Page 1

Original instructions

Diesel truck

RX70-16

RX70-18

RX70-20

7311 7312 7313

174749 EN - 03/2017

Page 2

Page 3

Preface

Address of manufacturer and contact details

STILL GmbH

Berzeliusstraße 10

22113 Hamburg, Germany

Tel. +49 (0) 40 7339-0

Fax: +49 (0) 40 7339-1622

Email: info@still.de

Website: http://www.still.de

g

749 EN - 03/2017 I

174

Page 4

Page 5

Table of contents

1 Foreword

Your truck .......................................................... 2

Descriptionofthetruck ................................................. 2

General ............................................................ 4

CElabelling ......................................................... 5

EC declaration of conformit

Accessoriesoverview ................................................. 7

Overview ........................................................... 8

Nameplate ......................................................... 10

Production number . . . ............................................... 11

StVZO(RoadTrafficLicensingRegulations)information ....................... 11

Use of truck ........................................................ 11

Proper usage ....................................................... 11

Proper use during towing .............................................. 12

Impermissibleuse ................................................... 12

Placeofuse ........................................................ 13

Usingworkingplatforms ............................................... 14

Information about docum

Documentationscope ................................................ 15

Supplementarydocumentation .......................................... 16

Issue date and topicali

Copyrightandtrademarkrights .......................................... 17

Explanation of information symbols used . . ................................ 17

List of abbreviations

Definitionofdirections ................................................ 20

Schematicviews .................................................... 20

Environmental con

Packaging ......................................................... 22

Disposal of components and batteries ..................................... 22

y in accordance with Machinery Directive ............... 6

entation ........................................ 15

tyoftheoperatinginstructions .......................... 17

.................................................. 18

siderations .......................................... 22

g

2Safety

Definition of respon

Operatingcompany .................................................. 24

Specialist .......................................................... 24

Drivers ........................................................... 25

Essentials for safe operation ........................................... 27

Insurance cover on company premises .................................... 27

Changes and retrofi

Changes to the overhead guard and roof loads .............................. 29

Warning regarding non-original parts ..................................... 29

sible persons ........................................ 24

tting ............................................... 27

749 EN - 03/2017 III

174

Page 6

Table of contents

g

Damage, defects and misuse of safety systems . . . ........................... 30

Tyres ............................................................. 30

Medicalequipment ................................................... 32

Exercise caution when handling gas springs and accumulators .................. 32

Lengthoftheforkarms ................................................ 33

Residual risk ....................................................... 34

Residual dangers, residual risks ......................................... 34

Specialrisksassociatedwithusingthetruckandattachments ................... 35

Overview of hazards and coun

Danger to employees ................................................. 41

Safety inspections ................................................... 42

Regular safety inspection

Checkingthedieselengineemissions ..................................... 42

Truckswithparticlefilters .............................................. 43

Insulationtesting .................................................... 44

Safety regulations when handling consumables ............................. 45

Permissibleconsumables ............................................. 45

Oils .............................................................. 45

Hydraulicfluid ...................................................... 46

Batteryacid ........................................................ 47

Dieselfuel ......................................................... 48

Coolantandcoolingfluid .............................................. 50

Disposalofconsumables .............................................. 50

Emissions ......................................................... 52

termeasures ................................. 38

ofthetruck ..................................... 42

3Overviews

General view ....................................................... 56

Driver's compartment ................................................. 57

Operating and displ

Display and operating unit . . . .......................................... 58

Operatingdevicesforhydraulicanddrivingfunctions .......................... 59

Double mini-lever

Three-waymini-lever ................................................. 61

Four-waymini-lever .................................................. 62

Joystick4Plus ...................................................... 63

Fingertip .......................................................... 64

Miniconsole ....................................................... 65

IV 1

ay elements ......................................... 58

.................................................... 60

74749 EN - 03/2017

Page 7

Table of contents

4 Operation

Testing and activities before daily use ..................................... 68

Visualinspections ................................................... 68

Checkingthecoolingfluidlevel .......................................... 71

Checking the engine oil level ........................................... 72

Climbing in and out of the tru

Shelvesandcupholders .............................................. 74

AdjustingtheMSG65/MSG75driver'sseat ................................ 75

Adjustingthearmrest ................................................. 79

Adjustingthesteeringcolumn ........................................... 80

Unlockingtheemergencyoffswitch ...................................... 80

Switchingonthekeyswitch

AccessauthorisationwithPINcode(variant) ................................ 84

Operating the signal horn .............................................. 94

Seatbelt .......................................................... 94

Driver'scab ........................................................ 97

Starting the engine ................................................... 98

Checking the brake syste

Checkingthesteeringsystemforcorrectfunction ............................101

Checking the emergency off function .....................................101

Zero adjustment of the l

Checking the vertical lift mast position (variant) for correct function . ...............104

Operation of the display operating unit ....................................105

Displays ........................................................ . . 105

Adjustingthedisplays ................................................106

Symbolsinthedisplay ................................................106

Setting the date or time

Resetting the daily kilometres and daily operating hours .......................111

Setting the language . . ...............................................112

Soft key button for operat

ConfiguringBlue-Qefficiencymode ......................................113

Blue-Q efficiency mode ...............................................115

Functional description . ...............................................1

Effects on additional consumers .........................................115

SwitchingefficiencymodeBlue-Qonandoff ................................116

Driving ............................................................117

Safety regulations when driving .........................................117

Driveways ....................................................... . . 119

Setting the drive prog

Selectingthedrivedirection ............................................122

Actuatingthedrivedirectionswitch,mini-leverversion .........................123

ck .......................................... 73

............................................ 81

mforcorrectfunction ..............................100

oadmeasurement(variant) ...........................102

................................................111

ing various equipment variants .......................112

rams .............................................122

g

15

749 EN - 03/2017 V

174

Page 8

Table of contents

g

Actuating the vertical rocker switch for the "drive direction", joystick 4Plusversion ....124

Actuating the drive direction switch, fingertip version ..........................124

Actuating the drive direction

Startingtodrive .....................................................125

Starting drive mode, dual-pedal version (variant) . . ...........................127

Operatingtheservicebrake ............................................13

Parkingbrake ......................................................131

Actuating the mechanical parking brake ...................................131

Actuating the electric park

Steering ...........................................................138

Driving on ascending and descending gradients . . ...........................139

Reducing speed with a raise

Automatic shut-off of the internal combustion engine (variant) ...................140

Parking ...........................................................141

Parking the truck securel

Wheel chock (variant) ................................................142

Lifting ............................................................143

Lifting system variants

Automaticliftcutout(variant) ...........................................143

Liftmastverticalposition(variant) ........................................144

Typesofliftmast ....................................................148

Malfunctionsduringliftingmode .........................................150

Hydraulicblockingfunction .............................................151

Lifting system operati

Controlling the lifting system using a double mini-lever .........................153

Controllingtheliftingsystemusingatriplemini-lever ..........................154

Controlling the lift

Controllingtheliftingsystemusingthejoystick4Plus ..........................156

Controlling the lifting system using the fingertip . . . ...........................158

Changing the fork arm

Forkextension(variant) ...............................................161

Operationwithreversibleforkarms(variant) ................................163

Workingwithloads ...................................................165

Safety regulations when handing loads ....................................165

Beforetakingupload .................................................166

Load measurement (va

Picking up loads .....................................................170

Danger area .......................................................171

Transportingpallets ..................................................17

Transporting suspended loads ..........................................172

Loadpickup ...................................................... . 173

ing system using a quadruple mini-lever ......................155

switch,mini-consoleversion ......................125

ingbrake ......................................133

dload(variant) ................................140

yandswitchingitoff ...............................141

................................................143

ngdevices .........................................152

s ...............................................159

riant) ...........................................167

0

2

VI 1

74749 EN - 03/2017

Page 9

Table of contents

Transportingloads ...................................................177

Settingdownloads ...................................................178

Drivingonlifts ......................................................180

Driving on loading bridges .............................................181

Attachments .......................................................182

Fittingattachments ..................................................182

Releasingthepressurefromthehydraulicsystem ............................184

Generalinstructionsforcontrollingattachments .............................186

Controlling attachments us

Controlling attachments using the double mini-lever and the 5th function ...........190

Controllingattachmentsusingatriplemini-lever .............................192

Controlling attachments u

Controlling attachments using a quadruple mini-lever .........................196

Controlling attachments using the quadruple mini-lever and the 5th function .........198

Controlling attachments

Controlling attachments using the joystick 4Plus and the 5th function . . . ...........201

Controlling the attachments with the fingertip ...............................202

Controlling attachment

Clamp locking mechanism (variant) ......................................205

Takingupaloadusingattachments ......................................208

Auxiliary equipment ..................................................20

Switchingthelightingonandoff .........................................209

Switching the rotating beacon on and off . . . ................................210

Switching the hazard wa

Switchingdirectionindicatorsonandoff ...................................211

Switching the double working spotlights on and off. ...........................214

STILL SafetyLight (v

Operatingthewindscreenwiper/washer ...................................217

Fillingthewashersystem ..............................................217

FleetManager (variant

Shock recognition (variant) .............................................218

Cruisecontrol(variant) ................................................218

Driver restraint syst

Cab ..............................................................223

Opening the cab door . . ...............................................223

Closing the cab door

Openingthesidewindows ........................................... . . 224

Closing the side windows ..............................................225

Operating the inte

Operating the rear window heating .......................................227

Radio(variant) ......................................................227

riorlighting ...........................................226

ing a double mini-lever ............................188

singthetriplemini-leverandthe5thfunction .............194

viathejoystick4Plus ...............................200

s with the fingertip and 5th function ......................203

rningsystemonandoff .............................210

ariant) .............................................216

) ................................................217

ems(variants) .......................................222

.................................................224

g

9

749 EN - 03/2017 VII

174

Page 10

Table of contents

g

Heatingsystem .....................................................228

Push-up roof window (variant) ..........................................229

Clipboard (variant) ...................................................230

Trailer operation ....................................................231

Towedload ....................................................... . 231

Coupling pin in the counterw

Automatictowcoupling ...............................................234

Towingtrailers ......................................................242

Display messages ...................................................244

Displaycontent .....................................................244

Errorcodetable .....................................................245

General messages ...................................................247

Drive-specificmessages ..............................................256

Malfunctionsintheelectricparkingbrake ..................................263

Refuelling .........................................................269

Dieselfuel-Specifications .............................................269

Topping up the diesel fuel ..............................................273

Cleaning ..........................................................275

Cleaning the truck ...................................................275

Cleaning the electrical system ..........................................277

Cleaning load chains .................................................27

Cleaning the windows ................................................278

Afterwashing .......................................................279

Behaviour in emergenc

Emergency shutdown ................................................279

Procedureiftrucktipsover .............................................281

Emergency hammer ..................................................282

Emergency lowering .................................................282

Emergency operation of the electric parking brake . ...........................284

Disconnecting the batte

Jumpstarting .......................................................286

Towing .......................................................... . 288

Transporting the truck ................................................290

Transport ..........................................................290

Craneloading ......................................................292

Shutdown .........................................................295

Shuttingdownandstoringthetruck ......................................295

Returningtoserviceafterstorage ........................................297

eight ........................................232

ies .............................................279

ry ..............................................285

8

I 174749 EN - 03/2017

VII

Page 11

Table of contents

5 Maintenance

Safety instructions for maintenance ......................................300

Generalinformation ..................................................300

Workingonthehydraulicequipment ......................................300

Working on the electrical equipment ......................................301

Working on the ignition syst

Safetydevices ......................................................302

Setvalues ....................................................... . . 302

Liftingandjackingup .................................................302

Workingatthefrontofthetruck ..........................................302

General maintenance information ........................................304

Personnel qualifications ...............................................3

Informationforcarryingoutmaintenance ..................................304

Maintenance - 1000 hours/annually ......................................307

Maintenance — 3000 hours/

Orderingsparepartsandwearingparts ....................................311

Quality and quantity of the required operating materials ........................312

Lubricationplan .....................................................313

Maintenance data table ...............................................314

Providing access to maintenance points ...................................317

Openingthebonnet ................................................ . . 317

Closing the bonnet ...................................................317

Installingandremovingthebottomplate ...................................318

Maintenance after first 5

Maintenance during the break-in period . . . ................................320

Remaining ready for operation ..........................................321

Cleaning the radiator,

Topping up the cooling fluid and checking the coolant concentration ...............321

Changing the air filter insert ............................................323

Draining water from the

Eberspächer particle filters - Regeneration . ................................326

Lubricatingthejointsandcontrols ........................................329

Maintaining the seat belt

Checkingthedriver'sseat .............................................331

Checking the door latch ...............................................332

Servicing wheels and tyre

Servicingthebattery .................................................334

Replacingfuses .....................................................336

Checking the hydraulic

Checkingthehydraulicsystemforleaks ...................................337

Lubricatingtheliftmastandrollertrack ....................................338

em ..........................................301

everytwoyears ................................311

0 operating hours ..................................320

checkingforleaks ...................................321

fuelfilter .........................................325

...............................................330

s .............................................332

oillevel ..........................................336

g

04

749 EN - 03/2017 IX

174

Page 12

Table of contents

g

Greasingtheautomatictowcoupling ......................................339

Changing the heating system fresh air filter .................................341

1000-hour maintenance / Annua

Othertasks ........................................................343

Checking theribbed V-belt . . . ..........................................343

Checking the exhaust gas sys

Changing the fuel filter ................................................344

Changing the fuel filter for Eberspächer particle filters .........................345

Checking the lift cylinders

Checkingtheforkarms ................................................346

Checkingthereversibleforkarms ........................................346

l maintenance ..............................343

tem .......................................343

and connections for leaks ..........................345

6 Technical data

Dimensions ........................................................348

VDI datasheet for RX70-16, RX70-18 and RX70-20 ..........................350

Ergonomic dimensions ................................................354

Fuse assignment ....................................................356

X17

4749 EN - 03/2017

Page 13

1

Foreword

Page 14

1 Foreword

Your truck

Your truck

Description of the truck

General

The internal combustion engine-powered

trucks of series RX70-16/18/20 with a load

capacity of up to 2 t are equipped with a

diesel-electric drive. The diesel-electric drive

combines the advantages of the diesel engine

with the precise control of an electric drive.

The bend-resistant and war

mast enables safe load hand

heavy loads. The comfortab

partment features the mo

gonomic design to preven

and increase safety.

The low centre of gravity of the truck provides

stability, which is guaranteed if the truck is

used according to its intended use.

Brake system

The brake system of the truck is comprised of

three different brakes:

• Service brake

• Regenerative brake

• Parking brake

The service brake is based on a wear-free,

oil-immersed multi-disc brake. This multi-disc

brake is used as the service brake for heavy

braking or emergency braking with the brake

pedal. In the normal working mode, the

regenerative brake of the electric traction

motor takes effect. The regenerative brake

converts the acceleration energy of the truck

into electrical energy. This causes the truck to

decelerate as soon as the accelerator pedal

is released. Completely removing your foot

from the accelerator pedal causes the truck to

brake until it comes to a standstill. A parking

brake ensures that the truck remains securely

in place when parked.

p-resistant lift

ling, even with

le driver's com-

st up-to-date er-

t signs of fatigue

Engine

The truck is equipped with

four-stroke diesel engin

217

a four-cylinder,

e. The engine is

4749 EN - 03/2017

Page 15

Foreword 1

Your truck

cooled by means of a closed coolant circuit.

The engine is lubricated via forced circulation

lubrication. The combustion air is drawn in and

cleaned by a dry air filter. Different equipment

variants are available, for example a diesel

particle filter.

Hydraulic system

All lift cylinders are hydraulically actuated.

The required oil volume flow is realised via a

gear pump, which is connected to the internal

combustion engine. The proportional valve

technology provides particularly sensitive

movements and safe handling of the load.

The hydraulic functions can be parameterised

individually by the authorised service centre.

Up to three hydraulic circ

activate attachments (va

the equipment, a hydrauli

available in the lifting c

dampening pressure peaks

system.

uitscanbeusedto

riant). Depending on

c accumulator is also

ircuit for the purpose of

in the hydraulic

Drive concept

The internal combustion engine drives an

electric generator. The generated current

is directed to an electric traction motor, which

drives the truck. An electronic speed controller

gently provides high torque for both forwards

and backwards travel.

The components for the drive unit and the

lift drive are enclosed in order to prevent the

ingress of dust or moisture. This means that

the truck is suitable for indoor and outdoor

use. In addition, all drives for traction, steering

and lifting are maintenance-free.

The driving characterist

haviour can be adapted to t

or driving habits. Five d

available for this purpo

driving speed is 22 km/h.

mode Blue-Q reduces ener

up to 10%, without impair

ics and lifting be-

he application

rive programmes are

se. The maximum

The energy-saving

gy consumption by

ing performance.

749 EN - 03/2017 3

174

Page 16

1 Foreword

Your truck

Operating devices

The truck is characterised by an accessible

operating concept. When purchasing the

truck, a variety of controls and equipment

variants are available:

• Double mini-lever

• Triple mini-lever

• Quadruple mini-lever

• Joystick 4Plus

• Fingertip switch

• Single pedal

• Dual pedal

Hands are always kept free for steering and

for controlling the operational movements to

allow efficient working. The forces that need

to be applied for this purpose are reduced to

a minimum thanks to the compact steering

wheel. The simple handling of the truck is

assisted by the agile steering axle.

General

The truck described in these operating instructions corresponds to the applicable standards

and safety regulations.

If the truck is to be operated on public roads, it

must conform to the existing national regulations for the country in which it is being used.

The driving permit must be obtained from the

appropriate office.

Thetruckshavebeenfitt

art technology. All tha

the truck safely and mai

These operating instructions provide the

necessary information to do this. Read and

observe the information provided before

commissioning the truck. This will prevent

accidents and ensure that the warranty

remains valid.

ed with state-of-the-

t remains is to handle

ntain its functionality.

417

4749 EN - 03/2017

Page 17

Foreword 1

Your truck

CE labelling

The manufacturer uses CE labe

cate that the truck complies w

and regulations valid at the t

This is confirmed by the issued

of conformity. The CE labelli

the nameplate.

An independent structural change or addition

to the truck can compromise safety, thus

invalidating the EC declaration of conformity.

The EC declaration of conformity must be

carefully stored and made available to the

responsible authorities.

llingtoindi-

ith the standards

ime of marketing.

EC declaration

ng is attached to

CE-Symbol

749 EN - 03/2017 5

174

Page 18

1 Foreword

Your truck

EC declaration of conformity in accordance with Machinery Directive

Declaration

STILL GmbH

Berzeliusstraße 10

D-22113 Hamburg Germany

We declare that the

Industrial truck

Model

according to these operating instructions

according to these operating instructions

conforms to the latest version of the Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC compliance declaration

STILL Gmb

.

617

H

4749 EN - 03/2017

Page 19

Foreword 1

Your truck

Accessories overview

• Key for key switch (2 pieces)

• Key for cab (variant)

• Hexagon socket wrench for emer

lowering

gency

749 EN - 03/2017 7

174

Page 20

1 Foreword

Your truck

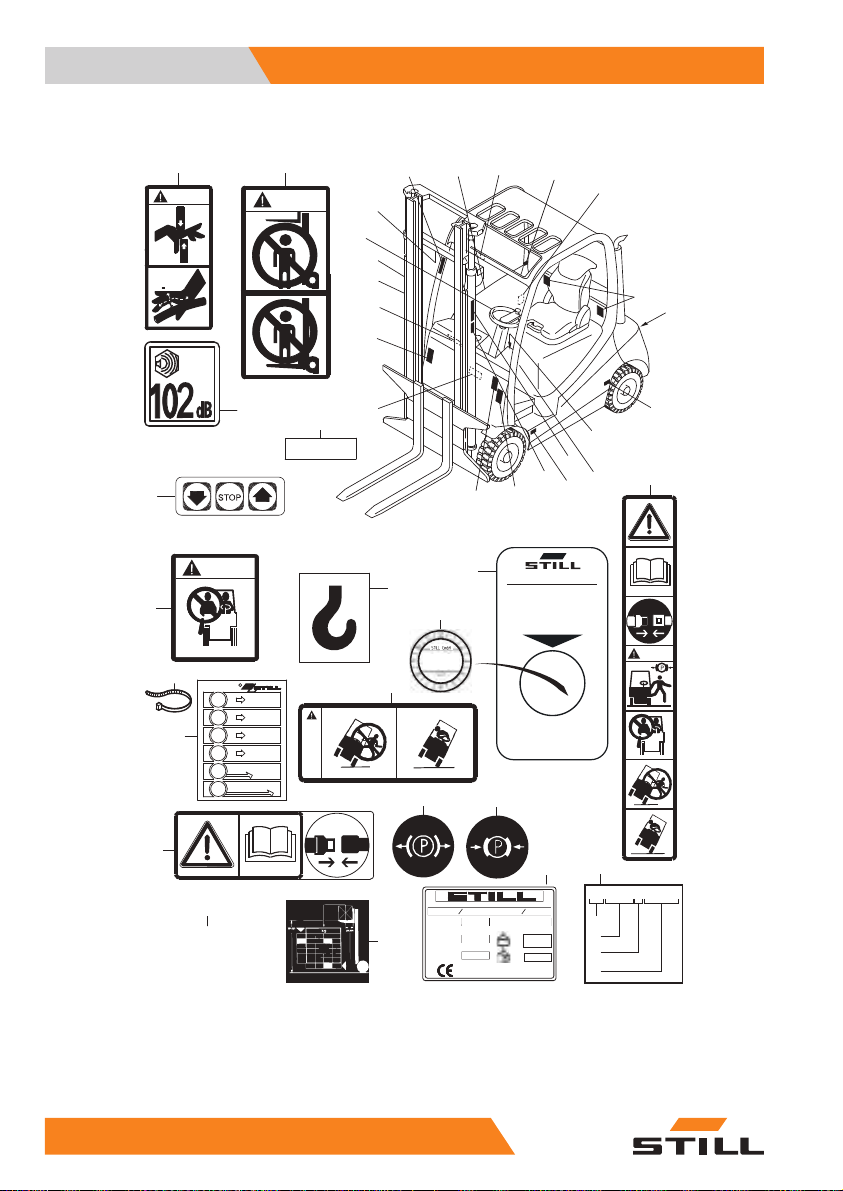

Overview

15

DANGER

DANGER

L

WA

16

DANGER

DANGER

18

22

17

11

21

12

8

9

2

15

10

5

6

16

1

5

11

17

10 bar

DANGER

9

8

19

2

5430

5030 1270

4430

4030 1150 1260 1200 1500

3730 1180 1290 1430 1500

3430 1210 1330 1470

7

D

A

N

G

E

R

1080

1080

1010

1050

1150 1310

1110 1230 1250 1500

3

800 700

1

13

14

2

15

7

Regelmäßige Prüfung

(FEM 4.004)

Nächste Prüfung

12

16

19

20

3

6

4

STILL GmbH Hamburg

nach nationalen Vorschriften

basierend auf den EG-Richtlinien:

2009/104/EG, 99/92/EG

20xx

10

Die Prüfplakette ersetzt nicht das Prüfprotokoll

Mitglied der:

Fédération

Européene

de la Manutention

13

1080

22

1500

600

500

1

14

Type-Modèle-Typ / Serial no.-No. de série-Serien-Nr. / year-année-Baujahr

Rated capacity

Capacité nominale

Nenn-Tragfähigkeit

Battery voltage

Tension batterie

Batteriespannung

Rated drive power

Puissance motr.nom.

Nenn-Antriebsleist.

Unladen mass

kg

Masse à vide

Leergewicht

V

kW

* see Operating instructions

voir Mode d'emploi

siehe Betriebsanleitung

max

min.*

*

20

kg

kg

kg

kg

21

xx xxxx x xxxxx

3

4

56344391019

1

2

3

4

7

18

DANGER

7314_003-017_V11

817

4749 EN - 03/2017

Page 21

Foreword 1

Your truck

1 Decal information: "Dual-pedal operation"

(variant)

2 Manufacturer's label text

3 Decal information: FEM audit

4 Inspection sticker

5 Warning sign: Passengers are not allowed

6 Decal information: Lifting gear attachment

point

7 Decal information: Tyre filling pressure

8 Decal information: Driving dynamics

9 Cable strap

10 Decal information: Do not jump off if the

truck is tipping over / Lean in the opposite

direction to which the truck is tipping

11 Decal information: Caution / Read the

operating instructions / Fasten the seat belt

12 Decal information: Lifting gear attachment

point

13 Decal information: Parking brake released

14 Decal information: Parking brake applied

15 Warning sign: Danger due to shearing /

Danger due to high fluid pressure

16 Warning sign: Do not stand underneath the

fork / Do not stand on the fork

17 Decal information: Sound power level

18 Decal information: Caution / Read the

operating instructions / Fasten the seat belt

/ Apply the parking brake when leaving the

truck / Passengers are not allowed / Do not

jump off if the truck is tipping over / Lean in

the opposite direction to which the truck is

tipping

19 Decal information: StVZO (German Road

Traffic Licensing Regulations) information

(variant)

20 Decal information: nameplate

21 Decal information: Factory number

22 Decal information: capacity rating plate

749 EN - 03/2017 9

174

Page 22

1 Foreword

Your truck

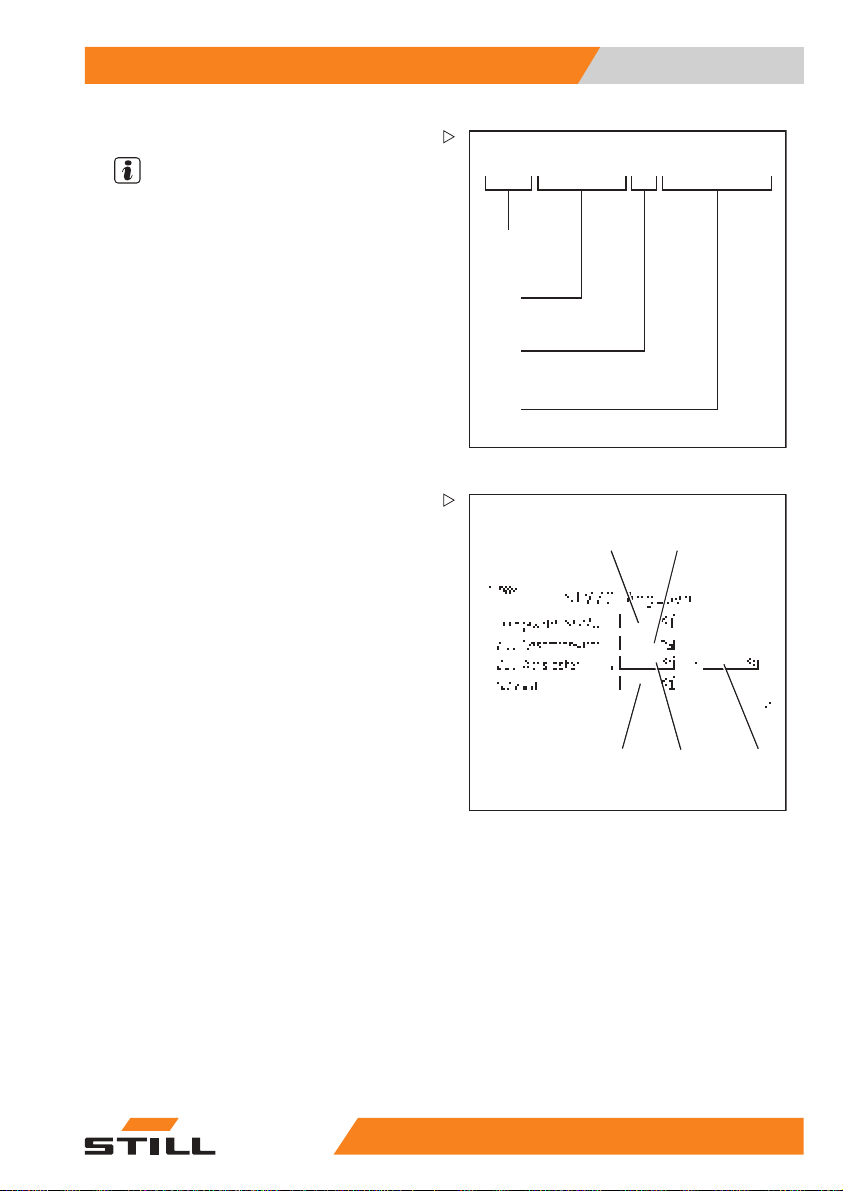

Nameplate

The truck can be identified from the information on the nameplate.

1

2

3

Type-Modèle-Typ / Serial no.-No. de série-Serien-Nr. / year-année-Baujahr

12

11

10

Rated capacity

Capacité nominale

Nenn-Tragfähigkeit

Battery voltage

Tension batterie

Batteriespannung

Rated drive power

Puissance motr.nom.

Nenn-Antriebsleist.

Unladen mass

kg

Masse à vide

Leergewicht

V

kW

* see Operating instructions

voir Mode d'emploi

siehe Betriebsanleitung

9

max

min.*

*

8

kg

kg

kg

kg

6210_921-003_V2

4

5

6

7

1 Type

2 Production number

3 Year of manufacture

4 Tare weight in kg

5 Max. permissible battery weight in kg (for

electric forklift trucks only)

6 Min. permissible battery weight in kg (for

electric forklift trucks only)

7 Ballast weight in kg (for electric forklift trucks

only)

8 Refer to the technical data listed in these

operating instructions for more detailed

information

9 CE labelling

10 Nominal drive power in kW

11 Battery voltage in V

12 Rated capacity in kg

10 1

74749 EN - 03/2017

Page 23

Foreword 1

Use of truck

Production number

NOTE

The production number is used to identify the

truck. It can be found on the nameplate and

must be referred to in all technical questions.

The production number contains the following

coded information:

(1) Production location

(2) Model

(3) Year of manufacture

(4) Sequential number

StVZO (Road Traffic Licensing

Regulations) information

This label includes information on the weight

and load distribution of the truck.

xx xxxx x xxxxx

1

2

3

4

7090_921-004

12

Use of truck

Proper usage

The truck described in these operating instructions is suitable for lifting, transporting

and stacking loads.

749 EN - 03/2017 11

174

1 Tare weig

2 Permitte

3 Permi

4Per

5 Payload (in kg)

ht (in kg)

d total weight (in kg)

tted front axle weight (in kg)

mitted rear axle weight (in kg)

5

34

7094_003-098

Page 24

1 Foreword

Use of truck

The truck may only be used for its proper

purpose as set out and described in these

operating instructions.

If the truck is to be used for purposes other

than those specified in the operating instructions, the approval of the manufacturer and, if

applicable, the relevant regulatory authorities

must be obtained beforehand to prevent hazards.

The maximum load to be lifted

the capacity rating plate (l

must not be exceeded; see als

entitled "Before picking up

Proper use during towing

This truck is suitable fo

of trailers and is equipp

for this purpose. This oc

not exceed 2% of the daily

the truck is to be used for

regular basis, the manu

consulted.

The regulations regarding trailer operation

must be observed; see chapter "Trailer

operation".

is specified on

oad diagram) and

o the chapter

a load".

r the occasional towing

ed with a towing device

casional towing may

operating time. If

towing on a more

facturer should be

Impermissible use

The operating company or driver, and not the

manufacturer, is liable for any hazards caused

by improper use.

NOTE

Please observe the definition of the following

responsible persons: "operating company"

and "driver".

Use for purposes other than those described

in these operating instructions is prohibited.

DANGER

There is a risk of fatal injury from falling

off the truck while it is moving!

– It is prohibited to carry passengers

on the truck.

12 1

74749 EN - 03/2017

Page 25

Foreword 1

Use of truck

The truck may not be operated in areas where

there is a risk of fire, explosion or corrosion, or

in areas that are particularly dusty.

Stacking or unstacking is not permissible on

inclined surfaces or ramps.

Place of use

The truck can be used outdoors.

If the truck is equipped wi

filter" equipment variant

prerequisites for use in v

national regulations for

must be observed.

Operation on public roads is only permitted

with the "StVZO" (Road Traffic Licensing

Regulations) equipment variant.

If the truck is to be operated on public roads, it

must conform to the existing national regulations for the country in which it is being used.

The ground must have an

capacity (concrete, a

surface. Routes, work

widths must conform to

these operating instr

entitled "Routes".

Driving on upward and downward gradients

is permitted provided the specified data and

specifications are observed; see the chapter

entitled "Routes".

The truck is suitable for use in many different

countries, ranging from those situated in the

Tropics to those in Nordic regions (temperature range: -20°C to +40°C).

This truck is not designed to

cold stores.

The operating company must ensure suitable

fire protection for the relevant application in

the truck's surroundings. Depending on the

application, additional fire protection must be

provided on the truck. If in doubt, contact the

relevant authorities.

th the "particle

, it fulfils the essential

entilated halls. The

the country of use

adequate load

sphalt) and a rough

ing areas and aisle

the specifications in

uctions; see the chapter

be operated in

749 EN - 03/2017 13

174

Page 26

1 Foreword

Use of truck

NOTE

Please observe the definition of the following

responsible person: "operating company".

DANGER

Risk to health from exhaust gases!

Exhaust gases from internal combustion engines

are harmful to your health. In particular, the soot

particles contained in the diesel exhaust gas can

cause cancer. When the internal combustion

engine is left running, there is a risk of poisoning

due to the CO, CH and NOx components contained

in the exhaust gas.

Modern exhaust gas treatment systems (e.g.

catalytic converters, particle filters or comparable

systems) can clean exhaust gases in a way that

reduces the health hazard and risk of poisoning

when operating the truck.

– Observe the national laws and regulations when

using trucks with an internal combustion engine

in entirely or partially enclosed working areas.

– Always ensure sufficient ventilation.

Using working platforms

WARNING

The use of working platforms is regulated by national law. The use of working platforms is only

permitted by virtue of the jurisdiction in the country

of use.

– Observe national legislation.

– Before using working platforms, consult the

national regulatory authorities.

14 1

74749 EN - 03/2017

Page 27

Foreword 1

Information about documentation

Information about documentation

Documentation scope

• Original operating instructions

• Original operating instructions for attachments (variant)

• Spare parts list

• VDMA rules for the proper use of industrial

trucks

• Depending on the truck equipment, "UPA"

operating instructions may also be provided

These operating instructi

measures necessary for the

and proper maintenance o

possible variants avail

printing. Special versi

requirements (UPA) are d

separate operating inst

any questions, please co

service centre.

Enter the production number and year of

manufacture from the nameplate in the space

provided:

Production number:

Year of manufacture:

ons describe all

safe operation

fthetruckinall

able at the time of

ons to meet customer

ocumented in

ructions. If you have

ntact your authorised

Please quote the product

technical enquiries

Each truck comes with a set of operating

instructions. These instructions must be

stored carefully and must be available to the

driver and operating company at all times.

The storage location is specified in the chapter

entitled "Overviews".

If the operating instructions are lost, the operating company must obtain a replacement

from the manufacturer immediately.

The operating inst

spare parts list and c

spare part.

The personnel responsible for operating and

maintaining the equipment must be familiar

with these operating instructions.

ion number in all

.

ructions are included in the

an be reordered as a

749 EN - 03/2017 15

174

Page 28

1 Foreword

Information about documentation

The operating company must ensure that all

users have received, read and understood

these operating instructions.

NOTE

Please observe the definition of the following

responsible persons: "operating company"

and "driver".

Thank you for reading and complying with

these operating instructions. If you have any

questions or suggestions for improvements,

or if you have found any errors, please contact

the authorised service centre.

Supplementary documentation

This industrial truck may deviate from the

standard equipment or from the variants and

be fitted with unplanned equipment (UPA).

This may include the following, for example:

• Special sensors

• Special attachments

• Towing devices

• Customer-specific attachments

In this case, the industrial truck has additional

documentation. This may be in the form of an

insert or separate operating instructions.

The original operating instructions for this

industrial truck are valid for the operation

of standard equipment and variants without

restriction. The operational and safety information in the original operating instructions

continues to be valid in its entirety unless it is

specifically countermanded in this additional

documentation.

The requirements for the qualification of

personnel as well as the time for maintenance

may vary. This is defined in the additional

documentation.

– If you have any questions, please contact

your authorised service centre.

16 1

74749 EN - 03/2017

Page 29

Foreword 1

Information about documentation

Issue date and topicality of the operating instructions

The issue date of these operating instructions

can be found on the title page.

STILL is constantly engaged in the further

development of trucks. These operating

instructions are subject to change, and any

claims based on the information and/or

illustrations contained in them cannot be

asserted.

Please contact your author

for technical support rela

ised service centre

ting to your truck.

Copyright and trademark

These instructions mus

translated or made acce

ties—including as exce

express written approv

al of the manufacturer.

Explanation of infor

rights

t not be reproduced,

ssible to third par-

rpts—except with the

mation symbols

used

DANGER

Indicates procedures that must be strictly adhered

to in order to prevent the risk of fatalities.

WARNING

Indicates procedures that must be strictly adhered

to in order to prevent the risk of injuries.

CAUTION

Indicates procedures that must be strictly adhered

to in order to prevent material damage and/or

destruction.

NOTE

For technical requirements that require

special attention.

749 EN - 03/2017 17

174

Page 30

1 Foreword

Information about documentation

ENVIRONMENT NOTE

To prevent environmental damage.

List of abbreviations

NOTE

This list of abbreviati

of operating instructi

viations that are liste

appear in these operati

Abbreviation

ABE

ArbSchG

BetrSichV

BG

BGG

BGR

DGUV

CE

CEE

DC Direct Current

DFÜ

DIN

EG

EN

FEM

F

max

GAA Gewerbeaufsichtsamt

Meaning

Display operating unit

Arbeitsschutzgesetz

Betriebssicherheitsverordnung

Berufsgenossenschaft

Berufsgenossenschaftlicher Grundsatz

Berufsgenossenschaftliche Regel

Berufsgenossenschaftliche Vorschrift German accident prevention regulations

Communauté Européenne

Commission on the Rules for the Approval

of the Electrical Equipment

Da

D

E

Eu

Fédération Européene de la Manutention

maximum Force

ons applies to all types

ons. Not all of the abbred here will necessarily

ng instructions.

tenfernübertragung

eutsches Institut für Normung

uropean Community

ropean standard

Explanation

German implementation of EU occupational health and safety directives

German implementation of the EU working

equipment directive

German insurance company for the company and employees

German principles and test specifications

for occupational health and safety

German rules and recommendations for

occupational health and safety

Confirms conformity with product-specific

European directives (CE mark)

International commission on the rules for

the approval of electrical equipment

Direct current

Remote data transmission

erman standardisation organisation

G

European Federation of Materials Handling and Storage Equipment

Maximum power

German authority for monitoring/issuing

regulations for worker protection, environmental protection, and consumer protection

18 1

74749 EN - 03/2017

Page 31

Foreword 1

Information about documentation

Abbreviation

GPRS General Packet Radio Service

Meaning

Explanation

Transfer of data packets in wireless

networks

ID no. ID number

ISO

International Organization for Standardization

International standardisation organisation

LAN Local Area Network Local area network

K

pA

LED

L

p

L

pAZ

LSP

MAK

Max. Maximum

Min. Minimum

PIN

PPE

SE

SIT

StVZO

TRGS

VDE

VDI

VDMA

Uncertainty of measurement of sound

pressure levels

Light Emitting Diode Light emitting diode

Sound pressure level at the workplace

Average continuous sound pressure level

in the driver's compartment

Load centre of gravity

Maximum workplace concentration

Distance of the centre of gravity of the load

from the front face of the fork backs

Maximum permissible air concentrations

of a substance at the workplace

Highest value of an amount

Lowest value of an amount

nal Identification Number

Perso

nal identification number

Perso

Personal protective equipment

Super-Elastic

Snap-In Tyre

Straßenverkehrs-Zulassungs-Ordnung

chnische Regel für Gefahrstoffe

Te

Verband der Elektrotechnik Elektronik

Informationstechnik

Verein Deutscher Ingenieure

Verband Deutscher Maschinen- und

Anlagenbau e.V.

Superelastic tyres (solid rubber tyres)

for simplified assembly, without

Tyres

rim parts

loose

an regulations for approval of vehi-

Germ

on public roads

cles

inance on hazardous materials appli-

Ord

in the Federal Republic of Germany

cable

German technical/scientific association

German technical/scientific association

German Mechanical Engineering Industry

Association

WLAN Wireless LAN Wireless local area network

.

749 EN - 03/2017 19

174

Page 32

1 Foreword

Information about documentation

Definition of directions

The directions "forwards" (1

"right" (2) and "left" (4) ref

position of the parts as seen f

compartment; the load is to th

), "backwards" (3),

er to the installation

rom the driver's

e front.

Schematic views

View of functions and operations

This documentation explains the (usually

sequential) chain of certain functions or operations. Schematic diagrams of a counterbalance truck are used to illustrate these procedures.

NOTE

These schematic diagrams are not representative of the structural state of the documented

truck. The diagrams are used solely for the

purpose of clarifying procedures.

1

4

2

3

6210_001-031

20 1

6210_003-062

74749 EN - 03/2017

Page 33

Foreword 1

Information about documentation

View of the display operating unit

NOTE

Views of operating statuses and values in

the display of the display operating unit are

examples and partly dependent on the truck

equipment. As a result, the displays shown

of the actual operating statuses and values

can vary. Information that is not relevant for

descriptions is not shown.

749 EN - 03/2017 21

174

Page 34

1 Foreword

Environmental considerations

Environmental considerations

Packaging

During delivery of the truck, certain parts

are packaged to provide protection during

transport. This packaging must be removed

completelyprior to initial start-up.

ENVIRONMENT NOTE

The packaging material must be disposed of

properly after delivery of the truck.

Disposal of components and batteries

The truck is composed of different materials. If

components or batteries need to be replaced

and disposed of, they must be:

•disposedof,

• treated or

• recycled in accordance with regional and

national regulations.

NOTE

The documentation provided by the battery

manufacturer must be observed when disposing of batteries.

ENVIRONMENT NOTE

We recommend working with a waste management company for disposal purposes.

22 1

74749 EN - 03/2017

Page 35

2

Safety

Page 36

2 Safety

Definition of responsible persons

Definition of responsible persons

Operating company

The operating company is the natural or legal

person or group who operates the truck or on

whose authority the truck is used.

The operating company must ensure that the

truck is only used for its proper purpose and in

compliance with the safety regulations set out

in these operating instructions.

The operating company must

all users read and understa

information.

The operating company is responsible for the

scheduling and correct performance of regular

safety checks.

We recommend that the national performance

specifications are adhered to.

Specialist

A qualified person is defined as a service

engineer or a person who fulfils the following

requirements:

• A completed vocation

demonstrably proves

expertise. This proo

a vocational qualifi

document.

• Professional experience indicating that

the qualified person has gained practical

experience of industrial trucks over a

proven period during their career During

this time, this person has become familiar

with a wide range of symptoms that require

checks to be carried out, such as based

on the results of a hazard assessment or a

daily inspection

• Recent professional involvement in the

field of the industrial truck test in question

and an appropriate further qualification

are essential. The qualified person must

have experience of carrying out the test

in question or of carrying out similar tests.

Moreover, this person must be aware of

the latest technological developments

cation or a similar

ensure that

nd the safety

al qualification that

their professional

f should consist of

24 1

74749 EN - 03/2017

Page 37

Safety 2

Definition of responsible persons

regarding the industrial truck to be tested

and the risk being assessed

Drivers

This truck may only be driven by suitable persons who are at least 18 years of age, have

been trained in driving, have demonstrated

their skills in driving and handling loads to

the operating company or an authorised representative, and have been specifically instructed to drive the truck. Specific knowledge

of the truck to be operated is also required.

The training requirements under §3 of the

Health and Safety at Work Act and §9 of the

plant safety regulations are deemed to have

been satisfied if the driver has been trained in

accordance with BGG (General Employers'

Liability Insurance Association Act) 925.

Observe the national regulations for your

country.

Driver rights, duties and rules of behaviour

The driver must be trai

duties.

The driver must be granted the required rights.

The driver must wear protective equipment

(protection suit, safety footwear, safety

helmet, industrial goggles and gloves) that

is appropriate for the conditions, the job and

the load to be lifted. Solid footwear should be

worn to ensure safe driving and braking.

Thedrivermustbefami

instructions and have ac

times.

The driver must:

• have read and understood the operating

manual

• have familiarised himself with safe operation of the truck

• be physically and mentally able t

truck safely

ned in his rights and

liar with the operating

cess to them at all

odrivethe

749 EN - 03/2017 25

174

Page 38

2 Safety

Definition of responsible persons

DANGER

The use of drugs, alcohol or medications that affect

reactions impair the ability to drive the truck!

Individuals under the influence of the aforementioned substances are not permitted to perform work

of any kind on or with the truck.

Prohibition of use by unauthorised

persons

The driver is responsib

working hours. He must n

rised persons to operat

When leaving the truck, the driver must secure

it against unauthorised use, e.g. by pulling out

the key.

le for the truck during

ot allow unautho-

ethetruck.

26 1

74749 EN - 03/2017

Page 39

Safety 2

Essentials for safe operation

Essentials for safe operation

Insurance cover on company premises

In many cases, company premises are

restricted public traffic areas.

NOTE

The business liability insurance should be

reviewed to ensure that, in the event of any

damage caused in restricted public traffic

areas, there is insurance cover for the truck in

respect of third parties.

Changes and retrofitting

If the truck is used for work that is not listed

in the guidelines or in these instructions and

has to be converted or retrofitted accordingly,

you must note that any change to its structural

state can affect the handling and stability of

the truck, which in turn can lead to accidents.

You should therefore contact your service

centre beforehand.

Changes that will adversely affect stability,

load capacity and safety systems, among

other things, must not be made without the

manufacturer's approval.

Thetruckmayonlybeconvertedwithwritten

approval from the manufacturer. Approval

from the responsible authority must be obtained if necessary.

Changes to the brakes, steering, control

elements, circumferential view, equipment

variants and attachments must also not be

made without the prior written approval of the

manufacturer.

We warn against installing and using restraint

systems not approved by the manufacturer.

749 EN - 03/2017 27

174

Page 40

2 Safety

Essentials for safe operation

DANGER

Risk of injury!

Even when using an approved restraint system,

there is some residual risk that the driver might be

injured if the truck tips over. Thisrisk of injury can be

reduced through the combined use of the restraint

system and the seat belt. In addition, the seat belt

protects against the consequences of rear-end

collisions and falling off a ramp.

– Use the seat belt too.

When carrying out welding work on the

truck, it is essential that the battery and all

connections to the electronic control cards are

disconnected. Contact your service centre.

DANGER

If the truck is not equipped with an overhead guard,

there is a risk to the driver's life, as he may be struck

by a load falling from a lift height of 1800 mm or

greater.

Operation of the forklift truck without an overhead

guard is prohibited with a lift height greater than

1800 mm.

– For lift heights of 1800 mm and greater, only use

trucks with on overhead guard

In the event that the manufacturer goes into

liquidation and the company is not taken

over by another legal person, the operating

company can make changes to the truck.

To do so, the operating company must fulfil

the following prerequisites:

Construction documents, test documents

and assembly instructions associated with

the change must be archived and remain

accessible at all times.

Check that the capacity rating plate, decal information, hazard warnings and the operating

instructions are consistent with regard to the

changes and modify if necessary.

The change must be designed, checked

and implemented by a design office that

specialises in industrial trucks in accordance

with the standards and directives valid at the

time the changes are made.

Decal information with the following data must

be permanently affixed to the truck so it is

clearly visible:

28 1

74749 EN - 03/2017

Page 41

Safety 2

Essentials for safe operation

– Type of change

– Date of change

– Name and address of the company

menting the change.

imple-

Changes to the overhead gua

rd and

roof loads

DANGER

In the event of the overhead guard failing due to

a falling load or the truck tipping over, there are

potentially fatal consequences for the driver. There

isarisktolife!

Welding and drilling on the overhead guard changes the material characteristics and the structural

design of the overhead guard. Excessive forces

caused by falling loads or the truck tipping over may

result in buckling of the modified overhead guard

andnoprotectionforthedriver.

– Do not perform welding on the overhead guard.

– Do not perform drilling on the overhead guard.

CAUTION

Heavy roof loads damage the overhead guard!

To ensure the stability of the overhead guard at

all times, a roof load may only be mounted on the

overhead guard if the structural design has been

tested and the manufacturer has given approval.

– Seek advice from the authorised service centre

for the mounting of roof loads.

Warning regarding non-original parts

Original parts, attachments and accessories

are specially designed for this truck. We

specifically draw your attention to the fact that

parts, attachments and accessories supplied

by other companies have not been tested and

approved by STILL.

749 EN - 03/2017 29

174

Page 42

2 Safety

Essentials for safe operation

CAUTION

Installation and/or use of such products may therefore have a negative impact on the design features

of the truck and thus impair active and/or passive

driving safety.

We recommend that you obtain approval from the

manufacturer and, if necessary, from the relevant

regulatory authorities before installing such parts.

The manufacturer accepts no liability for any damage caused by the use of non-original parts and

accessories without approval.

Damage, defects and misuse of safety systems

Damage or other defects on the truck or

attachment must be reported to the supervisor

or responsible fleet manager immediately so

that they can have the defect rectified.

Trucks and attach

or safe to drive ma

been properly re

Do not remove or deactivate safety systems

and switches.

Fixed set values may only be changed with the

approval of the manufacturer.

Work on the electric

a radio, additional

permitted with the

approval. All elec

must be documented.

Even if they are removable, roof panels may

not be removed, as they are designed to

protect against small falling objects.

ments that are not functional

y not be used until they have

paired.

al system (e.g. connecting

headlights etc.) is only

manufacturer's written

trical system interventions

Tyres

DANGER

Risk to stability!

Failure to observe the following information and

instructions can lead to a loss of stability. The truck

may tip over, risk of accident!

30 1

74749 EN - 03/2017

Page 43

Safety 2

Essentials for safe operation

Thefollowingfactorscanleadtoalossof

stability and are therefore prohibited:

• Different tyres on the same axle, e.g.

pneumatic tyres and superelastic tyres

• Tyres not approved by the manuf

• Excessive tyre wear

• Tyres of inferior quality

• Changing rim wheel parts

• Combining rim wheel parts from different

manufacturers

The following rules must be observed to

ensure stability:

• Only use tyres with equal and permitted

levels of wear on the same axle

• Only use wheels and tyres o

on the same axle, e.g. only

tyres

• Only use wheels and tyres approved by the

manufacturer

• Only use high-quality products

Wheels and tyres approv

facturer can be found on

If other wheels or tyres

thorisation from the ma

obtained beforehand.

– Contact the authorised service centre on

this matter.

When changing wheels or tyres, always

ensure that this does not cause the truck to

tilt to one side (e.g. always replace righthand and left-hand wheels at the same

time). Changes must only be made following

consultation with the manufacturer.

If the type of tyre used on

for example from super

matic tyres, the load dia

accordingly.

– Contact the authorised service centre on

this matter.

ed by the manu-

the spare parts list.

aretobeused,au-

nufacturer must be

an axle is changed,

elastic tyres to pneugram must be changed

acturer

f the same type

superelastic

749 EN - 03/2017 31

174

Page 44

2 Safety

Essentials for safe operation

Medical equipment

WARNING

Electromagneticinterferencemayoccuron medical

devices!

Only use equipment that is sufficiently protected

against electromagnetic interference.

Medical equipment, such as pacemakers or

hearing aids, may not work properly when the

truck is in operation.

– Ask your doctor or the manufacturer of

the medical equipment to confirm that the

medical equipment is sufficiently protected

against electromagnetic interference.

Exercise caution when handling gas springs and accumulators

WARNING

Gas springs are under high pressure. Improper

removal results in an elevated risk of injury.

For ease of operation, various functions on the

truck can be supported by gas springs. Gas springs

are complex components that are subject to high

internal pressures (up to 300 bar). They may under

no circumstances be opened unless instructed to

do so, and may be installed only when not under

pressure. If required, the authorised service centre

will depressurise the gas spring in accordance with

the regulations before removal. Gas springs must

be depressurised before recycling.

– Avoid damage, lateral forces, buckling, tempe-

ratures over 80°C and heavy contamination.

– Damaged or defective gas springs must be

changed immediately.

– Contact the authorised service centre.

WARNING

Accumulators are under high pressure. Improper

installation of an accumulator results in an elevated

risk of injury.

Before starting work on the accumulator it must be

depressurised.

– Contact the authorised service centre.

32 1

74749 EN - 03/2017

Page 45

Safety 2

Essentials for safe operation

Length of the fork arms

DANGER

Risk of accident due to the incorrect selection of

fork arms!

– The fork arms must match the depth of the load.

If the fork arms are too short, the load may

fall off the arms after it has been picked up.

In addition, be aware that the load centre of

gravity may shift as a result of dynamic forces,

such as braking. A load that is otherwise

resting safely on the fork arms may move

forwards and fall.

If the fork arms are too long, they can catch

on loading units behind the load that is to be

picked up. These other loading units then fall

over when the load is raised.

– For help with selecting the correctfork arms,

contact the authorised service centre.

749 EN - 03/2017 33

174

Page 46

2 Safety

Residual risk

Residual risk

Residual dangers, residual risks

Despite careful working and compliance with

standards and regulations, the occurrence

of other risks when using the truck cannot be

entirely excluded.

The truck and all other system components

comply with current safety requirements.

Nevertheless, even when the truck is used

for its proper purpose and all instructions

are followed, some residual risk cannot be

excluded.

Even beyond the narrow dan

truck itself, a residual r

Persons in this area aroun

exercise a heightened deg

so that they can react imme

of any malfunction, incid

WARNING

All persons that are in the vicinity of the truck

must be instructed regarding these risks that arise

through use of the truck.

In addition, we draw attention to the safety regulations in these operating instructions.

ger areas of the

isk cannot be excluded.

d the truck must

ree of awareness,

diately in the event

ent or breakdown etc.

Risks can include:

• Escape of consumables due to leakages,

rupture of lines and containers etc.

• Risk of accident when driving over difficult

ground such as gradients, smooth or

irregular surfaces, or with poor visibility

etc.

• Falling, tripping etc. when moving on

the truck, especially in wet weather, with

leaking consumables or on icy surfaces

• Fire and explosion risks due to batteriesand

electrical voltages

• Human error resulting from failure to

observe the safety regulations,

• Unrepaired damage or defective and worn

components,

• Insufficient maintenance and testing

• Use of incorrect consumables

• Exceeding test intervals

34 1

74749 EN - 03/2017

Page 47

Safety 2

Residual risk

The manufacturer is not held responsible for

accidents involving the truck caused by the

failure of the operating company to comply

with these regulations either intentionally or

carelessly.

Stability

The stability of the truck has been tested to the

latest technological standards and is guaranteed provided that the truck is used properly

and according to its intended purpose. These

standards only take into account the dynamic

and static tipping forces that can arise during

specified use in accordance with the operating rules and intended purpose. However, the

danger of exceeding the moment of tilt due to

improper use or incorrect operation and losing

stability can never be excluded.

Thelossofstabilitycanb

imised by the following ac

– Always secure the load against slipping,

e.g. by lashing.

– Always transport unstable loads in suitable

containers.

– Always drive slowly when

– Drive with the load lowered.

– Even with sideshifts, align the load as

centrally as possible with the truck and

transport in this position.

– Avoid turning and diagon

slopes or gradients.

– Never have the load facing downhill when

travelling on slopes or gradients.

– Pick up only loads of the approved width.

– Always take great care wh

suspended loads.

– Do not drive over ramp edges or steps.

e avoided or mintions:

cornering.

ally driving across

en transporting

Special risks associated with using the truck and attachments

Approval from the manufacturer and attachment manufacturer must be obtained each

749 EN - 03/2017 35

174

Page 48

2 Safety

Residual risk

time the truck is used in a manner that falls

outside the scope of normal use, and in cases

where the driver is not certain that he can use

the truck correctly and without the risk of accidents.

36 1

74749 EN - 03/2017

Page 49

Safety 2

Residual risk

749 EN - 03/2017 37

174

Page 50

2 Safety

Residual risk

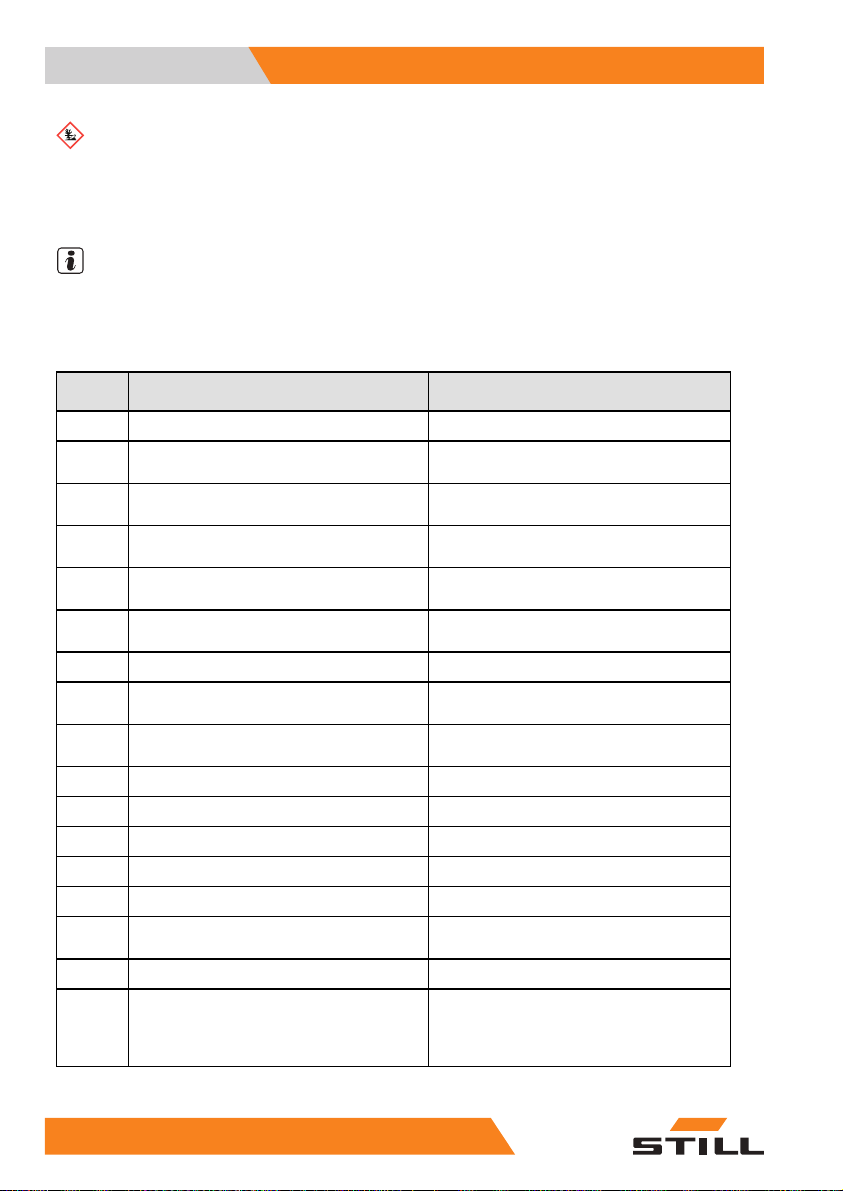

Overview of hazards and countermeasures

NOTE

This table is intended to help evaluate the

hazards in your facility and applies to all drive

types. It does not claim to be complete.

– Observe the national regulations for the

country in which the truck is being used.

Hazard Measure

Truck equipment does

not comply with local

regulations

Lackofskillsand

qualification of driver

Usage by unauthorised

persons

Truck not in a safe

condition

Risk of falli

using working

platforms

Impaired visibility due

to load

Contamination of

respiratory air

ng when

Test

Driver training (sit-on

and stand-on)

Access with key only

for authorised persons

Recurrent testing and

rectification of defects

Compliance wi

national regul

(different nat

Resource planning

Assessment of diesel

exhaust gases

Assessment of LPG

exhaust gases

th

ations

ional laws)

Check note

√ Complete

- Not applicable

O If in doubt, consult

O BGG 925

O

O German Ordinance on

O German Ordina

O German Ordi

O

O German threshold limit

Notes

competent factory

inspectorate or

employers' liability

insurance association

VDI 3313 driver permit

Industrial Safety and

Health (BetrSichV)

nce

on Industria

and Health (B

and employer's

insurance assoc

Industri

Health (B

Techn

for Ha

Sub

554

Ord

afety and Health

S

BetrSichV)

(

values list (MAK-Liste)

and the German

Ordinance on Industrial

Safety and Health

(BetrSichV)

l Safety

etrSichV)

liability

iations

nance on

al Safety and

etrSichV)

ical Regulations

zardous

stances (TRGS)

and the German

inance on Industrial

38 1

74749 EN - 03/2017

Page 51

Safety 2

Residual risk

Hazard Measure

Impermissible usage

(improper usage)

When fuelling

a) Diesel Note the German

b) LPG Note German Social

Issuing of operating

instructions

Written notice of

instruction to driver

Note the German

Ordinance on

Industrial Safety and

Health (BetrSichV),

the operating

instructions and the

German Engineering

Federation (VDMA)

rules

Ordinance on

Industrial Safety and

Health (BetrSichV),

the operating

instructions and the

German Engineering

Federation (VDMA)

rules

Accident Insurance

(DGUV) regulation

D34, the operating

instructions and the

German Engineering

Federation (VDMA)

rules

Check note

√ Complete

- Not applicable

O German Ordinance on

O German Ordinance on

O

O

O

Notes

Industrial Safety and

Health (BetrSichV) and

German Health and

labour protection law

(ArbSchG)

Industrial Safety and

Health (BetrSichV) and

German Health and

labour protection law

(ArbSchG)