Page 1

High power buck-boost white LED driver

Features

■ Buck-boost DC-DC converter

■ Drives one power LED up to 1 A in flash mode

■ Drives one power LED up to 800 mA in

continuous mode

■ LED temperature protection

■ Output current control

■ 1.8 MHz (typ.) fixed frequency PWM

■ Synchronous rectification

■ High efficiency across the total input voltage

range

■ Operational modes:

– Shutdown mode

– High current mode: up to 1 A

– Low current mode: from 20 mA

■ Adjustable current in both modes

■ Peak inductor limited to 2.3 A (typ.)

■ LED disconnected from the battery in

shutdown mode

■ NTC LED temperature protection

■ Overvoltage protection: 5.3 V

■ Short-circuit protection

■ Overtemperature protection

■ ULVLO function

■ 1 µA max shutdown current

■ QFN16 (4 x 4 x 1 mm) 16 leads

Applications

STCF07

QFN16 (4 x 4 mm)

Description

The STCF07 is a dedicated, size-optimized

solution for driving a power LED. The device is a

buck-boost converter which guarantees proper

LED current control over all possible battery

voltage and LED forward voltage conditions. The

output current control ensures good current

regulation over the forward voltage spread

characteristics of high-brightness LEDs. The

device includes various functions to protect the

chip and the power LEDs. These include soft-start

control as well as detection and protection of chip

overtemperature and shorted LEDs. An optional

external NTC is supported to protect the LEDs

against overheating. It is possible to separately

program the current intensity in HIGH and LOW

mode using the SEL pin. The device is housed in

a 16-lead QFN16 (4 x 4 mm) package with a

height less than 1 mm.

■ Camera flash for mobile phones

■ Power supply for high power LEDs

Table 1. Device summary

Order code Package Packaging

STCF07PNR QFN16 (4 x 4 mm) Tape and reel

April 2011 Doc ID 16757 Rev 2 1/26

www.st.com

26

Page 2

Contents STCF07

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Logic pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1 CSEL pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2 FAULT pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3 ENABLE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 Detailed description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.1 Buck-boost converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2 High current mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.3 Low current mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.4 Shutdown mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.5 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.6 STCF07 protection features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.6.1 Peak current and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . 13

8.6.2 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.6.3 Thermal shutdown protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.6.4 Sensing of LED temperature with the NTC resistor . . . . . . . . . . . . . . . . 13

8.6.5 Undervoltage lockout function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9 PCB design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.1 PCB design rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2 PCB design of the demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.3 Schematic of the demonstration board . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/26 Doc ID 16757 Rev 2

Page 3

STCF07 Contents

10 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11 External component selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.1 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.3 LED selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.4 RHC selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.5 RLC selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.6 NTC and RX resistor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

12 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Doc ID 16757 Rev 2 3/26

Page 4

Block diagram STCF07

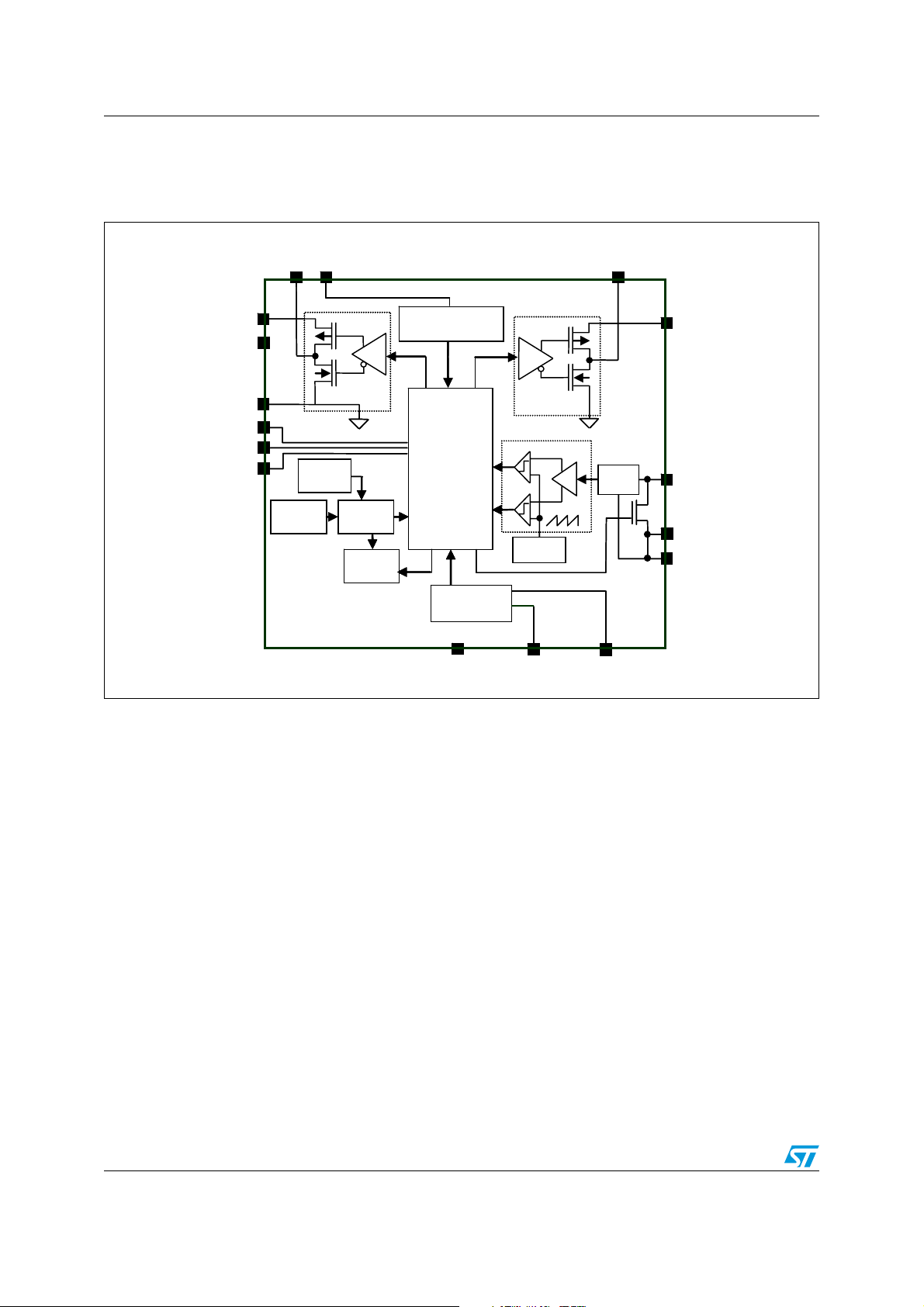

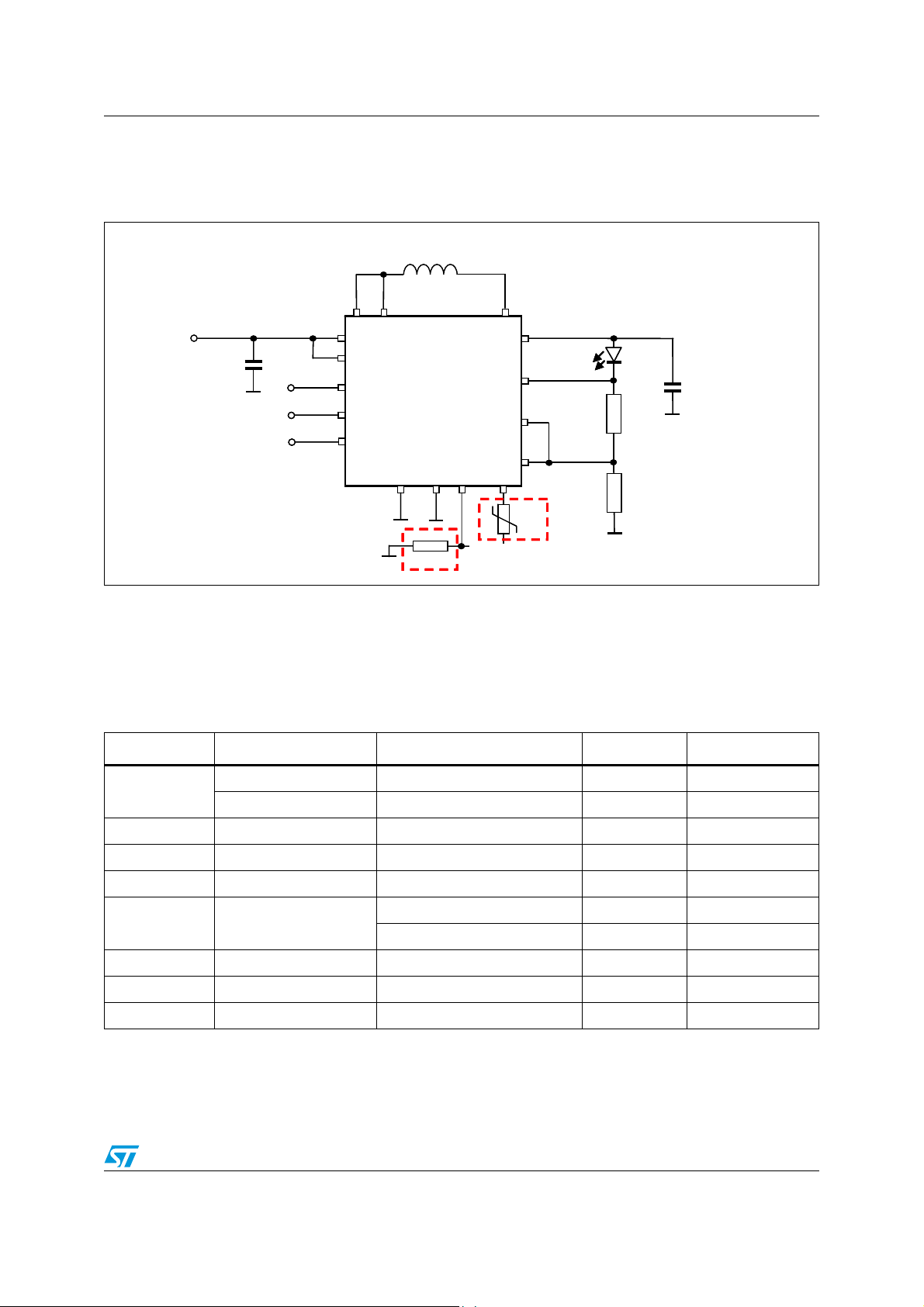

1 Block diagram

Figure 1. STCF07 block diagram

VLX2VLX1AVLX1B

VLX2VLX1AVLX1B

CURRENT

PVBAT

PVBAT

VBAT

VBAT

GND

GND

ENABLE

ENABLE

CSEL

CSEL

FAULT

FAULT

OVER

OVER

TEMP

TEMP

CURRENT

PROTECTION

PROTECTION

LOGIC

LOGIC

MX

MX

VOUT

VOUT

FB1

FB1

BANDGAP

BANDGAP

REF

REF

SOFT

SOFT

START

START

REF

REF

DRIVER

DRIVER

OSC

OSC

NTC

NTC

CONTROL

CONTROL

PNGD RX NTC

PNGD RX NTC

FB2

FB2

FB2S

FB2S

4/26 Doc ID 16757 Rev 2

Page 5

STCF07 Pin configuration

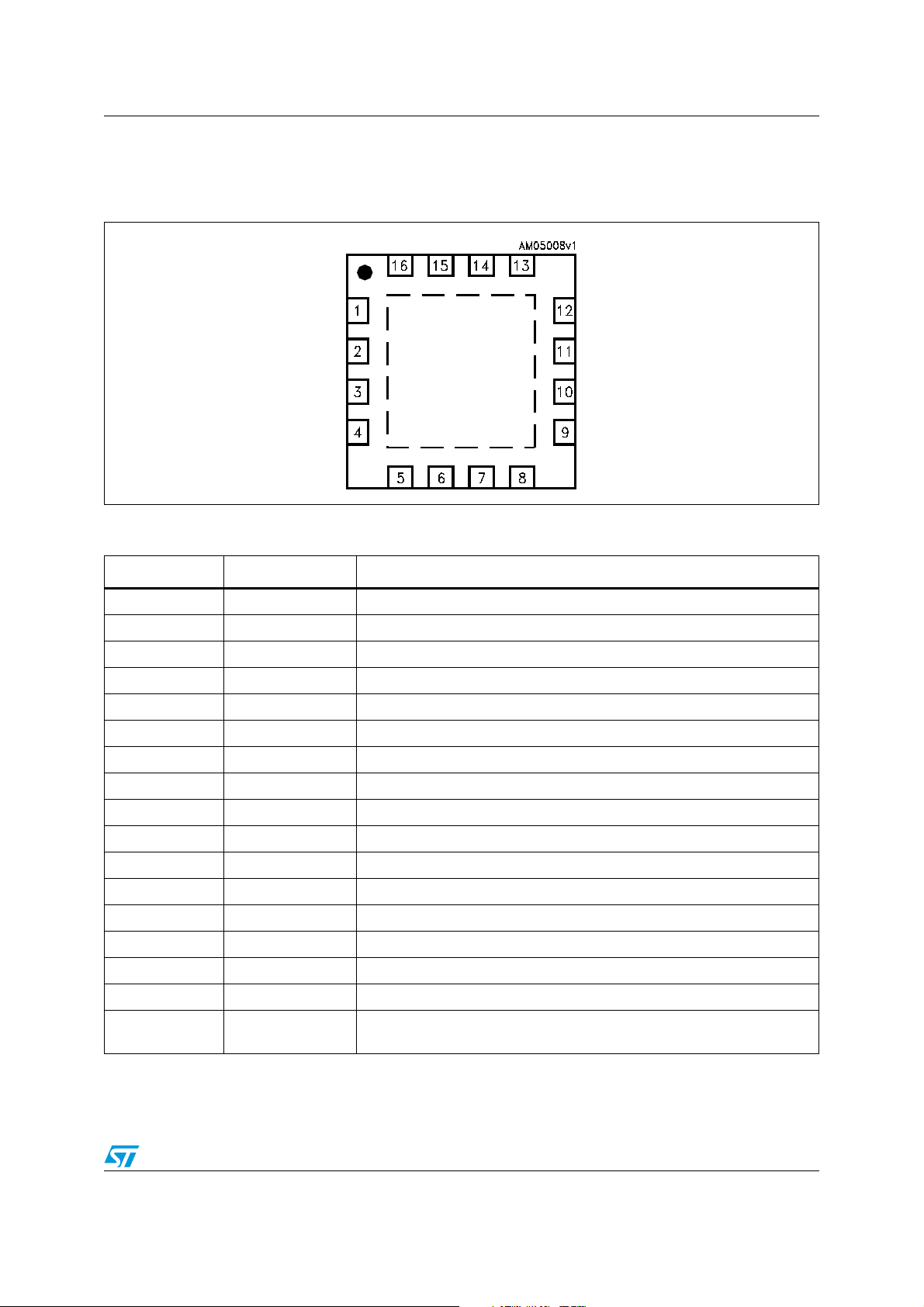

2 Pin configuration

Figure 2. STCF07 pin connections (top view)

Table 2. STCF07 pin description

Pin n° Symbol Description

1 VLX2 Inductor VLX2 connection

8RXR

resistor connection

X

2 NTC NTC resistor connection

3 VOUT Output voltage

4 FB1 Feedback pin [I

5FB2R

bypass

TR

6 FB2S Feedback pin [I

*(RHC+RLC)]

LED

LED*RHC

]

14 GND Signal ground

13 CSEL Current selection

7 EN Enable

16 FAULT Diagnostic

9 PVBAT Power supply voltage

10 VBAT Supply voltage

11 VLX1A Inductor VLX1 connection

12 VLX1B Inductor VLX1 connection

15 PGND Power ground

Exposed pad PGND

To be connected to the PCB ground plane for optimal electrical and

thermal performance

Doc ID 16757 Rev 2 5/26

Page 6

Maximum ratings STCF07

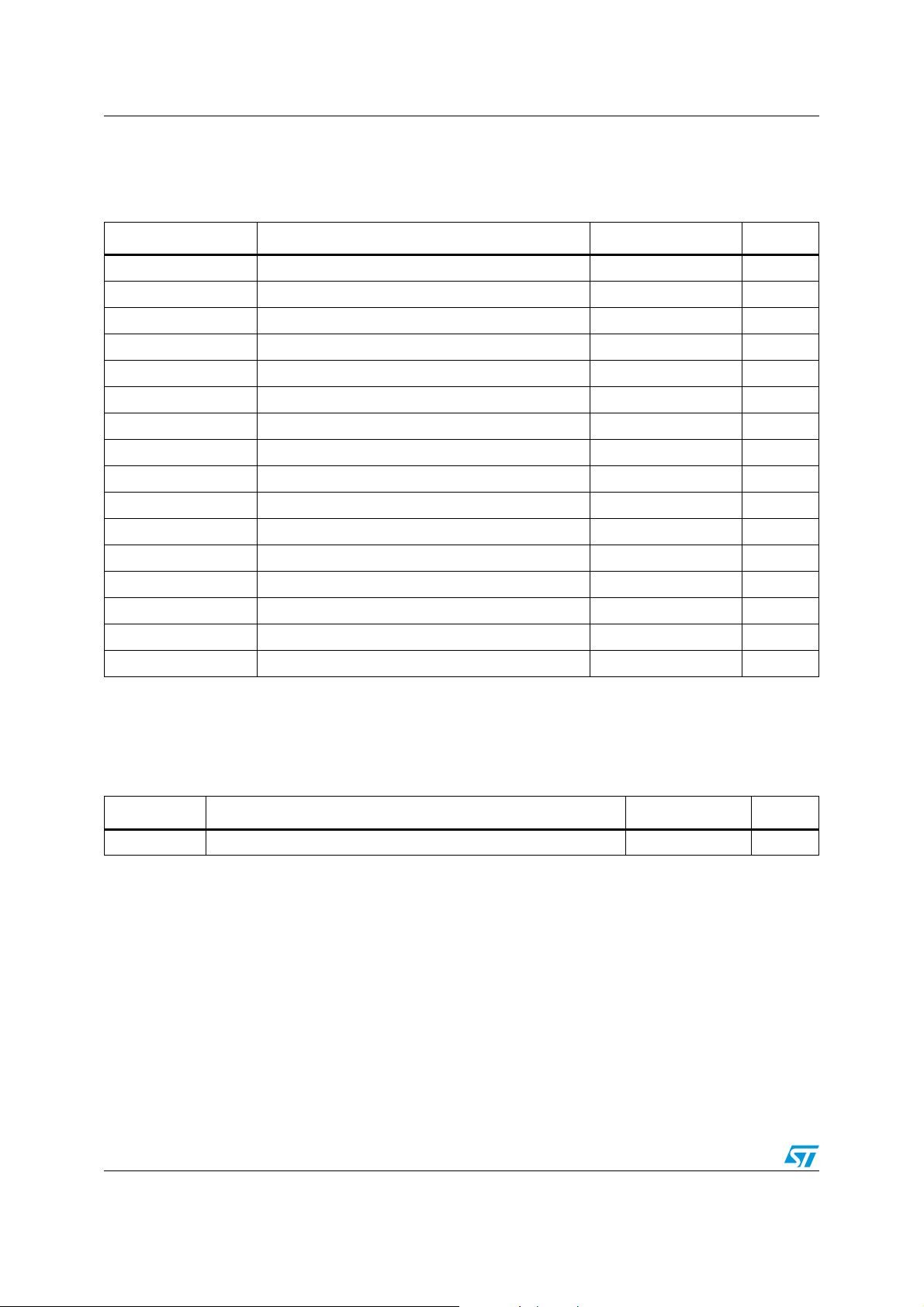

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

VBAT Signal supply voltage -0.3 to 6 V

PVBAT Power supply voltage -0.3 to 6 V

VLX1A, VLX1B Inductor connection 1 -0.3 to V

VLX2 Inductor connection 2 -0.3 to V

+0.3 V

I

+0.3 V

I

VOUT Output voltage -0.3 to 6 V

FB1, FB2, FB2S Feedback and sense voltage -0.3 to 3 V

R

X

CSEL Current selection -0.3 to V

EN Enable -0.3 to V

FAULT Diagnostic -0.3 to V

Connection for reference resistor -0.3 to 3 V

+0.3 V

I

+0.3 V

I

+0.3 V

I

NTC Connection for LED temperature sensing -0.3 to 3 V

ESD Human body model ±2kV

P

T

T

STG

TOT

OP

T

J

Continuous power dissipation (at TA = 70 °C) 800 mW

Operating junction temperature range -40 to 85 °C

Junction temperature -40 to 150 °C

Storage temperature range -65 to 150 °C

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these condition is not implied.

Table 4. Thermal data

Symbol Parameter Value Unit

(1)

R

thJA

1. Junction-to-ambient thermal resistance in JEDEC still air chamber. Thermal test board JESD51-7 (leaded surface mount

packages).

6/26 Doc ID 16757 Rev 2

Thermal resistance junction-ambient 31 °C/W

Page 7

STCF07 Application information

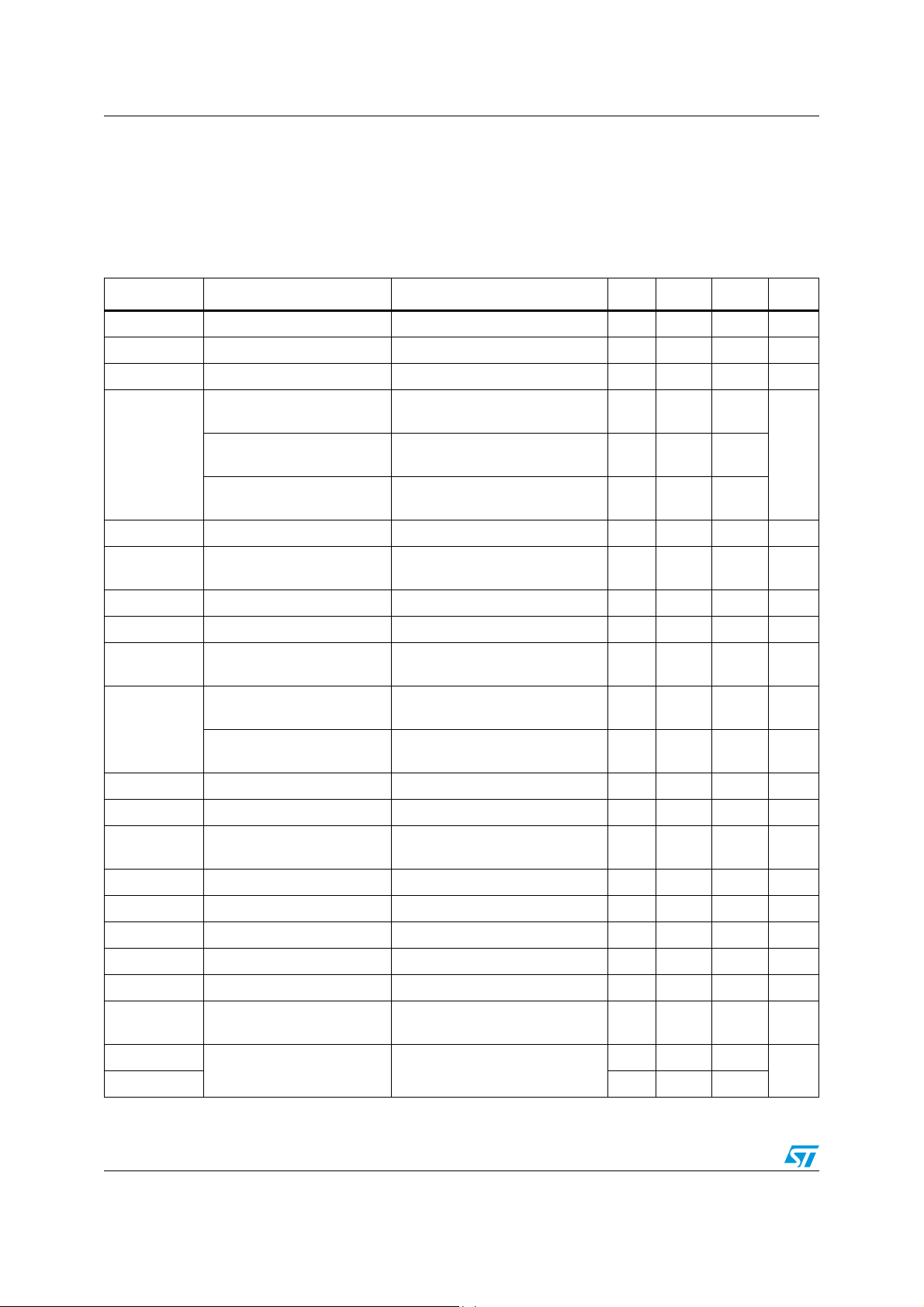

4 Application information

Figure 3. Application schematic diagram

L

L

V

V

IN

IN

C

C

IN

IN

VLX1 VLX1

VLX1 VLX1

PVBAT

PVBAT

VBAT

VBAT

ENABLE

ENABLE

CSEL

CSEL

FAULT

FAULT

GND PGND

GND PGND

RX

RX

VLX2

VLX2

VOUT

VOUT

FB1

FB1

FB2

FB2

FB2S

FB2S

NTC

NTC

NTC

NTC

LED

LED

R

R

LC

LC

R

R

HC

HC

C

C

OUT

OUT

R

R

X

X

Optional components

Optional components

Note: Represents a typical application schematic for an output current of 800 mA (max) in

continuous mode operation. For pulse/flash mode operation it is possible to increase the

maximum output current up to 1 A. If the battery voltage is higher than 3.1 V, the chip is

capable of delivering the maximum output current of up to 1 A in continuos mode.

Table 5. List of external components

Component Manufacturer Part number Value Size

C

NTC MURATA NCP18WF104J03RB 100 kΩ 0805

1. For 800 mA output current performance.

2. For 1000 mA output current performance.

Welwyn LR1206-R20FI

R

R

C

HC

LC

IN

OUT

KOA SR732BTTDR160F

Tyco Electronics CRL1220T1R8J 1.8 Ω 0805

TDK C1608X5R0J106MT 10 µF 0603

TDK C1608X5R0J475M 4.7 µF 0603

VLF4014ST-2R2M1R9

LTDK

VLF5014S-2R2M2R3

R

X

Tyco Electronics 1-1879132-9 15 kΩ 0402

LED Luxeon LXHL_PW09

(1)

(2)

(2)

(1)

0.2 Ω 1206

0.16 Ω 1206

2.2 µH / 1.4 A 3.5x3.8x1.4 mm

2.2 µH / 2.3 A 4.6x4.8x1.4 mm

Note: The above-listed external components refer to a typical application. Operation of the

STCF07 is not limited to the use of these components.

Doc ID 16757 Rev 2 7/26

Page 8

Electrical characteristics STCF07

5 Electrical characteristics

TA = 25 °C, VI = 3.6 V, 2 x CI = 10 µF, CO = 1 µF, L = 2.2 µH, RHC = 0.22 Ω, RLC = 1.8 Ω,

R

= 15 kΩ

X

Table 6. Electrical characteristics

Symbol Parameter Test conditions Min. Typ. Max. Unit

V

I

UVLO Undervoltage lockout V

V

PW_ONRESET

I

O

V

OUT

ILIM Inductor peak current

Input voltage supply 2.7 5.5 V

= 2.7 V 2.2 V

I

Power ON reset threshold VI rising 2.3 V

Output current - high current

level

Output current - high current

level

Output current - low current

level

CSEL = VI; VI = 2.7 V to 5.5 V;

R

= 0.16 Ω, P

HC

CSEL = V

R

HC

; VI = 3.2 V to 5.5 V;

I

= 0.16 Ω, P

CSEL = GND; V

R

+ R

LC

~ 2 Ω

HC

= 3.4 W

OUT

= 4 W

OUT

= 3.3 V to 5.5 V;

I

1000

1000

20

Regulated voltage range 2.5 5.3 V

V

= 2.7 V, V

I

operation

shorted during

OUT

2.3 A

FB1 Feedback voltage Low current (CSEL = 0 V) 152 160 168 mV

FB2 Feedback voltage High current (CSEL = VI) 152 160 168 mV

= GND

)

I

90 mΩ

1.8 mA

00.4

1.4 3

R

ON_

FB1-FB2 ON resistance

Quiescent current in

shutdown mode

I

Q

Quiescent current in high

current mode

f

s

Frequency VI = 2.7 V 1.8 MHz

n Efficiency V

OVP

OV

HYST

Output overvoltage

protection

Overvoltage hysteresis VI = 5.5 V, no load 0.3 V

OTP Overvoltage protection V

OT

V

V

NTC

HYST

NTC

RX

LEAK

V

IL

V

IH

Overvoltage hysteresis VI = 5.5 V 20 °C

NTC voltage reference VI = 2.7 V to 5.5 V 1.8 V

NTC voltage threshold I

RX-NTC switch OFF leakage

Input logic signal level CSEL,

EN

High current (CSEL = V

IO = 800 mA

EN = GND 1 µA

EN = V

5.5 V; R

; CSEL = VI; VI = 3.3 V to

I

= 0.22 Ω

HC

= 3.2 to 4.2 V, IO = 800 mA 85 %

I

VI = 5.5 V, no load 5.5 V

= 5.5 V 140 °C

I

= 1 mA Max 1.2 V

NTC

Shutdown mode,

= 2 V - V

V

NTC

= 2.7 V to 5.5 V

V

I

RX

mA

1µA

V

8/26 Doc ID 16757 Rev 2

Page 9

STCF07 Electrical characteristics

Table 6. Electrical characteristics (continued)

Symbol Parameter Test conditions Min. Typ. Max. Unit

FAULT

T

ON

Low level voltage I

Leakage current V

LED current rise time

I

LED

= 0 to I

LED

= max

= 5 mA 0.2 0.5 V

SINK

= 5 V 1 µA

FAU LT

2ms

Doc ID 16757 Rev 2 9/26

Page 10

Introduction STCF07

6 Introduction

The STCF07 is a buck-boost converter designed to power and control the current of a power

white LED. The device operates at a constant switching frequency of 1.8 MHz (typ). It

provides an output voltage from 2.5 V up to 5.3 V, from a 2.7 V to 5.5 V supply voltage. This

supply range allows the device to operate from a single-cell Lithium-Ion battery. The current

is adjustable up to 1 A for an input voltage ranging from 2.7 V to 5.5 V and maximum output

power up to 3.4 W. When the battery voltage is higher than 3.2 V, it is possible to increase

the output power up to 4 W. The device uses an external NTC resistor to sense the

temperature of the white LED. This function may not be needed in all applications, and in

these cases the relevant external components can be omitted.

10/26 Doc ID 16757 Rev 2

Page 11

STCF07 Logic pin description

7 Logic pin description

7.1 CSEL pin

This input pin allows the setting of two different levels of current. When the voltage on this

pin is low, the internal multiplexer switches the feedback to the FB1 pin, which is the

dedicated feedback pin for low current operation. When the voltage on the CSEL pin is high,

the internal multiplexer switches the feedback to the FB2s pin, and enables the shorting

transistor connected between the FB1 and FB2 pins. The feedback voltage is sensed

directly on the sensing R

current operation.

7.2 FAULT pin

When the STCF07 is in ON mode (EN is high), the device is able to detect disconnection or

failure of the LED. This information can be used by the system to signal that a problem has

occurred in the LEDs.

7.3 ENABLE pin

by the connection of FB2s. This sensing pin is dedicated to high

HC

This pin functions as an enable input. No internal pull-up or pull-down is provided.

Doc ID 16757 Rev 2 11/26

Page 12

Detailed description STCF07

8 Detailed description

8.1 Buck-boost converter

The regulation of the PWM controller is done by sensing the current of the LED through RLC

or R

flash LED, the device can automatically change between buck (step-down) and boost (stepup) mode:

8.2 High current mode

+ RHC, depending on the CSEL voltage. Depending of the forward voltage of the

LC

– Boost region = V

output voltage (V

– Buck region = V

– Buck / boost region = V

OUT

OUT

OUT

> V

BAT

= VF + I

< V

BAT

OUT

: this configuration is used in most cases, as the

LED

~ V

x R

IN

) is higher than V

SENSE

BAT

ENABLE = CSEL = V

BAT

The STCF07 operates continuously to supply maximum current to the LED up to 800 mA in

high current mode. If high current mode is used in flash applications, then it is possible to

increase the LED current up to 1066 mA.

The current can be adjusted with the R

I

= 160 mV / R

HC

HC

For a current programmed at 800 mA, the sensing resistor is equal to 0.20 Ω.

8.3 Low current mode

ENABLE = VBAT, CSEL = 0

The STCF07 can continuously provide an adjustable current starting from 20 mA in low

current mode. The current adjustment is done with resistor R

programmed at:

I

= 160 mV / (RHC + RLC)

LC

The NTC divider for measurement of the LED temperature is active.

8.4 Shutdown mode

resistor. The current is then programmed at:

HC

. The current is then

LC

ENABLE = 0

When the device is not used, it can be put in shutdown mode, which reduces the quiescent

current to 1 µA. The NTC protection in this mode is not active.

8.5 Soft-start

To avoid spikes on the battery during the startup sequence, a soft-start function has been

implemented. The soft-start function is achieved by progressively increasing the feedback

voltage reference. In worst-case conditions, the startup time, as defined below (I

does not exceed 2 ms.

12/26 Doc ID 16757 Rev 2

OUT

= I

MAX

),

Page 13

STCF07 Detailed description

Figure 4. Startup: LED current rise time

ENABLE

ENABLE

I

I

OUT

OUT

I

I

LED

LED

TON< 2 ms

TON< 2 ms

8.6 STCF07 protection features

8.6.1 Peak current and short-circuit protection

When the peak inductor current exceeds the maximum switch peak current limit of 2.3 A, the

PWM controller turns off and is enabled at the next oscillation period.

8.6.2 Overvoltage protection

The device includes power failure protection, which stops the operation of the PWM

controller when the voltage at the pin V

on pin V

is reduced by OV

OUT

, the operation of the controller recovers automatically.

HYST

8.6.3 Thermal shutdown protection

Internal thermal shutdown protection switches off the device when the junction temperature

exceeds 140 °C (typ). The hysteresis comparator allows the PWM controller to restart

automatically when the temperature is reduced to 120 °C.

8.6.4 Sensing of LED temperature with the NTC resistor

The device is capable of switching off the power circuit when a high temperature on the LED

is detected. (see Figure 5).

exceeds the OVP threshold. When the voltage

OUT

Doc ID 16757 Rev 2 13/26

Page 14

Detailed description STCF07

Figure 5. Typical LED temperature sensing application with the NTC resistor

R

= 100 k

R

= 100 k

NTC

NTC

NTC

NTC

Vref = 1.8 V

Vref = 1.8 V

V

= 1.2 V

V

= 1.2 V

REF

REF

RX= 15 k

RX= 15 k

8.6.5 Undervoltage lockout function

If the device is ON and the battery voltage is as low as 2.2 V, the device goes into a FAULT

state and the FAULT pin is put to LOW. To restart the device, the ENABLE pin must be reset

LOW and HIGH.

14/26 Doc ID 16757 Rev 2

Page 15

STCF07 PCB design

9 PCB design

9.1 PCB design rules

The STCF07 is a powerful switched device, so the PCB must be designed following the

rules for designing switched supplies. It is recommended to use at least a two-layer PCB.

The power wiring must be as short and wide as possible, due to the high current. All external

components should be placed close to the STCF07. High-energy switched loops should be

as small as possible to reduce EMI. Most LEDs require cooling, which may be implemented

by a defined copper area on the PCB. Use the reference guide for each LED to design the

heatsink. Place the R

PCB layer is required, the number of vias must be sufficient. Place the NTC resistor as close

as possible to the LED for good temperature sensing. Direct connection of GND and PGND

is needed to achieve accurate output current values. The LED current should not flow

through this track. Sensing of the voltage on the R

connecting a wire directly from pin 6 to the R

track. Pins 5 and 6 must be connected to the pin of the R

must be connected to the PGND, with a track as wide as possible. It is recommended to

place the copper plate, connected through the vias to the exposed pad, on the bottom layer

to create a heatsink for the device. It is further recommended that the copper plate used be

as large as possible to achieve optimal thermal performance.

resistor as close as possible to pins 5 and 6. When a change of

FLASH

resistor must be done by

FLASH

resistor; no current flows through this

FLASH

resistor. The exposed pad

FLASH

Doc ID 16757 Rev 2 15/26

Page 16

PCB design STCF07

9.2 PCB design of the demonstration board

Figure 6. Top layer

Figure 7. Bottom layer

16/26 Doc ID 16757 Rev 2

Page 17

STCF07 PCB design

Figure 8. Top overlay

Doc ID 16757 Rev 2 17/26

Page 18

PCB design STCF07

9.3 Schematic of the demonstration board

Figure 9. Schematic diagram of the STCF07 demonstration board

18/26 Doc ID 16757 Rev 2

Page 19

STCF07 Typical performance characteristics

10 Typical performance characteristics

Figure 10. I

100.000

100.000

95.000

95.000

90.000

90.000

85.000

85.000

80.000

80.000

75.000

75.000

70.000

70.000

65.000

65.000

Output Current [mA]

Output Current [mA]

60.000

60.000

55.000

55.000

50.000

50.000

2.50 3.00 3.50 4.00 4.50 5.00 5.50

2.50 3.00 3.50 4.00 4.50 5.00 5.50

Figure 12. Efficiency vs. V

100

100

95

95

90

90

85

85

80

80

75

75

70

70

Efficiency [%]

Efficiency [%]

65

65

60

60

55

55

50

50

2.5 3 3.5 4 4.5 5 5.5

2.5 3 3.5 4 4.5 5 5.5

80 mA vs. V

OUT

25 °C

25 °C

- 40 °C

- 40 °C

85°C

85°C

800 mA

800 mA

400 mA

400 mA

IN

Input Voltage [V]

Input Voltage [V]

IN

Input Voltage [V]

Input Voltage [V]

Figure 11. I

1000.000

1000.000

950.000

950.000

900.000

900.000

850.000

850.000

800.000

800.000

750.000

750.000

700.000

700.000

Output Current [mA]

Output Current [mA]

650.000

650.000

600.000

600.000

550.000

550.000

500.000

500.000

2.50 3.00 3.50 4.00 4.50 5.00 5.50

2.50 3.00 3.50 4.00 4.50 5.00 5.50

800 mA vs. V

OUT

25 °C

25 °C

- 40 °C

- 40 °C

85 °C

85 °C

IN

Input Voltage [V]

Input Voltage [V]

Figure 13. Efficiency vs. VIN, IO = 400 mA

100

100

95

95

90

90

85

85

80

80

75

75

70

70

Efficiency [%]

Efficiency [%]

65

65

60

60

55

55

50

50

2.5 3 3.5 4 4.5 5 5.5

2.5 3 3.5 4 4.5 5 5.5

-40°C

-40°C

25°C

25°C

85°C

85°C

Input Voltage [V]

Input Voltage [V]

Figure 14. Line transient

V

= 600 mVpp, Tr = 10 µs, Tf = 10 µs, V

step

= 3.6 V to 4.2 V

IN

Doc ID 16757 Rev 2 19/26

Page 20

External component selection STCF07

11 External component selection

11.1 Input and output capacitor selection

For input and output capacitors it is recommended to use ceramic capacitors with low ESR.

For good device stability when supplied by a low input voltage of 2.7 V at maximum ratings,

it is recommended to use 10 µF / 6.3 V as a minimum value for the input capacitor, and 4.7

µF / 6.3 V as a minimum value for the output capacitor.

Note: See recommended components in Table 5 on page 7.

11.2 Inductor selection

A thick, shielded inductor with low DC series wiring resistance is recommended for this

application. For good efficiency, it is recommended to use an inductor with a series DC

resistance of R

For nominal operation, the peak inductor current can be calculated using the formula:

I

= {(I

PEAK

OUT

where:

< RD / 10, where RD is the dynamic resistance of the LED.

DCL

/ η) + [(V

- VIN) x VIN²) / (2 x L x F x V

OUT

OUT

²)]} x V

OUT

/ V

IN

I

= peak inductor current

PEAK

I

= current sourced at pin V

OUT

OUT

η = efficiency of the STCF07

V

= output voltage at pin V

OUT

VIN = input voltage at pin V

OUT

IN

L = inductance value of the inductor

F = switching frequency

Note: See recommended components in Table 5 on page 7.

11.3 LED selection

All LEDs with forward voltages from 2.7 V to 5 V are suitable for use with STCF07 device.

The LED forward voltage must include the voltage spread of this value. It is possible to set

the LED current in the two different operating modes (high current mode and low current

mode) through two external sensing resistors.

Note: See recommended components in Table 5 on page 7.

11.4 RHC selection

The RHC resistor value can be calculated using equations R

* I

HC

2

, where P

is the dissipated power on the RHC resistor. It is recommended to

RHC

R

HC

use a 1206 package size thin metal film resistor with 1% or 5% maximum tolerance. The

maximum high LED current for the STCF07 device is 800 mA with a battery voltage range

2.7 V to 5.5 V.

20/26 Doc ID 16757 Rev 2

= 160 mV / IHC and P

HC

RHC

=

Page 21

STCF07 External component selection

11.5 RLC selection

RLC resistor value can be calculated with the following equations:

R

= (160 mV - I

LC

where P

* RHC) / ILC and P

LC

is the dissipated power on the RLC resistor. It is recommended to use a thin

RLC

RLC

= R

LC

* I

LC

2

metal film resistor with a 1% or 5% tolerance.

11.6 NTC and RX resistor selection

The NTC resistor for sensing LED temperature and the RX resistor create a voltage divider.

The output of this divider is compared with the 1.192 V internal voltage reference. When

voltage on the output of the voltage divider is increased over the reference, the logic

switches off the power circuit. Voltage divider is possible to supply from the NTC pin, where

is output of the 1.8 V internal reference.

Doc ID 16757 Rev 2 21/26

Page 22

Package mechanical data STCF07

12 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

22/26 Doc ID 16757 Rev 2

Page 23

STCF07 Package mechanical data

QFN16 (4 x 4) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A0.800.90 1.00 31.5 35.4 39.4

A1 0.02 0.05 0.8 2.0

A2 0.65 1.00 25.6 39.4

A3 0.20 7.9

b 0.18 0.25 0.307.1 9.8 11.8

D 3.85 4.00 4.15 151.6 157.5 163.4

D2 2.10 2.60 82.7 102.4

E 3.85 4.00 4.15 151.6 157.5 163.4

E2 2.10 2.60 82.7 102.4

e 0.50 19.7

L0.30 0.40 0.50 11.8 15.7 19.7

ddd 0.083.1

7653321A

Doc ID 16757 Rev 2 23/26

Page 24

Package mechanical data STCF07

Tape & reel QFNxx/DFNxx (4x4) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A 330 12.992

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N 99 101 3.898 3.976

T 14.4 0.567

Ao 4.35 0.171

Bo 4.35 0.171

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

24/26 Doc ID 16757 Rev 2

Page 25

STCF07 Revision history

13 Revision history

Table 7. Document revision history

Date Revision Changes

18-Nov-2009 1 First release.

12-Apr-2011 2 Updated Table 5 on page 7.

Doc ID 16757 Rev 2 25/26

Page 26

STCF07

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

26/26 Doc ID 16757 Rev 2

Loading...

Loading...