Page 1

Spektrum AR6255 User Guide

Spektrum AR6255 Bedienungsanleitung

Guide de l’utilisateur - Spektrum AR6255

Guida per l’utente Spektrum AR6255

Page 2

Spektrum AR6255 User Guide

Spektrum’s AR6255 6-channel full range receiver is designed for installations

in compact airplanes constructed of carbon fiber. Carbon fiber can create an RF

shielding effect that can significantly reduce radio range when using conventional

receivers and antennas. The AR6255 features an antenna design that overcomes RF

issues in these critical environments.

Compatibility

The AR6255 receiver features DSM2™ technology and is compatible with all

Spektrum™ and JR® aircraft radios that support DSM2 technology including:

JR12X JR11X

JRX9503 JRX9303

Spektrum DX8 Spektrum DX7

Spektrum DX6i Spektrum DX5e

Spektrum Module Systems

Note: The AR6255 receiver is not compatible with the Spektrum DX6 parkflyer

transmitter.

Features

• 6-channel receiver optimized for carbon ber fuselage installations

• Compact endpin design is ideal for F5D and hand launch sailplanes with small

cross sections

• Offers superior RF coverage with through-the-fuselage feeder antennas

• Includes one internal receiver with two 4-inch (101mm) feeder antennas

• Red LED indicates number of holds

• Preset failsafe system on throttle aileron and elevator optimized for sailplane and

F5D applications

• QuickConnect™ with Brownout Detection

• 2048 Resolution

• Flight Log Compatibility

• Compatible with Spektrum Aircraft

• Telemetry system

Applications

Compact airplanes with carbon structure including:

• Carbon/ Composite F5D electrics

• Carbon hand launch and DLH gliders

• Carbon Hot-liners

• Compact aircraft with signicant conductive materials (carbon, aluminum or

other metals) that could weaken the signal

Specifications

Type: DSM2 Full Range receiver for carbon aircraft

Channels: 6

Modulation: DSM2

Dimensions: 35mm x 22mm x 10mm

Weight: 5.5 grams

Voltage Range: 3.5 to 9.6

Resolution: 2048

Compatibility: All DSM2 aircraft transmitters

EN

Page 3

105mm

31mm

EN

Receiver Installation

Airplanes with signicant carbon ber construction can create an RF shielding effect,

reducing range. The AR6255 is designed to overcome these critical RF issues in

carbon airplanes by outfitting the aircraft with two external antennas at specific

points that will ensure secure RF coverage from all angles of the aircraft.

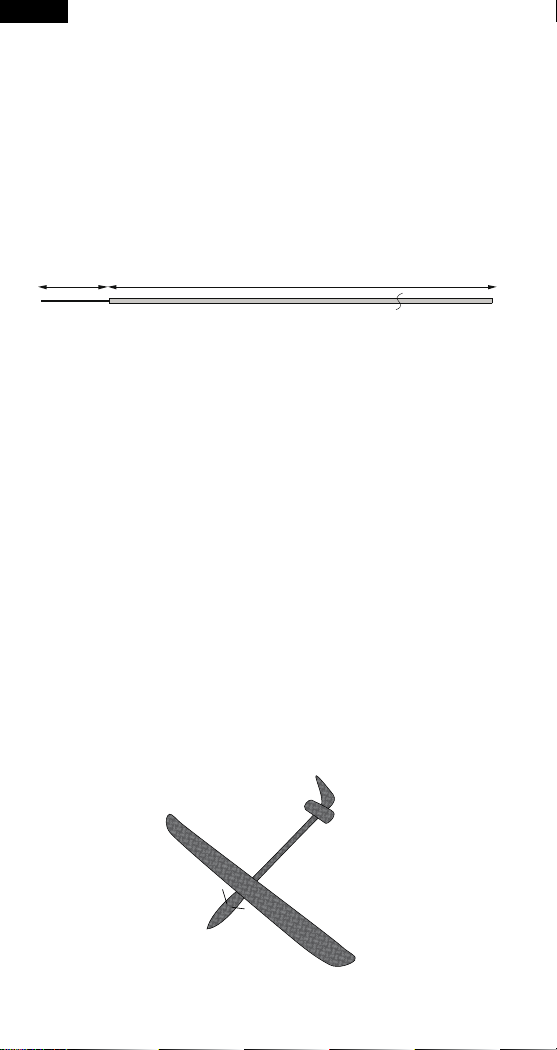

Feeder Antennas

The AR6255 incorporates two feeder antennas, which are designed to be easily

mounted through the fuselage in carbon airplanes. The receiver has two 4-inch

feeder antennas. Each feeder antenna includes a coaxial portion (which can be

thought of as an extension) and an exposed 31mm tip antenna. The last 31mm is the

active portion of the antenna.

Red LED Hold Indicator

The AR6255 features a red LED (labeled with H) that indicates the number of holds

that have occurred since the receiver was last powered on. The LED will ash the

number of holds then pause (e.g., ash, ash, ash, pause, ash, ash, ash,

pause indicates three holds occurred since the receiver was last turned on). Note

that holds are reset to zero when the receiver is turned off. During the rst ights of

a new airplane, it’s recommended to check the red LED hold indicator. If it’s ashing,

it’s important to optimize the installation (move or reposition antennas) until no

hold occurs. On later ights, the LED Hold Indicator can be used to conrm RF link

performance.

Step 1. Identifying the Type of Carbon Aircraft

While some Hand Launch Gliders and F5D airplanes are full carbon construction,

many only use carbon in areas that require extra strength. Some of the latest

aircraft are constructed with 2.4GHz friendly fuselages, meaning that the forward

section of the fuselage is constructed from non-conductive materials like fiberglass

and Kevlar that don’t affect RF. The first step in a proper installation is identifying the

type of fuselage.

A- Full Carbon

All components of the airplane including the entire fuselage, the wing and tail are

constructed of carbon fiber or have a carbon fiber weave throughout the aircraft.

External Antennas

Full Carbon

Page 4

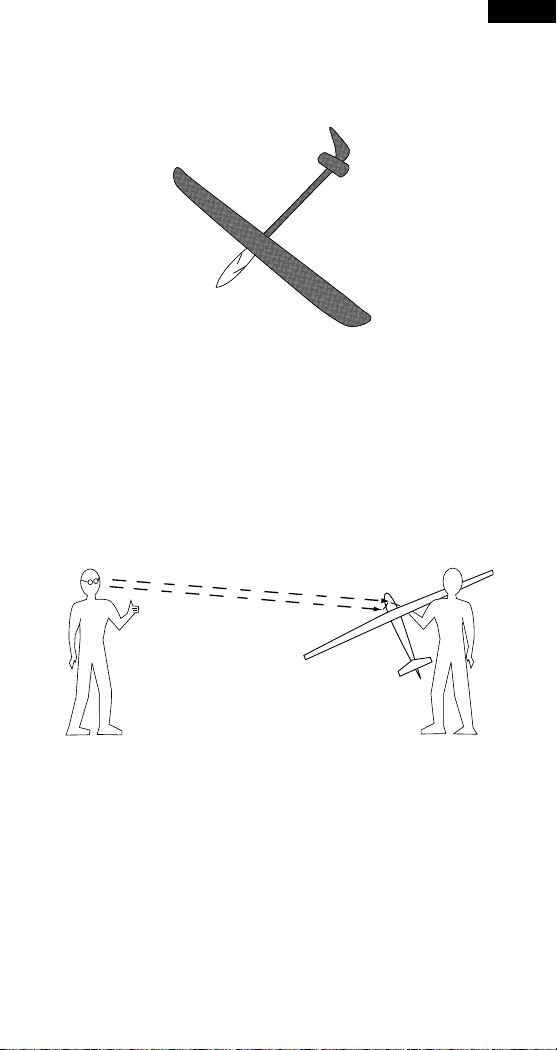

B- 2.4GHz Friendly Fuselage

The section forward of the wing is constructed of non-conductive materials like

berglass, Kevlar, etc. but the wing and possibly the tail section have carbon or

carbon weave construction.

EN

Internal Antennas

Step 2. Determining Antenna Mounting Positions

After determining which type of aircraft from the list above, use the above

illustrations as a guideline as to where the feeder antennas should be mounted. Note

that full carbon aircraft requires externally mounted antennas while the 2.4GHz-

friendly fuselage can have the antennas mounted internally. The goal is to mount the

antennas in a location so that at least one will always be in the RF visual line of sight

of the transmitter (e.g. not blocked by carbon ber structures) in all attitudes. This

can easily be visualized by having a helper stand about 20 feet away and rotate the

airplane in all attitudes confirming that in all positions there is a direct line between

you and at least one receiver antenna that isn’t blocked by carbon fiber structure.

Step 3. Installing the Receivers

Install the receiver in the normal position recommended by the

airplane’s manufacturer. Double-sided tape or foam can be used to secure the main

receiver in place.

Step 4. Mounting the Antennas

To install the antennas, drill a 1/16-inch hole in the desired antenna mounting

position.

Slide the feeder antenna through the hole until the 31mm tip, and about 2mm

of coaxial, completely exit the fuselage. Using a drop of CA, glue the antenna to

the fuselage making sure that the 31mm active portion of the antenna tip is fully

exposed.

2.4GHz Friendly

Page 5

EN

Note: If the antenna is to be mounted internally (in the front of a 2.4GHz fuse), the

coaxial can be taped into position. Be sure the 31mm tip is located at least

2 inches from any significant carbon structure.

Step 5. Plugging in the Servo Leads

Plug the servo leads into the appropriate servo ports in the receiver, noting the

polarity of the servo connector. Consult your radio’s manual for specific details as to

which servo plugs into which servo port channel.

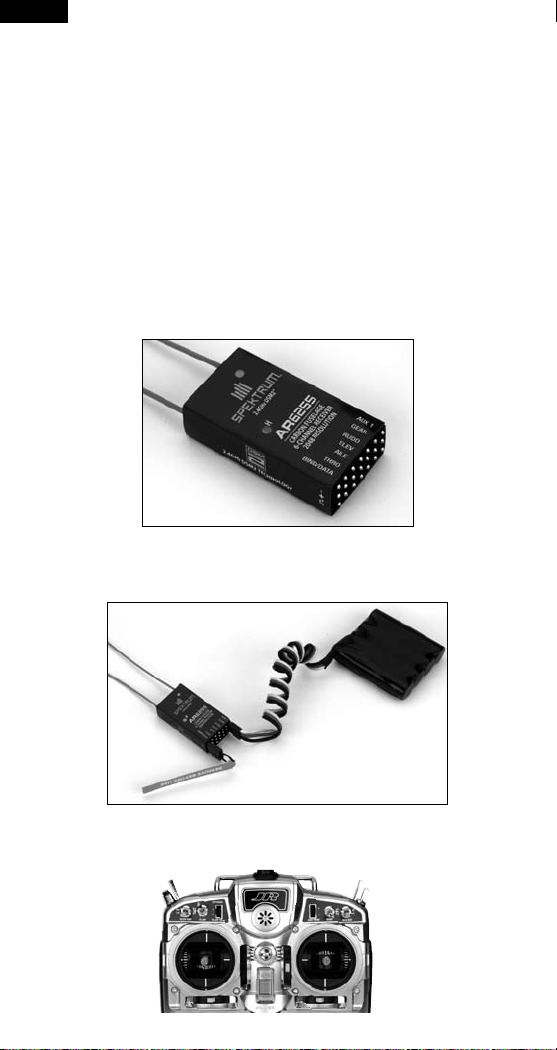

Step 6. Binding the Receiver

The AR6255 must be bound to the transmitter before it will operate. Binding is the

process of teaching the receiver the specific code of the transmitter so it will only

connect to that specific transmitter.

1. To bind an AR6255 to a DSM2 transmitter, insert the bind plug in the BIND/

DATA port on the receiver.

2. Power the receiver through any other port. Note that the orange LED on the

receiver should be ashing, indicating that the receiver is in bind mode and

ready to be bound to the transmitter.

3. Move the sticks and switches on the transmitter to the desired failsafe positions

for the throttle, elevator and aileron channels.

Page 6

4. Follow the procedures of your specic transmitter to enter Bind Mode; the

system will connect within a few seconds. Once connected, the orange LED on

the receiver will go solid indicating the system is connected.

5. Remove the bind plug from the BATT/BIND port on the receiver before you

power off the transmitter and store it in a convenient place.

IMPORTANT: Remove the bind plug to prevent the system from entering bind

mode the next time the power is turned on.

Step 7. Radio Setup and Programming

Following the instructions in your radio manual, program your airplane.

Step 8. Rebinding the Receiver

After you’ve programmed your model, it’s important to rebind the system so the true

failsafe control surface positions are set.

Step 9. Ground Range Testing and Verification Red LED

Advanced Range Testing

In airplanes that have signicant carbon ber construction, it is imperative to rst

do an advanced ground range check. This ground range check will confirm that

the receiver is operating optimally and that the antennas are properly mounted in

a position that will give positive RF coverage in all attitudes. This advanced range

check allows the RF performance of the receiver and the positions of each antenna to

be veried and to optimize the locations of the antennas.

Advanced Range Test

1. Turn on the system (Tx and Rx).

2. Have a helper hold your aircraft while observing the red LED (labeled with H)

located on the receiver.

3. Standing 30 paces away from the model, face the model with the transmitter in

your normal ying position and put your transmitter into range test mode. This

causes reduced power output from the transmitter.

4. Have your helper position the model covering all orientations (nose up, nose

down, nose toward the Tx, nose away from the Tx, etc.) while watching the red

LED, noting any correlation between the aircraft’s orientation and when holds

occur. Do this for one minute. The timer on the transmitter can be used here.

5. After one minute, release the range test button. A successful installation will

yield the following: no holds, no ashing red LED.

If any holds occur redo the test, noting the orientation of the aircraft when the holds

occur. This will allow you to change and optimize the antenna position(s) to a better

location.

Step 10. Short Test Flight Verification with Hold Indicator

When the system tests successfully, it’s time for a short near test ight. This rst

ight should be close (in less than 200 feet) and about ve minutes or less. After the

ight, land near yourself and check that no holds occurred. A successful ight will

result in 0 holds. Extend the ight distance and times, checking the Hold data after

every ight until you are condent with the results.

IMPORTANT: Y-Harnesses and Servo Extensions

When using Y-harness or servo extensions, it’s important to use standard nonamplied Y-harnesses and servo extensions as they can/will cause the servos to

EN

Page 7

EN

operate erratically or not function at all. Amplified Y-harnesses were developed

several years ago to boost the signal for some older PCM systems and should not

be used with Spektrum equipment. Note that when converting an existing model

to Spektrum, be certain that all amplied Y-harnesses and/or servo extensions are

replaced with conventional non-amplified versions.

Preset Failsafe

The AR6255 features preset failsafe on all channels. Preset failsafe is ideal for

sailplanes, allowing the aircraft to automatically dethermalize if the signal is lost. With

preset failsafe, all channels will go to their preset failsafe positions if the signal is

lost, preventing a yaway.

Receiver Power Only

• When the receiver only is turned on (no transmitter signal is present), all

channels have no output signal, to avoid overdriving the servos and linkages.

Note: Some analog servos may drift slightly during power-up even though no

signal is present. This is normal.

After Connection

• When the transmitter is turned on and after the receiver connects to the

transmitter, normal control of all channels occurs.

• After the system makes a connection, if loss of signal occurs Preset Failsafe

drives the throttle, aileron and elevator servos to their preset failsafe position set

during binding.

Receiver Power System Requirements

Inadequate power systems that are unable to provide the necessary minimum

voltage to the receiver during ight have become the number one cause of in-ight

failures. Some of the power system components that affect the ability to properly

deliver adequate power include:

• Receiver battery pack (number of cells, capacity, cell type, state of charge)

• The switch harness, battery leads, servo leads, regulators, etc.

• The BEC used in the speed controller won’t support the current required by the

servos.

The AR6255 has a minimum operational voltage of 3.5 volts; it is highly

recommended the power system be tested per the guidelines below.

Recommended Power System Test Guidelines

If a questionable power system is being used (e.g. a small or old battery that may

not support high-current draw, etc.), it is recommended that a voltmeter be used to

perform the following test.

Note: The Spektrum Flight Log (SPM9540) is the perfect tool to monitor voltage

in the test below.

Plug the Flight Log into an open channel port in the receiver and with the system

on, load the control surfaces (apply pressure with your hand) while monitoring the

voltage at the receiver. The voltage should remain above 4.8 volts even when all

servos are heavily loaded.

Page 8

Note: The latest generations of Nickel-Metal Hydride batteries incorporate a new

chemistry mandated to be more environmentally friendly. These batteries,

when charged with peak detection fast chargers, have tendencies to

false peak (not fully charge) repeatedly. These include all brands of NiMH

batteries. If using NiMH packs, be especially cautious when charging,

making absolutely sure that the battery is fully charged. It is recommended

to use a charger that can display total charge capacity. Note the number

of mAh put into a discharged pack to verify it has been charged to full

capacity.

QuickConnect™ With Brownout Detection

Your AR6255 features QuickConnect with Brownout Detection.

• Should an interruption of power occur (brownout), the system will reconnect

immediately when power is restored (QuickConnect).

• The orange LED on the receiver will ash slowly indicating a power interruption

(brownout) has occurred.

• Brownouts can be caused by an inadequate power supply (weak battery or

regulator), a loose connector, a bad switch, an inadequate BEC when using an

electronic speed controller, etc.

• Brownouts occur when the receiver voltage drops below 3.5 volts thus

interrupting control as the servos and receiver require a minimum of 3.5 volts

to operate.

How QuickConnect With Brownout Detection Works

• When the receiver voltage drops below 3.5 volts the system drops out (ceases

to operate).

• When power is restored the receiver immediately attempts to reconnect to the

last two frequencies that it was connected to.

• If the two frequencies are present (the transmitter was left on) the system

reconnects typically in about a fraction of a second.

QuickConnect with Brownout Detection is designed to allow you to y safely

through most short-duration power interruptions; however, the root cause of these

interruptions must be corrected before the next ight to prevent catastrophic safety

issues.

Note: If a brownout occurs in ight, it is vital that the cause of the brownout be

determined and corrected.

Flight Log (SPM9540 Optional)

The Flight Log is compatible with the AR6255. The Flight Log displays overall RF

link performance as well as the individual internal and external receiver link data.

Additionally it displays receiver voltage.

Using the Flight Log

After a ight and before turning off the receiver or transmitter, plug the Flight Log into

the Data port on the AR6255. The screen will automatically display voltage e.g. 6v2=

6.2 volts.

Note: When the voltage reaches 4.8 volts or less, the screen will ash indicating

low voltage.

EN

Page 9

EN

Press the button to display the following information:

A - Antenna fades on the internal antenna

B – Not used

L – Antenna fades on the external antenna

R – Not used

F - Frame loss

H - Holds

Antenna fades—represents the loss of a bit of information on that specific antenna.

Typically it’s normal to have as many as 50 to 100 antenna fades during a ight. If

any single antenna experiences over 500 fades in a single ight, the antenna should

be repositioned in the aircraft to optimize the RF link.

Frame loss—represents simultaneous antenna fades on all attached receivers.

If the RF link is performing optimally, frame losses per ight should be less than

20. A hold occurs when 45 consecutive frame losses occur. This takes about one

second. If a hold occurs during a ight, it’s important to evaluate the system, moving

the antennas to different locations and/or checking to be sure the transmitter and

receivers are all working correctly.

Note: A servo extension can be used to allow the Flight Log to be plugged in more

conveniently. On some models, the Flight Log can be plugged in, attached and left on

the model using double-sided tape. Mounting the Flight Log conveniently to the side

frame is common with helicopters.

ModelMatch™

Some Spektrum and JR transmitters offer a feature called ModelMatch that prevents

the possibility of operating a model using the wrong model memory, potentially

preventing a crash. With ModelMatch, each model memory has its own unique code

(GUID) and during the binding process the code is programmed into the receiver.

Later, when the system is turned on, the receiver will only connect to the transmitter

if the corresponding model memory is programmed onscreen.

Note: If at any time you turn on the system and it fails to connect, check to be

sure the correct model memory is selected in the transmitter. Please note

that the Spektrum Aircraft Modules do not have ModelMatch.

Tips On Using 2.4GHz

While your DSM equipped 2.4GHz system is intuitive to operate, functioning

nearly identically to 72MHz systems, following are a few common questions from

customers.

1. Q: Which do I turn on rst, the transmitter or the receiver?

A: If the receiver is turned on rst—all channels have no output pulses. When

the transmitter is then turned on, the transmitter scans the 2.4GHz band and

acquires two open channels. Then the receiver that was previously bound to the

transmitter scans the band and nds the GUID (Globally Unique Identier code)

stored during binding. The system then connects and operates normally.

If the transmitter is turned on rst—the transmitter scans the 2.4GHz band and

acquires two open channels. When the receiver is then turned on for a short

period (the time it takes to connect) all channels have no output pulses. The

Page 10

receiver scans the 2.4GHz band looking for the previously stored GUID. When it

locates the specic GUID code, it conrms the uncorrupted repeatable packet

information, the system connects and normal operation takes place. Typically

this takes 2 to 6 seconds.

2. Q: Sometimes the system takes longer to connect and sometimes it doesn’t

connect at all?

A: In order for the system to connect (after the receiver is bound) the receiver must

receive a large number of consecutive uninterrupted perfect packets from the

transmitter. This process is purposely critical of the environment ensuring that

it’s safe to y when the system does connect. If the transmitter is too close

to the receiver (less than 4 feet) or if the transmitter is located near metal

objects (metal Tx case, the bed of a truck, the top of a metal work bench, etc.),

connection will take longer and in some cases connection will not occur as the

system is receiving reected 2.4GHz energy from itself and is interpreting this

as unfriendly noise. Moving the system away from metal objects or moving the

transmitter away from the receiver and powering the system again will cause

a connection to occur. This only happens during the initial connection. Once

connected, the system is locked in and should a loss of signal occur (failsafe),

the system connects immediately when the signal is regained.

3. Q: I’ve heard that the DSM system is less tolerant of low voltage. Is this correct?

A: All DSM receivers have an operational voltage range of 3.5 to 9.6 volts. With

most systems this is not a problem as, in fact, most servos cease to operate at

around 3.8 volts. When using multiple high-current draw servos with a single

or inadequate battery/ power source, heavy momentary loads can cause the

voltage to dip below this 3.5-volt threshold thus causing the entire system

(servos and receiver) to brown out. When the voltage drops below the low

voltage threshold (3.5 volts), the DSM receiver must reboot (go through the

startup process of scanning the band and nding the transmitter) and this can

take several seconds. Please read the receiver power requirement section as

this explains how to test for and prevent this occurrence.

4. Q: Sometimes my receiver loses its bind and won’t connect requiring rebinding.

What happens if the bind is lost in ight?

A: The receiver will never lose its bind unless it’s instructed to. It’s important to

understand that during the binding process the receiver not only learns the

GUID (code) of the transmitter, but the transmitter learns and stores the type

of receiver that it’s bound to. If the transmitter is placed into bind mode, the

transmitter looks for the binding protocol signal from a receiver. If no signal is

present, the transmitter no longer has the correct information to connect to

a specific receiver and in essence the transmitter has been “unbound” from the

receiver. We’ve had several DX7 customers that use transmitter stands or trays

that unknowingly depress the bind button and the system is then turned on,

losing the necessary information to allow the connection to take place. We’ve

also had DX7 customers that didn’t fully understand the range test process

and pushed the bind button before turning on the transmitter also causing the

system to “lose its bind.”

EN

Page 11

EN

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties that the Products purchased (the

“Product”) will be free from defects in materials and workmanship for a period of 1 year from the

date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original Purchaser (“Purchaser”) and is not transferable. REPAIR

OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE

PURCHASER. This warranty covers only those Products purchased from an authorized Horizon

dealer. Third party transactions are not covered by this warranty. Proof of purchase is required for

warranty claims. Further, Horizon reserves the right to change or modify this warranty without notice

and disclaims all other warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCT. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE

PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall be that Horizon will, at its option,

(i) repair or (ii) replace, any Product determined by Horizon to be defective. In the event of a defect,

these are the Purchaser’s exclusive remedies. Horizon reserves the right to inspect any and all

equipment involved in a warranty claim. Repair or replacement decisions are at the sole discretion

of Horizon. This warranty does not cover cosmetic damage or damage due to acts of God, accident,

misuse, abuse, negligence, commercial use, or modification of or to any part of the Product. This

warranty does not cover damage due to improper installation, operation, maintenance, or attempted

repair by anyone other than Horizon. Return of any goods by Purchaser must be approved in writing

by Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCT,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

Further, in no event shall the liability of Horizon exceed the individual price of the Product on which

liability is asserted. As Horizon has no control over use, setup, final assembly, modification or

misuse, no liability shall be assumed nor accepted for any resulting damage or injury. By the act of

use, setup or assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability associated with the use of

this Product, you are advised to return this Product immediately in new and unused condition to the

place of purchase.

Law: These Terms are governed by Illinois law (without regard to conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a toy. It must be operated with caution and common sense

and requires some basic mechanical ability. Failure to operate this Product in a safe and responsible

manner could result in injury or damage to the Product or other property. This Product is not intended

for use by children without direct adult supervision. The Product manual contains instructions for safety,

operation and maintenance. It is essential to read and follow all the instructions and warnings in the

manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once

assembly, setup or use of the Product has been started, you must contact Horizon directly. This will

enable Horizon to better answer your questions and service you in the event that you may need any

assistance. For questions or assistance, please direct your email to

productsupport@horizonhobby.com, or call 877.504.0233 toll free to speak to the

Product Support department.

Inspection or Repairs

If this Product needs to be inspected or repaired, please call for a Return Merchandise Authorization

(RMA). Pack the Product securely using a shipping carton. Please note that original boxes may be

included, but are not designed to withstand the rigors of shipping without additional protection.

Ship via a carrier that provides tracking and insurance for lost or damaged parcels, as Horizon is

not responsible for merchandise until it arrives and is accepted at our facility. A Service Repair

Request is available at www.horizonhobby.com on the “Support” tab. If you do not have internet

access, please include a letter with your complete name, street address, email address and phone

Page 12

number where you can be reached during business days, your RMA number, a list of the included

items, method of payment for any non-warranty expenses and a brief summary of the problem. Your

original sales receipt must also be included for warranty consideration. Be sure your name, address,

and RMA number are clearly written on the outside of the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying the proof-ofpurchase date. Provided warranty conditions have been met, your Product will be repaired or

replaced free of charge. Repair or replacement decisions are at the sole discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty the repair will be completed and payment will be

required without notification or estimate of the expense unless the expense exceeds 50% of the

retail purchase cost. By submitting the item for repair you are agreeing to payment of the repair

without notification. Repair estimates are available upon request. You must include this request with

your repair. Non-warranty repair estimates will be billed a minimum of ½ hour of labor. In addition

you will be billed for return freight. Please advise us of your preferred method of payment. Horizon

accepts money orders and cashiers checks, as well as Visa, MasterCard, American Express, and

Discover cards. If you choose to pay by credit card, please include your credit card number and

expiration date. Any repair left unpaid or unclaimed after 90 days will be considered abandoned and

will be disposed of accordingly. Please note: non-warranty repair is only available on electronics and

model engines.

Country of Purchase Horizon Hobby Address Phone Number / Email Address

Horizon Service Center

United States of America

United Kingdom Horizon Hobby Limited

Germany

France Horizon Hobby SAS

(Electronics and engines)

Horizon Product Support

(All other products)

Horizon Technischer

Service

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Hamburger Str. 10

25335 Elmshorn

Germany

14 Rue Gustave Eiffel

Zone d’Activité du Réveil Matin

91230 Montgeron

877-504-0233

productsupport@horizonhobby.com

877-504-0233

productsupport@horizonhobby.com

+44 (0) 1279 641 097

sales@horizonhobby.co.uk

+49 4121 46199 66

service@horizonhobby.de

+33 (0) 1 60 47 44 70

FCC Information

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Caution: Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This product contains a radio transmitter with wireless technology which has been tested

and found to be compliant with the applicable regulations governing a radio transmitter in the

2.400GHz to 2.4835GHz frequency range.

EN

Page 13

EN

Compliance information for the European Union

Declaration of Conformity

(in accordance with ISO/IEC 17050-1)

No. HH20100618U1

Product(s): AR6255 Receiver, AR6255P Receiver

Item Number(s): SPMAR6255, SPMAR6255P

Equipment class: 1

The objects of declaration described above are in conformity with the requirements of the

specifications listed below, following the provisions of the European R&TTE directive 1999/5/

EC:

EN 301 489-1, 301 489-17 General EMC requirements

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

June 18, 2010

Steven A. Hall

Vice President

International Operations and Risk Management

Horizon Hobby, Inc.

Instructions for Disposal of WEEE by Users in the

European Union

This product must not be disposed of with other waste. Instead, it is the user’s

responsibility to dispose of their waste equipment by handing it over to a

designated collection point for the recycling of waste electrical and electronic

equipment. The separate collection and recycling of your waste equipment at

the time of disposal will help to conserve natural resources and ensure that it is

recycled in a manner that protects human health and the environment. For more

information about where you can drop off your waste equipment for recycling,

please contact your local city office, your household waste disposal service or

where you purchased the product.

DSM and DSM2 are trademarks or registered trademarks of Horizon Hobby, Inc. The Spektrum trademark is

used with permission of Bachmann Industries, Inc. Spektrum radios and accessories are exclusively available

US Patent Number 7, 391, 320. Other patents pending.

©2009 Horizon Hobby, Inc.

from Horizon Hobby, Inc.

Page 14

Spektrum AR6255 Bedienungsanleitung

Der Empfänger Spektrum AR6255 ist für den Einsatz in Kohlefaserrümpfen

entwickelt worden. Kohlefaser / Carbon hat eine abschirmende Eigenschaft und

verhindert das Durchdringen von Funkwellen / Sendersignalen. Der AR6255 ist mit

einem speziellen Antennenlayout ausgestattet, dass diese möglichen Abschirmungen

effektiv verhindert.

Kompatibilität

Der AR6255 Empfänger in DSM2™ Technologie ist kompatibel mit allen Spektrum™

und JR™ Flugfernsteuerungen die den DSM2 Standart unterstützen inklusive:

JR12X JR11X

JRX9503 JRX9303

Spektrum DX8 Spektrum DX7

Spektrum DX6i Spektrum DX5e

Spektrum Module

Hinweis: Der AR6255 Empfänger ist nicht kompatibel mit dem Spektrum DX6

Parkflyer Sender.

Features

• 6-Kanal Empfänger optimiert für den Einsatz in Carbon Rümpfen

• Die sehr kompakte Steckerauslegung ist ideal für F5D und Hand Launch Glider

(HLG) mit schmalen Rümpfenn

• Bietet beste Empfangsabdeckung mit zwei je 101mm Feeder Antennen, die zu

30mm durch den Rumpf geführt werden

• Eine rote LED zeigt die Anzahl der Holds

• Voreingestelltes Failsafe auf Gas, Quer- und Höhenruder, optimiert für den Einsatz

in Segelugzeugen oder F5D Typen

• Quick Connect mit Spannungsabfalldetektion

• Flight Log Kompatibel

• Kompatibel mit Spektrum Flug Telemetrie System

• Telemetrie system

Einsatzbereiche

• RC Flugzeuge mit Carbonstruktur z.B.

• Carbon / Composite F5D Flugzeuge

• Carbon Handlaunch und DLH Gliders

• Flugzeugtypen mit signikanten Anteil von abschirmenden Material (Carbon,

Aluminium oder andere Metalle) die Signale abschwächen können

Spezifikationen

Type: DSM2 Full Range Empfänger für Carbonrümpfe

Kanäle: 6

Modulation: DSM2

Abmessungen: 35mm x 22mm x 10mm

Gewicht: 5.5 g

Spannungsbereich: 3,5–9,6

Auösung: 2048

Kompatibel zu: allen DSM2 Flugfernsteuerungen und Modulen

Empfängerinstallation

Flugmodelle aus Carbonfaser Verbundstoffen oder mit sehr hohem Anteil an

DE

Page 15

DE

105mm

31mm

Carbonfaser können eine Abschirmung der Empfänger bewirken. Der AR6255 ist

speziell für solche Modelle entwickelt worden um eben dieses zu unterbinden. Der

AR6255 besitzt zwei sogenannte Feeder Antennen, die aus dem Rumpf geführt

werden können um die Empfangsqualität in optimaler Güte zu gewährleisten.

Die Feeder Antennen

Der AR6255 Empfänger verfügt über Feeder Antennen, die einfach durch den Rumpf

geführt werden können. Sie bestehen aus einer je 70mm langen Verlängerung aus

Koaxialkabel und einer 31mm langen aktiven Antenne.

Der LED Hold Indikator

Hold: Ein Hold tritt ein, wenn 45 aufeinander folgende Datenblöcke verloren gehen.

Dieses dauert ca. 1 Sekunde. Wenn ein Hold eintritt, muss das gesamte System, hier

insbesondere die Position der Antennen geprüft werden.

Der AR6255 ist mit einer roten Leuchtdiode ausgestattet (gekennzeichnet mit einem

H), die die Anzahl der Holds seit dem letzten Einschalten anzeigt Die LED blinkt und

zeigt dabei die Anzahl der Holds, danach erfolgt eine Pause. Beispiel: blink, blink,

blink, Pause, blink, blink, blink. Hier zeigt der Empfänger 3 Holds seit dem letzten

Einschalten. Bitte beachten Sie, dass dieser Speicher mit dem Ausschal-ten gelöscht

wird. Wir raten an, während erster Flüge mit einem neuen Modell die LED auf

Blinken zu kontrollieren. Sollte ein Blinken auftreten, optimieren Sie die Position des

Empfängers oder der Antennen bis kein Blinken mehr auftritt. Bei späteren Flügen

kann der LED Hold Indikator als für die Empfangleistung angesehen werden.

Schritt 1: Identifizieren des Carbon im Flugzeug

Es gibt Hand Launch Glider und F5D Flugzeuge, die komplett aus Carbon gefertigt

sind und es gibt andere Typen, die Carbon nur an besonders belasteten Stellen

verwenden. Einige der neuesten Typen haben eine 2.4 GHz freundliche Konstruktion,

wo der vordere Rumpfbereich aus Fiberglas oder Kevlar besteht, die die Funkwellen

nicht negativ beein¬ussen. Der erste Schritt für einen richtigen Einbau ist das

Erkennen des Rumpftypes.

A- Voll Carbon

Alle Komponenten des Flugzeuges wie Rumpf, Tragächen, Leitwerk bestehen aus

Car¬bon oder sind mit einem Carbon Laminat verkleidet.

Externe Antennen

Voll Carbon

Page 16

B- 2.4 GHz Freundliche Konstruktion

Die Rumpfsektion vor der Fläche ist aus nicht störenden Material wie zum Beispiel

Kevlar oder Fieberglas gebaut. Die Flächen oder der hintere Teil des Flugzeuges sind

aus Carbon gebaut.

DE

Antennen im Rump

Schritt 2: Bestimmen der Antennenposition

Nachdem Sie Ihren Flugzeugtyp bestimmt haben, nutzen Sie bitte die oben

abgebildeten Zeichnungen als Hilfestellung, wo die Antennen montiert werden sollten.

Bitte beachten Sie, dass bei Flugzeugen, die zu 100 % aus Carbon bestehen, die

Anten¬nen außen angebracht werden müssen, während bei 2.4 GHZ freundlichen

Konstruktio¬nen, die Antennen im Inneren montiert werden können. Wichtig ist,

dass mindestens immer eine der beiden montierten Antennen in Linie zum Sender

zeigt und nicht durch verbaute Carbonteile behindert wird. Sie können dieses einfach

ausprobieren, in dem ein Helfer ca. 6 Meter vom Flugzeug entfernt steht und Sie das

Flugzeug mit Hand um alle Achsen drehen. Es muss immer eine ununterbrochene

Sichtlinie zu mindestens einer Antenne bestehen.

Schritt 3: Einbauen des Empfängers

Bauen Sie den Empfänger an der vorgesehenen Position ein und befestigen Sie ihn

mit Klett- oder geschäumten doppelseitigen Klebeband.

Schritt 4. Einbau der Antennen

Bohren Sie mit einem 1,6 mm Bohrer ein Loch dort in den Rumpf, wo die Antennen

positioniert werden sollen. Führen Sie eine Feeder Antenne durch das Loch nach

außen, bis die gesamten 31mm des aktiven Teils der Antenne und ca. 2 mm der

Verlängerung außen sichtbar sind. Kleben Sie die Antenne mit einem Tropfen

Sekundenkleber fest.

Hinweis: Wenn die Antenne intern montiert wird, kann das Koaxial Kabel auch

mit Tape geklebt werden. Es ist aber unbedingt sicher zu stellen, dass

der aktive Teil der Antenne mindestens 5cm von Carbonbauteilen oder

Carbonstrukturen entfernt ist.

2.4Ghz Freundlich

Page 17

DE

Schritt 5. Anschließen der Servo Anschlüsse

Schließen Sie die Servokabel an die gewünschten Anschlüsse des Empfängers an.

Bitte achten Sie auf die richtige Polarität. Nehmen Sie die Bedienungsanleitung Ihres

Senders zur Hilfe welche Servos / Funktionen, in welche Anschlüsse des Empfängers

gesteckt werden müssen.

Schritt 6: Binden des Empfängers

Der AR 6255 muss vor dem Einsatz an den Sender gebunden werden. Mit Binden ist

der Prozess der Übermittlung eines Codes von Sender zu Empfänger gemeint der die

Verbindung ausschließlich zu diesem Empfänger herstellt.

1. Um den AR6255 Empfänger an einen DSM2 Sender zu binden, stecken Sie bitte

den Bindestecker in den BIND/DATA Anschluss des Empfängers.

2. Schließen Sie die Empfängerstromversorgung über einen beliebigen anderen

Anschluss an. Die orangefarbene LED wird nun anfangen zu blinken und zeigt

damit an, dass sich der Empfänger in Bindemodus bendet und bereit zum

Binden mit dem Sender ist.

3. Bringen Sie die Steuerknüppel und Schalter der Funktionen Gas, Höhen- und

Querruder Ihrer Fernsteuerung in die gewünschten Failsafe Positionen.

Page 18

4. Führen Sie den Bindevorgang mit Ihrem Sender durch. Das System wird sich

innerhalb weniger Sekunden binden. Die Orange LED wird nun leuchten und

so den erfolgreichen Bindevorgang anzeigen.

5. Entfernen Sie den Bindestecker bevor Sie den Sender ausschalten und heben Sie

ihn gut auf.

Wichtig: Der Bindestecker ist unbedingt nach dem Bindevorgang zu entfernen, da

sonst das System beim nächsten Einschalten wieder in den Bindemodus

geht..

Schritt 7: Programmierung der Fernsteueranlage

Folgen Sie den Instruktionen der Bedienungsanleitung Ihres Senders um das Modell

zu programmieren.

Schritt 8: Binden des Empfänger nach der Programmierung

Nach der Programmierung des Senders ist es wichtig den Bindevorgang erneut

auszuführen, damit alle Änderungen / Einstellungen der Programmierung

übernommen werden.

Schritt 9: Reichweiten Boden Test mit Hold Indikator LED

Bei Flugzeugen die einen signikanten Anteil an Carbon haben, ist es außerordentlich

wichtig, vor dem ersten Flug einen gründlichen Reichweiten Boden Test vor zu

nehmen. Dieser Test wird Ihnen anzeigen, ob der Empfänger und die Antennen an

den richtigen Stellen plaziert sind und somit das System einwandfrei arbeitet.

1. Schalten Sie den Sender und Empfänger ein

2. Bitten Sie einen Helfer das Flugzeug zu halten und die rote LED am Empfänger

zu beobachten.

3. Stellen Sie sich ca. 30 Meter vom Modell entfernt mit Blick auf das Modell.

Halten Sie den Sender so, als ob Sie iegen würden und aktivieren Sie den

Reichweitentest Ihrer Fernsteueranlage. Der Sender sendet jetzt mit verminderter

Leistung.

4. Bitten Sie den Helfer nun das Modell um alle Achsen zu drehen und dabei auf die

rote LED zu achten. Machen Sie diesen Test ungefähr für eine Minute, der Timer

an der Fernsteuerung kann hier helfen. Fängt die rote LED an zu blinken sind

Holds aufgetreten.

5. Lassen Sie nach einer Minute den Reichweitetestknopf los. Ist das System richtig

eingebaut, wird die rote LED nicht leuchten und der Test ist erfolgreich.

Sollte bei dem Test die rote LED anfangen zu leuchten, merken Sie sich bitte die

Posi¬tion des Flugzeuges, bei welcher das Leuchten auftritt und optimieren Sie die

Position der Antennen. Führen Sie nach der Optimierung den Test erneut durch.

DE

Schritt 10: Kurzer Test Flug mit Hold Indikator LED

Sind die vorherigen Systemtests erfolgreich verlaufen, ist es Zeit einen kurzen

Testug durchzuführen. Bitte iegen Sie nicht weiter als 60 Meter weg und nicht

länger als 5 Minuten. Überprüfen Sie nach der Landung mit der LED, ob Holds

angezeigt werden. Ist das System richtig eingebaut, wird die rote LED nicht leuchten

und der Test ist erfolgreich. Erweitern Sie in den nächsten Flügen den Radius und die

Flugzeit Schritt für Schritt und überprüfen Sie weiterhin danach die rote LED.

Page 19

DE

Wichtig: Servokabel und Servokabelverlängerungen

Wenn Sie Y- Kabel oder Servokabelverlängerungen einsetzen, achten Sie bitte darauf,

dass es Standardkabel sind und keine die Signale verstärken. Beim Einsatz von

verstärkenden Kabeln kann es zu Servofehlfunktionen kommen.

Failsafe Voreinstellung

Der AR6255 ist mit einem programmierbaren Failsafe auf allen ausgestattet und ist

damit ideal für Segelugzeuge. Mit aktivem Failsafe fahren die Servos / Regler in

die vorbestimmten Positionen im Falle eines Signalverlustes und verhindern so, das

Wegiegen des Modells.

Empfängeraktivität bei ausgeschalteten Sender

• Ist der Empfänger eingeschaltet, ohne das ein Sendersignal vorhanden ist

(Sender aus), gibt der Empfänger keine Signale an die Ausgänge (Servos / Regler)

und verhindert somit ein Überdrehen der Servos und Gestänge.

Hinweis: Einige analoge Servos können sich in dem oben beschriebenen Fall

Anforderungen an die Empfängerstromversorgung

Nicht ausreichende Empfängerstromversorgung ist einer der Hauptursachen von

Störungen oder Abstürzen. Folgende Komponenten müssen hierbei berücksichtigt

werden:

• Empfängerakku (Zellenanzahl, Kapazität, Zelltyp, Alter, Ladezustand)

• Schalter, Akkuanschlüsse und Regler etc.

• Das Regler BEC kann für die Anzahl der Servos zu schwach sein.

Der AR6255 benötigt eine Mindestspannung von 3,5 Volt. Wir raten dringend an,

diese mit den folgenden Richtlinien zur Überprüfung der Empfängerstromversorgung

zu testen.

etwas bewegen. Dieses ist normal für analoge Servos.

Überprüfung der Empfängerstromversorgung

Sollten Zweifel an der Leistungsfähigkeit der Empfängerstromversorgung bestehen

(evtl. durch alte oder schwache Empfängerakkus) kann dieses mit einem Voltmeter

oder mit dem Spektrum Flight Log (SPM9540) überprüft werden. Zum Aufzeichnen

von Flug¬daten ist das Flight Log mit dem Empfänger leider nicht kompatibel.

Schließen Sie das Flight Log an einem freien Kanal am Empfänger an. Schalten

Sie die Anlage ein und bewegen Sie die Servos. Geben Sie mit der Hand etwas

Widerstand auf die Servobewegungen und achten dabei auf die Voltangabe auf dem

Flightlog. Die Spannung sollte, wenn alle Servos unter Last sind, nicht unter 4,8 Volt

fallen.

Hinweis: Die neueste Generation von NiMh Zellen haben geänderte (mehr umwelt

freundliche) Inhaltstoffe. Diese Akkus neigen bei dem Peak Schnell- Ladeverfahren dazu falsche Peak Angaben dem Ladegerät mitzuteilen und

somit nicht ganz voll geladen zu werden. Dieses kann alle Marken von

neuesten NiMh Zellen betreffen. Wenn Sie also NiMh Zellen verwenden,

stellen Sie bitte immer sicher, dass diese Zellen auch voll geladen sind.

Wir empfehlen hier, um ganz sicher zu gehen, Ladegeräte zu verwenden,

die die geladene mA Menge anzeigen.

Page 20

QuickConnect™ mit Spannungsabfalldetektion

Ihr AR6255 ist mit einem QuickConnect mit Spannungsabfalldetektion ausgestattet.

• Sollte eine Unterbrechung der Stromversorgung (Brownout) stattnden, wird sich

das System unverzüglich wieder neu binden (QuickConnect)

• Die orange LED im Empfänger blinkt danach langsam, um die Unterbrechung der

Stromversorgung (Brownout) anzuzeigen

• Unterbrechungen der Stromversorgung können u. a. durch schwache

Empfängerakkus, Wackelkontakte, oder ein nicht ausreichendes BEC System

ausgelöst werden.

• Ein Spannungsabfall tritt ein, wenn der Empfängerstrom unter 3,5 Volt fällt.

So arbeitet das Quick Connect mit Spannungabfalldetektion

• Das System wird inaktiv wenn die Empfängerstromversorgung unter 3,5 Volt fällt.

• Ist die Spannung wieder hergestellt, wird sich das System unverzüglich mit den

letzten beiden Frequenzen verbinden, mit denen es verbunden war.

• Sind diese beiden Frequenzen vorhanden (Sender ist an), geschieht das im

Bruchteil einer Sekunde.

Quick Connect mit Spannungsabfalldetektion wurde entwickelt um einen sicheren

Flug auch bei kurzzeitigen Spannungsabfällen zu gewährleisten.

Hinweis: Sollten diese auftreten ist die Ursache zur Gefahrenabwehr vor dem

nächsten Flug zu beseitigen.

Flight Log (SPM9540 Optional)

Das Flight Log ist kompatibel zu dem AR 6255.

Das Flight Log zeigt ihnen die Gesamtempfangsleistung wie auch die Leistung jeder

einzelnen Antenne. Zusätzlich dazu wird Ihnen die Empfängerspannung angezeigt.

Der Gebrauch des Flight Log

Nach einem Flug und bevor Sie den Empfänger ausschalten, schließen Sie das

Flight Log an den Datenport des AR6255 an. Auf dem Display wird ihnen dann die

Empfängerspannung angezeigt 6c2 = 6,2 Volt

Hinweis: Erreicht die Spannung 4,8 oder darunter blinkt das Display und zeigt

ihnen damit die Unterspannung an.

Drücken Sie den Knopf auf dem Display um folgende Informationen abzurufen

A - Antennen Ausblendungen auf der internen Antenne

B – wird nicht benutzt

L – Antennen Ausblendungen auf der externen Antenne

R – wird nicht benutzt

F - Frame losses

H - Holds

Antenna fades—represents the loss of a bit of information on that specific antenna.

Typically it’s normal to have as many as 50 to 100 antenna fades during a ight. If

any single antenna experiences over 500 fades in a single ight, the antenna should

be repositioned in the aircraft to optimize the RF link.

DE

Page 21

DE

Antennenausblendungen—stehen für den Verlust an Informationsbits einer

spezischen Antenne. Es ist normal während des Fluges ca. 50 - 100

Antennenausblendungen zu haben. Sollte eine spezische Antenne während eines

Fluges mehr als 500 Ausblendungen haben, sollte die Antenne repositioniert werden,

um die RF Verbindung zu optimieren.

Hinweis: Nutzen Sie zur Verlängerung des Anschlußkabels eine Servoverlängerung.

Wenn das Flight Log im Modell verbleiben soll, befestigen Sie es an einem gut

sichtbaren Ort mit doppelseitigem Klebeband.

™

ModelMatch

Funktion

Einige Spektrum und JR Sender verwenden das Feature Modell Match. Durch diese

Technik wird sichergestellt, dass der Pilot nicht ein Modell mit einem falschen

Speicher iegt und es so zu einem Absturz kommen kann. Jedes Modell / Empfänger

erhält beim Binden einen eigenen spezischen Code (GUID), der senderseitig nur mit

der richtigen Auswahl des Speicherplatzes (Modell) angesprochen werden kann.

Hinweis: Sollte Ihr Modell nach dem einschalten nicht reagieren, überprüfen Sie

bitte, ob Sie den richtigen Speicherplatz gewählt haben.

Bitte beachten Sie, dass Spektrum Flugzeug Module kein Modelmatch haben.

Allgemeine Hinweise

Es ist unabdingbar, dass die Fernsteueranlage fachmännisch, korrekt und besonders

sorgfältig installiert wird. Weiterhin sollten Sie sicher sein, dass Sie selbst über

ausreichend Erfahrung verfügen, um das von Ihnen eingesetzte Modell zu jeder Zeit

sicher und umsichtig zu betreiben und zwar unter allen Bedingungen und Umständen. Wenn Sie ein Neuling in diesem Sport sind und über die erforderliche Erfahrung

nicht verfügen, suchen Sie nach Hilfestellungen von erfahrenen Piloten, Vereinen oder

Ihrem Fachhändler.

Sicherheitshinweise

• Stellen Sie sicher, dass die Akkus für Ihren Sender und für den Empfänger immer

ausreichend geladen sind.

• Behalten Sie die Zeit im Auge, die die Anlage insgesamt eingeschaltet ist, um zu

verhindern, dass die Anlage durch Energiemangel im Betrieb ausfällt.

• Führen Sie vor dem ersten Einsatz immer einen Reichweitentest durch. Sollten Sie

Ihr Modell an einem Tag wechseln, wiederholen Sie den Test. Besteht Zweifel an

der Reichweite, nehmen Sie das Modell in keinem Fall in Betrieb.

• Prüfen Sie alle Steckverbindungen und Servos vor jedem einzelnen Einsatz.

• Betreiben Sie Ihr Modell nicht in der Nähe von Zuschauern, geparkten Fahrzeugen

oder anderen Einrichtungen, die durch den Betrieb verletzt oder beschädigt

werden könnten.

• Betreiben Sie Ihr Modell nicht in ungeeigneten Wettersituationen. Schlechte Sicht

kann zur Desorientierung führen und einen Unfall verursachen.

• Zeigen Sie mit der Antenne nicht direkt auf Ihr Modell. Die Abstrahlung an der

Antennenspitze ist hier am geringsten.

• EGehen Sie kein Risiko ein. Wenn immer Sie während des Betriebs des Modells

ein ungewöhnliches Verhalten feststellen, stellen Sie sofort den Betrieb ein und

gehen Sie dem Problem auf den Grund. Sicherheit geht immer vor.

Page 22

Garantie und Service Informationen

Warnung

Ein ferngesteuertes Modell ist kein Spielzeug. Es kann, wenn es falsch eingesetzt wird,

zu erheblichen Verletzungen bei Lebewesen und Beschädigungen an Sachgütern führen.

Betreiben Sie Ihr RC-Modell nur auf freien Plätzen und beachten Sie alle Hinweise der

Bedienungsanleitung des Modells wie auch der Fernsteuerung. garantiezeitraum

Garantiezeitraum

Exklusive Garantie ¬ Horizon Hobby Inc (Horizon) garantiert, dass das gekaufte Produkt

(Produkt) frei von Material- und Montagefehlern ist. Der Garantiezeitraum entspricht

den gesetzlichen Bestimmung des Landes, in dem das Produkt erworben wurde. In

Deutschland beträgt der Garantiezeitraum 6 Monate und der Gewährleistungszeitraum

18 Monate nach dem Garantiezeitraum.

Einschränkungen der Garantie

(a) Die Garantie wird nur dem Erstkäufer (Käufer) gewährt und kann nicht übertragen

werden. Der Anspruch des Käufers besteht in der Reparatur oder dem Tausch im

Rahmen dieser Garantie. Die Garantie erstreckt sich ausschließlich auf Produkte, die

bei einem autorisierten Horizon Händler erworben wurden. Verkäufe an dritte werden

von dieser Garantie nicht gedeckt. Garantieansprüche werden nur angenommen,

wenn ein gültiger Kaufnachweis erbracht wird. Horizon behält sich das Recht vor, diese

Garantiebestimmungen ohne Ankündigung zu ändern oder modizieren und widerruft

dann bestehende Garantiebestimmungen.

(b) Horizon übernimmt keine Garantie für die Verkaufbarkeit des Produktes, die

Fähigkeiten und die Fitness des Verbrauchers für einen bestimmten Einsatzzweck des

Produktes. Der Käufer allein ist dafür verantwortlich, zu prüfen, ob das Produkt seinen

Fähigkeiten und dem vorgesehenen Einsatzzweck entspricht.

(c) Ansprüche des Käufers ¬ Es liegt ausschließlich im Ermessen von Horizon, ob das

Produkt, bei dem ein Garantiefall festgestellt wurde, repariert oder ausgetauscht wird.

Dies sind die exklusiven Ansprüche des Käufers, wenn ein Defekt festgestellt wird.

Horizon behält sich vor, alle eingesetzten Komponenten zu prüfen, die in den Garantiefall

einbezogen werden können. Die Entscheidung zur Reparatur oder zum Austausch liegt

nur bei Horizon. Die Garantie schließt kosmetische Defekte oder Defekte, hervorgerufen

durch höhere Gewalt, falsche Behandlung des Produktes, falscher Einsatz des Produktes,

kommerziellen Einsatz oder Modikationen irgendwelcher Art aus.

Die Garantie deckt Schäden, die durch falschen Einbau, falsche Handhabung, Unfälle,

Betrieb, Service oder Reparaturversuche, die nicht von Horizon ausgeführt wurden, aus.

Rücksendungen durch den Käufer direkt an Horizon oder eine seiner Landesvertretung

bedürfen der schriftlichen.

Schadensbeschränkung

Horizon ist nicht für direkte oder indirekte Folgeschäden, Einkommensausfälle oder

kommerzielle Verluste, die in irgendeinem Zusammenhang mit dem Produkt stehen

nicht verantwortlich, unabhängig ab ein Anspruch im Zusammenhang miteinem Vertrag,

der Garantie oder der Gewährleistung erhoben werden. Horizon wird darüber hinaus

keine Ansprüche aus einem Garantiefall akzeptieren, die über den individuellen Wert

des Produktes hinaus gehen. Horizon hat keine Einuss auf den Einbau, die Verwendung

oder die Wartung des Produktes oder etwaiger Produktkombinationen, die vom Käufer

gewählt werden. Horizon übernimmt keine Garantie und akzeptiert keine Ansprüche für in

der folge auftretende Verletzungen oder Beschädigungen. Mit der Verwendung und dem

Einbau des Produktes akzeptiert der Käufer alle aufgeführten Garantiebestimmungen

ohne Einschränkungen und Vorbehalte.

Wenn Sie als Käufer nicht bereit sind, diese Bestimmungen im Zusammenhang

mit der Benutzung des Produktes zu akzeptieren, werden Sie gebeten, dass Produkt

in unbenutztem Zustand in der Originalverpackung vollständig bei dem Verkäufer

zurückzugeben.

Sicherheitshinweise

Dieses ist ein hochwertiges Hobby Produkt und kein Spielzeug. Es muss mit Vorsicht

und Umsicht eingesetzt werden und erfordert einige mechanische wie auch mentale

Fähigkeiten. Ein Versagen, das Produkt sicher und umsichtig zu betreiben kann zu

Verletzungen von Lebewesen und Sachbeschädigungen erheblichen Ausmaßes

DE

Page 23

DE

führen. Dieses Produkt ist nicht für den Gebrauch durch Kinder ohne die Aufsicht

eines Erziehungsberechtigten vorgesehen. Die Anleitung enthält Sicherheitshinweise

und Vorschriften sowie Hinweise für die Wartung und den Betrieb des Produktes.

Es ist unabdingbar, diese Hinweise vor der ersten Inbetriebnahme zu lesen und zu

verstehen. Nur so kann der falsche Umgang verhindert und Unfälle mit Verletzungen und

Beschädigungen vermieden werden.

Fragen, Hilfe und Reparaturen

Ihr lokaler Fachhändler und die Verkaufstelle können eine Garantiebeurteilung ohne

Rücksprache mit Horizon nicht durchführen. Dies gilt auch für Garantiereparaturen.

Deshalb kontaktieren Sie in einem solchen Fall den Händler, der sich mit Horizon kurz

schließen wird, um eine sachgerechte Entscheidung zu fällen, die Ihnen schnellst

möglich hilft.

Wartung und Reparatur

Muss Ihr Produkt gewartet oder repariert werden, wenden Sie sich entweder an Ihren

Fachhändler oder direkt an Horizon. Packen Sie das Produkt sorgfältig ein. Beachten Sie,

dass der Originalkarton in der Regel nicht ausreicht, um beim Versand nicht beschädigt

zu werden. Verwenden Sie einen Paketdienstleister mit einer Tracking Funktion und

Versicherung, da Horizon bis zur Annahme keine Verantwortung für den Versand des

Produktes übernimmt.

Bitte legen Sie dem Produkt einen Kaufbeleg bei, sowie eine ausführliche

Fehlerbeschreibung und eine Liste aller eingesendeten Einzelkomponenten. Weiterhin

benötigen wir die vollständige Adresse, eine Telefonnummer für Rückfragen,

sowie eine Email Adresse.

Garantie und Reparaturen

Garantieanfragen werden nur bearbeitet, wenn ein Originalkaufbeleg von einem

autorisierten Fachhändler beiliegt, aus dem der Käufer und das Kaufdatum hervorgeht.

Sollte sich ein Garantiefall bestätigen wird das Produkt repariert oder ersetzt. Diese

Entscheidung obliegt einzig Horizon Hobby.

Kostenpflichtige Reparaturen

Liegt eine kostenpichtige Reparatur vor, erstellen wir einen Kostenvoranschlag, den wir

Ihrem Händler übermitteln. Die Reparatur wird erst vorgenommen, wenn wir die Freigabe

des Händlers erhalten. Der Preis für die Reparatur ist bei Ihrem Händler zu entrichten.

Bei kostenpichtigen Reparaturen werden mindestens 30 Minuten Werkstattzeit

und die Rückversandkosten in Rechnung gestellt. Sollten wir nach 90 Tagen keine

Einverständniserklärung zur Reparatur vorliegen haben, behalten wir uns vor, das Produkt

zu vernichten oder anderweitig zu verwerten.

Achtung: Kostenpichtige Reparaturen nehmen wir nur für Elektronik und Motoren vor.

Mechanische Reparaturen, besonders bei Hubschraubern und RC-Cars sind extrem

aufwendig und müssen deshalb vom Käufer selbst vorgenommen werden.

Sicherheit und Warnungen

Als Anwender des Produktes sind Sie verantwortlich für den sicheren Betrieb aus dem

eine Gefährdung für Leib und Leben sowie Sachgüter nicht hervorgehen soll. Befolgen

Sie sorgfältig alle Hinweise und Warnungen für dieses Produkt und für alle Komponenten

und Produkte, die Sie im Zusammenhang mit diesem Produkt einsetzen. Ihr Modell

empfängt Funksignale und wird dadurch gesteuert. Funksignale können gestört werden,

was zu einem Signalverlust im Modell führen würde. Stellen Sie deshalb sicher, dass Sie

um Ihr Modell einen ausreichenden Sicherheitsabstand einhalten, um einem solchen

Vorfall vorzubeugen.

€ Betreiben Sie Ihr Modell auf einem offenen Platz, weit ab von Verkehr, Menschen und Fahrzeugen.

€ Betreiben Sie Ihr Fahrzeug nicht auf einer öffentlichen Straße.

€ Betreiben Sie Ihr Modell nicht in einer belebten Straße oder einem Platz.

€ Betreiben Sie Ihren Sender nicht mit leeren Batterien oder Akkus.

€ Folgen Sie dieser Bedienungsanleitung mit allen Warnhinweisen sowie den Bedienungsanleitungen

aller Zubehörteile, die Sie einsetzen.

€ Halten Sie Chemikalien, Kleinteile und elektrische Komponenten aus der Reichweite von Kindern.

€ Feuchtigkeit beschädigt die Elektronik. Vermeiden Sie das Eindringen von Wasser, da diese

Komponenten dafür nicht ausgelegt sind.

Page 24

Land des Kauf Horizon Hobby Adresse Telefon / E-Mail Adresse

Konformitätserklärung gemäß Gesetz über Funkanlagen und Telekomunikationseinrichtungen (FTEG) und der

Richtlinie 1999/5/EG (R&TTE)

Declaration of conformity in accordance with the Radio and Telecommunications Terminal Equipment Act (FETG) and directive 1999/5/EG

(R&TTE)

Horizon Hobby GmbH

Hamburger Straße 10

D-25337 Elmshorn

erklärt das Produkt: Spektrum AR6255 Empfänger (SPMAR6255)

declares the product: Spektrum AR6255 Receiver (SPMAR6255)

Geräteklasse: 1

equipment class

den grundlegenden Anforderungen des §3 und den übrigen einschlägigen Bestimmungen des FTEG (Artikel 3 der R&TTE) entspricht.

complies with the essential requirments of §3 and other relevant provisions of the FTEG (Article 3 of the R&TTE directive).

Angewendete harmonisierte Normen:

Harmonised standards applied:

EN 60950 Gesundheit und Sicherheit gemäß §3 (1) 1. (Artikel 3(1)a))

Health and safety requirments pursuant to §3 (1) 1.(article 3(1)a))

EN 301 489-1 Schutzanforderungen in Bezug auf elektromagnetische Verträglichkeit

EN 301 489-17 §3 (1) 2, (Artikel 3 (1) b))

Protection requirement concerning electromagnetic compatibility

§3 (1) 2, (article 3 (1)b))

EN 300 328 Maßnahmen zur efzienten Nutzung des Frequenzspektrums

§ 3 (2)(Artikel 3 (2))

Measures for the efcient use of the radio frequency spectrum

§ 3 (2) (Article 3 (2))

Elmshorn, 12.07.2010

Konformitätserklärung gemäß Gesetz über Funkanlagen und Telekomunikationseinrichtungen (FTEG) und der

Richtlinie 1999/5/EG (R&TTE)

Declaration of conformity in accordance with the Radio and Telecommunications Terminal Equipment Act (FETG) and directive 1999/5/EG

(R&TTE)

Horizon Hobby GmbH

Hamburger Straße 10

D-25337 Elmshorn

erklärt das Produkt: Spektrum AR6255 Empfänger (SPMAR6255)

declares the product: Spektrum AR6255 Receiver (SPMAR6255)

Geräteklasse: 1

equipment class

den grundlegenden Anforderungen des §3 und den übrigen einschlägigen Bestimmungen des FTEG (Artikel 3 der R&TTE) entspricht.

complies with the essential requirments of §3 and other relevant provisions of the FTEG (Article 3 of the R&TTE directive).

Angewendete harmonisierte Normen:

Harmonised standards applied:

EN 60950 Gesundheit und Sicherheit gemäß §3 (1) 1. (Artikel 3(1)a))

Health and safety requirments pursuant to §3 (1) 1.(article 3(1)a))

EN 301 489-1 Schutzanforderungen in Bezug auf elektromagnetische Verträglichkeit

EN 301 489-17 §3 (1) 2, (Artikel 3 (1) b))

Protection requirement concerning electromagnetic compatibility

§3 (1) 2, (article 3 (1)b))

EN 300 328 Maßnahmen zur efzienten Nutzung des Frequenzspektrums

§ 3 (2)(Artikel 3 (2))

Measures for the efcient use of the radio frequency spectrum

§ 3 (2) (Article 3 (2))

Elmshorn, 12.07.2010

________________________ _______________________________

Jörg Schamuhn Birgit Schamuhn

Geschäfstführer Geschäftsführerin

Managing Director Managing Director

Deutschland

Horizon Technischer

Service

Hamburger Str. 10

25335 Elmshorn

Deutschland

+49 4121 46199 66

service@horizonhobby.de

Konformitätserklärung

DE

Richtlinie für die Entsorgung von Elektro- und Elektronikaltbzw. Schrottgeräten in der EU

Dieses Produkt muss getrennt entsorgt werden. Es ist bestehende

Nutzerpicht, Elek-tro- und Elektronikalt-bzw. Schrottgeräte an den dafür

vorgesehenen Sammelstellen abzugeben. Eine getrennte Entsorgung und

evtl. Wiederaufbereitung dieser Produkte trägt zum Umweltschutz und zum

sparsamen Umgang mit natürlichen Ressourcen bei und kann zur Zukunft

einer intakten Umwelt beitragen. Für weitere Informationen zur Abgabe

Ihres Altgerätes wenden Sie sich bitte an den zuständigen Recyclinghof,

die zuständige Gemeinde-/Stadtverwaltung oder an Ihren Händler.

Page 25

FR

Guide de l’utilisateur - Spektrum AR 6255

Le récepteur longue portée 6 voies Spektrum AR 6255 a été conçu pour être installé

dans des aéronefs compacts construits en bre de carbone. La bre de carbone

peut générer un effet d’écran aux Radio Fréquences (RF), lequel peut réduire

signicativement la portée des ondes lorsque l’on utilise des récepteurs et des

antennes conventionnels. L’AR 6255 est équipé d’une antenne conçue pour surmonter

les problèmes de RF dans ces conditions critiques.

Compatibilité

Le récepteur AR 6255 est équipé de la technologie DSM2™. Il est compatible avec

toutes les radios pour aéronefs Spektrum™ et JR® supportant la technologie DSM2,

y compris les modèles suivants :

JR12X JR11X

JRX9503 JRX9303

Spektrum DX8 Spektrum DX7

Spektrum DX6i Spektrum DX5e

Systèmes modulaires Spektrum

Nota : Le récepteur AR 6255 n’est pas compatible avec l’émetteur Spektrum

DX6 parkflyer.

Caractéristiques

• Récepteur 6 voies, optimisé pour les installations dans les fuselages en bre de

carbone

• La conception compacte de l’antenne s’avère idéale pour les modèles F5D et

les planeurs lancés à la main et à faible maître couple.

• Assure une couverture RF de qualité supérieure avec des antennes de réception

placées au travers du fuselage

• Comprend un récepteur interne avec deux antennes d’alimentation de 4 pouces

(101 mm)

• Une DEL rouge indique le nombre d’interruptions

• Système de sécurité préréglé sur les gaz, les ailerons et le gouvernail de

profondeur, optimisé pour les applications planeurs et F5D

• Système QuickConnect

• 2048 Résolution

• Compatible Flight Log

• Compatible avec les aéronefs Spektrum

• Système de télémétrie

Utilisation

Aéronefs compacts à structure en bre de carbone, y compris :

• Aéronefs en carbone/composites F5D à moteur électrique

• Planeurs en carbone à lancement manuel et DHL

• Aéronefs hot-liner en carbone

• Aéronefs compacts utilisant une quantité signicative de matériaux conducteurs

(carbone, aluminum ou autres métaux) pouvant affaiblir le signal

Spécifications

Type : récepteur DSM2 longue portée pour aéronefs en carbone

Voies : 6

Modulation : DSM2

Dimensions : 35 mm x 22 mm x 10 mm

Poids : 5.5 grammes

™

à détection de perte de tension

Page 26

Gamme de tension : 3,5 à 9,6

105mm

31mm

Résolution : 2048

Compatibilité : tous les émetteurs pour aéronefs DSM2

Installation du récepteur

Les avions construits avec une quantité importante de bre de carbone peuvent créer

un effet d’écran RF, réduisant ainsi la portée. L’AR 6255 a été conçu pour surmonter

ces problèmes RF critiques dans les aéronefs en carbone. L’aéronef est équipé

de deux antennes externes, implantées à des endroits spéciques. Ces antennes

assurent une couverture RF sûre de l’aéronef de tous les côtés.

Antennes d’alimentation

L’AR 6255 intègre deux antennes de réception, qui ont été conçues pour être montées

facilement au travers du fuselage des avions en carbone. Le récepteur dispose de

deux antennes d’alimentation de 4 pouces. Chaque antenne d’alimentation comprend

une partie coaxiale (une extension pour ainsi dire) et une extrémité apparente de 31

mm. Les derniers 31 mm forment la partie active de l’antenne.

DEL rouge d’indication d’interruption

L’AR 6255 est équipé d’une DEL rouge (marquée d’un H) indiquant le nombre d’interruptions qui sont survenues depuis la dernière mise en marche du récepteur. La DEL

clignotera pour indiquer le nombre d’interruptions, puis s’arrêtera (p. ex. 3 clignotements, arrêt, 3 clignotements, arrêt : indique que trois interruptions se sont produites

depuis la dernière mise en marche du récepteur). Notez que les interruptions sont

remises à zéro lorsque l’on éteint le récepteur. Il est conseillé de contrôler la DEL rouge

d’indication d’interruption pendant les premiers vols d’un nouvel avion. Si elle clignote,

il est important d’optimiser l’installation (déplacer ou repositionner les antennes) jusqu’à

ce qu’il ne se produise plus d’interruption. Au cours des vols ultérieurs, il est possible

d’utiliser la DEL indicatrice d’interruptions pour conrmer l’efcacité du lien RF.

Etape 1. Identification du type d’aéronef en carbone

Alors que certains planeurs lancés à la main et certains avions F5D sont entièrement

en carbone, beaucoup d’aéronefs utilisent le carbone uniquement dans des zones

nécessitant une résistance accrue. Quelques-uns des aéronefs

les plus récents sont construits avec des fuselages adaptés à la bande 2,4 GHz, ce

qui signie que la section avant du fuselage est en matériaux non conducteurs tels

la bre de verre ou le kevlar, qui n’affectent pas la RF. La première étape de toute

installation correcte consiste donc à identier le type de fuselage.

A- Carbone intégral

Tous les composants de l’avion, y compris l’intégralité du fuselage, les ailes et la

FR

Antennes externes

Carbone intégral

Page 27

FR

queue sont construits en fibre de carbone peau une tresse de fibre de carbone

parcourt la structure de l’aéronef.

Antennes internes

B- Fuselage adapté à la bande 2,4 GHz

La section située à l’avant des ailes est construite en matériaux non conducteurs tels

la bre de verre, le kevlar etc. tandis que les ailes et éventuellement la section de la

queue sont en carbone ou dotées d’une armure en carbone.

Etape 2. Détermination des positions de montage de l’antenne

Après avoir déterminé le type d’aéronef à l’aide de la liste, utilisez les

gures ci-dessus en tant qu’indications pour déterminer l’emplacement de montage

des antennes de réception. Veuillez noter qu’il est nécessaire de monter les antennes

à l’extérieur dans le cas d’aéronefs en carbone. Dans le cas de fuselages adaptés à

la bande 2,4 GHz, les antennes peuvent être montées à l’intérieur. L’objectif est de

monter les antennes de façon à ce qu’une d’entre elles au moins sera toujours dans

la ligne de visée RF de l’émetteur (p. ex. absence de blocage dû à des structures en

bre de carbone) dans toutes les positions. La mise en évidence en est simple : un

aide se tient à environ 6 mètres et fait tourner l’avion dans toutes les positions, ceci

afin de confirmer qu’il y a une ligne directe entre vous et au moins une antenne du

récepteur qui ne soit pas bloquée par une structure en bre de carbone.

Etape 3. Installation des récepteurs

Installez le récepteur dans la position normale recommandée par le fabricant de

l’avion. Vous pouvez utiliser du ruban adhésif double face ou de la mousse pour

maintenir le récepteur principal en place.

Etape 4. Montage des antennes

Pour installer les antennes, percez un trou de 1/16ème de pouce (1,58 mm) à

l’endroit souhaité pour le montage de l’antenne.

Faites passer l’antenne d’alimentation à travers le trou jusqu’à ce que les 31 mm

d’extrémité, plus 2mm de la partie coaxiale dépassent complètement du fuselage.

A l’aide d’une goutte de colle cyanoacrylate, collez l’antenne au fuselage en vous

Adapté à la bande 2,4 GHz

Page 28

assurant que la partie active de 31 mm de l’antenne est entièrement apparente.

Nota :

si l’antenne doit être montée à l’intérieur (à l’avant d’un «fuselage 2,4 GHz»),

le coaxial peut être mis en place à l’aide de ruban adhésif. Assurez-vous que

l’extrémité de 31 mm se trouve au moins à 5 centimètres de toute structure

en carbone conséquente.

Etape 5. Branchement des raccordements de servos

Branchez les raccordements des servos dans les prises de servo appropriées du

récepteur en tenant compte de la polarité du connecteur de servo. Consultez le

manuel de votre radio pour des détails spéciques (appariement des branchements

et prises de servo).

Etape 6. Affectation du récepteur

Avant de pouvoir fonctionner, l’AR 6255 doit être affecté à l’émetteur. L’affectation

est le processus qui apprend au récepteur le code spécique de l’émetteur, de sorte

qu’il se connecte uniquement à cet émetteur.

1. Pour affecter un AR 6255 à un émetteur DSM2, il faut brancher la prise

d’affectation sur le port BATT/BIND du récepteur.

2. Alimentez le récepteur par n’importe quel autre port. Notez que la DEL

orange située sur le récepteur doit clignoter, indiquant ainsi qu’il est en mode

affectation et prêt à être affecté à l’émetteur.

FR

3. Déplacez les manettes et interrupteurs de l’émetteur pour les amener dans

les positions de sécurité désirées pour les voies des gaz, de la gouverne de

profondeur et des ailerons.

Page 29

FR

4. Respectez les procédures spéciques à votre émetteur pour aller en mode

affectation. Le système se connectera en quelques secondes. Une fois la

connexion établie, la DEL orange du récepteur reste allumée, indiquant que le

système est connecté.

5. Retirez la prise d’affectation du port BATT/BIND du récepteur avant d’éteindre

l’émetteur et rangez-la dans un endroit approprié.

IMPORTANT : retirez la prise d’affectation pour éviter que le système entre à

Etape 7. Réglage et programmation de la radio

Programmez votre avion en suivant les instructions gurant dans le manuel de votre

radio.

Etape 8. Réaffectation du récepteur

Après avoir programmé votre modèle, il est important de réaffecter le système de

façon à ce que les vraies positions de sécurité des surfaces de commandes soient

réglées.

Etape 9. Essai de portée au sol et vérification de la DEL rouge

Test de portée avancé

Il est impératif de procéder à un contrôle de portée avancé au sol pour les avions

construits avec une quantité signicative de bre de carbone. Ce contrôle de portée

au sol conrmera que le récepteur fonctionne de manière optimale et que les

antennes sont montées correctement, dans une position qui assurera une couverture

RF effective dans tous les cas de gure. Ce contrôle de portée avancé permet de

vérier l’efcacité RF du récepteur et de la position de chaque antenne et d’optimiser

l’emplacement de ces dernières.

Test de portée avancé

1. Mettez le système en marche (émetteur et récepteur).

2. Demandez à un aide de tenir votre aéronef pendant que vous observez la DEL

rouge (marquée d’un H) se trouvant sur le récepteur.

3. Tenez-vous en face du modèle à 30 pas de celui-ci, l’émetteur étant dans votre

position de vol normale, et mettez votre émetteur en mode contrôle de portée.

Ceci provoque une sortie de puissance réduite de l’émetteur.

4. Demandez à votre aide de positionner le modèle dans toutes les orientations

possibles (nez levé, nez baissé, nez orienté vers l’émetteur, nez éloigné

de l’émetteur, etc.) tout en observant la DEL rouge et en notant toutes les

corrélations entre l’orientation de l’aéronef et la présence d’interruptions.

Procédez ainsi pendant une minute. Vous pouvez utiliser le chronomètre de

l’émetteur à cet effet.

5. Après une minute, relâchez le bouton de test de portée. Une installation réussie

produira les résultats suivants : pas d’interruptions, pas de clignotements de la DEL

rouge.

En cas d’interruptions, refaites le test en notant l’orientation de l’aéronef lorsqu’il se

produit des interruptions. Cela vous aidera à changer et à optimiser la position des

antennes à un meilleur emplacement.

Etape 10. Vérification / test lors d’un vol court avec indicateur

d’interruptions

Si le test du système a réussi, il est temps de procéder à un bref test en vol de

nouveau en mode affectation lors de la prochaine mise en marche

de l’alimentation.

Page 30

proximité. Ce premier vol doit se dérouler à proximité (à moins de 60 mètres) et

durer cinq minutes ou moins. Après le vol, faites atterrir l’aéronef près de vous et

vériez qu’aucune interruption ne s’est produite. Un vol réussi se sera déroulé sans

interruptions. Augmentez la distance et la durée des vols, en contrôlant les données

d’interruption après chaque vol jusqu’à ce que vous fassiez conance aux résultats.

IMPORTANT : Câbles Y et extensions servo

Lorsque vous utilisez des câbles Y ou des extensions servo pour votre installation,

il est essentiel d’utiliser des câbles Y et des extensions servo standard et non

ampliés, sans quoi les servos fonctionneront de manière aléatoire (ou pas du

tout). Les câbles Y ampliés ont été développés il y a quelques années déjà pour