Page 1

HC

3315,3330,3340

CHLORINEIBROMINE

HIGH

COMMERCIAL

CAPACITY

FEEDER

FEATURES:

+

Extra large capacity models.

+

For use with Tricolor or Bromine tablets or sticks.

+

No special venting required.

+

Completely enclosed - no escaping gases.

+

Positive external no - clog control valve.

+

No equipment damage. Feeds sanitizer directly to pool.

DANGER

It

IS

~mportant to read all

information will guide you in

due to improper installation.

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE OR PERSONA

INJLIRY.

IF YOUR POOL HAS COPPER PLLIMBING

into copper plumbing as pipe damage could occur.

NOTE:

installed to prevent possible damage and improper operation of CHECK

VALVE and other equipment subject to heat damage.

If a heater is used, a

-

READ CAREFULLY

information

lnstalllng your feeder properly and to avoid problems

IF INSTRUCTIONS ARE NOT FOLLOWED. FIRE

FIREMAN'S SWITCH

BEFORE

...

proceeding with the installation. The

STOP!

Never Install feeder

or equivalent must be

INSTALLATION

This feeder is designed for hard plumbing installation using 1

PVC pipe and includes standard threaded inlet and outlet

fittings. It operates by pressure differential which circulates

through the feeder. The inlet line, (control valve side of feeder)

connects to the plumbing between the pump and filter. The

outlet side of the feeder connects to pool return line after the

and/or heater, pool cleaner, diverter valves or any other

filter

piece of equipment (if installed). A corrosion resistant check

valves such as Rainbow's

between the feeder inlet and outlet and the equipment to help

prevent equipment damage. DAMAGE TO THE HEATER OR

OTHER EQUIPMENT COULD

CONCENTRATION OF SANlTlZER BACK FLOWING INTO IT

WHEN PUMP IS SHUT OFF. It is recommended that feeder be

bolted down.

#R172288 should be installed

RESULT FROM A

HIGH

"

OPERATING INSTRUCTIONS

Exercise extreme caution when operating or servicing feeder.

NEVER OPEN FEEDER WHEN PUMP IS RUNNING. DO NOT

INHALE FUMES, especially in hot weather which can create

more gases. Wear

manufacturer's instructions for handling the chemical. Before

start up of feeder your pool should be properly conditioned and

the chlorine residual should be 1.0 to

4.0 ppm). Consult your local dealer for water conditioning

information in your area. Because the sanitizer demand in your

pool is dependent on many factors (sunlight, high temperatures,

bather load, etc.) your valve setting may have to be changed

from time to time to adjust to these conditions. When possible,

increase the feed rate a day or two in advance. The recommended start up setting is

sanitizer residual. It is recommended that the sanitizer residual

be checked daily for the first

NOTE: Higher numbers dispense more chemical. Small gradual

changes are imperative for control.

protective gear. Follow chemical

1.5

ppm (Bromine 2.0 to

#I. Use a test kit to determine the

5

days to find the ideal setting.

Page 2

CHARGING INSTRUCTIONS

Exercise extreme caution when operating or servicing feeder.

DO NOT INHALE FUMES. es~eciallv in hot weather which can

create more gases. Wear protecthe gear. Follow chemical

manufacturer's instructions for handling the chemical.

1.

Shut off pump and close control valve. Wait one minute. If feeder is below

water level, before opening drain valve, be sure to close any in-line

prevent back flow. Open vent valve on top of lid. Open drain valve on bottom of

feeder. (Always drain water into plastic container and then pour contents back

into pool.)

2. Close drain valve. Then depress lock spring and unscrew lock ring counter-

clockwise. Remove lid and fill with proper size chlorine or bromine slow dissolve

tablets.

3.

Before replacing lid, clean and lubricate o-ring with Lifegard Silicone

Lubricant only. Push lid firmly into position. Close vent

clockwise until lock spring snaps into place. Do not force lock ring past lock

spring.

4.

Open any in-line valve(s) and turn on pump and timer switches.

5.

Adjust control valve to desired setting.

NOTE: If isolation valves are used anywhere in the system, you must remember to open

them before start-up. To prevent gas buildup and pressure in feeder, be sure to keep

return line

adding other chemicals to your pool, vacuuming, backwashing or adding DE to filter.

valve(s) open, except when opening or servicing unit. Close control valve when

WINTERIZING

If feeder is subject to freezing, drain all water from chamber. Carefully remove

any undissolved tablets or sticks. Rinse out feeder with water, replace lid with

vent valve slightly open and keep unit covered all winter.

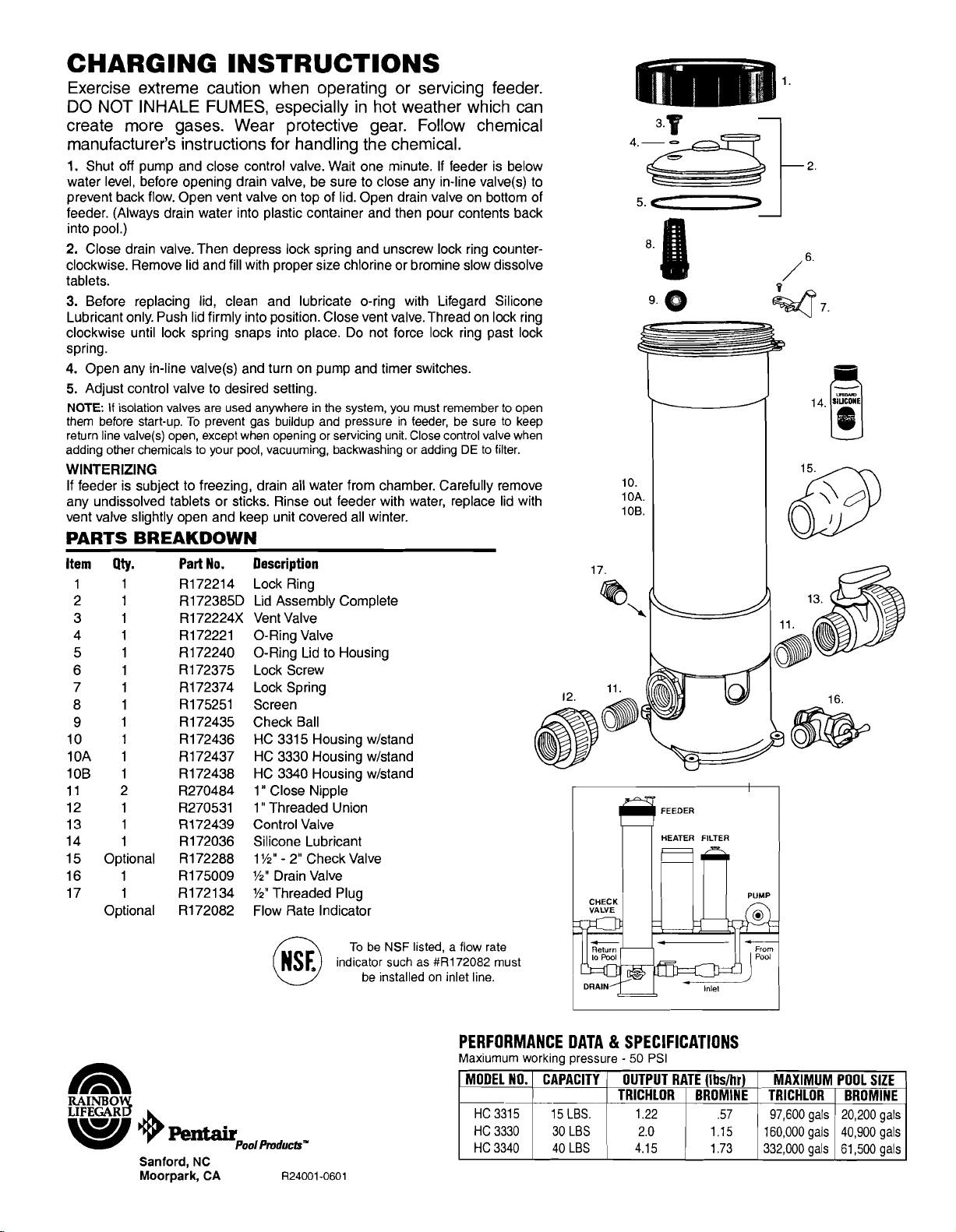

PARTS BREAKDOWN

Item

Qty.

1 1 R172214 Lock Ring

2 1

3 1

4 1

5 1

6 1

7 1

8 1

9

10 1

10A 1

1OB 1 R172438

11 2 R270484

12 1

13 1

14 1

15 Optional

16 1

17 1

1 R172435 Check Ball

Optional

Part

No. Description

R172385D Lid Assembly Complete

R172224X Vent Valve

R172221 0-Ring Valve

R172240 0-Ring Lid to Housing

R172375 Lock Screw

R172374 Lock Spring

R175251 Screen

R172436 HC 331 5 Housing wlstand

R172437 HC 3330 Housing wlstand

R270531 1 " Threaded Union

R172439

R172036 Silicone Lubricant

R172288 1

R175009

R172134

R172082 Flow Rate Indicator

,

,

valve.Thread on lock ring

HC 3340 Housing wlstand

1 " Close Nipple

Control Valve

%"

-

2" Check Valve

%"

Drain Valve

%"

Threaded Plug

valve(s) to

1

8.

9.

43

Sanford, NC

Moorpark, CA

@

R24001-0601

To be

NSF

indicator such as #R172082 must

be installed on inlet line.

listed, a flow rate

PERFORMANCE DATA & SPECIFICATIONS

Maxiumum working pressure - 50 PSI

Loading...

Loading...