Page 1

OWNER’S MANUAL

Battery Backup Systems

DB10018T-01

DB20018T

293 Wright Street, Delavan, WI 53115

© 2004, Sta-Rite Industries Printed in U.S.A. S739 (Rev. 4/16/04)

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-800-323-0620

ACPOWER ON

UMP RUN LARM

UD LE LARM

IR PR E R TR LD

T E BT ERY HR EMI TN R

IE CE

12 VOLT 8 AMP

OW A T

R A AM

HRG G E W

HRGED GREN

AUDB E A

DSA LE

ARM

AA M ES T

SOFT R SET

Page 2

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for

one of the following signal words and be alert to the

potential for personal injury!

DANGER warns about hazards that will

cause serious personal injury, death or major property

damage if ignored.

WARNING warns about hazards that can

cause serious personal injury, death or major property

damage if ignored.

CAUTION warns about hazards that will or

can cause minor personal injury or property damage if

ignored.

The word NOTICE indicates special instructions which

are important but not related to hazards.

1. To avoid risk of serious bodily injury due to electrical

shock or burns and property damage due to flooding,

read the safety instructions carefully before installing

pump.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC terminals to touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be

sure one hand is free when plugging in or unplugging

charger. If basement floor is wet, disconnect power to

basement before walking on floor.

Risk of flooding. Do not run pump dry. To

do so will damage seals and can cause leaking and property damage.

2. Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault circuit interrupter (GFCI) is recommended for use on

any electrical appliance submerged in water.

3. Use this system only for backup sump pump duty in

a residential application. It is not designed as a primary sump pump.

4. Do not lift pump by electrical cord.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

5. Pump clear water only with this pump.

6. Pump is permanently lubricated at the factory. Do

not try to lubricate it!

7. Keep battery charger and battery box off of the floor

and in a dry, cool, well ventilated area.

NOTICE: If a Carbon Monoxide (CO) sensor is

installed, it must be at least 15 feet away from battery charger in order to avoid nuisance CO alarms.

Please refer to your CO detector’s installation guidelines for more information.

8. To avoid danger of fire or explosion, keep sparks and

flame (pilot light) away from battery.

9. Maximum vertical pumping distance is 16 feet

(4.9M) for Model DB10018T-01 and 18 feet (5.5M)

for Model DB20018T.

10. Make sure sump is clear of debris. Debris can damage the pump which can result in flooding.

GENERAL INFORMATION

The battery back-up sump system is not a substitute for

your primary sump pump. It is designed to temporarily

back up your primary sump pump during a power outage or other problem which prevents normal operation

of the primary pump. Do not use this system to pump

flammable liquids or chemicals. Pump clear water only

with this pump.

Keep battery charger dry and protected from damage.

In an emergency (such as an extended power outage)

which depletes the system deep cycle battery, your automobile battery may be temporarily substituted. Be sure to

replace the system deep cycle battery as soon as possible. Use of an automobile battery instead of a 27M or

24M deep cycle battery in this system will significantly

reduce system total performance. Automobile batteries

are not designed for this type of application and will be

quickly ruined by the repeated charge/discharge cycling.

Do not use GEL-type batteries or maintenance-free

(sealed) batteries with this charger. GEL-type batteries

require a lower voltage than the charger is designed for;

they may overcharge. Maintenance-free (sealed) batteries

require a higher voltage and may never reach full charge.

NOTICE: This unit is not designed for applications involving salt water or brine! Use with salt water or brine will

void warranty.

Page 3

Ta b le of Contents 3

Page

General Safety .....................................................................................................2

Warranty..............................................................................................................3

Installation......................................................................................................4-12

Operation .....................................................................................................13-14

Troubleshooting .................................................................................................14

Repair Parts........................................................................................................15

LIMITED WARRANTY

Sta-Rite Industries, warrants to the original consumer of the products listed below, that they will be free from defects in material and workmanship for the Warranty Period from the date of original installation or manufacture as noted.

Product Warranty Period

Water Systems Products – jet pumps, whichever occurs first:

small centrifugal pumps, submersible pumps 1 year from date of original installation, or

and related accessories 2 years from date of manufacture

Hydro-Flow Filters 1 year from date of purchase

Signature 2000 Fibrewound Tanks 5 years from date of original installation

Pro-Source Steel Pressure Tanks 5 years from date of original installation

Pro-Source Epoxy-Line Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 1 year from date of original installation, or

2 years from date of manufacture

Our warranty will not apply to any product that has been subject to negligence, misapplication, improper installation or maintenance. In the event a three phase submersible motor is operated with single phase power through a phase converter, or

if three-leg ambient compensated, extra-quick trip overload relays of recommended size are not used, our warranty is void.

Buyer’s only remedy and Sta-Rite Industries’ only duty is to repair or replace defective products (at Sta-Rite Industries’

choice). Buyer agrees to pay all labor and shipping charges associated with this warranty and to request warranty service

through the installing dealer as soon as a problem is discovered. If warranty service is requested more than 30 days after

the Warranty Period has ended, it will not be honored.

STA-RITE INDUSTRIES SHALLNOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES

WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITYAND FITNESS

FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit the exclusion or limitation of incidental or consequential damages or the placing of limitations

on the duration of an implied warranty, therefore, the limitations or exclusions herein may not apply. This warranty sets forth

specific legal rights and obligations, however, additional rights may exist, which may vary from state to state.

Supersedes all previous publications.

Sta-Rite Industries, 293 Wright St., Delavan, WI 53115

Page 4

Installation 4

BATTERY BACKUP SYSTEM

INSTALLATION AND OPERATION

NOTICE:

• Install this system during a time when the primary

pump will not be needed. Gather all supplies before

starting. Read all warnings and installation steps

before you start.

• Be prepared for water to leak from the coupling or

piping when disassembling or cutting the discharge

pipe. Protect system components, tools and supplies

from getting wet. Dry any work areas that get wet.

BASIC TOOLS AND

MATERIALS NEEDED

Channel locks or large pliers

Tape measure

Socket wrench or 5/16” Nut driver

Side cutters

Hacksaw (to cut PVC pipe)

Medium size pliers

Pencil

Teflon tape

PVC glue (solvent weld)

PVC pipe cleaner

Cloth towel

Size 24M Marine Deep Cycle Battery

or a

Size 27M Marine Deep Cycle Battery

Required Battery Capacity:

DB10018T-01 – 100 ampere-hour maximum.

DB20018T – 130 ampere-hour maximum.

Personal injury and flood hazard. Do not

turn the pump on until all the fittings are glued and the

glue has dried. Loose fittings can explode off of pipes

and cause personal injury and flooding.

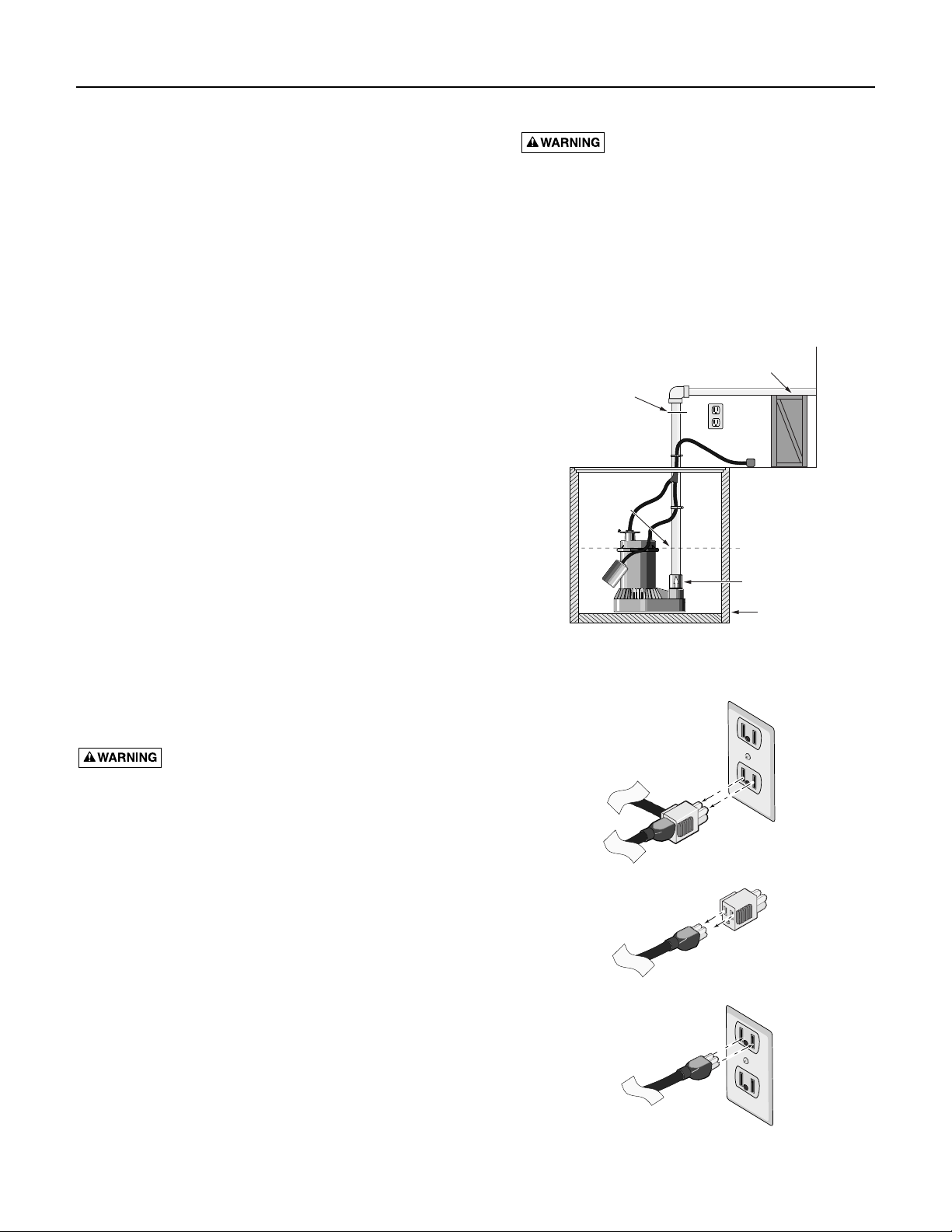

Remove Primary Pump From Sump Pit:

1. Locate the “on” water level of the primary sump

pump. Mark this location on the discharge pipe with

a pencil. See Figure 1.

2. Drain the sump pit. The water level must be pumped

down as low as possible before going on to the next

step. To drain the sump pit follow either step “2A” or

“2B”(below).

2A. Raise the float on the float switch until the

pump turns on. Use a wooden broom handle or

a stick to do this.

2B. If the sump pump has a piggy-back type power

cord, remove the float switch power cord plug

from the outlet and plug the pump power cord

plug directly into the outlet. See Figure 2.

Electrical shock hazard. Shock can burn

or kill. Do not use metal or any other electrical conducting material to raise the float. Do not make contact with the water in the sump pit. Failure to follow

this warning can result in personal injury or death.

3. Drain the sump.

NOTICE: Do not let the pump run dry. This will

damage the pump.

4. Unplug the pump.

Figure 1 – Mark and cut pipe as shown

Figure 2 - To bypass the float switch

Support the

Remove the

hose coupling

or mark the

1st cut here.

Mark pipe with

pencil here

(2nd cut).

Pipe before

cutting.

'Turn on'

water level of

Primary Pump

Check

Valve

Sump Pit

1.

Unplug the "Piggy-back"

float switch cord plug and

the pump power cord plug

from the grounded

electrical outlet.

2.

Separate the float switch cord plug

from the sump pump cord plug.

3.

Plug the pump power cord plug

directly into the outlet.

Grounded

Electrical

Outlet

4166 0402

Page 5

Installation 5

5. To separate the primary pump from the discharge pipe:

5A. For applications with hose couplings: remove

the coupling clamps with a nut driver.

5B. For applications without rubber couplings: cut

the PVC discharge pipe with a hacksaw above

the basement floor, at a comfortable level. New

rubber couplings are included for reassembly.

See Figure 1 on Page 4.

NOTICE: The discharge pipe is filled with water.

Drain the water from the discharge pipe assembly.

Keep the work area dry.

Risk of pinching hands or fingers. To

avoid a hand injury from a collapse of plumbing,

support the pipe above the separation before cutting

or disassembly. See Figure 1.

6. Lift the primary pump and discharge pipe assembly

out of the sump.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

lifting ring, discharge pipe, or handle on the pump.

Lifting by the cord can damage the cord.

INSTALL BACKUP PUMP

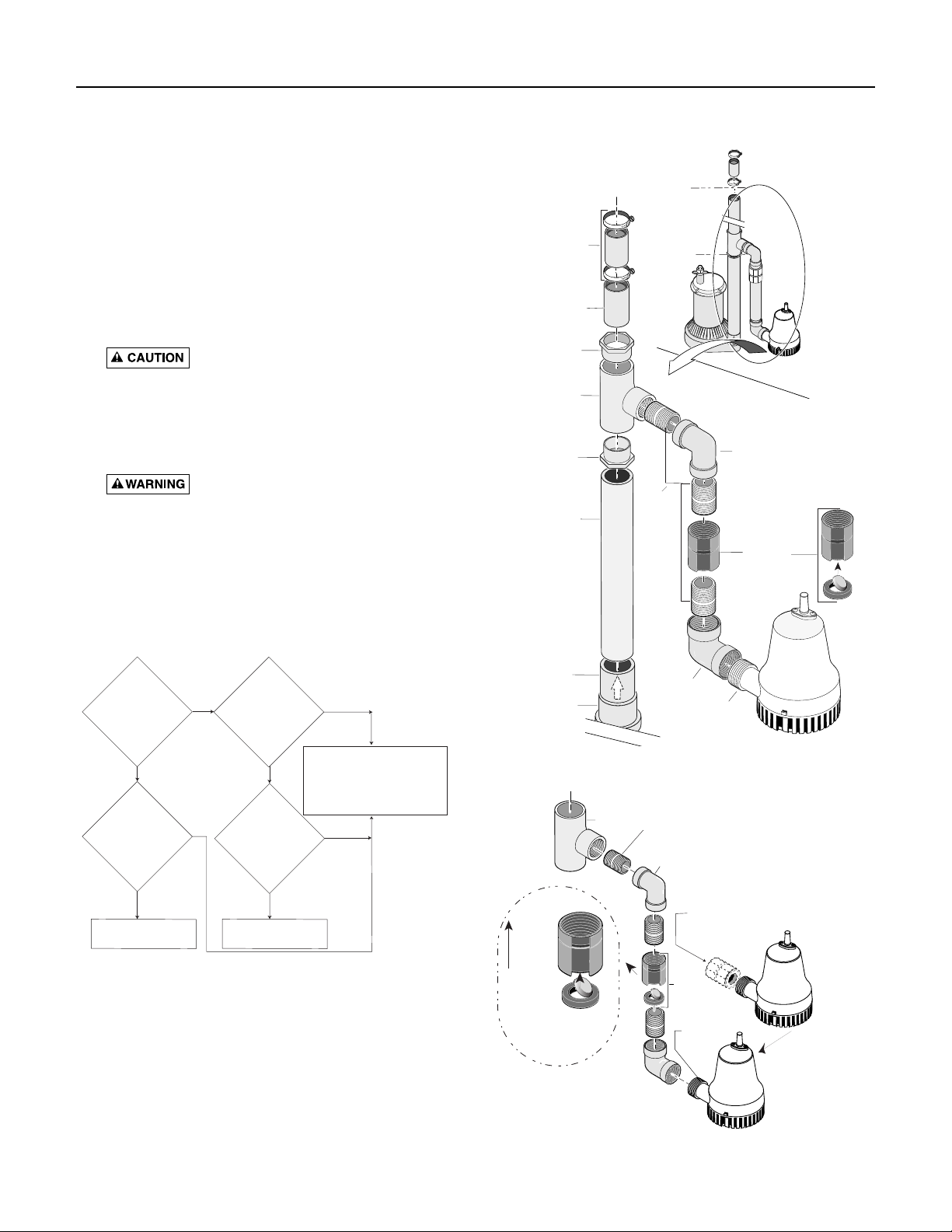

There are two ways to install the Battery Back-up Pump.

Method A and Method B. See Figure 3 to determine

which method to use. Both methods are acceptable.

Not to Scale

Switches and

Wiring omitted

for clarity

Hose Coupling

with Clamps

Cut-Off piece of

discharge pipe.

1-1/2"x1-1/4"

Reducer bushing

Tee

1-1/2"x 1-1/2"

slip x 1-1/4" FNPT

1-1/2"x1-1/4"

Reducer

bushing

Short Length

of Discharge Pipe

(may vary)

Primary Sump

Pump Check Valve

to prevent

recirculation

into the sump.

Backup Pump Installation

(Method A)

First Cut:

Second Cut:

at Marked

Water Line

Close

Pipe

Nipple

(1-1/4"

x 1-1/4")

(1 Nipple

is included

with the

back-up

pump

package)

1-1/4" Elbow

Check Valve

Assembly

Sump Pit

Diameter

at base ≥ 18"?

No No

Sump Pit

Diameter

at base ≥ 13.5"?

BBU System may still

Yes

Yes

be installed but the

installation may need

to be changed.

Sump Pit Depth

≥ 18"?

Yes

Method A

Sump Pit Depth

≥ 22"?

No

Method B

Yes

No

Figure 3 - Choose an installation method

Method A

Method A suggests installing both of the pumps on the

floor of the sump pit. See Figure 4. The minimum required

sump basin diameter, at the bottom of the pit and the recommended depth of the sump basin is 18”.

Some additional materials you will need are 2 1-1/4” 90°

elbows and 2 1-1/4” close pipe nipples.

1-1/4"

Elbow

Primary Pump

Discharge Port

Back-up Pump

Discharge Port

Figure 4 - Method A installation diagram

Close

Pipe

Nipple

Elbow

Check

Valve

Assembly

Battery Back-up Pump comes

preassembled with the check

valve assembly installed on the

discharge.

Remove this check

valve assembly.

Back-up Pump

Discharge

Water

Flow

through

valve

(The valve

flap opens

away from the

pump outlet)

Tee

Figure 5 - Remove the pre-assembled check valve

Page 6

Installation 6

1. Make the second cut in the discharge pipe at the

pencil mark as shown in Figure 1 on page 4, and in

Figure 4, on Page 5. Clean the pipe ends with a

cloth towel and set the cut-off piece of discharge

pipe aside.

2. Remove the check valve assembly (Key No. 4 on

Page 15) from the battery back-up pump (Key No. 5)

discharge and set it aside. See Figure 5. The check

valve assembly will be used later, during assembly.

3. Thread a 90° elbow (purchased locally) onto the discharge of the back-up pump.

4. Wrap the threads of all 3 of the close pipe nipples

(Key No. 3) with 2 turns of Teflon™ tape and thread

one of them into the elbow. Set the other 2 aside.

5. Thread the check valve assembly, removed back in

step 2, onto the close pipe nipple.

NOTICE: Make sure the check valve is installed in the

correct direction. See the inset drawing in Figure 5.

6. Thread a close pipe nipple into the other end of the

check valve.

7 Thread the second 90° elbow onto the pipe nipple.

8. Thread the last pipe nipple into the elbow.

9. Thread the tee onto the pipe nipple and set this

assembly aside.

10. Install a short length of pipe into the top of the check

valve in the primary pump discharge. See Figure 6.

NOTICE: There must be a check valve installed in

the Primary Sump Pump discharge pipe between the

tee and the Primary Sump Pump. This will prevent

recirculation into the Primary Pump when the

Backup Sump Pump comes on.

11. Slip a reducer bushing (Key No. 2A) onto the end of

the pipe coming from the primary pump discharge.

Do not glue this connection yet.

NOTICE: If your discharge pipe diameter is 1-1/4”,

you will need to glue the reducer bushings into the

tee first and then slip the cut off piece of discharge

pipe into the bushing.

12. Slip the tee and the back-up pump subassembly onto

the reducer bushing.

13. Glue the cut off piece of pipe into the top of the

reducer bushing in the top of the tee.

14. Mount the float switch assembly (Key No. 7) loosely

to the discharge pipe with the cable ties (Key Nos.

7A & 7B). See Figure 6. Approximately 2.5” (63.5

mm) of cord length should be left between the float

and the clamp. Do not tighten the cable ties.

Adjustments may be needed later.

15. Skip to the section “Cut the Discharge Pipe”, Page 7.

Method B

Method B suggests installing the back-up pump above

the primary sump pump. See Figure 7. The minimum

required sump basin diameter for this type of installation

is 13.5” at the bottom of the pit, and the minimum recommended depth of the basin is 22”.

1. Make a second cut in the discharge pipe at the pencil

mark made in step 1, on Page 4, and set the cut-off

piece of discharge pipe aside. See Figures 1 and 7.

TM

E.I. DuPont de Nemours and Company Corporation.

Backup Pump Installation

(Method B)

Discharge

Pipe

Hose

Coupling

and Clamps

Cable Ties

2" Minimum

Tee

Short length

of discharge

Pipe (length

may vary).

Check valve

Float Switch

Tether Length

2.5" (63.5 mm)

To the

back-up

pump

discharge

pipe.

Primary Sump

Pump Discharge

Pipe

Figure 6 - Back-up pump float switch tether length and

discharge pipe

Not to Scale

Switches and

Wiring omitted

for clarity

Hose Coupling

with Clamps

First Cut:

Cut-Off piece of

discharge pipe.

Backup

Sump

Pump

Check Valve

Assembly

(Included)

Primary Sump Pump

Check Valve to Prevent

Recirculation into Sump

Close

Pipe

Nipple

Second Cut:

at Marked

Water Line

1-1/2"x1-1/4"

Reducer

Bushing

Tee

1-1/2"x1-1/4"

Reducer

Bushing

Primary Pump

Discharge Pipe

Figure 7 – Method B installation diagram

Basement

Floor

Sump

Pit

Page 7

Installation 7

2. Wrap the threads of the close nipple (Key No. 3 on

Page 12) counterclockwise with 2 turns of Teflon

TM

tape and set aside.

NOTICE: There must be a check valve installed in

the Primary Sump Pump discharge pipe between the

tee and the Primary Sump Pump. This will prevent

recirculation into the Primary Pump when the

Backup Sump Pump comes on.

3. The backup pump (Key No. 6) and check valve

assembly (Key Nos. 4 and 5) come preassembled.

Thread the close pipe nipple into the check valve.

4. To thread the tee (Key No. 2B - also included reducer bushings) into the close nipple:

Hold the check valve assembly with the channel

locks, insert the screwdriver into the tee for leverage,

and tighten the tee with the screwdriver. Finish with

the tee in a straight up and down (vertical) position.

5. Clean the pipe ends with the cloth towel.

6. Glue the cut-off piece of discharge pipe into the top

of the tee.

NOTICE: If your pipe is 1-1/4”, you will need to glue

the reducer bushings into the tee and glue the pipe

into the bushing. Place the assembly onto the primary discharge pipe. Do not glue the tee onto the primary pump discharge pipe.

7. Mount the back-up pump float switch assembly (Key

No. 7) loosely to the discharge pipe with the cable ties

(Key Nos. 7A & 7B). See Figure 6, on Page 6.

Approximately 2.5” (63.5 mm) of cord length should

be left between the float and the clamp. Do not tighten the cable ties. Adjustments may be needed later.

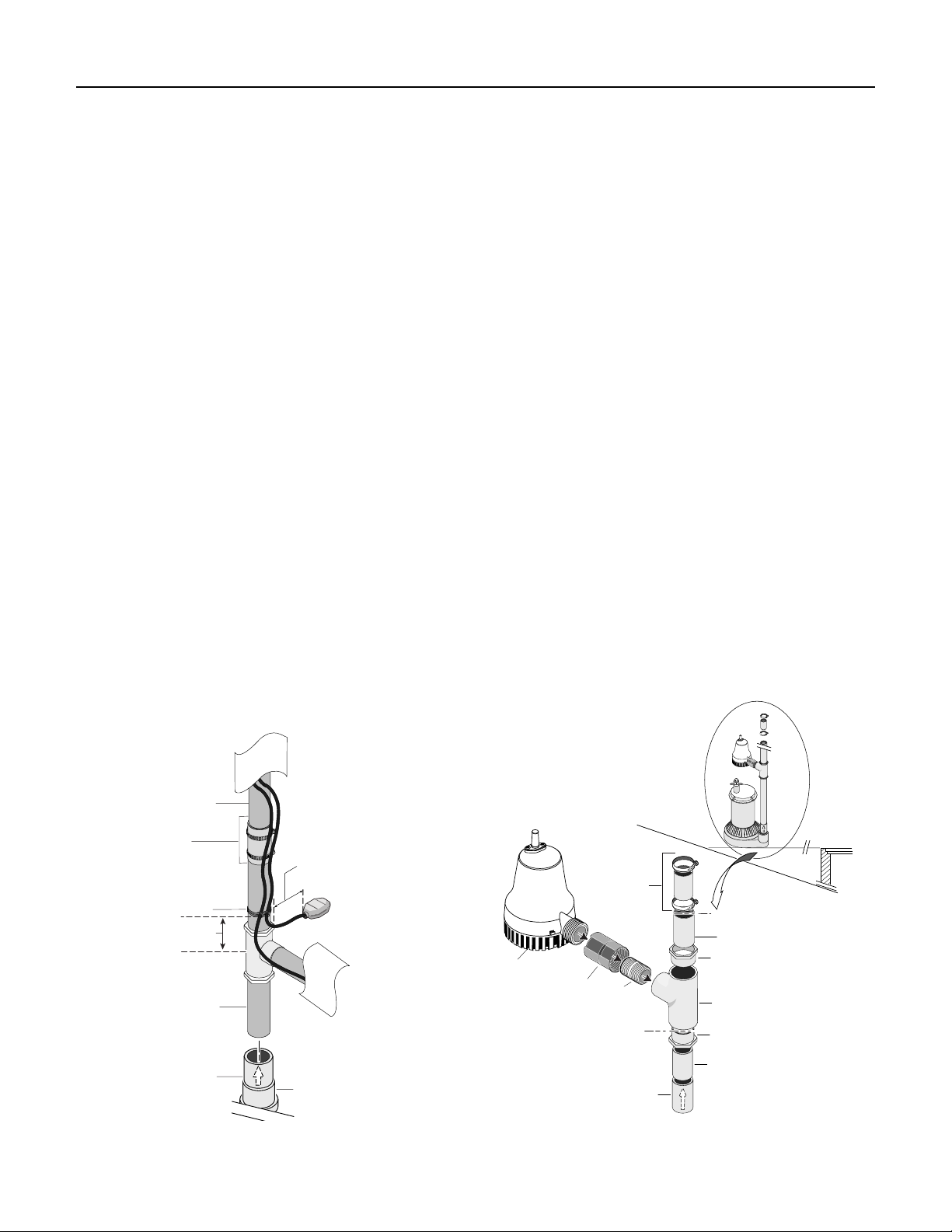

Cut the Discharge Pipe:

1. Put the double pump assembly into the sump pit.

NOTICE: The discharge pipe now overlaps the dis-

charge pipe that leads outside.

2. Mark the discharge pipe where it should be cut. Be

sure to leave a 1/4” air gap between the ends of the

pipes. This gap will absorb the noise from vibration

and allow for flexibility.

3. Make the third cut. See Figure 8.

TRIAL ASSEMBLY OF DOUBLE PUMP

ASSEMBLY IN THE SUMP PIT:

1. Connect the discharge pipe to the exterior discharge

pipe with the rubber coupling and clamp kit (Key

No. 1). Do not tighten the clamps until all the final

adjustments are complete.

2. Make the final adjustments. Make sure the pumps

and the switches do not interfere with each other.

Make sure there is plenty of room for the float

switches to either swing or to move up and down

from their “off” to their “on” positions.

Mark and Glue Assembly:

1. Mark the pipe and the fittings at all the connections

with a pencil. These marks will be used as a reassembly guide while gluing to be sure everything is still in

the right place and nothing has moved.

2. Loosen the rubber coupling and clamp connection.

3. Carefully pull the double pump assembly back out of

the pit.

4. Take the tee assembly off of the primary discharge

pipe. Do Not unscrew any of the TeflonTMtaped pipe

nipple connections.

5. Clean all the PVC pipe ends with the PVC cleaner.

Hazardous fumes. Follow the cement

and cleaner manufacturers instructions. Use the PVC

cement in a well ventilated area away from fire or

flames.

6. Glue the PVC fittings where indicated by the pencil

marks. Wait 10 minutes for the glue to cure.

Final Assembly:

1. Put the double pump assembly back into the pit.

2. Install and tighten the rubber coupling and clamp kit.

3. Make the final float switch adjustments and tighten

the cable ties.

Figure 8 – Make the third cut to remove the excess

discharge pipe

Method A Method B

Exterior

discharge

pipe

Make the Third Cut

(the overlap plus

the 1/4" air gap).

overlap

1/4" air gap

overlap

Exterior

discharge

pipe

Sump basin

inlet pipe (from

drain tiles to

sump basin).

2"

Recommended Minimum

2"

Previously marked

"on" water level

of Primary Sump Pump.

(See Figure 1, Page 4)

Note: Always install the back-up sump pump as close

to the bottom of the sump pit as possible.

Page 8

Installation 8

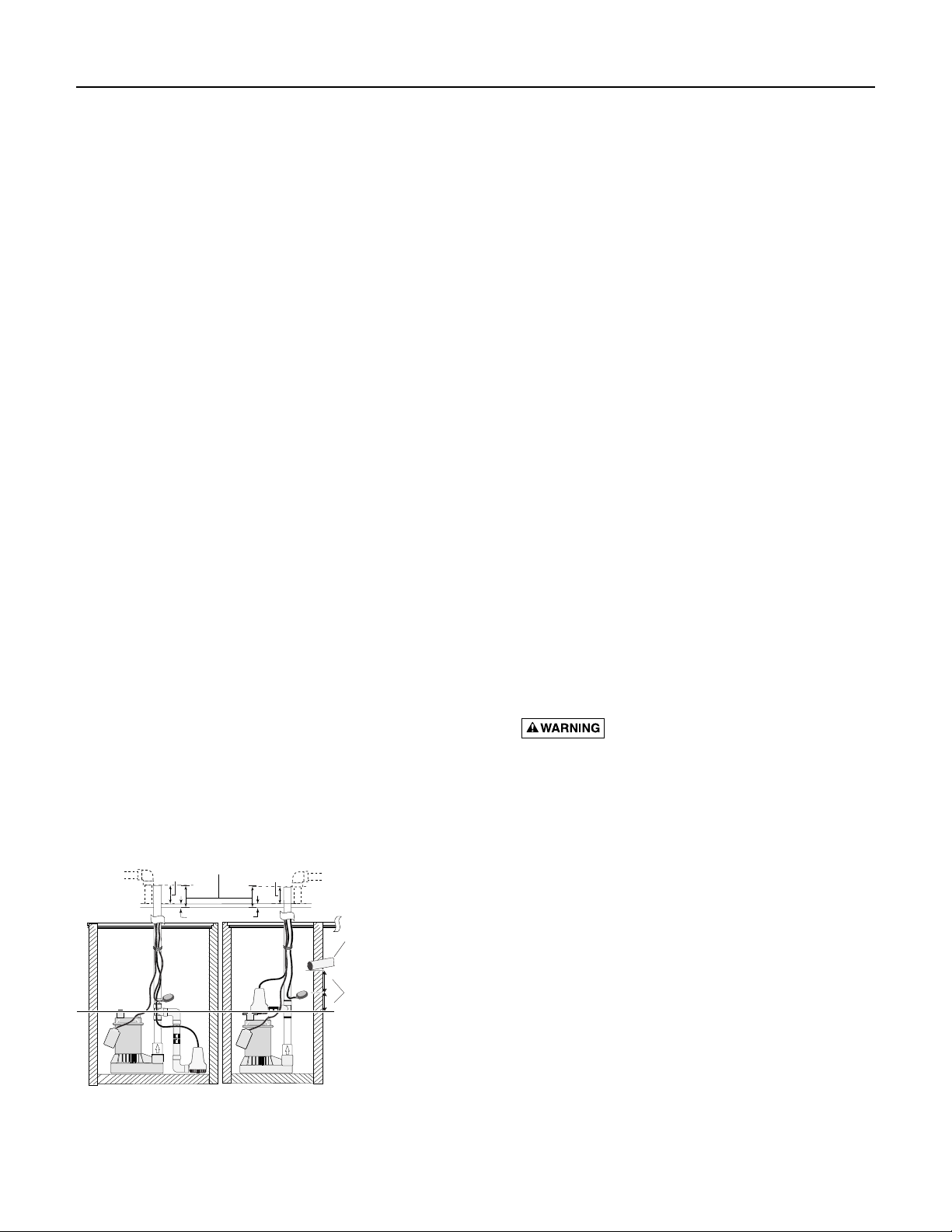

ELECTRICAL CONNECTIONS

Hazardous voltage. Can cause serious or

fatal electrical shock. Review safety instructions before

operating charger. Do not modify cord or plug.

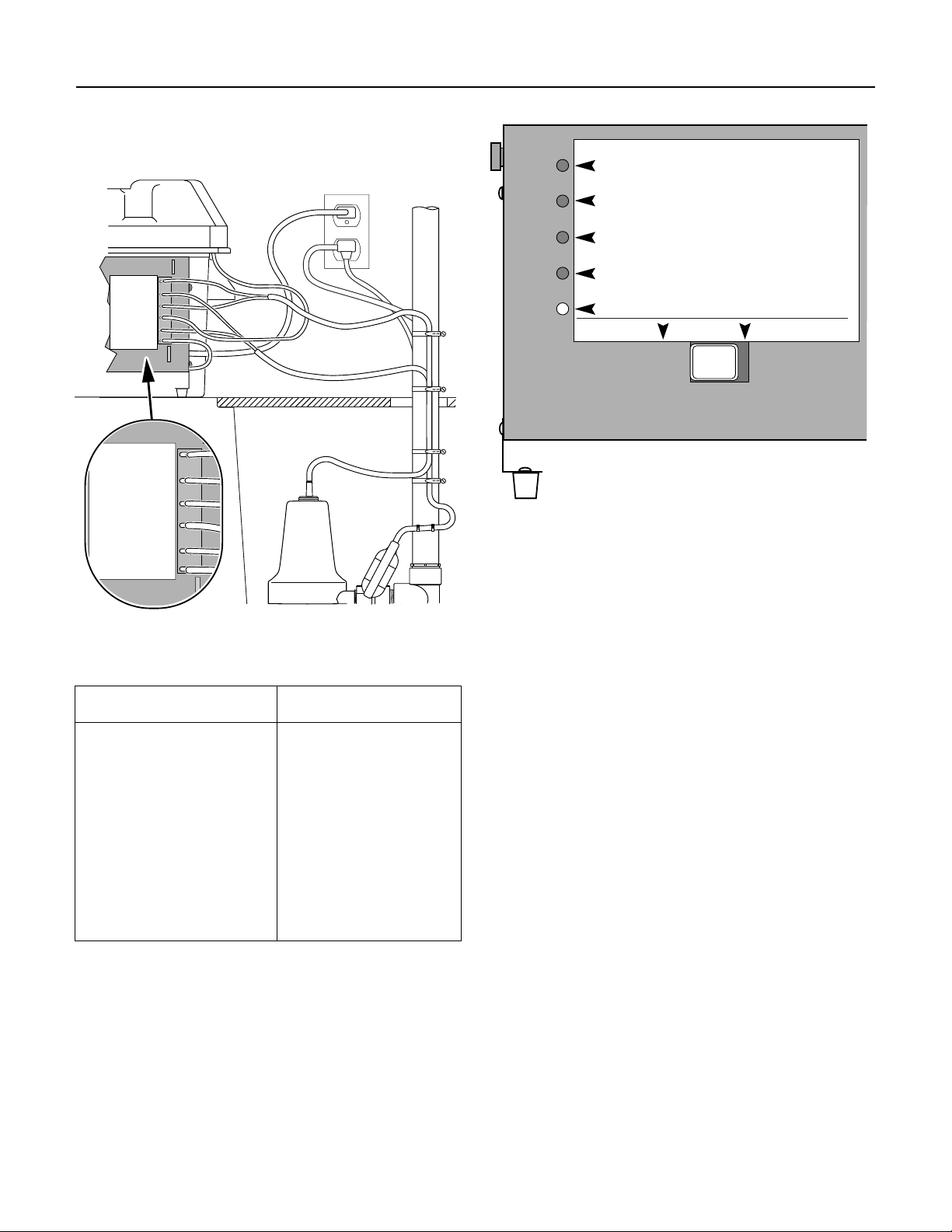

CHARGER/BATTERY INSTALLATION

NOTICE: An alarm, located in the junction box, auto-

matically sounds when the system runs if the alarm is in

the “Enable” position. The alarm is silenced when the

alarm switch is in the “Disable” position.

Model Number DB10018T-01:

1. Apply two pieces of two-sided tape (provided, Key

No. 9) to the back of the junction box. Press the

junction box onto the battery box as illustrated in

Figure 9 and on Page 15 (Exploded View).

2. Connect the charger as shown in Table I and

Figure 9.

3. Plug the charger into a 115-120 Volt AC outlet delivering at least 15 amps. Do not use a switch con-

trolled outlet. Mark circuit in main power panel

“Backup sump pump power supply; do not turn off”.

4. With the charger properly connected and plugged in,

the panel on the front of the charger will show one

of the conditions illustrated in Figure 10.

Red LED - AC power is present

Yellow LED - Prequalification test stage is complete and testing

or charging in process

Green/Occasional Yellow - Charger turns on intermittently to

maintain proper charge

Green LED - Charging complete

Green/Yellow LEDs Alternately Flashing - System is in Error Mode

(see Table II, Page 9)

NOTICE: For more detailed information, see “Charger Operation” on

Page 13.

Figure 9 – Wiring Connections DB10018T-01

Connect the To the Junction Box’s

Positive (+) lead from the battery Positive battery connection

Negative (–) lead from the battery Negative battery connection

Positive lead from the charger Positive charger connection

Negative lead from the charger Negative charger connection

Backup sump pump Float switch

float switch (2 wires) connection (2 wires)

Positive lead from the pump Positive pump connection

Negative lead from the pump Negative pump connection

TABLE I - DB10018T-01 Wiring Connections

Figure 10 – DB10018T-01 LED Panel

4 STAG EAD-ACID

BATTE CHARGER

BLA K ERMNAL EGA IVE )

RED ERM NAL P S T VE ( )

AUT

OMPLTE

HARGE

ATTERY CONNECTION

+

–

CHARGER CONNECTO

+

–

FLOA

T SWITCH CONNECTON

E WTH SAME 25 AMP

36V TYPE AND RATNG ON Y

PUMP FUSE &

CONNECTION

–

DSABLE ENABLE

AUDIBLE ALARM

DSABLE WHEN L T

BATTERY CONNECTION

+

CHARGER CONNECTION

+

FLOAT SWITCH CONNECTION

REPLACE FUSE WITH SAME 20 AMP

36V TYPE AND RATING ONLY

PUMP FUSE &

CONNECTION

+

–

–

20

–

DISABLE ENABLE

AUDIBLE ALARM

DISABLE WHEN LIT

Red

Green

Yellow

Page 9

Installation 9

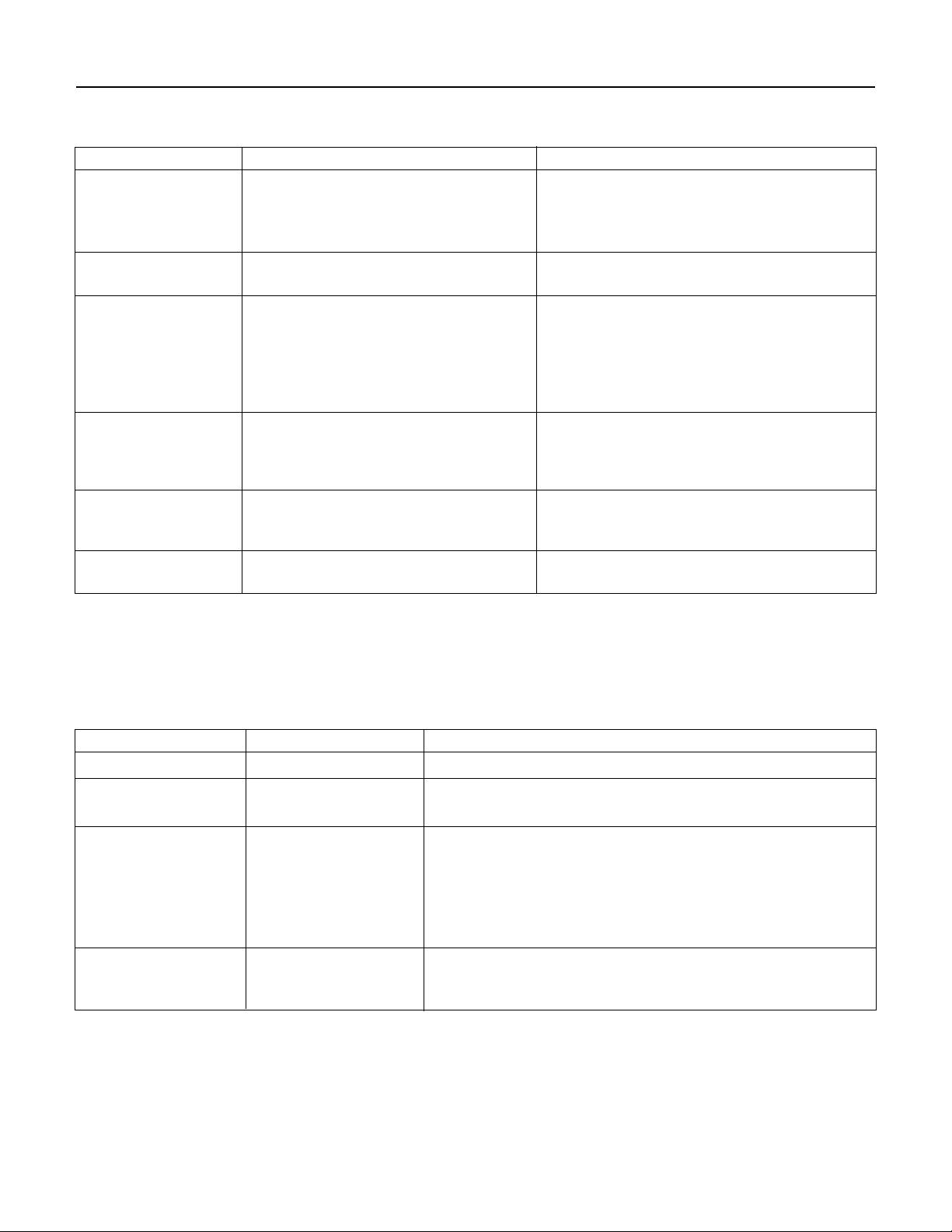

Error Description Possible Causes Fix

The Battery Failed The battery is highly sulfated Replace the battery with a 12-Volt deep-cycle

Pre-Qualification Test marine battery

The charger is connected to a Replace the battery with a 12-Volt deep-cycle

six-volt battery marine battery

Battery Over-Voltage The Charger is connected to a Replace the battery with a 12-Volt deep-cycle

24 Volt Battery marine battery

Charge Time Monitor Battery took too long to complete

its charge:

A. Load applied (e.g. the pump motor Be sure pump cannot start during charging;

started) during charging reset the charger

B. The battery ampere-hour rating Replace with correct size battery (see Page 4)

is too large (Max. 100 ampere-hours)

Excessive Battery Pump motor ran during charging Check primary sump pump. The BBU generally

Drain (that is, with the main A.C. power ON), runs only when the main A.C. power is out.

causing the system to shut down If there has not been any power outage and the BBU

has run, the primary pump itself may have failed

Reverse Battery Charger is connected backwards Reconnect Charger (+) to Battery (+)/(-) to (-)

Connection to the battery. (That is, Charger (+) to

Battery (-) and vice versa)

Battery Overheated Cells in an old battery may Replace battery with a 12-Volt deep-cycle

deteriorate with age marine battery

TABLE II - 800 mA Charger Error Table (Green and Yellow LEDs will flash alternately)

Charger Light On/Off/Flashing Indicates

All Lights Off System is not receiving AC power

Power (Red Light) On System is receiving AC power

Off System is NOT receiving AC power or battery leads are reversed

Charging (Yellow Light) Flashing 1x/Second Charger is running “Pre-Qualification” test (this lasts 45 seconds

to 6 hours)

On, steady Charger is either in “Constant Current” or “Constant Voltage” stage.

This may last up to 96 hours

Flashing alternately System is in an ERROR mode (see Table II, above)

with green light

Charged (Green Light) On, yellow light Off Battery is fully charged

Flashing alternately System is in an ERROR mode (see Table II, above)

with yellow light

TABLE III - 800 mA Charger Light Indications

Page 10

Installation 10

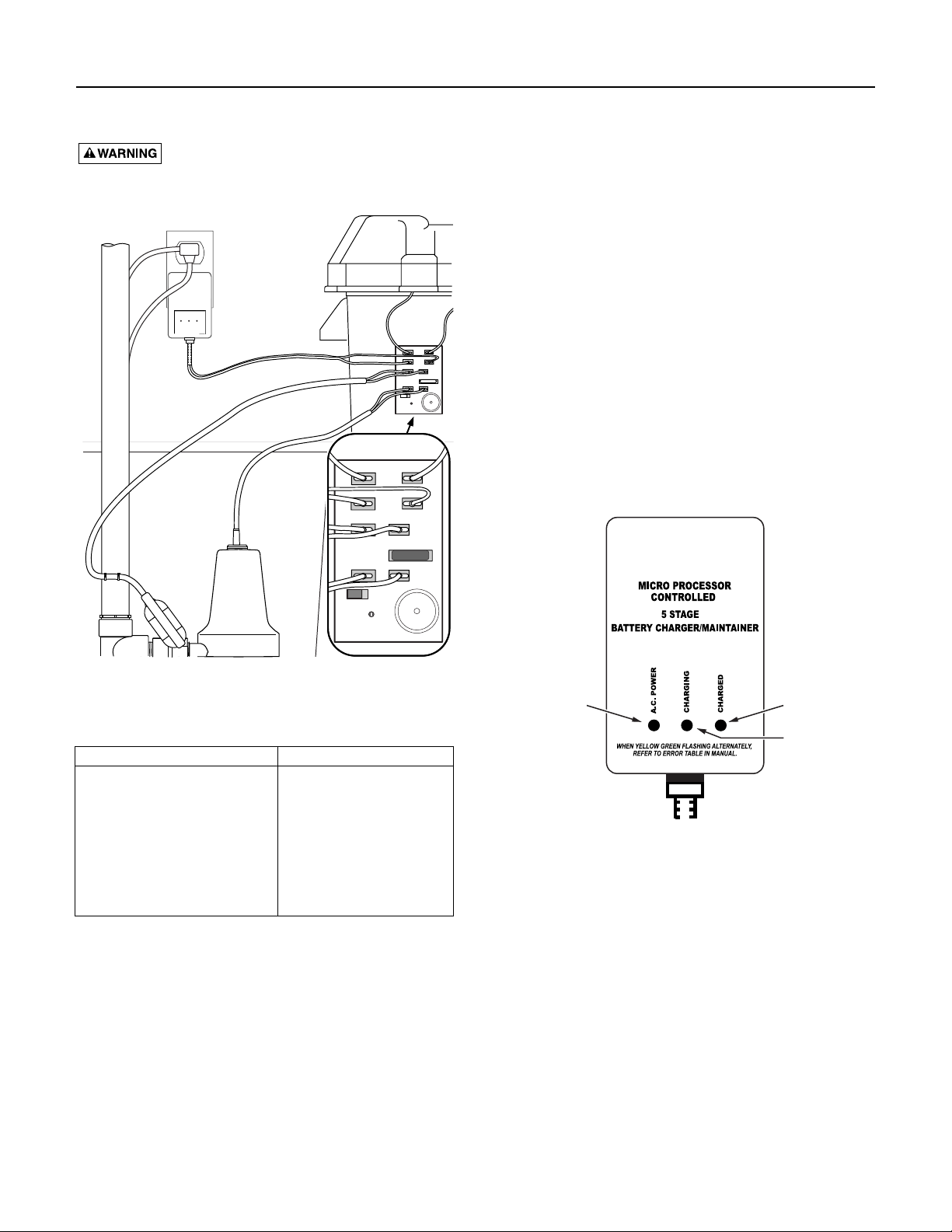

Model Number DB20018T:

1. Connect charger as shown in Table IV and Figure 11.

2. Plug the charger into a 115 Volt AC outlet delivering

at least 15 amps. Do not use a switch controlled

outlet. Mark the circuit in the main power panel

“Backup sump pump power supply; do not turn off”.

3. With the charger properly connected and plugged in,

the panel on the front of the charger will show one or

more of the following conditions (See Figure 12).

Red “AC Power Status” LED - AC power is present

Yellow (bicolor) LED on continuously - Prequalification test is com-

plete and charging is in process

Yellow “Charging” LED flashing on and off quickly - Equalization

charge stage

Green (bicolor) LED is on - Battery is being maintained at full

charge

Bicolor LED flashing yellow/green alternatively - See Charger

Error Table (Table VI, Page 11)

Test the Assembly:

1. Plug the primary pump into a properly grounded

3-prong outlet.

2. Fill the sump with water to start the primary pump.

Check for leaks.

3. Unplug the primary pump and fill the sump with

water to start the backup system pump. Check for

leaks.

4. Plug the primary pump back into a properly grounded

3-prong outlet. The system is now ready for operation.

Figure 11 – Wiring Connections DB20018T

To the position indicated

Connect the below, on the charger

Positive (+) lead from the battery Positive battery terminal

(leads are provided)

Negative (–) lead from the battery Negative battery terminal

(leads are provided)

Positive (+) “Backup sump Pump” Positive pump lead terminal

lead (BROWN wire)

Negative (–) “Backup sump Pump” Negative pump lead terminal

lead (BLACK wire)

Positive (+) Float switch Lead Positive float switch terminal

(WHITE wire)

Negative (–) Float Switch Lead Negative float switch terminal

(BLACK wire)

TABLE IV - DB20018T Wiring Connections

Figure 12 – DB20018T LED Panel

A.C.POWER

STATUS

PUMP RUN

STATUS

ALARM SILENCE

ÉTAT DU COURANT ALTERNATIF.

ESTADO DE LA CORRIENTE ALTERNA.

ÉTAT DE FONCTIONNEMENT DE

LA POMPE.

ESTADO DE FUNCIONAMIENTO DE

LA BOMBA.

ARRÉT D'ALARME.

SILENCIO DE ALARMA.

PUMP/POMPEBOMBA (+)

FLOAT/FLOTTEUR/FLOTADOR (+)

PUMPPOMPE BOMBA ( )

BATTERY/BATTERE/BATERÍA ( )

FLOAT/FLOTTEUR/FLOTADOR ( )

BATTERY/BATTERE BATERÍA (+)

PUMP/POMPE/BOMBA (+)

FLOAT/FLOTTEUR/FLOTADOR (+)

PUMP/POMPE/BOMBA (–)

BATTERY/BATTERIE/BATERÍA (–)

FLOAT/FLOTTEUR/FLOTADOR (–)

BATTERY/BATTERIE/BATERÍA (+)

BATTERY STATUS

CHARGER MODE

SILENCE

ARRÉT/SILENCIO

ÉTAT DE LA BATTERIE.

ESTADO DE LA BATERÍA.

MODE DU CHARGEUR.

MODO DE CARGADO.

ALARM

ALARME/ALARMA

RESET/RÉARMEMENT

REPOSICIÓN

3464 0799

Page 11

Installation 11

Error Description Possible Causes Fix

The Battery Failed The battery is highly sulfated Replace the battery with a 12-Volt deep-cycle

Pre-Qualification Test marine battery

The charger is connected to a Replace the battery with a 12-Volt deep-cycle

six-volt battery marine battery

Battery Over-Voltage The Charger is connected to a Replace the battery with a 12-Volt deep-cycle

24 Volt Battery marine battery

Charge Time Monitor Battery took too long to complete

its charge:

A. Load applied (e.g. the pump motor Be sure pump cannot start during charging;

started) during charging reset the charger

B. The battery ampere-hour rating Replace with correct size battery (see Page 4)

is too large (Max. 130 ampere-hours)

Excessive Battery Pump motor ran during charging Check primary sump pump. The BBU generally

Drain (that is, with the main A.C. power ON), runs only when the main A.C. power is out.

causing the system to shut down If there has not been any power outage and the BBU

has run, the primary pump itself may have failed

Reverse Battery Charger is connected backwards Reconnect Charger (+) to Battery (+)/(-) to (-)

Connection to the battery. (That is, Charger (+) to

Battery (-) and vice versa)

Battery Overheated Cells in an old battery may Replace battery with a 12-Volt deep-cycle

deteriorate with age marine battery

Charging Error An internal error occurred in the charger Unplug the charger

for 10 seconds and then plug it

during one of the charging stages

in again. If error occurs again, refer to Table VI, below

TABLE V - 8 Amp Charger Error Table

LED Status

A.C. Power Pump Run Alarm Charge

Status Status Silence Mode Error Mode

Flashing Off Off Flashing Yellow/Green Battery Overheated

Flashing Off Flashing Flashing Yellow/Green Charge Time Monitor

Flashing Flashing Off Flashing Yellow/Green Excessive Battery Drain

Flashing Flashing Flashing Flashing Yellow/Green Failed Pre-Qualification Test

Off Off Flashing Flashing Yellow/Green Battery Over-Voltage

Off Flashing Off Flashing Yellow/Green Reverse Battery Connection

Off Flashing Flashing Flashing Yellow/Green Output Over-Current

TABLE VI - 8 Amp Charger Error Light Indications

NOTE: This chart identifies light codes indicating various charg-

er error modes. It only applies when the ‘Charger Mode’ light

flashes YELLOW/GREEN alternately. The light codes listed here

DO NOT relate directly to the legends on the charger housing

(A.C. Power Status, Pump Run Status, Alarm Silence, etc.). The

legends on the charger apply ONLY when the ‘Charger Mode’

light is NOT flashing yellow/green.

“Silence Alarm/Reset” Rocker Switch:

Push the LEFT side of the rocker switch on the front of the

charger to silence the alarm. NOTE: This will NOT silence the

alarm when the battery is below 8.2 volts or the system is in

ERROR mode.

Push the RIGHT side of the rocker switch to reset the ‘Pump

System Status’ LED after the pump has run, or to reset the system from an error mode. When you reset the system, the charger will start its diagnostic procedure (pre-qualification test, etc.)

from the beginning. If the cause of the ERROR mode is not corrected, the system will go into the ERROR mode again.

Page 12

Installation 12

Charger Light On/Off/Flashing Alarm Buzzer Indicates

All LEDs Flash ONCE Off Connected system to AC power or to battery; or, pressed

‘Reset’ when in ERROR mode

AC Power On Off System is receiving AC power

Status

Very Slow Flash Off System is not receiving AC power

Pump Run Fast Flash (2x/second) Beep in synch Pump is running. Press LEFT side of rocker

Status with LED flash switch to silence alarm

Slow Flash (1x/2 seconds) Off Pump has run, but is not running now

Off Off Pump has not run

Alarm Silence On Alarm is silenced

Off Alarm is active

Battery Status On Off System is not connected to a battery or is connected to a

battery charged to less than 1 volt DC

Slow Flash On Battery voltage less than 10.9 volts. Alarm

can be silenced

Fast Flash On Battery voltage is less than 8.2 volts Alarm

CANNOT be silenced

Off Off System is properly connected to a battery

Charger Mode Slow YELLOW Flash Off System is in the “pre-qualification” stage. This will last

from 1 minute to 5 hours, depending on the condition

of your battery

Solid YELLOW Off System is in the “Constant Current Charge” stage. This

will continue until the battery voltage reaches

approximately 14.3 volts

Fast YELLOW Flash Off System is in the “Constant Voltage Charge stage”. This

could last up to 14.5 hours

Solid GREEN Off Battery is fully charged

Flashing alternately On - Beeping System is in an ERROR mode. Alarm will beep in synch

YELLOW/GREEN with one or more of the ‘AC Power Status’, ‘Pump Run

Status’, or ‘Alarm Silence’ LEDs. See Tables V and VI,

Page 11, for more information

TABLE VII - 8 Amp Charger Light Indications

Audio Alarm Mode Indicates Action

On - Beeping Slow Beep in Synch with Battery is Investigate cause; battery is very low. You

‘Battery Status’ LED down to about have limited pump run time left. Press

10.9 Volts and release LEFT side of toggle switch to

silence alarm

On - Beeping Fast Beep in Synch with Battery is Investigate cause; battery is nearly dead.

‘Battery Status’ LED down to about You have almost no pump run time left.

8.2 Volts Alarm CANNOT be silenced

On - Beeping Fast Beep in Synch with one or more System is Refer to ERROR Mode Charts, Page 11 for

of the ‘AC Power’, ‘Pump Run Status’, or in ERROR more information

‘Alarm Silence’ LEDs and with the mode

‘Charger Mode’ LED flashing alternately

YELLOW/GREEN

On - Beeping Fast Beep in Synch with Pump is None. Alarm will stop when pump stops

‘Pump Run Status’ LED running running. To silence alarm, press and release

LEFT side of toggle switch

TABLE VIII - 8 Amp Charger Audio Alarm Indications

Page 13

Operation 13

CHARGER OPERATION

The backup pump will activate automatically when the

backup sump water level rises far enough to trip the float

switch.

If the power to the charger circuit is interrupted, the

length of time that the backup pump will run depends on

the Ampere-hour capacity of the battery used, the battery

charge level, and the required vertical pumping distance.

Extended periods of operation (for example, during an

extended power outage) may exhaust the battery. The

battery charger will begin charging the battery as long as

the battery has a voltage differential of 3 Volts or more.

Recharge Time:

DB10018T-01: Approximately 100+ hours to fully

recharge a 27M battery in a “dead battery condition”.

The approximate recharge time for a 24M battery is 75

hours.

DB20018T: Approximately 19 hours to fully recharge a

27M battery in a “dead battery condition”. The approximate recharge time for a 24M battery is 15 hours.

Industrial standards define a “dead battery condition” as

9 Volts or less.

The 5 Stages of the Charging Process for

Model Number DB10018T-01:

NOTICE: The LED’s will only illuminate once the AC

power has been applied. They will not light up if the

charger is not plugged in.

1. Yellow LED light flashing on and off indicates:

Prequalification test stage is in progress. Normal duration of this stage ranges from 18 minutes to 27 hours.

If a battery has been left in a state of discharge for

long periods this stage may require 27 hours to determine if the battery will even accept a charge.

2. Yellow LED light continuously on indicates:

Constant current charge stage. Charger is charging battery at the full rated output. This stage ends when the

battery terminal voltage reaches the factory preset voltage level.

3. Yellow LED light continuously on also indicates:

Constant voltage charge stage. Battery cells are being

equalized. This stage could last up to 72 hours.

4. Green LED light on indicates:

Float charge stage. Battery is charged and ready for

use. Charging has stopped. To maintain a full charge

on the battery, the yellow and green LED may alternately turn back on. This means the charger is briefly

turning back on to keep the battery voltage from

falling below a preset voltage level.

5. Recycle charge stage:

The charger automatically initiates a charge cycle that

begins with the prequalification test stage. This occurs

once the battery has been in the float charge stage for

84 days.

The 5 Stages of the Charging Process for

Model Number DB20018T:

NOTICE: The LED’s will only illuminate once the AC

power has been applied. They will not light up if the

charger is not plugged in.

1. Yellow “charging”(bicolor) LED flashing slowly

indicates:

A. Prequalification test stage is in progress. The normal

duration of this stage is 20 seconds to 3 minutes.

However, if a battery has been left in a state of discharge for long periods or if the initial voltage is less

than 10.5 volts, this stage may require 5 hours to

determine if the battery will even accept a charge.

2. Yellow (bicolor)“charging” LED continuously on

indicates:

Constant current charge stage. Charger is charging

battery at full rated output.

3. Yellow (bicolor)“charging” LED flashing quickly

indicates:

Constant voltage charge stage. Battery cells are being

equalized. This could last up to 14.5 hours.

4. Green (bicolor) “charging” LED indicates:

Float charge stage. Battery terminal voltage is reduced

to a regulated voltage and battery is being maintained

at full charge.

VERTICAL PUMPING DISTANCE

8 FEET 10 FEET 12 FEET

Model Numbers DB10018T-01 DB20018T DB10018T-01 DB20018T DB10018T-01 DB20018T

Gallons Per Hour 1,440 2,088 1,200 1,770 840 1,380

Hours Available 10 6.8 11 6.0 13 6.0

Total Gallons Pumped 8,500 8,500 7,000 7,000 5,000 5,000

TABLE IX – Capacity Ratings with a 27M Marine Battery

* These flow rates were obtained with a constant 12.7 VDC battery source. The actual GPH will vary due to a reduction in output voltage from battery.

Page 14

Operation / Troubleshooting 14

5. Recycle charge stage:

The charger automatically initiates a charge cycle that

begins with the prequalification test stage. This occurs

once the battery has been in the float charge stage for

84 days.

Special Features:

• The chargers are equipped with reverse battery, short

circuit, and “run-away charge” protection.

•Abuilt-in safety timer starts when the charger enters

the Constant Current/Constant Voltage Charge stage

(Yellow LED is continuously on). The DB10018T-01

system has a 90 hour safety timer and the DB20018T

system has a 20.5 hour safety timer.

NOTICE: To reset the charger unplug it from the 120V

outlet for 10 seconds and then plug it back in.

BATTERY REQUIREMENTS

Hazardous electrical current. Can cause

severe burns and start a fire if battery terminals are short circuited. Install the battery in a battery box (See Key No. 8,

Page 15). To prevent accidental shorting across battery terminals, strap cover securely (See Figure 13) on the battery

box. Do not leave battery uncovered. Do not allow children

to play around the battery backup system installation.

Your backup sump pump depends on the battery used

with it for power. The better the battery, the better the

performance of the pump. We recommend the use of a

size 27M or a size 24M Marine Deep Cycle Battery.

They will perform as indicated in Table IX, on Page 13,

and they stand up well to long periods of little or no use.

NOTICE: A 24M battery will provide the same performance as a 27M battery, but for a shorter length of time.

Use of a standard automobile battery, GEL type, or a

Maintenance Free (sealed) battery with this charger is not

recommended. An automobile battery may require

charging after only 1-2 hours of continuous use, and the

repeated charging cycles may cause early plate failure in

the battery. GEL-type batteries require a lower voltage

than the charger is designed for; they may overcharge.

Maintenance-free (sealed) batteries require a higher voltage; they may never reach full charge.

Use only the recommended battery or one of the same

type and size so it will fit in the battery box (maximum

size 12-5/8" long, 7" wide and 9-3/8" high [320.7mm x

177.8mm x 238mm] including terminals) and supply

enough voltage for full performance.

BATTERY MAINTENANCE

Severe burn hazard. A filled battery contains

sulfuric acid. Avoid contact with skin, eyes or clothing.

NOTICE: To protect battery case from chipping and

gouging, do not let battery sit on concrete floor. Install

battery on a shelf or protective pad (plywood, 2x4s, etc.).

Always install battery in a dry location that is protected

from flooding.

Follow the battery manufacturer’s recommendations for

maintenance and safe use of battery.

TROUBLESHOOTING

Pump won’t run.

1. Check all wiring connections.

2. Check for low or defective battery.

3. Check that automatic switch is free to swing up and

down.

4. Check for a blown fuse in the junction box of the

DB10018T-01 system or in the charger of the

DB20018T system.

Motor hums but pump won’t run:

1. Check for low or defective battery.

Pump runs but pumps very little or no water:

1. Make sure a check valve is installed and functioning

between primary pump discharge and Backup Sump

Pump tee.

2. Check for obstruction in discharge pipe.

3. Discharge pipe length and/or height exceeds capacity

of pump. See Table IX, Page 13, for pump capacity.

4. Check for low or defective battery.

5. Positive (+) and negative (–) wires are reversed.

Pump cycles too frequently:

1. Tether length too short on automatic float switch.

Make sure that tether is at least 2.5" (63.5mm); see

Figure 6, Page 6.

2. Main check valve located between discharge of primary pump and the Backup Sump Pump tee is not

installed or is not working properly. Install or repair

as required.

Figure 13 – Battery Hold-down Strap Threading

3340 1198

Page 15

Repair Parts 15

8

7

2A

2B

2A

1

12

7A

9

BATT RY CON ECT ON

+

CHAR ER CONNECT ON

7B

6

3

5

4

+

LOAT W T H ONNEC ION

RE A U E W H SA E 25 AMP

3V TYPE AND ATNG O LY

PUMP FUSE &

CONNECTON

+

D A

BL

A IB E A

SAB E W

10

–

–

–

4 STAGE LEAD-ACID

BATTERY CHARGER

T

T

CMLTE

V )

11

TV )

HAGE

ALT

AC POW R ON

UMP R N AL RM

UDB E ALARM

IEN E

OW BATTE Y A ARM

CHARGNG YE OW

H RG D GRE N

AUDIBLE A ARM

DISABLE

MC

O P

5 STGE B T E Y HARGE M

CS OR O TR

12 VOLT 8 AMP

AL RM RESET

SOFT RESET

LED

I

AN R

3465 0799

14

13

Key No. Part Description DB10018T-01 DB20018T

1 Rubber Hose Coupling and Clamps (†) U74-68 U74-68

2A 1-1/2 x 1-1/4 PVC Slip Reducer Bushing (†)(2) U78-876P U78-876P

2B PVC Tee 1-1/2 x 1-1/2 Slip x 1-1/4 FNPT (†) U78-846P U78-846P

3 PVC Pipe Nipple, 1-1/4 NPT x Close (†) U37-66P U37-66P

4 Coupling/Check Valve Assembly, 1-1/4 FNPT x 1-1/4 FNPT ZB902110 ZB902110

5 DC Backup Pump PS17-118 PS17-115

6 Replacement Fuse, - ATO 20 Amp, 12 Volt * *

7 Float Switch - 1/2HP, 8’, 16 Gauge PS117-120P PS117-120P

7A Small Cable Ties (2) * *

7B Large Cable Tie * *

8 Battery Case (Complete) PS17-100 PS17-100

9Two Face Tape, 1/2” x 1” (†)(2) PS97-5 –

10 Charger Kit (DB10018T-01) (includes wires, junction box) PS217-156 –

11 Charger (DB10018T-01) (††) PS117-156 –

12 Battery Lead (††) PS117-114 –

13 Charger Kit (DB20018T) – PS217-119

14 Battery Leads (§) – PS17-155

• Fittings Package PS198-10 PS198-11

† Included in Fittings Package.

†† Includes 1-1/2 x 1-1/4 Reducer Bushings (2).

††† Included with Key No. 10.

§ Included with Key No. 13.

• Not illustrated.

* Purchase locally.

Page 16

16

Page 17

MANUAL DEL USUARIO

Systema de respaldo de la batería

DB10018T

DB20018T

293 Wright Street, Delavan, WI 53115

© 2004, Sta-Rite Industries Impreso en E.U.A. S739 (Rev. 4/16/04)

Instalación/Operación/Piezas

Para mayor información sobre el funcionamiento,

instalación o mantenimiento de la bomba:

Llame al 1-800-323-0620

ACPOWER ON

UMP RUN LARM

UD LE LARM

IR PR E R TR L D

T E BT ERY H R EM I T N R

IE CE

12 VOLT 8 AMP

OW A T

R A A M

HRG G E W

HRGED GRE N

AUDB E A

DSA LE

ARM

AA M ES T

SOFT R SET

Page 18

Seguridad 2

LEA Y SIGA LAS INSTRUCCIONES

DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando

usted vea este símbolo en su bomba o en este manual, busque alguna de las siguientes palabras de advertencia y esté alerta a la posibilidad de una herida personal.

advierte acerca de los peligros que oca-

sionarán lesiones personales serias, la muerte o un daño

severo a la propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que

pueden ocasionar lesiones personales serias, la muerte o un

daño severo a la propiedad si se ignoran dichos peligros.

advierte acerca de los peligros que

ocasionarán o podrán ocasionar lesiones personales

menores o daños a la propiedad si se ignoran dichos

peligros.

La etiqueta AVISO indica instrucciones especiales que

son importantes pero no relacionados a los peligros.

1. Para evitar riesgos de lesiones personales graves

debido a choques eléctricos o quemaduras, y daños

materiales debido a inundaciones, es importante que

lea atentamente las instrucciones de seguridad antes

de instalar la bomba.

El ácido de la batería es corrosivo.

No lo derrame sobre la piel, la ropa o el cargador de la

batería. Es importante usar protección contra los ojos y

la cabeza cuando se trabaje con la batería. Conecte y

desconecte los bornes de salida de corriente continua

solamente después de haber retirado el cargador del

tomacorriente de corriente alterna. Nunca permita que

los bornes de corriente continua se toquen entre sí.

Tensión peligrosa. Puede causar

choque eléctrico grave o fatal. No enchufe ni des-

enchufe el cargador de la batería mientras esté parado

sobre un piso húmedo o en el agua. Asegúrese de tener

una mano libre cuando enchufe o desenchufe el cargador. Si el piso del sótano está mojado, desconecte la

corriente al sótano antes de caminar sobre el piso.

Riesgo de inundación. No haga mar-

char la bomba en seco. Eso podría perjudicar las juntas y

provocar fugas y daños materiales.

2. Respete los códigos locales y/o nacionales de plom-

ería y electricidad cuando instale el sistema. Se

recomienda usar un disyuntor de escape a tierra

(“GFCI” en inglés) con todo aparato electrodoméstico que quede sumergido en agua.

3. Use este sistema solamente como bomba de sum-

idero de respaldo en aplicaciones residenciales. No

ha sido diseñado como un sistema primario de

bomba de sumidero.

4. No levante la bomba por medio del cordón eléctrico.

Riesgo de choque eléctrico. No

levante la bomba por medio del cordón eléctrico; lev-

ante la bomba solamente por medio de la tubería de

descarga, levantando el aro o el mango instalado en la

bomba. Si se levanta la bomba por medio del cordón

existe el riesgo de que se dañe el cordón.

5. Bombee agua limpia solamente con esta bomba.

6. La bomba viene lubricada en forma permanente de

la fábrica. No trate de lubricarla.

7. Mantenga el cargador de la batería y la caja de la

batería fuera del suelo y en una zona seca, fresca y

bien ventilada.

AVISO: Si se ha instalado un detector de

Monóxido de Carbono (CO), éste debe estar por lo

menos a 15 pies de distancia del cargador de la

batería para evitar que se disparen las alarmas de

presencia de CO. Es importante que consulte las

instrucciones de instalación del detector de CO

para obtener mayor información.

8. Para evitar peligros de incendio o explosiones, mantenga las chispas y llamas (luz piloto) lejos de la batería.

9. La distancia máxima vertical de bombeo es de 16

pies (4,9 m) para el Modelo DB10018T-01 y 18 pies

(5,5 m) para el Modelo DB20018T.

10. Asegúrese de que el sumidero esté libre de escombros. Los escombros pueden dañar la bomba y

causar inundaciones.

INFORMACIÓN GENERAL

El sistema de batería de respaldo para sumidero no es un

substituto de su bomba de sumidero primaria. Se ha diseñado para respaldar en forma temporaria a su bomba

de sumidero primaria durante cortes de corriente u otros

problemas que eviten un funcionamiento normal de la

bomba primaria. No use este sistema para bombear

líquidos o sustancias químicas inflamables. Bombee

agua limpia solamente con esta bomba.

Mantenga el cargador de la batería seco y protegido

contra daños.

En un caso de emergencia (como un corte de corriente

prolongado), que reduzca drásticamente la potencia de

la batería a descarga de empuje, es posible substituirla

con la batería de su automóvil temporalmente.

Asegúrese de volver a colocar la batería de descarga de

empuje lo más pronto posible. El uso de una batería de

automóvil en lugar de 27M, 24M o cualquier otro modelo de descarga de empuje en este sistema, reducirá el

rendimiento total del sistema en forma considerable. Las

baterías de automóvil no han sido diseñadas para este

tipo de usos y se arruinarán rápidamente con la repetición de los ciclos de carga y descarga. No use baterías

de tipo GEL, ni baterías selladas que no requieren mantenimiento, con el cargador. Las baterías de tipo GEL

requieren una tensión más baja que la carga para la cual

se diseñaron y se pueden sobrecargar. Las baterías sin

mantenimiento (selladas) requieren una tensión más alta

y es posible que nunca se carguen completamente.

AVISO: Esta unidad no ha sido diseñada para uso con

agua salada o salubre. El uso con agua salada o salubre

anulará la garantía.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

Page 19

Indice de Contenido 3

Página

Seguridad .........................................................................................................................2

Garantía ...........................................................................................................................3

Instalación...................................................................................................................4-12

Operación.................................................................................................................13-14

Localización de Fallas ....................................................................................................14

Refacciones ....................................................................................................................15

GARANTÍA LIMITADA

Sta-Rite Industries garantiza al consumidor original de los productos indicados a continuación, que se encontrarán libres de defectos

en material y mano de obra durante el Período de Garantía, desde la fecha de la instalación o fabricación inicial, según se indique.

Producto Período de Garantía

Productos de los sistemas de agua - lo que ocurra primero:

bombas de chorro, pequeñas bombas 1 año desde la fecha de la instalación

centrífugas, bombas sumergibles y inicial, o 2 años desde la fecha de

accesorios relacionados. fabricación

Filtros hydro-flow 1 año desde la fecha de compra

Tanques de enrollado de fibra 5 años desde la fecha de la instalación

Signature 2000 inicial

Tanques a presión de acero 5 años desde la fecha de la instalación

inoxidable Pro-Source inicial

Tanques Pro-Source Epoxy-Line 3 años desde la fecha de la instalación

inicial

Productos para sumideros/aguas 1 año desde la fecha de la instalación inicial,

residuales/vertidos o 2 años desde la fecha de fabricación

Nuestra garantía no corresponde a ningún producto que haya estado sujeto a negligencia, mala aplicación, instalación o mantenimiento inadecuados. En el caso en que se opere un motor trifásico sumergible con una potencia monofásica, a través de un convertidor de

fase, o si no se usan relés de sobrecarga de tres patas, con compensación ambiental, y disparo extra-rápido, del tamaño recomendado, nuestra garantía quedará anulada.

El único recurso del comprador, y la única obligación de Sta-Rite Industries serán el de reparar o reemplazar los productos defectuosos (a opción de Sta-Rite Industries). El comprador acuerda pagar por toda la mano de obra y los cargos de envío asociados con

esta garantía y solicitar un servicio de garantía a través del representante que haya realizado la instalación, tan pronto como se descubra el problema. No se aceptará ninguna solicitud de servicio bajo garantía si ésta se presenta pasados los 30 días después del

vencimiento del Período de Garantía.

STA-RITE INDUSTRIES NO SE HARÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENTE, INCIDENTAL O CONTINGENTE QUE

SEA.

LAS GARANTÍAS QUE PRECEDEN SON EXCLUSIVAS Y EN LUGAR DE TODA OTRA GARANTÍA EXPLÍCITA. LAS GARANTÍAS

IMPLÍCITAS, INCLUYENDO, PERO SIN LIMITARSE A LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD E IDONEIDAD PARA

UN FIN EN PARTICULAR, NO SE EXTENDERÁN MÁS ALLÁ DEL PERÍODO DE GARANTÍA PROPORCIONADO EN LA PRESENTE.

Ciertos estados no permiten la exclusión o limitación de daños incidentales o consecuentes, o la introducción de limitaciones a la

duración de una garantía implícita, por lo tanto, es posible que las limitaciones o exclusiones indicadas en la presente no correspondan. Esta garantía determina derechos y obligaciones legales específicos, sin embargo, es posible que existan derechos adicionales

que pueden variar de un estado al otro.

Reemplaza toda publicación anterior.

Sta-Rite Industries, 293 Wright St., Delavan, WI 53115

Page 20

Instalación 4

SISTEMA DE BATERÍA DE RESPALDO

INSTALACIÓN Y OPERACIÓN

AVISO:

• Instale este sistema durante el período en que no se necesite la bomba primaria. Reúna todos los elementos necesarios antes de comenzar. Lea todas las advertencias y los

pasos indicados para la instalación, antes de comenzar.

• Es importante que sepa pueden haber fugas de agua desde

el acoplamiento o la tubería cuando se desarme o se corte

el tubo de descarga. Proteja los componentes del sistema,

las herramientas y los accesorios contra la humedad.

Seque todas las zonas de trabajo que se hayan mojado.

HERRAMIENTAS Y MATERIALES

BÁSICOS QUE SE REQUIEREN

Tenazas ordinarias o grandes

Cinta métrica

Llave de tubo o llave para tuercas de 5/16”

Pinza de corte lateral

Sierra para metales (para cortar el tubo de PVC)

Tenacillas de tamaño mediano

Lápiz

Cinta de teflón

Adhesivo para PVC (soldadura a solvente)

Limpiador para tubos de PVC

Toalla de tela

Batería a descarga de empuje tipo marítimo tamaño 24 M

o una

Batería a descarga de empuje tipo marítimo tamaño 27 M

Capacidad de batería requerida;

DB10018T-01 – Máximo 100 amperios/hora.

DB20018T – Máximo 130 amperios/hora.

Peligro de lesiones personales e inun-

daciones. No encienda la bomba hasta que no se hayan pega-

do todos los accesorios y que el adhesivo se haya secado.

Accesorios flojos pueden hacer que los tubos exploten y salten

causando lesiones personales e inundaciones.

Saque la bomba primaria del foso del sumidero:

1. Ubique el nivel del agua de activación (“on”) de la bomba

de sumidero primaria. Marque esta ubicación en el tubo

de descarga con un lápiz. Consulte la Figura 1.

2. Drene el foso del sumidero. Es necesario bombear para

bajar el nivel del agua lo más posible antes de ir al paso

siguiente. Para drenar el foso del sumidero, siga el paso

“2A” o “2B” (a continuación).

2A. Eleve el flotador en el interruptor de flotador hasta

que la bomba se encienda. Use el mango de madera

de una escoba o una vara para hacerlo.

2B. Si la bomba de sumidero tiene un cordón eléctrico

de tipo superpuesto, saque el enchufe del cordón

eléctrico del interruptor de flotador del tomacorriente, y coloque el enchufe del cordón eléctrico de la

bomba directamente en el tomacorriente. Consulte la

Figura 2.

Peligro de choque eléctrico. Un

choque eléctrico puede provocar quemaduras o muerte. No

use metales ni ningún otro material que conduzca electricidad para elevar el flotador. No entre en contacto con el agua

dentro del foso del sumidero. Si se ignora esta advertencia,

existe el riesgo de que ocurran lesiones personales o muerte.

3. Drene el sumidero.

AVISO: No permita que la bomba marche en seco ya que

provocará daños a la bomba.

4. Desenchufe la bomba.

Figura 1 – Marque y corte el tubo según se ilustra

Figura 2 – Para pasar el interruptor de flotador por alto

Saque el acoplamiento

para manguera o marque

el primer corte aquí.

Apoye la tubería

antes de cortar.

“Encienda” el nivel

de agua de la

Bomba Primaria.

Válvula de retención

Foso del sumidero

Tomacorrient

e con puesta

a tierra

1. Desenchufe el enchufe del cordón

del interruptor de flotador superpuesto y el enchufe del cordón eléctrico de la bomba del tomacorriente

con puesta a tierra.

2. Separe el enchufe del cordón

del interruptor de flotador

superpuesto del enchufe

del cordón de la bomba de

sumidero.

3. Coloque el enchufe del cordón

eléctrico de la bomba directamente

en el tomacorriente.

Marque el tubo

con un lápiz aquí

(segundo corte)

ADVERTENCIA

ADVERTENCIA

4166 0402

Page 21

Instalación 5

5. Para separar la bomba primaria de la tubería de descarga:

5A. Para usos con acoplamientos para manguera: saque

las abrazaderas del acoplamiento con un sacatuercas.

5B. Para usos sin acoplamientos para manguera: corte la

tubería de descarga de PVC con una sierra de arco

por encima del piso del sótano, a un nivel cómodo.

Se incluyen acoplamientos para manguera nuevos

para volver a ensamblar. Consulte la Figura 1 en la

página 4.

AVISO: La tubería de descarga está llena de agua. Drene

el agua de la unidad de tubería de descarga. Mantenga el

área de trabajo seca.

PRECAUCIÓN

Peligro de que las manos o los dedos

queden atrapados. Para evitar lesiones en las manos

debido al desplome de los accesorios de plomería, apoye

la tubería por encima de la separación antes de cortarla o

desarmarla. Consulte la Figura 1.

6. Levante la unidad de bomba primaria y de tubería de

descarga y sáquela fuera del sumidero.

ADVERTENCIA

Riesgo de choque eléctrico. No

levante la bomba por medio del cordón eléctrico; levántela solamente por medio del aro de sujeción, del tubo de

descarga o del mango en la bomba. Si usa el cordón para

levantar la bomba, lo estropeará.

INSTALACIÓN DE LA BOMBA DE

RESPALDO

Hay dos formas de instalar la Bomba de Respaldo a Batería.

El Método A y el Método B. Consulte la Figura 3 para determinar

qué método debe emplear. Ambos métodos son aceptables.

Instalación de la bomba de respaldo (Método A)

No a escala

Interruptores y cables

omitidos para mayor

claridad

Acoplamiento para

manguera con

abrazaderas

Casquillo reductor

de 1-1/2” x 1-1/4”

Te de 1-1/2”x 1-1/2”

deslizar x 1-1/4” FNPT

Casquillo reductor

de 1-1/2” x 1-1/4”

Trozo corto de la

tubería de descarga

(puede variar)

Válvula de retención de

la bomba de sumidero

primaria para impedir la

recirculación hacia el

sumidero.

Trozo cortado

de la tubería

de descarga

Primer corte

Segundo corte:

en la línea de

agua marcada

Niple de

rosca

corrida

para tubos

(1-1/4” x

1-1/4”)

(1 niple

incluido

en el

paquete

de bomba

de

respaldo)

Codo de 1-1/4”

Unidad de

válvula de

retención

Diámetro

de la base

del foso del

sumidero ≥

18” ?

No No

Diámetro

de la base

del foso del

sumidero ≥

13.5”?

El sistema BBU aún se

Sí

puede instalar, pero

Sí

puede ser necesario

cambiar la instalación.

Profundidad

del foso del

sumidero ≥

18” ?

Sí

Profundidad

del foso del

sumidero ≥

No

No

22” ?

Sí

Método BMétodo A

Figura 3 – Escoja un método de instalación

Metodo A

El Método A sugiere una instalación de ambas bombas en el piso

del foso del sumidero. Consulte la Figura 4. El diámetro mínimo

requerido para el depósito de recogida, en el fondo del foso, y la

profundidad recomendada del depósito de recogida es 18”.

También necesitará ciertos materiales adicionales como 2

codos de 1-1/4” y 90° y 2 niples de rosca corrida para tubos

de 1-1/4”.

Codo de

1-1/4”

Orificio de descarga

de la bomba primaria

Orificio de descarga de

la bomba de respaldo

Figura 4 – Diagrama de instalación del Método A

Niple de rosca

Te

Flujo del

agua a

través de

la válvula

(La tapa de

la válvula se

abre en dirección

opuesta a la salida

de la bomba)

corrida para

tubos

La bomba de repuesto a batería

viene pre-ensamblada con la

Codo

unidad de válvula de retención

instalada en la descarga.

Saque esta unidad de

válvula de retención.

Unidad de

válvula de

retención

Descarga

de la

bomba de

respaldo

Figura 5 – Saque la válvula de retención pre-ensamblada

Page 22

Instalación 6

1. Haga el segundo corte en la tubería de descarga en donde

se encuentra la marca de lápiz, según se ilustra en la

Figura 1, en la página 4 y en la Figura 4, en la página 5.

Limpie los extremos del tubo con una toalla de paño y

ponga a un lado el trozo cortado de tubería de descarga.

2. Saque la unidad de válvula de retención (Claves No. 4 en

la página 15) de la descarga de la bomba de respaldo a

batería (Clave No. 5) y póngala a un lado. Consulte la

Figura 5. La unidad de válvula de retención se usará más

tarde durante el ensamblaje.

3. Enrosque un codo de 90° (comprado a nivel local) en la

descarga de la bomba de respaldo.

4. Envuelva las roscas de los 3 niples de rosca corrida para

tubos (Clave No. 3) con 2 vueltas de cinta de Teflón

TM

y

enrosque uno de ellos en el codo. Ponga los otros 2 a

un lado.

5. Enroque la unidad de válvula de retención que había sacado en el Paso 2, en el niple de rosca corrida para tubos.

AVISO: Verifique que la válvula de retención esté instalada

en la dirección correcta. Consulte el dibujo en el recuadro

de la Figure 5.

6. Enrosque un niple de rosca corrida para tubos en el otro

extremo de la válvula de retención.

7 Enrosque el segundo codo de 90° en el niple para tubos.

8. Enrosque el último niple para tubos en el codo.

9. Enrosque el Te en el niple para tubos y ponga esta unidad

a un lado.

10. Instale un trozo corto de tubería en la parte superior de la

válvula de retención en la descarga de la bomba primaria.

Consulte la Figura 6.

AVISO: Debe haber una válvula de retención instalada en

la tubería de descarga de la Bomba de Sumidero Primaria

entre el Te y la Bomba de Sumidero Primaria. Esto

impedirá la recirculación hacia la Bomba Primaria cuando

se encienda la Bomba de Sumidero de Repuesto.

11. Deslice un casquillo reductor (Clave No. 2A) en el

extremo de la tubería que viene desde la descarga de la

bomba primaria. No adhiera esta conexión todavía.

AVISO: Si el diámetro de su tubería de descarga es 1-1/4”,

usted primero deberá adherir los casquillos reductores al

Te y luego deslizar el trozo cortado de la tubería de

descarga en el casquillo.

12. Deslice el Te y el sub-ensamblaje de la bomba de respaldo

en el casquillo reductor.

13. Adhiera el trozo de tubo cortado a la parte superior del

casquillo reductor en la parte superior del Te.

14. Coloque la unidad del interruptor de flotador (Clave No. 7)

flojamente en la tubería de descarga con las ligaduras de

cable (Claves No. 7A & 7B). Consulte la Figura 6. Debe

quedar aproximadamente 2.5” (63.5 mm) de longitud de

cordón entre el flotador y la abrazadera. No apriete las ligaduras de cable. Es posible que requiera ajustes más tarde.

15. Pase a la sección de “Corte la Tubería de Descarga”,

Página 7.

Metodo B

El Método B sugiere una instalación de la bomba de respaldo

sobre la bomba de sumidero primaria. Consulte la Figura 7.

El diámetro mínimo requerido para el depósito de recogida

en este tipo de instalación es de 13.5” el fondo del foso, y la

profundidad mínima recomendada del depósito de recogida

es 22”.

1. Haga el segundo corte en la tubería de descarga en donde

se encuentra la marca de lápiz hecha en el Paso 1, en la

Página 4 y ponga el trozo cortado de tubería de descarga

cortado a un lado. Consulte las Figuras 1 y 7.

TM

E.I. DuPont de Nemours and Company Corporation.

Instalación de la bomba de

respaldo (Método B)

Tubería de

descarga

Acoplamiento para

manguera y

abrazaderas

Ligaduras de cable

Mínimo 2”

T

Te

Trozo corto de la

tubería de descarga

(el largo puede variar)

Válvula de retención

Largo de fijación del

interruptor de flotador

2.5” (63.5 mm)

Hacia la tubería de

descarga de la

bomba de respaldo

Tubería de descarga de

la bomba de sumidero

primaria

Figura 6 – Largo de fijación del interruptor de flotador y

tubería de descarga de la bomba de respaldo

No a escala

Interruptores y

cables omitidos

para mayor claridad

Acoplamiento

para manguera

con abrazaderas

Bomba de

sumidero

de respaldo

Unidad de

válvula de

retención

(incluida)

Segundo corte:

en la línea de

agua marcada

Válvula de retención de la bomba

de sumidero primaria para impedir

la recirculación hacia el sumidero.

Niple de

rosca corrida

para tubos

Primer corte

Trozo cortado de la

tubería de descarga

Casquillo reductor

de 1-1/2” x 1-1/4”

Te

Casquillo reductor

de 1-1/2” x 1-1/4”

Tubería de descarga

de la bomba primaria

Piso del

sótano

Figura 7 – Diagrama de instalación – Método B

Foso del

sumidero

Page 23

Instalación 7

2. Envuelva las roscas del niple de rosca corrida (Clave No. 3

en la página 12) en dirección opuesta a las agujas del

reloj, con 2 vueltas de cinta de Teflón

TM

, y póngalo a

un lado.

AVISO: Debe haber una válvula de retención instalada en

la tubería de descarga de la Bomba de Sumidero Primaria

entre el Te y la Bomba de Sumidero Primaria. Esto

impedirá la recirculación hacia la Bomba Primaria cuando

se encienda la Bomba de Sumidero de Repuesto.

3. La bomba de respaldo (Clave No. 6) y la unidad de válvula de retención (Claves No. 4 y 5) vienen pre-ensambladas. Enrosque el niple de rosca corrida para tubos en la

válvula de retención.

4. Para enroscar el Te (Clave No. 2B – también incluye

casquillos reductores) en el niple de rosca corrida:

Sostenga la unidad de válvula de retención con las pinzas

acanaladas, introduzca el destornillador en el Te para

hacer palanca, y apriete el Te con el destornillador.

Termine con el Te en posición vertical.

5. Limpie los extremos del tubo con una toalla de paño.

6. Adhiera el trozo cortado de la tubería de descarga a la

parte superior del Te.

AVISO: Si su tubería es de 1-1/4”, usted deberá adherir los

casquillos reductores al Te y adherir el tubo al casquillo.

Coloque la unidad en la tubería de descarga primaria.

No adhiera el Te a la tubería de descarga de la bomba

primaria.

7. Coloque la unidad del interruptor de flotador de la bomba

de respaldo (Clave No. 7) flojamente en la tubería de

descarga con las ligaduras de cable (Claves No. 7A & 7B).

Consulte la Figura 6 en la Página 6. Debe quedar aproximadamente 2.5” (63.5 mm) de longitud de cordón entre el

flotador y la abrazadera. No apriete las ligaduras de cable.

Es posible que requiera ajustes más tarde.

Corte la Tubería de Descarga:

1. Coloque la unidad de dos bombas en el foso del

sumidero.

AVISO: La tubería de descarga ahora está montada sobre

la tubería de descarga que conduce hacia afuera.

2. Haga una marca en donde se debe cortar la tubería de

descarga. Asegúrese de dejar un entrehierro de 1/4” entre

los extremos de los tubos. Este espacio absorberá el ruido

de las vibraciones y proporcionará flexibilidad.

3. Haga el tercer corte. Consulte la Figura 8.

ENSAMBLAJE DE PRUEBA DE LA

UNIDAD DE DOS BOMBAS EN EL

FOSO DEL SUMIDERO:

1. Conecte la tubería de descarga de la bomba a la tubería

de descarga exterior con el juego de acoplamiento para

manguera y abrazadera (Clave No. 1). No apriete las

abrazaderas hasta que no haya hecho los ajustes finales.

2. Haga los ajustes finales. Verifique que las bombas y los

interruptores no interfieran entre sí. Verifique que haya

suficiente espacio para que los interruptores de flotador

oscilen o se muevan hacia arriba y hacia abajo entre sus

posiciones de encendido y apagado.

Marcado y ensamblaje con adhesivo:

1. Marque el tubo y los accesorios en todas las conexiones

con un lápiz. Estas marcas se usarán como guía para

volver a ensamblar con adhesivo, para confirmar que todo

aún se encuentre en el lugar correcto y nada se haya

movido.

2. Afloje la conexión del acoplamiento para manguera y la

abrazadera.

3. Jale y vuelva a sacar la unidad de dos bombas del foso

con cuidado.

4. Saque la unidad de Te de la tubería de descarga primaria.

No destornille ninguna de las conexiones de niples para

tubos con cinta de Teflón.

5. Limpie todos los extremos de tubos de PVC con un producto para limpiar PVC.

Vapores peligrosos. Siga las

instrucciones del fabricante del adhesivo y del producto

de limpieza. Use el adhesivo de PVC en un área bien ventilada y lejos de llamas o de fuego.

6. Adhiera los accesorios de PVC en donde lo indican las

marcas de lápiz. Espere 10 minutos para que el adhesivo

se endurezca.

Ensamblaje final:

1. Vuelva a colocar la unidad de dos bombas en el foso.

2. Instale y apriete el juego de acoplamiento para manguera

y abrazadera.

3. Haga los ajustes finales en el interruptor de flotador y apriete las ligaduras de cable.

Figura 8 – Haga el tercer corte para eliminar el exceso de

tubería de descarga

Tubería de

descarga

exterior

Entrehierro

de 1/4”

Tubería de

descarga exterior

Tubería de admisión del

depósito de recogida

(desde el tubo de avenamiento al depósito de

recogida)

Mínimo recomendado

Nivel de agua “on” marcado

anteriormente de la bomba

de sumidero primaria

(Consulte la Figura 1,

página 26)

Nota: Siempre instale la bomba de sumidero de respaldo

lo más cerca posible del fondo del foso del sumidero)

Método A

Método B

Traslape

Traslape