Page 1

SERIES PS300

HIGH VOLTAGE

POWER SUPPLIES

MODEL PS310

MODEL PS325

MODEL PS350

1290-D Reamwood Ave.

Sunnyvale, CA 94089 U.S.A.

Phone: (408) 744-9040, Fax: (408) 744-9049

Copyright © 1998, 2000

Stanford Research Systems, Inc.

Al Rights Reserved

Revision 2.9

08/2004

Page 2

Page 3

TABLE OF CONTENTS

Safety and Preparation for Use

Series PS300 Specifications

Instrument Overview

Front Panel Summary 7

Power Button 7

High Voltage Enable Switch 7

LED Displays 7

Select, Enter, and Clear 7

Numeric and Cursor Keys 8

Instrument Status 8

Other Keys 8

Store and Recall 8

Rear Panel Summary 9

Power Entry Module 9

High Voltage Output Connector 9

High Voltage Polarity Selector 9

Analog Outputs 9

IEEE-488 Port 10

Guide to Operation

Setting Output Voltage 11

Setting Voltage Limit 11

Setting Current Limit 11

Setting Current Trip 11

Primary Trip 11

Reset Mode 11

Store and Recall 12

Error Messages 12

Analog Programming and Monitor 12

Default Setup 12

Guide to Programming

Remote Programming 13

Command Syntax 13

Detailed Command List 13

Output Control Commands 13

Setting Control Command 14

Interface Control Commands 14

Status Reporting Commands 15

Status Reporting 15

Serial Poll Status Byte 15

Standard Event Status Byte 16

GPIB Error Messages 16

Program Examples 17

3

5

Example 1 - IBM PC, Microsoft Basic,

Via Capitol Equipment Corp GPIB 17

Example 2 - IBM PC, Microsoft C 4.0,

Via Capitol Equipment Corp GPIB 19

Example 3 - IBM PC, Microsoft C 4.0,

Via National Instruments GPIB 21

Troubleshooting

Power On Reset 23

Stuck Keys 23

No High Voltage 23

Repeated Trips 23

Rear Panel Voltage Set 23

Front Panel Test 23

Calibration 24

Circuit Description

Introduction 25

Voltage Control 25

Low Voltage Pre-Regulator and

High Frequency Inverter 25

Limits and Trips 26

A/D's and D/A's 26

Microprocessor Control 26

GPIB and Front Panel Interface 26

Low Voltage Power Supplies 27

Front Panel 27

High Voltage Section 27

Component List

Main Board 29

Front Panel 35

HV Board - PS310, PS325, PS350 36

Miscellaneous Parts 40

Schematics

Voltage Control 1/11

High Voltage Drive 2/11

Limits and Trips 3/11

Analog Voltages and A/D 4/11

Microprocessor Section 5/11

GPIB and Front Panel 6/11

Low Voltage Power Supply 7/11

HV Front Panel 8/11

Model PS310 - 1250 V, 20 mA 9/11

Model PS325 - 2500 V, 10 mA 10/11

Model PS350 - 5000 V, 5 mA 11/11

1

Page 4

2

Page 5

SAFETY AND PREPARATION FOR USE

**********WARNING **********

This unit contains hazardous high voltages.

Please make certain that the high voltage is

completely discharged before removing the high

voltage cable. High voltage cables can store

charge if they are disconnected from the supply

while the high voltage is on. The charge on

the cable can cause injury or damage even after

the cable is disconnected from the unit.

Do not change the high voltage polarity unless

the power is off.

***********CAUTION **********

This instrument may be damaged if operated

with the LINE VOLTAGESELECTOR set for

the wrong AC line voltage or if the wrong fuse is

installed.

Line Voltage Section

The PS300 series operates from 100, 120, 220 or

240 Volts nominal AC power source with a line

frequency of 50 or 60 Hz. Before connecting the

power cord to a power source, verify that the

LINE VOLTAGE SELECTOR card, located in

the rear panel fuse holder, is set so the correct

AC input voltage is visible.

Conversion to other AC input voltages requires a

change in the fuse holder voltage card position

and fuse value. Disconnect the power cord, open the

fuse holder cover door, and rotate the fuse-pull lever

to remove the fuse. Remove the small printed circuit

board. Select the operating voltage by orienting the

printed circuit board. Press the circuit board firmly

into its slot, so the desired voltage is visible. Rotate

the fuse-pull lever back into its normal position.

Insert the correct fuse into the fuse holder.

Line Fuse

Verify that the correct line fuse is installed before

connecting the line cord. For 100 V / 120 V, use a 1

Amp fuse and for 220 V / 240 V, use a 1/2 Amp fuse.

Line Cord

The PS300 series use a detachable, three-wire power

cord for connection to the power source and to a

protective ground. The exposed metal parts of the

instrument are connected to the outlet ground which

provides protection against electrical shock. Always

use an outlet which has a properly connected

protective ground.

Connection to Other Instruments

The back panel BNC shields are connected to the

chassis ground and the AC power source ground via

the power cord. Do not apply any voltage to the

shield. The high voltage SHV connector is also

connected to the chassis ground and CANNOT be

floated away from ground.

3

Page 6

Page 7

SERIES PS300 SPECIFICATIONS

General Information

The PS300 series are programmable precision high voltage power supplies for use in laboratory or test

applications. They feature reversible polarity, excellent regulation and low output voltage ripple. The digital

displays provide accurate readings of voltage and current. Also, digital entry of the current and voltage

provides accurate resettability. Output voltage can be set from either the front panel, the remote analog voltage,

or over the optional GPIB interface. Voltage and current signals are also available for remote monitoring.

Electrical Specifications

Model Output Voltage Maximum Output Current

PS310 50 to ±1250 Volts 20 mA

PS325 50 to ±2500 Volts 10 mA

PS350 50 to ±5000 Volts 5 mA

Voltage Set Accuracy 0.01% + 0.05% of full scale

Voltage Display Accuracy V Set Accuracy ±1 Volt, typ ( ±2 Volt, max)

Voltage Resolution 1 Volt (set and display)

Voltage Resettability 1 Volt

Voltage Limit Range 0 to 100% of full scale

Voltage Regulation (*) Line: 0.001% for ±10% line voltage change

Load: 0.005% for 100% load change, typ

Output Ripple < 0.0015% of full scale, Vrms, typ

< 0.002% of full scale, Vrms, max

Current Limit and Trip Range 0 to 105% of full scale

Current Set accuracy 0.01% + 0.05% of full scale

Current Resolution PS310: 10 µA

PS325: 10 µA

PS350: 1 µA

Current Display Accuracy PS350: I Set Accuracy ±1 µA, typ ( ±2 µA, max)

PS325 or PS310: Accuracy ±10 µA, typ ( ±20 µA, max)

Stability 0.01% per hour, < 0.03% per 8 hours

Temperature Drift 50 ppm / °C, 0° to 50° C, typ

Protection Arc and short circuit protected; programmable voltage and

current limits and current trip.

(*) Regulation specifications apply for > 0.5% (full load) or 1.0% (no load) of full scale Voltage.

Below these values the unit may not regulate correctly.

5

Page 8

Recovery Time 12 ms for 40% step change in load current, typ

Discharge Time <6 sec (to < 1% of full scale voltage with no load, typ)

Trip Response Time <10 µs

Minimum Trip Current 10 µA

Monitor Outputs Output Scale: 0 to +10 Volts for 0 to full scale output

regardless of polarity

Current Rating: 10 mA, max

Output Impedance: < 1 Ω

Accuracy:0.2% of full scale

Update Rate: 8 Hz

External Voltage Set Input Scale: 0 to +10 Volts for 0 to full scale output

regardless of polarity

Input Impedance: 1 MΩ

Accuracy:0.2% of full scale

Update Rate: 16 Hz

Output Slew Rate: < 0.3 sec for 0 to full scale under full load

Mechanical Specifications

Dimensions 16.0" x 8.1" x 3.5" (L x W x H)

The PS300 series are 1/2 rack width (19 inch standard rack). Optional rack

mounting kits are available for single or double rack mounts. The single

rack mount provides mounting for one supply. The double rack mount

provides side by side mounting for 2 supplies.

Weight 8 lbs

Input power 50 watts, 100, 120, 220, 240 VAC ±10%, 50 or 60 Hz

Output High Voltage Connector SHV male (Kings Type 1704-1 or equivalent, not included)

Mating High Voltage Connector SHV female (Kings Type 1705-14 or equivalent, not included)

Warranty One year parts and labor on materials and workmanship

6

Page 9

INSTRUMENT OVERVIEW

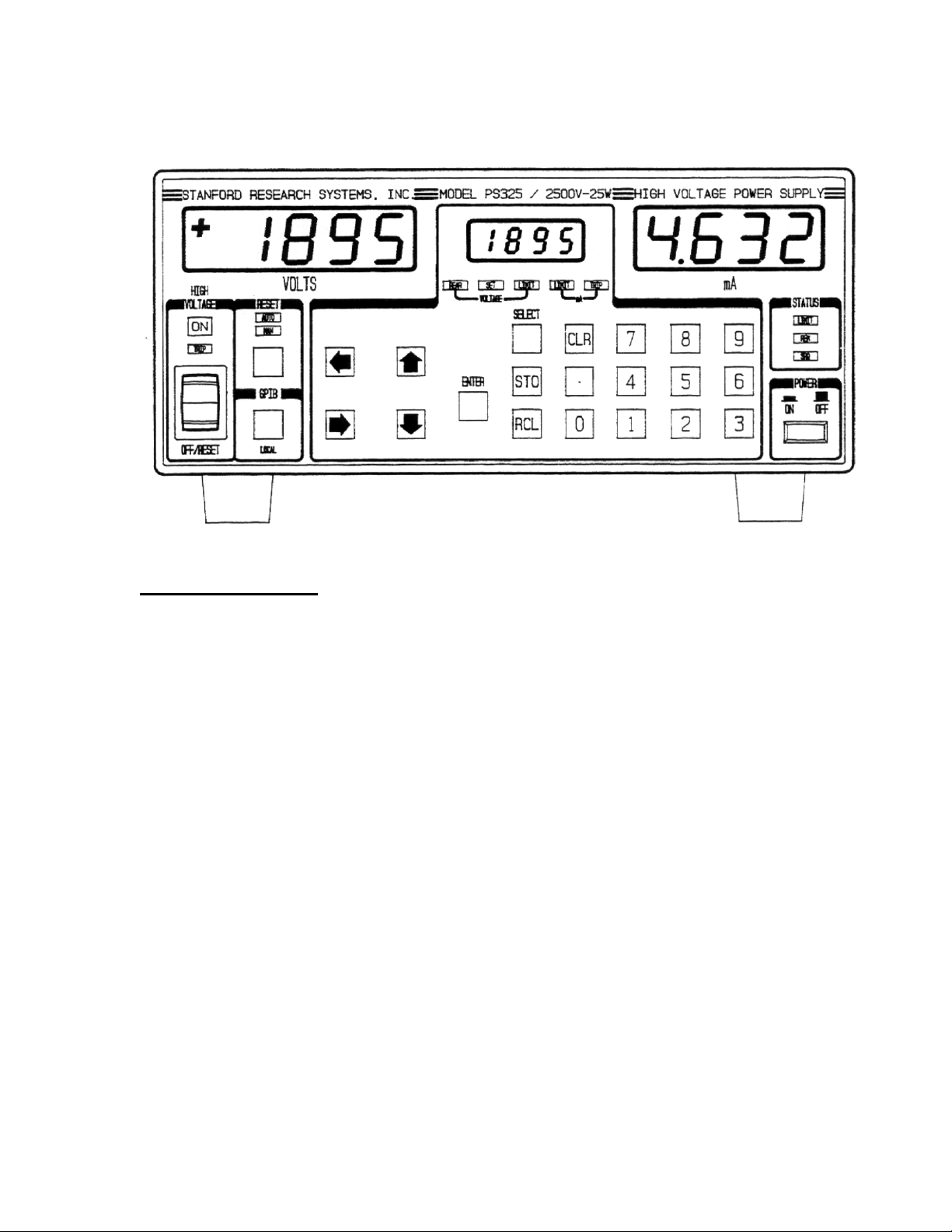

Front Panel Su m mary

Power Button

The PS300 series are turned on by depressing the

POWER button. The unit always powers up with

the high voltage OFF. All instrument settings are

stored in nonvolatile memory and are saved when

power is turned off. The model number (310, 325,

or 350), firmware version, and serial number are

displayed when power is turned on. If an error

appears on power on, then the stored settings were

lost and the default settings are used. If the default

settings are desired, hold down the CLR (clear) key

while turning on the power.

High Voltage Enable Switch

This is a three position switch that performs several

functions. In the down position, the high voltage is

off and all trips are cleared. In this position the

high voltage is locked OFF and cannot be turned

on by computer control. The up position is

momentary and turns on the high voltage for

manual or rear panel analog control. In the middle

position the high voltage is enabled (but not

necessarily on) and can be turned on by computer.

The large red LED above the switch indicates that

the high voltage is on; the yellow LED below it

indicates a trip has occurred.

LED Displays

The two large displays show output voltage and

current to four significant places. Polarity is

displayed on the left of the voltage display. The

smaller center display shows the value of the

parameter that is being entered or adjusted. That

parameter is indicated by the row of LEDs directly

below the center display.

Select, Enter, and Clear

The SELECT key is used to choose which

parameter is being displayed in the center display.

The ENTER key enters the parameter shown in the

center display. The clear (CLR) key erases the

value in the middle display and recalls the last

value that was entered. To adjust a value, the

SELECT key is pressed until the appropriate LED

is lit. When the value is being changed, that LED

will flash to indicate that the value in the center

display is not the current unit setting. If an

incorrect value is entered, press CLR (clear) to start

over. When the desired value is in the center

display, pressing the ENTER key updates the unit's

actual setting and stops the LED's flashing.

7

Page 10

Numeric and Cursor Keys

Other Keys

All parameters may be adjusted using the cursor or

numeric keys. When using the cursors, the digit

being adjusted in the center display will flash. The

UP and DOWN keys increment and decrement the

digit. The LEFT and RIGHT keys select the

flashing digit. When using direct numerical entry,

simply press the number and decimal point keys

until the desired value appears on the center

display. Note that the current is specified in mA.

Instrument Status

Three LED's indicate the instrument's status. The

LIMIT LED is on when the unit is in current limit.

REM is on when the front panel is locked out.

SRQ is on when a GPIB service request is pending.

RESET sets the reset mode to either AUTO or

MAN (manual).

GPIB displays the GPIB address in the center

display so it can be adjusted. It is also the LOCAL

key when the unit is in the remote mode.

Store and Recall

STO (store) and RCL (recall) allow up to 9

complete instrument settings to be saved in

nonvolatile memory. RCL 0 recalls the default

settings.

8

Page 11

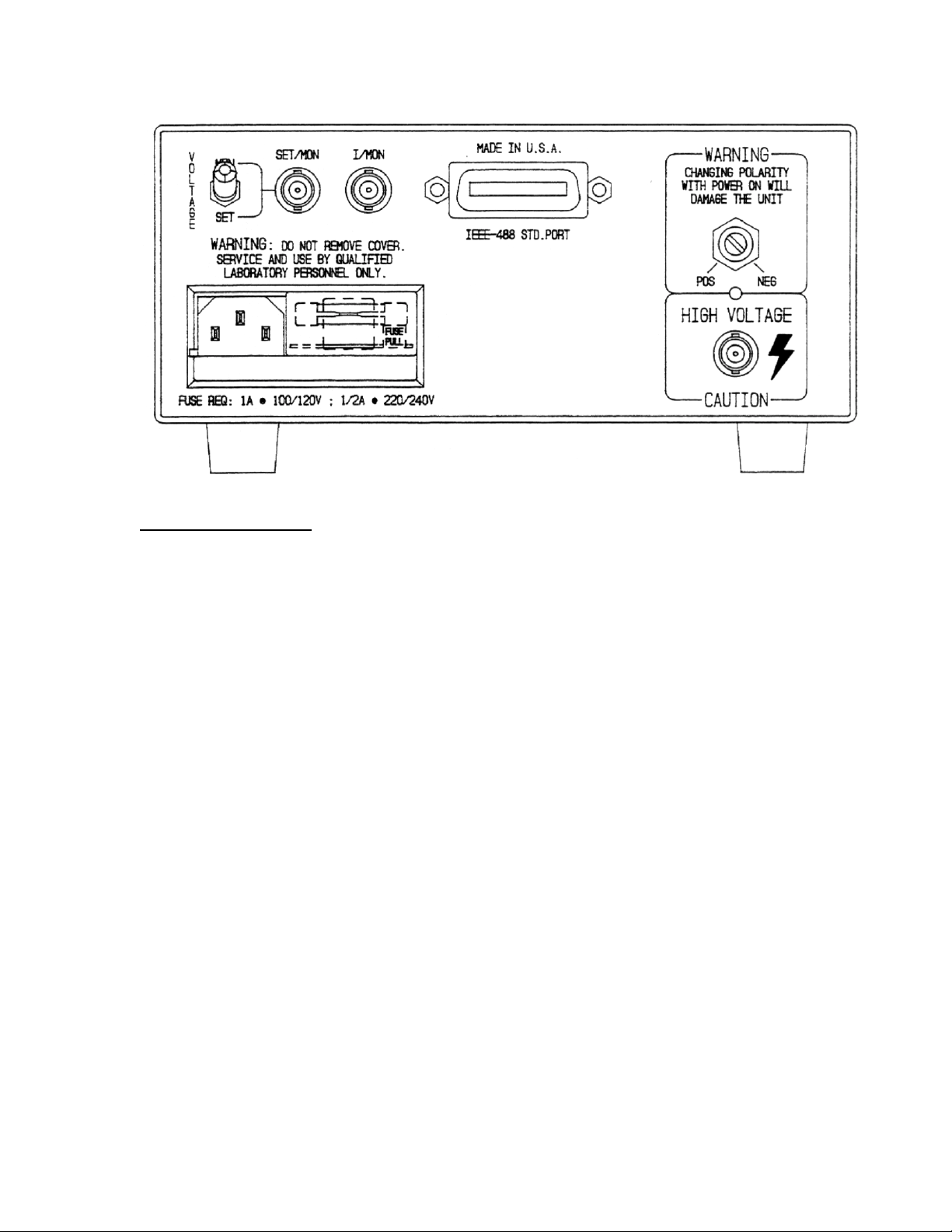

Rear Panel Summary

Power Entry Module

The power entry module is used to fuse the line,

select the line voltage, and block high frequency

noise from entering or exiting the unit. Refer to

the first page of the manual for instructions on

selecting the correct line voltage and fuse.

High Voltage Output Connector

WARNING: This unit contains hazardous

voltages. Please make certain that the high voltage

is completely discharged before removing or

connecting the high voltage cable. High voltage

cables can store charge if they are disconnected

from the supply while high voltage is present

which can cause injury or damage the unit.

The high voltage output connector is an SHV male

connector (Kings type 1704-1). Please make

certain that the high voltage is completely

discharged before changing the cable.

A 10 feet SHV-SHV or SHV-MHV cable is

available from SRS.

High Voltage Polarity Selector

WARNING: The unit must be turned off and the

high voltage should be completely discharged

before reversing the polarity. Failure to do this can

cause injury or damage the unit.

Polarity is indicated by the screwdriver slot on the

polarity switch as well as on the front panel's

voltage display. To reverse the polarity, turn the

unit off and allow the high voltage to completely

discharge. Then turn the polarity switch with a

large flathead screwdriver (clockwise for + to - and

counterclockwise for - to + ).

Analog Outputs

The two BNC's provide voltage and current

monitor signals, or an external voltage set and

current monitor. When the voltage select switch is

in the MON (monitor) position, both are 0 to +10

Volt outputs corresponding to 0 to full scale. When

the voltage select switch is in the SET position, the

current signal acts the same, but the voltage BNC

is an input, setting the the high voltage over the

same scale. When the switch is in the SET position,

the REAR LED on the front panel is lit, indicating

that the high voltage is under analog control and

cannot be adjusted from the keypad. All signals are

positive voltages, independent of output voltage

polarity.

9

Page 12

IEEE-488 Std Port (optional)

The 24 pin IEEE-488 (GPIB) connector allows

computer control of PS300 series supplies. The

address is set from the front panel using the GPIB

key.

10

Page 13

GUIDE TO OPERATION

Setting Output Voltage

The voltage set can be changed with the high

voltage on or off.

To set the high voltage output, press the SELECT

key until the VOLTAGE SET LED is lit. The

present value of the set voltage will be displayed in

the center window. To change the value, enter the

desired voltage by either the numeric or cursor

keys. After the new value has been entered into the

center display, press ENTER to update the output

voltage. The VOLTAGE SET LED will flash until

ENTER or CLR is pressed to remind you that the

displayed value is not the actual programmed

value. If an 'Err2' message appears (illegal

parameter entered), check the voltage limit to see

that it is greater than or equal to the desired set

voltage. Use the CLR key to clear any error

message.

If the REAR LED is lit, the high voltage is

programmed from the analog set input on the rear

panel. In this mode, when the center display is

showing VOLTAGE SET, the display is the

present programmed value of the high voltage and

cannot be adjusted from the front panel.

Setting Voltage Limit

The voltage limit is a protection feature to prevent

the output voltage from being set too high or

overshooting because of dramatic load changes.

The output voltage cannot be set higher than the

voltage limit. In addition, if the output ever

exceeds the limit by more than 10% of full scale,

the unit trips and the high voltage is disabled. If

this occurs, a 'VTRP'(voltage trip) message appears

in the middle display.

After a trip it is not necessary to clear the trip

before turning the high voltage back on. If it is

necessary to change a parameter before turning the

high voltage back on, pressing CLR or putting the

high voltage switch in the off position will clear the

trip.

To set the voltage limit, press the SELECT key

until the VOLTAGE LIMIT LED is lit. The present

value of the voltage limit is displayed in the center

window. Change it with either the numeric or

cursor keys and press ENTER to update the actual

limit value. If an 'Err2' message appears (illegal

parameter entered), check to see that the output

voltage is less than or equal to the voltage limit.

Setting Current Limit

Current limiting varies the output voltage to limit

the output current to less than or equal to the

programmed current limit value. When the unit is

current limited, the LIMIT LED is lit.

The current limit is set in the same fashion as the

voltage limit, by SELECTing the present value on

the center window, changing it and then

ENTERing the new value.

Setting Current Trip

The current trip shuts off the high voltage when the

output current exceeds the trip value. The current

trip value is set in the same fashion as the voltage

and current limits. After a current trip occurs, the

'ITRP' (current trip) message will appear in the

middle display. Current trips are cleared in the

same fashion as voltage trips.

Primary Trip

A PTRP (primary trip) message will occur if the

current through the primary side of the high

voltage transformer and the switching MOSFET's

exceeds about 5.3 Amps. This feature is included

to protect the transformer and FET's. The trip level

is not user programmable and may be cleared in the

same manner as the voltage and current trips. If

repeated PTRP's occur, see the troubleshooting

section.

Reset Mode

The reset mode determines how the unit responds

after a voltage or current trip.

MAN (manual) Mode: The high voltage remains

off after a trip and requires that the operator turn it

back on.

AUTO (automatic) Mode: The unit waits until

the output voltage has fallen to 1/50 of its full scale

value and then turns the high voltage back on. This

is useful when dealing with loads that occasionally

short circuit but recover after removing the high

voltage.

11

Page 14

Store and Recall

STO (store) and RCL (recall) allow up to 9

complete instrument setups to be saved. To store a

setup, press the STO key, followed by a number (1-

9) and then the ENTER key. To recall a setup,

press the RCL key, followed by a number (0-9) and

then the ENTER key. RCL 0 returns the setup to

the factory default. Whenever a setup is recalled,

the high voltage is turned off for safety. If an 'Err3'

(recall error) occurs, then that stored setup was lost

due to a memory error and must be re-entered.

Error Messages

The following error messages may appear in the

center display. The CLR key clears the errors.

and does not allow the rear panel voltage to set the

output above the voltage limit. If the rear panel

voltage is too high, the output voltage will stop at

the limit voltage.

Voltage Monitor/Set: When the Analog

Programming switch is in the MONITOR position,

the VOLTAGE BNC is a monitor output providing

0 to +10 Volts for 0 to full scale output regardless

of polarity. When the switch is in the SET position,

the BNC becomes an input over the same range.

An input of 0 to +10 Volts will program the high

voltage from 0 to full scale, regardless of polarity.

Current Monitor: This provides 0 to +10 Volts

out for 0 to full scale output regardless of the

output polarity.

Err1 Memory Error

Power on memory error of the unit's

last setup. Default setup is recalled.

Err2 Illegal Parameter Entered.

Err3 Stored Value Recall Error

The stored setup (from STO and

RCL) was lost.

Err4 Illegal Storage Address

STO 0 is reserved for default settings.

Err5 No GPIB Interface The unit does

not have the GPIB option so the

GPIB address cannot be set.

Err6 Syntax error over GPIB.

Err7 Illegal parameter entered over GPIB.

Parameter entered is out of range.

Err 8 GPIB Output queue full.

Analog Programming and Monitor

The rear panel voltage select switch determines

whether the output voltage is set from the front

panel or from the rear panel voltage input. If the

switch is in the MON (monitor) position, the front

panel will set the voltage. If the switch is in the

SET position, the rear panel voltage will set the

output voltage. When the switch is in the SET

position, the REAR (rear panel) LED is lit and the

output voltage being set by the rear panel is

displayed in the middle display when it is showing

VOLTAGE SET. The voltage limit is still active

If the switch position is changed while the high

voltage is on, the unit will shut the high voltage

off.

Default Setup

The factory default setup can be recalled by

pressing the CLR key while turning the unit on or

recalling setup 0 (RCL 0). The default setup is also

recalled after a power on memory error (ERR 1).

The default setups are shown below.

PS310 Voltage Set 0 V

Voltage Limit 1250 V

Current Limit 21 mA

Current Trip 21 mA

Reset Mode MAN

High Voltage OFF

GPIB Addr 14 (if applicable)

PS325 Voltage Set 0 V

Voltage Limit 2500 V

Current Limit 10.5 mA

Current Trip 10.5 mA

Reset Mode MAN

High Voltage OFF

GPIB Addr 14 (if applicable)

PS350 Voltage Set 0 V

Voltage Limit 5000 V

Current Limit 5.25 mA

Current Trip 5.25 mA

Reset Mode MAN

High Voltage OFF

GPIB Addr 14 (if applicable)

12

Page 15

GUIDE TO PROGRAMMING

Remote Programming

The PS300 series High Voltage Power Supplies

may be remotely programmed via the GPIB (IEEE-

488) interface. Any computer supporting this

interface may be used to program the PS300.

The PS300 supports the IEEE-488.1 (1978)

interface standard. Additionally, it also supports

the required common commands of the IEEE-488.2

(1987) Standard. Before attempting to

communicate with the PS300 over the GPIB

interface, the PS300's device address must be set.

The address is set from the front panel by pressing

the GPIB key and using the up and down arrow

keys to set the address to any number between 0

and 30. Pressing the ENTER key then sets the

selection.

Command Syntax

Communications with the PS300 use ASCII

characters. Commands may be in either UPPER or

lower case and may contain any number of

embedded space characters.

A command to the PS300 consists of a four

character command mnemonic, arguments if

necessary, and a command terminator. The

terminator is a linefeed <lf> or EOI. No command

processing occurs until a command terminator is

received. Command mnemonics beginning with an

asterisk "*" are IEEE-488.2 (1987) defined

common commands. Commands may require one

or more parameters. Multiple parameters are

separated by commas ",".

Multiple commands may be sent on one command

line by separating them by semicolons ";". The

difference between sending several commands on

the same line and sending several independent

commands is when a command line is parsed and

executed, the entire line is executed before any

other device action proceeds. This allows

synchronization to be achieved using the

synchronization commands.

There is no necessity to wait between commands.

The PS300 has a 256 character input buffer and

processes commands in the order received. If the

buffer fills up, the PS300 will hold off handshaking

on the GPIB. Similarly, the PS300 has a 256

character output buffer to store output until the host

computer is ready to receive it. If the output buffer

fills up, it is cleared and an error reported.

The present value of a particular parameter may be

determined by querying the PS300 for its value. A

query is formed by appending a question mark "?"

to the command mnemonic and omitting the

desired parameter from the command. If multiple

queries are sent on one command line (separated

by semicolons, of course), the answers will be

returned in a single response line with the

individual responses separated by semicolons. The

default response terminator that the PS300 sends

with any answer to a query is a linefeed plus EOI.

All commands return integer results except as

noted in individual command descriptions.

Examples:

VSET1.0E3<lf> sets VSET to 1000 V

VSET?<lf> queries the value of

VSET

*IDN? <lf> queries the device

identification (query, no

parameters)

VSET100.0;VSET? <lf> sets voltage to 100 V

and queries the voltage

Detailed Command List

The four letter mnemonic in each command

sequence specifies the command. The rest of the

sequence consists of parameters. Multiple

parameters are separated by commas. Commands

that may be queried have a question mark ? in

parentheses (?) after the mnemonic. Commands

that may ONLY be queried have a ? after the

mnemonic. Commands that MAY NOT be queried

have no?.

Output Control Commands

HVOF

The HVOF command turns the high voltage OFF.

HVON

The HVON command turns the high voltage ON

provided that the front panel high voltage switch is

not in the OFF position. If the switch is in the OFF

position, the high voltage is left off and an

13

Page 16

execution error is reported. This command also

automatically clears any voltage or current trips.

setting mode may only be changed by setting the

rear panel switch.

IOUT?

The IOUT? query returns the actual output current.

This is the same value as shown on the front panel

meter. Note: As with the front panel meters, this

value takes about a second to stabilize after a

change in current.

VOUT?

The VOUT? query returns the actual output

voltage. This is the same voltage as shown on the

front panel meter. The value returned is a floating

point value and includes the sign of the output

voltage. Note: As with the front panel meters, this

value takes about a second to stabilize after a

change in voltage.

Setting Control Commands

*RCL i

The *RCL command recalls stored setting i.

Setting 0 recalls the default settings. If the stored

setting is corrupted, an error is returned.

*SAV i

The *SAV command stores the present setup as

setting i. i may range from 1 to 9.

ILIM(?) x

TCLR

The TCLR command clears any voltage or current

trips.

TMOD(?) i

The TMOD command sets the trip reset mode. The

value i = 0 sets manual trip reset, while the value i

= 1 sets the trip reset mode to auto.

VLIM(?) x

The VLIM command sets the value of the voltage

limit to x where x is the value in Volts. The sign of

value x MUST match the PS300's polarity setting.

The VLIM? query returns the present VLIM

setting. As with front panel control, the VLIM

value must be greater than or equal to the VSET

value or an execution error will be returned.

VSET(?) x

The VSET command sets the value of the voltage

set to x if front panel control is enabled. If rear

panel control is enabled, an error is returned. The

value x is a number in the units of Volts and the

sign of the number MUST match the PS300's

polarity setting. The VSET? query returns the

current VSET value. As with front panel control,

the VSET value must be less than or equal to to

VLIM value or an execution error will be returned.

The ILIM command sets the value of the current

limit to x. The value x is a floating point value with

the units of Amps (e.g. 1 mA = 1E-3). The ILIM?

query returns the current limit setting.

ITRP(?) x

The ITRP command sets the value of the current

trip to x. The value x is a floating point value with

the units of Amps (e.g. 1 mA = 1E-3). The ITRP?

query returns the current trip setting.

SMOD?

The SMOD? query returns the VSET setting mode.

The value 0 means that the voltage value is

controlled by the front panel setting, while the

value 1 indicates that the output is controlled by the

rear panel voltage control input. Note that the

Interface Control Command

*RST

The *RST common command resets the PS300 to

its default configurations. It is the same as holding

down "CLR " at power on.

*IDN?

The *IDN common query returns the PS300's

device configuration. This string is in the format:

StanfordResearchSystems,PS3XX,serial number,

version number, where XX is the particular model

number, "serial number" is the serial number of the

particular unit, and "version number" is the 3 digit

firmware version number.

14

Page 17

Status Reporting Commands

*CLS

The *CLS common command clears all status

registers

*ESE (?) j

The *ESE common command sets the standard

status byte enable register. The parameter j is the

decimal value that the enable register is to be set to.

*ESR? {j}

such as SRQ on power up to be produced if

desired.

Serial Poll Status Byte

bit name

0 stable This indicates that the VSET or

1 v trip This indicates that a voltage trip

usage

ILIM value is stable. The value

depends on whether the PS300 's

in constant current or constant

voltage mode.

has occurred.

The *ESR common command reads the value of

the standard status register. If the parameter j is

present the value of bit j is returned. Reading this

register will clear it. Reading bit j will clear bit j

only.

*PSC (?) j

The *PSC common command sets the value of the

power-on status clear bit. If j = 1, the power on

status clear bit is set and all status registers and

enable registers are cleared on power up. If j = 0,

the bit is cleared and the status enable registers

maintain their values at power down. This allows

the production of a service request at power up, etc.

*SRE (?) j

The *SRE common command sets the value of the

serial poll enable register. The parameter j is the

decimal value that the register is to be set to.

*STB? {j}

The *STB? common query reads the value of the

serial poll byte. If the parameter j is present the

value of bit j is returned. Reading this register has

no effect on its value. It is just the summary of the

other status registers.

Status Reporting

2 itrip This indicates that a current trip

has occurred.

3 ilim This indicates that a current limit

condition has occurred.

4 MAV This indicates that the GPIB

output queue is non-empty.

5 ESB This indicates that an unmasked

bit in the standard status byte has

been set.

6RQS/ SRQ BIT.

MSS

7 hvon This indicates that the high

voltage is on.

The PS300 will make a service request (SRQ)

whenever one of these bits is set AND the

corresponding bit in the serial poll enable register

is set. Note that any status condition will produce

only one SRQ even if it is never cleared. The vtrip,

itrip and ilim bits are latched bits. They are set on

the occurrence of the appropriate event and stay set

until either the status byte is read or the *CLS

command is sent. This allows one to detect if a trip

condition has ever occurred. All of the other bits

indicate the current states of their respective

functions.

The PS300 reports on its status by means of two

status bytes: the serial poll byte, and the standard

status byte.

On power up, the PS300 may either clear all of its

status enable registers or maintain them in the state

they were in during power down. The action taken

is set by the *PSC command and allows things

15

Page 18

Standard Event Status By te

GPIB Error Messages

bit name

0 unused

1unused

2 Query Error set by an output queue

3 Recall Err set if a stored setting is

4 Execution Err set by an out of range

5 Command Err set by a command syntax

6 URQ set by any key press

7 PON set by power on

This status byte is defined by IEEE-488.2 (1987)

and is used primarily to report errors in commands

received over the communications interfaces. The

bits in this register stay set once set and are cleared

by reading them or by the *CLS command. If a bit

in the standard status register is set and the

corresponding bit in the standard status enable

register is set, then the ESB bit in the serial poll

register is set.

usage

overflow

corrupt

parameter, or noncompletion of some

command due to a condition

like overload

error or unrecognized

command.

The following error messages will appear on the

middle display if an error occurs due to a command

sent over GPIB:

Err6 Syntax Error over GPIB.

The command had an error in syntax or

was unrecognizable. A syntax error could

be a misspelling of a command or

forgetting to include a '-' when setting a

negative value for the voltage or voltage

limit. This error is the same as Command

Error, bit 5 of the Standard Event Status

Byte.

Err7 Illegal Parameter entered over GPIB.

A parameter was set out of range, or a

command could not be completed because

of an overload. This error is the same as

Execution Err, bit 4 of the Standard Event

Status Byte.

Err 8 GPIB Output Queue full.

The output queue overflowed and was

cleared. This could be due to querying the

unit repeatedly and not reading out all of

the characters, or a problem at the

recieving unit. This error is the same as

Query Error, bit 2 of the Standard Event

Status Byte.

16

Page 19

PROGRAM EXAMPLES

This section lists example programs which use the GPIB port to control the PS300. All of the programs do the

same thing, only the language is different. The programs set up the PS300 to ramp the output voltage from 0 to

1000 Volts while reading the output current.

Program Example 1:

IBM PC, Microsoft BASIC, Via GPIB

This program requires the Capital Equipment Corporation GPIB card for the IBM PC. It has firmware in ROM

to interface high level languages to the GPIB.

Subroutine calls in Microsoft BASIC are done to memory locations specified by the name of the subroutine.

The address is relative to the segment address specified by the DEF SEG statement preceding the CALL.

In this program, the CEC card's ROM starts at C000H, the system controller's address is 21, and the PS300 is at

GPIB address 23. Make sure the address in the unit is set correctly and that the HIGH VOLTAGE ENABLE

switch is not OFF.

10 'EXAMPLE PROGRAM TO RAMP THE PS300 HV OUTPUT AND READ THE CURRENT

20 'USING IBM PC BASIC AND THE CAPITAL EQUIPMENT CORP.

30 'GPIB INTERFACE CARD

40 '

50 '

60 'SET THE PS300 GPIB ADDR=23

70 '

80 DEF SEG = &HC000 'BASE ADDRESS OF CEC CARD

90 INIT=0: TRANSMIT=3: SEND=9: ENTER=21 'ADDRESSES OF CEC FIRMWARE ROUTINES

100 ADDR%=21: SYS%=0 'CONTROLLER ADDRESS

110 PS300%=23 'PS300 ADDRESS

120 '

130 'STRING DEFINITIONS

140 IN$="IFC UNT UNL REN MTA LISTEN 23 SDC" 'CLEAR PS300

150 HV$="HVON" 'HV ENABLE

160 CR$="*RST" 'RESET PS300

170 IR$="IOUT?" 'READ CURRENT

180 VS$="VSET" 'SET HV OUTPUT LEVEL

190 '

200 '

210 CALL INIT(ADDR%,SYS%) 'INIT CEC CARD

220 CALL TRANSMIT(IN$,STATUS%): GOSUB 480 'CLEAR INTERFACE

230 CALL TRANSMIT(CR$,STATUS%):GOSUB 480 'RESET PS300

240 '

250 X=0 'INITIAL VOLTAGE=0

260 '

270 CALL SEND(PS300%,HV$,STATUS%): GOSUB 480 'ENABLE HV

280 '

290 X = X+10 'INCREMENT OUTPUT BY 10V

300 PRINT "VOLTAGE = "; X;

310 P$=VS$ + STR$(X) 'MAKE VSET COMMAND STRING

320 CALL SEND(PS300%,P$,STATUS%):GOSUB 480

17

Page 20

330'

340 CALL SEND(PS300%,IR$,STATUS%):GOSUB 480 'QUERY CURRENT

350 ANS$=SPACE$(20) 'CLEAR RESULT STRING

360 CALL ENTER(ANS$,LENGTH%,PS300%,STATUS%):GOSUB 480 'READ CURRENT

370 N=VAL(ANS$) 'INTO VARIABLE N

380 PRINT " CURRENT = "; N 'PRINT VALUE

390 '

400 IF X<1000 THEN GOTO 290 'LOOP

410 STOP

420 '

480 'CHECK STATUS OF LAST GPIB COMMUNICATION FOR ERRORS

490 IF STATUS%=0 THEN RETURN 'STATUS OK

500 PRINT "GPIB ERROR STATUS CODE = ";STATUS% 'ELSE ERROR

510 STOP

18

Page 21

Program Example 2:

IBM PC, Microsoft C V4.0, Via GPIB

This program requires the Capital Equipment Corporation GPIB card for the IBM PC. It has firmware in ROM

to interface high level languages to the GPIB.

The header file MS-C488.H contains definitions of all of the CEC firmware routines which can be called from

C. Note that the order of arguments in the calls are reversed from those used by BASIC.

To use these routines, the large model must be used. Compile with the /AL/Ze switch and link with GPIBL.OBJ (on the CEC disk).

/* Compile with >MSC program name/AL/Ze;

link with GPIB-L.OBJ (on CEC disk)

include MS-C488.H

MS-C488.H defines all of the CEC firmware routines so that they

can be called from a C program. Remember that the order of the

arguments is REVERSED from the BASIC calls described in the manual.

Example program to ramp the PS300 output and read the current

using Microsoft C v4.0 (large model) and the Capital

Equipment Corp. GPIB interface card.

Set the PS300 for GPIB ADDR=23.

*/

#include <ms-c488.h>

#include <stdio.h>

char result[80];

main()

{

int i,status,ps300=23;

int my_address=21, system_controller=0;

char cmd[80], vstr[40];

float n;

float x;

initialize(&system_controller, &my_address); /* init GPIB controller */

/* clear interface */

transmit(&status, "IFC UNT UNL REN MTA LISTEN 23 SDC");

Statcheck(status);

/* reset PS300 */

TxGpib(ps300,"*RST");

x = 0; /* initial output value */

/* enable HV */

TxGpib(ps300,"HVON");

while (x<1000.0)

19

Page 22

do

{

x += 10.0; /* increment output voltage level */

sprintf(vstr, "VSET %7.1f",x); /* make VSET command string */

TxGpib(ps300,vstr); /* send command */

TxGpib(ps300,"IOUT?"); /*query current */

GetGpib(ps300); /* into result string */

if (!(sscanf(result,"%f",&n)))

Statcheck(255);

/* print level */

printf ("Voltage = %f current = %f\n",x,n);

}

}

/* ****************************************************** */

TxGpib(address,command) /* transmit a command to addressed device */

int address;

char *command;

{

int status;

char t_string[80];

sprintf(t_string, "UNT UNL MTA LISTEN %d DATA '%s' 10",address,command);

transmit(&status, t_string);

Statcheck(status);

}

/* ****************************************************** */

GetGpib(address) /* get result string from addressed device */

int address;

{

char r_string[40], temp[80];

int length, status;

sprintf(r_string, "UNT UNL MLA TALK %d",address);

transmit(&status, r_string); /* make device a talker */

Statcheck(status);

strcpy(temp, " "); /* clear result string */

receive(&status, &length, temp); /* get answer */

Statcheck(status);

strcpy(result, temp); /* move answer into global result string */

}

/* ****************************************************** */

Statcheck(status) /* check GPIB status */

int status;

{

if (status)

{

printf("GPIB error: status = %d",status);

exit();

}

}

20

Page 23

Program Example 3:

IBM PC, Microsoft C V4.0, Via GPIB

This program requires the National Instruments GPIB card for the IBM PC. It has firmware on board that

interfaces it to high level languages.

To interface the PS300 to a PC with the National Instruments card, the interface card and drivers must be

configured properly. The National Instruments card CANNOT be simply unpacked and put into your computer.

The card must be configured with jumpers and switches to set the I/O address and interrupt levels. You must

also run the program "IBCONF" to configure the resident GPIB driver for the card. Please refer to the National

Instruments manual for additional information.

Once all the hardware and GPIB drivers are properly configured, use the IBIC program. This terminal

emulation program allows you to send commands to the PS300 directly from your keyboard. If you cannot talk

to the PS300 from IBIC, your programs will not run.

The header file decl.h must be included and the file should be linked with the appropriate cib*.obj.

/*

Compile with >MSC program name/AL/Ze;

Link with the appropriate cib*.obj (on the Nat'l Inst disk)

Include decl.h.

Example program to set the PS325 to 1000 volts and read the

current using Microsoft C v4.0 (large model) and the National

instruments GPIB interface card.

*/

#include <stdio.h>

#include <stdlib.h>

#include <decl.h>

main();

{

int i,status,ps300;

float x;

char data[40];

/* get device ID for power supply */

ps325 = ibfind("PS325")

if (ps325<0)

{

printf ("Cannot find PS325; rerun IBCONF/n");

exit(0);

}

/* reset ps300 */

ibwrt (ps300,"*RST",4);

/* turn on high voltage */

ibwrt (ps300,"HVON",4);

/* set voltage to 1000 volts */

21

Page 24

ibwrt (ps300, "VSET1000",8);

/* read current */

ibwrt (ps300,"IOUT?",5);

ibrd (ps300,data,20);

/* print answer */

sscanf (data,"%f",&x);

printf ("Voltage = 1000 Current = %1f/n",x);

}

22

Page 25

TROUBLESHOOTING

Always make certain that the power entry module

is set for the correct line voltage and the correct

fuse is installed. The selected line voltage can be

seen through the window on the power entry

module. Verify that the line cord is plugged all the

way into the power entry module and the power

button on the front panel is pressed in.

Power on Reset

If the instrument turns on with odd combinations of

LEDs on, garbled displays, or is unresponsive to

the keyboard, the memory contents may have been

corrupted, causing the instrument to "hang". To

remedy the situation, turn the unit off and hold

down the CLR key while turning the power back

on. This causes the unit to initialize the memory

and load the default setup.

Stuck Keys

If the center display is filled with a particular

number (like 4444), or one particular message (like

Err2), and the keyboard is unresponsive, check to

see if a key is stuck down. If so, gently flick the

stuck key back to the center of its hole.

No High Voltage

3) Check the the REAR LED. If it is on, then the

high voltage is being programmed by the

analog set voltage input on the rear panel and

not by the front panel. If so, make sure the

rear panel switch is in the desired position.

Repeated Trips

Voltage Trips: This may occur if the load changes

too rapidly, causing the voltage to overshoot. Try

raising the voltage limit.

Current Trips: Disconnect the load and see if the

unit still trips. If it works with no load, there may

be a problem with the load. If it still trips, the unit

may be damaged. Please contact the factory for

further information.

Primary Trip: If repeated PTRP's occur, the

power supply may be damaged. Please contact the

factory for further information.

Rear Panel Voltage Set

If the output voltage is not correct, check the

REAR LED and rear panel switch to see that they

are in the SET mode. Also check that the voltage

limit is higher than the desired voltage.

Check to make sure that the HIGH VOLTAGE

LED is on. If the HIGH VOLTAGE LED is OFF,

check the following.

1) Make certain you hold down the high voltage

key for at least half a second. It is designed to

take a fairly long keypress to avoid having the

high voltage turned on accidentally by

bumping into the switch.

2) Check the voltage limit and current trip levels

to see that they are not too low for your load.

If the HIGH VOLTAGE LED is ON but the output

voltage is zero or lower than expected, check the

following.

1) Check if the LIMIT LED is on. If so, the

current limit value could be too low or the load

could be drawing excessive current.

2) Make sure the voltage limit is as large or

larger than the desired output voltage.

Front Panel Tes t

Hold down the ENTER key while turning on the

unit to run the front panel test. After power is

turned on, one segment of one numerical digit

should be lit. By pressing the UP arrow key, step

through all 8 segments of this digit and the

following one. This verifies that all of the segment

drivers are functional. On the next UP keypress, all

segments and one of the single LED's should be lit.

By repeatedly pressing the UP key, all of the single

LED's can be turned on, one at a time. The keypad

can then be tested by pressing each key and

observing the key code on the display. The codes

increase from top to bottom and left to right. After

this test, turn the power off and restart the

instrument.

23

Page 26

Calibration

The calibration parameters are determined by a

computer aided calibration procedure after burn-in

at the factory. These values are stored in the

permanent memory of each unit. Because of this

there are no user adjustable components to

calibrate.

24

Page 27

CIRCUIT DESCRIPTION

Introduction

Schematics for the PS300 series supplies are shown

on the following pages. They include the

following: Voltage Control (page 1/11), Low

voltage pre-regulator and high frequency inverter

(page 2/11), Limits and Trip Circuitry (page 3/11),

A/D and D/A (page 4/11), the Microprocessor

(page 5/11), GPIB and Front Panel Control (page

6/11), Low Voltage Power Supplies (page 7/11),

Front Panel (page 8/11), and the High Voltage

Sections (page 9/11 through 11/11).

Most of the components are located on the main

circuit board. The front panel and high voltage

section are located on separate boards. In addition,

the high voltage board is covered with an acrylic

coating and enclosed in a protective box.

Voltage Control

Since the output is transformer coupled, only the

magnitude can be set by the primary side control

circuitry. The polarity must be set in the high

voltage section by a multi-pole switch. However,

the sensed voltage and current vary with polarity

and must be converted to a unipolar signal before

they can be used to control the output. To minimize

the effects of noise, the sensed voltage and current

are converted to a -8.26 to +8.26 V range (-8.26 V

corresponding to 0 volts out, +8.26 to full scale).

This allows 13 bits of resolution from the D/A over

±10 V with a relatively large bit size of 2.5 mV.

The sensed voltage, V SENSE (coming from a

resistive divider in the high voltage section) is

buffered by a high input impedance differential

amplifier made up of U109A, U109B and U101D.

This provides a 0 to +8.26 V signal. Next the

polarity is set (for positive or negative output

voltages) with a programmable low offset inverter

(U102, U104A and U104B) and then scaled to

±8.26 V. Next, the voltage is compared to the

programmed voltage with U101B. This signal is

then frequency compensated (U108, U101C, and

related R's and C's) to provide an error voltage, V

ERR. D104 and D107 keep the large capacitors in

the frequency compensation circuitry from

saturating.

The sensed current is first amplified by U105 from

0 - 250 mV to 0 to +8.26 V. Next, the polarity is

set by the programmable inverter of U104C,

(page 1/11)

U104D and U106. It is scaled to ±8.26 V by

U107C. Then it is compared and frequency

compensated at U107B, to provide I ERR.

D102 acts as a crossover between the two error

signals to determine which one sets V DRIVE, the

control for the output voltage. If I ERR is higher

than V ERR (voltage control mode), then V ERR

controls V DRIVE. However if I ERR is lower

(supply is in current limit), it can pull down V

DRIVE(through D102) to the appropriate level,

since V ERR is isolated by R110.

Diodes D105 and D106 act to keep op amps

U101C and U107B out of saturation during large

load changes. This improves transient response.

Low Voltage Pre-Regulator and HIgh

Frequency Inverter

High voltage is made with a high frequency DC to

DC converter. It operates by driving the common

tap of a step-up transformer used as an inverter,

from 0 to 35 volts DC. This makes high voltage by

a combination of transformation and voltage

multiplication. Control is achieved by regulating

the common tap.

Pre-Regulator

The common voltage is made by a combination

step down pre-regulator followed by a

programmable linear regulator. Q203, D203, L201

and C203 form the step down regulator and U205

is the linear regulator.

U206, an LM311 comparator, senses the voltage

across U205. If it is less than 2.5 volts (determined

by D204, a 2.5 volt reference), its output goes

negative. This turns on Q203, allowing current to

flow through L201 onto C203, raising the voltage

at the input of U205. Once the voltage across U205

is greater than 2.5 volts (plus a small amount of

hysteresis set by R219 and C205), U206 shuts off

Q203. Current continues to flow through L201

during the off time since current can't change

instantly through an inductor. This causes the

voltage at pin 2 of Q203 to flyback negatively and

be clamped by D203. The voltage across U205 will

now decay until it is less than 2.5 volts, which

begins the cycle again.

(page 2/11)

25

Page 28

U205, a LT1085, is a low dropout adjustable

regulator which filters the output of the step down

section. U207 increases the V DRIVE signal of 012 volts to 0-33 volts which programs the common

tap of the step-up high voltage transformer.

Inverter

U201 is a LM555 timer configured as an astable

multivibrator at a frequency of 40 kHz with about a

60% duty cycle. U202 and U203 split this into two

phases of 20 kHz at a 30% duty cycle. U204

(SN75372) is a high current MOSFET driver for

the FETs (Q201,Q202) that drive the high voltage

step-up transformer (pages 9/11 through 11/11).

D201 and D202 clamp excessive inductive flyback

voltage.

If the primary current exceeds about 5.3 amps,

R212 - R215 and U301C sense the primary side

current and shut off the drive to the inverter (and

hence the high voltage). They do this by activating

the HV OFF line (page 3/11), which latches the

high voltage off until the processor releases it. The

high voltage can also be turned off by voltage or

current trips and by the processor.

Limits and Trips

U301 is a quad comparator that compares both the

scaled output voltage and current to both the limit

and trip values which are set by the processor and

D/A. If a trip value is exceeded, the high voltage is

shut off through the HV OFF signal and the change

of status is reported to the processor. If a limit is

exceeded, only the change of status is reported.

The processor can also set the HV OFF line via the

SHUTDOWN line.

U306 is a one-shot circuit used as a watch dog

timer. Unless the microprocessor resets it every 10

ms, the one-shot times out, turning off the high

voltage and forcing a system reset.

A/D's and D/A's

U410 is a 12 bit digital to analog converter that is

loaded 4 bits at a time from the processor. Its

output current is converted to a voltage by U402B

to provide a 0 to -10.00 VDC referenced from

LH0070 (U406), a precision reference. U407A,

U407B and U405 form a programmable low offset

inverter. After scaling, the output covers a range of

-10.24 to +10.24 VDC with 13 bits of resolution

and 2.5 mV bits. These outputs are multiplexed to

(page 3/11)

(page 4/11)

6 sample and hold circuits that provide control

voltages and outputs. Each sample and hold is

refreshed every 12 ms.

U402A and U404 form an integrating, successive

approximation analog to digital converter. U409

determines the input to be sampled and integrates it

through R404 on to C401. Then a successive

approximation 13 bit analog to digital conversion is

made using the D/A converter and comparator

U404. This takes about 100 µs.

Microprocessor Control

The microprocessor, U501 (a Z80), is clocked at 4

MHz by X501. U502, an 8K ROM, contains the

firmware and calibration constants. The 2K static

RAM, U503, is backed up by a lithium battery,

BT501. A power down circuit protects the RAM

contents by disabling the chip-select with Q501 if a

reset is asserted. The battery should have a useful

life of 5 to 10 years and shouldn't need to be

replaced.

U504 and U505 generate chip selects for the

various input and output ports. U506 and U512 are

input ports for status information, rear panel

switches, and the HV ON/OFF switch on the front

panel.

U509 and related parts form the power on reset

circuit. During power on, it asserts a reset for

about 250 ms so the supply voltages can stabilize.

If the +5 V power supply dips below 4.5 V

(determined by the +10.00 V reference), it asserts a

reset that will last until the voltage recovers and a

reset cycle has occurred. If the watch dog timer

isn't updated every 10 ms, it triggers U511, which

also forces a reset. During a reset, in addition to

the processor being reset and the RAM being

disabled, the high voltage is turned off.

(page 5/11)

GPIB and Front Panel Interface

(page 6/11)

GPIB

The GPIB (IEEE-488) interface is provided by the

TMS9914A controller, U601. U602 and U603 are

buffers to the GPIB connector, which is connected

to J602. U601 is programmed to interrupt the

processor whenever there is activity addressed to

the power supply.

26

Page 29

Front Panel Interface

Front Panel

(page 8/11)

The front panel has a 6 phase, multiplexed LED

display and keyboard. U604 is a data bus latch for

U605, a high current driver that provides the strobe

signals to the front panel. Each strobe selects 2

digits and 2 or 3 LED's to be refreshed. Only one

strobe is active at a time. U606 and U609 are pull

down lines for the digits with 390 Ohm current

limiting resistors (N601 and N602). The individual

LEDs are pulled down separately by U613AU613C with 12 Ohm current limiting

resistors(R602-R604). They are separated from the

digit pulldowns because the LED's require much

more current than the high efficiency 7 segment

displays. Strobes 2, 3 and 4 also go to the keypad

matrix which is read by U612, an input latch.

U610, a divider chip, takes the system clock of 4

MHz and divides it by 4096 which gives a 977 Hz

signal. This provides the processor with a a real

time interrupt which is used to synchronize

updating the display, analog voltages, and

instrument status.

Low Voltage Power Supplies

(page 7/11)

The front panel consists of twelve 7 segment high

efficiency displays, a ±1 display, 13 LED's, a

keypad and the high voltage on/off switch.

The displays are multiplexed by 6 strobes. During

each strobe, two of the twelve displays are on. In

addition, up to 2 (of a maximum of 3) LEDs are on

to indicate the instrument status and polarity. The

±1 display is driven the same as the LEDs, but it

has larger current limiting resistors R1 and R2 (390

Ohms), since it is far more efficient then the

ordinary LEDs. Finally strobes 2, 3 and 4 go to the

keypad matrix allowing 1/3 of the keys to be read

during each of these strobe cycles.

The High Voltage ON/OFF switch is separate from

the keypad matrix. Its signals go directly back to

one of the processor's input ports.

High Voltage Section

Note: These boards are covered to prevent

accidental shock or injury. DO NOT ATTEMPT

TO OPERATE THE UNIT WITH THE COVER

OFF !!!

Line power comes in at the power entry module

where it passes through a fuse and then a RFI filter.

Both the hot and neutral leads are switched. Next,

the voltage passes into the line voltage selector.

The transformer primary is tapped for 4 different

voltages: 100,120, 220, 240 VAC, 50 or 60 Hz.

The transformer has 3 secondaries, 32 VAC non

centertapped and 32 VAC and 15 VAC, center

tapped. The 15 volt tap is rectified by D703 and

D704. It is filtered by C706 to make +8 VDC

unregulated. Then it is regulated by U704 to make

the +5 VDC for the processor, digital logic. U707

regulates the +5VDC for the LED display. The 32

volt tap is full wave rectified by U701 and filtered

by C702 and C705 to provide ±18 VDC. These are

regulated by U702 and U703 to make ±15 VDC for

the analog circuitry.

The 32 volt non center tapped winding is rectified

by D701 and D702, and filtered by C701. It

provides +35 VDC at 1 amp to the pre-regulator for

the high voltage section. U705 provides a regulated

+33 VDC for the control circuits in the preregulator.

PS310 (page 9/11)

The biggest difference between models in the

PS300 series is the high voltage section. They are

configured to provide the proper combination of

voltage and current through the use of different

diode-capacitor multiplier circuits. For the PS310

(page 9/11), the output of transformer T1 is full

wave rectified by diodes D1-D4 and filtered by C3

and C4. Poles A and B of switch SW1 change the

polarity of the high voltage output and pole C

reports the polarity to the processor. C3, C4 and

R1-R3 are an output filter to reduce switching

noise. R4, R5 and R8 form the divider to provide

the voltage sense signal; R6 and R9 are the current

sense resistor.

PS325 (page 10/11)

The PS325 (page 10/11) is similar to the PS310

except the transformer output is fed to the voltage

doubling circuit of D1, D2, C1 and C2. Switch

SW1 acts in the same fashion as on the PS310.

The voltage sense circuit consists of R4, R5, R6

and R8. R7 and R9 are the current sense resistor.

The output filter is slightly different to reflect the

changes in output voltage and current.

27

Page 30

PS350 (page 11/11)

The PS350 (page 11/11) is similar to the other two,

but it has a voltage quadrupler made up of C1, C2,

C3, C4, D1, D2, D3 and D4. Switch SW1 acts the

same and R9 is again the current sense resistor.

The voltage sense circuit is made up of R2 and R3.

C5 provides some additional phase compensation.

Finally the output filter is set up for higher voltage

and lower current.

28

Page 31

COMPONENT LIST

Main Board Parts List

No. REF. SRS part # VALUE DESCRIPTION

1. BT501 6-00001-612

2. C 101 5-00066-513 .022U Capacitor, Mylar/Poly, 50V, 5%, Rad

3. C 102 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

4. C 103 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

5. C 104 5-00190-541 100U MIN Cap, Mini Electrolytic, 16V, 20% Radial

6. C 105 5-00264-513 .0015U Capacitor, Mylar/Poly, 50V, 5%, Rad

7. C 107 5-00059-512 .47U Cap, Stacked Metal Film 50V 5% -40/+85c

8. C 109 5-00264-513 .0015U Capacitor, Mylar/Poly, 50V, 5%, Rad

9. C 110 5-00335-513 .0039U Capacitor, Mylar/Poly, 50V, 5%, Rad

10. C 111 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

11. C 112 5-00058-512 .33U Cap, Stacked Metal Film 50V 5% -40/+85c

12. C 113 5-00067-513 .033U Capacitor, Mylar/Poly, 50V, 5%, Rad

13. C 114 5-00060-512 1.0U Cap, Stacked Metal Film 50V 5% -40/+85c

14. C 115 5-00264-513 .0015U Capacitor, Mylar/Poly, 50V, 5%, Rad

15. C 116 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

16. C 201 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

17. C 202 5-00064-513 .0047U Capacitor, Mylar/Poly, 50V, 5%, Rad

18. C 203 5-00176-509 3300U Capacitor, Electrolytic, 50V, 20%, Rad

19. C 204 5-00041-509 220U Capacitor, Electrolytic, 50V, 20%, Rad

20. C 205 5-00151-501 680P Capacitor, Ceramic Disc, 50V, 10%, SL

21. C 206 5-00012-501 330P Capacitor, Ceramic Disc, 50V, 10%, SL

22. C 207 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

23. C 208 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

24. C 209 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

25. C 210 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

26. C 211 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

27. C 212 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

28. C 213 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

29. C 215 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

30. C 216 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

31. C 217 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

32. C 218 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

33. C 219 5-00127-524 2.2U Capacitor, Tantalum, 50V, 20%, Rad

34. C 220 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

35. C 301 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

36. C 302 5-00065-513 .01U Capacitor, Mylar/Poly, 50V, 5%, Rad

37. C 303 5-00007-501 220P Capacitor, Ceramic Disc, 50V, 10%, SL

38. C 304 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

39. C 401 5-00136-519 .01U Capacitor, Polystyrene, 50V, 5%, Rad

40. C 402 5-00007-501 220P Capacitor, Ceramic Disc, 50V, 10%, SL

41. C 405 5-00061-513 .001U Capacitor, Mylar/Poly, 50V, 5%, Rad

42. C 406 5-00008-501 22P Capacitor, Ceramic Disc, 50V, 10%, SL

43. C 407 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

44. C 408 5-00061-513 .001U Capacitor, Mylar/Poly, 50V, 5%, Rad

45. C 409 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

46. C 410 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

VALUE

Battery

29

Page 32

No.

REF. SRS part # VALUE DESCRIPTION

47. C 411 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

48. C 412 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

49. C 413 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

50. C 414 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

51. C 415 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

52. C 501 5-00007-501 220P Capacitor, Ceramic Disc, 50V, 10%, SL

53. C 502 5-00007-501 220P Capacitor, Ceramic Disc, 50V, 10%, SL

54. C 503 5-00098-517 10U Capacitor, Tantalum, 35V, 20%, Rad

55. C 504 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

56. C 505 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

57. C 506 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

58. C 601 5-00098-517 10U Capacitor, Tantalum, 35V, 20%, Rad

59. C 701 5-00241-553 3900U Capacitor, Electrolytic, 80V, +/-20%

60. C 702 5-00172-544 1000U Cap, Mini Electrolytic, 25V, 20%, Radial

61. C 703 5-00192-542 22U MIN Cap, Mini Electrolytic, 50V, 20% Radial

62. C 704 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

63. C 705 5-00172-544 1000U Cap, Mini Electrolytic, 25V, 20%, Radial

64. C 706 5-00192-542 22U MIN Cap, Mini Electrolytic, 50V, 20% Radial

65. C 707 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

66. C 708 5-00169-520 4700U Capacitor, Electrolytic, 16V, 20%, Rad

67. C 709 5-00192-542 22U MIN Cap, Mini Electrolytic, 50V, 20% Radial

68. C 710 5-00100-517 2.2U Capacitor, Tantalum, 35V, 20%, Rad

69. C 711 5-00213-546 4.7U Cap, Mini Electro, 100V, 20%, Rad

70. C 712 5-00214-547 .1U Cap, Monolythic Ceramic, 100V, Z5U, 20%

71. C 713 5-00127-524 2.2U Capacitor, Tantalum, 50V, 20%, Rad

72. C 714 5-00127-524 2.2U Capacitor, Tantalum, 50V, 20%, Rad

73. C 715 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

74. C 716 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

75. C 717 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

76. C 718 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

77. C 719 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

78. C 720 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

79. C 721 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

80. C 722 5-00225-548 .1U AXIAL Capacitor, Ceramic, 50V,+80/-20% Z5U AX

81. C 724 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

82. C 725 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

83. C 726 5-00225-548 .1U AXIAL Capacitor, Ceramic, 50V,+80/-20% Z5U AX

84. C 727 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

85. C 728 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

86. C 729 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

87. C 730 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

88. C 731 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

89. C 732 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

90. C 733 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

91. C 734 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

92. C 735 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

93. C 736 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

94. C 737 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

95. C 738 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

96. C 739 5-00023-529 .1U Cap, Monolythic Ceramic, 50V, 20%, Z5U

97. C 740 5-00219-529 .01U Cap, Monolythic Ceramic, 50V, 20%, Z5U

30

Page 33

No.

REF. SRS part # VALUE DESCRIPTION

98. C 741 5-00219-529 .01U Cap, Monolythic Ceramic, 50V, 20%, Z5U

99. C 742 5-00219-529 .01U Cap, Monolythic Ceramic, 50V, 20%, Z5U

100. CX111 5-00098-517 10U Capacitor, Tantalum, 35V, 20%, Rad

101. CX116 5-00098-517 10U Capacitor, Tantalum, 35V, 20%, Rad

102. D 101 3-00004-301 1N4148 Diode

103. D 102 3-00004-301 1N4148 Diode

104. D 104 3-00004-301 1N4148 Diode

105. D 105 3-00004-301 1N4148 Diode

106. D 106 3-00004-301 1N4148 Diode

107. D 107 3-00004-301 1N4148 Diode

108. D 201 3-00221-301 1N4004 Diode

109. D 202 3-00221-301 1N4004 Diode

110. D 203 3-00228-301 MUR160 Diode

111. D 204 3-00291-340 LM336Z-2.5V Integrated Circuit (Thru-hole Pkg)

112. D 205 3-00004-301 1N4148 Diode

113. D 207 3-00380-301 1N5248 Diode

114. D 208 3-00221-301 1N4004 Diode

115. D 209 3-00380-301 1N5248 Diode

116. D 210 3-00381-301 SA64A Diode

117. D 211 3-00381-301 SA64A Diode

118. D 212 3-00390-301 1N969A/1N5251B Diode

119. D 501 3-00004-301 1N4148 Diode

120. D 502 3-00004-301 1N4148 Diode

121. D 503 3-00004-301 1N4148 Diode

122. D 703 3-00221-301 1N4004 Diode

123. D 704 3-00221-301 1N4004 Diode

124. J 401 1-00073-120 INSL Connector, BNC

125. J 402 1-00073-120 INSL Connector, BNC

126. J 601 1-00081-110 554434-1 SHIELD Pins & Connectors, AMP

127. J 602 1-00038-130 40 PIN DIL Connector, Male

128. J 603 1-00097-130 24 PIN DIL Connector, Male

129. L 201 6-00044-601 750UH Inductor

130. N 101 4-00333-421 10KX5 Res. Network, SIP, 1/4W,2% (Isolated)

131. N 103 4-00333-421 10KX5 Res. Network, SIP, 1/4W,2% (Isolated)

132. N 104 4-00244-421 10KX4 Res. Network, SIP, 1/4W,2% (Isolated)

133. N 301 4-00334-425 10KX5 Resistor Network SIP 1/4W 2% (Common)

134. N 501 4-00244-421 10KX4 Res. Network, SIP, 1/4W,2% (Isolated)

135. N 502 4-00334-425 10KX5 Resistor Network SIP 1/4W 2% (Common)

136. N 601 4-00420-420 390X8 Resistor Network, DIP, 1/4W,2%,8 Ind

137. N 602 4-00420-420 390X8 Resistor Network, DIP, 1/4W,2%,8 Ind

138. N 603 4-00276-425 10KX9 Resistor Network SIP 1/4W 2% (Common)

139. N 604 4-00285-421 470X3 Res. Network, SIP, 1/4W,2% (Isolated)

140. P 401 4-00657-452 500 Pot, Multi Turn Trim, Mini

141. PC1 7-00184-701 PS300-25 Printed Circuit Board

142. Q 201 3-00283-340 IRF530/IRF532 Integrated Circuit (Thru-hole Pkg)

143. Q 202 3-00283-340 IRF530/IRF532 Integrated Circuit (Thru-hole Pkg)

144. Q 203 3-00374-329 MTP20P06 Voltage Reg., TO-220 (TAB) Package

145. Q 501 3-00021-325 2N3904 Transistor, TO-92 Package

146. R 101 4-00450-407 681 Resistor, Metal Film, 1/8W, 1%, 50PPM

147. R 102 4-00194-407 5.11K Resistor, Metal Film, 1/8W, 1%, 50PPM

148. R 103 4-00185-407 4.02K Resistor, Metal Film, 1/8W, 1%, 50PPM

31

Page 34

No.

REF. SRS part # VALUE DESCRIPTION

149. R 104 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

150. R 105 4-00450-407 681 Resistor, Metal Film, 1/8W, 1%, 50PPM

151. R 110 4-00130-407 1.00K Resistor, Metal Film, 1/8W, 1%, 50PPM

152. R 111 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

153. R 112 4-00446-407 47.5K Resistor, Metal Film, 1/8W, 1%, 50PPM

154. R 113 4-00553-407 2.55K Resistor, Metal Film, 1/8W, 1%, 50PPM

155. R 114 4-00447-407 82.5K Resistor, Metal Film, 1/8W, 1%, 50PPM

156. R 115 4-00553-407 2.55K Resistor, Metal Film, 1/8W, 1%, 50PPM

157. R 116 4-00190-407 42.2K Resistor, Metal Film, 1/8W, 1%, 50PPM

158. R 117 4-00190-407 42.2K Resistor, Metal Film, 1/8W, 1%, 50PPM

159. R 119 4-00188-407 4.99K Resistor, Metal Film, 1/8W, 1%, 50PPM

160. R 122 4-00607-407 3.92K Resistor, Metal Film, 1/8W, 1%, 50PPM

161. R 123 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

162. R 124 4-00447-407 82.5K Resistor, Metal Film, 1/8W, 1%, 50PPM

163. R 125 4-00192-407 49.9K Resistor, Metal Film, 1/8W, 1%, 50PPM

164. R 201 4-00483-407 1.05K Resistor, Metal Film, 1/8W, 1%, 50PPM

165. R 202 4-00309-407 3.32K Resistor, Metal Film, 1/8W, 1%, 50PPM

166. R 203 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

167. R 204 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

168. R 205 4-00176-407 3.01K Resistor, Metal Film, 1/8W, 1%, 50PPM

169. R 206 4-00135-407 1.50K Resistor, Metal Film, 1/8W, 1%, 50PPM

170. R 207 4-00851-407 340 Resistor, Metal Film, 1/8W, 1%, 50PPM

171. R 208 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

172. R 209 4-00176-407 3.01K Resistor, Metal Film, 1/8W, 1%, 50PPM

173. R 210 4-00135-407 1.50K Resistor, Metal Film, 1/8W, 1%, 50PPM

174. R 212 4-00364-402 1 Resistor, Carbon Comp, 1/2W, 5%

175. R 213 4-00364-402 1 Resistor, Carbon Comp, 1/2W, 5%

176. R 214 4-00364-402 1 Resistor, Carbon Comp, 1/2W, 5%

177. R 215 4-00364-402 1 Resistor, Carbon Comp, 1/2W, 5%

178. R 216 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

179. R 217 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

180. R 218 4-00547-407 18.2K Resistor, Metal Film, 1/8W, 1%, 50PPM

181. R 219 4-00192-407 49.9K Resistor, Metal Film, 1/8W, 1%, 50PPM

182. R 220 4-00548-407 29.4K Resistor, Metal Film, 1/8W, 1%, 50PPM

183. R 221 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

184. R 222 4-00080-401 47 Resistor, Carbon Film, 1/4W, 5%

185. R 223 4-00080-401 47 Resistor, Carbon Film, 1/4W, 5%

186. R 224 4-00045-401 2.0K Resistor, Carbon Film, 1/4W, 5%

187. R 301 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

188. R 302 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

189. R 303 4-00312-401 270K Resistor, Carbon Film, 1/4W, 5%

190. R 304 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

191. R 305 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

192. R 306 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

193. R 307 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

194. R 308 4-00069-401 300K Resistor, Carbon Film, 1/4W, 5%

195. R 401 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

196. R 402 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

197. R 403 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

198. R 404 4-00164-407 20.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

199. R 409 4-00022-401 1.0M Resistor, Carbon Film, 1/4W, 5%

32

Page 35

No.

REF. SRS part # VALUE DESCRIPTION

200. R 410 4-00170-407 249K Resistor, Metal Film, 1/8W, 1%, 50PPM

201. R 411 4-00196-407 6.04K Resistor, Metal Film, 1/8W, 1%, 50PPM

202. R 412 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

203. R 413 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

204. R 414 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

205. R 415 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

206. R 416 4-00057-401 220 Resistor, Carbon Film, 1/4W, 5%

207. R 417 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

208. R 418 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

209. R 419 4-00021-401 1.0K Resistor, Carbon Film, 1/4W, 5%

210. R 420 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

211. R 421 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

212. R 422 4-00022-401 1.0M Resistor, Carbon Film, 1/4W, 5%

213. R 501 4-00027-401 1.5K Resistor, Carbon Film, 1/4W, 5%

214. R 502 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

215. R 503 4-00083-401 47K Resistor, Carbon Film, 1/4W, 5%

216. R 504 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

217. R 505 4-00034-401 10K Resistor, Carbon Film, 1/4W, 5%

218. R 506 4-00138-407 10.0K Resistor, Metal Film, 1/8W, 1%, 50PPM

219. R 507 4-00517-407 3.57K Resistor, Metal Film, 1/8W, 1%, 50PPM

220. R 508 4-00519-407 4.75K Resistor, Metal Film, 1/8W, 1%, 50PPM

221. R 601 4-00079-401 4.7K Resistor, Carbon Film, 1/4W, 5%

222. R 602 4-00314-401 12 Resistor, Carbon Film, 1/4W, 5%

223. R 603 4-00314-401 12 Resistor, Carbon Film, 1/4W, 5%

224. R 604 4-00314-401 12 Resistor, Carbon Film, 1/4W, 5%

225. R 701 4-00165-407 200 Resistor, Metal Film, 1/8W, 1%, 50PPM

226. R 702 4-00194-407 5.11K Resistor, Metal Film, 1/8W, 1%, 50PPM

227. R 703 4-00681-436 SG240 Thermistor, ICL (Inrush Current Limiter)

228. RX102 4-00900-407 20.5K Resistor, Metal Film, 1/8W, 1%, 50PPM

229. RX103 4-00279-407 3.09K Resistor, Metal Film, 1/8W, 1%, 50PPM