Sta-Rite HMSD-1FL Installation Manual

OWNERS MANUAL

INSTALLATION AND OPERATING INSTRUCTIONS

REPAIR PARTS LIST

Horizontal Multi-Stage Jet Pumps

“HMS-1FL” Series

MODELS

STA-RITE INDUSTRIES

293 Wright St., Delavan, WI 53115

© 2005 S1002 (Rev. 3/4/09)

3/4 HP 1 HP 1-1/2 HP

HMSD-1FL HMSE-1FL HMSF-1FL

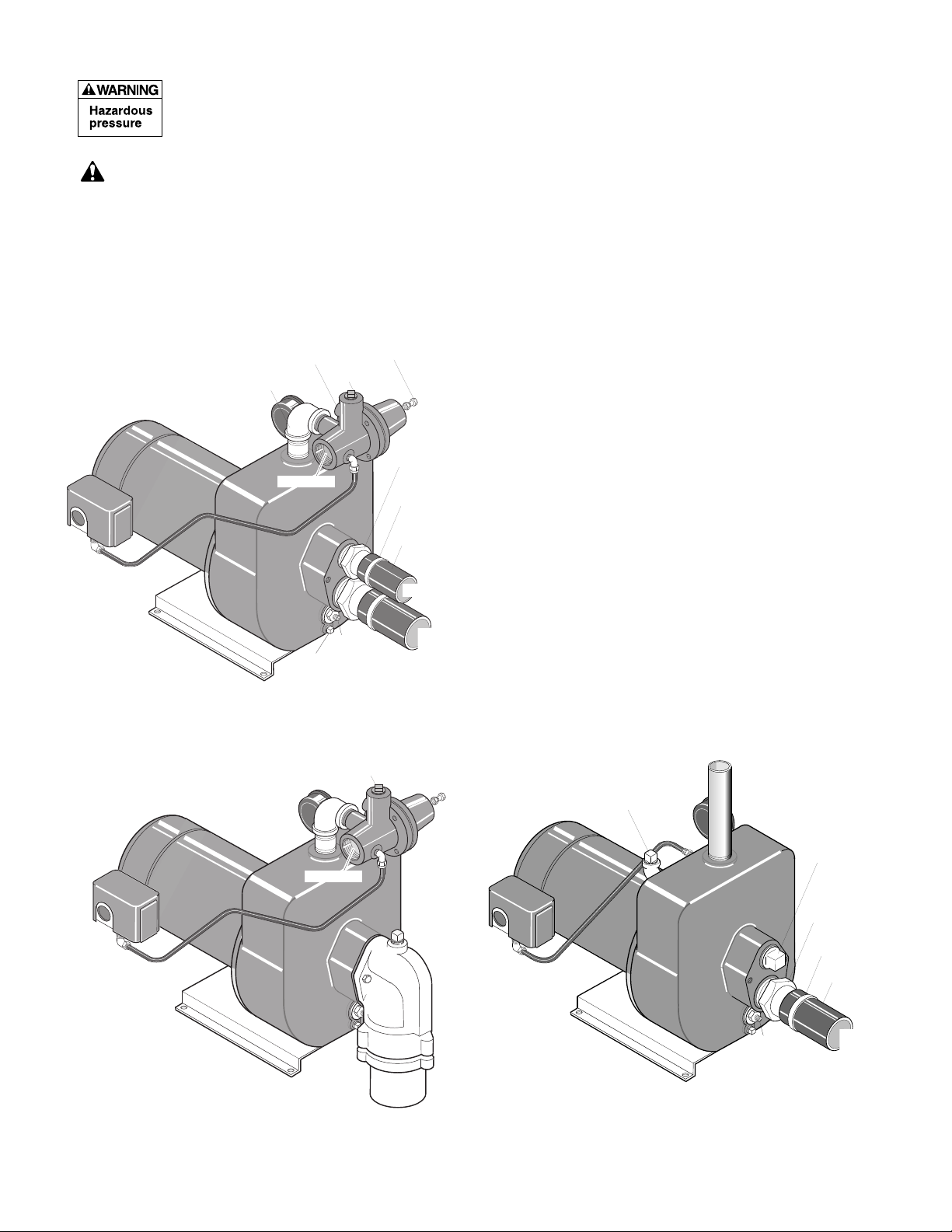

Deep Well Installation

Under certain conditions, horizontal multistage pumps can develop extremely high

pressure. Install a pressure relief valve

capable of passing entire pump flow at 75 PSI.

Do not allow pump, pressure tank, piping, or any

other system component containing water to freeze.

Freezing may damage system, leading to injury or flooding. Allowing pump or system components to freeze will

void warranty.

NOTICE: Support pump base to avoid strain on casing adapter

or pump. Lack of support can damage adapter or pump.

Figure 2 shows casing adapter bolted directly to pump body.

Shallow Well Installation

NOTICE: If no foot valve is used, install 1” check valve in

horizontal line.

Priming the Deep Well Pump

To prime pump, completely close the priming valve located

just below the suction opening by turning screw clockwise.

This valve will be left closed during operation in a deep well

installation. See Figure 1.

Close regulator adjusting valve, located on end of regulator,

by turning stem clockwise. See Figure 1.

Remove priming plug from top of regulator valve, see Figure

1, and fill with clean water. Replace plug.

Start pump and run a few moments.

If pressure does not build up, remove priming plug and refill

with more water. All of the trapped air in pump body was not

removed.

Restart pump.

When pump is completely primed and builds up pressure,

slowly open the regulator valve, (turn counter-clockwise), and

observe the pressure reading on the pressure gauge.

When the pump reaches a point where it will lose prime, cavitation noise can be heard.

The best, or correct, pressure gauge setting is approximately

3 pounds higher than the pressure gauge reading was when

the pump started to lose prime.

If pump loses prime, repeat the priming procedure above and

this time open regulator valve only until the correct pressure

reading is reached.

If a vacuum gauge is available, screw it into the 1/8” AVC

tapping on front of tank body. Adjust regulator until 20” of

vacuum is registered on the gauge. Tighten locknut on regulator. This method will give maximum performance of the

unit.

2

Priming

Valve

Pipe fittings not furnished

Drain

Plug

Drive Line

Suction

Line

Plastic Pipe

Adapter (2)

Plastic Hose

(2)

Hose Clamp

(2)

To Service

Regulator Adjusting

Valve

Priming Plug

Regulator

Va lv e

1" Close nipple &

90 Elbow

278 1093

To Service

Priming Plug

Regulator

Va l ve

279 1093

To Service

Priming

Valve

From

Well

1" Pipe Plug

Plastic Pipe

Adapter

Hose Clamp

Plastic

Hose

Pipe fittings not furnished

Priming Plug &

1/2" Street Elbow

240 1093

Figure 1 – Deep Well Installation

Figure 2 – Well Casing Adapter bolted directly

to pump

Figure 3 – Shallow Well Installation

HMSC pumps come equipped with pressure switch set to

operate within a 20-40 PSI range. HMSD, HMSE, and HMSF

pumps have 30-50 PSI pressure switches. When pump is

used with precharged tank in system, set tank pre-charge at

18 PSI with a 20-40 PSI switch; set tank pre-charge at 28

PSI with a 30-50 PSI switch. Check tank pre-charge annually

with an ordinary tire gauge. Pre-charge is set with no water

pressure on system.

Priming the Shallow Well Pump

Never run pump dry. Running pump without

water may cause pump to overheat, damaging seal and possibly causing burns to persons handling pump. Fill pump with

water before starting.

Never run pump against closed discharge.

To do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding persons handling pump.

To prime the pump, completely open the priming valve located just below the suction opening on the tank body by turning

the valve stem counter-clockwise all the way until it stops.

This valve may be left open during operation as a shallow

well pump with no jet. See Figure 3 and “NOTICE” below.

Remove priming plug from top of elbow (see Figure 3), and

fill with clean water. Replace plug.

Start pump and between 45-60 seconds. If water is not being

pumped, turn off pump and repeat priming process.

NOTICE: If a bolt-on jet is being used, after pump is primed,

close the priming valve during operation as a shallow well

pump.

Service – Draining for Winter

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for 20 minutes after shut-down before handling.

When the pump is to be disconnected from service, or is in

danger of freezing, it should be drained. The pump has a

drain plug which must be removed. Remove the priming plug

to vent the pump.

If pump and motor are damaged due to freezing, the

Warranty is void.

3

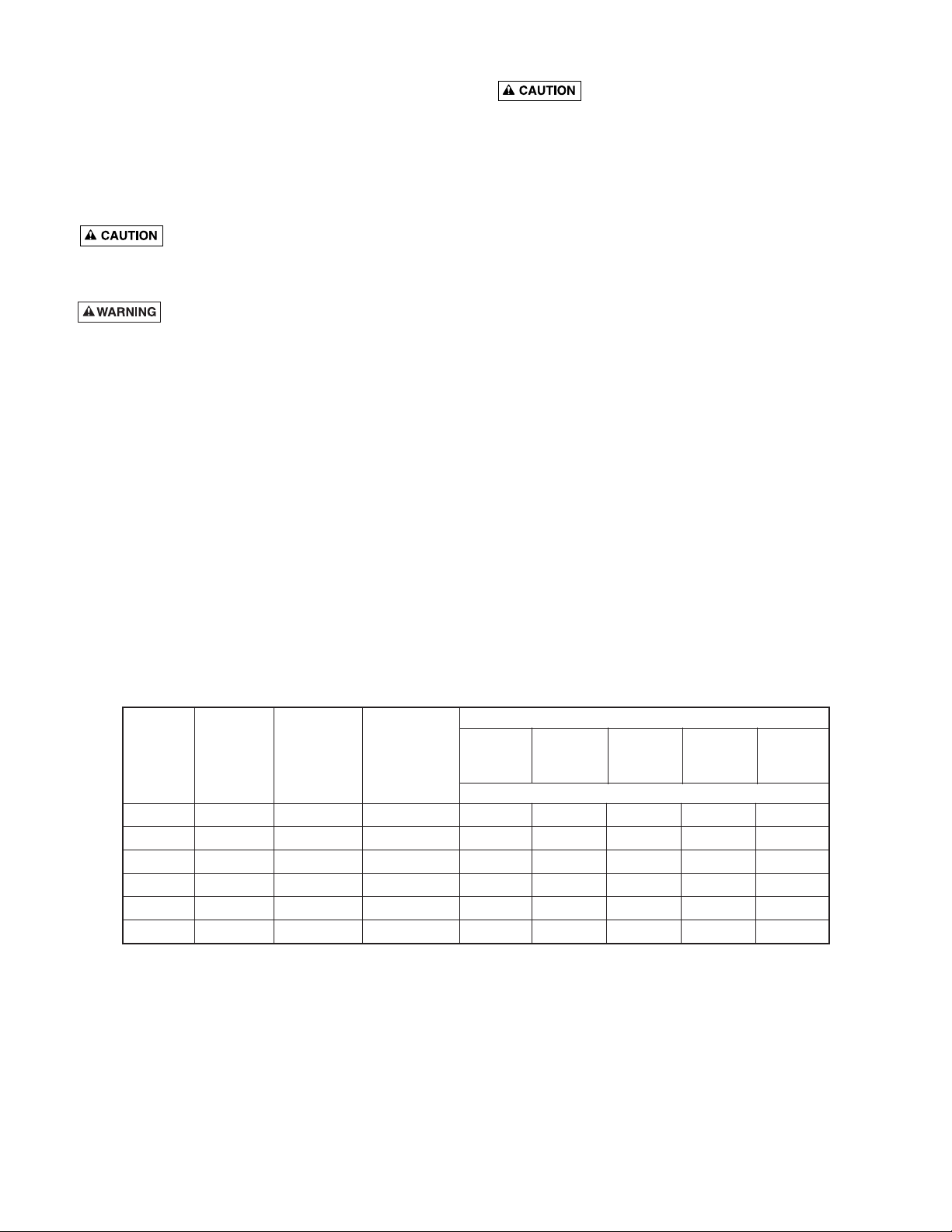

TABLE I

Recommended Fusing and Wiring Data – 60 Cycle Motors

DISTANCE IN FEET FROM MOTOR TO METER

BRANCH 0’ 101’ 201’ 301’ 401’

MAX. FUSE* to to to to to

MOTOR LOAD RATING 100’ 200’ 300’ 400’ 500’

HP VOLTS AMPERES AMPS

WIRE SIZE

3/4 115 14.8 20 12 8 6 6 4

3/4 230 7.4 15 14 14 14 12 10

1 115 19.2 25 10 8 6 4 4

1 230 9.6 15 14 14 12 10 10

1-1/2 115 24.0 30 10 6 6 4 3

1-1/2 230 12.0 15 14 14 12 10 10

*Fusetrons are recommended instead of fuses on all motor circuits.

Loading...

Loading...