Model SR630

16 Channel Thermocouple Reader

Thermocouple Reader

1290-D Reamwood Avenue

Sunnyvale, CA 94089 U.S.A.

Phone: (408) 744-9040 • Fax: (408) 744-9049

Email: info@thinkSRS.com • www.thinkSRS.com

Copyright © 1992, 1994, 1995, 1997

Stanford Research Systems, Inc.

All Rights Reserved

Revision 1.3 (09/2001)

1

2

Model SR630

Specifications 4

Preparations for Use 5

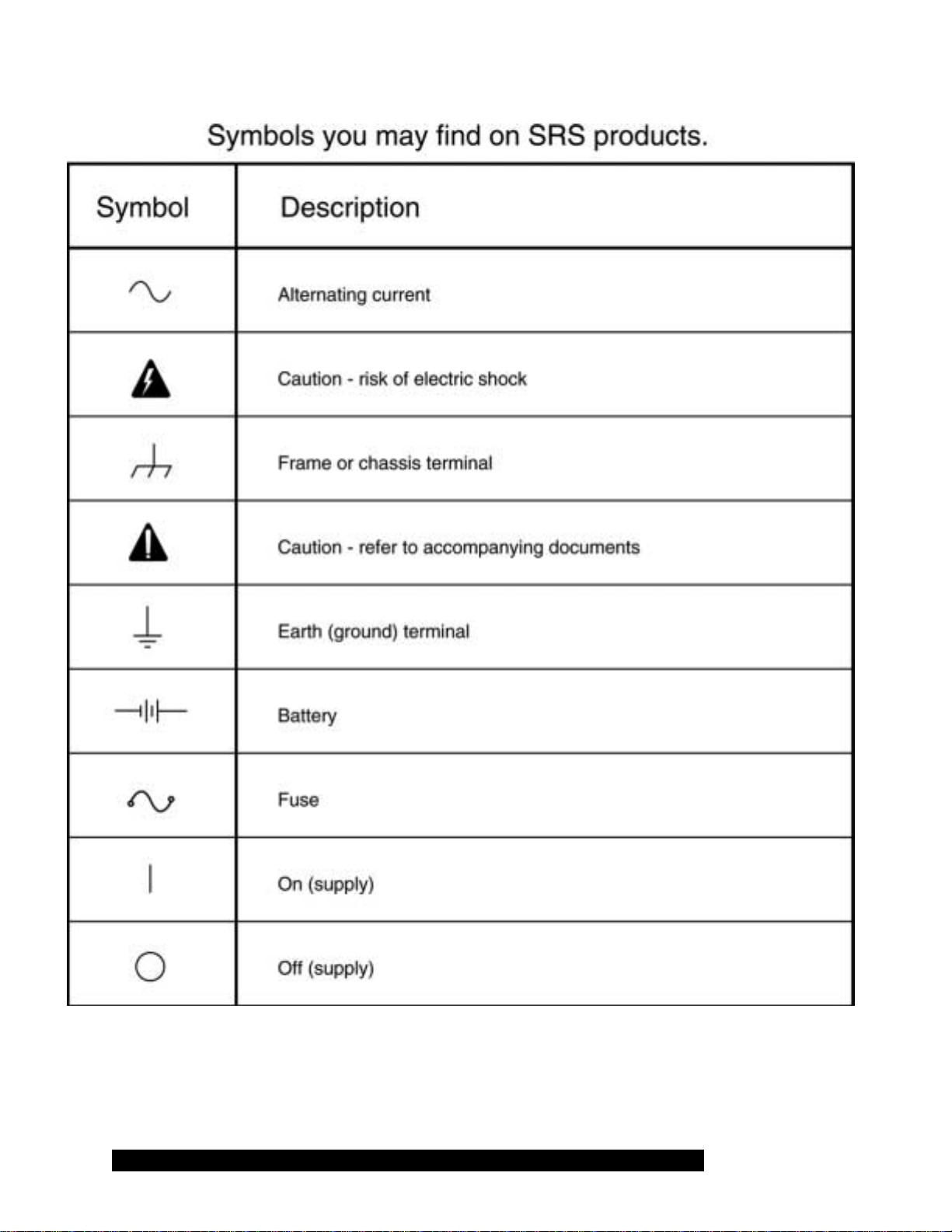

Symbols 6

Quick Start Instructions 7

Instrument Overview 8

Front Panel Description 9

Rear Panel Description 11

Operation 12

Connecting Thermocouples 12

Setting Instrument Parameters 12

(GPIB Address, RS232 Baud Rate,

Time and Date, Printer Mode,

and Scan Dwell Time/Logging Mode)

Setting Channel Parameters 13

(Measurement Units, Scan Enable,

TC Type, Nominal Temperature,

Temperature Deviation, Chart Span

Alarm Enable, Alarm Relay, and

Temperature Limits)

Troubleshooting and error messages 15

Table of Contents

Computer Interfaces 16

Command List 17

Programming Examples 22

Thermocouple Reference Data 26

Characteristics of Thermocouple Types 27

Calibration 29

Voltmeter Input Offsets 30

Voltmeter Gain Factors 30

Zone Block Temperature Offsets 30

Channel Temperature Offsets 31

Analog Output Gain Factors 31

Circuit Description 33

Microprocessor System 33

Display Drivers 33

Analog Outputs and Block Temperature 34

Time and Date 35

Relay Multiplexers 35

Input Amplifiers and ADC 35

Power Supplies 36

Computer Interfaces 36

Front Panel Display 37

Component Parts List 38

Circuit Schematic Diagrams 51

Thermocouple Reader

3

Specifications

Voltmeter Specifications

Channels 16

Input Type Independent, floating, and differential.

Input Resistance 10 MOhms between + & -, >1 GOhm to ground.

Input Capacitance .001 uF

Input Bias Current <100 pA

Input Protection 250 Vrms

Full Scale Display ±9.999, ±99.99, ±999.9 mVdc

±9.999, ±99.99 Vdc

Range Select Automatic

Resolution ±1 of least significant displayed digit.

Offset ±2 of least significant displayed digit.

Gain Accuracy 0.05%

Conversion Rate 10 Hz for 50 Hz line, 12 Hz for 60 Hz line.

Line Rejection >100:1

Thermocouple Specifications

(Input Specifications are same as the Voltmeter Specifications)

Channels 16

Thermocouple Types B, E, J, K, R, S, T

Display Units Degrees C, F and K

Display Resolution 0.1 Degree C

Temperature Displays Actual, Nominal, or Offset

Open Check Current 250 uA

Accuracy 0.5 Deg C for J, K, E, and T

1.0 Deg C for R, S, and B

(Errors are for the SR630 only. Standard errors for thermocouple

wire are 2 to 5 times the error due to the SR630. See section on

thermocouple reference data for additional information.)

Scanning and Data Logging Functions

Dwell Time 10 to 9999 seconds between successive scans.

Alarm Temperature or voltage limit for each channel.

Alarm Relay Rated for up to 1 amp and 100V DC/AC, 30W/60VA

maximum (resistive load).

Scan Enable Channel may be scanned or skipped.

Proportional Outputs For Channels 1, 2, 3 and 4, ±10V.

Printer Output Voltages, Temperatures, Time and Date

as a list or in a graphical format.

Data Memory Last 2048 measurements in battery

backed-up memory.

General

Store and Recall Nine locations for instrument set-up.

Interfaces RS232, GPIB, and Centronics Printer (Standard)

All instrument functions controllable via RS232 or GPIB.

Power 100/120/220/240 Vac, 50/60 Hz.

Rack Mount Optional

Dimensions 8.5" x 3.5" x 13" ( W x H x D )

Weight 9 lb.

4

Model SR630

(All specifications apply for 18° C to 28° C operation.)

**********CAUTION**********

Preparation for Use

This instrument may be damaged if operated with

the LINE VOLTAGE SELECTOR card set for the

wrong ac line voltage or if the wrong fuse is

installed.

Line Voltage

The SR630 can operate from a 100 V, 120 V,

220 V or 240 V ac power source having a line

frequency of 50 or 60 Hz. Before connecting the

power cord to a power source, verify that the LINE

VOLTAGE SELECTOR card, located in the rearpanel fuse holder of the unit, is set so that the

correct ac input voltage value is visible.

Conversion from one ac input voltage to another

requires a change in the fuse holder's LINE

VOLTAGE SELECTOR card position and a new

fuse. Disconnect the power cord, slide the fuse

holder cover to the left and rotate the fuse-pull

lever to remove the fuse. Remove the small printed

circuit board. Select the operating voltage by

orienting the printed circuit board. Press the circuit

board firmly into its slot, so the desired voltage is

visible. Rotate the fuse-pull lever back into its

normal position and insert the correct fuse into the

fuse holder.

electrical shock, always use a power source outlet

that has a properly grounded protective-ground

contact.

Power-Up

All instrument settings are stored in nonvolatile

memory (RAM backed-up) and are retained when

the power is turned off. They are not affected by

the removal of the line cord. If the power-on self

test passes, the unit will return to the settings in

effect when the power was last turned off. If an

error is detected, or if the backup battery is

exhausted, default settings will be used.

Use in Biomedical Applicat ions

Under certain conditions, the SR630 may prove to

be unsafe for applications involving human subjects.

Incorrect grounding, component failure, and

excessive common-mode input voltages are

examples of conditions in which the instrument may

expose the subject to large input currents.

Therefore, Stanford Research Systems does not

recommend the SR630 for such applications.

Furnished Accessories

Line Fuse

Verify that the correct line fuse is installed before

connecting the line cord to the unit. For 100 V and

120 V, use a 1/2 Amp fuse and for 220 V and 240

V, use a 1/4 Amp fuse.

Line Cord

The SR630 has a detachable, three-wire power

cord with a three-contact plug for connection to

both the power source and protective ground. The

protective ground connects to the accessible metal

parts of the instrument to ground. To prevent

Thermocouple Reader

- Power cord

- Operating manual

Environmental Conditions

OPERATING

Temperature: +10° C to +40° C

(Specifications apply over +18° C to +28° C)

Relative Humidity: < 90% Non-condensing

NON-OPERATING

Temperature: -25° C to +65° C

Humidity: < 95% Non-condensing

5

6

Model SR630

1. Remove the rear cover thermal shield and

attach a K-type (Chromel-Alumel) thermocouple to

channel #1's input on the rear panel. (One such

thermocouple has been provided with the unit.) The

red lead should be connected to the negative (-)

input and the yellow lead to the positive (+) input.

(These are US color codes.) Replace the thermal

shield.

2. Verify that the power entry module on the rear

panel is set for the voltage in your area. Using a

three wire power cord, connect the unit to line

power.

3. Press the POWER button to turn the unit 'ON'.

Use the CHANNEL SELECT keys to select channel

#1. Use the PARAMETER SELECT keys to select

'UNITS' from the parameter list. Select centigrade

scale by pressing the number '7' on the

PARAMETER ENTRY key pad. Then select 'TC

TYPE' from the parameter list, and set the

thermocouple type to K by pressing the number '3'.

Quick Start Instructions

4. The temperature, in degrees centigrade,

should be displayed in the MEASUREMENT

window. Warming the thermocouple with your

fingers should cause the temperature to rise: if the

reported temperature goes down, then the

thermocouple was probably attached with the

wrong polarity. (Remember, the red lead is

negative for the US, positive for European

standards.) Type K thermocouples have a standard

limit of error of ±2.2 °C. Type K thermocouples

supplied by SRS have special limits of error of

±1.1°C.

Thermocouple Reader

7

Instrument Description

Figure 1. SR630 Thermocouple Reader

Instrument Overview

The Model SR630 is a 16 Channel "computing"

microvoltmeter. The unit can digitize 16 rear panel

differential inputs with a resolution of 15 bits plus

sign. Gains and offsets are controlled to microvolt

levels. The dual slope integrating converter is

synchronized to the line frequency for high noise

immunity. The unit completes 10/12 conversions

per second when used on a 50/60 Hz line.

The unit determines the temperature of a

thermocouple junction by measuring the voltage

and computing the temperature from the known

characteristics of B, E, J, K, R, S or T type

thermocouples. Additional junctions are formed

where the thermocouples connect to the back

panel of the instrument, but the SR630

compensates for these by measuring the

temperature of the connector block and subtracting

the expected voltages (which depend on the

thermocouple type and connector block

temperature) before computing the thermocouple

temperature.

Four analog outputs on the rear panel of the

instrument may be used to drive strip chart

recorders or to adjust proportional temperature

controllers. Small offset voltages at the outputs

may be nulled from the front panel or via the

computer interfaces.

The SR630 has GPIB (IEEE-488), RS232 and

printer interfaces. The GPIB and RS232 may be

used to control all functions and to read data from

the instrument. The printer port may be used to log

data from the 16 channels in either a numerical or

graphic format.

An alarm may be set to signal when the measured

temperature goes above Tmax or below Tmin or if

the thermocouple becomes an open circuit. A rear

panel BNC provides a switch closure during an

alarm condition or when the unit is turned off.

A battery-backed-up real-time clock maintains the

time and date when the unit is off. An alarm may

be set to signal when the meausred temperature

goes above Tmax or below Tmin or if the

thermocouple becomes an open circuit. A rear

panel BNC provides a switch closure when there is

an alarm condition, or when the unit is turned

“OFF”.

8

Model SR630

Front Panel De sc r i pti on

Displays

The front panel has three display windows.

Generally, the left display indicates the selected

channel, the middle display an instrument or

channel parameter value (e.g. GPIB address or

temperature alarm limits), and the right display the

measured value (in the appropriate units).

Channel Select and Scanning Mode

The CHANNEL up/down buttons select one of

sixteen rear panel inputs. Pressing the up and

down buttons simultaneously causes the instrument

to begin scanning selected channels (A channel is

selected by setting its SCAN ENABLE parameter

to “yes”). In scan mode, the SCANNING LED will

be lit and selected channels will be read as rapidly

as possible, beginning with the lowest channel

number. If a printer is hooked up, scan data will be

printed (in either List or Graph mode) at the end of

the run. The DWELL TIME (10 to 9999 seconds)

sets the time between the start of subsequent

scans.

The rear panel analog outputs will be updated only

when the corresponding channel is scanned or

displayed manually. Printer activity stops when

scanning is stopped.

Parameter Select

PARAMETERs are selected for display and

modification using the parameter up/down keys.

These parameters are listed in Table 1. The first

six are "instrument parameters" which may be

modified regardless of the selected channel; the

rest are channel specific.

Store and Recall

Store (STO) and Recall (RCL) keys are used to

save and retrieve parameter settings for all

channels (not just a selected channel). There are

nine storage locations (1-9) and ten possible recall

locations(0-9). To store/recall location 7 press

STO/RCL 7 EXC. Recalling location 0 will set the

instrument to its default state.

Name Description

Instrument: GPIB ADD GPIB interface address, 1-31

RS232 BAUD RS232 baud rate, 150, 300, ... 9600 baud

DATE Month.Day.Year (US Format) Ex: 12/31/1999

TIME Hours.Minutes Seconds(24 Hour Format) Ex: 23:59:00

PRINTER Off, List, grph ( Off, list or graphics )

DWELL Time between start of scans, and buffer mode (stop/roll)

Each Channel: UNITS Select Degrees K, C, F, mVdc, or Vdc

SCAN ENABLE Select Yes or No for inclusion in scan list

TC TYPE Thermocouple type B, E, J, K, R, S, or T

Tnom Nominal temperature for this channel and chart center

∆T=T-Tnom Measured deviation from nominal temperature

CHART SPAN Range of values for strip charts and analog outputs

ALARM ENABLE Enable alarm if temperature exceeds limits

Tmax Upper limit before alarm

Tmin Lower limit before alarm

Table 1. List of instr ument and Channel Parameters

Thermocouple Reader

9

Front Panel De sc r i pti on

Channel: Display channel 1, not scanning.

Parameter: Display GPIB address. Set

parameters as follows:

GPIB ADD Not affected

RS232 BAUD Not affected

DATE Not affected

TIME Not affected

PRINTER Off

DWELL 10 s

key is pressed. The backspace key (BKSP) may

be used to delete a key press or to return to the

previous value if all of the new key presses are

deleted.

If the UNITS for a channel are changed, then

Tnom, CHART SPAN, Tmax and Tmin will be

calculated to replace the existing values. This

allows the user to change units without affecting

the operation of the alarms or analog outputs. The

relative temperature display will be in the new

units.

UNITS Deg C

SCAN ENABLE Yes

TC TYPE K

T NOM 0

CHART SPAN 1000

ALARM ENABLE Yes for 1 to 4

Tmax 1000

Tmin 0

Table 2. Instr ument Default St at e ( after RCL 0)

Parameter Entry

Parameters may be entered using the 15-button

keypad. If the instrument is in the GPIB REMOTE

mode, press the execute (EXC) key first to return

to LOCAL operation. Numeric parameters (e.g.

GPIB address or nominal temperatures ) may be

entered directly, while non-numeric ones (e.g.

printer mode and display units) are selected by

pressing the key directly below the desired legend.

The PARAMETER display indicates non-numeric

data as follows:

PRINTER oFF LISt grPh

UNITS AbS CEnt FrEn dC

SCAN EN yES no

The TEMP key provides a convenient way to enter

the present temperature for Tnom.

The MEASUREMENT Display will be formatted for

-999.9 to 9999. degrees or ±9.999 mV, ±99.99

mV, ±999.9 mV, ±9.999 V, or ±99.99 V. Minus

signs are displayed but plus signs are omitted on

all displays. Selected units for each channel are

indicated on the units indicators just to the right of

the display.

Status Indicators

Status indicators are located above the power

switch. These LEDs indicate the various conditions

detailed in Table 3.

REMOTE GPIB Remote state. (Press EXC

to go to LOCAL.)

GPIB Turns on for any GPIB activity,

and stays on until end-of-record.

RS232 Turns on for any RS232 activity,

and stays on until end-of-record.

PRINTER Turns on when data sent to

printer.

ERROR Red LED for command, parameter

or printer errors.

The entered parameter becomes valid when the

EXC key is pressed or when a parameter up/down

10

Table 3. St at us Indicators

Model SR630

Rear Panel Description

Figure 2. SR630 Rear Panel

The rear panel of the instrument is shown in Figure

2. The thermal shield has been removed by

unscrewing the thumbscrews on either end of the

shield. The printer port, GPIB (IEEE-488

compatible) and RS232 interfaces are located

along the top. All control functions and parameter

settings may be set via the GPIB or RS232

interfaces.

The RS232 port is type DCE and may be attached

directly to PCs by using a standard (i.e. not "nullmodem") serial cable. The RS232 baud rate may

be set from the front panel to any standard speed

from 150 to 9600 baud.

A Centronics compatible printer may be attached

(for data logging) by using a standard "PC" parallel

cable. The printer interface supports two print

modes: LIST mode which lists the time, date and

temperatures (or voltages) for all channels

selected to be scanned, and a graphics mode,

which prints a strip chart recording of the selected

channels, with a new line printed every Dwell

Time. A line of text which details all instrument

settings is printed whenever a print mode is

selected.

Four rear panel analog outputs provide dc outputs

in the range of ±10.0 Vdc. These outputs may be

set to track the difference between the nominal and

measured temperatures (or voltages) of the

corresponding channel (1 t hrough 4) f or

proportional temperature control or analog strip

chart recording. The analog voltage at these rear

panel outputs is given by:

Vout = 20 * ( T - Tnom ) / Chart Span

If the output voltage is used to control a heater to

maintain an object above ambient temperature, the

user should enter a negative chart span so that the

output voltage will decrease (reducing heater

power) as the measured temperature increases.

If desired, the analog outputs may also be

configured (via remote programming) as simple

voltage sources in the range +/- 10V.

The 16 differential inputs to the SR630 are also

located on the rear panel. Each input floats with

respect to chassis ground and has a 10 MΩ

resistance between the + and - terminals.

Thermocouple Reader

11

Instrument Opera tion

Connecting Thermocouples

Thermocouples may be connected to the

instrument by removing the thermal shield on the

rear panel. This shield is important for accurate

temperature measurements and should be

replaced after the thermocouples are attached.

Type B, E, J, K, R, S or T thermocouples may be

used. The thermocouple type must be specified for

each channel, either by front panel entry, or via one

of the computer interfaces.

Setting Instrument Parameters

Six parameters affect the entire instrument while

eight are channel-dependent. Instrument

parameters are GPIB address, RS232 baud rate,

printer mode, dwell time, logging mode, time and

date. Channel parameters are units (volts or

temperature), scan enable, thermocouple type,

nominal temperature (or voltage), chart span,

alarm enable and alarm limits (max,min).

Parameters are selected with the PARAMETER

SELECT up/down keys. Once selected, the current

parameter value will be displayed.

Some parameters, such as UNITS, become

effective as soon as the key is pressed. Others,

like GPIB address or time and date become

effective only after the EXC key is pressed, or

when another parameter is selected. This allows

editing of entered values from the front panel

before they take effect. The BKSP (backspace)

key may be used to delete entered values.

Backspacing through all the entered values for a

new parameter will cause the previous value of that

parameter to appear. The LED indicator for a

parameter will blink when a new value is entered

until that value takes effect.

All parameters may be set or read via the front

panel or computer interfaces. All parameters,

except for GPIB address, RS232 baud rate, time

and date, may be stored and recalled. Nine

settings (1-9) may be stored at any one time. RCL

0 will restore default settings.

GPIB Address

The GPIB address may be changed by entering a

number from 0 to 31. The default GPIB address for

the SR630 is 19. The new GPIB address will take

effect when the EXC key is pressed, or when a

PARAMETER SELECT up/down key is pressed.

RS232 Baud Rate

The RS232 baud rate, for serial communications

between the SR630 and a computer, may be set

by selecting the "RS232 BAUD" parameter. The

current RS232 baud rate will be displayed in the

PARAMETER window. A new value of 150, 300,

600, 1200, 2400, 4800, or 9600 baud may be

entered. The new RS232 baud rate will take effect

when the EXC key is pressed, or when either

PARAMETER SELECT key is pressed.

Date

The date may be displayed or modified by

selecting DATE(m,d,y) parameter. Dates are

entered and displayed in US format, with 0's. So,

to set the date to September 1, 1995 enter

09011995 . The new date will take effect when the

EXC key is pressed, or when either PARAMETER

SELECT key is pressed.

Time

The SR630 clock may be displayed or modified by

selecting the TIME(hr,min,sec) parameter. Times

are entered and displayed in a 24 hour format, with

0's. E.g. To set the time to 30 seconds after 5:00

pm enter 170030. The new time will take effect

when the EXC key is pressed, or when either

PARAMETER SELECT key is pressed.

Printer Mode

There are three printer modes: off, list, and

graphical. A printer may be used to log data of the

scanned channels. The list mode prints the time,

date, and value of all scanned channels whenever a

scan is completed. The graphic mode produces a

strip chart record on the printed output. The range

of values printed in the graphics mode is set by the

CHART SPAN parameter. To view or set the

printer mode select PRINTER and use the PRT

MODE key (the decimal point key) to toggle

between print modes. The new print mode will take

12

Model SR630

Rear Panel Description

effect when the EXC key is pressed, or when a PARAMETER SELECT up/down key is pressed.

Thermocouple Reader

13

Instrument Opera tion

Scan Dwell Time and Data Logging

The SR630 can scan any of 16 channels, storing

up to 2048 measurements with time and date

stamps, with or without printing. The time between

the beginning of scans, in seconds, may be viewed

or modified by selecting the DWELL parameter.

The dwell time may be set from 10 to 9999

seconds. The new dwell time will take effect when

the EXC key is pressed, or when a PARAMETER

SELECT up/down key is pressed. (See Scan

Enable in channel parameter description.)

When a scan is started, data will be stored in nonvolatile memory with time and date stamps. This

data buffer is large enough to hold 2048

measurements. When the buffer is full, the logger

will either stop or begin to overwrite (roll-over) the

oldest data, depending on the mode setting. The

logging mode will appear in the MEASUREMENT

window as either StoP or rOLL when the DWELL

parameter is selected. The YES/NO key (the minus

sign on the PARAMETER ENTRY key pad) may

then be used to change the logging status. This

change takes effect immediately. Note: Beginning a

scan from the front panel will automatically start

storage of data from the first memory location in

the data buffer (cf. remote programming).

Setting Channel Parameters

Eight parameters may be set for each of the 16

channels. Parameter set tings f or each channel are

independent of the settings for all the other

channels. For example, UNITS, nominal

temperature, and alarm limits may be set to

different values for each channel. The setting of the

channel parameters is detailed below. To set these

parameters for any particular channel, first select

the channel (1 to 16) by using the CHANNEL

SELECT up/down keys. Then select the channel

parameter of interest with the PARAMETER

SELECT up/down keys. The PARAMETER ENTRY

keypad may be used to modify the displayed

parameter.

Measurement Units

Display units for a measurement may be set when

UNITS is selected in the parameter list. Degrees

Kelvin (absolute), centigrade, Fahrenheit, volts or

millivolts may be selected by pressing the

corresponding key along the top row of keys in the

PARAMETER ENTRY section. Selected units

become effective immediately. Units are indicated

by an indicator to the right of the MEASUREMENT

window, and are abbreviated in the PARAMETER

window.

Scan Enable

A channel will be read during scanning if the SCAN

ENABLE parameter is set to "YES". To read or

modify the scan enable status, select SCAN

ENABLE from the list of channel parameters. The

YES/NO key (the minus sign on the PARAMETER

ENTRY keypad) may be used to change the scan

enable status. Scan enable status takes effect

immediately.

TC Type

The SR630 supports 7 different thermocouple

types. For details and characteristics of these

thermocouples, see the "Thermocouple Reference

Data" section. To display or modify the

thermocouple type for a selected channel, select

TC TYPE from the list of parameters. The TC

TYPE is displayed in the PARAMETER window as

a single digit number, 0 to 6 : B=0, E=1, J=2, K=3,

R=4, S=5, T=6 (as indicated on the parameterentry keypad). For example, pressing "3" when the

TC TYPE parameter is lit will cause the

thermocouple type to change immediately to K.

This parameter has no effect when voltages are

displayed.

Special Note: The CHART SPAN, Tnom, ∆T,

Tmax and Tmin parameters may be used to

specify either temperatures (the usual case) or

voltages. In this way, the SR630 may be used to

display, list, graph, and alarm either temperature or

voltage conditions. Values must be entered in the

same units which have been set for the channel: a

temperature should be entered if UNITS has been

set to degrees K, C or F, and a voltage should be

entered if UNITS has been set to volts or millivolts.

Nominal Temperature or Voltage

A nominal temperature (voltage) may be displayed

and set for each channel by selecting the Tnom

parameter. The nominal value is subtracted from

14

Model SR630

Instrument Opera tion

the present measurement when ∆T=T-Tnom is the

selected parameter. The nominal value also sets

Temperatur e or Voltage Deviation

Select ∆T=T-Tnom to display the deviation of the

present reading from the nominal temperature (or

voltage). The deviation from nominal is displayed

in the units set for the channel. No data may be

entered when ∆T=T-Tnom is displayed.

Chart Span

The CHART SPAN parameter sets the full-scale

temperature (or voltage) for the rear-panel analog

outputs and graphics mode printer output. To

display or modify the span, select CHART SPAN

with the PARAMETER SELECT up/down keys. For

example, if the span is set to 25 degrees, then the

analog output will be at full scale (+10 Vdc ) when

the temperature for that channel is 25 degrees

greater than nominal, and minus full scale (-10 Vdc

) when the temperature is 25 degrees below

nominal. CHART SPAN may be set to a negative

value, in which case the analog output decreases

as the temperature increases. This feature may be

used for controlling heaters in a closed-loop

system. In such a control system, the gain of the

feedback is increased when the chart span is

decreased.

Alar m Enable

The alarm feature may be enabled on a channelby-channel basis. To examine or modify the alarm

enable status for the currently selected channel,

use the PARAMETER SELECT up/down keys to

select the ENABLE (ALARM) parameter. The

YES/NO key ( the minus sign on the keypad ) may

be used to modify the current alarm enable status.

If the measured temperature ( or voltage ) exceeds

the set limits ( Tmax and Tmin ), and the alarm

enable status bit is set, then the audio alarm will

sound. The out-of-limit channel number is displayed

on the front panel, and a rear panel BNC provides

a switch closure (e.g. to turn on an alarm LED or

light).

Alarm R el ay

The relay switch is a Hasco HS212 in a SPST

layout, rated for up to 1A and 100V AC or DC,

30W/60VA maximum into a resistive load. Operate

the center value for the analog strip chart outputs

and for graphical printer outputs.

and release times are approximately 3 mS and 2

mS respectively.

Temperatur e ( Voltage) Limits

Both the upper and lower temperature (or voltage)

limits for the alarm function may be set for each

channel. To display or set the upper temperature

(or voltage) limit, use the PARAMETER SELECT

up/down keys to light the Tmax indicator. The

temperature (or voltage) limit may be entered using

the numeric PARAMETER ENTRY keypad. The

value must be entered in the units set for the

channel. Tmin may be entered in the same way.

If the UNITS parameter is changed between

degrees K, C or F, the alarm limits will also be

converted, so that the alarms will not be affected

by this change. However, different alarm limits are

saved for voltages, so selecting volts or millivolts

for the channel will affect alarm limits.

Note: The alarm will not activate if the specified

channel is never measured (i.e. not selected or not

enabled for scanning) even if the ALARM ENABLE

parameter is set to “YES.”

Multiplex e r Mode

The SR630 may be used as a 15 Channel

differential analog signal multiplexer. This allows

one of 15 analog signals selected by the SR630 to

be passed to other instruments.

In this mode of operation, the relay for channel 16

will always be enabled. The selected channel may

be read by the SR630 and is available to other

instruments on the terminals which are normally

used as an input to channel 16. To enter the

multiplex mode, press the Bksp and "-" buttons on

the front panel simultaneously.

This mode of operation may also be activated via

the GPIB or RS232 interfaces by using the

MPXM 1 command. The mode is disabled with the

MPXM 0 command, or whenever the unit is turned

off. Note: the relays will stay in their activated

positions on power-down and remain so until reset

upon power-up.

Thermocouple Reader

15

Instrument Opera tion

Once the multiplex mode is selected, a channel

may be selected from either the front panel or by

the computer.

16

Model SR630

Troubleshooting

Unit does not turn "O N":

1) Power cord and line voltage?

2) Fuse blown?

3) Power entry module set for local voltage?

Does not read voltages corr ect ly

1) Wrong channel selected?

2) Rear panel connections shorted or loose?

3) UNITS set incorrectly?

4) Defective internal relay? (try another channel)

5) Voltage greater than ±100 V?

6) Time, Date or Dwell displayed?

7) ac voltage present?

Does not read temperatur es cor r ect ly

..in addition to voltage problems above,..

1) Wrong thermocouple type specified?

2) Thermocouple + and - swapped? (Red="-")

3) Defective thermocouple?

4) Thermal shield not in place?

5) Outside temperature range for couple type?

Logging problems

1) Wrong mode selected (Roll vs. Stop)?

2) Not placed in scan mode?

3) Lost record by re-entering scan mode?

4) Scan enabled for channels of interest?

Miscellaneous problems

Key pad does not work -- GPIB Lockout? (press

EXC to go to LOCAL)

Does not scan -- Scan Enable off on all channels?

Does not retain settings when turned off or loses

time and date settings -- replace lithium battery

inside unit on main PCB.

Inst rument is "hung"-- RAM may be c orr upted, try

a cold boot by holding down the BKSP

(backspace) key while turning the unit "ON". This

will reset the instrument to its default state

(including GPIB address and RS232 baud rate);

factory calibration values are recalled from ROM,

and the time and date will need to be reset.

Alarms not work in g

1) Alarm limits in correct units?

2) Tmax set lower than Tmin?

3) Channel not scanned?

4) Alarm Enable turned "OFF"?

Printing problems

1) Printer error ?

2) Out of paper?

3) Printer off-line?

4) Not s canning?

5) Wrong print mode?

Error List

Error 0: Attempt to read empty log

Error 1: Memory checksum error

Error 2: No channels selected in scan mode

Error 3: Recalled set-up corrupted

Error 4: Problem reading logged data

Error 5: Printer time-out error

Error 6: Command syntax error

Error 7: Range error

Error 8: Communications buffer overflow

Thermocouple Reader

17

Computer Interfaces

Remo te P rogrammin g

The SR630 Thermocouple Reader may be

programmed remotely through either GPIB (IEEE-

488) or RS-232 interfaces. Any computer

supporting these interfaces may be used to control

and read data from the SR630 .

The SR630 supports both the IEEE-488.1 (1978)

interface standard and the required common

commands of the IEEE-488.2 (1987) Standard. To

communicate with the SR630 over the GPIB

interface, the proper device address must be set.

This may be done from the front panel by using the

PARAMETER SELECT up and down arrow keys to

select GPIB ADD from the parameter list. Use the

numeric keypad to enter a number between 1 and

31.

RS232 commands are identical to those used with

GPIB. The baud rate for RS-232 communications

may be set from 150 to 9600 baud by using the

PARAMETER SELECT up and down arrow keys to

select RS232 BAUD from the parameter list. Use

the numeric keypad to enter a baud rate (150,300,

600,.. 9600).

Command Syntax

Communications with the SR630 use ASCII

characters. Commands may be in either UPPER or

lower case and may contain any number of

embedded space characters.

A command to the SR630 consists of a four

character command mnemonic, arguments if

necessary, and a command terminator. The

terminator is a linefeed <lf> or EOI for GPIB, a

<cr> or <lf> for RS232. No command processing

occurs until a command terminator is received.

Command mnemonics beginning with an asterisk

are IEEE-488.2 (1987) defined common

commands. Commands may require one or more

parameters, with multiple parameters separated by

commas.

There is no need to wait between commands. The

SR630 has a 256 character input buffer and

processes commands in the order received. If the

buffer fills up, the SR630 will hold off handshaking

on the GPIB. Similarly, the instrument has a 256

character output buffer to store output until the host

computer is ready to receive it. If the output buffer

is filled, it is cleared and an error reported.

The present value of a particular parameter may

be determined by querying the SR630 for its value.

A query is formed by appending a question mark

"?" to the command mnemonic and omitting the

desired parameter from the command. If multiple

queries are sent on one command line (separated

by semicolons, of course), answers will be

returned in a single response line with the individual

responses separated by semicolons. All GPIB

responses are terminated with a linefeed and an

EOI; all RS232 responses are terminated with a

carriage return and a linefeed (<cr><lf>).

Examples:

UNIT 12, CENT Set units for channel 12 to

centigrade.

TTYP 12, K Specify K-type thermocouple

for channel 12 .

MEAS? 12 Measure temperature of

channel 12.

Detailed Command List

The four letter mnemonic in each command

sequence specifies the command. The rest of the

sequence consists of parameters. Multiple

parameters are separated by commas. Commands

that may be queried have a question mark in

parentheses (?) after the mnemonic. (The

parentheses are not actually sent as part of the

command string.) Commands that may ONLY be

queried have a ? after the mnemonic. Commands

that MAY NOT be queried have no question mark.

Multiple commands may be sent on one command

line by separating them by semicolons ";". Sending

multiple commands in one line ensures that they will

be executed simultaneously and allows

synchronization to be achieved using the

synchronization commands.

18

Model SR630

General (channel independent)

commands

Command

Channel-dependent commands

List

GPIB(?) n

The GPIB command sets or reads the GPIB

address. If remote commands are being sent over

GPIB, changing the address will stop

communications.

BAUD(?) n

The BAUD command sets or reads the RS232

baud rate. Choices are 150, 300, 600, 1200, 2400,

4800 and 9600. Sending this command is

recommended at the start of a program as this will

initialize the SR630's RS232 port. However,

changing the baud rate while talking over RS232

will stop communications (cf. GPIB).

TIME(?) n,n,n

The TIME command sets or reads the time on the

SR630. Command transmission order is Hr, Min,

Sec. Queries will return the time in the same

format separated by commas. Note: the SR630's

clock runs on 24hr time ( e.g. 5:00 PM = 17:00).

DATE(?) n,n, n

The DATE command sets or reads the date.

Proper format for transmission is Month, Day,

Year. Queries will return the date in the same

format separated by commas.

UNIT(?) ch, mnem

The UNIT command selects the units of channel ch.

Possible arguments are ABS (Kelvin), CENT,

FHRN, mDC (mV) or DC. Queries will return the

currently assigned mnemonic.

SCNE(?) ch,mnem

The SCNE commands enables or disables the scan

option on channel ch. Possible arguments are YES

or NO, and queries will return the same format.

TTYP(?) ch, mnem

The TTYP command selects the thermocouple type

for channel ch. Possible arguments are

B,E,J,K,R,S and T. Queries will return the

currently-assigned letter type. Note: although the

SR630 displays thermocouple type numerically on

the front panel, numeric arguments are not allowed

for this command.

TNOM(?) ch,n

The TNOM command sets the nominal temperature

value for channel ch to n. The range of possible

values is :

For temperature: -270 to +3300

For voltage: -99.999 to 99.999

PRTM(?) mnem

The PRTM command sets the printer mode. The

user can choose between GRPH and LIST modes,

or the printer may be turned OFF.

DWEL(?) n

The DWEL command sets the time between the

start of successive scans. The time n is specified in

seconds and is in the range 10 to 9999.

Thermocouple Reader

TDLT ? ch

The TDLT command returns the value of delta T for

channel ch, def ined as T measured - T nominal.

SPAN(?) ch, x

The SPAN command sets or reads the allowable

span for channel ch (to set printer graph ranges or

for the rear panel strip chart outputs).

19

Command Li st

ALRM(?) ch,mnem

The ALRM command enables (YES) or disables

(NO) the alarm function for channel ch.

TMIN(?) ch,x

The TMIN command sets the alarm lower voltage

or temperature limit of channel ch to x. The range

for x is the same as for the command TNOM.

TMAX(?) ch,x

The TMAX command sets the alarm upper voltage

or temperature limit of channel ch to x. The range

for x is the same as for TMIN and TNOM.

VMOD(?) ch, i

The VMOD command allows the user to set the

rear panel analog output ch to either (i=0) track the

corresponding channel or (i=1) act as a

programmable voltage source. The allowable range

for ch is 1-4.

VOUT(?) ch,x

The VOUT command sets the output voltage of

analog output ch (1-4) when set for programmable

output. The voltage can be in the range -9.999 to

9.999.

equal to the full-scale voltage of the range to be

calibrated.

The *CAL? command will return one of the

following values:

0 Calibration successful.

byte n Out of range result when attempting to

calibrate byte n.

200 Cal mode error (e.g. user was in relay

multiplex mode when trying to

calibrate).

CALB(?) n

The CALB command allows the user to read or

write cal byte n. For a full listing of the cal bytes

and their descriptions, see the chapter on

Calibration.

Data Logging Commands

SCAN(?) i

The SCAN command enables (i=1) or disables

(i=0) the scanning and logging mode. Note: Unlike

starting a scan via the front panel, the SCAN 1

command does not reset the buffer counter (NPTS)

each time, so successive scans may be run without

losing old data. Data may be cleared with the

BCLR command.

Calibration Commands

*CAL? n

The *CAL command allows the user to calibrate

either the offset or gain bytes. Options for n are:

0 autocal all offset bytes

1-8 calibrate individual offset byte n.

9-16 calibrate individual gain byte n.

Offset calibration is performed using channel 16 as

the reference (ch 16 must be shorted) while gain

calibration requires a reference on channel 15

20

DATM(?) i

The DATM command selects the logging data

mode of the 630. Options for i are:

0 ASCII mode.

2 Brief ASCII Mode (see RLOG below).

BUFM(?) i

The BUFM command determines whether the 630

will stop logging data (i=0) or begin overwriting the

oldest data (i=1) when the buffer is full. If the

buffer mode is changed after taking data, a BCLR

is highly recommended to prevent possible

overwrite problems.

Model SR630

Command

List

BCLR

The BCLR command clears the data buffer and

stops logging measurements.

NPTS?

The NPTS? query returns the number of

measurements stored in the logging buffer. The

maximum number of readings stored is 2048.

RLOG i,j

Read j measurements in the logging buffer,

beginning with item i. The maximum value of i is

2047, maximum for j is 2048-i or NPTS. ASCII data

has the format: Chan#, Units (0=ABS, 1=CENT,

2=FHRN, 3 = mDC, 4=DC), measured value,

Month, Day, Year, Hr, Min, Sec <lf>. Brief ASCII

omits time and date values.

RLOG queries sent as part of a multiple-command

line will not be returned with ';' delimiters but will be

separated by a <lf>.

Note: Although multiple measurements may be

returned using RLOG, reading only a single

measurement at a time is recommended (i.e.

RLOG x,1) for maximum program control. This also

minimizes possible synchronization problems.

M easurement Co mmands

MEAS? ch

The MEAS? query returns the value measured by

channel ch in the selected units. Note: mDC returns

values in milliVolts while DC returns values in Volts.

(See UNIT and CHAN commands.)

CHAN(?) ch

The CHAN command switches the 630 to read

from channel ch. The query version (CHAN?)

returns t he current channel number .

*WAI

The *WAI (wait) command holds off further

command execution until all commands cur rent ly in

progress are completed. This command ensures

that a particular operation is finished before

continuing.

GPIB Common Commands

*IDN?

The IDN? common query returns the SR630's

device identification string. The string format is:

Stanf ordResearchSyst ems, SR630,xxxxx,yyyy

where xxxxx is the serial number and yyyy is the

firmware version number.

*STO i

The *STO command stores the current parameter

settings for all 16 channels in memory. The

argument i can be in the range 1-9.

*RCL i

The *RCL command recalls parameter setting i

from memory. The argument can be from 1-9 or 0

to recall default settings.

*CLS

The *CLS command clears all status registers.

*ESE(? ) i

The *ESE command sets the standard status byte

enable register to the value i.

*ESR? i

The *ESR? command reads the value of the the

standard event status byte. If the parameter i is

present, the value of bit i is returned. Reading this

register will clear it while reading bit i will only clear

bit i.

Thermocouple Reader

21

Command Li st

*PSC? i

The *PSC common command sets the value of the

power-on status clear bit. If i=1, the power-on

status clear bit is set and all status and enable

registers are cleared on power-up. If j=0, the bit is

cleared and all the status and enable registers will

retain their values on power-down. This allows the

unit to send a service request on power-up.

*RST

The *RST command returns the SR630 to the

default configuration. This command is equivalent

to doing a RCL 0 from the front panel.

*SRE(?)

The *SRE common command sets the serial poll

enable register to the value i.

*STB? i

The *STB? common query reads the value of the

serial poll byte. If the argument i is present, the

value of bit i is returned. Reading this register has

no effect on its value as it is a summary of the

other status registers.

4 MAV The GPIB output queue is non-

empty.

5 ESB An unmasked bit in the

standard status byte has been

set.

6 RQS/MSS SRQ (service request) bit.

7 ALRM An Alarm condition has been

met. Query ALMS register to

determine which channel(s).

The ESB bit is set whenever any unmasked bit (i.e.

one with the corresponding bit in the byte enable

register set) in the standard event register is set.

This bit will not be cleared until the condition which

set the bit is cleared. A service request will be

generated whenever an unmasked bit in the serial

poll register is set. Note that service requests are

only produced when the bit is first set and thus any

condition will only produce one service request.

Accordingly, if a service request is desired every

time an event occurs, the status bit must be

cleared between events.

Standa r d Ev ent Stat us Byte:

bit name usage

Status Byte Definitions

Serial Poll Status Byte:

bit name usage

0 OVRG Overrange error. Query

overrange status register to

determine channel(s).

1 RLOG error No data in RLOG buffer when

queried.

2 RLOG timeout The SR630 timed-out while

waiting to send back RLOG

data. Timeout length is 65.5

seconds.

3 OPEN Open circuit error. Query

OPEN status register to

determine channel(s).

22

0 OPC Not used by the SR630.

1 unused

2 Query Error Set on output queue overflow

3 Device error RCL command failed or RAM

corrupted on power-up (reset

to defaults).

4 Execution Err Set by an out-of-range

parameter or non-completion

of some command due to an

error condition (e.g. overload).

5 Command Err Set by a command syntax

error or an unrecognized

command.

6 URQ Not used by the SR630.

7 PON Set by power on.

Model SR630

This status byte is defined by IEEE-488.2 (1987)

and is used primarily to report errors in commands

received over communications interfaces. The bits

Command

List

in this register stay set once set and are cleared

by reading them or by executing the *CLS

command.

Miscellaneous Commands

OPEN? { i}

The OPEN? query reads the open channel status

register (16 bits). A bit value of 1 signifies an open

channel. Each channel may be queried individually

by specifying the proper bit (bits 0-15 for channels

1-16 respectively), or if no argument is used, the

status of all channels will be returned as a 16 bit

integer. Note: this command only works when units

of temperature are selected.

OVRG? {i}

The OVRG query reads the channel overrange

status register. A bit value of 1 indicates that a

channel has exceeded its range limit (e.g. input

voltage >1.00V while on the mV scale). The

register contains 16 bits which may be queried

individually or collectively as per the OPEN? query.

ALMS? {i }

The ALMS query reads the alarm status register.

When an alarm condition is met, the bit for the

specified channel is set to 1. The 16 bits in this

register may be queried with or without an

argument as per the OVRG? and OPEN? queries.

Note: For each of the three preceding commands,

querying a register will clear it while querying a

specific bit will clear only that bit.

MPXM i

The MPXM command is used to set (i=1) or reset

(i=0) the "multiplex mode". In this mode of

operation, the relay for channel 16 is always

enabled, allowing the SR630 to serve as a 1:15

differential analog multiplexer so that any one of

the signals on channels 1 to 15 may be passed to

other instruments via the terminals for channel 16.

This command will be ignored if the unit is in

calibration mode or scanning mode.

Thermocouple Reader

23

Program Exam ples

This program is a simple example of interfacing the SR630 Thermocouple monitor to a PC via the RS232. A

standard serial cable is connected between the COM1 port of the PC and the RS232 port of the SR630. The

program was written in GW BASIC.

10 ' Example program to read measurements from the SR630

20 ' This program uses IBM Basic and communicates via the COM1

30 ' RS232 port

40 '

50 ' Set up COM1 for 9600 baud, no parity, 8 data bits, 2 stop bits

60 ' ignore dsr, and cd

70 OPEN "COM1:9600, n, 8, 2, ds, cd" as #1

80 PRINT #1," " 'Clear COM1

90 '

100 ' Now set up sr630: reset and choose units for ch1 and ch16

110 PRINT #1,"*RST; UNIT1,ABS; UNIT16, FHRN"

120 '

130 PRINT "Channel 1 (K) Channel 16 (F)"

140 PRINT #1,"MEAS?1" ' Measure channel 1

150 INPUT #1, VAL1 ' Get reading from sr630

160 PRINT #1,"MEAS?16" ' Now do the same for ch 16

170 INPUT #1, VAL2

180 PRINT VAL1, VAL2

190 GOTO 140 ' Loop forever

24

Model SR630

Program Exam ples

This program, written in Microsoft C, illustrates use of the SR630 Thermocouple Reader with the GPIB

interface bus. The program also uses the data logging buffer of the SR630. (Note: use of the data logging

buffer is optional. In most interface applications, the computer will select the channel and read the data without

the use of scans and data buffers.)

/* This program will scan three channels (1-3) then print out the first */

/* twenty-one points of logger data (received in Ascii form) */

/* This program is written in Microsoft C version 5.1. The header file */

/* for the GPIB interface is supplied by ms-c488.h and is supplied by CEC */

/* To compile this program, use the command: CL/AL/c prog.c. */

/* Then link the resulting object file with GPIB.obj (supplied by CEC) */

#include <ms-c488.h>

#include <stdio.h>

#include <stdlib.h>

#include <string.h>

#include <time.h>

#define sr630 19 /* GPIB address for thermocouple */

/* function prototypes */

void InitGpib(void);

void TxGpib(int,char*);

void GetGpib(int);

/* global variables */

char recv[40];

int status,length;

void main(void)

{

int i,chan,units;

double value;

char string[20];

time_t a,b;

InitGpib();

TxGpib(sr630,"*rst;unit1,abs;unit2,cent;unit3,fhrn"); /* reset sr630

ch 1 units: Kelvin

ch2: Centigrade

ch 3: Fahrenheit */

Thermocouple Reader

25

Program Exam ples

TxGpib(sr630,"bclr;dwel10;datm2"); /* clear buffer

10 second dwell time,

for (i=4;i<17;i++) /* disable scans for all other channels */

{

sprintf(string,"scne%d,NO",i);

TxGpib(sr630,string);

}

TxGpib(sr630,"scan1"); /* enter scan mode*/

/* scan for 75 seconds */

time(&a);

do time(&b);

while(difftime(b,a) <75.);

brief ascii logging */

TxGpib(sr630,"scan0"); /* turn off scan */

printf("Channel 1 (K) Channel 2 (C) Channel 3 (F)\n");

for (i=0;i<21;i++) /* now read measurements from buffer */

{ /* and print out in columns */

sprintf(string,"rlog%d,1",i); /* want the ith reading */

TxGpib(sr630,string);

GetGpib(sr630);

sscanf(recv,"%d,%d,%lf",&chan,&units,&value);

printf(" %6.3lf ",value);

if(i%3 ==2) printf("\n");

}

}

/* *********************************************************************************** */

void InitGpib (void) /* initialize the CEC GPIB card as controller */

{

int my_address, system_controller,seg;

/* Find the CEC card address */

for (seg=0x4000;seg<0xF000;seg+=0x400)

{

if ((peek(seg,50) == 'C') &&

(peek(seg,51) == 'E') &&

(peek(seg,52) == 'C'))

break;

}

26

Model SR630

Program Exam ples

if (pc488_seg(seg))

{

printf("No Gpib Card found.\n");

exit(0);

}

my_address = 21;

system_controller = 0;

initialize (&system_controller, &my_address);

transmit (&status, "IFC UNT UNL REN DCL ");

}

/* *********************************************************************************** */

void TxGpib (int address,char *command) /* transmit command to address */

{

char t_string[100];

int result;

result = sprintf (t_string,"UNT UNL MTA LISTEN %d DATA '%s' 10",

address,command);

transmit (&status, t_string);

}

/* *********************************************************************************** */

void GetGpib (int address) /* get an answer from device at address */

{

char r_string[40], temp[80];

sprintf (r_string, "UNT UNL MLA TALK %d", address);

transmit (&status, r_string);

strcpy (temp, " ");

receive (&status, &length, temp);

if (status==8)

{

printf("Timeout error.\n");

exit(0);

}

strcpy (recv, temp);

}

/* *********************************************************************************** */

Thermocouple Reader

27

Thermo couple Re ference Data

It was observed a long time ago ( Seebeck, 1822 )

that a voltage exists across the junction of

dissimilar metals. Figure 3 shows a thermocouple

junction formed by joining two metallic alloys, A

and B. The voltage across the thermocouple

junction depends on the type of metals used and

the temperature of the junction. The mechanism

responsible for this voltage is quite complicated,

but certain characteristics associated with this

phenomenon make the junction useful for

measuring temperature.

Figure 3. A T hermocouple Junction of Alloys A

and B.

tabulated values are referenced to the voltage

seen across a junction at 0 °C.

A problem arises when one tries to measure the

voltage across the dissimilar metal junction: two

additional thermocouple junctions are formed

where the wires are attached to the voltmeter.

Figure 4 illustrates this problem. If the wires leads

which connect to the voltmeter are made of alloy

"C", then thermal emf's exist at the A-C and B-C

junctions. There are two approaches to solving this

problem: use a reference junction at a known

temperature or make corrections for the

thermocouples formed by the connection to the

voltmeter.

The most important characteristic is that the

voltage generated is approximately linear with

temperature. The change in junction voltage as a

function of junction temperature is given by :

eq 1. ∆V = a x ∆T

where 'a' is the Seebeck coefficient. The

magnitude of this coefficient depends on the types

of metals used to form the junction: typical values

range from 0 to 100 µV/C. Unfortunately, the

magnitude of the coefficient depends on

temperature. It is generally smaller at low

temperatures, and may change by more than a

factor of two over the useful operating range of a

thermocouple. Despite this non-linearity, the

induced voltage is (usually) a monotonically

increasing function of temperature, and the

voltages generated by certain pairs of dissimilar

metals have been accurately tabulated. These

Figure 4. Measuring Thermocouple Voltage

Creates T wo Additional Junctions.

Figure 5 shows the use of a "reference" or

"compensating" junction. With this arrangement,

there are still two additional thermocouple junctions

formed where the compensated thermocouple is

connected to the voltmeter. However, the junctions

are identical (they are both junctions between

alloys A and C). If the junctions are at the same

temperature then the voltage across each junction

will be equal and opposite, and so will not affect

the meter reading. Typically, the reference junction

is held at 0 C (by an ice bath, for example) so that

the voltmeter readings may be used to determine

the temperature.

28

Model SR630

Figure 5. Using a Reference Junction to

Compensate Thermocouple (Not required for

the SR630)

The second approach to the problem depends on

the fact that the voltage across the junction A-C

plus the voltage across the junction C-B (Fig. 4) is

the same as would be seen across a junction of AB. The presence of an intermediate metal (C) has

no effect, as long as all the junctions are at the

same temperature. This allows us to correct for the

voltage seen by the voltmeter in Figure 4 by

measuring the temperature at the A-C and B-C

junctions and subtracting the voltage which we

would expect for an A-B junction at the measured

temperature. In the SR630 the temperature of the

A-C and C-B junctions are measured with a low

cost, high resolution semiconductor detector, and

the "expected voltage" is the tabulated voltage for

the A-B thermocouple at the measured

temperature of the A-C and C-B junctions.

Thermocouple Re fe r ence

Data

The advantage of the second method (which is

used in the SR630) is that any thermocouple type

may be used without having to change

compensation junctions or maintain ice baths.

Characteristics of Thermocouple Types

Any two dissimilar metals may be used to make a

thermocouple. Of the infinite number of

thermocouple combinations which can be made,

the world has settled on seven types which exhibit

a range of desirable features. These thermocouple

types are known by a single letter designation: J,

K, T, E, R, S or B. While the composition of these

thermocouples are international standards, the

color codes of the wires are not. For example, in

the US, the negative lead is always red, while the

rest of the world uses red to designate the positive

lead. Often, standard thermocouple types are

referred to by their trade names. For example, K

type is sometimes called Chromel-Alumel which are

the trade names of the Ni-Cr and Ni-Al wire alloys.

Important criteria for a good thermocouple include

a large, stable Seebeck coefficient, wide

temperature range and good corrosion resistance.

Generally, each wire of the thermocouple is an

alloy. Variations in alloy composition and the

condition of the junction between the wires are

sources of error in temperature measurements.

The standard error of thermocouple wire varies

from ±0.8C to ±4.4C depending on the type of

thermocouple used.

Type B E J K R S T

Positive Material Pt/Rh(30%) Ni/Cr Fe Ni/Cr Pt/Rh(13%) Pt/Rh(10%) Cu

Negative Material Pt/Rh(6%) Cu/Ni Cu/Ni Ni/Al Pt Pt Cu/Ni

Positive Color(USA) Grey Purple White Yellow Black Black Blue

Negative Color(USA) Red Red Red Red Red Red Red

Lowest Temperature 50C -200C 0C -200C 0C 0C -200C

Highest Temperature 1700C 900C 750C 1250C 1450C 1450C 350C

Minimum Std Error ±4.4C ±1.7C ±2.2C ±2.2C ±1.4C ±1.4C ±0.8C

Table 4. Thermocouple Reference Data

Thermocouple Reader

29

Thermo couple Re ference Data

Voltage vs. Temperature measurements have been

tabulated by NIST for each of the seven standard

thermocouple types. These tables are stored in the

read-only memory of the SR630 Thermocouple

Reader. The instrument's microprocessor

interpolates between the table entries in order to

achieve 0.1 C resolution when converting a voltage

measurement to a temperature.

The K type thermocouple is recommended for most

general purpose applications: it offers a wide

temperature range, low standard error, and has

good corrosion resistance. The K type

thermocouples provided by SRS have a standard

error of ±1.1C, half the error designated for this

type.

30

Model SR630

Overview

There are two areas of concern in the calibration of

the SR630: its performance as a microvoltmeter,

and its performance as a thermocouple reader. To

achieve a high degree of accuracy as a

microvoltmeter we need offset and gain

calibrations. For high accuracy as a thermocouple

reader we need to accurately determine the

"reference junction" temperature.

The hardware has been designed to minimize the

sources of error. Inputs are treated in a fully

differential manner, the input amplifiers are chopper

stabilized, and the reference junction "zone box" is

well-isolated and thermally massive. Additionally, a

small semiconductor sensor is implanted in the

“box” to accurately measure the reference junction

temperature. Small remaining errors are canceled

by firmware using final test calibration values.

Calibration

Locations of Calibration Constants

1 Voltage offset for 30 mV range

2 Voltage offset for 100 mV range

3 Voltage offset for 300 mV range

4 Voltage offset for 1V range

5 Voltage offset for 3V range

6 Voltage offset for 10 V range

7 Voltage offset for 30 V range

8 Voltage offset for 100V range

9 G ain constant for 30 mV range

10 Gain constant for 100 mV range

11 Gain constant for 300 mV range

12 Gain constant for 1V range

13 Gain constant for 3V range

14 Gain constant for 10V range

15 Gain constant for 30V range

16 Gain constant for 100V range

The factory calibration values are burned in

EPROM; these values are moved to battery

backed-up RAM when the unit is turned "ON" for

the first time, or if the BKSP key is held down

during power-up.

Calibration values may be changed from the front

panel if the calibration jumper (on the main PCB

inside the unit) is in the "enable" position. To

access calibration values, press the TEMP and

BKSP keys simultaneously. If the message "no

cAL JPr" appears, then the calibration jumper is in

the "disable"position.

The unit should be on for at least 1/2 hour prior to

calibration. Typically, input offset voltages on the

order of 10 µV will appear in the first few minutes

of operation.

Calibration constants may be changed directly, or,

in the case of offsets and gains, modified by

firmware calibration routines. These routines are

also accessed by pressing the TEMP and BKSP

keys together.

17 Temperature offset of connector block

18 Channel 1 temperature offset

19 Channel 2 temperature offset

20 Channel 3 temperature offset

21 Channel 4 temperature offset

22 Channel 5 temperature offset

23 Channel 6 temperature offset

24 Channel 7 temperature offset

25 Channel 8 temperature offset

26 Channel 9 temperature offset

27 Channel 10 temperature offset

28 Channel 11 temperature offset

29 Channel 12 temperature offset

30 Channel 13 temperature offset

31 Channel 14 temperature offset

32 Channel 15 temperature offset

33 Channel 16 temperature offset

34 #1 output voltage offset

35 #2 output voltage offset

36 #3 output voltage offset

37 #4 output voltage offset

Thermocouple Reader

31

Calibration

Input Offset Calibration Values

A firmware calibration routine is used to null the

input offset voltage for each of the 8 voltage

ranges. These offsets are expressed in ADC bits,

with a range of -128 to +127. (expected offsets

are about 10-20 bits.) The offset calibration

constant represents the number which is to be

subtracted from the ADC value such that 0.00 is

reported for the voltage of a shorted input.

(Increasing these calibration constants will

decrease the reported voltage.)

A short circuit should be placed on channel 16's

input. After the unit has warmed-up for at least 1/2

hour, press both the TEMP and BKSP keys

simultaneously to access the offset calibration

routine.

With the display showing "cL oFFS All", press the

EXC key to start the offset calibration routine. The

numbers 1 to 8 should appear on the right-most

display as the offset value is determined for each

gain range. Offsets are nulled to within 1 LSB of

the displayed voltage by this routine, i.e., to within

1 µV of zero on the 30 mV scale. The offset for a

single gain range may be calibrated also by

selecting the range (1-8) with the channel select

keys and pressing EXE.

Gain Factors

There are gain errors associated with the input

attenuator, the amplifier, and the ADC. The gain

errors are independent of the selected channel

because the multiplexer relays' resistances are

very much less than the 10 MOhm input

impedance.

To correct for these gain errors, known voltages

will be applied to channel 15, and read by the ADC.

A calibration constant will be determined for each

of the eight gain ranges which will be used to

correct subsequent measurements.

After the unit has warmed-up for at least 1/2 hour,

press both the TEMP and BKSP keys

simultaneously to access the gain calibration

routine. The display will show "cL oFFS ALL".

Press the PARAMETER SELECT ∆ (up-arrow) to

change the display to read "cL gAin 0.03".

Now apply 30.000±0.005 mV to channel 15 and

press the EXC key to calibrate the 30 mV voltage

scale.

Press the CHANNEL SELECT ∆ (up-arrow) key to

change the display to "cL gAin 0.1". Apply

100.00±0.01 mV to the channel 15 input and press

the EXC key to calibrate the 100 mV scale.

Repeat for the remaining ranges by pressing the

CHANNEL SELECT ∆ key, applying the full-scale

voltage indicated in the MEASUREMENT display,

and pressing the EXC button.

Range Applied Voltage

0.03 30.000 ±0.003 mV

0.10 100.00 ± 0.01 mV

0.30 300.00 ± 0.03 mV

1.00 1.000 ± 0.0001 V

3.00 3.000 ± 0.0003 V

10.0 10.00 ± 0.001 V

30.0 30.00 ± 0.003 V

100. 0 ± 0.01 V

Temperatur e Calibrations

To obtain the temperature from a voltage

measurement, we need to measure the

temperature of the "reference junction". This is the

thermocouple junction formed where the

thermocouple wires connect to the rear panel

terminal strip.

There is a semiconductor temperature sensor

located in the center of the metal block behind the

terminal strip. Unfortunately the sensor, which

provides a voltage of 10 mV per degree F, has an

error of about +-1 ° F, and so must be calibrated.

Calibration constant #17 is used to correct for the

sensor's error.

Knowing the correct temperature of the reference

junction allows the microprocessor to subtract the

emf generated by this junction from the measured

voltage in order to determine the emf of the

thermocouple junction of interest.

32

Model SR630

Calibration

Thermocouple Reader

33

Calibration

To calibrate the semiconductor sensor, attach a Ktype thermocouple to channel 8, and install the

thermal shield in such a way as to press the

thermocouple leads against the thermal block on

the rear panel of the instrument. Attach the other

end of this thermocouple to an thermometer with a

±0.1°C error. Use the SR630 to read the

temperature on channel 8. ( Be certain to configure

channel 8 to display in units of °C, and specify TC

TYPE = 3.) Subtract the reading on the SR630

from the temperature indicated on the reference

thermometer, and multiply by ten. The result should

be added to calibration constant #17, the block

temperature offset.

For example, if the reference thermometer reads

25.4 °C, and the SR630 indicates 25.0 °C, then

10*(25.4-25.0)=4 should be added to calibration

constant #17.

To adjust calibration constant #17, press the TEMP

and BKSP keys simultaneously, so that the display

shows "cL oFFS ALL". Then press the

PARAMETER SELECT ∆ (up-arrow) key twice to

display the first calibration constant. (See list in

preceding section.) Then press the CHANNEL

SELECT ∆ (up-arrow) key 16 times to display

calibration constant #17. Add the result of the

calibration calculation to the present value (which is

displayed in the MEASUREMENT window. Type

the sum using the numeric keypad, and press the

EXC key to enter the result.

After adjusting the block temperature calibration

constant, the SR630 should read the same

temperature as the reference thermometer. Note

that the standard limits of error for the

thermocouple wire used in the calibration do not

affect the accuracy of the calibration.

Channel Temperature Of fsets

Each channel has a calibration byte which simply

offsets the computed temperature, and these are

stored as calibration constants #18 through #33.

This allows the user to precisely calibrate the

instrument for each channel in order to remove any

remaining inaccuracies, such as the thermocouple

wire standard error. All of these temperature

offsets have a nominal value of zero.

These offsets have a range of ±127, allowing

temperature offsets of ±12.7 °C. Increasing these

calibration constants will increase the reported

temperature. To adjust calibration constant #18,

press the TEMP and BKSP keys simultaneously,

so that the display shows "cL oFFS ALL". Then

press the PARAMETER SELECT ∆ (up-arrow) key

twice to display the first calibration constant. (See

list in preceding section.) Then press the CHANNEL

SELECT ∆ (up-arrow) key 17 times to display

calibration constant #18. Type the desired

temperature offset for channel #1 (in tenths of ° C)

using the numeric keypad, and press the EXC key

to enter the result.

To access the next calibration value, press the

CHANNEL SELECT ∆ (up-arrow) once, and enter

the desired temperature offset for the next channel,

per the table at the beginning of this section.

Analog O ut put Voltage Off set s

There are four calibration constants (#34-37) which

are used to correct offset errors on the rear panel

analog outputs. To calibrate these offsets we will

set the rear panel outputs to zero, measure the

actual output voltage, compute the correction to the

calibration constant by dividing the actual offset by

0.005 V, and subtracting this correction to the

present calibration constant.

To set the rear panel outputs to zero, configure

channels 1 through 4 for UNITS = mV, and CHART

SPAN = 100. Place a short on channels 1 through

4. Use the CHANNEL SELECT keys to select

channel 1. Measure and record the output voltage

on the rear panel BNC #1. Repeat for channels 2,

3 and 4 by first selecting the channel, then

measuring the corresponding output.

Compute the required correction to each output's

offset calibration constant by dividing the observed

offset by 0.005. ( The offset may be corrected in 5

mV increments. ) These corrections will be

subtracted from the corresponding calibration

constant per the table in the preceding section.

34

Model SR630

For example, if the voltage at the #1 BNC output is

found to be 0.028 V, then calibration constant #34

will be decreased by 0.028/0.005 which rounds to

6.

To adjust calibration constant #34, press the TEMP

and BKSP keys simultaneously, so that the display

shows "cL oFFS ALL". Then press the

PARAMETER SELECT ∆ (up-arrow) key twice to

display the first calibration constant. (See list in

preceding section.) Then press the CHANNEL

SELECT ∆ (up-arrow) key to select calibration

constant #34.. Subtract the computed correction

to the existing calibration constant and key in the

new value using the numeric keypad, and press the

EXC key to enter the result.

Repeat for calibration constants #35, 36 and 37.

Calibration

Thermocouple Reader

35

Circ uit Descri ption

All circuitry for the SR630 are located on three

printed circuit boards. The front panel PCB

contains the LED lamps, seven segment displays

and the keypad matrix. The rear panel PCB

contains the GPIB, RS232 and printer interfaces.

The main PCB, which runs the length of the

instrument, contains all the other analog and digital

circuitry. The rear portion of the main PCB is

thermally isolated from the rest of the unit to

reduce thermal gradients which can reduce the

accuracy of temperature measurements.

The front panel PCB and the interface PCB attach

to the main PCB via 40 pin ribbon cables. The

terminal strip for the 16 differential input channels is

mounted directly to the main PCB. A metal block is

placed directly behind the terminal strip ( in thermal

contact with the terminal strip ) to reduce

temperature fluctuations. The temperature of the

metal block is measured with a semiconductor

sensor in order to compensate for the thermal

emf's created at the terminal strip connections.

Main PCB

Microprocessor Syst em. ( TC1C, Sheet 1 of 6).

The CPU is a CMOS Z80B, running at 4.9152 MHz.

This clock frequency is convenient for generating

baud rate, ADC and real-time interrupt clocks.

The CPU may be interrupted ( non-maskable ) by

the RTI ( real time interrupt ). During this interrupt

the next row of LEDs is refreshed, the next row of

keyboard lines is read and the ADC's busy bit is

read (data will also be read if the ADC BUSY just