Page 1

Operation and Service Manual

Stanford Research Systems

JFET Preamp

SIM910

Revision 2.1 • May 8, 2007

Page 2

Certification

Stanford Research Systems certifies that this product met its published specifications at the time

of shipment.

Warranty

This Stanford Research Systems product is warranted against defects in materials and workmanship for a period of one (1) year from the date of shipment.

Service

For warranty service or repair, this product must be returned to a Stanford Research Systems

authorized service facility. Contact Stanford Research Systems or an authorized representative

before returning this product for repair.

Information in this document is subject to change without notice.

Copyrightc Stanford Research Systems, Inc., 2003 – 2007. All rights reserved.

Stanford Research Systems, Inc.

1290–D Reamwood Avenue

Sunnyvale, CA 94089 USA

Phone: (408) 744-9040 • Fax: (408) 744-9049

www.thinkSRS.com • e-mail: info@thinkSRS.com

Printed in U.S.A. Document number 9-01553-903

SIM910 JFET Preamp

Page 3

Contents

General Information iii

Safety and Preparation for Use . . . . . . . . . . . . . . . . iii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1 Operation 1 – 1

1.1 Instrument Overview . . . . . . . . . . . . . . . . . . . 1– 2

1.2 Front Panel Operation . . . . . . . . . . . . . . . . . . 1 – 2

1.3 Rear Panel Output . . . . . . . . . . . . . . . . . . . . 1 –5

1.4 SIM Interface . . . . . . . . . . . . . . . . . . . . . . . . 1 – 6

2 Remote Operation 2 – 1

2.1 Index of Common Commands . . . . . . . . . . . . . . 2 – 2

2.2 Alphabetic List of Commands . . . . . . . . . . . . . . 2– 3

2.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 2– 4

2.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 5

2.5 Register Model . . . . . . . . . . . . . . . . . . . . . . 2 – 9

3 Performance Tests 3 – 1

3.1 Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 2

3.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 2

3.3 Performance Tests . . . . . . . . . . . . . . . . . . . . . 3 – 3

3.4 SIM910 Performance Test Record . . . . . . . . . . . . 3 – 4

4 Circuitry 4 – 1

4.1 Circuit Discussion . . . . . . . . . . . . . . . . . . . . . 4 – 2

4.2 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . 4– 4

4.3 Schematic Diagrams . . . . . . . . . . . . . . . . . . . 4 – 4

i

Page 4

ii Contents

SIM910 JFET Preamp

Page 5

General Information

The SIM910 JFET Preamp, part of Stanford Research Systems’ Small

Instrumentation Modules family, is a low noise general purpose voltage preamplifier with bandwidth from DC to 1 MHz.

Safety and Preparation for Use

Biomedical Applications

Under certain conditions, the SIM910 may prove to be unsafe for

WARNING

Regarding Use with Photomultipliers

CAUTION

applications involving human subjects. Incorrect grounding, component failure, and excessive common-mode input voltages are examples of conditions in which the instrument may expose the subject

to large input currents. Therefore, Stanford Research Systems does

not recommend the SIM910 for such applications.

The front-end amplifier of this instrument is easily damaged if a

photomultiplier is used improperly with the amplifier. When left

completely unterminated, a cable connected to a PMT can charge

to several hundred volts in a relatively short time. If this cable is

connected to the inputs of the SIM910, the stored charge may damage

the front-end JFETs. To avoid this problem, provide a leakage path of

about 100 kΩ to ground inside the base of the PMT to prevent charge

accumulation.

Service

Do not install substitute parts or perform any unauthorized modifications to this instrument.

The SIM910 is a single-wide module designed to be used inside the

SIM900 Mainframe. Do not turn on the power until the module is

completely inserted into the mainframe and locked in place.

iii

Page 6

iv General Information

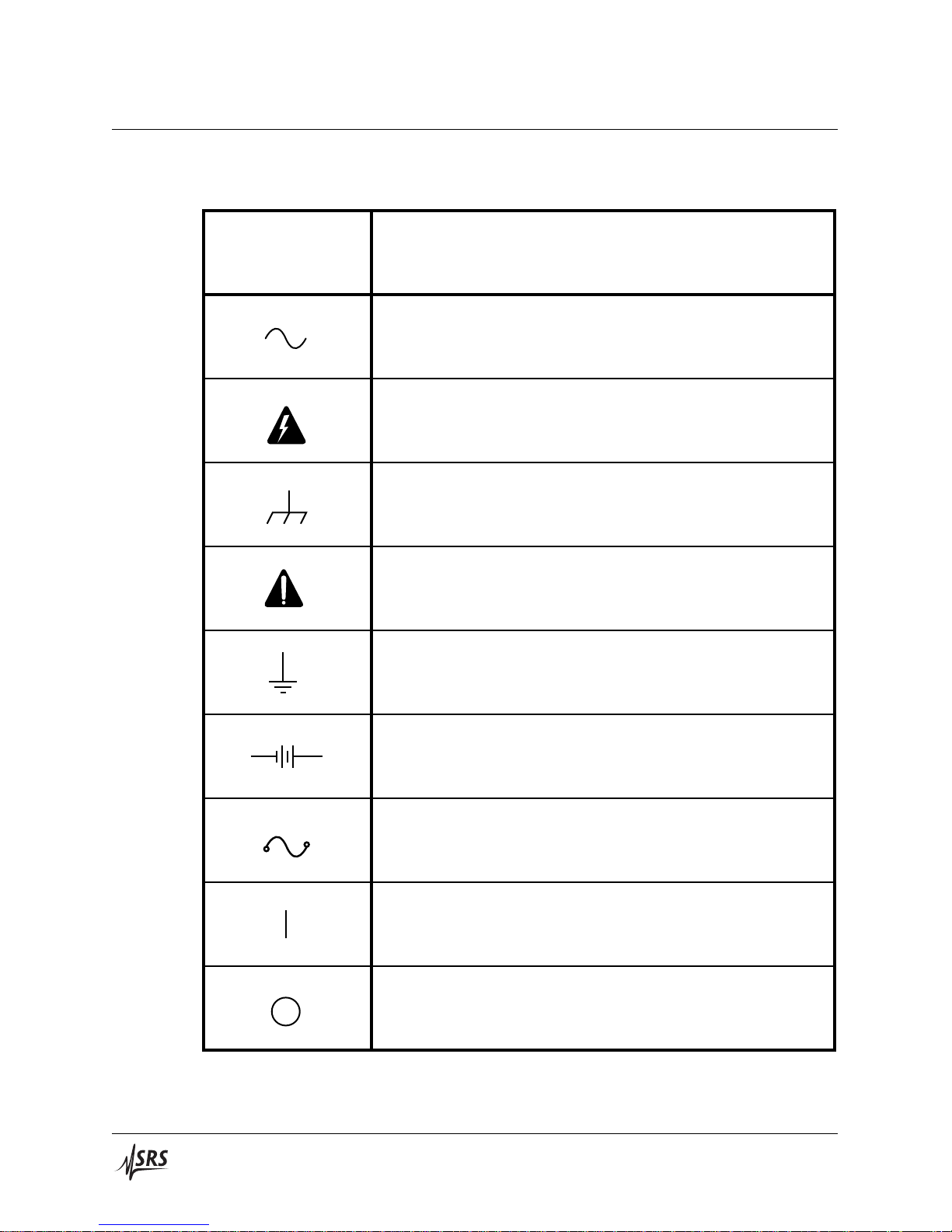

Symbol Description

Alternating current

Caution - risk of electric shock

Frame or chassis terminal

Caution - refer to accompanying documents

Earth (ground) terminal

Battery

Fuse

On (supply)

Off (supply)

Symbols you may Find on SRS Products

SIM910 JFET Preamp

Page 7

General Information v

Notation

The following notation will be used throughout this manual:

WARNING

CAUTION

A warning means that injury or death is possible if the instructions

are not obeyed.

A caution means that damage to the instrument or other equipment

is possible.

• Front-panel buttons are set as [Button];

[Adjust ] is shorthand for “[Adjust ] & [Adjust ]”.

• Front-panel indicators are set as OVLD.

• Remote command names are set as *IDN?.

• Literal text other than command names is set as OFF.

SIM910 JFET Preamp

Page 8

vi General Information

Specifications

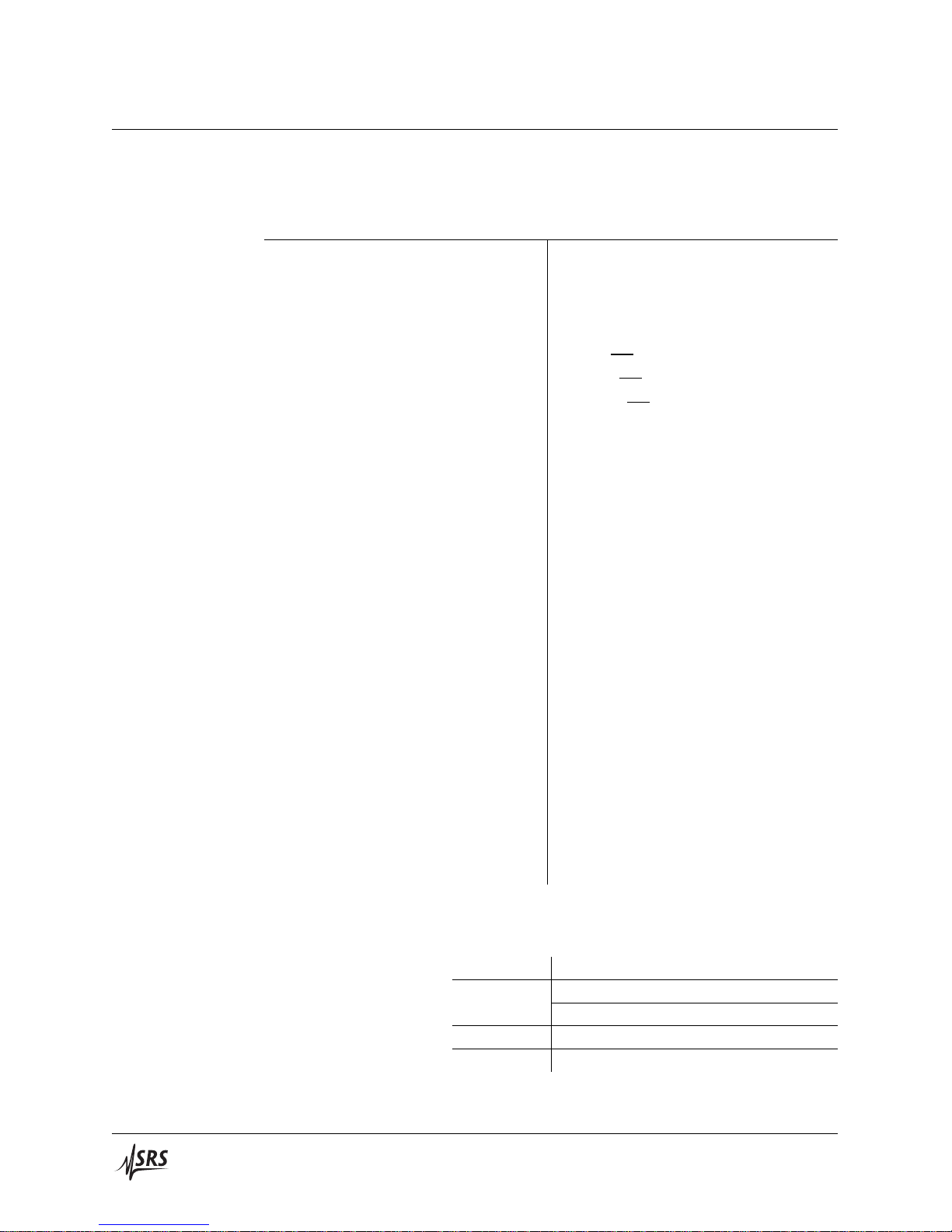

Performance Characteristics

Frequency range DC to 1 MHz; −3 dB @ 1.9 MHz, typ.

Gain 1, 2, 5, 10, 20, 50, 100

Gain accuracy ±0.5 % DC to 100 kHz

± 5 % @ 1 MHz, typ.

Gain stability 200 ppm/◦C

Input voltage noise (RTI, gain ≥ 10) 4 nV/√Hz@ 1 kHz, typ.

gain 1 12nV/√Hz@ 1 kHz, typ.

Input current noise <10 fA/√Hz, typ.

Input impedance 100MΩ // 35 pF

Input Bias Current (DC) 0.5 pA, typ.

Output impedance 50Ω

AC coupling frequency 16 mHz −3dB

Input selection A, A−B, GND

Input coupling AC or DC

Input shields Floating or ground

Maximum input, differential ±1 V before overload

Maximum input, common-mode ±5 V

clamped at ±6 V

Maximum output voltage ±10 V before overload

Maximum output current ±100 mA before overload

Maximum slew rate 0.4 V/µs RTI, typ.

2.4 V/µs RTO, typ.

CMRR 85 dB @ 1 kHz

Offset stability ±10 ppm/◦C max

General Characteristics

Operating temperature 0◦C to 40◦C, non-condensing

Power +5 V (50 mA typ., 100 mA max.)

±15 V (50 mA typ., 300 mA max.)

Interface Serial (RS-232) through SIM interface

Connectors BNC (3 front, 1 rear)

DB–15 (male) SIM interface

Weight 1.5 lbs

Dimensions 1.500W × 3.600H × 7.000D

SIM910 JFET Preamp

Page 9

1 Operation

In This Chapter

The SIM910 JFET Preamp is a flexible low noise voltage preamplifier

for general use from DC to 1 MHz. This chapter gives the necessary

information to get started quickly with the SIM910.

1.1 Instrument Overview . . . . . . . . . . . . . . . . . . 1 – 2

1.2 Front Panel Operation . . . . . . . . . . . . . . . . . . 1– 2

1.2.1 Gain . . . . . . . . . . . . . . . . . . . . . . . . 1 – 3

1.2.2 Offset . . . . . . . . . . . . . . . . . . . . . . . . 1 – 3

1.2.3 Overload . . . . . . . . . . . . . . . . . . . . . . 1– 3

1.2.4 Inputs . . . . . . . . . . . . . . . . . . . . . . . 1 – 4

1.2.5 Output . . . . . . . . . . . . . . . . . . . . . . . 1 – 4

1.3 Rear Panel Output . . . . . . . . . . . . . . . . . . . . 1 – 5

1.4 SIM Interface . . . . . . . . . . . . . . . . . . . . . . . 1 – 6

1.4.1 SIM interface connector . . . . . . . . . . . . . 1 – 6

1.4.2 Direct interfacing . . . . . . . . . . . . . . . . . 1 – 6

1 – 1

Page 10

1 – 2 Operation

A

B

INPUT

A / A-B

AC /

DC

SHIELD

FLOAT/GND

INPUT

GROUND

+

-

FRONT

END

PROGRAMMABLE

GAIN

Ω

50

OUTPUT

REAR

PANEL

OUT

INPUT

PROTECTION

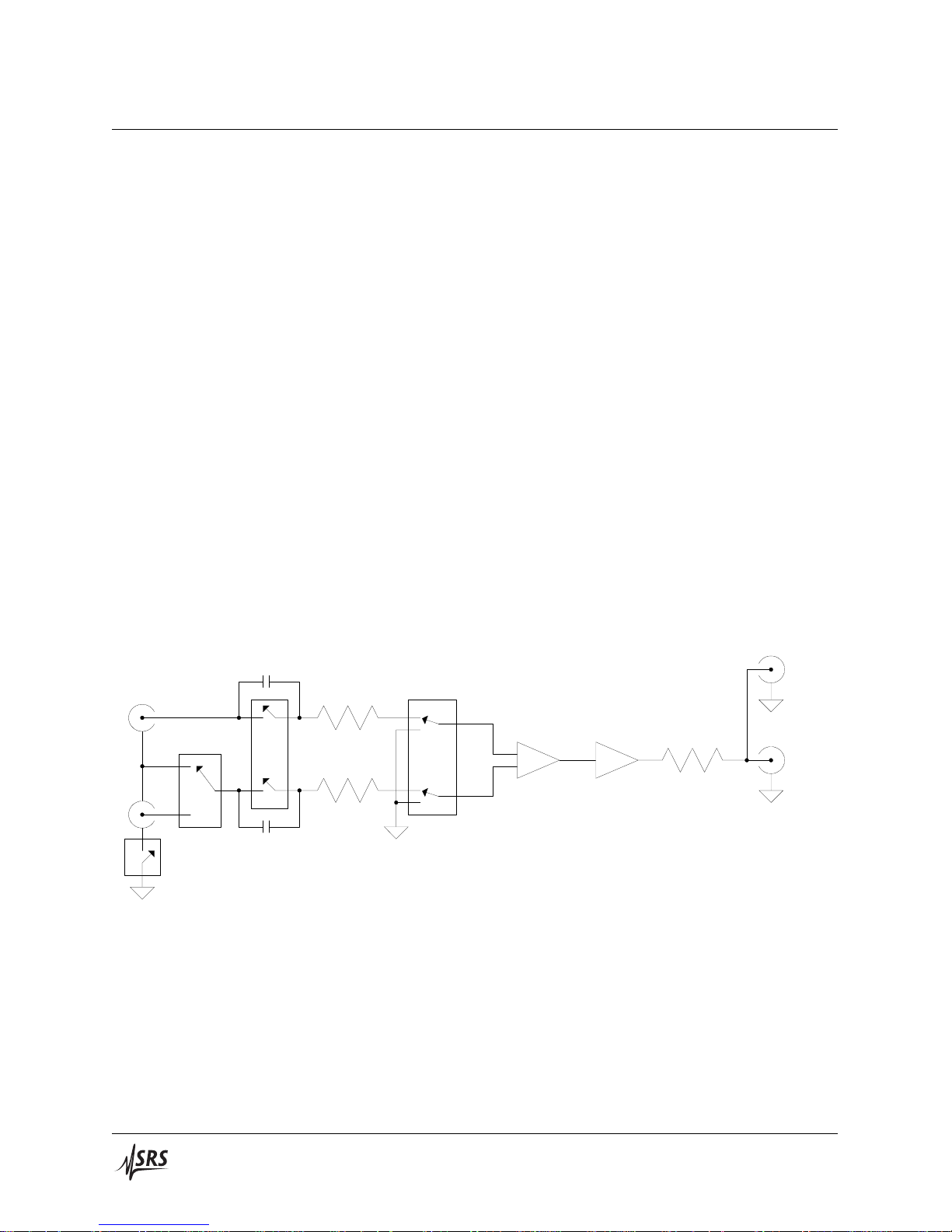

1.1 Instrument Overview

The SIM910 is a voltage preamplifier with low input and output

noise. It provides selectable gain from 1 to 100 of a single ended or

true differential signal. The amplifier runs from DC to 1 MHz, or can

be AC coupled with 16 mHz −3dB frequency. In addition, the input

BNC shields can be grounded or floated allowing the signal ground

to be referenced to a local or remote ground. An overload light

indicates when the input or output maximum voltage, or maximum

output current has been reached.

The amplifier settings can be controlled either by the front panel

buttons or the remote serial interface. Digital noise is eliminated by

only clocking the microprocessor when settings are being changed.

The complete amplifier configuration (i.e., gain settings, coupling,

etc.) is saved in non-volatile memory.

The front end amplifier of this instrument is protected with a pair of

100 Ω resistors (R103 & R104). Note that the internal-grounding input configuration grounds the amplifier inputs after these protection

resistors.

1.2 Front Panel Operation

A block diagram of the amplifier is shown below in Figure 1.1.

Figure 1.1: The SIM910 block diagram.

All SIM910 configurations can be specified either from the front

panel, or by commanding through the remote serial interface. The

front panel is shown below (Figure 1.2). The front panel contains the

SIM910 JFET Preamp

Page 11

1.2 Front Panel Operation 1 – 3

gain settings, the overload light, the input settings, the coupling and

the shield states, and the buttons to control them.

1.2.1 Gain

1.2.2 Offset

1.2.3 Overload

Figure 1.2: The SIM910 front and rear panel.

The gain is selectable from 1 to 100. Gain settings are 1, 2, 5, 10, 20, 50,

and 100 and are displayed as a product of 1, 2, or 5 and a multiplier

of 10 or 100. Gain is raised or lowered by pressing [Gain ] or [Gain ]

in the GAIN block on the upper right of the module. The change

is reflected in the LEDs to the left of the buttons. Pushing [Gain ]

when on gain 100 produces no effect. Pushing [Gain ] when on gain

1 produces no effect.

The offset is adjustable through a hole in the GAIN block of the

front panel with a small flat head screwdriver. See Section 3.1 for a

description of the offset trimming procedure.

There is an overload light in the gain section of the front panel. OVLD

is lit when the input common mode is outside ±5 V, the input signal is

SIM910 JFET Preamp

Page 12

1 – 4 Operation

greater than ±1 V, or the output is outside ±10 V. The overload signal

can also be asserted on the status pin. See section 2.4.5.

1.2.4 Inputs

The two input connectors, labeled A and B, are in the INPUT block

of the front panel. [Input] selects between A, A−B, and Ground. A

& B are voltage inputs with input impedance of 100 MΩ in parallel

with ∼35 pF. The connector shields are tied to each other, and can be

either floated or grounded to Signal Ground using [Shield]. Input

A is the non-inverting input. When input A−B is selected, B is the

inverting input.

When input A is selected, the connector shield is used as the inverting

input, and acts as the reference for the A signal. Thus by selecting

Shield Float, a remote ground reference can be brought to the unit

using a single BNC. As long as the common-mode voltage limit is

satisfied, this configuration can be useful in breaking ground loops.

If the common-mode limits are exceeded, the inputs will be (sepa-overload limits

rately) clamped to ∼ ±6 V through a series input resistor of 100 Ω.

The maximum signal voltage is ±1 V, while the maximum common

mode voltage is ±5V. Exceeding these limits will cause OVLD to

light up.

1.2.5 Output

When the Ground input is selected, the user inputs A & B are left

floating and the amplifier is internally grounded at the front-end,

after the series resistors. The Input grounded noise is the limit of the

amplifier’s noise.

Pressing [Couple] selects AC (16 mHz −3dB) or DC coupling.

The output of the instrument is located in the OUTPUT block of the

front panel. The output is referred to Signal Ground, which is tied to

the outside of the BNC connector.

The chassis of the SIM910 is tied to the power supply return, and notNote about grounds

Signal Ground. When operating in the SIM900, the chassis and Signal

Ground are tied together in the SIM900 Mainframe. If the amplifier is

operated with an independent supply, the output will be referenced

to Signal Ground (pin 1 on DB–15 J401). The Signal Ground and the

chassis are tied through back to back protection schottky diodes, so

they can’t be more than ∼ ±0.35 V apart.

The instrument’s output impedance is 50 Ω, and can drive load

impedances from ∞ down to 50 Ω. Note: when driving a 50 Ω load

the gain will be half that displayed on the LEDs.

SIM910 JFET Preamp

Page 13

1.3 Rear Panel Output 1 – 5

1.3 Rear Panel Output

The rear panel contains a BNC connected to the output, and the SIM

interface connector (see Figure 1.2).

The rear panel output is wired in parallel to the front panel output.

The output is not designed to drive 2 simultaneous 50Ω loads. If

one output is driving a 50 Ω load, the other should be connected to a

high impedance load.

SIM910 JFET Preamp

Page 14

1 – 6 Operation

1.4 SIM Interface

The primary connection to the SIM910 JFET Preamp is the rear-panel

DB–15 SIM interface connector. Typically, the SIM910 is mated to

a SIM900 Mainframe via this connection, either through one of the

internal mainframe slots, or the remote cable interface.

It is also possible to operate the SIM910 directly, without using the

SIM900 Mainframe. This section provides details on the interface.

CAUTION

The SIM910 has no internal protection against reverse polarity, missing

supply, or overvoltage on the power supply pins. Misapplication of power

may cause circuit damage. SRS recommends using the SIM910 together

with the SIM900 Mainframe for most applications.

1.4.1 SIM interface connector

The DB–15 SIM interface connector carries all the power and communications lines to the instrument. The connector signals are specified

in Table 1.1

Pin Signal Src ⇒ Dest Description

1 SIGNAL GND MF ⇒ SIM Ground reference for signal

2 −STATUS SIM ⇒ MF Status/service request (GND = asserted, +5 V= idle)

3 RTS MF ⇒ SIM HW Handshake (+5 V= talk; GND = stop)

4 CTS SIM ⇒ MF HW Handshake (+5 V= talk; GND = stop)

5 −REF 10MHZ MF ⇒ SIM 10 MHz reference (no connection in SIM910)

6 −5 V MF ⇒ SIM Power supply (no connection in SIM910)

7 −15 V MF ⇒ SIM Power supply (analog circuitry)

8 PS RTN MF ⇒ SIM Power supply return

9 CHASSIS GND Chassis ground

10 TXD MF ⇒ SIM Async data (start bit = “0”= +5 V; “1” = GND)

11 RXD SIM ⇒ MF Async data (start bit = “0”= +5 V; “1” = GND)

12 +REF 10MHz MF ⇒ SIM 10 MHz reference (no connection in SIM910)

13 +5 V MF ⇒ SIM Power supply (digital circuitry)

14

+15 V MF ⇒ SIM Power supply (analog circuitry)

15 +24 V MF ⇒ SIM Power supply (no connection in SIM910)

Direction

1.4.2 Direct interfacing

Table 1.1: SIM Interface Connector Pin Assignments, DB-15

The SIM910 is intended for operation in the SIM900 Mainframe, but

users may wish to directly interface the module to their own systems

without the use of additional hardware.

SIM910 JFET Preamp

Page 15

1.4 SIM Interface 1 – 7

The mating connector needed is a standard DB–15 receptacle, such as

Amp part # 747909-2 (or equivalent). Clean, well-regulated supply

voltages of +5, ±15 VDC must be provided, following the pin-out

specified in Table 1.1. Ground must be provided on pins 1 and 8,

with chassis ground on pin 9. The −STATUS signal may be monitored

on pin 2 for a low-going TTL-compatible output indicating a status

message.

1.4.2.1 Direct interface cabling

If the user intends to directly wire the SIM910 independent of the

SIM900 Mainframe, communication is usually possible by directly

connecting the appropriate interface lines from the SIM910 DB–15

plug to the RS-232 serial port of a personal computer.1Connect RXD

from the SIM910 directly to RD on the PC, TXD directly to TD, and

similarly RTS→RTS and CTS→CTS. In other words, a null-modem

style cable is not needed.

To interface directly to the DB–9 male (DTE) RS-232 port typically

found on contemporary personal computers, a cable must be made

with a female DB–15 socket to mate with the SIM910, and a female

DB–9 socket to mate with the PC’s serial port. Separate leads from

the DB–15 need to go to the power supply, making what is sometimes

know as a “hydra” cable. The pin-connections are given in Table 1.2.

DB–15/F to SIM910 Name

DB–9/F

3 ←→7 RTS

4 ←→8 CTS

10 ←→3 TxD

11 ←→2 RxD

5 Computer Ground

to P/S

7 ←→ −15 VDC

14 ←→ +15 VDC

13 ←→ +5 VDC

8,9 ←→ Ground (P/S return current)

1 ←→ Signal Ground (separate wire to Ground)

Table 1.2: SIM910 Direct Interface Cable Pin Assignments

1

Although the serial interface lines on the DB-15 do not satisfy the minimum

voltage levels of the RS-232 standard, they are typically compatible with desktop

personal computers

SIM910 JFET Preamp

Page 16

1 – 8 Operation

The Chassis Ground and Power Ground are tied together in the in-more about grounding

strument. The +5 V sections use the Power Ground, and the signal

sections of the instrument use the ±15 V and Signal Ground. The

Signal Ground and Power Ground are tied through protection schottky diodes, and can therefore not be more than ∼ ±0.35 V apart.

These two ground lines should be separately wired back to a single,

low-impedance ground source at the power supply.

1.4.2.2 Serial settings

The serial port settings at power-on are: 9600 baud, 8–bits, no parity,

1 stop bit, and hardware flow control (see Section 2.3.1). The serial

settings cannot be changed on the SIM910.

SIM910 JFET Preamp

Page 17

2 Remote Operation

In This Chapter

This chapter describes operating the module over the serial interface.

2.1 Index of Common Commands . . . . . . . . . . . . . 2 – 2

2.2 Alphabetic List of Commands . . . . . . . . . . . . . 2 – 3

2.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 2– 4

2.3.1 Power-on configuration . . . . . . . . . . . . . 2– 4

2.3.2 Buffers . . . . . . . . . . . . . . . . . . . . . . . 2 – 4

2.3.3 Device Clear . . . . . . . . . . . . . . . . . . . . 2 – 4

2.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . 2– 5

2.4.1 Command syntax . . . . . . . . . . . . . . . . . 2 – 5

2.4.2 Notation . . . . . . . . . . . . . . . . . . . . . . 2– 5

2.4.3 Examples . . . . . . . . . . . . . . . . . . . . . 2 – 5

2.4.4 Amplifier commands . . . . . . . . . . . . . . . 2 – 6

2.4.5 Status commands . . . . . . . . . . . . . . . . . 2 – 7

2.4.6 Interface commands . . . . . . . . . . . . . . . 2 – 8

2.5 Register Model . . . . . . . . . . . . . . . . . . . . . . 2– 9

2.5.1 Status Byte (SB) . . . . . . . . . . . . . . . . . . 2– 9

2.5.2 Service Request Enable (SRE) . . . . . . . . . . 2– 10

2 – 1

Page 18

2 – 2 Remote Operation

2.1 Index of Common Commands

symbol definition

i Integers

(?) Required for queries; illegal for set commands

{var} Required parameter for set commands; illegal for queries

Amplifier

*RST 2 – 6 Reset

GAIN(?) {i} 2 – 6 Gain

COUP(?) {i} 2 – 6 Coupling

INPT(?) {i} 2 – 6 Input

SHLD(?) {i} 2 – 6 Shield

Status

*STB? 2 – 7 Status Byte

*SRE(?) {i} 2 – 7 Service Request Enable

STOL(?) {i } 2 – 7 Status Monitors Overload

OVLD? 2 – 7 Overload

Interface

*IDN? 2 – 8 Identify

*TST? 2 – 8 Self Test

CONS(?) {i} 2 – 8 Console Mode

SIM910 JFET Preamp

Page 19

2.2 Alphabetic List of Commands 2 – 3

2.2 Alphabetic List of Commands

?

*IDN? 2 – 8 Identify

*RST 2 – 6 Reset

*SRE(?) {i} 2 – 7 Service Request Enable

*STB? 2 – 7 Status Byte

*TST? 2 – 8 Self Test

C

CONS(?) {i} 2 – 8 Console Mode

COUP(?) {i} 2 – 6 Coupling

G

GAIN(?) {i} 2 – 6 Gain

I

INPT(?) {i} 2 – 6 Input

O

OVLD? 2 – 7 Overload

S

SHLD(?) {i} 2 – 6 Shield

STOL(?) {i } 2 – 7 Status Monitors Overload

SIM910 JFET Preamp

Page 20

2 – 4 Remote Operation

2.3 Introduction

Remote operation of the SIM910 is through a simple command language documented in this chapter. Both set and query forms of most

commands are supported, allowing the user complete control of the

amplifier from a remote computer, either through the SIM900 Mainframe or directly via RS-232 (see Section 1.4.2.1).

See Table 1.1 for specification of the DB–15 SIM interface connector.

2.3.1 Power-on configuration

The settings for the remote interface are 9600 baud with no parity,

hardware flow control, and local echo disabled (CONS OFF).

Most of the SIM910 instrument settings are stored in non-volatile

memory, and at power-on the instrument returns to the state it was

last in when power was removed. Exceptions are noted in the command descriptions.

Reset values of parameters are shown in boldface.

2.3.2 Buffers

2.3.3 Device Clear

Incoming data from the host interface is stored in a 32-byte input

buffer. Characters accumulate in the input buffer until a command

terminator (either hCRi or hLFi) is received, at which point the message is parsed and executed. Query responses from the SIM910 are

buffered in a 64-byte output queue.

If the input buffer overflows, then all data in both the input buffer

and the output queue are discarded, and an error is recorded in the

CESR and ESR status registers.

The SIM910 host interface can be asynchronously reset to its poweron configuration by sending an RS-232-style hbreakisignal. From the

SIM900 Mainframe, this is accomplished with the SRST command;

if directly interfacing via RS-232, then use a serial break signal. After

receiving the Device Clear, the interface is reset to 9600 baud and

CONS mode is turned OFF. Note that this only resets the communi-

cation interface; the basic function of the SIM910 is left unchanged;

to reset the instrument, see *RST.

SIM910 JFET Preamp

Page 21

2.4 Commands 2 – 5

2.4 Commands

This section provides syntax and operational descriptions for remote

commands.

2.4.1 Command syntax

The four letter mnemonic (shown in CAPS) in each command sequence specifies the command. The rest of the sequence consists of

parameters.

Commands may take either set or query form, depending on whether

the “?” character follows the mnemonic. Set only commands are

listed without the “?”, query only commands show the “?” after the

mnemonic, and optionally query commands are marked with a “(?)”.

Parameters shown in { } are not always required. Parameters in { }

are required to set a value, and are omitted for queries. Parameters

listed without any surrounding characters are always required.

Do not send ( ) or { } as part of the command.

2.4.2 Notation

2.4.3 Examples

Multiple parameters are separated by commas. Commands are terminated by either hCRi or hLFi characters. Null commands and

whitespace are ignored. Execution of command(s) does not begin

until the command terminator is received.

The following table summarizes the notation used in the command

descriptions:

symbol definition

i Integers

(?) Required for queries; illegal for set commands

{var} required parameter for set commands; illegal for queries

Each command is provided with a simple example illustrating its

usage. In these examples, all data sent by the host computer to

the SIM910 are set as straight teletype font, while responses

received the host computer from the SIM910 are set as slanted

teletype font.

SIM910 JFET Preamp

Page 22

2 – 6 Remote Operation

2.4.4 Amplifier commands

These commands provide control over the settings of the amplifier

circuitry. All of these commands are persistent, in the sense that the

module will restore the last amplifier configuration upon power-on

reset.

Reset*RST

Reset the amplifier to default configuration.

In response to *RST, the amplifier settings become: unity gain, AC

coupling, input grounded, shield floated.

*RSTExample:

GainGAIN(?) {i}

Set (query) the amplifier gain {to i=(1, 2, 5, 10, 20, 50, 100)}.

GAIN?Example:

50

CouplingCOUP(?) {i}

Set (query) the amplifier input coupling.

COUP 1 sets AC coupling, while COUP 2 sets DC coupling.

COUP 1Example:

InputINPT(?) {i}

Set (query) the amplifier input.

INPT 1 sets the amplifier input to A, INPT 2 selects A−B, and INPT 3

grounds the amplifier front-end.

INPT 2Example:

ShieldSHLD(?) {i}

Set (query) the amplifier input BNC shield configuration.

SHLD 1 floats the A & B input shields, while SHLD 2 ties the input

shields to amplifier ground.

SHLD?Example:

1

SIM910 JFET Preamp

Page 23

2.4 Commands 2 – 7

2.4.5 Status commands

The Status commands query and configure registers associated with

status reporting of the SIM910.

Status Byte*STB?

Reads the Status Byte register.

Execution of the *STB? query clears all flag bits set in the Status Byte

register (see the Register Model section 2.5 for more about the Status

Byte register).

*STB also causes the −STATUS signal to be deasserted, as long as the

module is not in Status-Monitors-Overload mode (see STOL).

*STB?Example:

128

Service Request Enable*SRE(?) {i}

Set (query) the Service Request Enable register {to i} See section 2.5.

*SRE 128Example:

Status Monitors OverloadSTOL(?) {i }

Set (query) the Status-Monitors-Overload mode {to i=(0, 1)}.

STOL 1 causes the −STATUS signal (pin 2 on J401 Dsub-15 connec-

tor) to become a real-time monitor of the amplifier overload detect

circuit. STOL 0 restores −STATUS to reflect the overall service request message from the Status Byte register. In applications where

prompt flagging of an amplifier overload is required, STOL 1 mode

provides a single interface line for this signal.

The state of STOL is stored in non-volatile memory and restored

upon power-on reset. Neither *RST nor device-clear affects the state

of STOL.

STOL 0Example:

OverloadOVLD?

Reports the current overload condition. Query returns 0 for normal

operation, or 1 if the amplifier is presently in overload.

OVLD?Example:

1

SIM910 JFET Preamp

Page 24

2 – 8 Remote Operation

2.4.6 Interface commands

The interface commands provide information and control over the

communication link between the SIM910 and the host computer.

None of these commands have any effect on the amplifier function

itself.

Identify*IDN?

Query the device identification string.

The identification string is formatted as:

Stanford Research Systems,SIM910,S/N******,VER#.##

where ****** is the 6-digit serial number, and #.## is the firmware

revision level.

*IDN?Example:

Stanford Research Systems,SIM910,s/n003456,ver2.10

Self Test*TST?

Query the device self test.

The SIM910 does not perform any self tests, and will always return

the message 0 to this query.

*TST?Example:

0

Console ModeCONS(?) {i}

Set (query) the Console mode {to i=(0, 1)}.

CONS 1 causes each character received at the Input Buffer to be

echoed to the Output Queue. This mode can be useful when typing

interactively to the SIM910.

On device clear, CONS is set to 0 (off).

CONS?Example:

0

SIM910 JFET Preamp

Page 25

2.5 Register Model 2 – 9

2.5 Register Model

The SIM910 monitors and reports errors and other conditions using

a single 8-bit register, the Status Byte register. Each bit in the register

is mapped to a particular event category, and if that event occurs the

corresponding bit is set to 1. Bits in the Status Byte are “sticky,” in

the sense that once set to 1, the bit will not revert to the 0 (zero) value

even after the condition that caused the event has completed. Bits

are only cleared by querying the register.

A companion register, the Service Request Enable, acts as a bitwise

mask to the Status Byte for generating the −STATUS signal.

2.5.1 Status Byte (SB)

This is an 8-bit wide register. It can be read through the *STB?

command which also causes it to be cleared.

Weight Bit Flag

1 0 EXE

2 1 CMD

4 2 QRE

8 3 OVR

16 4 SERR

32 5 URQ

64 6 DCAS

128 7 OVLD

EXE : Execution Error. Indicates an error in a command that was

successfully parsed. Out-of-range parameters are an example.

CMD : Command Error. Indicates a parser-detected error.

QRE : Query Error. Indicates data in the Output Queue has been lost.

OVR : Input Buffer Overrun Error. Indicates data to the Input Buffer

has been lost.

SERR : Serial Communications Error. This can be either (1) an Overrun

Error (indicating received data has been lost), (2) a Noise Error

(indicating noise is present on the receive bits), or (3) a Framing

Error (indicating the stop bit is not detected). Note: A break

signal will not set the SERR bit.

URQ : User Request. Indicates that a button has been pushed.

DCAS : Device Clear. Indicates that a break signal has been received

on the serial interface.

OVLD : Overload. Indicates an overload condition has occurred.

SIM910 JFET Preamp

Page 26

2 – 10 Remote Operation

2.5.2 Service Request Enable (SRE)

The SRE is used to control the status line when Status-MonitorsOverload Mode is disabled (See STOL).

This is an 8-bit wide register. Each bit in the SRE corresponds one-toone with a bit in the SB register, and acts as a bitwise AND of the SB

flags. If any bits are simultaneously set in both the SB and the SRE,

then a service request is indicated and the −STATUS signal (pin 2 on

the Dsub-15 SIM Interface Connector) is asserted low.

This register is set and queried with the *SRE(?) command. On

Power-On, this register is cleared.

SIM910 JFET Preamp

Page 27

3 Performance Tests

In This Chapter

This chapter describes how to adjust the module to meet it’s specifications. The module should be warmed up for at least 15 minutes

before making any adjustments.

3.1 Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 2

3.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . 3– 2

3.2.1 Adjusting the CMRR . . . . . . . . . . . . . . . 3– 2

3.2.2 Adjusting the gain . . . . . . . . . . . . . . . . 3– 2

3.2.3 Adjusting the freq adjust . . . . . . . . . . . . . 3 – 3

3.3 Performance Tests . . . . . . . . . . . . . . . . . . . . 3– 3

3.4 SIM910 Performance Test Record . . . . . . . . . . . 3 – 4

3 – 1

Page 28

3 – 2 Performance Tests

3.1 Offset

The SIM910 front-panel offset adjustment provides an easy way for

the user to null the amplifier ’s DC offset. The module should be running for at least 15 minutes before setting the offset. To do this, set

the input to GND. Set the gain to 100. Insert a small flat screwdriver

through the front-panel OFFSET hole and adjust the offset potentiometer until the output of the amplifier is less than 1 mV. Return

to the desired input, A or A−B. Note: the offset will be affected by

CMRR adjustments. Thus the offset should be trimmed after any

CMRR adjustments.

3.2 Calibration

In addition to the offset trimpot, there are 3 internal trimmers that

are calibrated at the factory. They are ”CMRR Adjust” (R120), ”Gain

Adjust” (R215), and ”Freq Adjust” (C402). These are located on the

inside of the box and can easily be adjusted once the right side panel

of the SIM910 has been removed. Adjustments are most easily done

when the instrument is powered externally, or on the SIM900 Mainframe remote cable. The module should be running for at least 15

minutes before doing any adjustments

3.2.1 Adjusting the CMRR

3.2.2 Adjusting the gain

The common mode adjustment minimizes the common mode response of the amplifier by balancing the two sides of the front-end

JFET. Locate R120, the ”CMRR Adjust” trimpot, on the inside of the

SIM910. Set the module’s gain to 100, input mode to A−B, coupling

to DC, and shield to grounded. Generate a ±1 V amplitude sine wave

at 1 kHz. Carefully tee equal lengths of BNC cable to the module’s

A and B inputs from the signal source. Adjust the ”CMRR Adjust”

trimpot to minimize the output signal at 1 kHz; it should be below

±5 mV.

The relative gains in the amplifier are set by 0.1% resistors; however,

the overall gain is adjusted with a ”Gain Adjust” trimpot (R215).

Locate R215, the ”Gain Adjust” trimpot, on the inside of the SIM910.

Set the module’s gain to 100, input mode to A, coupling to DC, and

shield to grounded. Generate a ±10 mV amplitude sine wave at

1 kHz, or a swept sine wave of the same amplitude. Connect the

signal source to the module A input. Measure the transfer function

of the module output relative to the signal input. Adjust the ”Gain

Adjust” trimpot to make the transfer function equal 100 at 1 kHz.

SIM910 JFET Preamp

Page 29

3.3 Performance Tests 3 – 3

10

0

10

1

10

2

10

3

10

4

10

5

1

10

Frequency (Hz)

Voltage Noise (nV/√ Hz RTI)

G 100

G 10

G 1

2

5

20

50

3.2.3 Adjusting the freq adjust

The clocking of the microprocessor is done by an RC oscillator, which

must be adjusted to 1% of 2.5 MHz in order to insure the serial baud

rate is 9600 baud. This is done with the ”Freq Adjust” trimcap

(C402). Locate C402, the ”Freq Adjust” trimcap, on the inside of

the SIM910. Locate the Frequency Test Point, TP401, and connect

a probe to monitor the clock signal. To override the clock-stopping

circuitry, depress and hold down one of the front-panel buttons.

Adjust the ”Freq Adjust” trimcap to make the frequency at the test

point 2.5 MHz.

3.3 Performance Tests

The following curves are typical noise density vs. frequency for the

SIM910.

SIM910 JFET Preamp

Figure 3.1: The SIM910 noise density versus frequency.

These are noise plots with the input grounded internally.

If you are amplifying a small signal far from the SIM900 Mainframe

it could be preferable to run the SIM910 on an external supply, i.e.

the one which is powering your other electronics. To do this, simply

supply ±15 V and a signal ground to power the signal electronics

and +5V and Power ground to power the microprocessor. Use the

shield floated option on the module to use the external ground for

Page 30

3 – 4 Performance Tests

your signal reference. See table 1.1 for the power and communication

connector pin specifications.

3.4 SIM910 Performance Test Record

Description Measured Value

Serial Number

Clock Frequency at TP401

Gain 1

Gain 2

Gain 5

Gain 10

Gain 20

Gain 50

Gain 100

CMRR

Offset

Noise @ gain 100 @ 1 kHz

Table 3.1: Performance Record

SIM910 JFET Preamp

Page 31

4 Parts Lists and Schematics

This chapter presents a brief description of the SIM910 circuit design.

A complete parts list and circuit schematics are included.

In This Chapter

4.1 Circuit Discussion . . . . . . . . . . . . . . . . . . . . 4 – 2

4.1.1 Input amplifier and protection circuitry . . . . 4– 2

4.1.2 Programmable gain stages . . . . . . . . . . . . 4 – 2

4.1.3 Digital control . . . . . . . . . . . . . . . . . . . 4 – 2

4.2 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 4

4.3 Schematic Diagrams . . . . . . . . . . . . . . . . . . . 4 – 4

4 – 1

Page 32

4 – 2 Circuitry

4.1 Circuit Discussion

4.1.1 Input amplifier and protection circuitry

The front-end amplifier Q101 is a matched JFET pair biased with

5.5 mA per side. Closed-loop feedback is provided by U105 for an

overall first-stage gain of 10.

The JFET inputs are protected by TVS101. A pair of bootstrapped

diodes, D101 and D102, isolate the amplifier from this device. Series

input resistors R103 and R104 (100 Ω each) provide some passive

input protection as well, and limit the input current when TVS101

turns on. For excessive input overvoltages, one or both of these

resistors may be damaged or destroyed.

4.1.2 Programmable gain stages

To preserve pulse shapes while changing amplifier gain, a “fixedgains with attenuators” topology was chosen for the SIM910. Low

impedance precision divider ladders (R201 −R204, and R207 − R211)

provide programmable gain steps without introducing excessive

noise at lower gains. Gain allocations are noted on the schematic,

indicating which switches within U201 and U203 are closed based

on gain.

4.1.3 Digital control

The overall gain of the SIM910 is trimmed at U204, the gain of which

is adjustable by ±10 %. The final output stage rolls the gain off slowly

above 1 MHz, and includes a high-current output buffer (U207) capable of driving long coaxial cables and other reactive loads. Note

that the 50 Ω output resistor R225 is common to both the front- and

rear-panel output connectors. Because of this, at most one of the

outputs may be terminated with an external 50 Ω load.

The SIM910 is controlled by microcontroller U405. Amplifier configuration is set by shift registers U301 and U302, while the front panel

LED indicators are driven directly by processor port pins. U406 is a

serial EEPROM providing non-volatile memory for amplifier configurations.

A critical aspect of the design is the clock-stop circuitry implemented

by U403 and U404. A simple RC-oscillator is enabled or disabled at

pin 1 of U403, which is driven by synchronizing flip-flop U403B to

ensure that no “runt” clock pulses are produced that would violate

U405’s minimum clock periods. Four separate clock-starting signals

are combined by U402:

• Power-on reset

SIM910 JFET Preamp

Page 33

4.1 Circuit Discussion 4 – 3

• Amplifier overload

• Incoming serial data

• Front-panel button press

The fast start-time of the RC-oscillator ensures that incoming serial data will be correctly decoded by the microcontroller’s UART,

even when the clock is started by the serial start bit of the incoming

data. When the microcontroller has completed all pending activity,

it drives the STOP signal high (pin 24 of U405), effectively halting its

own processor clock. In this way, the SIM910 guarantees no digital

clock artifacts can be generated during quiescent operation.

SIM910 JFET Preamp

Page 34

4 – 4 Circuitry

Reference SRS P/N Part Value Reference SRS P/N Part Value

C102,C101 5-00069 0.1U-P R126,R127,R205,R206,R212, 4-01431 10

C103,C109,C111,C113,C202, 5-00319 10U-35V R213,R221,R222,R223,R224

C204,C206,C208,C213,C215, R128,R129 4-00306 100M

C217,C219,C404,C406,C408 R130,R131,R412,R414 4-01455 100

C104,C106,C108,C110,C112, 5-00299 0.1U R132,R302,R303,R304,R305, 4-01471 470

C116,C117,C201,C203,C205, R306,R307,R308,R309,R310,

C207,C212,C214,C216,C218, R311,R315

C403,C405,C407,C411,C412, R201,R207 4-00528 499.0

C413,C414,C415,C416 R202,R208 4-01656 301.0

C107,C114 5-00369 33P R203,R204,R211 4-00685 100.0

C115 5-00361 6.8P R209 4-01657 48.70

C209,C220 5-00363 10P R210 4-01658 52.30

C211,C210 5-00375 100P R214 4-00987 44.2

C301 5-00298 0.01U R215 4-00353 100.

C401 5-00381 330P R216 4-01084 453

C402 5-00106 9.0-50P R219 4-01041 162

C409,C410 5-00387 1000P R225 4-00913 49.9-2W

D102,D101 3-01400 BAV199W R232,R235,R236 4-01274 43.2K

D401 3-00945 BAT54S R233,R234,R237 4-01318 124K

D501,D502,D503,D504,D507, 3-00424 LED R240 4-01018 93.1

D509,D510,D511,D512,D513, R241 4-00988 45.3

D515 R301,R316,R402,R405,R407, 4-01527 100K

D508 3-00425 LEDRED R409,R410,R415

D514 3-00426 YELLOW R314,R401,R406,R408,R417 4-01503 10K

J101,J102,J201,J202 1-00003 BNC R403 4-01479 1.0K

J301 1-00609 HEADER 22 R404 4-01083 442

J401 1-00367 DB15 R413,R411 4-01465 270

J501 1-00610 HEADER 22 S501,S502,S503,S504,S505 2-00053 SW

K101,K102,K103,K104 3-01401 DS2E-ML-DC5V TVS101 3-01402 LCDA05

L401,L402,L403 6-00174 BEAD U101 3-00542 AD587JR

Q101 3-00545 2N5564 U103 3-01398 OPA2131

Q301 3-00580 MMBT3906 U105,U202,U204 3-01360 OPA228UA

R101,R102,R108 4-01213 10.0K U106 3-01403 OPA2130UA

R103,R104,R238 4-01021 100 U107,U208 3-00727 LM339

R105 4-01251 24.9K U201,U203 3-01358 DG444

R106,R226,R227,R228,R229, 4-01280 49.9K U206 3-00996 OPA227UA

R230,R231 U207 3-00279 LT1010CN8

R107 4-01687 2.0K U209 3-00728 LM393

R109,R217,R218,R220 4-01096 604 U302,U301 3-00787 74HC595

R110,R111 4-01079 402 U401 3-00903 MAX6348UR44

R112,R113 4-01367 402K U402 3-00663 74HC08

R117,R114 4-01121 1.10K U403 3-00742 74HC74

R116,R115 4-01027 115 U404 3-01405 74AC00

R118,R119 4-01611 8.25 U405 3-01406 68HC705C8A

R120 4-00486 50.0 U406 3-01407 93AA56

R122,R121 4-01355 301K U407 3-00662 74HC14

R125 4-01134 1.50K

4.2 Parts List

4.3 Schematic Diagrams

Schematic diagrams follow this page.

SIM910 JFET Preamp

Loading...

Loading...