Page 1

MODEL SR510

LOCK-IN AMPLIFIER

1290- D Reamwood Av enue

Sunnyvale, CA 940 89 U.S.A.

Phone: ( 408) 744- 9040 • Fax: (408) 744-9049

Email: info@thinkSRS.com • www.thinkSRS.com

Copyright © 1985, 1987, 198 9

Stanford Resear c h S y s tems, I nc .

All Rights Reserved

Revision: 3.3 (11/2003)

Page 2

Page 3

TABLE OF CONTENTS

Condensed Information

SAFETY and Preparation for use 1

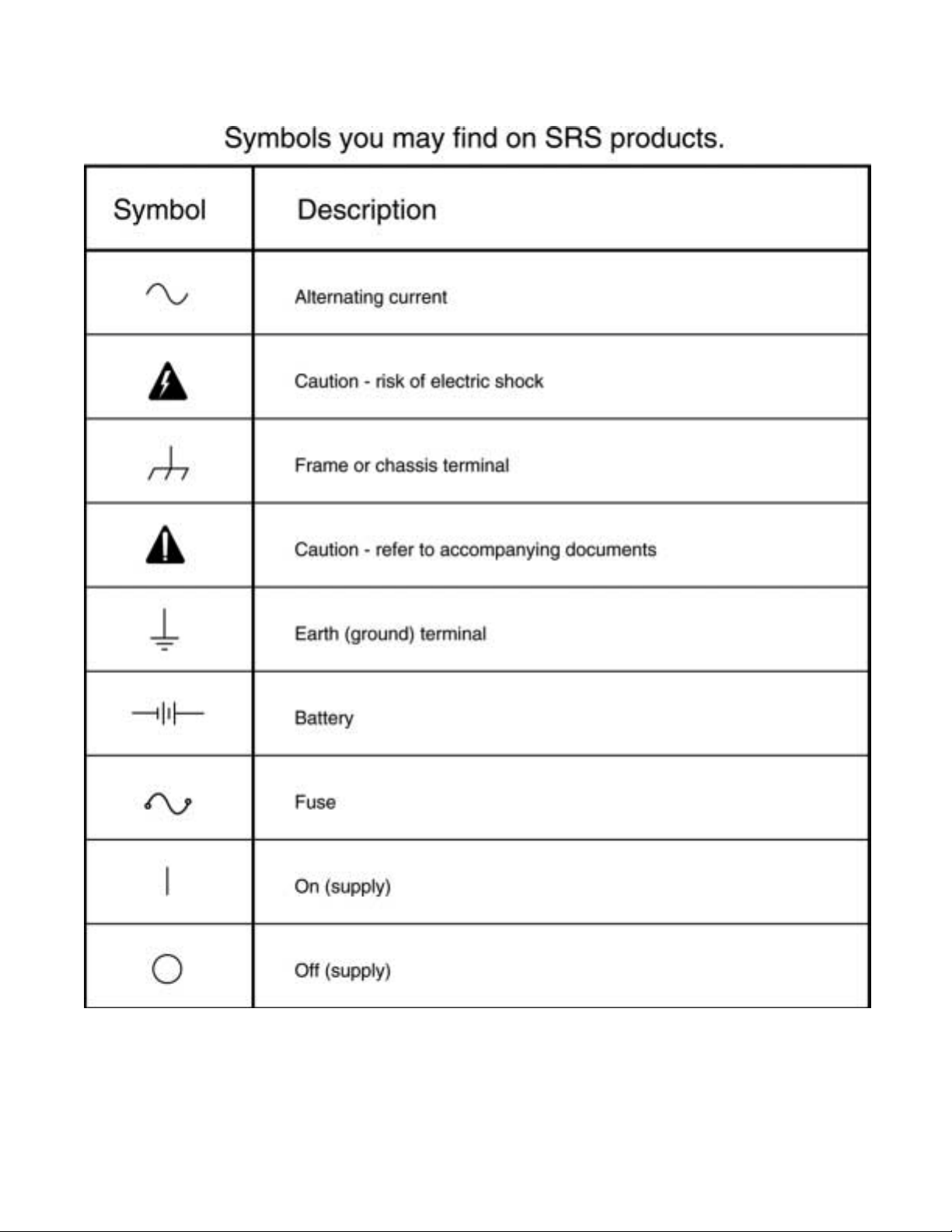

Symbols 2

Specifications 3

Front Panel Summary 5

Abridged Command List 6

Status Byte Definition 7

Configuration Switches 7

Guide to Operation

Front Panel 8

Signal Inputs 8

Signal Filters 8

Sensitivity 8

Dynamic Reserve 9

Status Indicators 9

Display Select 9

Output 9

Expand Function 9

Rel Function 9

Offset 10

Time Constants 10

Noise Measurements 10

Reference Input and Trigger Levels 11

Phase Controls 11

Power Switch 12

Local/Remote Operation 12

Default Settings 12

Rear Panel 13

AC Power 13

GPIB (IEEE-488) Connector 13

RS232 Interface 13

Signal Monitor Output 13

Pre-Amp Connector 13

A/D Inputs and D/A Outputs 13

Ratio Feature 13

Internal Oscillator 13

Guide to Programming

Communications 15

Command Syntax 15

Status LED's 15

RS232 Echo Feature 16

Try-out with an ASCII Terminal 16

Command List 17

Status Byte 20

Errors 20

Reset Command 20

Trouble-Shooting Interface Problems 21

Common Hardware Problems 21

Common Software Problems 21

RS232 Interface

Introduction to the RS232 21

Data Communications Equipment 22

Wait Command 22

Termination Sequence 22

GPIB (IEEE-488) Interface

Introduction to the GPIB 22

GPIB Capabilities 22

Response to Special GPIB commands 22

Serial Polls and SRQ's 23

Echo Mode using the RS232 23

Using Both the RS232 & GPIB 23

Lock-in Technique

Introduction to Lock-in Amplifiers 24

Measurement Example 24

Understanding the Specifications 25

Shielding and Ground Loops 25

Dynamic Reserve 26

Current Input 26

Auto-Tracking Bandpass Filter 26

Notch Filters 27

Frequency Range 27

Noise Measurements 27

Output Filters 27

Ratio Capability 27

Computer Interface 27

Internal Oscillator 27

SR510 Block Diagram

Block Diagram 28

Signal Channel 29

Reference Channel 29

Phase-Sensitive Detector 29

DC Amplifier and System Gain 29

Microprocessor System 29

Circuit Description

Introduction 30

Signal Amplifier 30

Current Amplifier 30

Notch Filters 30

Bandpass Filter 30

Reference Oscillator 31

PSD, LP Filters and DC Amplifier 31

Analog Output 31

A/D's 31

D/A's 32

Expand 32

Front Panel 32

Microprocessor Control 32

i

Page 4

RS232 Interface 32

GPIB Interface 32

Power Supplies 33

Internal Oscillator 33

Calibration and Repair

Introduction 34

Multiplier Adjustments 34

Amplifier and Filter Adjustments 34

CMRR Adjustment 34

Line Notch Filter Adjustment 35

2xLine Notch Filter Adjustment 35

Repairing Damaged Front-End 35

Appendix A: Noise Sources and Cures

Johnson Noise 36

'1/f' Noise 36

Noise Spectrum 36

Capacitive Coupling 37

Inductive Coupling 37

Ground Loops 38

Microphonics 38

Thermocouple Effect 38

Appendix B: RS232

Simplest Case Using the RS232 39

Using Control Lines 39

Baud Rates 39

Stop Bits 40

Parity 40

Voltage Levels 40

'Eavesdropping' 40

Appendix C: GPIB

Introduction to the GPIB 41

Bus Description 41

Appendix D: Program Examples

IBM PC, Microsoft Basic, via RS232 42

IBM PC, Microsoft Fortran, via RS232 43

IBM PC, Microsoft C, via RS232 45

IBM PC, Microsoft Basic, via GPIB 47

HP-85, HP Basic, via HPIB 49

Documentation

Part Numbering and Locations 50

Parts List, Main Assembly 51

Parts List, Internal Oscillator 65

Parts List, Miscellaneous 66

Parts List, Front Panel 67

Schematic Diagrams 71

ii

Page 5

Safety and Preparation for Use

***CAUTION***: This instr um ent m ay be damaged if oper at ed with the LINE VOLTAG E SELECTOR set f or

the wrong applied ac input-sour ce volt age or if the wrong f use is installed.

LINE VOLTAGE SELECTION

The SR510 operates fr om a 100V, 120V, 220V, or

240V nominal ac power source having a line

frequency of 50 or 60 Hz. Before connecting the

power cord to a power source, v erify that the LINE

VOLTAGE SELECTOR car d, located in the rear

panel fuse holder, is set so that the correct ac input

voltage value is visible.

Conversion to other ac input volt ages requires a

change in the fuse holder volt age car d pos ition and

fuse value. Disconnect the power cord, open the

fuse holder cover door and rotat e the fuse-pull lever

to rem ove the fuse. Remove the small printed circuit

board and select t he oper at ing voltage by orienting

the printed c ircuit boar d to position the desir ed

voltage to be visible when pushed firmly into it s slot .

Rotate the fuse-pull lever back into its normal

position and insert t he cor r ect fuse into the fuse

holder.

LINE FUS E

Verify that the correct line fuse is installed befor e

connecting the line cord. For 100V and 120V, use a

½ Amp fuse and for 220V and 240V, use a 1/4 Amp

fuse.

OPERATE WITH COVERS IN

PLACE

To avoid personal injury, do not remov e the

product cov er s or panels. Do not operate the

product without all covers and panels in place.

WARNING REGARDING USE

WITH PH OTOMULTIPLIERS

It is relatively easy to dam age t he signal inputs if

a photomultiplier is used improper ly with t he

lock-in amplifier. W hen left c ompletely

unt erminated, a PMT will charge a c ab le t o a

few hundred volts in a ver y short time. If this

cable is connected to t he lockin, the stored

charge may dam age the front-end transist or s.

To avoid this problem, pr ovide a leakage path of

about 100 KΩ to ground inside the base of the

PMT to prev ent charge acc um ulation.

LINE CORD

This instrument has a det achable, three- wire power

cord with a thr ee- contact plug for connect ion to both

the power sourc e and pr otective gr ound. The

protect ive gr ound cont ac t connect s to the accessible

metal part s of the instr um ent. To prevent electrical

shock, always use a power sour ce out let that has a

properly grounded pr ot ec t ive- gr ound cont act.

1

Page 6

2

Page 7

SR510 Specification Summary

General

Power 100, 120, 220, 240 VAC (50/60 Hz); 35 Watts Max

Mechanical 17" x 17" x 3.5" (Rack Mount Included) 12 lbs.

Warranty Two years parts and labor.

Signal Channel

Inputs Voltage: Single-ended or True Differential

Current: 10

Impedance Voltage: 100 MΩ + 25 pF, ac coupled

Current: 1 kΩ to virtual ground

Full Scale Voltage: 100 nV (10 nV on expand) to 500 mV

Sensitivity Current: 100 fA to 0.5 µA

Maximum Voltage: 100 VDC, 10 VAC damage threshold

Inputs 2 VAC peak-to-peak saturation

Current: 10 µA damage threshold

1 µA ac peak-to-peak saturation

Noise Voltage: 7 nV/√Hz at 1 kHz

Current: 0.13 pA/√Hz at 1 kHz

Common Mode Range: 1 Volt peak; Rejection: 100 dB dc to 1KHz

Above 1KHz the CMRR degrades by 6 dB/Octave

Gain Accuracy 1% (2 Hz to 100KHz)

Gain Stability 200 ppm/°C

Signal Filters 60 Hz notch, -50 dB (Q=10, adjustable from 45 to 65 Hz)

120 Hz notch, -50 dB (Q=10, adjustable from 100 to 130 Hz))

Tracking bandpass set to within 1% of ref freq (Q=5)

Dynamic Reserve 20 dB LOW (1 µV to 500 mV sensitivity)

40 dB NORM (100 nV to 50 mV sensitivity)

60 dB HIGH (100 nV to 5 mV sensitivity)

Bandpass filter adds 20 dB to dynamic reserve

Line Notch filters increase dynamic reserve to 100 dB

6

Volts/Amp

Reference Channel

Frequency 0.5 Hz to 100 kHz

Input Impedance 1 MΩ, ac coupled

Trigger SINE: 100 mV minimum, 1Vrms nominal

PULSE: ±1 Volt, 1 µsec minimum width

Mode Fundamental (f) or 2nd Harmonic (2f)

3

Page 8

Acquisition Time 25 Sec at 1 Hz

6 Sec at 10 Hz

2 Sec at 10 kHz

Slew Rate 1 decade per 10 S at 1 kHz

Phase Control 90° shifts

Fine shifts in 0.025° s t eps

Phase Noise 0.01° r m s at 1 kHz, 100 msec, 12 dB TC

Phase Drift 0.1°/°C

Phase Error Less than 1° above 10Hz

Demodulator

Stab ility 5 ppm /°C on LOW dynamic reserv e

50 ppm/°C on NORM dynamic reserve

500 ppm/°C on HIG H dynam ic reserve

Time Constants Pre: 1msec to 100 s ec (6 dB/Octav e)

Post: 1sec, 0. 1 sec, none (6 dB/Octave) or none

Offset Up to 1X full scale (10X on expand)

Harmonic Rej -55 dB (bandpass f ilter in)

Outputs & Interfaces

Outputs X (RcosØ), X Offset, Noise

Output Meter 2% Precision mirror ed analog m et er

Output LCD Four digit aut o- r anging LCD display shows same values as t he analog m et er s

Output BNC ±10 V output corresponds to full scale input

<1Ω output impedance

Reference LCD Four digit LCD display for r eference phase shift or frequency

RS232 Int er f ace contr ols all funct ions. Baud rates from 300 to 19.2 K

GPI B Inter face cont r o ls a ll f u n c tions. (I EEE-488 Std)

A/D 4 BNC inputs with 13 bit resolution ( ± 10. 24 V)

D/A 2 BNC outputs with 13 bit r esolution ( ± 10. 24 V)

Ratio Ratio output equals 10X output divided by the Denom inator input .

Interna l Oscillat o r Range: 1 Hz to 100 kHz, 1% accuracy

Stability: 150 ppm/°C

Distortion: 2% THD

Amplitude: 1% accurac y, 500 ppm/°C st ability

4

Page 9

Front Panel Summary

Signal Inputs Single Ended (A), Tr ue Diff erential (A-B), or Current (I)

Signal Filters Bandpass: Q-of- 5 Auto-tracking f ilter (In or Out)

Line Notch: Q- of - 10 Notch Filter at line frequency ( I n or Out)

2XLine Notch: Q-of - 10 Notch Filter at twice line frequency ( I n or Out)

Sensitivity Full scale sensitivity f r om 100 nV to 500 mV RMS for voltage inputs

or fr om 100 fA to 500 nA RMS for current inputs.

Dynamic Reserve Select Dynam ic Reserve Stability Sensitivity Rang es

LOW 20 dB 5 ppm 1 µV to 500 mV

NORM 40 dB 50 ppm 100 nV to 50 mV

HIGH 60 dB 500 ppm 100 nV t o 5 mV

Status I ndicat or s OVLD Signal O ver load

UNLK PLL is not locked to the referenc e input

ERR I llegal or Unrecognized command

ACT RS232 or GPIB interface Activity

REM Remot e m ode: front panel has been locked-out

Display Select X Signal Amplitude at t he select ed phase ( AcosØ )

OFST Display the off set which is being added to the signal output

NOISE Compute and display t he noise on t he signal

Analog Meters Displays Signal, Offset, or Noise as a fraction of full scale

Output LCD's Displays Signal, Offset, or Noise in absolute units

Output BNC's Output follows Analog Meter, ± 10 V for ± full scale

Expand Multiplies the Analog Met er and Out put voltage by a factor X1 or X10.

REL Set the Offset to null the output: subsequent readings are relat ive readings.

Offset Enables or Disables Offset, and allows any offset (up to full scale) to be enter ed.

Time Constants Pre-filter has time const ant s from 1 mS to 100 S (6 dB/Octave)

Post-f ilter has time const ant s of 0, 0.1 or 1.0 S (6 dB/Octave)

ENBW Equivalent Noise Bandwidth. Specifies t he bandwidth when making Noise

measurem ent s. (1Hz or 10 Hz ENBW)

Reference I nput 1 MΩ Input, 0. 5 Hz to 100 KHz, 100 mV minimum

Reference Tr igger Trigger on r ising edge, z er o cr os sing, or f alling edge

f/2f Mode PLL can lock t o eit her X1 or X2 of the reference input frequency

Phase Controls Adjust phase in smoothly accelerating 0.025° steps , or by

90° steps. Pres s both 90° buttons to zero the phase.

Reference LCD Display refer enc e phase sett ing or r eference frequenc y

Power Switch Instr um ent settings f r om the last use are recalled on power-up

5

Page 10

Abridged Command List

A Return t he ‘REL’ Status

A0 Turn t he ‘REL’ off

A1 Turn t he ‘REL’ on

B Return Bandpass Filter St at us

B0 Take out t he Bandpass Filter

B1 Put in the Bandpass Filter

C Retur n the Reference LCD Status

C0 Display the Reference Fr equency

C1 Display t he Ref er ence Phase Shift

N Retur n the ENBW sett ing

N0 Select 1 Hz ENBW

N1 Select 1 0 Hz ENBW

O Ret ur n O ffs et Stat us

O0 Turn off Offset

O1,v Turn on Offset, v = offset

P Return t he Phase Set t ing

Pv Set the Phase to v. Abs(v) < 999 deg

D Retur n Dynam ic Reserve Set t ing

D0 Set DR to LOW range

D1 Set DR to NORM range

D2 Set DR to HIGH range

En Return Expand St at us

En,0 Turn Expand off

En,1 Turn Expand on

F Return the Ref er ence Fr equenc y

G Ret ur n t he Sensit ivity Set t ing

G1 Select 10 nV Full-Scale

... (G 1- G3 with SRS preamp only)

G24 Select 500 mV Full-Scale

H Retur n Pr eam p St at us (1=inst alled)

I Ret ur n t he Rem ot e/ Local Status

I0 Select Local: Fr ont panel act ive

I1 Select Remote: Front panel inactive

I2 Sele c t Remote with f u ll lo c k -out

J Set RS232 End-of-Record to <cr>

Jn,m,o,p Set End-of-record to n,m,o,p

K1 Simulates Key-pr ess of button #1

... (see un- abr idged comm and list)

K32 Simulates Key- pr ess of but t on #32

Q Ret ur n t he value shown on t he Output

LCD

R Retur n the trigger mode

R0 Set the trigger for rising edge

R1 Set the trigger for + zero crossing

R2 Set the trigger for falling edge

S Return t he display st at us

S0 Disp lay X = Aco s Ø

S1 Display Offset setting

S2 Dis play Noise

T1 Return pre-filter setting

T1,1 Set the pre-filter TC to 1 mS

...

T1,11 Set the pre-filter TC to 100 S

T2 Return the post-filter sett ing

T2,0 Remove post filter

T2,1 Set the post filter TC to 0.1 S

T2,2 Set the post filter TC to 1.0 S

V Return t he value of the SRQ mask

Vn Set the SRQ Mask to the value n

(See the Stat us Byte def inition)

W Return the RS232 wait inter val

Wn Set RS232 wait interval to nX4mS

L1 Return Stat us of Line Notch Filter

L1,0 Remove Line Notch Filter

L1,1 Insert Line Notc h Filter

L2 Return Stat us of 2XLine Filter

L2,0 Remove 2XLine Notch Filter

L2,1 Insert 2XLine Notch Filter

M Return t he f/2f Stat us

M0 Set refer enc e mode to f

M1 Set refer enc e mode to 2f

Xn Return t he v oltage at the rear panel

analog port n. ( n from 1 to 6)

X5,v Set analog port 5 to voltage v

X6,v Set analog port 6 to voltage v

Y Return t he St at us Byte value

Yn Test bit n of the Status Byte

Z Reset to def ault s ettings and cancel

all pending command

6

Page 11

Status Byte Definition

Bit Meaning

0 Magnitude too small to calculat e

phase

1 Command Parameter is out-of -range

2 No detectable refer ence input

3 PLL is not locked to the reference

4 Signal Overload

5 Auto-off set failed: signal too large

6 SRQ generated

7 Unrecognized or illegal command

Configuration S witches

There are t wo banks of 8 switches, SW1 and

SW2, located on t he rear panel. SW1 sets the

GPIB address and SW2 set s the RS232

paramet er s. The conf igurat ion switches ar e read

continuously and any changes will b e e ffective

immediately.

SW1:GPIB Mode Switches

Bit Example Function

1 } up GPIB Address Switches

2 } up Address 0 to 30 allowed

3 } up 'up' for bit = 1

4 } down 'down' f or bit = 0

5 } up (Most Significant Bit)

6 down 'down' t o echo on RS232

(norm ally 'up')

7 up Not Used

8 up Not Used

If the GPIB mode switches ar e set as shown in the

example column above, t hen the lockin will be

addressed as G PIB device #23, and all GPI B

commands and dat a will b e e c hoed over t he

RS232 for de-bugging purposes.

SW2:RS232 Mode Swi t ches

Bit 1 Bit 2 Bit 3 Baud Rate

up up up 19200

down up up 9600

up down up 4800

down down up 2400

up up down 1200

down up down 600

up down down 300

Bit Setting Explanation

4 up Odd parity

down Even parit y

5 up No par ity

down Parit y enabled

6 up No echo ( f or comput er )

down Echo mode ( for terminal)

7 up Two st op bits

down O ne st op bit

8 unused

Eight data bits ar e always sent, regar dless of the

parity set t ing. The most significant bit is always

zero.

Example: Bit 1 'down' and all others 'up' for

RS232 communication at 9600 baud, no par it y,

two stop bits, and no echo or prom pt s by the

SR510.

7

Page 12

SR510 Guide to Operation

Front Panel

The front panel has been designed to be almost

self-explanator y . The effec t of each key press is

usually reflected in the c hange of a near by LED

indicator or by a change in t he quant it y shown on

a digital display. This discussion explains each

section of t he front panel, pr oceeding left to right .

Signal Inputs

There are t hr ee input connector s locat ed in the

SIGNAL INPUT section of the front panel. The

rocker switch locat ed abov e t he B input selects

the input mode, either single-ended, A, differential,

A-B, or current , I.

The A and B inputs are voltage inputs with 100

MΩ, 25 pF input impedance. Their connector

shields are isolated from t he c hassis gr ound by

10Ω. These inputs are pr otect ed to 100V dc but

the ac input should never ex ceed 10V peak. The

maximum ac input bef ore overload is 1V peak.

The I input is a current input with an input

impedance of 1 KΩ to a virtual ground. The

largest allowable dc curr ent before overload is 1

µA. No current larger than 10 mA should ever be

applied to t his input. The conver sion ratio is 10

V/A, thus , the full scale current sensit ivities r ange

from 100 fA to 500 nA with a max ac input before

overload of 1 µA peak. You should use short

cables when using the cur r ent input.

6

allowable signals at t he inputs . The notch

frequencies ar e set at the factory to either 50 Hz

or 60 Hz. The user can adjust these frequencies.

(See the Maint enance and Repair section for

alignment details.) These f ilter s pr ecede the

bandpass filter in t he signal amplifier.

The bandpass filter has a Q of 5 and a 6 dB roll off

in either direction. Thus, the pass band (between

70% pass points) is always equal to 1/5t h of the

center frequency . The center frequenc y is

continually adjusted t o be equal t o t he internal

demodulator f r equenc y. When the refer ence

mode is f, the filter tracks the reference. When the

mode is 2f, the filter frequency is t wice the

refer ence input frequency. The center frequency

tracks as fast as the reference oscillator c a n s lew

and may be used during frequency sc ans. The

bandpass filter adds up to 20 dB of dynamic

reserve f or noise signals outside the pass band,

and increases the har m onic r ejection by at least

13dB. (2nd harm onic attenuat ed by 13 dB, higher

harmonics at t enuat ed 6dB/ octave more.) If not

needed to improve the dynamic reserve or the

harmonic reject ion t hen t he filter should be left

OUT.

Sensitivity

The sensitivity is displayed as a v alue (1- 500) and

a scale (nV, µV, mV). When using the current

input, which has a gain of 106 V/A, these scales

read fA, pA, and nA. The two keys in the

SENSITIVITY section mov e t he sensit ivity up and

down. If eit he r key is held d o wn, the s en s itivity will

continue to change in the des ired direc t ion four

times a second.

Signal Filters

There are t hr ee user selectable signal filters

available; a line frequency not ch, a 2X line

frequency notch, and an auto-tracking bandpass.

Each of the filters has a pair of indicator LED's and

a function key locat ed in the SIG NAL FILTERS

section of t he front panel. Pres sing a key will

toggle the st at us of the appropr iate filter. The

status of each filter is displayed as IN, filter active,

or OUT, fi l te r in a c tive .

The notch filter s have a Q of 10 and a depth of at

least 50 dB. Thus, the line fr equency not c h is 6

Hz wide and the 2X line notch has a width of 12

Hz. Both of these filters can incr ease the dynamic

reserve up t o 50 dB at the notch frequencies. The

achievable reser ve is limited by the maximum

The full scale sensitivit y can r ange from 100 nV to

500 mV. The sensitivit y indication is not changed

by the EXPAND func t ion. The EXPAND function

increases the out put s ensit ivity ( Volts out / volts in)

as well as the resolution of t he digital output

display.

Not all dynamic reserves ar e av ailable at all

sensitivities. I f the sensitivity is changed to a

setting f or which the dynamic r eser ve is not

allo we d , the dy n a mic res e r v e will c hange t o the

next setting which is allo we d. Sensitivity takes

precedence over the dynamic reserve. The

sensitivity range of eac h dynam ic res er ve is

shown below.

8

Page 13

Dynamic Reserve Sensitivity Ran ge

LOW 1 µV through 500 mV

NORM 100 nV t hr ough 50 m V

HIGH 100 nV thr ough 5 m V

Dynam ic Reserve

REM indicates t hat t he unit is in the remote state

and that the front panel cont r ols ar e not operative.

There are t wo remote stat es. The Remot e-WithLock o ut will not a llow any inputs from the front

panel. The Remote- Wit hout - Lock out comm and

allows you to return the front panel to operation by

pressing the DI SPL AY UP key.

The dynamic reser ve ( DR) is set using the keys in

the DYNAMIC RES ERVE section. The r eser v e is

displayed by the three indicator LED's, HIGH,

NORM, LOW. Only those dynamic reserve

settings available for the sensitivity are allowed

(see above table) . For example, when the

sensitivity is 500 mV, the DR will always b e LOW.

The dynamic reser ve and out put st ability of e a c h

setting ar e shown below.

Setting Dy n amic Reserve Ou tput Sta bility

(ppm/°C)

LOW 20 dB 5

NORM 40 dB 50

HIGH 60 dB 500

Since a higher DR results in degraded output

sta b ility, y ou s hould use t he lowest DR sett ing f or

which there is no overload indication. Note t hat

using the Bandpass Filter prov ides about 20dB of

additional DR and so allows you to oper at e with a

lower DR s etting .

Status

Dip lay Sel ect

The keys in the DISPLAY section select the

paramet er to be displayed on the out put meters

and the output on the OUT PUT BNC connector.

The displayed param et er is indicated by one of t he

three LED’s and can be either t he demodulator

output ( X), the offset (OFST), or the rm s noise

(NOISE). When displaying NOISE, the equivalent

noise bandwidth (ENBW) is se lec ted in t h e TIME

CONSTANT section.

Output

The analog output is available at t he OUTPUT

BNC. The input signal equal t o t he s elected full

scale sensitivity will generate a ± 10V out put when

the EXPAND function is off. With the EXPAND on,

the output is multiplied by 10, eff ectively

increasing the full scale sensitivity by 10. The

ouptut impedanc e is <1Ω and t he output current is

limited to 20 mA.

The analog meter always displays the OUTPUT

voltage. Accur acy is 2% of full scale.

There are f ive STATUS LED's.

OVLD indicates a signa l over load. This condition

can occur when the signal is too large, the

sensitivity is too high, the dynamic reserve is too

low, the off set is on, the expand is on, the time

constant is not lar ge enough, or the ENBW is too

large.

UNLK in d ic ates t h at the referen c e o s c illator is n o t

phase locked to the external refer enc e input. This

can occur if the ref erence amplitude is t oo low, t he

frequency is out of range, or the trigger m ode is

incorrect f or the refer ence s ignal waveform .

ERR flashes when an er r or occ ur s on one of the

computer int erfaces, such as an incorrect

command, invalid parameter, etc.

ACT indicates act ivity on t he com put er interfaces.

This LED blinks every tim e a char act er is received

by the SR510 or transmit t ed by the SR510.

The OUTPUT LC D disp lay pr ovides a r ead- out of

the displayed paramet er in r eal units. The scale of

the displayed quantity is indicated by t he t hr ee

scale LED's to the r ight of the display. This readout auto r anges and will re flect the sens itivity

added when the EXPAND f unc t ion is on.

Expand

The output EXPAND is toggled by pressing the

key in the EXPAND section. The expand status is

indicated by the X10, ex pand on, and the X1,

expand off, LED's.

REL Function

The relative (aut o- zer o) func t ion is toggled by the

key in the REL section. Every time t he rel stat us

LED is turned ON the offset value is set to minus

the value of t he X output, thus zeroing the X

out p ut. This function will work e v en if X is not the

9

Page 14

current ly displayed param et er . If the output is

greater than 1.024 t im es full scale, the REL

fun c tion will not b e a ble to zer o the output and the

ON LED will blink . The of fset v a lue will then be set

to its max value. If NOISE is being displayed when

the REL function is turned on, the noise ouptut will

require a sew seconds to s ettle again.

If the manual OFFSET in ON when the REL

function is tur ned on, t he manual OFFSET will be

turned OFF before the auto zero is done.

The REL func t ion and t he m anual OFFSET are

both ways to ent er the offs et value. When the REL

function is tur ned off using t he REL key the offset

is turned of f but the value is not lost. If the manual

OFFSET is now tur ned ON, the off s et will b e that

set by the REL funct ion.

Offset

The OFFSET section controls the manual

OFFSET. The offset is turned ON and OFF using

the upper key in the OFFSET section. When the

offset is ON, the lower two keys are used to set

the amount of offset. A single key press will

advance the of f set by 0.025% of full scale. If the

key is held down, the off set advances in larger and

larger increments, the largest increment being

10% of full scale. When the offs et is turned OFF

the applied offset r eturns to zero but the offset

value is not lost. The next pres s of the upper

offset key (ret ur ns to ON) sets the offset to the

previously entered value.

If an attempt is made to advance the offset v alue

beyond full scale, the OFFSET ON LED will blin k .

An offset up to 1.024 tim es the full scale sensitivity

may be enter ed. When the expand is on, this is

10X the full scale output.

If the REL function is ON when the manual

OFFSET is t ur ned ON, the REL funct ion is tur ned

OFF but the off set value rem ains the same. The

OFFSET key s m ay now be used t o adjust this

offset value.

Note that the offsets (either manual off set or those

generated by t he REL function) represent a

fract ion of the full scale reading, and so their

absolute value will change when the s ensitivity

scale is changed. A signal which has been nulled

by an offset will n o t be nulled when t he sens itivity

scale is changed. The analog meter and the

output BNC indicate the sam e value given by the

equation:

V

= 10Ae(AvVicosØ+Vos)

out

where...

Ae= 1 or 10 per the Expand setting

Av= 1/Sensitivity

Vi= m agnitude of the signal

Ø = phase between signal & reference

Vos= of f s et (fract ion of FS < 1.024)

Time Constant

There are t wo post demodulator low pass f ilters ,

labeled PRE and POST. The PRE filter precedes

the POST filter in the output amplifier. Each filter

provides 6 dB/oct attenuat ion.

The PRE filter t im e const ant ranges from 1 mS to

100 S and is selected by the two keys below the

PRE filter indicator LED's. Holding down either

key will a d v ance the time constant twic e a s ec o n d

in the desired direction.

The POST filter time constant can be set to 1 S or

0.1 S, or can be removed altogether, NONE, using

the two keys below the ENBW indicators. When

set to NONE, the total attenuat ion is that of the

PRE filter, or 6 dB/ oct. When the POST filter is 1

S or 0.1S, the total attenuation is 12 dB/oct for

frequency c om ponent s beyond the larger of the

POST and PRE f ilter bandwidths ( r ecipr ocal tim e

constant).

Noise

When the DISPLAY is set to NOISE, none of the

PRE and POST ind icat or LED's ar e on. Inst ead,

one of the two ENBW indicator s will be on,

showing the Equivalent Noise Bandwidth of the

rms noise calculation. The ENBW is set using the

keys below the ENBW indicator LED's (same keys

as used to set the POST f ilter ). The PRE filter

keys do nothing in this case. Pressing the upper

key when the bandwidth is already 1 Hz will reset

the rm s noise average (out put) to zero, res t arting

the calculation. Likewise with pr ess ing the lower

key when 10 Hz is already selected.

The noise is the rms dev iation of the out put within

a 1 or 10 Hz equivalent noise bandwidth about the

refer ence frequency . A dc output does not

contribut e t o the noise, the noise is determ ined

10

Page 15

only by the ac 'wiggles' at t he output. By

measuring the noise at dif f erent frequencies, t he

frequency dependenc e of t he noise densit y can be

found. This usually has the form of v

The noise computat ion assum es t hat t he noise

has a Gaussian distr ibution ( such as J ohnson

noise). Since the com put ation takes m any time

constant s (reciproc al bandwidt h) , t he noise output

should be allowed to approach a st eady value

before a r eading is taken. For the 1 Hz ENBW,

this time is on the order of 15 to 30 seconds; for

the 10 Hz ENBW , the o utp ut stabilizes much

fas ter. The n ois e o u tput will var y s lig htly sinc e

the re will alwa y s b e n o is e v a riation s that a r e s lo w

compared t o the bandwidth. Any DC component

in th e ou tput will n o t cont ribute to the noise.

Howeve r , a larg e DC ou tput will c a u s e the nois e

computat ion t o initially rise to a large value bef or e

approaching the f inal answer. As a r esult, t he

com p utatio n will take longer to settle.

To obtain a value for the noise density, t he noise

reading should be divided by the squar e r oot of

the ENBW. Thus, when the ENBW is 1 Hz, the

noise output is the noise densit y, and when t he

ENBW is 10 Hz, the noise density is the noise

output divided by √10. For exam ple, if the input

noise is measured to be 7 nV with the ENBW set

to 1 Hz, the noise density is 7 nV/√Hz . Swit c h in g

the ENBW to 10 Hz results in a faster

measurem ent and a reading of 22 nV on the

output. The noise density is 22 nV/√10 Hz or 7

nV/√Hz. At frequencies » 10 Hz, the noise

density should be independent of t he ENBW.

noise ~

1/f.

Reference and Trigger Level

The REFERENCE I NPUT BNC is lo c a ted in t his

section. The input is ac c oupled and the

impedance is 1 MΩ. The dc voltage at this input

should not exceed 100 V and the largest ac signal

should be less than 10 V peak. The t hree

indicators above the input BNC display t he

TRIGGER MODE. The single key above the input

BNC is used to select the TRIGGER MODE.

If the center TRIGGER MODE LED is on, the

mode is SYMMETRIC and the reference oscillator

will lock to the positive zer o cr oss ings of the ac

refer ence input . The ac signal must be symmetric

(e.g. sine wave, s quar e wave, etc.) and have a

peak to peak amplitude gr eat er t han 100 mV. A

signal with 1 Vrms am plitude is r ecommended.

The phase accuracy of the reference channel is

specified for a 1Vr m s sinewave in the symmetric

trigger m ode.

If the upper TRIGGER MODE LED is on, the

mode is POSITIVE. The trigger threshold is +1V

and the ref erence oscillator will lock t o the positive

going transitions of t he refer ence input . This

mode tr iggers on the rising edges of a TTL type

pulse train. The pulse width mus t be great er than

1 µS.

If the lo w e r TRIGGER MODE LED is on, the mode

is NEGATIVE. The trigger threshold is -1V and

the referen c e o s c illa tor wil l lo c k to the negative

going transitions of t he refer ence input . This

mode tr iggers on a negative pulse tr ain or on the

falling edges of a TTL type pulse t r ain

(rem em ber ing that t he input is ac coupled). The

pulse width must be greater than 1 µS.

Above the TRIGGER MODE indicators are the

REFERENCE MO DE LED's. The key below the

REFERENCE MO DE indicators toggles bet ween f

and 2f. When the MODE is f, the lock-in will

detect s ignals at t he refer ence input fr equency.

When the MODE is 2f, the lock-in det ect s signals

at twice the refer ence input frequency . In either

case , the referen c e os c illa tor ha s a ma x im u m

frequency of 100 KHz, thus, when in the 2f mode,

the ref erence input f r equency may not exceed 50

KHz.

The REFERENCE DIGITAL DISPLAY shows

eith e r the ref erence o s c illa tor f r equenc y or

phaseshift. The displayed parameter toggles

between the t wo whenever t he SELECT key is

pressed. The appr opr iat e sc ale indicator below

the display will be on. It is useful to check the

frequency display t o ver if y that the lock-in has

correct ly locked t o y our ref erence. The reference

frequency is m easur ed to 1 part in 256 resolution.

Phase Controls

The phase shift bet ween t he refer ence osc illator

and the ref erence input is set using the f our keys

in the PHASE section. The t wo keys below the

FINE label increment t he phase setting in small

amounts. A single key press will change t he

phase by 0.025 degrees in the desir ed direction.

Holding the key down will continue to change the

phase with larger and larger s t eps with t he largest

step being 10 degrees. The two 90° keys are

used to change t he phase by 90 degree

increments . The upper key will add 90 degrees

and the lower key will su btract 90 degrees.

Holding both keys down at once s et s the phase

shift back to zero. The REFERENCE DIGITAL

DISPLAY automatically displays t he phas e

11

Page 16

whenever any of t he PHASE key s ar e pr essed.

The phase ranges fr om -180 degr ees to +180

degrees and is the phase delay f r om the refer ence

input signal.

Power

This is the instrume n t's POWER switch. When the

power is turned of f, the front panel settings are

retained so t hat the inst r ument will retur n to the

same settings when the power is next turned on.

When the power is tur ned on, the OUTPUT

DIGITAL DISPLAY will show the SERIAL

NUMBER of the instr ument and REFERENCE

DISPLAY shows the model number of the

instrument. All displays return to normal after 2

seconds.

Local and Remote

When the instr um ent is progr ammed via the

computer int erface t o be in the REMOTE state

WITHO UT LO CK-OUT, the DISPLAY UP key will

return the instrument to LOCAL f ront panel

control. If the instr ument is in the REMOTE WITH

LOCK-OUT state, no front panel key will ret u r n the

status to LOCAL. In this case, a RETURN TO

LOCAL c om m and m ust be s ent over the computer

interfac e or the power must be turned off and back

on.

Defaults

If the REL key is held down when the POWER is

turned on, the instr um ent settings will be s et to the

defaults shown below instead of t he settings in

effect when the power was t ur ned off.

Parameter Setting

BANDPASS OUT

LINE OUT

LINE X 2 OUT

SENSITIVITY 500 mV

DYN RES LOW

DISPLAY X

EXPAND OFF

REL OFF

OFFSET OFF (value=0)

PRE TIME CONSTANT 100 mS

POST TIME CONST ANT 0.1 S

ENBW 1 Hz

REFERENCE MO DE f

TRIGGER MODE SYMMETRIC

REFERENCE DISPLAY FREQUENC Y

PHASE 0°

Whenever def ault values ar e used at power up,

the red ERR LED will turn on f or about 3 seconds.

If the ERR LED is on when the instrument is

powered on without the LOCAL key down, then

the instr um ent is ignoring the ret ained settings.

This can be due to a low battery.

12

Page 17

SR510 Guide to Operation

Pin Voltage Current Available

Rear Panel

AC Power

The ac line voltage selector car d, line fuse, and

line cord receptacle ar e located in t he f use holder

at the left side of the rear panel. See the section,

Preparati on f or Use at the front of this manual for

instruct ions on set t ing t he ac voltage selector and

choosing the corr ect fuse.

GPIB Connector

The SR530 has an IEEE 488 ( G PI B) int er f ace built

in. The GPIB addr ess is set using SW1 located to

the right of t he interface c onnect or s. Refer to

page 7 for switch sett ing details.

RS232 Connector

The SR530 has an RS232 interf ace. The

connector is conf igur ed as a DCE. The baud rate,

parity, st op bits, and echo mode are select ed

using SW2 locat ed t o t he r ight of the interface

connectors . Refer to Page 7 for switch setting

details.

Signal Monitor O utput

1 + 20 100 mA

2 + 5 10 m A

6 - 20 100 mA

7 Signa l gr ound

8 Digital ground

Gene ral Purpose A/D and D/A

There are f our analog input port s, labeled X1

through X4. These inputs may be digitized and

read via the com put er interfaces. The range is -

10.24 V to +10.24 V and the resolution is 2.5 m V.

The input impedance is 1 MΩ. A digitization can

be perfor m ed in about 3 mS but the result may

take longer t o transm it over the interf ac e being

used.

There are t wo analog output ports, labeled X5 and

X6. The voltages at t hese ports m ay be

program m ed via t he computer interfaces. The

range is -10.24 V to +10. 24 V and the resolution is

2.5 mV. The output impedance is <1Ω and the

output cur r ent is limited to 20 mA.

Ratio

Output X5 is the ratio output when not

program m ed by the computer interface or s et via

the fr ont panel. X5 becom es the ratio output

whenever the unit is t ur ned on.

This BNC provides the buf f er ed output of t he

signal amplifiers and f ilter s . This is the signal just

before t he dem odulat or. The output impedanc e is

<1Ω. When a full scale input is applied, the peakto-peak am plitude at this output is 20 mV, 200 mV

or 2 V for dynamic reserve settings of high, norm,

and low, respectively.

Preamp Connector

This 9 pin "D" connector provides power and

control signals to ext er nal per ipherals such as pr eamplifiers. The av ailable power is descr ibed

below.

The voltage at X5 is t he ratio of the det ected

signal output, X, t o the analog voltage at port X1.

An output of 10 V corres ponds to a ratio of 1. The

ratio is comput ed by digitizing the dem odulat or

output and t he voltage at port X1 and then taking

the rat io. The resolution is 0. 0025 V. For best

accuracy, t he sens itivity should be set to provide

at least a 50% full scale signal and the analog

denominator ( X1) should be 5V or greater. The

ratio is updated appr oxim at ely ever y 1. 5 mS. For

the Ratio feat ur e to work, the voltage at the

denominator input m ust ex ceed 40 mV.

Internal Oscillator

The INTERNAL OSCILLATOR is a voltage

controlled oscillat or with a sine wave output . To

use the osc illator as the ref erence s o urce, connect

the REF O UTPUT on the r ear panel to the REF

INPUT on the fr ont panel. The REF OUTPUT is a

1 Vrms sine wave. The SINE OUTPUT may be

used as the st imulus to the experiment . The SINE

13

Page 18

OUTPUT can be set to three amplitudes, 1 V, 100

mV, and 10 mV (rms) using t he amplitude switch.

The output impedanc e is 600Ω. The AMP CAL

screw adjusts t he am plitude.

The oscillator frequency is controlled by the VCO

INPUT voltage. A voltage f r om 0V to 10V will

adjust the f r equency ac cor ding t o the VCO

RANGE select ed. Thr ee r anges ar e available, 1

Hz/V, 100 Hz/V, and 10 KHz/V. The input

impedance is 10 kΩ. Th e FREQUENC Y CAL

screw adjusts t he frequency.

There are f our ways to set the frequency:

1) Connect X5 or X6 (D/A outputs) to the VCO

INPUT. The fr equency is now cont r ollable via the

computer int erfaces by pr ogr amming X5 or X6.

2) If the VCO INPUT is left open, then the

oscillato r will run at the top of its range (i.e. 10 Hz,

1 KHz, or 100 KHz).

3) A 10 KΩ potentiomet er may be connected from

the VCO INPUT to ground. This pot will then set

the fr equency .

4) Connect t he VCO INPUT to an exter nal voltage

source which can provide 0 to 10V.

In all four cases, if the REF OUTPUT is connected

to the REFERENCE I NPUT on the front panel, the

frequency m ay be read on the front panel

REFERENCE DIGITAL DISPLAY or via the

computer int erfaces.

14

Page 19

SR510 Guide to

Programming

An example of a multiple comm and is:

G 5; T 1,4; P 45.10 <cr>

The SR510 Lock-in Amplifier is r em ot ely

program m able via both RS232 and GPI B

interfac es. It may be used with laboratory

computer s or simply with a terminal. All front

panel features ( except signal input selection and

power) may be controlled and read via t he

computer int erfaces. The SR510 can also read

the analog output s of other laboratory instr um ents

using its four gener al pur pose analog input por t s.

There are also two pr ogr ammable analog output

ports available to prov ide general purpos e cont r ol

voltages.

Comm unicating with the SR510

Before using either the RS232 or GPIB interface,

the appropr iate c onf iguration switches need t o be

set. There are two banks of 8 switches, SW1 and

SW2, locat ed on t he rear panel. SW1 sets the

GPIB address and SW2 sets the RS232

paramet er s. The conf igurat ion switches ar e read

continuously and any changes w ill be e ffective

immediately. For details on switch settings, s ee

page 7 at the front of this manual.

Command Syntax

Communications with the SR510 use AS CII

character s . Commands to t he SR510 may be in

eith er UPPER or lower cas e .

It is not necessary to wait between comm ands .

The SR510 has a command input buf f er of 256

character s and pr ocess es the commands in the

order r eceived. Likewise, t he SR510 has an

output buf fer (for each interfac e) of 256

characters.

In general, if a command is sent without

paramet er s, it is inter pr eted as a request to read

the status of the associated f unction or setting.

Values returned by t he SR510 are s ent as a string

of ASCII char act ers t erminated usually by car r iage

retur n, line-feed. For example, after the above

command is sent , the following read commands

would generate the r esponses s hown below.

Command Response from t he SR510

G <cr> 5<cr><lf>

T 1 <cr> 4<cr><lf>

P <cr> 45.10< cr > < lf>

The choice of ter m inat ing characters sent by the

SR510 is determined by which interfac e is being

used and whether t he 'ec ho' feat ur e is in use. The

term inating sequence f or the GPIB interf ace is

always <cr>< lf > (with EOI). The default sequenc e

for RS232 is <cr> when the echo mode is off, and

<cr> < lf> when the echo mode is on. The

term inating sequence f or the RS232 interface may

be changed using the J comm and.

A command t o the SR510 consists of one or two

command letters, arguments or parameters if

necessary, and an ASCII carriage ret ur n (<cr>) or

line-feed (<lf > ) or both. The different part s of the

command do not need to be separated by spaces .

If spac es are included, they will b e ignor ed. I f

more t han one paramet er is required by a

command, the param et ers m ust be separated by a

comma. Examples of commands ar e:

G 5 <cr> set the sensitivity to 200 nV

T 1,4 <cr> set the pre filter to 30 mS

F <cr> read the reference frequency

P 45.10 <cr > set phase shift to 45. 10°

X 5,-1. 23E-1 < cr> set por t X5 to -0.123 V

Multiple commands m ay be sent on a single line.

The commands m ust be separ at ed by a semicolon

(;) character. The commands will n o t be exec u ted

until the ter m inating car r iage return is sent.

Note that the terminating char act er s are sent with

each value retur ned by t he SR510. Thus, the

response to the command string G;T1; P< cr > while

using the RS232 non-echo mode would be

5<cr>4<cr>45.10<cr>.

Front Panel S ta tus LED's

The ACT LE D f lashes whenever t he SR510 is

sending or receiving charact er s ov er the comput er

interfaces.

The ERR LED f lashes whenever an er r or has

occurred, s uch as, an illegal command has been

received, a par am et er is out of range, or a

communicat ion buff er has exceeded 240

character s . This LED flashes for about thr ee

seconds on power-up if t he batt er y voltage is

insufficient t o r et ain pr evious instr um ent settings.

15

Page 20

The REM LED is on whenever t he SR510 is

program m ed to be in the remote state.

RS232 Echo and No Echo

Operation

In order to allow the SR510 to be operat ed from a

term inal, an echo f eature has been included which

causes the unit t o echo back commands rec eived

over the RS232 port . This feature is enabled by

setting switch 6 on SW2 to the DOWN position. In

this mode, the SR510 will send line-feeds in

addition to carr iage returns with each value

retur ned and will a ls o s end the prompts 'OK>' and

'?>' t o indicate that the pr evious com m and line

was either processed or contained an error.

Operat ing t he SR510 fr om a terminal is an ideal

way to learn the commands and r es ponses bef ore

attem pt ing t o program a computer to contr ol the

SR510. When the unit is controlled by a

computer , the ec ho featur e should be turned off t o

prevent t he s ending of spurious characters which

the comput er is not expecting.

Try-Out with an ASCII Terminal

Before at t em pting any detailed program m ing with

the SR510, it is best to try out the commands

using a terminal. Connect a term inal with an

RS232 port to t he RS232 connector on t he rear

panel of the SR510. Set the baud rat e, parit y, and

stop bits t o match the term inal by setting SW2 per

the switch set t ing t able given on page 7. The

echo mode should be enabled (switch 6 DOWN).

After setting SW2 and connecting the term inal,

hold down the REL key whi le turning the unit on.

This causes the SR510 to assum e its def ault

settings so t hat t he following discussion will agree

with the actual re sponses of t he SR510. The ACT

and ERR LED's on t he front panel will f la s h for a

second and the sign-on m essage will appear on

the terminal. Following the m es sage, the prom pt

'O K> ' will be displa y e d. This indicat e s that th e

SR510 is ready to accept commands .

to the terminal.

Now read the gain using the sensitivity r ead

command, G<cr>. The response should be 24

meaning that the sensitivity is at the 24th setting or

500 mV. Change the sensit ivity by typing

G19<cr >. The sensitivity should now be 10 mV.

Check the fr ont panel to mak e sure this is so.

The output of the lock- in is read by typing the

command, Q1<c r >. The response is a signed

floating point number with up t o 5 significant digits

plus a signed exponent. Change the gain to 10 uV

using the G10 com m and. The response to the Q1

command will now be sim ilar to the pre v iou s o n e

except t hat the exponent is differ ent.

Attach a DC voltmeter to the X6 output on the rear

panel. The range should allow for 10V readings.

The voltage at t he X6 output can be set using the

X6 command. Type X6,5.0<cr> and the X6 output

will change to 5.0V. To read this back to the

terminal, just type X6<cr>. When setting the X6

voltage, t he volt age m ay be sent as an integer (5),

real (5.000) , or floating point ( 0. 500E1) num ber.

Now connect the X6 out put to the X1 input (also

on the rear panel). X1 through X4 ar e analog

input ports . To read the voltage on X1, si mply

type X1<cr>. The response 5.000 should appear

on the terminal. The analog port s X1 through X6

can be used by your computer to read outputs of

other inst r um ent s as well as to control other

laboratory par am eters.

At this point, the user should experiment with a

few of the comm ands. A detailed command list

follows.

Type the lett er 'P' followed by a carriage ret ur n

(P<cr> ). The SR510 responds by sending to t he

term inal the char acters 0.00 indicating that t he

phase is set to 0 degrees. In general, a command

with no argument s or param et ers reads a sett ing

of the unit. To set the phase to 45 degrees, type

the comm and, P45<cr >. To see that the phase

did change, use the SELECT k ey on t he front

panel to display the phase on the REFERENCE

DIGITAL DISPLAY. Typing the phase read

command, P< cr>, will now return the s tr in g 45 .00

16

Page 21

SR510 Command List

The first letter in each command sequenc e is the

command. The rest of the sequence consists of

paramet er s. Multiple parameter s ar e separated by

a comma. Those param eters shown in {} are

optional while those without { } ar e required.

Variables m and n represent integer parameters

while v represent s a real number. Parameter s m

and n must be expressed in integer f ormat while v

may be in integer, real, or floating point f ormat .

F

The F command r eads the refer ence frequency.

For example, if the ref erence frequency is 100 Hz,

the F comm and retur ns the string "100. 0". If the

refer ence frequency is 100. 0 kHz, the string

"100.0E+3" is ret ur ned. The F command is a read

only command.

G {n}

If n is included, the G command sets t he gain

(sensitivity) . If n is absent, the gain setting is

returned.

A {n}

If n is "1", the A command causes the auto offset

routine to r un. Every time an "A 1" command is

received, t he aut o offs et function is executed. If n

is "0", then the auto offset is tur ned off. If n is

absent, then the auto offset st atus is returned.

Note that if the manual offset is on, an "A 1"

command will turn o ff the m anual offset befor e

executing the aut o offs et funct ion.

B {n}

If n is "1", the B command sets the bandpass filter

in. If n is "0", the bandpass filter is taken out. If n

is absent, t hen the bandpass f ilter status is

returned.

C {n}

If n is "1", the C command sets the reference LCD

display to show the phase setting. If n is "0", the

LCD will display the refer enc e frequency. If n is

absent, the paramet er being displayed (frequency

or phase) is returned. Note that the P and F

commands ar e used to read the act ual values of

the phase and fr equenc y.

D {n}

If n is included, the D command s ets the dynamic

reserve. If n is absent, the dynamic reserve

setting is ret ur ned.

n Sensitivity

1 10 nV

2 20 nV

3 50 nV

4 100 nV

5 200 nV

6 500 nV

71 µV

82 µV

95 µV

10 10 µV

11 20 µV

12 50 µV

13 100 µV

14 200 µV

15 500 µV

16 1 mV

17 2 mV

18 5 mV

19 10 mV

20 20 mV

21 50 mV

22 100 mV

23 200 mV

24 500 mV

Note that sensit ivity sett ings below 100 nV are

allowed only when a pre-amplifier is connect ed.

n Dyn Res

0LOW

1NORM

2 HIGH

Note that not all dynamic reserv e settings ar e

allowed at every s ensit ivity.

E {n}

If n is "1", the E command turns the output expand

on. If n is "0", the expand is turned off. If n is

absent, the expand status is returned.

H

The H command reads t he pre-ampli f i er stat us.

If a pre-am plifier is connect ed, a "1" is returned,

otherwise, a "0" is r et urned. The H command is a

read only command.

I {n}

If n is included, the I command sets t he remotelocal st atus. If n is absent, the remote-local stat us

is returned.

17

Page 22

n Status

0 Local: all front panel keys ar e oper ative

1 Remote: front panel keys ar e not

operative. The display up key re t urns the

status to local.

20 Quad Down

21 Select Display (f/ phase)

22 Sensitivity Up

23 Sensitivity Down

24 Dyn Res Up

25 Dyn Res Do wn

26 Display Up

27 Display Down

2 Lock-out: front panel keys are not

operative. No key retur ns the status to

local. Another I command is needed t o

return to loc a l.

When using the GPI B interface, the REN, LLO,

and GTL comm ands ar e not implement ed. The I

command is used by bot h interf aces to set the

remot e- local status.

J {n1,n2, n3, n4}

The J command sets the RS232 end-of-record

character s sent by the SR510 to those specif ied

by the ASCII codes n1- n4. If no argument is

included, t he end- of-r ec or d sequence r eturns to

the default ( a carriage return) , other wise, up to

four char acters may be specified. The end- ofrecord r equired by the SR510 when receiving

commands is not affected.

K n

The K command simulat es a front panel key

press. The effect is exactly the same as press ing

the selected key onc e. The paramet er n is

required.

nKey

1 Post Time Constant Up

2 Post Time Constant Down

3 Pre Time Constant Up

4 Pre Time Constant Down

5 Offset Up

6 Offset Down

7 Zero Phase (Simultaneous 90¡ Up and

Down)

8 Line Notch Filter

9 Bandpass Filter

10 Line X 2 Notch Filter

11 Relative (Auto Offset)

12 Offset (On/Off)

13 Expand

14 Local (Display Up when REMOTE)

15 Reference Trigger M ode

16 Reference Mode (f/2f)

17 Degrees Up

18 Degrees Down

19 Quad Up

L m {,n}

The L command set s and reads the status of the

line notch filters. If m is "1", then the 1X line

notch is selected, if m is "2", the 2X line notch is

selected. The par am et er m is required. If n is "1",

the L command sets the selected f ilter in. If n is

"0", the select ed filter is t aken out. If n is absent,

the status of the selected filter is ret urned.

M {n}

If n is "1", the M command sets the reference

mode to 2f. If n is "0", the reference mode is set

to f. If n is absent, the reference mode is returned.

N {m}

If m is "1", the N command sets the ENBW to 10

Hz. If m is "0", the ENBW is set to 1 Hz. If m is

absent, the ENBW setting is retur ned.

O {n} {,v}

If n is "1", the O command turns the offset on. If n

is "0", the offset is tur ned off. If n is absent, the

offset st at us (on or off) is returned. (The value of

the off s et is read using the S and Q commands.)

If n is included, then v may also be sent. v is the

offset value up to plus or minus full scale in units

of volts. For example, to offset half of full scale on

the 100 µV sensitivity, v should be "50. 0E-6" or an

equivalent value. However, if the sensitivit y is

then changed to 200 µV, the off s et is now half of

the new full scale or 100 µV. When the sensitivity

is changed, the offset is retained as a const ant

fract ion of full scale rat her than as a voltage

refer r ed to the input. The expand funct ion will, o n

the other hand, preser v e the value of the offset as

an input refer r ed voltage. Once a value of v is

sent, the of f set may be turned off and on without

losing the offset value by using the O command

without the v par am eter. Note that if the auto

offset is on, an "O 1" command will t u rn the au to

offset of f and tur n the manual offset on without

changing the actual offset value.

P {v}

If v is absent, the P command returns the phase

setting f r om -180 to +180 degrees. When v is

included, t he phase is set to the value of v up to

±999 degrees.

18

Page 23

Q

The Q comm and retur ns the output reading in

units of volts . For an input signal of 50 µV on a full

scale sensitivity of 100 µV, the Q com m a n d will

retur n the string "50.00E-6". The parameter read

is the same as that being shown on the output

display and can be changed with the S command.

R {n}

If n is included, the R command s ets the reference

input t ri gger m ode. If n is absent, the trigger

mode is retur ned.

n Mode

0 Positive

1 Symmetric

2 Negative

S {n}

If n is included, the S comm and select s the

paramet er shown on the analog meter and output

digital display as well as the out put BNC. If n is

absent, the paramet er being displayed is returned.

n Display

0X

1 Offset

2Noise

T m {,n}

The T command sets and reads the stat us of the

tim e const a nt s. If m is "1", the pre time constant

is selected, if m is "2", the post time constant is

selected. The par am et er m is required. If n is

included, t he T c ommand set s the select ed time

constant . If n is absent, the setting of the selected

time const ant is retur ned.

n Pre Time Constant ( m=1)

11mS

23mS

310mS

430mS

5 100mS

6 300mS

71S

83S

910S

10 30 S

11 100S

n Post Time Constant ( m=2)

0 none

1 0.1 S

21 S

U m {,n}

The U command set s and reads the unit's ROM

calibration bytes. m is the address offset of the

byte, 0- 255. If n is absent, the value of the

addressed calibration byt e is r et ur ned. If n is

included, t he addr ess ed calibrat ion byt e is set to

the value of n, 0-255. The new value will be in

effect unt il the power is t urned off or a reset

command is issued. Use of this command is not

recommended.

V {n}

If n is included, the V comm and sets the GPIB

SRQ (s er vice r equest ) mask to t he value n. If n is

absent, the value of the SRQ mask is returned.

W {n}

The W command s et s and reads the RS232

character wait interval. If n is included, the SR510

will wait n*4 mS between charact er s sent over the

RS232 interface. This allows slow comput er

interfac es t o keep up. n can range from 0 to 255.

If n is absent, the wait value is ret urned. The wait

interval is set t o 6 on power-up.

X n {, v}

n designates one of t he 6 general purpose analog

ports locat ed on t he rear panel. If n is 1,2,3, or 4,

the X comm and will r e turn the v o ltage on the

designated analog input por t (X1-X4) in volts. If n

is 5 or 6, then v may also be sent. If v is included,

the designated analog output por t (X5 or X6) will

be set to v volts where v has the range -10.24V to

+10.24V. If v is absent, the output value of the

selected port is retur ned. On power-up, port X5 is

the rat io out put. An "X 5" command will read the

ratio output. An "X 5" command with the

par ameter v will set port X5 to v v o lts, overrid in g

the r a tio outp ut. Port X5 will retur n to the ratio

output on power- up or reset.

Y {n}

The Y command reads the status byte. (See

below for a definition of t he Status Byt e.) n

designates one bit, 0- 7, of the status byt e. If n is

included, t he designat ed bit of t he status byte is

retur ned. The bit which is read is then reset. If n

is absent, t he value of the entire byt e is returned

and all status bits ar e then reset. This status byte

may also be read over the GPIB using the ser ial

poll command.

Z

The Z command caus es an int er nal reset. All

settings r et ur n to their default values. The ERR

19

Page 24

LED will be on for about 2 seconds to indicate that

the stor ed instrum ent set t ings are being ignored.

If the RS232 echo mode is on, the sign-on

message is sent over the RS232 interf ace.

Status Byte

Overload. This bit is set if there is a signal

overload. This can happen when the sensit ivity is

too high, t he dynam ic reserve is too low, the offset

is on, or the expand is on. Overloads on the

general purpose A/D inputs or t he ratio out put are

not detected.

The SR510 maintains an 8-bit st at us r egist er

which the user may r ead to obtain informat ion on

the unit's s t atus. The status byt e may be read in

two ways: by sending the Y command, which

retur ns the value of the byte in ASCII coded

decimal, or, when using the G PIB, by perfor m ing a

serial poll. The retur ned st atus byt e reflect s all of

the status conditions which have occurred since

the last t ime the byte was read. After the status

byte has been read, it is cleared. Thus, the status

byte should be read initially to clear all previous

conditions (especia lly aft er a power up or after

settings have been changed) .

The definitions for each bit of t he status byte are

given below:

Bit 0

Busy. When this bit is set, it indicates the SR510

has unprocessed com m ands pending on its

command queue. For RS232 communicat ions,

this bit is always high since the Y command its elf

will be an unprocessed comm and. This bit is not

reset when read but only when ther e ar e no

pending commands. Since the SR510 buff er s

incoming commands, it is not necessary to read

this bit befor e sending each com m and.

Commands received while t he SR510 is executing

a previous comm and ar e stored unt il all previously

received comm ands have been ex ecut ed.

Bit 5

Auto Offset Out of Range. This bit is set if the

auto off s et function cannot zer o the out put

because the out put exceeded 1.024X f ull scale.

Bit 6

SRQ. This bit is high if the SR510 has generated

an SRQ on the GPIB interface. This bit is reset

after the SR510 has been serial polled. This bit is

set only for stat us reads via a serial poll, ie., Bit 6

always zero for t he RS232.

Bit 7

Command Error. This bit is set when an ill egal

command st r ing is received.

Errors

Whenever a 'par am et er out of range' or an

'unrecognized comm and' er r or occur s, the

appropriate status bits are set and the ERR LED

flashes. I n addition, any com m ands remaining on

the curr ent comm and line (up to the next <cr>) are

lost. The ERR LED will also light if any of the

internal comm unicat ion buffers overflows. This

occurs when 240 charact ers are pending on the

command queue or out put queue. The ERR LED

will go off as soon as all buffers drop below 200

character s again.

Bit 1

Command Parameter Out of Range. This bit is

set if a paramet er associated with a com m and is

not in the allowed range.

Bit 2

No Refe rence. This bit is set when no reference

input is detected, either because the amplitude is

too low or the frequency is out of range.

Bit 3

Unlock. This bit is set when the reference

oscillator is not locked t o the referenc e input. If

there is no referenc e input, bit 2 (no ref erence) will

be set but bit 3 (unlock) may not be.

Bit 4

Reset

The Z command r esets the unit to its default state.

The default f r ont panel sett ings are list ed in the

DEFAULTS section of t he Guide to Operations.

In addition, t he int erface status returns to LOCAL,

the SRQ mask is clear ed, the RS232 charact er

WAIT interval is set to 6, and the terminat ing

sequence is reset t o the proper def aults.

The command and out put buffers are cleared by

the Z comm and. Therefore, it is bad pr actice to

use the Z command before all previous commands

have been processed and all responses have

been received.

20

Page 25

Troubl e-Shooting Interface

Problems

If you are having difficult y get t ing your comput er to

communicat e with t he SR510 look to t he sections

on the RS232 and GPIB inter f aces for some tips

specific to your particular inter f ac e.

An ASCII term inal is a valuable aid for debugging

interfac e pr oblems. You can use it to:

1) bec o m e familiar with the SR510's com m and

structure,

seen Microsof t ' s Interpreted Basic on the IBM

PC occasionally send a curly bracket ( ASCII

253) when it was supposed to have sent a

carriage ret ur n (ASCII 13) .

2) Your computer's baud rate has been changed

and no longer matches t he SR510's baud rate.

3) The initial com m and sent to t he SR510 was

invalid due to a garbage char ac t er left in the

command queue f r om power-up, or, the first

character in you com puter' s UART is garbage,

also due to power-up. It is good practice to

send a few carr iage returns to t he SR510

when your program begins, and have y our

program clear- out its UART at the start of your

program.

2) see GPI B bus transact ions by us ing the GPIB

echo mode,

3) eavesdrop on t r ans act ions when using the

RS232 interface,

4) substit ut e a hum an for the SR510 by using a

null modem cable ( to make the DTE a DCE )

and attaching t he term inal to the port to which

you would normally have connected t he

SR510. This allows you to tes t your program ' s

responses t o inputs which you pr ovide fr om

the terminal.

Common Hardware Problems include:

1) The RS232 or GPIB cables ar e not properly

attached.

2) The configuration switches for the RS232

character ist ics or GPIB addres s ar e not set

correct ly (Make sur e the RS232 echo is off

when using the RS232 interface with a

computer . The GPI B with RS232 echo mode

should be off when not debugging t he G PI B

interface.)

3) Your computer requires an RS232 control line

to be asserted, but your cable does not pass it

between the SR510 and the com put er, or,

your comput er is not ass erting the DTR line on

the RS232.

Commo n Software Problems incl ud e:

1) You have sent t he wrong c ommand t o ask for

data fr om the SR510. Your progr am will wait

forever for a response which is not going to

come. This m ay not be your fault; we have

4) The SR510 is not sending the corr ec t ' end- ofrecord' marker for your computer. For

example, it appear s t hat M icrosoft 's Rev 3.2

FORTRAN on the I BM PC under DOS 2.1

requires two car r iage returns for an end-ofrecord m ar ker. The J command can be used

to set the SR510 end-of- r ec ord mar ker to 2

carriage ret ur ns . [The end-of-recor d m arker is

that sequenc e which indicates that the

response is complet e. Fr om the keyboard, a

single carriage retur n is t he end- of-r ec or d

marker.]

5) Answers are com ing back f r om the SR510 too

fast, over writing t he end- of-r ecor d mark er s,

and causing the comput er to hang waiting for

a complete res ponse. In this case, the W

command can be used to slow down the

response tim e of the SR510 prevent ing

overwriting.

6) Answers are com ing back f r om the SR510 too

slowly due to the W6 default setting f or the

character int er val t ime. Use the W command

to speed up the trans m ission from the SR510.

This can cause problems f or the GPI B

interfac e if the echo mode is on (switch 6 of

SW21).

Th e S R510 with t he RS232 Int erf ace

The RS232 is a popular serial interf ac e st andar d

for bit s erial communication. Despite t he

existence of t he standar d t here are many

permut at ions of contr ol lines, baud r at es, and data

form at s. If you do not have a lot of experience

interfac ing RS232 equipment you should read

Appendix B for a description of the RS232 and

interfac ing tips.

21

Page 26

Data Communications Equipment

(DCE)

The SR510 is configured as DCE so that it may be

connected direct ly t o a term inal. If the SR510 is to

be interfac ed with anot her DCE device, a special

cable (somet imes r eferred to as a 'modem' cable)

is required. To use the RS232 interf ace you m ust

set the s witches in SW2 to match your computer ' s

baud rate, par it y, and number of stop bits. Refer

to Page 7 for details.

Wait Command

The SR510 normally waits unt il the RS232 'Clear

to Send' cont r ol line (CTS) is assert ed bef ore

sending character s. However, some comput er s

do not set and reset the CTS line, possibly

causing the SR510 to send data when t he

computer is not ready to read it. The SR510 may

be 'slowed down' using the W comm and. Sending

'Wn' causes t he unit to wait nX4 mS before

sending each character ov er the RS232 bus. The

command W0 s et s the wait inter val to zero and

results in the fastest tr ansm ission. The wait

interval is set t o 6 (24 mS) on power-up.

Termination Sequences

The default RS232 termination characters ar e

sufficient to interface with most computers,

howev er, it will o c c as ionally be nec e s s a r y to send

special terminating sequences t o f it t he

requirement s of some computers. This can be

done with the J comm and. The format for the

command is:

J {n1,n2, n3,n4}

where n1, n2, n3, and n4 are decimal values

between 0 and 255 corres ponding to t he dec imal

ASCII codes of t he desired termination char act ers.

For instance, if the desired terminat ion sequence

is an asterisk, (ASCII 42), t wo carriage ret ur ns,

(ASCII 13), and a line feed, (ASCII 10) , the

appropriate com m and is:

J 42,13,13,10

Up to four terminating charac t er s may be specified

by the J command. If no arguments are sent with

the J command, the t erminating sequence r et ur ns

to the default ( echo on: <cr>< lf>; ec ho off: <cr>).

The J command does not affect the t erminating

character (<cr >) required at t he end of commands

received by the SR510. It also does not affect the

term inating sequence sent with data over the

GPIB interface.

The SR51 0 with the GP IB

Interface

For a brief introduct ion t o the GPI B standard,

please read Appendix C at the back of this

manual. Befor e using t he GPIB interface you

must set t he switches in SW1 per the instruct ions

on page 7.

GPIB Capabilities

The GPIB capabilit ie s o f the SR510 consist ent

with IEEE standard 488 ( 1978) ar e shown in the

table below. Also shown are the responses of the

SR510 to some standar d c ommands.

Code Function

SH1 Sour ce handshake c apabi lity

AH1 Accept or hands hake capabil it y

T5 Basic Talker, Serial Po ll, Unaddress ed t o

talk if addressed to listen

L4 Basic Listener , Unaddressed to listen if

addressed to talk

SR1 Ser vice reques t capability

PP0 No parallel poll capabil ity

DC1 Device Clear capability

RL0 REN,LLO, GTL not im plement ed.

'I' command sets Remote-Loc al.

SR510 Response to GPIB Commands

Mnemonic Command Response

DCL Device Clear Same as Z com m and

SDC Selected Same as Z com m and

Device Clear

SPE Ser ial Poll Send St at us Byt e,

Enable & clear status byte

If a G command is sent requiring an answer of 24

(sensitivity = 500 m V), the SR510 would respond

with the str ing

24*<cr><cr><lf>

Because the SR510 can be controlled by an

RS232 interface as well as the GPI B, the remotelocal functions are not standard. There is no local

with lock out stat e. When in the local state,

remot e commands ar e processed, even without

the REN command being issued. This is because

22

Page 27

the RS232 interfac e has no pr ovision for bus

commands and r em ote com m ands over the

RS232 interface would never be enabled.

Serial Poll s and Service Requests

The status byt e sent by the SR510 when it is serial

polled is the same stat us byte which is read using

the Y comm and (except for bit 6, SRQ). Of

course, when t he SR510 is serial polled, it does

not encode the stat us byte as a decimal num ber.

The SR510 can be programm ed t o gener ate a

service request ( SRQ) to the G PIB controller ever y

time a given status condition occurs. This is done

using the V{n} com m and. The mask byte, n (0-

255), is t he SRQ mask byte. The mask byte is

always logically anded with the st atus byte. If the

result is non-zer o, the SR510 generates an SRQ

and leaves the stat us byte unchanged until the

controller per f or m s a serial poll to determine the

cause of t he service request . When the unit has

been serial polled, t he st atus byt e is reset to

reflect all of the status conditions which have

occurred since t he SRQ was gener at ed.

For example, if we want to generat e an SRQ

whenever there is an over load or unlock condition,

we need an SRQ mask byte equal to 00011000

binary, or 24 dec imal ("V24" com m and). The byte

00011000 binary corres ponds t o the status byte

with the 'no referenc e' and ' unlock' stat us bit s set.

If an overload occurs, then an SRQ will be

generated. The ser ial poll will return a stat us byte

showing SRQ and overload. If an unlock condition

occurs bef or e the serial poll is concluded, another

SRQ will be generated as soon as t he serial poll is

finished. A second serial poll will reflect t he unlock

condition.

GPIB with RS232 E cho Mode