Page 1

IIssooTToouurr™™ PPuummpp

MMaaiinntteennaannccee MMaannuuaall

2874

2874-009-002 Rev A.1

EN

2019/08

Page 2

Page 3

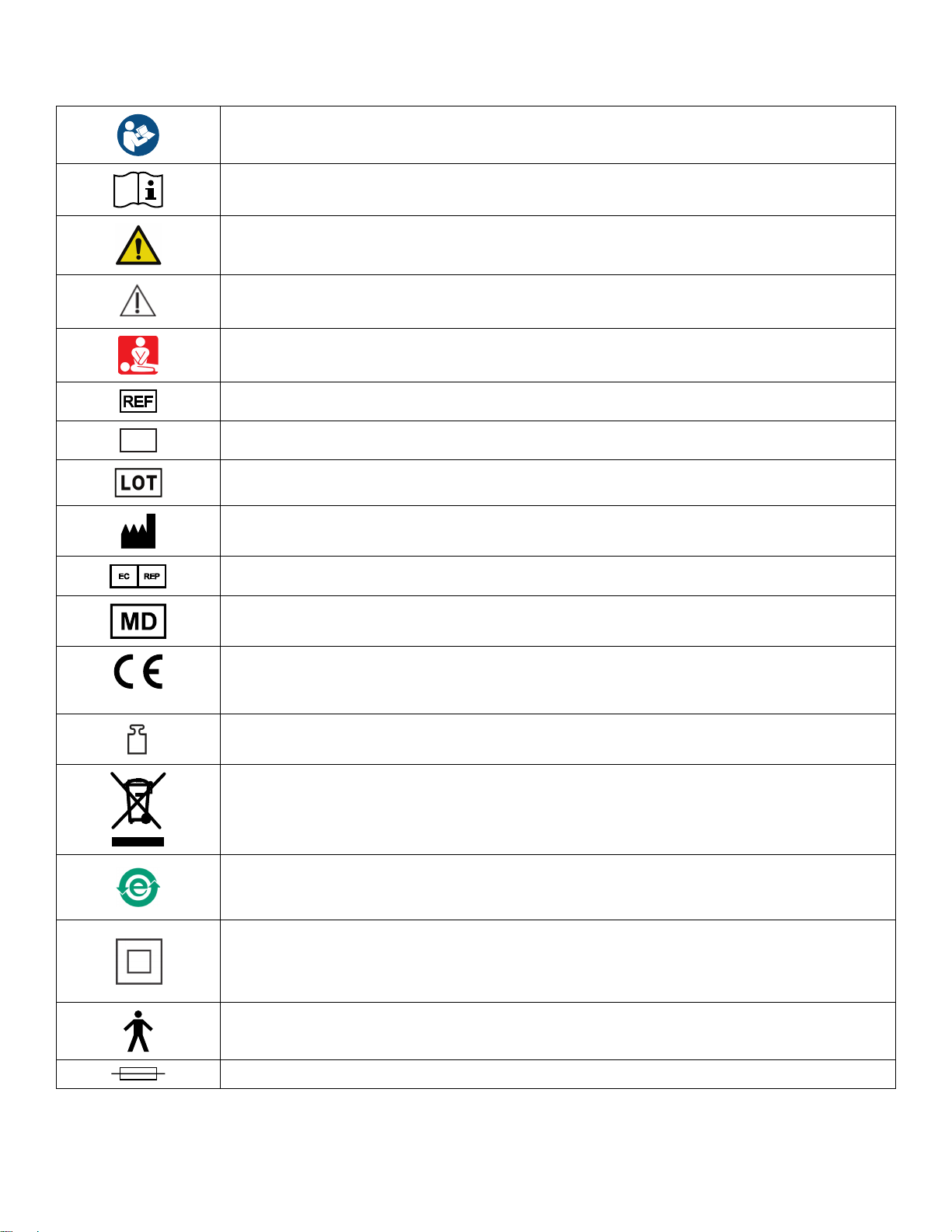

SSyymmbboollss

Refer to instruction manual/booklet

Operating instructions/Consult instructions for use

General warning

Caution

Cardiopulmonary resuscitation (CPR), disconnection point

Catalogue number

Serial number

Batch code

2797

Manufacturer

Authorized representative in the European Community

European medical device

CE mark

Mass of product

In accordance with European Directive 2012/19/EU on Waste Electrical and Electronic

Equipment (WEEE) as amended, this symbol indicates that the product should be collected

separately for recycling. Do not dispose of as unsorted municipal waste. Contact local distributor

for disposal information. Ensure infected equipment is decontaminated prior to recycling.

Indicates that this product does not contain toxic and hazardous substances or elements above

the maximum concentration of all 6 values defined by the China RoHS legislation. This product is

an environmentally friendly product which can be recycled and reused.

Class II electrical equipment: equipment in which protection against electric shock does not rely

on basic insulation only, but in which additional safety precautions such as double insulation or

reinforced insulation are provided, there being no provisions for protective earthing or reliance

upon installation conditions.

Type B applied part - 2872 IIssooTToouurr support surface

Fuse

2874-009-002 Rev A.1 EN

Page 4

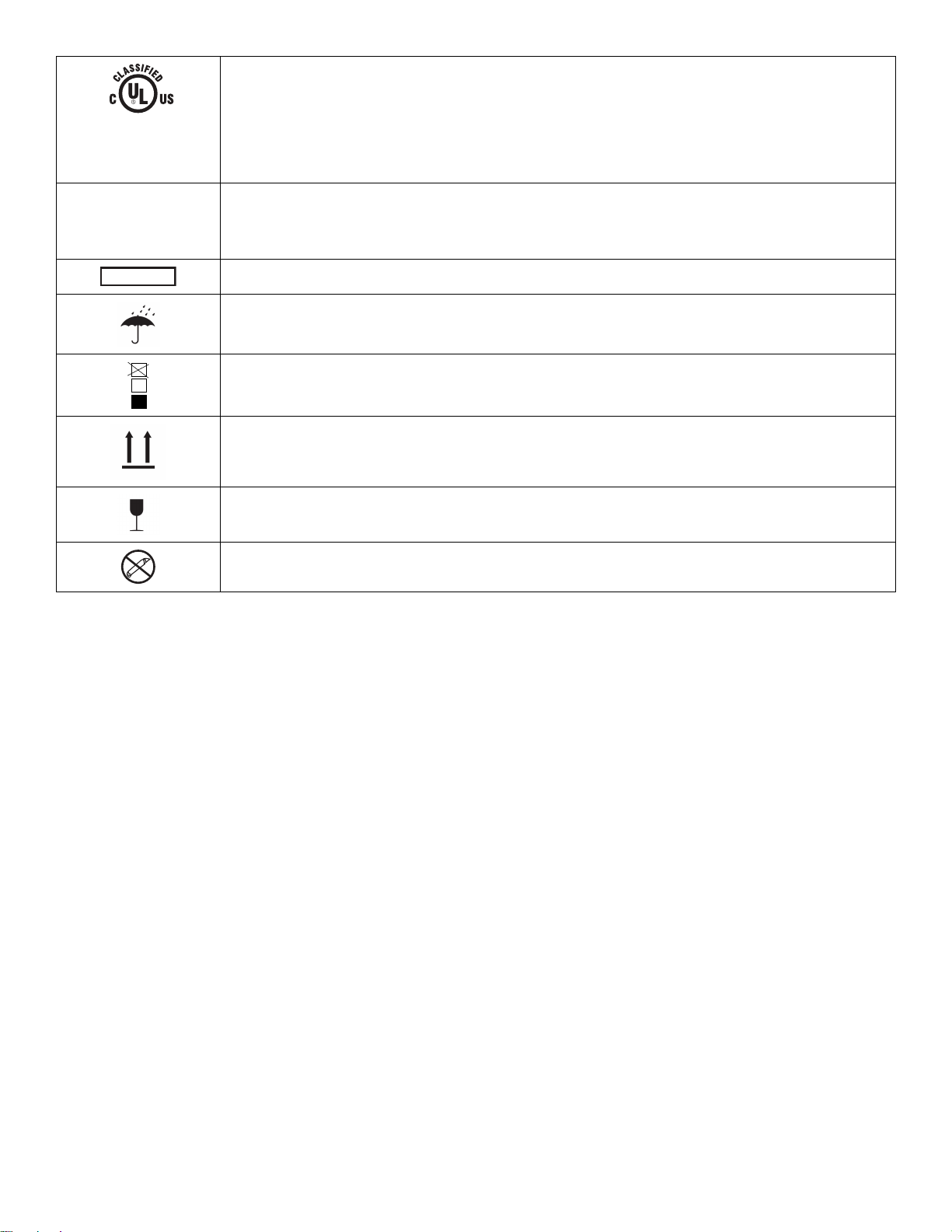

E347196

MEDICAL

ELECTRICAL

EQUIPMENT

Medical Equipment Classified by Underwriters Laboratories Inc. With Respect to Electric Shock,

6

Fire, and Mechanical Hazards Only in Accordance with ANSI/AAMI ES60601-1:2012, IEC

60601-1-8:2012, and CAN/CSA-C22.2 No. 60601-1:16.

IIPP2211

Solids: Protection from touch by fingers and objects greater than 12 mm

Liquids: Protection from the fall of vertical water drops

For US Patents see www.stryker.com/patents

Keep dry

Do not stack more than 6 high

This side up

Fragile

Do not use sharp objects to open the package

EN 2874-009-002 Rev A.1

Page 5

TTaabbllee ooff CCoonntteennttss

Warning/Caution/Note Definition ..............................................................................................................................3

Summary of safety precautions ................................................................................................................................3

Introduction ...............................................................................................................................................................4

Product description .................................................................................................................................................4

Intended use ..........................................................................................................................................................4

Expected service life ...............................................................................................................................................4

Disposal/recycle .....................................................................................................................................................4

Contraindications ....................................................................................................................................................4

Specifications .........................................................................................................................................................5

Environmental conditions ....................................................................................................................................5

Product illustration ..................................................................................................................................................6

Contact information .................................................................................................................................................6

Serial number .........................................................................................................................................................7

Date of manufacture................................................................................................................................................7

Service ......................................................................................................................................................................8

Protecting against electrostatic discharge (ESD) .......................................................................................................8

Powering off the pump.............................................................................................................................................8

Fuse replacement ...................................................................................................................................................8

Bumper replacement...............................................................................................................................................8

Foot replacement....................................................................................................................................................9

Filter replacement ...................................................................................................................................................9

LCD screen replacement .......................................................................................................................................10

Transport handle replacement ...............................................................................................................................10

Hook replacement.................................................................................................................................................11

Front pump housing replacement ........................................................................................................................... 11

Power supply replacement.....................................................................................................................................12

Power inlet replacement ........................................................................................................................................ 13

PCB assembly replacement...................................................................................................................................13

LED board replacement.........................................................................................................................................14

Solenoid/valve replacement...................................................................................................................................14

Pump replacement................................................................................................................................................15

Access diagnostic mode .........................................................................................................................................16

Preventive maintenance ......................................................................................................................................... 17

Troubleshooting ......................................................................................................................................................18

Power cords ............................................................................................................................................................19

Pump housing assembly 2874-007-017 .................................................................................................................20

Top panel assembly 2874-007-018 ........................................................................................................................21

Hook assembly 2874-007-019................................................................................................................................ 22

Bumper pack 2874-007-020 ...................................................................................................................................23

Pump housing rubber foot assembly 2874-007-022 .............................................................................................. 24

Compressor assembly 2874-007-023 .................................................................................................................... 25

Power supply assembly 2874-007-024 ..................................................................................................................26

PCBA assembly 2874-007-025 ..............................................................................................................................27

HEPA filter 2874-007-026....................................................................................................................................... 28

Air filter guard 2874-007-027 .................................................................................................................................. 29

3 way digital valve assembly 2874-007-028........................................................................................................... 30

5 way digital valve assembly 2874-007-029........................................................................................................... 31

Front LED module assembly 2874-007-030........................................................................................................... 32

Handle assembly 2874-007-031 ............................................................................................................................33

Mattress hose assembly 2874-007-034 ................................................................................................................. 34

2874-009-002 Rev A.1 1 EN

Page 6

EMC information ..................................................................................................................................................... 35

EN 2 2874-009-002 Rev A.1

Page 7

WWaarrnniinngg//CCaauuttiioonn//NNoottee DDeeffiinniittiioonn

The words WWAARRNNIINNGG, CCAAUUTTIIOONN, and NNOOTTEE carry special meanings and should be carefully reviewed.

WWAARRNNIINNGG

Alerts the reader about a situation which, if not avoided, could result in death or serious injury. It may also describe

potential serious adverse reactions and safety hazards.

CCAAUUTTIIOONN

Alerts the reader of a potentially hazardous situation which, if not avoided, may result in minor or moderate injury to the

user or patient or damage to the product or other property. This includes special care necessary for the safe and effective

use of the device and the care necessary to avoid damage to a device that may occur as a result of use or misuse.

NNoottee -- Provides special information to make maintenance easier or important instructions clearer.

SSuummmmaarryy ooff ssaaffeettyy pprreeccaauuttiioonnss

Always read and strictly follow the warnings and cautions listed on this page. Service only by qualified personnel.

WWAARRNNIINNGG

• Do not modify or change this device. Service should only be completed by qualified personnel. Failure could result in

injury and void your warranty.

• The use of accessories, transducers, and cables, other than those specified or provided by the manufacturer, could

result in increased electromagnetic emissions or decreased electromagnetic immunity and result in improper operation.

• Portable RF communications equipment, including peripherals such as antenna cables and external antennas, should

be no closer than 12 inches (30 cm) to any part of IIssooTToouurr, including cables specified by the manufacturer.

• Avoid stacking or placing equipment adjacent with other equipment to prevent improper operation of the products. If

such use is necessary, carefully observe stacked or adjacent equipment to make sure that they are operating properly.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

• Always use a grounded static strap to prevent static coming into contact with the PCB assembly.

2874-009-002 Rev A.1 3 EN

Page 8

IInnttrroodduuccttiioonn

This manual assists you with the operation or maintenance of your Stryker product. Read this manual before operating or

maintaining this product. Set methods and procedures to educate and train your staff on the safe operation or maintenance

of this product.

CCAAUUTTIIOONN

• Improper usage of the product can cause injury to the patient or operator. Operate the product only as described in this

manual.

• Do not modify the product or any components of the product. Modifying the product can cause unpredictable operation

resulting in injury to patient or operator. Modifying the product also voids its warranty.

NNoottee

• This manual is a permanent part of the product and should remain with the product even if the product is sold.

• Stryker continually seeks advancements in product design and quality. This manual contains the most current product

information available at the time of printing. There may be minor discrepancies between your product and this manual. If

you have any questions, contact Stryker Customer Service or Technical Support at 1-800-327-0770.

PPrroodduucctt ddeessccrriippttiioonn

The Stryker Model 2874, IIssooTToouurr™™ PPuummpp is an electric pump for use with the Stryker Model 2872, IIssooTToouurr Support

Surface. This pump provides Low Air Loss for the IIssooTToouurr standard or the premium support surface.

The pump, when connected to the premium support surface delivers the air to inflate and deflate the air bladders for the

TTrruuTTuurrnn™™ function.

IInntteennddeedd uussee

The IIssooTToouurr PPuummpp is for use with the IIssooTToouurr support surface assists in the prevention and treatment of pressure injuries

or pressure ulcers (all stages, Unstageable injury, and Deep tissue injury). We recommend you implement this product in

combination with clinical evaluation of risk factors and skin assessments made by a healthcare professional.

This pump is for use with the IIssooTToouurr support surface in an acute care setting. This may include critical care, step down,

progressive care, med/surg, sub-acute care, and post anesthesia care unit (PACU), or other locations as prescribed by a

physician. Operators of this pump include healthcare professionals (such as nurses, nurse aids, or doctors).

This product is not intended to be sterile, does not include a measuring function, and is not for use in a home healthcare

environment.

EExxppeecctteedd sseerrvviiccee lliiffee

The IIssooTToouurr PPuummpp has a 5 year expected service life under normal use, conditions, and with appropriate periodic

maintenance.

The air hose has a 2 year expected service life under normal use, conditions, and with appropriate periodic maintenance.

DDiissppoossaall//rreeccyyccllee

Always follow the current local recommendations and/or regulations governing environmental protection and the risks

associated with recycling or disposing of the equipment at the end of its useful life.

CCoonnttrraaiinnddiiccaattiioonnss

The TTrruuTTuurrnn feature is not intended for use with patients that have unstable spine.

EN 4 2874-009-002 Rev A.1

Page 9

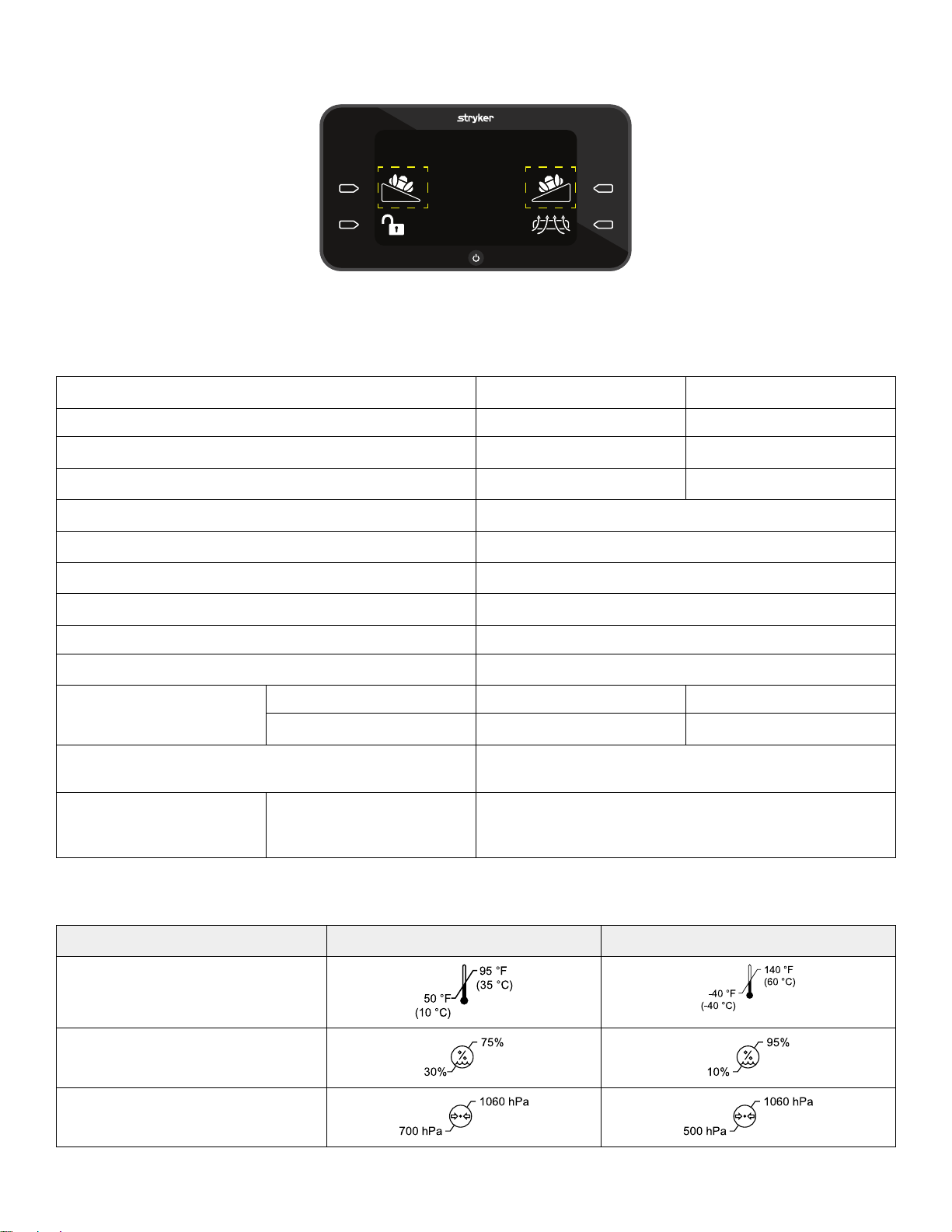

NNoottee -- TTrruuTTuurrnn requires the IIssooTToouurr pump to be connected for use. The TTrruuTTuurrnn feature is visually identified by the icons

on the IIssooTToouurr pump (Figure 1).

FFiigguurree 11 –– TTrruuTTuurrnn iiccoonn

SSppeecciiffiiccaattiioonnss

Height 17.25 in. 43.8 cm

Width 9.25 in. 23.5 cm

Depth 7.25 in. 18.4 cm

Weight 16.3 lb 7.4 kg

Interface control panel LCD

Input voltage 100-240V

Current 0.7 Amps

Input frequency 50/60 Hz

Noise level <50 dba

Mode of operation Continuous

Power cord Short 3.2 ft 1 m

Long 16.4 ft 5 m

Compliance IEC 60601-1 3.1 Edition; RoHS Directive 2002/95/EC

Reach; IEC 60601-1-8:2012, IEC 60601-1-2:2014

Compatible with bed frame IIssooTToouurr standard and

premium support surface

with an IIssooTToouurr pump

33000022 SS33™™, 33000055 SS33™™, IInnTToouucchh™™, SSppiirriitt SSeelleecctt™™

EEnnvviirroonnmmeennttaall ccoonnddiittiioonnss

EEnnvviirroonnmmeennttaall ccoonnddiittiioonnss

OOppeerraattiioonn SSttoorraaggee aanndd ttrraannssppoorrttaattiioonn

Ambient temperature

Relative humidity (non-condensing)

Atmospheric pressure

2874-009-002 Rev A.1 5 EN

Page 10

Stryker reserves the right to change specifications without notice.

C

L

I

K

A

B

C

E

F

D

G

H

J

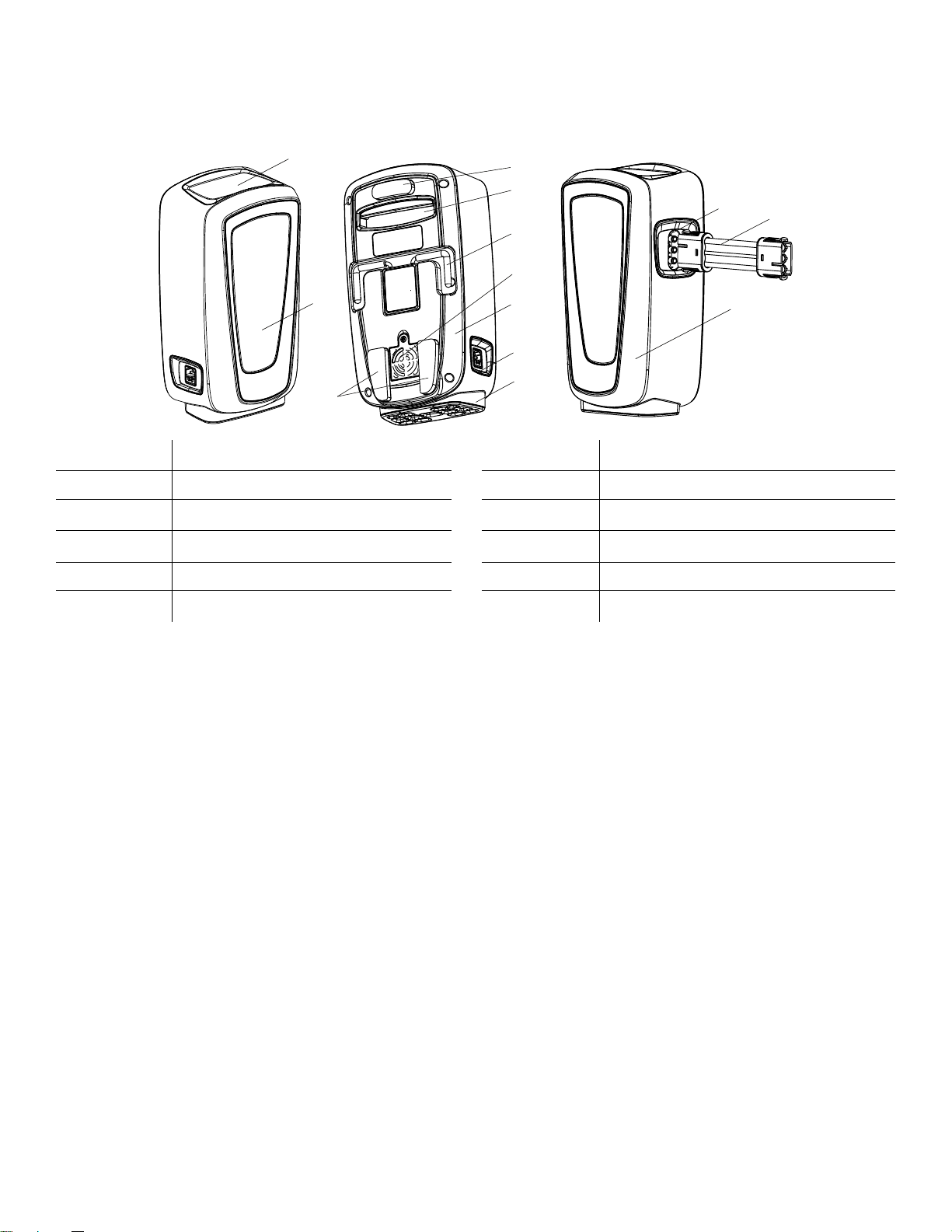

PPrroodduucctt iilllluussttrraattiioonn

A

B Status indicators H Power inlet

C

D

E Hooks K Hose

F

Graphical user interface

Bumpers

Transport handle

HEPA filter

G

I Anti-vibration foot

J

L

Back pump house

Hose port

Front pump housing

CCoonnttaacctt iinnffoorrmmaattiioonn

Contact Stryker Customer Service or Technical Support at: 1-800-327-0770.

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

NNoottee -- The user and/or the patient should report any serious product-related incident to both the manufacturer and the

Competent authority of the European Member State where the user and/or patient is established.

To view your operations or maintenance manual online, see https://techweb.stryker.com/.

Have the serial number (A) of your Stryker product available when calling Stryker Customer Service or Technical Support.

Include the serial number in all written communication.

EN 6 2874-009-002 Rev A.1

Page 11

SSeerriiaall nnuummbbeerr

A

DDaattee ooff mmaannuuffaaccttuurree

The year of manufacture is the first four digits of the serial number.

2874-009-002 Rev A.1 7 EN

Page 12

SSeerrvviiccee

PPrrootteeccttiinngg aaggaaiinnsstt eelleeccttrroossttaattiicc ddiisscchhaarrggee ((EESSDD))

CCAAUUTTIIOONN

• Always use ESD protective equipment before opening antistatic bags and servicing electronic parts.

• Do not place unprotected circuit boards on the floor.

NNoottee -- Always ship back circuit boards to Stryker in the same antistatic bags that the new boards were originally shipped in.

The electronic circuits in the product are completely protected from static electricity damage when factory assembled.

Always use adequate static protection when servicing the electronic systems of the product. All service personnel must use

static protection whenever they are touching wires.

Sample antistatic protection equipment includes:

• 1 antistatic wrist strap

• 1 grounding plug

• 1 test lead with a banana plug on one end and an alligator clip on the other end

Make sure that you follow the ESD manufacturer’s instructions for appropriate protection against static discharge.

PPoowweerriinngg ooffff tthhee ppuummpp

Press the power button and hold for 2 seconds to power off the pump.

NNoottee

• Allow the support surface to deflate before you unplug the power cord.

• For optional deflation, remove the CPR plug from the support surface.

FFuussee rreeppllaacceemmeenntt

Fuse rating: F2AH250V

TToooollss rreeqquuiirreedd::

• Flat head screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a flat head screwdriver, remove and save the fuse cover located below the power inlet.

5. Remove and dispose of the fuse.

6. Reverse the steps to reinstall.

7. Verify proper operation before you return the product to service.

BBuummppeerr rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• Pick

EN 8 2874-009-002 Rev A.1

Page 13

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump with the front pump housing side down on a work surface.

4. Using a pick, remove and discard the bumper from the back pump housing (

5. Place and press the bumper in place.

Bumper pack 2874-007-020

(page 23)).

FFoooott rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• 6 mm socket

• Ratchet

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove the six screws that secure the back pump housing to the front pump housing. Save the

screws.

5. Using two hands, rotate the pump assembly to the right so the front is on your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. Using a ratchet and a 6 mm socket, remove the six nuts that secure the foot to the front pump housing. Save the nuts.

8. Remove and discard the foot.

9. Reverse the steps to reinstall (

10.Run and pass the diagnostic test.

11.Verify proper operation before you return the product to service.

Pump housing rubber foot assembly 2874-007-022

(page 24)).

FFiilltteerr rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the screw that secures the filter access door.

5. Remove and save the access door.

6. Remove and dispose of the filter.

7. Reverse the steps to reinstall (

8. Verify proper operation before you return the product to service.

2874-009-002 Rev A.1 9 EN

Air filter guard 2874-007-027

(page 29)).

Page 14

LLCCDD ssccrreeeenn rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• #2 Phillips screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. Unplug all cables from the PCB assembly.

NNoottee -- Pay attention to the hose locations for reinstallation.

8. Using a #2 Phillips screwdriver, remove the two screws that secure the support bracket holding the PCB assembly and

the screen to the front pump housing. Save the screws.

9. Using a #2 Phillips screwdriver, remove and save the three screws that secure the board to the PCB assembly to the

screen.

10.Using a #2 Phillips screwdriver, remove and save the four screws that secure the LCD screen and gasket to the front

pump housing.

11.Remove and discard the LCD screen and gasket.

12.Reverse the steps to reinstall (

13.Run and pass the diagnostic test.

14.Verify proper operation before you return the product to service.

Top panel assembly 2874-007-018

(page 21)).

TTrraannssppoorrtt hhaannddllee rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• #2 Phillips screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front pump housing is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. Using a #2 Phillips screwdriver, remove and save the five screws that secure the back board to the back pump hosing.

8. Remove and save the back board.

9. Using a #2 Phillips screwdriver, remove and save the four screws that secure the handles to the back pump housing.

10.Remove and discard the handle.

11.Reverse the steps to reinstall (

12.Run and pass the diagnostic test.

Handle assembly 2874-007-031

(page 33)).

EN 10 2874-009-002 Rev A.1

Page 15

13.Verify proper operation before you return the product to service.

HHooookk rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• Stubby #2 Phillips screwdriver

• Pick

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a pick, remove and discard the information label on the hook assembly.

5. Using a #2 Phillips, remove the screw (under the label removed in step 4) that secure the hook assembly to the back

pump housing.

6. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

7. Using two hands, rotate the pump assembly to the right so the front is to your left.

8. Separate the front and back pump housing. Place the back pump housing down on the work surface.

9. Unplug the power input cable and the power output cable from the power supply.

10.Using one hand to hold the fish paper and a #2 Phillips screwdriver, remove and save the four Phillips screws and

washers that secure the power supply to the main frame.

11.Remove the power supply to the side and fish paper.

12.Using a #2 Phillips screwdriver, remove and save the four screws that secure the pump frame to the main frame and set

aside.

13.Using a #2 Phillips screwdriver remove and save the six screws that secure the hook assembly to the back pump

housing.

14.Remove and discard the hook assembly.

15.Reverse the steps to reinstall (

16.Run and pass the diagnostic test.

17.Verify proper operation before you return the product to service.

Hook assembly 2874-007-019

(page 22)).

FFrroonntt ppuummpp hhoouussiinngg rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• #2 Phillips screwdriver

• Stubby #2 Phillips screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

2874-009-002 Rev A.1 11 EN

Page 16

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

CCAAUUTTIIOONN -- Always use a grounded static strap to prevent static coming into contact with the PCB assembly.

7. Unplug all cables from the PCB assembly.

NNoottee -- Pay attention to the cable connection locations for reinstallation.

8. Using a #2 Phillips screwdriver, remove the two screws that secure the support bracket holding the PCB assembly and

the screen to the front pump housing. Save the screws and support bracket.

9. Using a #2 Phillips screwdriver, remove and save the three screws that secure the board to the screen.

10.Grasp each of the air hoses individually and pull out from the mattress hose connector to detach each hose from the

connector.

NNoottee -- Pay attention to the air hose connection locations for reinstallation.

11.Grasp each of the pressure transducer hoses individually and pull out from the mattress hose connector to detach each

hose from the connector.

NNoottee -- Pay attention to the pressure transducer hose connection locations for reinstallation.

12.Using a stubby #2 Phillips screwdriver, remove the four screws that secure the LED board assembly to the front pump

housing assembly. Save the screws.

13.Remove the PCB assembly.

14.Remove and discard the front pump housing.

15.Reverse the steps to reinstall (

16.Run and pass the diagnostic test.

17.Verify proper operation before you return the product to service.

Pump housing assembly 2874-007-017

(page 20)).

PPoowweerr ssuuppppllyy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• #2 Phillips screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. Grasp the hose at the manifold coming from the pump and pull to remove the hose from the manifold.

8. Unplug the power input cable and the power output cable from the power supply.

9. Using one hand to hold the fish paper and a #2 Phillips screwdriver, remove the four Phillips screws and washers that

secure the power supply to the main frame. Save the screws, washers, and fish paper.

10.Remove and discard the power supply.

11.Reverse the steps to reinstall (

12.Run and pass the diagnostic test.

13.Verify proper operation before you return the product to service.

Power supply assembly 2874-007-024

(page 26)).

EN 12 2874-009-002 Rev A.1

Page 17

PPoowweerr iinnlleett rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• Flat blade screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. Unplug the power inlet from the power supply.

8. Using a flat blade screwdriver and your finger, push out on the power inlet while you push in on each of the power inlet

locks to loosen the power inlet from the front pump housing. Repeat on the other side to remove.

9. Remove and discard the power inlet.

10.Reverse the steps to reinstall (

11.Run and pass the diagnostic test.

12.Verify proper operation before you return the product to service.

Pump housing assembly 2874-007-017

(page 20)).

PPCCBB aasssseemmbbllyy rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• #2 Phillips screwdriver

• ESD

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

CCAAUUTTIIOONN -- Always use a grounded static strap to prevent static coming into contact with the PCB assembly.

7. Unplug all cables from the PCB assembly.

NNoottee -- Pay attention to the cable connection locations for reinstallation.

8. Grasp each of the pressure transducer hoses individually and pull out from the PCB assembly to detach each hose from

the PCB assembly.

NNoottee -- Pay attention to the pressure transducer hose connection locations for reinstallation.

9. Using a #2 Phillips screwdriver, remove the two screws that secure the support bracket that hold the PCB assembly and

the screen to the front pump housing. Save the screws and support bracket.

10.Using a #2 Phillips screwdriver, remove and save the three screws that secure the board to the screen.

2874-009-002 Rev A.1 13 EN

Page 18

11.Remove and discard the PCB assembly.

12.Reverse the steps to reinstall (

13.Run and pass the diagnostic test.

14.Verify proper operation before you return the product to service.

PCBA assembly 2874-007-025

(page 27)).

LLEEDD bbooaarrdd rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• Stubby #2 Phillips screwdriver

•

Protecting against electrostatic discharge (ESD)

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

(page 8)

CCAAUUTTIIOONN -- Always use a grounded static strap to prevent static coming into contact with the PCB assembly.

7. Unplug the LED board cable from the PCB assembly.

NNoottee -- Pay attention to the cable connection locations for reinstallation.

8. Using a stubby #2 Phillips screwdriver, remove and save the four screws that secure the LED board assembly to the

front pump housing assembly.

9. Unplug and save the cable from the LED board assembly.

10.Remove and discard the LED board assembly.

11.Reverse the steps to reinstall (

12.Run and pass the diagnostic test.

13.Verify proper operation before you return the product to service.

Front LED module assembly 2874-007-030

(page 32)).

SSoolleennooiidd//vvaallvvee rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• #2 Phillips screwdriver

• 2.5 mm hex wrench

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

EN 14 2874-009-002 Rev A.1

Page 19

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. On the solenoid/valve that needs to be replaced, make note of the hose locations first, then unplug each hose from the

valve.

NNoottee -- Pay attention to the hose locations for reinstallation.

8. Unplug the solenoid cable from the PCB.

9. Using a #2 Phillips screwdriver, remove and save the two screws that secure the valve to the valve bracket.

10.Remove and discard the solenoid/valve.

11.Reverse the steps to reinstall (

2874-007-029

12.Run and pass the diagnostic test.

13.Verify proper operation before you return the product to service.

(page 31)).

3 way digital valve assembly 2874-007-028

(page 30) or

5 way digital valve assembly

PPuummpp rreeppllaacceemmeenntt

TToooollss rreeqquuiirreedd::

• T20 Torx driver

• Wire cutters

• #2 Phillips screwdriver

PPrroocceedduurree::

1. Unplug the pump from AC power.

2. Unplug the mattress tubing from the pump.

3. Place the pump front down on a work surface.

4. Using a T20 Torx driver, remove and save the six screws that secure the back pump housing to the front pump housing.

5. Using two hands, rotate the pump assembly to the right so the front is to your left.

6. Separate the front and back pump housing. Place the back pump housing down on the work surface.

7. Grasp the hose at the manifold coming from the pump and pull to remove the hose from the manifold.

8. Using wire cutters, cut the four zip ties that secure the pump power cable to the rest of the cables.

CCAAUUTTIIOONN -- Always use a grounded static strap to prevent static coming into contact with the PCB assembly.

NNoottee

• Use care when you cut the zip ties that you do not cut or damage the cables.

• Replace the zip ties when you reinstall.

9. Unplug the pump power cable from the PCB assembly.

10.Using a #2 Phillips screwdriver, remove and save the screw that secures the pump cable p-clamp to the main frame.

Remove and save the p-clamp.

11.Using a T20 Torx driver, remove and save the four screws that secure the pump frame to the main frame.

12.Remove the spring from the hose and insert into the new pump assembly hose.

13.Remove and discard the pump assembly.

14.Reverse the steps to reinstall (

15.Run and pass the diagnostic test.

16.Verify proper operation before you return the product to service.

2874-009-002 Rev A.1 15 EN

Compressor assembly 2874-007-023

(page 25)).

Page 20

AAcccceessss ddiiaaggnnoossttiicc mmooddee

IsoTour

V vx.x.x.xxx

PPrroocceedduurree::

1. Make sure that the support surface hoses are plugged into the pump and there is no weight on the support surface.

2. Power on the pump.

3. As the software loads, within 5 seconds of pressing the on button (Figure 2), press and hold the upper left button (Figure

3).

FFiigguurree 22 –– SSooffttwwaarree llooaaddiinngg

4. Press the lower left button to start the diagnostics mode.

NNoottee -- The software version is located on the service screen (Figure 3).

5. The diagnostic results should all pass with OK.

a. If diagnostic results do not pass, investigate failed area referenced in the diagnostic test results.

FFiigguurree 33 –– SSeerrvviiccee ssccrreeeenn aanndd vveerrssiioonn

EN 16 2874-009-002 Rev A.1

Page 21

PPrreevveennttiivvee mmaaiinntteennaannccee

WWAARRNNIINNGG -- Do not modify or change this device. Service should only be completed by qualified personnel. Failure could

result in injury and void your warranty.

NNoottee

• At a minimum, check all items listed during annual preventive maintenance for all Stryker Medical products. You may

need to perform preventive maintenance checks more often based on your level of product usage.

• Remove product from service before you perform preventive maintenance.

• Consult your local regulations to dispose of electronic equipment.

Inspect the following items:

All fasteners are secure

Pump housing or components (hoses, power cords, or case) for cracks, holes, or damaged

Hooks that hang the pump on the bed frame are not damaged

No air leaks from the pump or the attached connectors or hoses

Graphical user interface is not cracked or damaged

HEPA filter (replace each year)

Fuse

All functions on graphical user interface operate

Run diagnostic test (All okay)

Product serial number:

Completed by:

Date:

2874-009-002 Rev A.1 17 EN

Page 22

TTrroouubblleesshhoooottiinngg

29:59

PPrroobblleemm SSccrreeeenn CCaauussee RReeccoommmmeennddeedd aaccttiioonn

Kinked air hoses

Missed connection with air

hoses

Air hose is bent or an

obstruction in the hose may

cause air flow to be

compromised

TTrruuTTuurrnn was attempted but

you have a standard model

(bottom cover is orange)

Air hoses is not connected

to the pump or the support

surface

1. Make sure that the hoses

are straight and air flow is

not obstructed.

2. Press the action button

next to the Alarm off icon

to reset the pump.

Contact sales support for

TTrruuTTuurrnn option

1. Make sure that the hoses

are seated all the way

onto the hose ports on

the pump or the support

surface.

2. Press the action button

next to the Alarm off icon

to reset the pump.

Power loss, product does

not turn on

Power loss, while TTrruuTTuurrnn

is in use

Button not responsive

TTrruuTTuurrnn not shown on

screen

TTrruuTTuurrnn shown on screen

Power cord not seated,

power cord unplugged from

outlet, or possible internal

damage, Button is stuck.

Unintentional or intentional

power loss.

Lock function active. Button

is stuck.

Kinked hose during setup.

IIssooTToouurr standard model is

connected.

Graphical user interface

shows TTrruuTTuurrnn but you

have a standard model

(bottom cover is orange)

Make sure that the power

cord is plugged into the

product and the outlet.

Replace the LCD screen.

Pull the hose from the pump

or the support surface to

activate CPR. The bladder

deflates and returns the

support surface to a flat

position.

Press and hold the action

button next to the locked icon

for 2 seconds to turn off the

lock. Replace the LCD

screen. Power cycle the

pump.

Check for kinked hoses.

Verify that you have premium

bottom cover (black).

Contact sales support for

TTrruuTTuurrnn option.

Turn off the pump to reset

the pump features. Make

sure that the air hose is

connected before you turn

the pump on.

EN 18 2874-009-002 Rev A.1

Page 23

PPoowweerr ccoorrddss

PPaarrtt NNuummbbeerr

Power cord, type B, 1 meter 2874-007-001

Power cord, type B, 5 meter 2874-007-002

Power cord, type E/F, 1 meter 2874-007-003

Power cord, type E/F, 5 meter 2874-007-004

Power cord, type J, 1 meter 2874-007-007

Power cord, type J, 5 meter 2874-007-008

Power cord, type I, 1 meter 2874-007-009

Power cord, type I, 5 meter 2874-007-010

Power cord, type G, 1 meter 2874-007-011

Power cord, type G, 5 meter 2874-007-012

Power cord, type L, 1 meter 2874-007-013

Power cord, type L, 5 meter 2874-007-014

Power cord, type N, 1 meter 2874-007-015

Power cord, type N, 5 meter 2874-007-016

2874-009-002 Rev A.1 19 EN

Page 24

PPuummpp hhoouussiinngg aasssseemmbbllyy 22887744--000077--001177

EN 20 2874-009-002 Rev A.1

Page 25

TToopp ppaanneell aasssseemmbbllyy 22887744--000077--001188

A

C

B

D

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 517M064022 Gasket 1

B Reference only Top panel subassembly 1

C 521096S05 Screws 3

D 521M064051 Screws 4

2874-009-002 Rev A.1 21 EN

Page 26

HHooookk aasssseemmbbllyy 22887744--000077--001199

A

C

B

D

E

F

H

G

G

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 515M064013 Hook 2

B 515M064014 Hook stopper 2

C 511M064104 Hook clutch gear A 2

D 511M064105 Hook clutch gear B 2

E 523M064001 Hook spring 2

F 511M104016 Hook back cover 1

G 521M064005 Internal screws 7

H 622M104003 Hook, back cover label 1

EN 22 2874-009-002 Rev A.1

Page 27

BBuummppeerr ppaacckk 22887744--000077--002200

A

C

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 517M104004 Bumper left bottom 1

B 517M104005 Bumper right bottom 1

C 517M104006 Bumper top 1

2874-009-002 Rev A.1 23 EN

Page 28

PPuummpp hhoouussiinngg rruubbbbeerr ffoooott aasssseemmbbllyy 22887744--000077--002222

A

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 517M104001 Molded rubber foot 1

B 521096N01 Nut fasteners 6

EN 24 2874-009-002 Rev A.1

Page 29

CCoommpprreessssoorr aasssseemmbbllyy 22887744--000077--002233

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A Compressor subassembly 1

B 521M064026 Screws 4

C 511M092013 Nylon wire tie (not shown) 6

2874-009-002 Rev A.1 25 EN

Page 30

PPoowweerr ssuuppppllyy aasssseemmbbllyy 22887744--000077--002244

A

C

B

D

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 553M104003 Power supply 1

B 521M064024 Isolation paper 1

C 521096B07 Mounting screws 4

D 521M064050 Screw gasket 8

E 555M064028 Cable (not shown) 1

F 511M092013 Cable nylon tie (not shown) 4

EN 26 2874-009-002 Rev A.1

Page 31

PPCCBBAA aasssseemmbbllyy 22887744--000077--002255

A

C

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A Reference only PCBA subassembly 1

B 521096505 Screws 3

C 511M104013 Molded PCB holder 1

2874-009-002 Rev A.1 27 EN

Page 32

HHEEPPAA ffiilltteerr 22887744--000077--002266

A

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 517M104015 HEPA filter 1

EN 28 2874-009-002 Rev A.1

Page 33

AAiirr ffiilltteerr gguuaarrdd 22887744--000077--002277

A

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 511M104015 Molded air filter guard 1

B 521M064029 Screw 1

2874-009-002 Rev A.1 29 EN

Page 34

33 wwaayy ddiiggiittaall vvaallvvee aasssseemmbbllyy 22887744--000077--002288

B

A

C

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A Reference only 3 way digital valve subassembly 1

B 521M064025 Screws 2

C 521M064026 Screws 4

EN 30 2874-009-002 Rev A.1

Page 35

55 wwaayy ddiiggiittaall vvaallvvee aasssseemmbbllyy 22887744--000077--002299

A

C

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A Reference only 5 way digital valve subassembly 1

B 521M064025 Screws 2

C 521M064026 Screws 4

2874-009-002 Rev A.1 31 EN

Page 36

FFrroonntt LLEEDD mmoodduullee aasssseemmbbllyy 22887744--000077--003300

A

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A Reference only Front LED PCB subassembly 1

B 521M064051 Screws 4

EN 32 2874-009-002 Rev A.1

Page 37

HHaannddllee aasssseemmbbllyy 22887744--000077--003311

A

B

IItteemm NNuummbbeerr NNaammee QQuuaannttiittyy

A 511M104017 Molded handle 1

B 521M064005 Screws 4

2874-009-002 Rev A.1 33 EN

Page 38

MMaattttrreessss hhoossee aasssseemmbbllyy 22887744--000077--003344

518M104001

EN 34 2874-009-002 Rev A.1

Page 39

EEMMCC iinnffoorrmmaattiioonn

WWAARRNNIINNGG -- The use of accessories, transducers, and cables, other than those specified or provided by the manufacturer,

could result in increased electromagnetic emissions or decreased electromagnetic immunity and result in improper

operation.

NNoottee

• The emissions characteristics of this equipment make it suitable for use in industrial areas and hospitals (CISPR 11

class A). If it is used in a residential environment (for which CISPR 11 class B is normally required) this equipment might

not offer adequate protection to radio-frequency communication services. The user might need to take mitigation

measures, such as relocating or re-orienting the equipment.

• This equipment is suitable for use in hospitals except for near active HF surgical equipment and the RF shielded room of

an ME system for magnetic resonance imaging, where the intensity of EM disturbances is high.

GGuuiiddaannccee aanndd mmaannuuffaaccttuurreerr’’ss ddeeccllaarraattiioonn -- eelleeccttrroommaaggnneettiicc eemmiissssiioonnss

The 2874 IIssooTToouurr pump is intended for use in the electromagnetic environment specified below. The customer or the

user of the 2874 IIssooTToouurr pump should assure that it is used in such an environment.

EEmmiissssiioonnss tteesstt

RF Emissions

CISPR 11

RF Emissions

CISPR 11

Harmonic Emissions

IEC 61000-3-2

Voltage Fluctuations

Flicker Emissions

IEC 61000-3-3

WWAARRNNIINNGG

• Portable RF communications equipment, including peripherals such as antenna cables and external antennas, should

be no closer than 12 inches (30 cm) to any part of IIssooTToouurr, including cables specified by the manufacturer.

• Avoid stacking or placing equipment adjacent with other equipment to prevent improper operation of the products. If

such use is necessary, carefully observe stacked or adjacent equipment to make sure that they are operating properly.

CCoommpplliiaannccee EElleeccttrroommaaggnneettiicc eennvviirroonnmmeenntt

The 2874 IIssooTToouurr pump uses RF energy only for its

Group 1

Class A

Class A

Complies

internal function. Therefore, its RF emissions are

very low and are not likely to cause any interference

in nearby electronic equipment.

The 2874 IIssooTToouurr pump is suitable for use in all

establishments other than domestic and those

directly connected to the public low voltage power

supply network that supplies buildings used for

domestic purposes.

RReeccoommmmeennddeedd sseeppaarraattiioonnss ddiissttaanncceess bbeettwweeeenn ppoorrttaabbllee aanndd mmoobbiillee RRFF ccoommmmuunniiccaattiioonn eeqquuiippmmeenntt aanndd tthhee 22887744

IIssooTToouurr ppuummpp

The 2874 IIssooTToouurr pump is intended for use in an electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the 2874 IIssooTToouurr pump can help prevent electromagnetic interferences by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the

2874 IIssooTToouurr pump as recommended below, according to the maximum output power of the communications

equipment.

BBaanndd ((MMHHzz))

2874-009-002 Rev A.1 35 EN

SSeerrvviiccee

MMaaxxiimmuumm PPoowweerr

((WW))

MMiinniimmuumm SSeeppaarraattiioonn DDiissttaannccee

((mm))

Page 40

RReeccoommmmeennddeedd sseeppaarraattiioonnss ddiissttaanncceess bbeettwweeeenn ppoorrttaabbllee aanndd mmoobbiillee RRFF ccoommmmuunniiccaattiioonn eeqquuiippmmeenntt aanndd tthhee 22887744

IIssooTToouurr ppuummpp

380-390 TETRA 400 1.8 0.3

430-470

704-787

800-960

1,700-1,990

2,400-2,570

5,100-5,800

For transmitters rated at a maximum output power not listed above, the recommended separation distance

(m) can be estimated using the equation applicable to the frequency of the transmitter, where

power rating of the transmitter in watts (W) according to the transmitter manufacturer.

GMRS 460;

FRS 460

LTE Band 13, 17

GSM 800/900;

TETRA 800;

iDEN 820;

CDMA 850;

LTE Band 5

GSM 1800;

CDMA 1900;

GSM 1900;

DECT;

LTE Band 1, 3, 4, 25;

UMTS

Bluetooth;

WLAN;

802.11 b/g/n;

RFID 2450;

LTE Band 7

WLAN 802.11 a/n 0.2 0.3

2.0 0.3

0.2 0.3

2.0 0.3

2.0 0.3

2.0 0.3

P

is the maximum output

d

in meters

NNoottee -- These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

GGuuiiddaannccee aanndd mmaannuuffaaccttuurreerr’’ss ddeeccllaarraattiioonn -- eelleeccttrroommaaggnneettiicc iimmmmuunniittyy

The 2874 IIssooTToouurr pump is suitable for use in the electromagnetic environment specified below. The customer or the

user of the 2874 IIssooTToouurr pump should assure that it is used in such an environment.

IImmmmuunniittyy tteesstt

Electrostatic Discharge

(ESD)

IEC 61000-4-2

Electrostatic fast transient/

burst

IEC 61000-4-4

IIEECC 6600660011 tteesstt lleevveell

+8 kV contact

+15 kV air

+2 kV for power supply lines

+1 kV for input/ output lines

CCoommpplliiaannccee lleevveell

+8 kV contact

+15 kV air

+2 kV for power supply lines

+1 kV for input/ output lines

EElleeccttrroommaaggnneettiicc

eennvviirroonnmmeenntt--gguuiiddaannccee

Floors should be wood,

concrete, or ceramic tile. If

floors are covered with

synthetic material, the

relative humidity should be

at least 30%.

Main power quality should

be that of a typical

commercial or hospital

environment.

Surge

±1 kV for input/output lines ±1 kV for input/output lines

IEC 61000-4-5

EN 36 2874-009-002 Rev A.1

Main power quality should

be that of a typical

commercial or hospital

environment.

Page 41

GGuuiiddaannccee aanndd mmaannuuffaaccttuurreerr’’ss ddeeccllaarraattiioonn -- eelleeccttrroommaaggnneettiicc iimmmmuunniittyy

Voltage dips, voltage

variations and short

interruptions on power

supply input lines

IEC 61000-4-11

Power frequency (50/60 Hz)

magnetic field

IEC 61000-4-8

0%U

for 0.5 cycle at 0°,

T

45°, 90°, 135°, 180°, 225°,

270°, and 315°

0%U

for 1 cycle

T

70%U

(30% dip in UT) for

T

25/30 cycles

0% U

for 250/300 cycles

T

30 A/m 30 A/m

for 0.5 cycle at 0°,

0%U

T

45°, 90°, 135°, 180°, 225°,

270°, and 315°

0%U

for 1 cycle

T

70%U

(30% dip in UT) for

T

25/30 cycles

0% U

for 250/300 cycles

T

Main power quality should

be that of a typical

commercial or hospital

environment. If the user of

the 2874 IIssooTToouurr pump

requires continued

operation during power

main interruptions, it is

recommended that the

device be powered from an

uninterrupted power supply

or a battery.

Power frequency magnetic

fields should be at levels

characteristic of a typical

location in a typical

commercial or hospital

environment.

NNoottee -- U

is the a.c. mains voltage before applications of the test level.

T

2874-009-002 Rev A.1 37 EN

Page 42

Conducted RF

IEC 61000- 4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2.7 GHz

3 Vrms

3 V/m

Portable and mobile RF

communications equipment

should be used no closer to

any part of the 2874

IIssooTToouurr pump, including

cables, than the

recommended separation

distance calculated from the

equation appropriate for the

frequency of the transmitter.

Recommended separation

distance

P

D=(1.2) (√

)

80 MHz to 800 MHz

P

D=(2.3) (√

)

800 MHz to 2.7 GHz

where

P

is the maximum

output power rating of the

transmitter in watts (W)

according to the transmitter

manufacturer and

d

is the

recommended separation

distance in meters (m).

Field strengths from fixed

RF transmitters, as

determined by an

electromagnetic site

a

survey

, should be less than

the compliance level in each

frequency range

b

.

Interference may occur in

the vicinity of equipment

marked with the following

symbol:

NNoottee

• At 80 MHz and 800 MHz, the higher frequency range applies.

• These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection

from structures, objects and people.

• The ISM (Industrial, Scientific, and Medical) bands between 0.15 MHz and 80 MHz are 6.765 MHz to 6.795 MHz;

13.553 MHz to 13.567 MHz; 26.957 MHz to 27.283 MHz; and 40.66 MHz to 40.70 MHz.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile

radios, amateur radio, AM and FM radio broadcast, and TV broadcast cannot be predicted theoretically with accuracy. To

assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be

considered. If the measured field strength in the location in which the 2874 IIssooTToouurr pump is used exceeds the applicable

RF compliance level above, the 2874 IIssooTToouurr pump should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as reorienting or relocating the 2874 IIssooTToouurr

pump.

b

Over the frequency range 150 kHz to 80 MHz, field strengths are less than 3 Vrms.

EN 38 2874-009-002 Rev A.1

Page 43

Page 44

Stryker Medical

3800 E. Centre Avenue

Portage, MI 49002

USA

2874-009-002 Rev A.1

WCR: AA.21

2019/08

Loading...

Loading...