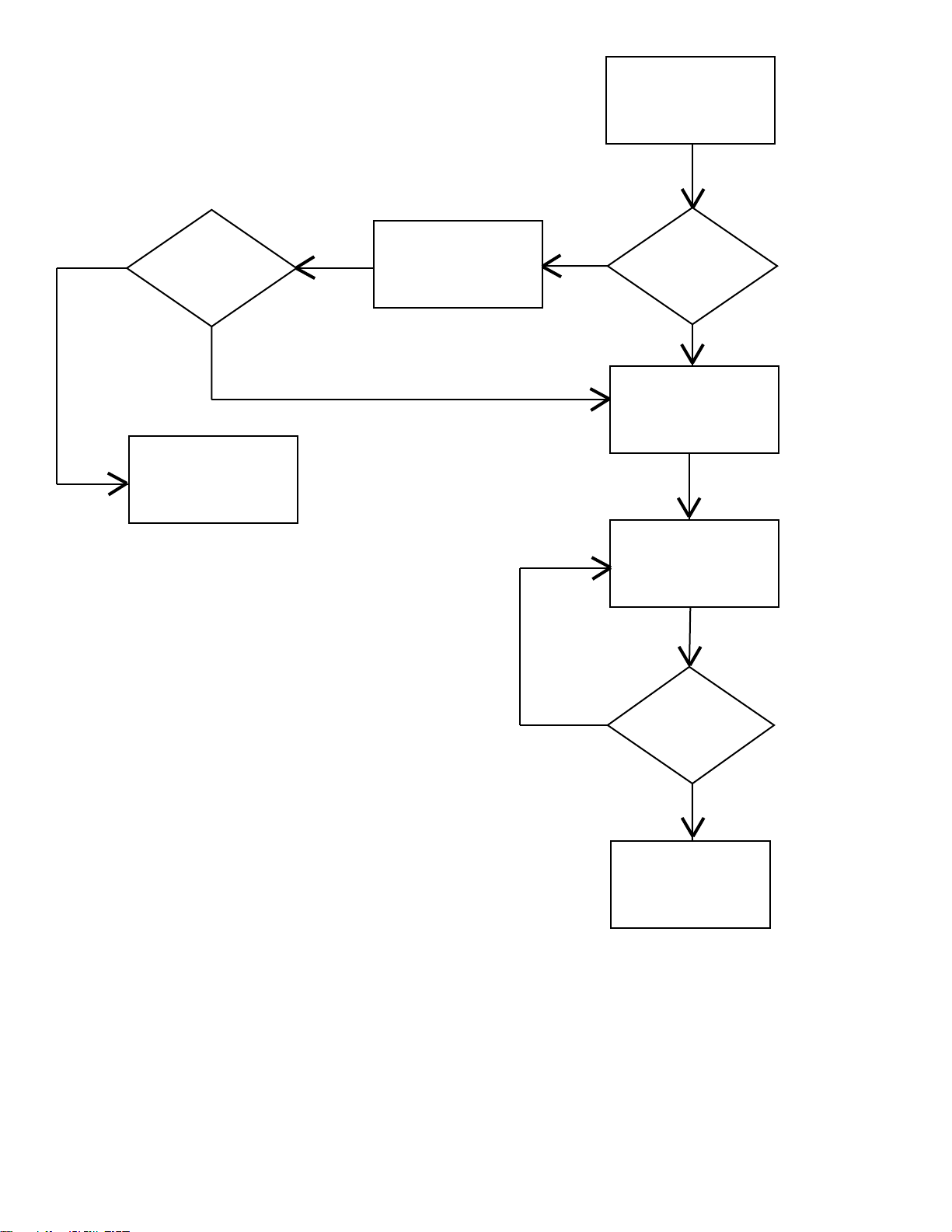

EElleeccttrriiccaall ssyysstteemm bblloocckk ddiiaaggrraamm –– llooaadd

Lower and retract function

6506-109-002 Rev G.1 23 EN

Page 30

Press (–) Button

Pressure Switch

Open?

Hold B-Valve open until

button released or pressure

switch closes

Open B-Valve

Open B-Valve and Ramp in

Motor

Ramp out motor and stop,

Close B-Valve

Bottom Hall Effects

Sensor Detected?

Run motor at max speed

Pressure Switch

Open?

Yes

No

No

No

Yes

Yes

LLiitttteerr ddrriiffttss ((wwiitthhoouutt ppaattiieenntt wweeiigghhtt))

1. Check the manual release cable adjustment.

2. Change the locking manual valve.

3. Change “B” valve.

EN 24 6506-109-002 Rev G.1

Page 31

BBaassee ddrriiffttss ((wwiitthhoouutt ppaattiieenntt wweeiigghhtt))

1. Check the manual release cable adjustment.

2. Change non-locking manual valve.

3. Change “A” valve.

LLiitttteerr ddooeess nnoott lloowweerr iinn tthhee ppoowweerreedd mmooddee

Check the power indicator LED.

1. If blinking constant RED, change the battery.

2. If blinking a patterned AMBER short, short, long flash:

a. Check for broken or disconnected wires.

b. Check for 24 VDC at connector (C) on the main cable by the motor while pressing the retract (-) button. If voltage is

present, replace (in order) the solenoid and/or “B” valve. If voltage is not present, go to step c.

c. Check for 24 VDC on electronics assembly pins, 1 blue and 5 orange, on (F) while pressing the retract (-) button. If

voltage is not present, replace the electronics assembly. If voltage is present, replace the wire harness.

3. If the GREEN light turns on, but does not lower the litter, try the other switch. If the other switch works, replace the bad

switch.

LLiitttteerr ddooeess nnoott eexxtteenndd iinn tthhee ppoowweerreedd mmooddee -- cchheecckk mmoottoorr

Check the motor.

1. If the motor runs, but does not raise the cot:

a. Check the manual release cable for too much tension.

b. Lightly tap the manual locking valve.

c. Replace the manual locking valve.

2. If the motor is stalled, replace the “A” valve.

3. If the light is GREEN, but the motor does not run:

a. Check for 24 VDC at connector (E) on the main cable. If voltage is present and the motor does not run, replace the

hydraulic sub-assembly. If voltage is not present, go to step b.

b. Check for 24 VDC on electronics assembly connection (H) (-) lead on black (+) lead on green while pressing the

extend (+) button. If voltage is not present, replace the electronics assembly. If voltage is present, replace the main

cable.

LLiitttteerr ddooeess nnoott eexxtteenndd iinn ppoowweerreedd mmooddee -- cchheecckk tthhee ppoowweerr iinnddiiccaattoorr LLEEDD

Check the power indicator LED.

1. If blinking constant RED, change the battery.

2. If blinking a patterned AMBER short, short, long flash:

a. Check for broken or disconnected wires.

b. Check for 24 VDC at connector (B) on the main cable by the motor while pressing the extend (+) button. If voltage is

present, replace (in order) the solenoid and/or “A” valve. If voltage is not present, go to step c.

c. Check for 24 VDC on the electronics assembly pins, 2 white and 6 red, on (F) while pressing the extend (+) button. If

voltage is not present, replace the electronics assembly. If voltage is present replace the wire harness.

3. If the GREEN light turns on, but does not lower, try the other switch. If the other switch works, replace the bad switch.

6506-109-002 Rev G.1 25 EN

Page 32

BBaassee ddooeess nnoott rreettrraacctt iinn tthhee ppoowweerreedd mmooddee

Check the power indicator LED.

1. If blinking constant RED, change the battery.

2. If blinking a patterned AMBER short, short, long flash:

a. Check for broken or disconnected wires.

b. Check for 24 VDC at connector (B) on the main cable by the motor while pressing the extend (+) button. If voltage is

present, replace (in order) the solenoid and/or “A” valve. If voltage is not present, go to step c.

c. Check for 24 VDC on electronics assembly pins, 2 white and 6 red, on (F) while pressing the extend (+) button. If

voltage is not present, replace the electronics assembly. If voltage is present, replace the wire harness.

BBaassee ddooeess nnoott eexxtteenndd iinn tthhee mmaannuuaall mmooddee

1. Check manual cable adjustment.

2. Change the non-locking manual valve.

BBaassee ddooeess nnoott rreettrraacctt iinn tthhee mmaannuuaall mmooddee

1. Check manual release cable adjustment.

2. Change locking manual valve.

LLiitttteerr ddooeess nnoott rreettrraacctt iinn tthhee mmaannuuaall mmooddee ((wwiitthh ppaattiieenntt wweeiigghhtt))

1. Make sure that the weight is off of the casters before lowering the cot.

2. Check the manual cable adjustment.

3. Replace the locking manual valve.

LLiitttteerr ddooeess nnoott eexxtteenndd iinn tthhee mmaannuuaall mmooddee

1. Check the manual cable adjustment.

2. Change the non-locking manual valve.

HHiigghh ssppeeeedd rreettrraacctt ddooeess nnoott eennggaaggee

1. Check that the weight is off of the casters.

2. Change the pressure switch.

LLCCDD eerrrroorr ccooddeess -- mmaaiinn mmiiccrroo

LCD display Error desciption Detection period

ERR 01 RAM diagnostic failure Initialization

ERR 02 Program memory failure Initialization

EN 26 6506-109-002 Rev G.1

Page 33

ERR 03 EE diagnostic failure Initialization

ERR 04 EEPROM type and hardware type

incompatible

ERR 10 Valves diagnostic failure Initialization

ERR 61 EEPROM rev and firmware rev

incompatible

ERR 21 Motor shorted Initialization

ERR 22 Motor open Initialization

ERR 23 High power gating relay shorted Initialization

ERR 51 Motor drive FET shorted - Q15 Initialization

ERR 52 Motor drive FET shorted - Q11 Initialization

ERR 55 Motor drive FET shorted - Q16 Initialization

ERR 56 Motor drive FET shorted - Q12 Initialization

Initialization

Initialization

ERR 62 Main Micro and ASIC current limit

mismatch

ERR 80 Extend (+) or retract (-) button

detected without key

ERR 31 Electronics board over temp (280.22 °

F +/- 5%)

ERR 81 Bad hall effect sensor combination Run Time

ERR 93 Safety Micro non-responsive Run Time

Initialization

Run Time

Run Time

LLCCDD eerrrroorr ccooddeess -- ssaaffeettyy mmiiccrroo

LCD display Error description Detection period

ERR 05 RAM diagnostic failure Initialization

ERR 06 Program memory diagnostic failure Initialization

ERR 08 EEPROM type and hardware type

incompatible

6506-109-002 Rev G.1 27 EN

Initialization

Page 34

ERR 40 Data error Run Time

ERR 41 Charging failed battery voltage Run Time

ERR 42 Charging failed read battery Run Time

ERR 43 Charging failed battery charging time

or over voltage limit

ERR 44 Charging failed charging current Run Time

ERR 45 Charging failed delta temp Run Time

ERR 63 EEPROM rev and firmware rev

incompatible

ERR 83 Extend (+) or retract (-) button

detected without key

ERR 90 ASIC driving without microprocessor

instruction

Run Time

Initialization

Run Time

Run Time

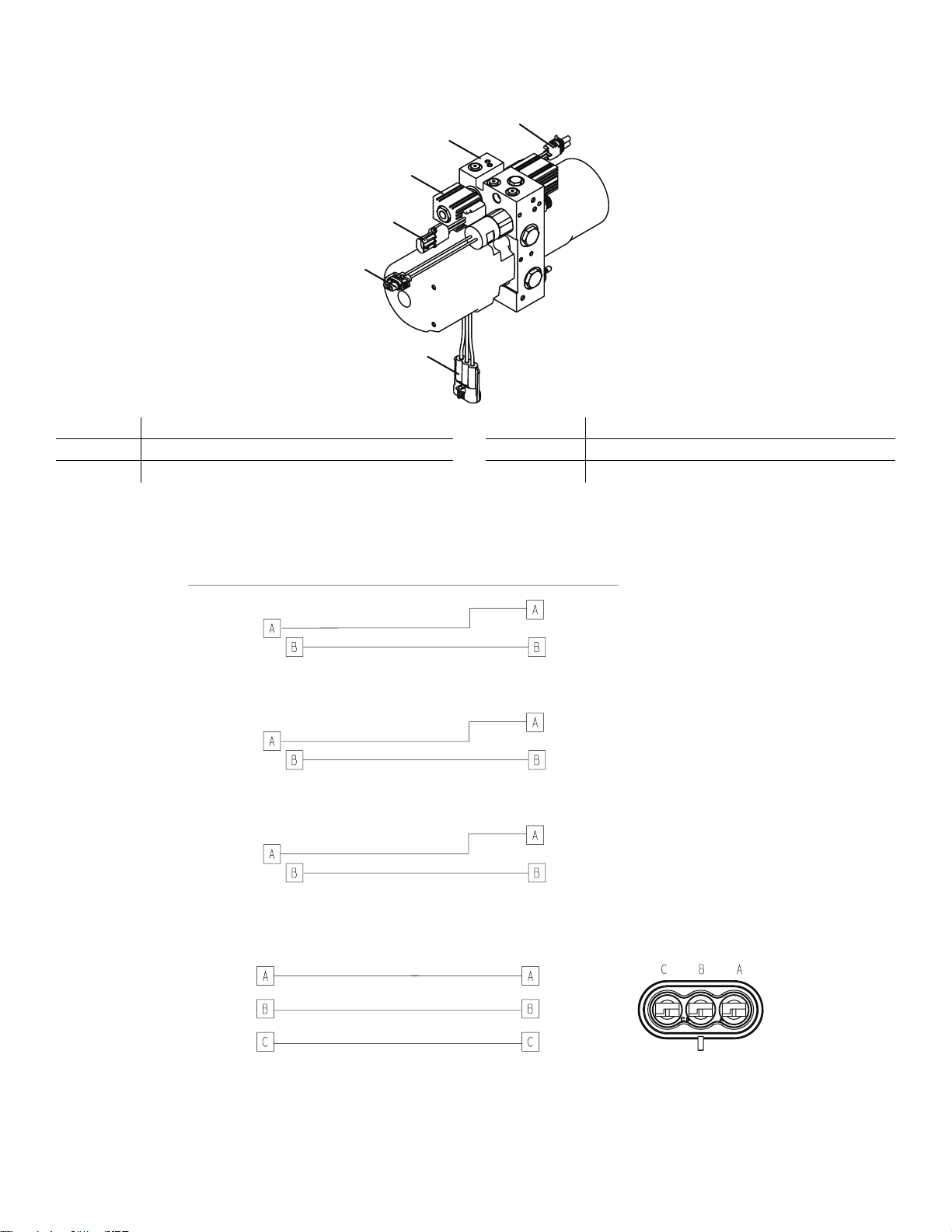

MMaaiinn ccaabbllee aasssseemmbbllyy

EN 28 6506-109-002 Rev G.1

Page 35

MMaaiinn ccaabbllee aasssseemmbbllyy wwiirriinngg sscchheemmaattiiccss

CCoonnttrrooll bbooaarrdd aasssseemmbbllyy

6506-109-002 Rev G.1 29 EN

Page 36

CCoonnttrrooll bbooaarrdd aasssseemmbbllyy wwiirriinngg sscchheemmaattiiccss

SSMMRRTT cchhaarrggeerr ppoowweerr LLEEDD iiss NNOOTT iilllluummiinnaatteedd

Make sure that the AC power supply or DC cable is connected properly.

1. If using an AC power supply, make sure that the:

a. AC power cord is plugged into a wall outlet and the wall outlet has AC power.

b. AC power cord is plugged into the power supply.

c. AC power supply output cord is plugged into the charger.

2. If using a DC cable, make sure that the:

a. DC cable is plugged into a power source with 12.5 - 16 VDC

NNoottee -- The DC power supply output cord adaptor LED should be illuminated.

b. Power cord adaptor internal fuse has continuity. If not, replace the fuse. See

replacement

c. DC cable is plugged into the charger.

3. Check for 12.5 to 16 VDC at the power supply output cord that plugs into the charger.

a. If 12.5 to 16 VDC is not present, replace the power supply assembly.

b. If 12.5 to 16 VDC is present, replace the charger.

(page 31).

12 VDC automotive cable fuse

SSMMRRTT cchhaarrggeerr wwiillll nnoott cchhaarrggee tthhee SSMMRRTT PPaakk

1. Make sure that the charger power LED is illuminated.

EN 30 6506-109-002 Rev G.1

Page 37

a. If not, see

2. Make sure that the charger indicator LEDs flash when the charger is first powered.

a. If the LEDs flash at start up, go to step 3.

b. If the LEDs do not flash at start up, replace the charger.

3. Reinsert the SSMMRRTT Pak on the charger and check the charger indicator LEDs for the status of the SSMMRRTT Pak:

SMRT charger indicator LEDs are NOT illuminated when the Pak is inserted

(page 31).

a. Solid amber = a SSMMRRTT Pak error. See

(page 32).

b. Flashing amber = a temperature delay. Allow the SSMMRRTT Pak time to get to normal operating temperature. Reinstall

the SSMMRRTT Pak and recheck step 3.

c. Solid green = a fully charged and ready SSMMRRTT Pak. See

power for cot operation

(page 32).

A fully charged SMRT Pak does not provide sufficient power for cot operation

A fully charged SMRT Pak does not provide sufficient

SSMMRRTT cchhaarrggeerr iinnddiiccaattoorr LLEEDDss aarree NNOOTT iilllluummiinnaatteedd wwhheenn tthhee PPaakk iiss iinnsseerrtteedd

1. Unplug the charger, wait five seconds, and plug the charger back into the wall outlet.

2. Make sure that the charger power LED is illuminated. If not, see

30).

3. Make sure that the SSMMRRTT Pak is fully inserted into the charger. If not, reinsert the SSMMRRTT Pak fully, listen for an audible

click, and make sure that the charger indicator LEDs illuminate.

4. Try another SSMMRRTT Pak to identify any issues.

NNoottee -- Separate and label SSMMRRTT Paks during troubleshooting.

a. If the charger indicator LEDs do not illuminate, replace the charger.

b. If the charger indicator LEDs illuminate, replace the original SSMMRRTT Pak.

SMRT charger power LED is NOT illuminated

(page

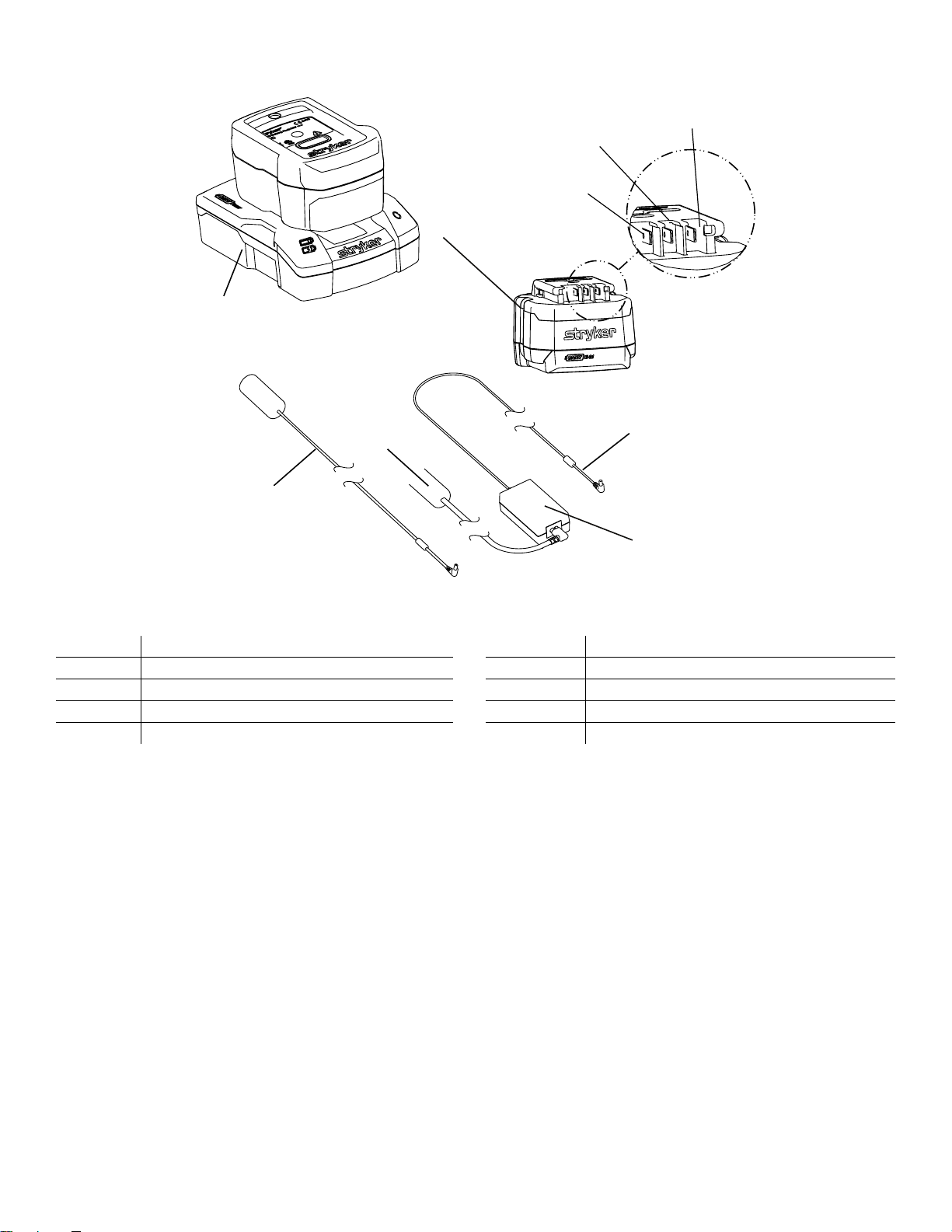

1122 VVDDCC aauuttoommoottiivvee ccaabbllee ffuussee rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• None

PPrroocceedduurree::

1. Unplug the adaptor cable from the plug (B) and the plug connector (A).

2. Unscrew the tip on the source end and remove the fuse (

NNoottee -- The source tip and the fuse tension spring are loose and could be dropped.

3. Install the new 10A 250V fuse into the source end of the adaptor cable and screw the tip back on.

4. Plug both ends back into the source and the charger.

5. Test the charger for functionality before you return it to service.

12 VDC automotive cable fuse replacement

(page 31)).

6506-109-002 Rev G.1 31 EN

Page 38

A

B

FFiigguurree 66 –– 1122 VVDDCC aauuttoommoottiivvee ccaabbllee

AA ffuullllyy cchhaarrggeedd SSMMRRTT PPaakk ddooeess nnoott pprroovviiddee ssuuffffiicciieenntt ppoowweerr ffoorr ccoott ooppeerraattiioonn

1. Fully charge the SSMMRRTT Pak for two hours.

a. If the charger indicator LED is solid green, indicating a fully charged and ready SSMMRRTT Pak, go to step 2.

b. If the charger indicator LED is solid amber, indicating a SSMMRRTT Pak error, replace the SSMMRRTT Pak.

2. Immediately following a full charge, remove the SSMMRRTT Pak from the charger and check the voltage at the power

terminals on the Pak for 26 VDC minimum.

a. If the Pak has a 26 VDC minimum, go to step 3.

b. If the VDC is less than 26 VDC, replace the Pak.

3. Wait exactly one hour and charge the SSMMRRTT Pak again.

a. If the charger indicator LED turns solid green (indicating a fully charged and ready SSMMRRTT Pak) in less than one

minute, call Stryker Technical Support.

b. If the charger indicator LED flashes green for longer than one minute, replace the Pak.

SSMMRRTT cchhaarrggeerr iinnddiiccaatteess aa SSMMRRTT PPaakk eerrrroorr ((aammbbeerr LLEEDD)),, bbuutt tthhee PPaakk ppeerrffoorrmmss

wweellll oonn tthhee ccoott

1. Fully discharge the SSMMRRTT Pak by powering a cot until the cot indicator LED flashes red.

2. Recharge the Pak.

a. If the charger indicator LED is solid green, indicating a fully charged and ready Pak, then the Pak is ready for use.

b. If the charger indicator LED is solid amber, indicating a Pak error, call Stryker Technical Support.

CChhaarrggeerr iinnddiiccaatteess aa tteemmppeerraattuurree ddeellaayy ((ffllaasshhiinngg aammbbeerr LLEEDD)),, bbuutt tthhee PPaakk iiss

wwiitthhiinn tthhee nnoorrmmaall ooppeerraattiinngg tteemmppeerraattuurree rraannggee

1. Remove the SSMMRRTT Pak from the charger and allow the Pak to cool for at least four hours at room temperature.

2. Insert the Pak into the charger.

a. If the charger indicator LED is flashing green, then the Pak is charging.

b. If the charger indicator LED is flashing amber, indicating a temperature delay, replace the Pak.

EN 32 6506-109-002 Rev G.1

Page 39