Page 1

®

LUCAS

CHEST COMPRESSION SYSTEM

3

SERVICE MANUAL

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 1 of 91

Page 2

Table of Contents

Table of Contents ............................................................................................................................................................... 2

Preface ............................................................................................................................................................................... 5

Disclaimer ....................................................................................................................................................................... 5

Trademarks..................................................................................................................................................................... 5

Definitions, Acronyms , and Abbrev iat ions ...................................................................................................................... 5

Contacting Physic-Control .............................................................................................................................................. 6

Service Personnel Qualification...................................................................................................................................... 6

Service Information ......................................................................................................................................................... 6

Configuration Information ............................................................................................................................................... 7

Device Tracking .............................................................................................................................................................. 7

Recycling Information ..................................................................................................................................................... 7

Warnings and Precautions ............................................................................................................................................. 8

Warranty ......................................................................................................................................................................... 8

Device Information ............................................................................................................................................................. 9

LUCAS® 3 Components ................................................................................................................................................. 9

Control Panel ................................................................................................................................................................ 10

Electronics Block Diagram ............................................................................................................................................ 11

Compression Mechanism ............................................................................................................................................. 12

Device Communication ................................................................................................................................................. 13

LUCAS® 3 Program Loader ............................................................................................................................................. 13

Software installation ..................................................................................................................................................... 13

Connect the device via Bluetooth ................................................................................................................................. 15

Connect the device via USB cable ............................................................................................................................... 19

View Error Code ........................................................................................................................................................... 22

Set Device S/N, Date, and Data ................................................................................................................................... 25

Change Device S/N ...................................................................................................................................................... 26

Set Latest Service Date ................................................................................................................................................ 26

Store View .................................................................................................................................................................... 26

Checksum ..................................................................................................................................................................... 27

Update LUCAS Software .............................................................................................................................................. 28

Calibrate Linear Sensor ................................................................................................................................................ 29

Failed calibration .......................................................................................................................................................... 31

Update LUCAS 3 sw 3.0 to LUCAS 3 sw 3.1 ............................................................................................................... 32

Setup ............................................................................................................................................................................ 32

Update and Test procedure .......................................................................................................................................... 33

Setup Options - LUCAS 3 Version 3.1 (Part No: 250041-00) ................................................................................... 35

Troubleshooting ............................................................................................................................................................... 39

Troubleshooting Table .................................................................................................................................................. 39

LUCAS Malfunction Alarm ............................................................................................................................................ 40

Error Codes .................................................................................................................................................................. 41

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 2 of 91

Page 3

Error Codes from Control CPU ..................................................................................................................................... 42

Warnings from Control CPU ......................................................................................................................................... 45

Error Codes from Protective CPU ................................................................................................................................ 48

Error Codes from Charger CPU ................................................................................................................................... 49

User Errors ................................................................................................................................................................... 50

Bluetooth Connection Error .......................................................................................................................................... 50

Troubleshooting Tips .................................................................................................................................................... 51

Spare Parts and Accessories ........................................................................................................................................... 51

Spare Parts ................................................................................................................................................................... 51

Other Orderable Spare Parts........................................................................................................................................ 52

Accessories .................................................................................................................................................................. 54

Tools ................................................................................................................................................................................. 54

Standard Tools ............................................................................................................................................................. 54

Special Tools ................................................................................................................................................................ 55

Substances ................................................................................................................................................................... 55

Software ........................................................................................................................................................................ 55

Preventive Maintenance ................................................................................................................................................... 56

Maintenance Procedure ............................................................................................................................................... 56

Clean Electric Fan and Mesh Grill ................................................................................................................................ 57

Compression Module Lubrication ................................................................................................................................. 57

Claw Lock Lubrication .................................................................................................................................................. 58

Replacing Parts or Modules in LUCAS ............................................................................................................................ 58

How to Apply Thread Lock Fluid .................................................................................................................................. 58

How to Replace the Hood ............................................................................................................................................. 58

How to Replace the Bellows ......................................................................................................................................... 60

How to Replace the Compression Module ................................................................................................................... 62

How to Replace the Drive Belt...................................................................................................................................... 66

How to Replace the Electric Motor ............................................................................................................................... 67

How to Replace the Control PCBA ............................................................................................................................... 69

How to Replace the Protective PCBA .......................................................................................................................... 70

How to Replace the Electric Fan .................................................................................................................................. 71

How to Replace the Support Leg.................................................................................................................................. 73

How to Replace the Antenna ........................................................................................................................................ 80

How to Replace the Communication PCB .................................................................................................................... 82

Replacing the Power Inlet ............................................................................................................................................. 84

Replacing the Main Body/Frame Assembly ................................................................................................................. 86

Function Check ................................................................................................................................................................ 87

Introduction ................................................................................................................................................................... 87

Mechanics Test ............................................................................................................................................................ 87

Electronics Test ............................................................................................................................................................ 88

Accessories ...................................................................................................................................................................... 89

LUCAS Battery Charger ............................................................................................................................................... 89

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 3 of 91

Page 4

LUCAS Car Cable ........................................................................................................................................................ 89

LUCAS Power Supply .................................................................................................................................................. 90

Appendix A (wiring diagram) ........................................................................................................................................ 91

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 4 of 91

Page 5

Preface

This Manual describes how to maintain, test, troubleshoot, and repair the LUCAS® 3.

Another publication, the LUCAS

clinicians, and emergency care providers. The IFU provides step-by-step instructions for use, as well as operator-level

testing and maintenance.

Disclaimer

Physio-Control does not accept liability for injury to personnel or damage to equipment that may result from misuse of

LUCAS. Under no circumstances shall Physio-Control be liable for incidental or consequential damage arising from the

use of LUCAS.

All discovered failures that directly or indirectly have, or may have, affected patient or user safety shall, with no delay,

be reported directly to the Quality Department at Physio-Control, Inc.

All the screenshots or pictures in this document are for the example only; they are subject to change without matching

the latest versions of software.

Trademarks

LUCAS® 3 is a trademark of Jolife AB. LUCAS 3 Report Generator is a trademark of Physio-Control, Inc. Microsoft and

Windows are registered trademarks of Microsoft Corporation in the US and/or other countries. Specifications are

subject to change without notice.

®

3 Chest Compression System - Instruction for Use (IFU) is for physicians,

Definitions, Acronyms, and Abbrevia ti ons

IFU Instructions for Use, LUCAS 3, PNs/CAT #: 3326785-0## / 26500-00####

Instructions for Use, LUCAS 3 Version 3.1, PNs/CAT #: 3326785-1## /

26500-00####

LRG LUCAS® 3 Report Generator, a data download Software

DT Express Data Transfer Express

FSR Field Service Representative (services products in the Field)

LUCAS LUCAS® 3 Chest Compression System

LIFENET LIFENET System including website

Nm Unit for torque value in Newton Meter

PCO file

Physio Case Object file, a data format for a combination of device data and

user-entered data. Data in this format can be imported and exported by

Physio-Control data management applications.

PIP Performance Inspection Procedure

SmartDesk LIFENET connectivity support

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 5 of 91

Page 6

Contacting Physic-Control

Stryker South Pacific

MANUFACTURER

Fax. +46 46 286 50 10

Physio-Control, Inc.

11811 Willows Road NE

Redmond, WA 98052-2003 USA

Telephone: 425.867.4000

Toll Free (USA only): 800.442.1142

Fax: 800.426.8049

Internet: www.physio-control.com

Stryker European Operations B.V.

Herikerbergweg 110, 1101 CM

Amsterdam, The Netherlands

Tel: +31 (0)20 2192600

Fax: +31 (0)20 2192703

8 Herbert Street

St Leonards, NSW 2065

Australia

Tel: +61 (0)2 94671000

Jolife AB

Scheelevagen 17

Ideon Science Park

SE-223 70 LUND

Sweden

Tel. +46 46 286 50 00

Service Personnel Qualification

Service personnel must be properly qualified and trained, and thoroughly familiar with the operation of the LUCAS® 3.

They must meet at least one of the following requirements (or the equivalent):

• Physio-Control Service Depot technicians

• Physio-Control Field Service Representatives

rd

Party Service Providers that have service agreements with Ph ysio-Control

• 3

Service Information

Before attempting to clean or repair any assembly in the device, the Service personnel should be familiar with the

information provided in Pre ven ti ve Ma inte nance .

A qualified Technic al Supp or t s hou ld inspec t any device that has been dropped, damaged, or abused to verify that the

device is operating within performance standards listed in the Performance Inspection Procedures (PIP).

Replacement procedures for the device are limited to those items accessible at the final assembly level. Replacements

and adjustments must be made by qualified service personnel. Replacements at the final assembly level simplify repair

and servicing procedures and help ensure correct device operation and calibration.

To obtain service and maintenance for your device, contact your local Physio-Control service or sales representative.

In the USA, call Physio-Control Technical Support at 1.800.442.1142. Outside the USA, contact your local PhysioControl representative.

When you call Physio-Control to request service, provide the following information:

• Model number and part number

• Serial number

• Observation of the problem that led to the call

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 6 of 91

Page 7

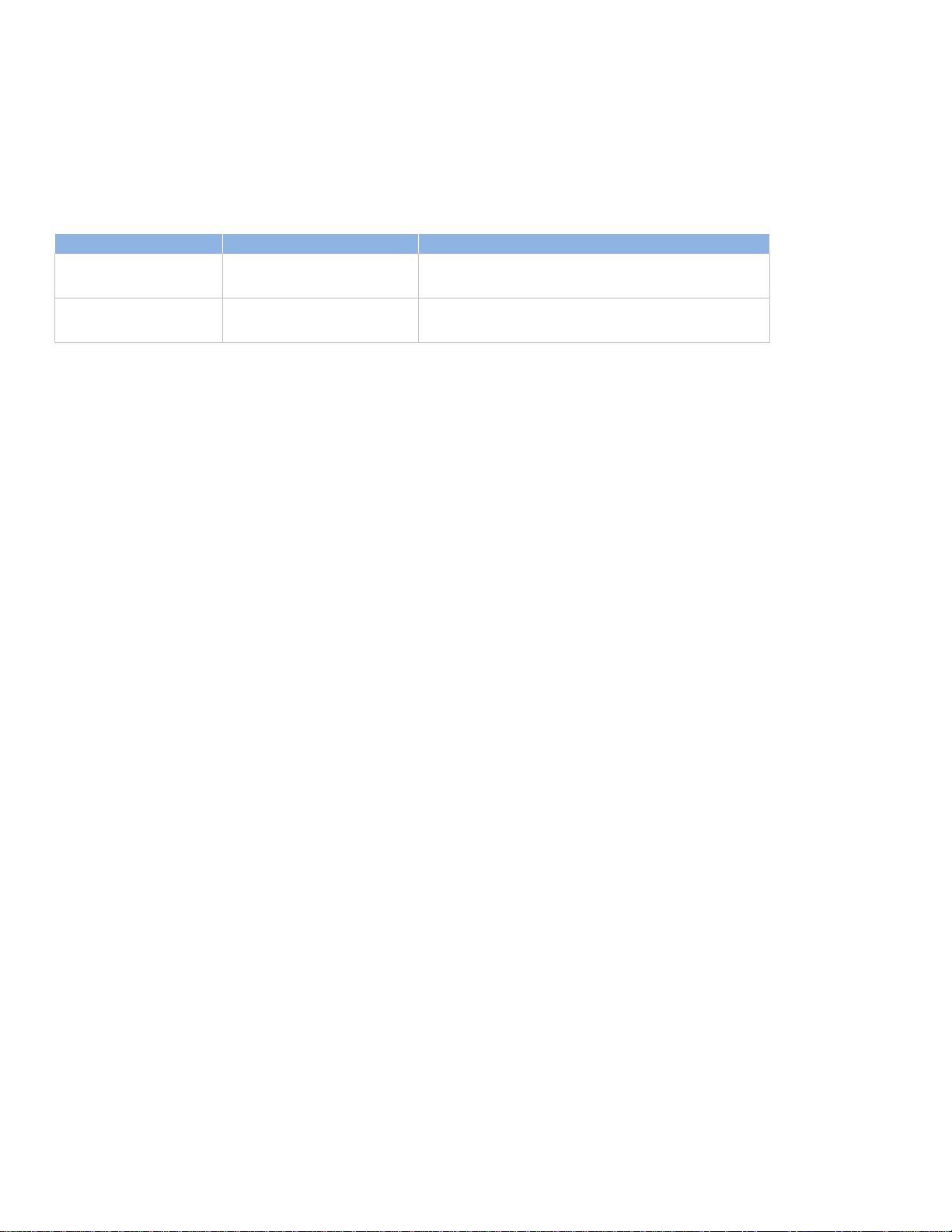

Configuration Inf orm a ti on

Item Number

Catalog Number

Description

This service manual covers the LUCAS® 3 also known as LUCAS in this manual.

Unless otherwise noted, functions and features are consistent as specified throughout this manual. Differences are

noted as appropriate.

3326785-0## 99576-0000## LUCAS 3, *

3326785-0## 99576-0000## LUCAS 3 version 3.1, *

Note:

# in the dash number of Item Number and Catalog Number is different for each language specification.

* Description contains country specification.

Device Tracking

All performed service where modules are replaced, the serial no./batch no. of each module shall be stated in the

service report. This information is then sent to Physio-Control, Inc., on a monthly basis.

The modules that have traceability are:

• Compression Module

• Electronic PCBs

• Electric Motor

• Battery

• Main Body

• Support Leg

• Hood

• Back plate

Recycling Information

Important!

The Battery used in LUCAS shall be returned to the local recycling station or dealer/distributor for correct recycling.

LUCAS contains of several materials as listed below:

• Polyphthalamide (PPA) with 50% glass fiber

• Polyamide reinforced with 30% glass fiber

• Polycarbonate/Polybutylene Terephthalate

• Polycarbonate

• Polyurethane

• PVC

• POM

• Silicone

• Chloroprene

• Aluminum

• Stainless steel

• Brass

For further recycling information please contact Jolife AB, Sweden.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 7 of 91

Page 8

Warnings and Precautions

Except the warnings stated below, there are also warnings and precautions mentioned in the following documents that

are of relevance during service and maintenance of LUCAS.

LUCAS

LUCAS®3 Version 3.1 Chest Compression System - Instruction for Use (PNs/CAT #: 3326785-1## / 26500-00####)

®

3 Chest Compression S ystem - Instruction for Use (PNs/CAT #: 3326785-0## / 26500-00####)

• Electrical Hazard

Use caution when examining or operating the device without its covers.

• Chemical Hazard

The Battery contains chemicals, in case of leakage use extreme caution to avoid injuries. Never try to open the

casing of the Battery.

• ESD Protection

Always use ESD protection when handling electronic boards and connections.

Warranty

To obtain a detailed warranty statement, contact your local Physio-Control representative or go to www.physio-

control.com

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 8 of 91

Page 9

Device Information

LUCAS® 3 Components

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 9 of 91

Page 10

TRANSMIT

DATA

ACTIVE

ACTIVE (30:2)

Bluetooth LED

WiFi LED

Power ON/OFF

ADJUST

PAUSE

MUTE

Battery Indicator

WARNING

LUCAS has two Support Legs that lock to the Back Plate with Claw Locks. The Support Legs are foldable for

convenient transportation.

The Claw Locks automatically lock to the Back Plate when LUCAS is pressed on to it. To unlock the Claw Locks, pull

the Release Rings

Control Panel

The User Control Panel is the user interface with which the device can be controlled and monitored through seven

button switches and a number of LED’s. The User Control Panel is situated on the hood and is connected to the

protective/charger system that sends the signals to the control system. For further details on the User Control Panel

please read chapter 2.7 in the Instructions for Use which also explains the different states on the Battery indicator.

LED

(continuous)

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 10 of 91

Page 11

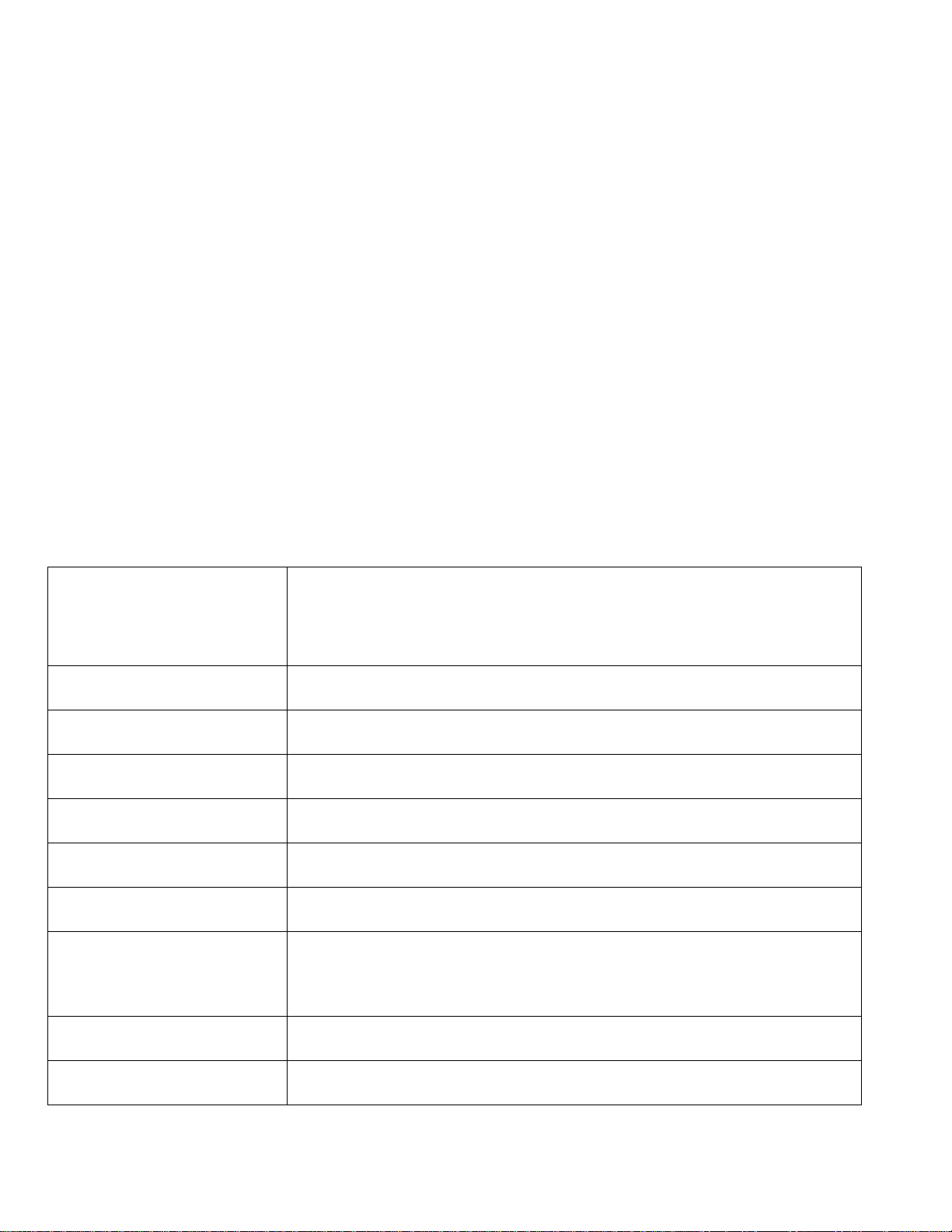

Electronics Block Diagram

Control

PCB

Protective &

Charger

PCB

Battery

User Control

Panel

Electric

Motor

Rotation Sensor

Linear Sensor 2

Linear

Sensor 1

Power

Power

Power

Fan

Speaker

Communication

PCB

LUCAS is driven by a rechargeable Lithium Ion Polymer (LiPo) Battery. The Battery can be charged during operation

by an external Power Supply, connected to a wall outlet, or with a Car Power Cable. You can also remove the Battery

from LUCAS and recharge it in a separately sold Battery Charger of desktop model.

NOTE: The Battery must be connected even when the device is supplied by the power supply.

The Battery is mechanically keyed in LUCAS and in the Battery Charger to make sure you get the correct installation.

The top of the Battery has connections for power and communication to the Battery Charger and to LUCAS.

The Battery has built in intelligence to monitor the number of usage cycles and battery age to tell the user when to

replace the Battery. It also monitors the internal temperature of the Battery.

The Battery supplies the electronics and the electrical Motor. The Motor is connected to the linear unit via a drive belt.

The electronics is divided in four parts but situated on three separate PCB’s:

1. The Control System that controls the motor with information from the user interface and from the rotation and

linear sensors.

2. The Communication System that sends data wirelessly via Bluetooth and WiFi to/from computer.

3. The Protective System that controls inputs and outputs and shut off in case of a problem. The internal Battery

Charger that controls the charging sequence of the Battery.

There are two separate linear measuring sensors that monitor the movement of the Suction Cup:

1. Linear sensor 1 is for the Control System,

2. Linear sensor 2 works as a reference to the Protective System.

An electrical fan is situated at the bottom of the device for cooling the electrical motor and other electronics, the fan

starts when the internal temperature reaches 40°C and stops when the temperature is below 30°C

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 11 of 91

Page 12

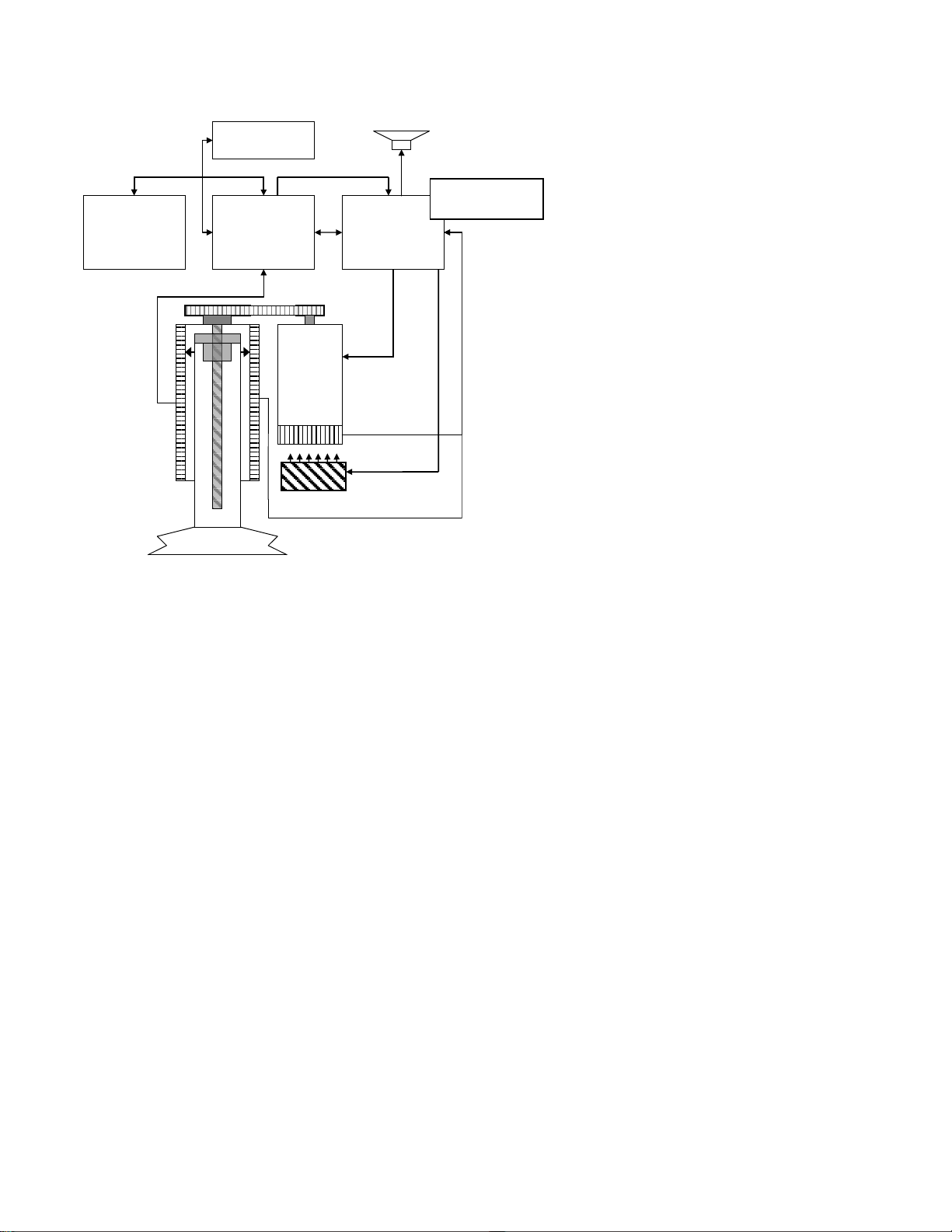

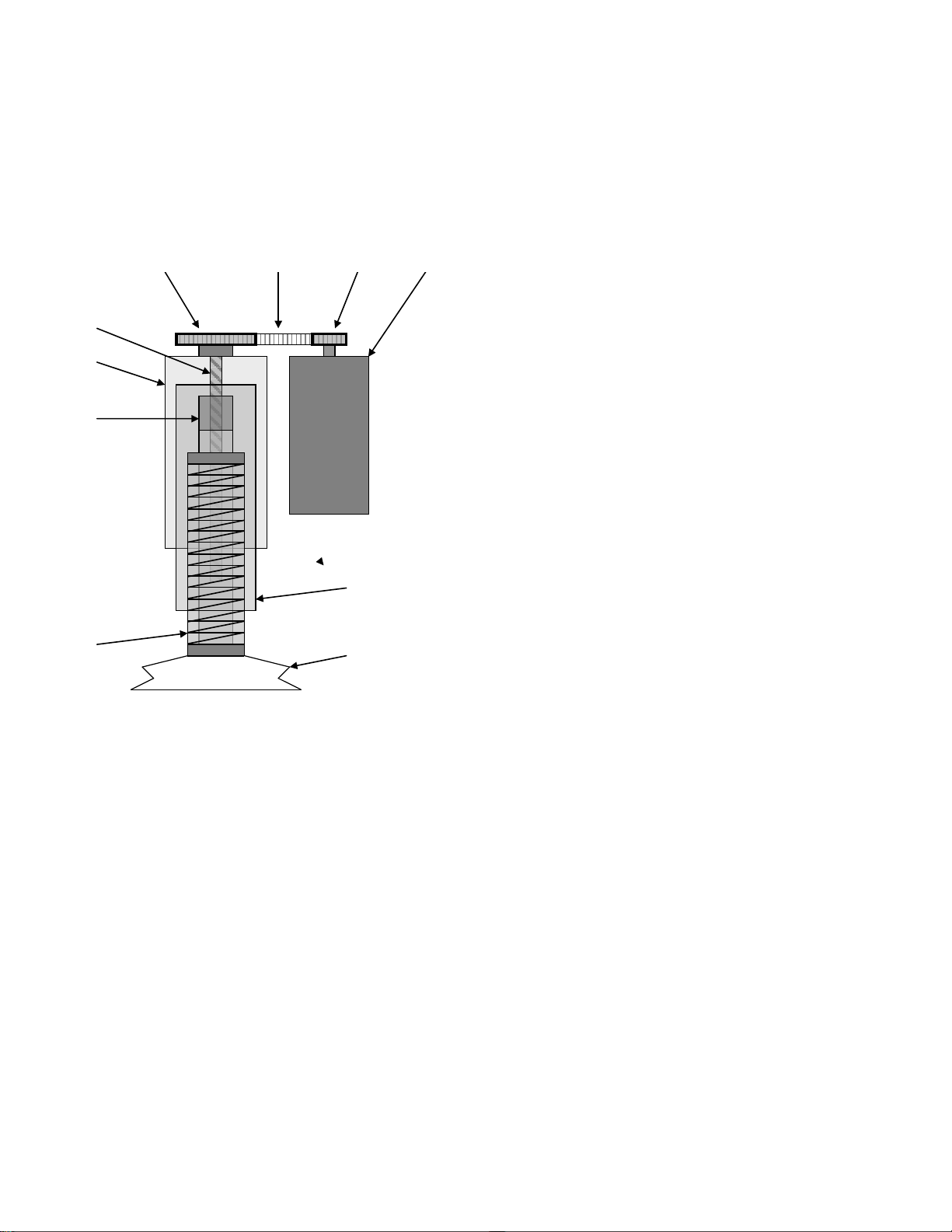

Compression Mechanism

1. Belt Wheel Large

2. Drive Belt

3. Belt Wheel Small

4. Electric Motor

5. Carry Ball Screw

6. Outer Tube

7. Carry Ball Nut

8. Decompression

Spring

9. Adjustment tube

10. Suction Cup

5

6

7

8

9

10

The Drive Belt, driven by the electrical Motor, drives the Carry Ball Screw forcing the Carry Ball Nut up and down.

The Carry Ball Nut is fitted to a piston that moves the suction cup piston up and down.

The Decompression Spring reduces the upstroke force.

The Suction Cup is adjusted to the patients’ chest with a servo aid system. The suction cup can easily be replaced

with respect to hygiene.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 12 of 91

Page 13

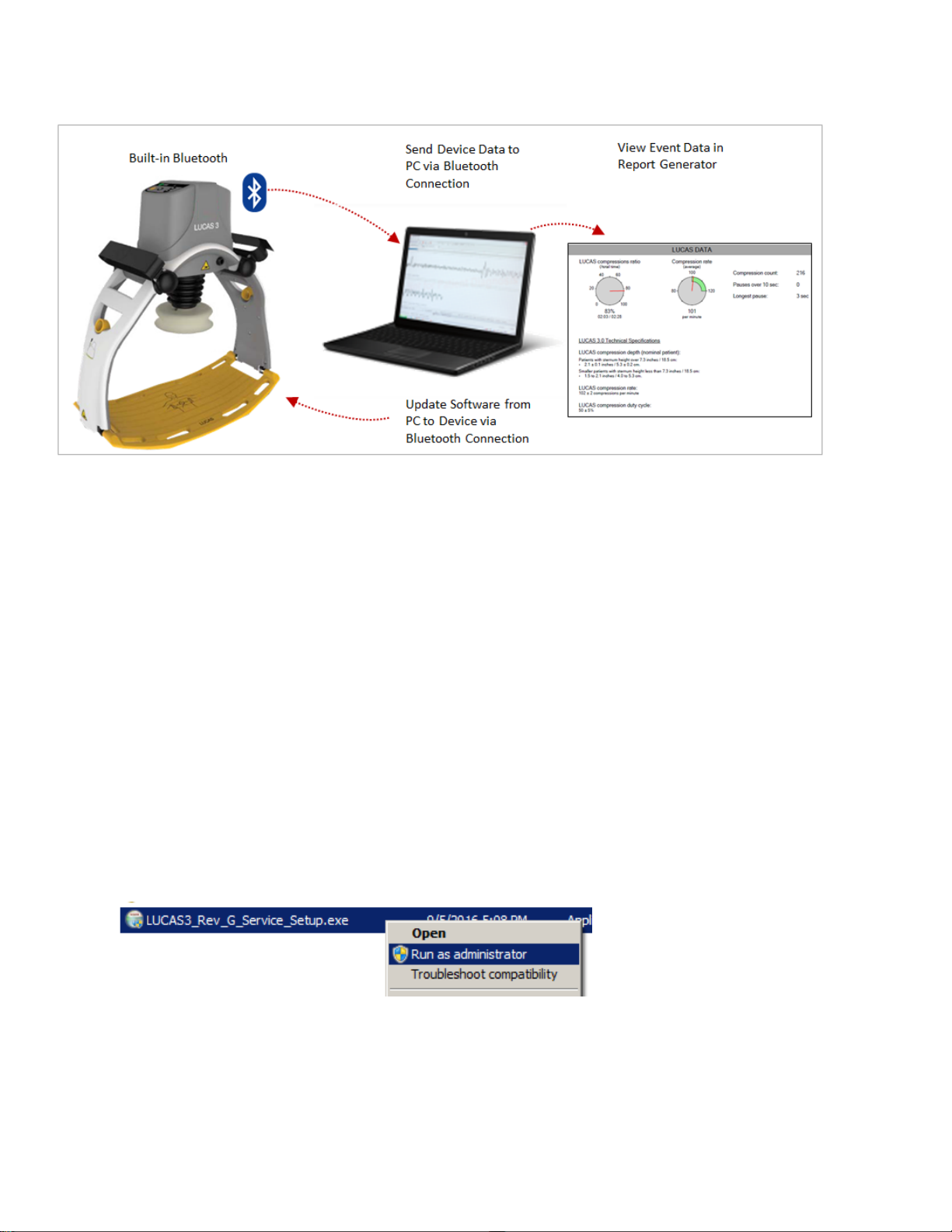

Device Communicati on

LUCAS

®

3 has a built-in communication board with Bluetooth or WiFi connection, it allows:

1. Post-event data being download to the PC without opening the hood, and view Event Data in the Report

Generator after data download.

2. WiFi with LIFENET connectivity.

3. Setup Options configurable via LIFENET through WiFi or with the LUCAS

4. Using LUCAS

device log, and perform sensor calibration.

®

3 Program Loader with Bluetooth connection to update Software from PC to Device, view

®

3 Program Loader.

LUCAS® 3 Program Loader

LUCAS® 3 program loader is software for updating the program and change the Setup options in LUCAS. It can also

be used to read errors and warnings from the device, and perform the sensor calibration. This section explains how the

software works.

• LUCAS 3 Program Loader should only be used by trained personnel

• Antivirus protection and fire walls shou ld be installed on the computer that have the LUCAS 3 Program Loader

installed.

• All suspected cyber security threats shall be reported to Physio-Control.

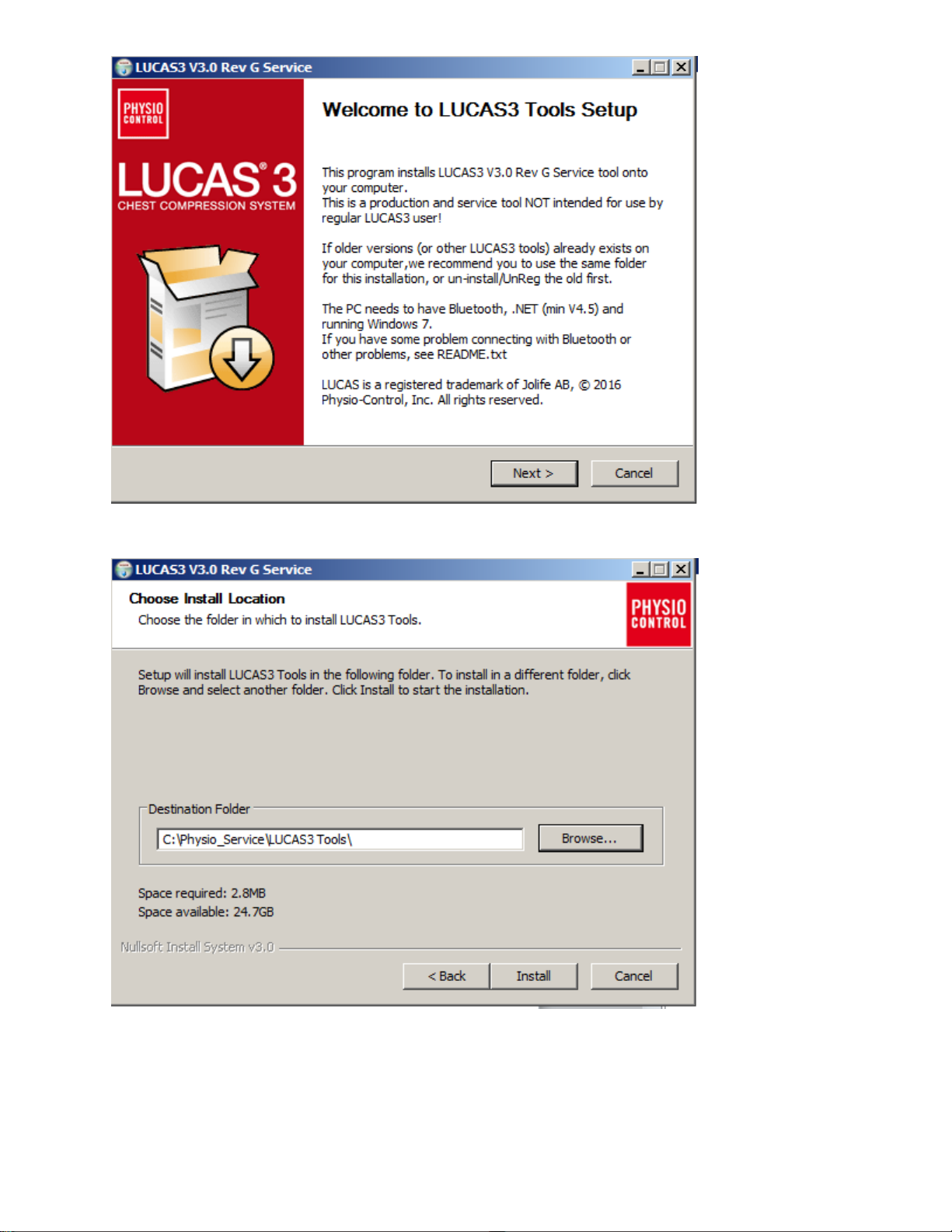

Software installation

To install LUCAS 3 Program Loader version 3.x:

1. Right Click on LUCAS3_V3X_RevX_Service_Setup.exe, and Run as administrator

2. Installation starts

3. Click on Next from this screen:

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 13 of 91

Page 14

(Visual differences in screen interface may occur for different software versions.)

4. Choose installation location on PC, and Click Install

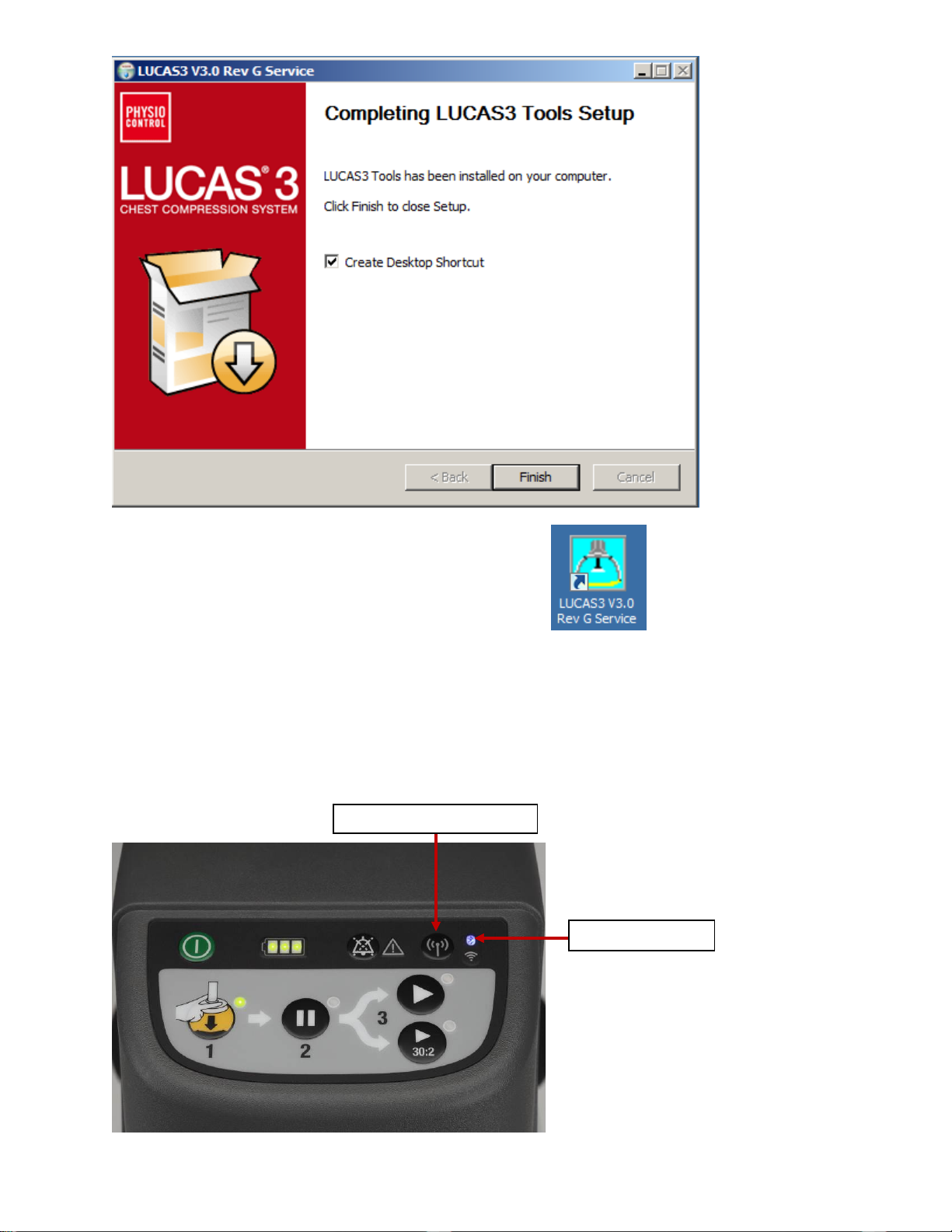

5. Click Finish to add the shortcut on the Desktop

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 14 of 91

Page 15

Bluetooth symbol

TRANSMIT DATA button TRANSMIT DATA button

6. Test LUCAS 3 Program Loader by double click on desktop icon

(Note. Different software versions can occur)

Connect the device via Bl ue t oot h

When updating the program in LUCAS using the Bluetooth connection, there is no need to open the hood.

1. Ensure the LUCAS Device is powered OFF and no LEDs are on.

2. Press and hold TRANSMIT DATA button for one second to turn on Bluetooth mode, ensuring the Bluetooth

symbol lights up and flashing.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 15 of 91

Page 16

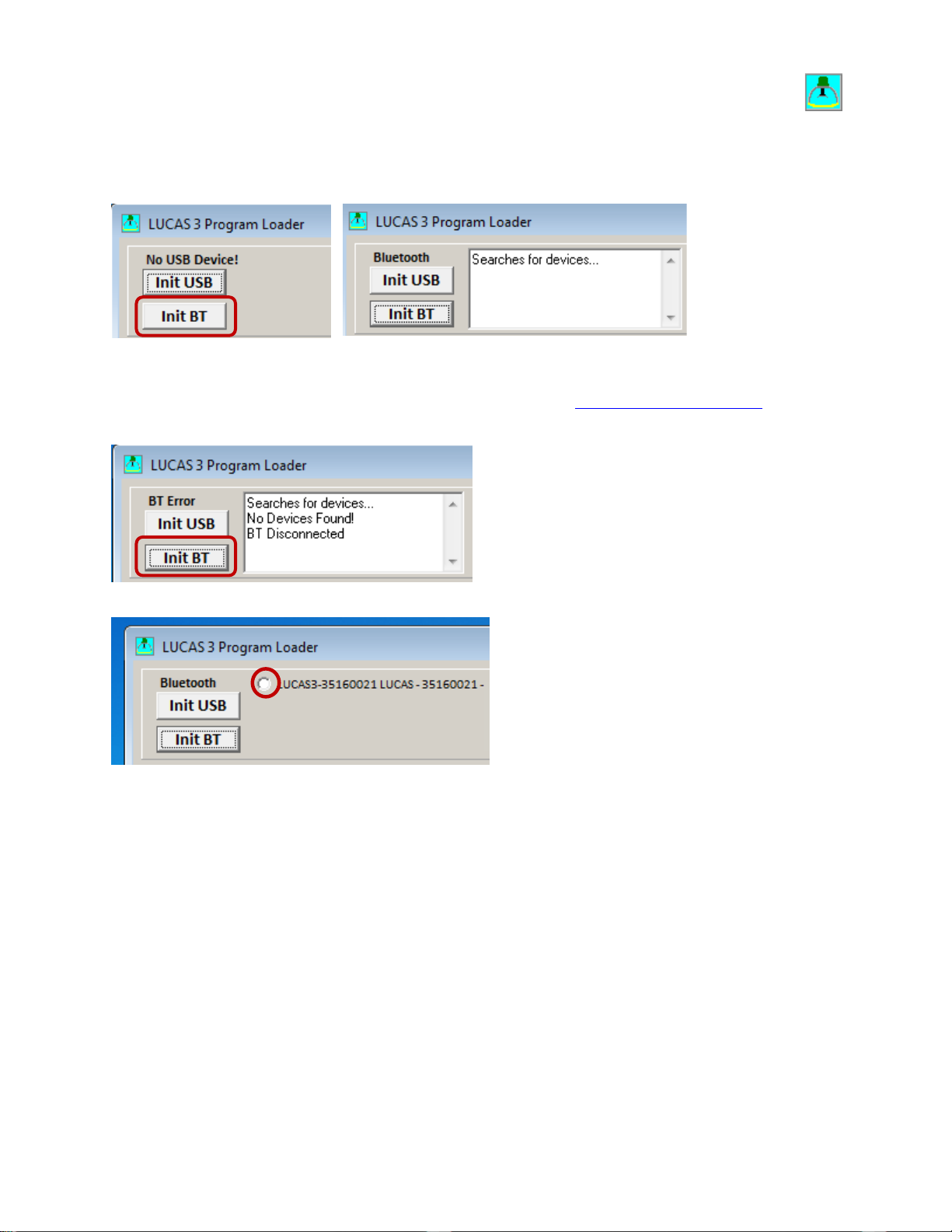

3. Start the LUCAS 3 Program Loader sof t ware by exec ut ing LUCAS3_V3_X_REV_X_Service.exe file,

.

(Note. Different software versions can occur)

4. Click Init BT to connect PC to LUCAS 3 device via Bluetooth, and Wait for Program Loader to search for

LUCAS 3 device…

5. If No Devices Found message displayed, click Init BT and try again. Note: It may take up to 30 seconds for

the LUCAS 3 communication app to boot up. You may have to click Init BT 2 ~ 3 times before LUCAS device

shows up on the screen. If “BT Error” occurred repeatedly, refer to Bluetooth Connection Error

in

troubleshooting chapter.

6. When Program Loader found LUCAS 3, select the LUCAS that shall be connected.

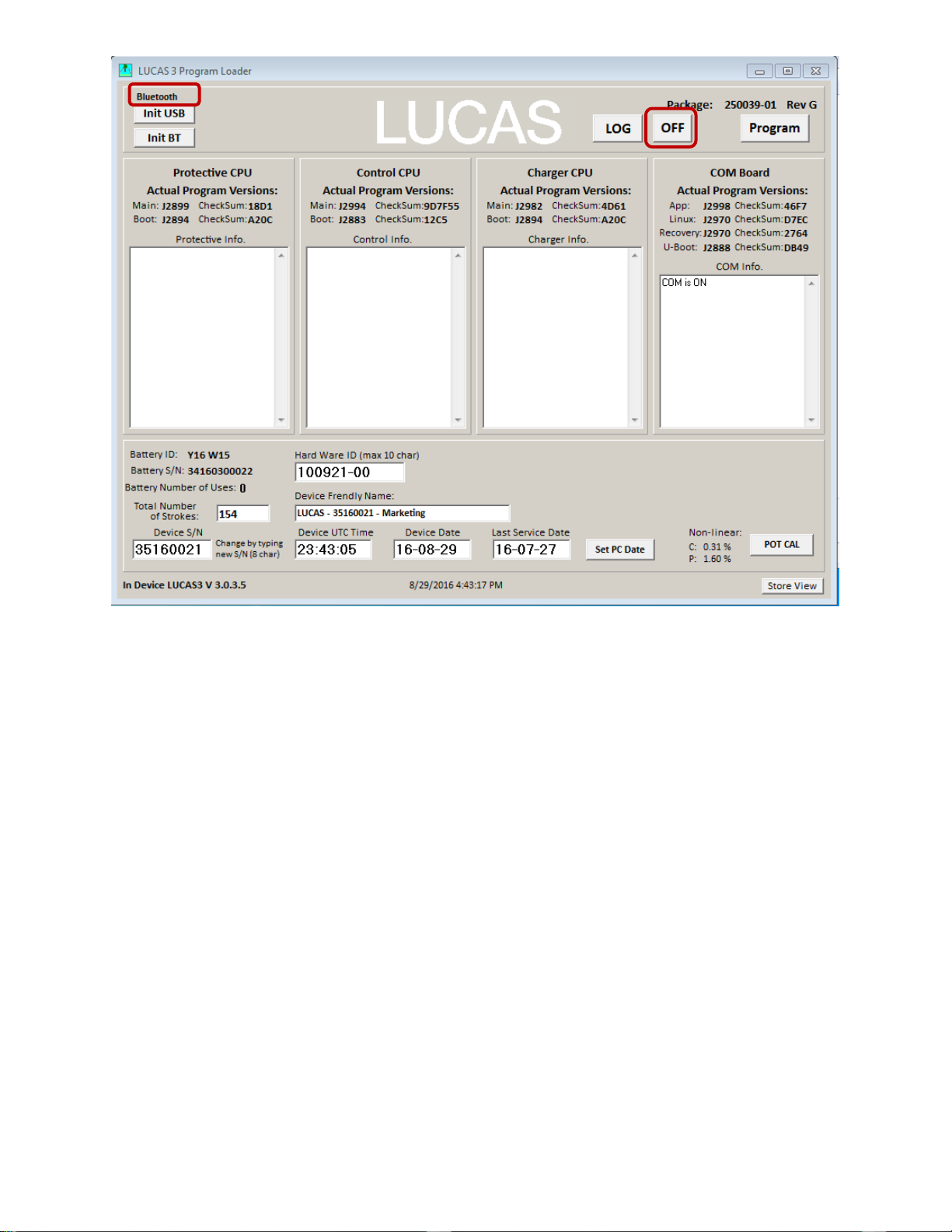

7. When Bluetooth connection is established, the Program Loader screen will show CPUs information shown as

following pictures.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 16 of 91

Page 17

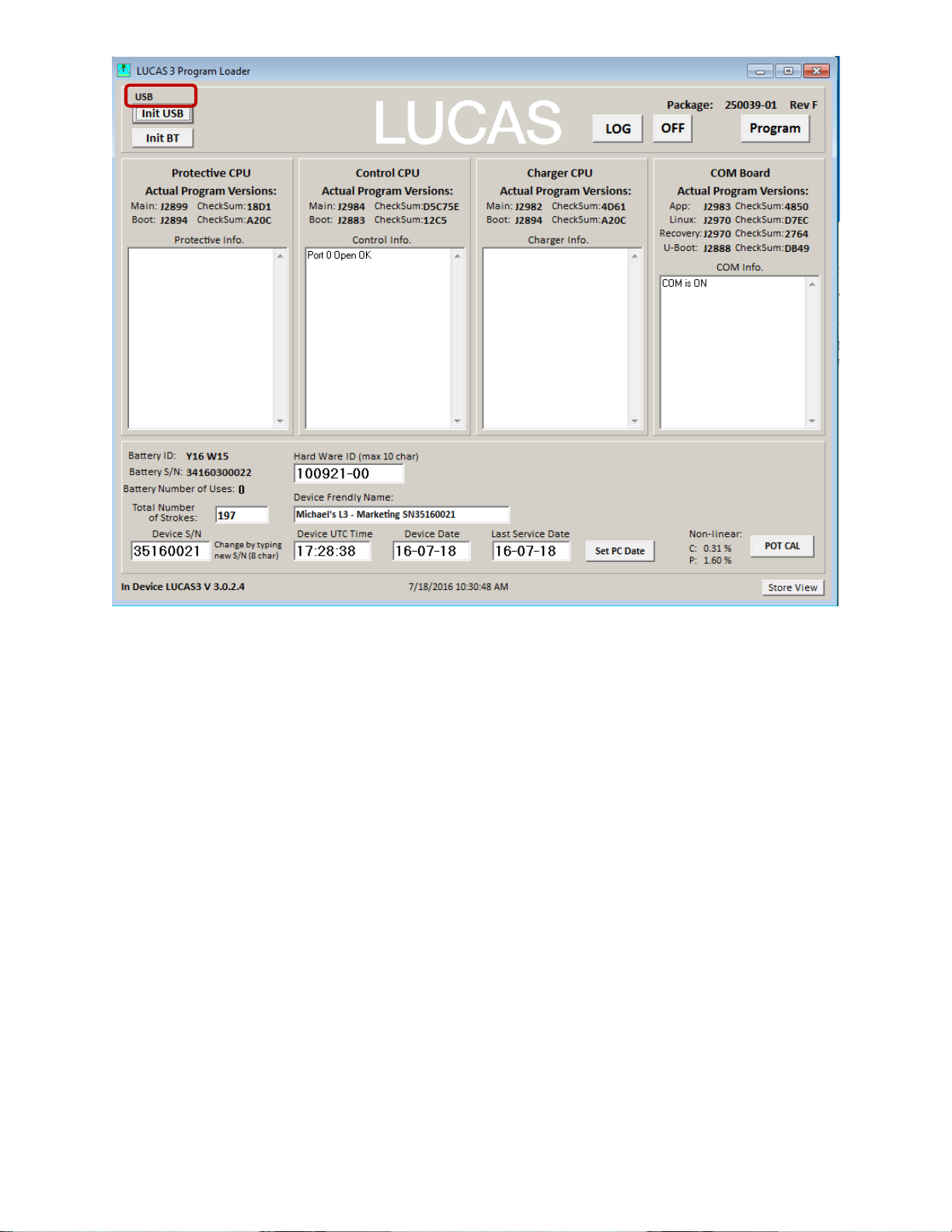

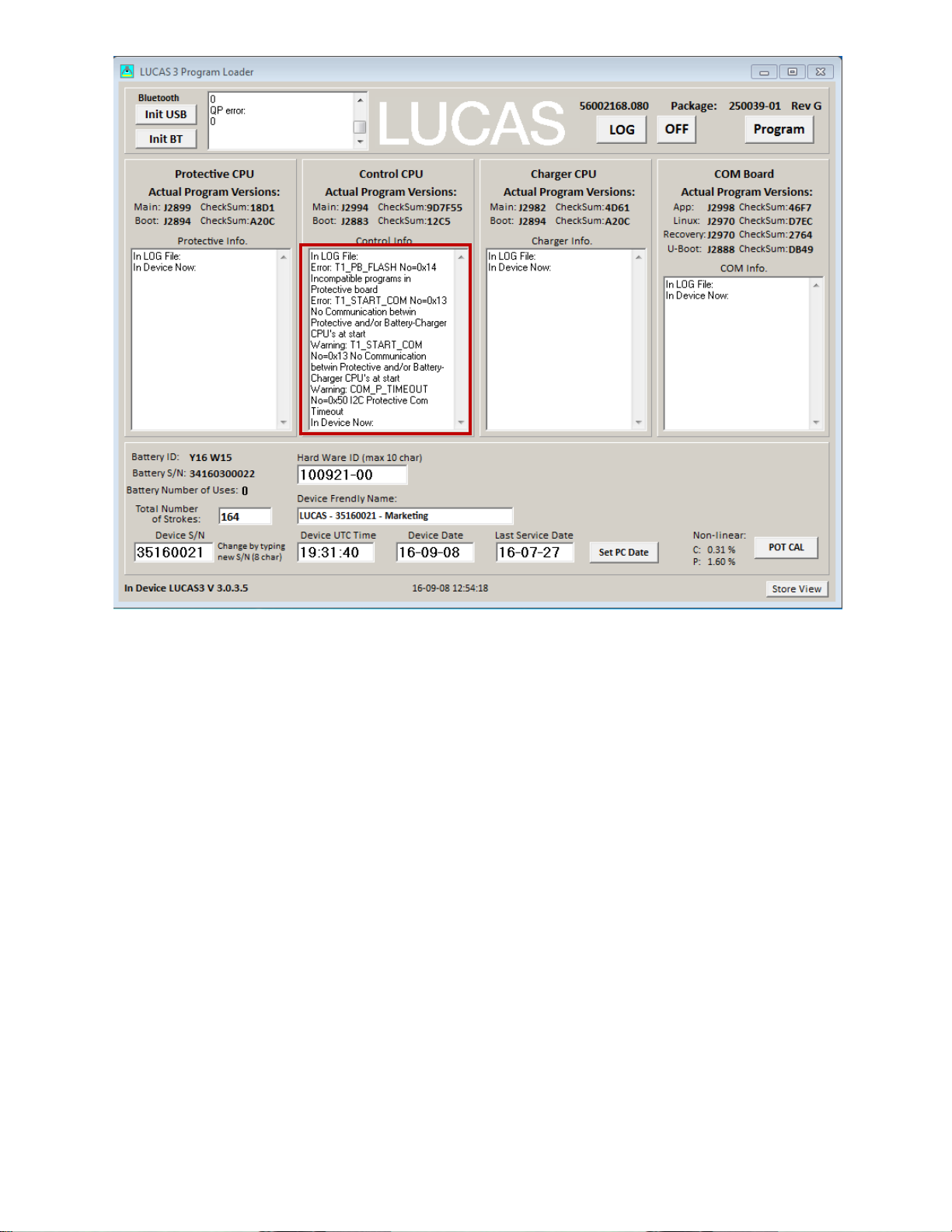

- Picture shows connection via Bluetooth for LUCAS 3 Version 3.0 (Part No: 250039-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versio ns –

• Check that the serial number (S/N) in the Device S/N window is equal as the S/N number on the device type

label

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 17 of 91

Page 18

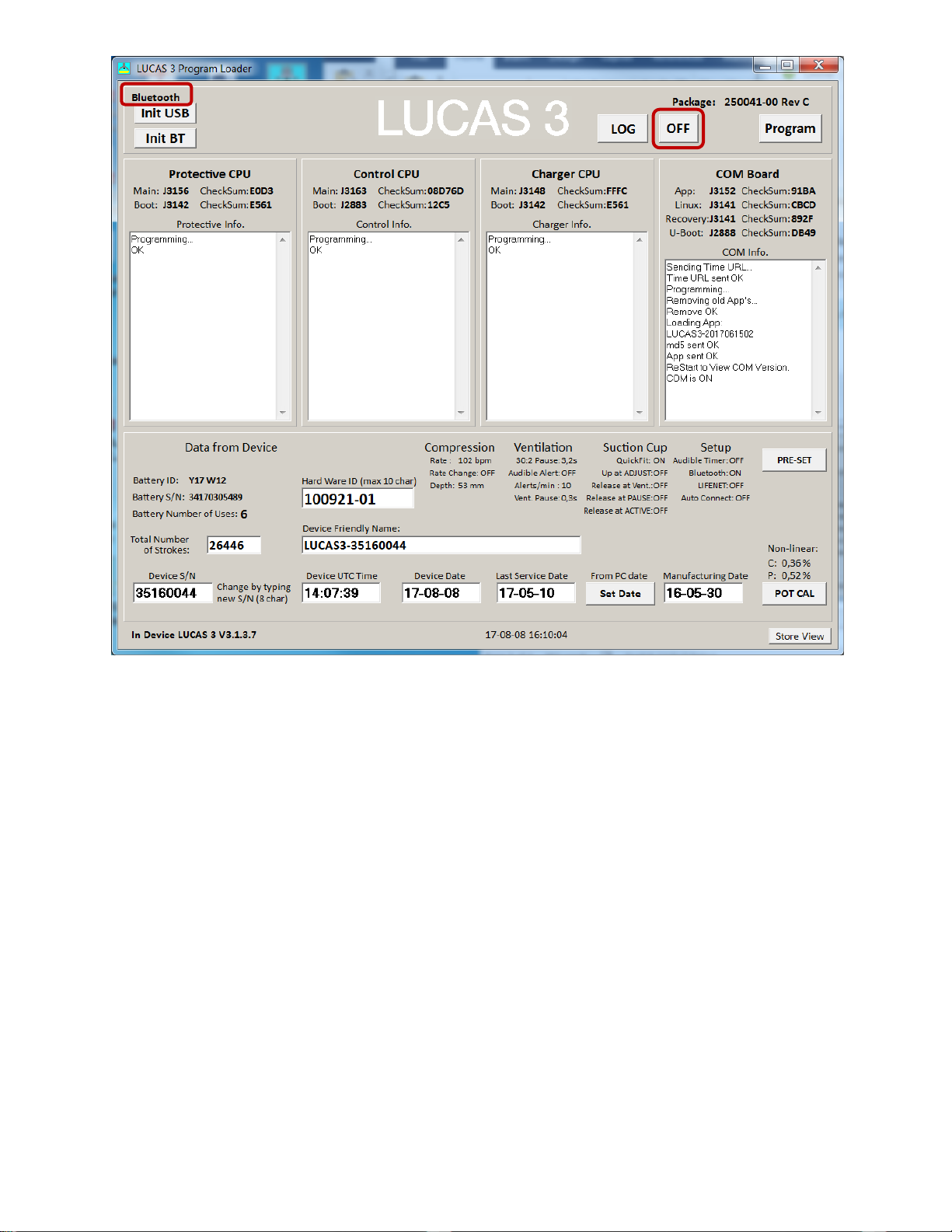

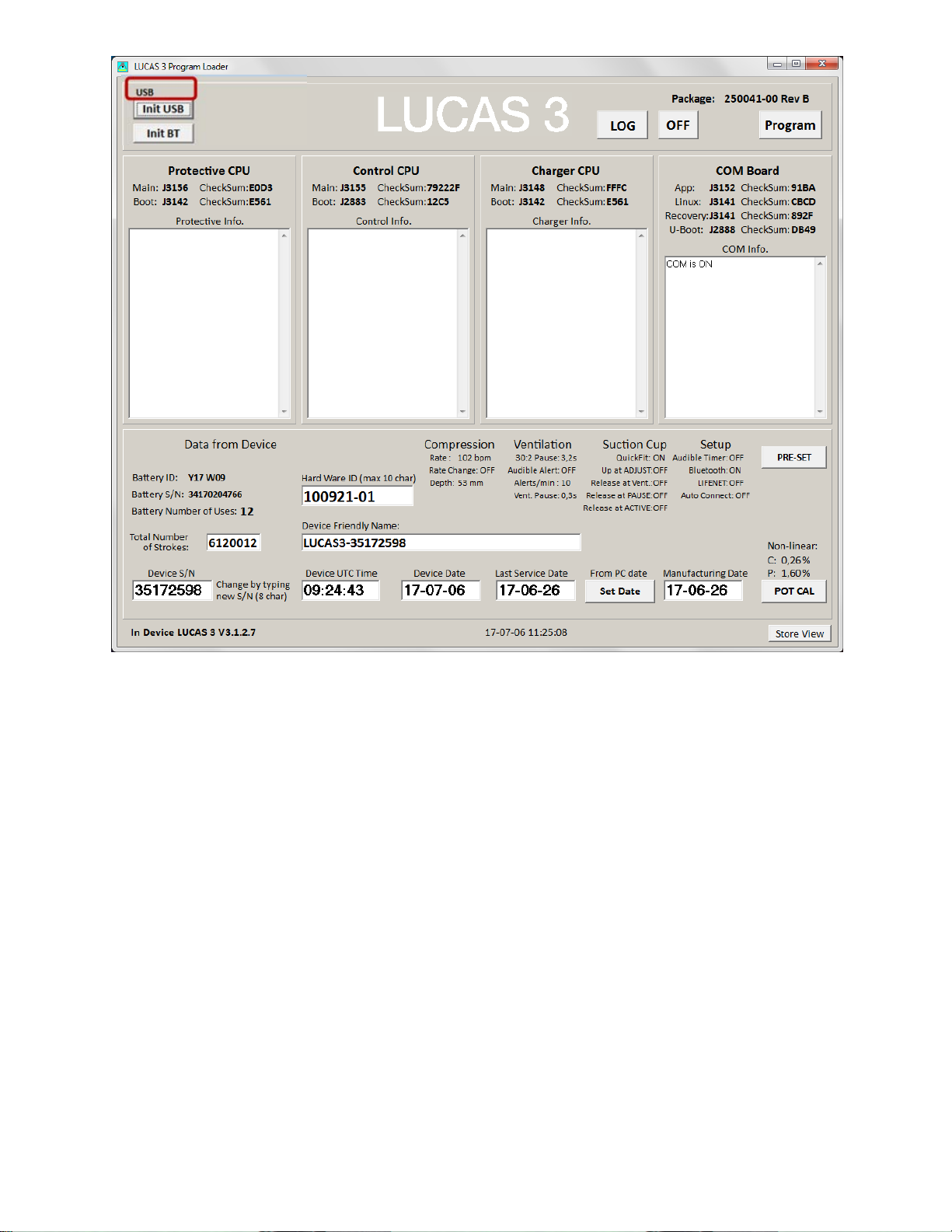

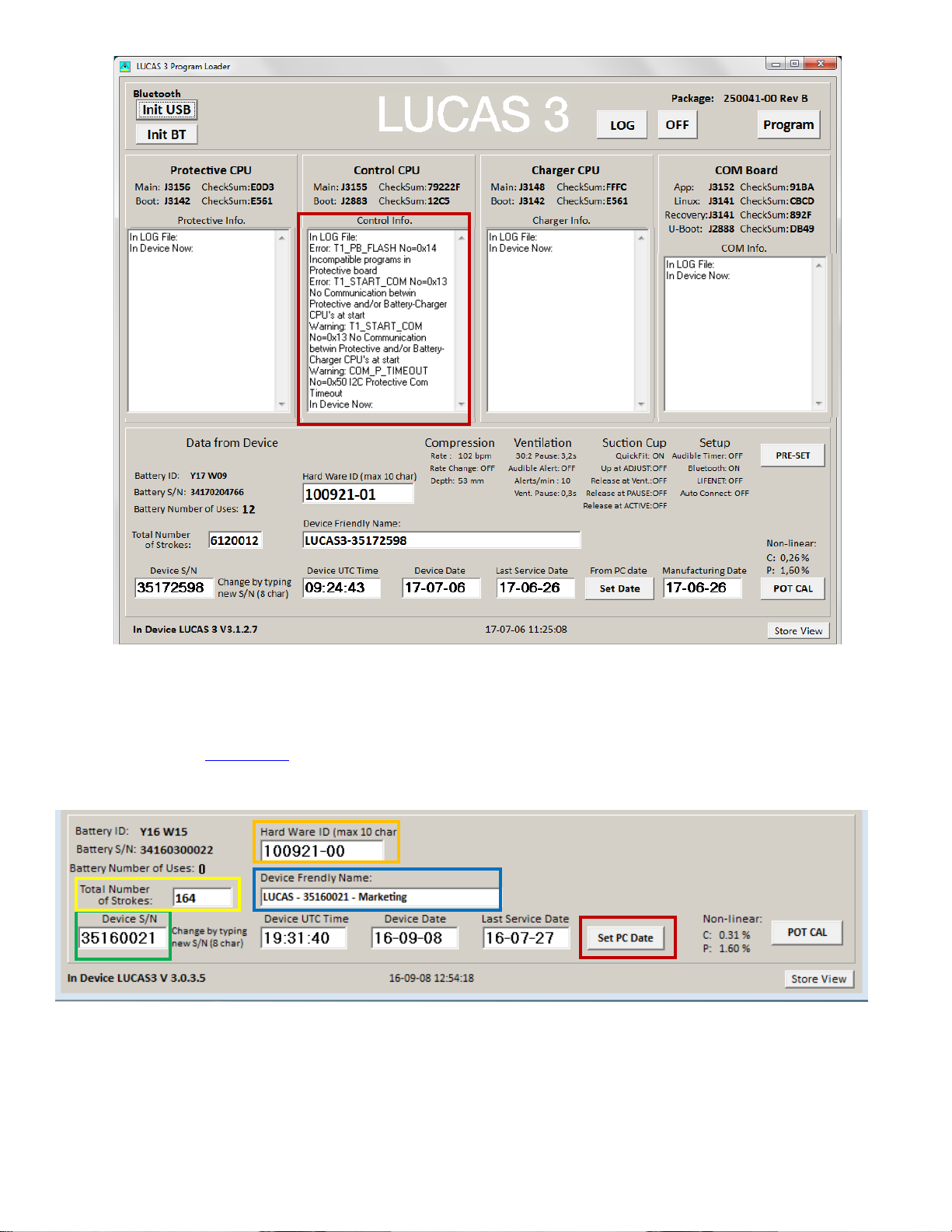

- Picture shows connection via Bluetooth for LUCAS 3 Version 3.1 (Part No: 250041-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versions –

• Check that the serial number (S/N) in the Device S/N window is equal as the S/N number on the device type

label

8. To disconnect Bluetooth connection, click on OFF button. The Bluetooth symbol light will go off.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 18 of 91

Page 19

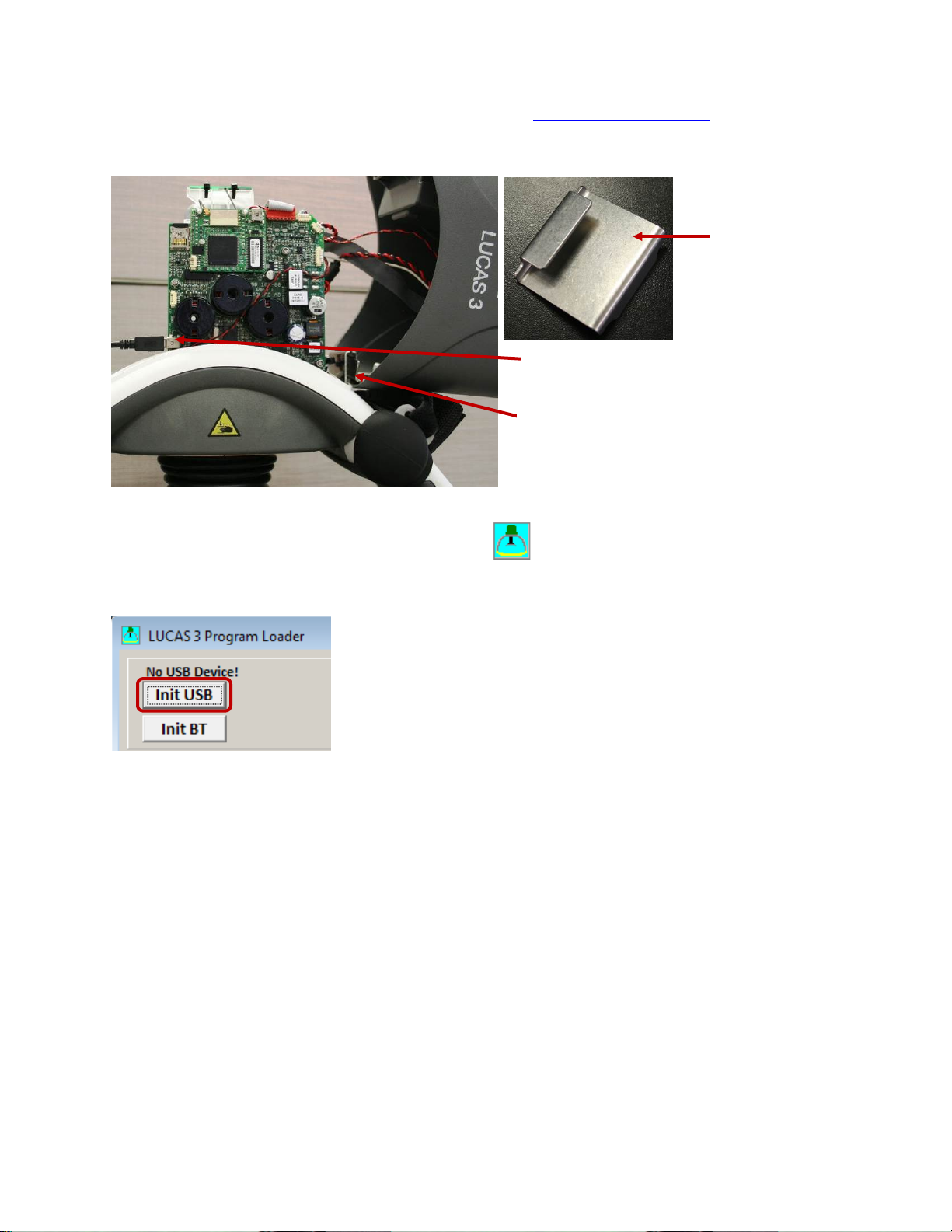

Connect the device via USB cable

Hood Holder Bracket

USB Port Location

Hood Holder Bracket Location

1. Remove the hood according to Disassembling instruction in How to Replace the Hood, and use the Hood

Holder bracket to hold the hood on the side and the battery should be installed.

2. Connect an USB cable between the computer and the device, the connector is situated at the lower left side of

the Control PCB.

3. Start the device

4. Start the software by executing LUCAS3_V3_0.exe file,

(Note. Different software versions might occur)

5. Normally the software detects the device at start. If not, then Click Init USB.

6. When USB connection is established, the Program Loader screen will show CPUs information

.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 19 of 91

Page 20

- Picture shows connection via USB cable for LUCAS 3 Version 3.0 (Part No: 250039-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versio ns –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 20 of 91

Page 21

- Picture shows connection via USB cable for LUCAS 3 Version 3.1 (Part No: 250041-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versions –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 21 of 91

Page 22

View Error Code

3.

2.

1.

Once the connection is made from Bluetooth or USB cable, the information about the device should appear in the

designated CPU windows.

The device Errors and Warnings will appear in each CPU’s box window.

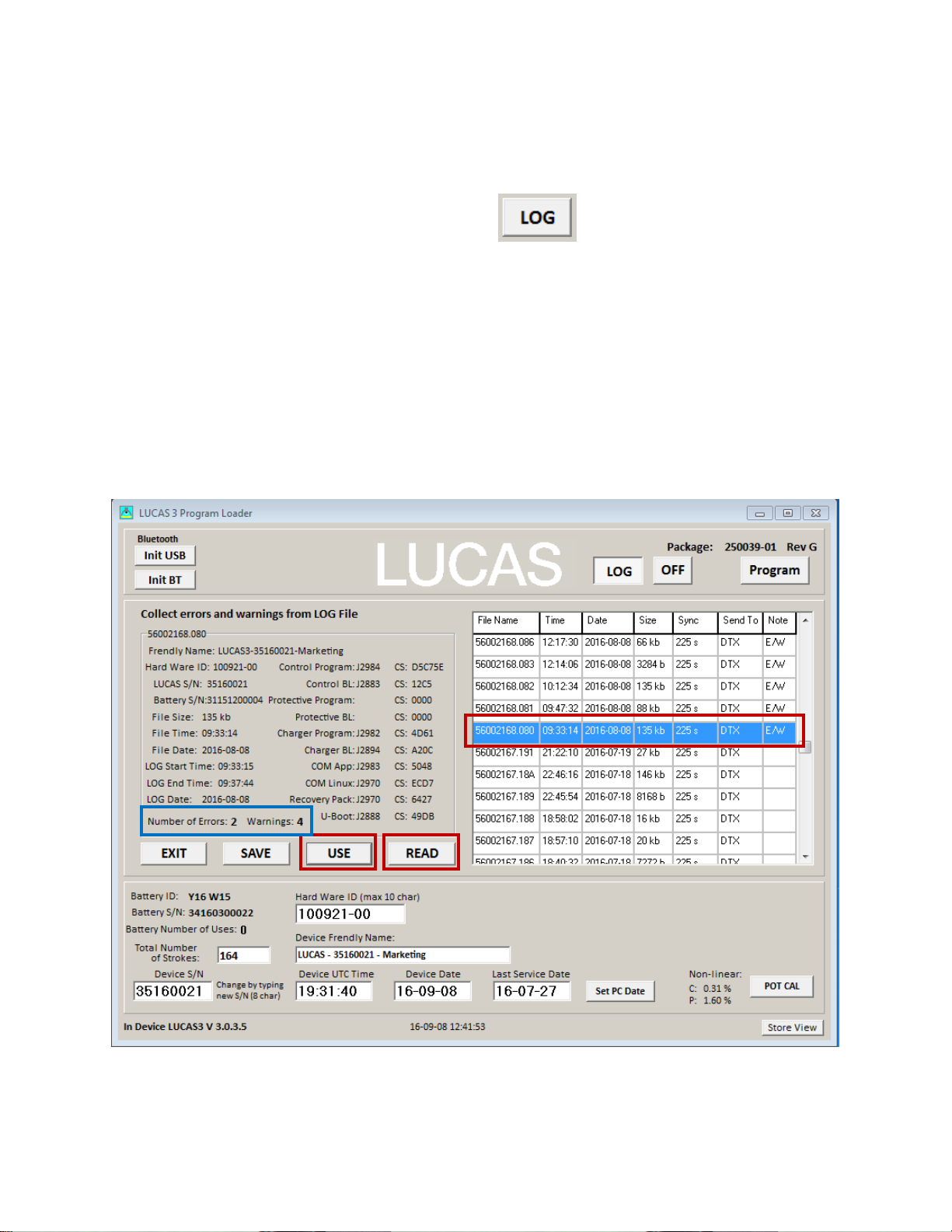

To view existing log information on the device, click LOG button,

Highlight a row

• Press READ to view log data

• Press USE to see the Error and Warnings code in different CPU windows

• Press SAVE to save the raw log file data to PC (only for developers to use)

• Press EXIT to exit LOG view

Example:

1. Highlight a row according to Date and Time the error occurred from LOG view;

2. Click READ and wait to see the “Collect errors and warnings from LOG File” to show up on the left side of

window;

3. If the Number of Errors or Warnings are not 0, Click USE to see the highlighted LOG Error code in the CPU

windows (USE will exit LOG view also).

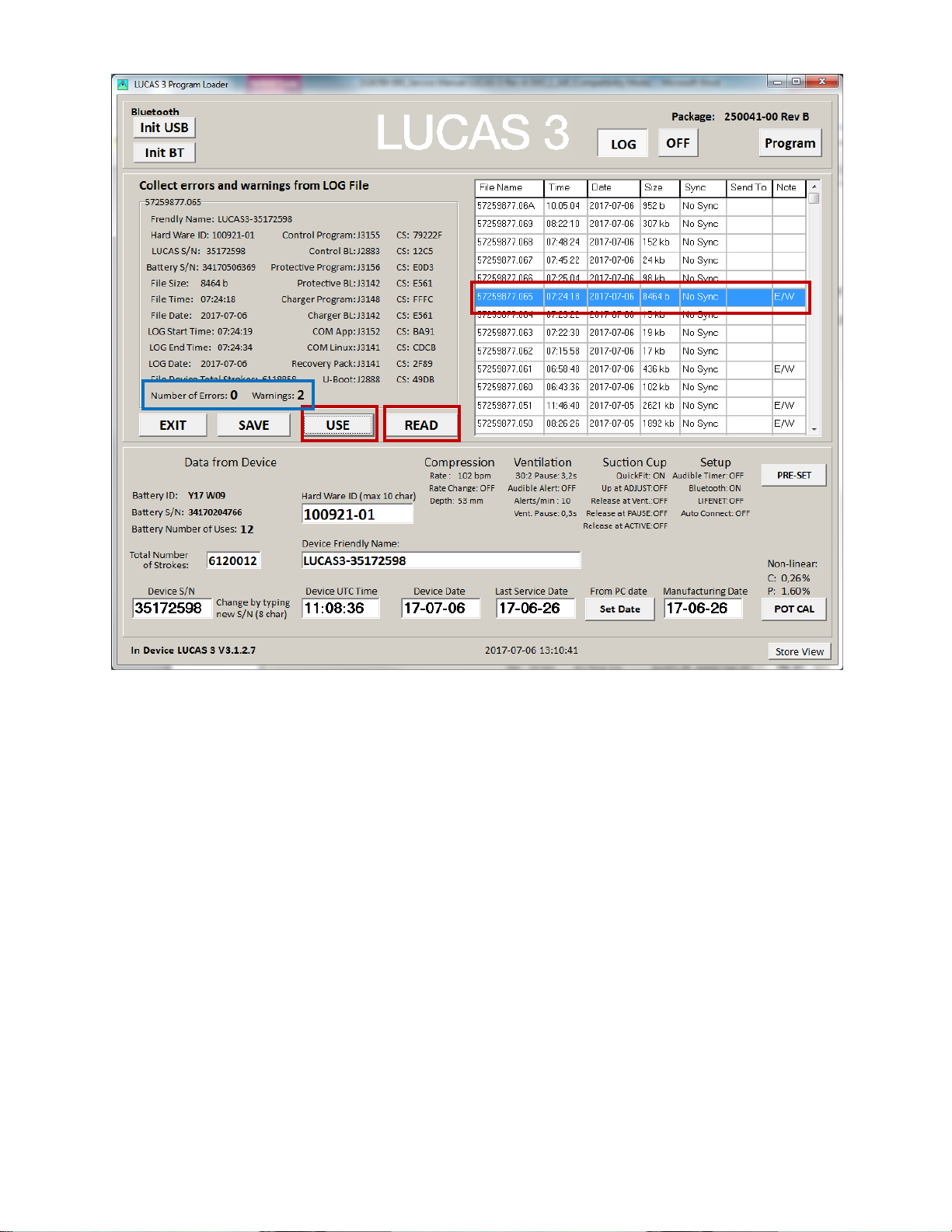

, Log view shows log data on screen.

- Picture shows LOG File content on the left for LUCA S 3 Version 3.0 (Part No: 250039-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versions –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 22 of 91

Page 23

3.

2.

1.

- Picture shows LOG File content on the left for LUCAS 3 Version 3.1 (Part No: 250041-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versions –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 23 of 91

Page 24

- Picture shows Error Codes in CPU window for LUCAS 3 Versi o n 3.0 (Part No: 250039-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versions –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 24 of 91

Page 25

- Picture shows Error Codes in CPU window for LUCAS 3 Version 3.1 (Part No: 250041-00)

Note, differences in J-numbers and CheckSum Numbers may occur due to different program versions –

4. Then refer to Error Codes

Tables for more information about how to handle the errors.

Set Device S/N, Date, and Data

- LUCAS 3 Version 3.0 (Part No: 250039-00) –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 25 of 91

Page 26

- LUCAS 3 Version 3.1 (Part No: 250041-00) –

-

It’s also possible to set the Device ID(S/N), Friendl y Name, Time and Last Service Date, and reset total number of

Strokes.

NOTE:

• When setting up Device Time, always use UTC-0 time

• Both Device Date and Last Service Date are in YY-MM-DD format

• Setup will be automatically saved to the device

Change Device S/N

The Device S/N (=Serial number of the device) can be set simply by typing in the wanted S/N (8 char), typically

3516XXXX. The S/N is automatically saved.

Set Latest Service Date

Set latest Service date by pressing SET PC Date / SET Date.

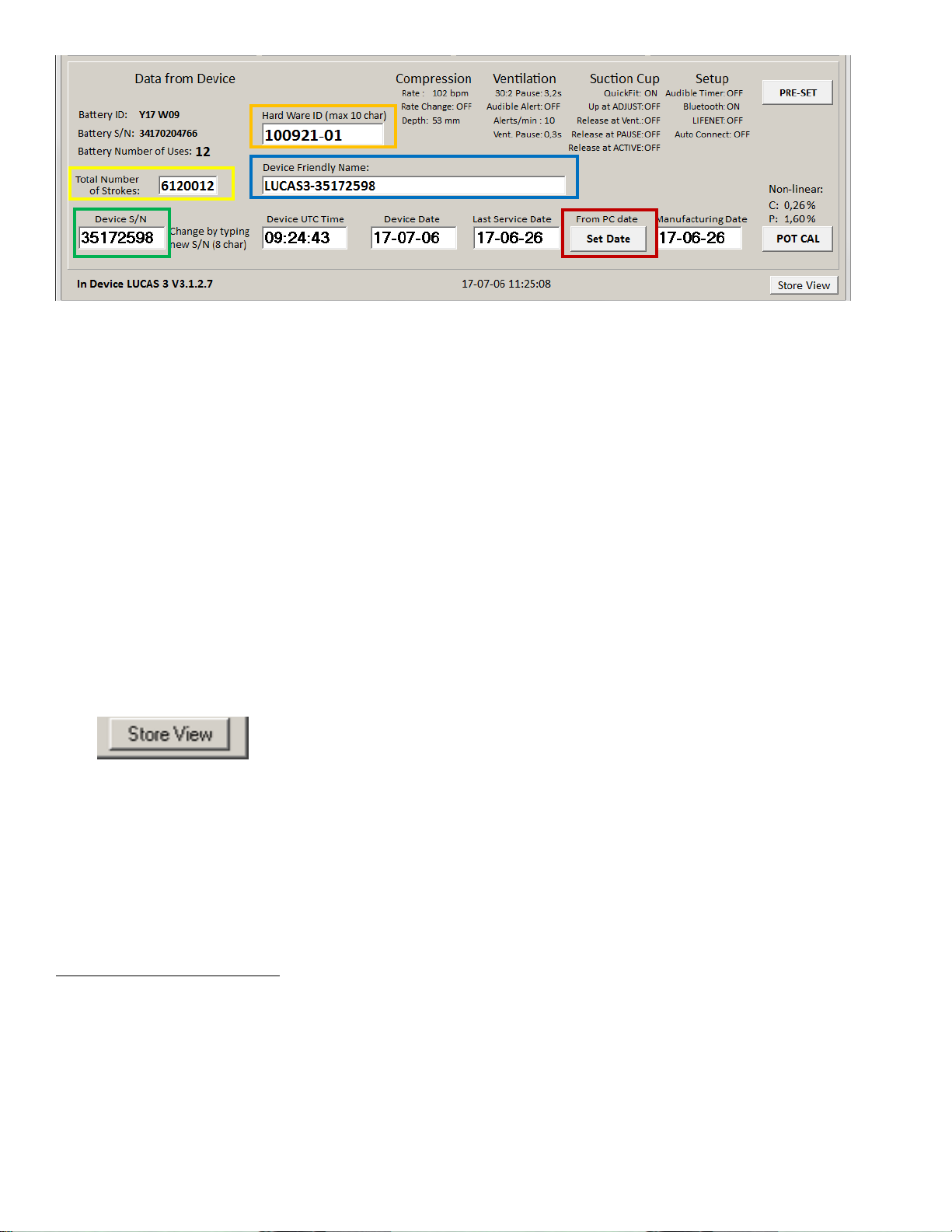

Store View

The Program Loader screenshot can be stored for future reference by clicking “Store View”.

The screenshot will be saved in a sub-folder “Pictures” where the Program Loader folder is with the serial number as

1

file name

. At the same time the screenshot will be printed at the selected default printer. If no printer is connected, a

message will appear which can be cancelled; the picture will be saved and can be printed at any time.

1

An administrative right to the ”LUCAS3 Tools” folder is necessary to save the screenshot. This can either be done by

right-clicking the LUCAS

®

3 program loader.exe file and chose “Run as administrator” every time you want a

screenshot saved to the “Pictures” subfolder or by locating the ”LUCAS3 Tools” folder on your computer, right-click the

folder, chose Properties, choose the Security tab, highlight your “Users” name, e.g. Users (ANRESN-L1\Users), click

Edit, chose your “Users” name again, then in the “Permissions for Users” window in the Allow column make sure that

the Write-box is marked, then chose Apply. This allows the program to save screenshots to the ”LUCAS3 Tools” folder

®

and subfolders without having to run the LUCAS

3 program loader.exe as Administrator.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 26 of 91

Page 27

Checksum

Protective

Control

Charger

COM CPU

Program

ver:

A20C or

E561

A20C or

E561

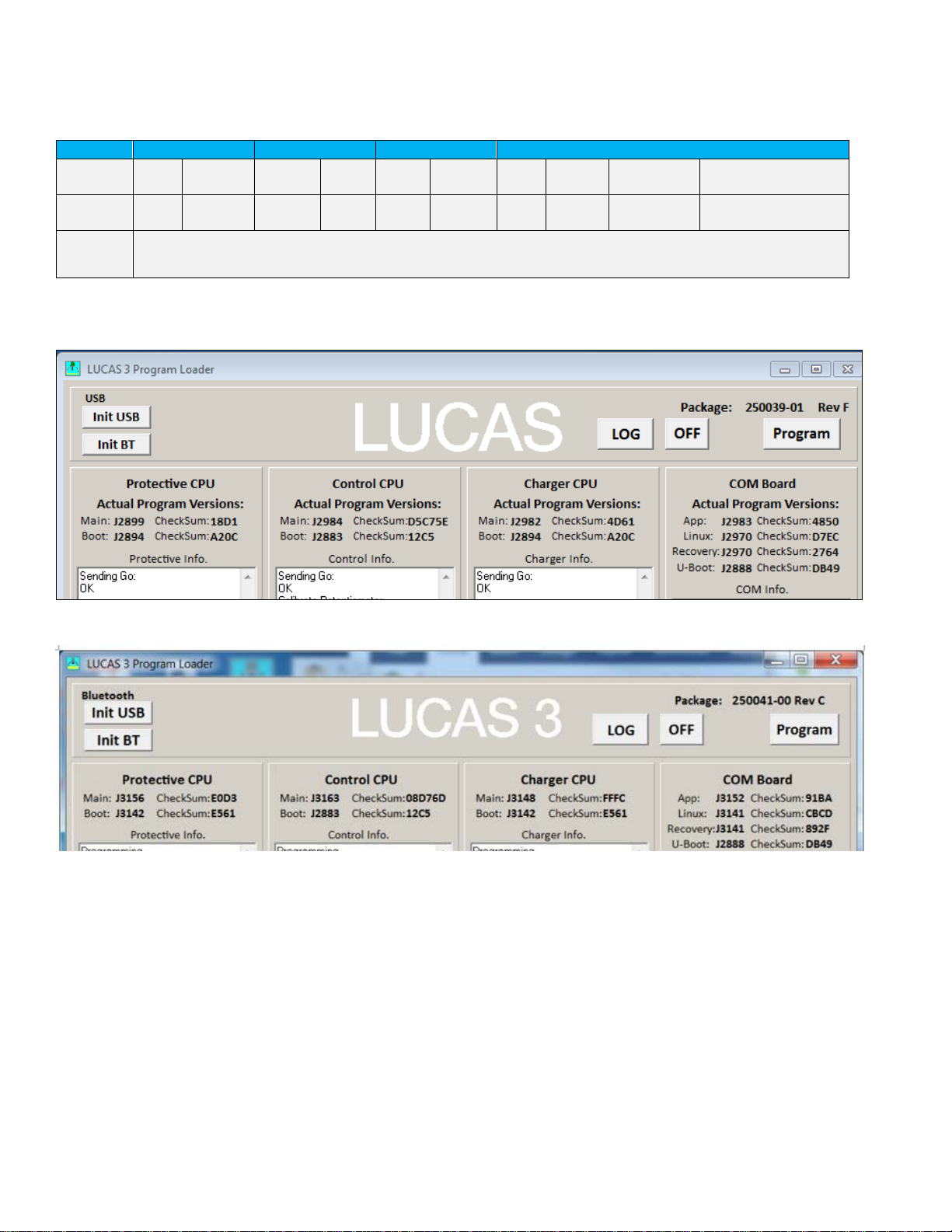

To identify the installed program version you can check the CheckSum values to match table below:

Main Boot Main Boot Main Boot App Linux Recovery U-Boot

3.0 18D1

3.1

Following picture shows the example where to see the CheckSum values on each CPU and COM Board fr om

Program Loader.

The Change Order Numbers and CheckSum Numbers are automatically checked by Program Loader

250041-00

9D7F55 12C5 4D61

- LUCAS 3 Version 3.0 (Part No: 250039-00) –

46F7 D7EC 2764 DB49

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

- LUCAS 3 Version 3.1 (Part No: 250041-00) –

Page 27 of 91

Page 28

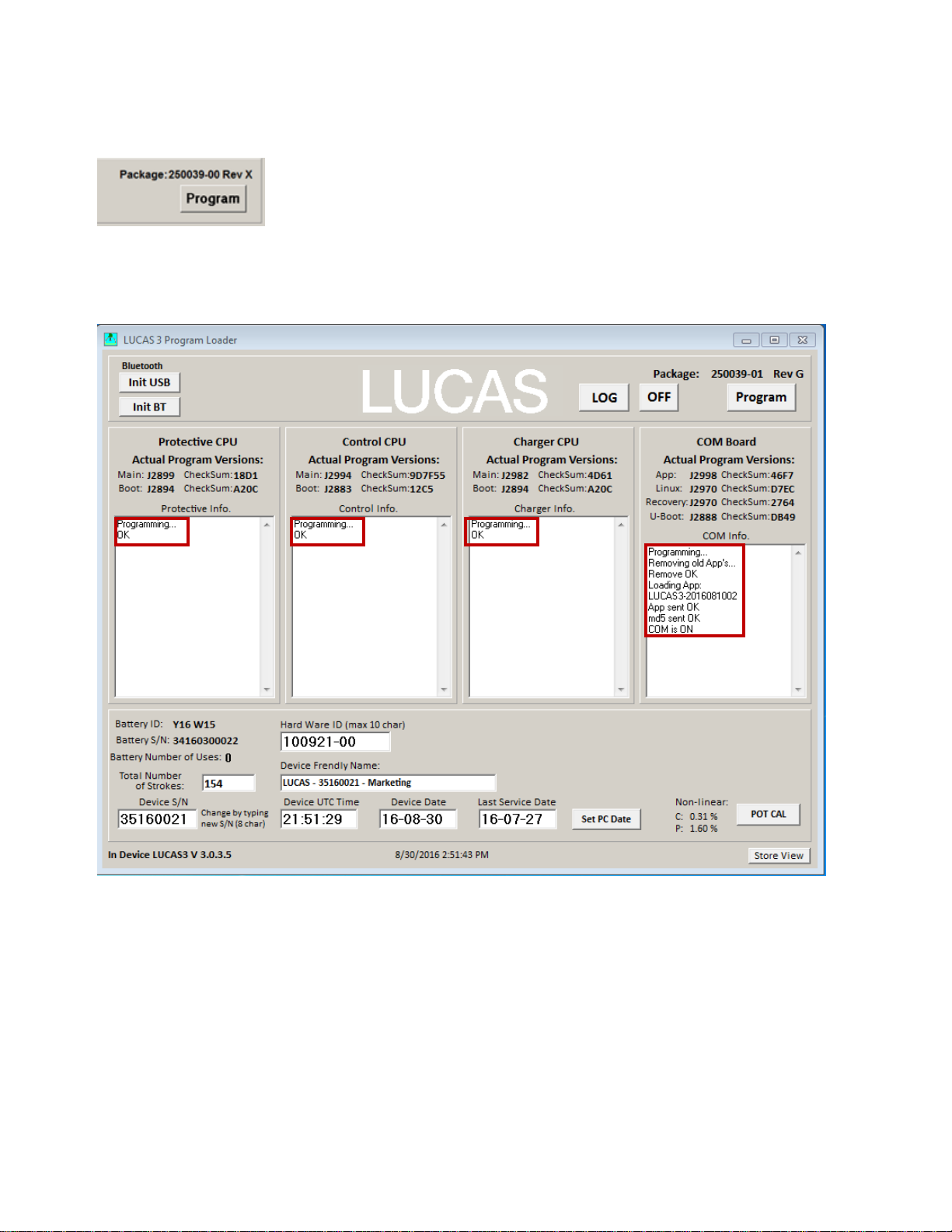

Update LUCAS Software

1. Click Program in the upper right corner to update LUCAS software.

The programming process will start and update the software for each CPU. Note: Do not disconnect the

connection during the software update. When all four CPUs are updated, following window will appear. Each

CPU window will have OK to indicate the update is complete.

- LUCAS 3 Version 3.0 (Part No: 250039-00) –

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 28 of 91

Page 29

- LUCAS 3 Version 3.1 (Part No: 250041-00) –

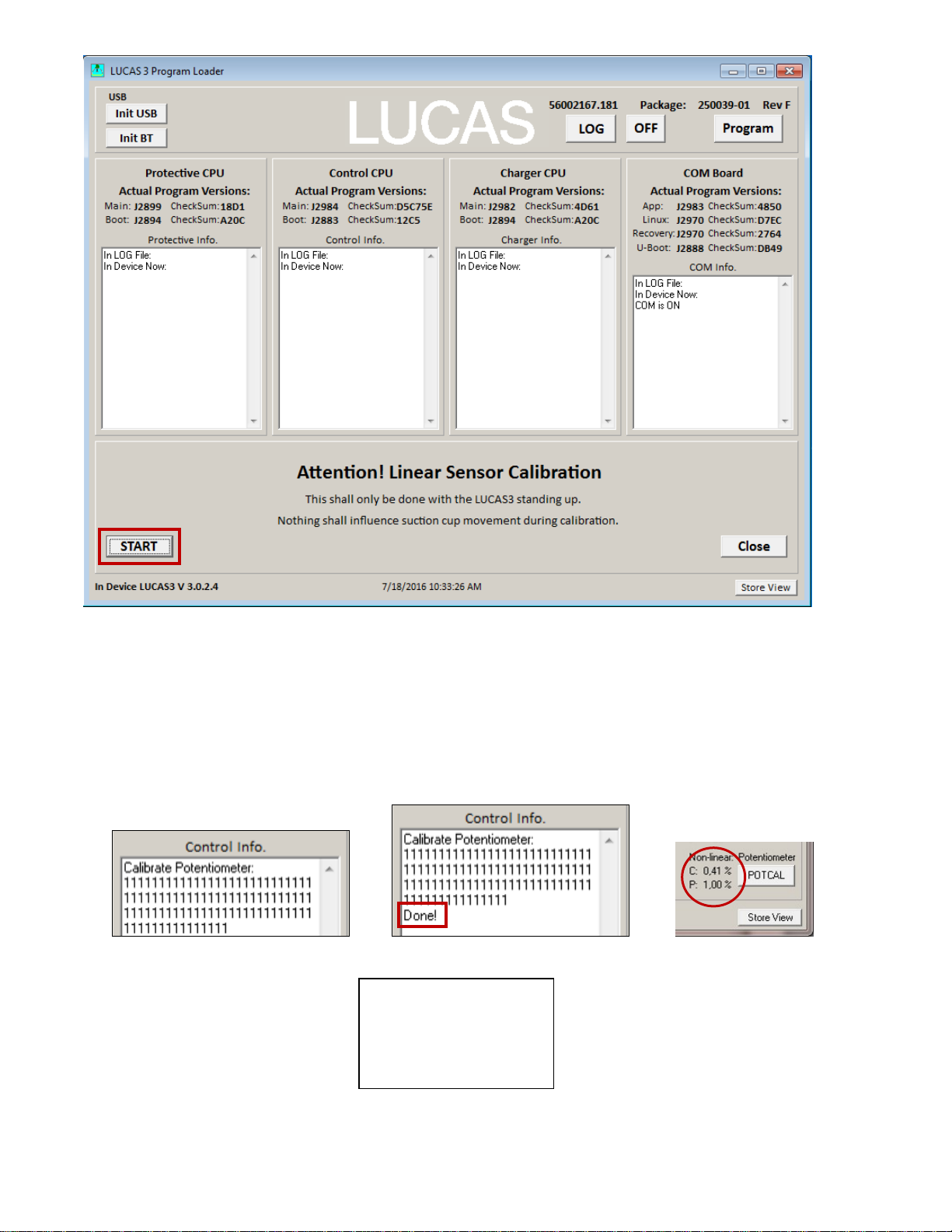

Calibrate Linear Sensor

After software update is complete, Click POT CAL to calibr ate Li near Se ns or. Before you click the Start button please

make sure that nothing can influence the movement of the suction cup, that the device is in its upright position and

that the Suction Cup is approximately 20mm (~1 inch) down from its upmost position.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 29 of 91

Page 30

- Example LUCAS 3 Version 3.0 (Part No: 250039-00) –

POT CAL

- LUCAS 3 Version 3.1 (Part No: 250041-00) –

1. Click START to calibrate Linear Sensor .

2. When the Calibration process starts, the progress will be shown in the Control CPU’s window. When the

calibration is done, the result is shown in the lower right corner.

- POT CAL In Progress - - POT CAL Done - - POT CAL Values –

Acceptable Values:

C: < 6%

P: < 3.1%

3. Click Store View to print the result.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 30 of 91

Page 31

Failed calibration

Case 1:

If the value for Control exceeds 6% or if the value for Protective exceeds 3.1%, the device will make an alarm and an

error code will be shown in the Control CPU’s window, the sensor calibration has failed.

To recalibrate:

1. Mute the alarm

2. Check that nothing interferes with the movement of the suction cup

3. The device is upright

4. Click POTCAL to make a new calibration.

If the second calibration also fails it might be necessary to replace the Compression Module.

Case 2:

If this error “Cup not moved to top” showed in Control CPU window, manually move the suction cup down an inch

and then click POT CAL again to recalibrate.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 31 of 91

Page 32

Update LUCAS 3 sw 3.0 to LUCAS 3 sw 3.1

Setup

Note. First time the USB programming cable is used on the computer (PC), following has to be done:

1. Connect the USB connector to the PC and let the PC install the driver for the USB programming cable

2. Start the Device manager on the PC

3. Expand Ports and select Properties for the used COM Port

4. Select Port Settings.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 32 of 91

Page 33

5. Select Advanced...

6. Change Latency Timer to 1 ms.

7. Press OK.

Close all windows and restart PC.

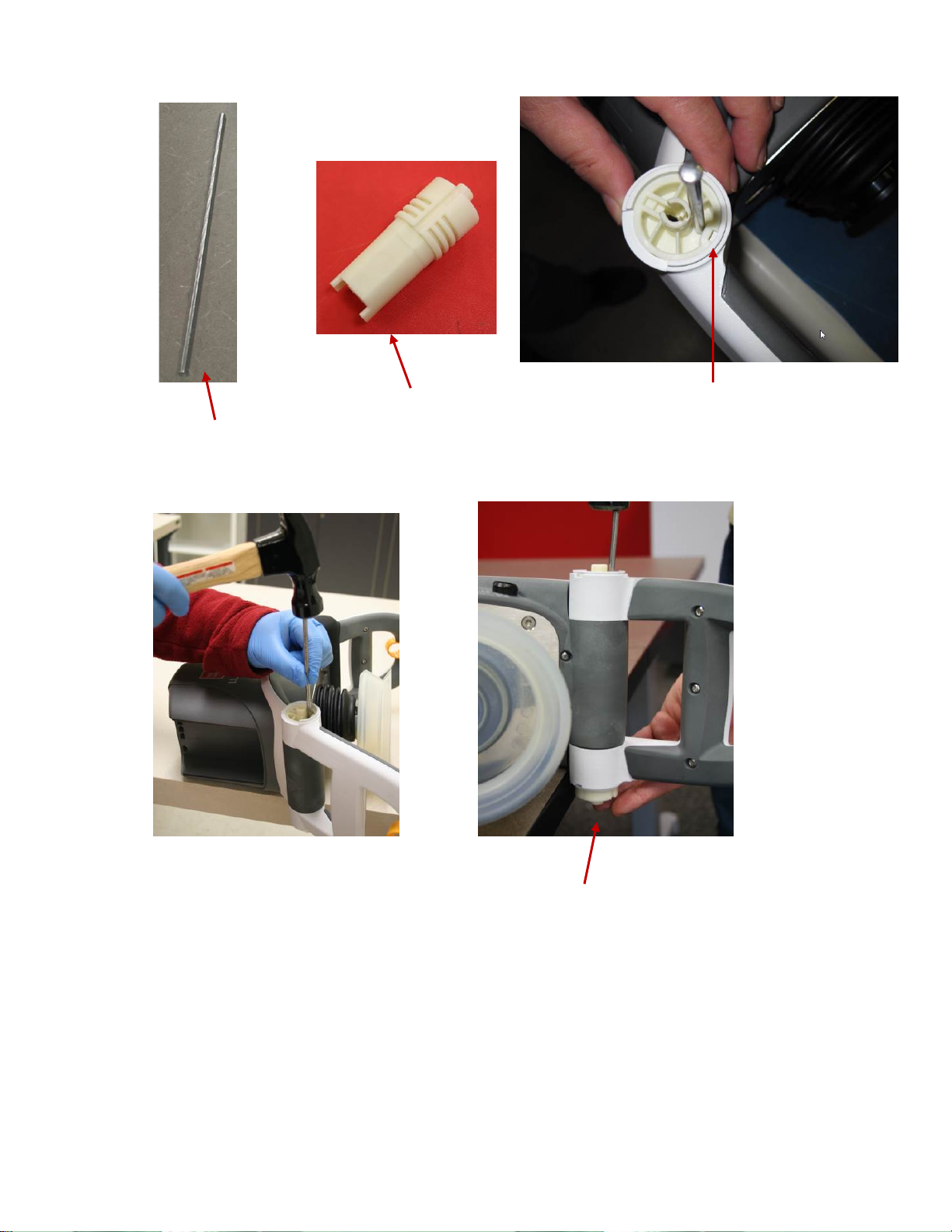

Open the Hood of the device (see instructions for Hood disassembly/reassembly) and connect the USB programming

cable to connector X2 on the Com Board. Plug the USB connector to the computer and assemble the battery to the

device.

Update and Test procedure

1. Start Tera Term software.

2. Select Serial and used COM Port (+ OK). Note that COM-port might be different

3. Select menu "Setup"-> Serial port...

4. Change Baud rate: to 921600 (+ OK).

5. Place cursor in the Tera Term window.

6. Start Lucas device communication (by COM button) and press a key on the keyboard fast (within 3s).

7. Type "run loadngo" + return.

8. Select menu "File"->"Transfer"->"Kermit"->"Send..." and select new Linux binary file to load (250042-00).

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 33 of 91

Page 34

9. Wait until program loaded.

10. Wait until LINUX and App have started, Wait until "......." is started to be written.

11. Turn Off the LUCAS3 device by pressing ON/OFF key two times.

12. Disconnect the USB cable.

13. Assemble the LUCAS3 device.

14. Press the Transmit key on the LUCAS3 device and confirm that the blue LED is flashing.

15. Start the Service-tool software (LUCAS3_V3_1_RevX.exe) and press “Init BT”-button.

16. When the device and PC is paired, press the “Progam”-button to program new Main software.

17. When the programming is completed, perform Linear sensor-calibration.

18. When the calibration is completed, press the “Off”-button.

19. Press the Transmit key on the device and confirm that the blue LED is flashing.

20. Start the Service-tool software (LUCAS3_V3_1_RevX.exe) with the latest revision and press “Init BT”-button.

21. When the device and PC is paired, verify the checksums are written in black text and not red that indicates that the

software in the device not have the latest version.

22. Press the “Off”-button.

23. Run the device in continuous mode for at least one minute and turn it off.

24. Press the Transmit key on the device and confirm that the blue LED is flashing.

25. Start the Service-tool software (LUCAS3_V3_1_RevX.exe) and press “Init BT”-button.

26. When the device and PC is paired, verify that the LOG-file from the latest run has no errors or warnings.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 34 of 91

Page 35

Setup Options - LUCAS 3 Version 3.1 (Part No: 250041-00)

The Setup Options are configurable for a LUCAS 3 Version 3.1 device. To enter the configuration tool press the

“PRE-SET” key.

The preset Options are depicted and described below. To enter the factory default setting, press the key “Set Default”.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 35 of 91

Page 36

The compression parameters can bet set according to IFU 3326785-1##, section 9.2 Compression parameters, refer to

• 1.5 to 2.1 ±0.1 inches / 40 to 53 ±2 mm

• 1.5 inches / 40mm to [set compression depth] ±0.1 inches / ±2mm

102 ±2 compressions per minute

Setup options

compressions.

Compression duty cycle

50 ±5%

Continuous compressions with ventilation LED alert 10 times per minute

compressions.

30:2 (30 compressions followed by a 3-second ventilation pause)

by pushing ACTIVE key (continuous or 30:2) during

below.

Category Specifications

Compression depth

(nominal patient)

Factory default setting

Patients with sternum height greater than or equal to

7.3 inches / 185mm:

• 2.1 ±0.1 inches / 53 ±2 mm

Smaller patients with sternum height less than 7.3 inches /

185 mm:

Setup options

Compression depth can be set to a value between

1.8 and 2.1 ±0.1 inches / 45 to 53 ±2mm.

Patients with sternum height greater than or equal to

7.3 inches / 185mm:

• [set compression depth] ±0.1 inches / ±2mm

Smaller patients with sternum height less than 7.3 inches /

185 mm:

Compression frequency Factory default setting

The device can be setup to provide a rate of any of

the following values: 102, 111, 120 ±2 compressions

per minute.

The device can be setup to enable the operator to change

rate during operation. The rate is changed by pushing

the ACTIVE key (30:2 or continuous) during ongoing

Compression mode ACTIVE

continuous

Compression mode ACTIVE

30:2

Factory default setting

Setup options

The device can be setup to provide ventilation alerts

of a value between 6 to 10 alerts per minute.

The device can be setup to provide an audible ventilation

alert (ON/OFF).

The device can be setup to provide a ventilation pause

duration of a value between 0.3 to 2 seconds.

The device can be setup to enable the operator to change

compression rate during operation. The rate is changed by pushing

the ACTIVE key (continuous or 30:2) during ongoing

Factory default setting

Setup options

The device can be setup to provide a compression/

ventilation ratio of any of the following ratios: 30:2 and 50:2

The device can be setup to provide a ventilation pause

duration of a value between 3 to 5 seconds.

The device can be setup to enable the operator to

change compression rate during operation. The rate is changed

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 36 of 91

Page 37

ongoing compressions.

Category (continued) Specifications (continued)

30 mm, and then the LUCAS device locks the Start Position.

will occur.

Manual: The Suction Cup has to be pulled up manually

modes.

The device stops compressions and locks the pressure pad in its Start Position.

pressure pad moves up 0.4 inch / 10 mm above the Start Position during PAUSE.

Position.

ventilation pauses.

compression

compression.

Suction Cup Start Position Factory default setting

QuickFit: The operator manually lowers the Suction Cup to the chest. When

pushing the PAUSE key, coming from ADJUST mode, the LUCAS device finetunes the Suction Cup height position to the chest within a distance of 1.2 inches /

Setup options

The device can be setup for QuickFit, AutoFit or Manual.

AutoFit: The device automatically lowers the Suction Cup from its upper position

down to the chest and finds and locks the Start Position. The device will do the

AutoFit when the operator pushes PAUSE key coming from ADJUST mode.

Manual: The operator manually lowers the Suction Cup to the chest. When

pushing the PAUSE key, the LUCAS device locks the Start Position. No fine-tuning

Suction Cup in ADJUST

mode

Pressure pad in PAUSE

mode

Pressure pad during

ventilation pauses in

ACTIVE modes

Pressure pad in ACTIVE

modes

Factory default setting

Setup options

The device can be setup so that the Suction Cup automatically returns up from the

chest when the operator pushes the ADJUST key coming from PAUSE or ACTIVE

Factory default setting

Setup options

To allow for chest rise during ventilation, the device can be setup so that the

Factory default setting

The device temporarily stops compressions and locks the pressure pad in its Start

Setup options

To allow for chest rise during ventilation, the device can be setup so that the

pressure pad moves up 0.4 inch / 10 mm above the Start Position during

Factory default setting

The pressure pad returns to Start Position between each

Setup options

To allow for chest rise during asynchronous ventilation, the device can be setup so

that the pressure pad moves up 0.4 inch / 10 mm above the Start Position at every

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 37 of 91

Page 38

Category (continued) Specifications (continued)

No timer (OFF)

Timer is set for 2 minutes, the device will alert every 2 minutes until power off.

Audible timers Factory default setting

Setup options

The device can be setup to provide a recurring audible alert at a specified time

interval of any value between 1 to 15 minutes. The audible alert is a short signal

sequence. The timer can be setup as either CPR Timer or Continuous Timer:

CPR Timer: The device only measures the time in uninterrupted ACTIVE (30:2 or

continuous) modes. The CPR Timer stops and resets when the operator pushes

PAUSE or ADJUST keys. The CPR Timer starts from zero again the next time the

operator pushes the ACTIVE (30:2 or continuous) key. For example if CPR Timer

is set for 2 minutes, the device will alert after every 2 minutes of compressions.

Continuous Timer: The device measures the time continuously, independent of

what mode the device is in. The Continuous Timer starts when the operator

pushes the ACTIVE (30:2 or continuous) key the first time and will alert at the

defined time interval until the device is powered off. For example if Continuous

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 38 of 91

Page 39

Troubleshooting

In this session, it explains the common troubleshooting methods for LUCAS.

Troubleshooting Table

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 39 of 91

Page 40

LUCAS Malfunction Alarm

Below is a list on all alarms that can occur on the LUCAS. All these alarms are possible to mute for 60 seconds by

pressing MUTE button

The audible alarms were updated in LUCAS 3 with regards to sound patterns; please refer to Instructions for Use

PNs/CAT #: 3326785-0## / 26500-00#### and 3326785-1## / 26500-00#### LUCAS 3 Version 3.1 for information.

.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 40 of 91

Page 41

Error Codes

In the software, LUCAS 3 Program Loader, it is possible to read error codes from the device. Below tables show these

codes and the explanation on how to find the cause and corrective actions.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 41 of 91

Page 42

Error Codes from Control CPU

Error Code

Explanation

Probable Cause

Module to

replace

User

LRG Text

T1_C_EE

Control EE-

data error

CPU fault

Replace

High priority

Internal fault -

T1_C_RAM

Control Preset

CPU fault or

Use Service

Control board

High priority

Internal fault -

T1_START_COM

No

at start

I2C communication

Check cable

After 3 start

Self-test fault

T1_PB_FLASH

Incompatible

board

Change of boards.

Reprogram

High priority

Internal fault -

T1_CAL_EE

Control

Un-calibrated or

Perform a

Control board

Delayed

Internal fault -

T1_C_INITCURR

High Current

Fault read current to

fault.

If needed

After 3 start

Alarm.

Self-test fault

T1_P_STATE_1

Start of

Protective start

Check for

boards.

After 3 start

Self-test fault

T1_C_RELEASE

Current

P45 module fault or in

Cable

board.

After 3 start

Self-test fault

T1_P_STATE_3

Start of Current

Protective

Current detected by

Check for

After 3 start

Self-test fault

No=0x10

No=0x11

No=0x13

No=0x14

No=0x15

Prom

CheckSum

CheckSum

data error

Communication

between

Protective

and/or BatteryCharger CPU's

programs in

Protective

Potentiometer

Calibration

data

CheckSum

fault

communication faults

faults. Halted

Protective or Charger

CPU.

Too un-linear or

CPU EE fault

check /

Control board

Tool to set

default preset

or replace

between

boards.

Protective

board.

device.

new

calibration. If

un-linear fault

replace

compression

module. If

CPU EE fault

replace

Notification

Alarm.

Alarm.

attempt,

High priority

Alarm.

Alarm.

(10s) High

priority

Alarm.

contact Technical

Support

contact Technical

Support

contact Technical

Support

contact Technical

Support

No=0x20

No=0x21

No=0x22

No=0x23

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

detected at

Start

Release Test

time out (from

Protective)

detected at

release/disable

test by Control

Test time out

(from

Protective),

Current

detected by

Page 42 of 91

motor or broken driver

FET’s. +/- 12V supply

Error’s. I2C

communication faults.

cable between

boards.

Protective or I2C

communication faults.

replace

Control board

Protective

Error’s. Cable

between

between

boards.

Protective or

Control

Protective

Error’s.

Protective

board.

attempt,

High priority

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

Page 43

T1_C_LOWCURR

No=0x24

Too low

Motor not connected

Motor, HALL

Control board

After 3 start

Self-test fault

T1_P_DISABLE

Protective

P45 module fault or in

Cable

board.

After 3 start

Self-test fault

T1_P_POT

Read

I2C communication

Cable

board.

After 3 start

Self-test fault

T1_C_POT

Pot value

Control and Protective

Check POT

faults.

After 3 start

Self-test fault

T1_P_STATE_5

No end of

Protective current

Check for

board.

After 3 start

Self-test fault

T1_B_OFF

No Battery

Charger CPU not

Check for

board.

After 3 start

Self-test fault

T1_C_DOWN

Control not

test

Motor connections.

Motor. Check

After 3 start

Alarm.

Self-test fault

T1_P_REW

Protective Time

Motor connections.

Motor.

Error’s.

After 3 start

Self-test fault

T1_C_TOTOP

Control Time

Motor and HALL

module.

Motor.

After 3 start

Alarm.

Self-test fault

INT_C_TEMP

Too High

Fan disconnected or

faults.

Fan. Control

High priority

Too high

INT_CODE

Access of vital

fault (10ms)

Halted or disturbed

Control

High priority

Internal fault Support

Current at

Current test

or broken. HALL

sensor signal faults or

Internal voltages.

cable. Check

for internal

voltages

faults.

attempt,

High priority

Alarm.

No=0x25

No=0x27

No=0x28

No=0x29

No=0x2A

Disable at

current test

Protective POT

time out

incorrect (Miss

match at start)

or not changed

at moving.

Protective

Current Test

(time out)

Charger T1 test

done (time out)

cable between

boards.

faults. Halted

Protective CPU.

POT value divergence

> 10mm at start. POT

fault or un- linear.

Reference voltage

faults.

read fault. I2C

communication faults.

done T1 test correct

or I2C communication

faults.

between

boards.

Protective or

Control

between

boards.

Protective

values and

POT cables.

Compression

module.

Check for

voltages

Protective

Error’s.

Protective

Charger

Error’s.

Protective

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

No=0x2D

No=0x2E

No=0x2F

No=0x34

No=0x36

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

moving down

before REW

out at Rew test

out at move to

top

internal board

temp.

> 85°C

function Code

Page 43 of 91

Protective stop by

disable line.

Protective POT signal.

Locked compression

module.

connections.

Locked compression

jammed. Broken

Temp sensor or

internal reference

Control CPU.

for Protective

Error’s.

Protective

POT. Check

for Protective

Compression

module.

PCB

board.

attempt,

High priority

attempt,

High priority

Alarm.

attempt,

High priority

Alarm.

Alarm.

temperature

contact Technical

Page 44

INT_C_POTCAL

No=0x3D

Control

Too un-linear Control

Repeat

module.

Delayed

Internal fault -

INT_P_POTCAL

Protective

Too un-linear

calibration

Repeat

module.

Delayed

Internal fault RUN_TIMEOUT

Piston not

mode ( > 1s)

Disconnected motor

compression module.

Compression

connections.

High priority

Disruption of

RUN_TOO_DEEP

Piston too deep

Control potentiometer

Assure un-

module.

High priority

In Pause:

Suction Cup

In Active:

RUN_TOO_SHALLOW

Piston too

50 strokes < Target

Assure

module.

High priority

Compressions out

RUN_RATIO

Piston Ratio

strokes)

Too high load. Ratio

Check load.

High priority

Compressions out

RUN_PROTECTIVE

Halt or reverse

mode ( > 1s)

Active mode disabled

Check

High priority

RUN_TIMEUP

Time Up too

Large 13N release in

Assure

module.

High priority

Compressions out

Potentiometer

linearity fault

potentiometer or

influenced at

calibration

calibration or

replace

compression

(10s) High

priority

Alarm.

contact Technical

Support

No=0x3E

No=0x40

No=0x41

No=0x42

Potentiometer

linearity fault

moved during

active (moving)

shallow

(50

consecutive

strokes @ 100

bpm)

Protective

potentiometer or

influenced at

(mechanical/electrical)

or locked

fault. Rough or

influenced

compression

movement at run with

no load. Hall signal

missing.

stroke length - 10mm

(@ 100bpm). Too

high load and/or too

low battery voltage.

Locked module.

calibration or

replace

compression

module.

Motor

influenced

movement of

the

compression

module (retest). Check

Hall. Replace

motor or

compression

correct

movement of

the

compression

module. If

needed

replace the

compression

(10s) High

priority

Alarm.

Alarm.

Alarm.

Alarm.

contact Technical

Support

Suction Cup

Disruption of

Compressions out

of range

of range

No=0x44

No=0x45

No=0x47

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

fault

(50

consecutive

by Protective

System during

active (moving)

long > 0.15s

(50

consecutive

strokes)

Page 44 of 91

fault (Preset Ratio +/20%) at 50

consecutive strokes.

by the Protective

system.

active mode or

mechanical locked

compression.

Protective

error’s for

cause.

correct

movement of

the

compression

module. If

needed

replace the

compression

Alarm.

Alarm.

Alarm.

of range

of range

Page 45

RUN_TIMEDOWN

No=0x48

Time Down too

strokes)

Too high load and/or

Check load

High priority

Compressions out

RUN_POTCAL

Potentiometer

139).

Movement fault at

Check

At

Internal fault -

RUN_NO_POTCAL

Potentiometer

139).

Not calibrated or other

Check for

Delayed

Internal fault RUN_P_STOP

Protective

Protective system

Check

cause.

High priority

Warning Code

Explanation

Probable Cause

Module to check

/ replace

User

Observation

LRG Text

T1_START_COM

No

first start.

I2C communication

Check cable

Prolonged

T1_C_INITCURR

High Current

well.

Fault read current to

If needed replace

Prolonged

T1_P_STATE_1

Start of Release

well.

Protective start

Check Cable

Prolonged

T1_C_RELEASE

Current detected

first start.

P45 module delayed

Cable between

voltages.

Prolonged

T1_P_STATE_3

Start of Current

by Protective

Current first detected

Cable between

Prolonged

long or too

Shallow.

(50

consecutive

too low battery

voltage. Motor fault.

and motor.

Alarm.

of range

No=0x4A

No=0x4B

No=0x4C

Calibration

fault, not

moved or pot

read.

(See ID in

Control vector,

at position

not calibrated

(See ID in

Control vector,

at position

system have

stopped

operation

Warnings from Control CPU

calibration or large

potentiometer fault

calibration fault.

error.

potentiometer

connections

and

mechanical

movement,

repeat

calibration.

other fault or

perform a

new

calibration.

Protective

system error

codes for

Calibration:

High priority

Alarm.

(10s) High

priority

Alarm.

Alarm.

contact Technical

Support

contact Technical

Support

No=0x13

No=0x20

No=0x21

No=0x22

No=0x23

Communication

from Protective

and/or BatteryCharger CPU's at

detected at Start,

next automatic

restart worked

Test time out

(from Protective),

next automatic

restart worked

at release/disable

test by Control at

Test time out

(from Protective)

at first start.

Current detected

startup faults. Delayed

start of Protective or

Charger CPU.

motor or unstable

driver FET’s +/- 12V

supply.

delayed. I2C

communication startup

faults.

or loose cable

between boards.

by Protective or I2C

communication faults.

between boards

or Protective

board.

Control board.

between boards.

Protective board.

boards. Check

Protective

boards.

Protective board.

startup test

time.

startup test

time.

startup test

time.

startup test

time.

startup test

time.

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 45 of 91

Page 46

T1_C_LOWCURR

No=0x24

Too low Current

Motor wires loose.

Motor, HALL

board

Prolonged

T1_P_DISABLE

Protective Disable

P45 delayed or loose

Cable between

Control board.

Prolonged

T1_P_POT

Read Protective

I2C communication

start.

Cable between

warnings.

Prolonged

T1_C_POT

Miss match at

Control and Protective

POT fault or un- linear.

Preform a new

voltages faults.

LUCAS V2

T1_P_STATE_5

No end of

first start.

Protective current read

interference.

Check Protective

Prolonged

T1_B_OFF

Battery Charger

out) at first start.

Charger CPU not done

Check Charger

Prolonged

T1_C_DOWN

Control not

at first start.

Motor connections.

at start test.

Motor. Check if

Prolonged

T1_P_REW

Protective Time

Motor connections.

module.

Motor. Protective

at start test.

Prolonged

T1_C_TOTOP

Control Time out

Motor and HALL

Motor.

at start test.

Prolonged

INT_P_5V

Protective 5V <

Cable between

Check cable.

Protective board.

None.

INT_C_5V

Control 5V < 4.5V

Electrical fault. Control

back plate.

Control board.

Control warnings.

None.

INT_C_24V

Control 24V < 18V

Battery fault. Internal

Check other

charged battery.

None.

INT_C_REF

Control 2.5V Ref <

Electrical fault. Control

+2.5V shortcut.

Check reference

board.

None.

INT_C_TEMP

High internal

Fan disconnected or

reference faults.

Fan. Control

Temperature

High

detected at first

Current test.

HALL sensor signal

loose or delayed

internal voltages.

cable. Check for

internal voltages

warnings. Control

startup test

time.

No=0x25

No=0x27

No=0x28

No=0x29

No=0x2A

No=0x2D

No=0x2E

at current test at

first start.

POT time out at

first start.

warm start.

Protective Current

Test (time out) at

not answered T1

test done (time

moving down

before REW test

out at Reverse

test at first start.

cable between boards.

delayed. Halted

Protective CPU at first

POT value divergence

> 10mm at warm start.

fault at first start.

I2C communication

T1 test correct or I2C

communication faults.

Protective stop by

disable line. High load

Protective POT signal.

Locked compression

boards.

Protective or

boards. Check

Protective

POT calibration.

Check for

voltages.

Protective board.

voltages.

Protective board.

start test is done

with load.

POT. Use free

piston movement

startup test

time.

startup test

time.

operation.

startup test

time.

startup test

time.

startup test

time.

startup test

time.

No=0x2F

No= 0x30

No=0x31

No=0x32

No=0x33

No=0x34

at move to top at

first start.

4.5V or > 5.5V

or > 5.5V

2V or > 3V

board temp.

> 70°C Warning

connections.

Locked compression

module.

boards. Incorrect

Protective 5V. Internal

reference faults.

board pin connected to

reference faults.

board pin connected to

back plate or POT

jammed. Broken Temp

sensor or internal

Compression

module. Use free

piston movement

Protective 5V.

Control internal

voltages faults.

Check for other

Control internal

voltages faults.

Test with a new

voltage or

replace Control

PCBA

startup test

time.

LOG file

stopped.

warning

signal.

temperature

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Page 46 of 91

Page 47

INT_POTHALL

No=0x37

PotPos./Hall

Control POT fault or

Preform a new

module.

LUCAS V2

INT_CURRENT

Current fault

Mean current to motor

Current read fault.

Motor.

board.

None.

INT_P_REBOOT

No=0x39

Protective reboot

in active mode

Protective electrical

fault.

Protective board.

Restart of

startup test.

INT_1msCODE

Warning Access of

timeout.

Halted or disturbed

Control board.

None.

INT_C_HALL

Motor Hall sensor

Motor or Hall sensor

Check Hall

replace Motor.

Slow or weak

s.

RUN_ADJUST

Incorrect Motor

Too high Motor Power

Incorrect current read.

Motor. Control

Adjust servo

RUN_13N

13N release (force

13N release > 10mm.

Assure correct

module.

13N release

Start

COM_P_TIMEOUT

I2C Protective

No I2C communication

Check cable

Protective board.

Device

COM_RTC

Real Time Clock

Reel Time Clock read

Charge “BAT1”

board.

LOG file date

Internal fault

COM_SD_MEM

No=0x54

Fault SD card

Communication

SD card not inserted

or broken.

SD card.

No LOG file

created.

sensor mismatch

after a correct

start.

un- linear. A start with

13N release. Rough

compression

movement.

POT calibration.

If warning

repeated replace

the compression

operation.

No=0x38

No=0x3A

No=0x3C

No=0x46

No=0x49

No=0x50

1ms Code

fault.

power at adjust

mode

UP too high)

Communication

Timeout

>20A. Jam of

compression module.

Control CPU.

cable fault.

(>25W) at Adjust

servo.

Too high start position

or mechanical locked

compression

movement.

with Protective system

>100s. I2C

communication fault or

halted Protective CPU.

Compression

module. Control

sensor cable or

board.

start and

movement of the

compression

module. If

needed replace

the compression

between boards.

Restart LUCAS3

and run for 30

minutes. If fault

repeats replace

compression

switched off.

information

signal (3 fast

signals).

cannot be

started in

active mode.

Position

adjustment

required

No=0x53

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

Fault

fault at start. SPI com

fault or too low “BAT1”

voltage.

by starting the

LUCAS3 and

press PAUSE

leave the

machine ON for

30 minutes, set

and time

fault.

Hot restart

after battery

switch not

functional.

- contact

Technical

Support

correct time and

date with the

LUCAS3.exe

program. After

this restart and

check for

COM_RTC

warning. If

needed replace

the Control

Page 47 of 91

Page 48

COM_B_TIMEOUT

No=0x55

I2C Battery

No I2C communication

Check cable

Protective board.

Device

COM_I2C

I2C faults too high

Disturbed I2C

Check cable

Control board.

Poor

Error Code

Explanation

Probable Cause

Module to check

/ replace

User

Notification

LRG Text

T1_RAM

Internal RAM

Protective CPU fault.

Protective board

High priority

Internal fault

Support

T1_E2_PROM

Internal E2 prom

Protective CPU fault.

Protective board

High priority

Internal fault

Support

T1 PISTON

Reverse test not

Motor not moved

Protective

(P45 fault)

After 3 start

Self-test

T1 PISTON

Protective

Current detected at

Check cable

(P45 fault)

After 3 start

Self-test

TOO_DEEP

Too deep

Protective

Check

High priority

In Pause:

Suction Cup

In Active:

range

TOO_SHALLOW

Too shallow

strokes)

Protective

Check load and

High priority

Compressio

INTERNAL

Protective board

Fan or Protective

Fan, Protective

(below +40°C).

High priority

Too high

Charger

Communication

Timeout

with Charger system

>100s.

I2C communication

fault or halted Charger

CPU.

between boards.

Restart LUCAS3

and run for 30

minutes. If fault

repeats replace

cannot be

operated.

Switch off by

removing

battery.

N0=0x56

communication.

Error Codes from Protective CPU

test detect fault

at start.

test detect fault

at start.

REVERSE ERROR

RELEASE ERROR

done correct at

start

release line

operation fault at

start

correct or fault

current read.

disable test or moved

too low at enable test.

between boards.

Protective or

board, check

cable between

boards or

Control board

between

boards,

Protective board

or Control board

response to

keystrokes.

Alarm.

Alarm.

attempt, High

priority

Alarm.

attempt, High

priority

Alarm.

- contact

Technical

- contact

Technical

fault

fault

COMPRESSION

COMPRESSION

TEMPERATURE

LUCAS® 3 Chest Compression System – Service Manual

3328798-002, ©2017 Physio-Control, Inc.

compression

detected in

active mode.

compression

detected in

active mode.

(50 consecutive

temperature

detected

> 85°C

Page 48 of 91

potentiometer fault.

Jam of compression

module at run with no

load.

potentiometer fault.

Compression module