Still RX60-25, RX60-25-600, RX60-25L, RX60-25L-600, RX60-30 Operator Manual

...

Original instructions

Electric forklift truck

RX60-25

RX60-25/600

RX60-25L

RX60-25L/600

RX60-30

RX60-30L

RX60-30L/600

RX60-35

6345 6346 6347 6348 6353

6354 6355 6356

56338011803 EN - 10/2016

Preface

Address of manufacturer and contact details

STILL GmbH

Berzeliusstraße 10

22113 Hamburg, Germany

Tel. +49 (0) 40 7339-0

Fax: +49 (0) 40 7339-1622

Email: info@still.de

Website: http://www.still.de

g

338011803 EN- 10/2016 I

56

Table of contents

1 Foreword

Your truck .......................................................... 2

General ............................................................ 2

CElabelling ......................................................... 2

EC declaration of conformity in accordance with Machinery Directive ............... 3

Accessories ......................................................... 4

Information about the documentation ...................................... 5

Documentationscope ................................................. 5

Issue date and topicality o

Copyrightandtrademarkrights ........................................... 6

Explanation of information symbols used . . ................................. 6

Listofabbreviations ................................................... 7

Definitionofdirections ................................................. 9

Schematicviews ..................................................... 9

Environmental consider

Packaging ......................................................... 11

Disposal of components and batteries ..................................... 11

ftheoperatinginstructions ........................... 6

ations .......................................... 11

2 Introduction

Using the truck ...................................................... 14

Proper usage ....................................................... 14

Proper use during towing .............................................. 14

Impermissibleuse ................................................... 14

Placeofuse ........................................................ 15

Parkingintemperaturesbelow-10°C ..................................... 16

Using working platf

Residual risk ....................................................... 17

Residual dangers, residual risks ......................................... 17

Special risks assoc

Overviewofhazardsandcountermeasures ................................. 20

Danger to employees . . ............................................... 23

orms ............................................... 16

iatedwithusingthetruckandattachments ................... 18

g

3Safety

Definition of resp

Operatingcompany .................................................. 26

Specialist .......................................................... 26

Drivers ........................................................... 27

Basic principles for safe operation ....................................... 29

Insurance cover on company premises .................................... 29

onsible persons ........................................ 26

338011803 EN - 10/2016 III

56

Table of contents

g

Changes and retrofitting ............................................... 29

Changes to the overhead guard and roof loads . . . ........................... 32

Warning regarding non-origin

Damage, defects and misuse of safety systems . . . ........................... 33

Tyres ............................................................. 33

Medicalequipment ................................................... 34

Exercise caution when handling gas springs and accumulators .................. 35

Lengthoftheforkarms ................................................ 35

Safety tests ........................................................ 37

Regularsafetyinspectionofthetruck ..................................... 37

Insulationtesting .................................................... 37

Safety regulations for han

Permissibleconsumables ............................................. 39

Oils .............................................................. 39

Hydraulicfluid ...................................................... 40

Batteryacid ........................................................ 41

Disposalofconsumables .............................................. 42

Emissions ......................................................... 43

alparts ..................................... 32

dling consumables ............................... 39

4Overviews

General view ....................................................... 48

General view of driver’s compartment ..................................... 50

Operating devices an

Display operating unit ................................................. 52

Operatingdevicesforhydraulicandtractionfunctions ......................... 54

Multi-lever ......................................................... 55

Doublemini-lever .................................................... 56

Three-waymini-lever ................................................. 57

Four-way mini-leve

Joystick4Plus ...................................................... 59

Fingertip .......................................................... 60

Miniconsole ....................................................... 61

Identification points .................................................. 62

Overview .......................................................... 62

Nameplate ......................................................... 64

Productionnumber .................................................. 65

StVZO (Road Traffic Licensing Regulations) information ....................... 65

d displayelements ................................... 52

r .................................................. 58

IV

56338011803 EN - 10/2016

Table of contents

5 Operation

Checks and tasks to be carried out prior to commissioning ...................... 68

Visualinspections ................................................... 68

Fillingthewashersystem .............................................. 70

Checking the condition of the wheels and tyres .............................. 71

Adjusting the MSG 65/MSG 75 d

Adjustingthearmrest ................................................. 76

Adjustingthesteeringcolumn ........................................... 77

Commissioning ..................................................... 78

Climbinginandoutofthetruck .......................................... 78

Connecting the battery male connector .................................... 80

Shelvesandcupholders .............................................. 80

Unlockingtheemergencyoffswitch ...................................... 81

Switchingonthekeyswitch ............................................ 81

Access authorisation wit

Operating the signal horn .............................................. 94

Seatbelt .......................................................... 95

Driver’scab ........................................................ 98

Checkingthebrakesystemforcorrectfunction .............................. 98

Checkingthesteeringsystemforcorrectfunction ............................ 99

Checking the emergency

Zeroadjustmentoftheloadmeasurement(variant) ...........................100

Checking the vertical lift mast position (variant) for correct function . ...............102

Traction ...........................................................103

Safety regulations when driving .........................................103

Roadways .........................................................105

Setting the drive pro

Reducing speed with a raised load (variant) ................................109

Selectingthedrivedirection ............................................109

Actuating the drive d

Actuatingthedrivedirectionswitch,mini-leverversion .........................111

Actuating the vertical rocker switch for the "drive direction", joystick 4Plus version . . . . 111

Actuate the drive di

Actuatingthedrivedirectionswitch,mini-consoleversion ......................112

Startingdrivemode ..................................................112

Starting drive mode

Operatingtheservicebrake ............................................117

Parkingbrake .................................................... . . 118

Actuating the mech

Actuatetheelectricparkingbrake ........................................120

Steering ...........................................................127

gramme ............................................108

irectionswitch,multiple-leverversion ......................110

rectionswitch,fingertipversion ...........................112

, dual-pedal version (variant) .............................115

anicalparkingbrake ...................................118

river’sseat ................................ 72

hPINcode(variant) ................................ 84

offfunction .....................................100

g

338011803 EN - 10/2016 V

56

Table of contents

g

Reducing speed when turning (Curve Speed Control) .........................128

Lifting ............................................................129

Liftingsystemvariants ................................................129

Automaticliftcutout(variant) ...........................................129

Liftmastverticalposition(variant) ........................................130

Typesofliftmast ....................................................134

Malfunctionsduringliftingmode .........................................136

Liftingsystemoperatingdevices .........................................137

Hydraulic blocking functio

Multi-leverliftingsystem ...............................................139

Controlling the lifting system using a double mini-lever .........................140

Controlling the lifting sy

Controlling the lifting system using a quadruple mini-lever ......................142

Controllingtheliftingsystemusingthejoystick4Plus ..........................143

Controlling the lifting s

Changing the fork arms ...............................................146

Forkextension(variant) ...............................................148

Operation with reversib

Handling loads ......................................................152

Safety regulations when handing loads ....................................152

Beforetakingupload .................................................15

Loadmeasurement(variant) ...........................................154

Picking up loads .....................................................157

Danger area .......................................................158

Transportingpallets ..................................................159

Transporting suspended loads ..........................................159

Loadpickup ...................................................... . 160

Transporting loads ...................................................164

Setting down loads ...................................................165

Driving on ascending

Drivingonlifts ......................................................167

Drivingonloadingbridges .............................................169

Workingwithattach

Fittingattachments ..................................................170

Releasingthepressurefromthehydraulicsystem ............................172

General instructio

Controlling attachments using multi-lever operation ...........................176

Controlling attachments using multi-lever operation and the 5th function ...........177

Controlling attac

Controlling attachments using the double mini-lever and the 5th function ...........181

Controllingattachmentsusingatriplemini-lever .............................183

hments using a double mini-lever . ...........................179

n .............................................138

stemusingatriplemini-lever ..........................141

ystemwiththefingertipconsole .........................145

leforkarms(variant) ................................150

and descending slopes ...............................167

ments .............................................170

nsforcontrollingattachments .............................174

3

VI

56338011803 EN - 10/2016

Table of contents

Controlling attachments using the three-way mini-lever and the 5th function .........185

Controlling attachments using a quadruple mini-lever .........................187

Controlling attachments usin

Controllingattachmentsviathejoystick4Plus ...............................191

Controlling attachments using the joystick 4Plus and the 5th function . . . ...........192

Controlling the attachments w

Controlling attachments with fingertip and the 5th function ......................194

Clamp locking mechanism (variant) ......................................196

Taking up a load using attach

Operating auxiliary equipment ..........................................200

Switchingthelightingonandoff .........................................200

Switching the rotating bea

Switchingthehazardwarningsystemonandoff .............................201

Switchingdirectionindicatorsonandoff ...................................202

Switching the double work

Operatingthewindscreenwiper/washer ...................................206

FleetManager (variant) . ...............................................206

Accident recorder (vari

Driverrestraintsystems(variants) .......................................207

Cab operation ......................................................208

Opening the cab door . . ...............................................208

Closingthecabdoor ............................................... . . 209

Openingthesidewindows ........................................... . . 209

Closing the side window

Operatingtheinteriorlighting ...........................................210

Operating the rear window heating .......................................211

Radio(variant) ......................................................211

Heatingsystem(variant) ..............................................212

Push-up roof window (variant) ..........................................215

Clipboard (variant)

Trailer operation ....................................................216

Towedload ....................................................... . 216

Coupling pin in the c

Automatic tow coupling ...............................................219

Towingtrailers ......................................................227

Useincoldstores ....................................................22

Operating the display and operating unit ...................................232

Indicators .........................................................232

Adjusting the dis

Symbolsinthedisplay ................................................235

Settingthedateortime ................................................240

ounterweight ........................................217

plays ................................................235

gthefour-waymini-leverandthe5thfunction ..........189

ith fingertip . . ................................193

ments ......................................199

cononandoff ...................................201

ingspotlightsonandoff. ...........................204

ant) .............................................207

s ..............................................209

...................................................215

g

9

338011803 EN - 10/2016 VII

56

Table of contents

g

Resetting the daily kilometres and daily operating hours .......................240

Setting the language .................................................241

Soft key button for operating v

Blue-Q efficiency mode ...............................................243

Functionaldescription ................................................243

Effects on additional consu

SwitchingefficiencymodeBlue-Qonandoff ................................244

ConfiguringBlue-Qefficiencymode ......................................245

Display messages ...................................................247

Displaycontent .....................................................247

Errorcodetable .....................................................247

General messages ...................................................250

Drive-specificmessages ..............................................259

Operating in special operating situations ...................................262

Transport ..........................................................262

Towing .......................................................... . 265

Craneloading ......................................................267

Procedure in emergencie

Emergency shutdown ................................................271

Procedureiftrucktipsover .............................................272

Emergency hammer ..................................................273

Emergency lowering .................................................273

Emergency operation of the electric parking brake . ...........................275

Handling the battery ..................................................2

Safety regulations when handling the battery ...............................277

Opening/closing the battery cover ........................................280

Disconnecting the ba

Maintainingthebattery ................................................284

Checkingthebatterycondition,acidlevelandaciddensity ......................286

Checking the battery

Chargingthebattery ..................................................287

Equalisingchargetopreventadeepdischargeofthebattery ....................290

Changing to a differ

General information on replacing the battery ................................292

Replacingthebatteryusingforklifttruckorpallettruck .........................293

Battery transport

Replacing the battery using a change frame (variant) ..........................296

Replacingthebatterywiththehydraulicbatterycarrier .........................301

Charging the batt

ttery male connector ..................................283

chargestatus .......................................287

entbatterytype .......................................292

withcrane ............................................296

erywiththebatterychargingflap ............................308

arious equipment variants .......................241

mers .........................................243

s .............................................270

77

II 56338011803 EN - 10/2016

VI

Table of contents

Decommissioning ...................................................313

Parkingthetrucksecurelyandswitchingitoff ...............................313

Wheelchock(variant) ................................................315

Shuttingdownandstoringthetruck ......................................315

Recommissioningafterstorage .........................................317

Cleaning ..........................................................319

Cleaningthetruck ...................................................319

Cleaningtheelectricalsystem ..........................................321

Cleaningloadchains .................................................322

Cleaningthewindows .............................................. . . 323

Afterwashing .......................................................323

6 Maintenance

General maintenance inf

Personnel qualifications ...............................................326

Informationforcarryingoutmaintenance ..................................326

Maintenance — 1000 hour

Maintenance - 3000 hours/every two years . ................................333

Orderingsparepartsandwearingparts ....................................333

Quality and quantity o

Lubricationplan .....................................................334

Maintenance data table ...............................................336

Safety regulations fo

Generalinformation ..................................................339

Workingonthehydraulicequipment ......................................339

Working on the elect

Safetydevices ......................................................340

Setvalues ....................................................... . . 340

Lifting and jacking

Workingatthefrontofthetruck ..........................................341

Providing access to maintenance points ...................................343

Removing/install

Servicing ..........................................................344

Lubricatingthejointsandcontrols ........................................344

Checking the batte

Maintainingtheseatbelt ...............................................346

Checkingthedriver’sseat .............................................347

Maintaining whee

Servicingthesteeringaxle .............................................350

Checkingthebattery .................................................352

ormation ........................................326

s/annually .....................................329

f the required operating materials ........................333

r maintenance .......................................339

rical equipment ......................................339

up .................................................340

ingthevalvecover ......................................343

ryinterlockandbatterycover .............................344

lsandtyres ...........................................348

g

338011803 EN - 10/2016 IX

56

Table of contents

g

Checkingthefuses ...................................................352

Replacingfuses .....................................................354

Checking the hydraulic oil lev

Checkingthehydraulicsystemforleaks ...................................357

Lubricatingtheliftmastandrollertrack ....................................358

Greasing the automatic tow cou

Maintenancefortrucksusedincoldstores .................................361

Maintaining the heater ................................................361

1000-hour maintenance/ann

Othertasks ........................................................363

Checking the cable connections .........................................363

Checking the function of th

Checkingthehydraulicoillevelofthehydraulicbatterycarrier ...................364

Lubricatingtheslideelements ..........................................366

Oilingthecatchrails ..................................................366

Checking the lift cylinders and connections for leaks ..........................368

Checkingforkarms ..................................................369

Checking the reversible

Checking the double pedal . . . ..........................................370

Checking the battery changeover frame ...................................370

el ..........................................356

pling ......................................358

ual maintenance ...............................363

ebatterycoversensor ............................363

forkarms ........................................369

7 Technical data

Dimensions ........................................................372

VDI datasheet for RX60-25 and RX60-25/600 ...............................374

VDI datasheet for RX60-25L and RX60-25L/600 .............................378

VDI datasheet for RX

VDI datasheet for RX60-30L and RX60-30L/600 .............................386

Ergonomic dimensions ................................................390

Battery specificati

Fuse assignment ....................................................393

Fuse assignment standard equipment ....................................393

Fuse assignment e

60-30 and RX60-35 ..................................382

ons .................................................391

quipmentvariants .....................................394

X5

6338011803 EN - 10/2016

1

Foreword

1 Foreword

Your truck

Your truck

General

The truck described in these operatinginstructions corresponds to the applicable standards

and safety regulations.

If the truck is to be operated on public roads, it

must conform to the existing national regulations for the country in which it is being used.

The driving permit must be obtained from the

appropriate office.

Thetruckshavebeenfittedw

art technology. All that re

the truck safely and maint

These operating instructions provide the

necessary information to do this. Read and

observe the information provided before

commissioning the truck. This will prevent

accidents and ensure that the warranty

remains valid.

CE labelling

The manufacturer uses CE labelling to indicate that the truck complies with the standards

and regulations valid at the time of marketing.

This is confirmed by the issued EC declaration

of conformity. The CE labelling is attached to

the nameplate.

An independent structural change or addition

to the truck can compromise safety, thus

invalidating the EC declaration of conformity.

The EC declaration o

carefully stored an

responsible author

dmadeavailabletothe

ities.

ith state-of-the-

mains is to handle

ain its functionality.

f conformity must be

25

6338011803 EN - 10/2016

CE-Symbol

Foreword 1

Your truck

EC declaration of conformity in accordance with Machinery Directive

Declaration

STILL GmbH

Berzeliusstraße 10

D-22113 Hamburg Germany

We declare that the

Industrial truck

Model

according to these operating instructions

according to these operating instructions

conforms to the latest version of the Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC compliance declaration

STILL Gmb

.

H

338011803 EN - 10/2016 3

56

1 Foreword

Your truck

Accessories

• Key for key switch (2 pieces)

• Key for cab (variant)

• Hexagon socket wrench for emer

lowering

• Battery replacement frame

gency

45

6338011803 EN - 10/2016

Foreword 1

Information about the documentati

on

Information about the documentation

Documentation scope

• Original operating instructions

• Original operating instructions for attachments (variant)

• Spare parts list

• VDMA rules for the proper use of industrial

trucks

These operating instructions describe all measures necessary for the safe operation and

proper maintenance of your truck in all possible variants available at the time of printing.

Special versions to meet customer requirements are documented in separate operating

instructions. If you have any questions, please

contact your authorised service centre.

Enter the production num

manufacturer from the na

provided:

Production number

...............................................

Year of manufacture

...................................................

Please quote the produ

technical enquiries.

Each truck comes with a set of operating

instructions. These instructions must be

stored carefully and must be available to the

driver and operatingcompany at any time. The

storage location isspecified in the "Overviews"

chapter.

If the operating instructions are lost, the

operator must obtain a replacement from the

manufacturer immediately.

The operating instr

spare parts list and

a spare part.

The personnel responsible for operating and

maintaining the equipment must be familiar

with these operating instructions.

The operating company must ensure that all

users have received, read and understood

these operating instructions.

ber and year of

meplate in the space

ction number during all

uctions are included in the

can be reordered there as

338011803 EN - 10/2016 5

56

1 Foreword

Information about the documentati

NOTE

Please observe the definition o

responsible persons: "operat

ing company"

and "driver".

Thank you for reading and complying with

these operating instructions. If you have any

questions or suggestions for improvements,

or if you have found any errors, please contact

the authorised service centre.

Issue date and topicality of the operating instructions

The issue date of these operating instructions

can be found on the title page.

STILL is constantly engaged in the further

development of trucks. These operating

instructions are subject to change, and any

claims based on the information and/or

illustrations contained in them cannot be

asserted.

Please contact your au

for technical support

thorised service centre

relating to your truck.

on

f the following

Copyright and tradem

These instruction

translated or made

ties—including as

express written ap

s must not be reproduced,

excerpts—except with the

proval of the manufacturer.

Explanation of in

ark rights

accessible to third par-

formation symbols

used

DANGER

Indicates procedures that must be strictly adhered

to in order to prevent the risk of fatalities.

WARNING

Indicates procedures that must be strictly adhered

to in order to prevent the risk of injuries.

65

6338011803 EN - 10/2016

Foreword 1

on

CAUTION

Indicates procedures that must be strictly adhered

to in order to prevent material damage and/or

destruction.

NOTE

Information about the documentati

For technical requirements that require

special attention.

ENVIRONMENT NOTE

To prevent environmental damage.

List of abbreviations

NOTE

This list of abbreviations applies to all types

of operating instructions. Not all of the abbreviations that are listed here will necessarily

appear in these operating instructions.

Abbreviation

ABE

Arb-

SchG

Betr-

SichV

BG

BGG

BGR

DGUV

CE

CEE

DC Direct Current

DFÜ

DIN

EG

Meaning

Display operating unit

Arbeitsschutzgesetz

Betriebssicherheitsverordnung

Berufsgenossenschaft

Berufsgenossenschaftlicher Grundsatz

Berufsgenossenschaftliche Regel

Berufsgenossenschaftliche Vorschrift German accident prevention regulations

Communauté Européenne

Commission on theRules forthe Approval

of the Electrical Equipment

Datenfernübertragung

Deutsches Institut für Normung German standardisation organisation

European Community

Explanation

German implementation of EU occupational health and safety directives

German implementation of the EU working equipment directive

German insurance company for the

company and employees

German principles and test specifications

for occupational health and safety

German rules and recommendations for

occupational health and safety

Confirms conformity with product-specific

European directives (CE mark)

International commission on the rules for

the approval of electrical equipment

Direct current

Remote data transmission

338011803 EN - 10/2016 7

56

1 Foreword

Information about the documentati

on

Abbreviation

EN

FEM

F

max

Meaning

European standard

Fédération Européene de la Manutention

maximum Force

Explanation

European Federation of Materials Handling and Storage Equipment

Maximum power

German authority for monitoring/issuing

GAA Gewerbeaufsichtsamt

regulations for worker protection, environmental protection, and consumer protection

GPRS General Packet Radio Service

Transfer of data packets in wireless

networks

ID no. ID number

ISO

International Organization for Standardization

International sta

ndardisation organisation

LAN Local Area Network Local area network

K

pA

LED

L

p

L

pAZ

LSP

MAK

Max

Min

PIN

PP

SE

SIT

StVZO

TRGS

VDE

Uncertainty of measurement of sound

pressure levels

Light Emittin

g Diode

Light emittin

g diode

Sound pressure level at the workplace

Average co

in the driv

Load centre of gravity

Maximum workplace concentration

.

Max

.

Min

ntinuous sound pressure level

er’s compartment

imum

imum

e of the centre of gravity of the load

Distanc

e front face of the fork backs

from th

Maximum permissible air concentrations

of a substance at the workplace

Highest value of an amount

Lowest value of an amount

Personal Identification Number Personal identification number

Personal protective equipment

E

Super-Elastic Superelastic tyres (solid rubber tyres)

Snap-In Tyre

Straßenverkehrs-Zulassungs-Ordnung

Technische Regel für Gefahrstoffe

Verband der Elektrotechnik Elektronik

Informationstechnik

Tyres for simplified assembly, without

loose rim parts

German regulations for approval of

vehicles on public roads

Ordinance on hazardous materials applicable in the Federal Republic of Germany

German technical/scientific association

85

6338011803 EN - 10/2016

Foreword 1

Information about the documentati

on

Abbreviation

VDI

VDMA

WLAN Wireless LAN Wireless local area network

.

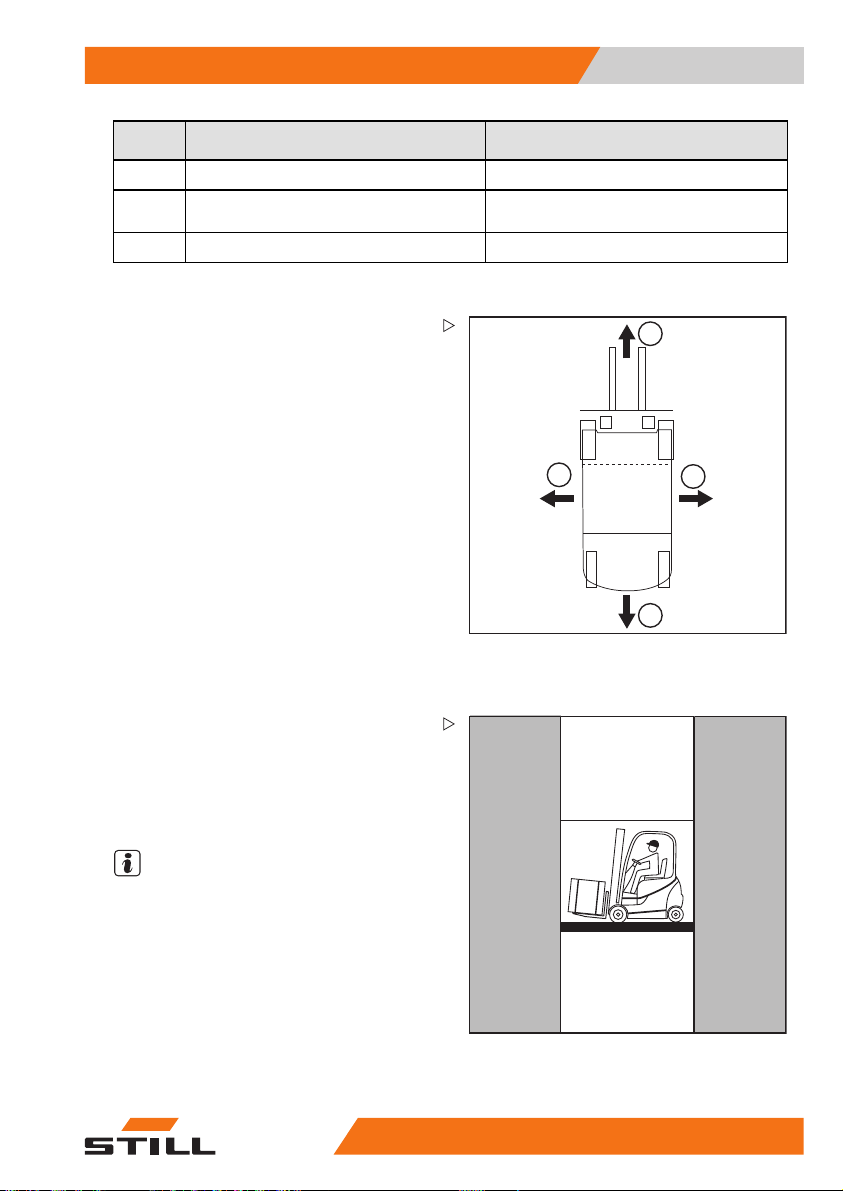

Definition of directio

The directions "forwa

"right" (2) and "left"

position of the parts a

compartment; the loa

Meaning

Verein Deutscher Ingenieure

Verband Deutscher Maschinen- und

Anlagenbau e.V.

ns

rds" (1), "backwards" (3),

(4) refer to the installation

s seen from the driver’s

d is to the front.

Explanation

German technical/scientifica

German Mechanical Enginee

Association

1

4

3

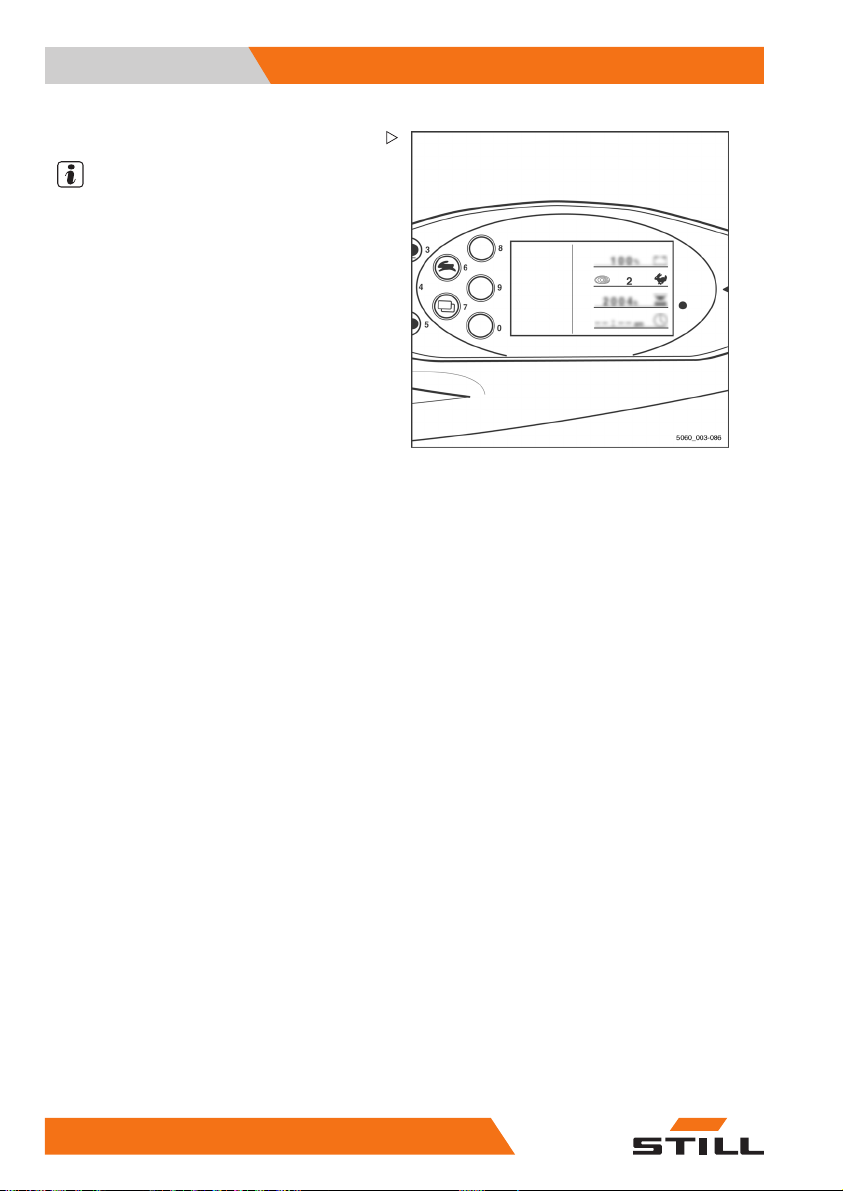

Schematic views

View of functions and operations

This documentation explains the (usually

sequential) chain of certain functions or operations. Schematic diagrams of a counterbalance truck are used to illustrate these procedures.

ssociation

ring Industry

2

6210_001-031

NOTE

These schematic diagrams are not representative of the structural state of the documented

truck. The diagrams are used solely for the

purpose of clarifying procedures.

338011803 EN - 10/2016 9

56

6210_003-062

1 Foreword

Information about the documentati

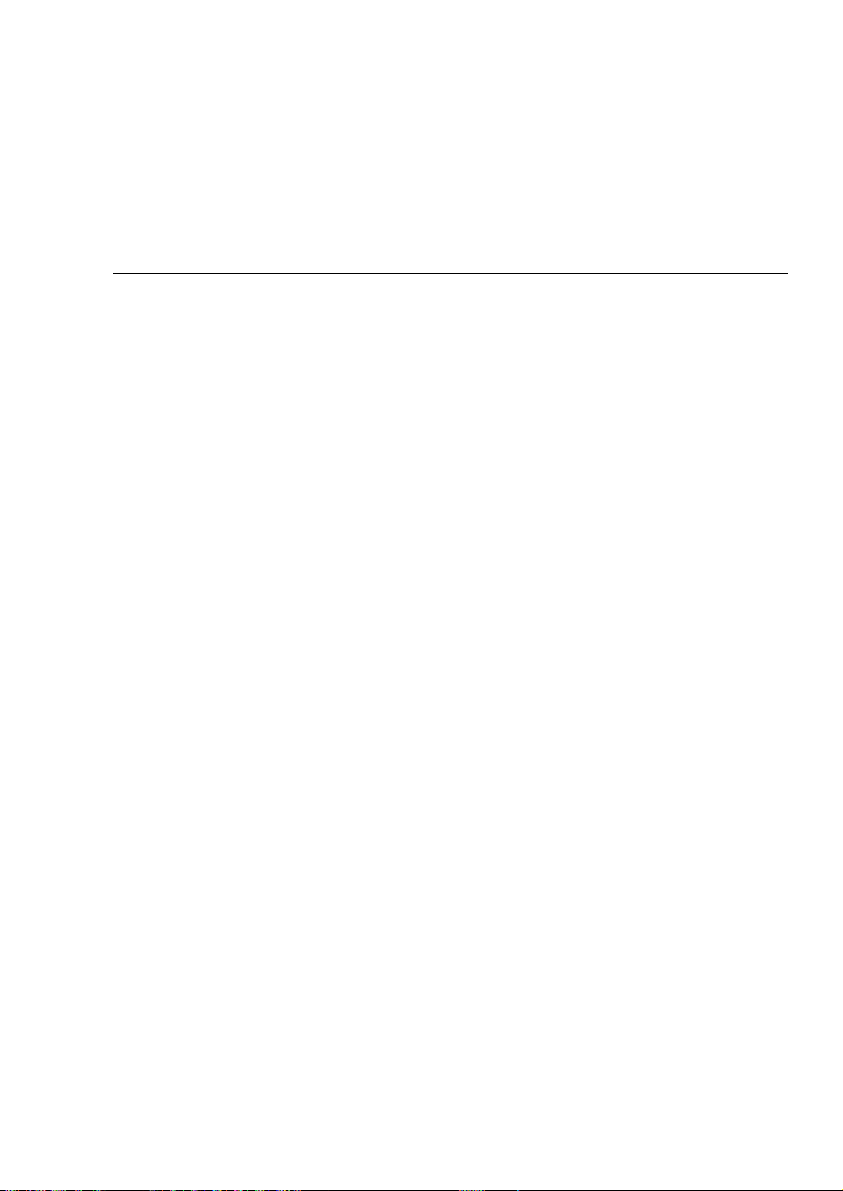

View of the display operating unit

NOTE

Views of operating statuses and values in

the display of the display operating unit are

examples and partly dependent on the truck

equipment. As a result, the displays shown

of the actual operating statuses and values

can vary. Information that is not relevant for

descriptions is not shown.

on

10

56338011803 EN - 10/2016

Foreword 1

Environmental considerations

Environmental considerations

Packaging

During delivery of the truck, certain parts

are packaged to provide protection during

transport. This packaging must be removed

completely prior to initial start-up.

ENVIRONMENT NOTE

The packaging material mu

properly after delivery o

st be disposed of

f the truck.

Disposal of component

s and

batteries

The truck is composed

components or batter

and disposed of, they

• disposed of,

• treated or

• recycled in accorda

national regulatio

NOTE

The documentation provided by the battery

manufacturer must be observed when disposing of batteries.

ENVIRONMENT NOTE

We recommend working with a waste management company for disposal purposes.

of different materials. If

ies need to be replaced

must be:

nce with regional and

ns.

338011803 EN - 10/2016 11

56

1 Foreword

Environmental considerations

12

56338011803 EN - 10/2016

2

Introduction

2 Introduction

Using the truck

Using the truck

Proper usage

The truck described in these operating instructions is suitable for lifting, transporting

and stacking loads.

The truck may only be used for its proper

purpose as set out and described in these

operating instructions.

If the truck is to be used for

than those specified in the o

tions, the approval of the m

applicable, the relevant r

must be obtained beforeha

ards.

The maximum load to be lifted is specified on

the capacity rating plate (load diagram) and

must not be exceeded; see also the chapter

entitled "Before picking up a load".

Proper use during towing

This truck is suitable for the occasional towing

of trailers and is equipped with a towing device

for this purpose. This occasional towing may

not exceed 2% of the daily operating time. If

the truck is to be used for towing on a more

regular basis, the manufacturer should be

consulted.

The regulations regarding trailer operation

must be observed; see chapter "Trailer

operation".

purposes other

perating instruc-

anufacturer and, if

egulatory authorities

nd to prevent haz-

Impermissible use

The operating company or driver, and not the

manufacturer, is liable for any hazards caused

by improper use.

NOTE

Please observe the definition of the following

responsible persons: "operating company"

and "driver".

Use for purposes other than those described

in these operating instructions is prohibited.

14

56338011803 EN - 10/2016

Introduction 2

Using the truck

DANGER

There is a risk of fatal injury from

falling off the truck while it is moving!

– It is prohibited to carry passengers

on the truck.

The truck may not be operated in areas where

there is a risk of fire, explosion or corrosion, or

in areas that are particularly dusty.

Stacking or unstacking is not permissible on

inclined surfaces or ramps.

Place of use

The truck can be used both outside and in

buildings. Operation on public roads is only

permitted if the "StVZO" (German Road Traffic

Licensing Regulations) equipment variant is

installed.

If the truck is to be operated on public roads, it

must conform to the existing national regulations for the country in which it is being used.

The ground must have an adequate load

capacity (concrete, asphalt) and a rough

surface. Routes, work areas and aisle widths

must conform to the specifications in these

operating instructions, see the "Routes"

chapter.

Driving on upward and downward gradients

is permitted provided the specified data and

specifications are observed, see the "Routes

"chapter.

The forklift truck is suitable for indoor and

outdoor use in countries ranging from the

Tropics to Nordic regions (temperature range:

-20°C to +40°C).

If the truck is to be used in a cold store, it must

be configured accordingly and, if necessary,

approved for such an environment; see the

chapter entitled "Cold store application".

338011803 EN - 10/2016 15

56

2 Introduction

Using the truck

CAUTION

Batteries can freeze!

If the truck is parked in an ambient temperature of

below –10 °C for an extended period, the batteries

cool down. The electrolyte may freezeand damage

the batteries. The truck is then not ready for operation.

– In an ambient temperature of below –10 °C, only

park the truck for short periods.

The operating company must ensure suitable

fire protection for the relevant application in

the truck’s surroundings. Depending on the

application, additional fire protection must be

provided on the truck. If in doubt, contact the

relevant authorities.

NOTE

Please observe the definition of the following

responsible person: "operating company".

Parking in temperatures below -10°C

CAUTION

Batteries can freeze!

Ifthetruckisparkedinanambienttemperature

below -10°C for an extended period, the batteries

will cool down. The electrolyte may freeze and

damage the batteries. The truck is then not ready

for operation.

– When the ambient temperature is below -10°C,

only park the truck for short periods of time.

Using working platforms

WARNING

The use of working platforms is regulated by national law. The use of working platforms is only

permitted by virtue of the jurisdiction in the country

of use.

– Observe national legislation.

– Before using working platforms, consult the

national regulatory authorities.

16

56338011803 EN - 10/2016

Introduction 2

Residual risk

Residual risk

Residual dangers, residual risks

Despite careful working and compliance with

standards and regulations, the occurrence

of other risks when using the truck cannot be

entirely excluded.

The truck and all other system components

comply with current safety requirements.

Nevertheless, even when the truck is used

for its proper purpose and all instructions

are followed, some residual risk cannot be

excluded.

Even beyond the narrow dan

truck itself, a residual r

Persons in this area aroun

exercise a heightened deg

so that they can react imme

of any malfunction, incid

WARNING

All persons that are in the vicinity of the truck

must be instructed regarding these risks that arise

through use of the truck.

In addition, we draw attention to the safety regulations in these operating instructions.

ger areas of the

isk cannot be excluded.

d the truck must

ree of awareness,

diately in the event

ent or breakdown etc.

Risks can include:

• Escape of consumables due to leakages,

rupture of lines and containers etc.

• Risk of accident when driving over difficult

ground such as gradients, smooth or

irregular surfaces, or with poor visibility

etc.

• Falling, tripping etc. when moving on

the truck, especially in wet weather, with

leaking consumables or on icy surfaces

• Fire and explosion risks due to batteries and

electrical voltages

• Human error resulting from failure to

observe the safety regulations,

• Unrepaired damage or defective and worn

components,

• Insufficient maintenance and testing

• Use of incorrect consumables

• Exceeding test intervals

338011803 EN - 10/2016 17

56

2 Introduction

Residual risk

The manufacturer is not held responsible for

accidents involving the truck caused by the

failure of the operating company to comply

with these regulations either intentionally or

carelessly.

Stability

The stability of the truck has been tested to the

latest technological standards and is guaranteed provided that the truck is used properly

and according to its intended purpose. These

standards only take into account the dynamic

and static tipping forces that can arise during

specified use in accordance with the operating rules and intended purpose. However, the

danger of exceeding the moment of tilt due to

improper use or incorrect operation and losing

stability can never be excluded.

The loss of stability can b

imised by the following ac

– Always secure the load against slipping,

e.g. by lashing.

– Always transport unstable loads in suitable

containers.

– Always drive slowly whe

– Drive with the load lowered.

– Even with sideshifts, align the load as

centrally as possible with the truck and

transport in this position.

– Avoid turning and dia

slopes or gradients.

– Never have the load facing downhill when

travelling on slopes or gradients.

– Pick up only loads of the approved width.

– Always take great ca

suspended loads.

– Do not drive over ramp edges or steps.

e avoided or min-

tions:

n cornering.

gonally driving across

re when transporting

Special risks associated with using the truck and attachments

Approval from the manufacturer and attachment manufacturer must be obtained each

18

56338011803 EN - 10/2016

Loading...

Loading...