Page 1

RX 60 Technical Data

Electric Forklift Truck

@

RX 60-16

RX 60-18

RX 60-20

Page 2

RX 60-16/20 Electric Forklift Truck

Non-stop action

This specification sheet to VDI Guideline 2198 only gives the technical figures for the standard

truck. Different tyres, other masts, additional equipment etc. could give different figures.

1.1 Manufacturer STILL STILL STILL

1.2 Manufacturer’s type designation RX 60-16 RX 60-18 RX 60-20

Manufacturer model number 6311 6313 6315

1.3 Drive Electric Electric Electric

1.4 Operation Seated Seated Seated

1.5 Nominal load capacity/load Q kg 1600 1800 2000

1.6 Load centre distance c mm 500 500 500

Distinguishing marks

1.8 Load spacing x mm 355 355 365

1.9 Wheel base y mm 1448 1448 1448

2.1 Empty weight (incl. battery) kg 3479 3479 3517

2.2 Axle loading, laden front/rear kg 4175/904 4495/784 4873/644

Weights

2.3 Axle loading, unladen front/rear kg 1615/1864 1615/1864 1569/1858

3.1 Tyres Superelastic Superelastic Superelastic

3.2 Tyre size front mm 18 x 7-8 200/50-10 200/50-10

3.2 Tyre size rear mm 16 x 6-8 16 x 6-8 16 x 6-8

3.5 Wheels, number (x = driven) front/rear 2x/2 2x/2 2x/2

Tyres/chassis

3.6 Track width front/rear b

10/b11

mm 932/865 942/865 942/866

4.1 Tilt of mast/fork carriage forward/backward α/β ° 3/8 3/8 3/8

4.2 Height mast lowered h

4.3 Free lift h

4.4 Lift

1

4.5 Height mast extended h

4.7 Height above protected roof (cabin) h

4.8 Seat height in terms of SIP h

4.12 Coupling height h

4.19 Total length l

4.20 Length including fork backs l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 40/80/800 40/80/800 40/80/800

Basic dimensions

4.23 Fork carriage ISO 2328, class/form A, B ISO ll/A ISO ll/A ISO ll/A

4.24 Fork carriage width b

4.31 Ground clearance under mast m

4.32 Ground clearance centre wheel base m

4.34.1 Working aisle width with pallet 1000 x 1200 crossways A

4.34.2 Working aisle width with pallet 800 x 1200 lengthways A

4.35 Turning radius W

4.36 Smallest pivoting distance b

1

2

h

3

4

6

7

10

1

2

1

3

1

2

st

st

a

13

mm 2160 2160 2160

mm 150 150 150

mm 3230 3230 3150

mm 3873 3873 3725

mm 2240 2240 2240

mm 1173 1173 1173

mm 460/350 460/350 460/350

mm 2908 2908 2918

mm 2108 2108 2118

mm 1099 1138 1138

mm 980 980 980

mm 90 90 90

mm 123 123 123

mm 3439 3439 3449

mm 3638 3638 3648

mm 1883 1883 1883

mm 538.5 538.5 538.5

5.1 Driving speed laden/unladen km/h 20/20 20/20 20/20

5.2 Lifting speed laden/unladen m/s 0.53/0.62 0.52/0.62 0.45/0.58

5.3 Lowering speed laden/unladen m/s 0.51/0.47 0.52/0.48 0.53/0.49

5.5 Drawbar pull laden/unladen N 2775/2916 2611/2916 2602/2905

5.6 Max. drawbar pull laden/unladen N 9967/9789 9983/9789 90663/9785

5.7 Gradeability laden/unladen % 11.6/17.0 10.7/17.0 10.2/16.8

5.8 Max. gradeability laden/unladen % 20.2/26.0 19.4/26.0 18.0/26.3

Performance data

5.9 Acceleration time laden/unladen s 4.1/4.0 4.3/4.1 4.3/4.2

5.10 Service brake

Electric/

mechanical

Electric/

mechanical

6.1 Drive motor, output with S3 = 60 min kW 2 x 5.5 2 x 5.5 2 x 5.5

6.2 Lifting motor, output at 15 % ED kW 11 11 11

6.3 Battery according to DIN 43531/35/36 A, B, C, no DIN 43536 A DIN 43536 A DIN 43536 A

6.4 Battery voltage U V 80 80 80

6.4.1 Battery capacity K

Electric engine

6.5 Battery weight kg 1238 1238 1238

5

Ah 420 (-480) 420 (-480) 420 (-480)

6.6 Energy consumption 60 VDI combustion cycles/hour kWh/h 4.4 4.5 4.7

10.1 Working pressure for accessory equipment bar 250 250 250

10.2 Oil volume for accessory equipment l/min 30 30 30

10.7 Sound pressure level L

Miscellaneous

1

The nominal lift stated includes the tyre deflection and tyre diameter tolerances

2

No cab; different values with cab

Human vibrations: acceleration in accordance with EN 13059 m/s² <0.7 <0.7 <0.7

10.8 Trailer coupling, item/DIN type Bolt Bolt Bolt

(operator’s position)

pAZ

2

dB(A) <70 <70 <70

Electric/

mechanical

2

Page 3

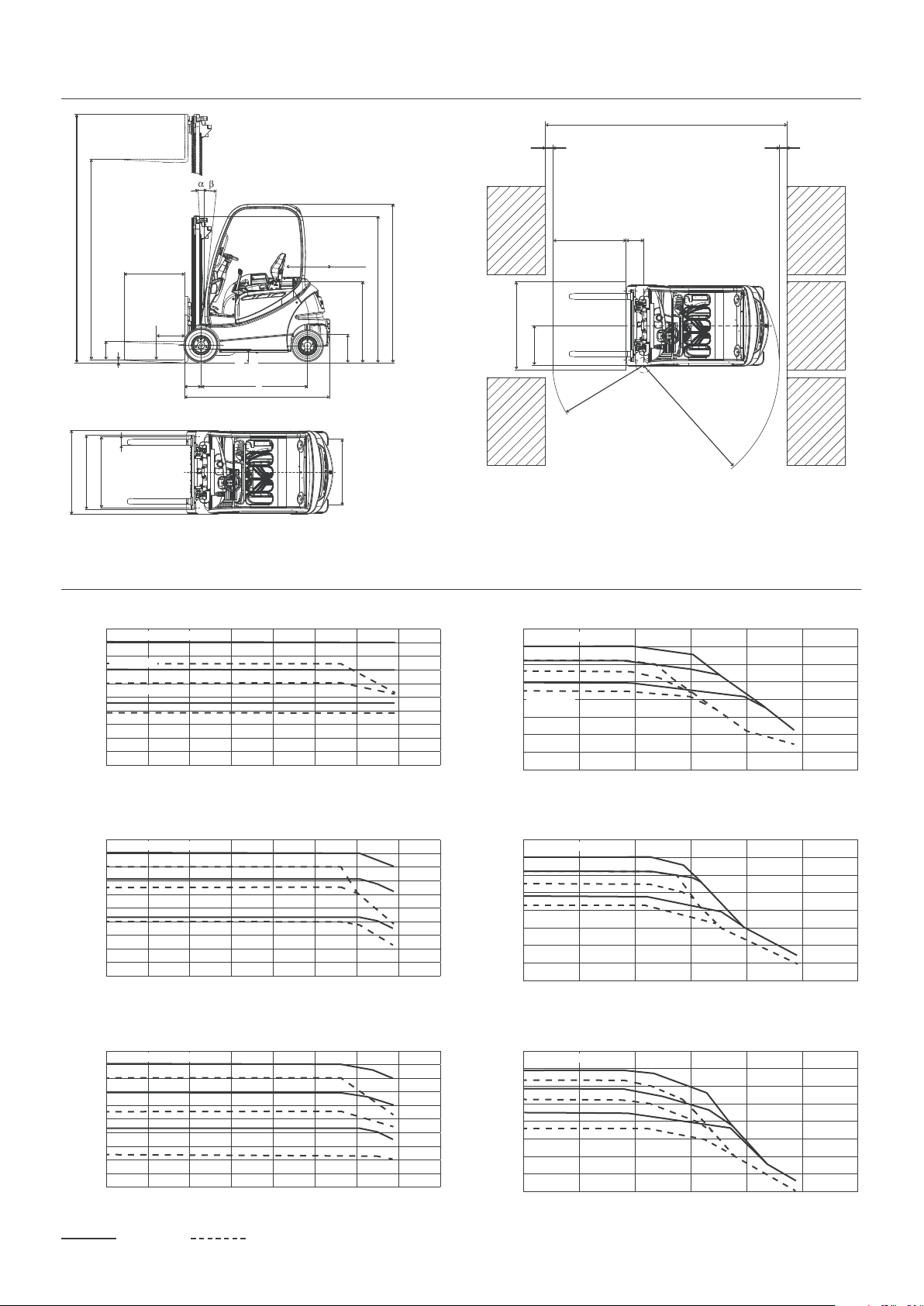

RX 60-16/20 Electric Forklift Truck

Technical Drawings

A

st

100100

4

h

3

h

2

h

l

Q

c

1

s

x

m2m

y

l

2

Side view

e

1

10

b3b

b

Top view

Basic Load Capacities

Load capacity RX 60-16 Telescopic/HiLo mast

Load centre c = 500 mm

1600

1500

c = 600 mm

1400

1300

c = 800 mm

1200

110 0

1000

Load capacity in kg

900

800

700

up to

2500 3000 3500 4000 4500 5000 55002000

2000

Lift height in mm

Seat

adjustable

10

h

l

6

6

1

h

h

7

h

12

b

13

b

R

W

a

Sizes relate to vertically

aligned mast

11

b

Top view

Load capacity RX 60-16 Triplex mast

Load centre c = 500 mm

1600

1400

c = 600 mm

1200

1000

c = 800 mm

800

Load capacity in kg

600

400

200

up to

3000

4000 5000 6000 7000 80003000

Lift height in mm

Load capacity RX 60-18 Telescopic/HiLo mast

Load centre c = 500 mm

1800

1700

c = 600 mm

1600

1500

c = 800 mm

1400

1300

1200

Load capacity in kg

110 0

1000

900

up to

2500 3000 3500 4000 4500 5000 55002000

2000

Lift height in mm

Load capacity RX 60-20 Telescopic/HiLo mast

Load centre c = 500 mm

2000

1900

1800

1700

c = 600 mm

1600

1500

1400

c = 800 mm

Load capacity in kg

1300

1200

900

up to

2500 3000 3500 4000 4500 5000 55002000

2000

Fork carriage Side shift

Lift height in mm

Load capacity RX 60-18 Triplex mast

Load centre c = 500 mm

1800

1600

c = 600 mm

1400

1200

c = 800 mm

1000

Load capacity in kg

800

600

400

up to

3000

4000 5000 6000 7000 80003000

Load capacity RX 60-20 Triplex mast

Load centre c = 500 mm

2000

1800

c = 600 mm

1600

1400

c = 800 mm

1200

Load capacity in kg

1000

800

600

up to

3000

3000

4000 5000 6000 7000 8000

Lift height in mm

Lift height in mm

3

Page 4

4

RX 60-16/20 Electric Forklift Truck

Mast Tables

Maximum distance that can be driven in 60 minutes.

Example: With a load of 2,000kg and an incline of 10 %, a RX60-20 can drive a distance of 350 m up to ten times in an hour.

Dry rough concrete = coefficient of friction 0.80

Battery: Standard as per data sheet

Speed is variable

Gradient Maximum distance in m

RX 60-16 RX 60-18 RX 60-20

17 % 1689 1577 1420

10 % 3767 3704 3500

5 % 10551 10452 9987

2.8 % 14068 13798 13438

26 % 1530 1556 1582

17 % 3259 3304 3314

9 % 10261 10312 10351

3 % 19325 19453 19650

Without load

With load

Gradients

1

Fork carriage ISO 2A standard

2

Deviations depending on 4/6-stop fork carriages

RX 60-16

Telescopic mast

Nominal lift h

3

mm 2830 3030 3230 3530 3930 4230 4730 5430

Overall height h

1

mm 1960 2060 2160 2310 2510 2660 2910 3260

Free lift

1, 2

h2/h

5

mm 150 150 150 150 150 150 150 150

Maximum height

1, 2

h

4

mm 3473 3673 3873 4173 4573 4873 5373 6073

Tilt of mast/fork carriage forward/backward α/β ° 3/8

Fork lock-in position centre–centre mm 216 / 368 / 445 / 521 / 673 / 760

Tyres front/rear 18 x 7-8 / 16 x 6-8

Track front/rear b

10/b11

mm 932 / 865 990 / 865

Maximum width b

1

mm 1099 1188

RX 60-18

Telescopic mast

Nominal lift h

3

mm 2830 3030 3230 3530 3930 4230 4730 5430

Overall height h

1

mm 1960 2060 2160 2310 2510 2660 2910 3260

Free lift

1, 2

h2/h

5

mm 150 150 150 150 150 150 150 150

Maximum height

1, 2

h

4

mm 3473 3673 3873 4173 4573 4873 5373 6073

Tilt of mast/fork carriage forward/backward α/β ° 3/8

Fork lock-in position centre–centre mm 216 / 368 / 445 / 521 / 673 / 760

Tyres front/rear 200/50-10 // 16 x 6-8

Track front/rear b

10/b11

mm 942 / 865 990 / 865

Maximum width b

1

mm 1138 1188

RX 60-20

Telescopic mast

Nominal lift h

3

mm 2750 2950 3150 3450 3850 4150 4650 5350

Overall height h

1

mm 1960 2060 2160 2310 2510 2660 2910 3260

Free lift

1, 2

h2/h

5

mm 150 150 150 150 150 150 150 150

Maximum height

1, 2

h

4

mm 3325 3525 3725 4025 4425 4725 5225 5925

Tilt of mast/fork carriage forward/backward α/β ° 3/8

Fork lock-in position centre–centre mm 216 / 368 / 445 / 521 / 673 / 760

Tyres front/rear 200/50-10 // 16 x 6-8

Track front/rear b

10/b11

mm 942 / 865 990/865

Maximum width b

1

mm 1138 1188

5

External LED lighting for excellent light conditions

Comfortable and high-quality driver’s cabIlluminated clipboard makes documents easily legible

Driver information available centrally (e. g. display of energy consumption)

Detailed Photos

HiLo mast Triplex mast

2975 3175 3375 3575 3975 4320 4620 4920 5220 5620 6070 6820 7870

1960 2060 2160 2260 2460 1960 2060 2160 2260 2460 2610 2860 3210

1362 1462 1562 1662 1862 1362 1462 1562 1662 1862 2012 2262 2612

3593 3793 3993 4193 4593 4938 5238 5538 5838 6238 6688 7438 8488

3/6 3/6

216 / 368 / 445 / 521 / 673 / 760 216 / 368 / 445 / 521 / 673 / 760

18 x 7-8 / 16 x 6-8 18 x 7-8 / 16 x 6-8

932 / 865 932 / 865 990 / 865

1099 1099 1188

HiLo mast Triplex mast

2875 3075 3275 3475 4143 4170 4470 4770 5070 5470 5920 6670 7720

1960 2060 2160 2260 2460 1960 2060 2160 2260 2460 2610 2860 3210

1312 1412 1512 1612 1812 1312 1412 1512 1612 1812 1962 2212 2562

3543 3743 3943 4143 4543 4838 5138 5438 5738 6138 6588 7338 8388

3/6 3/6

216 / 368 / 445 / 521 / 673 / 760 216 / 368 / 445 / 521 / 673 / 760

200/50-10 // 16 x 6-8 200/50-10 // 16 x 6-8

942 / 865 942 / 865 990 / 865

1138 1138 1188

HiLo mast Triplex mast

2870 3070 3270 3470 3870 4165 4465 4765 5065 5665 6115 6865 7915

1960 2060 2160 2260 2460 1960 2060 2160 2260 2460 2610 2860 3210

1405 1505 1605 1705 1905 1405 1505 1605 1705 1905 2055 2305 2655

3445 3645 3845 4045 4445 4755 5055 5355 5655 6255 6705 7455 8505

3/6 3/6

216 / 368 / 445 / 521 / 673 / 760 216 / 368 / 445 / 521 / 673 / 760

200/50-10 // 16 x 6-8 200/50-10 // 16 x 6-8

942 / 865 943 / 865 990 / 865

1138 1138 1188

Page 5

RX 60-16/20 Electric Forklift Truck

Non-stop action

Display showing remaining power and current charge status

Blue-Q energy saving mode

Optimum availability due to convenient and safe lateral battery

change

With a lifting capacity of 1.6 to 2.0 tonnes, the popular RX60 forklift

truck models are now better than ever: following a comprehensive

overhaul, this smart electric forklift truck now sets new standards

when it comes to transporting heavy goods weighing between 1.6 and

2.0 tonnes. Never before has it been easier to keep an eye on energy

consumption. A display shows you just how many hours of use the

truck has left using the current driving programme.

Extensive Equipment

Power

■

Can lift up to two tonnes with a load centre of 500mm

■

Full power: maintenance-free rotary current drive with 80 Volt

technology

■

Move goods effectively: driving speed of up to 20km/h

■

Sufficient energy for multi-shift operations: high battery capacity and

lateral battery replacement

■

Perfect performance control: display shows truck’s remaining usage

time using the current driving programme

Precision

The RX60 is a fantastic all-rounder in tight working areas, both over

short and long distances, and is ideally suited for combined indoor

and outdoor use, making it the perfect forklift truck for a range of

applications. This includes drinks, fruit and vegetable storage in the

food and drinks industry, as well as applications in printing firms,

freight carrier receipt and dispatch of goods and multi-shift operations

in the car industry, e. g. for the provision of equipment on production

lines.

■

Feel at home: standard, easy-to-use operating concept across the

whole RX product line

■

Comfortable: simple and safe entry and exit

■

Choose from a range of individual control options: multi-lever, mini-

lever, Fingertip or Joystick 4Plus

Compactness

■

Ideal for use in small spaces: compact truck dimensions and extreme

manoeuvrability allow for operation in narrow aisles

■

Narrow truck frames enable efficient block forklifting

■

Outstanding driving stability when turning

■

Driving programmes allow the user to switch between maximum

handling performance or optimum efficiency

■

Adjustable to suit every task: speed, acceleration and braking can all

be individually set

■

Sensitive operation and continuous control of lifting speed: the latest

proportional valve technology

■

Intuitive one-pedal control

■

Precise load handling: driver’s seat and steering column set to one

side giving optimal view past loads

Ergonomics

■

Spacious, comfortable driver’s cab that can be individually set up

and offers numerous storage compartments

■

Even more comfortable: premium driver’s seat option provides

perfect seat ergonomics

6

Safety

■

Perfect all-round view: large viewing window allows vision on all sides,

including the overhead guard

■

Optimum safety thanks to the truck’s low centre of gravity

Environmental Responsibility

■

Low operating costs: low energy consumption and long maintenance

intervals (1000 operating hours)

■

Emission-free drive

■

Blue-Q efficiency mode allows energy savings of up to 20 % at the

touch of a button with no loss of performance

■

Over 95 % of all installed materials are recyclable

Page 6

RX 60-16/20 Electric Forklift Truck

Equipment Variants

Safe and ergonomic driver’s seat, with a large step, spacious footwell, excellent all-round visibility and optimal

control element lay-out

Drive-in overhead guard with Makrolon roof

Weather-protected, canvas or full cab

Tinted front windscreen, roof window made of either green-tinted or Makrolon laminated safety glass,

windscreen wiper and wash system

Low operating costs due to low energy consumption

Sunshade and sun blind

Roof liner with interior lighting

Driver’s seat with leatherette cover

Textile cover, airsprung, lumbar support, extra-wide seat pad, large suspension travel, height-adjustable back

extension, heated seat

One-pedal control, switching the direction of travel using the hydraulic control

Double-pedal control

Driver’s seat

Splash-proof operating unit featuring display and function buttons

Grab handle on protective roof

Cold storage version, display and hydraulic oil can be used up to –30 °C

Electrical heating 1500 W incl. defrosting blaster for front windscreen and footwell

Document pocket on the back of the driver’s seat

Built-in storage and drink holder

Horizontal spring plate for driver’s seat to minimise human vibrations

Adjustable roof window for instant cabin ventilation

Seat can be rotated 20° to the right

Pad with clipboard, removable

Radio/MP3 player with USB connection

Free view mast available in telescopic, HiLo and triplex versions

Load backrest

Mast vertical position

Hydraulic accumulator in the lifting cylinder to attenuate pressure peaks in the hydraulic system

Mast

Bellows protect the tilt cylinder from dust and moisture

Stroke shut-off via push button

Fork wear protection

Superelastic/SIT system

Superelastic/natural colour/SIT system Superelastic/Continental/SIT system Superelastic/

Tyres

anti-static/SIT system

Multi-lever operation

Mini-lever with armrest, 2, 3 or 4 levers, Fingertip or Joystick 4Plus

Noise-optimised hydraulic pump

Custom parametrisation of hydraulic functions

Hydraulics

Proportional valve technology for high-precision movements

High handling control due to powerful rotary current drive

Blue-Q energy saving mode

Display showing energy consumption and remaining driving time based on current charge

Drive

Maintenance-free engines for driving, steering and lifting

Operating hours counter only operational with drive and lifting motor

5 driving programmes

Wear-free disc brakes that run in an oil bath

Low operating and maintenance costs due to low energy consumption, energy recovery during braking, wear-

free electrical braking, enclosed disc brakes

Energy recovery when braking

Brake

Mechanical parking brake

Electromagnetic parking brake, parking assistant for safe parking of the truck

Protective grille roof

Headlights and LED lighting performance

Forklift has a low centre of gravity and steering axle with high self-aligning bearing for optimum levels of safety

Panoramic mirror

STILL Safety Light warning device, illuminated blue

Assistance system (ATC – Assistance Truck Control): for safe exit/parking and seat belt control

Assistance system (ATC – Assistance Truck Control): speed limiter controlled by steering angle

Assistance system (ATC – Assistance Truck Control): speed limited when fork carrier is raised

Safety

Driver-adjusted speed limiter

Direction can be changed both left- and right-handed via mini-console

Load measuring with ±3 % precision

EasyBelt restraint system for quick and safe fastening and unfastening

Sauermann type HRS-E/ERS restraint system or IWS restraint system with strap opening on the left

FleetManager: access authorisation, shock detection, reports

RX 60-16 RX 60-18 RX 60-20

●●●

○○○

○○○

○○○

●●●

○○○

○○○

●●●

○○○

●●●

○○○

●●●

●●●

○○○

○○○

○○○

●●●

○○○

○○○

○○○

○○○

○○○

○○○

○○○

○○○

○○○

○○○

○○○

○○○

●●●

○○○

●●●

○○○

●●●

○○○

○○○

●●●

●●●

●●●

●●●

●●●

●●●

●●●

●●●

●●●

●●●

○○○

○○○

○○○

●●●

○○○

○○○

○○○

○○○

○○○

●●●

○○○

○○○

○○○

○○○

○○○

▯ Standard ○ Optional ─ Not available

7

Page 7

@

STILL Materials Handling Ltd

Aston Way

Leyland Preston

PR26 7UX

Tel.: +44 (0)8456036827

STILL Materials Handling Ltd

Jacks Way

Hill Barton

Business Park

Clyst St. Mary

Exeter

EX5 1FG

Tel.: +44 (0)345 603 6827

info@still.co.uk

For further information please visit:

www.still.co.uk

STILL is certified in the following

areas: Quality management,

occupational safety, environmental

protection and energy management.

RX 60 16 20 EN 01/17 Subject to technical modifications.

Loading...

Loading...