Still RX70-60, RX70-70, RX70-80 Operator Manual

Original instructions

Diesel trucks

With SCR (Selective Catalytic Reduction)

RX70-60

RX70-70

RX70-80

7341 7342 7343 7344

57348011800 EN - 07/2016

Preface

g

Address of manufacturer and

contact details

STILL GmbH

Berzeliusstraße 10

22113 Hamburg, Germany

Tel. +49 (0) 40 7339-0

Fax: +49 (0) 40 7339-1622

Email: info@still.de

Website: http://www.still.de

57

348011800 EN- 07/2016 I

Table of contents

g

1 Foreword

Your truck .......................................................... 2

General ............................................................ 2

Note regarding SCR (Selective Catalytic Reduction) as exhaust gas treatment ........ 2

CElabelling ......................................................... 3

EC declaration of conformit

y in accordance with Machinery Directive ............... 4

Accessories ......................................................... 5

Information about the documentation ...................................... 6

Documentationscope ................................................. 6

Issuedateandtopicalityoftheoperatinginstructions ........................... 7

Copyrightandtrademarkrights ........................................... 7

Explanation of informatio

nsymbolsused ................................... 7

Listofabbreviations ................................................... 8

Definitionofdirections ................................................ 11

Schematicviews .................................................... 11

Environmental considerations .......................................... 13

Packaging ......................................................... 13

Disposal of components a

ndbatteries ..................................... 13

2 Introduction

Using the truck ...................................................... 16

Proper usage ....................................................... 16

Proper use during tow

ing .............................................. 16

Impermissibleuse ................................................... 16

Placeofuse ........................................................ 17

Using working platf

orms ............................................... 18

Residual risk ....................................................... 19

Residual dangers, residual risks ......................................... 19

Special risks assoc

iatedwithusingthetruckandattachments ................... 20

Overviewofhazardsandcountermeasures ................................. 22

Danger to employees . . ............................................... 25

3Safety

Definition of resp

onsible persons ........................................ 28

Operatingcompany .................................................. 28

Specialist .......................................................... 28

Drivers ........................................................... 29

Basic principles for safe operation ....................................... 31

Insurance cover on company premises .................................... 31

57

348011800 EN - 07/2016 III

Table of contents

g

Changes and retrofitting ............................................... 31

Changes to the overhead guard and roof loads . . . ........................... 33

Warning regarding non-origin

alparts ..................................... 33

Damage, defects and misuse of safety systems . . . ........................... 34

Tyres ............................................................. 34

Medicalequipment ................................................... 36

Exercise caution when handling gas springs and accumulators .................. 36

Lengthoftheforkarms ................................................ 37

Safety tests ........................................................ 38

Regularsafetyinspectionofthetruck ..................................... 38

Checkingthedieselengineemissions ..................................... 38

Particlefilter ........................................................ 39

Insulationtesting .................................................... 40

Safety regulations for handling consumables ............................... 41

Permissible consumables

............................................. 41

Oils .............................................................. 41

Hydraulicfluid ...................................................... 42

Batteryacid ........................................................ 43

Dieselfuel ......................................................... 44

Coolantandcoolingfluid .............................................. 46

Disposal of consumable

s .............................................. 46

Emissions ......................................................... 48

4Overviews

Overview .......................................................... 54

Overview of the driv

er’s compartment ..................................... 55

Operating devices and display elements ................................... 56

Display and operating unit . . . .......................................... 56

Operating devices f

orhydraulicanddrivingfunctions .......................... 57

Doublemini-lever .................................................... 58

Three-waymini-lever ................................................. 59

Four-way mini-lev

er .................................................. 60

Joystick4Plus ...................................................... 61

Fingertip .......................................................... 62

Miniconsole ....................................................... 63

Labelling points ..................................................... 64

Overview .......................................................... 64

Nameplate ......................................................... 66

Productionnumber .................................................. 67

IV

57348011800 EN - 07/2016

Table of contents

g

StVZO(RoadTrafficLicensingRegulations)information ....................... 67

5 Operation

Checks and tasks to be carried out prior to commissioning ...................... 70

Visualinspections ................................................... 70

Fillingthewashersystem .............................................. 72

Checking the condition of the wheels and tyres .............................. 72

Checking the cooling fluid l

evel .......................................... 74

Checking the engine oil level ........................................... 74

AdjustingtheMSG65/MSG75driver’sseat ................................ 76

Adjustingthearmrest ................................................. 79

Adjustingthesteeringcolumn ........................................... 80

Cleaningthedustvalve ............................................... 81

Checking the pre-cleane

r .............................................. 81

Checkingtheoiltankontheoilbathairfilter ................................. 82

Commissioning ..................................................... 83

Climbing into and out of

thetruck ........................................ 83

Unlockingtheemergencyoffswitch ...................................... 86

Switchingonthekeyswitch ............................................ 86

Access authorisation

withPINcode(variant) ................................ 89

Operating the signal horn .............................................. 99

Seatbelt .......................................................... 99

Using the driver’s cab

.................................................102

Starting the engine ...................................................103

Checkingthebrakesystemforcorrectfunction ..............................105

Checking the steeri

ngsystemforcorrectfunction ............................106

Checking the emergency off function .....................................106

Zeroadjustmentoftheloadmeasurement(variant) ...........................107

Checking the vertic

alliftmastposition(variant)forcorrectfunction ................109

Driving ............................................................110

Safety regulations when driving .........................................110

Roadways .........................................................112

Settingthedriveprogramme ............................................114

Selectingthedrivedirection ............................................115

Actuating the driv

edirectionswitch,mini-leverversion .........................116

Actuating the vertical rocker switch for the "drive direction", joystick 4Plus version . . . . 117

Actuating the drive direction switch, fingertip version ..........................117

Actuating the driv

edirectionswitch,mini-consoleversion ......................118

Startingtodrive .....................................................118

Starting drive mode, dual-pedal version (variant) .............................120

57

348011800 EN - 07/2016 V

Table of contents

g

Operatingtheservicebrake ............................................123

Parkingbrake ......................................................124

Actuating the mechanical park

ingbrake ...................................124

Steering ...........................................................126

Reducing speed when turning (Curve Speed Control) .........................127

Reducing speed with a raised lo

ad(variant) ................................128

Automatic shut-off of the internal combustion engine (variant) ...................128

Lifting ............................................................129

Liftingsystemvariants ................................................129

Automaticliftcutout(variant) ...........................................129

Liftmastverticalposition(variant) ........................................130

Typesofliftmast ....................................................134

Malfunctionsduringliftingmode .........................................135

Hydraulicblockingfunction .............................................136

Lifting system operating

devices .........................................137

Controlling the lifting system using a double mini-lever .........................138

Controllingtheliftingsystemusingatriplemini-lever ..........................139

Controlling the lifting

system using a quadruple mini-lever ......................140

Controllingtheliftingsystemusingthejoystick4Plus ..........................141

Controlling the lifting system using the fingertip . . . ...........................143

Changing the fork arms ...............................................1

44

Forkextension(variant) ...............................................146

Operationwithreversibleforkarms(variant) ................................148

Handling loads ......................................................150

Safety regulations when handing loads ....................................150

Beforetakingupload .................................................151

Load measurement (va

riant) ...........................................152

Picking up loads .....................................................155

Danger area .......................................................156

Transporting pallet

s ..................................................157

Transportofswingingloads ............................................157

Loadpickup ...................................................... . 158

Transporting loads

...................................................162

Setting down loads ...................................................163

Driving on ascending and descending slopes ...............................165

Drivingonlifts ......................................................165

Drivingonloadingbridges .............................................166

Particle filter system ..................................................167

Particlefilter-Fu

nction ................................................167

Particle filter - Performing parked regeneration . . . ...........................169

Particlefilter-Displays ................................................173

VI

57348011800 EN - 07/2016

Table of contents

g

Working with attachments .............................................175

Fittingattachments ..................................................175

Releasing the pressure from th

ehydraulicsystem ............................177

Generalinstructionsforcontrollingattachments .............................179

Controlling attachments using a double mini-lever ............................181

Controlling attachments usin

g the double mini-lever and the 5th function ...........183

Controllingattachmentsusingatriplemini-lever .............................185

Controlling attachments using the triple mini-lever and the 5th function .............187

Controlling attachments us

ing a quadruple mini-lever .........................188

Controlling attachments using the quadruple mini-lever and the 5th function .........190

Controllingattachmentsviathejoystick4Plus ...............................191

Controlling attachments u

singthejoystick4Plusandthe5thfunction ..............192

Controlling the attachments with the fingertip ...............................193

Controlling attachments with the fingertip and 5th function ......................194

Clamp locking mechanism (

variant) ......................................196

Takingupaloadusingattachments ......................................200

Operating auxiliary equipment ..........................................201

Switching the lighting o

nandoff .........................................201

Switching the rotating beacon on and off . . . ................................202

Switchingthehazardwarningsystemonandoff .............................203

Switching the directio

nindicatorsonandoff ................................203

Switching the double working spotlights on and off. ...........................205

Operatingthewindscreenwiper/washer ...................................207

FleetManager (variant

) ................................................207

Accidentrecorder(variant) .............................................208

Cruisecontrol(variant) ................................................208

Driver restraint sys

tems(variants) .......................................212

Cab operation ......................................................212

Opening the cab door . . ...............................................212

Closingthecabdoor .................................................2

13

Openingthesidewindows ........................................... . . 213

Closing the side windows ..............................................214

Operating the inter

iorlighting ...........................................214

Operating the rear window heating .......................................215

Radio(variant) ......................................................216

Heating system (var

iant) ..............................................216

Air conditioning (variant) ...............................................218

Push-up roof window (variant) ..........................................219

Clipboard (varian

t) ...................................................219

Trailer operation ....................................................220

Towedload ....................................................... . 220

57

348011800 EN - 07/2016 VII

Table of contents

g

Coupling pin in the counterweight ........................................221

Automatictowcoupling ...............................................223

Towingtrailers ......................................................231

Operating the display and operating unit ...................................232

Displays ..........................................................232

Adjustingthedisplays ................................................233

Symbolsinthedisplay ................................................233

Settingthedateortime ................................................238

Resetting the daily kilomet

res and daily operating hours .......................238

Setting the language .................................................239

Soft key button for operating various equipment variants .......................239

Configuring Blue-Q efficien

cymode ......................................240

Blue-Q efficiency mode ...............................................242

Functionaldescription ................................................242

Effects on additional con

sumers .........................................242

SwitchingefficiencymodeBlue-Qonandoff ................................243

Display messages ...................................................245

Displaycontent .....................................................245

Errorcodetable .....................................................246

General messages ...................................................249

Drive-specific message

s ..............................................258

Operating in special operating situations ...................................266

Transport ..........................................................266

Towing .......................................................... . 268

Craneloading ......................................................271

Jump-starting ......................................................274

Procedure in emergen

cies .............................................276

Emergency shutdown ................................................276

Procedureiftrucktipsover .............................................277

Emergency hammer ..................................................278

Emergency lowering .................................................278

Releasing the spring-operated brake .....................................280

Disconnecting the b

attery ..............................................283

Refuelling .........................................................283

Dieselfuel—Specifications ............................................283

Filling up with die

selfuel ...............................................287

Usingthefuelhandpump ..............................................288

Topping up AdBlue ..................................................290

Decommissioning

...................................................291

Parkingthetrucksecurelyandswitchingitoff ...............................291

VI

II 57348011800 EN - 07/2016

Table of contents

g

Wheelchock(variant) ................................................292

Shuttingdownandstoringthetruck ......................................292

Recommissioning after shutdo

wn ........................................294

Cleaning ..........................................................295

Cleaningthetruck ...................................................295

Cleaning the electrical sys

tem ..........................................297

Cleaningloadchains .................................................298

Cleaningthewindows .............................................. . . 298

Afterwashing .......................................................299

6 Maintenance

General maintenance information ........................................302

Personnel qualifications ...............................................302

Information for carryin

goutmaintenance ..................................302

Maintenance instructions ..............................................305

Maintenance - 500 hours/half-yearly ......................................305

Maintenance - 1000 hour

s/annually ......................................307

Maintenance - 3000 hours/every two years . ................................311

Orderingsparepartsandwearingparts ....................................311

Quality and quantity o

f the required operating materials ........................312

Maintenance data table ...............................................313

Safety regulations for maintenance .......................................316

Generalinformation ..................................................3

16

Workingonthehydraulicequipment ......................................316

Working on the electrical equipment ......................................317

Working on the ignit

ionsystem ..........................................317

Safetydevices ......................................................318

Setvalues ....................................................... . . 318

Lifting and jacking

up .................................................318

Workingatthefrontofthetruck ..........................................318

Providing access to maintenance points ...................................320

Opening the bonnet

..................................................320

Closing the bonnet ...................................................321

Removingandattachingtheleftsidecover .................................322

Installing and rem

ovingthebottomplate ...................................322

Opening and closing the right-hand service flap ..............................324

Service work .......................................................326

Cleaning the radi

atorandcheckingforleaks ................................326

Topping up the cooling fluid and checking the coolant concentration ...............327

Drainingwaterfromthefuelfilter .........................................329

57

348011800 EN - 07/2016 IX

Table of contents

g

Cleaning the pre-cleaner ..............................................331

Cleaning the oil tank on the oil bath air filter .................................331

Replacing the air filter cartri

dges .........................................332

Lubricatingthejointsandcontrols ........................................334

Checking the door latch ...............................................334

Maintainingtheseatbelt ...............................................335

Checkingthedriver’sseat .............................................336

Changing the heating system fresh air filter .................................337

Replacing the recirculated

air filter for the heating system ......................338

Greasingtheautomatictowcoupling ......................................338

Servicingwheelsandtyres .............................................341

Replacingthefuses ..................................................343

Checkingthehydraulicoillevel ..........................................343

Checkingthehydraulicsystemforleaks ...................................345

Lubricating the lift mast

androllertrack ....................................346

7 1000-hour maintenance/

annual maintenance

Other tasks ........................................................348

Checking the exhaust gas system .......................................348

Checking the lift cyli

nders and connections for leaks ..........................348

Checking the fork arms ................................................348

Checking the reversible fork arms ........................................349

8 Technical data

Dimensions ........................................................352

VDI datasheet ......................................................353

Ergonomic dimensions ................................................358

Fuse assignment ....................................................36

0

X5

7348011800 EN - 07/2016

1

Foreword

1 Foreword

Your truck

Your truck

General

The truck described in these operatinginstruc-

tions corresponds to the applicable standards

and safety regulations.

If the truck is to be operated on public roads, it

must conform to the existing national regula-

tions for the country in which it is being used.

The driving permit must be obtained from the

appropriate office.

Thetruckshavebeenfittedw

ith state-of-the-

art technology. All that re

mains is to handle

the truck safely and maint

ain its functionality.

These operating instructions provide the

necessary information to do this. Read and

observe the information provided before

commissioning the truck. This will prevent

accidents and ensure that the warranty

remains valid.

Note regarding SCR (Selective

Catalytic Reduction) as exhaust gas

treatment

This truck uses the Selective Catalytic Reduc-

tion (SCR) process of exhaust gas treatment.

To enable the SCR process to be performed,

the truck uses AdBlue (32.5% urea solution, in

accordance with DIN 70070 / ISO 22241).

It is recommended t

hattheAdBluetankbe

refilled with AdBlu

e every time the diesel fuel

is topped up; see th

e section "Topping up

AdBlue".

The applicable European emission require-

ments (97/68/EC) state that new engines must

have an SCR system.

25

7348011800 EN - 07/2016

Foreword 1

Your truck

CE-Symbol

CE labelling

The manufacturer uses CE labelling to indi-

cate that the truck complies with the standards

and regulations valid at the time of marketing.

This is confirmed by the issued EC declaration

of conformity. The CE labelling is attached to

the nameplate.

An independent structural change or addition

to the truck can compromise safety, thus

invalidating the EC declaration of conformity.

The EC declaration of confo

rmity must be

carefully stored and made a

vailable to the

responsible authorities.

57

348011800 EN - 07/2016 3

1 Foreword

Your truck

EC declaration of conformity in accordance with Machinery Directive

Declaration

STILL GmbH

Berzeliusstraße 10

D-22113 Hamburg Germany

We declare that the

Industrial truck

according to these operating instructions

Model

according to these operating instructions

conforms to the latest version of the Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC compliance declaration

STILL Gmb

H

.

45

7348011800 EN - 07/2016

Foreword 1

Your truck

Accessories

• Key for key switch (two pieces)

• Key for cab (variant)

• Hexagon socket wrench for emer

gency

lowering

57

348011800 EN - 07/2016 5

1 Foreword

Information about the documentati

on

Information about the documentation

Documentation scope

• Original operating instructions

• Original operating instructions for attach-

ments (variant)

• Spare parts list

• VDMA rules for the proper use of industrial

trucks

These operating instructions describe all mea-

sures necessary for the safe operation and

proper maintenance of your truck in all pos-

sible variants available at the time of printing.

Special versions to meet customer require-

ments are documented in separate operating

instructions. If you have any questions, please

contact your authorised service centre.

Enter the production num

ber and year of

manufacturer from the na

meplate in the space

provided:

Production number

...............................................

Year of manufacture

...................................................

Please quote the produ

ction number during all

technical enquiries.

Each truck comes with a set of operating

instructions. These instructions must be

stored carefully and must be available to the

driver and operatingcompany at any time. The

storage location is specified inthe "Overviews"

chapter.

If the operating instructions are lost, the

operator must obtain a replacement from the

manufacturer immediately.

The operating instr

uctions are included in the

spare parts list and

can be reordered there as

a spare part.

The personnel responsible for operating and

maintaining the equipment must be familiar

with these operating instructions.

The operating company must ensure that all

users have received, read and understood

these operating instructions.

65

7348011800 EN - 07/2016

Foreword 1

Information about the documentati

on

NOTE

Please observe the definition o

f the following

responsible persons: "operat

ing company"

and "driver".

Thank you for reading and complying with

these operating instructions. If you have any

questions or suggestions for improvements,

or if you have found any errors, please contact

the authorised service centre.

Issue date and topicality of the

operating instructions

The issue date of these operating instructions

can be found on the title page.

STILL is constantly engaged in the further

development of trucks. These operating

instructions are subject to change, and any

claims based on the information and/or

illustrations contained in them cannot be

asserted.

Please contact your au

thorised service centre

for technical support

relating to your truck.

Copyright and tradem

ark rights

These instruction

s must not be reproduced,

translated or made

accessible to third par-

ties—including as

excerpts—except with the

express written ap

proval of the manufacturer.

Explanation of in

formation symbols

used

DANGER

Indicates procedures that must be strictly adhered

to in order to prevent the risk of fatalities.

WARNING

Indicates procedures that must be strictly adhered

to in order to prevent the risk of injuries.

57

348011800 EN - 07/2016 7

1 Foreword

Information about the documentati

on

CAUTION

Indicates procedures that must be strictly adhered

to in order to prevent material damage and/or

destruction.

NOTE

For technical requirements that require

special attention.

ENVIRONMENT NOTE

To prevent environmental damage.

List of abbreviations

NOTE

This list of abbreviations applies to all types

of operating instructions. Not all of the abbre-

viations that are listed here will necessarily

appear in these operating instructions.

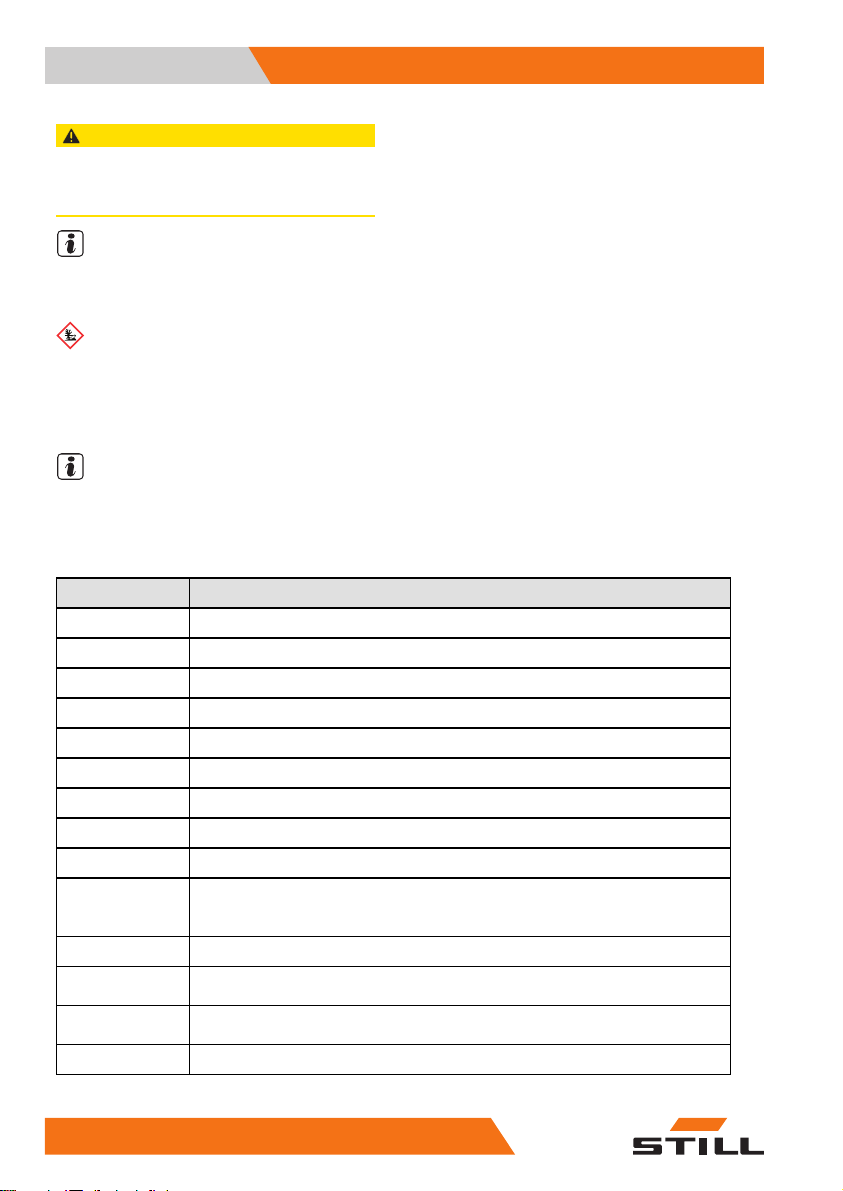

Abbreviation

Meaning

°C

Degrees Celsius

°F

Degrees Fahrenheit

A

Amperes

ABE

Display operating unit

ArbSchG

German labour protection law

BetrSichV

German Ordinance on Industrial Safety and Health

BG

Employers’ liability insurance association

BGG

Employers’ liability insurance association act

BGR

Employers’ liability insurance association rule

German Social

Accident

Insurance

Employers’ liability insurance association regulation

Approx.

Approximately

CE

Symbol that confirms conformity with the valid product-specific European

directives

CEE

International Commission on the Rules for the Approval of Electrical Equip-

ment

cm

Centimetres

85

7348011800 EN - 07/2016

Foreword 1

Information about the documentati

on

Abbreviation

Meaning

cm

3

Cubic centimetres

dB Decibels

DFÜ

Remote data transmission

DIN German standard

EG

European Community

EN

European standard

FEM

Fédération Européene de

la Manutention

F

max

Maximum power

g

Grams

GAA

Industrial inspectorate

If applicable If applicable

GPRS General Packet Radio Service

h/d

Hours per day (time driven each day in hours)

ID no. ID number

ISO International standard

kg Kilograms

kg/m

3

Kilograms per cubic metre

km/h

Kilometres per hour

km/d

Kilometres per day (kilometres driven each day)

kN Kilonewtons

kW Kilowatts

kWh/h

Energy consumption

lLitres

l/h

Litres per hour

l/min

Litres per minute

LAN Local area network

LED

Light emitting diode

L

p

Sound pressure level

L

pAZ

Continuous sound pressure level in driver’s compartment

LSP

Load centre of gravity

o.s.

Or si

milar

m

Metres

57

348011800 EN - 07/2016 9

1 Foreword

Information about the documentati

on

Abbreviation

Meaning

m/s

Metres per second

m/s

2

Metres per second squared

MAK

Maximum workplace concentration

Max. Maximum

Min. Minimum

min Minutes

rpm

Revolution(s) per minute

mm

Millimetres

N Newtons

Nm Newton metres

PIN

Personal identifica

tion number

SE

Superelastic

SIT

Snap-in tyre for simplified assembly

StVZO

German Road Traffic Licensing Regulations

t

Tonnes

TRGS

Technical Regulations for Hazardous Substances

a.s.

And similar

VVolts

VDE

Association for Electrical, Electronic & Information Technologies

VDI

Association of German Engineers

VDMA

German Engineering Federation

W Watts

WLAN Wireless

local area network

e.g.

For example

.

10

57348011800 EN - 07/2016

Foreword 1

Information about the documentati

on

6210_001-031

4

2

3

1

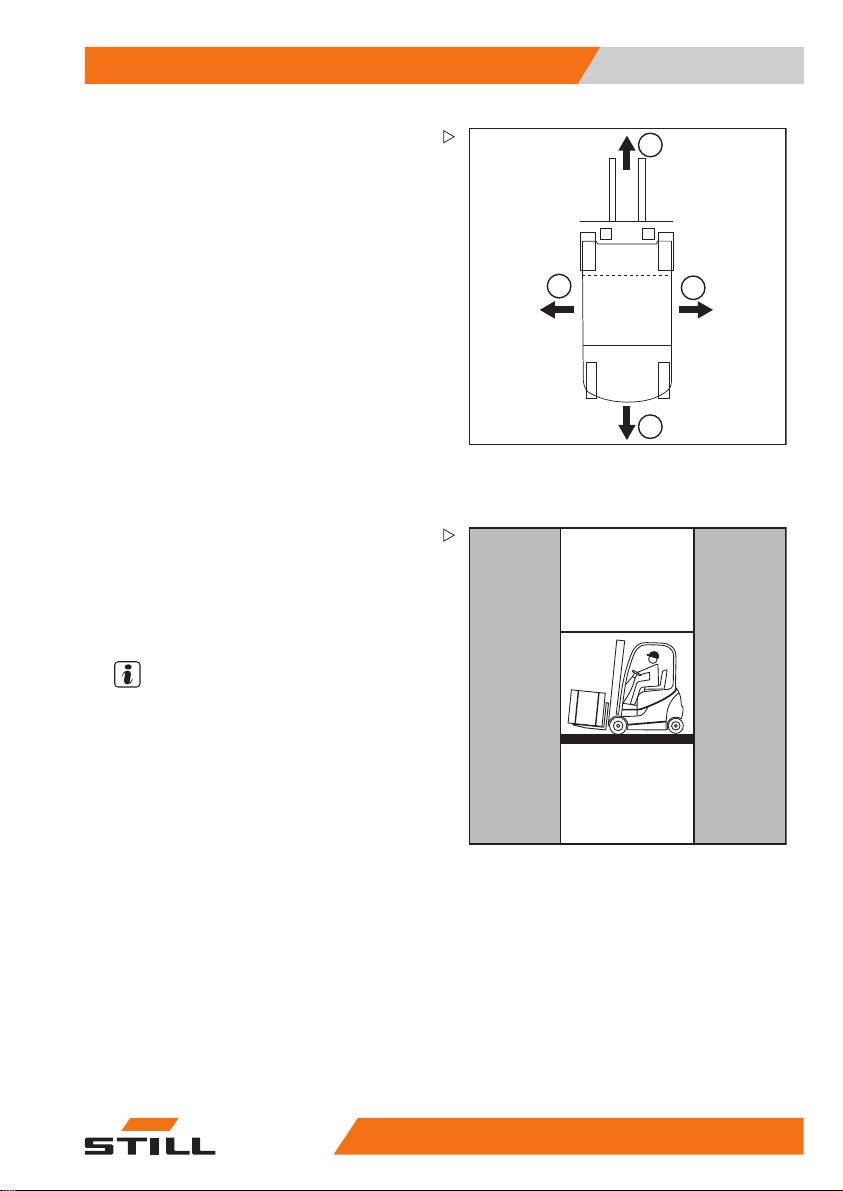

Definition of directions

The directions "forwards" (1), "backwards" (3),

"right" (2) and "left" (4) refer to the installation

position of the parts as seen from the driver’s

compartment; the load is to the front.

Schematic views

6210_003-062

View of functions and operations

This documentati

on explains the (usually

sequential) cha

in of certain functions or oper-

ations. Schemat

ic diagrams of a counterbal-

ance truck are us

ed to illustrate these proce-

dures.

NOTE

These schemati

c diagrams are not represen-

tative of the s

tructural state of the documented

truck. The dia

grams are used solely for the

purpose of cla

rifying procedures.

57

348011800 EN - 07/2016 11

1 Foreword

Information about the documentati

on

View of the display operating unit

NOTE

Views of operating statuses and values in

the display of the display operating unit are

examples and partly dependent on the truck

equipment. As a result, the displays shown

of the actual operating statuses and values

can vary. Information that is not relevant for

descriptions is not shown.

12

57348011800 EN - 07/2016

Foreword 1

Environmental considerations

Environmental considerations

Packaging

During delivery of the truck, certain parts

are packaged to provide protection during

transport. This packaging must be removed

completely prior to initial start-up.

ENVIRONMENT NOTE

The packaging material mu

st be disposed of

properly after delivery o

f the truck.

Disposal of component

s and

batteries

The truck is composed

of different materials. If

components or batter

ies need to be replaced

and disposed of, they

must be:

• disposed of,

• treated or

• recycled in accorda

nce with regional and

national regulatio

ns.

NOTE

The documentation provided by the battery

manufacturer must be observed when dispo-

sing of batteries.

ENVIRONMENT NOTE

We recommend working with a waste mana-

gement company for disposal purposes.

57

348011800 EN - 07/2016 13

1 Foreword

Environmental considerations

14

57348011800 EN - 07/2016

2

Introduction

2 Introduction

Using the truck

Using the truck

Proper usage

The truck described in these operating in-

structions is suitable for lifting, transporting

and stacking loads.

The truck may only be used for its proper

purpose as set out and described in these

operating instructions.

If the truck is to be used for

purposes other

than those specified in the o

perating instruc-

tions, the approval of the m

anufacturer and, if

applicable, the relevant r

egulatory authorities

must be obtained beforeha

nd to prevent haz-

ards.

The maximum load to be lifted is specified on

the capacity rating plate (load diagram) and

must not be exceeded; see also the chapter

entitled "Before picking up a load".

Proper use during towing

This truck is suitable for the occasional towing

of trailers and is equipped with a towing device

for this purpose. This occasional towing may

not exceed 2% of the daily operating time. If

the truck is to be used for towing on a more

regular basis, the manufacturer should be

consulted.

The regulations regarding trailer operation

must be observed; see chapter "Trailer

operation".

Impermissible use

The operating company or driver, and not the

manufacturer, is liable for any hazards caused

by improper use.

NOTE

Please observe the definition of the following

responsible persons: "operating company"

and "driver".

Use for purposes other than those described

in these operating instructions is prohibited.

16

57348011800 EN - 07/2016

Introduction 2

Using the truck

DANGER

There is a risk of fatal injury from

falling off the truck while it is moving!

– It is prohibited to carry passengers

on the truck.

The truck may not be operated in areas where

there is a risk of fire, explosion or corrosion, or

in areas that are particularly dusty.

Stacking or unstacking is not permissible on

inclined surfaces or ramps.

Place of use

The truck can be used outdoors.

The truck has a closed particle filter system

and therefore fulfils the essential prerequisites

for use in ventilated halls. The national

regulations for the country of use must be

observed.

Operation on public roads is only permitted

with the "StVZO" (Road Traffic Licensing

Regulations) equipment variant.

If the truck is to be operated on public roads,

it must conform to the national regulations for

the country in which it is being used.

The ground must have an adequate load

capacity (concrete, asphalt) and a rough

surface. Routes, work areas and aisle widths

must conform to the specifications in these

operating instructions, see the "Routes"

chapter.

Driving on upward and downward gradients

is permitted provided the specified data and

specifications are observed, see the "Routes

"chapter.

The truck is suitable for use in many different

countries, ranging from those situated in the

Tropics to those in Nordic regions (tempera-

ture range: -20°C to +40°C).

This truck is not designed to be operated in

cold stores.

The operating company must ensure suitable

fire protection for the relevant application in

57

348011800 EN - 07/2016 17

2 Introduction

Using the truck

the truck’s surroundings. Depending on the

application, additional fire protection must be

provided on the truck. If in doubt, contact the

relevant authorities.

NOTE

Please note the definition of "operating com-

pany" in the sense of responsible persons!

DANGER

Risk to health from exhaust gases!

Exhaust gases from internal combustion engines

are harmful to your health. In particular, the soot

particles contained in the diesel exhaust gas can

cause cancer.

When the internal combustion engine is running,

there is a risk of poisoning from the CO, CH and

NOx components contained in the exhaust gas.

Modern exhaust gas treatment systems (e.g.

catalytic converters, particle filters or comparable

systems) can clean exhaust gases in a way that

reduces the health hazard and risk of poisoning

when operating the truck.

– Observe the national laws and regulations when

using trucks with an internal combustion engine

in entirely or partially enclosed working areas.

– Always ensure sufficient ventilation.

Using working platforms

WARNING

The use of working platforms is regulated by na-

tional law. The use of working platforms is only

permitted by virtue of the jurisdiction in the country

of use.

– Observe national legislation.

– Before using working platforms, consult the

national regulatory authorities.

18

57348011800 EN - 07/2016

Loading...

Loading...