Page 1

Operation and Service Manual

Stanford Research Systems

Analog PID Controller

SIM960

Revision 2.3 • October 10, 2013

Page 2

Certification

Stanford Research Systems certifies that this product met its published specifications at the time

of shipment.

Warranty

This Stanford Research Systems product is warranted against defects in materials and workmanship for a period of one (1) year from the date of shipment.

Service

For warranty service or repair, this product must be returned to a Stanford Research Systems

authorized service facility. Contact Stanford Research Systems or an authorized representative

before returning this product for repair.

Information in this document is subject to change without notice.

Copyrightc Stanford Research Systems, Inc., 2003 – 2013. All rights reserved.

Stanford Research Systems, Inc.

1290–D Reamwood Avenue

Sunnyvale, CA 94089 USA

Phone: (408) 744-9040 • Fax: (408) 744-9049

www.thinkSRS.com • e-mail: info@thinkSRS.com

Printed in U.S.A. Document number 9-01558-903

SIM960 Analog PID Controller

Page 3

Contents

General Information iii

Safety and Precautions for Use . . . . . . . . . . . . . . . . iii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1 Getting Started 1 – 1

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.2 Front Panel Operation . . . . . . . . . . . . . . . . . . 1 – 2

1.3 Rear Panel Monitoring . . . . . . . . . . . . . . . . . . 1–7

1.4 SIM Interface . . . . . . . . . . . . . . . . . . . . . . . . 1 – 8

2 Advanced Topics 2 – 1

2.1 PID Tuning Basics . . . . . . . . . . . . . . . . . . . . . 2 – 2

2.2 Ziegler-Nichols’ Tuning . . . . . . . . . . . . . . . . . 2–5

2.3 Anti-Windup and Conditional Integration . . . . . . . 2–7

2.4 Bumpless Transfer . . . . . . . . . . . . . . . . . . . . . 2 – 8

3 Remote Operation 3 – 1

3.1 Index of Common Commands . . . . . . . . . . . . . . 3 – 2

3.2 Alphabetic List of Commands . . . . . . . . . . . . . . 3–4

3.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.5 Status Model . . . . . . . . . . . . . . . . . . . . . . . . 3–25

4 Performance Tests 4 – 1

4.1 Getting Ready . . . . . . . . . . . . . . . . . . . . . . . 4 – 2

4.2 Performance Tests . . . . . . . . . . . . . . . . . . . . . 4–2

4.3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 6

5 Circuitry 5 – 1

5.1 Circuit Descriptions . . . . . . . . . . . . . . . . . . . . 5 – 2

5.2 Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 4

5.3 Schematic Diagrams . . . . . . . . . . . . . . . . . . . 5 – 7

i

Page 4

ii Contents

SIM960 Analog PID Controller

Page 5

General Information

Safety and Precautions for Use

Because of the variety of uses for the SIM960, those responsible for

the application and use of this control equipment must satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

Service

WARNING

The SIM960 is not designed, intended, or sold for use in hazardous

environments requiring fail-safe operation, including without limitation, operation of nuclear facilities, aircraft or spacecraft control

systems, and life support or weapons systems. The user must assure

that any failure or misapplication of the SIM960 cannot lead to a consequential failure of any interconnected equipment that could lead

to loss of life or limb, or property damage.

The illustrations, charts, and discussions shown in this manual are

intended solely for purposes of example. Since there are many variables and requirements associated with any particular control application, Stanford Research Systems does not assume responsibility

or liability for actual use based upon the examples shown in this

publication.

Do not install substitute parts or perform any unauthorized modifications to this instrument.

The SIM960 is a double-wide module designed to be used inside the

SIM900 Mainframe. Do not turn on the power to the Mainframe or

apply voltage inputs to the module until the module is completely

inserted into the mainframe and locked in place. Do not exceed

±18 V at any input or output connector.

iii

Page 6

iv General Information

Symbol Description

Alternating current

Caution - risk of electric shock

Frame or chassis terminal

Caution - refer to accompanying documents

Earth (ground) terminal

Battery

Fuse

On (supply)

Off (supply)

Symbols you may Find on SRS Products

SIM960 Analog PID Controller

Page 7

General Information v

Notation

The following notation will be used throughout this manual.

WARNING

CAUTION

A warning means that injury or death is possible if the instructions

are not obeyed.

A caution means that damage to the instrument or other equipment

is possible.

Typesetting conventions used in this manual are:

• Front-panel buttons are set as [Button];

[Adjust ] is shorthand for “[Adjust ] & [Adjust ]”.

• Front-panel indicators are set as Overload.

• Remote command names are set as *IDN?.

• Literal text other than command names is set as OFF.

Remote command examples will all be set in monospaced font. In

these examples, data sent by the host computer to the SIM960 are set

as straight teletype font, while responses received by the host

computer from the SIM960 are set as slanted teletype font.

SIM960 Analog PID Controller

Page 8

vi General Information

Specifications

Performance Characteristics

Min Typ Max Units

Amplifier Settings Control type Analog, PID+Offset

Input Range −10 +10 V common mode

−1 +1 V differential

Proportional gain 10

Integral gain 10

eff. time const. 2 ×10

Derivative gain 10

−1

−2

−6

−6

Offset −10 +10 V

resolution 1 mV

Amplifier Performance Bandwidth 100 kHz

Propagation delay 1 µs

Noise (f > 20 Hz) 8 nV/√Hz, RTI

Output Range −10 +10 V

Configuration Parameter control Digital

Parameter accuracy 1 %

Stability 200 ppm/◦C

Display Resolution 4 digits

3

10

V/V

5 ×1051/s

2

10

s

10 s

Inputs Measure BNC, 1 MΩ, ±10 V range

Setpoint Generator Setting −10 +10 V

Operating Temperature [14] 0 40

General Characteristics

Ext. Setpoint BNC, 1 MΩ, ±10 V range

resolution 1 mV

Ramp Rate 10

−3

10

4

V/s

Noise (f > 100 Hz) 20 nV/√Hz, RTI

◦

C

Power ±15, +5 V DC

Supply current 150 (±15 V), 80 (+5 V) mA

Number of inputs 2

Interface Serial (RS-232) through SIM interface

Connectors BNC (3 front, 2 rear); DB–15 (male) SIM interface

Weight 2.1 lbs

Dimensions 3.000W ×3.600H ×7.000D

SIM960 Analog PID Controller

Page 9

1 Getting Started

In This Chapter

This chapter gives you the necessary information to get started

quickly with your SIM960 Analog PID Controller.

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 – 2

1.2 Front Panel Operation . . . . . . . . . . . . . . . . . . 1 – 2

1.2.1 Inputs . . . . . . . . . . . . . . . . . . . . . . . 1 – 4

1.2.2 Ramping . . . . . . . . . . . . . . . . . . . . . . 1 – 5

1.2.3 Connections . . . . . . . . . . . . . . . . . . . . 1 – 5

1.2.4 Bar displays . . . . . . . . . . . . . . . . . . . . 1 – 6

1.2.5 Restoring the default configuration . . . . . . 1 – 6

1.3 Rear Panel Monitoring . . . . . . . . . . . . . . . . . . 1 – 7

1.3.1 Error Monitor . . . . . . . . . . . . . . . . . . . 1 – 7

1.3.2 Input Setpoint Monitor . . . . . . . . . . . . . 1 – 7

1.4 SIM Interface . . . . . . . . . . . . . . . . . . . . . . . 1 – 8

1.4.1 SIM interface connector . . . . . . . . . . . . . 1–8

1.4.2 Direct interfacing . . . . . . . . . . . . . . . . . 1 – 8

1 – 1

Page 10

1 – 2 Getting Started

1.1 General

The SIM960 is designed to maintain stability in systems requiring

low noise and wide bandwidth. The controller design consists of

a front end differential input amplifier, followed by an integrator

and a differentiator, arranged in what is known as the “ideal” PID

topology. The input amplifier (the “error amplifier”) differences the

the two single ended inputs, Setpoint and Measure , and multiplies

the resulting error signal (ε) by the proportional gain. The amplified

error is then passed to three parallel control paths:

1. The proportional path, no change is made to the signal.

2. The integral path with gain I.

3. The derivative path gain D.

These three signals can be independently selected to combine at a

summing amplifier, which is then buffered to the output. A constant

offset can also be added, which can be useful in applications that do

not use the I term. Mathematically, the behavior is

where the three terms within the braces, and Offset, can be independently enabled or zeroed.

For internal stability, the actual differentiator is “rolled off” to limit

the derivative gain to +40 dB.

The output circuitry includes a soft limiter that turns on when the

output exceeds user specified upper and lower limits and clamps the

output to the limit level. The output bar display on the right side of

the front panel has red LEDs at each end to indicate when the output

is being limited.

1.2 Front Panel Operation

This section discusses the essentials of operating the SIM960 locally,

from the front panel. See Chapter 3 for remote operation.

ε ≡ Setpoint − Measure (1.1)

)

Output = P ×(ε + IZε dt + D

• Press [Select] to choose which configuration parameter to view

in the numerical display. The indicator to the left of each

descriptor shows which parameter is displayed. When Shift

is highlighted, pressing [Select] steps the parameter selection

backwards.

dε

+ Offset (1.2)

dt

SIM960 Analog PID Controller

Page 11

1.2 Front Panel Operation 1 – 3

Figure 1.1: The SIM960 front panel.

• The P, I, D, Offset, and SP Ramp parameters may be enabled/disabled with [On/Off]. Each of these parameters has an

additional indicator to the right of the descriptor to indicate the

on/off status.

• The Limits parameter has two sublevels: upper and lower

limit.

• The Setpoint , Measure, P × ε, and Output values are displayonly. All the other values can be changed using the [ ] buttons; the digit selected for adjustment is indicated by its flashing brightness. Change the digit selection while Shift is highlighted ([ ]).

• There are two formats for the numeric display: Exponential,

and fixed decimal. The format used for a particular parameter depends on its range. Parameters P, I, D and SP Ramp

(rate) vary by several orders of magnitude and are therefore

displayed in exponential format, while all other parameters

range from −10 V to +10 V and are displayed in fixed decimal

format.

SIM960 Analog PID Controller

• For exponential format, themantissa may bechanged using the

up/down arrow buttons. The active digit maybe selected using

the left/right buttons (= shift, followed by up/down button).

Page 12

1 – 4 Getting Started

The right-most digit (after ) is the power of ten exponent.

For example, the display = 1200.

• The P parameter has a selectable “±” indicator before the

mantissa.This allows the polarity of the controller to be tog-Polarity =⇒

gled by the user. All other exponentially displayed parameters

are unipolar, so no sign is displayed for these parameters.

• In fixed decimal format a value between −10 and +10 may be

selected using [ ] (and [Shift]).

• The two outputs, P × ε, and Output , are accompanied by bar

displays on the right side of the front panel. P × ε simply

ranges from −10 V to +10 V. However, since the controller output ranges between the user-programmed upper and lower

limits, the output bar display is normalized to that range. For

example, if the limits were set to +5 V and −1 V, the full range

of the bar display would be 6 V, and 0 V would no longer correspond to the center of the bar display, but would be1/6th of

the way up from the bottom. The default limits are ±10 V.

1.2.1 Inputs

• Use [Setpoint] in the INPUTS section of the front panel to

choose between an external setpoint input, and the internally

generated setpoint. An external setpoint can be supplied at the

Setpoint BNC input. When the internal setpoint is selected the

BNC connector is disconnected from the SIM960 circuitry.

• The Output BNC connector can be toggled between PID Control mode and Manual mode using [Output] (in the OUTPUT

section of the front panel). In manual mode, the SIM960 output

is set to the value indicated by the manual parameter.

The common mode range of the “Measure” and “Setpoint” inputs

extends from −10V to +10V. If either input is outside this range, the

overload LED indicator lights.

The differential input rangeis ±1 V. Whenever thedifference between

Setpoint and Measure exceeds this range, the overload LED indicator turns on. When connected with overall negative feedback and

reasonably well tuned, the SIM960 keeps the difference between the

setpoint and measure inputs as small as possible, so the differential

input range is unlikely to be exceeded. Before the SIM960 has been

tuned for a given system, however, this may not be true. It is helpful

to keep in mind that exceeding the ±1 V differential input range will

saturate the error amplifier, even if theoutput signalwouldotherwise

be within the upper and lower Limits setting. In such situations, the

controller will be effectively limited at some intermediate value.

SIM960 Analog PID Controller

Page 13

1.2 Front Panel Operation 1 – 5

1.2.2 Ramping

The ramping feature of the SIM960 PID Controller allows the user to

linearly slew the internally generated setpoint level from its current

value to a new value. The slew rate may be changed using the

SP Ramp parameter on the front panel.

The indicator to the right of SP Ramp shows whether ramping is enabled or disabled. Use [On/Off] (with SP Ramp selected) to enable/disable ramping. When disabled, changes to

the Internal Setpoint parameter take effect immediately. When

ramping is enabled, however, changes to Internal Setpoint do not

immediately take effect. Instead, Internal (in the Setpoint block of

the INPUTS section of the front panel) begins to blink, showing that

a new setpoint has been entered and a ramp event is now pending.

To begin the ramp, press [Ramp Start/Stop]. Now, the Internal blink

rate doubles, indicating that the setpoint is ramping. To pause the

ramp, press [Ramp Start/Stop]˙When the ramp is paused, the In-

ternal blink rate becomes uneven. To continue the ramp, press

[Ramp Start/Stop] again. When the setpoint reaches the new programmed value, the ramp automatically terminates, and Internal

stops blinking.

1.2.3 Connections

Note, SP Ramp has no sign in the numerical display. This is because the polarity of the ramp rate is unambiguously determined

by whether the newly entered setpoint is greater or less than the

current setpoint. The range of available ramp rates is from 1mV/s

to 10,000V/s. For ramp rates less than or equal to 1 V/s, the rate

is dynamically trimmed based on real-time measurements from the

onboard A-to-D converter.

Connect the sensor output of the system to be controlled to the “Measure”input of the SIM960˙If an external setpoint isto be supplied, connect this to the “Setpoint” input, and use the button in the INPUTS

section of the front panel to select “External” input. Before connecting the SIM960 output to the system to control, it may be necessary to

set the user programmable output upper and lower Limits to guard

against damaging the system. Care should be taken to insure that

the programmed output range is consistent with the system input

range. Once the limits have been programmed, connect the SIM960

output to the system input.

SIM960 Analog PID Controller

Page 14

1 – 6 Getting Started

1.2.4 Bar displays

Two LED bar displays have been included on the right side of the

SIM960 front panel to provide visual information about the P × ε

and Output signals. This reduces the need to frequently return to

those fields on the numerical display while trying to adjust other

tuning parameters. Some time should be taken to understand what

information these bar displays provide.

Each bar has two lighted LEDs; one for the maximum peak of the

signal, and one for the minimum peak. The peaks are determined

with respect to time variation of the signal, and they decay back to

the DC level with a decay time of ∼100 ms.

To understand how a signal is represented in the bar display, consider an input sine wave of frequency 1 Hz. Since frequency is low

compared to the inverse of the decay time, the maximum and minimum peak values are indistinguishable, and the signal appears as

a single LED that tracks the sine wave. As the frequency increases,

the maximum peak does not decay quickly enough to track the negative excursions the signal, and the minimum peak also fails to track

positive excursions. So there appear to be two lighted LEDs slightly

separated, roughly tracking the sine wave. As the frequency is further increased to well above the decay time inverse, the two lighted

LEDs no longer decay at all from their peak levels, so there appear

to be two lighted LEDs marking the maximum and minimum peaks

of the sine wave.

Thus, a slowly varying signal appears as a single lighted LED in the

display, tracking the signal changes with time. But a quickly varying

signal, however, appears as two lighted LEDs marking themaximum

and minimum excursions of the signal in time.

The range of the P × ε bar display is ±10 V. The Output bar display

has a range determined by the user programmed upper and lower

limits. For example, if the limits were set to +5 V and −1 V, the full

range of the bar display would be 6 V, and 0 V would no longer

correspond to the center of the bar display, but would be1/6th of the

way up fromthe bottom. Also, the Output bar display has a red LED

on each end to indicate whether the controller output is saturated at

its limit.

1.2.5 Restoring the default configuration

The default configuration of the SIM960 can be restored in either of

two ways: From the front panel, or via the remote interface.

To restore from the front panel, first turn off the power to the SIM960

by switching its SIM900 Mainframe to “Standby,” then switch the

SIM960 Analog PID Controller

Page 15

1.3 Rear Panel Monitoring 1 – 7

power on while holding down [Ramp Start/Stop]. Keep the button

depressed for about one second after power comes on.

The default configuration can also be restored via the remote interface

using the *RST command.

1.3 Rear Panel Monitoring

Two analog monitor signals are available at the rear panel of the

SIM960 (see Figure 1.2).

1.3.1 Error Monitor

The upper BNC connector carries a buffered copy of the P × ε output

of the error amplifier. This output is always available, even when

the P term is disabled from the control law. It is also active when the

main SIM960 output is set to Manual mode.

1.3.2 Input Setpoint Monitor

The lower BNC is a copy of the internally generated setpoint voltage.

This output is also always available, even when the Setpoint mode

is set to External.

SIM960 Analog PID Controller

Figure 1.2: The SIM960 rear panel.

Page 16

1 – 8 Getting Started

1.4 SIM Interface

The primary connection to the SIM960 Analog PID Controller is the

rear-panel DB–15 SIM interface connector. Typically, the SIM960 is

mated to a SIM900 Mainframe via this connection, either through

one of the internal mainframe slots, or the remote cable interface.

It is also possible to operate the SIM960 directly, without using the

SIM900 Mainframe. This section provides details on the interface.

CAUTION

The SIM960 has no internal protection against reverse polarity, missing

supply, or overvoltage on the power supply pins. Misapplication of power

may cause circuit damage. SRS recommends using the SIM960 together

with the SIM900 Mainframe for most applications.

1.4.1 SIM interface connector

The DB–15 SIM interface connector carries allthe power and communications lines to the instrument. The connector signals are specified

in Table 1.1

Pin Signal Src ⇒ Dest Description

1 SIGNAL GND MF ⇒SIM Ground reference for signal

2 −STATUS SIM ⇒ MF Status/service request (GND = asserted, +5 V= idle)

3 RTS MF ⇒ SIM HW Handshake (+5V= talk; GND = stop)

4 CTS SIM ⇒MF HW Handshake (+5 V= talk; GND= stop)

5 −REF 10MHZ MF ⇒ SIM 10 MHz reference (optional connection)

6 −5 V MF ⇒ SIM Power supply (no connection in SIM960)

7 −15 V MF ⇒ SIM Power supply (analog circuitry)

8 PS RTN MF ⇒ SIM Power supply return

9 CHASSIS GND Chassis ground

10 TXD MF ⇒ SIM Async data (start bit = “0”= +5V; “1” = GND)

11 RXD SIM ⇒ MF Async data (start bit = “0”= +5 V; “1” = GND)

12 +REF 10MHz MF ⇒ SIM 10MHz reference (optional connection)

13 +5 V MF ⇒ SIM Power supply (digital circuitry)

14

+15 V MF ⇒ SIM Power supply (analog circuitry)

15 +24 V MF ⇒ SIM Power supply (no connection in SIM960)

Direction

1.4.2 Direct interfacing

Table 1.1: SIM Interface Connector Pin Assignments, DB-15

The SIM960 is intended for operation in the SIM900 Mainframe, but

users may wish to directly interface the module to their own systems

without the use of additional hardware.

SIM960 Analog PID Controller

Page 17

1.4 SIM Interface 1 – 9

The mating connector needed is a standard DB–15 receptacle, such as

Amp part # 747909-2 (or equivalent). Clean, well-regulated supply

voltages of +5,±15VDC must be provided, following the pin-out

specified in Table 1.1. Ground must be provided on Pins 1 and 8,

with chassis ground on Pin 9. The −STATUS signal maybemonitored

on Pin 2 for a low-going TTL-compatible output indicating a status

message.

1.4.2.1 Direct interface cabling

If the user intends to directly wire the SIM960 independent of the

SIM900 Mainframe, communication is usually possible by directly

connecting the appropriate interface lines from the SIM960 DB–15

plug to the RS-232 serial port of a personal computer.1Connect RXD

from the SIM960 directly to RD on the PC, TXD directly to TD, and

similarly RTS→RTS and CTS→CTS. In other words, a null-modem

style cable is not needed.

To interface directly to the DB–9 male (DTE) RS-232 port typically

found on contemporary personal computers, a cable must be made

with a female DB–15 socket to mate with the SIM960, and a female

DB–9 socket to mate with the PC’s serial port. Separate leads from

the DB–15 need to go to the power supply, makingwhat is sometimes

know as a “hydra” cable. The pin-connections are given in Table 1.2.

DB–15/F to SIM960 Name

DB–9/F

3 ←→ 7 RTS

4 ←→ 8 CTS

10 ←→ 3 TxD

11 ←→ 2 RxD

5 Computer Ground

to P/S

7 ←→ −15 VDC

14 ←→ +15 VDC

13 ←→ +5 VDC

8,9 ←→ Ground (P/S return current)

1 ←→ Signal Ground (separate wire to Ground)

Table 1.2: SIM960 Direct Interface Cable Pin Assignments

1

Although the serial interface lines on the DB-15 do not satisfy the minimum

voltage levels of the RS-232 standard, they are typically compatible with desktop

personal computers

SIM960 Analog PID Controller

Page 18

1 – 10 Getting Started

1.4.2.2 Serial settings

The initial serial port settings at power-on are: 9600 Baud, 8–bits, no

parity, 1 stop bit, and RTS/CTS flow control. These may be changed

with the BAUD, FLOW, or PARI commands.

The maximum standard baud rate that the SIM960 supports is 38400.

The minimum baud rate is 110. Above 38400, the SIM960 can be

set to the following (non-RS–232-standard) baud rates: 62500, 78125,

104167, 156250. Note that these rates are typically not accessible on

a standard PC RS–232 port, but can be used between the SIM960 and

the SIM900 Mainframe.

SIM960 Analog PID Controller

Page 19

2 Advanced Topics

In This Chapter

This chapter discusses a simple “closed-loop” tuning procedure,

along with some of the advanced features of the SIM960 Analog

PID Controller.

2.1 PID Tuning Basics . . . . . . . . . . . . . . . . . . . . 2 – 2

2.2 Ziegler-Nichols’ Tuning . . . . . . . . . . . . . . . . . 2 – 5

2.2.1 Open-loop tuning . . . . . . . . . . . . . . . . . 2 – 5

2.2.2 Closed-loop tuning . . . . . . . . . . . . . . . . 2–6

2.3 Anti-Windup and Conditional Integration . . . . . . 2 – 7

2.4 Bumpless Transfer . . . . . . . . . . . . . . . . . . . . 2 – 8

2.4.1 Manual-to-PID . . . . . . . . . . . . . . . . . . 2 – 8

2.4.2 PID-to-Manual . . . . . . . . . . . . . . . . . . 2 – 8

2 – 1

Page 20

2 – 2 Advanced Topics

2.1 PID Tuning Basics

PID control provides a simple way to minimize the effect of disturbances to a system. The system consists of a closed feedback

loop between two elements, the SIM960 controller and the user pro-

cess. The controller has two inputs, Setpoint and Measure , and an

Output. The process consists of a power source that can be directly

changed by the controller, in conjunction witha sensor to monitor the

process behavior. The sensor signal, after any necessary conditioning, is the process output. This should be connected to the Measure

input of the SIM960, and the SIM960 Output should be connected to

the process input, forming a feedback loop.

The difference between the Setpoint and Measure inputs is the error

signal, ε ≡ Setpoint − Measure (Eqn 1.1). In the SIM960 the error

signal is amplified by the proportional gain. The controller uses the

amplified error, P × ε, to generate three control signals:

1. Proportional, the P amplified error with no changes.

2. Integral, the time integral of the amplified error signal multiplied by a gain coefficient I.

3. Derivative, the time derivative of the amplified error signal

multiplied by a gain coefficient D.

These signals, as well as an Offset, are combined at a summing

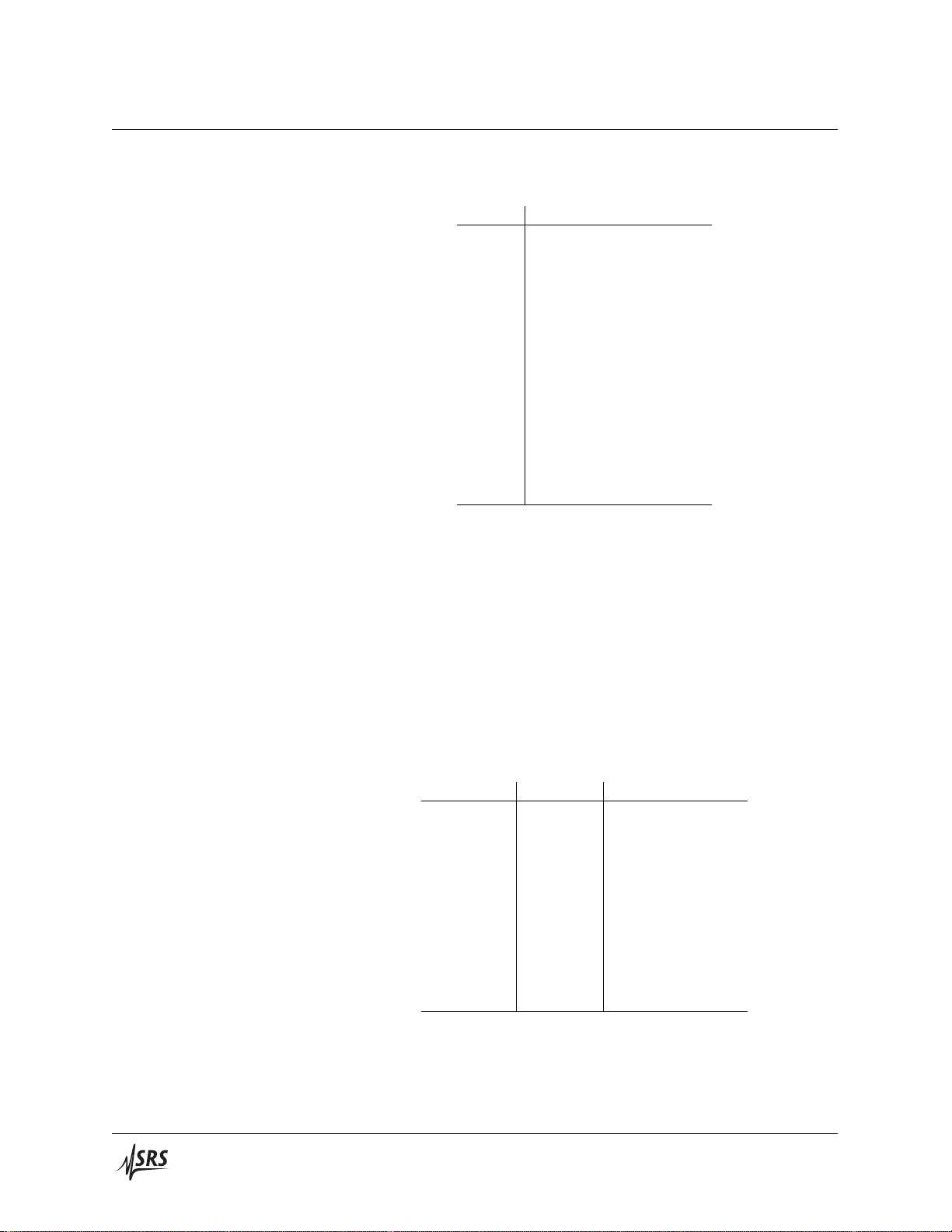

junction to produce the controller output (see Eqn 1.2). Figure 2.1

shows a schematic representation of the SIM960 controller topology.

Note the proportional gain coefficient is commontoall three terms, so

the net integral and derivative gains are P ×I and P ×D, respectively,

whether or not proportional control is enabled.

The controller monitors the process output and makes small adjustments to the process in order to minimize deviations of Measure

from Setpoint due to external disturbances. To accomplish this, the

controller must be properly tuned, meaning that the gains for each

of the three control signals—proportional, integral, and derivative—

must be chosen appropriately to match the behavior of the process.

A well-tuned controller should be able to maintain a stable process

output.

The control loop feedback should be negative. However, because

the polarity of the process response to the controller output is an

arbitrary function of the design of the system, it is vital that the

controller polarity be chosen properly. Based on the topology of the

SIM960 design, feedback polarity can be changed simplybychanging

the polarity of the proportional gain parameter P. The user must

first determine which polarity will provide negative feedback. If the

SIM960 Analog PID Controller

Page 21

2.1 PID Tuning Basics 2 – 3

Manual

Control

Output

P

ε

×

P

ε

×

+

−

× 1

D

I

Offset

Control

Σ

Internal

Setpoint/Ramp

Generator

SP

M

Monitor Output

(rear panel BNC)

P

External

Setpoint

Input

Measure

Input

ε

= SP − M

*

Output**

Selector

* Antiwindup circuitry (see text)

** Bumpless transfer when I is enabled

Output Buffer w/User

Controlled Limits

SIM960 Analog PID Controller

Figure 2.1: The SIM960 block diagram.

processisnoninverting, i.e. a small positive change at its input results

in a positive change at its output, then using positive P polarity will

ensure negative feedback in the loop. Tosee this, follow the effect of a

small positive change at the process output. Since the process output

is connected to the Measure input of the SIM960, a small positive

change would cause a negative change to ε. The resulting change at

the controller Outputwould also be negative, as would be that of the

process output. Thus, the initial small positive change at the process

output is “corrected” by a negative change after going around the

feedback loop. As a general rule, if the process is noninverting, then

the P-polarity should be positive. If the process is inverting, negative

P-polarity should be used.

Care should be taken in designing the process. The sensor should be

situated so that it is responsive to changes to the part of the system

under control. Placing the sensor too remotely can result in a time

delay which limits the quality of control. Also, the sensor should

primarily measure the system’s response to external changes, rather

than measure the changes directly. The latter can sometimes be used

to help the controller anticipate transients, but attheriskof sacrificing

accuracy in reaching the target setpoint.

Tuning a PID controller amounts to determining what the relative

contributions should be from each of the three types of control. The

simplest approach is to start with proportional control and add inte-

Page 22

2 – 4 Advanced Topics

gral and derivative one at a time. A simple P-controller generates a

control variable that is proportional to the error signal.

1

Increasing the P gain should cause the process output to respond

by moving closer to the setpoint. Generally, enough amplification

should be used so that the process output is broughtreasonably close

to the setpoint. Too much gain, however, will cause the system to

oscillate. Start with a small P gain, and increase by factors of two

until the system begins to oscillate. Then back off in small amounts

until stability is recovered.

While it is possible to maintain stability with a simple P controller,

in general this will lead to a finite, non-zero ε. Increasing P will

tend to reduce the resulting ε, but too much proportional gain will

eventually lead to oscillations.

One way to eliminate this nonzero error problem is to include an

offset at the controller output. The SIM960 Offset parameter can be

turned on and adjusted toholdthe process power at a level thatmaintains a smaller error. However, this is only a coarse improvement,

since the necessary power level may change with time.

Integral control provides an “automatic” way to dynamically adjust

the effective offset to zero the error; in older controllers, integral

action was called “automatic reset” for this reason. Integral control

simply integrates the error signal with respect to time. Thus the

controller output changes until the error has been reduced to zero,

near which point the controller output slows and stops changing. If

the error drifts over time, the integrator responds by adjusting the

controller output to cancel the error. So it is much like having a

dynamic output offset constantly responding to system changes. As

with proportional gain, too much integral gain can cause oscillation.

Again, start with a small I gain and increase by factors of two until

oscillation begins, then back off until stability is recovered.

Though integral control is effective at reducing the error, it is not as

effective as proportional control at responding quickly to changes.

This is because the integrator needs time to build up a response. To

further enhance the response of the process to rapid changes, derivative control is often employed. Derivative control is proportional

to the rate of change of the error, so it is relatively unresponsive to

slow changes, but rapid changes to the system produce a significant

response. Derivative control reduces oscillations that can resultfrom

step changes to a system.

1

During the tuning process, it is important to keep in mind that the differential

input range of the SIM960 is ±1.0 V. It is good practice to occasionally glance at

the OVLD indicator to ensure the input amplifier is not saturated.

SIM960 Analog PID Controller

Page 23

2.2 Ziegler-Nichols’ Tuning 2 – 5

2.2 Ziegler-Nichols’ Tuning

For many applications, a good starting point for tuning is one of

the two classic Ziegler-Nichols methods2. These two methods are

briefly described below; for more details, see, for example, Åstr¨om

& H¨agglund, PID Controllers: Theory, Design, and Tuning, Instru-

ment Society of America (1995).

2.2.1 Open-loop tuning

The open-loop Ziegler-Nichols method involves introducing a small

step change to the process under control, and making a few measurements from the response. The procedure is:

• Switch the SIM960 into Manual mode, and then adjust until

the process is stable and near the desired operating point.

• Now make a small, suddenstep change, ∆, in the control signal.

Call this time t = 0.

• Record the process response in the Measure signal. Define the

(dimensionless) process step-response function:

h(t) =

Measure(t) −Measure(0)

∆

• Observe the point of maximum slope in h. Extend a straight

line through this point, tangent to h, downward(see Figure2.2).

• Let L be the time coordinate where the straight line crosses

h = 0; and let a be the negative of the h–intercept (i. e., a > 0 in

Figure 2.2).

• Note thatit is not necessaryto wait for the processto completely

settle following the step change ∆—it is sufficient to simply wait

until the maximum slope is observed in Measure.

From a and L, Ziegler and Nichols suggest tuning for P, PI, and PID

control as shown in Table 2.1

Control P I D

P 1/a

PI 0.9/a 1/(3L)

PID 1.2/a 1/(2L) L/2

Table 2.1: Ziegler-Nichols open-loop tuning parameters

2

SIM960 Analog PID Controller

Ziegler, J. G., & Nichols, N. B. 1942, Trans. ASME, 64, 759

Page 24

2 – 6 Advanced Topics

t

h(t)=

L

a

t

0

Manual(t)

∆

∆

Meas–Meas(0)

0

maximum

slope

2.2.2 Closed-loop tuning

Figure 2.2: The open-loop step response of the process.

An alternate method, also due to Ziegler and Nichols, is based on

measuring the gain at which the process just begins to oscillate. The

procedure is:

• Switch the SIM960 into PID mode, with I and D both disabled.

Choose a value for Setpoint around the desired operating

point, and set P so some small value.

• Slowly increase P until the process starts to oscillate.

• Record this value of P as Ku, the “ultimate” gain. Also observe

the period of the oscillations, Tu.

From Kuand Tu, Ziegler and Nichols again suggest tuning for P, PI,

and PID control as shown in Table 2.2

Control P I D

P Ku/2

PI 2Ku/5 5/(4Tu)

PID 3Ku/5 2/T

Tu/8

u

Table 2.2: Ziegler-Nichols closed-loop tuning parameters

SIM960 Analog PID Controller

Page 25

2.3 Anti-Windup and Conditional Integration 2 – 7

2.3 Anti-Windup and Conditional Integration

For better integral performance, the SIM960 features anti-windup

circuitry in the form of conditional integration. The purpose of antiwindup is to improve the controller’s ability to recover from output

saturation. When the output saturates, the error is likely to be large,

since the process is unable to provide power fast enough to recover

the process output. However, the integrator contribution may not

account for the full amount of the controller output in this case.

Subsequently, the integrator continues to integrate the error until the

integrator output saturates. This “winding up” aspect of integral

control becomes a problem when the process recovers and the error

level passes through zero, because the error must move significantly

beyond zero for the integrator to “unwind” from saturation. In

general, once the controller output is clamped at a limit, nothing is

accomplished by drivingit harder into that limit by moreintegration.

In fact, it only makes it harder to recover from saturation, since the

result is usually large swings back and forth from limit to limit.

There are a variety of anti-windup strategies to mitigate this effect. A

simple way to implement anti-windup is to switch off the integrator

whenever the output saturates. This is not the same as resetting the

integrator (zeroing its output by discharging the feedback capacitance) because the output simply stops moving, but does not go to

zero. It is equivalent to momentarily zeroing the integrator input, so

that there is no signal to integrate while the output is saturated.

An improvement to this scheme comes from recognizing that not

all saturation conditions cause unwanted integrator wind-up. For

example, suppose the controller/process history were such as to produce the following conditions:

• Error signal negative

• Integrator output finite, not saturated

• Controller output saturated at the positive limit

Then, the integrator output would be moving in the negative direction, since its input, the error, is negative. This would not cause

the controller output to be pushed harder into saturation; in fact it

may eventually pull it out of saturation. So stopping the integrator

would hinder the controller’s effort to recover the process variable.

The SIM960 uses a technique called “conditional integration:” Con-

ditional integration only stops the integrator when the polarity of the error

is such as to drive the integrator toward the saturated limit.

SIM960 Analog PID Controller

Page 26

2 – 8 Advanced Topics

2.4 Bumpless Transfer

When switching the output mode between Manual and PID Control, transients on the output signal can disturb the system under

control. Minimizing these switching transients is known as “bumpless transfer.” The SIM960 supports bumpless transfer under certain

conditions, as described below.

2.4.1 Manual-to-PID

When switching from Manual output to PID Control output, bumpless transfer is only possible if the integral term is enabled.3When I

is turned on and the SIM960 is in Manual output mode, the input to

the integrator is rerouted to integrate the difference between Manual

and the (deselected) PID Control output. This effectively allows the

PID Control to “track” the Manual value, presetting the integrator

as necessary. Then, when the output is switched back to PID Control,

the controller output is already the same as the Manual output level.

Were this not the case, the integrator output would likely saturate

while in manual mode, and uponswitching to PID Controlmode, the

controller output would suddenly jump. Bumpless transfer insures

that the transition from Manual to PID Control mode is smooth.

2.4.2 PID-to-Manual

An additional feature of the SIM960 isthe ability to presetthe manual

level to the current PID control output level, so that switching from

PID mode to manual mode will also be smooth. With the module

in PID mode, select the Manual field. Press [On/Off] and hold it

down for at least one second. After one second the manual display

reading will shift to the current PID output level. The output mode

will remain in PID control mode until it is manually switched on the

front panel or through the remote interface. But the new manual

output level will be equal to the PID control output.

3

This can be understood mathematically, since only the integral term has an “unspecified” initial offset value that can be set to an arbitrary valuewithoutviolating

Eqn 1.2.

SIM960 Analog PID Controller

Page 27

3 Remote Operation

In This Chapter

This chapter describes operating the module over the serial interface.

3.1 Index of Common Commands . . . . . . . . . . . . . 3 – 2

3.2 Alphabetic List of Commands . . . . . . . . . . . . . 3 – 4

3.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 3 – 7

3.3.1 Power-on configuration . . . . . . . . . . . . . 3 – 7

3.3.2 Buffers . . . . . . . . . . . . . . . . . . . . . . . 3 – 7

3.3.3 Device Clear . . . . . . . . . . . . . . . . . . . . 3 – 7

3.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . 3 – 8

3.4.1 Command syntax . . . . . . . . . . . . . . . . . 3 – 8

3.4.2 Examples . . . . . . . . . . . . . . . . . . . . . 3 – 9

3.4.3 Controller settings commands . . . . . . . . . 3 – 10

3.4.4 Controller configuration commands . . . . . . 3 – 12

3.4.5 Monitor commands . . . . . . . . . . . . . . . 3 – 14

3.4.6 Display commands . . . . . . . . . . . . . . . . 3 – 16

3.4.7 Serial communication commands . . . . . . . 3 – 17

3.4.8 Status commands . . . . . . . . . . . . . . . . . 3 – 17

3.4.9 Interface commands . . . . . . . . . . . . . . . 3–20

3.5 Status Model . . . . . . . . . . . . . . . . . . . . . . . 3 – 25

3.5.1 Status Byte (SB) . . . . . . . . . . . . . . . . . . 3 – 26

3.5.2 Service Request Enable (SRE) . . . . . . . . . . 3 – 26

3.5.3 Standard Event Status (ESR) . . . . . . . . . . 3 – 27

3.5.4 Standard Event Status Enable (ESE) . . . . . . 3 – 27

3.5.5 Communication Error Status (CESR) . . . . . . 3 – 27

3.5.6 Communication Error Status Enable (CESE) . 3 – 28

3.5.7 Instrument Status (INCR) . . . . . . . . . . . . 3 – 28

3.5.8 Instrument Status (INSR) . . . . . . . . . . . . 3–29

3.5.9 Analog to Digital Status Enable (INSE) . . . . 3–29

3.5.10 Analog to Digital Status (ADSR) . . . . . . . . 3 – 29

3.5.11 Analog to Digital Status Enable (ADSE) . . . . 3 – 30

3 – 1

Page 28

3 – 2 Remote Operation

3.1 Index of Common Commands

symbol definition

i,j Integers

f,g Floating-point values

z Literal token

(?) Required for queries; illegal for set commands

var Parameter always required

{var} Required parameter for set commands; illegal for queries

[var] Optional parameter for both set and query forms

Controller Settings

PCTL(?) z 3 – 10 Proportional action ON/OFF

ICTL(?) z 3 – 10 Integral action ON/OFF

DCTL(?) z 3 – 10 Derivative action ON/OFF

OCTL(?) z 3 – 10 Offset ON/OFF

GAIN(?) {f } 3 – 10 Proportional Gain

APOL(?) z 3 – 11 Controller Polarity

INTG(?) {f } 3 – 11 Integral Gain

DERV(?) {f } 3 – 11 Derivative Gain

OFST(?) {f } 3 – 11 Output Offset

Controller Configuration

AMAN(?) z 3 – 12 Output (Manual Output/PID Control)

INPT(?) z 3 – 12 Input (Internal/External Setpoint)

SETP(?) {f } 3 – 12 New setpoint

RAMP(?) z 3 – 12 Internal setpoint ramping ON/OFF

RATE(?) {f } 3 – 12 Setpoint ramping Rate

RMPS? 3 – 13 Setpoint ramping status

STRT z 3 – 13 Pause or continue ramping

MOUT(?) {f } 3 – 13 Manual Output

ULIM(?) {f } 3 – 13 Upper Output Limit

LLIM(?) {f } 3 – 14 Lower Output Limit

Monitor

SMON? [i] 3 – 14 Setpoint Input Monitor

MMON? [i] 3 – 14 Measure Input Monitor

EMON? [i] 3 – 15 Amplified Error Monitor

OMON? [i] 3 – 15 Output Monitor

RFMT(?) {z} 3 – 15 Output Streaming Records Format

SOUT [z] 3 – 16 Stop Streaming

FPLC(?) {i} 3 – 16 Frequency of Power Line Cycle

SIM960 Analog PID Controller

Page 29

3.1 Index of Common Commands 3 – 3

Display

DISP(?) {z} 3 – 16 Select Field

SHFT(?) {z} 3 – 16 Shift Status

DISX(?) {z} 3 – 17 Front Panel Display Enable

Serial Communications

BAUD(?) {i} 3 – 17 Baud Rate

FLOW(?) {z} 3 – 17 Flow Control

PARI(?) {z} 3 – 17 Parity

Status

*CLS 3 – 17 Clear Status

*STB? [i] 3 – 18 Status Byte

*SRE(?) [i,] {j} 3 – 18 Service Request Enable

*ESR? [i] 3 – 18 Standard Event Status

*ESE(?) [i,] {j} 3 – 18 Standard Event Status Enable

CESR? [i] 3 – 18 Comm Error Status

CESE(?) [i,]{j} 3 – 19 Comm Error Status Enable

INCR? [i] 3 – 19 Instrument condition register

INSR? [i] 3 – 19 Instrument status register

INSE(?) [i], {j} 3 – 19 Instrument status enable register

ADSR? [i] 3 – 19 A-to-D status register

ADSE(?) [i], {j} 3 – 19 A-to-D status enable register

PSTA(?) {z} 3 – 20 Pulse −STATUS Mode

Interface

*RST 3 – 20 Reset

CONS(?) {z} 3 – 21 Console Mode

*IDN? 3 – 21 Identify

*TST? 3 – 21 Self Test

*OPC(?) 3 – 22 Operation Complete

WAIT i 3 – 22 Wait

LEXE? 3 – 22 Execution Error

LCME? 3 – 23 Command Error

LBTN? 3 – 23 Last Button

TOKN(?) {z} 3 – 24 Token Mode

TERM(?) {z} 3 – 24 Response Termination

SIM960 Analog PID Controller

Page 30

3 – 4 Remote Operation

3.2 Alphabetic List of Commands

?

*CLS 3 – 17 Clear Status

*ESE(?) [i,] {j} 3 – 18 Standard Event Status Enable

*ESR? [i] 3 – 18 Standard Event Status

*IDN? 3 – 21 Identify

*OPC(?) 3 – 22 Operation Complete

*RST 3 – 20 Reset

*SRE(?) [i,] {j} 3 – 18 Service Request Enable

*STB? [i] 3 – 18 Status Byte

*TST? 3 – 21 Self Test

A

ADSE(?) [i], {j} 3 – 19 A-to-D status enable register

ADSR? [i] 3 – 19 A-to-D status register

AMAN(?) z 3 – 12 Output (Manual Output/PID Control)

APOL(?) z 3 – 11 Controller Polarity

B

BAUD(?) {i} 3 – 17 Baud Rate

C

CESE(?) [i,]{j} 3 – 19 Comm Error Status Enable

CESR? [i] 3 – 18 Comm Error Status

CONS(?) {z} 3 – 21 Console Mode

D

DCTL(?) z 3 – 10 Derivative action ON/OFF

DERV(?) {f } 3 – 11 Derivative Gain

DISP(?) {z} 3 – 16 Select Field

DISX(?) {z} 3 – 17 Front Panel Display Enable

E

EMON? [i] 3 – 15 Amplified Error Monitor

F

FLOW(?) {z} 3 – 17 Flow Control

FPLC(?) {i} 3 – 16 Frequency of Power Line Cycle

G

GAIN(?) {f } 3 – 10 Proportional Gain

SIM960 Analog PID Controller

Page 31

3.2 Alphabetic List of Commands 3 – 5

I

ICTL(?) z 3 – 10 Integral action ON/OFF

INCR? [i] 3 – 19 Instrument condition register

INPT(?) z 3 – 12 Input (Internal/External Setpoint)

INSE(?) [i], {j} 3 – 19 Instrument status enable register

INSR? [i] 3 – 19 Instrument status register

INTG(?) {f } 3 – 11 Integral Gain

L

LBTN? 3 – 23 Last Button

LCME? 3 – 23 Command Error

LEXE? 3 – 22 Execution Error

LLIM(?) {f } 3 – 14 Lower Output Limit

M

MMON? [i] 3 – 14 Measure Input Monitor

MOUT(?) {f } 3 – 13 Manual Output

O

OCTL(?) z 3 – 10 Offset ON/OFF

OFST(?) {f } 3 – 11 Output Offset

OMON? [i] 3 – 15 Output Monitor

P

PARI(?) {z} 3 – 17 Parity

PCTL(?) z 3 – 10 Proportional action ON/OFF

PSTA(?) {z} 3 – 20 Pulse −STATUS Mode

R

RAMP(?) z 3 – 12 Internal setpoint ramping ON/OFF

RATE(?) {f } 3 – 12 Setpoint ramping Rate

RFMT(?) {z} 3 – 15 Output Streaming Records Format

RMPS? 3 – 13 Setpoint ramping status

S

SETP(?) {f } 3 – 12 New setpoint

SHFT(?) {z} 3 – 16 Shift Status

SMON? [i] 3 – 14 Setpoint Input Monitor

SOUT [z] 3 – 16 Stop Streaming

STRT z 3 – 13 Pause or continue ramping

T

TERM(?) {z} 3 – 24 Response Termination

SIM960 Analog PID Controller

Page 32

3 – 6 Remote Operation

TOKN(?) {z} 3 – 24 Token Mode

U

ULIM(?) {f } 3 – 13 Upper Output Limit

W

WAIT i 3 – 22 Wait

SIM960 Analog PID Controller

Page 33

3.3 Introduction 3 – 7

3.3 Introduction

Remote operation of the SIM960 is through a simple command language documented in this chapter. Both set and query forms of most

commands are supported, allowing the user complete control of the

amplifier from a remote computer, either through the SIMmainframe

or directly via RS-232 (see section 1.4.2.1).

See Table 1.1 for the specification of the DB–15 SIM Interface Connector.

3.3.1 Power-on configuration

The settings for the remote interface are 9600 baud with no parity

and hardware flow control, and local echo disabled (CONS OFF).

Most of the SIM960 instrument settings are stored in non-volatile

memory, and at power-on the instrument returns to the state it was

last in when power was removed. Exceptions are noted in the command descriptions.

Reset values of parameters are shown in boldface.

3.3.2 Buffers

3.3.3 Device Clear

The SIM960 stores incoming bytes from the host interface in a 32byte Input Buffer. Characters accumulate in the Input Buffer until

a command terminator (either hCRi or hLFi) is received, at which

point the message is parsed and executed. Query responses from the

SIM960 are buffered in a 32-byte Output Queue.

If the Input Buffer overflows, then all data in both the Input Buffer

and the Output Queue are discarded, and an error is recorded in the

CESR and ESR status registers.

The SIM960 host interface can be asynchronously reset to its poweron configuration by sending an RS-232-style hbreakisignal. From the

SIM900 Mainframe, this is accomplished with the SRST command;

if directly interfacing via RS-232, then use a serial break signal. After

receiving the Device Clear, the interface is reset to 9600 baud and

CONS mode is turned OFF. Note that this only resets the communi-

cation interface; the basic function of the SIM960 is left unchanged;

to reset the meter, see *RST.

The Device Clear signal will also terminate any streaming outputs

fromtheSIM960duetoanSMON?, MMON?, EMON? and/or OMON?

query of multiple conversions.

SIM960 Analog PID Controller

Page 34

3 – 8 Remote Operation

3.4 Commands

This section provides syntax and operational descriptions for remote

commands.

3.4.1 Command syntax

The four letter mnemonic (shown in CAPS) in each command sequence specifies the command. The rest of the sequence consists of

parameters.

Commands may take either set or query form, depending on whether

the “?” character follows the mnemonic. Set only commands are

listed without the “?”, query only commands show the “?” after the

mnemonic, and optionally query commands are marked with a “(?)”.

Parameters shown in { } and [ ] are not always required. Parameters

in { } are required to set a value, and should be omitted for queries.

Parameters in [ ] are optional in both set and query commands.

Parameters listed without any surrounding characters are always

required.

Do not send ( ) or { } or [ ] as part of the command.

Multiple parameters are separated by commas. Multiple commands

may be sent on one command line by separating them with semicolons (;) so long as the Input Buffer does not overflow. Commands

are terminated by either hCRi or hLFi characters. Null commands

and whitespace are ignored. Execution of the command does not

begin until the command terminator is received.

Token parameters (generically shown as z in the command de-tokens

scriptions) can be specified either as a keyword or integer value.

Command descriptions list the valid keyword options, with each

keyword followed by its corresponding integer value. For example,

to set the response termination sequence to hCRi+hLFi, the following

two commands are equivalent:

TERM CRLF —or— TERM 3

For queries that return token values, the return format (keyword or

integer) is specified with the TOKN command.

The following table summarizes the notation used in the command

descriptions:

SIM960 Analog PID Controller

Page 35

3.4 Commands 3 – 9

symbol definition

i,j Integers

f,g Floating-point values

z Literal token

(?) Required for queries; illegal for set commands

var Parameter always required

{var} Required parameter for set commands; illegal for queries

[var] Optional parameter for both set and query forms

3.4.2 Examples

Each command is provided with a simple example illustrating its

usage. In these examples, all data sent by the host computer to

the SIM960 are set as straight teletype font, while responses

received the host computer from the SIM960 are set as slanted

teletype font.

The usage examples vary with respect to set/query, optional parameters, and token formats. These examples are not exhaustive, but are

intended to provide a convenient starting point for user programming.

SIM960 Analog PID Controller

Page 36

3 – 10 Remote Operation

3.4.3 Controller settings commands

Proportional action ON/OFFPCTL(?) z

Set (query) the proportional control {to z=(OFF 0, ON 1)}.

When ON, the PID Control path includes the proportional control

term.

PCTL 1Example:

Integral action ON/OFFICTL(?) z

Set (query) the integral control {to z=(OFF 0, ON 1)}.

When ON, the PID Control path includes the integral control term.

ICTL?Example:

0

Derivative action ON/OFFDCTL(?) z

Set (query) the derivative control {to z=(OFF 0, ON 1)}.

When ON, the PID Control path includes the derivative control term.

DCTL OFFExample:

Offset ON/OFFOCTL(?) z

Set (query) the offset control {to z=(OFF 0, ON 1)}.

When ON, the PID Control path includes the constant output offset.

OCTL?Example:

ON

Proportional GainGAIN(?) {f }

Set (query) the proportional gain (P) {to f }, in V/V.

Values may be entered in decimal or exponential format, and are

signed.

GAIN may be set with 2 digits of resolution for 1.0 ≤ |P| ≤ 103, and

with single-digit resolution for 0.1 ≤ |P| ≤ 0.9. Note that setting

GAIN does not modify whether the proportional term is enabled or

disabled. For on/off control, see PCTL.

Setting GAIN overrides the previous setting of APOL.

The allowed range for GAIN is 10−1≤ |P| ≤ 103.

GAIN +2.5E+2Example:

SIM960 Analog PID Controller

Page 37

3.4 Commands 3 – 11

Controller PolarityAPOL(?) z

Set (query) the proportional gain polarity {to z=(POS 1, NEG 0)}. Set-

ting APOL will override the sign of a previously-commanded GAIN.

APOL?Example:

POS

Integral GainINTG(?) {f }

Set (query) the integral gain (I) {to f }, in V/(V·s).

INTG may be set with 2 digits of resolution for 10−1≤ I ≤ 5 × 105,

and with single-digit resolution for 10−2≤ I ≤ 9 × 10−2. Integral

gains are unsigned (positive values only). Note that setting INTG

does not modify whether the integrator is enabled or disabled. For

on/off control, see ICTL.

The allowed range for INTG is 10−2≤ I ≤ 5 × 105.

INTG?Example:

+1.5E+3

Derivative GainDERV(?) {f }

Set (query) the derivative gain {to f }, in V/(V/s).

DERV may be set with 2 digits of resolution for 10−5≤ D ≤ 10, and

with single-digit resolution for 10−6≤ I ≤ 9 × 10−6. Derivative gains

are unsigned (positive values only). Note that setting DERV does

not modify whether the derivative is enabled or disabled. For on/off

control, see DCTL.

The allowed range for DERV is 10−6≤ D ≤ 10.

DERV 0.000015Example:

DERV?

+1.5E-5

Output OffsetOFST(?) {f }

Set (query) the output offset {to f }, in volts.

The offset voltage can be set with millivolt resolution. Note that setting OFST does not modify whether the offset is enabled or disabled.

For on/off control, see OCTL.

The allowed range is −10.000 ≤ OFST +10.000.

OFST -12.3E-2; OFST?Example:

-0.123

SIM960 Analog PID Controller

Page 38

3 – 12 Remote Operation

3.4.4 Controller configuration commands

Output (Manual Output/PID Control)AMAN(?) z

Set (query) controller output state {to z=(MAN 0, PID 1)}.

AMAN?Example:

1

Input (Internal/External Setpoint)INPT(?) z

Set (query) setpoint input state {to z=(INT 0, EXT 1)}.

INPT INTExample:

New setpointSETP(?) {f }

Set (query) the setpoint value {to f }, in volts.

The setpoint can be set with millivolt resolution. If ramping is enabled (see RAMP), SETP will initiate a ramp to f. Otherwise, the

setpoint value changes immediately to the new value.

The allowed range is −10.000 ≤ SETP ≤ +10.000.

SETP -1.234Example:

Internal setpoint ramping ON/OFFRAMP(?) z

Set (query) internal setpoint ramping {to z=(OFF 0, ON 1)}.

When ON, the changes to the internal setpoint are made with constant

slew-rate ramping enabled.

RAMP 1Example:

Setpoint ramping RateRATE(?) {f }

Set (query) the setpoint rate {to f }, in V/s.

RATE may be set with 2 digits of resolution for values above 10−2,

and with signle-digit resolution below that. Note that setting RATE

does not modify whether setpoint changes are made with constant

slew-rate ramping or not. For on/off control of linear ramping, see

RAMP.

The allowed range is 10−3≤ RATE ≤ 104.

RATE 2.2E-3Example:

RATE?

+0.2E-2

SIM960 Analog PID Controller

Page 39

3.4 Commands 3 – 13

Setpoint ramping statusRMPS?

Query the ramp status.

For slow ramps of the internal setpoint, the RMPS? query will monitor the real-time status of a setpoint transition.

The response is one of the following token values: IDLE 0, PENDING

1, RAMPING 2, PAUSED 3.

RMPS?Example:

RAMPING

Pause or continue rampingSTRT z

Cause a setpoint ramping event in progress to pause (STOP) or con-

tinue (START). z=(STOP 0, START 1).

Note that STRT cannot be used to initiate a new setpoint transition

from the RMPS PENDING state—this can only be accomplished by

pressing [Ramp Start/Stop] on the front panel.

STRT STARTExample:

Manual OutputMOUT(?) {f }

Set (query) the manual output value {to f }, in volts.

The manual output can be set with millivolt resolution. Note that

setting MOUT does not modify whether the controller is in manual or

PID control mode. For on/off control of manual output, see AMAN.

The allowed range for MOUT is −10.000 ≤ MOUT ≤ +10.000.

MOUT?Example:

+8.000

Upper Output LimitULIM(?) {f }

Set (query) the upper output limit {to f }, in volts.

The upper limit can be set with 10mV resolution. Note that, regardless of the operating mode of the SIM960 (see AMAN), the output voltage will always be clamped to remain less positive than the

ULIM limit. Combined with the LLIM limit, this results in the output

obeying:

The allowed range is LLIM ≤ ULIM ≤ +10.00.

SIM960 Analog PID Controller

−10.00 ≤ LLIM ≤ Output ≤ ULIM ≤ +10.00

Page 40

3 – 14 Remote Operation

Lower Output LimitLLIM(?) {f}

Set (query) the lower output limit {to f }, in volts.

The lower limit can be set with 10 mV resolution. The output voltage

of the SIM960 will always be clamped to remain less negative than

the LLIM limit. See ULIM for more details.

The allowed range is −10.00 ≤ LLIM ≤ ULIM.

3.4.5 Monitor commands

Setpoint Input MonitorSMON? [i]

Query the Setpoint input voltage to the error amplifier, in volts.

If INPT INT is set, then SMON? monitors the value of the internallygenerated setpoint. If INPT EXT, then SMON? monitors the voltage

applied at the front-panel Setpoint BNC input.

i is an optional parameter that causes streaming of Setpoint data.

If i is specified, then i measurements will be output at a rate of

approximately two measurements per second. If i is specified as 0,

then measurements will be output indefinitely. The SOUT command

can be used to stop streaming.

SETP 1.2; SMON? 5Example:

+01.004496

+01.066567

+01.128909

+01.191273

+01.200073

Measure Input MonitorMMON? [i]

Query the Measure input voltage to the error amplifier, in volts.

MMON? always reports the voltage applied at the front-panel Measure BNC input.

i is an optional parameter that causes streaming of Measure data.

If i is specified, then i measurements will be output at a rate of

approximately half a second per measurement. If i is specified as 0,

then measurements will be output indefinitely. The SOUT command

can be used to stop streaming.

MMON?Example:

-00.005900

SIM960 Analog PID Controller

Page 41

3.4 Commands 3 – 15

Amplified Error MonitorEMON? [i]

Query the P × ε voltage, in volts.

i is an optional parameter that causes streaming of (P × ε) data. If i

is specified, then i measurements will be output at a rate of approximately half a second per measurement. If i is specified as 0, then

measurements will be output indefinitely. The SOUT command can

be used to stop streaming.

EMON?Example:

+00.105537

Output MonitorOMON? [i]

Query the Output voltage, in volts.

OMON? alwaysreportsthevoltagegeneratedatthefront-panelOUTPUT BNC connector (regardless of the state of AMAN).

i is an optional parameter that causes streaming of Output data.

If i is specified, then i measurements will be output at a rate of

approximately half a second per measurement. If i is specified as 0,

then measurements will be output indefinitely. The SOUT command

can be used to stop streaming.

OMON?Example:

+01.106139

Output Streaming Records FormatRFMT(?) {z}

Set (query) the output streaming record format {to z=(OFF 0, ON 1)}.

When ON, data are output on a single line with three comma delimiters. Since there are four monitor channels that can be streamed to

output, and any combination of the four may be streamed, thecomma

delimiters allow unambiguous identification of channel data.

The record format is hSMONi,hMMONi,hEMONi,hOMONi

RFMT ONExample:

SMON? 3; MMON? 3; EMON? 3; OMON? 3

+00.099909,-00.006053,+00.105601,+01.106135

+00.099909,-00.006031,+00.105615,+01.106123

+00.099915,-00.006001,+00.105636,+01.106151

SIM960 Analog PID Controller

Page 42

3 – 16 Remote Operation

Stop StreamingSOUT [z]

Turn off streaming (of channel z= (SMN 0, MMN 1, EMN 2, OMN 3)).

If the optional parameter z is not specified, then all streaming outputs

are turned off.

SOUTExample:

Frequency of Power Line CycleFPLC(?) {i}

Set (query) the power line cycle frequency {to i=(50, 60)} Hz.

FPLC is used to program the power-line rejection frequency for the

precision voltage monitors (SMON?, MMON?, EMON?, OMON?).

FPLC?Example:

60

3.4.6 Display commands

Select FieldDISP(?) {z}

Set (query) the field level to be displayed {to z}. Allowed values of z

are

PRP 0 Proportional gain

IGL 1 Integral gain

DER 2 Derivative gain

OFS 3 Output offset

RTE 4 Setpoint rate

STP 5 Setpoint value

MNL 6 Manual output value

ULM 7 Upper limit of output

LLM 8 Lower limit of output

SMN 9 ADC measurement of Setpoint input

MMN 10 ADC measurement of Measure input

EMN 11 ADC measurement of P-Amplified error

OMN 12 ADC measurement of PID/Manual Output

DISP 1Example:

Shift StatusSHFT(?) {z}

Set (query) the current shift status {to i=(OFF 0, ON 1)}.

SHFT?Example:

OFF

SIM960 Analog PID Controller

Page 43

3.4 Commands 3 – 17

Front Panel Display EnableDISX(?) {z}

Set (query) the front panel display status {to z=(OFF 0, ON 1)}.

When the display is turned off (DISX OFF), all front panel indicators

and buttons are disabled.

DISX OFFExample:

3.4.7 Serial communication commands

Baud RateBAUD(?) {i}

Set (query) the baud rate {to i}.

At power-on, the baud rate defaults to 9600. Changing baud

rate must be carefully orchestrated to ensure proper connectivity

throughout the transaction (see the SIM900 manual discussion of the

BAUD command for more examples).

BAUD 38800Example:

3.4.8 Status commands

Flow ControlFLOW(?) {z}

Set (query) flow control {to z=(NONE 0, RTS 1, XON 2)}.

At power-on, the SIM960 defaults to FLOW RTS flow control.

FLOW 0Example:

ParityPARI(?) {z}

Set (query) parity {to z = (NONE 0, ODD 1, EVEN 2, MARK 3, SPACE 4)}.

At power-on, the SIM960 defaults to PARI NONE.

PARI?Example:

NONE

The Status commands query and configure registers associated with

status reporting of the SIM960.

Clear Status*CLS

*CLS immediately clears the ESR, CESR, and the SIM960 status reg-

isters.

*CLSExample:

SIM960 Analog PID Controller

Page 44

3 – 18 Remote Operation

Status Byte*STB? [i]

Reads the Status Byte register [bit i].

Execution of the *STB? query (without the optional bit i) always

causes the −STATUS signal to be deasserted. Note that *STB? i will

not clear −STATUS, even if bit i is the only bit presently causing the

−STATUS signal.

*STB?Example:

16

Service Request Enable*SRE(?) [i,] {j}

Set (query) the Service Request Enable register [bit i] {to j}.

*SRE 32; *SRE? 5Example:

1

Standard Event Status*ESR? [i]

Reads the Standard Event Status Register [bit i].

Upon executing *ESR?, the returned bit(s) of the ESR register are

cleared.

GAIN 0Example:

ESR?

16

The binary value (16) corresponds to anExecutionError, since GAIN 0

is an illegal value (minimum gain is 0.1).

Standard Event Status Enable*ESE(?) [i,] {j}

Set (query) the Standard Event Status Enable Register [bit i] {to j}.

*ESE 16Example:

Comm Error StatusCESR? [i]

Query Comm Error Status Register [for bit i].

Upon executing a CESR? query, the returned bit(s) of the CESR

register are cleared.

CESR?Example:

0

SIM960 Analog PID Controller

Page 45

3.4 Commands 3 – 19

Comm Error Status EnableCESE(?) [i,]{j}

Set (query) Comm Error Status Enable Register [bit i] {to j}.

CESR 0Example:

Instrument condition registerINCR? [i]

Query the instrument condition register [bit i].

The values of the bits in the instrument condition register are determined by the current (real-time) condition of the events defined in

the instrument status register (see Section 3.5.8).

Reading the instrument condition register does not affect the register.

INCR?Example:

16

Instrument status registerINSR? [i]

Query the instrument status register [bit i].

INSR?Example:

16

Instrument status enable registerINSE(?) [i], {j}

Set (query) the instrument status enable register [bit i] {to j}.

INSE 16Example:

A-to-D status registerADSR? [i]

Query the analog to digital status register [bit i].

When new data become available from the A-to-D converter, the Ato-D status register bit corresponding to the channel of the new data

is set (see Section 3.5.10).

ADSR?Example:

15

A-to-D status enable registerADSE(?) [i], {j}

Set (query) the A-toD status enable register [bit i] {to j}.

ADSE 2Example:

SIM960 Analog PID Controller

Page 46

3 – 20 Remote Operation

Pulse −STATUS ModePSTA(?) {z}

Set (query) the Pulse −STATUS Mode {to z=(OFF 0, ON 1)}.

When PSTA ON is set, any new service request will only pulse the

−STATUS signal low (for a minimum of 1 µs). The default behavior

is to latch −STATUS low until a *STB? query is received.

At power-on, PSTA is set to OFF.

PSTA?Example:

OFF

3.4.9 Interface commands

The Interface commands provide control over the interface between

the SIM960 and the host computer.

Reset*RST

Reset the SIM960 to its default configuration. The effect of this com-

mand is equivalent to the following sequence of commands:

• DISX ON

• DISP PRP

• SHFT OFF

• GAIN 1.0

• APOL POS

• INTG 1.0

• DERV 1.0E-6

• OFST 0.0

• RATE 1.0

• PCTL ON

• ICTL OFF

• DCTL OFF

• OCTL OFF

• RAMP OFF

• SETP 0.0 (must not precede RAMP OFF)

• MOUT 0.0

• ULIM +10.0

SIM960 Analog PID Controller

Page 47

3.4 Commands 3 – 21

• LLIM -10.0

• INPT EXT

• AMAN PID

• TOKN OFF

• SOUT

The baud rate of the SIM960 is unaffected by *RST. The entire status

model is also unaffected by *RST.

*RSTExample:

Console ModeCONS(?) {z}

Set (query) the Console mode {to z=(OFF 0, ON 1)}.

CONS causes each character received at the Input Buffer to be copied

to the Output Queue.

At power-on, CONS is set to OFF.

CONS ONExample:

Identify*IDN?

Read the device identification string.

The identification string is formatted as:

Stanford Research Systems,SIM960,s/n******,ver#.#

where SIM960 is the model number, ****** is the 6-digit serial number, and #.# is the firmware revision level.

*IDN?Example:

Stanford Research Systems,SIM960,s/n003173,ver2.15

Self Test*TST?

There is no internal self-test in the SIM960, so this query always

returns 0.

*TST?Example:

0

SIM960 Analog PID Controller

Page 48

3 – 22 Remote Operation

Operation Complete*OPC(?)

Operation Complete. Sets the OPC flag in the ESR register.

The query form *OPC? writes a 1 in the Output Queue when complete, but does not affect the ESR register.

*OPC?Example:

1

WaitWAIT i

Wait i milliseconds before processing morecommands from the host.

When using the WAIT command, be careful to not overflow the input

buffer of the SIM960 (see section 3.3.2).

SETP 0Example:

RATE 0.1

SETP 1.0; WAIT 5000; SMON?

+00.483159

Execution ErrorLEXE?

Query the last execution error code. Valid codes are:

Value Definition

0 No execution error since last LEXE?

1 Illegal value

2 Wrong token

3 Invalid bit

16 Invalid parameter

17 Missing parameter

18 No change

20 Ramp in progress

21 Limits conflict

*STB? 12; LEXE?; LEXE?Example:

3

0

The error (3, “Invalid bit,”) is because *STB? only allows bit-specific

queries of 0–7. The second read of LEXE? returns 0.

SIM960 Analog PID Controller

Page 49

3.4 Commands 3 – 23

Command ErrorLCME?

Query the last command error code. Valid codes are:

Value Definition

0 No execution error since last LCME?

1 Illegal command

2 Undefined command

3 Illegal query

4 Illegal set

5 Missing parameter(s)

6 Extra parameter(s)

7 Null parameter(s)

8 Parameter buffer overflow

9 Bad floating-point

10 Bad integer

11 Bad integer token

12 Bad token value

13 Bad hex block

14 Unknown token

*IDNExample:

LCME?

4

The error (4, “Illegal set”) is due to the missing “?”.

Last ButtonLBTN?

Query the last button that was pressed. The values returned are:

Value Button

0 no button pressed since last LBTN?

1 [Setpoint]

2 [Output]

3 [Ramp Start/Stop]

4 [Shift]

5 [Select]

6 [On/Off]

7 [ ]/ [ ]

8 [ ]/ [ ]

LBTN?Example:

5

SIM960 Analog PID Controller

Page 50

3 – 24 Remote Operation

Token ModeTOKN(?) {z}

Set (query) the Token Query mode {to z=(OFF 0, ON 1)}.

If TOKN ON is set, then queries to the SIM960 that return tokens will

return the text keyword; otherwise they return the decimal integer

value.

Thus, the only possible responses to the TOKN? query are ON and 0.

At power-on, TOKN is set to OFF.

TOKN OFFExample:

Response TerminationTERM(?) {z}

Set (query) the htermi sequence {to z=(NONE 0, CR 1, LF 2, CRLF 3,

LFCR 4)}.

The htermi sequence is appended to all query responses sent by

the module, and is constructed of ASCII character(s) 13 (carriage

return) and 10 (line feed). The token mnemonic gives the sequence

of characters.

At power-on, the default is TERM CRLF.

TERM?Example:

3

SIM960 Analog PID Controller

Page 51

3.5 Status Model 3 – 25

7

X

5

4

3

2

1

0

CESB

MSS

ESB

IDLE

undef

undef

ADSB

INSB

7

6

5

4

3

2

1

0

Status Byte

SB SRE

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

OPC: Operation Complete

INP: Input Buffer Error

DDE: Device Error

EXE: Execution Error

CME: Command Error

URQ: User Request

PON: Power On

QYE: Query Error

ESR ESE

Standard Event Status

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

PARITY: Parity Error

FRAME: Framing Error

HWOVRN: Hardware Overrun

OVR: Input Buffer Overrun

RTSH: RTS Halted

CTSH: CTS Halted

DCAS: Device Clear

NOISE: Noise Error

CESR CESE

Communication Error Status

-

STATUS

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

ADSETP: Setpoint Mon

ADMEAS: Measure Mon

ADOUT: Output Mon

undef

undef

undef

undef

ADERR: Error Signal Mon

ADSR ADSE

Analog to Digital Status

7

6

5

4

3

2

1

0

7

6

5

4

3

2

1

0

OVLD

ULIMIT

ANTIWIND

RSTOP

undef

undef

undef

LLIMIT

Instrument Status

INSEINSR

7

6

5

4

3

2

1

0

INCR

3.5 Status Model

The SIM960 status registers follow the hierarchical IEEE–488.2 format. AblockdiagramofthestatusregisterarrayisgiveninFigure3.1.

Condition Registers : These read-only registers correspond to the real-time condi-

Event Registers : These read-only registers record the occurrence of defined

SIM960 Analog PID Controller

Enable Registers : These read/write registers define a bitwise mask for their cor-

Figure 3.1: Status Register Model for the SIM960 Analog PID Controller.

There are three categories of registers in the SIM960 status model:

tion of some underlying physical property being monitored.

Queries return the latest value of the property, and have no