Page 1

MX-PRO® R3

Model 6082

Operations/Maintenance Manual

For parts or technical assistance:

USA: 1-800-327-0770

2010/06 6082-109-005 REV A www.stryker.com

Page 2

6082

Model 6082 MX--PROt Ambulance Cot

Modèle 6082 MX--PROt Civière d’ambulance RUGGED

Modell 6082 RuggedRPROt Ambulanztrage

Modello 6082 MX--PROt Barella per ambulanza RUGGED

Modelo 6082 RUGGEDRMX--PROt C amilla para ambulanc ia

R

Modell 6082 MX--PROt RUGGED

Patientvagn

OPERATIONS MANUAL

R

R

MANUEL D’UTILISATION ET D’ENTRETIEN

BEDIENUNGS-- UND WARTUNGSANLEITUNG

MANUALE OPERATIVO/DI MANUTENZIONE

MANUAL DE USO

ANVÄNDAR--/UNDERHÅLLSMANUAL

For replacement parts or service, contact your Stryker representative.

Pour les pièces de rechange vous pouvez vous adresser à votre fournisseur de Stryker.

Für Ersatzteile können Sie sich an Ihren Stryker--Lieferanten wenden.

Per i pezzi di ricambio potete rivolgerVi al V ostrofornitore di prodotti Stryker.

Para solicitar repuestos o servicio técnico, póngase en contacto con su representante

de Stryker.

Reservdelar och teknisk rådgivning får du av din närmaste STRYKER--distributör.

Page 3

Table of Contents

Introduction

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning / Caution / Note Definition 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty

Obtaining Parts and Service 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Warranty Coverage 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Authorization 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freight Damage Claims 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Safety Precautions 6, 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-Up Procedures 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vehicle Safety Hook Selection 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cot Positions 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Restraint Straps 16, 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Pedi-Matet Instructions 18, 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transferring the Patient to the Cot 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rolling the Cot 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the Cot into a Vehicle 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading an Empty Cot into a Vehicle 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the Cot from a Vehicle 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Additional Assistance 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Optional Wheel Lock 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Wheel Locking Force 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Cot Height with Two Operators 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Height of an Empty Cot 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Leg Rest 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Backrest 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Siderails 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Breakaway Head Section 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating I.V. Poles 32, 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventative Maintenance

Cleaning 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventative Maintenance Schedule & Checklist 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Lubrication 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic Fowler Adjustment 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Record 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Training Record 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Introduction

INTRODUCTION

This manualisdesigned to assist you with the operation andmaintenanceofthe6082 MX--PRO Ambulance Cot. Read it thoroughly before using the equipment or beginning any maintenance on it.

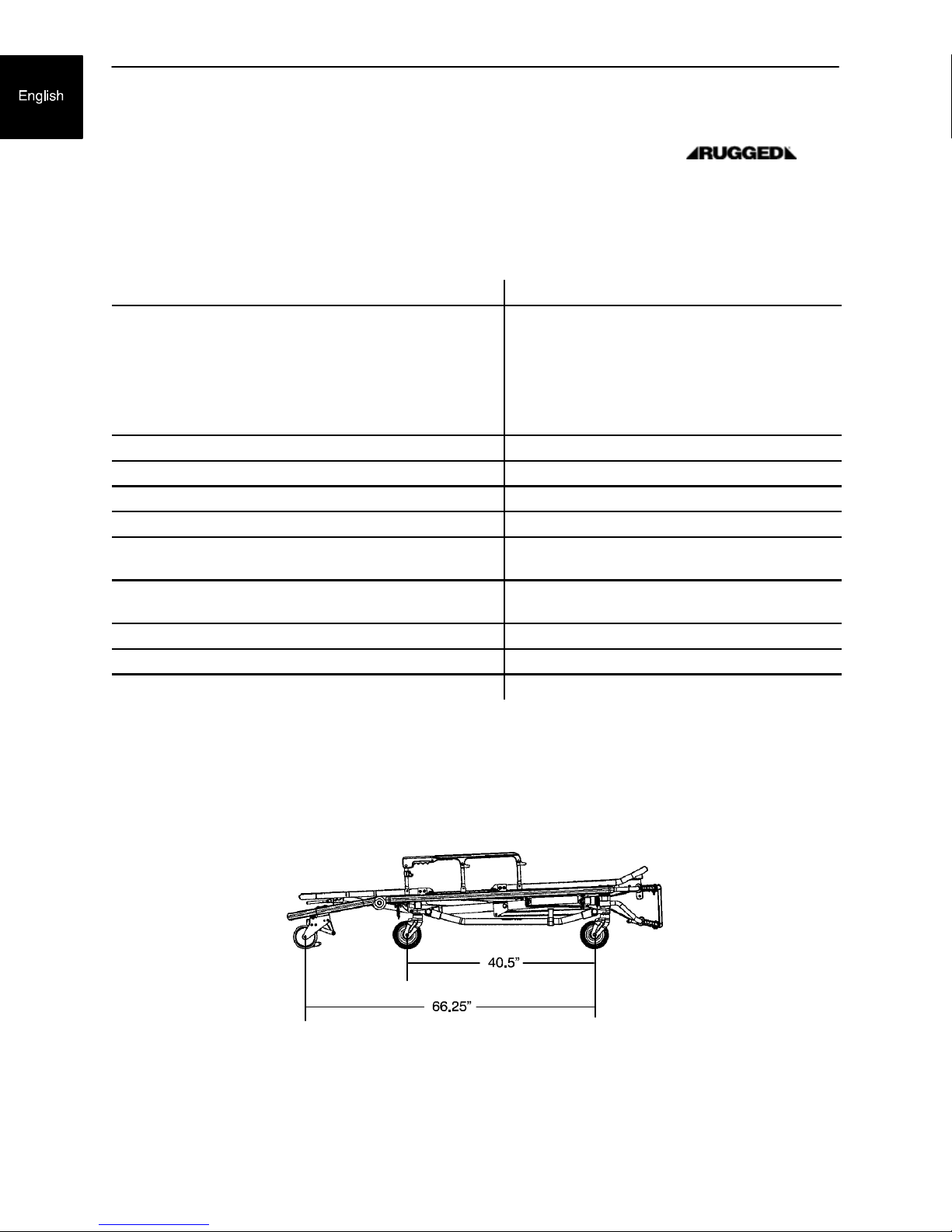

SPECIFICATIONS

Overall Length/Minimum Length/Width 80.5”/61.75”/23”

Height! -- Position 1

Position 2

Position 3

Position 4

Position 5

Position 6

Position 7

Backrest Articulation/Shock Position 2_ to 73° /+14_

Weight@ 81 pounds

Maximum Weight Capacity 650 pounds

Caster Diameter/Width 6”/2”

Minimum Operators Required for Loading/Unloading

an Occupied Cot

Recommended Fastener Systems Model 6370/6374/6377/6378 Floor Mount Type

Recommended Floor Height# Up to 32”

Roll--In Style Yes

Single Wheel Lock / Double Wheel Lock Optional

13.5”

21.0”

25.5”

29.0”

32.0”

35.0”

37.5

2

Model 6371/6375 Wall Mount Type

! Height measured from bottom of mattress at seat section to ground level.

@ Cot is weighed without mattress and restraints.

# Cot may be loaded from any height and a height limiting kit (p/n 6060--202--000) is available to limit the load height of the cot.

Stryker reserves the right to change specifications without notice.

The MX--PRO is designed to conform to the FederalSpecification for the Star--of--Life Ambulance KKK--A--1822.

Figure 1 -- Lowest Height Position

The yellow and black color scheme is a proprietary trademark of Stryker Corporation.

1-- 2

Page 5

Introduction

WARNING / CAUTION / NOTE DEFINITION

The words WARNING, CAUTION and NOTE carry special meanings and should be carefully reviewed.

WARNING

Thepersonalsafety of thepatient orusermaybeinvolved. Disregarding this informationcouldresult ininjury

to the patient or user.

CAUTION

These instructions point out special proceduresor precautions that must be followed to avoid damaging the

equipment.

NOTE

This provides special information to make maintenance easier or important instructions clearer.

1-- 3

Page 6

Warranty

StrykerEMS,a division of the StrykerCorporation,offerstwodistinct warrantyoptions

in the United States:

One(1)yearpartsand labor. Under this option, StrykerEMS warrantsto theoriginal

purchaserthatits products should be free frommanufacturingnon--conformancesthat

affect product performance and customer satisfaction for a period of one (1) year after

date of delivery. Stryker’s obligation under this warranty is expressly limited to supplying replacement parts and labor for, or replacing, at its option, any product that is, in

the sole discretion of Stryker, found to be defective.

Two (2) yearparts.Under this option, Stryker EMS warrants to the originalpurchas-

er that non--expendable components of its products should be free from manufacturing non--conformances that affect product performance and customer satisfaction for

a period of two (2) years after date of delivery. Stryker’s obligation under thiswarranty

is expressly limited to supplying replacement parts for, or replacing, at its option, any

product which is, in the sole discretion of Stryker, found to be defective. Expendable

components, i.e. mattresses, restraints, IV poles, storage nets, storage pouches, O2

straps, and other soft goods, have a one (1) year limited warranty with this option.

Under either warranty option, Stryker Medical EMS products are designed for a

ted service life under normal use, conditions, and with appropriate periodic

expec

maintenance as described in the maintenance manual for each device. Stryker warrants to the original purchaser that the welds on its EMS products will be free from

structuraldefectsfor the expected

c

haser owns theproduct. Originalpurchasers will also obtain a three (3) year limit-

pur

ed parts warranty for the X frame components of the MX--PRO R3 stretcher provided

they also purchaseX--frame guardsat the time of the originalpurchaseand the guards

are installed on the MX--PRO before it is put into service.

If Stryker requests,products or parts for which an original purchaser makes a warranty

claim,the purchasershall return the productor part prepaid freight to Stryker’sfactory.

Any improper use or alteration or repair by unauthorized service providers in such a

manner as in Stryker’s judgment affects the product materially and adversely, shall

void this warranty. Any repair of Stryker products using parts not provided or authorized by Stryker shall void this warranty. No employee or representative of Stryker is

authorized to change this warranty in any way.

This statement constitutes Stryker EMS’s entire warranty with respectto the aforesaid

equipment.STRYKERMAKES NOOTHERWARRANTYORREPRESENTATIONEITHER EXPRESSED OR IMPLIED, EXCEPT AS SET FORTH HERIN. THERE IS NO

WARRANTY OF MERCHANTABILITY AND THERE ARE NO WARRANTIES OF FITNESS FOR ANY PARTICULARPURPOSE. IN NO EVENT SHALL STRYKERBE LIABLE HEREUNDER FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM OR IN ANY MANNER RELATED TO SALES OR USE OF ANY SUCH

EQUIPMENT.

ear life of the EMS product as long as the original

5 y

5 y

ear

1-- 4

Page 7

Warranty

Stryker EMS Return Policy

Cots, Stair Chairs, Evacuation Chairs, Cot Fasteners and Aftermarket Accessories:

may be returned up to 180 days of receipt if they meet the following guidelines:

Prior to 30

S 30 day money back guarantee in effect

S Stryker EMS is responsible for all charges

S Returns will not be approved on modified items

Prior to 90

S Product must be unused, undamaged and in the original packaging

S Customer is responsible for a 10% restocking fee

Prior to 180

S Product must be unused, undamaged and in the original packaging

S Customer is responsible for a 25% restocking fee

Return Authorization:

Merchandisecannot be returnedwithoutapprovalfrom the StrykerCustomerService

Department. An authorization number will be provided whichmust be printed on the

returned merchandise. Stryker reservesthe right to charge shipping and restocking

fees on returned items.

SPECIAL, MODIFIED, OR DISCONTINUED ITEMS NOT SUBJECT TO RETURN.

Days

Days

Days

Damaged Merchandise:

ICCRegulationsrequirethat claimsfor damaged merchandisemustbemade withthe

carrier within fifteen (15) days of receipt of merchandise. DO NOT ACCEPT DAMAGED SHIPMENTS UNLESS SUCH DAMAGE IS NOTEDON THE DELIVERY RECEIPT ATTHETIME OFRECEIPT. Upon promptnotification, Strykerwill file a freight

claimwiththeappropriatecarrierfordamagesincurred. Claimwillbelimitedinamount

to the actual replacement cost. In the event that this information is not received by

Strykerwithinthe fifteen (15)day period following the deliveryof the merchandise, or

the damage was not noted on the delivery receiptat the timeof receipt, the customer

will be responsible for payment of the original invoice in full.

Claims for any short shipment must be made within thirty (30) days of invoice.

International Warranty Clause:

This warranty reflects U.S. domestic policy. Warranty outside the U.S. may vary by

country. PleasecontactyourlocalStrykerMedicalrepresentativeforadditionalinformation.

Patent Information

Ruggedr Products are covered by one or more of the following patents:

United States 5,575,026 6,276,010 6,648,343 6,908,133 6,796,757

5,537,700 6,125,485 6,735,794 7,100,224 D527,103

Other Patents Pending

1-- 5

Page 8

Summary of Safety Precautions

The following is a list of safety precautions that must be observed when operatingor servicingthis unit. The

precautions are repeated throughout the manual, where applicable. Carefully read this list before using or

servicing the unit.

WARNING

S Improper usage of the

only as described in this manual.

S Always use all restraint straps to securethepatienton the cot. An unrestrainedpatient may fall from the

cot and be injured.

S Siderails are not intended toserve as apatient restraint device. Refer to pages 1--12and 1--13for proper

restraint strap usage. Failure to utilize the siderails properly could result in patient injury.

S Never leave a patient unattended on the cot or injury could result. Hold thecot securely while a patient

is on the cot.

S Never apply the optional wheel lock(s)while a patient is on the cot. Tipping could occur if thecot is moved

while wheel locks are applied, resulting in injury to the patient or operator and/or damage to the cot.

S Wheel locks are only intendedto help prevent the cot from rollingwhile unattended. Wheel locks may not

provide sufficient resistance on all surfaces or under loads.

S Never install or use wheel locks on a cot with excessively worn wheels. Installing or using wheel locks

on wheels with less than a 6” diameter couldcompromise the holding ability of the wheel lock, resulting

in injury to the patient or operator and/or damage to the cot or other equipment.

S Be sure the undercarriage has engaged and locked beforeremovingtheloading wheels from the patient

compartment floor of the vehicle. An unlocked undercarriagewill not support the cotand injury to the patient and/or operator could result.

S Do not allow untrained helpers to assist in the operation of the cot. Untrained technicians/helpers can

cause injury to the patient or themselves.

S Grasping the

Keep hands, fingers and feetaway frommovingparts. T oavoid injury,use extreme caution when placing

your feet near the base tubes while raising and lowering the cot.

S Have the vehicle safety hook installed by a certified mechanic. Improper safety hook installation can

cause injury to the patient or operator or damage to the unit.

S Failure tousethevehicle safety hook cancauseinjurytothe patient or operator. Install and usethesafety

hook as described in this manual.

S When the optional head end storage pouch is being used, ensure it does not interfere withthe operation

of the safety bar and safety hook. Injury to the patient or operator could occur.

S Donot pull orliftonthesafety barwhenunloading thecot. Damage tothesafetybar couldresultandinjury

to the patient or operator could occur.

S Do not modify the

in injury to the patient or operator. Modifying the cot will also void its warranty (see page 1--4).

S Improper maintenance can cause injuryordamageto theunit. Maintainthecotasdescribedin thismanu-

al. Use only Stryker approved parts and maintenanceprocedures. Using unapproved parts and procedures could cause unpredictable operation and/or injury and will void the product warranty.

S Do not ride on the base of the

to the patient or operator.

S Failure to properly clean or dispose of contaminatedmattress or cot components will increase therisk of

exposure to bloodborne pathogens and may cause injury to the patient or the operator.

S To avoidaccidentalrelease of the Pedi--Matet, and possible injuryto the infant, ensure the buckle is lo-

cated away from obstructions on the cot or head end storage pouch.

S Operating the cot with the breakaway head section lowered may cause injury to the patient or operator

or damage to the cot. Use only positions 5--7 when using this configuration.

Cot improperly can cause injury. Grasp only the lifting bars to lift thecot.

Cot cancause injury to the patient or operator. Operate the cot

Cot. Modifying the cot can cause unpredictable operation resulting

cot. Damage to the cot could occur, resulting in injury

1-- 6

Page 9

Summary of Safety Precautions

CAUTION

S Damage tothe cot can occur if the cot is lowered in the shortened position. Use only positions 5--7 (see

page 1--11) when the cot is shortened.

S Lifting the cot by the safety bar can cause damage to the cot. Lift the cot only by the lifting bars.

S Do not allow the cot undercarriage to drop unassisted (commonly known as a “hot drop”) when removing

the cot from the vehicle. Repeated hot dropping will cause premature wear or damage to the cot.

S Height limit kit is recommended for ambulance deck heights less than 30 inches (76cm) — Strykerpart

number 6060--202--000.

S The weight of the monitoringequipment must not exceed 75 pounds (34 kg) with the defibrillatorplatform

(if equipped). Monitoring equipment should not be stored on the cot or on the defibrillator platform when

in the ambulance vehicle.

1-- 7

Page 10

Set--Up Procedures

Ensure that all shipping and packaging materials have been removed from the product(s) prior to use.

Unpack the cartons and check all items for proper operation. It is important that the

working properly before it is put into service. Have a qualified serviceperson use the following list and the

operation instructions to check the cot before it is put into service.

S All fasteners secure (reference all assembly drawings)

S All welds intact, not cracked or broken

S No bent or broken tubing or sheet metal

S No debris in wheels

S All wheels secure, rolling and swivelling properly

S Siderails move and latch properly

S Backrest operating properly

S Optional accessories intact and operating properly

S Height positioning latch functioning properly

S Cot secure in each height position

S Undercarriage folds properly

Cot is

S Breakaway head section operating properly

S Safety bar operating properly

S Foot rest operating properly

S No rips or cracks in mattress cover

S Body restraints intact and working properly

S Wheel lock(s) operating properly (optional equipment)

S Does the vehicle safetyhook engage the safety bar so thatthecotloads and unloads easily from the ve-

hicle?

S Is there an approved crash--stable fastener (Stryker part number 6370/6374/6377/6378or 6371/6375 --

not included) installed in the vehicle?

The patient compartment of the vehicle in which the

S A smooth rear edge for cot loading.

S A level floor large enough for the folded cot.

S Stryker 6370/6374/6377/6378 or 6371/6375 crash stable cot fastener (not included).

S 32” (81 cm.) maximum loading height.

S Space to install the safety hook.

When necessary, modify the vehicle to fit the cot. Do not modify the cot.

Cot will be used must have:

WARNING

Donot modifythe Cot. Modifyingthe cot can cause unpredictable operationresulting in injury to the patient or operator. Modifying the cot will also void its warranty (see page 1--4).

1-- 8

Page 11

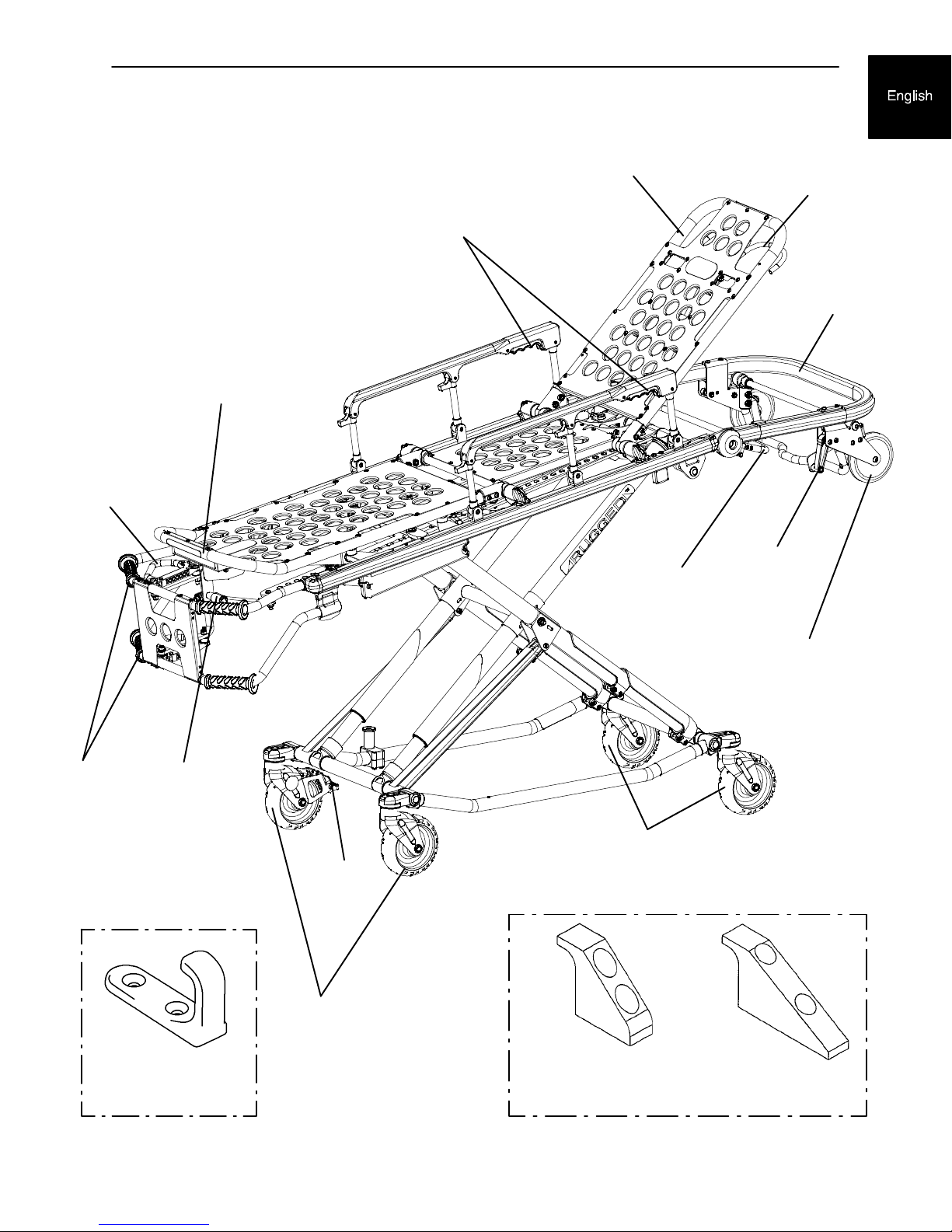

Component Identification

t

Figure 2 -- MX--PRO R3 Cot

HeightAdjustment

Release Handle

(1 of 3)

Foot Rest

SiderailRelease Handles

Backrest (Head Section)

Breakaway

Head Section

Release Bar

BackrestAdjustmen

Release Handle

HEAD END

Breakaway

Head Section

Safety Bar

Release

Lever

LiftingBar

J Safety Hook

Strykerpart number

6092--036--018

Loading Wheels

(1 of 2)

Foot Rest

Release

Handle

TransportWheels

Wheel Lock

(Optional)

TransportWheels

LONG SAFETY HOOKSHORT SAFETY HOOK

(Forinstallationinstructions,see page1 -- 10.)

1-- 9

Page 12

Vehicle Safety Hook Selection

The vehicle safety hook is a device that ships with the cot. The cot safety bar and vehicle safety hook are designed

to keep the cot from being accidentally removed from the vehicle and to provide increased operator assurance and

confidence when loading and unloading. The safety hook was designed for compatibility and proper operation when

loading and unloading the cot from a vehicle that is compliant with Federal Regulation KKK-A-1822.

Stryker offers three different types of safety hooks that are ordered and shipped with your ambulance cot. These

safety hook types are designed to meet the needs of various emergency vehicle configurations, specifically the length

and location of the floor structure support that is located in the rear of the vehicle.

Consider the following information when selecting

which safety hook is appropriate for your vehicle

configuration:

• Determine the location of the floor structure

support where there is adequate room to mount

the safety hook.

• Ensure that the safety hook can be securely

mounted into the back of the vehicle while

providing adequate bumper clearance to allow the

cot to be loaded and unloaded from the vehicle.

• Note the differences in vehicle design. Each safety

hook provides a different mounting location option

to maintain the appropriate distance between the

face of the safety hook and the edge of the door

sill.

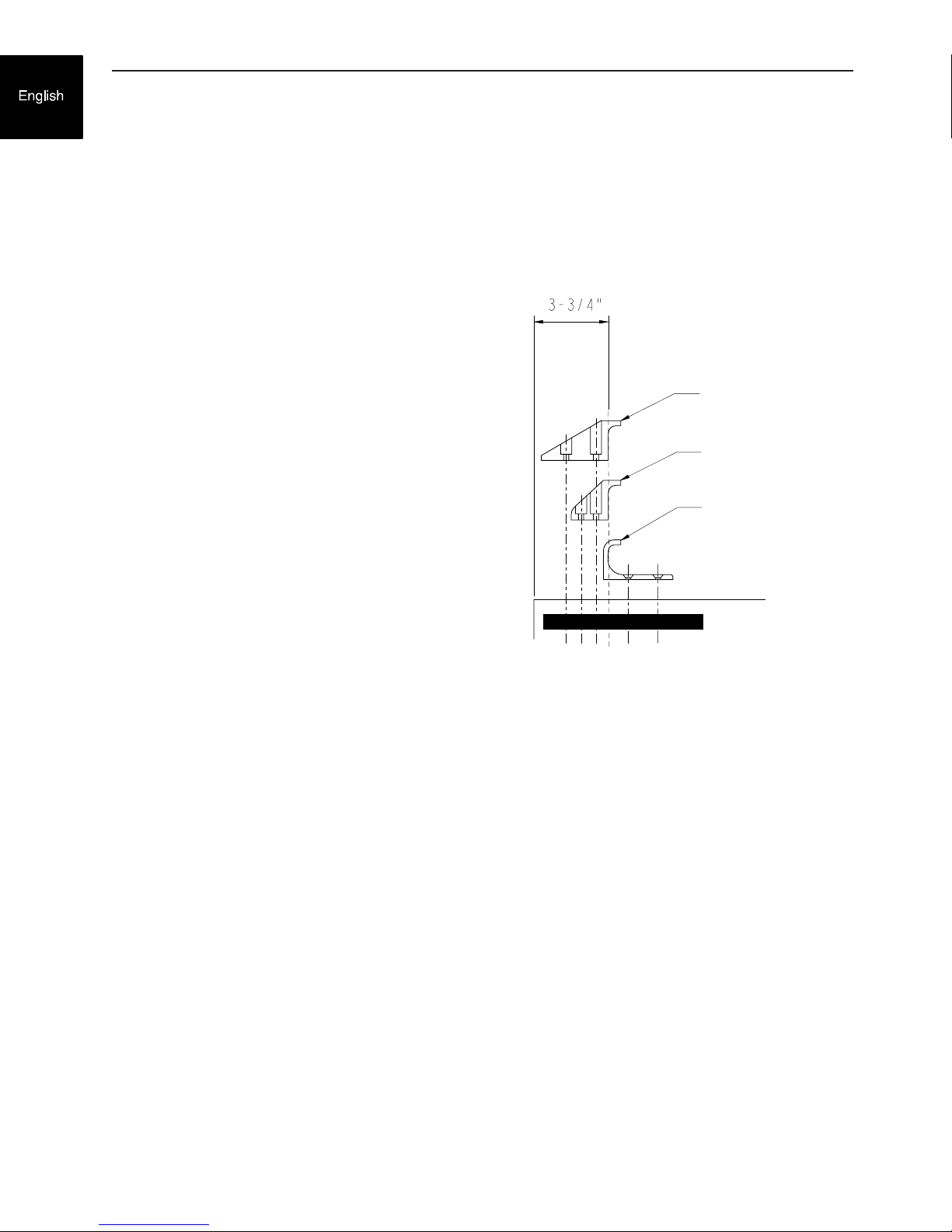

Long Safety Hook

6060-036-018

Short Safety Hook

6060-036-017

J-Style Safety Hook

6092-036-018

Due to the differences in vehicle dimensions and the

floor structure support locations, each safety hook

requires a different mounting location. See “Vehicle

Safety Hook Installation” to determine the correct

positioning for safety hook installation.

Safety Hook Types

Note: When replacing an existing safety hook with a new style, adjust the mounting location to maintain the proper

position of the safety hook face.

1--10

Page 13

Vehicle Safety Hook Installation

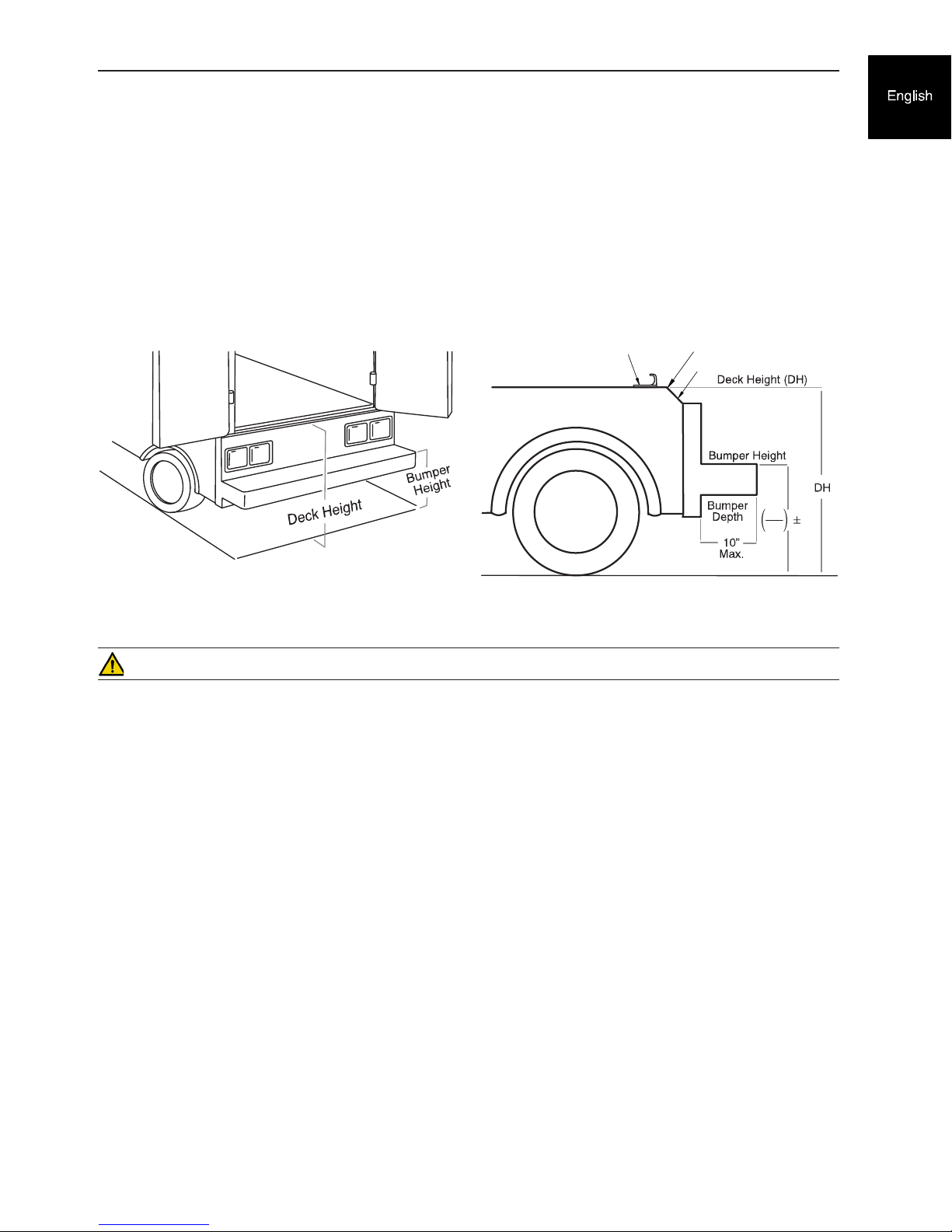

VEHICLE CONFIGURATION

According to federal regulations (reference KKK-A-1822), the bumper height of the vehicle shall be installed equidistant

± 5 cm (2 inches) from the vehicle floor to the ground level, which is defined as the vehicle deck height. The bumper

step shall have a minimum depth of 13 cm (5 inches) and a maximum depth of 25 cm (10 inches). If the bumper depth

is greater than 18 cm (7 inches), then the bumper must be able to fold. Installation of the safety hook into any vehicle

compliant with this federal specification provides adequate clearance for the cot base to lower to its fully extended

position. The cot is compatible with all vehicle deck heights (see specifications for maximum load height) as long as

the vehicle meets the federal specifications that are outlined in KKK-A-1822.

Sill Edge

Sill

DH

2

2

Vehicle Deck Height

Safety Hook

Vehicle Deck Height

CAUTION

• Set the cot load height to the proper stop height prior to operation.

• Installation of the safety hook should be done by a certified mechanic familiar with ambulance vehicle construction.

Consult the vehicle manufacturer before installing the safety hook and be sure that the installation of the safety

hook does not damage or interfere with the brake lines, oxygen lines, fuel lines, fuel tank or electrical wiring of

the vehicle.

REQUIRED HARDWARE FOR INSTALLATION OF THE SAFETY HOOK (NOT SUPPLIED)

(2) Grade 5, 1/4”-20 Socket Head Cap Screws*

(2) Grade 5, 1/4”-20 Flat Socket Head Cap Screws*

(2) Flat Washers

(2) Lock Washers

(2) 1/4”-20 Nuts

* The length of the socket head cap screws depends on the thickness of the vehicle floor. Use screws that are long

enough to go completely through the patient compartment floor, washer and nut by at least two full threads.

1--11

Page 14

Vehicle Safety Hook Installation

WARNING

• Have the vehicle safety hook installed by a certified mechanic. Improper safety hook installation can cause injury

to the patient or operator and/or damage to the cot.

• Failure to install the safety hook can cause injury to the patient or operator.

• The face of the safety hook that engages the safety bar should be located at least 3-3/4” from the leading edge

of the door sill. After installation, verify that the cot legs lock into the load position without contacting the vehicle

bumper.

• To avoid injury, verify that the safety bar has engaged the safety hook before removing the cot from the patient

compartment.

Note: Stryker recommends that, prior to installation, the certified mechanic plan the placement of the safety hook in

the rear of the vehicle.

Before installing the safety hook into your vehicle, check the front to back and side to side positioning when unloading

and loading the cot to ensure that the safety hook will be installed properly. The cot safety bar must engage the safety

hook every time, regardless of cot position.

FRONT TO BACK POSITIONING OF THE SAFETY HOOK

1. Select the appropriate safety hook for your vehicle configuration.

2. Position the safety hook at least 3-3/4” from the leading edge of the door sill.

3. Ensure that the safety hook can be securely mounted into the back of the vehicle while providing adequate bumper

clearance to allow the cot to be loaded and unloaded from the vehicle.

4. See “Side to Side Positioning of the Safety Hook” to confirm the side to side placement.

Safety Hook Placement

Long Safety Hook

6060-036-018

Short Safety Hook

6060-036-017

J-Style Safety Hook

6092-036-018

1--12

Page 15

Vehicle Safety Hook Installation

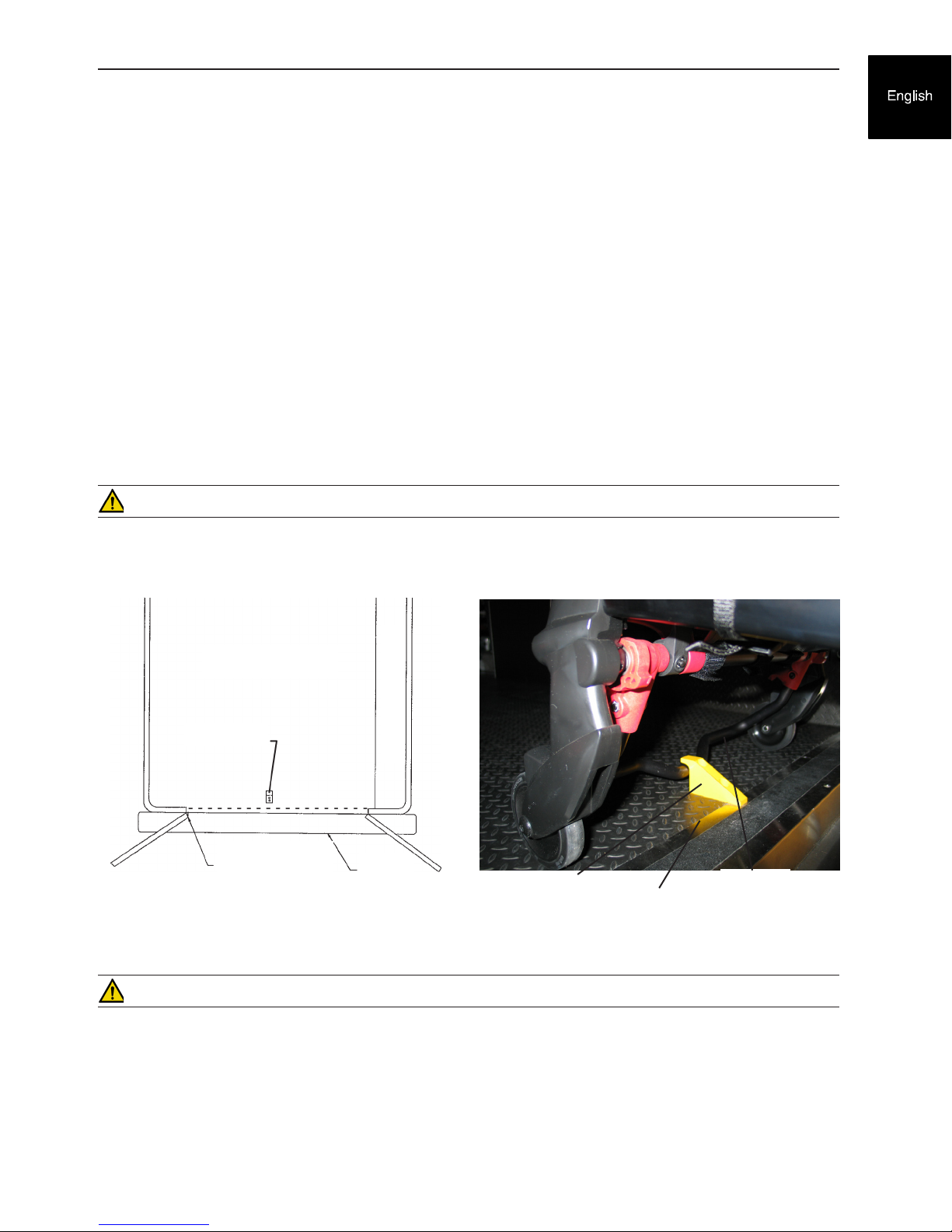

SIDE TO SIDE POSITIONING OF THE SAFETY HOOK

1. Remove the cot from the fastener and unload it from the vehicle.

2. While the cot is being removed, note the position of the load wheels and the safety bar.

3. Mark the center of the cot safety bar on the vehicle floor.

4. Verify that the position marked in Step 3 is where the safety bar engages the safety hook every time when unloading

the cot in a variety of positions (all the way to the left and all the way to the right), regardless of cot position.

• If the cot safety bar does not engage the safety hook in any of these positions (left, center, or right), modify

the vehicle, not the cot or safety hook.

• If the cot safety bar engages the safety hook every time, install the safety hook.

INSTALLING THE SAFETY HOOK

1. Determine the correct safety hook front to back and side to side positioning, so the cot safety bar engages the

safety hook every time.

2. Drill the holes for the socket head cap screws.

3. Fasten the safety hook to the patient compartment floor and verify that the safety hook always engages the cot

safety bar regardless of how the cot is unloaded from the vehicle.

WARNING

Verify that the safety hook always engages the cot safety bar regardless of how the cot is unloaded from the vehicle

or injury to the patient or operator and/or damage to the cot may occur.

Top View of Vehicle

Bumper

Squad Bench

Safety Hook

Safety Bar Engaging Safety Hook

Floor Edge

Safety Bar

Safety Hook

Door Frame

Safety Hook Placement

(For Reference Only)

WARNING

The cot must have at least 5/8” of clearance between the vehicle bumper and the cot to disengage the safety bar when

unloading the cot from the vehicle. Verify that the cot legs lock into the load position before disengaging the safety

bar from the safety hook. Failure to properly lock the cot into position can cause injury to the patient or operator and/

or damage to the cot.

1--13

Page 16

Note

1-14

Page 17

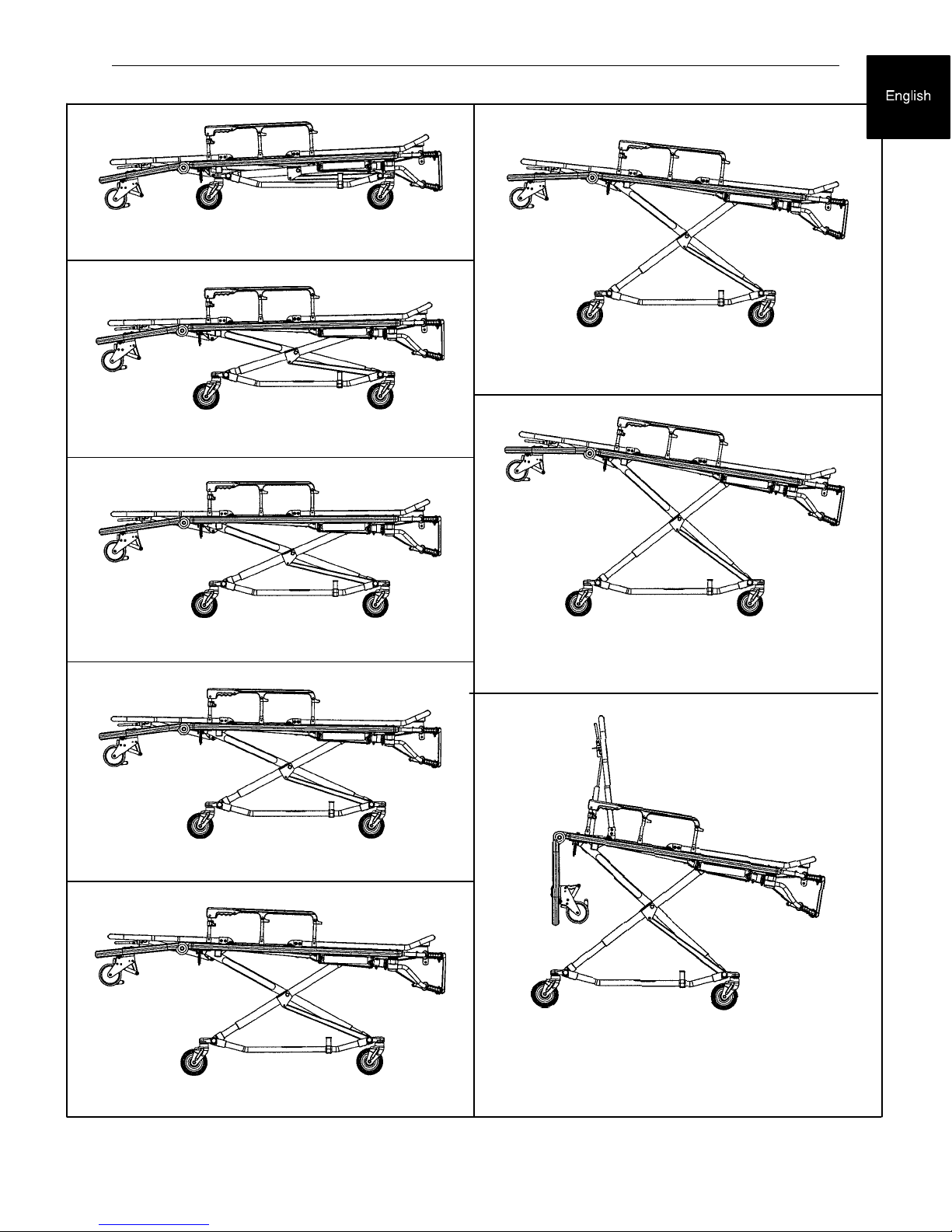

Cot Positions

Position 1 - Use for patient transfer.

Position 2 - Use for patient transfer/cot rolling.

Position 6 - Use for patient transfer/cot rolling.

Position 3 - Use for patient transfer/cot rolling.

Position 4 - Use for patient transfer/cot rolling.

Position 5 - use for patient transfer/cot rolling.

Position 7 - Use for patient transfer/cot rolling.

WARNING - Operating the cot with the breakaway

head section lowered may cause injury to the patient

or operator or damage to the cot. Use only positions

5-7 when using this configuration.

1-15

Page 18

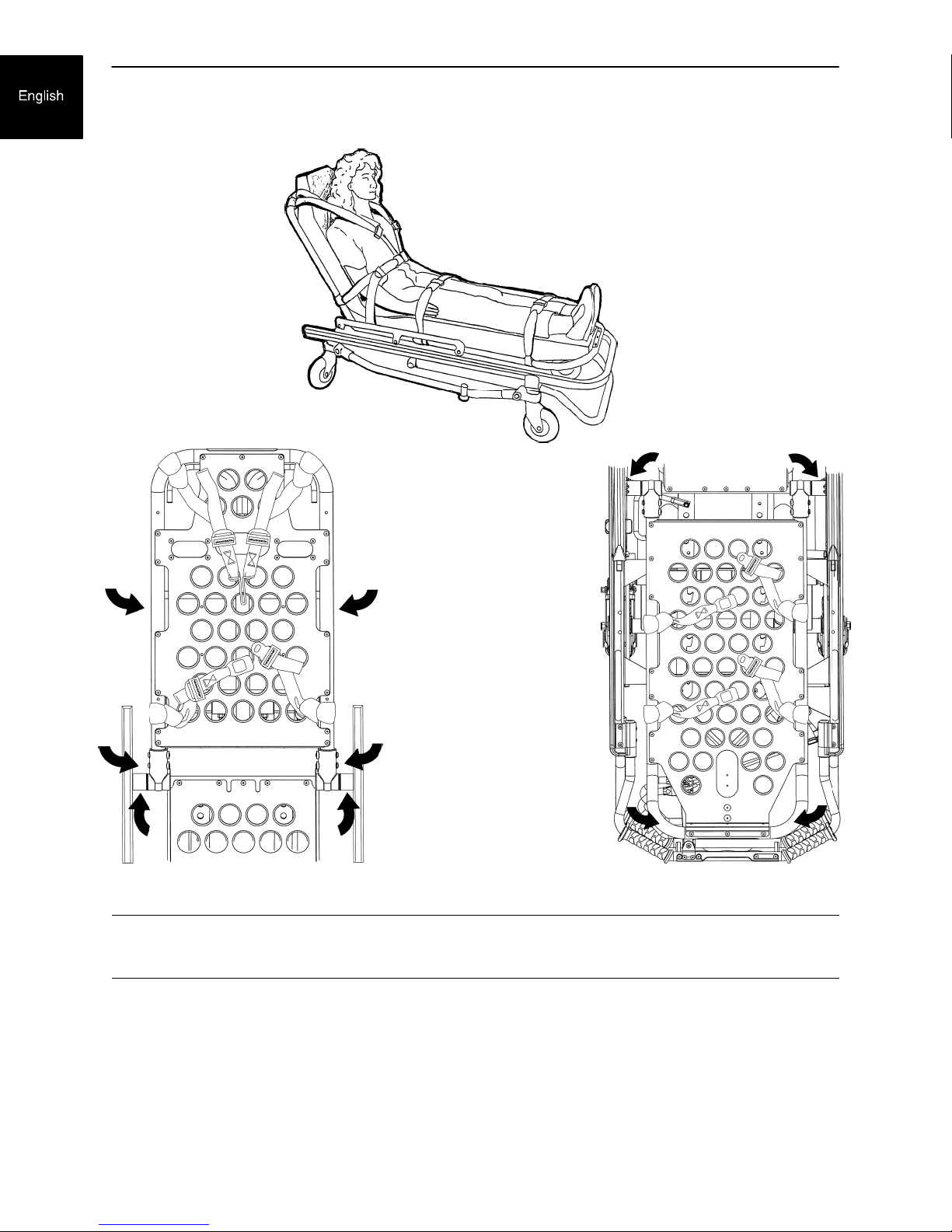

Using Restraint Straps

Cot Operation

Figure 6 - Safety Restraints

Figure 7 - Back Rest Restraints Figure 8 - Foot Section Restraints

WARNING

Always use all restraint straps to secure the patient on the cot. An unrestrained patient may fall from the cot

and be injured.

Always secure the patient on the cot with all the restraint straps. Buckle the restraints across the patient's

chest/shoulders, waist and legs (Figure 6). Keep the restraint straps buckled when the cot is not being used

with a patient to avoid damage to the buckles and straps.

When attaching the restraint straps to the cot, keep in mind the attachment points should provide strong an‐

chorage and proper restraint position while not interfering with equipment and accessories. Wrap the strap

around the cot frame and back through the loop on the end of the strap as shown in Figures 7 and 8. The

arrows indicate alternate attachment areas.

1-16

Page 19

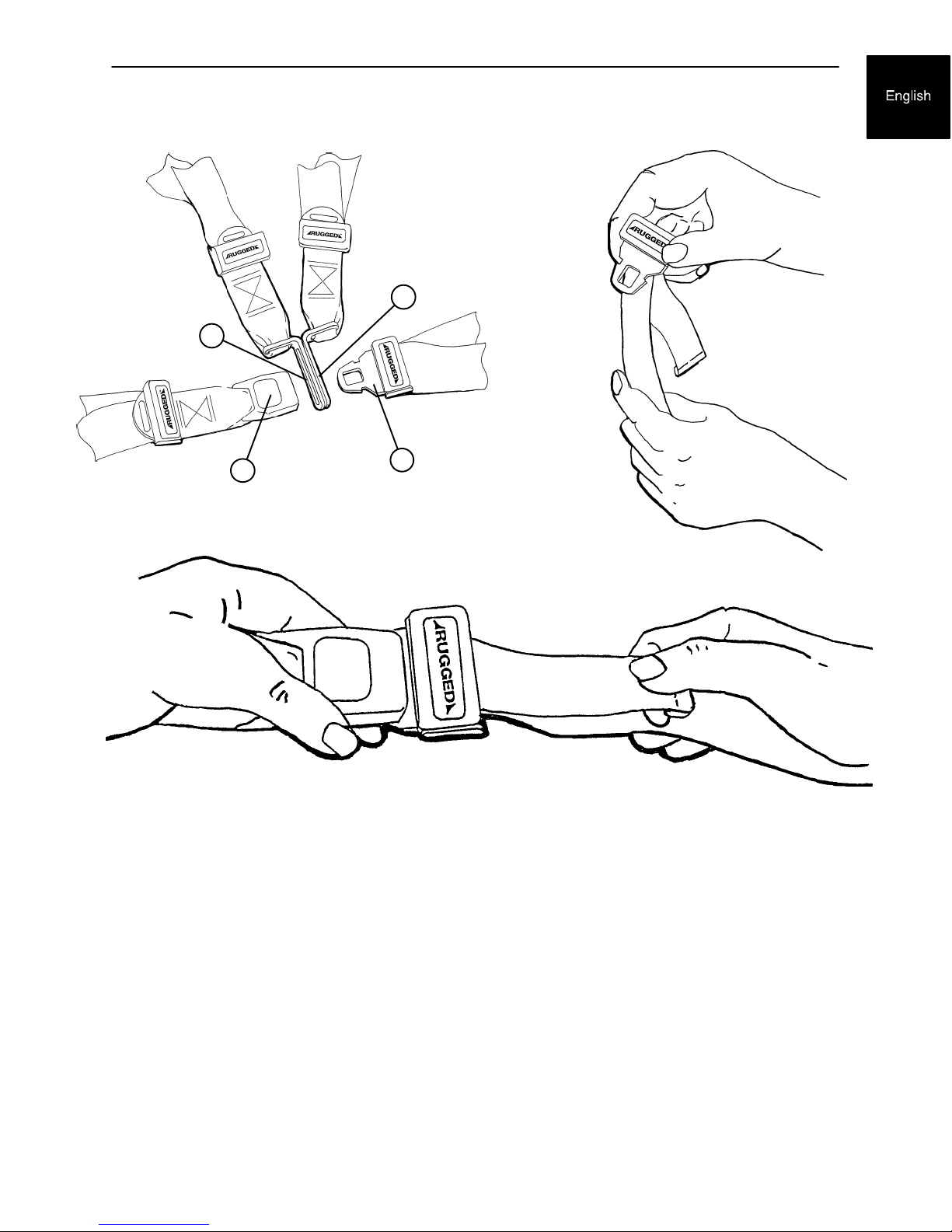

Cot Operation

Using Restraint Straps (Continued)

C

C

A

Figure 9 - Buckling the Safety Restraint

Figure 11 - Shortening the Safety Restraint

When the cot is put into service, the restraints are opened and placed to either side of the cot until the patient

is positioned on the cot mattress. The restraint is lengthened, buckled around the patient and shortened until

the required tightness is achieved.

To open the restraint, press the red button (A) on the front of the buckle ”receiver”. This releases the buckle

”tang” (B) which can then be pulled out of the receiver (Figure 9).

To close the restraint, push the tang into the receiver until a ”click” is heard. When fastening the chest restraint

be sure the tang passes through both links (C) on the shoulder strap (Figure 9).

To lengthen the restraint, grasp the buckle tang, turn it at an angle to the webbing, then pull it out (Figure 10).

A hemmed tab at the end of the webbing prevents the tang from coming off the strap.

To shorten the restraint, grasp the hemmed tab and pull the webbing back through the tang until the required

tightness is achieved (Figure 11).

Whenever a restraint is buckled on a patient, the attendant should check to be sure the tang is fully engaged

and that the extra webbing is not tangled in the cot or hanging loose.

Inspection of the restraints should be done at least once a month (more frequently if used heavily). Inspection

should include checking for a bent or broken receiver or tang, torn or frayed webbing, etc. Any restraint show‐

ing wear or not operating properly must be replaced immediately.

B

Figure 10 - Lenghtening the Safety Restraint

1-17

Page 20

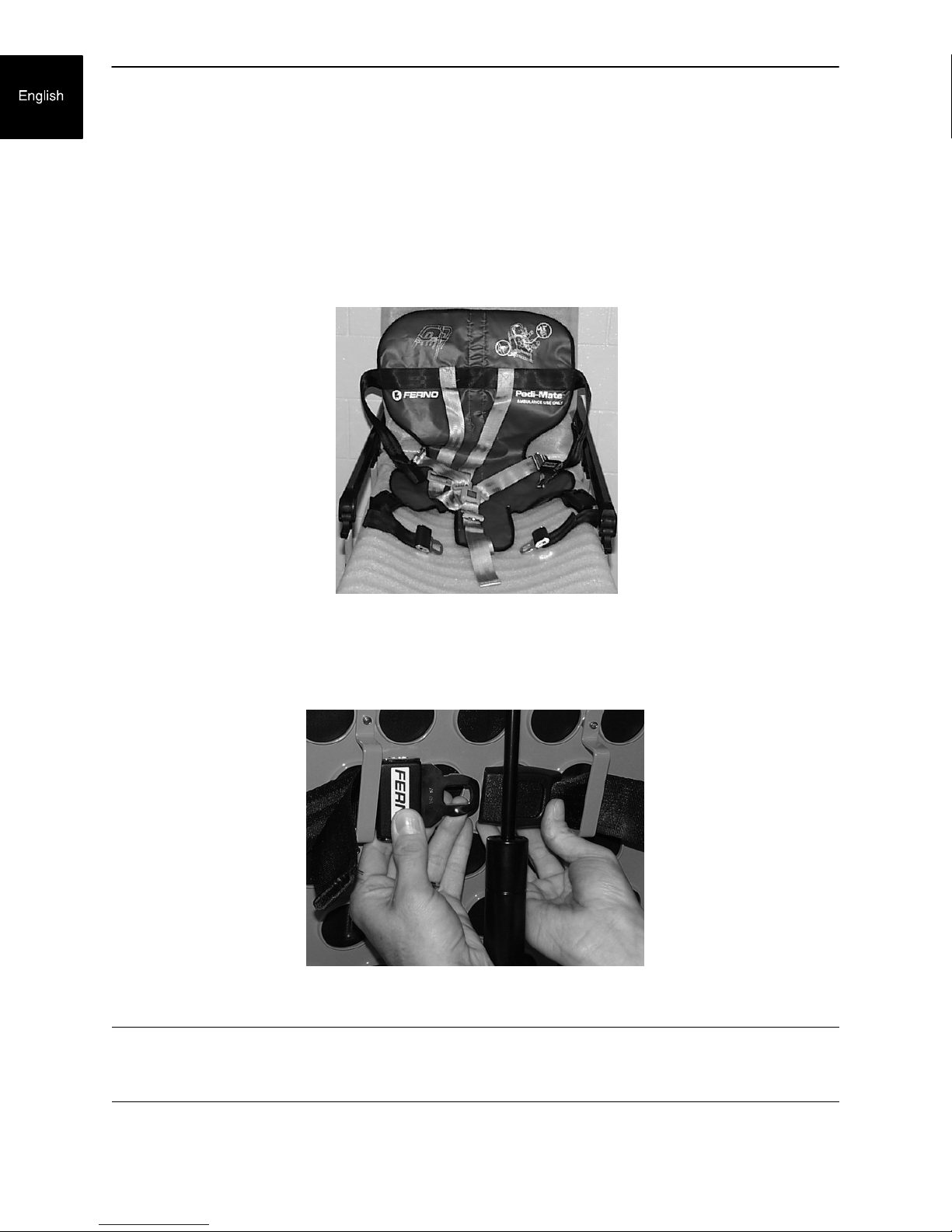

Pedi-Mate t Infant Restraint System Attachment Instructions

Refer to the Pedi-Matet users manual for the manufacturer's recommendations for the use, operation and

care of the Pedi-Matet Infant Restraint System.

Securing the Pedi-Matet to the cot

1. Remove any restraints already attached to the cot.

2. Raise the cot backrest to the full upright position.

3. Position the Pedi-Matet pad flat on the backrest with the black backrest straps out (see Figure 12).

Figure 12 - Positioning the Pedi-Matet

4. Wrap the straps around the backrest and insert the ends of the straps through the brackets. Securely

fasten the buckle (see Figure 13).

Figure 13 - Fastening the Pedi-Matet Buckle

WARNING

To avoid accidental release of the Pedi-Matet, and possible injury to the infant, ensure the buckle is located

away from obstructions on the cot or head end storage pouch.

1-18

Page 21

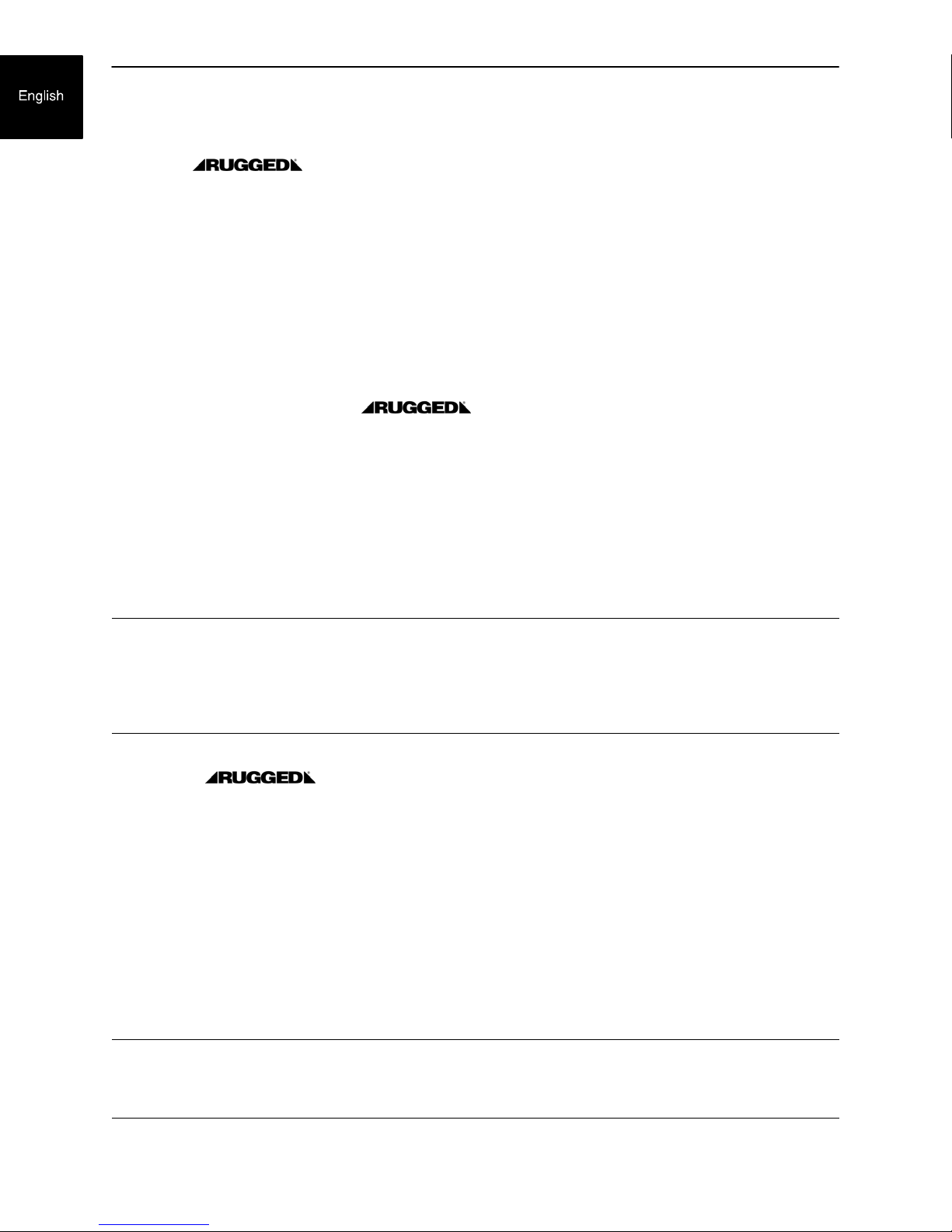

Pedi-Mate t Infant Restraint System Attachment Instructions

5. Pull firmly on the end of the adjustable backrest strap and tighten it securely.

6. Thread the mainframe straps down between the cot frame and the mattress. To be sure the release but‐

ton is toward the foot end of the cot, insert the buckle behind the crossbrace and bring the it up in front

of the crossbrace. Secure the buckle around the litter crossbrace leaving a little slack in the strap for final

adjustment (see Figure 14).

Figure 14 - Securing the Safety Restraints on a RuggedtCot

WARNING

To avoid accidental release of the Pedi-Matet, and possible injury to the infant, ensure the buckle is located

away from obstructions on the cot.

7. Verify all the straps are snug and fastened securely (see Figure 15).

Figure 15- Pedi-Matet Strapped to a Ruggedt Cot

These are general instructions for installation of the Pedi-Matet. Safe and proper use of the Pedi-Matet is solely at

the discretion of the user. Stryker recommends all users be trained on the proper use of the Pedi-Matet before using it

in an actual situation.

Retain these instructions for future reference. Include them with the product in the event of transfer to new users.

Pedi-Mate t is a trademark of Ferno-Washington Inc.

1-19

Page 22

Cot Operation

Operating Guidelines

S Use the Cot only as described in this manual.

S Read all labels and instructions on the cot before using the cot.

S Use a minimum of two operators to manipulate the cot while a patient is on the cot.

S Do not adjust, roll or load the cot without advising the patient. Stay with the patient and control the cot

at all times.

S Never apply the optional wheel lock while a patient is on the cot.

S Always use the restraint straps and keep the siderails up when a patient is on the cot.

S Use properly trained helpers when necessary to control the cot and patient.

Transferring the Patient to the Cot

1. Roll the cot to the patient.

2. Place the cot beside the patient and raise/lower the cot to the patient's level.

3. Lower the siderails and open the restraint straps.

4. Transfer the patient to the cot using accepted EMS procedures.

5. Use all the restraints to secure the patient to the cot (see page 1-16 for restraint strap usage instructions).

6. Raise the siderails and adjust the backrest and leg rest as necessary.

WARNING

Always use all restraint straps to secure the patient on the cot. An unrestrained patient may fall from the cot

and be injured.

Never apply the optional wheel lock while a patient is on the cot. Tipping could occur if the cot is moved while

the wheel lock is applied, resulting in injury to the patient or operator and/or damage to the cot.

Rolling the Cot

1. Make sure all the restraint straps are securely buckled around the patient (see page 1-16 & 1-17 for re‐

straint strap usage instructions).

2. Place the cot in positions 2-7 for rolling (see page 1-15 for cot positions).

3. When rolling the cot, position an operator at the foot end and one at the head end at all times.

NOTES

Loose items or debris on the patient compartment floor can interfere with the operation of the safety hook

and cot fastener. Keep the patient compartment floor clear.

The cot can be loaded with the siderails down only if the restraint belts are properly buckled around the patient.

WARNING

Operating the cot with the breakaway head section lowered may cause injury to the patient or operator or

damage to the cot. Use only positions shown on the Cot Positions page when using this configuration.

1-20

Page 23

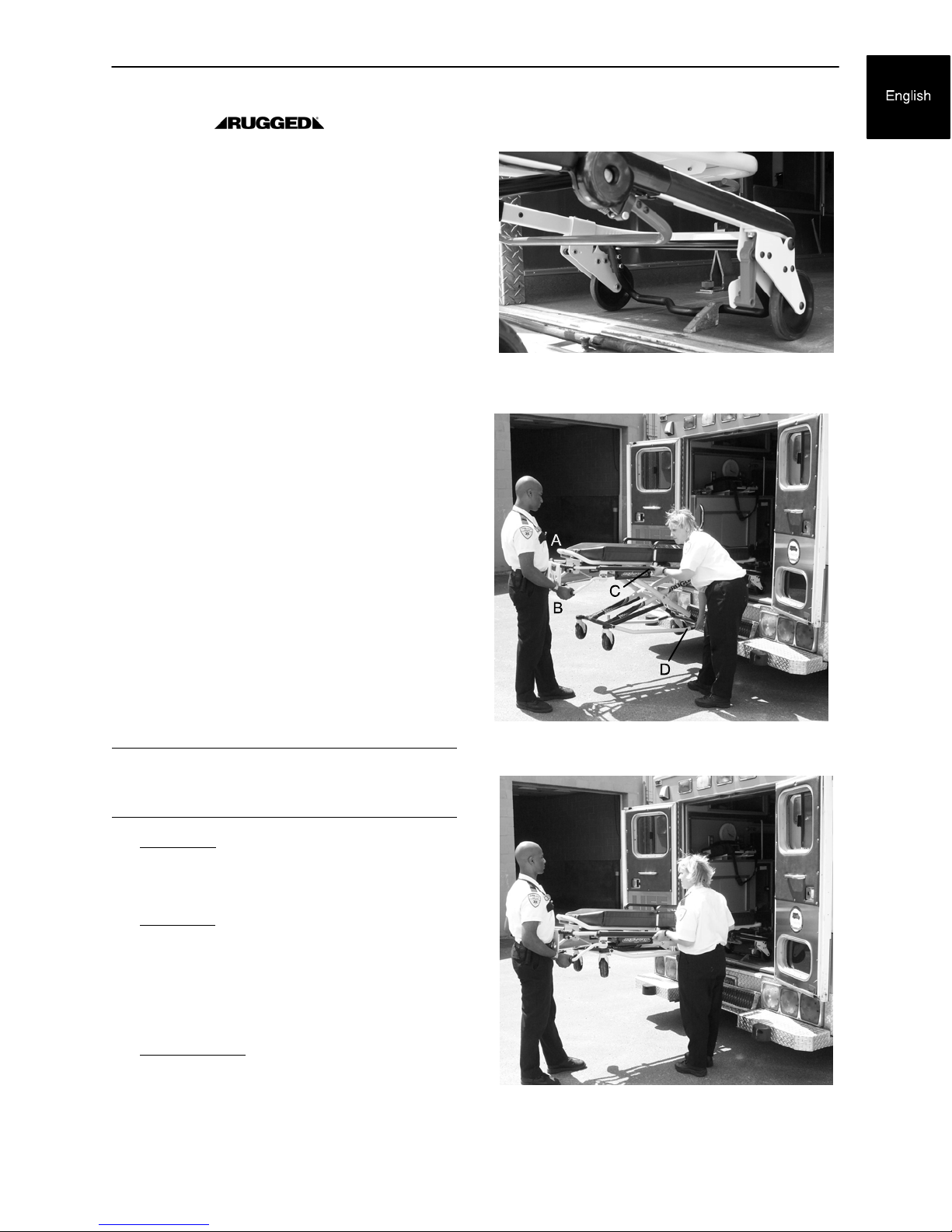

Cot Operation

Loading the Cot into a

Vehicle with Two Operators

When loading the cot into a vehicle, an operator

should remember the following important issues:

S Two operators must be present when the cot is

occupied.

S There must be a safety hook properly installed

in the vehicle so that the bumper does not inter‐

fere with the front legs of the base frame. (See

page NO TAG, safety hook installation instruc‐

tions.)

S Operators must be able to lift the total weight of

the patient, cot and any items on the cot.

S The higher an operator must lift the cot, the more

difficult it becomes to hold the weight. An opera‐

tor may need help loading the cot if he/she is too

short or if the patient is too heavy to lift safely.

The operator must be able to lift the cot high

enough for the cot's legs to unfold completely

and lock when the cot is unloaded. A shorter op‐

erator will have to raise his/her arms higher to

enable the undercarriage to unfold.

1. Place the cot in a loading position (any position

where the loading wheels meet the vehicle floor

height). Roll the cot to the open door of the pa‐

tient compartment. Lift the vehicle bumper to

the raised position (if possible).

2. Push the cot forward until the loading wheels

are on the patient compartment floor and the

safety bar passes the safety hook (Figure 16).

3. For maximum clearance to lift the base, pull the

cot back until the safety bar engages the safety

hook.

WARNING

Failure to use the safety hook can result in injury.

Install and use the hook as described in this manual.

Figure 16 - Safety Bar Engaging Safety Hook

Figure 17 - 2 Operators - One Lifting the Base

4. Operator 1 - Grasp the cot frame at the foot

end. Lift the foot end of the cot until the weight

is off the latching mechanism. Squeeze and

hold the release handle (location A or B).

5. Operator 2 - Stabilize the cot by placing your

hand on the outer rail (location C). Grasp the

base frame where indicated (location D). After

the foot end operator has lifted the cot and

squeezed the release handle, raise the under‐

carriage until it stops in the uppermost position

and hold it there (Figure 17).

6. Both Operators - Push the cot into the patient

compartment (Figure 18), engaging the cot fas‐

tener (not included).

Figure 18 - 2 Operators - Base Full Up

1-21

Page 24

Cot Operation

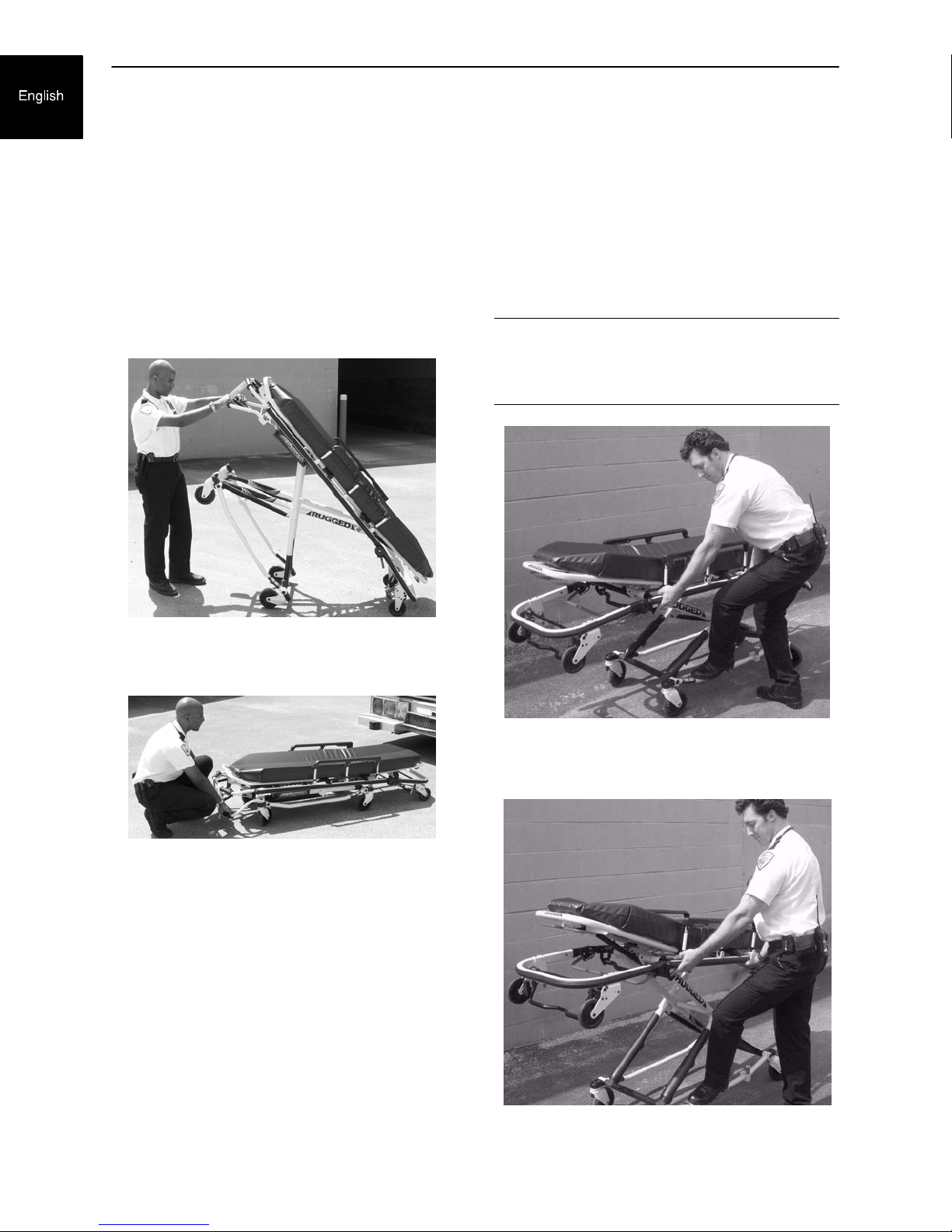

Loading an Empty Cot into a

Vehicle with One Operator

WARNING

This procedure is for use only with an empty cot. Do

not use this procedure when loading a patient. Inju‐

ry to the patient and/or operator could result.

1. Place the cot in a loading position (any position

in which the load wheels meet the vehicle floor

height – see page 1-15 ).

2. Roll the cot to the open door of the patient

compartment.

3. Lift the vehicle bumper to the raised position (if

possible).

4. Push the cot forward until the loading wheels

are on the compartment floor and the safety bar

passes the safety hook.

5. Pull the cot back until the safety bar engages

the safety hook.

6. Grasp the cot frame at the foot end and

squeeze and hold the release handle (A or B)

(Figure 19).

7. Lower the foot end of the cot to the ground,

making sure the cot locks in position 1 (Figure

20).

8. Lift the foot end of the cot until it is level with the

compartment floor.

9. Grasp the base of the cot with one hand and pull

up the base of the cot towards the litter, reduc‐

ing the space between the base and the litter

(Figure 21).

10. Push the cot into the patient compartment,

guiding it into the cot fastener.

Figure 19 - Squeeze the Release Handle

Figure 20 - Lower the Foot End of the Cot

Figure 21 - Pull Up the Base of the Cot

1-22

Page 25

Cot Operation

Unloading the Cot from a Vehicle with Two

Operators

1. Disengage the cot from the cot fastener. (For

more detailed instructions, reference the cot

fastener installation/operation manual - Stryk‐

er part number 6370-90-10).

2. Operator 1 - Grasp the cot frame. Pull the cot

out of the patient compartment until the safety

bar engages the safety hook.

WARNING

Failure to use the safety hook can cause injury to

the patient or operator. Install and use the safety

hook as described in this manual.

3. Operator 2 - Grasp the base frame where indi‐

cated, lift slightly, and lower the base frame to

its fully extended position while operator 1

squeezes and holds the release handle.

4. Operator 1 - Let go of the release handle and

be sure the undercarriage locks into place.

5. Operator 2 - Disengage the safety bar from the

safety hook by pushing the safety bar release

lever forward.

Unloading an Empty Cot

from a Vehicle with One Operator

WARNING

This procedure is for use only with an empty cot. Do

not use this procedure when unloading a patient. In‐

jury to the patient and/or operator could result.

1. Lift the vehicle bumper to the raised position (if

possible).

2. Grasp the cot frame at the foot end; pull the cot

from the vehicle until the safety bar engages the

safety hook.

3. Lower the foot end of the cot to the ground (see

Figure 20).

4. Squeeze and hold the release handle (A or B see Figure 21) and raise the foot end of the cot

back to a level position with the compartment

floor.

5. Disengage the safety bar from the safety hook

by pushing the safety bar release lever forward

and roll the cot out of the vehicle.

WARNING

Do not pull or lift on the safety bar when unloading

the cot. Damage to the safety bar could result and

injury to the patient or operator could occur.

6. Remove the cot loading wheels from the ve‐

hicle. Place the cot in a rolling position (posi‐

tions 2-7 - see page 1-15 ).

CAUTION

Do not allow the cot undercarriage to drop unassist‐

ed (commonly known as a “hot drop”) when remov‐

ing the cot from the vehicle. Repeated hot dropping

will cause premature wear or damage to the cot.

WARNING

Be sure the undercarriage has engaged before re‐

moving the loading wheels from the patient

compartment floor of the vehicle. An unlocked un‐

dercarriage will not support the cot and injury to the

patient or operator could result.

1-23

Page 26

USING ADDITIONAL ASSISTANCE

Cot Operation

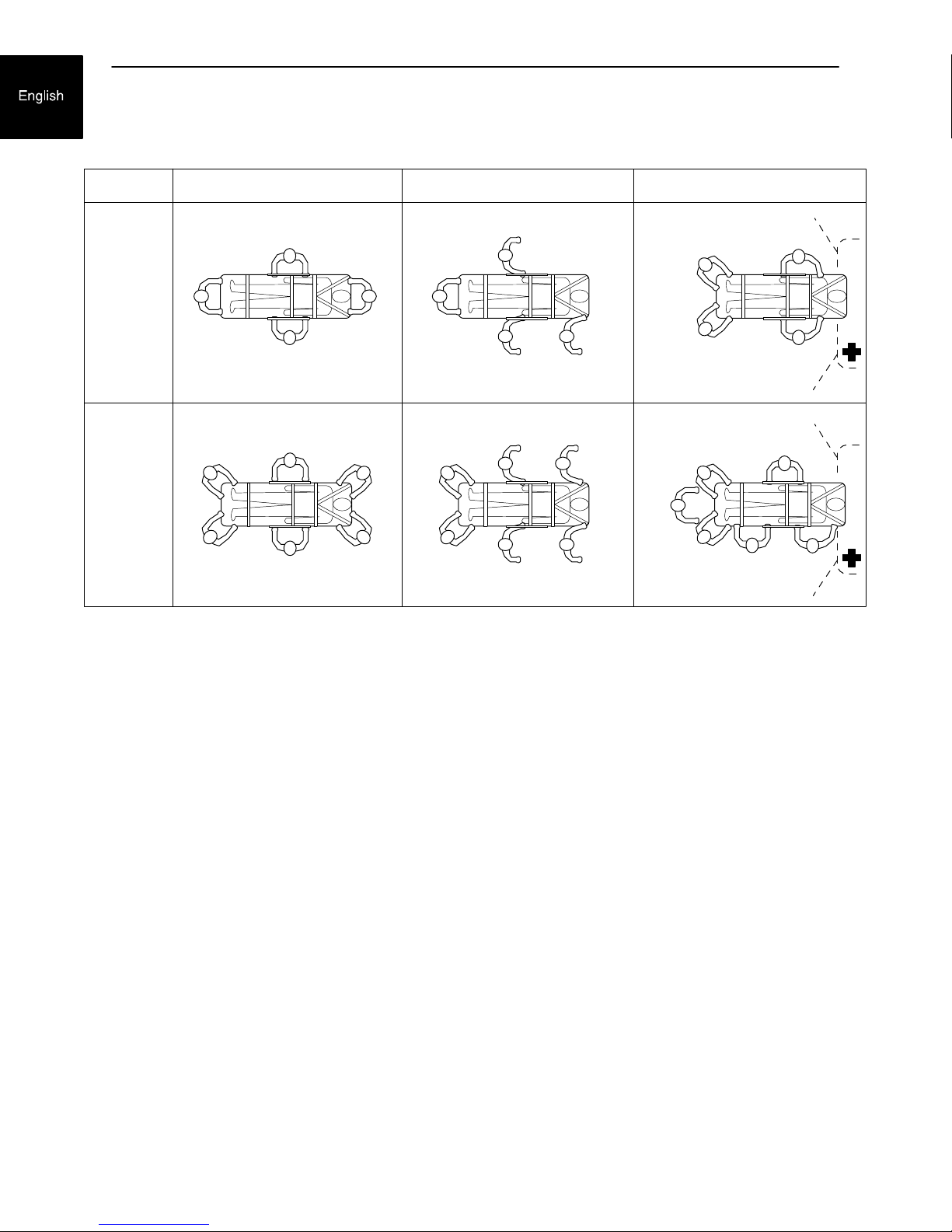

Tw o

Operators

Tw o

Helpers

Tw o

Operators

Four

Helpers

Changing Levels

Helper

Operator Operator

Helper

Helper

Operator

Helper

Helper

Operator

Helper

Operator

Helper

Operator

Rolling

Helper

OperatorHelper

Helper Helper

OperatorHelper

Loading/Unloading

Helper

Operator

Helper

Helper

Operator

Helper

Helper

Operator

Helper

Operator

1-24

Page 27

Cot Operation

OPERATING THE OPTIONAL WHEEL LOCK(S)

A

Figure 22 - Ruggedr Wheel Lock

1. To activate the optional wheel lock(s), press fully down on the pedal (A) until it stops.

2. To release the optional wheel lock(s), depress the upper face of the pedal with your foot or lift up with your

toe under the pedal. The upper portion of the pedal will rest against the caster frame when the wheel

lock is released.

WARNING

Never apply the optional wheel lock(s) while a patient is on the cot. Tipping could occur if the cot is moved

while a wheel lock is applied, resulting in injury to the patient or operator and/or damage to the cot.

Wheel lock(s) are only intended to help prevent the cot from rolling while unattended. A wheel lock may not

provide sufficient resistance on all surfaces or under loads.

Never leave a patient unattended on the cot or injury could result. Hold the cot securely while a patient is

on the cot.

Never install or use a wheel lock on a cot with excessively worn wheels. Installing or using a wheel lock on

a wheel with less than a 6” diameter could compromise the holding ability of the wheel lock, resulting in injury

to the patient or operator and/or damage to the cot or other equipment.

1-25

Page 28

Cot Operation

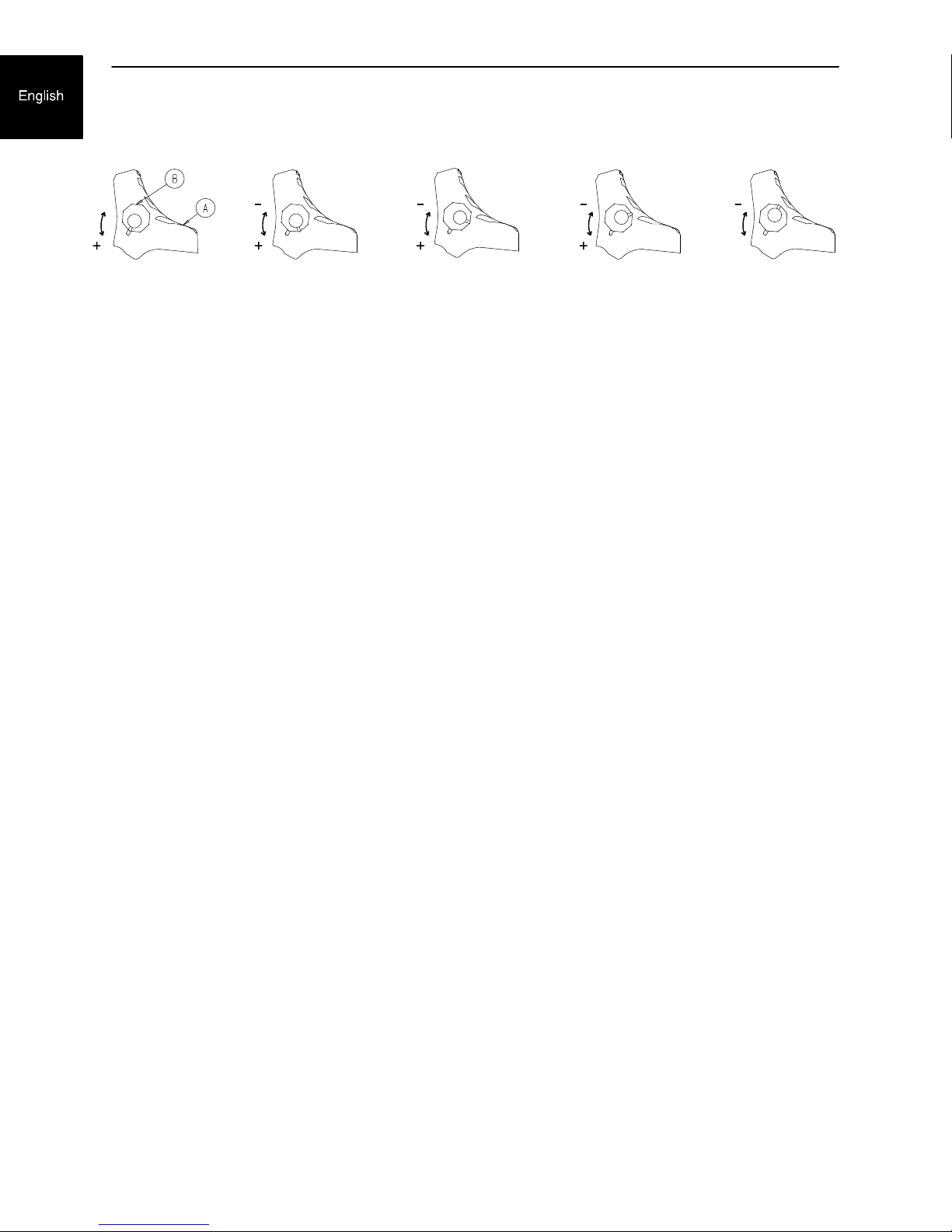

ADJUSTING THE WHEEL LOCKING FORCE

MINIMUM MAXIMUM

1. To adjust the wheel locking force, remove the hex socket screw from the center of the lock pedal. The

wheel lock is initially assembled with the pedal set at the minimum locking force. The marker on the pedal

(item A) is aligned with the marker on the octagonal sleeve (item B).

2. Remove the sleeve (B). Rotate the sleeve counterclockwise to increase the pedal locking force and

clockwise to decrease the locking force. Insert the sleeve into the pedal. Reinstall the hex socket screw.

3. Test the pedal locking force and verify it holds properly before returning the cot to service.

Figure 23 - Wheel Locking Force Adjustment

1-26

Page 29

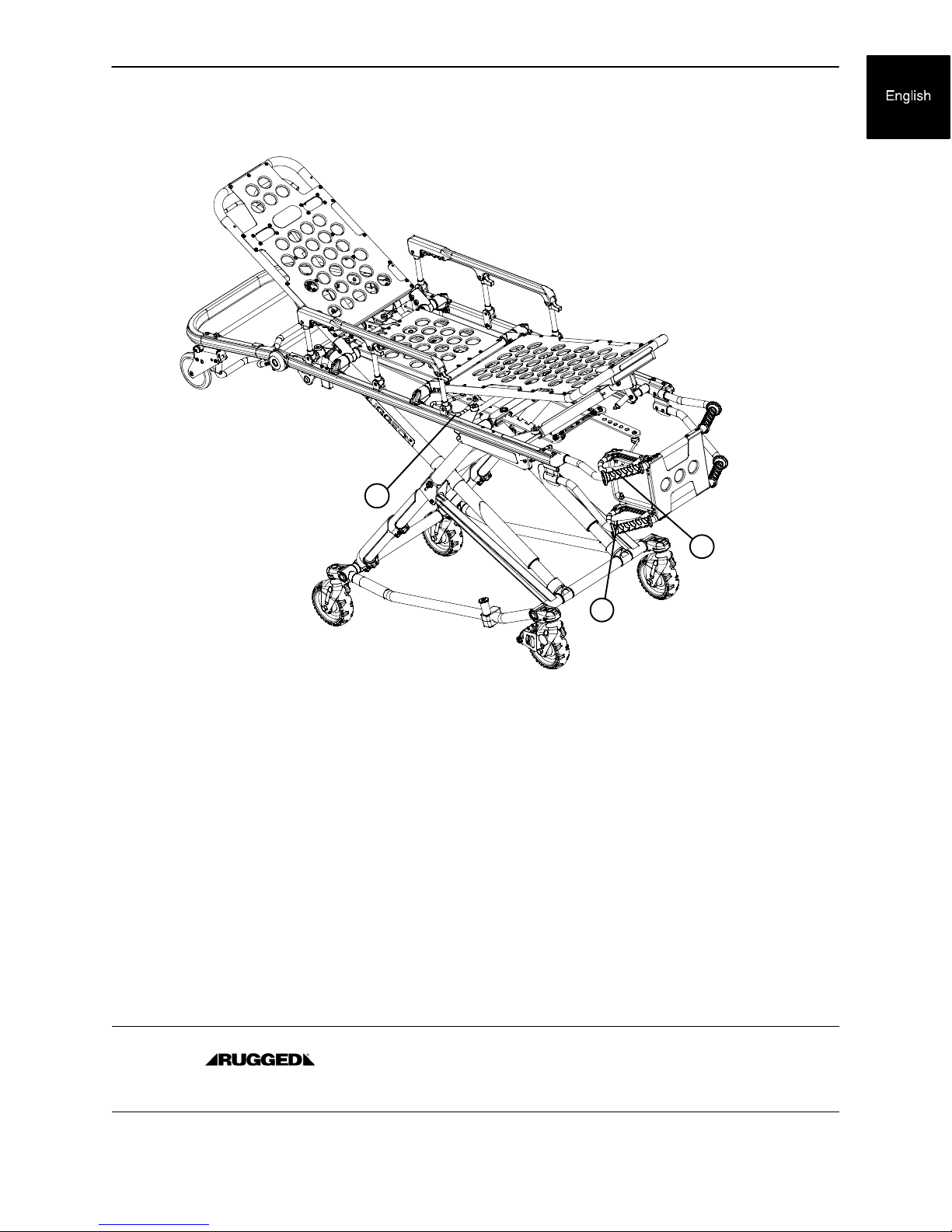

Cot Operation

CHANGING COT HEIGHT WITH TWO OPERATORS

C

FOOT END

B

A

Figure 24 - Release Handle Locations

NOTE

Changing the height while a patient is on the cot requires a minimum of two operators, positioned at both ends

or on each side of the cot. Each operator must grasp the cot frame securely.

To lower the cot from the ends, the operator at the foot end of the cot positions his/her hands so the release

handle (A or B) can be squeezed while a secure grip is maintained on the lifting bars. Both operators must

lift the cot until the weight is off the latching mechanism (approximately 1/4”). The operator at the foot end

squeezes and holds the release handle and both operators then raise or lower the cot together. The handle

is released when the desired position is reached. Both operators should maintain a secure grip on the litter

frame until the latching mechanism is securely locked into position.

To lower the cot from the sides, the operator on the patient's right positions his/her hands so he/she can

reach the release handle at the midpoint of the litter (C). Both operators must lift the cot until the weight is

off the latching mechanism (approximately 1/4”). The operator at the patient's right squeezes and holds the

release handle. Both operators then raise or lower the cot together. The handle is released when the desired

position is reached. Both operators should maintain a secure grip on the litter frame until the latching mecha‐

nism is securely locked into position.

WARNING

Grasping the Cot improperly can cause injury. Grasp only the litter frame or the lifting bar

to lift the cot. Keep hands, fingers and feet away from moving parts. To avoid injury, use extreme caution

when placing your feet near the base tubes while raising and lowering the cot.

1-27

Page 30

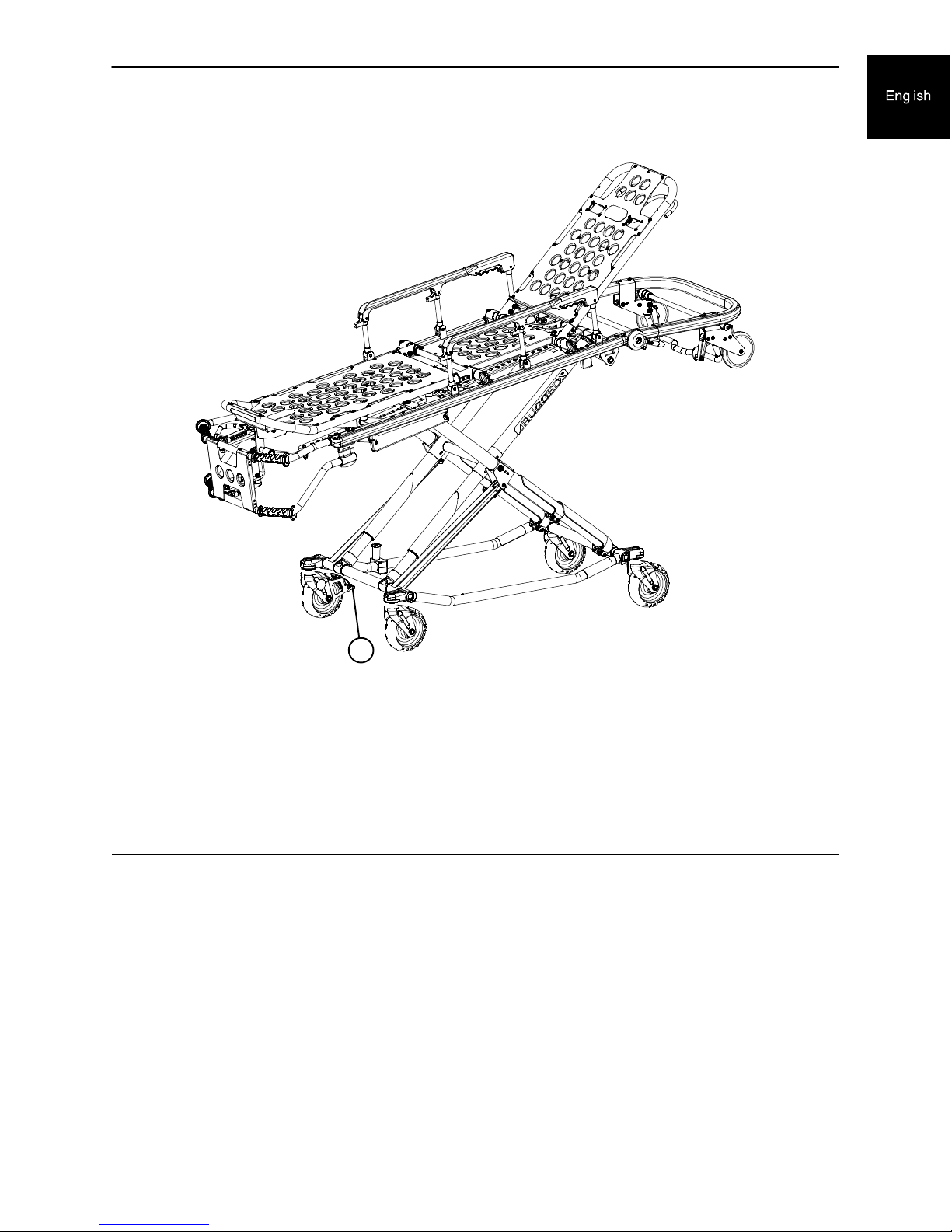

Cot Operation

Changing the Height of an Empty Cot with One Operator

To raise/lower the cot from the foot end:

1. Standing at the foot end of the cot, grasp the

lower foot end lift tube.

2. Tip the cot up onto the load wheels (Figure 25).

3. Squeeze and hold the release handle and raise

or lower the foot end to the desired position.

4. Lower the cot back onto the four base wheels

(Figure 26).

To raise/lower the cot from the side:

1. Place one foot on the outer base tube.

2. Grasp the side release handle with one hand.

Place your other hand on the outer support rail

to help stabilize the cot (Figure 27).

3. Squeeze the side release handle and raise or

lower the cot to the desired position.

WARNING

If lowering the cot to the lowest position (position 1),

remove your foot from the base tube or injury could

result (Figure 28).

Figure 25 - Cot Tipped on Load Wheels

Figure 26 - Cot Lowered to Ground

Figure 27 - Holding Outer Support Rail

Figure 28 - Lowering Cot from Side

1-28

Page 31

Adjusting the Leg Rest

Cot Operation

A

B

FOOT END

Figure 29 - Leg Rest Elevated

The leg rest is adjustable to allow for elevation of the patient's legs.

To raise the leg rest, lift the leg rest frame (A) as high as possible. The support bracket will engage automati‐

cally. Release the frame after the support bracket has engaged.

To lower the leg rest, lift the leg rest frame (A) and, while holding the frame, lift up on the release handle

(B) until the bracket disengages. Lower the leg rest until flat.

1-29

Page 32

A

HEAD END

Cot Operation

B

Figure 30 - Backrest Elevated and Siderails Raised

Operating the Backrest

To raise, squeeze handle (A) for pneumatic assist in lifting the Backrest to the desired height. Remove

hand(s) from handle when desired height is achieved.

To lower, squeeze handle (A) and push down on the Backrest frame until the Backrest has reached the de‐

sired height. Remove hand(s) from handle when desired height is achieved.

Operating the Siderails

To raise, lift up until the latch clicks and the siderail locks into place. When a patient is on the cot, always

keep the siderails in the raised position unless the patient is being transferred.

To lower, squeeze handle (B) to release the siderail latch. Guide the siderail down toward the foot end until

flat.

WARNING

Siderails are not intended to serve as a patient restraint device. Refer to pages 1-16 and 1-17 for proper

restraint strap usage. Failure to utilize the siderails properly could result in patient injury.

1-30

Page 33

Cot Operation

Operating the Breakaway Head Section

A

Figure 31 - Breakaway Head Section

Release Bar

The head end of the cot litter folds down to shorten the length of the cot and allow for maneuvering when space

is limited in elevators, halls, etc.

The breakaway head section should only be used when the cot is in positions 5-7 (see page 1-15 ).

To lower the breakaway head section, raise the backrest to its uppermost position (see page 1-30 for back‐

rest operation instructions). Squeeze the release bar (A) at the head end of the cot with one hand while sup‐

porting the head section with the other hand. Lower the head section.

To raise the breakaway head section, lift the break-away head section until the release bar clicks and the

head section locks into place.

CAUTION

Damage to the cot can occur if the cot is lowered in the shortened position. Use only positions 5-7 (see page

1-15 ) when the cot is shortened.

Figure 32 - Lowered Breakaway

Head Section

1-31

Page 34

Operating the 2-Stage I.V. Pole

Figure 33 - 2-Stage I.V. Pole

Storage Position

Cot Operation

D

C

B

A

Figure 34 - 2-Stage I.V. Pole

1. Lift and pivot the pole from the storage position and push down until it is locked into receptacle (A).

2. To raise the height of the pole, turn the lock actuator (B) counterclockwise and pull up on the telescoping

portion (C) of the pole to raise it to the desired height.

3. Turn the lock actuator (B) clockwise to lock the telescoping portion in place.

4. Hang I.V. bags on the I.V. hook (D).

CAUTION

The weight of the I.V. bags or equipment must not exceed 40 pounds.

1-32

Page 35

Cot Operation

Operating the 3-Stage I.V. Pole (Optional Equipment)

1. Lift and pivot the pole from the storage position and push down un‐

til it is locked into receptacle (A).

2. To raise the height of the pole, turn the lock actuator (B) counter‐

clockwise and pull up on the bottom telescoping portion (C) of the

pole to raise it to the desired height.

3. Turn the lock actuator (B) clockwise to lock the bottom telescoping

portion in place.

4. For a higher I.V. pole, pull up on section (D) until the spring clip (E)

engages.

5. Hang I.V. bags on the I.V. hook (F).

CAUTION

The weight of the I.V. bags or equipment must not exceed 40 pounds.

6. To lower the I.V. pole, push in on the spring clip (E) and slide sec‐

tion (D) down into section (C). Turn the lock actuator (B) counter‐

clockwise and slide section (C) into the bottom tube.

7. Lift up and pivot the pole down into the storage position.

F

D

E

C

B

Figure 35

3-Stage I.V. Pole

Storage Position

A

Figure 36 - 3-Stage I.V. Pole

1-33

Page 36

Cleaning

The 6082 MX-PRO R3 ambulance cot is designed to be power washable. The unit may show some signs

of oxidation or discoloration from continuous washing, however, no degradation of the cots performance char‐

acteristics or functionality will occur due to power washing as long as the proper procedures are followed.

Clean Velcro AFTER EACH USE. Saturate Velcro with disinfectant and allow disinfectant to evaporate.

(Appropriate disinfectant for nylon Velcro should be determined by the hospital.)

Washing Limitations

WARNING

Use any appropriate personal safety equipment (goggles, respirator, etc.) to avoid the risk of inhaling conta‐

gion. Use of power washing equipment can aerate contamination collected during the use of the cot.

CAUTION

Failure to properly clean or dispose of contaminated mattress or cot components will increase the risk of expo‐

sure to bloodborne pathogens and may cause injury to the patient or the operator.

S DO NOT STEAM CLEAN OR ULTRASONICALLY CLEAN THE UNIT.

S Maximum water temperature should not exceed 180 degrees F/ 82 degrees C.

S Maximum air dry temperature (cart washers) is 240 degrees F /115 degrees C.

S Maximum water pressure should not exceed 1500 psi/130.5 bar. If a hand held wand is being used

to wash the unit, the pressure nozzle must be kept a minimum of 24 inches/61 cm from the unit.

S Towel dry all casters and interface points.

S After washing the cot, follow the lubrications procedure on the following page.

S Failure to comply with these instructions may invalidate any/all warranties.

1-34

Page 37

Cleaning

In general, when used in those concentrations recommended by the manufacturer, either phenolic type or

quaternary type disinfectants can be used. Iodophor type disinfectants are not recommended for use be‐

cause staining may result.

Suggested cleaners for the 6082 MX-PRO R3 cot surface:

S Quaternary Cleaners (active ingredient - ammonium chloride)

S Phenolic Cleaners (active ingredient - o-phenylphenol)

S Chlorinated Bleach Solution (5.25% - less than 1 part bleach to 100 parts water)

Avoid over saturation and ensure the product does not stay wet longer than the chemical manufacturer s

guidelines for proper disinfecting.

WARNING

S SOME CLEANING PRODUCTS ARE CORROSIVE IN NATURE AND MAY CAUSE DAMAGE TO

THE PRODUCT IF USED IMPROPERLY. If the products described above are used to clean Stryker

patient care equipment, measures must be taken to insure the cots are wiped with a cloth soaked in

clean water and thoroughly dried following cleaning.

S Failure to properly rinse and dry the cots will leave a corrosive residue on the surface of the cots,

possibly causing premature corrosion of critical components.

NOTE

Failure to follow the above directions when using these types of cleaners may void this product's warranty.

Removal of Iodine Compounds

Use a solution of 1-2 tablespoons Sodium Thiosulfate in a pint of warm water to clean the stained area. Clean

as soon as possible after staining occurs. If stains are not immediately removed, allow solution to soak or

stand on the surface. Rinse surfaces which have been exposed to the solution in clear water before returning

unit to service.

WARNING

Failure to properly clean or dispose of contaminated mattress or cot components will increase the risk of expo‐

sure to blood borne pathogens and may cause injury to the patient or the operator.

1-35

Page 38

Preventative Maintenance

Operation Schedule Procedure

Cleaning & Disinfecting Each use. See page 1-34 .

Inspection For 1-25 calls per month, in‐

spect cot every 6 months.

For 26-200 calls per month, in‐

spect cot every 3 months.

For 201+ calls per month, in‐

spect cot monthly.

NOTE

Keep up-to-date maintenance records using the form on page 1-39 .

CHECKLIST

All fasteners secure (reference all assembly drawings)

All welds intact, not cracked or broken

No bent or broken tubing or sheet metal

No debris in wheels

All wheels secure, rolling and swivelling properly

Optional wheel lock holds wheel securely when on and clears wheel when off

Siderails move and latch properly

Backrest operating properly

Optional accessories intact and operating properly

Height positioning latch functioning properly

Cot secure in each height position

Undercarriage folds properly

Breakaway head section operating properly

Safety bar operating properly

Foot rest operating properly

No rips or cracks in mattress cover

Body restraints intact and working properly

Lubricate base tubes (optional)

See below for checklist.

Serial No.______________

Completed By:_________________________________ Date:_____________

1-36

Page 39

Preventative Maintenance

BASE LUBRICATION

NOTE

The MX-PRO has been designed to operate without the need for lubrication. Tri-Flow t

with TeflonR lubricant may be used to reduce the force required to raise the undercarriage and to minimize

wear. Do not use silicone, WD-40t, or lithium grease. They could harm the moving parts of the cot.

FOOT END

B

APPLY LUBRICATION

A

Figure 37 - Base Lubrication Locations

1. Place the cot in the highest position.

2. Turn the cot upside down with the base legs facing up.

3. Using the plastic applicator tube, spray Tri-Flow t with TeflonR lubricant (Stryker part number

6082-199-12) in the gap between the upper (item A) and lower lift tubes (item B) on both foot end legs.

4. Apply Tri-Flow to right and left height adjustment Height Adjustment Racks racks providing an even ap‐

plication.

5. Apply Tri-Flow to the right and left slide plates providing an even application.

6. Let the cot sit for 5 minutes.

7. Turn the cot back over. Raise and lower the cot a few times to work the lubricant throughout the applied

areas.

8. Wipe any excess lubricant from the base tubes. Slide plates.

1-37

Page 40

Preventative Maintenance

PNEUMATIC BACKREST ADJUSTMENT

Required Tools:

1/2” Wrench 5/32” Allen Wrench Locktite 3/32” Allen Wrench

Adjustment Procedure:

1. For easier access, move backrest to 75 degrees.

NOTE

Before continuing with the backrest adjustment procedure, be sure the pneumatic cylinder (item A) is com‐

pletely threaded into the yoke (item B) so no threads are showing on the shaft of the cylinder. If threads are

showing, use a 3/32” Allen wrench to remove the set screw (item C) in the center of the yoke and remove

the E-clip and pin (items D & E) holding the bottom of the pneumatic cylinder. Thread cylinder shaft (item

A) completely into yoke (item B). Replace the E-clip and pin (items D & E) and replace the set screw (item

C) using Locktite.

2. Using a 1/2” wrench, loosen the hex nut (item F) on the backrest pivot (item J) while holding the set screw

(item H) fixed in the pivot.

3. Using a 5/32” Allen wrench, turn the set screw (item H) until there is no play between the backrest release

handle (item K) and the pneumatic cylinder release button.

4. Be sure the backrest will travel from flat to at least 75 degrees. If it doesn't, turn the set screw (item H)

clockwise 1/2 turn. Repeat until at least 75 degrees of travel is achieved.

5. Lower the backrest to a 5-10 degree angle and release the handle. Apply approximately 50 pounds

downward force to the end of the backrest. If the backrest drifts down, turn the set screw (item H) counter‐

clockwise. Repeat until the backrest does not drift downward.

6. Using the 1/2” wrench, tighten the hex nut (item F) while holding the set screw (item H) fixed in the pivot.

A

K

J

H

F

D

E

Figure 38 - Pneumatic Cylinder and Fowler Crossbrace

1-38

C

B

Page 41

Maintenance Record

Date Maintenance Operation Performed By

1-39

Page 42

Training Record

Training Date Training Method

Trainee Name Basic

Training

Refresher

Update

Owner's Manual, In-Service,

Formal Class, Etc.

1-40

Page 43

Table des matières

Introduction

Spécifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signification de Mise en garde / Attention / N.B. 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Garantie

Obtention de pièces et de service 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Couverture de garantie supplémentaire 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autorisation de retour 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Réclamations liées aux dommages pendant le transport 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Résumé des précautions de sécurité 6, 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procédures d'assemblage 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification des composants 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sélection du crochet de sécurité du véhicule 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positions de la civière 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emploi des sangles de sécurité 16, 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions pour le Pedi–Matet optionnel 18, 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfert du patient vers la civière 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roulage de la civière 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chargement de la civière dans un véhicule 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chargement d'une civière vide dans un véhicule 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Déchargement de la civière depuis un véhicule 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emploi du bloqueur de roue optionnel 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utilisation de l'aide supplémentaire 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Réglage de la force de blocage des roues 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changement de la hauteur de civière par deux opérateurs 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changement de la hauteur d'une civière vide 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Réglage du repose-jambes 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utilisation du dossier 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utilisation des lisses latérales 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utilisation de la tête escamotable 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utilisation de potences à perfusion 32, 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entretien préventif

Nettoyage 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entretien préventif Planning & Liste de vérifications 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrification de la base 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Réglage du Fowler pneumatique 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Registre d'entretien 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Registre de formation 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 44

Introduction

INTRODUCTION

Ce manuel a été conçuepour vous aider à l’utilisation et à l’entretien de la civière d’ambulance 6082 RUGGEDRMX--PRO.Il convient delelire soigneusement avant d’utilisercematérieloude commencer sonentretien.

SPÉCIFICATIONS

Longueur hors--tout/Longueur minimale/Largeur 80.5”/61.75”/23”

Hauteur! -- Position 1

Position 2

Position 3

Position 4

Position 5

Position 6

Position 7

Position du dossier articulation/choc 2_ à73° /+14_

Poids@ 81 livres

Charge utile maximale 650 livres

Diamètre/Largeur des roues 6”/2”

Nombre minimal d’opérateurs requis pour

charger/décharger une civière occupée

Systèmes d’attache recommandé Modèle 6370/6374/6377/6378 type montage au sol

Hauteur recommandée par rapport au sol# Jusqu’à 32”

Style Roll–In Oui

Bloqueur de roue simple / Bloqueur de roue double Optionnel

13.5”

21.0”

25.5”

29.0”

32.0”

35.0”

37.5

2

Model 6371/6375 Type montage mural

! Hauteur mesurée depuis le fond du matelas au niveau de l’assise jusqu’asol.

@ La civière a été peséesans matelas ni sangles.

# La civièrepeut être chargée à partir de n’importe quelle hauteur.Un kit de limitation de hauteur (p/n 6060–202--000)est disponible pour

limiter la hauteur de charge de la civière.

Stryker se réservele droit de modifier ces caractéristiques sans préavis.

La MX–PRO a été conçue pour êtreconforme aux spécifications fédérales de l’ambulance Star–of–Life KKK–A–1822.

Figure1–Positionenhauteurminimale

La combinaison de couleur jaune et noir est une marque déposée de Stryker Corporation.

2--2

Page 45

Introduction

DEFINITION DES TERMES MISE EN GARDE / ATTENTION / N.B.

Les termes MISEEN GARDE,ATTENTIONet N.B. ontdessignifications particulières.Il convient d’enprendre attentivement connaissance.

MISE EN GARDE

La sécurité personnelle du patient ou de l’utilisateur peut être impliquée.La négligence de cette information

peut donner lieu à une blessure du patient ou de l’utilisateur.

ATTENTION

Ces instructions soulignent l’existence de procédures ou de précautions spéciales à suivre pour éviter que

la matériel soit endommagé.

N.B.

Cetermefournit une informationspécialepour faciliterl’entretien oupour rendre desinstructions importantes

plus claires.

2--3

Page 46

Garantie

Stryker EMS, une division de Stryker Corporation, offre deux options de garantie

distinctes aux États--Unis :

Un (1) an -- pièces et main--d’œuvre. Au titre de cette option, Stryker EMS garantit à l’acheteur initial que

ses produits seront exempts de toute non--conformité de fabrication affectant la performance du produit et

la satisfaction du client, pendant une période d’un (1) an après la date de livraison. Pour tout produit reconnu

par Stryker comme défectueux à sa discrétion, l’obligation de Stryker au titre de cette garantie se limite

expressément à la fourniture de pièces de rechange et de main--d’œuvre ou à son remplacement, à son

choix.

Deux (2) ans -- pièces. Au titre de cette option, Stryker EMS garantit à l’acheteur initial que les éléments

non consommables de ses produits seront exempts de toute non--conformité de fabrication affectant la

performance du produit et la satisfaction du client, pendant une période de deux (2) ans après la date de

livraison. Pour tout produit reconnu par Stryker comme défectueux à sa discrétion, l’obligation de Stryker au

titre de cette garantie se limite expressément à la fourniture de pièces de rechange ou à son remplacement,

à son choix. Les éléments consommables, c’est--à--dire les matelas, dispositifs de retenue, supports de

perfusion, filets de rangement, poches de rangement, sangles O2 et autres composants souples, ont une

garantie limitée d’un (1) an avec cette option.

Sous l’une ou l’autre option de garantie, les produits Stryker EMS sont conçus pour une durée de vie utile

prévue de 5 ans

décr

it dans le manuel d’entretien de chaque dispositif. Stryker garantit à l’acheteur initial que les soudures

présentes sur ses produits EMS seront indemnes de défauts structurels pendant la durée de vie utile prévue

de 5 ans

initiaux

châssis X du brancard MX--PRO R3, à conditiond’avoir aussi acheté des protections dechâssis X aumoment

de l’achat initial et de les avoir installées sur le MX--PRO avant sa mise en service.

du produit EMS aussi longtemps que l’acheteur initial est en possession du produit. Les acheteurs

obtiendront également une garantie limitée de trois (3) ans pour les pièces des composants du

dans des conditions d’utilisation normale, et avec un entretien périodique adapté comme

À la demande de Stryker, tout produit ou pièce faisant l’objet d’une réclamation de garantie de la part d’un

acheteur initial doit être retourné en port payé à l’usine de Stryker.

Tout usage incorrect ou toute modification ou réparation effectuée par un prestataire de services non agréé

qui, selon l’avis de Stryker, a un effet matériel et indésirable sur le produit, annule la présente garantie. Toute

réparation de produits Stryker effectuée avec des pièces non fournies ou non agréées par Stryker annule

cette garantie. Aucun employé ou représentant de Stryker n’est autorisé à modifier la présente garantie de

quelque manière que ce soit.

Cette déclaration constitue l’intégralité de la garantie offerte par Stryker EMS relativement à l’équipement

susdit. HORMIS LES CLAUSES ÉNONCÉES AUX PRÉSENTES, STRYKER NE FAIT AUCUNE AUTRE

GARANTIE OU DÉCLARATION, EXPRESSE OU IMPLICITE. AUCUNE GARANTIE N’EST FAITEQUANT

À LA QUALITÉ MARCHANDE OU L’ADÉQUATION À UN USAGE PARTICULIER. EN AUCUN CAS

STRYKER NE PEUT ÊTRE TENUE RESPONSABLE, AU TITRE DES PRÉSENTES, DE TOUT

DOMMAGE ACCESSOIRE OU INDIRECT RÉSULTANT DE, OU LIÉ DE TOUTE AUTRE MANIÈRE À LA

VENTE OU À L’UTILISATION D’UN TEL ÉQUIPEMENT.

2--4

Page 47

Garantie

Réglementation de Stryker EMS relative aux renvois

Les civières, les chaises--civières, les chaises d’évacuation, les dispositifs de fixation de civière et les accessoires de rechange peuvent être renvoyés dans les 180 jours après leur réception s’ils satisfont aux

critères suivants :

Avant 30 jours

S Garantie de remboursement sous 30 jours en vigueur

S Tous les frais sont à la charge de Stryker EMS

S Le renvoi d’articles modifiés ne sera pas autorisé

Avant 90 jours

S Le produit doit être non utilisé, non endommagé et dans son emballage d’origine

S L’acheteur est responsable de frais de restockage de 10 %

Avant 180 jours

S Le produit doit être non utilisé, non endommagé et dans son emballage d’origine

S L’acheteur est responsable de frais de restockage de 25 %

Autorisation de retour:

Lesproduitsnepeuvent êtreretournésquesur approbation duservice--clientsdeStryker. Ilvous seraattribué

unnumérod’autorisation que vous devezimprimer surleproduitretourné. Strykerse réservele droit de vous

compter le transport et les frais de réapprovisionnement des articles retournés.

LES ARTICLES SPECIAUX, MODIFIES OU NON--SUIVIS NE PEUVENT ETRE RETOURNES.

Marchandise endommagée :

Les règlements ICC exigent que les réclamationsvisant une marchandise endommagée doivent êtrefaites

parle transporteur dansles quinze(15)joursqui suiventlaréception delamarchandise.NEPASACCEPTER

LESENVOIS ENDOMMAGES SAUF SILEDOMMAGEEST NOTESURLEBON DE LIVRAISON AUMOMENT DE LA RECEPTION. Sur notification rapide, Stryker enregistrera une réclamation de fret avec le

transporteur approprié pour les dommages subis. La réclamationse limitera au coût de remplacement réel.

Au cas où cette notification ne serait pas reçue par Strykerdans les quinze (15) joursqui suiventlalivraison

de la marchandise ou si le dommage n’a pas été noté sur le bon de livraison au moment de la livraison, le

client s’acquittera entièrement de la facture initiale.