Original instructions

Diesel truck

RX70-40

RX70-45

RX70-50

7331 7332 7333 7334

57348011825 EN - 12/2015

Preface

Address of manufacturer and contact details

STILL GmbH

Berzeliusstraße 10

22113 Hamburg, Germany

Tel. +49 (0) 40 7339-0

Fax: +49 (0) 40 7339-1622

Email: info@still.de

Website: http://www.still.de

g

348011825 EN- 12/2015 I

57

Table of contents

1 Foreword

List of abbreviations ................................................... 2

Your truck .......................................................... 4

General ............................................................ 4

CElabelling ......................................................... 5

EC declaration of conformit

Information about the documentation ...................................... 7

Documentationscope ................................................. 7

Issue date and topicality o

Copyrightandtrademarkrights ........................................... 8

Explanation of information symbols used . . ................................. 8

Explanation of the cross-

Definitionofdirections ................................................. 9

Schematicviews .................................................... 10

Environmental consider

Packaging ......................................................... 11

Disposal of components and batteries ..................................... 11

y in accordance with Machinery Directive ............... 6

ftheoperatinginstructions ........................... 8

references ....................................... 9

ations .......................................... 11

2 Introduction

Using the truck ...................................................... 14

Proper usage ....................................................... 14

Proper use during towing .............................................. 14

Impermissibleuse ................................................... 14

Placeofuse ........................................................ 15

Usingworkingplatforms ............................................... 16

Residual risk ....................................................... 17

Residual dangers, residual risks ......................................... 17

Specialrisksassociatedwithusingthetruckandattachments ................... 18

Overview of hazards

Danger to employees . . ............................................... 23

andcountermeasures ................................. 20

g

3Safety

Definition of terms used for responsible persons ............................. 26

Operating compan

Specialist .......................................................... 26

Drivers ........................................................... 27

Basic principle

Insurance cover on company premises .................................... 29

Changes and retrofitting ............................................... 29

y .................................................. 26

s for safe operation ....................................... 29

348011825 EN - 12/2015 III

57

Table of contents

g

Changes to the overhead guard and roof loads . . . ........................... 31

Warning regarding non-original parts ..................................... 31

Damage, defects and misuse of s

Lengthoftheforkarms ................................................ 32

Tyres ............................................................. 33

Medicalequipment ................................................... 34

Exercise caution when handling gas springs and accumulators .................. 35

Safety tests ........................................................ 36

Regular safety inspection o

Checkingthedieselengineemissions ..................................... 36

Truckswithparticlefilters .............................................. 37

Insulationtesting .................................................... 38

Safety regulations for handling consumables ............................... 39

Permissibleconsumables ............................................. 39

Oils .............................................................. 39

Hydraulicfluid ...................................................... 40

Batteryacid ........................................................ 41

Dieselfuel ......................................................... 42

Coolantandcoolingfluid .............................................. 44

Disposalofconsumables .............................................. 44

Emissions ......................................................... 46

afetysystems .............................. 32

fthetruck ..................................... 36

4Overviews

Truck overview ..................................................... 50

Overview of driver’s compartment ........................................ 51

Operating devices a

Display and operating unit . . . .......................................... 52

Operatingdevicesforhydraulicanddrivingfunctions .......................... 53

Doublemini-lever .................................................... 5

Three-waymini-lever ................................................. 55

Four-waymini-lever .................................................. 56

Joystick4Plus ...................................................... 57

Fingertip .......................................................... 58

Identification points .................................................. 59

Overview .......................................................... 59

Nameplate ......................................................... 60

Productionnumber .................................................. 61

StVZO (Road Traf

IV

nd display elements ................................... 52

fic Licensing Regulations) information ....................... 61

57348011825 EN - 12/2015

4

Table of contents

Equipment ......................................................... 62

Accessories ........................................................ 62

5 Operation

Checks and tasks to be carrie

Visualinspections ................................................... 64

Checkingthesidecoverislocked ........................................ 66

Fillingthewashersystem .............................................. 6

Checking the condition of the wheels and tyres .............................. 67

Topping up the coolant and checking the concentration of the coolant additive ....... 68

Checking the engine oil le

AdjustingtheMSG65/MSG75driver’sseat ................................ 70

Adjustingthearmrest ................................................. 74

Adjusting the steering c

Cleaningthedustvalve ............................................... 75

Commissioning ..................................................... 76

Climbing into and out of

Climbingintoandoutofatruckwitharaiseddriver’scab ....................... 77

Shelvesandcupholders .............................................. 79

Unlocking the emergen

Switchingonthekeyswitch ............................................ 80

AccessauthorisationwithPINcode(variant) ................................ 83

Operating the signal h

Seatbelt .......................................................... 93

Usingthedriver’scab ................................................. 96

Starting the engine

Checkingthebrakesystemforcorrectfunction .............................. 99

Checkingthesteeringsystemforcorrectfunction ............................100

Checking the emerge

Zeroadjustmentoftheloadmeasurement(variant) ...........................101

Checking the vertical lift mast position (variant) for correct function . ...............103

Driving ............................................................104

Safety regulations when driving .........................................104

Roadways .........................................................106

Setting the drive p

Actuatingthedrivedirectionswitch,mini-leverversion .........................109

Actuating the vertical rocker switch for the "drive direction", joystick 4Plus version . . . . 109

Actuating the driv

Startingtodrive .....................................................110

Starting drive mode, dual-pedal version (variant) .............................112

................................................... 97

rogrammes ...........................................108

e direction switch, fingertip version ..........................110

d out prior to commissioning ...................... 64

vel ........................................... 69

olumn ........................................... 75

thetruck ........................................ 76

cyoffswitch ...................................... 80

orn .............................................. 92

ncyofffunction .....................................100

g

6

348011825 EN - 12/2015 V

57

Table of contents

g

Operatingtheservicebrake ............................................115

Actuating the mechanical parking brake ...................................116

Steering ...........................................................118

Reducing speed with a raised load (variant) ................................119

Automatic shut-off of the internal combustion engine (variant) ...................119

Lifting ............................................................120

Liftingsystemvariants ................................................120

Automaticliftcutout(variant) ...........................................120

Lift mast vertical position

Typesofliftmast ....................................................125

Malfunctionsduringliftingmode .........................................126

Hydraulic blocking functi

Liftingsystemoperatingdevices .........................................128

Controlling the lifting system using a double mini-lever .........................130

Controlling the lifting s

Controlling the lifting system using a quadruple mini-lever ......................132

Controllingtheliftingsystemusingthejoystick4Plus ..........................133

Controlling the lifting

Changing the fork arms ...............................................136

Forkextension(variant) ...............................................138

Operation with reversi

Handling loads ......................................................142

Safety regulations when handing loads ....................................142

Beforetakingupload .................................................14

Loadmeasurement(variant) ...........................................144

Picking up loads .....................................................147

Danger area .......................................................148

Transportingpallets ..................................................149

Transporting suspended loads ..........................................149

Loadpickup ...................................................... . 150

Transporting loads ...................................................154

Setting down loads ...................................................155

Shake function (var

Driving on ascending and descending slopes ...............................160

Drivingonlifts ......................................................161

Drivingonloadingb

Particle filter system ..................................................163

Particlefilter-Function ................................................163

Particlefilter-Pe

Particlefilter-Displays ................................................168

(variant) ........................................121

on .............................................128

ystemusingatriplemini-lever ..........................131

system using the fingertip . . . ...........................135

bleforkarms(variant) ................................140

iant) ...............................................156

ridges .............................................162

rforming parked regeneration . . . ...........................165

3

VI

57348011825 EN - 12/2015

Table of contents

Working with attachments .............................................170

Fittingattachments ..................................................170

Releasing the pressure from th

Generalinstructionsforcontrollingattachments .............................174

Controlling attachments using a double mini-lever ............................176

Controlling attachments usin

Controllingattachmentsusingatriplemini-lever .............................180

Controlling attachments using the triple mini-lever and the 5th function .............182

Controlling attachments us

Controlling attachments using the quadruple mini-lever and the 5th function .........185

Controllingattachmentsviathejoystick4Plus ...............................186

Controlling attachments u

Controlling the attachments with the fingertip ...............................188

Controlling attachments with the fingertip and 5th function ......................189

Clamp locking mechanism (

Takingupaloadusingattachments ......................................195

Operating auxiliary equipment ..........................................196

Switching the lighting o

Switching the rotating beacon on and off . . . ................................197

Switchingthehazardwarningsystemonandoff .............................198

Switching direction in

Switching the double working spotlights on and off. ...........................201

Operatingthewindscreenwiper/washer ...................................203

FleetManager (variant

Accidentrecorder(variant) .............................................204

Driverrestraintsystems(variants) .......................................204

Cab operation ......................................................204

Opening the cab door . . ...............................................204

Closingthecabdoor ............................................... . . 205

Opening the side wind

Closing the side windows ..............................................206

Operating the rear window heating .......................................207

Radio(variant) ......................................................207

Heatingsystem(variant) ..............................................208

Air conditioning (variant) ...............................................209

Trailer operation ....................................................2

Towedload ....................................................... . 210

Coupling pin in the counterweight ........................................211

Automatic tow coup

Towingtrailers ......................................................221

dicatorsonandoff ...................................198

ling ...............................................213

ehydraulicsystem ............................172

g the double mini-lever and the 5th function ...........178

ing a quadruple mini-lever .........................183

singthejoystick4Plusandthe5thfunction ..............187

variant) ......................................191

nandoff .........................................196

) ................................................203

ows .............................................205

g

10

348011825 EN - 12/2015 VII

57

Table of contents

g

Operating the display and operating unit ...................................223

Displays ..........................................................223

Adjustingthedisplays ................................................224

Symbolsinthedisplay ................................................224

Settingthedateortime ................................................229

Resetting the daily kilometre

Setting the language .................................................230

Soft key button for operating various equipment variants .......................230

Configuring Blue-Q efficienc

Additional settings ...................................................232

Blue-Q efficiency mode ...............................................233

Functionaldescription ................................................23

Effects on additional consumers .........................................233

SwitchingefficiencymodeBlue-Qonandoff ................................234

Display messages ...................................................236

Displaycontent .....................................................236

Errorcodetable .....................................................237

General messages ...................................................239

Drive-specificmessages ..............................................248

Operation in special operating situations ...................................256

Transport ..........................................................256

Towing .......................................................... . 258

Craneloading ......................................................260

Jump-starting ......................................................263

Procedure in emergencies .............................................264

Emergency shutdown ................................................264

Procedure if truck ti

Emergency hammer ..................................................266

Emergency lowering .................................................267

Disconnecting the ba

Refuelling .........................................................270

Dieselfuel-Specifications .............................................270

Filling up with dies

Cleaning ..........................................................276

Cleaning the truck ...................................................276

Cleaning the elect

Cleaning load chains .................................................279

Cleaning the windows ................................................279

Afterwashing .......................................................280

psover .............................................265

elfuel ...............................................274

ricalsystem ..........................................278

s and daily operating hours .......................229

ymode ......................................231

ttery ..............................................269

3

II 57348011825 EN - 12/2015

VI

Table of contents

Decommissioning ...................................................281

Parkingthetrucksecurely .............................................281

Wheelchock(variant) ................................................282

Shuttingdownandstoringthetruck ......................................282

Recommissioningaftershutdown ........................................284

6 Maintenance

General maintenance infor

Personnel qualifications ...............................................286

Informationforcarryingoutmaintenance ..................................286

Maintenance instruction

Orderingsparepartsandwearingparts ....................................289

Quality and quantity of the required operating materials ........................289

Lubricationplan .....................................................290

Maintenance data table ...............................................291

Intervals for maintenance and inspection ..................................295

Maintenance — 1000 hour

Maintenance - 3000 hours/every two years . ................................299

Safety regulations for maintenance .......................................300

Generalinformation ..................................................3

Workingonthehydraulicequipment ......................................300

Working on the electrical equipment ......................................301

Working on the ignitio

Safetydevices ......................................................302

Setvalues ....................................................... . . 302

Lifting and jacking

Workingatthefrontofthetruck ..........................................302

Providing access to maintenance points ...................................304

Opening the side ser

Closingthesideserviceflap ............................................305

Openingthebonnet ................................................ . . 306

Closing the bonnet

Installingandremovingthebottomplate ...................................307

Maintenance .......................................................309

Cleaning the radia

Replacing the air filter cartridges .........................................309

Drainingwaterfromthefuelfilter .........................................311

Lubricating the j

Checking the door latch ...............................................313

Maintainingtheseatbelt ...............................................313

ointsandcontrols ........................................312

mation ........................................286

s ..............................................289

s/annually .....................................295

nsystem ..........................................301

up .................................................302

viceflap ...........................................304

...................................................307

tor,checkingforleaks ...................................309

g

00

348011825 EN - 12/2015 IX

57

Table of contents

g

Checkingthedriver’sseat .............................................315

Greasingtheautomatictowcoupling ......................................315

Servicingwheelsandtyres .............................................318

Servicingthebattery .................................................320

Replacingfuses .....................................................322

Lubricating the lift mast and r

ollertrack ....................................322

7 1000 hour maintenance/ann

Other tasks ........................................................324

Checking the hydraulic system for leaks ...................................324

Checking the hydraulic oi

Checking the lift cylinders and connections for leaks ..........................326

Checking the fork arms ................................................326

Checking the reversibl

l level ..........................................325

e fork arms ........................................327

ual maintenance

8 Technical data

Dimensions ........................................................330

VDI datasheet ......................................................332

Fuse assignment ....................................................335

X5

7348011825 EN - 12/2015

1

Foreword

1 Foreword

List of abbreviations

List of abbreviations

NOTE

This list of abbreviations applies to all types

of operating instructions. Not all of the abbreviations that are listed here will necessarily

appear in these operating instructions.

Abbreviation

°C

°F

A

ABE

ArbSchG

BetrSichV

BG

BGG

BGR

German Social

Accident

Insurance

Approx.

CE

CEE

cm

3

cm

dB Decibels

DFÜ

DIN

EG

EN

FEM

F

max

g

GAA

Meaning

Degrees Celsius

Degrees Fahrenheit

Amperes

Display operating unit

German labour protec

German Ordinance on Industrial Safety and Health

Employers’ liability insurance association

Employers’ liability insurance association act

Employers’ liability insurance association rule

Employers’ liability insurance association regulation

Approximately

Symbol that confirms conformity with the valid product-specific European

directives

International Commission on the Rules for the Approval of Electrical Equipment

Centimetres

Cubic centimetres

Remote data transmission

German standard

European Community

European standard

Fédération Européene de la Manutention

Maximum power

Grams

trial inspectorate

Indus

tion law

25

7348011825 EN - 12/2015

Foreword 1

List of abbreviations

Abbreviation

Meaning

If applicable If applicable

GPRS General Packet Radio Service

h/d

Hours per day (time driven each day in hours)

ID no. ID number

ISO

International standard

kg Kilograms

3

kg/m

km/h

km/d

Kilograms per cubic metre

Kilometres per hour

Kilometres per day (kilometres driven each day)

kN Kilonewtons

kW Kilowatts

kWh/h

Energy consumption

lLitres

l/h

l/min

LAN Local area ne

LED

L

p

L

pAZ

LSP

o.s.

m

m/s

2

m/s

MAK

Litres per hour

Litres per minute

twork

Light emitting diode

Sound pressure level

Continuous sound pressure level in driver’s compartment

Load centre of gravity

Or similar

Metres

Metres per second

Metres per second squared

Maximum workplace concentration

Max. Maximum

Min. Minimum

min Minutes

rpm

mm

Revolution(s) per minute

Millimetres

N Newtons

Nm New

ton metres

348011825 EN - 12/2015 3

57

1 Foreword

Your truck

Abbreviation

PIN

SE

SIT

StVZO

t

TRGS

a.s.

VVolts

VDE

VDI

VDMA

W Watts

WLAN Wireless local area network

e.g.

.

Meaning

Personal identification number

Superelastic

Snap-in tyre for simplified ass

German Road Traffic Licensing

Tonnes

Technical Regulations fo

And similar

Association for Electr

Association of Germa

German Engineering

For example

ical, Electronic & Information Technologies

n Engineers

Federation

Your truck

General

The truck des

tions corre

and safety r

If the truck is to be operated on public roads, it

must conform to the existing national regulations for the country in which it is being used.

The driving permit must be obtained from the

appropriate office.

The trucks have been fitted with state-of-theart technology. All that remains is to handle

the truck safely and maintain its functionality.

These oper

necessary

observe th

commissio

accidents

remains va

cribed in these operating instruc-

sponds to the applicable standards

egulations.

ating instructions provide the

information to do this. Read and

e information provided before

ning the truck. This will prevent

and ensure that the warranty

lid.

embly

Regulations

r Hazardous Substances

45

7348011825 EN - 12/2015

Foreword 1

Your truck

CE labelling

The manufacturer uses CE labelling to indicate that the truck complies with the standards

and regulations valid at the time of marketing.

This is confirmed by the issued EC declaration

of conformity. The CE labelling is attached to

the nameplate.

An independent structural change or addition

to the truck can compromise safety, thus

invalidating the EC declaration of conformity.

The EC declaration of confo

carefully stored and made a

responsible authorities.

rmity must be

vailable to the

CE-Symbol

348011825 EN - 12/2015 5

57

1 Foreword

Your truck

EC declaration of conformity in accordance with Machinery Directive

Declaration

STILL GmbH

Berzeliusstraße 10

D-22113 Hamburg Germany

We declare that the

Industrial truck

Model

according to these operating instructions

according to these operating instructions

conforms to the latest version of the Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC compliance declaration

STILL Gmb

.

65

H

7348011825 EN - 12/2015

Foreword 1

Information about the documentati

on

Information about the documentation

Documentation scope

• Original operating instructions

• Original operating instructions for attachments (variant)

• Spare parts list

• VDMA rules for the proper use of industrial

trucks

These operating instructions describe all measures necessary for the safe operation and

proper maintenance of your truck in all possible variants available at the time of printing.

Special versions to meet customer requirements are documented in separate operating

instructions. If you have any questions, please

contact your authorised service centre.

Enter the production num

manufacturer from the na

provided:

Production number

...............................................

Year of manufacture

...................................................

Please quote the produ

technical enquiries.

Each truck comes with a set of operating

instructions. These instructions must be

stored carefully and must be available to the

driver and operatingcompany at any time. The

storage location isspecified in the "Overviews"

chapter.

If the operating instructions are lost, the

operator must obtain a replacement from the

manufacturer immediately.

The operating instr

spare parts list and

a spare part.

The personnel responsible for operating and

maintaining the equipment must be familiar

with these operating instructions.

The operating company must ensure that all

users have received, read and understood

these operating instructions.

ber and year of

meplate in the space

ction number during all

uctions are included in the

can be reordered there as

348011825 EN - 12/2015 7

57

1 Foreword

Information about the documentati

NOTE

Please observe the definition o

responsible persons: "operat

ing company"

and "driver".

Thank you for reading and complying with

these operating instructions. If you have any

questions or suggestions for improvements,

or if you have found any errors, please contact

the authorised service centre.

Issue date and topicality of the operating instructions

The issue date of these operating instructions

can be found on the title page.

STILL is constantly engaged in the further

development of trucks. These operating

instructions are subject to change, and any

claims based on the information and/or

illustrations contained in them cannot be

asserted.

Please contact your au

for technical support

thorised service centre

relating to your truck.

on

f the following

Copyright and tradem

These instruction

translated or made

ties—including as

express written ap

s must not be reproduced,

excerpts—except with the

proval of the manufacturer.

Explanation of in

ark rights

accessible to third par-

formation symbols

used

DANGER

Indicates procedures that must be strictly adhered

to in order to prevent the risk of fatalities.

WARNING

Indicates procedures that must be strictly adhered

to in order to prevent the risk of injuries.

85

7348011825 EN - 12/2015

Foreword 1

on

CAUTION

Indicates procedures that must be strictly adhered

to in order to prevent material damage and/or

destruction.

NOTE

Information about the documentati

For technical requirements that require

special attention.

ENVIRONMENT NOTE

To prevent environmental damage.

Explanation of the cross-references

Cross references are used to direct the reader

to the appropriate section or chapter.

Examples:

• Cross reference to a section: ⇒ Chapter "Explanation of the cross-references",P.1-9

• Cross reference to a chapter: ⇒ Chapter "Definition of terms used for responsible

persons", P. 26

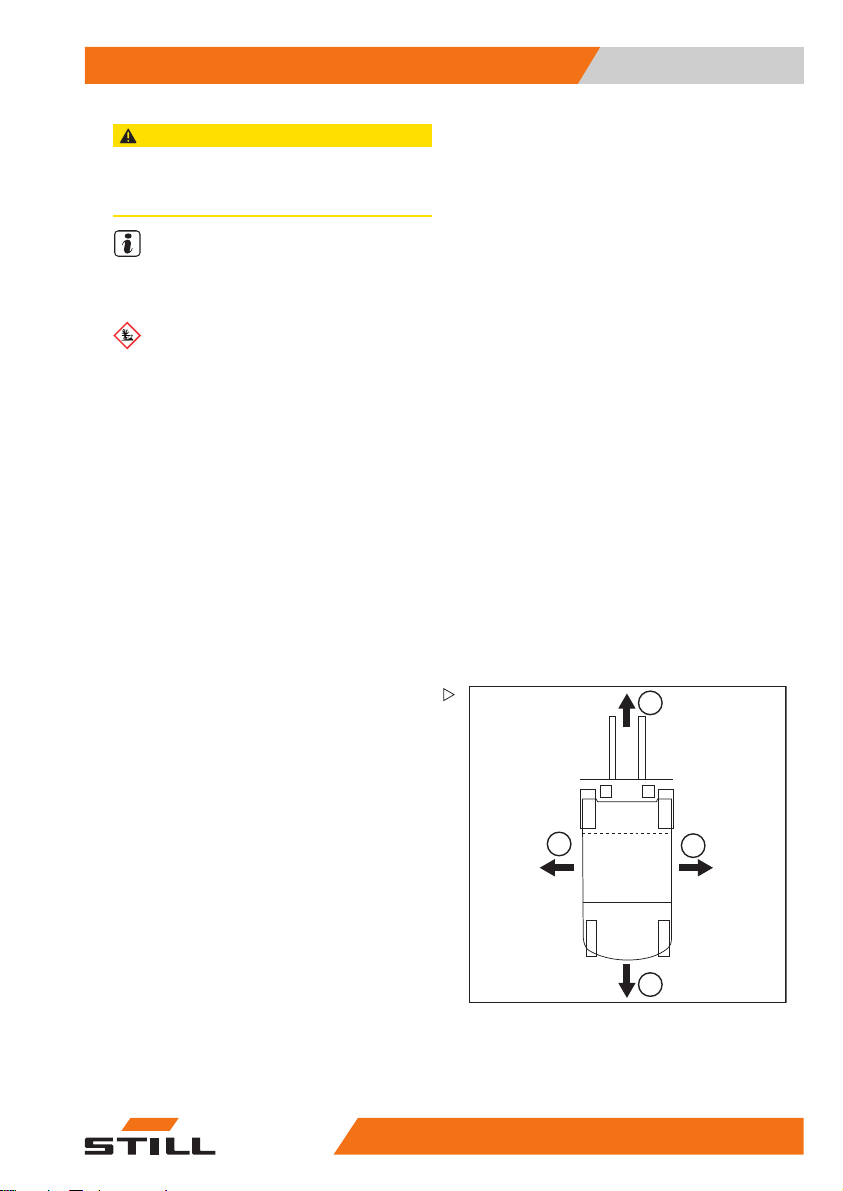

Definition of directions

The directions "forwards" (1), "backwards" (3),

"right" (2) and "left" (4) refer to the installation

position of the parts as seen from the driver’s

compartment; the load is to the front.

348011825 EN - 12/2015 9

57

1

4

2

3

6210_001-031

1 Foreword

Information about the documentati

Schematic views

View of functions and operations

This documentation explains the (usually

sequential) chain of certain functions or operations. Schematic diagrams of a counterbalance truck are used to illustrate these procedures.

NOTE

These schematic diagrams are not representative of the structural state of the documented

truck. The diagrams are used solely for the

purpose of clarifying procedures.

View of the display operating unit

NOTE

Views of operating statuses and values in

the display of the display operating unit are

examples and partly dependent on the truck

equipment. As a result, the displays shown

of the actual operating statuses and values

can vary. Information that is not relevant for

descriptions is not shown.

on

6210_003-062

10

57348011825 EN - 12/2015

Foreword 1

Environmental considerations

Environmental considerations

Packaging

During delivery of the truck, certain parts

are packaged to provide protection during

transport. This packaging must be removed

completely prior to initial start-up.

ENVIRONMENT NOTE

The packaging material mu

properly after delivery o

st be disposed of

f the truck.

Disposal of component

s and

batteries

The truck is composed

components or batter

and disposed of, they

• disposed of,

• treated or

• recycled in accorda

national regulatio

NOTE

The documentation provided by the battery

manufacturer must be observed when disposing of batteries.

ENVIRONMENT NOTE

We recommend working with a waste management company for disposal purposes.

of different materials. If

ies need to be replaced

must be:

nce with regional and

ns.

348011825 EN - 12/2015 11

57

1 Foreword

Environmental considerations

12

57348011825 EN - 12/2015

2

Introduction

2 Introduction

Using the truck

Using the truck

Proper usage

The truck described in these operating instructions is suitable for lifting, transporting

and stacking loads.

The truck may only be used for its proper

purpose as set out and described in these

operating instructions.

If the truck is to be used for

than those specified in the o

tions, the approval of the m

applicable, the relevant r

must be obtained beforeha

ards.

The maximum load to be lifted is specified on

the capacity rating plate (load diagram) and

must not be exceeded; see also the chapter

entitled "Before picking up a load".

Proper use during towing

This truck is suitable for the occasional towing

of trailers and is equipped with a towing device

for this purpose. This occasional towing may

not exceed 2% of the daily operating time. If

the truck is to be used for towing on a more

regular basis, the manufacturer should be

consulted.

The regulations regarding trailer operation

must be observed; see chapter "Trailer

operation".

purposes other

perating instruc-

anufacturer and, if

egulatory authorities

nd to prevent haz-

Impermissible use

The operating company or driver, and not the

manufacturer, is liable for any hazards caused

by improper use.

NOTE

Please observe the definition of the following

responsible persons: "operating company"

and "driver".

Use for purposes other than those described

in these operating instructions is prohibited.

14

57348011825 EN - 12/2015

Introduction 2

Using the truck

DANGER

There is a risk of fatal injury from

falling off the truck while it is moving!

– It is prohibited to carry passengers

on the truck.

The truck may not be operated in areas where

there is a risk of fire, explosion or corrosion, or

in areas that are particularly dusty.

Stacking or unstacking is not permissible on

inclined surfaces or ramps.

Place of use

The truck can be used outdoors.

If the truck is equipped with the "particle

filter" equipment variant, it fulfils the essential

prerequisites for use in ventilated halls. The

national regulations for the country of use

must be observed.

Operation on public roads is only permitted

with the "StVZO" (Road Traffic Licensing

Regulations) equipment variant.

If the truck is to be operated on public roads, it

must conform to the existing national regulations for the country in which it is being used.

The ground must have an adequate load

capacity (concrete, asphalt) and a rough

surface. Routes, working areas and aisle

widths must conform to the specifications in

these operating instructions; see the chapter

entitled "Routes".

Driving on upward and downward gradients

is permitted provided the specified data and

specifications are observed; see the chapter

entitled "Routes".

The truck is suitable for use in many different

countries, ranging from those situated in the

Tropics to those in Nordic regions (temperature range: -20°C to +40°C).

This truck is not designed to be operated in

cold stores.

The operating company must ensure suitable

fire protection for the relevant application in

348011825 EN - 12/2015 15

57

2 Introduction

Using the truck

the truck’s surroundings. Depending on the

application, additional fire protection must be

provided on the truck. If in doubt, contact the

relevant authorities.

NOTE

Please observe the definition of the following

responsible person: "operating company".

DANGER

Risk to health from exhaust gases!

Exhaust gases from internal combustion engines

are harmful to your health. In particular, the soot

particles contained in the diesel exhaust gas can

cause cancer. When the internal combustion

engine is left running, there is a risk of poisoning

due to the CO, CH and NOx components contained

in the exhaust gas.

Modern exhaust gas treatment systems (e.g.

catalytic converters, particle filters or comparable

systems) can clean exhaust gases in a way that

reduces the health hazard and risk of poisoning

when operating the truck.

– Observe the national laws and regulations when

using trucks with an internal combustion engine

in entirely or partially enclosed working areas.

– Always ensure sufficient ventilation.

Using working platforms

WARNING

The use of working platforms is regulated by national law. The use of working platforms is only

permitted by virtue of the jurisdiction in the country

of use.

– Observe national legislation.

– Before using working platforms, consult the

national regulatory authorities.

16

57348011825 EN - 12/2015

Introduction 2

Residual risk

Residual risk

Residual dangers, residual risks

Despite careful working and compliance with

standards and regulations, the occurrence

of other risks when using the truck cannot be

entirely excluded.

The truck and all other system components

comply with current safety requirements.

Nevertheless, even when the truck is used

for its proper purpose and all instructions

are followed, some residual risk cannot be

excluded.

Even beyond the narrow dan

truck itself, a residual r

Persons in this area aroun

exercise a heightened deg

so that they can react imme

of any malfunction, incid

WARNING

All persons that are in the vicinity of the truck

must be instructed regarding these risks that arise

through use of the truck.

In addition, we draw attention to the safety regulations in these operating instructions.

ger areas of the

isk cannot be excluded.

d the truck must

ree of awareness,

diately in the event

ent or breakdown etc.

Risks can include:

• Escape of consumables due to leakages,

rupture of lines and containers etc.

• Risk of accident when driving over difficult

ground such as gradients, smooth or

irregular surfaces, or with poor visibility

etc.

• Falling, tripping etc. when moving on

the truck, especially in wet weather, with

leaking consumables or on icy surfaces

• Fire and explosion risks due to batteries and

electrical voltages

• Human error resulting from failure to

observe the safety regulations,

• Unrepaired damage or defective and worn

components,

• Insufficient maintenance and testing

• Use of incorrect consumables

• Exceeding test intervals

348011825 EN - 12/2015 17

57

2 Introduction

Residual risk

The manufacturer is not held responsible for

accidents involving the truck caused by the

failure of the operating company to comply

with these regulations either intentionally or

carelessly.

Stability

The stability of the truck has been tested to the

latest technological standards and is guaranteed provided that the truck is used properly

and according to its intended purpose. These

standards only take into account the dynamic

and static tipping forces that can arise during

specified use in accordance with the operating rules and intended purpose. However, the

danger of exceeding the moment of tilt due to

improper use or incorrect operation and losing

stability can never be excluded.

The loss of stability can b

imised by the following ac

– Always secure the load against slipping,

e.g. by lashing.

– Always transport unstable loads in suitable

containers.

– Always drive slowly whe

– Drive with the load lowered.

– Even with sideshifts, align the load as

centrally as possible with the truck and

transport in this position.

– Avoid turning and dia

slopes or gradients.

– Never have the load facing downhill when

travelling on slopes or gradients.

– Pick up only loads of the approved width.

– Always take great ca

suspended loads.

– Do not drive over ramp edges or steps.

e avoided or mintions:

n cornering.

gonally driving across

re when transporting

Special risks associated with using the truck and attachments

Approval from the manufacturer and attachment manufacturer must be obtained each

18

57348011825 EN - 12/2015

Loading...

Loading...