Page 1

OWNER’S MANUAL

Shallow Well Jet Pumps/

Tank Systems

© 2005, Sta-Rite Industries S410 (Rev. 7/13/05)

293 Wright Street, Delavan, WI 53115

“HN” Series

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-262-728-9181

Page 2

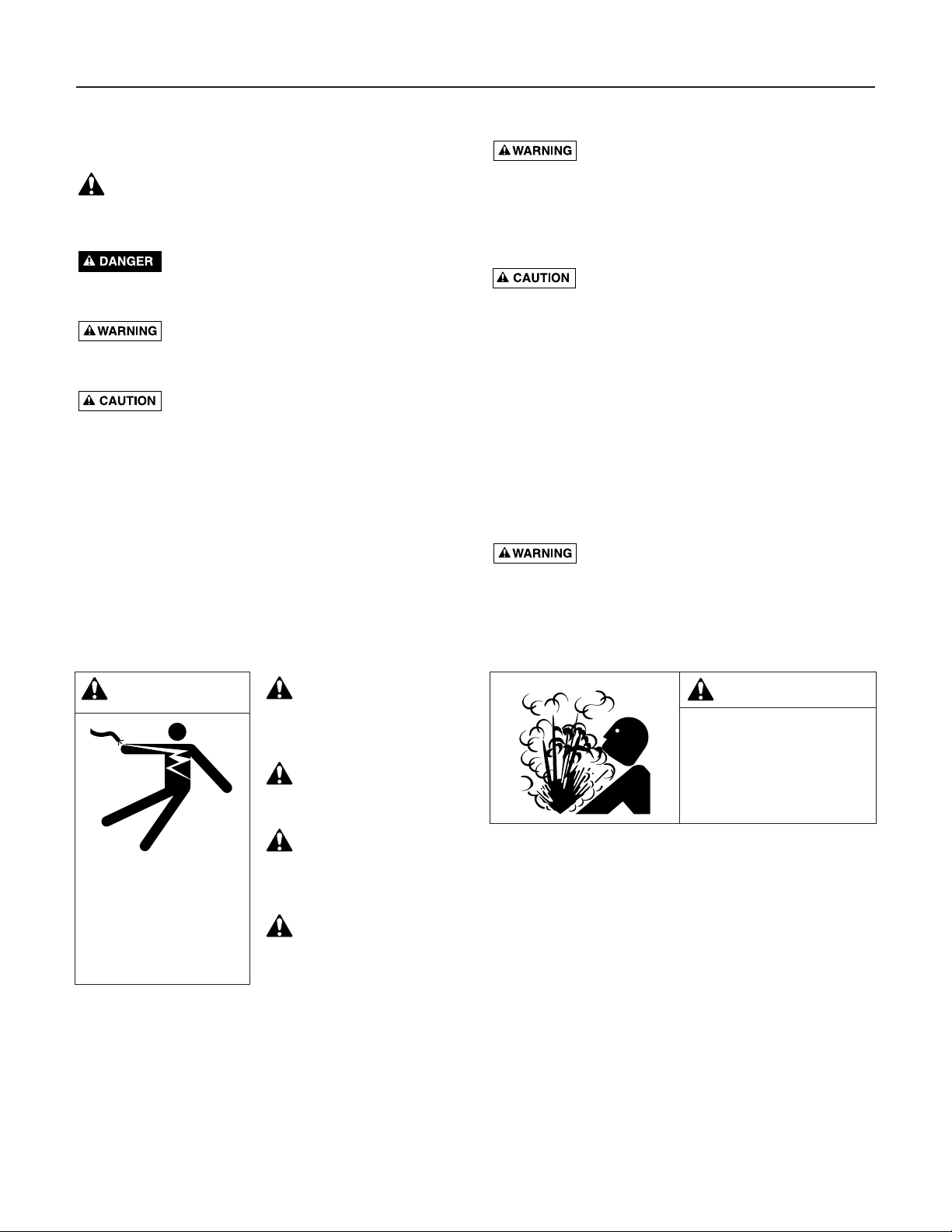

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

ELECTRICAL SAFETY

Capacitor voltage may be hazardous. To dis-

charge motor capacitor, hold insulated handle screwdriver

BY THE HANDLE and short capacitor terminals together.

Do not touch metal screwdriver blade or capacitor terminals. If in doubt, consult a qualified electrician.

GENERAL SAFETY

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for 20

minutes after shut-down before handling.

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Pump body may explode if used as a

booster pump unless relief valve capable of passing full

pump flow at 75 psi is installed.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See “Electrical”

section of this manual and

motor nameplate.

Ground motor before

connecting to power

supply.

Meet National Electri-

cal Code, Canadian

Electrical Code, and local

codes for all wiring.

Follow wiring instruc-

tions in this manual

when connecting motor to

power lines.

Page 3

Table of Contents 3

Thank you for purchasing a top quality, factory tested pump.

Page

General Safety .....................................................................................................2

Installation ........................................................................................................4,5

Connecting Discharge Piping...............................................................................6

Electrical ...........................................................................................................7,8

Preparing To Start The Pump................................................................................9

Troubleshooting..................................................................................................10

Repair Parts .......................................................................................................11

Warranty............................................................................................................12

Model Disch.

GPM at depth to water

Shut Off

HP PSI 5 Ft. 10 Ft. 15 ft. 20 Ft. 25 Ft. Pressure PSI

HNC-L 30 15.0 13.0 11.6 8.7 6.9

1/2 HP 40 12.5 11.4 10.1 8.2 6.8 70

50 8.0 6.8 6.1 4.8 3.5

HND-L 30 21.4 19.1 16.5 13.3 9.5

3/4 HP 40 20.8 18.7 15.8 13.2 9.3 67

50 13.5 11.6 10.1 7.4 2.4

HNE-L* 30 28.5 25.0 21.4 17.4 12.6

1 HP 40 28.3 24.4 21.0 17.2 12.3 67

50 21.5 18.3 10.9 3.1 1.6

Performance Chart

* Performance taken with 1-1/2 NPT suction pipe.

Model Disch.

GPM at depth to water

Shut Off

HP PSI 5 Ft. 10 Ft. 15 ft. 20 Ft. 25 Ft. Pressure PSI

HNDX 30 15.0 13.0 11.6 8.7 6.9

3/4 HP 40 12.5 11.4 10.1 8.2 6.8 70

50 8.0 6.8 6.1 4.8 3.5

HNEX 30 21.4 19.1 16.5 13.3 9.5

1 HP 40 20.8 18.7 15.8 13.2 9.3 67

50 13.5 11.6 10.1 7.4 2.4

HNFX 30 28.5 25.0 21.4 17.4 12.6

1-1/2 HP 40 28.3 24.4 21.0 17.2 12.3 67

50 21.5 18.3 10.9 3.1 1.6

Performance Chart for Export Models

Page 4

Installation 4

REPLACING AN OLD PUMP

Hazardous voltage. Disconnect power to pump before work-

ing on pump or motor.

Step 1. Drain and remove the old pump. Check the old pipe for scale, lime,

rust, etc., and replace it if necessary.

Step 2. Install the pump in the system. Make sure that all pipe joints in the

suction pipe are air-tight as well as water tight.

If the suction pipe

can suck air, the pump will not be able to pull water from the well.

Step 3. Adjust the pump mounting height so that the plumbing connections

do not put a strain on the pump body. Support the pipe so that the

pump body does not take the weight of piping or fittings.

You have just completed the well plumbing for your new shallow

well jet pump. Please go to Page 6 for discharge pipe and tank connections.

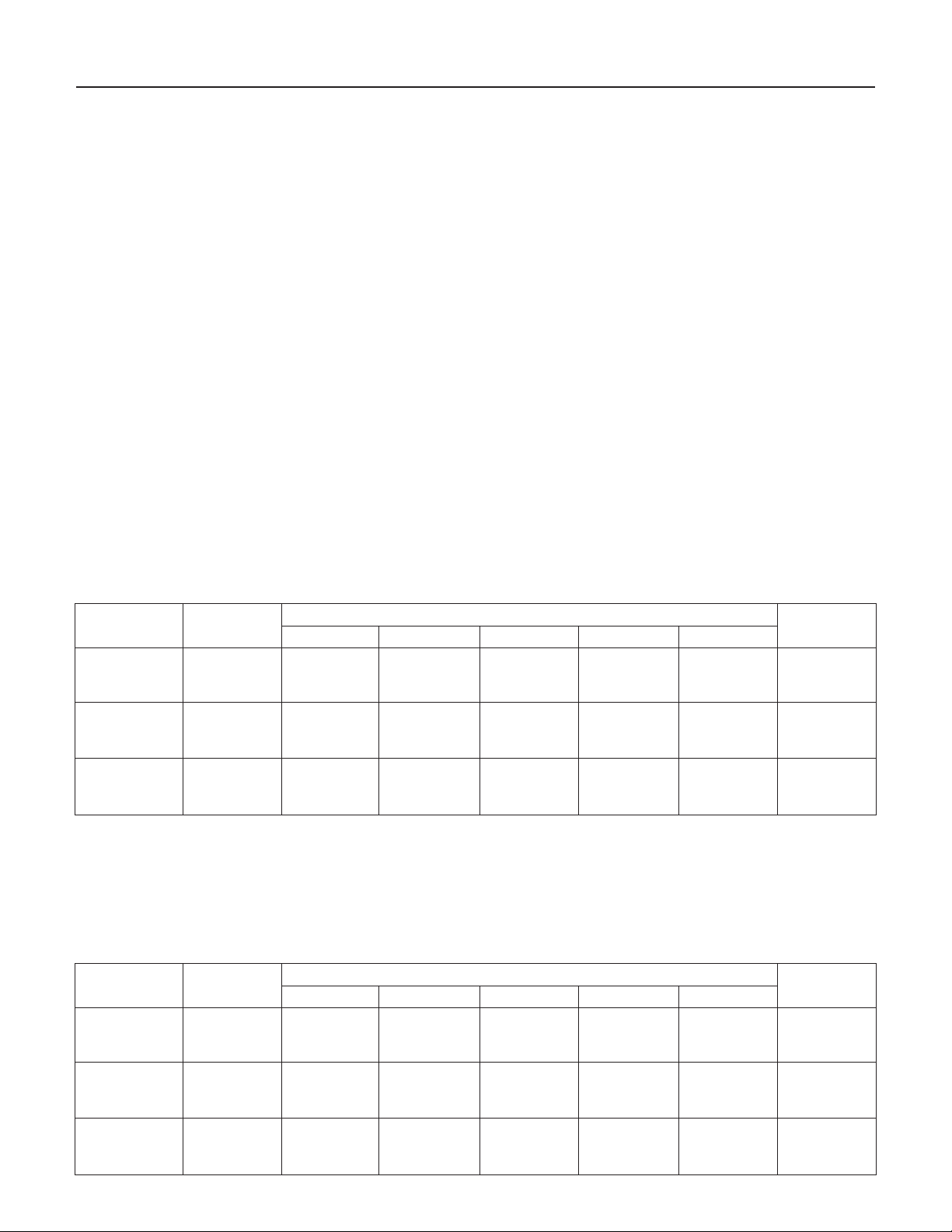

WELL POINT (DRIVEN POINT) INSTALLATION

(Figure 1)

Step 1. Drive the well, using “drive couplings” and a “drive cap”. “Drive

fittings” are threaded all the way through and allow the pipe ends to

butt against each other so that the driving force of the maul is carried by the pipe and

not

by the threads. The ordinary fittings found

in hardware stores are not threaded all the way through the fitting

and can collapse under impact. “Drive fittings” are also smoother

than standard plumbing fittings, making ground penetration easier.

Step 2. Mount the pump as close to the well as possible

Step 3. Use the fewest possible fittings (especially elbows) when connecting

the pipe from the well point to the pump suction port. The suction

pipe should be at least as large as the suction port on the pump

(include a check valve if your pump is not equipped with one – see

Figure 1). Support the pipe so that there are no dips or sags in the

pipe, so it doesn’t strain the pump body, and so that it slopes slightly upward from the well to the pump (high spots can cause air

pockets which can air lock the pump). Seal the suction pipe joints

with teflon tape or a teflon based pipe joint compound. Joints must

be air- and water-tight.

If the suction pipe can suck air, the pump

cannot pull water from the well.

If one well point does not supply

enough water, consider connecting two or three well points to one

suction pipe.

You have just completed the suction piping for your new shallow

well jet pump. Please go to Page 6 for discharge pipe and tank connections

CASED WELL INSTALLATION, 2" OR LARGER

CASING (Figure 2)

Step 1. Mount the pump as close to the well as possible.

Step 2. Assemble the foot valve, strainer, and well pipe (see Figure 2). Make

sure that the foot valve works freely.

Step 3. Lower the pipe into the well until the strainer is five feet above the

bottom of the well. It should also be at least 10 feet below the well’s

water level

while the pump is running

in order to prevent the pump

from sucking air. Install a sanitary well seal.

Figure 1: Driven Point Installation

Figure 2: Cased Well Installation

To Household

Water System

Pump Priming

Tee and Plug

Drive point

below water

level

2346 0396

Suction Pipe

From Well

Priming

Tee and

Plug

Check

Valve

Drive

Coupling

Drive

Point

Not

to

Scale

To Household

Water System

Check

Valve

Pump Priming

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

Sanitary

Well Seal

Well

Casing

2347 0396

Not

10'

Min.

Foot

Valve

to

Scale

5–10'

Page 5

Installation 5

Step 4. Install a priming tee, priming plug, and suction pipe to the pump

(see Figure 2). Connect the pipe from the well to the pump suction

port, using the fewest possible fittings – especially elbows – as fittings increase friction in the pipe (however, include a foot valve –

see Figure 2). The suction pipe should be at least as large as the

suction port on the pump. Use teflon tape or a teflon-based pipe

joint compound on threaded pipe joints. Support the pipe so that

there are no dips or sags in the pipe, so it doesn’t strain the pump

body, and so that it slopes slightly upward from the well to the

pump (high spots can cause air pockets which can air lock the

pump). Seal the suction pipe joints with teflon tape or a teflon

based pipe joint compound. Joints must be air- and water-tight.

If

the suction pipe can suck air, the pump cannot pull water from the

well.

You have just completed the suction piping for your new shallow

well jet pump. Please go to Page 6 for discharge pipe and tank

connections.

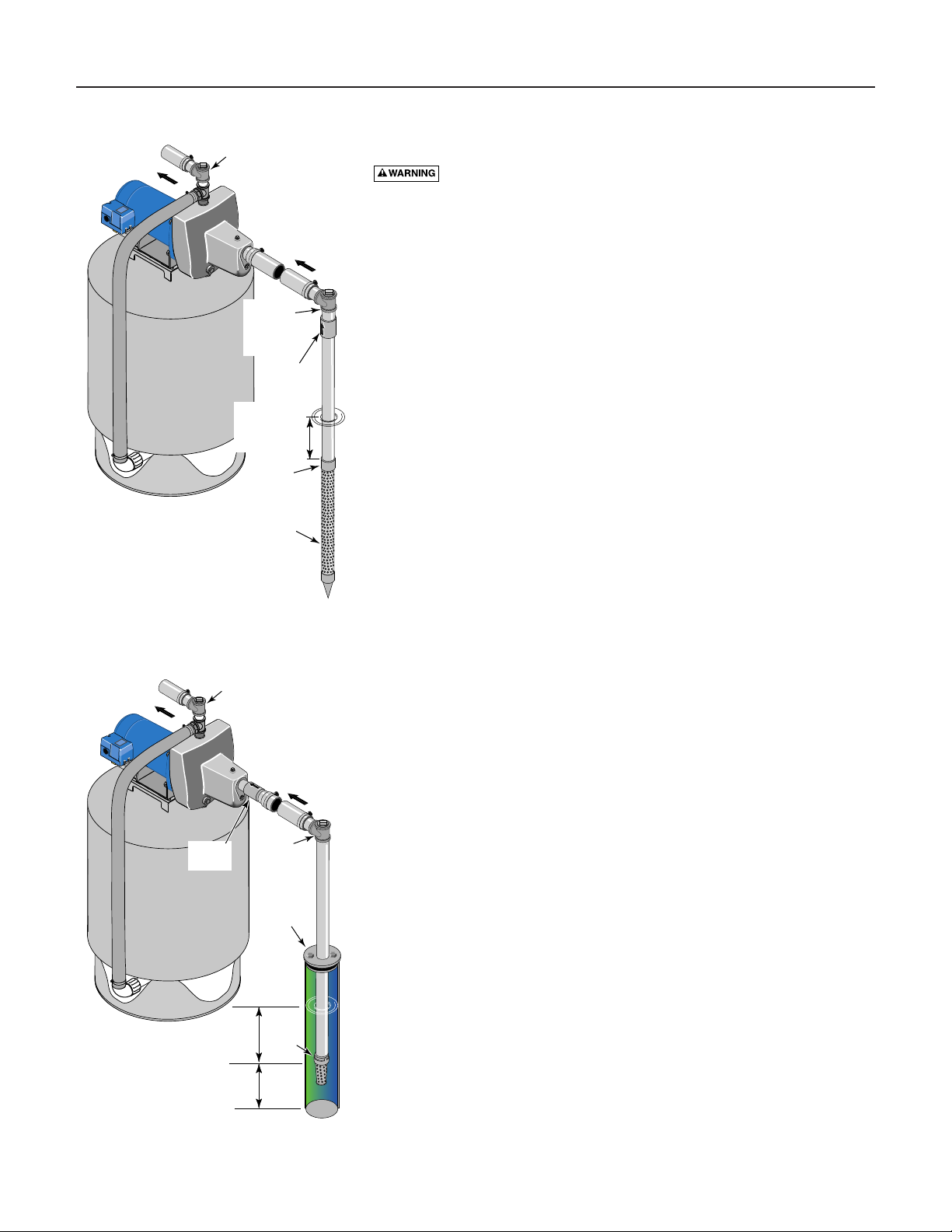

INSTALLATION FOR SURFACE WATER (Figure 3)

Step 1. The pump should be installed as close to the water as possible,

with the fewest possible fittings (especially elbows) in the suction

pipe. The suction pipe should be at least as large as the suction port

on the pump.

Step 2. Assemble a foot valve and suction pipe (see Figure 3). Make sure

that the foot valve works freely. Use teflon tape or a teflon-based

pipe joint compound on threaded pipe joints. Protect the foot valve

assembly from fish, trash, etc, by installing a screen around it (see

Figure 3).

Step 3. Lower the pipe into the water until the strainer is five feet above the

bottom. It should also be at least 10 feet below the water level in

order to prevent the pump from sucking air.

Step 4. Install a priming tee, priming plug, and suction pipe to the pump

(see Figure 3). Support the pipe so that there are no dips or sags in

the pipe, so it doesn’t strain the pump body, and so that it slopes

slightly upward from the well to the pump (high spots can cause air

pockets which can air lock the pump). Seal the suction pipe joints

with teflon tape or a teflon based pipe joint compound. Joints must

be air- and water-tight.

If the suction pipe can suck air, the pump

cannot pull water from the well.

You have just completed the plumbing for your new shallow well

jet pump. Please go to Page 6 for discharge pipe and tank connections.

Figure 3: Surface Water Installation

To Household

Water System

Not

Check

Valve

2348 0396

Pump Priming

Tee and Plug

Suction Pipe

From Well

Priming

Tee and

Plug

to

Scale

10'

Min.

5–10'

Foot

Valve

Screen

Page 6

Discharge Pipe and Pressure Tank Connections 6

PRE-CHARGE TANK CONNECTION (Figure 4)

Step 1. Install two tees in the pump discharge port (see Figure 4). The pipe

size must be at least as large as the discharge port.

Step 2. Run a pipe or reinforced hose from one arm of the first tee to the

port on the pre-charged tank.

Step 3. Connect the other end of the discharge tee to your plumbing system.

Step 4. Check the pre-charge of air in the tank with an ordinary tire gauge.

The pre-charge should be 2 PSI less than the cut-in setting of the

pump’s pressure switch. The pre-charge is measured

when there is

no water pressure in the tank.

Your new pump has a 30/50 PSI

switch, so adjust the tank pre-charge pressure to 28 PSI.

Congratulations! You have just completed the tank connection for

your jet pump.

Please go to Pages 7 and 8 for electrical hookup.

STANDARD TANK CONNECTION (Figure 5)

Step 1. Install one tee in the pump discharge port (see Figure 5).

Step 2. Run a pipe from the pump discharge port to the inlet port of your

tank. The pipe size must be at least as large as the discharge port.

Step 3. Remove the 1/8" NPT pipe plug from the pump Air Volume Control

(AVC) port (see Figure 5). Run tubing from the pump’s AVC port

(see Figure 5) to the port on the AVC mounted on the tank. See

instructions provided with tank and AVC for details. AVC port location will vary, depending on your pump model (see exploded view,

Page 11).

Congratulations! You have just completed the tank connection for

your jet pump.

Please go to Pages 7 and 8 for electrical hookup.

Figure 4: Pre-charged Tank Connections

Figure 5: Standard Tank Connections

Sealing Pipe Joints

Use only Teflon tape or Teflon based joint compounds for

making all threaded connections to the pump itself. Do not use

pipe joint compounds on plastic pumps: they can react with

the plastic in pump components. Make sure that all pipe joints

in the suction pipe are air tight as well as water tight.

If the

suction pipe can suck air, the pump will not be able to pull

water from the well.

To Household

Water System

Pressure

Switch

2349 0396

Pump Priming

Tee and Plug

From Well

Check

Valve

To Household

Water System

Air Volume

Control

Pump

Priming Tee

and Plug

Air Volume

Control Tube

2350 0396

From

Pressure

Switch

Check

Valve

Well

Page 7

Electrical 7

Disconnect power before working on pump, motor, pressure switch, or wiring.

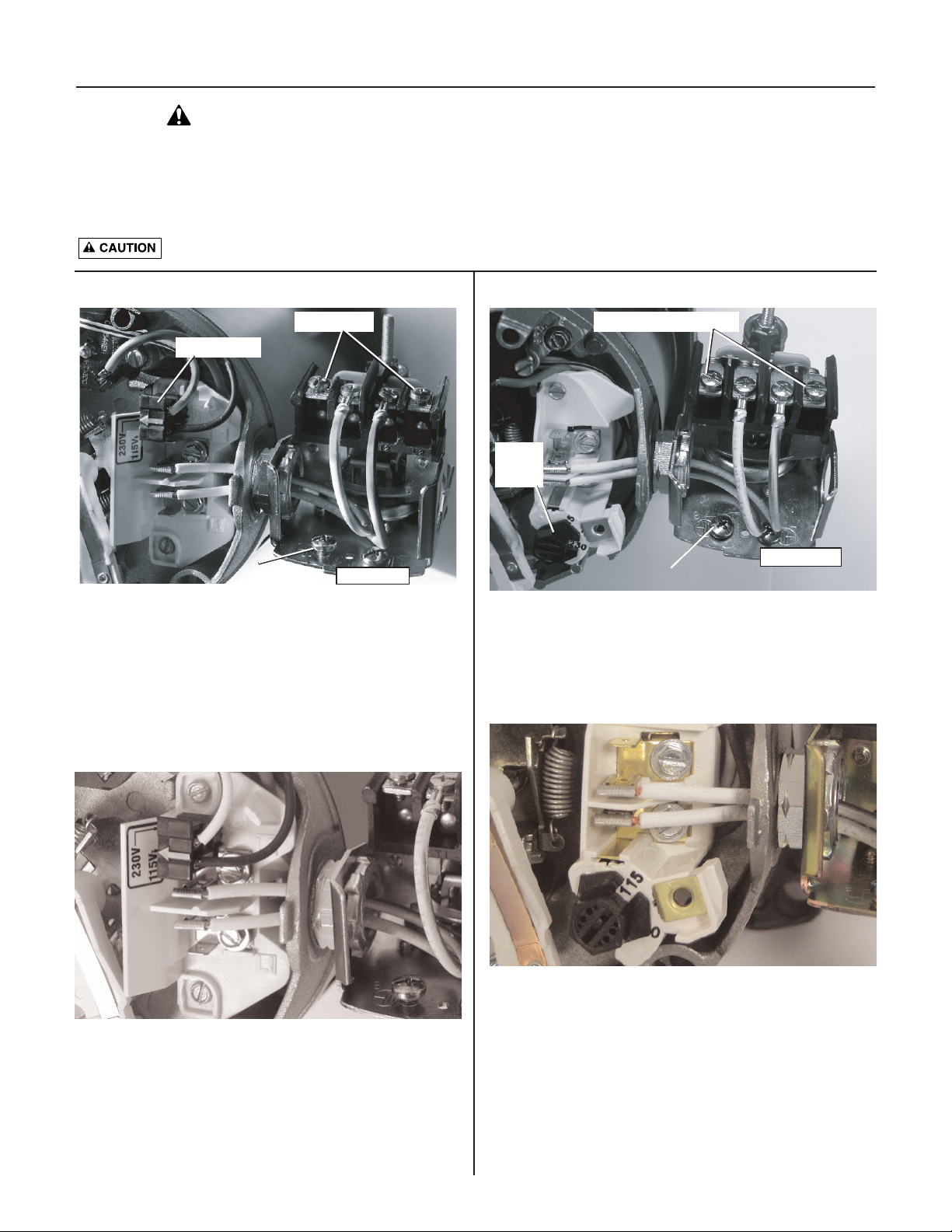

Plug Type Voltage Selector

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Pull the voltage change plug off of the tabs.

3. Move the voltage change plug to the 115 volt position. The plug will now cover 2 metal tabs and the

arrow on the plug will line up with the 115V arrow on

the label (see Figure 7).

4. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 6.

5. Attach the ground wire to one of the grounding

connections, shown in Figure 6.

6. If there are other wires, they should be capped.

7. Reinstall the Motor end cover.

Dial Type Voltage Selector

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in the

dial window as shown in Figure 9.

3. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 8.

4. Attach the ground wire to the grounding connections

as shown in Figure 8.

5. If there are other wires, they should be capped.

6. Reinstall the Motor end cover.

NOTE: 1/2 HP motors are wired for 115 volts only, and have no motor wiring to change.

3/4 HP or 1 HP motor terminal boards (located under the motor end cover) should look like one of those below.

If the motor can operate at either 115 or 230 volts, it is set at the factory to 230 volts. Do not change motor wiring

if line voltage is 230 volts, or if you have a single voltage motor.

Never wire a 115 volt motor to a 230 volt line.

MOTOR SWITCH SETTINGS

Figure 6:Voltage set to 230 volts, Plug Type

Figure 7:Voltage set to 115 volts, Plug Type

Figure 8:Voltage set to 230 volts, Dial Type

Figure 9:Voltage set to 115 volts, Dial Type

Power Connections

Voltage Change Plug

ound Wire Connection

Pressure Switch

Power Supply Connections

Voltage

Change

Dial

Pressure Switch

Ground Wire Connection

Page 8

Electrical 8

Hazardous voltage. Can shock, burn, or

kill. Connect ground wire before connecting power supply wires. Use the wire size (including the ground wire)

specified in the wiring chart. If possible, connect the

pump to a separate branch circuit with no other appliances on it.

Explosion hazard. Do not ground to a gas

supply line.

WIRING CONNECTIONS

Fire hazard. Incorrect voltage can cause a

fire or seriously damage the motor and voids the warranty. The supply voltage must be within ±10% of the motor

nameplate voltage.

NOTICE: Dual-voltage motors are factory wired for 230

volts. If necessary, reconnect the motor for 115 volts, as

shown. Do not alter the wiring in single voltage motors.

Install, ground, wire, and maintain your pump in compliance with the United States National Electrical Code

(NEC) or the Canadian Electrical Code (CEC), as applicable, and with all local codes and ordinances that apply.

Consult your local building inspector for code information.

Connection Procedure:

Step 1. Connect the ground wire first as shown in Figure

6. The ground wire must be a solid copper wire

at least as large as the power supply wires.

Step 2. There must be a solid metal connection between

the pressure switch and the motor for motor

grounding protection. If the pressure switch is not

connected to the motor, connect the green

ground screw in the switch to the green ground

screw under the motor end cover. Use a solid

copper wire at least as large as the power supply

wires.

Step 3. Connect the ground wire to a grounded lead in a

service panel, to a metal underground water

pipe, to a metal well casing at least ten feet (3M)

long, or to a ground electrode provided by the

power company or the hydro authority.

Step 4. Connect the power supply wires to the pressure

switch as shown in Figure 6.

You have just completed the wiring for your

pump.

Please go to Page 9 for startup preparations.

DISTANCE IN FEET(METERS) FROM MOTOR TO SUPPLY

0 - 100 101 - 200 201 - 300 301 - 400 401 - 500

Max. Load Branch Fuse

(0 - 30) (31 - 61) (62 - 91) (92 - 122) (123 - 152)

Model Volts Amp Rating Amp AWG WIRE SIZE (mm2)

HNC-L 115/230 12.2/6.1 20/15 12/14 (3/2) 10/14 (5.5/2) 8/14 (8.4/2) 6/12 (14/3) 6/12 (14/3)

HND-L 115/230 14.8/7.4 20/15 12/14 (3/2) 8/14 (8.4/2) 6/14 (14/2) 6/12 (14/3) 4/10 (21/5.5)

HNE-L 115/230 19.9/10.0 25/15 10/14 (5.5/2) 8/14 (8.4/2) 6/12 (14/3) 4/10 (21/5.5) 4/10 (21/5.5)

Wiring Chart – Recommended Wire and Fuse Sizes

DISTANCE IN FEET(METERS) FROM MOTOR TO SUPPLY

0 - 100 101 - 200 201 - 300 301 - 400 401 - 500

Max. Load Branch Fuse

(0 - 30) (31 - 61) (62 - 91) (92 - 122) (123 - 152)

Model Volts Amp Rating Amp AWG WIRE SIZE (mm2)

HNDX 115/230 12.2/6.1 20/15 12/14 (3/2) 10/14 (5.5/2) 8/14 (8.4/2) 6/12 (14/3) 6/12 (14/3)

HNEX 115/230 14.8/7.4 20/15 12/14 (3/2) 8/14 (8.4/2) 6/14 (14/2) 6/12 (14/3) 4/10 (21/5.5)

HNFX 115/230 19.9/10.0 25/15 10/14 (5.5/2) 8/14 (8.4/2) 6/12 (14/3) 4/10 (21/5.5) 4/10 (21/5.5)

Wiring Chart – Recommended Wire and Fuse Sizes - HNX Series Pumps

Page 9

Preparing to Start the Pump 9

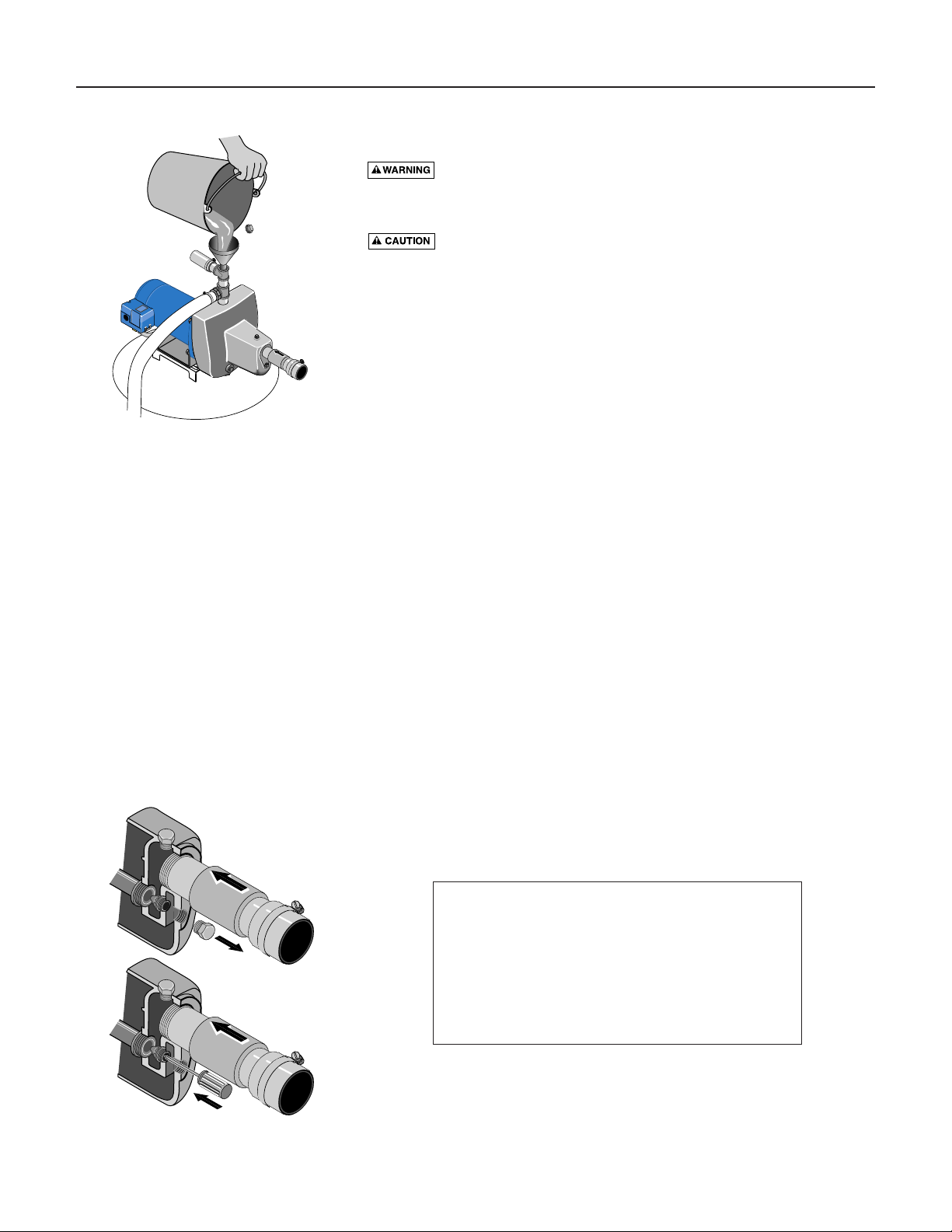

PRIMING

Never run pump against closed discharge. To do so can boil

water inside pump, causing hazardous pressure in unit, risk of explosion

and possibly scalding persons handling pump.

Never run pump dry. Running pump without water may cause

pump to overheat, damaging seal and possibly causing burns to persons

handling pump. Fill pump with water before starting.

Step 1. Remove the priming plug from the pump and fill the pump, fill all

piping between the pump and the well, and make sure that all piping in the well is full. If you have also installed a priming tee in the

suction piping, remove the plug from the tee and fill the suction

piping.

Step 2. Replace all fill plugs.

Step 3. Power on! Start the pump. If you don’t have water after 2 or 3 min-

utes, stop the pump and remove the fill plugs. Refill the pump and

piping. You may have to repeat this several times in order to get all

the trapped air out of the piping. A pump lifting water 25’ may take

as long as 15 minutes to prime.

Step 4. After the pump has built up pressure in the system and shut off,

check the pressure switch operation by opening a faucet or two and

running enough water out to bleed off pressure until the pump

starts. The pump should start when pressure drops to 30 PSI and

stop when pressure reaches 50 PSI. Run the pump through one or

two complete cycles to verify correct operation. This will also help

clean the system of dirt and scale dislodged during installation.

Congratulations on a successful installation.

If you were unsuccessful, please refer to the Troubleshooting section

(Page 10) or call our customer service technical staff.

Figure 10: Prime the Pump

Figure 11: Use Icepick or Brad Awl to

Clean Out Nozzle

Nozzle Clean Out (Low Pressure)

Use an icepick or brad awl to clean out

the nozzle – 3/16" maximum diameter

(see Figure 11). Be sure you DO NOT

enlarge the hole in the nozzle. Use teflon

tape on plug when reassembling to seal it.

2351 0396

Fill pump

and piping

through

priming tee.

1465 0497

Page 10

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not run Disconnect switch is off Be sure switch is on.

Fuse is blown or circuit breaker tripped Replace fuse or reset circuit breaker.

Starting switch is defective DISCONNECT POWER; Replace starting switch.

Wires at motor are loose, Refer to instructions on wiring (Pages 7 and 8). DISCONNECT POWER;

disconnected, or wired incorrectly check and tighten all wiring.

Capacitor voltage may be hazardous. To discharge

capacitor, hold insulated handle screwdriver BY THE HANDLE and

short capacitor terminals together. Do not touch metal screwdriver

blade or capacitor terminals. If in doubt, consult a qualified electrician.

Pressure switch contacts are dirty DISCONNECT POWER and file contacts with emery board or nail file.

Motor runs hot and Motor is wired incorrectly Refer to instructions on wiring.

overload kicks off

Voltage is too low Check with power company. Install heavier wiring if wire size is too small

(See Electrical / Wiring Chart).

Pump cycles too frequently See section below on too frequent cycling.

Motor runs but no Pump in new installation did In new installation:

water is delivered* not pick up prime through:

1. Improper priming 1. Re-prime according to instructions.

2. Air leaks 2. Check all connections on suction line, AVC, and ejector with

soapy water or shaving cream.

3. Leaking foot valve or check valve 3. Replace foot valve or check valve.

Pump has lost prime through: In installation already in use:

1. Air leaks 1. Check all connections on suction line and shaft seal.

2. Water level below suction pipe inlet 2. Lower suction line into water and re-prime. If receding water level

in well exceeds 25’ (7.6M), a deep well pump is needed.

Foot valve or strainer is plugged Clean foot valve or strainer.

Ejector or impeller is plugged Clean ejector or impeller.

Check valve or foot valve is stuck shut Replace check valve or foot valve.

Pipes are frozen Thaw pipes. Bury pipes below frost line. Heat pit or pump house.

Foot valve and/or strainer are Raise foot valve and/or strainer above bottom of water source.

buried in sand or mud Clean foot valve and strainer.

Water level is too low for shallow well A deep well jet package may be needed (over 25 ft. to water)

setup to deliver water to deliver water.

Pump does not Water level in well is lower than A deep well jet will be needed if your well is more than 25’ (7.6M)

deliver water to full estimated depth to water.

capacity

Steel piping (if used) is corroded or Replace with plastic pipe where possible, otherwise with new steel pipe.

limed, causing excess friction

Piping is too small in size Use larger piping.

Packed well point Backflush well point or sink new point.

Pump delivers water but

Pressure switch is out of adjustment or DISCONNECT POWER; adjust or replace pressure switch.

does not shut off or contacts are welded together

pump cycles too

Faucets have been left open Close faucets.

frequently

Venturi, nozzle or impeller is clogged Clean venturi, nozzle or impeller.

Standard pressure tank is waterlogged Drain tank to air volume control port. Check AVC for defects. Check

and has no air cushion all connections for air leaks.

Pipes leak Check connections.

Foot valves leak Replace foot valve.

Air charge too low in pre-charged tank DISCONNECT POWER and open faucets until all pressure is relieved.

Using tire pressure gauge, check air pressure in tank at valve stem

located on the tank. If less than pressure switch cut-in setting (30-50

PSI), pump air into tank from outside source until air pressure is 2 PSI

less than cut-in setting of switch. Check air valve for leaks (use soapy

solution) and replace core if necessary.

Air spurts from faucets Pump is picking up prime When pump has picked up prime, it should pump solid water with no air.

Leak in suction side of pump Suction pipe is sucking air. Check joints for leaks with soapy water.

Well is gaseous Consult factory about installing a sleeve in the well

Intermittent over-pumping of well. Lower foot valve if possible, otherwise restrict pump discharge

(Water drawn down below foot valve.)

Troubleshooting 10

* (Note:

Stop pump;

then check prime

before looking for

other causes.

Unscrew

priming

plug and see if water

is in priming hole).

Page 11

Repair Parts 11

1

2

3

4

5

6

7

8

11

12

12

11A

9

10

11B

18

19

20

14

13

15

16

17

2763 0197

Nozzle

Cleanout

Port

Key HNC-L HNDX HND-L HNEX HNE-L HNFX

No. Part Description Qty. 1/2 HP 3/4 HP 3/4 HP 1 HP 1 HP 1-1/2 HP

1 Motor 1 J218-590PKG J218-590PKG J218-596PKG J218-596PKG J218-601PKG J218-601PKG

2 Capscrew 3/8-16x1-1/4"Lg. Hex Hd. 4 U30-75ZP U30-75ZP – – – –

2 Capscrew 3/8-16x1-1/2"Lg. Hex Hd. 2 – – U30-76ZP U30-76ZP U30-76ZP U30-76ZP

3 Water Slinger 1 17351-0009 17351-0009 17351-0009 17351-0009 17351-0009 17351-0009

4 Seal Plate Assembly 1 N3-9 N3-9 L3-10 L3-10 L3-10 L3-10

5 Gasket, Seal Plate 1 N20-35 N20-35 C20-21 C20-21 C20-21 C20-21

6 Shaft Seal 1 U109-6A U109-6A U109-6A U109-6A U109-6A U109-6A

7 Impeller 1 J105-42P J105-42P J105-8PAN J105-8PAN J105-22PA J105-22PA

8 Volute Diffuser 1 L1-25P L1-25P L1-23P L1-23P L1-23P L1-23P

9 Gasket, Diffuser 1 N20-34 N20-34 N20-34 N20-34 N20-34 N20-34

10 Quick Connect, 1/4"NPT 1 U11-217P U11-217P U11-217P U11-217P U11-217P U11-217P

11 Pump Body Assembly* 1 N176-43B N176-43B N176-44 N176-44 N176-44A N176-44A

11A Venturi 1 N32P-75 N32P-75 N32P-64 N32P-64 N32P-65 N32P-65

11B Nozzle 1 N34P-21 (#47) N34P-21 (#47) J34P-44 (#54) J34P-44 (#54) J34P-44 (#54) J34P-44 (#54)

12 Pipe Plug, 1/4"NPT Hex Hd. ( ) U78-941ZPV(3) U78-941ZPV(3) U78-941ZPV(4) U78-941ZPV(4) U78-941ZPV(4)

U78-941ZPV(4

)

13 Capscrew 3/8-16x1-1/2"Lg. Hex Hd. 2 – – U30-76ZP U30-76ZP U30-76ZP U30-76ZP

14 Base 1 J4-9 J4-9 J4-9C J4-9C J4-9C J4-9C

15 Rubber Pad 1 C35-5 C35-5 C35-5 C35-5 C35-5 C35-5

16 Tube, 1/4"I.D. (length varies) 1 U37-676P U37-676P U37-672P U37-672P U37-677P U37-677P

17 Quick Connect Elbow, 1/4"NPT 1 U11-218P U11-218P U11-218P U11-218P U11-218P U11-218P

18 Pressure Switch 1 U217-1216 U217-1216 U217-1216 U217-1216 U217-1216 U217-1216

19 Locknut, 1/2

"

1 U36-112ZPP U36-112ZPP U36-112ZPP U36-112ZPP U36-112ZPP U36-112ZPP

20 Connector 1 L43-5C L43-5C L43-5C L43-5C L43-5C L43-5C

• Diffuser Screw, #8-32x3/4

"

3 – – U30-489SS U30-489SS U30-489SS U30-489SS

• Diffuser Washer, #8 Ext. Tooth 3 – – U43-21SS – U43-21SS U43-21SS

• Pulsation Plug 1 – – – – U17-1131 U17-1131

REPAIR PARTS LIST

• Not illustrated.

* Models HNC-L and HNDX require 3 pipe plugs; other models require 4 pipe plugs.

Page 12

12

LIMITED WARRANTY

Sta-Rite Industries warrants to the original consumer of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period from the date of original installation or manufacture

as noted.

Product Warranty Period

Water Systems Products – jet pumps,

whichever occurs first:

small centrifugal pumps, submersible pumps 1 year from date of original installation, or

and related accessories 2 years from date of manufacture

Hydro-Flow Filters 1 year from date of purchase

Signature 2000 Fibrewound Tanks 5 years from date of original installation

Pro-Source Steel Pressure Tanks 5 years from date of original installation

Pro-Source Epoxy-Line Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 1 year from date of original installation, or

2 years from date of manufacture

Our warranty will not apply to any product that has been subject to negligence, misapplication, improper installation or maintenance. In the event a three phase submersible motor is operated with single phase power through

a phase converter, or if three-leg ambient compensated, extra-quick trip overload relays of recommended size

are not used, our warranty is void.

Buyer’s only remedy and Sta-Rite Industries’ only duty is to repair or replace defective products (at Sta-Rite

Industries’ choice). Buyer agrees to pay all labor and shipping charges associated with this warranty and to

request warranty service through the installing dealer as soon as a problem is discovered. If warranty service is

requested more than 30 days after the Warranty Period has ended, it will not be honored.

STA-RITE INDUSTRIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit the exclusion or limitation of incidental or consequential damages or the placing of

limitations on the duration of an implied warranty, therefore, the limitations or exclusions herein may not apply.

This warranty sets forth specific legal rights and obligations, however, additional rights may exist, which may vary

from state to state.

Supersedes all previous publications.

Sta-Rite Industries, 293 Wright St., Delavan, WI 53115

Loading...

Loading...