Page 1

P100 Powered Support Surface

2880

Operations/Maintenance Manual

2017/12 476004 - 5210 V1.5 www.stryker.com

Page 2

Page 3

Table of Contents

Symbols and Definitions.................................................................................4

Symbols ..........................................................................................4

Warning/Caution/Note Definition .....................................................................5

Technical Specification..................................................................................6

Introduction............................................................................................7

Contraindications...................................................................................7

Intended Use of Product.............................................................................7

Expected Service Life...............................................................................7

Contact Information.................................................................................8

Product Serial Number Location/Identification..........................................................8

Summary of Safety Precautions ..........................................................................9

Product Description ...................................................................................10

Control Unit Front..................................................................................10

Control Unit Rear ..................................................................................10

P100.............................................................................................10

Control Panel .....................................................................................10

Instructions ...........................................................................................11

Cleaning and Disinfection ..............................................................................12

Troubleshooting .......................................................................................13

Service Information ....................................................................................14

Cover Replacement ...............................................................................14

Air Cell Replacement ..............................................................................14

Control Unit Replacement ..........................................................................14

Hose Replacement ................................................................................14

Preventive Maintenance ................................................................................15

Checklist .........................................................................................15

Appendix A: EMC Information ...........................................................................17

Guidance and Manufacturer’s Declaration- Electromagnetic Emissions:...................................17

Guidance and Manufacturer’s Declaration- Electromagnetic Immunity:....................................18

Warranty .............................................................................................20

Limited Warranty ..................................................................................20

To Obtain Parts and Service ........................................................................20

Return Authorization ...............................................................................20

Damaged Merchandise ............................................................................20

International warranty clause ........................................................................20

www.stryker.com 476004-5210 V1.5 3

Page 4

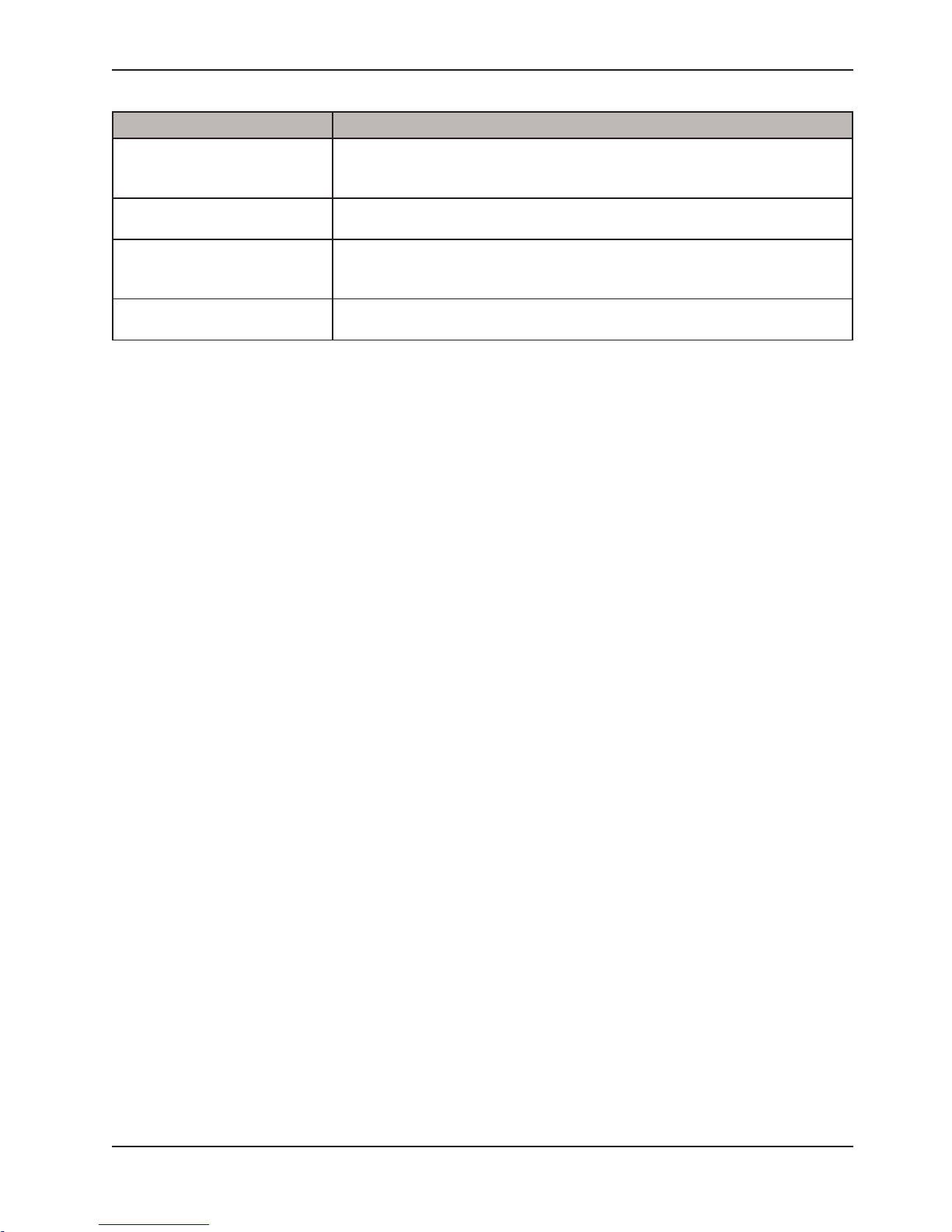

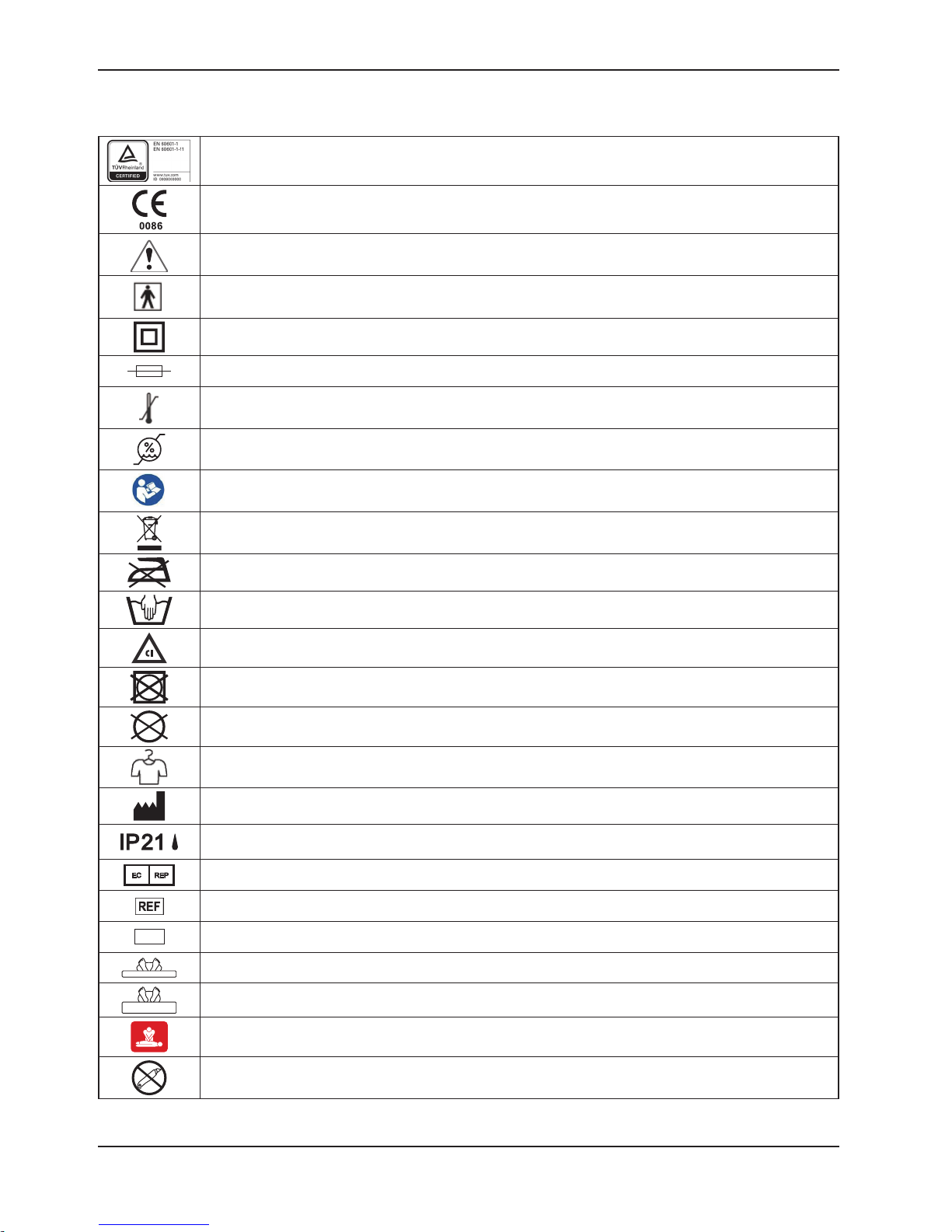

SYMBOLS

SN

Symbols and Definitions

TUV marking

CE marking

Warning / Caution, consult accompanying documentation

Type BF equipment

Double Insulation

Fuse

Temperature Limitation, Operating: 10°C to 40°C, Storage: -15°C to 50°C

Humidity Limitation, 10% - 90%

Refer to instruction manual/ booklet

Disposal: Contact local distributor who will take the necessary steps according to your national

market.

Do Not Iron

Damp Wipe Only

Chlorinated Bleach: concentration less than or equal to 1000 ppm chlorinate or 70% alcohol

Do Not Tumble Dry

Do Not Dry Clean

Allow to Completely Air Dry

Manufacturer

Protected against solid foreign objects of 12,5 mm and greater; Protection against vertically falling

water drops

Authorized representative in the European community

Catalogue Number (model)

Serial Number

Minimum inflation level of the mattress

Maximum inflation level of the mattress

CPR

Do Not Open with Cutter

Return To Table of Contents

4 476004- 5210 V1.5 www.stryker.com

Page 5

Introduction

WARNING/CAUTION/NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CAUTION

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the equipment or other property. This includes special care necessary for the safe and

effective use of the device and the care necessary to avoid damage to a device that may occur as a result of use or

misuse.

NOTE

Provides special information to make maintenance easier or important instructions clearer.

www.stryker.com 476004-5210 V1.5 5

Return To Table of Contents

Page 6

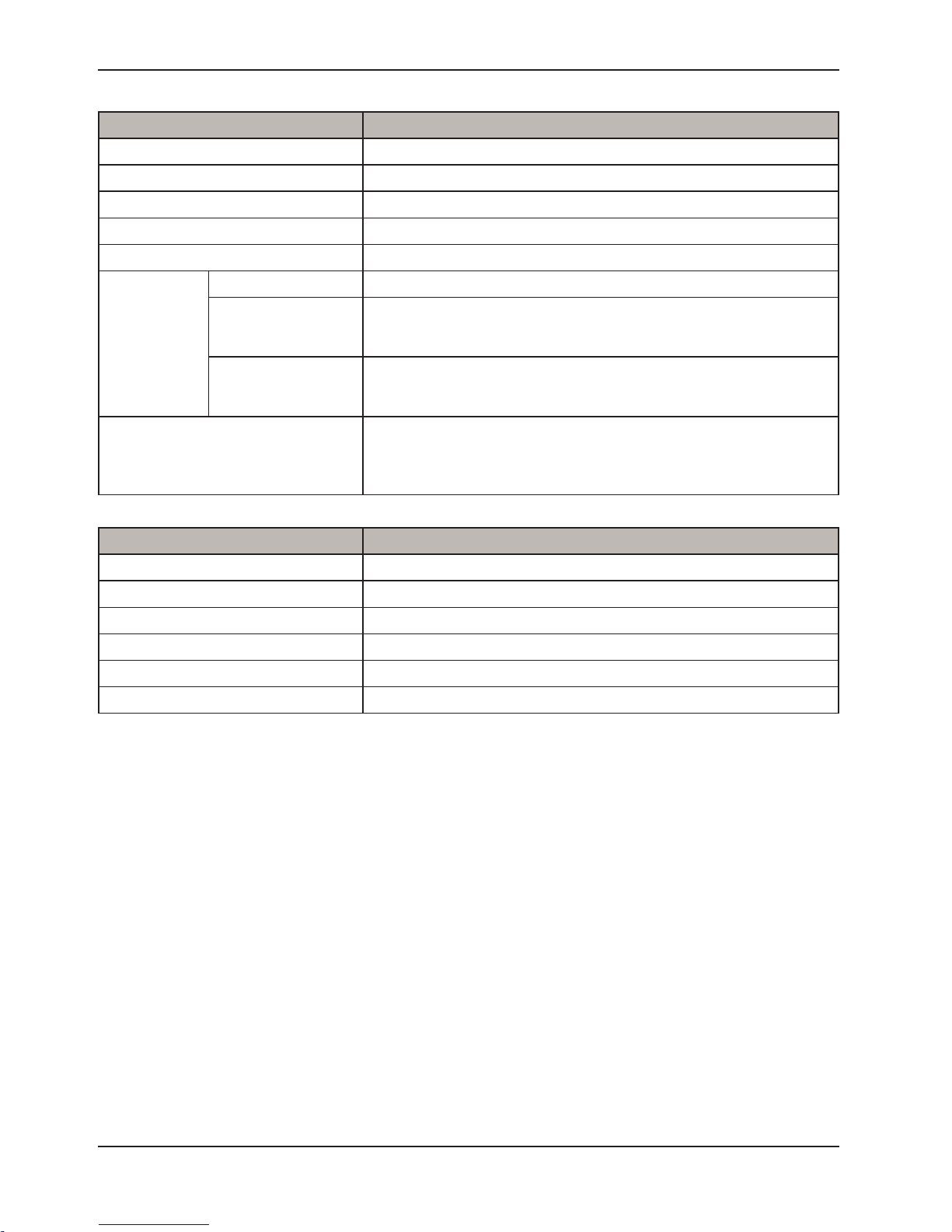

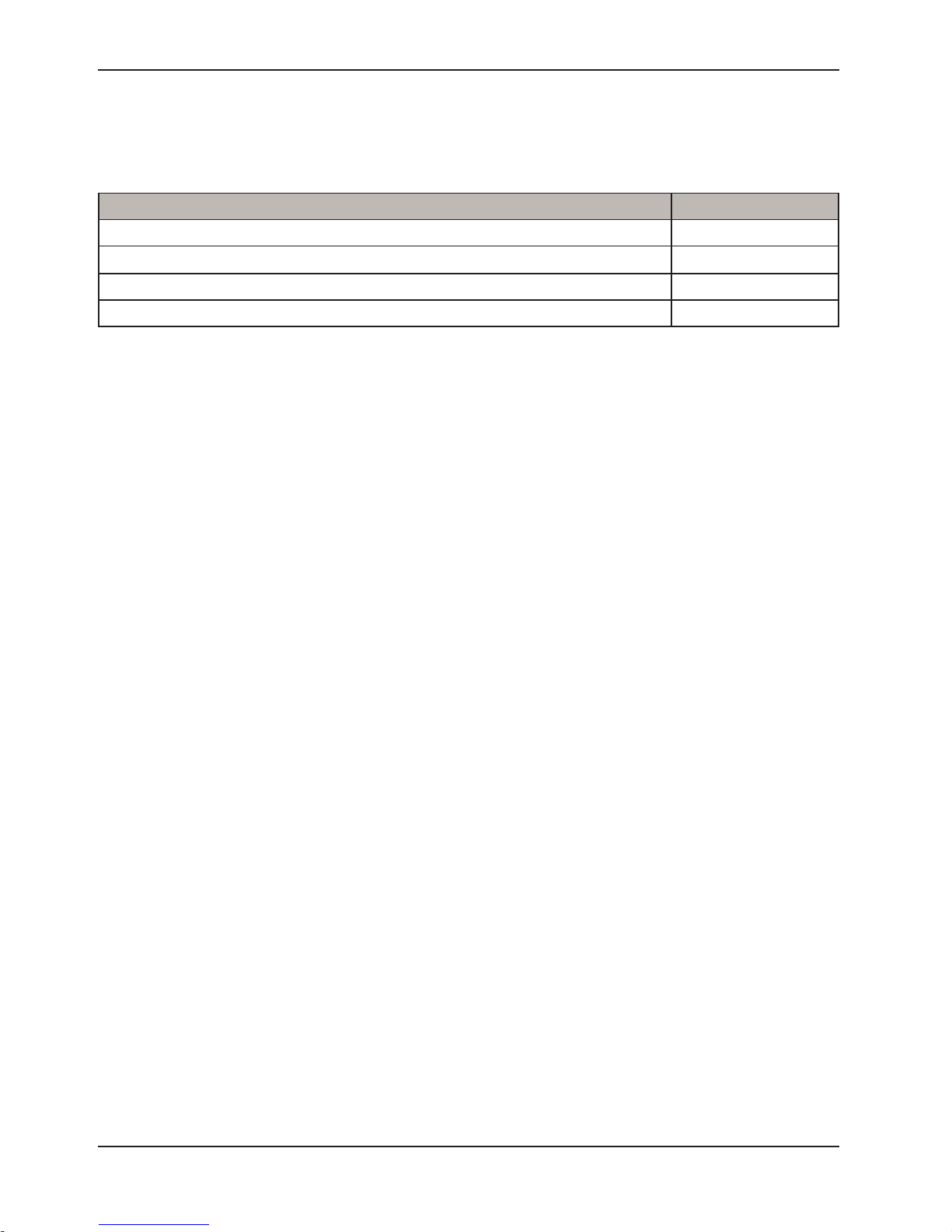

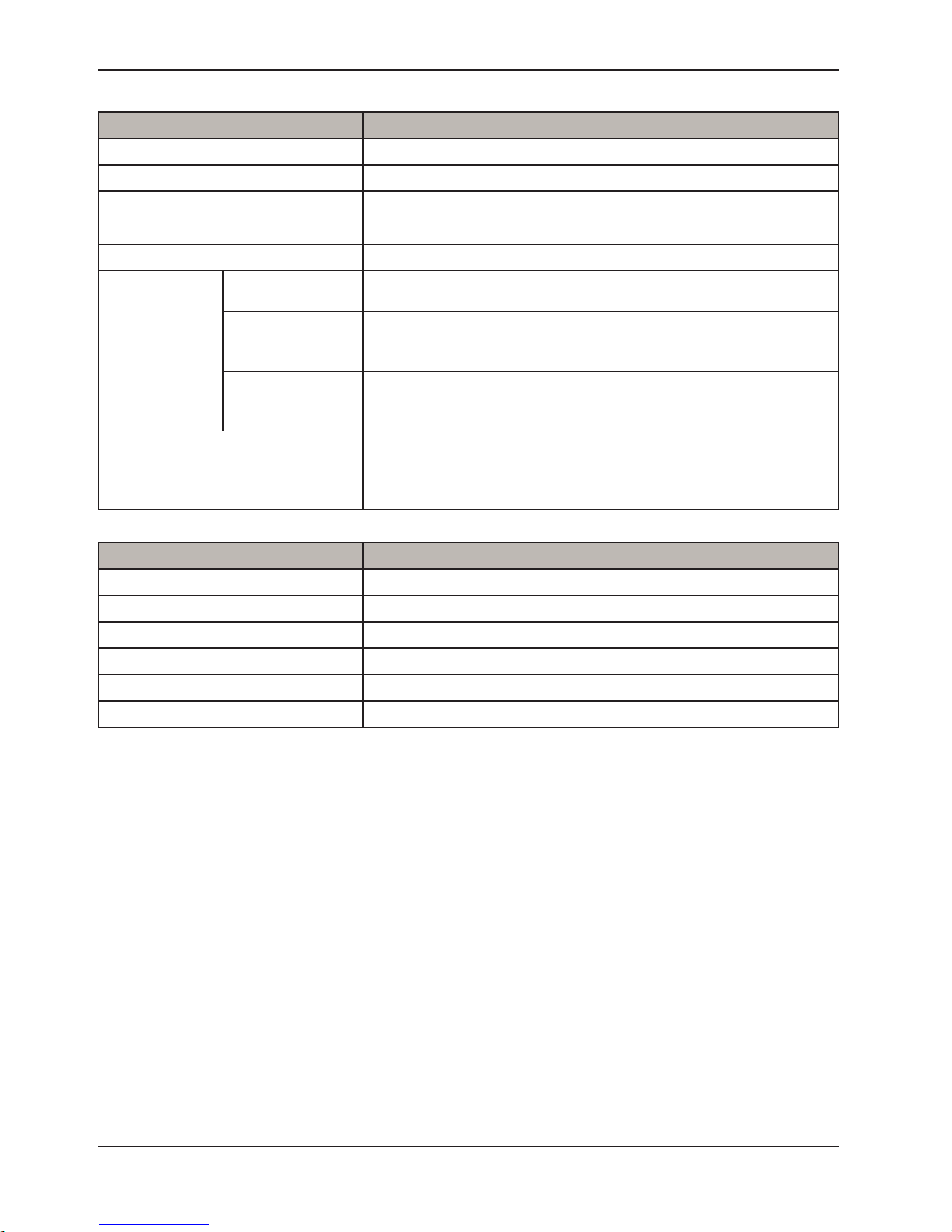

Technical Specification

Item Specification

Power Supply AC230V 50Hz, 0.05A ( for 230V system )

Fuse Rating T1AL, 250V

Dimension (L x W x H) 25 x 12.5 x 8.5 cm / 9.8” x 4.9” x 3.3”

Weight 1.4 kg / 3.1 lbs

Cycle Time 8 min/60 Hz, 9.6 min/50 Hz

Atmospheric Pressure 700 hPa to 1013.25 hPa

• Operation: 10°C to 40°C (50°F to 104°F)

Temperature

Environment

Humidity

Classification

• Storage: -15°C to 50°C (5°F to 122°F)

• Shipping: -15°C to 70°C (5°F to 158°F)

• Operation: 10% to 90% non-condensing

• Storage: 10% to 90% non-condensing

• Shipping: 10% to 90% non-condensing

• Class II, Type BF, IP21

• Applied Part: Air Mattress

• Not suitable for use in the presence of a flammable anesthetic mixture (No AP or APG protection)

Air Mattress Specification

Model P100

Model Number 2880

Flame Retardant Standards EN 597-1 and EN 597-2

Safe Working Load 135 kg / 297 lbs

Dimension (L x W x H) 193 x 89 x 18 cm / 76”x 35” x 7.1”

Weight 5.75 kg / 12.7 lbs

Return To Table of Contents

6 476004- 5210 V1.5 www.stryker.com

Page 7

Introduction

This manual is designed to assist with the operation and maintenance of the P100 Powered Support Surface. Carefully

read this manual thoroughly before using or beginning maintenance on the support surface. To ensure safe operation

of this equipment, it is recommended that methods and procedures are established for educating and training staff on

the safe operation of the support surface.

CONTRAINDICATIONS

Air support therapy is not recommended when spinal stability is a concern. This support surface is not intended to

support a patient in the prone position.

INTENDED USE OF PRODUCT

P100 is a constant low pressure powered support surface intended to provide pressure redistribution to aid in the

prevention and treatment of pressure ulcers. The system consists of a control unit combined with an alternating air

cell mattress. The air cells redistribute the patient’s weight over the surface and aid in the reduction of tissue interface

pressure. It is recommended that the product be operated by personnel who are qualified to perform general nursing

procedures and have received adequate training in the prevention and treatment of pressure ulcers.

This support surface is intended to be used with human patients in a general hospital, nursing home or homecare

environment and for patients at risk of developing pressure ulcers, as well as those who require therapy for pre- existing

pressure ulcers. The safe working load for P100 is 135 kg /297 lbs; the patient must not exceed safe working load

specified by the support surface, frame, and accessories. Patients shall meet the minimum age requirement of 2 years

old.

P100 shall be used with a mattress cover at all times.

The support surface is not intended to be a sterile product nor is it intended to include a measuring function.

EXPECTED SERVICE LIFE

The products are intended to offer safe and reliable operation when in use or installed according to the instructions

provided by Stryker Medical. Stryker Medical recommends that the system be inspected and serviced by authorized

technicians if there are any signs of wear or concerns with device function and indication on products. Otherwise,

service and inspection of the devices generally should not be required. P100 has an expected service life of 2 years.

www.stryker.com 476004-5210 V1.5 7

Return To Table of Contents

Page 8

Introduction

CONTACT INFORMATION

Contact Stryker Customer Service or Technical Support at: (800) 327-0770 or (269) 324-6500.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

Please have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical

Support. Include the serial number in all written communication.

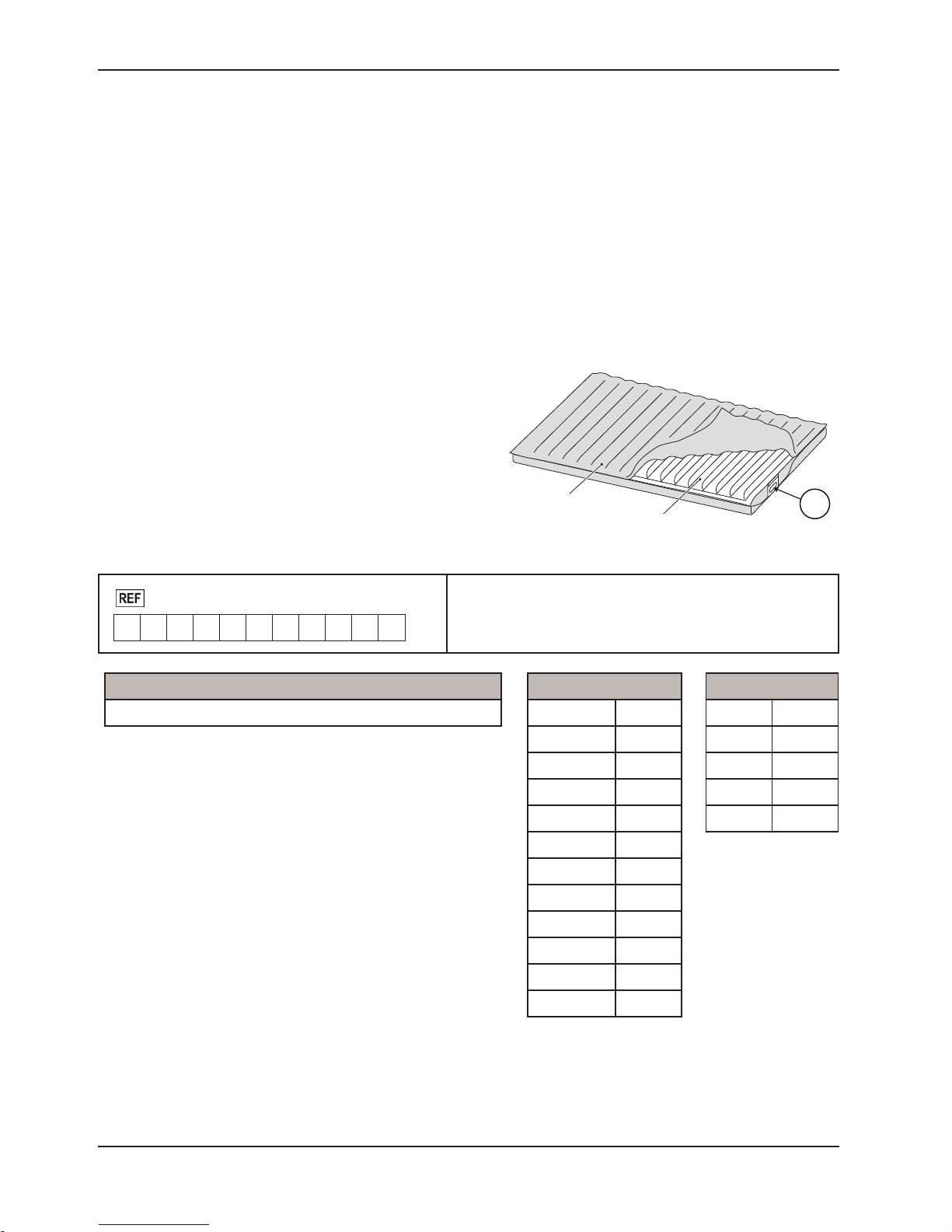

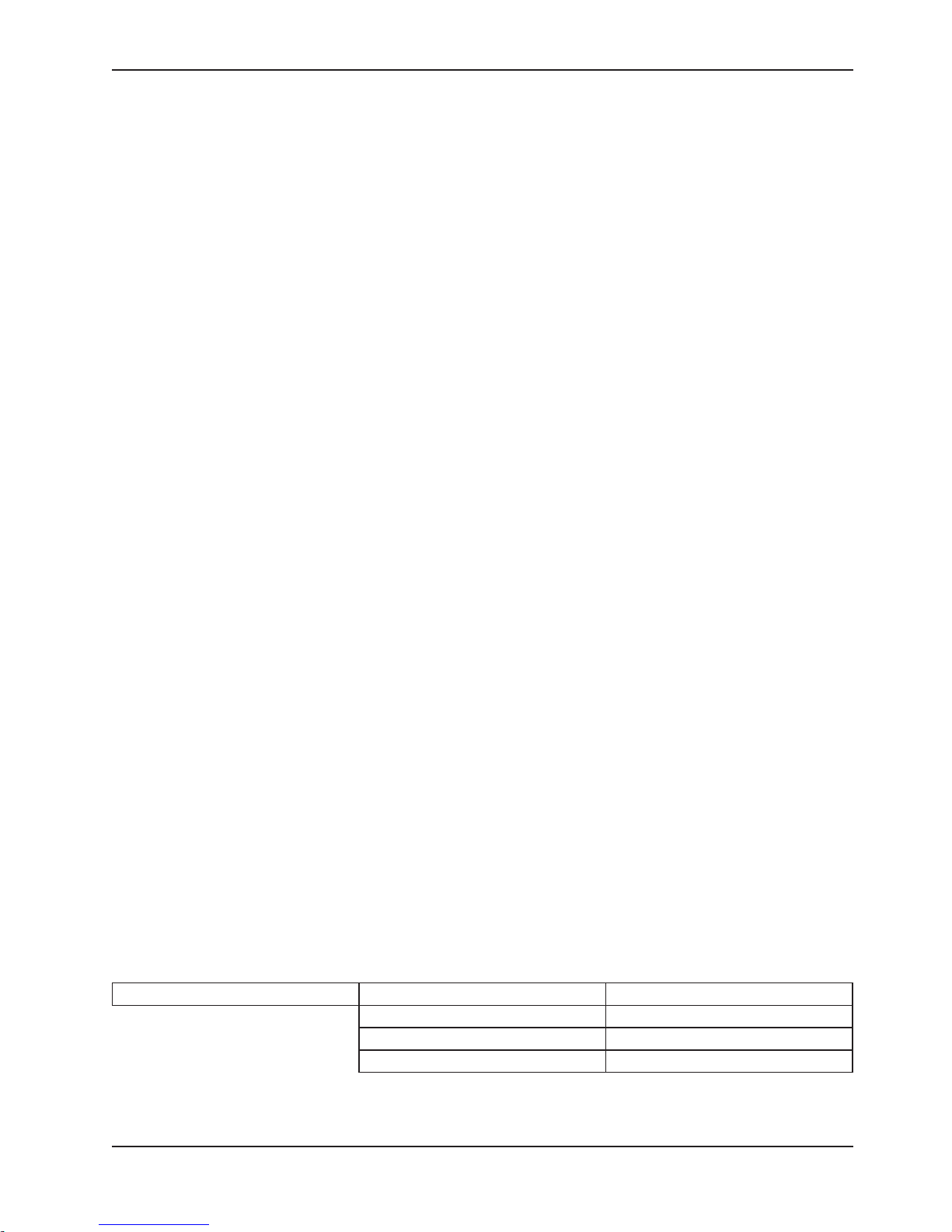

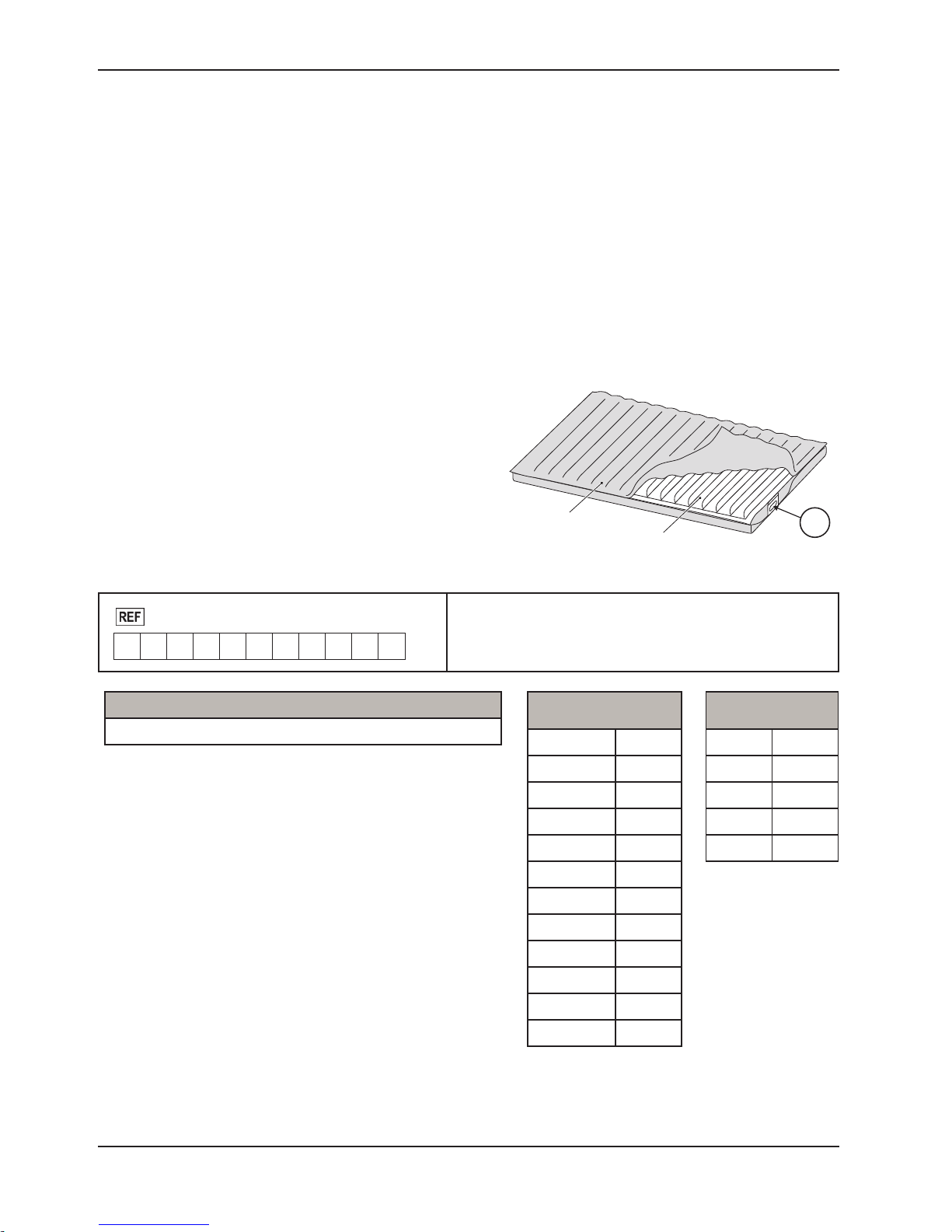

PRODUCT SERIAL NUMBER LOCATION/IDENTIFICATION

The serial number (A) is located at the mattress cover near

foot right corner of the mattress as shown in Figure 1. Also

on the foam crib and air cell with stamp on it, to reference the

serial number, unzip the cover about one foot to access the

foam crib and air cell. The serial number is also located at the

bottom casing of control unit.

▼

Figure 1

Format:

2880

M Y Y M M - S S S S S

Model Number Legend (X)

2880 P100

P100 Mattress

Foam and Air Cell

• M = Mattress

• YY = Year

• MM = Month

• SSSSS = Sequence (Numeric)

Month Legend (MM)

January 01

February 02

March 03

April 04

May 05

June 06

July 07

August 08

September 09

October 10

A

Year Legend (YY)

2012 12

2013 13

2014 14

2015 15

2016 16

Return To Table of Contents

8 476004- 5210 V1.5 www.stryker.com

November 11

December 12

Page 9

Summary of Safety Precautions

WARNING

• Check patient’s skin regularly. Consult physician if any redness or skin break occurs. Serious injury could result if

the patient’s skin condition is left untreated.

• Do not place the control unit in the patient’s bed, in contact with the patient, or under sheets or other coverings.

• Doing so could cause serious injury or could affect control unit performance.

• Do not use in the presence of a flammable anesthetic mixture or with oxygen (O2) or nitrous oxide (N2O).

• Verify bed side rails are compatible with bed frame and existing mattress. A risk assessment must be performed

by a suitably qualified person, especially when side rails are prescribed, to ensure that the bed meets the IEC

60601-2-52 bed standard.

• Use with appropriate top sheet and minimize layers of bedding between patient and mattress.

• Assess patient’s risk of entrapment according to protocols and monitor accordingly.

• Close supervision is necessary when this product is used on or near children. Electrical burns or choking may

result from a child swallowing a small part detached from the device.

• Use this product only for its intended use as described in this manual.

• Do not operate product if the power cord or plug has been damaged.

• Keep the cord away from heated surfaces.

• Never block any air openings of this product or place it on soft surfaces, such as a bed or couch, where openings

may be blocked. Keep the air opening free of lint, hair, and other similar particles.

• Never drop or insert any object into any opening or hose.

• Do not modify this equipment without the authorization of the manufacturer.

• Mattress covers have passed skin sensitization and skin irritation tests. However, if you suspect that you may have

had or are having an allergic reaction, please consult a physician immediately.

• The power cord to the Control Unit should be positioned to avoid a strangulation hazard and/or damage to the cord.

Careful consideration is required when routing the power cable. It is recommended that placing the cord under the

bed frame and attaching it to an electrical outlet at the head of bed.

• Serious injury or death can result from the use (potential entrapment) or non-use (potential patient falls) of siderails

or other restraints. The safe use of the support surface is maximized when used in conjunction with siderails;

there may be an increased risk of falls when siderails are not present. Local policies regarding the use of siderails

should be taken into account. Whether and how to use siderails is a decision that should be based on each patient’s individual needs and should be made by the physician, operators, and responsible parties.

• The risk of entrapment can develop when the support surface is placed on bed frames that leave gaps of even a

few inches between the support surface and the headboard, footboard, and siderails. The support surface is NOT

to be used when such gaps are present.

• When cleaning the support surface, ensure that no liquid is allowed to seep into the zipper area and watershed

cover barrier (underside); fluids allowed to come in contact with the zipper may leak into the support surface.

• Do not expose the mattress to excessive moisture. Personal injury or equipment damage could occur.

• The use of quaternaries containing glycol ethers and/or accelerated hydrogen peroxides may compromise the

cover integrity and legibility.

• Be aware of devices or equipment placed on the top of the support surface. Damage to the surface may occur due

to the weight of the equipment, heat generated by the equipment, or sharp edges on the equipment.

• Do not put overlays or accessories inside the cover. Doing so may reduce pressure redistribution performance.

• It is the responsibility of the caregiver team to evaluate the appropriate CPR protocol to be used with the surface.

• If there is a possibility of electro-magnetic interference with mobile phones, please increase the distance (3.3m)

between devices or turn off the mobile phone.

NOTE

The P100 support surface must be used with a mattress cover at all times. The support surface cover may interact

with all external skin.

www.stryker.com 476004-5210 V1.5 9

Return To Table of Contents

Page 10

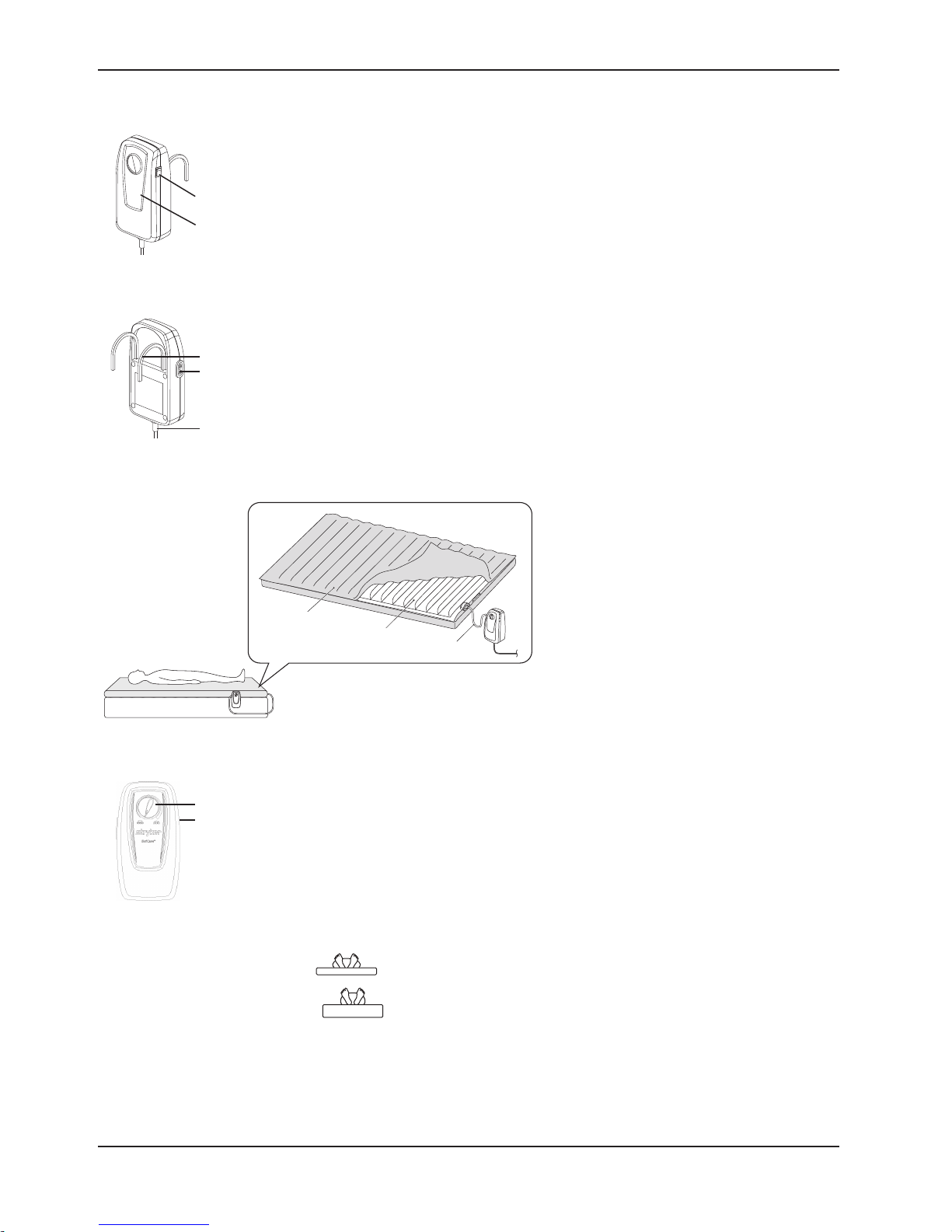

CONTROL UNIT FRONT

Figure 2

◄

1. Power Switch On/Off

2. Front Panel

1

2

CONTROL UNIT REAR

Figure 3

◄

3

4

5

3. Hanger

4. Air Hose Port

5. Power Cord

P100

Product Description

Figure 4

◄

6. P100 Mattress

7. Foam and Air Cell

8. Air Hose

CONTROL PANEL

9

10

6

Figure 5

◄

9. Pressure Adjust Knob

Pressure adjust knob controls the air pressure output. When turning

clockwise, the output pressure will increase. Vice versa for decreasing air

pressure. Please consult your care giver for a suitable setting.

10. Power Switch

To turn on/off the control unit:

a. Power ON/OFF Switch on side of unit.

b. COMFORT CONTROL DIAL adjusts for patient comfort.

Soft(

Firm (

7

)—Minimum inflation level of the mattress

)—Maximum inflation level of the mattress.

8

Return To Table of Contents

10 476004-5210 V1.5 www.stryker.com

Page 11

12

Instructions

1. Place control unit on flat surface or suspend control unit on end of bed using attached hooks. See Figure 2 and

Figure 3. Remove the plug to disconnect the device.

2. Position the mattress on bed frame.

3. Connect the hose assembly between the mattress air cell and the control unit. Unscrew the cap from the air

valve of the mattress and screw the adaptor from control unit onto the air valve tightly.

4. Plug the power cord and adjust the pressure control knob to highest setting for quick inflation and turn control

unit on using green on/off switch. The unit will take approximately 40 minutes to inflate the mattress.

5. After installation, make sure the flap is not folding upwards to avoid fluid seeping through mattress cover.

NOTE

Make sure the control unit is suitable for the local power voltage and frequency.

6. Position patient on the mattress and adjust the pressure control knob for patient comfort.

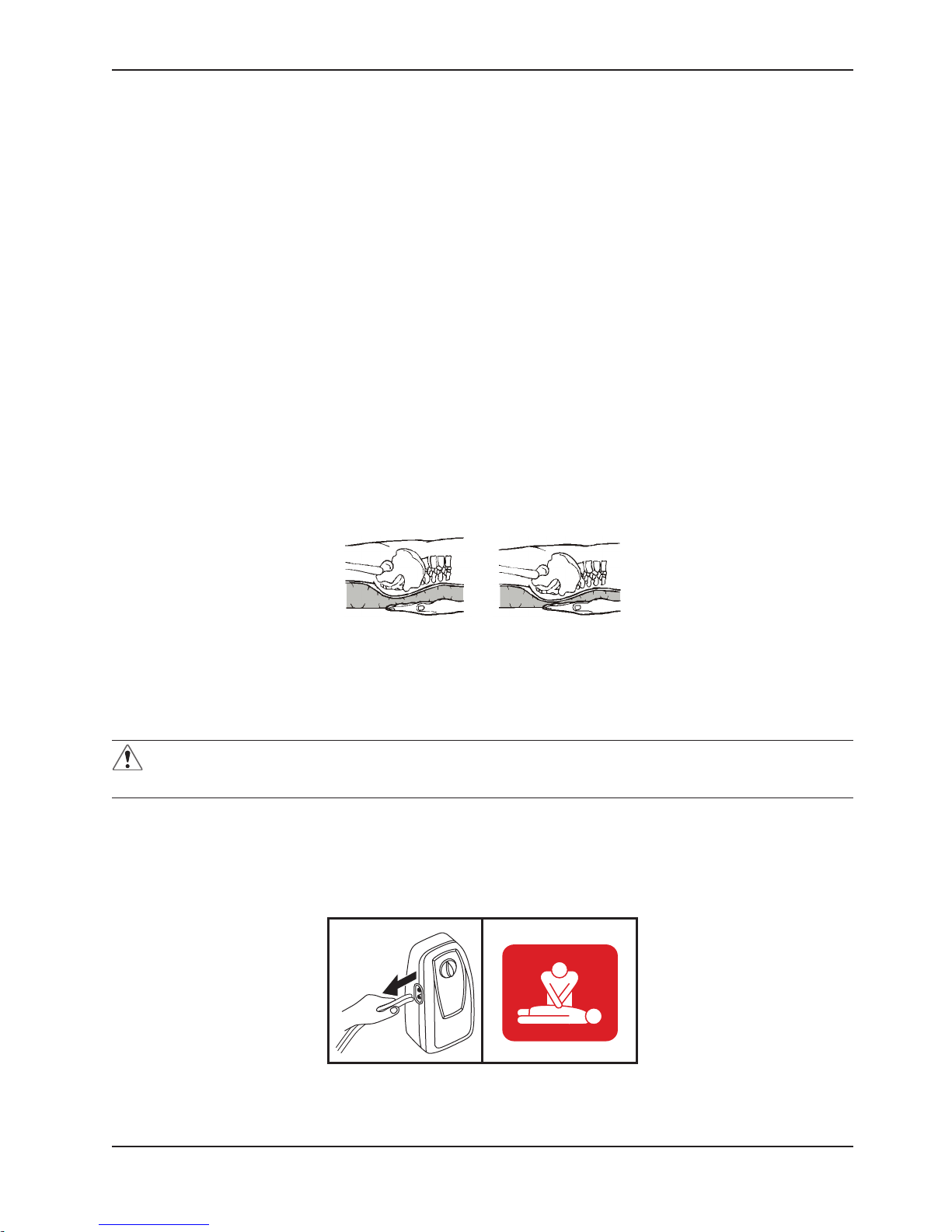

7. A Hand Check must be performed every 8 hours to verify proper operation of the device. See Figure 6.

8. To perform the Hand Check:

With the patient on his or her back, slide hand, flat and palm up, between the overlay and the mattress. Hand

should be directly under the air cell that is under the patient’s buttocks (or other bony area). See Figure 6.

Figure 6

▼

HAND CHECK

Properly inflated Under-inflated

Wait for full inflation of the air cell directly above hand. If the patient’s body is not in direct contact with hand, the system

is operating correctly. If, during full inflation of air cell, the patient’s body is in direct contact with flat hand, the system

is not operating properly. Adjust the pressure control to a higher setting. Wait 10 minutes and repeat the Hand Check.

If the Hand Check fails, check that the hoses are not kinked or pinched. If repeated Hand Check fails and hoses are

not kinked, contact Stryker for further instruction.

WARNING

Deflate before CPR or CPR could be ineffective.

To deflate mattress for CPR:

Disconnect the hoses from the control unit. See Figure 7. The air cell will deflate in approximately 20 seconds.

Proceed with CPR procedures.

Figure 7

▼

www.stryker.com 476004-5210 V1.5 11

Return To Table of Contents

Page 12

Cleaning and Disinfection

The control unit housing, tubing, and mattress should be cleaned between patients.

• To clean, use water and a clean cloth to wipe down the Control Unit, power cord, hoses, mattress top cover,

middle layer and bottom cover. Do not clean the foam. Do not use abrasive cleaners on the mattress. Note:

Blood and other body fluids must be thoroughly cleaned from all surfaces before applying disinfectants.

• Apply disinfectants to the external surfaces of the control unit, hoses and mattress top cover, middle layer and

bottom cover by wiping. Stryker recommends a chlorine-based solution with a concentration less than or equal to

1000 ppm or 70% alcohol twice a week.

• It is not recommended to disinfect the internal parts of the mattress on a regular basis, but only as needed for

particular instance, the air cell and the middle layer of the cover could be wiped with a cloth and disinfectants as

recommended above.

• Wipe down the mattress with a clean, dry cloth to remove any excess of disinfectant.

• If other detergent or other cleaning agent is used, choose one that will not have adverse chemical effects on the

surface of the plastic case of the control unit, mattress cover and any other component of the device.

• When cleaning the support surface, ensure that no liquid is allowed to seep into the zipper area and watershed

cover barrier (underside); fluids allowed to come in contact with the zipper may leak into the support surface.

• Avoid dust and proximity to dusty areas.

• All components should be air dried thoroughly before use.

WARNING

• Do not use phenolic based products for cleaning.

• Do no dry the mattress in direct sunlight.

Return To Table of Contents

12 476004-5210 V1.5 www.stryker.com

Page 13

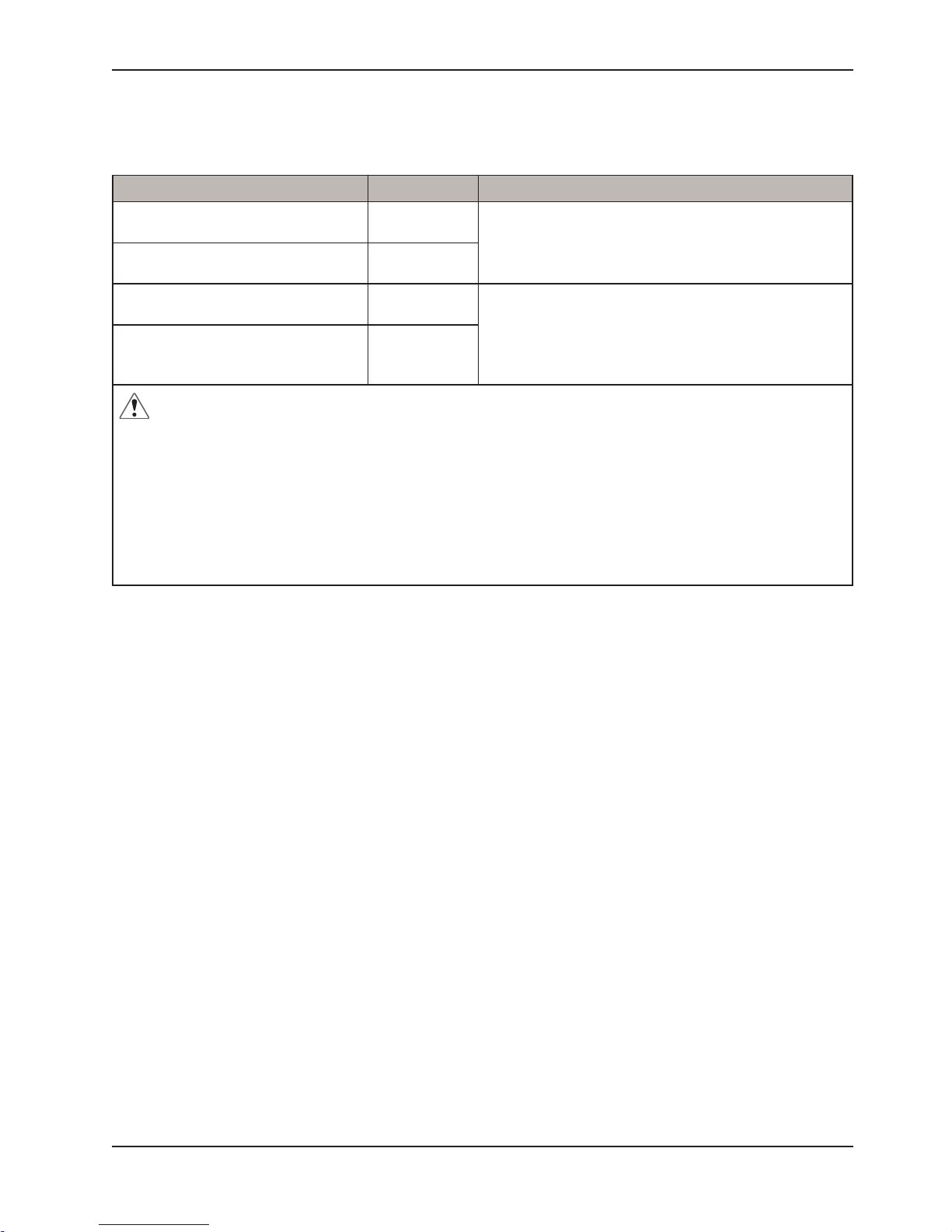

Troubleshooting

Problem Solution

Loss of power Check if the plug is connected to mains.

Patient is bottoming out

Air cells fail to inflate

No air produced from some air

outlets of the air tube connector

Pressure setting might be inadequate for the patient. Adjust comfort range 1 to 2

levels higher and wait for a few minutes for best comfort.

Make sure the air hose is not kinked, cracked, or split. Verify that the power

switch is illuminated, signifying the control unit has power. Verify that the air

hoses are fully inserted with a positive connection.

This is normal since there is alternating mode. Air outlets take turns to produce

air during their cycle time.

www.stryker.com 476004-5210 V1.5 13

Return To Table of Contents

Page 14

Service Information

COVER REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the hose assembly between the mattress air cell and control unit.

2. Unzip the top cover.

3. Remove the air cell.

4. Unzip the middle layer at the patient’s right side and then remove the foam from the bottom part.

5. Discard the old cover.

6. Place the new cover, unzipped and open the top cover and middle layer.

7. Carefully slide the foam to the bottom part and zip the middle layer to close.

8. Carefully place the air cell on the top part and zip the cover to close.

9. Verify proper operation of the unit before returning it to service.

AIR CELL REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the hose assembly from the air valve of mattress.

2. Unzip the top cover.

3. Remove and discard the old air cell.

4. Place the new air cell and zip the cover to close

CONTROL UNIT REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the plug from mains power and hose.

2. Discard the old control unit.

3. Place the new control unit and connect the plug to mains power and hose.

HOSE REPLACEMENT

Tools Required: None

Procedure:

1. Disconnect the hose from control unit and mattress.

2. Discard the old hose.

3. Connect the new hose to control unit and mattress.

Return To Table of Contents

14 476004-5210 V1.5 www.stryker.com

Page 15

Preventive Maintenance

Preventative maintenance should be performed annually, at a minimum. A preventative maintenance program should

be established for all Stryker Medical equipment. Preventative maintenance may need to be performed more frequently

based on the usage level of the product.

CHECKLIST

_______ Cover zipper opens and closes properly and has no visible damage.

_______ No tears, rips, holes, cracks, or other openings in the mattress cover.

_______ Check labels for legibility, proper adherence, and integrity.

_______ Support surface cover straps and snaps are intact and are not damaged.

_______ Straps properly secure the support surface assembly to the crib.

_______ Foam and other components have not degraded or come apart.

_______ Check main power cord and do not plug if there is an abrasion or excessive wear.

_______ Check airflow from the air hose.

_______ Check the air hose if there is kink or breaks.

_______ Verify proper operation of the unit before returning it to service.

Product Serial Number:

Completed by: _____________________________________________ Date: _______________________

www.stryker.com 476004-5210 V1.5 15

Return To Table of Contents

Page 16

Quick Reference Replacement Parts

The parts and accessories listed on this page are currently available for purchase. Some of the parts identified on the

assembly drawing parts in this manual may not be individually available for purchase. Please call Stryker Customer

service USA at 1-800-327-0770 for availability and pricing.

Part Name Part Number

P100 mattress cover assembly 2880-030-100

Air cell assembly 2880-030-400

P100 control unit 2880-030-500

Air hose, PVC, P100 2880-030-520

Return To Table of Contents

16 476004-5210 V1.5 www.stryker.com

Page 17

Appendix A: EMC Information

GUIDANCE AND MANUFACTURER’S DECLARATION- ELECTROMAGNETIC EMISSIONS:

This device is intended for use in the electromagnetic environment specified below. The user of this device should make

sure it is used in such an environment.

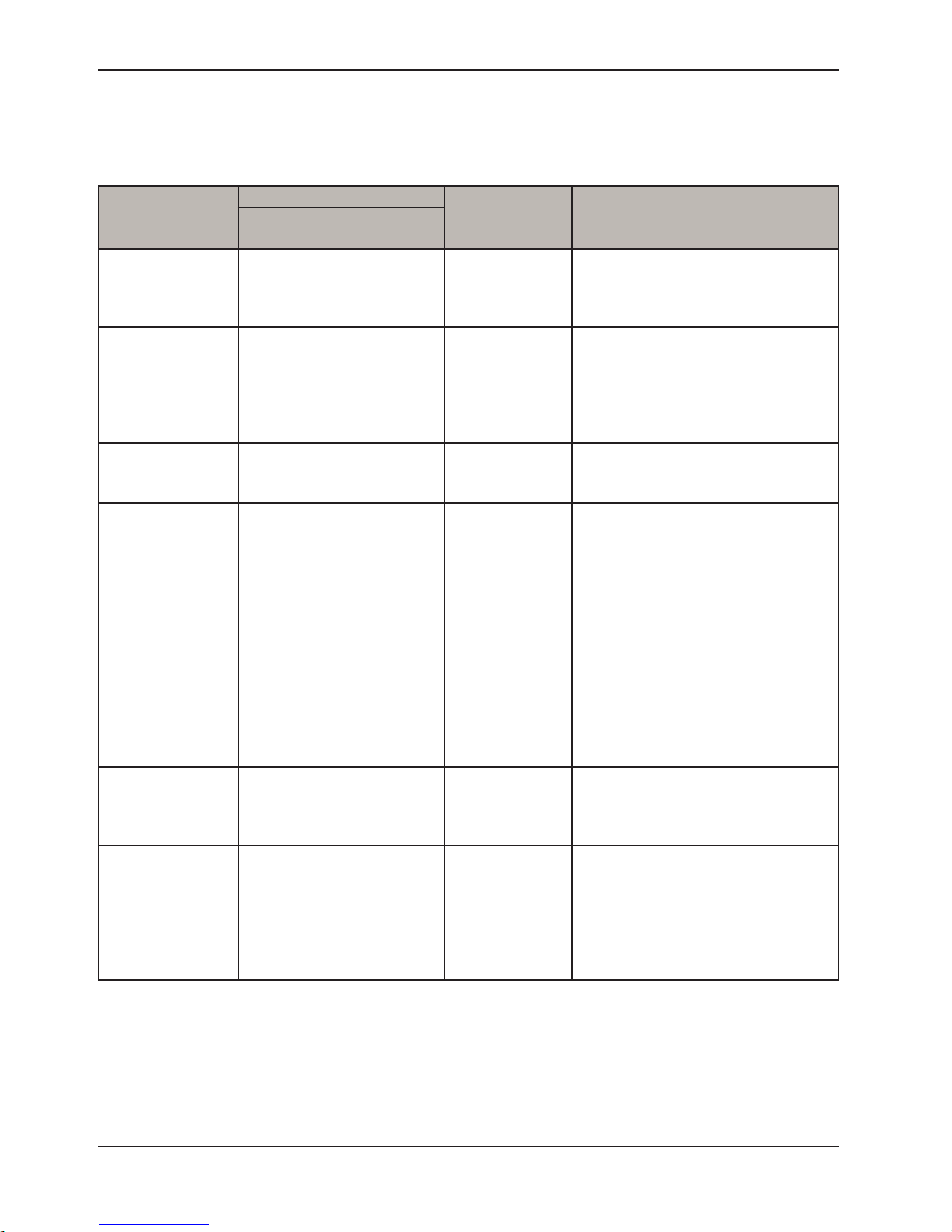

Emissions Test Compliance Electromagnetic Environment-Guidance

RF emissions

CISP R 11

RF emissions

CISP R 11

Harmonic emissions

IEC61000-3-2

Voltage fluctuations / Flicker

emissions

IEC61000-3-3

WARNING

1. The device should not be used adjacent to or stacked with other equipment. If adjacent or stacked use is

necessary, the device should be observed to verify normal operation in the configuration in which it will be used.

2.Use of accessories, transducers and cables other than those specified or provided by the manufacturer of this

equipment could result in increased electromagnetic emissions or decreased electromagnetic immunity of this

equipment and result in improper operation.

3. Portable RF communications equipment (including peripherals such as antenna cables and external antennas)

should be used no closer than 30 cm (12 inches) to any part of the Pump, including cables specified by the

manufacturer. Otherwise, degradation of the performance of this equipment could result.

Group1

Class B

Class A

Complies

The device uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely

to cause any interference in nearby electronic equipment

The device is suitable for use in all establishments,

including domestic establishments and those directly

connected to the public low-voltage power supply

network

www.stryker.com 476004-5210 V1.5 17

Return To Table of Contents

Page 18

Appendix A: EMC Information

GUIDANCE AND MANUFACTURER’S DECLARATION- ELECTROMAGNETIC IMMUNITY:

This device is intended for use in the electromagnetic environment specified below. The user of this device should make

sure it is used in such an environment.

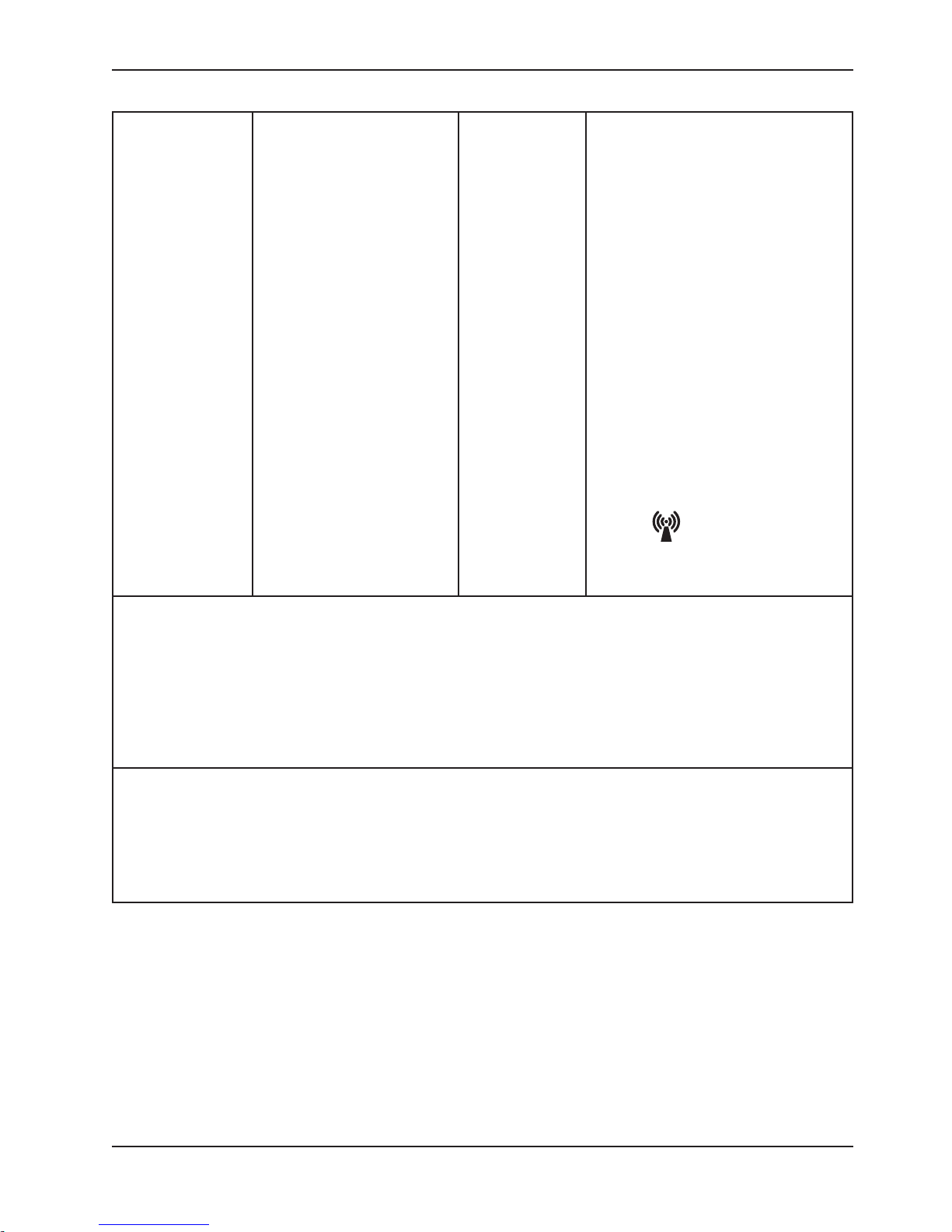

Basic EMC

standard

Electrostatic

Discharge (ESD)

IEC61000-4-2

Electrical fast

transient/ burst

IEC61000-4-4

Immunity Test Levels Compliance

HOME HEALTHCARE

Levels

ENVIRONMENT

±8kV contact

±15kV air

±2kV for power supply line

±1kV for input/output line

±8kV contact

±15kV air

±2kV for power

supply line

±1kV for input/

output line

Electromagnetic

Environment-Guidance

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30 %.

Mains power quality should be that

of a typical commercial or hospital

environment

Surge

IEC61000-4-5

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC61000-4-11

Power frequency

(50/60Hz) magnetic

field

IEC61000-4-8

Conducted RF

IEC 61000-4-6

± 1 kV line(s) to

line(s)

± 2 kV line(s) to earth

Voltage Dips:

i) 100% reduction for 0.5

period,

ii) 100% reduction for 1 period,

iii) 30% reduction for 25/30

period,

Voltage Interruptions:

100% reduction for 250/300

period

± 1 kV line(s) to

line(s)

(1)

230V (U

)

T

Voltage Dips:

i) 100% reduction

for 0.5 period,

ii) 100% reduction

for 1 period,

iii) 30% reduction

for 25/30 period,

Voltage

Mains power quality should be that

of a typical commercial or hospital

environment.

Mains power quality should be that

of a typical commercial or hospital

environment. If the user of this

device requires continued operation

during power mains interruptions, it

is recommended that the device be

powered from an uninterruptible power

supply or a battery.

Interruptions:

100% reduction

for 250/300

period

30 A/m 30 A/m Power frequency magnetic fields should

be at levels characteristic of a typical

location in a typical commercial or

hospital environment.

3 Vrms

0,15 MHz – 80 MHz

6 Vrms in ISM and amateur

radio bands between

0,15 MHz and 80 MHz

80 % AM at 1 kHz

(4)

6Vrms Portable and mobile RF

communications equipment should

be used no closer to any part of this

device, including cables, than the

recommended separation distance

calculated from the equation applicable

to the frequency of the transmitter.

Return To Table of Contents

18 476004-5210 V1.5 www.stryker.com

Page 19

Appendix A: EMC Information

Radiated RF EM

Fields

IEC61000-4-3

10 V/m 80 MHz to 2,7 GHz

80 % AM at 1 kHz

385-6000 MHz, 9-28V/m, 80%

AM(1kHz) pulse mode and

other modulation

10V/m Recommended separation distance

d=√P 150kHz to 80MHz

d=0.6√P 80MHz to 800MHz

d=1.2√P 800 MHz to 2.7G Hz

Where P is the maximum output

power rating of the transmitter

in watts (W) according to the

transmitter manufacturer and d is the

recommended separation distance in

meters (m).

b

Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey ,a should be

less than the compliance level in each

frequency ranged.

Interference may occur in the vicinity

of equipment marked with the following

symbol:

NOTE 1: UT is the a.c. mains voltage prior to the application of the test level

NOTE 2: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 3: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people

NOTE 4: The ISM (industrial, scientific and medical) bands between 0.15 MHz and 80 MHz are 6.765 MHz to 6.795

MHz; 13.553 MHz to 13.567 MHz; 26.957 MHz to 27.283 MHz; and 40.66 MHz to 40.70 MHz. The amateur radio

bandsbetween 0.15 MHz and 80 MHz are 1.8 MHz to 2.0 MHz, 3.5 MHz to 4.0 MHz, 5.3 MHz to 5.4 MHz, 7 MHz to

7.3 MHz,10.1 MHz to 10.15 MHz, 14 MHz to 14.2 MHz, 18.07 MHz to 18.17 MHz, 21.0 MHz to 21.4 MHz, 24.89 MHz to

24.99MHz, 28.0 MHz to 29.7 MHz and 50.0 MHz to 54.0 MHz.

a)Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically

with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site

survey should be considered. If the measured field strength in the location in which the device is used exceeds

the applicable RF compliance level above, the device should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as reorienting or relocating the device.

b)Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 10 V/m.

www.stryker.com 476004-5210 V1.5 19

Return To Table of Contents

Page 20

Warranty

LIMITED WARRANTY

Stryker Medical Division, a division of Stryker Corporation, warrants to the original purchaser P100 Powered Support

Surface to be free from defects in material and workmanship for a period of one (1) years for the support surface

assembly and the control unit after date of delivery under normal use*. Stryker’s obligation under this warranty is

expressly limited to supplying replacement parts and labor for, or replacing, at this option, any product which is, in the

sole discretion of Stryker, found to be effective. If requested by Stryker, products or parts for which a warranty claim

is made shall be returned repaid to the factory. Any improper use or any alteration or repair by others in such manner

as in Stryker’s judgment affects the product materially and adversely shall void this warranty. Any repair of Stryker

products using parts not provided or authorized by Stryker shall void this warranty. No employee or representative of

Stryker is authorized to change this warranty in any way.

CONDITIONS AND LIMITATIONS

Stryker Medical’s P100 Powered Support Surface is designed for an expected service life as listed below under normal

use conditions, and with appropriate periodic maintenance as described in the operations/maintenance manual for

each device.

This statement constitutes Stryker’s entire warranty with respect to the aforesaid equipment. Stryker makes no other

warranty or representation, either expressed or implied, except as set forth herein. There is no warranty of

merchantability and there are no warranties of fitness for any particular purpose. In no event shall Stryker be

liable here under for incidental or consequential damages arising from or in any manner related to sales or use of

any such equipment. This warranty does not extend to, nor cover:

• Normal wear and tear; or

• Damage or product failure due to causes beyond Stryker’s control such as, but not limited to abuse, theft, fire,

flood, wind , lightning, freezing, clogging of mattress pores due to tobacco smoke, unusual atmosphere conditions, material degradation due to exposure to moisture; or

• Damage to support surface or support surface handles through the use of the support surface for patient transfer or transport.

* Normal use is defined as normal hospital or facility usage. Damages arising from abnormal use such as those caused

by needle punctures, burns, chemicals, negligent use or improper care or improper cleaning or staining resulting from

it are exempt from warranty coverage.

TO OBTAIN PARTS AND SERVICE

Stryker products are supported by a nationwide network of dedicated Stryker Field Service Representatives. These

representatives are factory trained, available locally, and carry a substantial spare parts inventory to minimize repair

time. Simply call your local representative or call Stryker Customer Service USA at 1-800-327-0770.

RETURN AUTHORIZATION

Merchandise cannot be returned without approval from the Stryker Customer Service Department. An authorization

number will be provided which must be printed on the returned merchandise. Stryker reserves the right to charge

shipping and restocking fees on return merchandise. Special, modified, or discontinued items not subject to return.

DAMAGED MERCHANDISE

ICC Regulations require that claims for damaged merchandise must be made with the carrier within fifth (15) days of

receipt of merchandise. Do not accept damaged shipments unless such damage is noted on the delivery receipt

at the time of receipt. Upon prompt notification, Stryker will file a freight claim with the appropriate carrier for damages

incurred. Claim will be limited in amount to the actual replacement cost. In the event that this information is not received

by Stryker within the fifteen (15) day period following the delivery of the merchandise, or the damage was not noted on

the delivery receipt at the time of receipt, the customer will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

INTERNATIONAL WARRANTY CLAUSE

This warranty reflects U.S. domestic policy. Warranty outside the U.S. may vary by country. Please contact your local

Stryker Medical representative for extra information.

Return To Table of Contents

20 476004-5210 V1.5 www.stryker.com

Page 21

www.stryker.com 476004-5210 V1.5 21

Return To Table of Contents

Page 22

Stryker Medical

3800 E. Centre Avenue

Portage, Michigan 49002

USA

Stryker European Operations B.V.

Herikerbergweg 110

Amsterdam

1101 CM

Netherlands

www.stryker.com

Page 23

Support motorisé P100

2880

Manuel d’utilisation et d’entretien

2017/12 476004 - 5210 V1.5 www.stryker.com

Page 24

Page 25

Table des matières

Symboles et définitions .................................................................................4

Symboles .........................................................................................4

Définition Des Termes Avertissement/Attention/Remarque...............................................5

Spécification technique .................................................................................6

Introduction............................................................................................7

Contre-indications ..................................................................................7

La thérapie sur support à air n’est pas recommandée en cas de problèmes de stabilité rachidienne. Ce support

n’est pas prévu pour soutenir un patient couché sur le ventre. ............................................7

Utilisation Prévue Du Produit .........................................................................7

Durée De Vie Prévue ...............................................................................7

Nous Contacter ....................................................................................8

Localisation/Identification Du Numéro De Série Du Produit ..............................................8

Résumé des consignes de sécurité .......................................................................9

Description du produit .................................................................................10

Face Avant Du Dispositif De Commande .............................................................10

Face Arrière Du Dispositif De Commande ............................................................10

P100.............................................................................................10

Panneau De Commande ...........................................................................10

Instructions ...........................................................................................11

Nettoyage et désinfection ..............................................................................12

Résolution des problèmes..............................................................................13

Information relative à l’entretien .........................................................................14

Remplacement de la Housse .......................................................................14

Remplacement de la Cellule D’air....................................................................14

Remplacement Du Dispositif De Commande..........................................................14

Remplacement Du Tuyau...........................................................................14

Entretien préventif .....................................................................................15

Liste De Vérification ...............................................................................15

Annexe A : Information relative à la compatibilité électromagnétique .........................................17

Directive et déclaration du fabricant - Émissions électromagnétiques: ....................................17

Directive et déclaration du fabricant - Immunité électromagnétique: ......................................18

Garantie .............................................................................................20

Garantie Limitée...................................................................................20

Demande De Pièces Et Service Après-Vente..........................................................20

Autorisation De Retour .............................................................................20

Marchandise Endommagée.........................................................................20

Clause de garantie internationale....................................................................20

www.stryker.com 476004-5210 V1.5 3

Page 26

SYMBOLES

SN

Symboles et définitions

Marquage TUV

Marquage CE

Avertissement / Attention, se reporter à la documentation jointe

Appareil de type BF

Double isolation

Fusible

Limitation de température, fonctionnement : +10°C – +40°C, stockage : -15°C – +50°C

Limitation de l’humidité, 10 % – 90 %

Se reporter au manuel/livret d’instructions

Élimination : contactez votre distributeur local qui prendra les dispositions nécessaires conformément

aux règles de votre marché national.

Ne pas repasser

Nettoyer uniquement avec un chiffon humide

Blanchiment au chlore : concentration en chlore inférieure ou égale à 1000 ppm ou 70 % en alcool

Ne pas sécher au sèche-linge

Ne pas nettoyer à sec

Laisser complètement sécher à l’air libre

Fabricant

Protégé contre les corps étrangers solides de 12,5 mm et plus ; protection contre les chutes de

gouttes d’eau verticales

Représentant agréé dans la Communauté européenne

Numéro de référence (modèle)

Numéro de série

Niveau de gonflage minimum du matelas

Niveau de gonflage maximum du matelas

Réanimation cardio-respiratoire (RCR)

Ne pas ouvrir avec un couteau

Retour à la Table des matières

4 476004- 5210 V1.5 www.stryker.com

Page 27

Introduction

DÉFINITION DES TERMES AVERTISSEMENT/ATTENTION/REMARQUE

Les termes AVERTISSEMENT, ATTENTION et REMARQUE ont une signification particulière et doivent faire l’objet

d’une attention particulière..

AVERTISSEMENT

Avertit le lecteur d’une situation qui, si elle n’est pas évitée, pourrait avoir des conséquences mortelles ou entraîner des

blessures graves. Il peut également décrire des effets indésirables potentiellement graves et des risques pour la sécurité.

ATTENTION

Avertit le lecteur d’une situation potentiellement dangereuse qui, si elle n’est pas évitée, peut entraîner des blessures

légères ou modérées chez l’utilisateur ou le patient ou endommager l’équipement ou d’autres biens. Cela comprend le

fait de veiller à utiliser l’appareil de manière efficace et en toute sécurité et de veiller à éviter les dommages qui peuvent

se produire sur un appareil en raison de l’utilisation ou de la mauvaise utilisation qui en est faite.

REMARQUE

Fournit des informations spécifiques pour faciliter l’entretien ou clarifier des instructions importantes.

www.stryker.com 476004-5210 V1.5 5

Retour à la Table des matières

Page 28

Spécification technique

Dispositif de commande Spécification

Alimentation électrique CA 230 V 50 Hz, 0,05 A (pour une installation en 230 V)

Calibre du fusible T1AL, 250V

Dimensions (L x l x h) 25 x 12.5 x 8.5 cm

Poids 1,4 kg

Temps de cycle 8 min/60 Hz, 9.6 min/50 Hz

Environnementt

Classification

Pression

atmosphérique

Température

Humidité

de 700 hPa à 1013,25 hPa

• Fonctionnement : de 10°C à 40°C

• Stockage de -15°C à 50°C

• Transport : de -15°C à 70°C

• Fonctionnement : de 10 % à 90 % sans condensation

• Stockage de 10 % à 90 % sans condensation

• Transport : de 10 % à 90 % sans condensation

• Classe II, Type BF, IP21

• Partie appliquée : Matelas à air

• Non approprié à une utilisation en présence d’un mélange anesthésique inflammable (pas de protection de type AP ou APG)

Matelas à air Spécification

Modèle P100

Numéro du modèle 2880

Normes ignifuges EN 597-1 et EN 597-2

Charge maximale d'utilisation 135 kg

Dimensions (L x l x h) 193 x 89 x 18 cm

Poids 5,75 kg

Retour à la Table des matières

6 476004- 5210 V1.5 www.stryker.com

Page 29

Introduction

Ce manuel a été conçu pour aider à l’utilisation et à l’entretien du support motorisé P100. Veuillez lire attentivement ce

manuel avant d’utiliser ou de commencer l’entretien du support. Pour assurer un fonctionnement en toute sécurité de

cet équipement, il est recommandé d’établir des méthodes et procédures pour l’instruction et la formation du personnel

concernant une utilisation en toute sécurité du support.

CONTRE-INDICATIONS

La thérapie sur support à air n’est pas recommandée en cas de problèmes de stabilité rachidienne. Ce support n’est

pas prévu pour soutenir un patient couché sur le ventre.

UTILISATION PRÉVUE DU PRODUIT

P100 est un support motorisé à faible pression constante, conçu pour permettre une répartition de la pression afin

d’aider à la prévention et au traitement des escarres de décubitus. Le système comprend un dispositif de commande

associé à un matelas à cellules d’air à air alterné. Les cellules d’air répartissent le poids du patient sur toute la surface

et aident à réduire la pression d’interface au niveau des tissus. Il est recommandé que le produit soit utilisé par du

personnel qualifié pour effectuer des procédures générales de soins infirmiers et correctement formé en matière de

prévention et de traitement des escarres de décubitus.

Ce support est destiné à être utilisé pour des patients humains dans un hôpital général, une maison de santé ou un

environnement de soins à domicile, et pour des patients présentant des risques de développement d’escarres de

décubitus, ainsi que pour ceux nécessitant une thérapie pour des escarres de décubitus préexistants. La charge

maximale d’utilisation pour le support P100 est de 135 kg ; le patient ne doit pas dépasser la charge maximale

d’utilisation spécifiée pour le support, le cadre et les accessoires. Les patients doivent être âgés au minimum de 2 ans.

P100 doit être à tout moment utilisé avec une housse de matelas.

Le support n’est pas conçu comme un produit stérile et n’est pas non plus destiné à inclure une fonction de mesure.

DURÉE DE VIE PRÉVUE

Les produits sont conçus pour offrir un fonctionnement fiable et en toute sécurité lorsqu’ils sont utilisés ou installés

conformément aux instructions fournies par Stryker Medical. Stryker Medical recommande de confier l’inspection et

l’entretien du système à des techniciens agréés en cas d’apparition de signes d’usures ou de problèmes concernant une

fonction de l’appareil et une indication sur les produits. À part dans ces cas, les appareils ne devraient généralement

pas nécessiter d’entretien ou d’inspection. La durée de vie prévue du support P100 est de 2 ansservice and inspection

of the devices generally should not be required. P100 has an expected service life of 2 years.

www.stryker.com 476004-5210 V1.5 7

Retour à la Table des matières

Page 30

Introduction

NOUS CONTACTER

Contactez le service clientèle ou l’assistance technique de Stryker aux numéros suivants : +1 (800) 327-0770 or (269)

324-6500.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

Veuillez vous munir du numéro de série (A) de votre produit Stryker lorsque vous appelez le service clientèle ou

l’assistance technique de Stryker. Indiquez le numéro de série dans toute communication écrite..

LOCALISATION/IDENTIFICATION DU NUMÉRO DE SÉRIE DU PRODUIT

Le numéro de série (A) est situé au niveau de la housse du

matelas près du coin droit au pied du matelas, comme indiqué

sur la Figure 1. Le numéro de série est également apposé sur

la base en mousse et cellule d’air ; pour le consulter, ouvrez la

fermeture éclair de la housse d’environ 30 cm pour accéder à

la base en mousse et à la cellule d’air. Le numéro de série est

également situé sur la partie inférieure du boîtier du dispositif

de commande.

Matelas P100

Mousse et cellule d’air

▼

Figure 1

A

Format:

2880

M A A M M - S S S S S

Légende du numéro du modèle (X)

2880 P100

• M = Matelas

• AA = Année

• MM = Mois

• SSSSS = Séquence (Numérique)

Légende du mois

(MM)

Janvier 01

Février 02

Mars 03

Avril 04

Mai 05

Juin 06

Juillet 07

Août 08

Septembre 09

Octobre 10

Novembre 11

Légende de

l'année (AA)

2012 12

2013 13

2014 14

2015 15

2016 16

Retour à la Table des matières

8 476004- 5210 V1.5 www.stryker.com

Décembre 12

Page 31

Résumé des consignes de sécurité

AVERTISSEMENT

• Vérifiez régulièrement la peau du patient. Consultez un médecin en cas de rougeur ou de déchirure de la peau. De graves

blessures pourraient s’ensuivre si l’état de la peau du patient n’est pas pris en charge.

• Ne placez pas le dispositif de commande dans le lit du patient, en contact avec le patient ou sous des draps ou d’autres

couvertures.

• Cela pourrait provoquer de graves blessures ou affecter la performance du dispositif de commande.

• N’utilisez pas l’équipement en présence d’un mélange anesthésique inflammable ou avec de l’oxygène (O

nitreux (N

• Vérifiez que les barres latérales du lit sont compatibles avec le cadre du lit et le matelas existant. Une évaluation des risques doit être effectuée par une personne suffisamment qualifiée, en particulier si des barres latérales sont prescrites, pour

s’assurer que le lit est conforme à la norme CEI 60601-2-52 relative à la sécurité des lits.

• Utilisez le produit avec un drap de dessus approprié et maintenez les couches de literie entre le patient et le matelas à un

minimum.

• Évaluez le risque de piégeage du patient conformément aux protocoles et effectuez une surveillance en conséquence.

• Une surveillance étroite est nécessaire lorsque ce produit est utilisé pour des enfants ou à côté d’eux. L’ingestion par un

enfant d’une petite pièce détachée de l’appareil peut entraîner des brûlures électriques ou un risque d’étouffement.

• Utilisez uniquement ce produit pour l’usage auquel il est destiné, comme décrit dans ce manuel.

• Ne faites pas fonctionner ce produit si le cordon d’alimentation ou la prise a été endommagé(e).

• Maintenez le cordon éloigné de surfaces chauffées.

• N’obstruez jamais les orifices d’aération de ce produit ou ne le placez jamais sur des surfaces souples, comme un lit ou un

canapé, là où les orifices pourraient être obstrués. Assurez-vous de l’absence de peluches, cheveux ou autres particules

similaires dans les orifices d’aération.

• Ne laissez jamais tomber ou n’insérez jamais d’objet dans un orifice ou un tuyau.

• Ne modifiez pas cet équipement sans l’autorisation du fabricant.

• Les housses du matelas ont été soumises à des tests de sensibilisation et d’irritation de la peau. Toutefois, si vous pensez

que vous pourriez avoir eu ou avoir une réaction allergique, veuillez consulter immédiatement un médecin.

• Le cordon d’alimentation raccordé au dispositif de commande doit être positionné de sorte à éviter tout risque

d’étranglement et/ou d’endommagement du cordon. L’acheminement du câble d’alimentation doit faire l’objet d’une attention

particulière. Stryker recommande de placer le cordon sous le cadre du lit et de le fixer à une prise de courant située à la

tête du lit.

• L’utilisation (possible piégeage) ou la non-utilisation (possibles chutes du patient) de barres latérales ou autres dispositifs de

retenue peut avoir des conséquences mortelles ou entraîner de graves blessures. Le support est utilisé dans des conditions

de sécurité optimales lorsque des barres latérales sont également utilisées ; l’absence de barres latérales peut augmenter

le risque de chutes. Les règles locales en matière d’utilisation de barres latérales doivent être prises en compte. La décision d’utiliser ou non des barres latérales et la manière de les utiliser doit être fondée sur les besoins individuels de chaque

patient et être prise par le médecin, les opérateurs et les parties responsables.

• Le risque de piégeage peut apparaître lorsque le support est placé sur des cadres de lit qui laissent des écarts même de

quelques centimètres entre le support et la tête de lit, le pied de lit et les barres latérales. Le support NE doit PAS être

utilisé lorsque de tels écarts sont présents.

• Lors du nettoyage du dessous du support, assurez-vous qu’aucun liquide ne peut s’infiltrer dans la zone de la fermeture

éclair et la barrière imperméable de la housse ; les fluides qui arrivent à entrer en contact avec la fermeture éclair peuvent

se répandre dans le support.

• N’exposez pas le matelas à un niveau d’humidité excessif. Cela pourrait entraîner des blessures corporelles ou endommager

l’équipement.

• L’utilisation de composés quaternaires contenant des éthers de glycol et/ou du peroxyde d’hydrogène accéléré peut compromettre l’intégrité de la housse et la lisibilité des indications présentes sur celle-ci.

• Soyez bien attentifs aux appareils et à l’équipement placés au-dessus du support. Des dommages peuvent se produire à la

surface en raison du poids de l’équipement, de la chaleur générée par celui-ci ou de ses bords tranchants.

• Ne placez pas de couvertures ou accessoires à l’intérieur de la housse. Cela risquerait de réduire les performances de

répartition de la pression.

• L’évaluation du protocole de réanimation cardio-respiratoire (RCR) approprié à utiliser avec le support relève de la responsabilité de l’équipe soignante.

• En cas de possibles interférences électromagnétiques avec les téléphones portables, veuillez augmenter la distance (3,3 m)

entre les appareils ou éteindre le téléphone portable.

O).

2

) ou de l’oxyde

2

REMARQUE

Le support P100 doit être en permanence utilisé avec une housse de matelas. La housse du support peut interagir avec toute peau

extérieure.

www.stryker.com 476004-5210 V1.5 9

Retour à la Table des matières

Page 32

Description du produit

FACE AVANT DU DISPOSITIF DE COMMANDE

Figure 2

◄

1. Interrupteur de marche/arrêt

2. Partie frontale du boîtier

1

2

FACE ARRIÈRE DU DISPOSITIF DE COMMANDE

Figure 3

◄

3

4

5

P100

3. Crochet

4. Prise de raccordement du tuyau d’air

5. Cordon d’alimentation

Figure 4

◄

6. Matelas P100

7. Mousse et cellule d’air

8. Tuyau d’air

PANNEAU DE COMMANDE

Figure 5

◄

9

10

9. de réglage de la pression

Le bouton de réglage de la pression contrôle la pression de l’air à sa sortie. Lorsqu’il

est tourné dans le sens des aiguilles d’une montre, la pression de sortie augmente.

Lorsqu’il est tourné dans sens inverse, la pression de l’air diminue. Veuillez consulter

votre personnel soignant pour connaître le réglage adapté.

10. Interrupteur d’alimentation

Pour allumer/éteindre le dispositif de commande :

a. Allumez/éteignez l’interrupteur sur le côté de l’appareil.

b. SÉLECTEUR DE RÉGLAGE DU CONFORT pour le confort du patient.

6

Souple (

Ferme (

7

)—Niveau de gonflage minimum du matelas

)—Niveau de gonflage maximum du matelas

8

Retour à la Table des matières

10 476004-5210 V1.5 www.stryker.com

Page 33

12

Instructions

1. Placez le dispositif de commande sur une surface plane ou suspendez-le à l’extrémité du lit en utilisant des crochets de

fixation. Voir Figure 2 et Figure 3. Retirez la prise pour débrancher l’appareil.

2. Placez le matelas sur le cadre du lit.

3. Branchez le tuyau de raccordement entre la cellule d’air du matelas et le dispositif de commande. Dévissez le bouchon de

la valve d’entrée d’air du matelas et vissez l’adaptateur du dispositif de commande sur la valve d’entrée d’air en serrant

bien.

4. Branchez le cordon d’alimentation et placez le bouton de réglage de la pression sur la position la plus élevée pour un

gonflage rapide et allumez le dispositif de commande en utilisant l’interrupteur vert de marche/arrêt. Le gonflage du matelas

prendra environ 40 minutes.

5. Après l’installation, assurez-vous que le rabat n’est pas replié vers le haut pour éviter l’infiltration de liquide dans la housse

du matelas.

REMARQUE

Assurez-vous que le dispositif de commande est adapté à la tension d’alimentation et à la fréquence locales.

6. Placez le patient sur le matelas et tournez le bouton de réglage de la pression pour son confort.

7. Une vérification manuelle doit être effectuée toutes les 8 heures afin de contrôler que l’appareil fonctionne correctement.

Voir Figure 6.

8. Pour effectuer la vérification manuelle :

Avec le patient couché sur le dos, glissez la main, à plat et la paume vers le haut entre la couverture et le matelas. La main

doit être directement sous la cellule d’air qui se situe sous les fesses du patient (ou un os de cette zone). Voir Figure 6.

Figure 6

▼

VÉRIFICATION MANUELLE

Correctement gonflé Pas assez gonflé

Attendez quela cellule d’air située directement au-dessus de la main soit entièrement gonflée. Si le corps du patient n’est pas

directement en contact avec la main, alors le système fonctionne correctement. Si pendant le gonflage total de la cellule d’air,

le corps du patient est en contact direct avec la main à plat, alors le système ne fonctionne pas correctement. Placez le bouton

de réglage de la pression sur une position plus élevée. Attendez 10 minutes et recommencez la vérification manuelle. En cas

d’échec de la vérification manuelle, vérifiez que les tuyaux ne sont pas tordus ou coincés. En cas de nouvel échec de la vérification

manuelle et si les tuyaux ne sont pas tordus, contactez Stryker pour des instructions supplémentaires.

AVERTISSEMENT

Dégonflez le matelas avant d’effectuer une réanimation cardio-respiratoire, sinon celle-ci pourrait s’avérer inefficace.

Pour dégonfler le matelas pour effectuer une réanimation cardio-respiratoire :

Débranchez les tuyaux du dispositif de commande. Voir Figure 7. La cellule d’air se dégonflera en environ 20 secondes.

Poursuivez en effectuant les procédures de réanimation cardio-respiratoire.

Figure 7

▼

www.stryker.com 476004-5210 V1.5 11

Retour à la Table des matières

Page 34

Nettoyage et désinfection

Le boîtier du dispositif de commande, les tubes et le matelas doivent être nettoyés entre chaque patient.

• Pour effectuer le nettoyage, utilisez de l’eau et un chiffon propre pour essuyer le dispositif de commande, le cordon d’alimentation, les tuyaux, la housse supérieure du matelas, la couche intermédiaire et la housse inférieure.

Ne nettoyez pas la mousse. N’utilisez pas de nettoyants abrasifs sur le matelas. Remarque : Le sang et autres

fluides corporels doivent être soigneusement nettoyés sur toutes les surfaces avant l’application de désinfectants.

• Appliquez du désinfectant sur les surfaces externes du dispositif de commande, les tuyaux et la housse supérieure du matelas, la couche intermédiaire et la housse inférieure en essuyant. Stryker recommande d’utiliser une

solution à base de chlore, avec une concentration inférieure ou égale à 1000 ppm ou 70 % d’alcool, deux fois

par semaine.

• Il n’est pas recommandé de désinfecter les parties internes du matelas régulièrement, mais uniquement lorsque

cela est nécessaire dans certains cas, la cellule d’air et la couche intermédiaire de la housse peuvent être essuyées avec un chiffon et du désinfectant, comme recommandé ci-dessus.

• Essuyez le matelas avec un chiffon propre et sec pour éliminer tout excès de désinfectant..

• Si un autre détergent ou un autre nettoyant est utilisé, choisissez-en un qui ne produira pas d’effets chimiques

indésirables sur la surface du boîtier en plastique du dispositif de commande, sur la housse du matelas et tout

autre composant de l’appareil.

• Lors du nettoyage du dessous du support, assurez-vous qu’aucun liquide ne peut s’infiltrer dans la zone de la fermeture

éclair et la barrière imperméable de la housse ; les fluides qui arrivent à entrer en contact avec la fermeture éclair peuvent

se répandre dans le support.

• Évitez la poussière et la proximité avec des zones poussiéreuses.

• Tous les composants doivent être minutieusement séchés à l’air avant d’être utilisés.

AVERTISSEMENT

• N’utilisez pas de produits à base de phénolique pour le nettoyage.

• Ne séchez pas le matelas en plein soleil.

Retour à la Table des matières

12 476004-5210 V1.5 www.stryker.com

Page 35

Résolution des problèmes

Problème Solution

Perte de puissance Vérifiez si la prise est raccordée au secteur.

Il se peut que le réglage de la pression ne soit pas adapté au patient. Réglez le

Le patient touche le fond

Les cellules d’air ne se gonflent

pas

Certains orifices de sortie d’air

du connecteur du tuyau d’air ne

produisent pas d’air

niveau de confort en augmentant la pression d'une ou deux positions et attendez

quelques minutes pour un meilleur confort.

Assurez-vous que le tuyau d'air n'est pas tordu, fendu ou fissuré. Vérifiez que

l'interrupteur d'alimentation est allumé, ce qui signifie que le dispositif de

commande est sous tension. Vérifiez que les tuyaux d'air sont bien insérés et

correctement raccordés.

Ceci est normal du fait de l'existence d'un mode alterné. Les orifices de sortie

d'air se relaient pour produire de l'air pendant leur temps de cycle.

www.stryker.com 476004-5210 V1.5 13

Retour à la Table des matières

Page 36

Information relative à l’entretien

REMPLACEMENT DE LA HOUSSE

Outils nécessaires : aucun

Procédure :

1. Débranchez le tuyau de raccordement entre la cellule d’air du matelas et le dispositif de commande.

2. Ouvrez la fermeture éclair de la housse supérieure.

3. Retirez cellule d’air.

4. Ouvrez la fermeture éclair de la couche intermédiaire sur le côté droit du patient, puis enlevez la mousse de la

partie inférieure.

5. Jetez la vieille housse.

6. Placez la nouvelle housse, la fermeture éclair étant défaite, puis ouvrez la housse supérieure et la couche intermédiaire.

7. Glissez délicatement la mousse dans la partie inférieure et refermez la fermeture éclair de la couche intermédiaire.

8. Placez délicatement la cellule d’air sur la partie supérieure et refermez la fermeture éclair de la housse.

9. Vérifiez que l’appareil fonctionne correctement avant de le remettre en marche.

REMPLACEMENT DE LA CELLULE D’AIR

Outils nécessaires : aucun

Procédure :

1. Débranchez le tuyau de raccordement de la valve d’entrée d’air du matelas.

2. Ouvrez la fermeture éclair de la housse supérieure.

3. Retirez et jetez la vieille cellule d’air.

4. Placez la nouvelle cellule d’air et refermez la fermeture éclair de la housse.

REMPLACEMENT DU DISPOSITIF DE COMMANDE

Outils nécessaires : aucun

Procédure :

1. Débranchez la prise du secteur et le tuyau.

2. Jetez le vieux dispositif de commande.

3. Placez le nouveau dispositif de commande et raccordez la prise au secteur et le tuyau.

REMPLACEMENT DU TUYAU

Outils nécessaires : aucun

Procédure :

1. Débranchez le tuyau du dispositif de commande et du matelas.

2. Jetez le vieux tuyau.

3. Raccordez le nouveau tuyau au dispositif de commande et au matelas.

Retour à la Table des matières

14 476004-5210 V1.5 www.stryker.com

Page 37

Entretien préventif

L’entretien préventif doit être réalisé au moins une fois par an. Un programme d’entretien préventif doit être établi

pour l’ensemble de l’équipement de Stryker Medical. Il peut être nécessaire d’effectuer l’entretien préventif plus

fréquemment, en fonction du niveau d’utilisation du produit.

LISTE DE VÉRIFICATION

_______ La fermeture de la housse s’ouvre et se ferme correctement et ne présente aucun dommage apparent.

_______ La housse du matelas ne présente aucun accroc, aucune déchirure, aucun trou, aucune fissure ou autre

brèche.

_______ Vérifiez que les étiquettes sont lisibles, bien collées, et intactes.

_______ Les sangles et fermetures à pression du support sont intactes et ne sont pas endommagées.

_______ Les sangles assurent une bonne fixation du dispositif de support à la base du lit.

_______ La mousse ou les autres composants ne se sont pas détériorés ou ne sont pas tombés en morceaux.

_______ Vérifiez le cordon d’alimentation principal et ne le branchez pas en cas d’abrasion ou d’usure excessive.

_______ Vérifiez le flux d’air au niveau du tuyau d’air.

_______ Vérifiez que le tuyau d’air ne présente aucun nœud ou aucune rupture.

_______ Vérifiez que l’appareil fonctionne correctement avant de le remettre en marche.

Numéro de série du produit :

Rempli par : _______________________________________________ Date : _______________________

www.stryker.com 476004-5210 V1.5 15

Retour à la Table des matières

Page 38

Liste des pièces de rechange usuelles

Les pièces et accessoires répertoriés sur cette page sont actuellement disponibles à l’achat. Certaines des pièces

identifiées sur le schéma d’ensemble de ce manuel peuvent ne pas être individuellement disponibles à l’achat. Veuillez

contacter le service clientèle de Stryker aux États-Unis au +1-800-327-0770 pour connaître la disponibilité et les prix.

Nom de la pièce Référence pièce

Ensemble de housse du matelas P100 2880-030-100

Dispositif de cellules d’air 2880-030-400

Dispositif de commande P100 2880-030-500

Tuyau d'air, PVC, P100 2880-030-520

Retour à la Table des matières

16 476004-5210 V1.5 www.stryker.com

Page 39

Annexe A : Information relative à la compatibilité électromagnétique

DIRECTIVE ET DÉCLARATION DU FABRICANT - ÉMISSIONS ÉLECTROMAGNÉTIQUES:

L’appareil doit être utilisé dans un environnement électromagnétique indiqué ci-dessous. L’utilisateur de cet appareil doit

garantir que l’appareil est utilisé dans un environnement approprié.

Test d'émissions Conformité Environnement électromagnétique - Directive

Emissions RF CISPR 11 Groupe 1

Emissions RF CISPR 11 Classe B

Rayonnements harmoniques CEI

61000-3-2

Emissions dues aux fluctuations

de tension/au papillotement CEI

61000-3-3

ATTENTION :

1. L’appareil ne doit pas être utilisé à proximité ou empilé avec d’autres équipements. Si une utilisation adjacente ou

empilée est nécessaire, le dispositif doit être observé pour vérifier le fonctionnement normal dans la configuration

dans laquelle il sera utilisé.

2. L’utilisation d’accessoires, de transducteurs et de câbles autres que ceux spécifiés ou fournis par le fabricant

de cet équipement peut entraîner une augmentation des émissions électromagnétiques ou une diminution de

l’immunité électromagnétique de cet équipement et entraîner un fonctionnement incorrect.

3. Les appareils de communication RF portables (y compris les périphériques tels que les câbles d’antenne et les

antennes externes) doivent être utilisés à une distance de 30 cm (12 pouces) de toute partie de la Pompe, y compris

les câbles spécifiés par le fabricant. Sinon, une dégradation des performances de cet équipement pourrait en

résulter.

Classe A

Conforme

L’appareil utilise de l’energie RF uniquement pour son

fonctionnement interne. Par

consequent, les emissions RF sont tres faibles et ne

devraient pas causer d’interferences

avec l’equipement electronique environnant.

L’appareil peut etre utilise dans dans toutes les

installations, y compris les installations

domestiques et celles directement raccordees au reseau

public de distribution a basse

tension qui fournit de l’electricite aux batiments utilises a

des fins domestiques.

www.stryker.com 476004-5210 V1.5 17

Retour à la Table des matières

Page 40

Annexe A : Information relative à la compatibilité électromagnétique

DIRECTIVE ET DÉCLARATION DU FABRICANT - IMMUNITÉ ÉLECTROMAGNÉTIQUE:

L’appareil doit être utilisé dans un environnement électromagnétique indiqué ci-dessous. L’utilisateur de cet appareil doit

garantir que l’appareil est utilisé dans un environnement approprié.

Norme EMC de

base

Décharge

électrostatique

(ESD) IEC61000-4-2

Perturbations

transitoires

électriques rapides/

en salves

IEC61000-4-4

Niveau du test d'immunité Niveau du

Environnement des

Conformité

établissements de santé

professionnels

Contact ± 8kV

Air ±15kV

Contact ± 8kV

Air ±15kV

±2kV pour la ligne

d’alimentation

±1kV pour la ligne d’entrée/

sortie

±2kV pour la ligne

d’alimentation

±1kV pour la ligne

d’entrée/sortie

Environnement électromagnétique

- Directive

Le sol doit être en bois, en béton ou en

carreaux de céramique. Si les sols sont

recouverts de matériaux synthétiques,

l’humidité relative doit être de 30 %

minimum.

La qualité du secteur doit toujours

satisfaire les conditions commerciales

ou hospitalières types.

Surtension

transitoire

IEC61000-4-5

Baisse de tension,

interruptions

courtes et variations

de tension sur les

lignes d’entrée

d’alimentation.

IEC61000-4-11

Fréquence

d’alimentation

Champ magnétique

(50/60Hz)

IEC61000-4-8

±1kV pour le mode

différentiel

±2kV pour le mode

±1kV pour le mode

différentiel

La qualité du secteur doit toujours

satisfaire les conditions commerciales

ou hospitalières type.

commun

Tension Dips:

I) réduction de 100% pour

0,5 période,

Ii) réduction de 100% pour

la période,

Iii) réduction de 30% pour la

période 25/30,

Interruptions de tension:

100% de réduction pour la

période 250/300

230V U

)

T

I) réduction de 100%

pour 0,5 période,

Ii) réduction de 100%

pour la période,

Iii) réduction de

30% pour la période

25/30,

Interruptions de

tension:

La qualité du secteur doit toujours

satisfaire les conditions commerciales

ou hospitalières type. Si l’utilisateur

de cet appareil requiert une opération

continue pendant les interruptions de

secteur, il est recommandé soit de

l’alimenté à partir de l’alimentation sans

coupure ou d’une batterie.

(1)

100% de réduction

pour la période

250/30 0

30 A/m 30 A/m Les champs magnétiques de

fréquence industrielle doivent se

trouver aux niveaux standard pour

des emplacements commerciaux ou

hospitaliers.

RF par conduction

induite

IEC 61000-4-6

3 Vrms

0,15 MHz - 80 MHz

6 Vrms dans les bandes

ISM

Entre 0,15 MHz et 80 MHz

80% AM à 1 kHz

Retour à la Table des matières

18 476004-5210 V1.5 www.stryker.com

6Vrms L’équipement de communication RF

portable et mobile, y compris les câbles,

ne doit pas être utilisé près de cet

appareil à une distance supérieure à

l’intervalle de séparation recommandée,

(4)

calculée avec l’équation applicable à la

fréquence de l’émetteur.

Page 41

Annexe A : Information relative à la compatibilité électromagnétique

Radiated RF EM

Fields

IEC61000-4-3

10 V / m 80 MHz à 2,7 GHz

80% AM à 1 kHz

385-6000 MHz, 9-28V /

m, 80% AM (1kHz) mode

impulsionnel et autres

modulations

10V/m Distance de séparation recommandée

d=√P 150kHz à 80MHz

d=0.6√P 80MHz à 800MHz

d=1.2√P 800 MHz à 2,7G Hz

Où P est la valeur nominale de sortie

maximum de l’émetteur en watts (W)

selon le fabricant de l’émetteur et d

représente la distance de séparation

recommandée en mètres (m).

b

Les intensités de champ des émetteurs

RF fixes, telles que déterminées par

une enquête électromagnétique du

site,a doivent être inférieures au niveau

de conformité dans chaque plage de

fréquence.

Le brouillage peut se produire dans le

voisinage de l’appareil doté du symbole

suivant:

REMARQUE 1: UT est la tension du secteur avant l’application du niveau de test

REMARQUE 2: A 80 MHz et 800 MHz, la plage de fréquence la plus élevée s’applique.

REMARQUE 3: Ces directives peuvent ne pas être applicables dans toutes les situations. La propagation

électromagnétique est affectée par l’absorption et la réflexion des structures, objets et personnes.

REMARQUE 4: Les bandes ISM (industrielles, scientifiques et médicales) comprises entre 0,15 MHz et 80 MHz sont

comprises entre 6,765 MHz et 6,795 MHz; 13,553 MHz à 13,567 MHz; 26,957 MHz à 27,283 MHz; et 40,66 MHz à 40,70

MHz. Les bandes radioamateurs entre 0,15 MHz et 80 MHz sont de 1,8 MHz à 2,0 MHz, de 3,5 MHz à 4,0 MHz, de 5,3

MHz à 5,4 MHz, de 7 MHz à 7,3 MHz, de 10,1 MHz à 10,15 MHz, de 14,0 MHz à 14,2 MHz, de 18,07 MHz à 18,17 MHz

MHz, 21,0 MHz à 21,4 MHz, 24,89 MHz à 24,99 MHz, 28,0 MHz à 29,7 MHz et 50,0 MHz à 54,0 MHz

a)Les intensités de champ provenant des émetteurs fixes, tels que les stations de base pour les téléphones

(cellulaire/sans fil) radio et les radios mobile et terrestres, la radio amateur, la diffusion radio AM et FM et la diffusion

TV ne sont théoriquement pas prévisibles avec précision. Pour évaluer l’environnement électromagnétique provenant

d’émetteurs RF fixes, il faut envisager une inspection électromagnétique du site. Si l’intensité du champ mesuré à

l’emplacement dans lequel l’appareil doit être utilisé, dépasser le niveau de conformité RF applicable, il faut observer

l’appareil pour en confirmer une opération normale. Si une performance anormale est observée, des mesures

additionnelles s’avèrent nécessaires, telles que la réorientation ou le déplacement de l’appareil.

b)Sur une plage de fréquence entre 150 kHz et 80 MHz, les intensités de champ doivent être inférieures à 10 V/m.

www.stryker.com 476004-5210 V1.5 19

Retour à la Table des matières

Page 42

Garantie

GARANTIE LIMITÉE

Stryker Medical Division, une division de Stryker Corporation, garantit à l’acheteur d’origine que le support motorisé P100 est

exempt de vices de matériaux et de fabrication pendant une période d’un (1) an pour le dispositif de support et pour le dispositif

de commande, à compter de la date de livraison, dans des conditions normales d’utilisation*. En vertu de la présente garantie,

l’obligation de Stryker se limite expressément à la fourniture de pièces de rechange et de la main d’œuvre, ou au remplacement,

selon son choix, de tout produit qui à l’entière discrétion de Stryker, s’avérerait être défectueux. Si Stryker le demande, les produits

ou pièces pour lesquels une réclamation au titre de la garantie est effectuée, devront être retournés à l’usine en port payé. Toute

utilisation impropre ou toute modification ou réparation effectuée par d’autres prestataires, qui selon Stryker affecte le produit

d’un point de vue matériel et de manière préjudiciable, annulera la présente garantie. Toute réparation des produits de Stryker en

utilisant des pièces non fournies ou agréées par Stryker, annulera la présente garantie. Aucun employé ou représentant de Stryker

n’est autorisé à modifier cette garantie, en aucune façon.

CONDITIONS ET LIMITATIONS

Le support motorisé P100 de Stryker Medical est conçu pour une durée de vie prévue telle qu’indiquée ci-dessous, dans des