General features

■ Buck-boost DC/DC Converter

■ Drives one power white led:

up to 600mA between 2.7 to 4.5V

■ Led temperature protection

■ Output current control

■ 1.8 MHz (typ) fixed frequency PWM

■ Synchronous rectification

■ High efficiency across the total input voltage

range

■ Operational modes:

- Shutdown mode

- Shutdown mode with NTC

- Flash mode up to 600 mA

- Medium flash mode

- Torch mode: up to 250 mA

■ Adjustable current in all three modes

■ LED disconnected from the battery in

shutdown mode

■ Programmable safety shutdown in flash mode

■ LED short and open circuit protection

■ Overvoltage protection

■ < 1µA Shutdown current

■ QFN20 4mm x 4 mm package

Applications

■ Cell phone and smart phones

■ Camera flashes/strobes

■ PDAS and digital still cameras

STCF02

High power white led driver

QFN20 (4mm x 4mm)

Description

The STCF02 is a high efficiency power supply

solution to drive a single flash LED in camera

phone, PDAs and other hand-held devices. It is a

buck-boost converter that guarantees a proper

LED current control over the battery voltage

(particularly in the case, when the output voltage

is lower than the input voltage); the output current

control ensures a good current regulation over the

forward voltage spread characteristics of the

Flash LED.

Three logic input signals can select 5 modes of

operation: Shutdown mode (quiescent current

less than 1µA typ), Shutdown mode with NTC

active, Torch mode (drives the LED up to 250mA),

Flash mode (up to 600mA), and Medium flash

mode (reduces the flash current).

This highly efficient converter is able to accept

input current from the battery (lower than 1.5A),

while limiting the peak inductor current to 2.3A

(typ). Other features include Soft start control,

thermal shutdown, short circuit protection,

overvoltage protection, and LED temperature

protection. An alternative to LED temperature

protection is that a safety flash time-out feature

can be implemented instead. This device is

available in a QFN20, 4mm x 4mm, no-lead

package (height is less than 1mm).

Order code

Part number Package Packaging

STCF02PNR QFN20 (4x4 mm) 4500 parts per reel

February 2007 Rev. 6 1/19

www.st.com

19

Contents STCF02

Contents

1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Detailed operating description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Buck-Boost converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.4 Medium flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.5 Torch mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.6 Shutdown mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.7 Soft start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.8 LED Failure Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.9 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.10 Thermal shutdown protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.11 Sensing of LED temperature by NTC resistor . . . . . . . . . . . . . . . . . . . . . . . . 14

6.12 Safety shutdown in flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/19

STCF02 Application

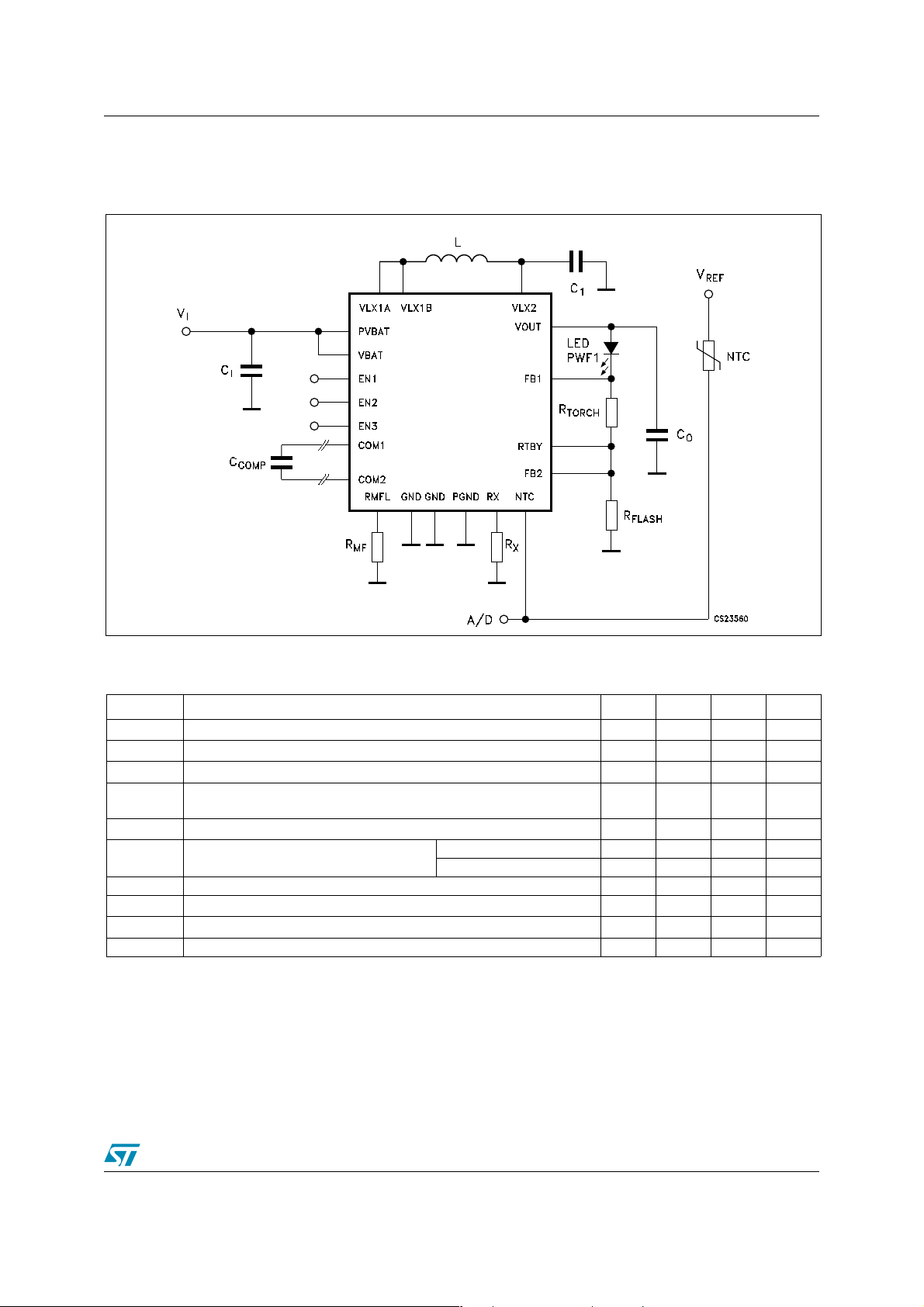

1 Application

Figure 1. Application circuit

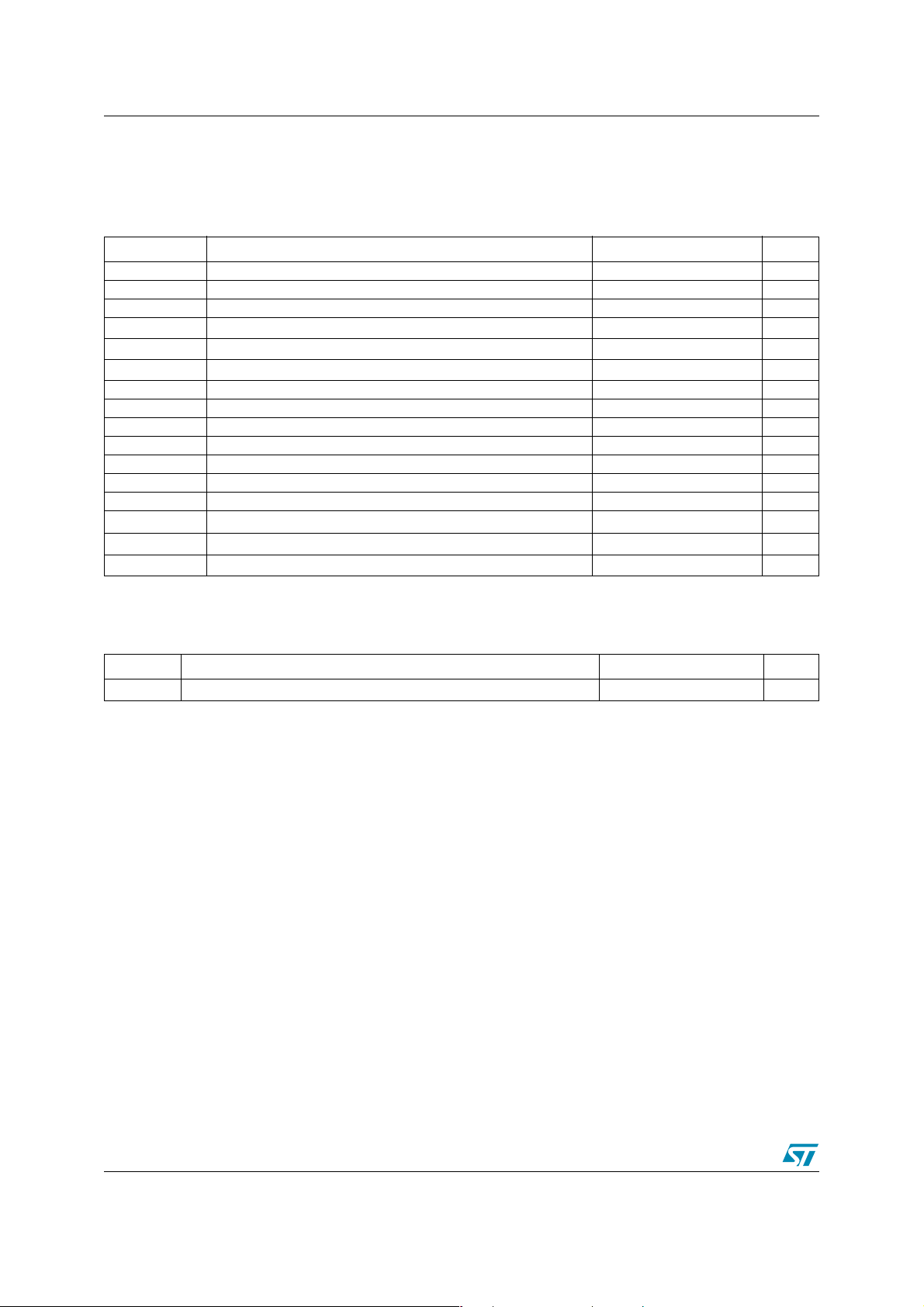

Table 1. External components

Symbol Parameter Min. Typ. Max. Unit

R

FLASH

R

TORCH

R

C

C

NTC Negative thermistor - NCP18WF104J03RB - Thick film type 100 kΩ

C

COMP

R

C1 Ceramic Capacitor 47 pF

Sensing flash current resistor - thick film type (0805) 0.27 Ω

Sensing torch current resistor - thick film type (0603) 6.2 Ω

Setting resistor for middle flash mode - thick film type (0402) 8200 Ω

MF

Two Input filtering capacitor TDK C1608X5R0J106MT - Ceramic

I

type (0603) 6.3V

Output capacitance - Ceramic type 0603 6.3V 4.7 µF

O

L TDKVLF5014A-4R7

Compensation capacitor - 0402 100 820 pF

Reference resistor - 0402 15 kΩ

X

INDUCTANCE 4.7 µH

DCR 0.12 Ω

10 2x10 µF

Note: - The external components proposal should be considered as a design reference guide. The

performances mentioned in the electrical characteristics table are not guaranteed for all the

possible electrical parameters of the components included in this list. On the other hand the

operation of STCF02 is not limited with the use of the external components listed above.

- The C

is optional and may be used if the error amplifier bandwidth (which by default is

COMP

set to 2 KHz) has to be decreased because of an unstable driver function. Unstable operation

could be caused by using different values of inductor and output capacitor then recommended.

3/19

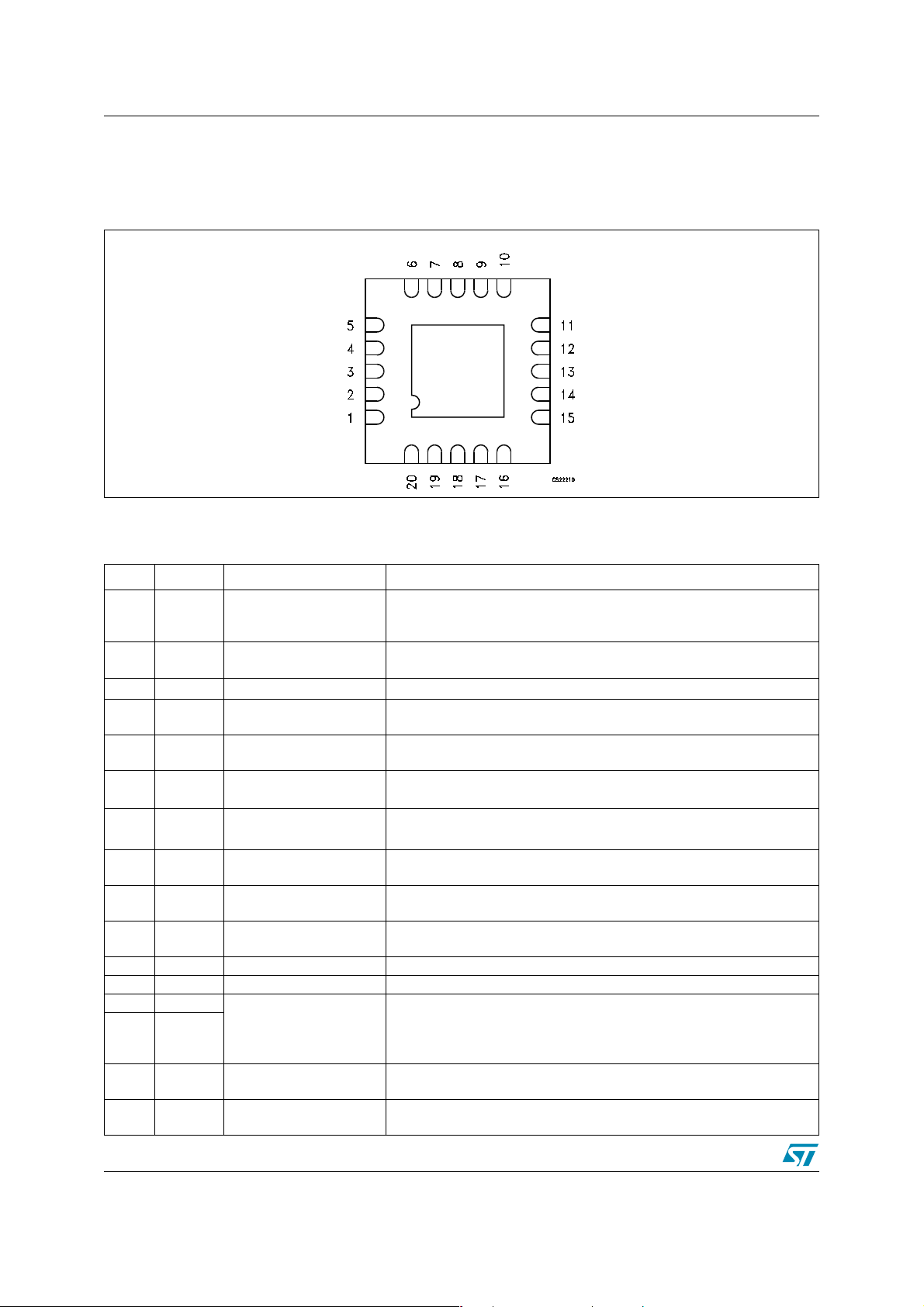

Pin connections STCF02

2 Pin connections

Figure 2. Pin configuration (bottom view)

Table 2. Pin description

Pln N° Symbol Name and function Note

External coil is connected between this pin and VLX1. It should be

1 VLX2 Inductor connection

2 RX Rx Resistor connection

V

3

4 NTC NTC Resistor connection

5FB1

6RTBY

7FB2

8, 10 GND Signal ground

9COM1

11 COM2

12 VBAT Supply voltage Supply pin of the device.

13 PVBAT Power supply voltage Power supply pin of the device.

14 VLX1A

15 VLX1B

16 EN3 Enable Pin 3

17 EN2 Enable Pin 2

Output voltage Anode of the LED is connected to this pin.

O

Feedback pin for torch

mode

TORC H

Bypass

R

Feedback pin for flash

mode

Compensation

connection

Compensation

connection

Inductor connection

placed as close as possible to the device in order to minimize

resistance which cause losses.

Rx resistor is connected between this pin and ground to set LED over

temperature threshold.

This pin is used for the LED temperature sensing using an external

NTC resistor.

This pin is used for current sensing in Torch mode – Cathode of the

Flash LED and RTorch resistor are connected to this pin.

This pin is used to short-circuit the R

MIDDLE FLASH MODE.

This pin is used to sense the voltage across R

directly connected to the non-grounded terminal of R

This is the signal ground pin related to digital and analog signals and

must be connected as close as possible to the sensing resistor.

Optional external compensation should be connected to these pins.

Optional external compensation should be connected to these pins.

External coil is connected between these pins and VLX2. They should

be placed as close as possible to the device in order to minimize

resistance which causes losses. It is mandatory to connect VLX1A

and VLX1B together.

Digital input that allows selection of the operational modes of the

device (refer to truth table).

Digital input that allows selection of the operational modes of the

device (refer to truth table).

during FLASH and

TORCH

FLASH

. It must be

.

FLASH

4/19

STCF02 Pin connections

Pln N° Symbol Name and function Note

18 PGND Power ground

19 RMFL

20 EN1 Enable Pin 1

Exp-

pad

PGND Power ground

Middle flash resistor

connection

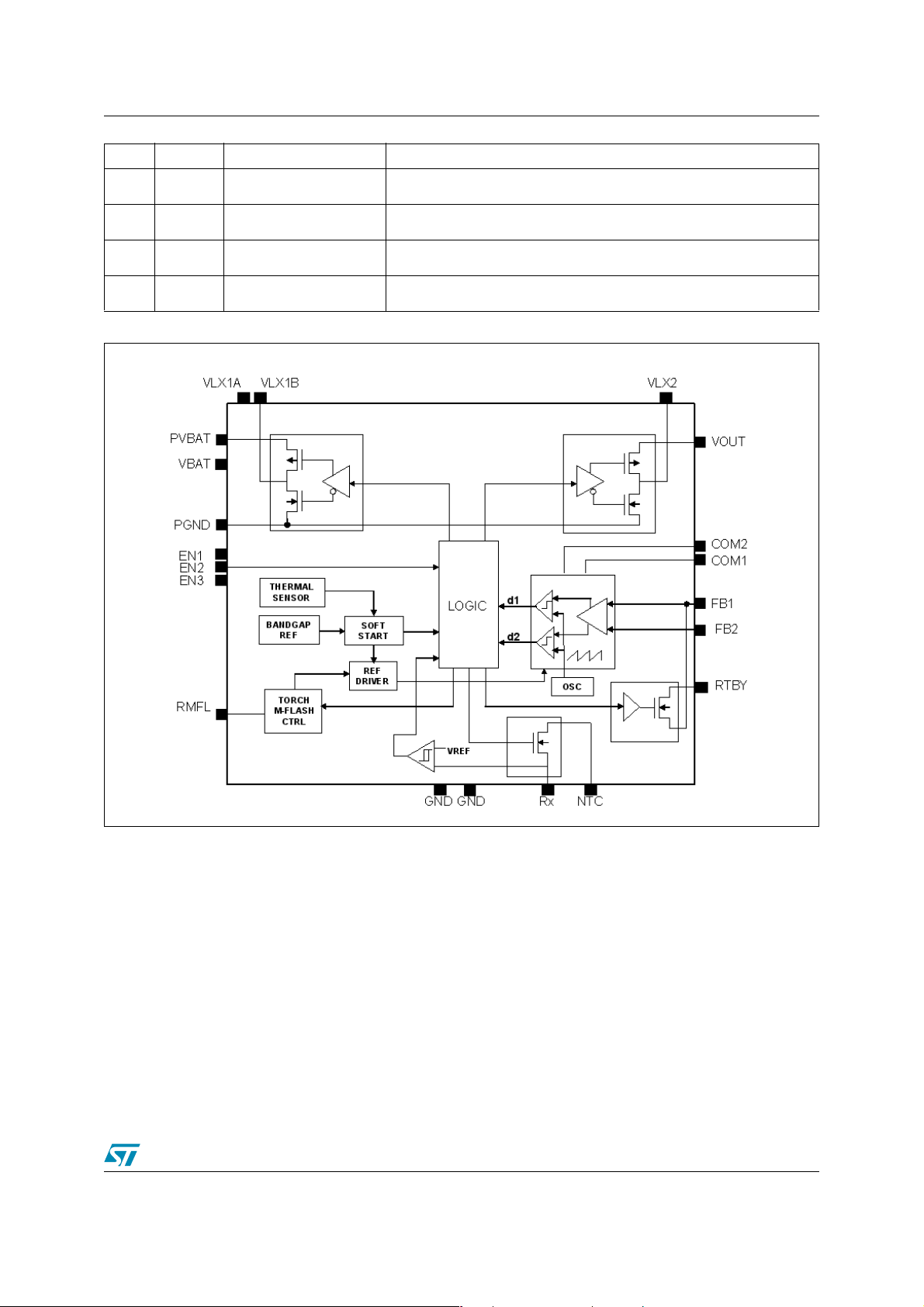

Figure 3. Block diagram

Power ground pin for power analog circuit. To be connected to the

PCB ground plane.

This pin is used for the current setting in Middle Flash Mode – RMF

resistor is connected to this pin.

Digital input that allow selecting the operational modes of the device

(refer to truth table).

To be connected to the PCB Ground Plane for optimal electrical and

thermal performance.

5/19

Maximum ratings STCF02

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

VBAT Signal supply voltage -0.3 to 6 V

PVBAT Power supply voltage -0.3 to 6 V

EN1,2,3 Enable input -0.3 to 6 V

V

O

VLX1A-VLX1B Inductor connection 1

VLX2 Inductor connection 2

FB1 Feedback for torch current -0.3 to 3 V

FB2 Feedback for flash current -0.3 to 3 V

RTBY MOS Switch connection -0.3 to 3 V

RX Connection for reference resistor -0.3 to 3 V

RMFL Connection for setting resistor for middle flash -0.3 to 6 V

NTC LED temperature sensing connection -0.3 to 6 V

COM1,COM2 Compensation connection -0.3 to 3 V

T

OP

T

STG

V

ESD

1. STCF02 is guaranteed to meet specification from 0°C to 70°C – specifications over the -40°C to 85°C operating

temperature range are assured by design, characterization and correlation with statistical process control.

Output voltage -0.3 to 6 V

+ 0.3

I

O

+ 0.3

V

V

Ambient operating temperature

(1)

-0.3 to V

-0.3 to V

-40 to + 85 °C

Storage temperature range -65 to + 150 °C

ESD rating 2 KV

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

(*) Typical Application on a two layer board.

Thermal resistance junction-ambient (*) 59 °C/W

6/19

STCF02 Characteristics

4 Characteristics

Table 5. Electrical characteristics

(All typical values are referred to T

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

I

CC

V

UVLO

I

∆I

V

FB1,2 Feedback Voltage Flash Mode 150 160 170 mV

I

e1

e2

I

PK

OVP Over voltage protection

OTP Over temperature protection

OT

HYST

NTC Voltage Reference

NTC

NTC

EN1, EN2,

EN3

I_ENx Enable input current ±1µA

T

FL/TR

T

1. Not include tolerance of sensing resistor

Input Operating Voltage 2.7 5.5 V

I

Under voltage lockout threshold

Output Current Adjustment

Range, I

Output Current Adjustment

O

Range, I

FLASH

MFLASH

Output Current Adjustment

Range, I

Output current variation

O

Regulated voltage range 2.5 5.1 V

O

Quiescent Current in Stand By

Q

f

Frequency

TORCH

Efficiency

Inductor peak current

Overtemperature hysteresis

Hysteresis 0.3 V

HYST

Voltage Reference leakage EN1=EN2=0, EN3=X ±1µA

LEAK

Logic signals level

Transition time from PIN (Flash)

to PIN (Torch) (see

Led current rise time I

ON

I

= max (see

LED

Figure 11

Figure 13

LED

)

= 0 to

)

= 25°C, VI = 3.6V)

A

Torch mode 616 686 757

µAMedium flash mode 590 688 733

Flash mode 555 660 728

rising

V

I

VI falling

5.1 5.3

5.1 5.3

V

Flash mode for VI = 2.7V to 4.5V

R

FLASH_MIN

R

FLASH_MAX

Medium flash mode for VI = 2.7V to

4.5V RM

RM

FLASH_MAX

=1.6Ω to

=0.27Ω

FLASH_MIN

=500kΩ

=1.1kΩ to

100 600

25%

I

FLASH

I

FLASH

mA

Torch mode VI = 2.7V to 4.5V

R

TORCH+RFLASH

R

TORCH+RFLASH

Flash and medium flash mode

=6.4Ω to

=0.64Ω

(1)

25 250

±10 %

Torch mode ±5%

EN1=EN2=EN3=0 1

EN1=EN2=0 EN3=X (NTC ON) 3

VI = 2.7V

Application Circuit

Figure 2

VI = 3.2 V to 4.2V, IO=600mA

Application Circuit

Figure 2

VI = 3.2 V to 4.2V, IO=25mA

= 2.7V, IO=600mA

V

I

V

= 4.2V No load

I

= 2.7V to 4.5V (

V

I

= 2.7V to 4.5V (

V

I

VI = 4V, I

NTC

Disable Low V

Enable High V

Note: 1

Note: 1

= 2mA max

IL

IH

)

)

78 85 %

72 75 %

5.2 V

1.4

1.8 MHz

1.23 A

140 °C

1.192 V

PIN (IO=600mA) to PIN

(IO=100mA) (

Note: 1

)

EN1=EN2=0 to EN1=0 & EN2=1

or EN1=EN2=1 (Note 1)

20 °C

0.4

µA

V

30 µs

2ms

Note: 1 Guaranteed by design

7/19

Characteristics STCF02

Table 6. Truth table selection mode

EN1 EN2 EN3

I

LED

I

LED_MAX

(mA)

Mode NTC

0 0 X 0 0 Shutdown OFF

1 0 1 0 0 Shutdown ON

01X I

I

MFLASH

I

FLASH

(R

111

100

110

=160mV/

TORCH

TORCH+RFLASH

= f (I

FLASH,RMFLASH

= 160mV/R

)

FLASH

250 Torch ON

)

500 Medium Flash ON

600 Flash ON

8/19

STCF02 Typical characteristics

5 Typical characteristics

Figure 4. IIN vs VIN in torch mode Figure 5. IO vs VIN in torch mode 25 mA

Figure 6. IO vs VIN in flash mode 600 mA Figure 7. VFB1 vs temp in torch mode

Figure 8. Efficiency vs IO in torch mode Figure 9. Start-up to torch mode 25 mA at

V

= 3.6V

BATT

9/19

Typical characteristics STCF02

Figure 10. Start-up to flash mode 600 mA at

V

= 3.6V

BATT

10/19

STCF02 Detailed operating description

6 Detailed operating description

6.1 Introduction

The STCF02 is a buck-boost converter, dedicated to power and control the current of a Power White Led

in a camera cell Phone. The device operates at a constant switching frequency of 1.8MHz typ. It provides

an output voltage down to 2.5V and up to 5.1 V, from a single cell 2.7 V to 5.5 V lithium-ion battery. The

flash current is adjustable from 100mA to 600mA for the input voltage range from 2.7V to 4.5V. Torch

current is adjustable from 25mA to 250mA. The device also includes a medium flash mode with the

current set between the 25% of flash current and flash current. The device contains a pin for connection

of NTC which senses the temperature of the LED.

6.2 Buck-Boost converter

Regulation of the PWM controller is made by sensing the current of the led through the R

(see

Figure 2

). Depending on the forward voltage of the Flash LED, the device can automatically change

FLASH

resistor

the operation mode between buck (step down) and boost (step up) mode. Three case can occur:

Boost region (V

I

x R

LED

FLASH

> VBAT): this configuration is used in most cases, as the output voltage (VO = V

O

) is higher than VBAT; Buck region (VO < V

); Buck / Boost region (VO ~ VI).

BAT

fLED

6.3 Flash mode

To select Flash mode the Enable pins have to be connected as follows: EN1=1, EN2=1, EN3=0.

The STCF02 operates continuously to supply maximum current to the flash LED (up to 600 mA).

The flash current can be adjusted by the R

voltage across R

I

= 160mV / R

FLASH

. The flash current is then programmed at:

FLASH

FLASH.

For a flash current programmed at 600mA, the sensing resistor is equal to 0.27Ω.

During this operation mode the MOS Switch between FB1 and RTBY pins is closed.

If the EN3 is forced to High during Flash mode operation, the current is reduced to that of Torch mode.

Such reduction of input power during transition from Flash to Torch mode is achieved within less than

30µs. The NTC divider for measuring LED temperature is active.

resistor. The control loop uses the FB2 pin to sense the

FLASH

+

11/19

Detailed operating description STCF02

Figure 11. Reducing power during the EN3

6.4 Medium flash mode

To select this operating mode the Enable pins have to be connected as follows:

EN1=1, EN2=0, EN3=0

In medium flash mode the current is set between the Torch and the flash mode levels and can be adjusted

by connecting a resistor between the RMFL pin and the ground:

The medium flash current is then programmed using the following equation:

I

=10-5/RFL • [3000+(13000• RMF/13000+RMF)]. (See

MF

Figure 12

).

12/19

STCF02 Detailed operating description

Figure 12. Middle Flash Current (as a percentage of flash current) vs RMF

6.5 Torch mode

To select this operating mode the Enable pins have to be connected to any one of the follow states:

EN1 = 0, EN2 = 1, EN3 = x

EN1 = 1, EN2 = 1, EN3 = 1.

The STCF02 can continuously provide a torch current adjustable between 25mA and 250mA. The torch

current adjustment is made by resistor R

voltage across R

I

TORCH

=160mV/(R

FLASH+RTORCH

FLASH+RTORCH

. The torch current is then programmed using the following equation:

).

If the programmed Flash current is 600mA (R

R

resistance is equal to 0.37Ω.

TORCH

TORCH

(

Figure 2

FLASH

). The control loop uses the FB1 pin to sense the

= 0.27Ω) and a 250mA Torch current is needed, the

During Torch operation mode the MOS Switch between FB1 and RTBY pins is opened.

The NTC divider for measuring LED temperature is active.

6.6 Shutdown mode

When the device is not used, two shutdown modes are available. They can be selected by the enable

pins:

EN1=0, EN2=0, EN3=X

With this combination the NTC divider for measuring of LED temperature is not active. The quiescent

current is less than 1µA.

EN=1, EN2=0, EN3=1

This combination of enable pins provides shutdown modes with an active NTC divider for sensing LED

temperature. This Mode is useful for measuring the temperature before starting both TORCH and FLASH

MODE operations.

13/19

Detailed operating description STCF02

6.7 Soft start

To avoid spikes the battery during start-up sequence, a soft start function has been implemented. This

soft start is achieved by progressively increasing the feedback voltage reference. In the worst case

scenario the start up time as defined below (I

Figure 13. Start up - LED current rise time

O

= I

) will not exceed 6ms.

MAX

6.8 LED Failure Protection

The device is self protected when the LED fails as a result of a short or open circuit. Such performances

are tested using a standard mobile phone Lithium battery with internal resistance 170mΩ typ.

6.9 Overvoltage protection

The device includes a power switch protection that stops the operation of the PWM controller when the

voltage at the pin V

exceeds the OVP threshold.

O

6.10 Thermal shutdown protection

Internal thermal shutdown protection will switch off the device when the junction temperature exceeds

140°C typical. The hysteresis comparator allows for the automatic restart of the PWM controller, when the

temperature is reduced by 20°C.

6.11 Sensing of LED temperature by NTC resistor

The device is able to switch off the power circuit, if high temperature on the LED is detected (see

Figure 14

).

14/19

STCF02 Detailed operating description

6.12 Safety shutdown in flash mode

To avoid LED burning during flash mode, which could be brought on by a micro-controller fault, a simple

programmable R

Figure 15

).

Figure 14. Typical application of LED temperature sensing by NTC resistor

circuit is possible to shutdown the device after a selected time through the RX Pin (see

C

Figure 15. Typical Application of Safety Shutdown

EN1 EN2 Mode

0 0 All OFF N/A

01 Torch NO

1 0 Mid-Flash YES

1 1 Full-Flash YES

Time-

Out

15/19

Package mechanical data STCF02

7 Package mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK® packages.

These packages have a Lead-free second level interconnect. The category of second level

interconnect is marked on the package and on the inner box label, in compliance with JEDEC

Standard JESD97. The maximum ratings related to soldering conditions are also marked on

the inner box label. ECOPACK is an ST trademark. ECOPACK specifications are available at:

www.st.com.

16/19

STCF02 Package mechanical data

QFN20 (4x4) MECHANICAL DATA

mm. mils

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

A 0.8 0.9 1.0031.535.439.4

A1 0.02 0.05 0.8 2.0

A2 0.65 1.00 25.6 39.4

A3 0.25 9.8

b 0.18 0.23 0.30 7.1 9.1 11.8

D 3.875 4.00 4.125 152.6 157.5 162.4

D2 0.75 1.7 2.25 29.5 66.9 88.6

E 3.875 4.00 4.125 152.6 157.5 162.4

E2 0.75 1.7 2.25 29.5 66.9 88.6

e 0.450.500.5517.719.721.7

L 0.350.550.7513.821.725.9

ddd 0.08 3.1

7169619-D

17/19

Revision history STCF02

8 Revision history

Table 7. Revision history

Date Revision Changes

10-Nov-2005 1 First release.

19-Dec-2005 2 Document updating.

29-Jun-2006 3 The table 5 has been updated and add typical characteristics.

27-Jul-2006 4

18-Oct-2006 5 Text updates.

Mistake on table 5 figure reference T

FL/TR

parameter.

09-Feb-2007 6

Mistake value of IO test condition RM

FLASH_MAX

= 500Ω ==> 500kΩ on

Ta b l e 5 .

18/19

STCF02

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

19/19

Loading...

Loading...