Page 1

OWNER’S MANUAL

“ED”, “EDD”, and “EEDD” SERIES

ENGINE DRIVEN SELF-PRIMING

CENTRIFUGAL PUMPS

MODELS

EEDDH-29

EEDD-29

EDDH-29R

EEDDH-29R

EDPH-29R

STA-RITE INDUSTRIES, DELAVAN, WISCONSIN 53115

©2005, Sta-Rite Industries S91 (Rev. 6/13/05)

LIMITED WARRANTY

Sta-Rite Industries warrants to the original consumer of the products listed below, that they will be free from defects in material and workmanship for

the Warranty Period from the date of original installation or manufacture as noted.

Product Warranty Period

Water Systems Products – jet pumps,

whichever occurs first:

small centrifugal pumps, submersible pumps 1 year from date of original installation, or

and related accessories 2 years from date of manufacture

Hydro-Flow Filters 1 year from date of purchase

Signature 2000®Fibrewound Tanks 5 years from date of original installation

Pro-SourceTMSteel Pressure Tanks 5 years from date of original installation

Pro-SourceTMEpoxy-Lined Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 1 year from date of original installation, or

2 years from date of manufacture

Our warranty will not apply to any product that has been subject to negligence, misapplication, improper installation or maintenance. In the event

a three phase submersible motor is operated with single phase power through a phase converter, or if three-leg ambient compensated, extra-quick

trip overload relays of recommended size are not used, our warranty is void.

Buyer’s only remedy and Sta-Rite Industries’ only duty is to repair or replace defective products (at Sta-Rite Industries’ choice). Buyer agrees to

pay all labor and shipping charges associated with this warranty and to request warranty service through the installing dealer as soon as a problem is discovered. If warranty service is requested more than 30 days after the Warranty Period has ended, it will not be honored.

STA-RITE INDUSTRIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit the exclusion or limitation of incidental or consequential damages or the placing of limitations on the duration of an

implied warranty, therefore, the limitations or exclusions herein may not apply. This warranty sets forth specific legal rights and obligations, however, additional rights may exist, which may vary from state to state.

Supersedes all previous publications.

Sta-Rite Industries, 293 Wright St., Delavan, WI 53115

Page 2

MODEL EEDD-29 PUMP UNIT ONLY

To mount pump to your engine, proceed as follows:

1. Loosen clamp assembly (Key No. 4C) on shaft extension.

Position pump adapter on motor; insert engine shaft into shaft

extension. BE SURE pump adapter pilot fits pilot bore in engine.

2. Attach pump adapter to engine using (4) 5/16 x 3/4” capscrews

and lockwashers–(5/16-24 capscrews are required for engines

with aluminum blocks, and 5/16-18 capscrews are required for

engines with cast iron blocks).

3. Push shaft extension toward pump until fibre spacer will not rotate

freely on shaft. Tighten clamp assembly on shaft extension. Hold

the shaft extension with a screwdriver in one of the slots while

tightening the nut.

4. As the fibre spacer is used to establish impeller clearance only, it

will burn out shortly after pump is put into operation and need not

be replaced.

NOTE: If engine is removed, a new fibre washer should be

obtained to re-establish clearance before replacing engine.

5. Use one of the following engines:

(a) Briggs and Stratton

(b) Kohler

(c) Tecumseh

Refer to engine manufacturer’s service manual for parts or service

to engine.

BE SURE to fill crankcase with recommended grade of oil.

Do NOT run pump until it has been primed, as this could ruin

the seal.

NOTE: MODEL EDG-105 IS BUILT FOR USE WITH SWIMMING

POOLS.

MODEL EDG-105 IS SHIPPED WITH A 1-1/2” SUCTION FLANGE

ASSEMBLY.

* These parts are not furnished. Order Strainer Fittings Package

C298-9, which includes these parts.

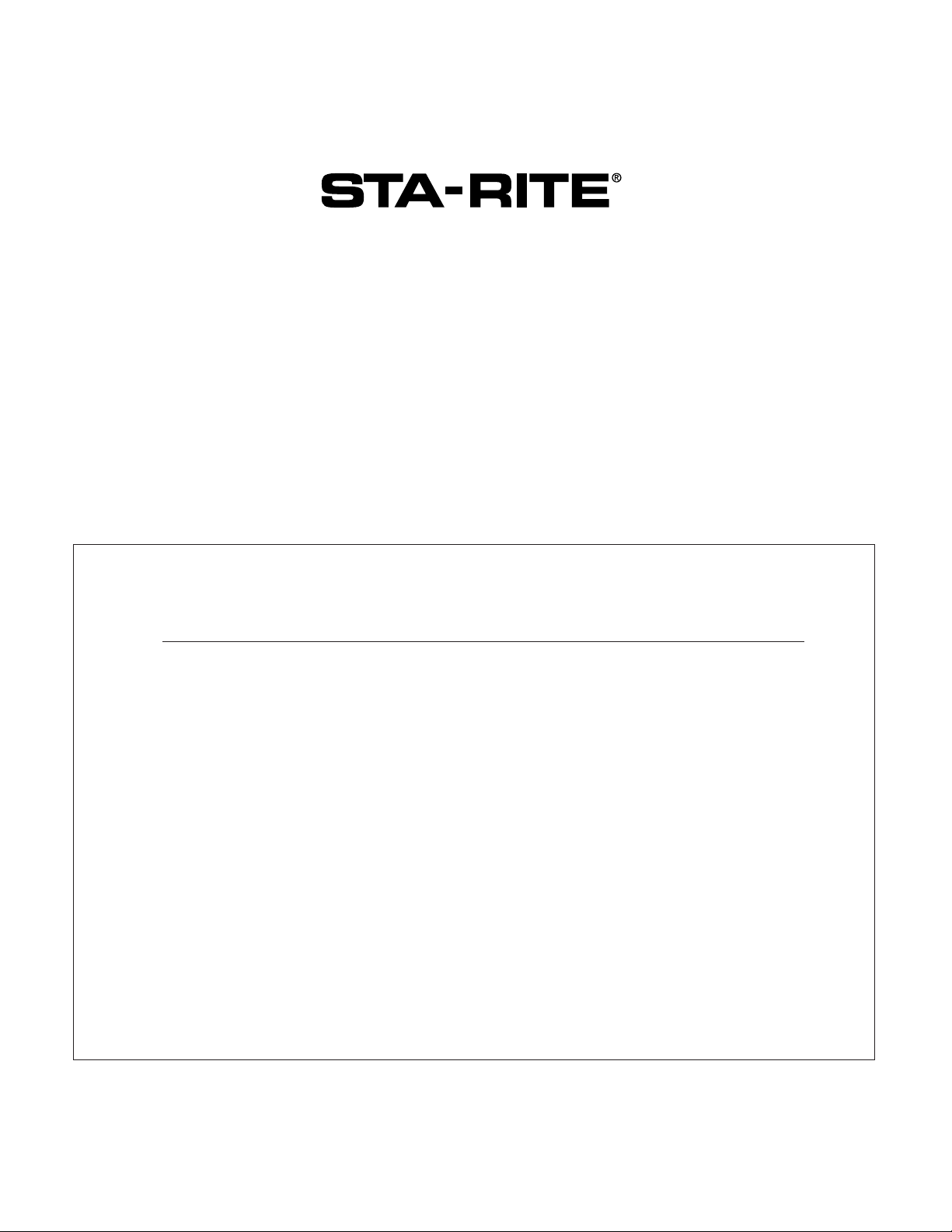

PLACING THE PUMP

This pump is portable, and should be placed on a level foundation or

firm level ground as near the water source as possible, for efficient

operation. Model EEDD-29 can be mounted on an available gasoline engine. It must have the engine supported to the same level as

the pump mount, to avoid placing strain on the pump adapter or

engine. All suction and discharge piping should also be supported

independently near the pump, to avoid strain on the unit. Standard

piping can be used, or as the pump is portable, reinforced suction

hose can be used on the suction inlet. This hose must have the

equivalent capacity of 2” iron pipe. A strainer should be used on the

end of the suction pipe or hose. See Figures 1 and 2 for typical

installations.

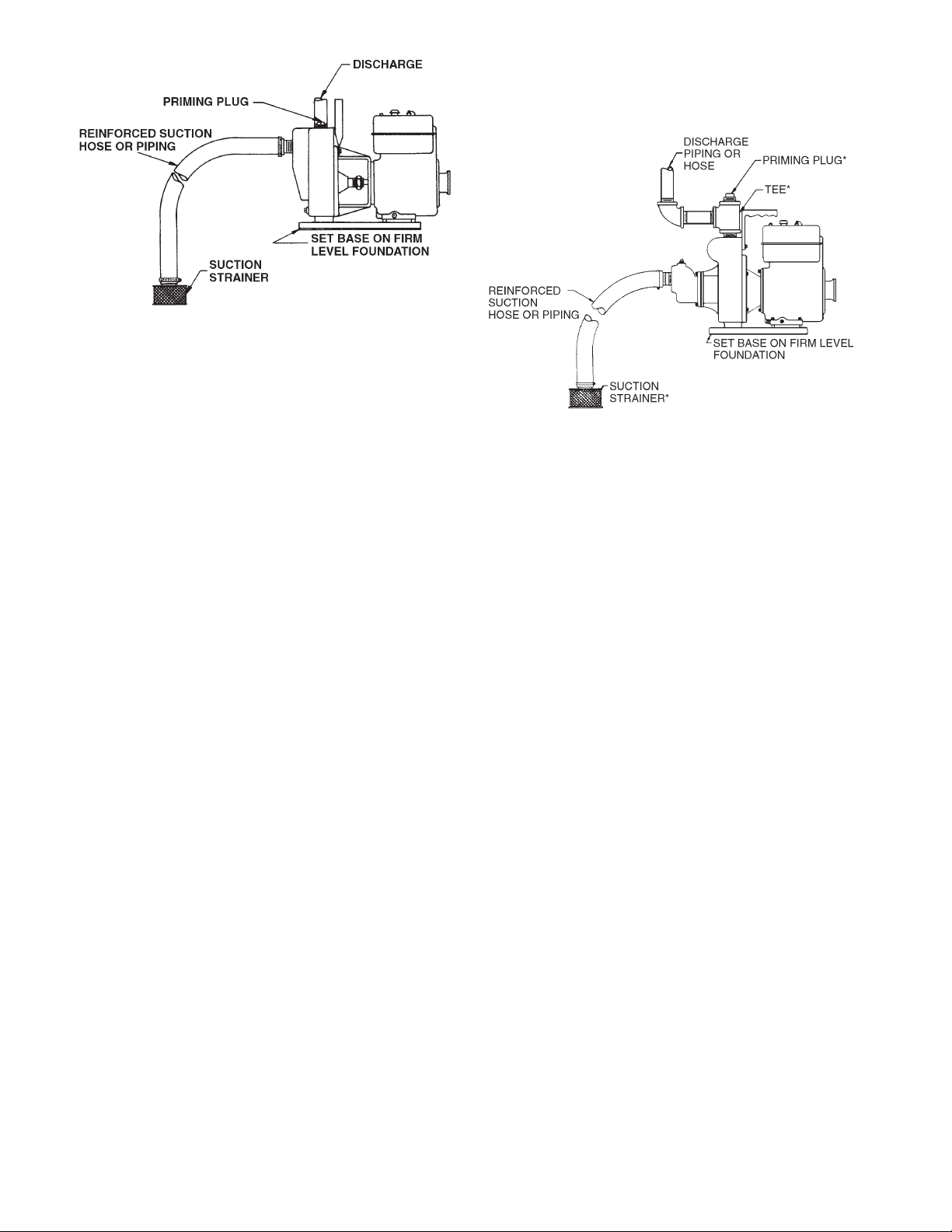

PRIMING THE PUMP

Install pipe tee in the discharge opening of the pump with a nipple.

Provide a priming plug in the top opening.

See Figure 2.

Fill the pump with water and tighten the priming plug. Start the

engine, and the pump will prime, with priming time depending upon

the suction lift and the horizontal distance to water.

OPERATING SPEED

Models With Engine

These pumps leave the factory with a gas engine set to operate at

3500 rpm when pumping, which is the correct speed for maximum

efficiency. Model EEDD-29 must be provided with an engine which

will operate at approximately the same speed (3500 rpm).

Always start the unit at full speed until unit is primed and pumping

water. It can be throttled to lower the pump’s capacity while pumping.

Figure 1

Figure 2

2

Page 3

PUMP SERVICE

Due to the simple, rugged construction of the pump, it should require

little service. However, if it should be necessary to replace a part, the

following procedure should be used.

1. Remove the capscrews, Key No. 8, which hold the pump body to

the engine adapter.

2. The pump body can now be removed.

3. A tap on the volute diffuser, Key No. 18, will enable you to remove

it, exposing the impeller.

4. Remove the impeller from the engine shaft by turning counterclockwise.

5. Seal replacement. The shaft seal consists primarily of two parts,

a rotating member and a floating seat.

The highly polished and lapped faces of this seal

are easily damaged. Read instructions and handle the seal with

care.

Some models are equipped with an impeller screw, which has a left

hand thread. Before unscrewing the impeller, remove the impeller

screw.

Removal of Old Seal

1. After unscrewing impeller, carefully remove rotating part of seal

by prying up on sealing washer, using two screwdrivers (see

Figure 3A, below). Use care not to scratch motor shaft.

2. Remove seal plate from motor and place on flat surface, face

down. Use a screwdriver to push ceramic seat out from seal cavity (see Figure 3B, below).

Installation of Floating Seat (Figure 3C)

1. Clean polished surface of floating seat with clean cloth.

2. Turn seal plate over so seal cavity is up. Clean cavity thoroughly.

3. Lubricate outside rubber surface of ceramic seat with soapy water

and press firmly into seal cavity with finger pressure. If seat will

not locate properly in this manner, place cardboard washer over

polished face of seat and press into seal cavity using a 3/4” socket or 3/4” piece of standard pipe.

4. Dispose of cardboard washer. Be sure polished surface of seat is

free of dirt and has not been damaged by insertion.

Installation of Rotating Part of Seal Unit (Figure 3D)

1. Reinstall seal plate.

2. Inspect shaft to make sure that it is clean.

3. Clean face of sealing washer with clean cloth.

4. Lubricate inside diameter and outer face of rubber drive ring with

soapy water and slide assembly on motor shaft (sealing face first)

until rubber drive ring hits shaft shoulder.

5. Screw impeller on shaft until impeller hub hits shaft shoulder. This

will automatically locate seal in place and move the sealing washer face up against seat facing. Reinstall impeller screw (if used).

MAINTENANCE

Be sure to drain pump during freezing weather to prevent damage

from frost. To drain, remove drain plug directly below the suction

inlet of the pump; also remove the priming plug. Drain the suction

pipe at a point below the frost line. All pipe exposed to freezing temperatures should also be drained. Before restarting pump, replace

all connections and plugs and reprime.

For service and maintenance to the engine, see the booklet which

comes with the engine.

Figure 3

TROUBLE – CAUSES AND REMEDY

Trouble

No water delivered or not enough

water delivered.

Probable Cause

Pump not primed

Speed too low

Suction line clogged

Suction lift too high

Air leak in suction line

Impeller plugged

Suction end not submerged deep

enough

Remedies

Fill pump body with water

Pump should operate about 3500

RPM - Check engine

Clean suction screen

Put pump closer to water

Tighten connections or replace with

new hose or pipe

Use pipe compound to seal all male

threads

Clean impeller

Submerge suction hose or piping

enough so that no air enters while

pump is operating

3

685 0294

Mechanical seal

rotating half

Seal Plate

3/4" socket

or pipe

Cardboard

washer

(supplied w/seal)

Rubber

surface

Mechanical seal

stationary half

Polished

surface

o

n

v

r

e

u

r

T

Shaft

shoulder

Rubber drive

ring

Sealing

face

Impeller

A-Seal removal-rotating half B-Seal removal-stationary half C-Stationary half installation D-Rotating half installation

Page 4

13

4

4A

4B

4C

20

19

16

17

18

15

14

10

9

8

7

6

4

5

3

2

12

21

22

11

1

25

24

23

25

28

27

26

4

EXPLODED VIEW

EEDD-29*

EEDDH-29R EDDH-29R EDG-105 EDPH-29R

Key Part No. 3-1/2 HPPump 3-1/2 HP Pump 2 HP Pump 3-1/2 HP Pump

No. Description Used w/ or w/oEngine w/Engine w/Engine w/Engine

1 Gas Engine 1 U277-24BR U277-24R U277-10 U277-24R

2 Grease Seal - Shaft 1 — — U9-42 —

3 Water Slinger 1 — 17351-0009 C69-2 17351-0009

4 Adapter 1 C2-49 C2-14B C2-14F C2-14B

4A Spacer 1 C43-37 — — —

4B Shaft Extension 1 C10-22 — — —

4C Clamp Assembly 1 C111-1 — — —

5 Capscrew - 3/8 - 16 x 3/4” Lg. 2 U30-72SS U30-72SS U30-72SS U30-72SS

6 Gasket 1 C20-21 C20-21 C20-21 C20-21

7 Shaft Seal 1 U109-106SS U109-93SS U109-106SS U109-106SS

8 Impeller 1 C5-60 C5-60 C5-60H C5-60

9 Diffuser 1 C1-51 C1-51 C1-51 C1-51

10 Diffuser Ring 1 C21-2 C21-2 C21-2 C21-2

11 Capscrew - 3/8 - 16 x 7/8” Lg. 2 U30-73SS U30-73SS — —

11 Cap Screw 3/16-16x1” Long 2 — — U30-74C U30-74C

12 Lock Washer 3/8” 2 — — U43-12C U43-12C

13 Handle 1 C54-29 C54-29 C54-9B C54-9B

14 Pump Body 1 C76-52 C76-52F C176-1D C176-1

• 1-1/2” Suction Flange Assembly 1 — — C203-22 —

15 Valve Plate (1) — — C61-5SS —

16 Gasket – Flange (1) — — C20-15 —

17 Valve Washer (1) — – C43-15SS —

18 Cap Screw – 1/4-20x1/2” Long (1) — — U30-50SS —

• Hex Nut – 1/4-20 (1) — — U36-36SS —

19 Pipe Plug – 1/4” NPT (1) — — U78-57SST —

20 Suction Flange (1) — — C3-22 —

21 Cap Screw – 5/16-18x3/4” Long (4) — — U30-60SS U30-60SS

22 Pipe Plug - 1/4” NPT 1 U78-57SS U78-57CT U78-57SST U78-57SST

23 Base 1 C104-9 C4-73 C104-9 C104-9

24 Capscrew - 5/16 - 18 x 7/8” Lg. 4 U30-777C U30-777C U30-777C U30-777C

25 Lockwasher - 5/16” 8 U43-11C U43-11C U43-11C U43-11C

26 Capscrew - 5/16 - 18 x 1-3/4” Lg. 4 U30-66C U30-65C U30-665C U30-665C

27 Engine Pads 4 C43-20 — C43-20 C43-20

28 Nut - 5/16” - 18 4 U36-37C U36-37C U36-37C U36-37C

• Pipe Plug - 3/4” NPT 1 U78-60S U78-60S — —

REPAIR PARTS LIST

* Model EEDD-29 is identical to Model EEDDH-29R except that it does not include engine or engine hardware (Key Nos. 1, 23-28).

• Not illustrated.

Loading...

Loading...