Page 1

Operating Room Information System

Pre-Installation Manual

July 2014 1004-400-059 REV K www.stryker.com

Page 2

Page 3

Operating Room

Information System

Pre-Installation Manual

is manual contains condential information that shall not be disclosed or duplicated for any reason

other than to use and maintain a STRYKER OPERATING ROOM INFORMATION SYSTEM. is

restriction does not limit the right to use information contained in this manual if it is obtained from

another source without restriction. e information subject to this restriction is contained in all pages

of this manual.

© July 2014 Stryker Communications. All Rights Reserved. Information in this document is subject to

change without notice.

Stryker and Stryker logo are registered trademarks of Stryker. Endosuite® OR and iSuite® are registered

trademarks of Stryker.

All Rights Reserved

Operating Room Information System Pre-Installation Manual

1004-400-059 REV K

Page 4

Page 5

S

Contents

1. Scope .................................................................................................................................................................... 4

2. Warnings and Cautions ......................................................................................................................................... 5

2.1 Warnings ............................................................................................................................ 5

3. Product Symbol Denition.................................................................................................................................... 6

3.1 EMC Precautions .................................................................................................................. 7

4. Party Responsibilities ........................................................................................................................................... 8

4.1 Hospital Responsibilities ..................................................................................................... 8

4.2 Contractor Responsibilities ................................................................................................. 8

4.3 Stryker Responsibilities ...................................................................................................... 9

5. iSuite Operating Room ....................................................................................................................................... 10

5.1 Documentation Station (Stryker Provided) ......................................................................... 10

5.1.1 Receiving and Assembling the Documentation Station ................................................10

5.1.2 Additional Documentation Station Notes ...................................................................11

5.1.3 Installing the Documentation Station ........................................................................12

5.2 Documentation Station (Hospital Provided) ........................................................................ 16

5.3 Documentation Station Equipment Requirements .............................................................. 16

5.4 iSuite Equipment Integration Notes ................................................................................... 19

5.4.1 Wall Mounted 46" or 55" LCD Monitor or 42" TouchPanel ..............................................19

5.4.2 Wall/Ceiling Mounted Room Status Camera (WRC, CRC) LA ..........................................19

5.4.3 Wall Plates ...............................................................................................................20

5.4.4 Observation Room Touch Panel, Microphone and Speaker (OBS) LA .............................20

5.4.5 Cable Run to Video Network Hub (HRN).......................................................................20

5.4.6 Equipment Boom Cable Kit (Brand) (EQB)....................................................................21

5.4.7 Anesthesia Boom Cable Kit (Brand) (ANB) ...................................................................21

5.4.8 Navigation Arm (NAM) ...............................................................................................21

5.4.9 Stryker Single Flat Panel Arm Cable Kit .......................................................................22

5.4.10 Stryker Dual Flat Panel Arm Cable ...............................................................................22

5.4.11 Single Flat Panel Arm Cable Kit (Non-Stryker Flat Panel Arm) (NAM) ..............................22

5.4.12 Dual Flat Panel Arm Cable Kit (Non-Stryker Flat Panel Arm) .........................................22

6. Innity Based Conference System (IBC) Rooms LA ............................................................................................. 23

6.1 SPI3 Customer Supplied Casework (SCW) ............................................................................ 23

1

Page 6

S

6.2 IBC Unit with Tower (ICW1) LA............................................................................................ 23

6.3 IBC Unit with Stryker Credenza (ICW2) LA .......................................................................... 23

6.4 IBC with Customer Supplied Casework (ICW3) LA ................................................................ 24

6.5 Casework Equipment ......................................................................................................... 24

6.5.1 SwitchPoint Innity 2 (A2) LA ...................................................................................24

6.5.2 SPI2 Touch Panel, 19" (B2) .........................................................................................24

6.5.3 Wireless Microphone Receiver (M) ..............................................................................24

6.5.4 SD CODEC (L1) ............................................................................................................25

6.6 IBC Podium with Touch Panel LA........................................................................................ 25

7. Level Systems Room ............................................................................................................................................26

7.1 Customer Supplied Casework (CSC) ...................................................................................... 26

7.2 Casework Equipment ........................................................................................................ 26

7.2.1 Level One System (S1) LA ..........................................................................................26

7.2.2 Level Two System (S2) LA ..........................................................................................26

7.2.3 Level System Touch Panel (T) .....................................................................................27

7.3 Remote Level System Touch Panel (LTP) .............................................................................. 27

8. Equipment Integration Notes .............................................................................................................................. 28

8.1 Wall Mounted 46" or 55" LCD Monitor, or 42" Touch Panel LA ................................................ 28

8.1.1 SPI3 Cable Specications ...........................................................................................28

8.1.2 SPI3 42” Touch Panel Cable Specications ...................................................................28

8.1.3 IBC Cable Specications LA .......................................................................................28

8.1.4 Level System Cable Specications ..............................................................................29

8.2 Motorized Projection Screen (MPS) ...................................................................................... 29

8.3 Motorized Projection Screen Wall Switch (SWS) .................................................................... 29

8.4 Ceiling Mounted Projector ................................................................................................... 29

8.4.1 SPI3 Cable Specications ...........................................................................................29

8.4.2 IBC Cable Specications .............................................................................................30

8.4.3 Level System Cable Specications ..............................................................................30

8.5 Bracket Mounted Wall /Ceiling Speaker ................................................................................ 30

8.6 Flush Mounted Rectangular Wall/Ceiling Speaker ................................................................. 31

8.7 Flush Mounted Circular Ceiling Speaker ................................................................................ 31

8.8 Wall/Ceiling Mounted Pan/Tilt/Zoom Camera LA .................................................................. 31

2

Page 7

S

8.9 Wall/Ceiling Mounted HD Pan/Tilt/Zoom Camera LA ............................................................. 32

8.10 Echo Canceling Microphone with Internal Speaker LA ......................................................... 32

8.11 Ceiling Mounted Microphone ............................................................................................. 33

8.12 Lutron Controller (LTC) ....................................................................................................... 33

8.13 Lutron Lighting Control Integration Series .......................................................................... 33

8.14 Outside the OR Touch Panel, Keyboard, Mouse for SPI3 ........................................................ 33

9. ConnectSuite ..................................................................................................................................................... 35

9.1 SuiteStream...................................................................................................................... 35

9.2 SuiteLink/SuiteView .......................................................................................................... 35

9.3 Osite Package ................................................................................................................. 35

10. Status Systems LA ........................................................................................................................................... 36

10.1 Operating Room Status Systems ......................................................................................... 36

10.1.1 Partial Floor and Elevation Drawings ..........................................................................36

10.1.2 Site Preparation Requirements ..................................................................................37

10.2 SuiteStatus Systems .......................................................................................................... 38

10.3 Site Preparation Requirements .......................................................................................... 39

10.3.1 SuiteStatus System ...................................................................................................39

10.3.2 Power ......................................................................................................................39

10.3.3 Mounts .....................................................................................................................39

10.3.4 External Display ........................................................................................................39

Appendix A: PRI Provisioning Instructions and Form ............................................................................................... 41

A.1 Setting Up a PRI Line ......................................................................................................... 42

A.2 PRI Setup Responsibility Matrix ......................................................................................... 42

Appendix B: ORIS Network Connectivity .................................................................................................................. 45

B.1 Network Connectivity Information .................................................................................... 45

B.1.1 Ports and Bandwidth ................................................................................................45

B.1.2 Gateway/Session Border Controller (V2IU) ..................................................................45

B.1.3 Bridging Services ......................................................................................................45

B.2 Network Connectivity Questionnaire (Response Required) ......................................46

Appendix C: Remote Device Management Network Security SORN ......................................................................... 47

Appendix D: OSHPD Pre-Approved Mounting Solution ............................................................................................ 49

Contact Information ................................................................................................................................................ 51

3

Page 8

S

1. Scope

is document describes the rough-in requirements and specications for Stryker Operating Room

Information System (ORIS) equipment. It covers pre-installation requirements for all electrical and

information systems services needed. It does not describe in detail the installation of this equipment

which is accomplished by Stryker Communications' technicians.

Note Please refer to the Boom and Lights Pre-Installation Manuals for mechanical and

structural requirements for Stryker equipment booms, surgical lights, at panel

arms, and navigation arms.

Note Junction boxes are called out in this manual. e term dual gang junction box

with single gang mud ring refers to an actual dual gang junction box with an

adaptor that is designed for attachment of a single gang wall plate. is provides

more internal room for cabling and wire termination. e exact type used depends on local building codes and electrical standards.

4

Page 9

S

2. Warnings and Cautions

Please read this manual and follow its instructions carefully. e words WARNING, CAUTION, and

Note carry special meanings and should be carefully reviewed.

WARNING e personal safety of the patient or user may be involved. Disregarding

this information could result in injury to the patient.

Caution Special service procedures or precautions must be followed to avoid dam-

aging the instrument.

Note Special information to make maintenance easier or important information more

clear.

2.1 Warnings

To avoid potential serious injury to the user and the patient, the user must:

1. Read this manual thoroughly, and be familiar with its contents prior to using this equipment.

2. Be qualied physician/technician or medical personnel, having complete knowledge of the use

of this equipment.

3. Test this equipment prior to a surgical procedure. is product was fully tested at the factory

before shipment.

4. DO NOT remove covers on the product, to avoid an electric shock.

5. DO NOT perform internal repairs or adjustments unless specically instructed to do so in this

manual.

6. e electrical installation of relevant operating room equipment must comply with the applicable IEC, CEC, and NEC requirements, and any other applicable international requirements

where this product is sold. In the case where the information in this manual conicts with local

building/electrical regulations, local regulations will take precedence.

5

Page 10

S

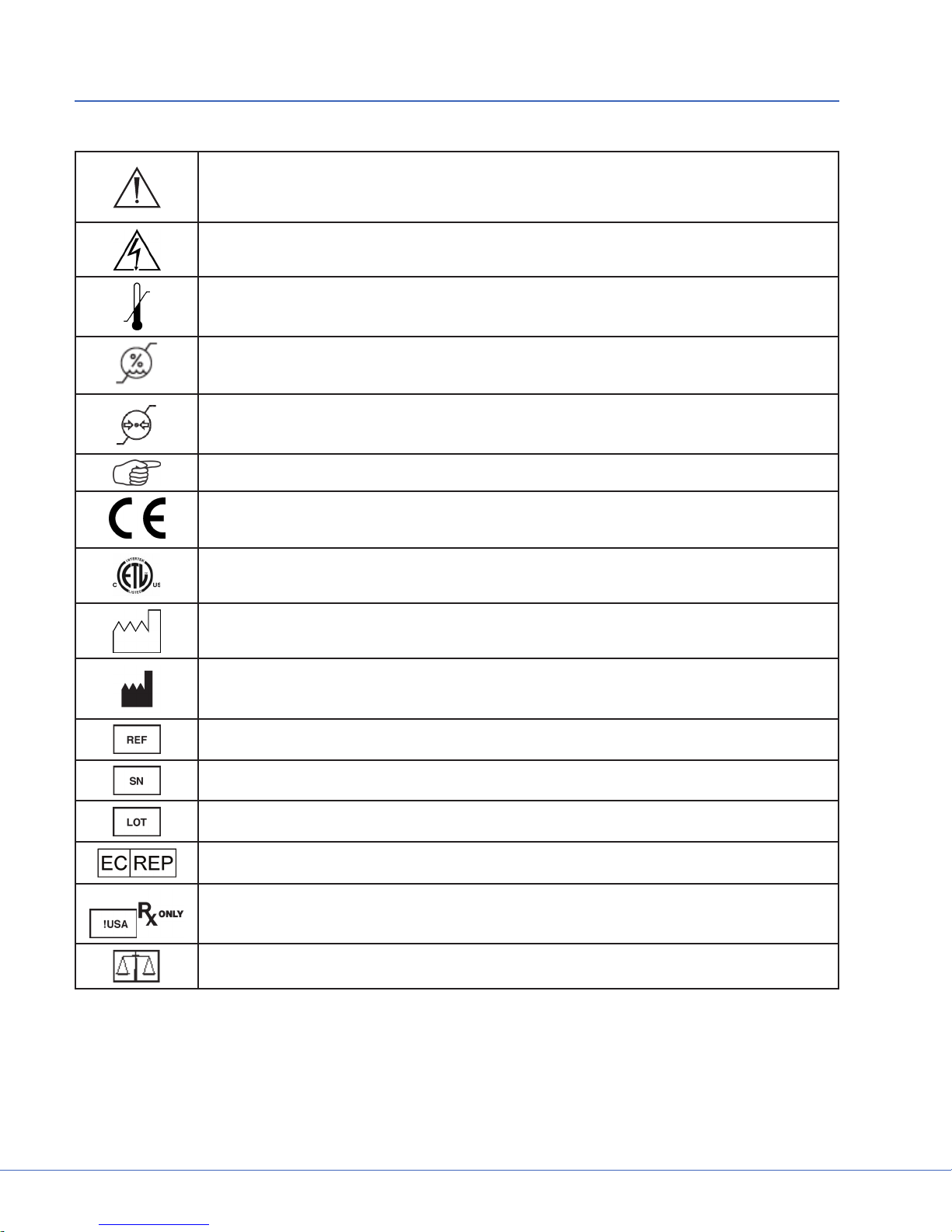

3. Product Symbol Denition

e following symbols may be found on the Stryker SwitchPoint Innity® 3 equipment:

An exclamation mark within a triangle is intended to alert the user to the presence

of important operating and maintenance (service) instructions in the literature accompanying the product.

A lightning bolt within a triangle indicates the presence of hazardous voltage. Refer

all service to authorized personnel.

Denotes temperature limits.

Denotes humidity limits.

Denotes pressure limits.

Denotes usage tips and useful information.

Denotes compliance to European Community Directive 93/42/EEC.

Denotes compliance to CSA Standard C22.2, 60601-1 - M90, AS 3200, IEC 60601-1,

UL 60601-1, EN 60601-1

Denotes the date the equipment was manufactured.

Denotes the manufacturer of the device.

Denotes product/part number.

Denotes product/serial number.

Denotes lot or batch number.

Denotes European Representative.

For U.S. audience only - Caution: Federal Law (USA) restricts this device to sale by

or on the order of a physician.

Denotes quantity.

6

Page 11

S

Denotes Class 1

Class 1 Equipment: equipment in which the protection against electric shock does

not rely on Basic Insulation only, but includes an additional safety precaution in

such a way that means are provided for the connection of Accessible Conductive

Parts to Protective (ground) Conductor in the xed wiring of the installation in such

a way that Accessible Conductive Parts cannot become Live in the event of a failure

of the Basic Insulation.

In accordance with European Community Directive 2002/96/EC on Waste Electrical and Electronic Equipment, this symbol indicates that the product must not be

disposed of as unsorted municipal waste but should be collected separately.

Note: e device does not contain any hazardous materials.

Legal regulations may include specications regarding the disposal of this product. We request that you contact Stryker when you plan to withdraw this device

from service for discard.

Denotes the device contains more than .002% cadmium.

Denotes the device contains more than .0005% mercury.

Denotes the device contains more than .004% lead.

LA

NSP

Limited Availability - Equipment may not be available in all regions.

Not Stryker Provided - Doc Stations must be provided by the customer outside the

U.S.

3.1 EMC Precautions

is device is considered medical electrical equipment and requires special precautions regarding

EMC and needs to be installed and put into service according to the information provided.

Portable and mobile RF communications equipment can aect this device's performance and must be

used in accordance with the following information.

WARNING e use of accessories, transducers, or cables other than those specied,

with the exception of those sold by Stryker, may result in increased emissions or decreased immunity of the equipment or system.

WARNING e equipment should not be used adjacent to or stacked with other equip-

ment. If stacking or adjacent placement is necessary, the equipment should

be observed to verify normal operation in the conguration in which it

will be used.

7

Page 12

S

4. Party Responsibilities

e responsibilities associated with planning and preparation for installation of Operating Room

Information System equipment will be shared between the Hospital, Contractor, and Stryker. ese

responsibilities are outlined below.

4.1 Hospital Responsibilities

1. Fill out the Ship and Installation Conrmation Form provided by the Stryker Representative.

is must be completed eight (8) weeks prior to the requested installation date.

2. e hospital must supply Stryker with up-to-date drawings in .dwg format (CAD) including but

not limited to:

• Room layout plans (current and proposed)

• Electrical services drawings

• Mechanical services drawings

• Elevation drawings

• Structural steel (support structure) drawings

• Ceiling drawings

3. e hospital must ensure Stryker is notied of all revisions and changes to drawings prior to and

during the scope of the project.

4. Accept delivery of Stryker equipment.

5. All Stryker-supplied equipment should be stored in a clean, temperature-controlled, dry environment prior to installation. Failure to comply may result in damage to the equipment, failure

of life support components, damage, and the.

6. On or before the installation start date, deliver Stryker crates and equipment to the proper

room(s).

7. Remove and dispose of the pallets, boxes, and trash during and aer the installation.

8. On the nal day of installation, sign Stryker Installation Acknowledgement Form. is form

must be signed before the room can be turned over to the hospital.

4.2 Contractor Responsibilities

1. Coordinate subcontractors.

2. Prior to the installation start date, provide all rough-in requirements as explained in this manual

and the Stryker rough-in drawings.

3. Prior to the installation start date, run all cabling, electrical, and data as instructed in this

manual and the Stryker Communications drawings.

4. Provide and pull all cables outside the operating room as specied in this manual.

5. Prior to the installation start date, connect all the required electrical circuits.

6. Prior to the installation start date, complete all work involving dust, paint, and ooring.

7. All non-Stryker equipment that is going to be connected to Stryker's ORIS equipment must be

installed prior to Stryker's installation start date.

8. All Stryker equipment that attaches to the building structure, such as Documentation Stations, Plasma/LCD display mounting brackets, and LCD projector mounting brackets, must be

mounted prior to Stryker's installation date. Exceptions are Stryker's booms and lights.

9. Prior to installation start date, any documentation station or cabinets that will house Stryker

8

Page 13

S

ORIS equipment must be fully assembled and connected to phone, data and power.

10. e proper Stryker cable kits must be pulled through any non-Stryker ceiling-mounted equipment prior to the Stryker installation date.

- International Only: If Stryker technicians are requested to pull cables through non-Stryker

ceiling-mounted equipment, the vendor of the equipment must be present to assist and provide instructions. e vendor will maintain responsibility for the nished, combined product.

11. All rooms must be reserved for Stryker Installation technicians only at all times during the

installation dates.

4.3 Stryker Responsibilities

1. Provide design assistance and recommendations.

2. Provide rough-in, cabling, electrical, and voice/data requirements listed in this manual.

3. Provide rough-in drawings.

4. Provide the hospital with a scope of work for Stryker's equipment installation.

5. Inventory all Stryker ORIS System components.

6. Pull all cables within the operating room. Hospital provides and pulls all cables outside of the

operating room, including auditoriums and conference rooms.

7. Terminate and test all low voltage cabling used to connect ORIS equipment with actual equipment or functionally equivalent signal generators.

8. Break down packaging material and gather all trash in a central location in the work area for

Hospital/Contractor removal.

9. Perform a nal review and "walk through" of the installation to ensure all equipment is functioning and all installation requirements have been met.

9

Page 14

S

5. iSuite Operating Room

e Stryker iSuite may consist of, but is not limited to, the following Stryker Communications equipment: SwitchPoint Innity, SwitchPoint Element, Documentation Station, Stryker Booms and Lights,

Speakers, PTZ Camera, and Wall Mounted Plasma/LCD. e operating room may also integrate with

an ORIS Video Network Hub and may contain a Fixed OR Status Camera. is section describes site

preparation requirements necessary for the installation phase of all Stryker ORIS equipment in the

operating room.

Note All electrical circuits called out in this manual are single Branch Circuits. For

example: 20 Amp/115 VAC within the US and 16/13 Amp 230 VAC in Europe or

equivalent per local electrical codes.

5.1 Documentation Station (Stryker Provided)

e Stryker-provided documentation station houses all the essential components of the iSuite. Prior

to receiving the documentation station the customer/Contractor must complete the Documentation

Station Order Conrmation Form (Provided by the Stryker Project Manager) and return to the PM at

least eight (8) weeks prior to the desired delivery date.

5.1.1 Receiving and Assembling the Documentation Station

Note Hospital/Contractor is responsible for receiving and assembling the documenta-

tion station prior to Stryker installation. e assembly may require up to four

people to complete the lis.

e documentation station will be delivered in three large wooden crates (top, middle, and base). is

is a large delivery and may require extra labor.

Dimensions of the Shipping Crates:

• 3-Bay: 40 x 80 x 36 40 x 80 x 42 40 x 80 x 48

• 2-Bay: 40 x 54 x 36 40 x 54 x 42 40 x 54 x 48

• 1-Bay: 40 x 60 x 48

Shipping crates:

10

Page 15

S

Upon delivery, uncrate the Stryker Documentation Station, transport to the appropriate location, and

assemble the three sections:

1. Roll the base section into place.

2. Li and level the base by adjusting the four leg levelers, found at each corner, with a screw

driver.

3. Li the middle section and set it on top of the base.

4. Center the middle section over the base and then push the middle section back until it stops.

5. Use the 2" #10 fasteners provided by the manufacturer to screw the middle section to the base

section. Use the pre-drilled holes at the top of each of the four corners of the base section to attach the two sections.

6. Repeat steps 2-5 to attach the top section to the middle section.

Note OSPHD anchoring details available from project manager upon request.

5.1.2 Additional Documentation Station Notes

• e right side of the documentation station is the standard side for the Innity router.

• Stryker provides the back boxes for all the outlets in the documentation station. All electrical

outlets and face plates must be provided and installed by the hospital/Contractor.

• Stryker does not engrave or label circuit IDs on faceplates.

• Use the duplex outlet, in the bottom le cabinet of the documentation station, for the Ethernet/

Comm connection plate. Stryker only supplies the metal back box for this outlet.

• e bottom section is on casters and will easily roll into place. is allows for the electrician to

easily run power to the documentation station before rolling into place.

• ere will be a 1" gap between the base of the cabinet and the nished oor. Stryker recommends coving/ashing up the oor for cleaning purposes.

• Once in place, Stryker recommends sealing or caulking the sides of the documentation station

to the wall.

• e top of the documentation station is a at surface and Stryker does not provide a sot.

• Stryker recommends one circuit to feed the top and middle outlets, one circuit to feed the Innity side of the cabinet, and one circuit for the Power Supply box side of the cabinet.

11

Page 16

S

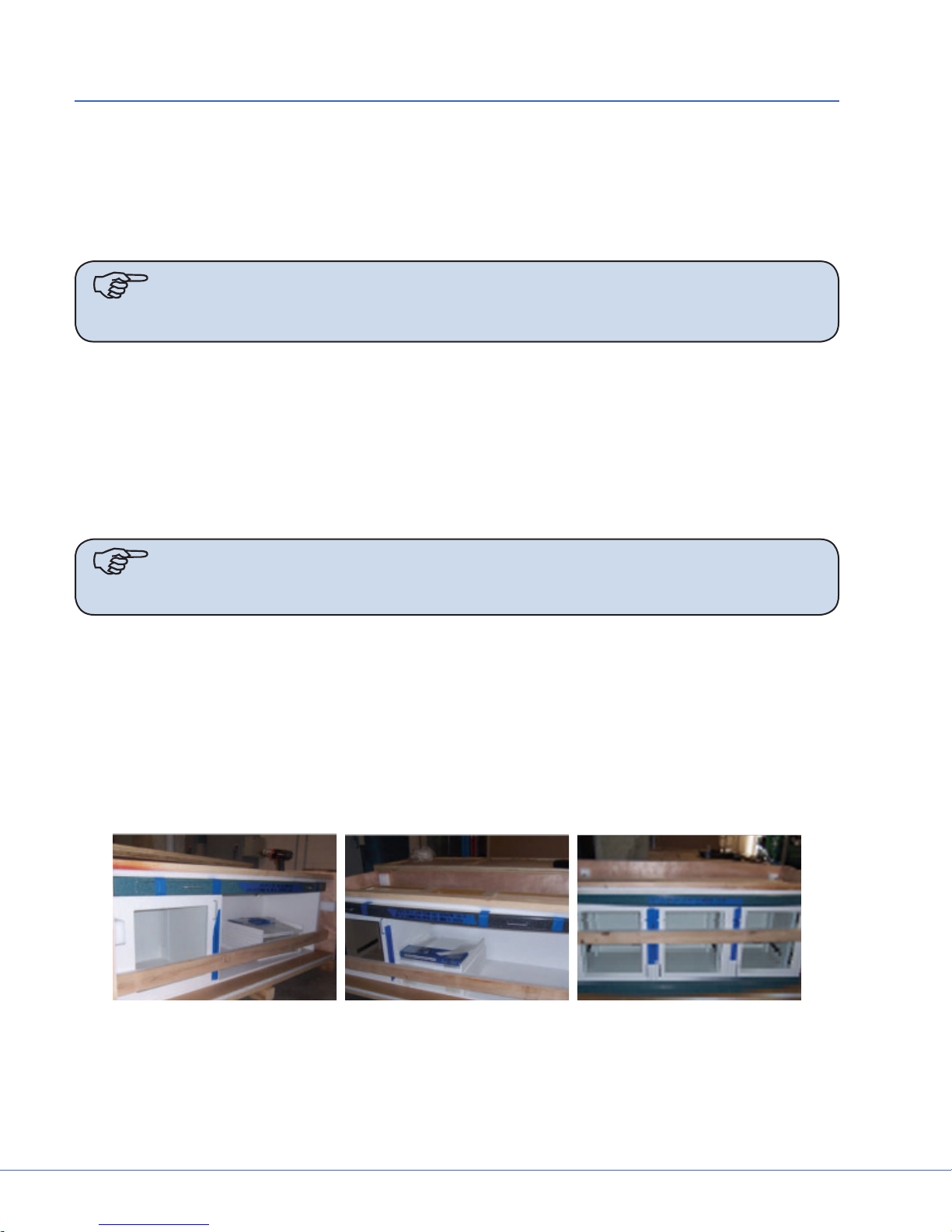

5.1.3 Installing the Documentation Station

Note All conduits should be provided with pull strings and should have minimum

bends or curves. All conduits have a maximum length of 45'. Conduits must have

insulated bushings on all open ends.

Install two (2) Ethernet connections for the SORN (Stryker's Remote Device Management System) and

SDC, respectively. A telephone connection may be desired for a nurse’s phone. Similarly, additional

Ethernet connections may be desired for a Nurses Computer and/or PACS Computer. If local Video

Conferencing via a CODEC is installed, an additional Ethernet connection is required. All additional

telephone/Ethernet connections will be specied by the Hospital.

ONE-BAY DOCUMENTATION STATION (DOC1)

US

Dimensions 25.5"W x 90"H x 30.2"D

Power ree (3) – 20 Amp circuits

• One (1) circuit for quad outlet in lower section.

• One (1) circuit for 2 duplex outlets in lower section.

• One (1) circuit for quad outlet in upper section.

• All documentation station circuits require critical power.

Data Per listed equipment

Backbox Per listed equipment

TWO-BAY DOCUMENTATION STATION (DOC2)

US

Dimensions 48"W x 90"H x 37"D

Power Recommend Six (6) - 20 amp circuits:

• One (1) circuit for quad outlet in lower section behind video router.

• One (1) circuit for quad outlet in lower section behind the light power supply box (if required).

• One (1) circuit for duplex outlet in lower section under touch panel.

• One (1) circuit for quad outlet in middle section behind digital capture device.

• One (1) circuit for quad outlet in upper le section (if required).

• One (1) circuit for quad outlet in upper right section (if required).

• All documentation station circuits require critical power.

Data Per listed equipment

Backbox Per listed equipment

12

Page 17

S

THREE-BAY DOCUMENTATION STATION (DOC3)

US

Dimensions 72"W x 90"H x 37"D

Power Recommend seven (7) - 20 amp circuits

• One (1) circuit for quad outlet in lower section behind video router.

• One (1) circuit for quad outlet in lower section behind light PSB (if required).

• One (1) circuit for duplex outlet in lower section under touch panel.

• One (1) circuit for quad outlet in middle section behind digital capture

device.

• One (1) circuit for quad outlet in upper le section (if required).

• One (1) circuit for quad outlet in upper middle section (if required).

• One (1) circuit for quad outlet in upper right section (if required).

• All documentation station circuits require critical power.

Data Per listed equipment

Backbox Per listed equipment

13

Page 18

S

29.1"

90.0"

66.0"

41.8"

28.0"

21.9"

7.9"

18.0"

15.0"

23.5"

82.8"

28.6"

24.0" 11.4"

12.1"

18.1"

24.0"

10.5"

14.4"

8.8"

4.5"

4.4"

19.1"

19.3"

16.4"16.5"

14.0"

(5X) ELECTRICAL

QUAD

(2X) ELECTRICAL

DUPLEX

CUT-OUT

FLEX

CONDUIT

4"(80mm) x 4"(80mm)

ELECTRICAL

J-BOX

4"(80mm) x 4"(80mm)

ELECTRICAL

J-BOX

18" x 18"

SWITCHPOINT

INFINITY J-BOX

J-BOX (FOR STRYKER

LIGHTS ONLY)

4"(80mm) x 4"(80mm)

ELECTRICAL

J-BOX

4"(80mm) x 4"(80mm)

ELECTRICAL

J-BOX

FLEX

CONDUIT

WALL

ELECTRICAL

DUPLEX

(5X) ELECTRICAL

QUAD

1. THIS DRAWING IS FOR REFERENCE OF CUT-OUT LOCATIONS ONLY. IT IS NOT INTENDED FOR

MANUFACTURING USE.

2. DRAWING DISPLAYS FRONT VIEW OF DOCUMENTATION STATION WITH DOORS OMITTED.

3. PROVIDE AND INSTALL SIX (6) ELECTRICAL QUAD OUTLETS AND SIX (6) DUAL GANG FACE PLATES AS

WELL AS TWO (2) ELECTRICAL DUPLEX OUTLETS WITH TWO (2) SINGLE GANG FACE PLATES INTO THE

ELECTRICAL JUNCTION BOXES PROVIDED.

4. INSTALL AND CONNECT FLUORESCENT LIGHTING FIXTURE IF PROVIDED.

5. PROVIDE AND CONNECT 20 AMP CIRCUITS FOR THE STRYKER DOCUMENTATION STATION FOR EACH

QUAD PLEX OUTLET: ONE (1) 20 AMP CIRCUIT FOR EACH OF THE TWO (2) DUPLEX OUTLETS IN THE

DOCUMENTATION STATION WITH ONE (1) CIRCUIT ALSO POWERING THE FLUORESCENT LIGHTING. IF

INSTALLING STRYKER VISUM LIGHTS, ONE (1) 20 AMP CIRCUIT IS REQUIRED FOR EACH LIGHT POWER

SUPPLY BOX (REFER TO VISUM PRE-INSTALLATION GUIDE FOR LOCATION OF POWER SUPPLY BOX).

POWER SHOULD BE CONNECTED USING CONDUIT FROM THE WALL TO FACILITATE FUTURE ACCESS TO

THE CABLE CHASE IN THE BACK OF THE DOCUMENTATION STATION. ALL STRYKER DOCUMENTATION

STATION CIRCUITS SHOULD BE ON CRITICAL POWER.

SCALE: 1" = 1'

CUTOUT

5X 4.25 X 4.25 CUTOUT

(ELECTRICAL QUAD)

4X 2.5 DIA.

(GROMMET)

SHEET:

NOTES: (UNLESS OTHERWISE SPECIFIED)

1. EQUIPMENT LIST:

Figure 5.4 - Two-Bay Documentation Station

LA

14

Page 19

5. PROVIDE AND CONNECT 20 AMP CIRCUITS FOR THE STRYKER DOCUMENTATION STATION FOR EACH

QUAD PLEX OUTLET: ONE (1) 20 AMP CIRCUIT FOR EACH OF THE TWO (2) DUPLEX OUTLETS IN THE

DOCUMENTATION STATION WITH ONE (1) CIRCUIT ALSO POWERING THE FLUORESCENT LIGHTING. IF

INSTALLING STRYKER VISUM LIGHTS, ONE (1) 20 AMP CIRCUIT IS REQUIRED FOR EACH LIGHT POWER

SUPPLY BOX (REFER TO VISUM PRE-INSTALLATION GUIDE FOR LOCATION OF POWER SUPPLY BOX).

POWER SHOULD BE CONNECTED USING CONDUIT FROM THE WALL TO FACILITATE FUTURE ACCESS TO

THE CABLE CHASE IN THE BACK OF THE DOCUMENTATION STATION. ALL STRYKER DOCUMENTATION

STATION CIRCUITS SHOULD BE ON CRITICAL POWER.

www.stryker.com

A

FLOWER MOUND, TEXAS 75028

1410 LAKESIDE PARKWAY, SUITE 100

PHONE: (877) 789-8106

FAX: (972) 410-7001

SHEET:

B

C

02

02

14.0 X 14.0 CUTOUT

23.8"

16.2"

HARD-PIPED

(BEHIND SHELVES) IF

4.8"7.4"

90.0"

78.5"

6X 4.25 X 4.25 CUTOUT

(ELECTRICAL QUAD)

3X 66.0"

41.8"

28.0"

21.9"

14.0"

S

7.8"

14.0 X 20.0 CUTOUT

21.7"

1.4"

11.2"

5.1"

28.5"

16.3"

4"(80mm) x 4"(80mm)

WALL

4"(80mm) x 4"(80mm)

ELECTRICAL

FLEX

J-BOX

ELECTRICAL

J-BOX

FLEX

6X 2.5 DIA.

CONDUIT

CONDUIT

(GROMMET)

CUTOUT

(DATA / AV)

2.25 X 4.13 CUTOUT

QUAD

(6X) ELECTRICAL

(2X) ELECTRICAL

DUPLEX

ELECTRICAL

DUPLEX

CUT-OUT

18.0"

29.1"

4"(80mm) x 4"(80mm)

J-BOX

ELECTRICAL

15"

SWITCHPOINT

INFINITY J-BOX

18" x 18"

10.0"

Figure 5.5 - ree-Bay Documentation Station

MANUFACTURING USE.

1. THIS DRAWING IS FOR REFERENCE OF CUT-OUT LOCATIONS ONLY. IT IS NOT INTENDED FOR

NOTES: (UNLESS OTHERWISE SPECIFIED)

1. EQUIPMENT LIST:

15

WELL AS TWO (2) ELECTRICAL DUPLEX OUTLETS WITH TWO (2) SINGLE GANG FACE PLATES INTO THE

ELECTRICAL JUNCTION BOXES PROVIDED.

2. DRAWING DISPLAYS FRONT VIEW OF DOCUMENTATION STATION WITH DOORS OMITTED.

4. INSTALL AND CONNECT FLUORESCENT LIGHTING FIXTURE IF PROVIDED.

3. PROVIDE AND INSTALL SIX (6) ELECTRICAL QUAD OUTLETS AND SIX (6) DUAL GANG FACE PLATES AS

DOC STATION CENTER POINT

QUAD

(6X) ELECTRICAL

DATA / AV

CONNECTION

CUT-OUT

J-BOX

ELECTRICAL

4"(80mm) x 4"(80mm)

J-BOX (FOR STRYKER

6"(150mm) X 6"(150mm)

20"

6"

LIGHTS ONLY)

Page 20

S

5.2 Documentation Station (Hospital Provided)

Note All conduits should be provided with pullstrings and have minimum bends or

curves. All conduits have a maximum length of 45' (13.7m). Conduits must have

insulated bushings on all open ends.

e hospital-provided documentation station must allow for the physical dimensions and power requirements for all equipment it is to hold.

CUSTOMER SUPPLIED DOCUMENTATION STATION (DOC4)

Power Recommend four (4) - 20 amp circuits

• One (1) circuit for quad outlet behind video router.

• One (1) circuit for quad outlet behind light PSB (if required).

• One (1) circuit for duplex outlet under touch panel.

• One (1) circuit for quad outlet behind digital capture device.

• All documentation station circuits require critical power.

Space Requirements Doc station must allow for a minimum 2" cable passage between all compo-

nents housed inside.

• Section housing video router must have an interior dimension of at

least 27.5"W x 31"H x 29"D.

• Section housing video router must be vented.

• Doc station must allow for direct access to backboxes per requirements

listed below.

Data Per listed equipment

Backbox Per listed equipment

Install two (2) Ethernet connections for the SORN (Stryker's Remote Device Management System) and

SDC, respectively. A telephone connection may be desired for a nurse's phone. Similarly, additional

Ethernet connections may be desired for a Nurses Computer and/or PACS Computer. If local Video

Conferencing via a CODEC is installed, an additional Ethernet connection is required. All additional

telephone/Ethernet connections will be specied by the Hospital.

5.3 Documentation Station Equipment Requirements

SWITCHPOINT INFINITY 3 (A1)

Dimensions • Media Router: 20.6"W x 24"H x 17"D

• Control Section: 12.5"W x 2.6"H x 17"D

• Total Space Required: 27.5"W x 31"H x 29"D

Data One (1) Ethernet connection

Back Box • One (1) 18"W x 18"H x 4"D (or larger) junction box ush mounted.

• Set bottom of box 9" above nished oor.

• Terminate all integration conduits to this junction box.

16

Page 21

S

SPI3-LITE (A4)

Dimensions • Media Router: 16.4"W x 15.3"H x 17.4"D

• Control Section: 12.5"W x 2.6"H x 17"D

• Total Space Required: 27.5"W x 31"H x 29"D

Data One (1) Ethernet connection

Back Box • One (1) 18"W x 18"H x 4"D (or larger) junction box ush mounted.

• Set bottom of box 9" above nished oor.

• Terminate all integration conduits to this junction box.

SPI3 TOUCH PANEL, 22" (B1)

Dimensions 20.3"W x 15.8"H x 13.5"D with stand

SPI3 TOUCH PANEL, 19" (C)

Dimensions 17.7"W x 15"H x 11.8"D with stand

SWITCHPOINT INFINITY 2 (A2)

Dimensions • Router: 21.0"W x 24.0"H x 22.3"D

• Total space required: 27.5"W x 31"H x 29"D

Data One (1) Ethernet connection

Back Box • One (1) 18"W x 18"H x 4"D (or larger) junction box ush mounted.

• Set bottom of box 9" above nished oor.

• Terminate all integration conduits to this junction box.

SPI2 TOUCH PANEL, 19" (B2)

Dimensions 16.9"W x 15.5"H x 8.2"D with stand

SWITCHPOINT ELEMENT (A3)

Dimensions • Video Router: 12.5"W x 10"H x 15"D

• Control System: 12.5"W x 2"H x 15"D

• Total Space Required: 27.5"W x 31"H x 29"D

Data One (1) Ethernet connection

Back Box • One (1) 18"W x 18"H x 4"D (or larger) junction box ush mounted.

• Set bottom of box 9" above nished oor.

• Terminate all integration conduits to this junction box.

SPE TOUCH PANEL, 12" (B3)

Dimensions 11.9"W x 11.3"H x 6.6"D with stand

SUITESTREAM CODEC (D)

Dimensions 12.7"W x 2.6"H x 17.3"D

17

Page 22

S

Data • Two (2) Ethernet connections

• Please refer to Stryker ConnectSuite Pre-Install document,

SOP0304.08 for specic network requirements..

SDC ULTRA (F)

Dimensions 12.5"W x 7"H x 16.2"D

Data One (1) Ethernet connection

SDP1000 PRINTER (H)

Dimensions 12.5"W x 8.2"H x 16.7"D

SIDNE (I)

Dimensions 12.6"W X 4.5"H X 16.2"D

WISE TRANSMITTER (J)

Dimensions 12.5"W X 3.3"H X 15.2"D

NAVIGATION PC (K)

Dimensions 17"W X 20"H X 24"D

Data One (1) Ethernet connection

HD CODEC (L)

Dimensions 5.1"W X 13.9"H X 11"D

Data • One (1) Ethernet connection

• Please consult project manager if ISDN is utilized

SD CODEC (L1)

Dimensions 19.5"W X 2"H X 12"D

Data One (1) Ethernet connection

Please consult project manager if ISDN is utilized

WIRELESS MICROPHONE RECEIVER (M)

Dimensions 8.3"W X 1.93"H X 7.2"D

VISUM HALOGEN POWER SUPPLY BOX (N)

Dimensions • PSB: 17.8"W X 6"H X 15.8"D

• Total Space Required: 20"W X 9"H X 21"D

Back Box • One (1) 6"W x 6"H x 4"D (or larger) junction box ush mounted.

• Set bottom of box 14" above nished oor.

• Terminate all surgical light conduits to this junction box

18

Page 23

S

VISUM LED POWER SUPPLY BOX (N1)

Dimensions • PSB: 12.5"W X 7"H X 15.5"D

• Total Space Required: 20"W X 9"H X 21"D

Back Box • One (1) 6"W x 6"H x 4"D (or larger) junction box ush mounted.

• Set bottom of box 14" above nished oor.

• Terminate all surgical light conduits to this junction box

5.4 iSuite Equipment Integration Notes

Note All conduit runs include insulated bushings and pull strings.

Note Conduit runs cannot exceed 50' from end-to-end. Do not exceed four (4) 90 de-

gree bends.

5.4.1 Wall Mounted 46" or 55" LCD Monitor or 42" TouchPanel

Conduit One (1) 1 1/4" conduit

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Mounted directly above the top of the mounting bracket.

Power One (1) standard duplex outlet mounted adjacent to junction box

Structural • Customer/Contractor to mount Stryker provided bracket to the wall in the de-

sired location with proper reinforcement to support the monitor prior to Stryker

installation.

• Stryker Project Manager will provide mounting specications.

ITEM-ITEM QTY SIZE

WMM – A

5.4.2 Wall/Ceiling Mounted Room Status Camera (WRC, CRC)

1

1 1/4"

LA

Conduit One (1) ¾" conduit terminated at nearest corridor cable tray

Back Box • 4"W x 4"H junction box with single-gang mud ring

• Flush mounted at 12" below nished ceiling (wall mounted only)

Power None

Cabling • One (1) power cable and one (1) video cable

• One (1) Belden 8723 / 88723 (maximum 1000')

• One (1) Belden 8241 / 88241 (maximum 1000')

• Cables require 15' service loop at both ends

Note All Status System cabling must be provided and pulled by the Hospital/Contrac-

tor prior to Stryker Installation.

19

Page 24

S

ITEM-ITEM QTY SIZE

WRC/CRC – *

5.4.3 Wall Plates

Conduit One (1) ½" conduit

Back Box • 4"W x 4"H junction box with single-gang mud ring

Power None required, but should be located next to outlet

ITEM-ITEM QTY SIZE

Copper DVI (CDP) – A

VGA/S-Video/BNC (TRP) - A

Pass-rough (PTP) - A

Fiber Optical DVI - A

1

¾"

• 4"W x 4"H junction box with dual-gang mud ring (Fiber optical DVI only)

• Mounted 18" above nished oor.

1

1 ½"

1 1"

1 1"

1 1"

5.4.4 Observation Room Touch Panel, Microphone and Speaker (OBS)

LA

Conduit One (1) 1" conduit terminated

Cabling For runs over 50', Hospital/Contractor provides the following:

• Two (2) Belden 8723 / 88723 (maximum 1000')

• One (1) CAT6 cable (maximum 328')

• Cables require 15' service loop at both ends

• Cabling provided and pulled by Hospital/Contractor before Stryker installation

Back Box • 4"W x 4"H junction box with single-gang mud ring

• Mounted within 18" of touch panel location

Power One (1) standard outlet within 18" of touch panel location

ITEM-ITEM QTY SIZE

OBS – A

1

1"

5.4.5 Cable Run to Video Network Hub (HRN)

Conduit One (1) 2" conduit terminated at nearest corridor cable tray.

Cabling • Four (4) Belden 8241/88241 or equivalent (maximum 1000' - consult Project Man-

ager for runs over 1000')

• Two (2) Belden 8723 / 88723 or equivalent (maximum 1000' - consult Project Manager for runs over 1000')

• One (1) CAT6 cable (maximum 328' - consult Project Manager for runs over 328'))

• Cables require 15' service loop at both ends

• Hub cabling provided and pulled by Hospital/Contractor before Stryker installation

ITEM-ITEM QTY SIZE

HRN – *

20

1

2"

Page 25

S

5.4.6 Equipment Boom Cable Kit (Brand) (EQB)

Cabling All cabinets within the boom must be pulled by Hospital/Contractor if not already

pulled by boom manufacturer

Conduit Terminated within 18" of the center of the ceiling mount

Power Per boom manufacturer specications

Plumbing Per boom manufacturer specications

Access Panel One (1) 24" x 24" access panel adjacent to suspension

Structural Per boom manufacturer specications

ITEM-ITEM QTY SIZE

EQB – A

5.4.7 Anesthesia Boom Cable Kit (Brand) (ANB)

Cabling All cables within the boom must be pulled by Hospital/Contractor if not already

Conduit Terminated within 18" of the center of the ceiling mount

Power Per boom manufacturer specications

Plumbing Per boom manufacturer specications

2

pulled by boom manufacturer

2"

Access Panel One (1) 24" x 24" access panel adjacent to suspension

Structural Per boom manufacturer specications

ITEM-ITEM QTY SIZE

ANB – A

1

2"

5.4.8 Navigation Arm (NAM)

Conduit Terminated to 10" x 10" x 4" NEMA type 1 box within 18" of the center of the ceiling

mount.

Power No additional power required.

Access Panel One (1) 24" x 24" access panel adjacent to suspension

Structural • Optimal location for center of Navigation camera is 47" above nished oor.

• Stryker preinstall plate is installed per customer structural engineer specs at 4"

above nished ceiling.

• A 21" circular hole centered on Stryker preinstall plate in the nished ceiling is

required for installation. A 24" diameter ceiling cover conceals hole aer suspension is installed.

• e Contractor/electrician to hardwire Stryker electrical whip during Stryker

installation.

• Load location: X=31", Y=45"

• Maximum deection: 1 degree

ITEM-ITEM QTY SIZE

NAM – A

21

1

2"

Page 26

S

5.4.9 Stryker Single Flat Panel Arm Cable Kit

Conduit One (1) 2" (50mm) conduit terminated with insulated bushings within 18" (450mm)

of the center of the ceiling mount. is conduit must be accessible from the access

panel and terminated in a horizontal orientation. Pull strings should be provided.

Power One (1) - 20 AMP circuit located at junction box within 18" of center of Stryker pre-

install plate. Hospital/Contractor should hardwire during installation.

Access Panel One (1) 24" x 24" access panel adjacent to suspension

5.4.10 Stryker Dual Flat Panel Arm Cable

Conduit One (1) 2" (50mm) conduit terminated with insulated bushings within 18" (450mm)

of the center of the ceiling mount. is conduit must be accessible from the access

panel and terminated in a horizontal orientation. Pull strings should be provided.

Power One (1) - 20 AMP circuit located at junction box within 18" of center of Stryker pre-

install plate. Hospital/Contractor should hardwire during installation.

Access Panel One (1) 24" x 24" (610mm x 610mm) access panel adjacent to suspension

5.4.11 Single Flat Panel Arm Cable Kit (Non-Stryker Flat Panel Arm) (NAM)

Conduit Two (2) 2" (50mm) conduit terminated with insulated bushings within 18" (450mm)

of the center of the ceiling mount. is conduit must be accessible from the access

panel and terminated in a horizontal orientation. Pull strings should be provided.

Power Two (2) - 20 AMP circuit located at junction box within 18" of center of Stryker pre-

install plate. Hospital/Contractor should hardwire during installation.

Access Panel One (1) 24" x 24" (610mm x 610mm) access panel adjacent to suspension

5.4.12 Dual Flat Panel Arm Cable Kit (Non-Stryker Flat Panel Arm)

Conduit Two (2) 2" (50mm) conduit terminated with insulated bushings within 18" (450mm)

of the center of the ceiling mount. is conduit must be accessible from the access

panel and terminated in a horizontal orientation. Pull strings should be provided.

Power Two (2) - 20 AMP circuit located at junction box within 18" of center of Stryker pre-

install plate. Hospital/Contractor should hardwire during installation.

Access Panel One (1) 24" x 24" (610mm x 610mm) access panel adjacent to suspension

22

Page 27

S

6. Innity Based Conference System (IBC) Rooms

LA

Note All cabling must be provided and pulled by Hospital/Contractor prior to Stryker's

arrival.

IBC's are most oen installed in auditoriums, classrooms, and large conference rooms. e IBC can be

installed in a variety of places. e control system can either sit in a closet or in the back of the room.

A podium is recommend to accommodate the IBC Touch Panel and cable runs to the control system.

6.1 SPI3 Customer Supplied Casework (SCW)

Data Per listed equipment

Back Box Per listed equipment

Power Recommended two (2) - 20 amp circuits:

• One (1) circuit for quad outlet behind video router

• One (1) circuit for quad outlet behind support equipment

Space

Requirements

• Casework must allow for a minimum 2" cable passage between all components housed inside.

• Section housing video router must have an interior dimension of at least

27.5"W X 31"H X 29"D.

• Section housing video router must be vented.

• Must allow for direct access to backboxes per requirements listed below.

6.2 IBC Unit with Tower (ICW1)

LA

Dimensions 27.5"W X 65"H X 30"D

Data One (1) Ethernet connection

Back Box • One(1) 18"W X 18"H X 4"D (minimum) junction box ush mounted.

• Set bottom of the box 9" above nished oor within the footprint of the tower.

• Terminate all integration conduits to this junction box.

• Hospital/Contractors will provide and pull all cables.

Power One (1) - 20 AMP circuit for quad outlet behind the tower.

6.3 IBC Unit with Stryker Credenza (ICW2)

LA

Data One (1) Ethernet connection

Back Box • One(1) 18"W X 18"H X 4"D (minimum) junction box ush mounted.

• Set bottom of the box 9" above nished oor within the foot print of the tower.

• Terminate all integration conduits to this junction box.

• Hospital/Contractor will provide and pull all cables.

Power One (1) - 20 amp circuit for quad outlet behind the tower.

Note Customer/Contractor responsible for receiving and installing Credenza prior to

Stryker installation.

23

Page 28

S

6.4 IBC with Customer Supplied Casework (ICW3)

LA

Data Per listed equipment

Back Box • One(1) 18"W X 18"H X 4"D (minimum) junction box ush mounted.

• Set bottom of the box 9" above nished oor within the foot print of the tower.

• Terminate all integration conduits to this junction box.

• Hospital/Contractor will provide and pull all cables.

Power • One (1) - 20 amp circuit for outlets behind video router.

• One (1) - 20 amp circuit for quad outlet behind casework.

Space

Requirements

• Must allow for a minimum 2" cable passage between all components housed

inside.

• Section housing video router must have an interior dimension of at least

27.5"W X 31"H X 29"D.

• Section housing the video router must be vented.

• Must allow for direct access to backboxes per requirements listed below.

Note Customer/Contractor responsible for installation of casework prior to Stryker

installation.

6.5 Casework Equipment

6.5.1 SwitchPoint Innity 2 (A2)

Dimensions • Router 19.5"W X 28.5"H X 23"D

• Total Space Required: 27.5"W X 31"H X 29"D

Data One (1) Ethernet connection

Back Box • One(1) 18"W X 18"H X 4"D (minimum) junction box ush mounted.

• Set bottom of the box 9" above nished oor.

• Terminate all integration conduits to this junction box.

Power One (1) standard outlet within 3'.

6.5.2 SPI2 Touch Panel, 19" (B2)

Dimensions 16.9"W X 15.5"H X 8.2"D with stand

Power One (1) standard outlet within 3'

6.5.3 Wireless Microphone Receiver (M)

Dimensions 8.3"W X 1.93"H X 7.2"D

Power One (1) standard outlet within 3'

LA

24

Page 29

6.5.4 SD CODEC (L1)

Dimensions 19.5"W X 2"H X 12"D

Data • One (1) Ethernet connection

• Please consult Project Manager if ISDN is utilized.

Power One (1) standard outlet within 3'

S

6.6 IBC Podium with Touch Panel

LA

Note Customer/Contractor responsible for installation of podium prior to Stryker

installation.

Dimensions 32"W X 46"H X 24.3"D

Cabling • Cables provided by the Hospital/Contractor for runs over 50'.

• Cables pulled by the Hospital/Contractor.

• Leave a 15' (4.5m) service loop at each end for terminations.

• Cable Specications: Cables may vary depending on conference room congurations. Please consult Project Manager for site specic requirements:

• Touch Panel:

º One (1) Belden 8723 or equivalent (maximum 1000')

º One (1) Extron MHR5 or equivalent (maximum 150')

• Laptop Connection:

º One (1) Belden 8723 or equivalent (maximum 1000')

º One (1) Extron MHR5 or equivalent (maximum 150')

• PC Connection:

º One (1) Belden 8723 or equivalent (maximum 1000')

º One (1) Extron MHR5 or equivalent (maximum 150')

• Podium Microphone

º One (1) Belden 8723 or equivalent (maximum 1000')

• Network

º Two (2) CAT6 cables (maximum 328')

Conduit Two (2) 2" conduits

Back Box • 12"W X 12"H junction box

• Flush mounted in the oor under the podium

Power • One (1) standard outlet

• Flush mounted in the oor beneath podium adjacent or within 12" X 12" junction box

ITEM-ITEM QTY SIZE

IPD – ICW

25

2

2"

Page 30

S

7. Level Systems Room

Note All cabling must be provided and pulled by Hospital/Contractor prior to Stryker's

arrival.

Level System's are most oen installed in integrated doctor's oces, small conference rooms, and

pathology or nuclear medicine labs. is control system is placed in a cabinet next to or in the room's

cabinetry or desk. Cable passage must be allowed to the junction box for all equipment placed on the

desk or in the cabinetry.

7.1 Customer Supplied Casework (CSC)

Data Per listed equipment

Back Box Per listed equipment

Power One (1) - 20 amo circuit for outlets behind video router

Space

Requirements

• Must allow for a minimum 2" cable passage between all components housed

inside.

• Section housing video router must have an interior dimension of at least 21"W

X 16"H X 22"D

• Section housing router must be vented.

• Must allow for direct access to back boxes per requirements listed below.

Note Customer/Contractor responsible for installation of casework prior to Stryker

installation.

7.2 Casework Equipment

7.2.1 Level One System (S1)

Dimensions 20.5"W X 8.5"H X 16"D

Data None

Back Box • One (1) 6"W X 6"H X 4"D (minimum) junction box ush mounted at

same height as Level System

• Terminate all integration conduits to this junction box

Power One (1) duplex outlet next to junction box

7.2.2 Level Two System (S2)

Dimensions 20.5"W X 14"H X 19"D

Data None

Back Box • One(1) 12"W X 12"H X 4"D (minimum) junction box ush mounted at

same height as Level System

• Terminate all integration conduits to this junction box

Power One (1) duplex outlet next to junction box

LA

LA

26

Page 31

7.2.3 Level System Touch Panel (T)

Dimensions • Touch Panel: 11.9"W X 11.3"H X 6.6"D

• Touch Panel Interface: 19"W X 2"H X 11"D

Power One (1) duplex outlet

7.3 Remote Level System Touch Panel (LTP)

Dimensions • Touch Panel: 11.9"W X 11.3"H X 6.6"D

• Touch Panel Interface: 19"W X 2"H X 11"D

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) services loop at each end for terminations

• Cable Specications:

º ree (3) Belden 8723 or equivalent (maximum 1000')

º One (1) Belden 8241 or equivalent (maximum 1000')

Conduit One (1) 1" conduit

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Mounted within 18" of touch panel location

Power One (1) standard outlet within 18" of touch panel location

S

ITEM-ITEM QTY SIZE

LTP – S

1

1"

27

Page 32

S

8. Equipment Integration Notes

8.1 Wall Mounted 46" or 55" LCD Monitor, or 42" Touch Panel

Dimensions • 46" Monitor: 41.6" X 24.0" X 4.1" (1055.4 x 608.6 x 103mm)

• 55" Monitor: 51.9" X 30.5" X 4.7" (1317.8 x 775.8 x 118.9mm)

• 42" Touch Panel: 40.2" X 24.1" X 5.2" (1020 x 132 x 613mm)

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Mounted directly above the top of the mounting bracket

Power One (1) standard duplex outlet mounted adjacent to the junction box

Structural • Customer/Contractor to mount Stryker provided bracket to the wall in the

desired location with proper reinforcement to support the monitor

• Stryker Project Manager will provide mounting specications

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) service loop at each end for terminations

LA

8.1.1 SPI3 Cable Specications

• One (1) Belden 8723 or equivalent (maximum 1000')

• One (1) - Four (4) strand, multimode ber optic cable

º Quantity of bers within cable - four (4)

º LC Connectors on each end

º 50/125 Micron

ITEM-ITEM QTY SIZE

3WM – A

1

1 1/4"

8.1.2 SPI3 42” Touch Panel Cable Specications

• One (1) Extron MHR5 or equivalent (maximum 150')

• One (1) Cat5, Cat5E, or Cat6 network cable (maximum 150')

ITEM-ITEM QTY SIZE

3WM – A

8.1.3 IBC Cable Specications

• One (1) Belden 8723 or equivalent (maximum 1000')

• One (1) Extron MHR2 or equivalent (maximum 150')

• One (1) Extron MHR5 or equivalent (maximum 150')

ITEM-ITEM QTY SIZE

IWM – ICW

1

1

1 1/4"

LA

1 1/4"

28

Page 33

S

8.1.4 Level System Cable Specications

• One (1) Belden 8723 or equivalent (maximum 1000')

• One (1) Belden 8241 or equivalent (maximum 1000')

ITEM-ITEM QTY SIZE

LWM – S

8.2 Motorized Projection Screen (MPS)

Conduit One (1) 3/4" conduit

Back Box Junction box is located in le end cap of assembly

Power • Customer/Contractor to hardwire to standard electrical circuit prior to Stryker

Structural • Customer/Contractor to mount Stryker provided bracket to the wall in the

1

• Installation instructions included with assembly

• Stryker Project Manager will provide mounting specications

1"

installation

desired location with proper reinforcement to support the monitor

8.3 Motorized Projection Screen Wall Switch (SWS)

Conduit One (1) 3/4" conduit

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Flush mounted at standard light switch height

Power • Customer/Contractor to hardwire to standard electrical circuit prior to Stryker

installation

• Installation instructions included with assembly

ITEM-ITEM QTY SIZE

MPS – SWS

1

3/4"

8.4 Ceiling Mounted Projector

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' service loop at each end for terminations

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Mounted 12" (minimum) behind projector mounting bracket

Power One (1) standard duplex outlet ceiling mounted adjacent to junction box

Structural • Customer/Contractor to mount Stryker provided bracket to the ceiling in the

designated location with proper reinforcement to support the projector prior

to Stryker installation

• Stryker Project Manager will provide mounting specications

8.4.1 SPI3 Cable Specications

• One (1) Belden 8723 or equivalent (maximum 1000')

29

Page 34

S

• One (1) Extron MHR5 or equivalent (maximum 150')

• One (1) - Four (4) strand, multimode ber optic cable

º Quantity of bers within cable - Four (4)

º LC Connectors on each end

º 50/125 Micron

ITEM-ITEM QTY SIZE

3PR – A

8.4.2 IBC Cable Specications

• One (1) Belden 8723 or equivalent (maximum 1000')

• One (1) Extron MHR5 or equivalent (maximum 150')

• One (1) Extron MHR5 or equivalent (maximum 150')

ITEM-ITEM QTY SIZE

IPR – ICW

8.4.3 Level System Cable Specications

1

1

1 1/4"

1 1/4"

• One (1) Belden 8723 or equivalent (maximum 1000')

• One (1) Belden 8241 or equivalent (maximum 1000')

ITEM-ITEM QTY SIZE

LPR – S

1

1"

8.5 Bracket Mounted Wall /Ceiling Speaker

Conduit One (1) 3/4" conduit

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) service loop at each end for terminations

• Cable Specications:

º One (1) Belden 8723 or equivalent (maximum 1000')

Back Box • 4"W X 4"H junction box with single-gang mud ring.

• Mounted 12" (minimum) behind projector mounting bracket (wall mounted

only)

• Flush Mounted in ceiling (ceiling mounted only)

Power None

ITEM-ITEM QTY SIZE

3WS/3CS – A (SPI3)

IWS/ICS – ICW (IBC)

30

1

1

3/4"

3/4"

Page 35

S

8.6 Flush Mounted Rectangular Wall/Ceiling Speaker

Conduit One (1) 3/4" conduit terminated 2" above speaker cutout

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) service loop at each end for terminations

• Cable Specications:

º One (1) Belden 8723 or equivalent (maximum 1000')

Power None

Structural • Customer/Contractor to cut one 7 1/4"W X 10 3/4"L (template supplied with

speaker) in the wall at each speaker mounting location. Fits into a standard 2"

X 4" wall (wall mounted only)

• Minimum 4" ceiling clearance (ceiling mounted only)

ITEM-ITEM QTY SIZE

3RW/3RC – A (SPI3)

IRW/IRC – ICW (IBC)

1

1

3/4"

3/4"

8.7 Flush Mounted Circular Ceiling Speaker

Conduit One (1) 3/4" conduit terminated 6" above speaker cutout

Cabling • Cables provided by the Hospital/Contractor for runs over 50'.

• Cables pulled by the Hospital/Contractor.

• Leave a 15' (4.5m) service loop at each end for terminations.

• Cable Specications:

º One (1) Belden 8723 or equivalent (maximum 1000')

Power None

Structural • Customer/Contractor to cut one 10 3/4" diameter circle at speaker mounting

location

• Outer diameter dimension is 13.4"

• Minimum 4" ceiling clearance

ITEM-ITEM QTY SIZE

3CC – A (SPI3)

ICC – ICW (IBC)

8.8 Wall/Ceiling Mounted Pan/Tilt/Zoom Camera

1

1

3/4"

3/4"

LA

Conduit One (1) 1" conduit

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) service loop at each end for terminations

• Cable Specications:

º Two (2) Belden 8723 or equivalent (maximum 150')

º One (1) Extron MHR2 or equivalent (maximum 150')

31

Page 36

S

Back Box • 4"W X 4"H junction box with dual-gang mud ring

• Flush mounted in wall 12" below nished ceiling (wall mounted only)

• Flush mounted in ceiling (ceiling mounted only)

Power None

ITEM-ITEM QTY SIZE

3WP/3CP – A (SPI3)

IWP/ ICP – ICW (IBC)

1

1

1"

1"

8.9 Wall/Ceiling Mounted HD Pan/Tilt/Zoom Camera

LA

Conduit One (1) 1" conduit

Cabling • Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) service loop at each end for terminations

• Cables provided by Stryker (max length 50')

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Flush mounted in wall 12" below nished ceiling (wall mounted only)

• Flush mounted in ceiling (ceiling mounted only)

Power None

ITEM-ITEM QTY SIZE

3HW/3HC – A

8.10 Echo Canceling Microphone with Internal Speaker

1

1"

LA

Conduit One (1) 1" conduit

Cabling • Cables provided by the Hospital/Contractor for runs over 50'.

• Cables pulled by the Hospital/Contractor.

• Leave a 15' (4.5m) service loop at each end for terminations.

• Cable Specications:

º Four (4) Belden 8723 or equivalent (maximum 1000')

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Mounted in desired location near microphone

Power One (1) standard outlet within 18" of touch panel location.

ITEM-ITEM QTY SIZE

3EM – A (SPI3)

IEM – ICW (IBC)

LEM – S (Level)

32

1

1

1

1"

1"

1"

Page 37

8.11 Ceiling Mounted Microphone

Conduit One (1) 3/4" conduit

Cabling • Cables provided by the Hospital/Contractor for runs over 50'

• Cables pulled by the Hospital/Contractor

• Leave a 15' (4.5m) service loop at each end for terminations

• Cable Specications:

º One (1) Belden 8723 or equivalent (maximum 1000')

Back Box • 4"W X 4"H junction box with single-gang mud ring

• Flush mounted in desired location

Power None

ITEM-ITEM QTY SIZE

3CM – A (SPI3)

ICM – ICW (IBC)

1

1

3/4"

3/4"

8.12 Lutron Controller (LTC)

Conduit One (1) 1" conduit

Back Box Per Manufacturer

Power Per Manufacturer

S

Note e Stryker Innity Router is compatible with Grak Eye 3000/4000 Systems.

ITEM-ITEM QTY SIZE

LTC – A

1

1"

8.13 Lutron Lighting Control Integration Series

Conduit Cabling must run from the IBC to the Lutron Controller. Conduit determined by

Hospital/Contractor.

Cabling • Cables provided by the Hospital/Contractor for runs over 50'.

• Cables pulled by the Hospital/Contractor.

• Leave a 15' (4.5m) service loop at each end for terminations.

• Cable Specications:

º One (1) Belden 8723, 88723 or equivalent

Power None

8.14 Outside the OR Touch Panel, Keyboard, Mouse for SPI3

Conduit Cabling must run from the SPI3 to the Touch Panel, Keyboard, Mouse and/or

PC(s). One 2"(50mm) conduit is recommended. Conduit to be determined by

Hospital/Contractor.

33

Page 38

S

Cabling Any cable runs outside of the Operating Room or over 50’, unless other wise

specied, are the responsibility of the Hospital/Contractor to source, supply, pull

and install.

Cable Specications: Four (4) strand, multimode rugged ber optic DVI cable or

equivalent. Number of cables dependent on number of devices being set up.

Power One (1) standard outlet within 18" of touch panel, Keyboard/Mouse location and

each PC.

ree (3) standard outlets or Two (2) standard duplex outlet mounted adjacent to

the SPI3.

34

Page 39

S

9. ConnectSuite

Note Refer to Stryker ConnectSuite Pre-Install document, for specic requirements.

ConnectSuite is Stryker’s new IP video teleconferencing platform that replaces the previous generation

Video Hub 2 (VH2). ConnectSuite is compatible with only SPI3 routers at this time. Its advantages

are that rather than running over baseband cable like the VH2, it enables OR-integrated calls over the

customer’s existing network and it also has the optional SuiteView component, which allows customer

computers to view into room endpoints concurrent with room to room calls.

SuiteLink is always required in every installation; it is like the new “hub,” which coordinates calls and

keeps track of room status. SuiteStream is the codec that must be installed into every room that wants

to stream calls. SuiteView is completely optional soware that is installed on the SuiteLink server

AND on customer computers to enable the desktop view function. e Osite Package is an optional

component needed if the customer wants to make calls to other facilities with 3rd party codecs such as

Polycom Codecs or Polycom H.323 room-conferencing systems.

e ConnectSuite Pre-Install document is required to be lled out and returned prior to scheduling

installation. e product has strict customer network requirements. All requirements are NOT listed

in this document.

9.1 SuiteStream

Note

Dimensions 12.7”W x 2.6”H x 17.3”D

Data Two (2) Ethernet drops at each SuiteStream location.

SuiteStream cannot be installed on an SPI3 endpoint in parallel with a local HD

codec (Polycom).

Two SuiteStreams in one OR would require 4 Ethernet drops.

9.2 SuiteLink/SuiteView

Note Server is racked in a customer provided-rack, any location with network access is

acceptable.

Dimensions 17.32”W x 1.75”(1U)H x 22”D

Data One (1) drop at its location.

9.3 Osite Package

Note Osite Package is racked in a customer-provided rack adjacent to the SuiteLink

server.

Dimensions 13”W x 5.6”(4U)H x 17.3”D

Data ree (3) drops each at SuiteLink server location. Internet connectivity on

one drop is required.

Two osite packages would require six (6) Ethernet drops.

35

Page 40

S

10. Status Systems

LA

10.1 Operating Room Status Systems

e Room Status System combines the Fixed OR Status Camera video signals from separate rooms

into one display located at the OR Control Desk. All video, touch panel control, and power cables are

run to a central location, usually the Video Network Hub or IT/storage closet. is section describes

site preparation requirements necessary prior to the installation phase of the OR Status System.

Note All cabling will be provided and pulled by the Hospital/Contractor prior to

Stryker's arrival.

10.1.1 Partial Floor and Elevation Drawings

Figure 10.1 - Partial Overhead View—Room Status System

36

Page 41

S

10.1.2 Site Preparation Requirements

e following provide instructions that must be completed before installation.

10.1.2.1 Status System Controller

Each Status System Controller can support up to sixteen (16) cameras. If there is a Video Network

Hub, the Status System Controller will sit on top of it and will be powered through the Hub. is controller will be operated by the touch panel.

Rough-in and cabling

One (1) 12" x 4" (300mm x 100mm) wall mounted cable chase from ceiling to 36" (1m) above the

nished oor for cabling to each Fixed OR Status Camera. Leave up to 15' (4.5m) of cable on both ends

of cable runs for Stryker Technician termination and cable management. If any of the cables exceed the

maximum length specied, please consult your Project Manager for necessary amplication/transmission equipment.

Power

is controller will plug into an outlet on the video network hub. If a hub is not present, one (1) standard electrical outlet is required.

10.1.2.2 Status Camera Power Supply

Each Camera Power Supply can support up to eight (8) cameras. e number of Camera Power Supplies depends upon the number of Fixed OR Status Cameras. Please consult the Project Manager if it is

unclear as to the number of Camera Power Supplies the site must be prepared for.

Rough-in and cabling

Hospital/Contractor must install this power supply (usually in the ceiling above the Video Network

Hub) and will wire the cameras into the power supply. If a hub is not present, the placement of the

power supply box is at the Hospital's discretion.

Power

Hospital/Contractor must hard-wire this power supply to the 120V/60Hz Hospital power.

10.1.2.3 Wall/Ceiling Mounted Fixed Room Status Camera (WRC, CRC)

LA

Conduit One (1) ¾" conduit terminated at nearest corridor cable tray

Back Box • 4"W x 4"H junction box with single-gang mud ring

• Flush mounted at 12" below nished ceiling (wall mounted only)

Power None

Cabling • One (1) power cable and one (1) video cable

• One (1) Belden 8723 / 88723 (maximum 1000')

• One (1) Belden 8241 / 88241 (maximum 1000')

• Cables require 15' service loop at both ends

Note All Status System cabling must be provided and pulled by the Hospital/Contrac-

tor prior to Stryker Installation.

37

Page 42

S

ITEM-ITEM QTY SIZE

WRC/CRC – *

10.1.2.4 Touchpanel

Conduit e control cable must be run to the touchpanel location with a 15' (4.5m) service loop.

Power One (1) electrical wall outlet adjacent to the empty junction box.

Cabling One (1) Belden 8723 or 88723 cable from the junction box to the controller (maximum

10.1.2.5 All Displays

Conduit e signal cable must be run from the system controller to a double gang junction

Structural Hospital/Contractor to mount the Stryker provided mounting bracket to the wall (for

Power One (1) standard electrical outlet mounted adjacent to the empty junction box. (See

Cabling One (1) Belden 8241 or 88241 (or equivalent) from the display to the controller (maxi-

1

Conduit required to pull the cables listed below will be determined by the Hospital/

Contractor.

300' [91.5m])

box with single gang mud ring ush mounted in the wall directly above the mounting bracket with a 15' (4.5m) service loop. Conduit required to accomplish this will be

determined by the Hospital/Contractor.

40" LCD option) in the desired location with proper reinforcement to support the correct display before Stryker installation. e mounting bracket and instructions will be

delivered with the LCD. (See Appendix A for equipment weight, power, and dimension

specications.)

Appendix A for power consumption.)

mum 1000' [305m])

¾"

10.2 SuiteStatus Systems

e SuiteStatus System combines the Fixed, IP Camera video signals from separate rooms into one

display located at the OR Control Desk. All video feeds will be sent over a provided network, using the

Internet Protocol standard, and are accessible from up to three All-In-One Computer Systems. is

section describes site preparation requirements necessary prior to the installation phase of the SuiteStatus System.

Note All networking requirements should be met prior to Stryker’s arrival for installa-

tion.

38

Page 43

S

Figure 11.12- - Basic Network Diagram

10.3 Site Preparation Requirements

e following provide instructions that must be completed before installation.

10.3.1 SuiteStatus System

Each SuiteStatus System can support up to sixty-four (64) cameras and three (3) All-In-One Viewing

Systems. Each All-In-One Viewing System and SuiteStatus camera must reside on the same network

with one CAT-5e (or above) Ethernet cable connection at each device.

10.3.2 Power

e All-In-One Viewing System(s) must have one (1) standard electrical outlet available. Each SuiteStatus camera must have one (1) standard electrical outlet (12V DC outlet) or Power-over-Ethernet

(PoE) connection that is located where the camera will reside.

10.3.3 Mounts

A wall or ceiling mount is required when installing a camera; therefore, the number of mounts must

match the total number of cameras. Please consult with the Project Manager if there is a discrepancy.

e ceiling mount will require a 184mm diameter circle in the ceiling where the camera will reside.

e wall mount will require 3, 5/16” holes to be drilled into the wall. Plastic dowels will be included

with each camera to ll these holes. For both mounts, ensure that an Ethernet cable extends to the

mount to supply the camera with network and/or power connectivity.

10.3.4 External Display

External displays are available for purchase to duplicate the screen of the All-In-One Viewing System.

Consult with the Project Manager and/or Engineer to ensure the correct parts are on order.

39

Page 44

S

Conduit One 2” conduit terminated by All-In-One Viewing system, as converter and cable will

extend from system to external display.

Power One (1) standard electrical outlet available for external display(s).

Note All SuiteStatus cabling must be provided and pulled by the Hospital/Contractor

prior to Stryker Installation.

40

Page 45

S

Appendix A: PRI Provisioning Instructions and Form

ORIS PRI Provisioning Instructions