Page 1

Original instructions

Reach trucks

FM-X, FM-X N, FM-X W,

FM-X EW

FM-X-10

FM-X-12

FM-X-14

FM-X-17

FM-X-20

FM-X-22

FM-X-25

1900 1901 1902 1903 1904

1905 1906 1907 1908 1909

1910 1914 1915 1916 1917

1918 1919 1920 1921 1922

50988078001 EN - 04/2015

Page 2

Page 3

Table of contents

1 Foreword

Your truck .......................................................... 2

General ............................................................ 2

CElabelling ......................................................... 2

EC declaration of conformity in accordance with Machinery Directive ............... 3

Information about the docum

Documentationscope ................................................. 4

Issuedateandtopicalityoftheoperatinginstructions ........................... 5

Copyright and trademark ri

Explanation of information symbols used . . ................................. 5

Listofabbreviations ................................................... 6

Definingdirections .................................................... 9

Schematicviews .................................................... 10

Environmental considerations .......................................... 11

Packaging ......................................................... 11

Disposal of components and batteries ..................................... 11

entation ...................................... 4

ghts ........................................... 5

2 Introduction

Using the truck ...................................................... 14

Proper usage ....................................................... 14

Impermissibleuse ................................................... 14

Placeofuse ........................................................ 15

Parking in temperatu

Usingworkingplatforms ............................................... 16

Residual risk ....................................................... 17

Residual dangers, r

Specialrisksassociatedwithusingthetruckandattachments ................... 18

Overviewofhazardsandcountermeasures ................................. 20

Danger to employees

resbelow-10°C ..................................... 15

esidual risks ......................................... 17

................................................. 22

g

3Safety

Definition of terms used for responsible persons ............................. 26

Operatingcompany .................................................. 26

Specialist .......................................................... 26

Drivers ........................................................... 27

Basic principles for safe operation ....................................... 29

Insurance cover

Changes and retrofitting ............................................... 29

Modifications to the overhead guard and cabs ............................... 31

on company premises .................................... 29

988078001 [EN] I

50

Page 4

Table of contents

g

SafetyinformationforFM-XWide,ExtraWide(W,EW) ........................ 32

Warning regarding non-original parts ..................................... 32

Damage, defects and misuse of s

Tyres ............................................................. 33

Medicalequipment ................................................... 34

Exercise caution when handlin

Safety tests ........................................................ 35

Regularsafetyinspectionofthetruck ..................................... 35

Insulationtesting .................................................... 35

Safety regulations for handling consumables ............................... 36

Permissibleconsumables ............................................. 36

Oils .............................................................. 37

Hydraulicfluid ...................................................... 38

Batteryacid ........................................................ 39

Brakefluid ......................................................... 40

Disposalofconsumables .............................................. 41

Emissions ......................................................... 41

afetysystems .............................. 33

ggasspringsandaccumulators .................. 34

4Overviews

Overview .......................................................... 46

Overview of the driver’s compartment ..................................... 47

Operating devices and display elements ................................... 48

Display and operatin

Operatingdevicesforhydraulicandtractionfunctions ......................... 48

Joystick4Plus ...................................................... 49

Fingertip .......................................................... 50

Identification points .................................................. 51

Overview .......................................................... 51

Nameplate ......................................................... 52

Productionnumber .................................................. 53

gunit ............................................. 48

5 Operation

Checks and tasks to be carried out prior to commissioning ...................... 56

Visual inspecti

Fillingthewashersystem(variant) ....................................... 58

Checking the condition of the wheels and tyres . . . ........................... 59

Adjusting the MS

Electricaldriver’scompartmentadjustment(variant) .......................... 64

Adjustingthesteeringcolumn ........................................... 65

II

ons ................................................... 56

G65/MSG75driver’sseat ................................ 60

50988078001 [EN]

Page 5

Table of contents

Commissioning ..................................................... 65

Climbingintoandoutofthetruck ........................................ 65

Shelvesandcupholders .............................................. 67

Connecting the battery male connector .................................... 67

Enablingtruckfunctionsusingthefootswitchandseatswitch ................... 68

Unlocking the emergency off sw

Switchingonthekeyswitch ............................................ 70

AccessauthorisationwithPINcode(variant) ................................ 73

Entering truck operating da

Operating the signal horn .............................................. 79

Checkingthebrakesystemforcorrectfunction .............................. 79

Checking the steering syst

Checking the emergency off function ..................................... 81

Checking the "automatic tilting centre position" (variant) for correct function ......... 82

Setting the drive program

OPTISPEED - Continuously variable reduction in driving speed or hydraulic functions

(variant) ......................................................... 84

Driving ............................................................ 85

Safety regulations when

Roadways ......................................................... 88

Side chassis supports . ............................................... 90

Selecting the drive dir

Actuatingthedrivedirectionswitch,joystick4Plus ............................ 92

Actuating the drive direction switch, fingertip ................................ 92

Starting drive mode, si

Starting drive mode, dual-pedal version (variant) ............................. 94

Operatingtheservicebrake ............................................ 96

Applying the electro

Steering ...........................................................100

Lifting ............................................................102

Lifting system varia

Automaticliftcutout(variant) ...........................................103

Reach-lowerlock(variant) .............................................104

Automatic centre po

Liftmastversions ....................................................106

Malfunctionsinliftingmode ............................................107

Lifting system oper

Joystick4Plusliftingsystem ............................................109

Fingertip lifting system . ...............................................112

Load backrest (var

Changing the fork arms ...............................................114

ection ............................................ 91

ngle-pedal version . . ................................ 92

magnetic parking brake ................................ 97

nts ................................................102

sition(variant) .......................................105

atingdevices .........................................108

iant) ................................................114

itch ...................................... 70

taviathedisplayandoperatingunit .................. 74

emforcorrectfunction ............................ 81

me ............................................ 83

driving ......................................... 85

g

988078001 [EN] III

50

Page 6

Table of contents

g

Forkextension(variant) ...............................................117

Workingplatforms ...................................................118

Handling loads ......................................................119

Safety regulations when handing loads ....................................119

Beforepickingupaload ...............................................119

Picking up loads .....................................................121

Danger area .......................................................122

Transportingpallets ..................................................123

Transporting swinging load

Pickingupaload ....................................................125

Transporting loads ...................................................128

Setting down loads ...................................................130

Drivingonupwardanddownwardgradients ................................132

Drivingontolifts .....................................................132

Workingwithattachments

Fittingattachments ..................................................134

Releasingthepressurefromtheauxiliaryhydraulics ..........................136

General instructions fo

Controlling attachments (variant) using the joystick 4Plus (5th/6th hydraulic function)

...............................................................138

Controlling attachments (variant) with the fingertip (5th/6th hydraulic function) .......141

Operating the clamp loc

Operating the clamp locking mechanism (variant) with the fingertip switch ..........145

Pickingupaloadusingattachments ......................................146

Operating auxiliary e

Switchingtheworkingspotlights(variant)onandoff ..........................147

Clipboard (variant) ...................................................148

FleetManager (varia

Accident recorder (variant) . . . ..........................................148

Active Load Stabilisation ALS (variant) ....................................149

Camera/monitor syst

Loadmeasurement ................................................. . 150

Battery change frame (variant) ..........................................152

General . . .........................................................152

Safe handling ......................................................153

Load capacity ......................................................153

Area of application

Adjustingthetransferheight ............................................154

Lockingthebatterychangeframe ........................................154

Battery replaceme

ntarea ..............................................155

s ............................................124

.............................................134

rcontrollingattachments .............................137

king mechanism (variant) with a joystick 4Plus . ............143

quipment ..........................................147

nt) ................................................148

em(variant) ........................................150

...................................................153

IV

50988078001 [EN]

Page 7

Table of contents

Lift height preselector (variant) ..........................................156

General ......................................................... . . 157

Definitionofterms ...................................................157

AUTOMODEfunction ................................................ 158

Operatingtheliftheightpreselector .......................................161

Teach-in, general ....................................................165

Performingateach-in .................................................166

Cab operation (variant) ...............................................169

General information about t

Opening the cab door . . ...............................................170

Closingthecabdoor ............................................... . . 171

Emergency exit window in th

Cab operating devices . ...............................................172

Cabinteriorlighting(variant) ............................................173

Heating system in the cab (

Cold store application .................................................175

General ......................................................... . . 175

Areasofapplication ..................................................176

Batteryinthecoldstore ...............................................177

Description of the cold store equipment ....................................177

Warmingupthetruck ............................................... . . 178

Operating the display and operating unit ...................................178

Operating status displays on the display and operating unit .....................178

Blue-Q efficiency mode

Functional description . ...............................................180

SwitchingtheBlue-Qefficiencymodeonandoff .............................180

Fault displays ......................................................181

View on the display and operating unit .....................................181

Operating in special operating situations ...................................181

Transportation ......................................................181

Towing .......................................................... . 184

Crane loading ......................................................186

Procedure in emerg

Emergency shutdown . ...............................................190

Procedure if truck tips over .............................................191

Emergency lowerin

Handling the battery ..................................................192

Safety regulations when handling the battery ...............................192

General informat

Actuatingthebatterylock ..............................................197

iononbatteryreplacement ................................196

hecab .......................................169

ecab .......................................171

variant) .......................................174

...............................................180

encies .............................................189

g .................................................192

g

988078001 [EN] V

50

Page 8

Table of contents

g

Disconnecting the battery male connector ..................................199

Batteryreplacementusingacrane .......................................200

Changing the battery using the

Batterycommissioning ................................................211

Adjustingthebatterylock ..............................................211

Settingthebatterydata ...............................................213

Batterytransportwithcrane ............................................215

Maintainingthebattery ................................................216

Decommissioning ...................................................220

Parkingthetrucksecurely .............................................220

Shuttingdownandstoringthetruck ......................................222

Re-commissioning after sh

Cleaning ..........................................................224

Cleaning the truck ...................................................224

Cleaning load chains .................................................225

After cleaning .......................................................226

internal roller channel (variant) ...................205

utdown .......................................223

6 Maintenance

General maintenance information ........................................228

Personnel qualificati

Information for carrying out maintenance ..................................228

Maintenance-1000hours/year .........................................231

Maintenance - 3000 hou

Additional maintenance guidelines for using the truck in a cold store - 500 hours or

every12weeks ...................................................238

Orderingsparepartsandwearingparts ....................................239

Quality and quantit

Maintenancedatatable ...............................................240

Safety regulations for maintenance .......................................242

General informatio

Working on the hydraulic equipment ......................................242

Workingontheelectricalequipment ......................................242

Safetydevices ......................................................243

Setvalues .........................................................243

Liftingandjackingup .................................................243

Working at the fron

Servicing ..........................................................245

Checkingthebatterycondition,acidlevelandaciddensity ......................245

Maintaining whee

Checkingthehydraulicsystemforleaks ...................................248

ons ...............................................228

rs/everytwoyears .................................235

y of the required operating materials ........................239

n ..................................................242

tofthetruck ..........................................243

lsandtyres ...........................................246

VI

50988078001 [EN]

Page 9

Table of contents

Greasingtheliftmastandrollertracks .....................................249

Checking the battery change frame .......................................249

7 Technical data

Dimensions ........................................................252

VDI datasheet FM-X 10 (N), FM-X 12 (N)* ..................................253

VDI datasheet FM-X 14 (N), FM-X 17 (N)* ..................................257

VDI datasheet FM-X 20 (N, W

VDI datasheet FM-X 22* ...............................................264

VDI datasheet FM-X 25* ...............................................269

Wheels and tyres ....................................................272

,EW)* ......................................261

g

988078001 [EN] VII

50

Page 10

Page 11

1

Foreword

Page 12

1 Foreword

Your truck

Your truck

General

The truckdescribed inthese operating instructions corresponds to the applicable standards

and safety regulations.

The trucks have been fitted with state-of-theart technology. All that remains is to handle

the truck safely and maintain its functionality.

CE labelling

The manufacturer uses CE labelling to indicate that the truck complies with the standards

and regulations valid at the time of marketing.

This isconfirmed by the issued EC declaration

of conformity. The CE labelling is attached to

the nameplate.

An independent structu

to the truck can comprom

invalidating the EC de

The EC declaration of conformity must be

carefully stored and made available to the

responsible authorities.

ral change or addition

ise safety, thus

claration of conformity.

These operating instructions provide the

necessary information to do this. Read and

observe the information provided before

commissioning the truck. This will prevent

accidents and ensure that the warranty

remains valid.

25

0988078001 [EN]

CE-Symbol

Page 13

Foreword 1

Your truck

EC declaration of conformity in accordance with Machinery Directive

Declaration

STILL GmbH

Berzeliusstraße 10

D-22113 Hamburg Germany

We declare that the

Industrial truck

Model

according to these operating instructions

according to these operating instructions

conforms to the latest version of the Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC compliance declaration

STILL Gmb

.

H

988078001 [EN] 3

50

Page 14

1 Foreword

Information about the documentati

on

Information about the documentation

Documentation scope

• Operating instructions

• Operating instructions for attachments

(variant)

• Spare parts list

• VDMA rules for the proper use of industrial

trucks

These operating instructions describeall measures necessary for the safe operation and

proper maintenance of your truck in all possible variants available at the time of printing.

Special versions to meet customer requirements are documented in separate operating

instructions. If you have any questions,please

contact your authorised service centre.

Enter the production num

manufacturer from the na

provided:

Production number

...............................................

Year of manufacture

...................................................

Please quote the produ

technical enquiries.

Each truck comes with a set of operating

instructions. These instructions must be

stored carefully and must be available to the

driver and operating company atany time. The

storage location is specified in the "Overviews"

chapter.

If the operating instructions are lost, the

operator must obtain a replacement from the

manufacturer immediately.

The operating instr

spare parts list and

a spare part.

The personnel responsible for operating and

maintaining the equipment must be familiar

with these operating instructions.

The operating company must ensure that all

users have received, read and understood

these instructions.

ber and year of

meplate in the space

ction number during all

uctions are included in the

can be reordered there as

45

0988078001 [EN]

Page 15

Foreword 1

on

NOTE

Please observe the definition o

responsible persons: "operat

Information about the documentati

f the following

ing company"

and "driver".

Thank you for reading and complying with

these instructions. If you have any questions

or suggestions for improvements, or if you

have found any errors, please contact your

authorised service centre.

Issue date and topicality of the operating instructions

The issue date of these operating instructions

can be found on the title page.

STILL is constantly engaged in the further

development of trucks. These operating

instructions are subject to change, and any

claims based on the information and/or

illustrations contained in them cannot be

asserted.

Please contact your au

for technical support

thorised service centre

relating to your truck.

Copyright and tradem

These instruction

translated or made

ties—including as

express written ap

s must not be reproduced,

excerpts—except with the

proval of the manufacturer.

Explanation of in

ark rights

accessible to third par-

formation symbols

used

DANGER

Indicates proceduresthat must be strictly adhered

to in order to prevent the risk of fatalities.

WARNING

Indicates procedures that must be strictly adhered

to in order to prevent the risk of injuries.

988078001 [EN] 5

50

Page 16

1 Foreword

Information about the documentati

CAUTION

Indicates procedures that must be strictly adhered

to in order to prevent material damage and/or

destruction.

NOTE

For technical requirements that require

special attention.

ENVIRONMENT NOTE

To prevent environmental damage.

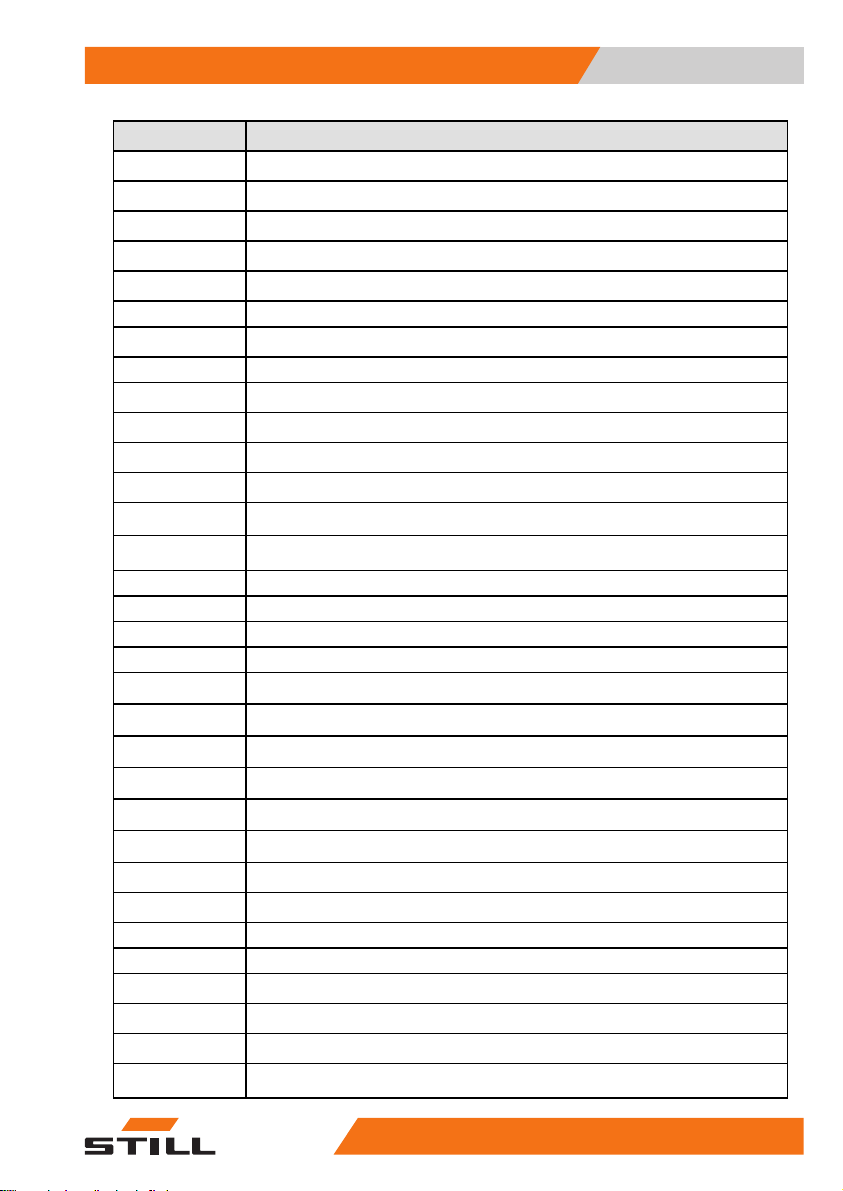

List of abbreviations

NOTE

This list of abbreviations applies to all types

of operating instructions. Not all of the abbreviations that are listed here will necessarily

appear in these operating instructions.

on

Abbreviation

°C

°F

A

ABE

ArbSchG

BetrSichV

BG

BGG

BGR

BGV

Approx.

CE

CEE

cm

3

cm

65

Meaning

Degrees Celsius

Degrees Fahrenheit

Amperes

Display operating unit

German labour protection law

German Ordinance on Industrial Safety and Health

Employers’ liability insurance association

Employers’ liability insurance association act

Employers’ liability insurance association rule

Employers’ liability insurance association regulation

Approximately

Symbol that confirms conformity with the valid product-specific European

directives

International Commission on the Rules for the Approval of Electrical Equipment

Centimetres

Cubic centimetres

0988078001 [EN]

Page 17

Foreword 1

Information about the documentati

on

Abbreviation

Meaning

dB Decibels

DFÜ

Remote data transmission

DIN German standard

EG

EN

FEM

F

max

g

GAA

European Community

European standard

Fédération Européene de l

Maximum power

Grams

Industrial inspectorate

a Manutention

If applicable If applicable

GPRS General Packet Radio Service

h/d

Hours per day (time driven each day in hours)

ID no. ID number

ISO International standard

kg Kilograms

3

kg/m

km/h

km/d

Kilograms per cubic metre

Kilometres per hour

Kilometres per day (kilometres driven each day)

kN Kilonewtons

kW Kilowatts

kWh/h

Energy consumption

lLitres

l/h

l/min

Litres per hour

Litres per minute

LAN Local area network

LED

L

p

L

pAZ

LSP

o.s.

m

m/s

Light emitting diode

Sound pressure level

Continuous sound pressure level in driver’s compartment

Load centre of gravity

milar

Or si

Metres

Metres per second

988078001 [EN] 7

50

Page 18

1 Foreword

Information about the documentati

on

Abbreviation

2

m/s

MAK

Meaning

Metres per second squared

Maximum workplace concentration

Max. Maximum

Min. Minimum

min Minutes

rpm

mm

Revolution(s) per minute

Millimetres

N Newtons

Nm Newton metres

PIN

SE

SIT

StVZO

t

TRGS

a.s.

Personal identification number

Superelastic

Snap-in tyre for simp

German Road Traffic L

lified assembly

icensing Regulations

Tonnes

Technical Regula

tions for Hazardous Substances

And similar

VVolts

VDE

VDI

VDMA

Association fo

Association o

German Engin

r Electrical, Electronic & Information Technologies

f German Engineers

eering Federation

W Watts

WLAN Wireless local area network

e.g.

.

For example

85

0988078001 [EN]

Page 19

Foreword 1

Information about the documentati

on

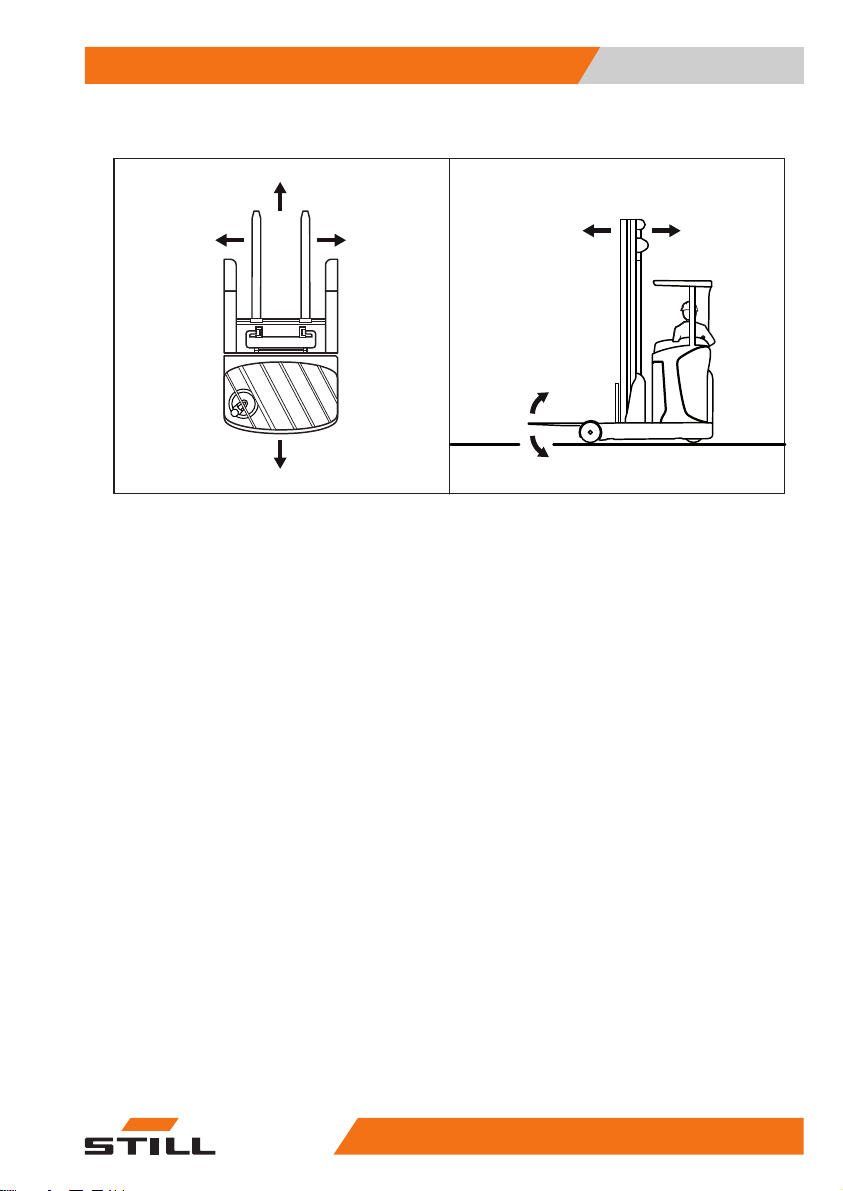

Defining directions

3

1

2

4

General:

• left (1)

•right(2)

Drive directions:

• Travelling in the load direction (backwards)

(3)

• Travelling in t

(4)

Movements of th

• Extending the reach carriage (in the load

direction) (5)

• Retracting the reach carriage (in the drive

direction) (6)

Tilting the lift mast or fork:

• Backward tilt

•Forwardtilt(8)

Thedriversitscrosswisetothedrivedirection.

he drive direction (forwards)

e reach carriage:

(7)

56

7

8

988078001 [EN] 9

50

Page 20

1 Foreword

Information about the documentati

Schematic views

View of functions and operating procedures

At many points in this documentation, the

(mostly sequential) operation of certain functions or operating procedures is explained. To

illustrate these operations, schematic views of

a reach truck are used.

NOTE

These schematic views are not representative

of thestructural state of thedocumented truck.

The views are used solely for the purpose of

clarifying procedures.

View of the display and operating unit

NOTE

Views of operating statuses and values in the

display of the display and operating unit are

examples and partly dependent on the truck

equipment. As a result, the displays shown of

the actual operating statuses and values may

vary.

on

10

50988078001 [EN]

Page 21

Foreword 1

Environmental considerations

Environmental considerations

Packaging

During delivery of the truck, certain parts

are packaged to provide protection during

transport. This packaging must be removed

completely prior to initial start-up.

ENVIRONMENT NOTE

The packaging material mu

properly after delivery o

st be disposed of

f the truck.

Disposal of component

s and

batteries

The truckis composed

components or batter

and disposed of, they

• disposed of,

• treated or

• recycled in accorda

national regulatio

NOTE

The documentation provided by the battery

manufacturer must be observed when disposing of batteries.

ENVIRONMENT NOTE

We recommend working with a waste management company for disposal purposes.

of different materials. If

ies need to be replaced

must be:

nce with regional and

ns.

988078001 [EN] 11

50

Page 22

1 Foreword

Environmental considerations

12

50988078001 [EN]

Page 23

2

Introduction

Page 24

2 Introduction

Using the truck

Using the truck

Proper usage

The truck described in these operating instructions is suitable for lifting, transporting

and stacking loads.

The truck may only be used for its proper

purpose as set out and described in these

operating instructions.

If the truck is to be used for

than those specified in the o

tions, the approval of the m

applicable, the relevant r

must be obtained beforeha

ards.

The maximum load to be lifted is specified on

the capacity rating plate (load diagram) and

must not be exceeded; see also the chapter

entitled "Before picking up a load".

Impermissible use

The operating company or driver, and not the

manufacturer, is liable for any hazards caused

by improper use.

purposes other

perating instruc-

anufacturer and, if

egulatory authorities

nd to prevent haz-

NOTE

Please observe the

responsible perso

definition of the following

ns: "operating company"

and "driver".

Use for purposes other than those described

in these operating instructions is prohibited.

DANGER

There is a risk of fatal injury from

falling off the truck while it is moving!

– It is prohibited to carry passengers

on the truck.

The truck may not be operated in areas where

there is a risk of fire, explosion or corrosion, or

in areas that are particularly dusty.

Stacking or unstacking is not permissible on

inclined surfaces or ramps.

14

50988078001 [EN]

Page 25

Introduction 2

Using the truck

Place of use

The truck is only approved for indoor use.

The ground must have an adequate load

capacity (concrete, asphalt) and a rough

surface. Roadways, working areas and aisle

widths must conform to the specifications in

these operating instructions; see the chapter

entitled "Roadways".

Driving on upward and downwa

is permitted provided the de

specifications are observed

entitled "Roadways".

The truck is suitable for indoor use in many

different countries, ranging from those situated in the Tropics to those in Nordic regions

(temperature range: -10°C to +40°C).

If the truck is to be used in a cold store, it must

be configured accordingly and, if necessary,

approved for such an environment; see the

chapter entitled "Cold store application".

The operating company (

titled "Definition of te

rms used for responsible

persons") must provide

tion in the area surroun

dance with its applicat

application, addition

ding the truck in accor-

ion. Depending on the

al fire protection must be

provided on the truck. I

relevant authorities.

rd gradients

fined data and

; see the chapter

see the chapter en-

sufficient fire protec-

f in doubt, contact the

Parking in temperatu

res below -10°C

CAUTION

Batteries can freeze!

If the truck is parked in an ambient temperature

below -10°C for an extended period, the batteries

will cool down. The electrolyte may freeze and

damage the batteries. The truck is then not ready

for operation.

– When the ambient temperature is below -10°C,

only parkthe truck for short periodsof time.

988078001 [EN] 15

50

Page 26

2 Introduction

Using the truck

Using working platforms

WARNING

The use of working platforms is regulated by national law. The use of working platforms is only

permitted by virtue of the jurisdiction in the country

of use.

– Observe national legislation.

– Before using working platforms, consult the

national regulatory authorities.

16

50988078001 [EN]

Page 27

Introduction 2

Residual risk

Residual risk

Residual dangers, residual risks

Despite careful working and compliance with

standards and regulations, the occurrence

of other risks when using the truck cannot be

entirely excluded.

The truck and all other system components

comply with current safety requirements.

Nevertheless, even when the truck is used

for its proper purpose and all instructions

are followed, some residual risk cannot be

excluded.

Even beyond the narrow dan

truck itself, a residual r

Persons in this area aroun

exercise a heightened deg

so that they can react imme

of any malfunction, incid

WARNING

All persons that are in the vicinity of the truck

must be instructed regarding these risks that arise

through use of the truck.

In addition,we draw attention to the safety regulations in these operating instructions.

ger areas of the

isk cannot be excluded.

d the truck must

ree of awareness,

diately in the event

ent or breakdown etc.

The risks can include:

• Escape of consumables due to leakages,

rupture of lines and containers etc.

• Risk of accident when driving over difficult

ground such as gradients, smooth or

irregular surfaces, or with poor visibility

etc.

• Falling, tripping etc. when moving on

the truck, especially in wet weather, with

leaking consumables or on icy surfaces

• Fire and explosion risks due to batteriesand

electrical voltages

• Human error resulting from failure to

observe the safety regulations,

• Unrepaired damage or defective and worn

components,

• Insufficient maintenance and testing

• Use of incorrect consumables

• Exceeding test intervals

988078001 [EN] 17

50

Page 28

2 Introduction

Residual risk

The manufacturer is not held responsible for

accidents involving the truck caused by the

failure of the operating company to comply

with these regulations either intentionally or

carelessly.

Stability

The stability of the truck has been tested to

the latest technological standards and is

guaranteed if the truck is used properly and

according to its intended purpose. These

standards only take into account the static

and dynamic tipping forces that can arise

during specified use in accordance with the

operating rules and intended purpose. The

risk of exceeding the moment of tilt that arises

from improper use or incorrect operation

cannot be excluded in extreme cases, and

will impact stability.

The risks can include:

• loss of stability due to un

loads etc.

• cornering at excessive speeds,

• moving with the load raised,

• moving with a load that i

side (e.g. sideshift),

• turning and driving diagonally across

slopes,

• driving on slopes with the load on the

downhill side,

• loads that are too wide

• swinging loads,

• ramp edges or steps.

stable or sliding

s protruding to the

,

Special risks associated with using the truck and attachments

Approval from the manufacturer and attachment manufacturer must be obtained each

time the truck is used in a manner that falls

outside the scope of normal use, and in cases

where the driver is not certain that he can use

the truck correctly and without the risk of accidents.

18

50988078001 [EN]

Page 29

Introduction 2

Residual risk

988078001 [EN] 19

50

Page 30

2 Introduction

Residual risk

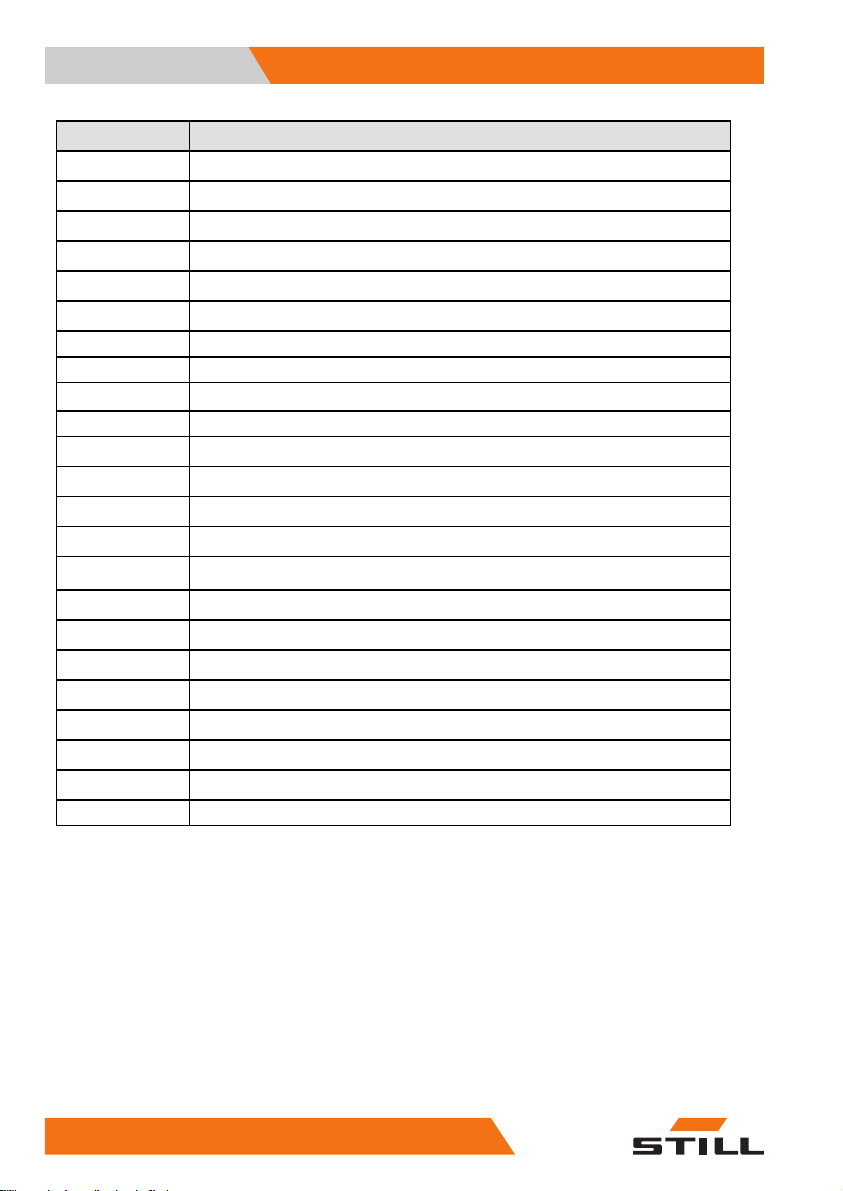

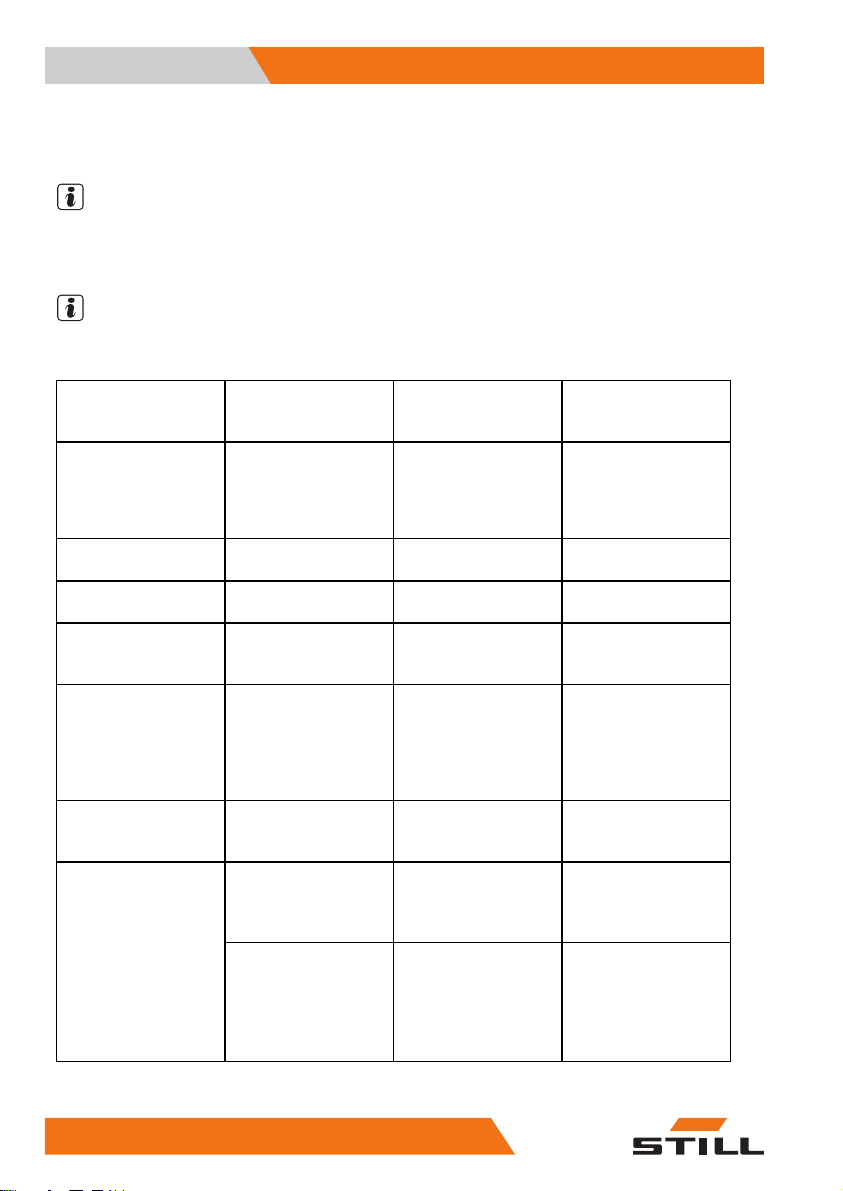

Overview of hazards and countermeasures

NOTE

This table is intended to help evaluate the

hazards in your facility and applies to all drive

types. It does not claim to be complete.

NOTE

Observe the national re

country!

Hazard Measure

Truck equipment does

not comply with local

regulations

Lack of skills and

qualification of driver

Usage by unauthorised persons

Truck not in a safe

condition

Risk of falling when

using working

platforms

Impaired visibility due

to load

Contamination of

respiratory air

gulations for your

Test

Driver training (sit-on

and stand-on)

Access with key only

for authorised persons

Recurrent testing and

rectification of defects

Compliance with

national regulations

(different national

laws)

Resource planning

Assessment of diesel

exhaust gases

Assessment of LPG

exhaust gases

Check note

√ actioned

- not applicable

O If in doubt, consult

O BGG 925

O

OBetrSichVO

OBetrSichVO

OBetrSichVO

O TRGS 554 and

OMAK(Maximum

Notes

competent factory

inspectorate or

employers’ liability

insurance association

VDI 3313 driver permit

(Workplace Safety

Ordinance)

(Workplace

Safety Ordinance)

and employer’s

liability insurance

associations

(Workplace Safety

Ordinance)

BetrSichVO

(Workplace Safety

Ordinance)

Workplace

Concentrations) list

and BetrSichVO

(Workplace Safety

Ordinance)

20

50988078001 [EN]

Page 31

Introduction 2

Residual risk

Hazard Measure

Impermissible usage

(improper usage)

When fuelling

a) Diesel Observe BetrSichVO

b) LPG Observe BGV D34,

When charging the

traction battery

When using battery

chargers

When parking LPG

trucks

Issuing of operating

instructions

Written notice of

instruction to driver

Observe BetrSichVO

(Workplace Safety

Ordinance), operating

instructions and

VDMA (German

Engineering

Federation) rules

(Workplace Safety

Ordinance), operating

instructions and

VDMA (German

Engineering

Federation) rules

operating instructions

and VDMA rules

Observe BetrSichVO

(Workplace Safety

Ordinance), operating

instructions and

VDMA (German

Engineering

Federation) rules

Observe BetrSichVO

(Workplace Safety

Ordinance), BGR

104 and operating

instructions

Observe BetrSichVO

(Workplace Safety

Ordinance), BGR

104 and operating

instructions

Check note

√ actioned

- not applicable

O BetrSichVO

O BetrSichVO

O

O

O

O

O BetrSichVO

O BetrSichVO

Notes

(Workplace Safety

Ordinance) and

ArbSchG (Health and

Safety at Work Act)

(Workplace Safety

Ordinance) and

ArbSchG (Health and

Safety at Work Act)

VDE 0510: In

particular

- Ensure ventilation

- Insulation value

within permissible

range

(Workplace Safety

Ordinance) and BGR

104

(Workplace Safety

Ordinance) and BGR

104

988078001 [EN] 21

50

Page 32

2 Introduction

Residual risk

Hazard Measure

With driverless transport systems

Roadway quality

inadequate

Load carrier

incorrect/slipped

Drive behaviour

unpredictable

Driveways blocked Mark driveways

Driveways intersect

No person detection

during depositing and

retrieval

.

Danger t

Accordi

ordinan

law (Arb

determi

ation, a

and safe

ees (Bet

must the

instruc

availab

must be a

o employees

ng to the German workplace safety

ce (BetrSichVO) and labour protection

SchG), the operating company must

ne and assess hazards during oper-

nd establish the occupational health

ty measures required for employrSichVO). The operating company

refore draw up appropriate operating

tions (§ 6 ArbSchG) and make them

le to the driver. A responsible person

ppointed.

Clean/clear driveways O BetrSichVO

Reattach load to pallet

Employee training

Keep driveways clear

Announce right-ofway rule

Employee training

Check note

√ actioned

- not applicable

OBetrSichVO

OBetrSichVO

OBetrSichVO

OBetrSichVO

OBetrSichVO

Notes

(Workplace Safety

Ordinance)

(Workplace Safety

Ordinance)

(Workplace Safety

Ordinance)

(Workplace Safety

Ordinance)

(Workplace Safety

Ordinance)

(Workplace Safety

Ordinance)

NOTE

Please observe the definition of the following

responsible persons: "operating company"

and "driver".

The construction and equipment of the

truck correspond to the Machinery Directive

2006/42/EC and are therefore marked with

CE labelling. These elements are therefore

not included in the hazard assessment. At-

22

50988078001 [EN]

Page 33

Introduction 2

Residual risk

tachments possess their own CE labelling and

likewise are not included for that reason. The

operating company must, however, select the

type and equipment of thetrucks so as to comply with the local provisions for deployment.

The result must be documented (§ 6 ArbSchG). In the case of truck applications involving similar hazard situations, the results may

be summarised. This overview (see chapter

"Overview of hazards and countermeasures")

provides help on complying with this regulation. The overview specifies the main hazards

that are the most frequent cause of accidents

in the event of non-compliance. If other major

operational hazards are involved, they must

also be taken into consideration.

The conditions of use for tr

similar in many plants, so t

be summarised in one overvi

the information provided b

employers’ liability insu

this subject.

ucks are broadly

he hazards can

ew. Observe

y the relevant

rance association on

988078001 [EN] 23

50

Page 34

2 Introduction

Residual risk

24

50988078001 [EN]

Page 35

3

Safety

Page 36

3 Safety

Definition of terms used for respons

ible persons

Definition of terms used for responsible persons

Operating company

The operating company is the natural or legal

person or group who operates the truck or on

whose authority the truck is used.

The operating company must ensure that the

truck is only used for its proper purpose and in

compliance with the safety regulations set out

in these operating instructions.

The operating company must

all users read and understa

information.

The operating company is responsible for the

scheduling andcorrect performance of regular

safety checks.

We recommend that the national performance

specifications are adhered to.

Specialist

A qualified person is defined as a service

engineer or a person who fulfils the following

requirements:

• A completed vocation

demonstrably proves

expertise. This proo

a vocational qualifi

document.

• Professional experience indicating that

the qualified person has gained practical

experience of industrial trucks over a

proven period during their career During

this time, this person has become familiar

with a wide range of symptoms that require

checks to be carried out, such as based

on the results of a hazard assessment or a

daily inspection

• Recent professional involvement in the

field of the industrial truck test in question

and an appropriate further qualification

are essential. The qualified person must

have experience of carrying out the test

in question or of carrying out similar tests.

Moreover, this person must be aware of

the latest technological developments

cation or a similar

ensure that

nd the safety

al qualification that

their professional

f should consist of

26

50988078001 [EN]

Page 37

Safety 3

Definition of terms used for respons

regarding the industrial truck to be tested

and the risk being assessed

ible persons

Drivers

This truck may only be driven by suitable persons who are at least 18 years of age, have

been trained in driving, have demonstrated

their skills in driving and handling loads to

the operating company or an authorised representative, and have been specifically instructed to drive the truck. Specific knowledge

of the truck to be operated is also required.

The training requirements under §3 of the

Health and Safety at Work Act and §9 of the

plant safety regulations are deemed to have

been satisfied if the driver has been trained in

accordance with BGG (General Employers’

Liability Insurance Association Act) 925.

Observe the national regulations for your

country.

Driver rights, duties and rules of behaviour

The driver must be trai

duties.

The drivermust be grantedthe required rights.

The driver must wear protective equipment

(protection suit, safety footwear, safety

helmet, industrial goggles and gloves) that

is appropriate for the conditions, the job and

the load to be lifted. Solid footwear should be

worn to ensure safe driving and braking.

Thedrivermustbefa

instructions and ha

times.

The driver must:

• have read and understood the operating

manual

• have familiarised himself with safe operation of the truck

• be physically and m

truck safely

ned in his rights and

miliar with the operating

ve access to them at all

entally able to drive the

988078001 [EN] 27

50

Page 38

3 Safety

Definition of terms used for respons

DANGER

The use of drugs, alcohol or medicationsthat affect

reactions impair the ability to drive the truck!

Individuals under the influence of the aforementioned substancesare not permitted to perform work

of any kind on or with the truck.

Prohibition of use by unauthorised

persons

The driver is responsible for the truck during

working hours. He must not allow unauthorised persons to operate the truck.

When leavingthe truck, thedriver must secure

it against unauthorised use, e.g. by pulling out

the key.

ible persons

28

50988078001 [EN]

Page 39

Safety 3

Basic principles for safe operatio

Basic principles for safe operation

Insurance cover on company premises

In many cases, company premises are

restricted public traffic areas.

NOTE

The business liability insurance should be

reviewed to ensure that, in the event of any

damage caused in restricted public traffic

areas, there is insurance cover for the truck in

respect of third parties.

Changes and retrofitting

If the truck is used for work that is not listed

in the guidelines or in these instructions and

has to be converted or retrofitted accordingly,

you must note that any change to its structural

state can affect the handling and stability of

the truck, which in turn can lead to accidents.

You should therefor

centre beforehand.

Changes that will adversely affect stability,

load capacity, safety systems etc. must not be

made without the manufacturer’s approval.

Thetruckmayonlybeconvertedwithwritten

approval from the manufacturer. Approval

from the relevant authority must be obtained

where applicable.

In addition, chan

control elements

ment variants (e.

made without the p

manufacturer.

DANGER

There isa risk of accident due to restrictedvisibility.

Additional attachments (e.g. terminals, printers,

mirrors) in the driver’s compartment area can

restrict the driver’s field of vision.

– Only install attachments (variants) that have

been specifically approved by STILL in accordance with the safety regulations.

e contact your service

ges to the brakes, steering,

, circumferential view, equipg. attachments) must not be

rior written approval of the

n

988078001 [EN] 29

50

Page 40

3 Safety

Basic principles for safe operatio

Only restraint systems (variants) that have

been specifically approved by STILL may be

installed and used.

DANGER

Risk ofinjury if truck tips over!

Even if the driver has fastened the

seat belt (variant), there is still a

residual risk of injury if the truck

tips over. In addition, the seat belt

protects against the consequences

of rear-endcollisions and falling off a

ramp.

– The seatbelt (variant)must always

be used.

When carrying out welding work on the

truck, it is essential that the battery and all

connections to the electronic control cards are

disconnected. Contact the authorised service

centre on this matter.

In the event of the manufacturer going into

liquidation and the company not being taken

over by another legal person, the operating

company can make changes to the truck.

To do so, the operating company must fulfil

the following prerequisites:

Design documents, test documents and

assembly instructions associated with the

change must be archived and remain accessible at all times.

The capacity rating plate, decal information,

hazard warnings and the operating instructions must be checked to ensure they are

consistent with the changes and modified if

required.

The modification must be designed, checked

and implemented by a design office that

specialises in industrial trucks in accordance

with the standards and directives valid at the

time the modification is made.

Decal information with the following data must

be permanently affixed to the truck so that it is

clearly visible:

– Type of modification

– Date of modification

n

30

50988078001 [EN]

Page 41

Safety 3

Basic principles for safe operatio

– Name and address of the company imple-

menting the modification.

Modifications to the overhead guard

and cabs

DANGER

The overhead guard or the weather protection

cab/cold store cab may fail. A falling load or the

truck tipping over couldresult in fatalconsequences

for the driver. There is a risk of fatal injury!

Work on the overhead guard or on the weather

protection cab/cold store cab reduces its stability.

Excessive forces caused by falling loads or the

truck tipping over may result in buckling of the

modified chassis, bodywork and fittings. This could

mean thatthe driver is no longerprotected.

– Do not weld on the overhead guard or the

weather protection cab/cold store cab.

– Do not drill on the overheadguard orthe weather

protection cab/cold store cab.

– Do not make any incisions on the overhead

guard or the weather protection cab/cold store

cab.

DANGER

Risk of explosion from additional

bores on the truck chassis, weather

protection cab or cold store cab!

Explosive gases can escape and

lead to potentially fatalinjuries if they

explode. Sealing bores with plugs

is not sufficient to prevent gas from

escaping.

– Do not drill any additional holes

in the truck chassis, weather

protection cab or cold store cab.

n

Roof loads

To ensure the stability of the chassis, bodywork and fittings at all times, do not mount any

additional roof loads on the truck.

988078001 [EN] 31

50

Page 42

3 Safety

Basic principles for safe operatio

CAUTION

Additional roof loads damage the overhead guard

or the weather protection cab/cold store cab.

– Do not mount any additional roof loads on the

truck.

Safety information for FM-X Wide, ExtraWide(W,EW)

The W (Wide) and EW (Extra Wide) versions

differ from the standard truck by having

additional cover sheets (1) between the

overhead guard and the widened chassis.

These sheets are located on each side of the

truck. They are not designed to be walked on

by people.

WARNING

Risk of accident if a person steps on to the lateral

cover sheets

If a person steps on to the cover plates, the plates

can be damaged by the weight of the person, who

may also slip and suffer injury.

– Do not step on the lateral cover sheets

n

1

Warning regardingnon-original parts

Original parts, attachments and accessories

are specially designed for this truck. We

specifically draw your attention to the fact that

parts, attachments and accessories supplied

by other companies have not been tested and

approved by STILL.

CAUTION

Installation and/or use ofsuch products may therefore have a negative impact on the design features

of the truck and thus impair active and/or passive

driving safety.

We recommend that you obtain approval from the

manufacturer and, if necessary, from the relevant

regulatory authorities before installing such parts.

The manufacturer accepts no liability for any damage caused by the use of non-original parts and

accessories without approval.

32

50988078001 [EN]

Page 43

Safety 3

Basic principles for safe operatio

Damage, defects and misuse of safety systems

Damage or other defects on the truck or

attachment must be reported to the supervisor

or responsible fleet manager immediately so

that they can have the defect rectified.

Trucks andattachments that are not functional

or safe to drivemay not be used until they have

been properly repaired.

Do not remove or deactivate

and switches.

Fixed set valuesmay only be changed withthe

approval of the manufacturer.

Work onthe electrical system (e.g. connecting

a radio, additional headlights etc.) is only

permitted with the manufacturer’s written

approval. All electrical system interventions

must be documented.

Even if they are removabl

not be removed, as they a

protect against small f

safety systems

e, roof panels may

re designed to

alling objects.

Tyres

n

DANGER

Using different tyres has a negative effect on the

stability of the truck. There is a risk of accident!

Only originaltyres may be fitted to the truck.

– Make sure that only original tyres are fitted.

Tyre quality affects the stability and handling

of the truck. Changes must only be made in

consultation with the manufacturer. When

changing wheels or tyres, always ensure that

this does not cause the truck to tilt to one side

(e.g. always replace right and left wheels at

the same time).

988078001 [EN] 33

50

Page 44

3 Safety

Basic principles for safe operatio

Medical equipment

WARNING

Electromagneticinterference may occuron medical

devices!

Only use equipment that is sufficiently protected

against electromagnetic interference.

Medical equipment, such as pacemakers or

hearing aids, may not work properly when the

truck is in operation.

– Ask your doctor or the manufacturer of

the medical equipment to confirm that the

medical equipment is sufficiently protected

against electromagnetic interference.

Exercise caution when handling gas springs and accumulators

WARNING

Gas springs are under high pressure. Improper

removal resultsin an elevated risk of injury.

For ease of operation, various functions on the

truck can be supported by gas springs. Gas springs

are complex components that are subject to high

internal pressures (up to 300 bar). They may under

no circumstances be opened unless instructed to

do so, and may be installed only when not under

pressure. If required, the authorised service centre

will depressurisethe gas spring in accordancewith

the regulationsbefore removal. Gas springs must

be depressurised before recycling.

– Avoid damage, lateralforces, buckling, tempe-

ratures over 80°C and heavy contamination.

– Damaged or defective gas springs must be

changed immediately.

– Contact the authorisedservice centre.

n

WARNING

Accumulators are under high pressure. Improper

installation of an accumulatorresults in an elevated

risk of injury.

Before startingwork on the accumulator it must be

depressurised.

– Contact the authorisedservice centre.

34

50988078001 [EN]

Page 45

Safety 3

Safety tests

Safety tests

Regular safety inspection of the truck

Safetyinspectionbasedontimeand

extraordinary incidents

The operating company must ensure that the

truck is checked by a specialist at least once a

year or after particular incidents.

As part of this inspection

of the technical conditio

performed with regard to a

In addition, the truck mus

checked for damage that co

have been caused by impro

log must be created. The r

inspection must be retai

inspections have been ca

The inspection date is indicated by an adhesive label on the truck.

– Arrange for the service centre to perform

periodic safety inspections on the truck.

– Observe guidelines fo

on the truck in accorda

The operator is responsible for ensuring any

defects are remedied without delay.

– Contact your service centre.

, a complete check

n of the truck must be

ccident safety.

t be thoroughly

uld potentially

per use. A test

esults from the

ned until a further two

rried out.

r checks carried out

nce with FEM 4.004.

NOTE

Observe the national regulations for your

country!

Insulation testing

The truck insulation must have sufficient insulation resistance. For this reason, insulation

testing in accordance with DIN EN 1175 and

DIN 43539, VDE 0117 and VDE 0510 must be

conducted at least once a year.

NOTE

The truck’s el

ries must be ch

ectrical system and drive batte-

ecked separately.

988078001 [EN] 35

50

Page 46

3 Safety

Safety regulations for handling co

Measuring the battery’s insulation

resistance

NOTE

Nominal battery voltage < test voltage < 500

V.

– Measure the insulation resistance with a

suitable measuring device.

The insulation resistance can be considered

sufficient if it measures at least 500

nominal battery voltage against ground.

– Contact the authorised service centre.

Measuring the insulation resistance of

the electrical system

NOTE

Nominal battery voltage < test voltage < 500

V.

– Ensure that all volt

disconnected from t

– Measure the insulation resistance with a

suitable measuring device.

The insulation resistance can be considered

sufficient if it measures at least 1000

the nominal battery voltage against ground.

– Contact the author

age sources have been

he circuit to be tested.

ised service centre.

nsumables

/V for the

/V for

Safety regulati

Permissible co

DANGER

Failure to observethe safety regulations relating to

consumables may result in a risk of injury, death or

damage to the environment.

– Observe the safety regulations when handling

these materials.

Refer to the maintenance data table for information regarding the permissible substances

that are necessary for operation (refer to the

chapter entitled "Maintenance data table").

36

ons for handling consumables

nsumables

50988078001 [EN]

Page 47

Safety 3

Safety regulations for handling co

nsumables

Oils

DANGER

Oils are flammable!

– Follow the statutory regulations.

– Donotallowoilstocomeinto

contact with hot engine parts.

– No smoking,fires ornaked flames!

DANGER

Oils are toxic!

– Avoid contact and consumption.

– If vapour or fumes are inhaled,

move to fresh air immediately.

– In the event of contact with the

eyes, rinsethoroughly (for at least

10 minutes) with water and then

consult an eye specialist.

– If swallowed, do not induce

vomiting. Seek immediate medical

attention.

WARNING

Prolonged intensive contact with the

skin can result in dryness and irritate

the skin!

– Avoid contact and consumption.

– Wear protective gloves.

– After any contact, wash the skin

with soap and water, and then

apply a skin care product.

– Immediately change soaked

clothing and shoes.

WARNING

There is a risk of slipping on spilled oil, particularly

when combined with water!

– Spilt oil should be removed immediately with

oil-binding agents and disposed of according to

the regulations.

988078001 [EN] 37

50

Page 48

3 Safety

Safety regulations for handling co

ENVIRONMENT NOTE

Oil is a water-polluting subst

•

Always store oil in containers

ance!

with the applicable regulatio

•

Avoid spilling oils.

•

Spilt oil should be removed immediately

with oil-binding agents and disposed of

according to the regulations.

•

Dispose of old oils accordin

tions.

Hydraulic fluid

WARNING

These fluids are pressurised during

operation of the truck and are

hazardous to your health.

– Do not spill the fluids.

– Follow the statutory regulations.

– Do not allow the fluids to come into

contact withhot engine parts.

nsumables

that comply

ns.

gtotheregula-

WARNING

These fluids are pressurised during

operation of the truck and are

hazardous to your health.

– Do not allow the fluids to come into

contact with the skin.

– Avoid inhaling spray.

– Penetration of pressurised

fluids into the skin is particularly

dangerous if these fluids escape

at high pressure due to leaks in

the hydraulic system. In case of

such injury, immediate medical

assistance is required.

– To avoid injury, use appropriate

personal protective equipment

(e.g. protective gloves, industrial

goggles, skin protection and skin

care products).

38

50988078001 [EN]

Page 49

Safety 3

nsumables

ENVIRONMENT NOTE

Hydraulic fluid is a water-poll

•

Always store hydraulic fluid in

Safety regulations for handling co

uting substance.

containers

that comply with regulations

•

Avoid spills

•

Spilt hydraulic fluid should be removed

immediately with oil-binding agents and

disposed of according to the regulations

•

Dispose of old hydraulic flui

d according to

the regulations

Battery acid

WARNING

Battery acid contains dissolved

sulphuric acid. This is toxic.

– Avoid touching or swallowing the

battery acid at all costs.

– In case of injury, seek medical

advice immediately.

WARNING

Battery acid contains dissolved

sulphuric acid. This is corrosive.

– When working with battery acid,

always wear a protection suit and

eye protection.

– When working with battery

acid, never wear a watch or any

jewellery.

– Do not allow any acid to get

onto clothing or skin or into the

eyes; if this does happen, rinse

immediately with plenty of clean

water.

– In case of injury, seek medical

advice immediately.

– Immediately rinse away spilt

battery acid with plenty of water.

– Follow the statutory regulations.

ENVIRONMENT NOTE

– Dispose of used battery acid in line with the

applicable regulations.

988078001 [EN] 39

50

Page 50

3 Safety

Safety regulations for handling co

Brake fluid

WARNING

Brake fluid is poisonous!

– Avoid swallowing. In the event

of swallowing, do not induce

vomiting. Rinse out your mouth

thoroughly with water and ask a

doctor for advice.

– Avoid aerosolisation and inha-

lation. In the event of inhalation,

seek freshair. Ask a doctor for ad-

vice if necessary.

WARNING

Brake fluid is hazardous to your

health!

Brake fluid irritates the eyes and

can dry out the skin upon prolonged

contact.

– Coat your hands with a protective

skin cream prior to starting work.

– Avoid prolonged or intensive

skin contact. In the event of skin

contact, clean the wetted skin with

water and soap, and subsequently

apply a skin care product.

– Prevent contact with the eyes. In

the event of contact with the eyes,

wash out the affected eye(s) with

clean water for ten minutes and

then ask a doctor for advice.

– Change clothing soiled with brake

fluid as soon as possible.

nsumables

CAUTION

Brake fluid is flammable!

– Do not allow brake fluid to come into contact with

hot motor parts.

– Smoking, fires and naked flames are prohibited.

CAUTION

Brake fluid has strong dissolvingand colour-changing properties.

– Immediately rinse off any brake fluid that has

splashed on paint, clothing, and shoes with

plenty of water

40

50988078001 [EN]

Page 51

Safety 3

Emissions

ENVIRONMENT NOTE

Brake fluid is a water pollutant

•

Always store brake fluid in cont

complying with the regulation

•

Do not spill brake fluid.

•

Spilt brake fluid must be removed immedia-

!

ainers

s..

tely using an oil binding agent and disposed

of in accordance with regulations

•

Dispose of old brake fluid acc

ording to the

regulations.

•

Observe the national regulations for the

country in which the truck is being used.

Disposal of consumables

ENVIRONMENT NOTE

Materials that accumulate during repair,

maintenance and cleaning must be collected

properly and disposed of in accordance with

the national regulations for the country in

which the truck is being used. Work must

only be carried out in areas designated for the

purpose. Care must be taken to minimise any

environmental pollution.

– Soak up any spilt fluids such as hydraulic

oil, brake fluid or gearbox oil using an

oil-binding agent.

– Neutralise any spil

ately.

– Always observe national regulations con-

cerning the disposal of used oil.

t battery acid immedi-

Emissions

The values specified apply to a standard truck

(see technical datasheet). Different tyres,

lift masts, additional units etc. may produce

different values.

Noise emissions

The values were determined using the measuring procedures from the EN 12053 stan-

988078001 [EN] 41

50

Page 52

3 Safety

Emissions

dard (noise measurement for industrial trucks

based on EN 12001 and EN ISO 3744 and the

requirements of EN ISO 4871).

This machine emits the following sound

pressure level:

Continuous sound pressure lev

driver’s compartment

el in the

L

pAZ

< 69.5 dB(A)

The values were determined in the test cycle

on an identical machine from the weighted

values for operating statuses and idling.

Time proportions:

• Lifting 18%

• Idling 58%

• Driving 24%

However, the specified noi

truck cannot be used to det

emissions occurring in wo

dance with the most rece

2003/10/EC (daily pers

necessary, these value

directly at the workpla

tions present there (ad

special application co

se levels in the

ermine the noise

rkplaces in accor-

nt version of Directive

onal noise pollution). If

s must be determined

ce in the actual condi-

ditional noise sources,

nditions, sound reflec-

tions).

Vibrations

The vibrations of the machine have been

determined on an identical machine in accordance with the standards DIN EN 13059

"Safety of industrial trucks - Test methods

for measuring vibration" and DIN EN 12096

"Mechanical vibration - Declaration and verification of vibration emission values".

Weighted effective value of accelerationto which the body

(feet or seat surface) is subjected.

Uncertainty K

0.39 m/s

0.117 m/s

2

2

Tests have indicat

hand and arm vibrat

or the operating d

2

2.5 m/s

. There ar

ment guidelines f

42

or these measurements.

ed that the amplitude of the

ions on the steering wheel

evices in trucks is less than

e therefore no measure-

50988078001 [EN]

Page 53

Safety 3

Emissions

The personal vibration load on the driver

over a working day must be determined in

accordance with Directive 2002/44/EC by the

operating company at the actual place of use,

in order to consider all additional influences,

such as driving route, intensity of use etc.

Battery

DANGER

Risk of explosion due to flammable

gases!

During charging, the batteryreleases

a mixture of oxygen and hydrogen

(oxyhydrogen gas). This gas mixture

is explosive and must not be ignited.

– Make sure that there is always

sufficient ventilation in working

areas that are entirely or partially

enclosed.

– Keep away from open flames and

flying sparks.

– Observe the safety regulations for

handling the battery.

988078001 [EN] 43

50

Page 54

3 Safety

Emissions

44

50988078001 [EN]

Page 55

4

Overviews

Page 56

4 Overviews

Overview

Overview

321

4

11

1 Overhead guard

2 Driver’s compartment

3Liftmast

4 Fork arms

5 Load wheel

6Batteryframe

46

910

8

7Battery

8 Side support (tilt protection)

9 Control compartment

10 Drive wheel

11 Step

50988078001 [EN]

7

5

6

Page 57

Overviews 4

Overview of the driver’s compartme

Overview of the driver’s compartment

nt

123

1 Steering wheel

2 Working spotlightpush button (variant)

3 Key switch or push button (variant)

4 Reserved

5 Electrical seat adjustment push button

(variant)

6 Compartment (reserved for add-on sys-

tems)

7 Display and operating unit

8 Cup holderfor max. 1.5-l bottles

4

5

67

8

9

10

11

12131415

9 Operating devices for hydraulic and traction

functions

10 Emergency off switch

11 Push button for additional hydraulic func-

tions

12 Accelerator pedal

13 Brake pedal

14 Foot switch

15 Driver’s seat

988078001 [EN] 47

50

Page 58

4 Overviews

Operating devices and display elem

ents

Operating devices and display elements

Display and operating unit

1 Display of t

2 Keypad for l

or PIN code

3Keypadfo

terisin

4Drivep

5 Blue-Q

6Parki

rating devices for hydraulic and

Ope

ction functions

tra

ferent versions of the operating devices are

Dif

ilable for operating the truck’s hydraulic

ava

traction functions. The truck can be

and

ipped with the following operating devices:

equ

• Joystick 4Plus

• Fingertip

48

he operatingstatuses

ift height preselection (variant)

access (variant)

r onboard diagnostics, parame-

g

rogramme button (P1-P4)

button

ng brake button

50988078001 [EN]

Page 59