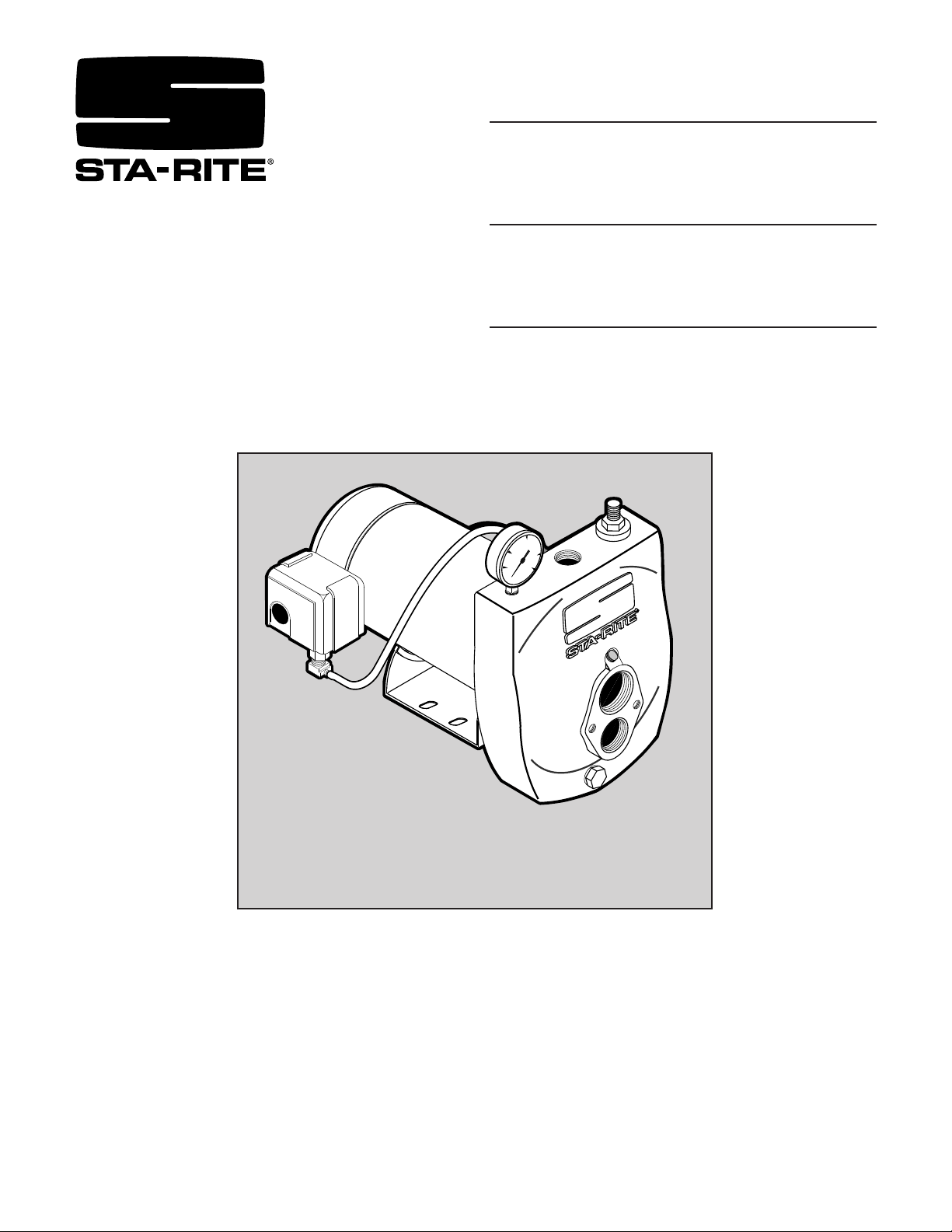

Page 1

OWNER’S MANUAL

Convertible Deep Well Jet Pumps

NOTICE D’UTILISATION

Pompe à éjecteur transformables

pour puits profonds

MANUAL DEL USUARIO

Bombas Convertibles tipo “Jet”

para Pozos Profundos

Installation/Operation/Parts

For further operating, installation, or

maintenance assistance:

Call 1-262-728-5551

English . . . . . . . . . . . . . . Pages 2-12

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le

1 (262) 728-5551

Français . . . . . . . . . . . Pages 13-23

Instalación/Operación/Piezas

Para mayor información sobre el

funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 1-262-728-5551

Español . . . . . . . . . . .Paginas 24-34

20

40

60

80

100

S416 (Rev. 4/23/09)

293 Wright Street, Delavan, WI 53115

“SL” Series / Série “SL” / Serie “SL”

“HL” Series / Série “HL” / Serie “HL”

Page 2

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury:

warns about hazards that will cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if

ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which

are important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

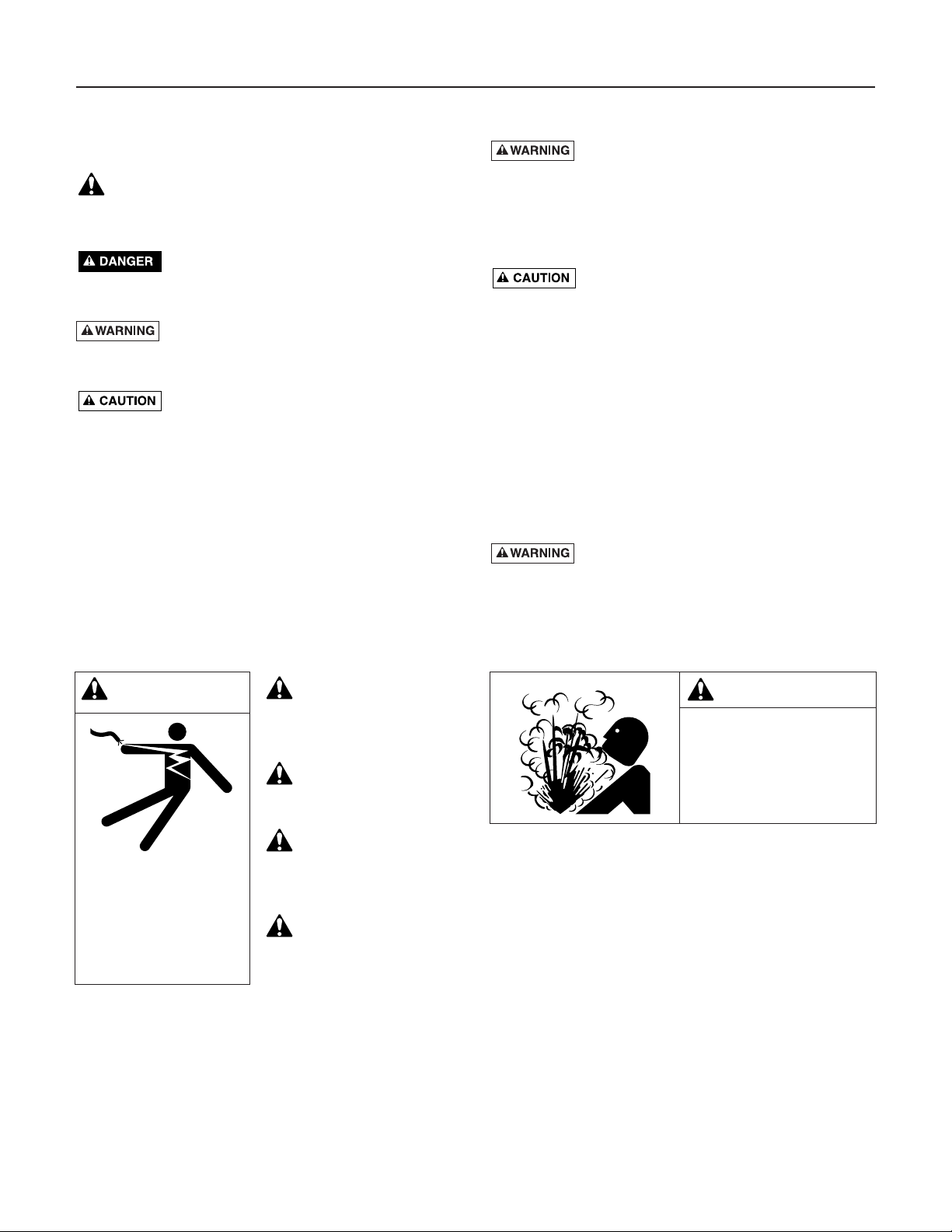

ELECTRICAL SAFETY

Capacitor voltage may be hazardous. To dis-

charge motor capacitor, hold insulated handle screwdriver

BY THE HANDLE and short capacitor terminals together.

Do not touch metal screwdriver blade or capacitor terminals. If in doubt, consult a qualified electrician.

GENERAL SAFETY

Do not touch an operating motor. Modern

motors are designed to operate at high temperatures. To

avoid burns when servicing pump, allow it to cool for 20

minutes after shut-down before handling.

Do not allow pump or any system component to freeze.

To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system components.

Wear safety glasses at all times when working on pumps.

Keep work area clean, uncluttered and properly lighted;

store properly all unused tools and equipment.

Keep visitors at a safe distance from the work areas.

Pump body may explode if used as a

booster pump unless relief valve capable of passing full

pump flow at 100 psi is installed.

WARNING

Hazardous pressure!

Install pressure relief

valve in discharge pipe.

Release all pressure on

system before working on

any component.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply. Disconnect power

before working on pump,

motor or tank.

Wire motor for correct

voltage. See “Electrical”

section of this manual and

motor nameplate.

Ground motor before

connecting to power

supply.

Meet National Electri-

cal Code, Canadian

Electrical Code, and local

codes for all wiring.

Follow wiring instruc-

tions in this manual

when connecting motor to

power lines.

Page 3

Table of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

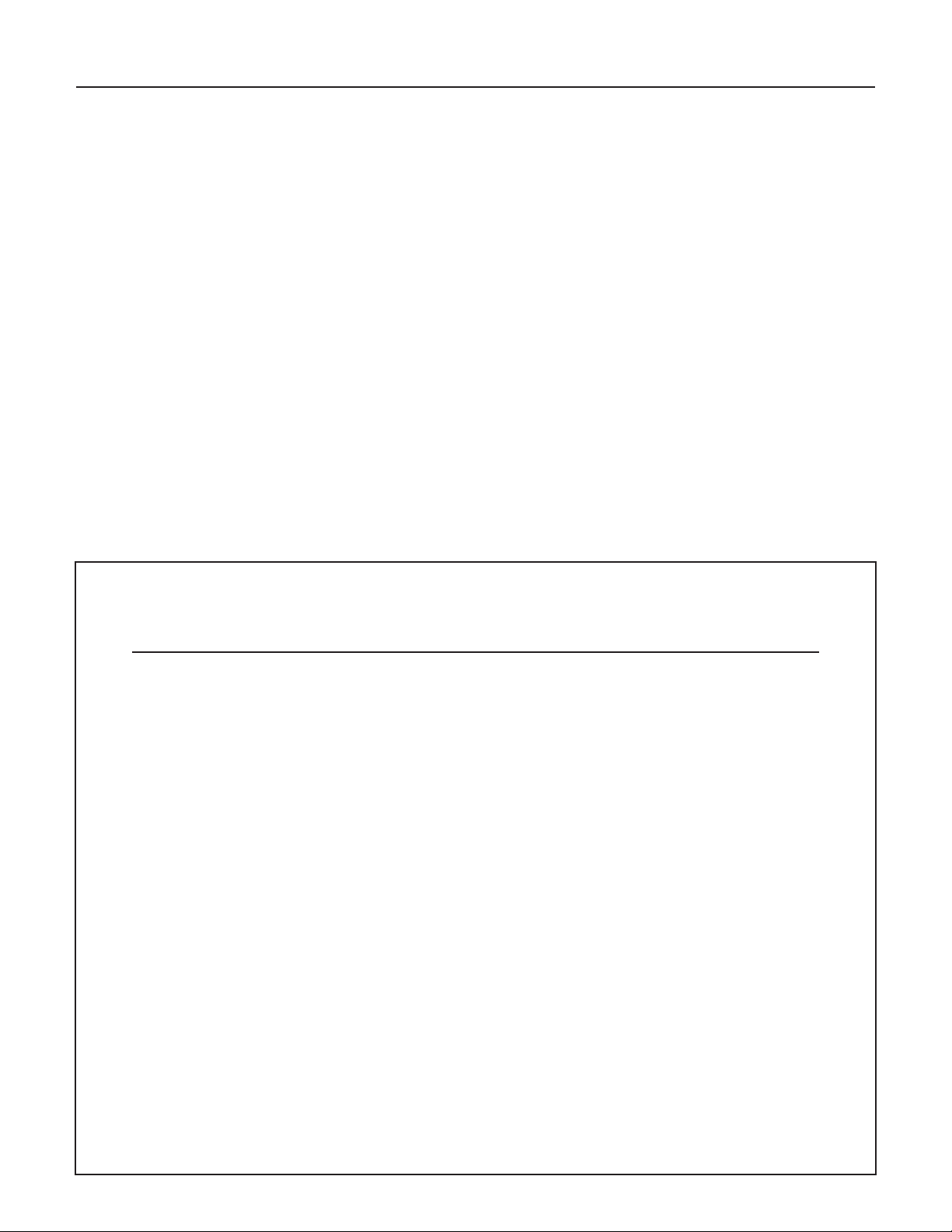

Typical Installations..............................................................................................4

Discharge Pipe and Pressure Tank Connections ...................................................5

Electrical..........................................................................................................6, 7

Preparing To Start The Pump – Deep Well ...........................................................8

Preparing To Start The Pump – Shallow Well ......................................................9

Repair Parts .................................................................................................10, 11

Troubleshooting..................................................................................................12

LIMITED WARRANTY

STA-RITE warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be

free from defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems Products — jet pumps,

whichever occurs first:

small centrifugal pumps, submersible pumps 12 months from date of original installation, or

and related accessories 18 months from date of manufacture

Pro-Source

TM

Composite Tanks 5 years from date of original installation

Pro-Source

TM

Steel Pressure Tanks 5 years from date of original installation

Pro-Source

TM

Epoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 12 months from date of original installation, or

18 months from date of manufacture

Our warranty will not apply to any product that, in our sole judgement, has been subject to negligence, misapplication,

improper installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single

phase power through a phase converter will void the warranty. Note also that three phase motors must be protected by

three-leg, ambient compensated, extra-quick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and STA-RITE’s only duty, is that STA-RITE repair or replace defective products (at STA-RITE’s choice).

You must pay all labor and shipping charges associated with this warranty and must request warranty service through the

installing dealer as soon as a problem is discovered. No request for service will be accepted if received after the Warranty

Period has expired.This warranty is not transferable.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES

WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.THE FOREGOING WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION

EXPRESSLY PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on the duration

of an implied warranty, so the above limitations or exclusions may not apply to You.This warranty gives You specific legal

rights and You may also have other rights which vary from state to state.

This warranty supersedes and replaces all previous warranty publications.

STA-RITE INDUSTRIES

293 Wright St., Delavan,WI 53115

Page 4

0

0

60

80

100

20

0

6

80

100

Drive Pipe

sends water

down the well

to drive water

up through the

Suction Pipe

to Pump Suction

Drive

over

Suction

Piping omitted

for clarity

Discharge

1799 0497

Suction

over

Drive

20

40

60

80

100

Suction

Pipe

Drive

Pipe

Well

Head

If well head and pump

don't match, twist

reinforced flexible pipe

to connect drive

and suction pipes.

1800 0497

1903 0497

20

0

60

80

100

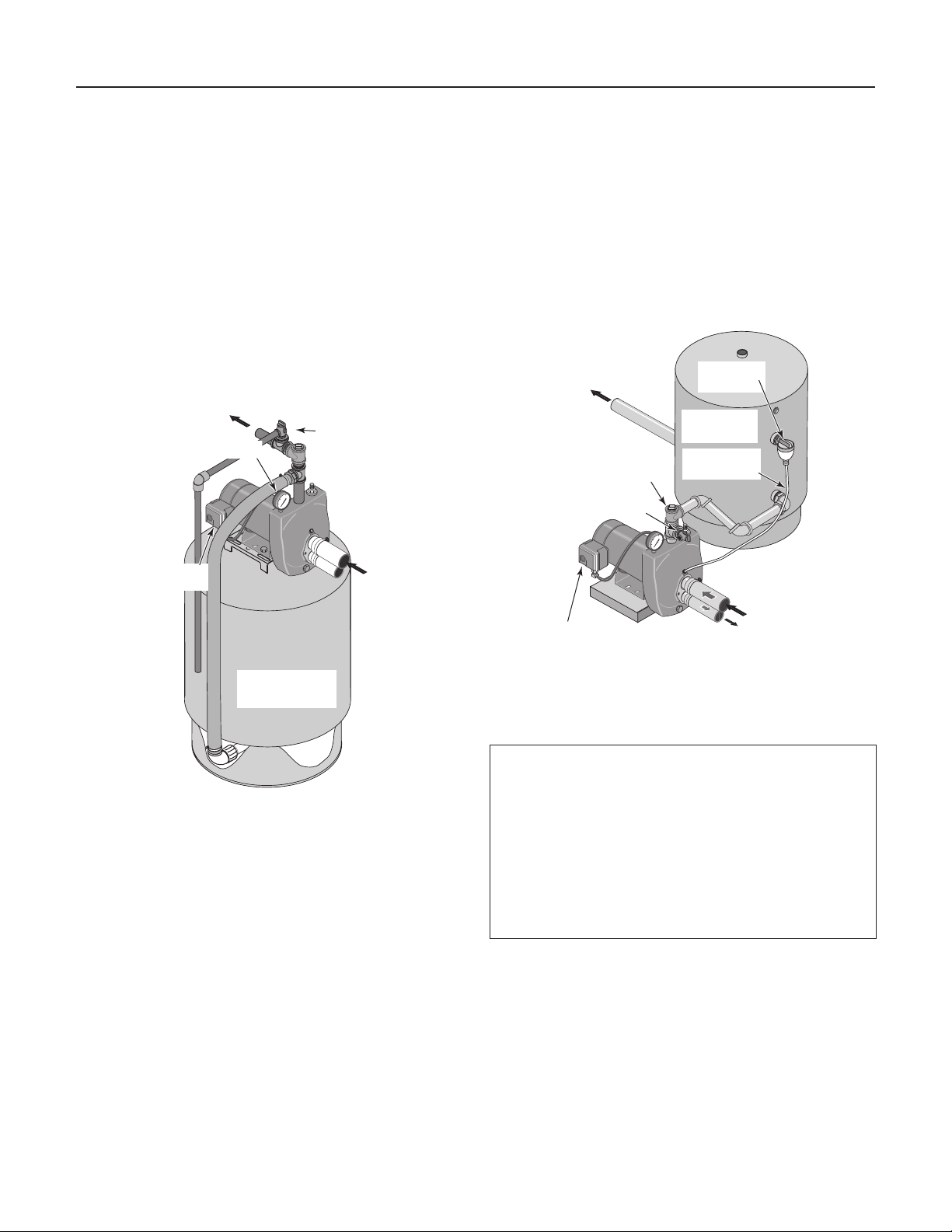

Figure 1: Drive and Suction Functions

Figure 2: Reversed Connections

to Well

Figure 3: Mount Ejector –

Shallow Well

Typical Installations 4

To Household

Water System

Not

to

Scale

Relief Valve

Drive

Point

Precharged

Tank

Check

Valve

2097 0497

20

0

60

8

10

Priming

Tee and

Plug

Drive

Coupling

Drive

Point

Check

Valve

Drive point

below water

level

Pressure Gauge

Figure 5:Typical Shallow Well Installations

Venturi

Suction (Larger)

Pipe from Well

Well

Head

Drive

(Smaller)

Pipe to

Well

Nozzle

Ejector

Foot Valve

Strainer

1

ET NO

J 2P

24

Well Casing

serves as

Drive Pipe

Leather

Cup Seals

"Double Pipe"

(4" and Larger

Diameter Well)

"Single Pipe"

(2" and 3"

Diameter Well)

1834 0695

Figure 4:Typical Deep Well Installations

To Household

Water System

Air Volume

Control

Standard

Tank

60

0

8

0

10

Drive Pipe

To Well

Air Volume

Control Tube

2096 0497

Suction Pipe

From Well

Priming Tee

and Plug

Relief Valve

Pressure

Switch

Cased

Well

Foot

Valve

Strainer

Suction Pipe

From Well

Priming

Tee and

Plug

Sanitary

Well Seal

Well

Casing

Foot

10'

Min.

Valve

5–10'

Screen

1836 0695

Open

Water

Page 5

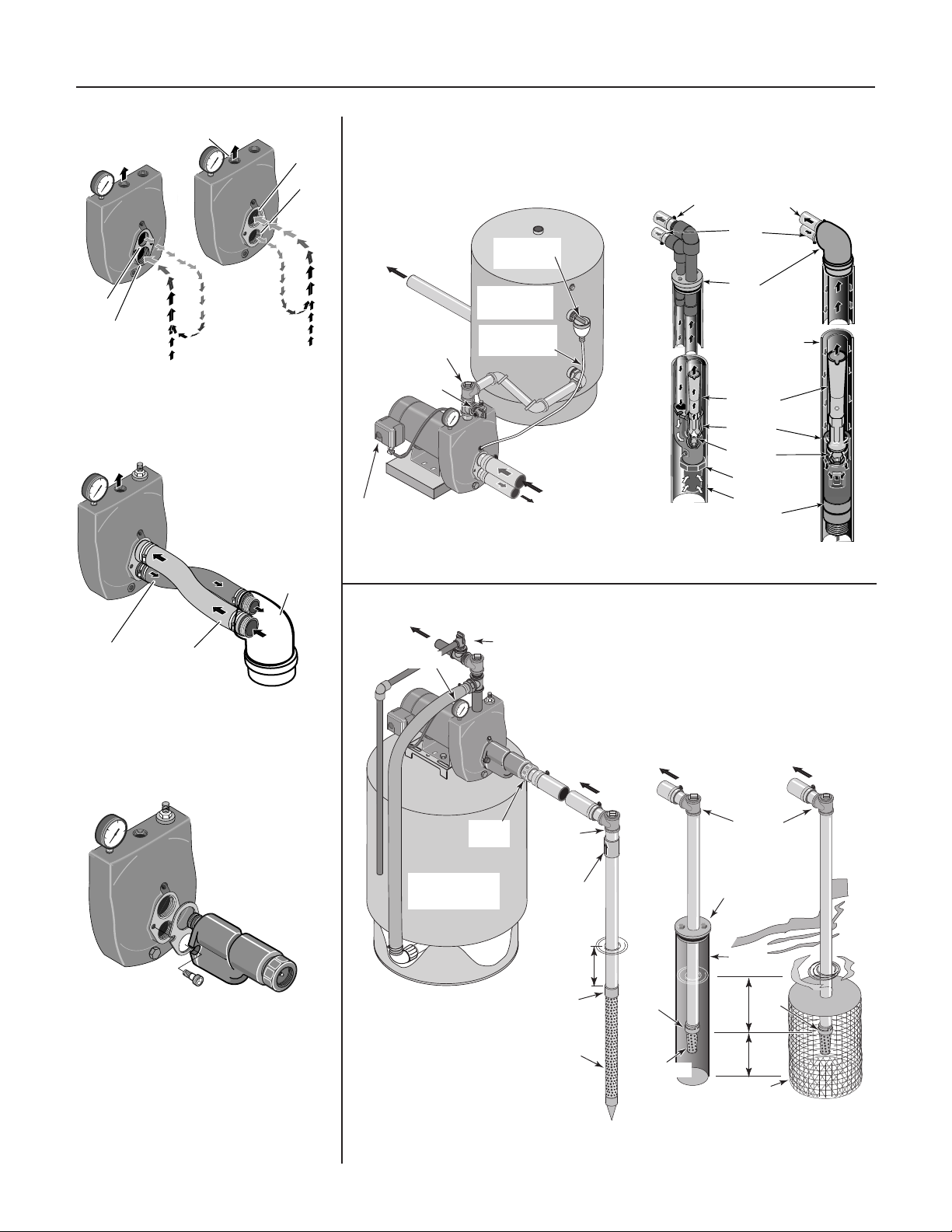

Discharge Pipe and Pressure Tank Connections 5

PRE-CHARGE TANK CONNECTION (Figure 6)

If your system uses a Con-Aire (pre-charged) tank, it

should be connected to the pump as shown in Figure 6.

The relief valve must be capable of passing the entire

pump capacity at 100 PSI pressure.

Check the pre-charge of air in the tank with an ordinary

tire gauge. the pre-charge is measured

when there is no

water pressure in the tank.

Disconnect power to the

pump and drain the tank before checking the pre-charge.

Your pump has a 30/50 PSI switch, so the tank precharge pressure should be 28 PSI (that is, it should be 2

PSI lower than the cut-in pressure of the pressure switch.

No AVC is required for a pre-charged tank; the 1/8" NPT

AVC port on the pump body should be plugged.

STANDARD TANK CONNECTION (Figure 7)

If your system uses a standard tank, connect it to the

pump as shown in Figure 7. The relief valve used with a

standard tank must be capable of passing the entire

pump capacity at 75 PSI pressure.

Connect the Air Volume Control (AVC) tube to the 1/8"

NPT AVC port on the pump body. Run the tubing from

the pump’s AVC port to the AVC mounted on the tank.

See the instructions provided with tank and AVC for

details.

Sealing Pipe Joints

Use only Teflon tape or Teflon based joint compounds for making all threaded connections to the

pump itself. Do not use pipe joint compounds on

plastic pumps: they can react with the plastic in

pump components. Make sure that all pipe joints in

the suction pipe are air tight as well as water tight.

If

the suction pipe can suck air, the pump will not be

able to pull water from the well.

From

Well

To Household

Water System

Relief Valve

Pre-Charged

Tank

20

0

60

8

10

Pressure Gauge

Pressure

Switch

Figure 6: Pre-charged Tank Connections

Figure 7: Standard Tank Connections

To Household

Water System

Priming Tee

and Plug

Relief Valve

0

60

0

0

10

Air Volume

Control

Standard

Tank

Air Volume

Control Tube

2096 0497

Suction Pipe

From Well

Pressure

Switch

Drive Pipe

To Well

Page 6

Electrical 6

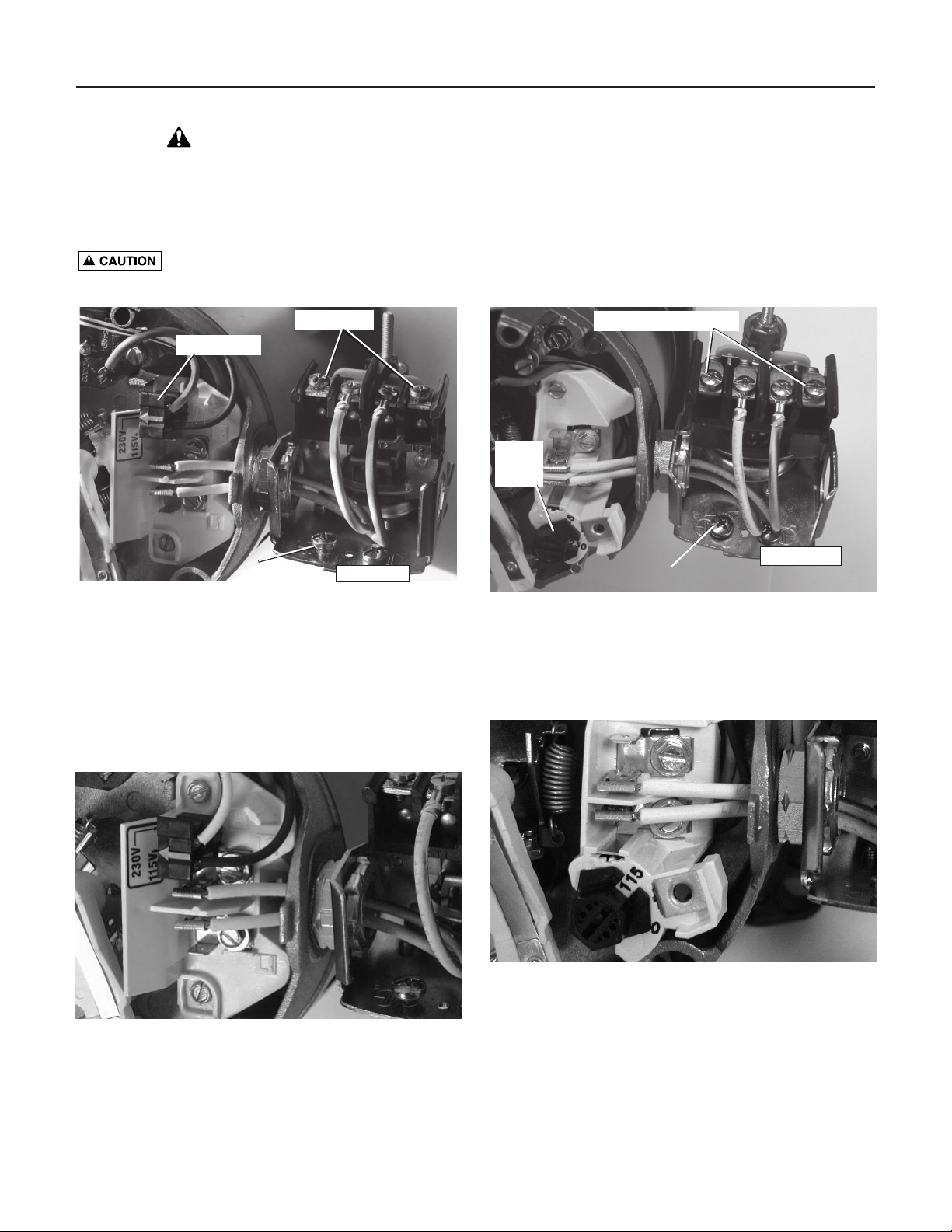

Plug Type Voltage Selector

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Pull the voltage change plug off of the tabs.

3. Move the voltage change plug to the 115 volt position. The plug will now cover 2 metal tabs and the

arrow on the plug will line up with the 115V arrow on

the label (see Figure 9).

4. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 8.

5. Attach the ground wire to one of the grounding

connections, shown in Figure 8.

6. If there are other wires, they should be capped.

7. Reinstall the Motor end cover.

Dial Type Voltage Selector

Voltage is factory set to 230 volts. To change to 115 volts:

1. Make sure power is off.

2. Turn the dial counter-clockwise until 115 shows in the

dial window as shown in Figure 11.

3. Attach the incoming power leads to the two outer

screws on the pressure switch as shown in Figure 10.

4. Attach the ground wire to the grounding connections

as shown in Figure 10.

5. If there are other wires, they should be capped.

6. Reinstall the Motor end cover.

Disconnect power before working on pump, motor, pressure switch, or wiring.

NOTE: 1/2 HP motors are wired for 115 volts only, and have no motor wiring to change.

3/4 HP or 1 HP motor terminal boards (located under the motor end cover) should look like one of those below.

If the motor can operate at either 115 or 230 volts, it is set at the factory to 230 volts. Do not change motor wiring

if line voltage is 230 volts, or if you have a single voltage motor.

Never wire a 115 volt motor to a 230 volt line.

MOTOR SWITCH SETTINGS

Figure 8:Voltage set to 230 volts, Plug Type

Ground Wire Connection

Voltage Change Plug

Pressure Switch

Power Connections

Figure 9:Voltage set to 115 volts, Plug Type

Figure 10:Voltage set to 230 volts, Dial Type

Power Supply Connections

Voltage

Change

Dial

Pressure Switch

Figure 11:Voltage set to 115 volts, Dial Type

Page 7

Electrical 7

For parts or assistance, call Flotec Customer Service at 1-800-365-6832

Hazardous voltage. Can shock, burn, or kill.

Connect ground wire before connecting power supply wires.

Use the wire size (including the ground wire) specified in

the wiring chart. If possible, connect the pump to a separate

branch circuit with no other appliances on it.

Explosion hazard. Do not ground to a gas supply line.

WIRING CONNECTIONS

Fire hazard. Incorrect voltage can cause a

fire or seriously damage the motor and voids the warranty.

The supply voltage must be within ±10% of the motor

nameplate voltage.

NOTICE: Dual-voltage motors are factory wired for 230

volts. If necessary, reconnect the motor for 115 volts, as

shown. Do not alter the wiring in single voltage motors.

Install, ground, wire, and maintain your pump in compliance with the National Electrical Code (NEC) or the

Canadian Electrical Code (CEC), as applicable, and with

all local codes and ordinances that apply. Consult your

local building inspector for code information.

Connection Procedure:

Step 1. Connect the ground wire first as shown in Figure

11. The ground wire must be a solid copper wire

at least as large as the power supply wires.

Step 2. There must be a solid metal connection between

the pressure switch and the motor for motor

grounding protection. If the pressure switch is not

connected to the motor, connect the green

ground screw in the switch to the green ground

screw under the motor end cover. Use a solid

copper wire at least as large as the power supply

wires.

Step 3. Connect the ground wire to a grounded lead in a

service panel, to a metal underground water

pipe, to a metal well casing at least ten feet (3M)

long, or to a ground electrode provided by the

power company or the hydro authority.

Step 4. Connect the power supply wires to the pressure

switch as shown in Figure 11.

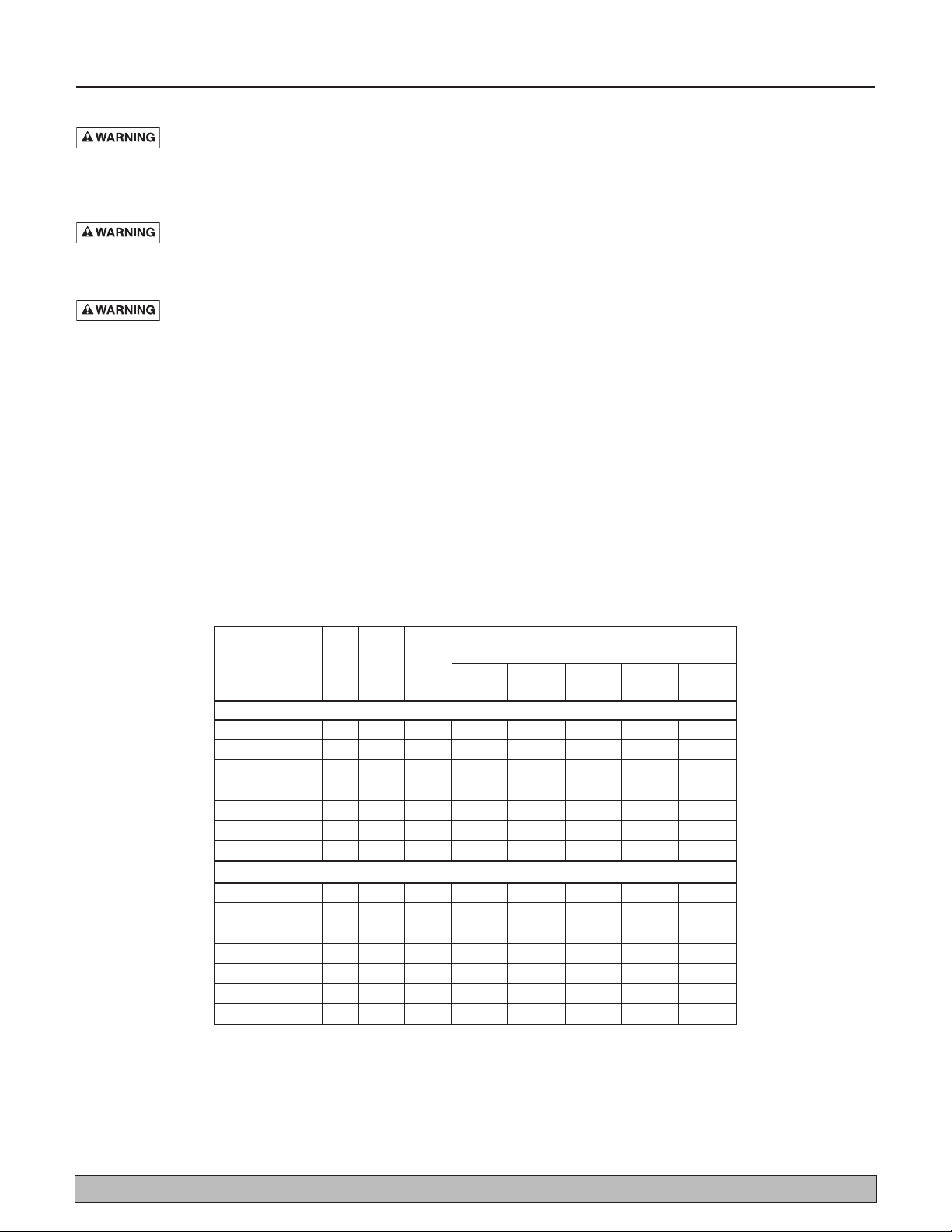

Table I: Wiring Chart – Recommended Wire and Fuse Sizes

Branch Distance in Feet (Meters);

Max Fuse Wire Size AWG (mm2)

Load Rating 0-100 101-200 201-300 301-400 401-500

Model HP Amps Amps (0-30) (31-61) (62-91) (92-122) (123-152)

115Volts:

SLC 1/2 9.9 15 14(2) 10(5.5) 8(8.4) 8(8.4) 6(14)

HLC 1/2 12.4 20 12(3) 10(5.5) 8(8.4) 6(14) 6(14)

SLD 3/4 12.4 20 12(3) 10(5.5) 8(8.4) 6(14) 6(14)

HLD 3/4 14.8 20 12(3) 8(8.4) 6(14) 6(14) 4(21)

SLE 1 14.8 20 12(3) 8(8.4) 6(14) 6(14) 4(21)

HLE 1 19.9 25 10(5.5) 8(8.4) 6(14) 4(21) 4(21)

SLF 1-1/2 19.9 25 10(5.5) 8(8.4) 6(14) 4(21) 4(21)

230 Volts:

SLC 1/2 4.9 15 14(2) 14(2) 14(2) 14(2) 12(3)

HLC 1/2 6.2 15 14(2) 14(2) 14(2) 12(3) 12(3)

SLD 3/4 6.2 15 14(2) 14(2) 14(2) 12(3) 12(3)

HLD 3/4 7.4 15 14(2) 14(2) 14(2) 12(3) 10(5.5)

SLE 1 7.4 15 14(2) 14(2) 14(2) 12(3) 10(5.5)

HLE 1 9.9 15 14(2) 14(2) 12(3) 10(5.5) 10(5.5)

SLF 1-1/2 9.9 15 14(2) 14(2) 12(3) 10(5.5) 10(5.5)

Page 8

Never run pump against closed discharge. To

do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding

persons handling pump.

Never run pump dry. Running pump without

water may cause pump to overheat, damaging seal and

possibly causing burns to persons handling pump. Fill

pump with water before starting.

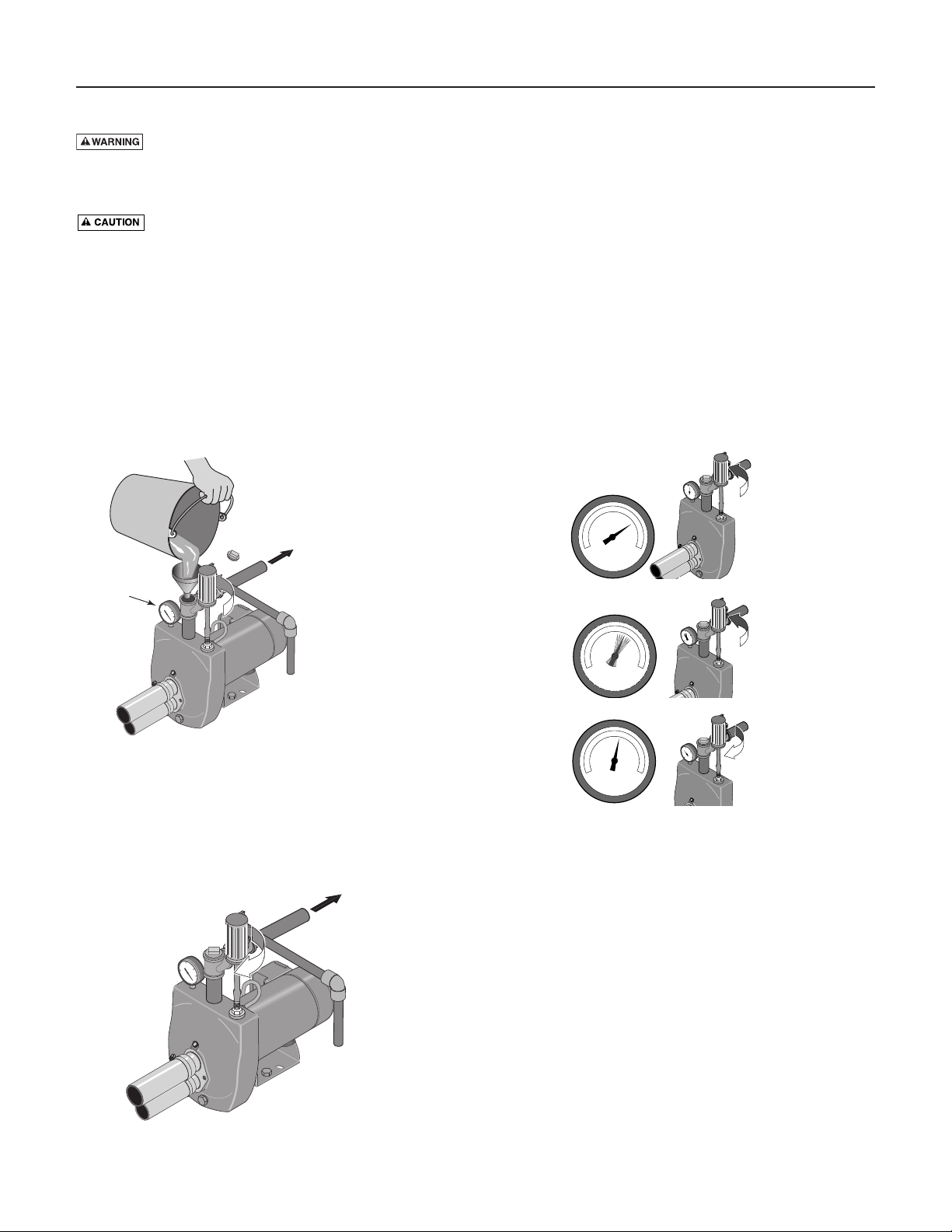

Step 1. Open the control valve as far as possible (see

Figure 12). Then remove the priming plug from

the pump and fill the pump, fill all piping

between the pump and the well, and make sure

that all piping in the well is full. If you have also

installed a priming tee in the suction piping,

remove the plug from the tee and fill the suction

piping.

Step 2. Replace all fill plugs and close the control valve

completely (Figure 13).

Step 3. Power on! Start the pump and watch the pressure

gauge. The pressure should build rapidly to 50

PSI as the pump primes.

Step 4. After 2 or 3 minutes, the gauge should show pres-

sure. If not, stop the pump, remove the fill plugs,

reopen the control valve, and refill the pump and

piping. You may have to repeat this two or three

times in order to get all the trapped air out of the

piping. Don’t forget to close the control valve each

time before you start the pump.

Step 5. When pressure has built up and stabilized at

about 50 PSI, slowly open the control valve (see

Figure 14) and let the pressure drop until the

pressure gauge needle starts to flutter. When the

needle flutters, close the valve just enough to

stop the flutter (see Figure 14). Your pump is now

operating at its most efficient point.

Step 6. After the pump has built up pressure in the sys-

tem and shut off, check the pressure switch operation by opening a faucet or two and running

enough water out to bleed off pressure until the

pump starts. The pump should start when pressure drops to 30 PSI and stop when pressure

reaches 50 PSI. Run the pump through one or

two complete cycles to verify correct operation.

This will also help clean the system of dirt and

scale dislodged during installation.

NOTICE: Packer jets (2" and 3" single pipe wells) do not

form a perfect seal. Normal irregularities in the cup seal

leather and the inner walls of the casing will allow the

pressure in a dormant system to leak off over time. This

will cause the pump to cycle periodically to maintain the

system pressure level.

Figure 13: Prime Pump

Figure 14: Set Control Valve

C-Close Control Valve until Pressure

Stabilizes

2146 0497

A-Open Control Valve

B-Watch for Pressure Gauge to Flutter

0

2

6

0

00

20

10

40

2

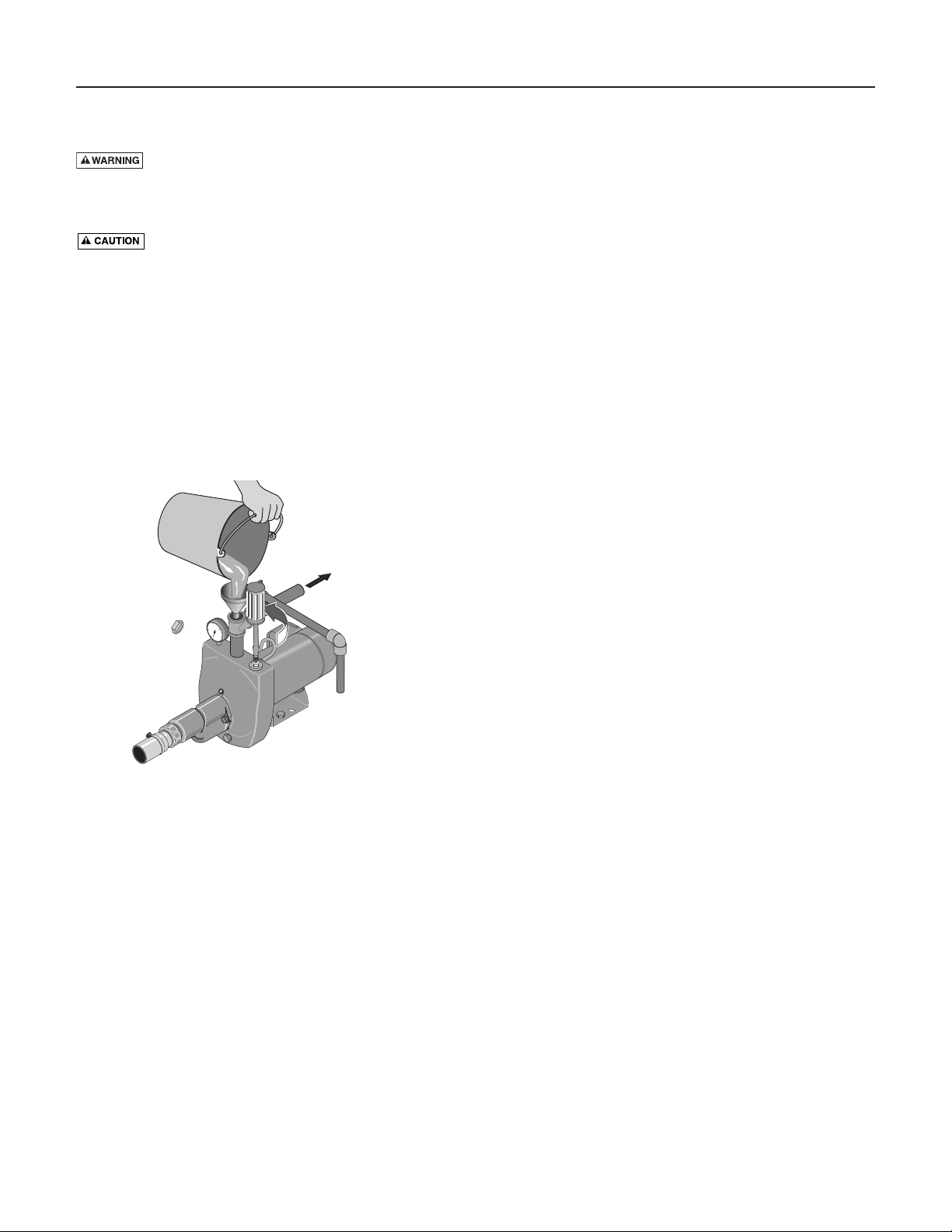

Figure 12: Fill Pump

Preparing to Start the Pump – Deep Well 8

Open control valve

as far as possible

and fill pump and

piping through

priming tee.

To Household

Pressure

Gauge

60

0

0

20

100

Water System

2117 0497

Replace all

fill plugs and

close control

valve completely.

To Household

Water System

60

40

8

20

100

2120 0497

Page 9

Preparing to Start the Pump – Shallow Well 9

Never run pump against closed discharge. To

do so can boil water inside pump, causing hazardous

pressure in unit, risk of explosion and possibly scalding

persons handling pump.

Never run pump dry. Running pump without

water may cause pump to overheat, damaging seal and

possibly causing burns to persons handling pump. Fill

pump with water before starting.

Step 1. Open the control valve as far as possible (see

Figure 15). Then remove the priming plug from

the pump and fill the pump, fill all piping

between the pump and the well, and make sure

that all piping in the well is full. If you have also

installed a priming tee

in

the suction piping,

remove the plug from the tee and fill the suction

piping.

Step 2. Replace all fill plugs. Leave the control valve

open (in a shallow well installation, the control

valve always stays open).

Step 3. Power on! Start the pump. The pump should

pump water in two or three minutes.

Step 4. If you don’t have water after 2 or 3 minutes, stop

the pump and remove the fill plugs. Refill the

pump and piping. You may have to repeat this

two or three times in order to get all the trapped

air out of the piping. The control valve remains

open throughout this procedure.

Step 5. After the pump has built up pressure in the sys-

tem and shut off, check the pressure switch operation by opening a faucet or two and running

enough water out to bleed off pressure until the

pump starts. The pump should start when pressure drops to 30 PSI and stop when pressure

reaches 50 PSI. Run the pump through one or

two complete cycles to verify correct operation.

This will also help clean the system of dirt and

scale dislodged during installation.

Open control valve

as far as possible

and fill pump and

piping through

priming port

or priming tee.

2411 0497

To Household

Water System

60

0

1 0

0

2

Figure 15: Open Control Valve

Page 10

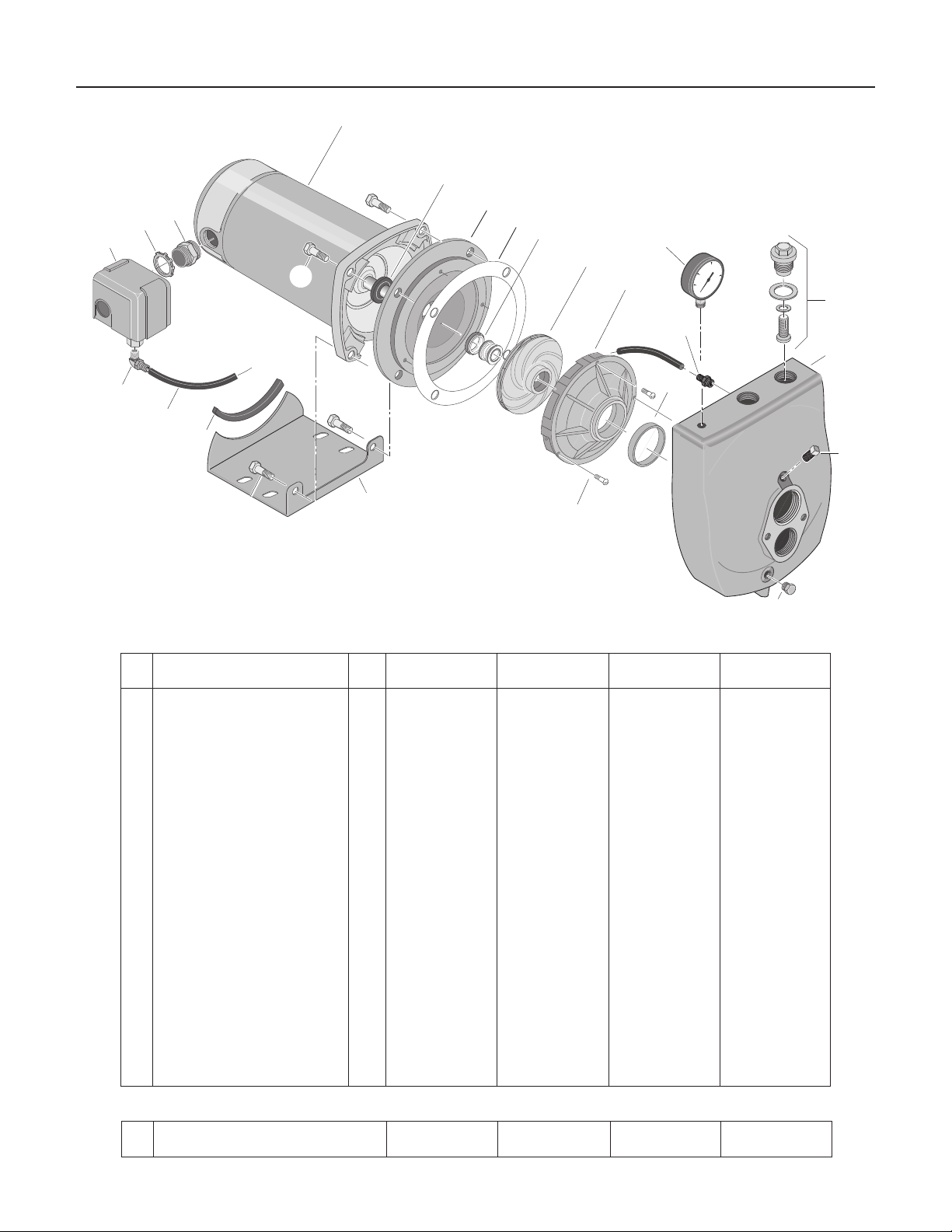

Repair Parts 10

1

2

3

4

5

6

7

7A

8

14

9

10

11

16

17

18

19

20

21

1623 0497

12

13

15A

15

22

20

40

60

80

100

Key Part HLD-L SLE-L HLE-L SLF-L

No. Description Qty. 3/4 HP 1 HP 1 HP 1-1/2 HP

1 Motor 1 J218-596PKG J218-596PKG J218-601PKG J218-601PKG

#§2 Water Slinger 1 17351-0009 17351-0009 17351-0009 17351-0009

3 Seal Plate 1 L3-10 L3-10 L3-10 L3-10

#§4 Seal Plate Gasket 1 C20-21 C20-21 C20-21 C20-21

#§5 Shaft Seal 1 U109-6A U109-6A U109-6A U109-6A

#6 Impeller 1 J105-85P J105-85P J105-22PA J105-22PA

#7 Diffuser 1 L1-47P L1-47P L1-23P L1-23P

7A 8-32x3/4" Rd. Hd. Capscrew 3 U30-489SS U30-489SS U30-489SS U30-489SS

#§8 Diffuser Ring 1 L21-1 L21-1 L21-1 L21-1

9 Quick Connect – Straight 1 U11-217P U11-217P U11-217P U11-217P

10 Pressure Gauge 1 U239-2 – U239-2 –

11 Control Valve Assembly 1 L262-5PS L262-5PS L262-5PS L262-5PS

12 Pump Body 1 L76-49 L76-49 L76-49 L76-49

13 Pipe Plug 1 U78-56ZPS U78-56ZPS U78-56ZPS U78-56ZPS

14 Drain Plug 1 U78-941ZPV U78-941ZPV U78-941ZPV U78-941ZPV

15 Base 1 J104-9C J104-9C J104-9C J104-9C

15A Motor Pad 1 C35-5 C35-5 C35-5 C35-5

16 3/8-16x1-1/2" Capscrew 2 U30-76ZP U30-76ZP U30-76ZP U30-76ZP

17 Switch Tube 1 U37-672P U37-677P U37-677P U37-677P

18 Quick Connect – Elbow 1 U11-218P U11-218P U11-218P U11-218P

19 Pressure Switch 1 U217-1216 U217-1225 U217-1216 U217-1225

20 Lock Nut 1 U36-112ZP U36-112ZP U36-112ZP U36-112ZP

21 Connector 1 L43-5C L43-5C L43-5C L43-5C

22 3/8-16x1-1/4" Capscrew 2 U30-75ZP U30-75ZP U30-75ZP U30-75ZP

§ Seal and Gasket Kit PP1551 PP1551 PP1551 PP1551

# Overhaul Kit PP1566 PP1566 PP1564 PP1564

NOTE: § Included in Seal and Gasket Kit. # Included in Overhaul Kit.

Page 11

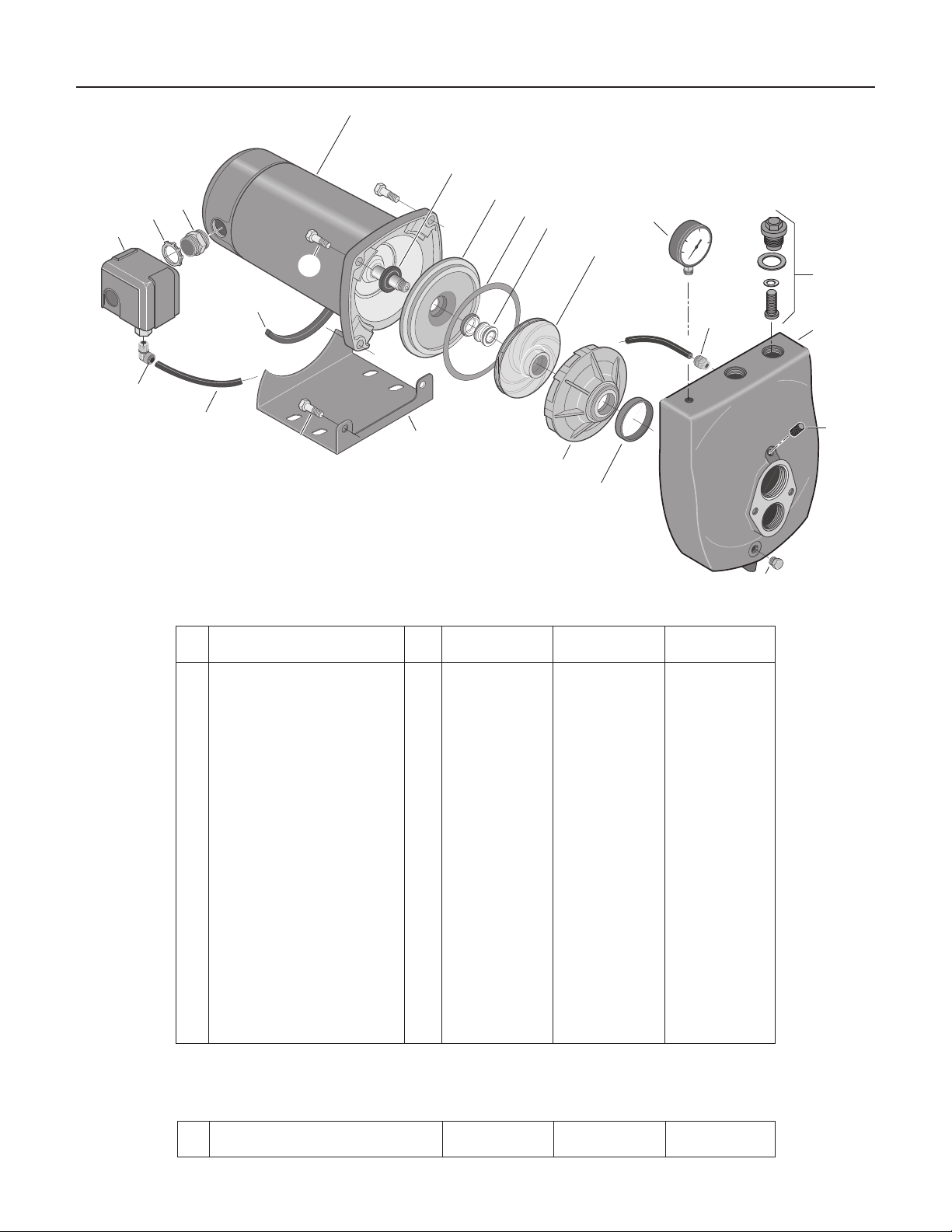

Repair Parts 11

1

2

3

4

5

6

7

8

16

17

18

19

20

21

15A

15

16

14

9

11

10

2879 0697

12

13

20

40

60

80

100

Key Part SLC-L SLD-L HLC-L

No. Description Qty. 1/2 HP 3/4 HP 1/2 HP

1 Motor 1 J218-582APKG J218-590PKG J218-590PKG

#§2 Water Slinger 1 17351-0009 17351-0009 17351-0009

3 Seal Plate 1 N3-1043P N3-1043P N3-1043P

#§4 Seal Plate Gasket 1 N20-35 N20-35 N20-35

#§5 Shaft Seal 1 U109-6A U109-6A U109-6A

#6 Impeller 1 J105-40P J105-86P J105-86P

#7 Diffuser 1 L1-25P L1-48P L1-48P

#§8 Diffuser Ring 1 L21-1 L21-1 L21-1

9 Quick Connect – Straight 1 U11-217P U11-217P U11-217P

10 Pressure Gauge 1 – – U239-2

11 Control Valve Assembly 1 01322 01322 01322

12 Pump Body 1 L76-48 L76-48 L76-48

13 Pipe Plug 1 U78-56ZPS U78-56ZPS U78-56ZPS

14 Drain Plug 1 U78-941ZPV U78-941ZPV U78-941ZPV

15 Base 1 J104-9C J104-9C J104-9C

15A Motor Pad 1 C35-5 C35-5 C35-5

16 3/8-16x1-1/4" Capscrew 4 U30-75ZP U30-75ZP U30-75ZP

17 Switch Tube 1 U37-672P U37-672P U37-672P

18 Quick Connect – Elbow 1 U11-218P U11-218P U11-218P

19 Pressure Switch 1 U217-1225 U217-1225 U217-1216

20 Lock Nut 1 U36-112ZP U36-112ZP U36-112ZP

21 Connector 1 L43-5C L43-5C L43-5C

• Plug 1 U78-941ZPV U78-941ZPV –

Repair Parts – Cast Iron Jet Pumps

SERVICE KITS

§ Seal and Gasket Kit PP1551 PP1551 PP1551

# Overhaul Kit PP1560 PP1565 PP1566

NOTE: § Included in Seal and Gasket Kit. # Included in Overhaul Kit.

• Not illustrated.

Page 12

Troubleshooting 12Troubleshooting 12

Symptoms Things to Do:

A. Motor will not run. A. Check that the disconnect switch is ON and that the circuit breaker

has not tripped or the fuse has not blown.

DISCONNECT POWER and make sure that wires connecting motor to

power supply and pressure switch are tight and correctly connected

(see Page 6).

If the remedies above do not solve the problem, call your well

professional.

B. Motor runs hot and overload trips. B. Turn to electrical instructions on Page 6 and verify that motor is

correctly wired.

Check with the power company or hydro authority to make sure

that the voltage at the pump is within +

10% of the motor’s rated

nameplate voltage.

DISCONNECT POWER and make sure that the wires connecting the

motor to the power supply are sized according to Table I, Page 7.

If not, rewire according to the instructions on Page 6.

If the pump is cycling too frequently, see Section E, below.

C. Motor runs but no water is delivered. C. FIRST, check the prime; that is, make sure that the pump and all the

suction piping plus the piping in the well are full of water. If they

aren’t, fill them up.

In cold weather, make sure that the pipes and pump are not frozen.

If they are, thaw them, watching out for split pipes and fittings as you

work. Heat the pump pit or pump house and bury all piping below

the frost line.

Other possible causes (call your pump professional if you suspect one

of these): Air leaks in the suction line, dropping water level in the well,

foot valve stuck or plugged, ejector plugged, impeller plugged, foot

valve or strainer stuck in the mud in the bottom of the well, a shallow

well pump installed on a well with more than 25 ft depth to water

(in this case a deep well jet pump is needed).

D. Pump does not deliver water to full capacity. D. Possible causes are: the well water level is lower than estimated,

making a different nozzle/venturi combination necessary; steel piping

(if used) is corroded or limed, restricting capacity and increasing

friction; or the piping is too small for the installation. Consult your

well professional for any of these conditions.

E. Pump cycles too frequently or does not shut E. Make sure no faucets have been left open.

off at all. If system has a standard tank, make sure it isn’t waterlogged. If it is,

drain it down to the level of the air volume control. Make sure the

AVC isn’t defective and that there are no leaks at any connections.

If system has a precharged tank, disconnect power, open all system

faucets and bleed all pressure off of tank. Use a tire gauge to check

the air pressure in the tank. This should be lower than the cut-in setting

of the pressure switch by 2 PSI (that is, if the pressure switch starts the

pump at 30 PSI, the precharge should be 28 PSI). Check the air valve

for leaks (use a soap solution) and replace the core if necessary.

If you suspect any of the following conditions, consult your well

professional: leaky pipes, leaky foot valve, water level in the well

lower than estimated, clogged ejector or impeller.

F. Air spurts from faucets. F. Pump may still be priming; when priming is complete all air will have

been ejected from the system.

If you suspect leaks in the suction piping, gasses in the well, or that the

pump is intermittently overpumping the well (that is, drawing the water

level down below the foot valve), consult your well professional.

G. Pump leaks around clamp. G. Tighten clamp nut 1-2 turns.

Do not overtighten.

Page 13

Sécurité 13

LIRE TOUTES CES INSTRUCTIONS

ET LES SUIVRE!

Ce symbole indique qu'il faut être prudent.

Lorsque ce symbole apparaît sur la pompe ou dans

cette Notice, rechercher une des mises en garde qui

suivent, car elles indiquent un potentiel possible de

blessures corporelles :

avertit d'un danger qui causera des blessures

corporelles, la mort ou des dommages matériels importants si

on l'ignore.

avertit d'un danger qui risque de causer des

blessures corporelles, la mort ou des dommages matériels

importants si on l'ignore.

avertit d'un danger qui causera ou qui

risquera de causer des blessures corporelles, la mort ou des

dommages matériels importants si on l'ignore.

Le mot NOTA indique des instructions spéciales et importantes

n'ayant aucun rapport avec les dangers.

Lire attentivement toutes les consignes de sécurité

contenues dans cette Notice ou collées sur la pompe.

Garder les autocollants de sécurité en bon état; les remplacer

s'ils manquent ou s'ils ont été endommagés.

SÉCURITÉ CONCERNANT L'ÉLECTRICITÉ

La tension du condensateur peut être dan-

gereuse. Pour décharger le condensateur du moteur, tenir un

tournevis à manche isolé PAR LE MANCHE et mettre en courtcircuit les bornes du condensateur. Ne pas toucher la lame

métallique du tournevis ni les bornes du condensateur. En cas

de doute, consulter un électricien qualifié.

SÉCURITÉ GÉNÉRALE

Ne pas toucher un moteur qui fonctionne. Les

moteurs modernes sont conçus pour fonctionner par des températures élevées. Pour ne pas se brûler lorsque l'on interviendra sur la pompe, la laisser refroidir pendant 20 minutes après

l'avoir arrêtée avant de la toucher.

Ne pas laisser geler la pompe ni aucun autre élément du système, sinon la garantie sera annulée.

Ne pomper que de l'eau avec cette pompe.

Périodiquement, inspecter la pompe et tous les éléments du

système.

Toujours porter des lunettes de sécurité lorsque l'on intervient

sur une pompe.

Garder la zone de travail propre, non encombrée et bien

éclairée; tous les outils et tout l'équipement non utilisés doivent

être entreposés correctement.

Ne pas laisser les visiteurs s'approcher de la zone de travail.

Le corps de la pompe peut exploser si la

pompe est utilisée en tant que pompe de surpression, à moins

qu'une soupape de sûreté pouvant laisser passer le débit maximum de la pompe à 100 lb/po

2

soit posée.

AVERTISSEMENT

Tension dangereuse. Risque

de secousses électriques, de

brûlures, voire de mort.

Mettre à la terre la pompe

avant de la brancher sur le

courant électrique. Couper

l'arrivée de courant avant d'intervenir sur la pompe, sur le

moteur ou sur le réservoir.

Câbler le moteur en

fonction de la bonne

tension. Voir la Section

«Électricité» de cette Notice

et la plaque signalétique du

moteur.

Mettre à la terre le

moteur avant de le

brancher sur le courant

électrique.

Conforme au Code

national de l'électricité, au Code canadien de

l'électricité et aux codes

municipaux pour tous les

câblages.

Respecter les instructions de câblage figurant dans

cette Notice lorsque l'on branche le moteur sur

une ligne haute tension.

AVERTISSEMENT

Pression dangereuse!

Poser une soupape de sûreté

sur le tuyau de refoulement.

Dissiper toute la pression

du système avant d'intervenir

sur un élément.

Page 14

Table des matières 14

Page

Sécurité...............................................................................................................................13

Garantie..............................................................................................................................14

Installations typiques...........................................................................................................15

Branchements du tuyau de refoulement et sur un réservoir sous pression...........................16

Électricité......................................................................................................................17, 18

Préparations avant le démarrage de la pompe - Puits profond ............................................19

Préparations avant le démarrage de la pompe - Puits peu profond .....................................20

Pièces de rechange .......................................................................................................21, 22

Diagnostic des pannes ........................................................................................................23

GARANTIE LIMITÉE

STA-RITE garantit au consommateur initial (ci-après appelé l’« Acheteur ») que les produits énumérés dans les présentes sont

exempts de défaut de matériau et de fabrication pendant la durée des garanties à compter de la durée des garanties indiquées

ci-dessous.

Produits Durée des garanties

Produits de systèmes d’eau —

Selon le premier terme atteint

:

Pompes à éjecteur, petites pompes 12 mois à compter de la date de la première installation ou

centrifuges, pompes submersibles et 18 mois à compter de la date de fabrication

tous les accessoires connexes

Réservoirs composites Pro-Source

TM

5 ans à compter de la date de la première installation

Réservoirs sous pression en acier Pro-Source

TM

5 ans à compter de la date de la première installation

Réservoirs revêtus d’époxyde Pro-Source

TM

3 ans à compter de la date de la première installation

Produits de puisard/d’égout/d’effluents 12 mois à compter de la date de la première installation ou

18 mois à compter de la date de fabrication

Nos garanties ne s’appliquent pas aux produits ayant fait l’objet de négligence, d’une mauvaise utilisation, d’une mauvaise

installation ou d’un manque d’entretien adéquat. Sans aucune limitation des présentes, la garantie des moteurs triphasés

submersibles sera nulle et non avenue si ces moteurs sont branchés et fonctionnent sur le courant monophasé par l’intermédiaire d’un déphaseur. Il faut également noter que les moteurs triphasés doivent être protégés par un relais de surcharge tripolaire

thermocompensé à déclenchement extrêmement rapide du calibre recommandé, sinon la garantie sera nulle et non avenue.

Le seul recours de l’Acheteur et la seule responsabilité de STA-RITE consistent à réparer ou à remplacer (au choix de

STA-RITE) les produits qui se révéleraient défectueux. L’Acheteur s’engage à payer tous les frais de main-d’œvre et d’expédition

du produit couvert par sa garantie et de s’adresser au concessionnaire-installateur ayant procédé à l’installation dès qu’un

problème est découvert pour obtenir un service sous garantie. Aucune demande de service en vertu de sa garantie ne sera

acceptée après expiration de la durée de sa garantie. Ces garanties ne sont pas transférables.

STA-RITE DÉCLINE TOUTE RESPONSABILITÉ POUR TOUT DOMMAGE INDIRECT OU FORTUIT QUEL QU’IL SOIT.

LES PRÉSENTES GARANTIES SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE FORMELLE

ET TACITE, Y COMPRIS, MAIS SANS S’Y LIMITER, TOUTE GARANTIE TACITE DE QUALITÉ MARCHANDE OU DE

CONVENANCE DU PRODUIT À UNE FIN PARTICULIÈRE. LA DURÉE DES PRÉSENTES GARANTIES NE DEVRA PAS

DÉPASSER LA DURÉE DES GARANTIES FORMELLES STIPULÉES DANS LES PRÉSENTES.

Certains états, territoires et certaines provinces ne permettent pas l’exclusion ou la limitation des dommages indirects ou fortuits,

ni les limitations relatives à la durée des garanties tacites. Par conséquent, il se peut que les limitations ou les exclusions

stipulées dans les présentes ne s’appliquent pas dans ce cas. Ces garanties accordent des droits juridiques précis, bien que l’on

puisse bénéficier d’autres droits, selon la province, le territoire ou l’état dans lequel on réside.

Ces garanties remplacent et annulent toutes les garanties précédemment publiées.

STA-RITE INDUSTRIES

293 Wright St., Delavan,WI 53115

Page 15

20

0

60

0

100

0

40

0

8

100

1799 0497

20

0

60

8

100

1800 0497

1903 0497

0

40

60

80

100

Figure 1 : Fonctions eau motrice et

aspiration

Figure 2 : Branchement inversé

dans le puits

Figure 3 : Montage de l’éjecteur puits peu profonds

Installations typiques 15

P ed

T

Ch

2097 0497

0

0

60

8

00

P i i

Figure 5 : Installations typiques dans un puits peu profond

1

ET NO

J 2P

24

1834 0695

Figure 4 : Installations typiques dans

un puits profond

Tuyauterie non montrée pour plus de clarté

Tuyau d’eau

motrice

(le plus petit)

Tête du

puits

Tuy a u

d’aspiration

(le plus gros)

Si la tête du puits et la pompe

ne s’assortissent pas, utiliser un

adaptateur inverseur ou bien

croiser le tuyau souple renforcé

pour brancher la pompe sur la

tête du puits.

Tuyau d’eau

motrice

Renvoie l’eau dans

le puits où elle est

Eau

motrice,

puis

aspiration

Aspiration,

puis eau

motrice

Refoulement

refoulée dans le

tuyau d’aspiration, puis

aspirée par la pompe

Vers le système

d’eau de la maison

Contrôleur

d’air

Tube du

contrôleur d’air

Té d’amorçage

et bouchon

Soupape de sûreté

Manocontacteur

Réservoir

standard

Tuyau d’aspiration

provenant

du puits

Tuyau d’eau

motrice

vers

le puits

«Deux tuyaux» «Un seul tuyau»

(puits de 4 po de dia. (puits de 2

et plus grand) et 3 po)

Tuyau d’aspiration

(le plus gros)

provenant

du puits

Tuyau d’eau

motrice (le plus

petit)

vers

le

puits

Tête du

puits

Tubage du puits

servant de tuyau

d’eau motrice

Venturi

Éjecteur

Buse

Clapet de pied

Crépine

Coupelles d’étanchéité

en cuir

Réservoir

Conaire

Pas

à

l’échelle

Crépine

Tamis

5 à

10 pi

Clapet

de pied

Minimum

de 10 pi

Clapet

de pied

Pointe

filtrante

Tube

d’enfoncement

de la pointe

Pointe filtrante

plus basse que

le niveau de

l’eau

Clapet

Tubage du

puits

Joint sanitaire

du puits

Té

d’amorçage

et bouchon

Tuyau d’aspiration

provenant du puits

Eau à

ciel

Puits à

tubage

Pointe

filtrante

Clapet

anti-retour

Té

d’amorçage

et bouchon

Soupape de sûreté

Manomètre et orifice

d’amorçage

Vers le système

d’eau de la maison

60

0

80

0

10

2096 0497

F

1836 0695

Page 16

Branchements du tuyau de refoulement et du réservoir sous pression 16

BRANCHEMENT SUR UN RÉSERVOIR

PRÉCHARGÉ (Figure 6)

Si le système est branché sur un réservoir Con-Aire® (réservoir

préchargé), il devra être branché sur la pompe, comme il est

illustré à la Figure 6. La soupape de sûreté doit pouvoir laisser

passer tout le débit de la pompe à une pression de 100 lb/po

2

.

Vérifier la précharge d’air dans le réservoir avec un manomètre

pour pneu. La précharge se mesure

lorsque le réservoir n’est

pas sous pression d’eau

. Couper le courant électrique parvenant à la pompe et vider le réservoir avant de vérifier la

précharge. Cette pompe neuve est équipée d’un manocontacteur de 30-50 lb/po

2

; la pression de précharge du réservoir

devra donc être réglée à 28 lb/po

2

, ce qui représente 2 lb/po

2

de moins que le réglage de la pression d’enclenchement du

manocontacteur de la pompe.

Aucun contrôleur d’air n’est requis dans le cas d’un réservoir

préchargé; l’orifice de 1/8 de pouce NPT prévu pour le contrôleur d’air et pratiqué dans le corps de la pompe devra être

bouché.

BRANCHEMENT SUR UN RÉSERVOIR STANDARD (Figure 7)

Si le système est branché sur un réservoir standard, le brancher

sur la pompe comme il est illustré à la Figure 7. La soupape de

sûreté utilisée avec un réservoir standard doit pouvoir laisser

passer tout le débit de la pompe à une pression de 75 lb/po

2

.

Brancher le tube du contrôleur d’air sur l’orifice de 1/8 de

pouce NPT pratiqué dans le corps de la pompe. Amener le

tube de l’orifice du contrôleur d’air de la pompe jusqu’au contrôleur d’air monté sur le réservoir. Pour plus de détails, se

reporter aux instructions fournies avec le réservoir et le contrôleur d’air.

Étanchéité des raccords des tuyaux

N'utiliser que du ruban téflon ou de la pâte d'étanchéité pour raccords filetés à base de téflon pour

procéder à tous les raccords filetés sur la pompe. Ne

pas utiliser de pâte pour raccords filetés sur les pompes en plastique : cette pâte peut réagir avec les élé-

ments en plastiques de la pompe. S'assurer que tous les

raccords du tuyau d'aspiration sont bien étanches, aussi

bien à l'air qu'à l'eau.

Si le tuyau d'aspiration aspire de

l'air, la pompe ne pompera pas l'eau du puits.

W

T H h ld

0

0

60

8

10

P

Figure 6 : Branchements sur un réservoir préchargé

Manocontacteur

Réservoir

préchargé

Manomètre et

bouchon d’amorçage

Vers le système

d’eau de la maison

Soupape de sûreté

En

provenance

du puits

Figure 7 : Branchements sur un réservoir standard

Contrôleur

d’air

Réservoir

standard

Tuyau d’eau motrice

vers

le puits

Tube du

contrôleur d’air

Soupape de sûreté

En provenance

du puits

Manocontacteur

Té d’amorçage

et bouchon

Vers le système

d’eau de la maison

0

0

80

100

2096 0497

Page 17

Électricité 17

Sélecteur de tension à fiche

La tension est réglée en usine à 230 volts. Pour passer au

courant de 115 volts :

1. S’assurer que le courant est coupé.

2. Décrocher la fiche de sélection de tension de ses pattes.

3. Déplacer la fiche sur le courant de 115 volts. Sur cette

position, la fiche couvre 2 pattes métalliques et la flèche

sur la prise est alignée sur la flèche 115V de l’étiquette

(figure 9).

4. Fixer les fils d’arrivée de courant aux deux vis extérieures

du manostat (figure 8).

5. Relier le fil de terre à l’une des bornes de mise à la terre

(figure 8).

6. S’il y a d’autres fils, leurs bouts doivent être isolés.

7. Reposer le couvercle d’extrémité du moteur.

Sélecteur de tension à cadran

La tension est réglée en usine à 230 volts. Pour passer au

courant de 115 volts :

1. S’assurer que le courant est coupé.

2. Tourner le cadran dans le sens des aiguilles d’une montre

jusqu’à ce que le nombre 115 soit visible dans la fente

du cadran (figure 11).

3. Fixer les fils d’arrivée de courant aux deux vis extérieures

du manostat (figure 10).

4. Relier le fil de terre aux bornes de raccord de mise à la

terre (figure 10).

5. S’il y a d’autres fils, leurs bouts doivent être isolés.

6. Reposer le couvercle d’extrémité du moteur.

Débrancher le courant électrique avant d'intervenir sur la pompe, le moteur, le manostat ou le câblage.

REMARQUE : Les moteurs de 1/2 ch sont câblés pour fonctionner sur un courant de 115 volts seulement; il ne faut donc changer

aucun câble.

Les plaquettes de connexions des moteurs de 3/4 ch ou de 1 ch (situées sous le couvercle arrière du moteur) ressemblent à l’un des

types décrits ci-dessous. Si le moteur peut fonctionner sur courant de 115 ou de 230 volts, il est réglé en usine pour un courant de

230 volts. Ne pas modifier le câblage du moteur si le courant est de 230 volts ou s’il s’agit d’un moteur à une tension.

Ne jamais relier un moteur de 115 volts à une canalisation de 230 volts.

RÉGLAGES DE L’INTERRUPTEUR DU MOTEUR

Figure 8 :Tension réglée à 230 volts sur sélecteur à fiche

Figure 9 :Tension réglée à 115 volts sur sélecteur à fiche

Figure 10 :Tension réglée à 230 volts sur sélecteur à cadran

Figure 11 :Tension réglée à 115 volts sur sélecteur à cadran

Fiche de sélection

de tension

Manocontacteur

Bornes de

branchement électrique

Borne du fil de mise à la terre

Cadran de

sélection

de tension

Manocontacteur

Bornes de branchement électrique

Borne du fil de mise à la terre

Page 18

Électricité 18

Tension dangereuse. Risque de secousses électriques, de brûlures, voire la mort. Brancher le fil de terre avant

de brancher les fils de tension. Utiliser des fils de calibre spécifié (y compris le fil de terre) dans le tableau de câblage. Dans la

mesure du possible, brancher la pompe sur un circuit séparé, sur

lequel aucun autre appareil ne sera branché.

Risque d'explosion. Ne pas mettre à la terre sur

une conduite de gaz.

CONNEXIONS DES FILS

Risque d'incendie. L'utilisation d'une mauvaise

tension risque de causer un incendie ou d'endommager gravement le moteur et d'annuler la garantie. La tension d'alimentation doit correspondre à ± 10 % de la tension figurant sur la

plaque signalétique du moteur.

NOTA : Les moteurs bi-tension sont câblés à l'usine pour

fonctionner sur le 230 volts. Au besoin, recâbler le moteur pour

qu'il fonctionne sur le 115 volts, comme il est illustré. Ne pas

modifier le câblage des moteurs fonctionnant sur une tension.

Installer la pompe, la mettre à la terre, la câbler et l'entretenir

conformément au National Electrical Code (NEC) ou au Code

canadien de l'électricité, selon le cas, et conformément à tous

les codes et décrets en vigueur de la municipalité. Consulter

l'inspecteur des bâtiments de la localité pour plus de renseignements sur les codes.

Méthodes de connexion :

1 ° Brancher tout d'abord le fil de mise à la terre, comme il

est illustré à la Figure 11. Le fil de mise à la terre doit être

un fil de cuivre massif d'un diamètre au moins aussi gros

que le diamètre des fils de tension.

2 ° Il doit y avoir un raccordement en métal solide entre le

manostat et le moteur pour une protection à la terre du

moteur. Si le manostat n'est pas branché sur le moteur,

brancher la vis verte de mise à la terre du manostat sur la

vis verte de mise à la terre qui se trouve sous le couvercle

du moteur. Utiliser un fil de cuivre massif ayant un

diamètre au moins aussi gros que celui des fils de tension.

3 ° Brancher le fil de mise à la terre sur le fil de mise à la

terre du tableau de distribution, sur un tuyau métallique

d'eau enterré, sur le tubage d'un puits en métal ayant au

moins 10 pieds (3 mètres) de long, ou sur une électrode

de mise à la terre que fournira la compagnie d'électricité.

4 ° Brancher les fils de tension sur le manostat, comme il est

illustré à la Figure 11.

Tableau I : Câblage - Câbles et diamètres des fusibles recommandés

Fusible

Distance en pieds (mètres)

;

Charge Intensité

Diamètre des fils - calibre AWG (mm

2

)

max. en en

0-100 101-200 201-300 301-400 401-500

Modèle ch

ampères ampères

(0-30) (31-61) (62-91) (92-122) (123-152)

115 volts :

SLC 1/2 9,9 15 14(2) 10(5,5) 8(8,4) 8(8,4) 6(14)

HLC 1/2 12,4 20 12(3) 10(5,5) 8(8,4) 6(14) 6(14)

SLD 3/4 12,4 20 12(3) 10(5,5) 8(8,4) 6(14) 6(14)

HLD 3/4 14,8 20 12(3) 8(8,4) 6(14) 6(14) 4(21)

SLE 1 14,8 20 12(3) 8(8,4) 6(14) 6(14) 4(21)

HLE 1 19,9 25 10(5.5) 8(8,4) 6(14) 4(21) 4(21)

SLF 1-1/2 19,9 25 10(5.5) 8(8,4) 6(14) 4(21) 4(21)

230 volts :

SLC 1/2 4,9 15 14(2) 14(2) 14(2) 14(2) 12(3)

HLC 1/2 6,2 15 14(2) 14(2) 14(2) 12(3) 12(3)

SLD 3/4 6,2 15 14(2) 14(2) 14(2) 12(3) 12(3)

HLD 3/4 7,4 15 14(2) 14(2) 14(2) 12(3) 10(5,5)

SLE 1 7,4 15 14(2) 14(2) 14(2) 12(3) 10(5,5)

HLE 1 9,9 15 14(2) 14(2) 12(3) 10(5,5) 10(5,5)

SLF 1-1/2 9,9 15 14(2) 14(2) 12(3) 10(5,5) 10(5,5)

Page 19

Ne jamais faire fonctionner la pompe contre

un refoulement fermé, sinon l’eau risque de bouillir à l’intérieur de la pompe, une accumulation dangereuse de pression

risque de se produire, un danger d’explosion risque de s’ensuivre et les personnes qui manipuleront la pompe pourront

peut-être être ébouillantées.

Ne jamais faire fonctionner la pompe à sec.

Faire fonctionner la pompe sans eau risque de causer une surchauffe de la pompe, d’endommager les joints et, possiblement, causer des brûlures aux personnes qui manipuleront la

pompe. Faire le plein d’eau de la pompe avant de la démarrer.

1 ° Ouvrir au maximum la vanne de réglage (voir la Figure

12), déposer le bouchon d’amorçage de la pompe, puis

faire le plein de la pompe, de toutes les tuyauteries entre

la pompe et le puits et s’assurer que toutes les tuyauteries

du puits sont pleines d’eau. Si un té d’amorçage a été

posé sur le tuyau d’aspiration, déposer le bouchon du té

et faire le plein de la tuyauterie d’aspiration.

2 ° Reposer tous les bouchons de remplissage et fermer com-

plètement la vanne de réglage (voir la Figure 13).

3 ° Établir le courant! Démarrer la pompe et surveiller le

manomètre. Au fur et à mesure que la pompe s’amorce, la

pression doit rapidement monter jusqu’à 50 lb/po

2

.

4 ° Après 2 ou 3 minutes, le manomètre doit indiquer la pres-

sion. Sinon, arrêter la pompe, déposer les bouchons de

remplissage, rouvrir la vanne de réglage et refaire le plein

de la pompe et des tuyauteries. Il sera peut-être nécessaire

de répéter cette opération deux ou trois fois de façon à

chasser tout l’air pouvant être emprisonné dans les tuyauteries. Ne pas oublier de refermer la vanne de réglage

avant de redémarrer la pompe.

5 ° Lorsque la pression s’est accumulée et stabilisée à environ

50 lb/po

2

, ouvrir lentement la vanne de réglage (voir la

Figure 14) et laisser chuter la pression jusqu’à ce que

l’aiguille du manomètre commence à osciller. Pendant que

l’aiguille oscille, fermer suffisamment la vanne de réglage

pour arrêter l’aiguille d’osciller (voir la Figure 14). La

pompe fonctionne maintenant à son point le plus efficace.

6 ° Après que la pression se sera accumulée dans le système

et que la pompe se sera arrêtée, vérifier le fonctionnement

du manocontacteur en ouvrant un ou deux robinets du

système; laisser couler suffisamment d’eau pour dissiper la

pression jusqu’à ce que la pompe redémarre. La pompe

doit redémarrer lorsque la pression chute à 30 lb/po

2

et

s’arrêter lorsque la pression atteint 50 lb/po

2

. Faire fonctionner la pompe pendant un ou deux cycles complets

pour confirmer son bon fonctionnement. Ceci permettra

également de nettoyer le système de toute la saleté et de

tout le tartre qui se seront détachés pendant l’installation.

NOTA : Les éjecteurs packer (puits de 2 pouces et de 3 pouces à

un seul tuyau) ne forment pas un joint parfait. Les irrégularités

normales du cuir de la coupelle d’étanchéité et de la parol

intérieure du tubage permettront, avec le temps, à la pression de

fuir d’un système au repos. La pompe fonctionnera donc

périodiquement pour maintenir le niveau de pression du système.

Préparations avant le démarrage de la pompe - Puits profond 19

Figure 13 :Amorçage de la pompe

Figure 14 : Régler la vanne de réglage

0

0

6

10

40

20

1

0

40

2

Figure 12 : Remplissage de la pompe

Ouvrir la vanne de réglage au

maximum et faire le plein de

la pompe et des tuyauteries

par l'orifice d'amorçage

ou le té d'amorçage.

Reposer tous les bouchons de

remplissage et bien fermer la

vanne de réglage.

Vers le système

d’eau de la maison

A-Ouvrir la vanne de réglage

B-Surveiller le manomètre jusqu'à ce que l'aiguille oscille

C-Fermer la vanne de réglage jusqu'à

ce que la pression se stabilise

Vers le système

d’eau de la maison

Manomètre

et orifice

d’amorçage

60

0

0

20

100

2117 0497

R l ll

0

40

8

20

10

2120 0497

Page 20

Préparations avant le démarrage de la pompe - Puits peu profond 20

Ne jamais faire fonctionner la pompe contre

un refoulement fermé, sinon l’eau risque de bouillir à l’intérieur de la pompe, une accumulation dangereuse de pression risque de se produire, un danger d’explosion risque de

s’ensuivre et les personnes qui manipuleront la pompe pourront peut-être être ébouillantées.

Ne jamais faire fonctionner la pompe à sec.

Faire fonctionner la pompe sans eau risque de causer une surchauffe de la pompe, d’endommager les joints et, possiblement, causer des brûlures aux personnes qui manipuleront la

pompe. Faire le plein d’eau de la pompe avant de la démarrer.

1 ° Ouvrir au maximum la vanne de réglage (voir la Figure

15), déposer le bouchon d’amorçage de la pompe, puis

faire le plein de la pompe, de toutes les tuyauteries entre

la pompe et le puits et s’assurer que toutes les tuyauteries

du puits sont pleines d’eau. Si un té d’amorçage a été

posé sur le tuyau d’aspiration, déposer le bouchon du té

et faire le plein de la tuyauterie d’aspiration.

2 ° Reposer tous les bouchons filetés. Laisser la vanne de

réglage ouverte (dans les puits peu profonds, la vanne de

réglage reste toujours ouverte).

3 ° Établir le contact! Démarrer la pompe. La pompe doit

pomper l’eau dans les deux ou trois minutes qui suivent.

4 ° Si la pompe ne pompe pas d’eau dans les 2 ou 3 minutes

qui suivent, l’arrêter et déposer les bouchons de remplissage. Faire le plein de la pompe et des tuyauteries. Il faudra peut-être répéter cette opération deux ou trois fois de

façon à chasser tout l’air pouvant être emprisonné dans la

tuyauterie. La vanne de réglage reste ouverte pendant

cette opération.

5 ° Après que la pression se sera accumulée dans le système

et que la pompe se sera arrêtée, vérifier le fonctionnement du manocontacteur en ouvrant un ou deux robinets du système; laisser couler suffisamment d’eau pour

dissiper la pression jusqu’à ce que la pompe redémarre.

La pompe doit redémarrer lorsque la pression chute à 30

lb/po

2

et s’arrêter lorsque la pression atteint 50 lb/po2.

Faire fonctionner la pompe pendant un ou deux cycles

complets pour confirmer son bon fonctionnement. Ceci

permettra également de nettoyer le système de toute la

saleté et de tout le tartre qui se seront détachés pendant

l’installation.

Figure 15 : Ouvrir la vanne de réglage

Ouvrir la vanne de réglage au

maximum et faire le plein de la

pompe et des tuyauteries par

l’orifice d’amorçage

ou le té d’amorçage.

Vers le système

d’eau de la maison

0

8

0

2

100

2411 0497

Page 21

Pièces de rechange 21

Pièces de rechange - pompes en fonte à éjecteur

1

2

3

4

5

6

7

7A

8

14

9

10

11

16

17

18

19

20

21

1623 0497

12

13

15A

15

22

20

40

60

80

100

Désignation HLD-L SLE-L HLE-L SLF-L

Réf. des pièces Qté 3/4 ch 1 ch 1 ch 1-1/2 ch

1 Moteur 1 J218-596PKG J218-596PKG J218-601PKG J218-601PKG

#§2 Déflecteur d’eau 1 17351-0009 17351-0009 17351-0009 17351-0009

3 Plaque d’étanchéité 1 L3-10 L3-10 L3-10 L3-10

#§4 Joint de plaque d’étanchéité 1 C20-21 C20-21 C20-21 C20-21

#§5 Joint d’arbre 1 U109-6A U109-6A U109-6A U109-6A

#6 Impulseur 1 J105-85P J105-85P J105-22PA J105-22PA

#7 Diffuseur 1 L1-47P L1-47P L1-23P L1-23P

7A Vis à tête ronde de 8-32x3/4 de po 3 U30-489SS U30-489SS U30-489SS U30-489SS

#§8 Bague du diffuseur 1 L21-1 L21-1 L21-1 L21-1

9 Branchement rapide - droit 1 U11-217P U11-217P U11-217P U11-217P

10 Manomètre 1 U239-2 – U239-2 –

11 Vanne de réglage 1 L262-5PS L262-5PS L262-5PS L262-5PS

12 Corps de la pompe 1 L76-49 L76-49 L76-49 L76-49

13 Bouchon fileté 1 U78-56ZPS U78-56ZPS U78-56ZPS U78-56ZPS

14 Bouchon de vidange 1 U78-941ZPV U78-941ZPV U78-941ZPV U78-941ZPV

15 Socle 1 J104-9C J104-9C J104-9C J104-9C

15A Support en caoutchouc 1 C35-5 C35-5 C35-5 C35-5

16 Vis à tête de 3/8-16x1-1/2 po 2 U30-76ZP U30-76ZP U30-76ZP U30-76ZP

17 Tube de manocontacteur 1 U37-672P U37-677P U37-677P U37-677P

18 Branchement rapide - coude 1 U11-218P U11-218P U11-218P U11-218P

19 Manocontacteur 1 U217-1216 U217-1225 U217-1216 U217-1225

20 Contre-écrou 1 U36-112ZP U36-112ZP U36-112ZP U36-112ZP

21 Raccord 1 L43-5C L43-5C L43-5C L43-5C

22 Vis à tête de 3/8-16x1-1/4 po 2 U30-75ZP U30-75ZP U30-75ZP U30-75ZP

§ Nécessaire de joints et

de bagues d’étanchéité PP1551 PP1551 PP1551 PP1551

# Nécessaire de révision PP1566 PP1566 PP1564 PP1564

NOTA : § Font partie du nécessaire de joints et de bagues d’étanchéité. # Font partie du nécessaire de révision.

Page 22

Pièces de rechange 22

Pièces de rechange - pompes en fonte à éjecteur

1

2

3

4

5

6

7

8

16

17

18

19

20

21

15A

15

16

14

9

11

10

2879 0697

12

13

20

40

60

80

100

Désignation SLC-L SLD-L HLC-L

Réf. des pièces Qté 1/2 ch 3/4 ch 1/2 ch

1 Moteur 1 J218-582APKG J218-509PKG J218-509PKG

#§2 Déflecteur d’eau 1 17351-0009 17351-0009 17351-0009

3 Plaque d’étanchéité 1 N3-1043P N3-1043P N3-1043P

#§4 Joint de plaque d’étanchéité 1 N20-35 N20-35 N20-35

#§5 Joint d’arbre 1 U109-6A U109-6A U109-6A

#6 Impulseur 1 J105-40P J105-86P J105-86P

#7 Diffuseur 1 L1-25P L1-48P L1-48P

#§8 Bague du diffuseur 1 L21-1 L21-1 L21-1

9 Branchement rapide - droit 1 U11-217P U11-217P U11-217P

10 Manomètre 1 – – U239-2

11 Vanne de réglage 1 01322 01322 01322

12 Corps de la pompe 1 L76-48 L76-48 L76-48

13 Bouchon fileté 1 U78-56ZPS U78-56ZPS U78-56ZPS

14 Bouchon de vidange 1 U78-941ZPV U78-941ZPV U78-941ZPV

15 Socle 1 J104-9C J104-9C J104-9C

15A Support en caoutchouc 1 C35-5 C35-5 C35-5

16 Vis à tête de 3/8-16x1-1/4 po 4 U30-75ZP U30-75ZP U30-75ZP

17 Tube de manocontacteur 1 U37-672P U37-672P U37-672P

18 Branchement rapide - coude 1 U11-218P U11-218P U11-218P

19 Manocontacteur 1 U217-1225 U217-1225 U217-1216

20 Contre-écrou 1 U36-112ZP U36-112ZP U36-112ZP

21 Raccord 1 L43-5C L43-5C L43-5C

• Bouchon 1 U78-941ZPV U78-941ZPV –

§ Nécessaire de joints et

de bagues d’étanchéité PP1551 PP1551 PP1551

# Nécessaire de révision PP1560 PP1565 PP1566

NOTA : § Font partie du nécessaire de joints et de bagues d’étanchéité.

# Font partie du nécessaire de révision.

• Non illustrée.

Page 23

Diagnostic des pannes 23

Symptômes Quoi faire :

A. Le moteur ne tourne pas.

B. Le moteur chauffe et le dispositif de

protection contre les surcharges saute.

C. Le moteur fonctionne mais l’eau n’est

pas pompée*.

D. La pompe ne pompe pas l’eau à pleine

capacité.

E. La pompe s’arrête et repart trop

fréquemment ou bien elle ne s’arrête

pas du tout.

F. L’air jaillit des robinets.

G. La pompe fuite autour de serrage.

A. S’assurer que le sectionneur est sur MARCHE et que le disjoncteur ne s’est

pas désenclenché ou que le fusible n’a pas sauté.

COUPER LE COURANT D’ALIMENTATION et s’assurer que tous les fils

raccordant le moteur au courant d’alimentation et au manocontacteur sont

bien serrés et bien branchés (voir la page 17).

Si les remèdes précédents ne permettent pas de résoudre le problème,

appeler un spécialiste en puits.

B. Se reporter aux instructions concernant l’électricité à la page 17 et

s’assurer que le moteur est bien câblé.

Vérifier auprès de la compagnie qui fournit l’électricité ou les responsables

d’hydro pour s’assurer que la tension parvenant à la pompe correspondent

à ±10 % de la tension nominale indiquée sur la plaque signalétique du

moteur.

DÉBRANCHER LE COURANT D’ALIMENTATION et s’assurer que les fils

raccordant le moteur au courant d’alimentation sont du calibre indiqué au

Tableau I, de la page 18.

Sinon, recâbler conformément aux instructions de la page 17.

Si la pompe s’arrête ou redémarre trop fréquemment, se reporter à la

Section E ci-dessous.

C. TOUT D’ABORD, vérifier l’amorçage; c’est-à-dire, que la pompe et que

toutes les tuyauteries d’aspiration et du puits sont remplies d’eau. Si elles

ne sont pas pleines d’eau, en faire le plein.

Par temps froid, s’assurer que les tuyaux et que la pompe n’ont pas gelé.

S’ils sont gelés, les dégeler, s’assurer qu’il n’y a pas de tuyaux ni de raccords éclatés. Chauffer la fosse de la pompe ou l’enceinte de la pompe et

enterrer toutes les tuyauteries sous la limite du gel.

Autres causes possibles (dans ce cas, appeler un spécialiste en pompes si

l’on soupçonne une de ces causes) : Prises d’air dans la conduite d’aspiration, baisse de niveau d’eau dans le puits, clapet de pied grippé ou

bouché, éjecteur bouché, impulseur bouché, clapet de pied ou crépine

enfoui dans la boue au fond du puits et pompe pour puits peu profond

posée dans un puits dont la profondeur est supérieure à 25 mètres jusqu’à

l’eau (dans ce cas, une pompe à éjecteur pour puits profond est requise).

D. Causes possibles : Le niveau d’eau dans le puits est inférieur à celui éval-

ué, ce qui rend une combinaison buse/venturi différente obligatoire; tuyauterie en acier (le cas échéant) corrodée ou entartrée, limitant la capacité et

augmentant le frottement; ou bien les tuyauteries sont trop petites pour

l’installation. Consulter un spécialiste en puits pour toutes ces conditions.

E. S’assurer qu’aucun robinet n’a été laissé ouvert.

Si le système fonctionne sur un réservoir standard, s’assurer qu’il n’est pas

saturé d’eau. Dans l’affirmative, le vider jusqu’au niveau du contrôleur

d’air. S’assurer que le contrôleur d’air n’est pas défectueux et qu’aucun

raccord n’aspire de l’air. Si le système est branché sur un réservoir

préchargé, couper le courant d’alimentation, ouvrir tous les robinets du

système et purger toute la pression du réservoir. Utiliser un manomètre

pour pneu pour vérifier la pression d’air dans le réservoir. Elle doit être de

2 lb/po

2

inférieure au réglage d’enclenchement du manocontacteur, c’est-à-

dire que si le manocontacteur démarre la pompe à 30 lb/po

2

, la précharge

doit être de 28 lb/po

2

. S’assurer que la valve ne fuit pas (utiliser une solution savonneuse) et remplacer l’obus au besoin.

Si l’on pense qu’une des conditions suivantes existent, consulter un spécialiste en puits : fuites des tuyauteries, fuites du clapet de pied, niveau

d’eau dans le puits inférieur à celui évalué, éjecteur ou impulseur bouché.

F. La pompe est peut-être en train de s’amorcer. Lorsque l’amorçage est ter-

miné, tout l’air sera éjecté du système.

Si l’on pense que les tuyauteries d’aspiration fuient, qu’il y a des gaz dans

le puits, ou que la pompe vide le puits par intermittence (c’est-à-dire

qu’elle amène le niveau d’eau plus bas que le clapet de pied, consulter un

spécialiste en puits.

G. Serrer l’ecrou de 1 ou 2 tours.

Ne pas trop serrer.

Page 24

Seguridad 24

LEA Y SIGA LAS INSTRUCCIONES

DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando

usted vea este símbolo en su bomba o en este manual, busque alguna de las siguientes palabras de advertencia

y esté alerta a la posibilidad de una herida personal:

advierte acerca de los peligros que oca-

sionarán lesiones personales serias, la muerte o un daño

severo a la propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que

pueden ocasionar lesiones personales serias, la muerte o un

daño severo a la propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que oca-

sionarán o podrán ocasionar lesiones personales menores o

daños a la propiedad si se ignoran dichos peligros.

La etiqueta AVISO indica instrucciones especiales que son

importantes pero no relacionados a los peligros.

Lea y siga cuidadosamente todas las instrucciones de

seguridad en este manual y en la bomba.

Mantenga las etiquetas de seguridad en buenas condiciones.

Reemplace las etiquetas de seguridad faltantes o dañadas.

SEGURIDAD ELECTRICA

El voltaje del capacitor puede ser

peligroso. Para descargar el capacitor del motor, tome un

desatornillador con mango aislado POR EL MANGO y

ponga en corto las terminales del capacitor. No toque la

superficie de metal del desatornillador ni las terminales del

capacitor. Si tiene alguna duda, consulte a un electricista

calificado.

SEGURIDAD GENERAL

No toque un motor en operación. Los

motores modernos están diseñados para operar a temperaturas altas. Para evitar quemaduras al realizar el servicio a

una bomba, déjela enfriar por 20 minutos después de

apagarla.

No permita que la bomba o cualquier componente del sistema se congele. Hacerlo invalidará la garantía.

Utilice esta bomba sólo para agua.

Inspeccione la bomba y los componentes del sistema per-

iódicamente.

Utilice gafas de seguridad durante todo el tiempo mientras

trabaje en la bomba.

El área de trabajo se debe mantener limpia, ordenada y con

iluminación adecuada; guarde las herramientas y el equipo

que no utilice en el lugar apropiado.

Mantenga a los visitantes a una distancia segura de las áreas

de trabajo.

El cuerpo de la bomba puede

explotar si se utiliza como una bomba propulsora a menos

que se instale una válvula de alivio que sea capaz de pasar

todo el flujo de la bomba a 100 psi.

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

Presión peligrosa!

Instale una válvula de alivio

de presión en la tubería de

descarga.

Libere toda la presión en el sistema antes de trabajar en

alguno de los componentes.

ADVERTENCIA

Voltaje peligroso.

Puede ocasionar conmoción,

quemaduras e incluso la

muerte.

Conecte la bomba a tierra

antes de conectarla a la alimentación eléctrica.

Desconecte la alimentación de

energía antes de trabajar en la

bomba, el motor o el tanque.

Conecte el motor al

voltaje correcto. Vea la

sección “Electricidad” en este

manual y la placa del motor.

Conecte el motor a tier-

ra antes de conectarlo a

la alimentación de energía.

Cumpla con las indica-

ciones del Código

Nacional Eléctrico, el de

Canadá y los códigos locales

para toda la conexión eléctrica.

Siga las instrucciones de

conexión eléctrica en

este manual al conectar el

motor a las líneas de energía

eléctrica.

Page 25

Indice de Contenido 25

Página

Seguridad General .................................................................................................24

Garantía.................................................................................................................25

Instalación típica....................................................................................................26

Tubería de Descarga y Conexiones del Tanque de Presión ....................................27

Electricidad......................................................................................................28, 29

Preparación para Arrancar la Bomba - Pozo Profundo...........................................30

Preparación para Arrancar la Bomba - Pozo poco Profundo..................................31

Solución de Problemas ....................................................................................32, 33

Refacciones ..........................................................................................................34

GARANTÍA LIMITADA

STA-RITE le garantiza al comprador/consumidor original (“Comprador” o “Usted”) de los productos enumerados abajo, que estos

estarán libres de defectos en material y mano de obra durante el Período de Garantía indicado a continuación.

Producto Período de Garantía

Productos de sistemas de agua — bombas de chorro,

lo que ocurra primero:

pequeñas bombas centrífugas, bombas sumergibles 12 meses desde la fecha de la instalación inicial, o y

accesorios asociados 18 meses desde la fecha de fabricación

Tanques de compuesto Pro-Source

MC

5 años desde la fecha de la instalación inicial

Tanques a presión de acero Pro-Source

MC

5 años desde la fecha de la instalación inicial

Tanques con revestimiento epoxídico Pro-Source

MC

3 años desde la fecha de la instalación inicial

Productos para sumideros/aguas residuales/efluente 12 meses desde la fecha de la instalación inicial, o

18 meses desde la fecha de fabricación

Nuestra garantía no se aplicará a ningún producto que, a nuestro sólo juicio, haya sido sometido a negligencia, mal uso,

instalación inadecuada o mal mantenimiento. Sin prejuicio a lo que antecede, la garantía quedará anulada en el caso en que un

motor trifásico se haya usado con una fuente de alimentación monofásica, a través de un convertidor de fase. Es importante

indicador que los motores trifásicos deben estar protegidos por relés de sobrecarga de disparo extra-rápido, con compensación

ambiental de tres etapas, del tamaño recomendado, de lo contrario, la garantía quedará anulada.

Su único recurso, y la única obligación de STA-RITE es que STA-RITE repare o reemplace los productos defectuosos (a juicio de

STA-RITE). Usted deberá pagar todos los cargos de mano de obra y de envío asociados con esta garantía y deberá solicitar el

servicio bajo garantía a través del concesionario instalador tan pronto como se descubra un problema. No se aceptará ninguna

solicitud de servicio bajo garantía que se reciba después del vencimiento del Período de Garantía. Esta garantía no se puede

transferir.

STA-RITE NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE.

LAS GARANTÍAS QUE ANTECEDEN SON EXCLUSIVAS Y EN LUGAR DE TODA OTRA GARANTÍA EXPLÍCITA O IMPLÍCITA,

INCLUYENDO PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA UN FIN

ESPECÍFICO. LAS GARANTÍAS QUE ANTECEDEN NO SE EXTENDERÁN MÁS ALLÁ DE LA DURACIÓN EXPRESAMENTE

SUMINISTRADA EN LA PRESENTE.

Algunos estados no permiten la exclusión o limitación de daños incidentales o consecuentes o de limitaciones de tiempo sobre

garantías implícitas, de modo que es posible que las limitaciones o exclusiones que preceden no correspondan en su caso. Esta

garantía le otorga derechos legales específicos y es posible que usted también tenga otros derechos que pueden variar de un

estado al otro.

Esta garantía reemplaza toda garantía publicada anteriormente.

STA-RITE INDUSTRIES

293 Wright St., Delavan,WI 53115

Page 26

0

0

60

80

00

0

40

60

8

100

1799 0497

20

0

60

8

100

1800 0497

1903 0497

20

40

60

80

100

Figura 1: Funciones de Succión y

Transmisión

Figura 2: Conexiones Invertidas

hacia el Pozo

Figura 3: Monte el Eyector - Pozo

Poco Profundo

Instalación típica 26

P d

T

2097 0497

0

40

60

8

100

Figura 5: Instalación típica para pozo poco profundo

1

ET NO

J 2P

24

1834 0695

Figura 4: Instalación típica para pozo

profundo

Tubería omitida para

mayor claridad

Tubería de

Transmisión

(más pequeña)

Cabeza de

pozo

Tubería de

Succión

(más grande)

Si la cabeza del pozo y la

bomba no embonan, utilice un

adaptador inversor o tubería flexible reforzada para conectar la

bomba a la cabeza del pozo.

La Tubería de

Transmisión envía

el agua hacia el

pozo para sacar

Transmisión

encima de

succión

Succión

encima de

transmisión

Descarga

agua a través de la

Tubería de Succión

Al Sistema Doméstico

de Agua

Control de

Volumen de Aire

Tubo de Control de

Volumen de Aire

“T” y Tapón

para Cebar

Válvula de Alivio

Interruptor de

Presión

Tanque

estándar

Tubería de succión

del pozo

Tubería de

transmisión al pozo

"Tubería doble" "Tubería simple"

(diámetro del pozo: (diámetro del pozo:

4" mínimo) 2" y 3")

Tubería de succión del

pozo (más grande)

Tubería de

transmisión al

pozo (más

pequeña)