Page 1

SURVEY PRO

for Ranger

User’s Manual

©2007 Tripod Data Systems, Inc.

All Rights Reserved

Page 2

IMPORTANT: BY OPENING THE SEALED MEDIA PACKAGE, YOU ARE AGREEING TO BE BOUND BY THE TERMS AND CONDITIONS OF

THE LICENSE AGREEMENT AND LIMITATIONS OF LIABILITY ("Agreement"). THIS AGREEMENT CONSTITUTES THE COMPLETE

AGREEMENT BETWEEN YOU AND TRIPOD DATA SYSTEMS, INC. ("Licensor"). CAREFULLY READ THE AGREEMENT AND IF YOU DO

NOT AGREE WITH THE TERMS, RETURN THE UNOPENED MEDIA PACKAGE AND THE ACCOMPANYING ITEMS (including written

materials and binders or other containers) TO THE PLACE WHERE YOU OBTAINED THEM FOR A FULL REFUND.

LICENSE. LICENSOR grants to you a limited, non-exclusive license to (i) install and operate the copy of the computer program contained in this

package ("Program") on a single computer (one central processing unit and associated monitor and keyboard) and (ii) make one archival copy of the

Program for use with the same computer. LICENSOR retains all rights to the Program not expressly granted in this Agreement.

OWNERSHIP OF PROGRAMS AND COPIES. This license is not a sale of the original Program or any copies. LICENSOR retains the ownership of

the Program and all subsequent copies of the Program made by you, regardless of the form in which the copies may exist. The Program and

accompanying manuals ("Documentation") are copyrighted works of authorship and contain valuable trade secrets and confidential information

proprietary to LICENSOR. You agree to exercise reasonable efforts to protect LICENSOR'S proprietary interest in the Program and Documentation

and maintain them in strict confidence.

USER RESTRICTIONS. You may physically transfer some Programs from one computer to another provided that the Program is operated only on

one computer. Other Programs will operate only with the computer that has the same security code and cannot be physically transferred to anothe r

computer. You may not electronically transfer the Program or operate it in a time-sharing or service bureau operation. You agree not to translate,

modify, adapt, disassemble, de-compile, or reverse engineer the Program, or create derivative works based on the Program or Documentation or any

portions thereof.

TRANSFER. The Program is provided for use in your internal commercial business operations and must remain at all times upon a single computer

owned or leased by you. You may not rent, lease, sublicense, sell, assign, pledge, transfer or otherwise dispose of the Program or Documentation, on

a temporary or permanent basis, without the prior written consent of LICENSOR.

TERMINATION. This License is effective until terminated. This License will terminate automatically without notice from LICENSOR if you fail to

comply with any provision of this License. Upon termination you must cease all use of the Program and Documentation and return them, and any

copies thereof, to LICENSOR.

GENERAL. This License shall be governed by and construed in accordance with the laws of the State of Oregon, United States of America.

LICENSOR grants solely to you a limited warranty that (i) the media on which the Program is distributed shall be substantially free from material

defects for a period of NINETY (90) DAYS, and (ii) the Program will perform substantially in accordance w ith the material descriptions in the

Documentation for a period of NINETY (90) DAYS. These warranti es commence on th e day you first obtain the Program and extend only to you, the

original customer. These limited warranties give you specific legal rights, and you may have other rights, which vary from state to state.

Except as specified above, LICENSOR MAKES NO WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING THE

PROGRAM, MEDIA OR DOCUMENTATION AND HEREBY EXPRESSLY DISCLAIMS THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. LICENSOR does not warrant the Program will meet your requirements or that its operations will be

uninterrupted or error-free.

If the media, Program or Documentation are not as warranted above, LICENSOR will, at its option, repair or replace the nonconforming item at no

cost to you, or refund your money, provided you return the item, with proof of the date you obtained it, to LICENSOR within TEN (10) DAYS after

the expiration of the applicable warranty period. If LICENSOR determines that the particular item has been damaged by accident, abuse, misuse or

misapplication, has been modified without the written permission of LICENSOR, or if any LICENSOR label or serial number has been removed or

defaced, the limited warranties set forth above do not apply and you accept full responsibility for the product.

The warranties and remedies set forth above are exclusive and in lieu of all others, oral or written, express or implied. Statements or

representations which add to, extend or modify these warranties are unauthorized by LICENSOR and should not be relied upon by you.

LICENSOR or anyone involved in the creation or delivery of the Program or Documentation to you shall have no liability to you or any third party

for special, incidental, or consequential damages (including, but not limited to, loss of profits or savings, downtime, damage to or replacement of

equipment and property, or recovery or replacement of programs or data) arising from claims based in warranty, contract, tort (including

negligence), strict liability, or otherwise even if LICENSOR has been advised of the possibility of such claim or damage. LICENSOR'S liability for

direct damages shall not exceed the actual amount paid for this copy of the Program.

Some states do not allow the exclusion or limitation of implied warranties or liability for incidental or consequential damages, so the above

limitations or exclusions may not apply to you.

If the Program is acquired for use by or on behalf of a unit or agency of the United States Government, the Program and Documentation are provided

with "Restricted Rights". Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, and to all other regulations, restrictions and limitations applicable

to Government use of Commercial Software. Contractor/manufacturer is Tripod Data Systems, Inc., PO Box 947, Corvallis, Oregon, 97339, United

States of America.

Should you have questions concerning the License Agreement or the Limited Warranties and Limitation of Liability, please contact in writing:

Tripod Data Systems, Inc., PO Box 947, Corvallis, Oregon, 97339, United States of America.

Ranger, the TDS triangles logo, the TDS icons and Survey Pro are trademarks of Tripod Data Systems, Inc. ActiveSync, Windows and the Windows

logo are trademarks or registered trademarks of Microsoft Corporation in the United States and/or other countries. Bluetooth and the Bluetooth

symbol are registered trademarks of Bluetooth SIG Inc. USA. Socket is a registered trademark of Socket Communications, Inc. All other names

mentioned are trademarks, registered trademarks or service marks of their respective companies. This software is based i n part on the work of the

Independent JPEG Group.

900-0030-XXQ 090407

TRIPOD DATA SYSTEMS SOFTWARE LICENSE AGREEMENT

LIMITED WARRANTIES AND LIMITATION OF LIABILITY

U.S. GOVERNMENT RESTRICTED RIGHTS

TRADEMARKS

ii

Page 3

Table of Contents

Welcome ________________________________________________ 1

Getting Started __________________________________________ 3

Manual Conventions _______________________________ 3

Survey Pro Installation______________________________ 4

Registering________________________________________ 4

Angle and Time Conventions________________________ 6

Azimuths _________________________________________________ 6

Bearings __________________________________________________ 6

Time _____________________________________________________ 6

Using Survey Pro __________________________________ 7

Navigating Within the Program______________________ 9

Command Bar ____________________________________________ 10

Parts of a Screen __________________________________ 12

Input Fields ______________________________________________ 12

Output Fields_____________________________________________ 12

Input Shortcuts ___________________________________________ 14

Quick Pick _______________________________________________ 18

Smart Targets ____________________________________ 19

Selecting Smart Targets ____________________________________ 19

Manage Smart Targets _____________________________________ 20

Map View________________________________________ 22

Basemaps ________________________________________ 24

Basemap Files ____________________________________________ 24

Manage Basemaps_________________________________________ 25

The Settings Screen________________________________ 27

File Management and ForeSight DXM _______________ 28

Job Files _________________________________________ 29

Raw Data Files____________________________________ 30

Control Files _____________________________________ 31

Import Control File________________________________________ 31

External Control File_______________________________________ 32

Description Files __________________________________ 33

Description Files without Codes_____________________________ 33

Description Files with Codes________________________________ 34

Opening a Description File _________________________________ 35

iii

Page 4

Feature Codes ____________________________________ 36

Features__________________________________________________ 37

Attributes ________________________________________________37

Using Feature Codes in Survey Pro___________________________38

Layers___________________________________________ 39

Layer 0___________________________________________________39

Other Special Layers _______________________________________ 39

Managing Layers __________________________________________40

Working with 2D Points ___________________________ 42

Polylines_________________________________________ 44

Alignments ______________________________________ 44

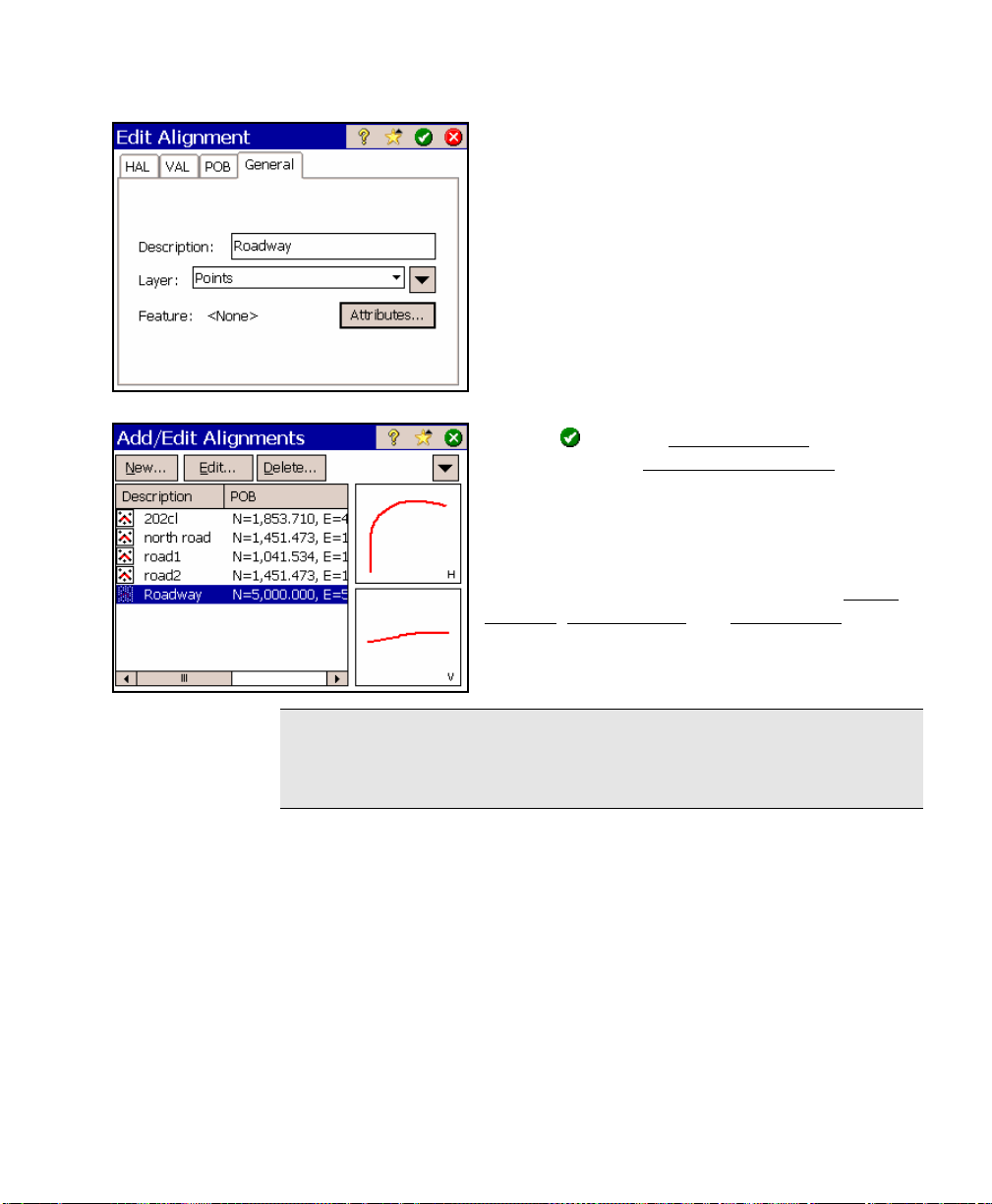

Creating an Alignment _____________________________________45

Conventional Fieldwork__________________________________51

Scenario One______________________________________________ 52

Scenario Two _____________________________________________52

Scenario Three ____________________________________________53

Scenario Four _____________________________________________54

Summary_________________________________________________54

Data Collection Example___________________________ 56

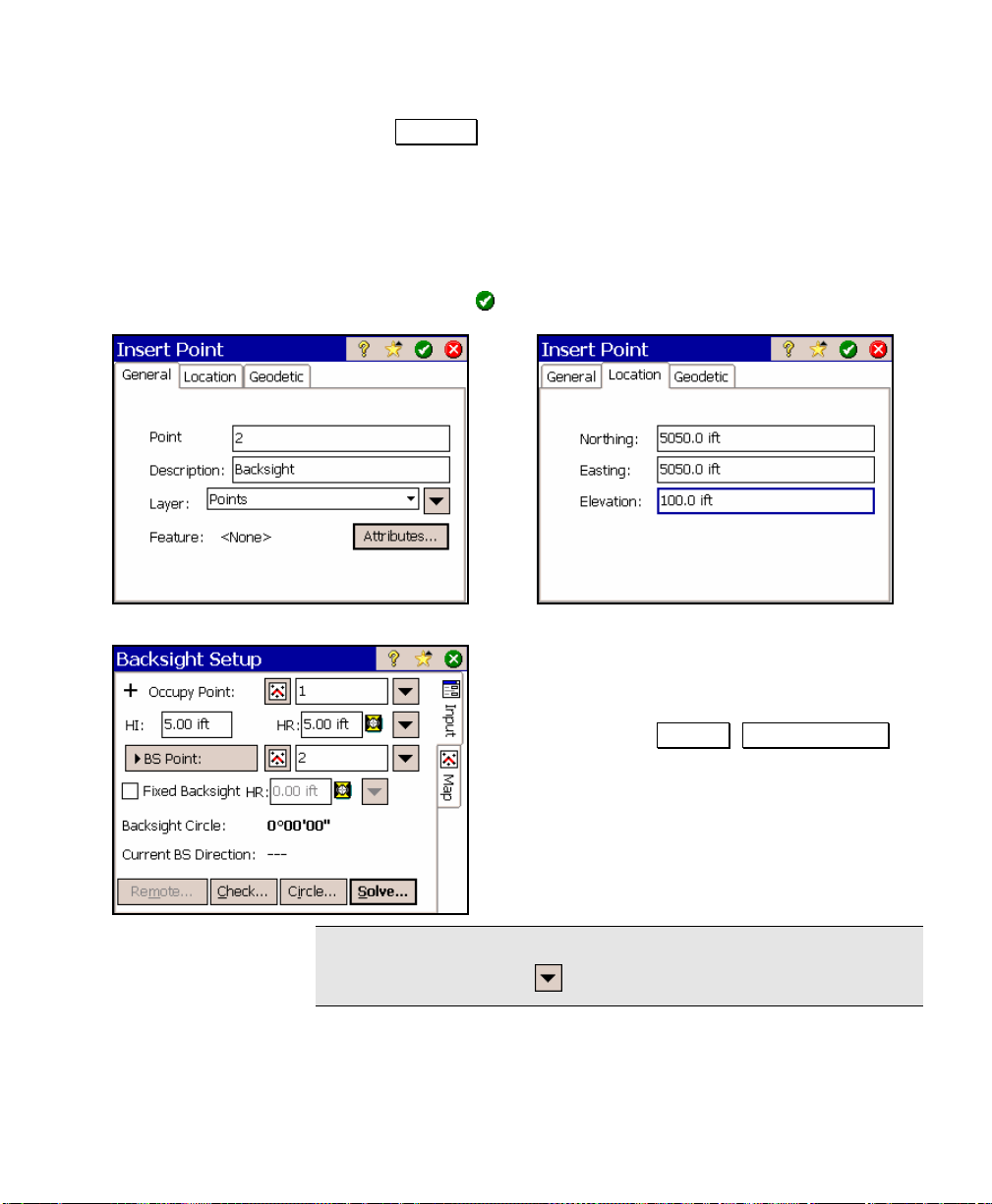

Setup ____________________________________________________56

Performing a Side Shot _____________________________________61

Performing a Traverse Shot _________________________________62

Data Collection Summary___________________________________64

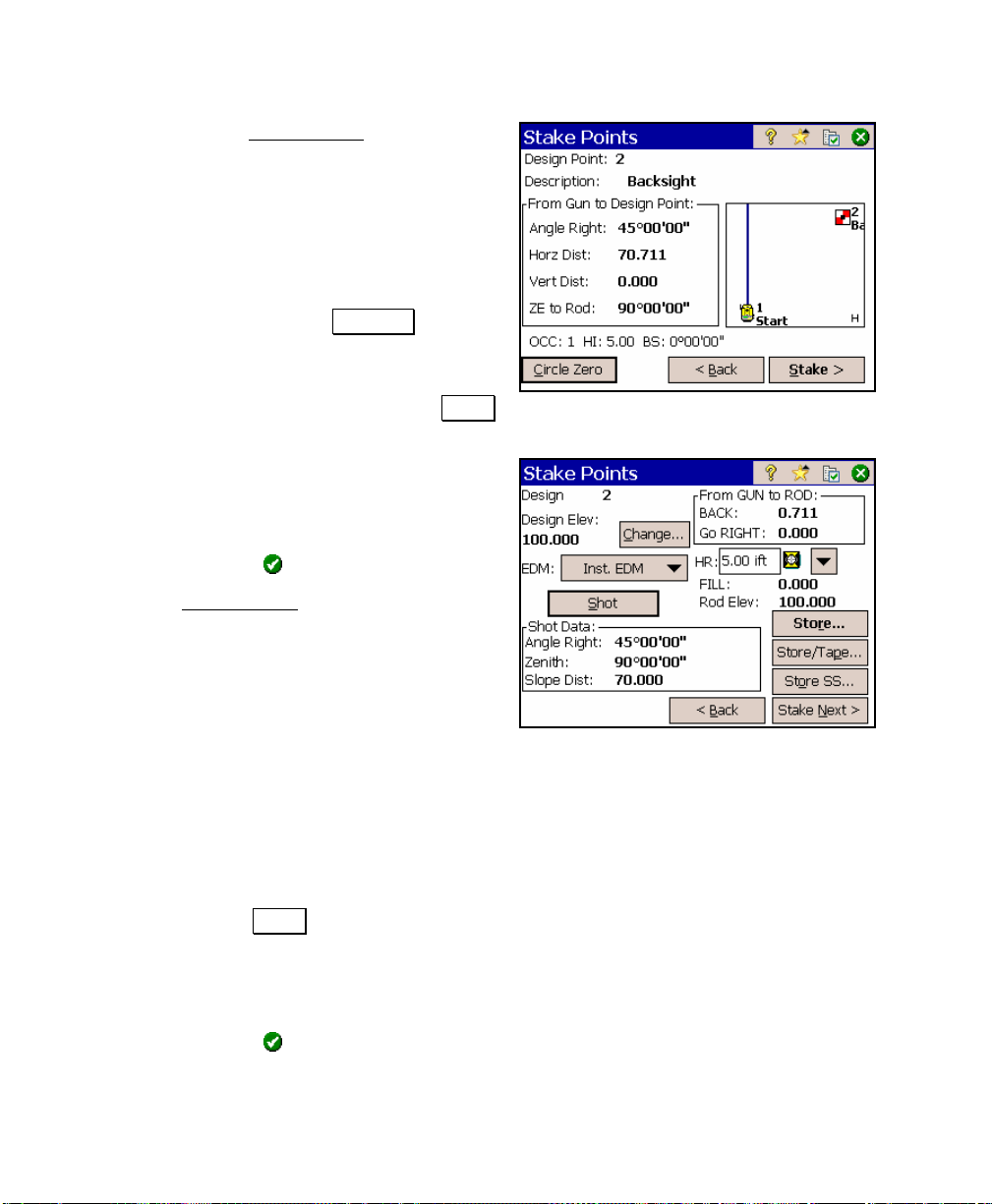

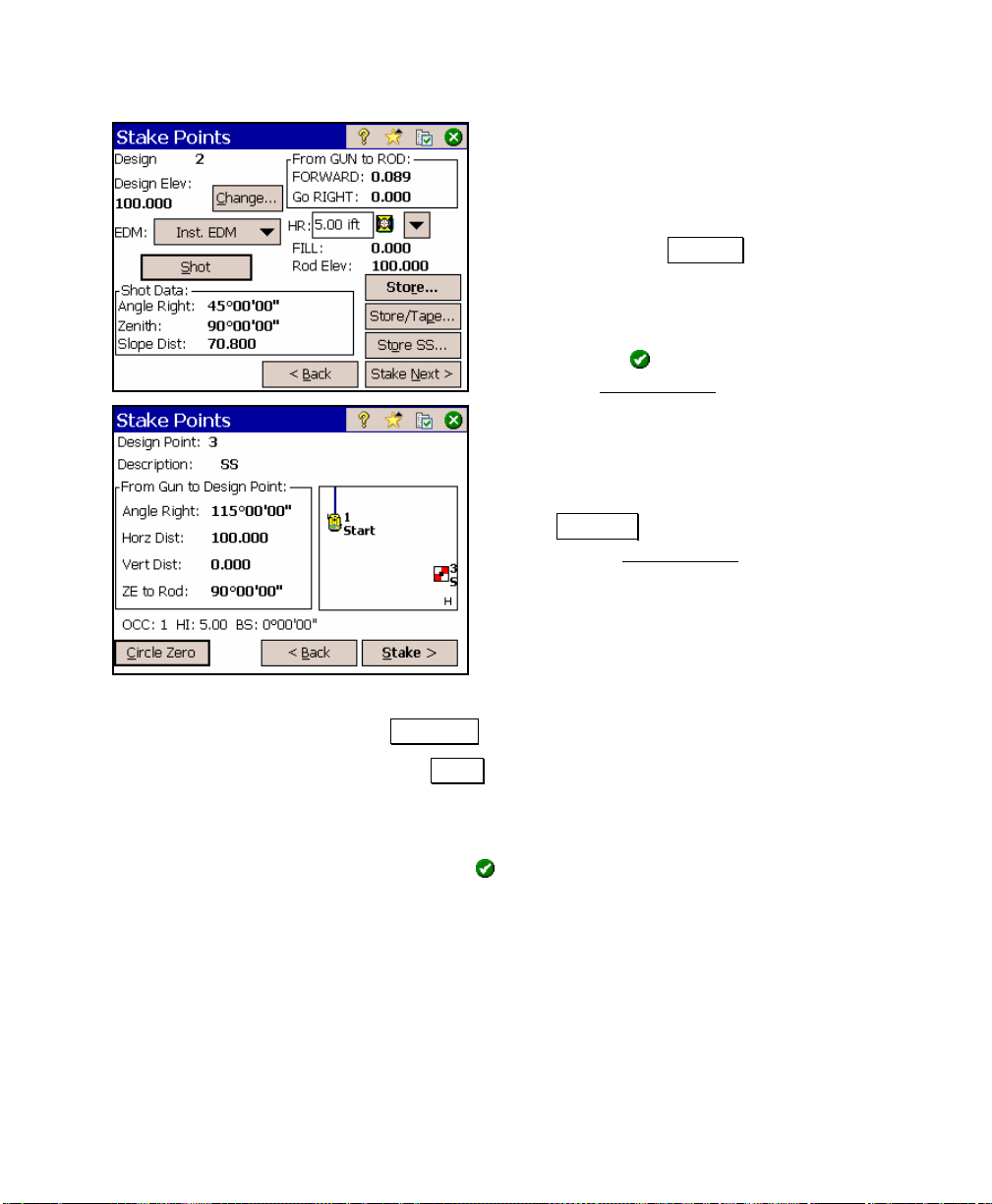

Stakeout Example_________________________________ 65

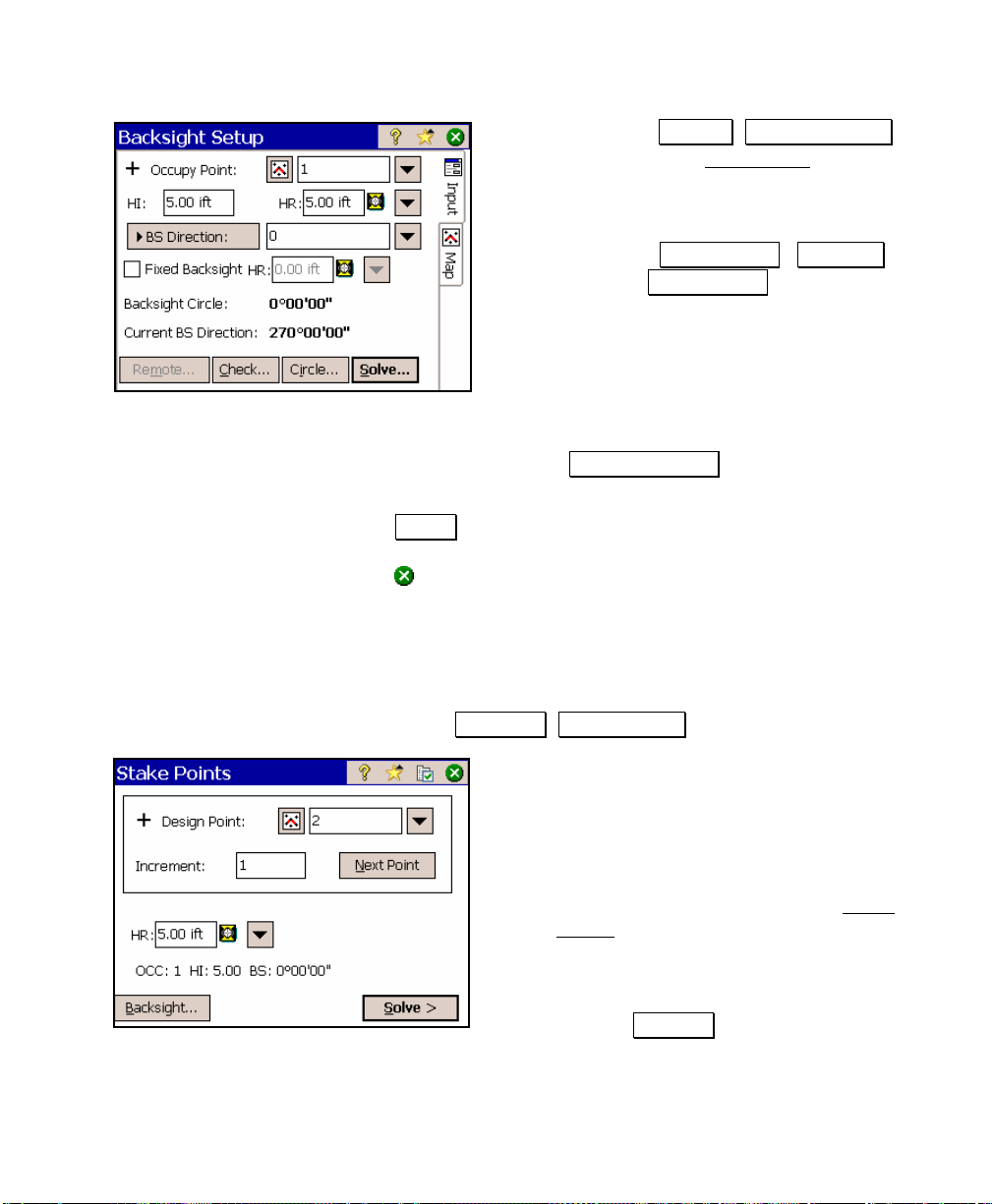

Set Up____________________________________________________66

Staking Points_____________________________________________67

Point Staking Summary_____________________________________70

Surveying with True Azimuths _____________________ 71

Road Layout ____________________________________________73

Horizontal Alignment (HAL)________________________________73

Vertical Alignment (VAL)___________________________________73

Templates ________________________________________________73

POB _____________________________________________________74

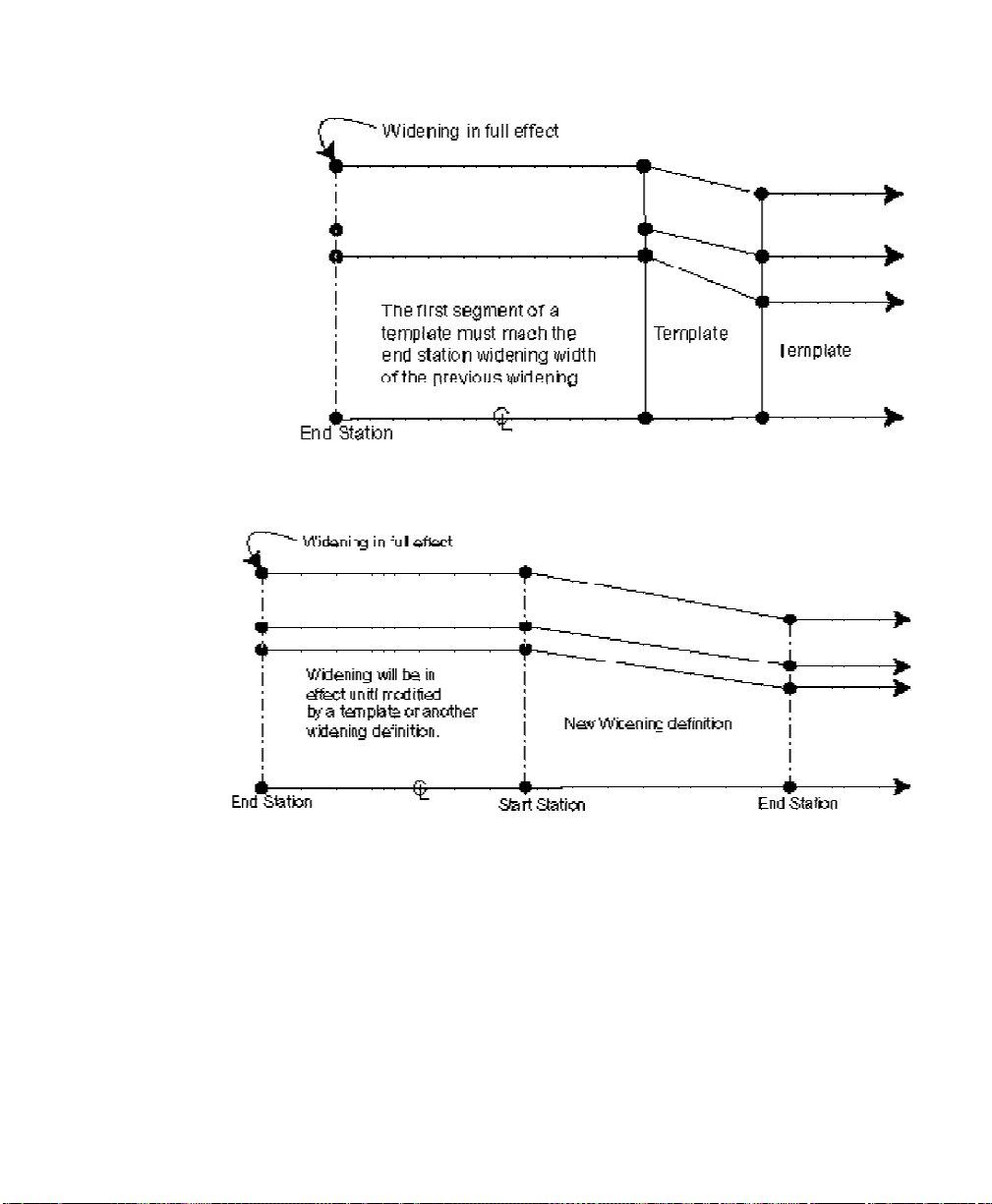

Road Component Rules____________________________ 75

Alignments _______________________________________________75

Templates ________________________________________________75

Widenings and Super Elevations_____________________________76

Road Rules Examples ______________________________________78

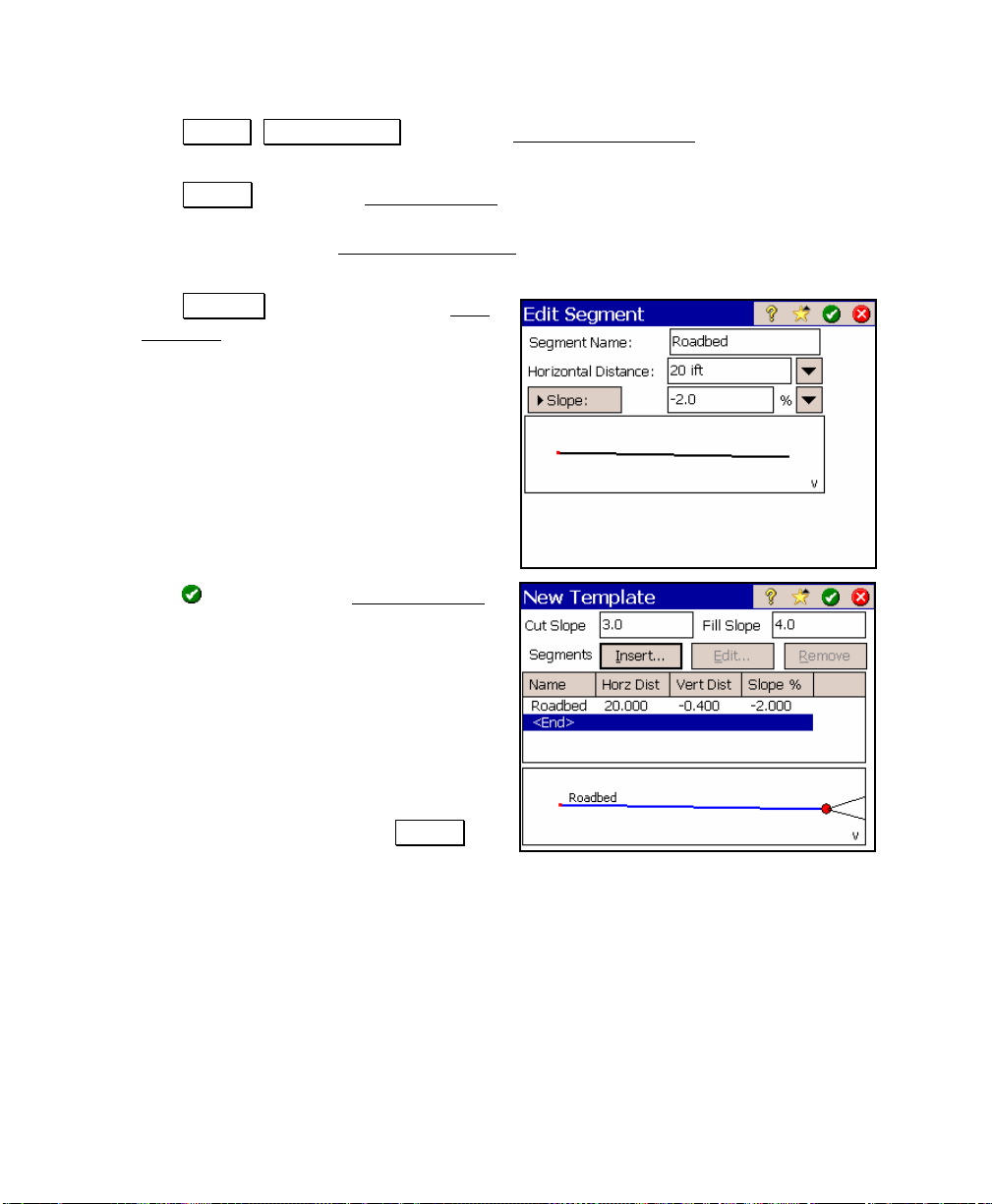

Creating Templates _______________________________ 81

Building an Alignment ____________________________ 84

iv

Page 5

Putting the Road Together _________________________ 84

Staking the Road__________________________________ 91

Slope Staking the Road ____________________________ 93

Station Equation __________________________________ 95

DTM Stakeout__________________________________________ 97

Reference DTM Surface____________________________ 97

Set Up the Job ____________________________________ 98

Select Your Layers________________________________________ 100

Select a Boundary (optional) _______________________________ 100

Select any Break Lines (optional) ___________________________ 101

Stake the DTM___________________________________ 103

View the DTM___________________________________________ 103

View the DTM___________________________________________ 104

Other Tutorials ________________________________________ 107

Import / Export _________________________________ 107

Importing *.JOB Coordinates_______________________________ 108

Importing *.CR5 Coordinates ______________________________ 108

Importing LandXML Files_________________________________ 109

Import Control___________________________________________ 112

Exporting Coordinates____________________________________ 112

Repetition Shots _________________________________ 113

Repetition Settings Screen _________________________________ 114

Repetition Shots Screen ___________________________________ 115

Radial Sideshots _________________________________ 117

Shoot From Two Ends ____________________________ 120

Offset Shots _____________________________________ 121

Distance Offset Screen ____________________________________ 121

Horizontal Angle Offset Screen_____________________________ 123

Vertical Angle Offset Screen _______________________________ 124

Resection _______________________________________ 125

Performing a Resection____________________________________ 125

Solar Observations _______________________________ 127

Performing a Sun Shot ____________________________________ 127

What to Do Next _________________________________________ 130

Remote Control__________________________________ 131

The Remote Control Screen________________________________ 131

Taking a Shot in Remote Mode_____________________________ 132

Stake Out in Remote Mode ________________________________ 133

Slope Staking in Remote Mode_____________________________ 134

v

Page 6

GeoLock ________________________________________ 135

Configuring GeoLock _____________________________________136

Localizing _______________________________________________137

Using GeoLock___________________________________________137

Slope Staking____________________________________ 138

Defining the Road Cross-Section____________________________ 139

Staking the Catch Point____________________________________141

Intersection _____________________________________ 144

Map Check______________________________________ 145

Entering Boundary Data___________________________________145

Editing Boundary Data ____________________________________146

Adding Boundary Data to the Current Project ________________146

Predetermined Area______________________________ 147

Hinge Method____________________________________________147

Parallel Method __________________________________________148

Horizontal Curve Layout _________________________ 149

PC Deflection ____________________________________________150

PI Deflection _____________________________________________150

Tangent Offset ___________________________________________151

Chord Offset_____________________________________________ 151

Parabolic Curve Layout___________________________ 153

Spiral Layout____________________________________ 154

Curve and Offset_________________________________ 154

Curve and Offset_________________________________ 155

Define Your Curve________________________________________155

Setup Your Staking Options________________________________156

Aim the Total Station______________________________________157

Stake the Point ___________________________________________ 157

Scale Adjustment ________________________________ 158

Translate Adjustment_____________________________ 159

Translate by Distance and Direction_________________________160

Translate by Coordinates __________________________________160

Rotate Adjustment _______________________________ 161

Traverse Adjust__________________________________ 162

Angle Adjust_____________________________________________ 162

Compass Rule____________________________________________163

Adjust Sideshots__________________________________________ 16 3

Performing a Traverse Adjustment__________________________ 164

Surface Scan_____________________________________ 166

vi

Page 7

Leveling Fieldwork_____________________________________ 171

Key Terms ______________________________________________ 171

Leveling Set Up__________________________________ 172

Leveling Methods ________________________________________ 173

Level Loop Procedure ____________________________ 175

Creating a New Loop _____________________________________ 175

Level Screen_____________________________________________ 177

Adjustment______________________________________________ 184

2 Peg Test_______________________________________ 185

GPS Overview_________________________________________ 187

RTK and Post Processing__________________________ 188

GPS Measurements_______________________________ 189

Differential GPS__________________________________________ 189

GPS Network Servers, NTRIP, and VRS _____________________ 191

GPS Coordinates_________________________________ 193

Datums _________________________________________________ 193

Coordinate Systems ______________________________ 200

Horizontal Coordinate Systems ____________________________ 202

Vertical Coordinate Systems _______________________________ 207

GPS Coordinates In Survey Pro__________________________ 209

Projection Mode _________________________________ 210

Projection Mode Configuration_____________________________ 214

Localization Default Zone _________________________________ 215

Localization Reset Origin__________________________________ 216

Localization Select Zone___________________________________ 217

Mapping Plane Select Zone ________________________________ 217

Key In Zone _____________________________________________ 218

Mapping Ground Coordinates _____________________________ 221

Coordinate System Database_______________________________ 224

Managing GPS Coordinates in Survey Pro___________ 225

Edit Points ______________________________________________ 225

Import__________________________________________________ 226

ForeSight DXM, SPSO, TGO, and TTC ______________ 228

ForeSight DXM __________________________________________ 228

Spectra Precision Survey Office ____________________________ 228

TGO / TTC______________________________________________ 229

GPS Module___________________________________________ 231

Receiver Settings_________________________________ 232

RTK Settings_____________________________________________ 235

Post Processing Settings___________________________________ 235

vii

Page 8

Start GPS Survey_________________________________ 235

Start GPS Survey – Choose One Point Setup __________________236

Start GPS Survey - Choose Projection Mode __________________236

Start GPS Survey – Choose Geoid ___________________________237

Start GPS Survey – Choose Base Setup_______________________238

Start GPS Survey – Connect to Receiver______________________239

Start GPS Survey – Base Setup______________________________239

Start GPS Survey – Rover Setup_____________________________242

Rover Setup – Set Base Reference Position____________________ 243

Start GPS Survey - Solve Localization________________________ 246

Solve Localization________________________________ 247

Localization with Control Points____________________________248

Localization Parameters Exp lained__________________________252

One Point Localizations Explained __________________________257

Remote Elevation_________________________________________259

Import GPS Control_______________________________________ 260

RTK Data Collection______________________________ 264

Measure Mode ___________________________________________ 264

Data Collection___________________________________________265

RTK Stake Out___________________________________ 270

Roving/Occupying _______________________________________ 270

Post Processing __________________________________ 270

Field Procedure __________________________________________ 271

Office Procedure__________________________________________273

Projection Utilities _______________________________ 274

Adjust with Projection_____________________________________274

Projection Calculator______________________________________ 278

Tutorial GPS Jobs ________________________________ 279

Bluetooth & Windows Networking with GPS Module 294

Bluetooth________________________________________________294

Windows Networking_____________________________________ 299

Basic GPS Module ______________________________________305

GPS Receiver Connections ________________________ 305

Serial Connection_________________________________________306

Bluetooth Connection _____________________________________307

RTK Data Modem Configuration ___________________________ 308

Basic GPS Start Survey____________________________ 313

Start Survey – Connect to Base and Rover ____________________313

Start Survey – Connect to Rover (Remote Base or Internet Base) _315

Hanging Up and Redialing a Cellular Phone__________________317

viii

Page 9

Solve Projection__________________________________ 317

Localization Quality of Solutions ___________________________ 323

Connect to Base and Rover – TDS Localization ‘One Point

Setup’ __________________________________________ 325

Traverse Base____________________________________ 326

Traverse Now Routine ____________________________________ 327

Occupy Then Traverse Routine_____________________________ 327

Projection Solve Localization ______________________ 328

Post Processing __________________________________ 328

References ____________________________________________ 329

ix

Page 10

Page 11

Welcome

Congratulations on your decision to purchase a Tripod Data Systems

product. TDS is serious about providing the best possible products to

our customers and know that you are serious about your tools. W e are

proud to welcome you to the TDS family.

Survey Pro can be run in three modes: Conventional, Leveling and

one of two versions of GPS. The first portion of this User's Man ual

explains how to get started with Survey Pro no matter which mode

you are running in. Conventional surveying examples start on Page

51, which are useful when performing traditional surveying methods

with a total station. Leveling mode is discussed on Page 171. The

last portion of the User's Manual explains how to perform GPS

surveying and starts on Page 187.

The TDS Survey Pro team is continually improving and updating

Survey Pro. Please take a few minutes to register your copy so that

you will be eligible for upgrades. You can do this either by completing

and returning the product registration card or by visiting our Web

site: www.tdsway.com

.

1

Page 12

Page 13

Getting Started

TDS Survey Pro is available with the following modules, each sold

separately:

• Standard

• Pro

• Basic GPS

• GPS

• Robotic

• Leveling

• Trimble System Extension

Throughout the manual and software, it is simply called Survey Pro.

For a listing of which features are included in each product, contact

your local TDS dealer.

This manual covers the routines that are available in all of the

different modules.

Manual Conventions

Throughout the Survey Pro Manual, certain text formatting is used

that represents different parts of the software. The formatting used

in the manual is explained below.

Fields

When referring to a particular field, the Field Label, or its

Corresponding Value is shown with text that is similar to what you

would see in the software.

Screens and Menus

When referring to a particular screen or menu, the text is underlined.

Buttons

When referring to a particular button, the text is shown in a

Button Format , similar to that found in the software.

3

Page 14

User’s Manual

Survey Pro Installation

Survey Pro is installed from the Installation CD running on a PC. It

will load Survey Pro and then install it on the data collect or with the

next ActiveSync connection.

1. Turn on the data collector and connect it to your PC. If you are

using ActiveSync it will attempt to make a connection.

2. With an ActiveSync connection, you will be asked if you want

to install TDS Survey Pro. Answering YES will install the

application on the Recon. An installation routine will also run

on the data collector to complete the process.

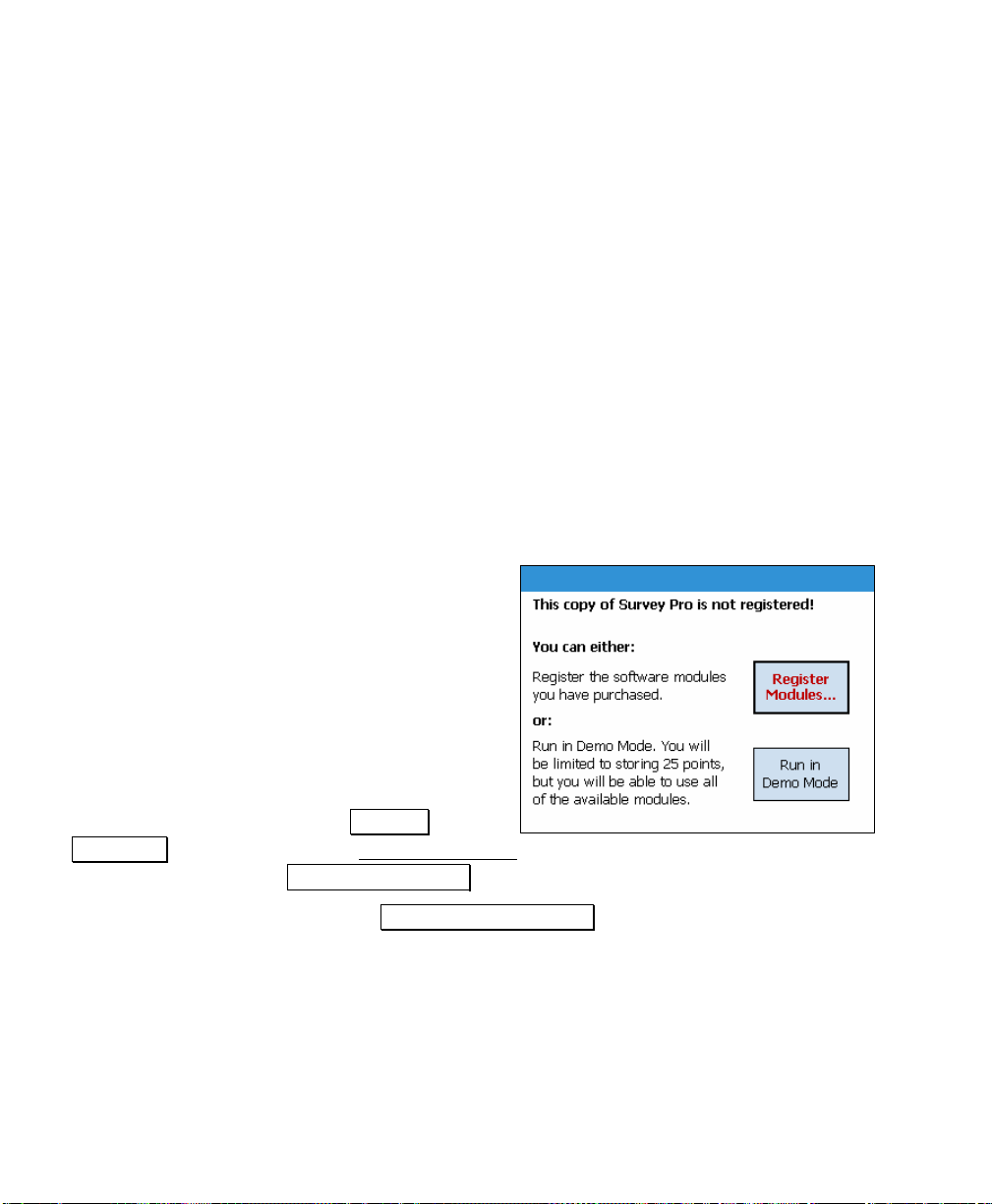

Registering

After Survey Pro is installed, the Standard

Module must be registered for Survey Pro to be

fully functional. If it is not registered, Survey

Pro will only run in demo mode, which means

all jobs will be limited to no more than 25

points, and if a job is stored on the data

collector that exceeds this limit, it cannot be

opened.

If you start Survey Pro and the standard

module has not yet been registered, the screen

shown here will open. Tap the Register

Modules… button to access the Register Modules screen. To run in

demo mode, simply tap Run In Demo Mode .

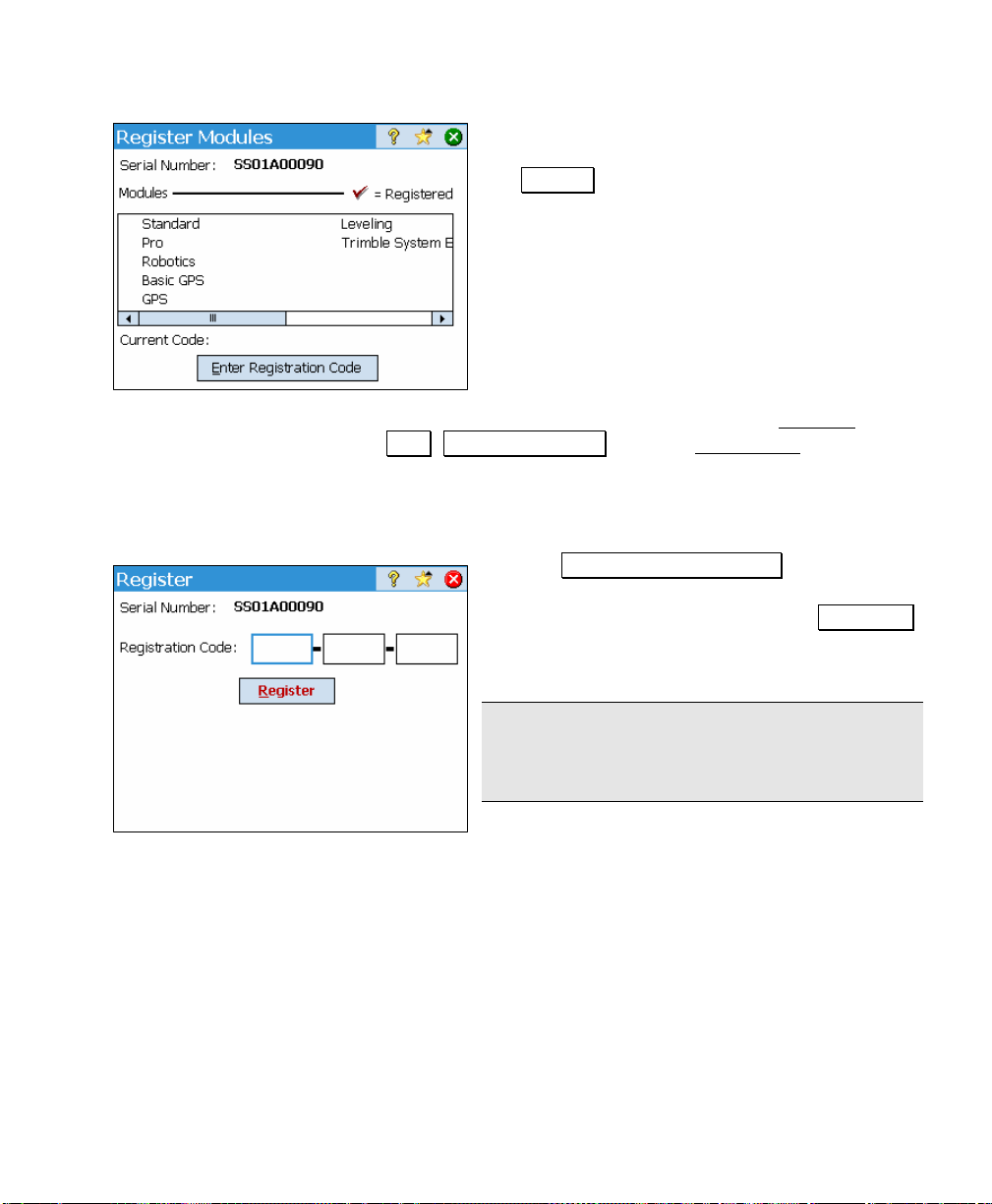

To register your Modules, tap the Enter Registration Code button.

4

Page 15

Getting Started

Enter the registration code provided by your

TDS dealer in the Registration Code field and

tap Register. This will register all of the

modules that you have purchased. If there are

modules that you feel should be registered but

are not, contact TDS tech support.

Add-on modules can also be purchased from

your local TDS dealer to upgrade your TDS

Survey Software. Upgrading involves simply

registering the appropriate module using the

same method as described above

If you want to register a particular module, access the Register

by tapping File , Register Modules from the Main Menu

screen

.

Contact your TDS dealer and give him your unique serial number

that is displayed on this screen. He will give you a registration code

for the module that you purchased.

Tap the Enter Registration Code button for the

appropriate module, enter the registration code

in the dialog box that opens and tap Register…

. All the features for the module that you

purchased will now be available.

Note: You should keep a record of all

registration codes purchased in case they need

to be reentered at some point.

5

Page 16

User’s Manual

Angle and Time Conventions

Throughout the software, the following conventions are followed

when inputting or outputting angles and time:

Azimuths

Azimuths are entered in degree-minutes-seconds format and are

represented as DD.MMSSsss, where:

• DD One or more digits representing the degrees.

• MM Two digits representing the minutes.

• SS Two digits representing the seconds.

• sss Zero or more digits representing the decimal fraction

part of the seconds.

For example, 212.5800 would indicate 212 degrees, 58 minutes, 0

seconds.

Bearings

Bearings can be entered in either of the followin g formats:

• S32.5800W to indicate South 32 degrees, 58 minutes, 0

seconds West.

• 3 32.5800 to indicate 32 degrees, 58 minutes, 0 seconds in

quadrant 3.

Time

When a field accepts a time for its input, the time is entered in hoursminutes-seconds format, which is represented as HH.MMSSsss

where:

• HH One or more digits representing the hours.

• MM Two digits representing the minutes.

• SS Two digits representing the seconds.

• sss Zero or more digits representing the decimal fraction

part of the seconds.

6

Page 17

Getting Started

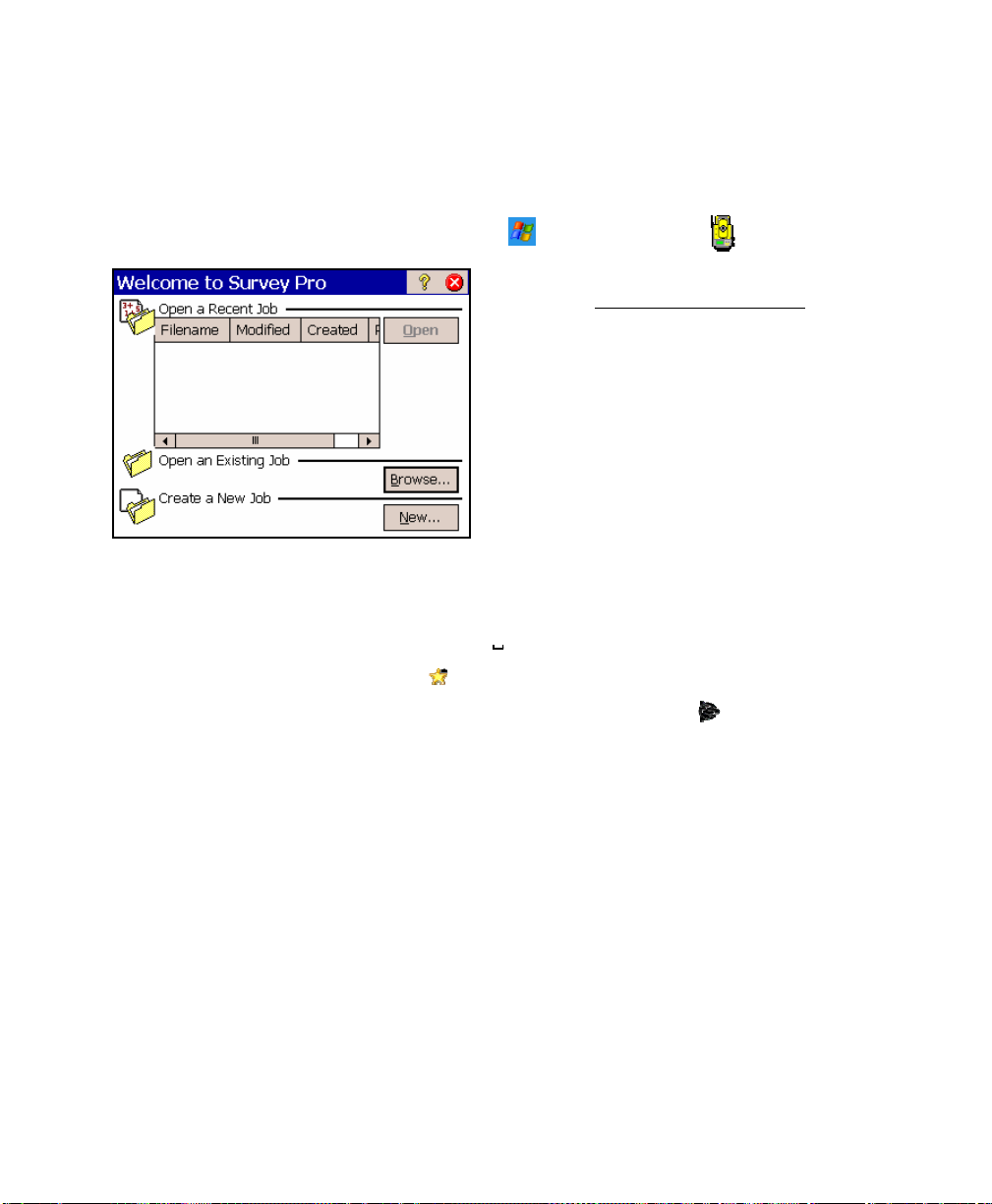

Using Survey Pro

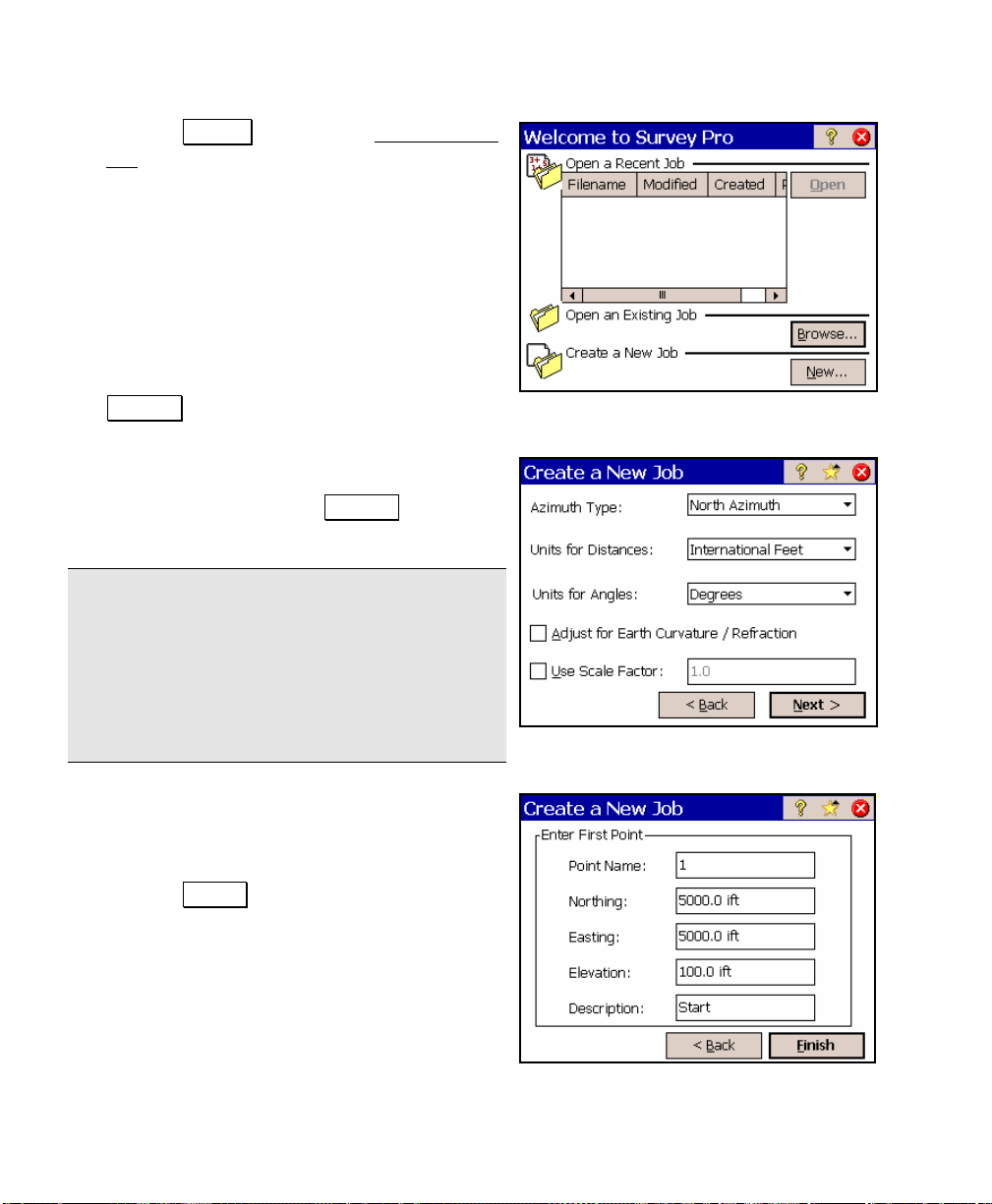

To start Survey Pro, tap Start > Programs >

Survey Pro cannot start without a job being

open so the Welcome to Survey Pro

ask if you want to open a recently opened job,

open an existing job, or create a new job. For

this example we will create a new job so you

can begin exploring the software.

Selections and cursor control in Survey Pro can

be made by simply tapping the screen with

your finger or a stylus.

You can temporarily disable the touch-screen if you need to clean it

by using any of the methods below:

screen will

• Press [CTRL] - [

• Use the

• Ranger 300X/500X only: Press [Fn] - [

Repeat to reactivate the touch-screen.

] and press [ESC] to reactivate the screen.

, Suspend Screen quick pick.

] (Trimble logo).

7

Page 18

User’s Manual

1. Tap the New… button. The Create a New

Job dialog box will open, which prompts

you for a job name where the current date

is the default name.

2. Either type in a new job name or accept the

default name. Control points can

optionally be used or imported from

another existing job by checking the Use or

Import a Control File checkbox. (See Page 31

for more information on control files.) For

this example, leave this unchecked and tap

Next > to continue.

Another screen will open where you select

some of the job settings. Select the settings

that you desire and tap Next > to

continue.

Note: When creating a new job, it is important

that the Units for Distances field be set to the

correct units. This allows you to seamlessly

switch between different units in mid-job.

Problems can arise if these units are

inadvertently set to the incorrect units when

new data is collected.

3. Since all jobs must have at least one point

to start with, the final screen displays the

default point name and coordinates for the

first point. Accept the default values by

tapping Finish . This will create and store

the new job. You are now ready to explore

the software.

8

Page 19

Getting Started

Note: The settings and values entered for a new job become th e

default values for any subsequent new jobs with the exception of the

Use Scale Factor setting, which always defaults to off.

Navigating Within the Program

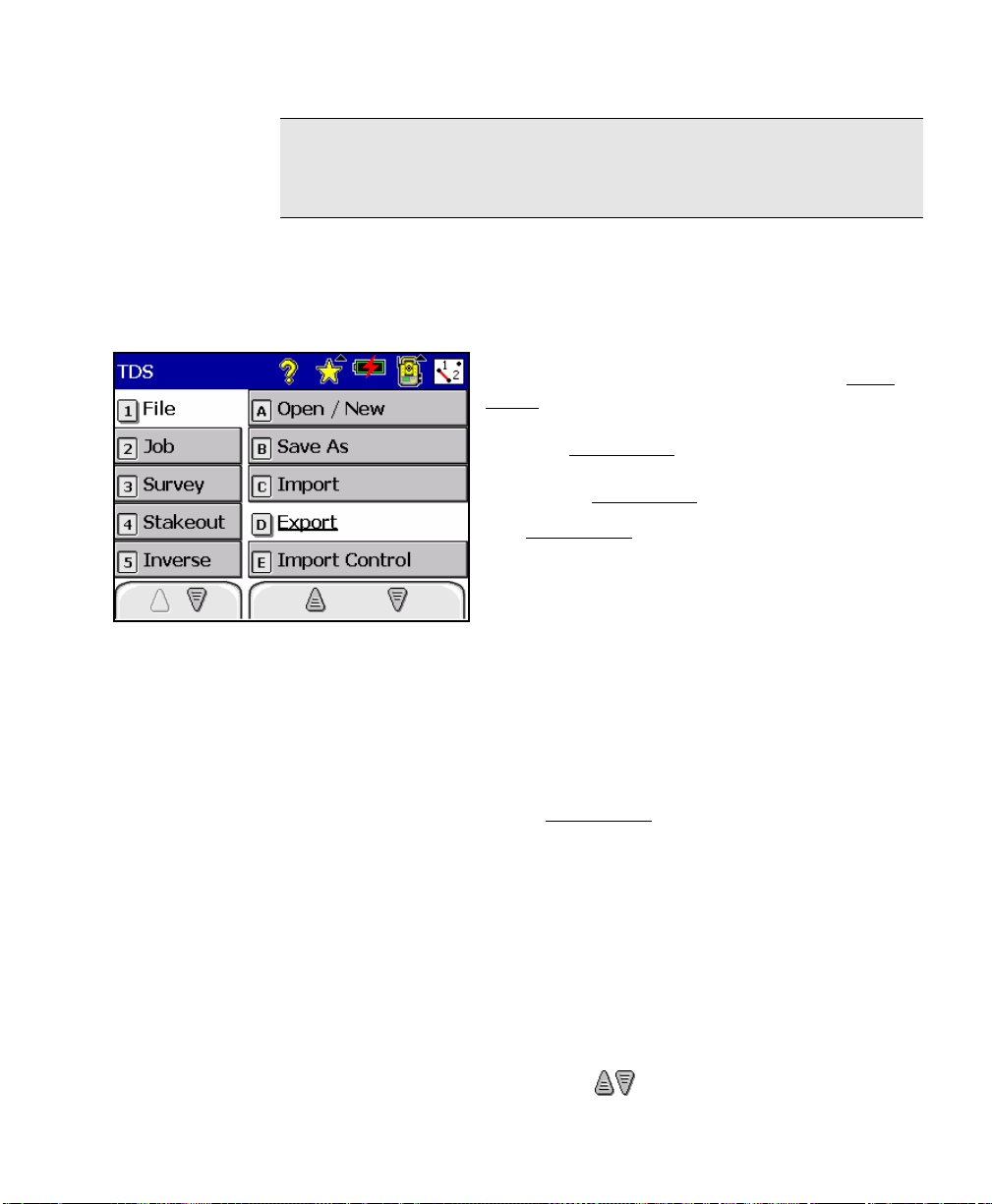

The starting point in Survey Pro, which

appears once a job is open, is called the Main

Menu, shown here. All the screens that are

available in Survey Pro are accessed startin g

from the Main Menu

screens in Survey Pro will eventually take you

back to the Main Menu

. Likewise, closing the

.

The Main Menu

left column contains all of the available menus

and the column on the right contains the menu

items associated with the active menu.

When a menu is selected from the left column, th e corresponding

menu items will become available in the right hand column. When a

menu item is activated from the right hand column, the

corresponding screen will open. It is from these screen s where you do

your work.

Navigation through the menus and menu items can be done using

any of the methods described below. The best way to become familiar

with navigating through the Main Menu

Each menu has a number associated with it, whereas the menu items

have letters associated with them. Pressing the associated number or

letter on the data collector’s keypad will activate th e corresponding

menu or menu item.

You can scroll through the list of menus and menu items by using the

arrow keys on the keypad. The up and down arrow keys will scroll up

and down through the selected column. The other column can be

selected by using the horizontal arrow keys.

You can also scroll through the list of menus and menu items by

tapping the special arrow buttons

consists of two columns. The

is to simply try each method.

on the screen located at the

9

Page 20

User’s Manual

bottom of each column. If one of these buttons appears blank, it

indicates that you can scroll no further in that direction.

When the desired menu item is selected, it can be activated by

tapping it or pressing the [Enter] key on the keypad.

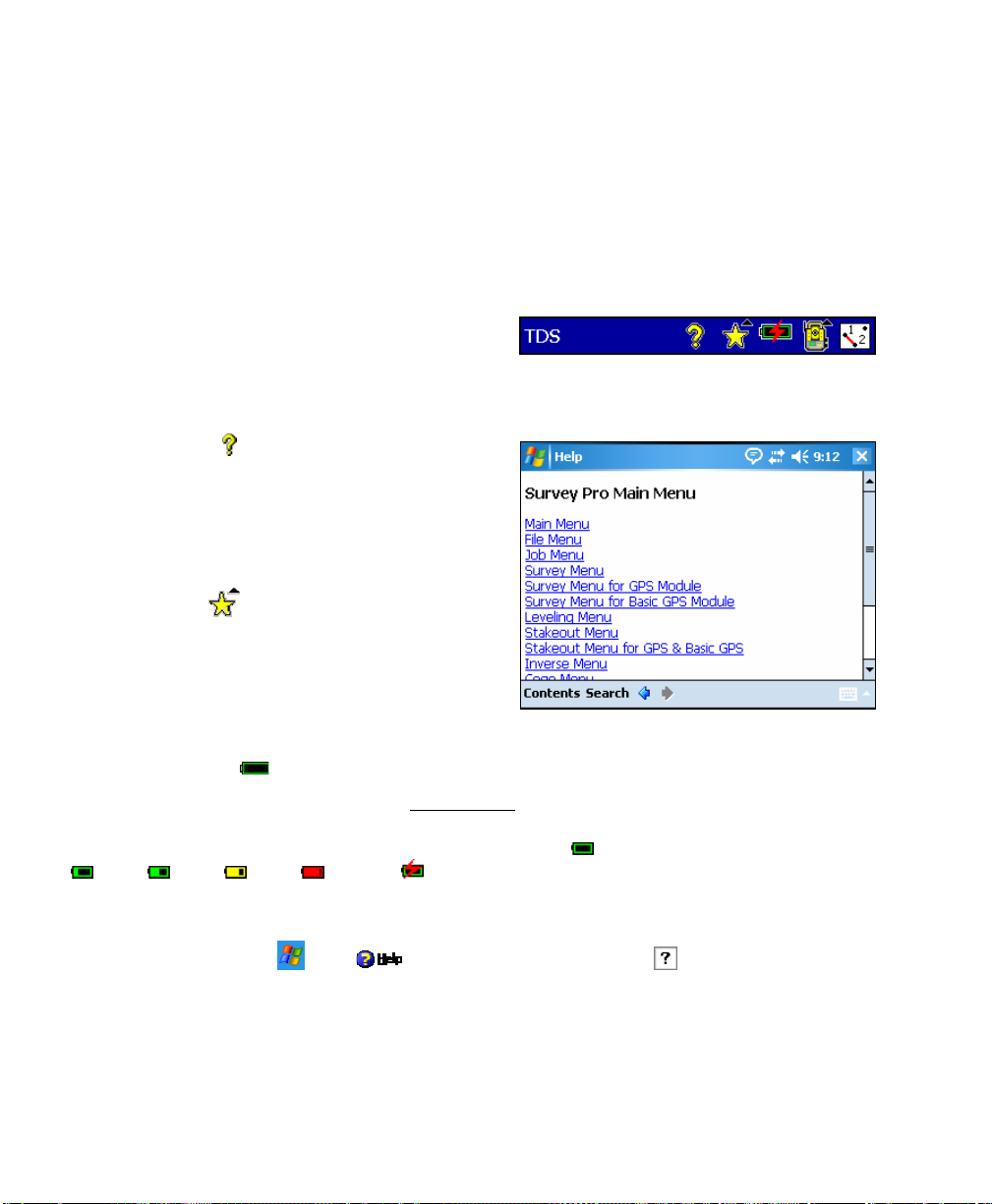

Command Bar

The command bar is the top portion of each

Survey Pro screen and it contains buttons that

are appropriate for the current screen. All of the possible buttons are

described below.

Online Help

This button opens the online help, which

allows you to access information for each

screen similar to the information you would

find in the reference manual.

Quick Pick

The Quick Pick button will open a

customizable list of routines. To quickly access

a routine, just tap on it. See Page 18 for more

information.

Battery Level

The battery icon at the bottom of the Main Menu displays the

condition of the Survey Pro’s rechargeable batt ery. T he icon has five

variations depending on the level of charge remaining:

75%, 50%, 25%, 5% and charging.

Tapping the battery icon is a shortcut to the Microsoft Power Settings

screen. You can view the online help for this screen on a Rang er

300X/500X by tapping

10

then

, or on a Ranger by tapping .

100%,

Page 21

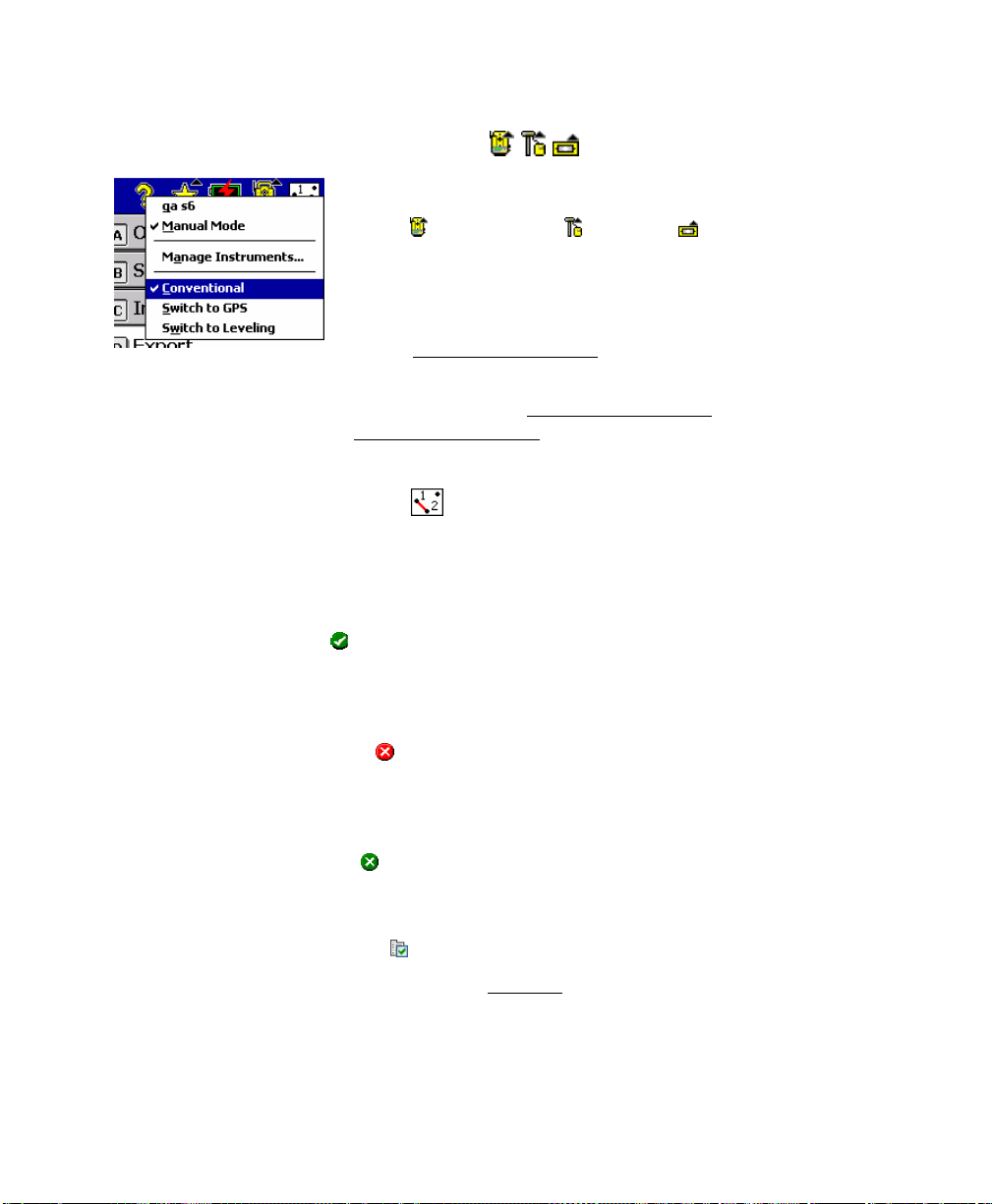

Surveying Mode

The instrument icon indicates which collection mode the

software is running in. There are three possible surveying

modes:

icon will open a list of options to do any of the f ol lowing:

for more information.)

Conventional, GPS, and Leveling. Tapping this

• Switch to another instrument mode.

• Quickly select a different instrument profile. (See the

Instrument Settings

screen in the Reference Manual

Getting Started

• Quickly access the Instrument Settings

Instrument Settings

information.)

screen in the Reference Manual for more

screen. (See the

Map View

This button will access the map view of the current job when it is

tapped. The map view is available from m any screens and is

discussed in detail on Page 22.

OK

This button performs the desired action then closes the current

screen.

Cancel

This button is red in color and closes the current screen without

performing the action intended by the screen.

Close

This button is green in color and closes the current screen.

Settings

This button opens the Settings screen associated with the curre nt

screen.

11

Page 22

User’s Manual

GPS Status

This is used to view the current status and access the settings for a

GPS receiver when using the GeoLock feature (Page 135). This is only

available from the Remote Control

using a supported robotic total station.

and Remote Shot screens when

Parts of a Screen

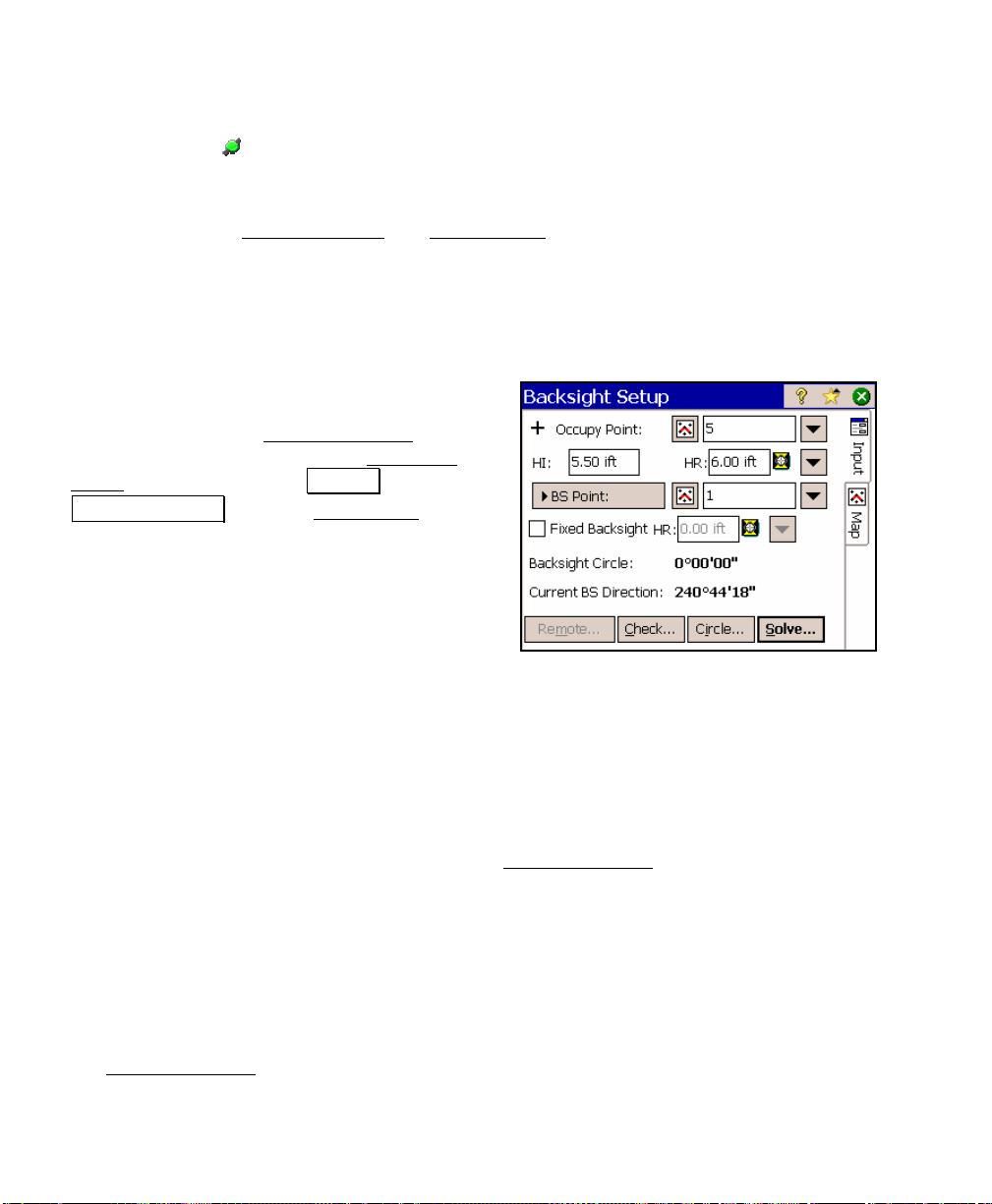

Many screens share common features. To

illustrate some of these features, we will

examine parts of the Backsight Setup

shown here. You can access the Backsight

Setup screen by selecting .Survey ,

Backsight Setup from the Main Menu.

screen,

Input Fields

An input field is an area where a specific value is entered by the user.

An input field consists of a point label, which identifies the data that

is to be entered in that field. It has a rectangular area with a white

background, where the data is entered. A field must first be selected

before data can be entered in it. You can select a field by tapping on

it or pressing the [Tab] key on the data collector repeatedly until it is

selected. When a field is selected, a dark border is drawn around it

and a blinking cursor is inside the field. In the Backsight Setup

screen above, the Occupy Point field is selected.

Output Fields

Output fields only display information. These fields typically display

values in bold text, do not have a special colored background, and

the value cannot be changed from the current screen. For example, in

the Backsight Setup

field.

12

screen, the Backsight Circle value is an output

Page 23

Getting Started

Power Buttons

The Backsight Setup screen contains two power buttons. Power

buttons are typically used to provide alternate methods of entering or

modifying data in the corresponding field. To use a pow er but t on,

simply tap it. Once tapped, a dropdown list will appear with several

choices. The choices available vary depending on with which field the

power button is associated with. Simply tap the desired choice from

the dropdown list.

Tapping the first power button in the Backsight Setup screen allows

you to specify an occupy point using other methods or view the details

of the currently selected point. You should experiment with the

options available with various power buttons to become familiar with

them.

Choose From Map Button

The Choose From Map Button is always associated with a field where

an existing point is required. When the button is tapped, a map view

is displayed. To select a point for the required field, just tap it from

the map.

Note: If you tap a point from the map view that is located next to

other points, another screen will open that displays all of the points

in the area that was tapped. Tap the desired point from the list to

select it.

Scroll Buttons

When a button label is preceded with thesymbol, it indicates that

the button label can be changed by tapping it, thus changing the type

of value that would be entered in the associated field. As you

continue tapping a scroll button, the label will cycle through all the

available choices.

In the Backsight Setup

point or a direction by toggling the scroll button between

BS Point and BS Direction .

Button.

screen, the backsight can be defined by a

13

Page 24

User’s Manual

Index Cards

Many screens actually consist of multiple screens. The different

screens are selected by tapping on various tabs, which look like the

tabs on index cards. The tabs can appear along the top of the screen

or the right edge.

The Backsight Setup

and the other is titled Map.

The Settings

accessing several screens and is discussed in more detail starting on

Page 27.

screen has a variant of the Index Card format for

screen consists of two cards. One is titled Input,

Input Shortcuts

Distances and angles are normally entered in the appropriate fields

simply by typing the value from the keypad, but you can use

shortcuts to simplify the entry of a distance or angle.

If you want to enter the distance between two points in a particular

field, but you do not know offhand what that distance is, you can

enter the two point names that define that distance separated by a

hyphen. For example, entering 1-2 in a distance field would compute

the horizontal distance from Point 1 to Point 2. As soon as the cursor

is moved from that field, the horizontal distance between the points

will be computed and entered in that field.

An alternate method to using this shortcut is to tap the

button, select Choose from map… and then tap the two points that

define the distance that you want to enter. Once you tap

Map View

appear in the corresponding field.

Likewise, there is a similar shortcut to enter angles in fields that

accept them. If you wanted to enter the angle, α, from the

illustration shown here, you would simply enter 1-2-3 in the

appropriate field. As soon as the cursor is moved from that field, the

angle formed by the three points entered will be entered in that field.

As with specifying a distance, you could also use the power button as

described above and tap the points of the angle in the correct order.

, the horizontal distance between the two tapped points will

power

from the

1

α

2

3

Another shortcut can be used to enter distances with fractional inches

(architectural units). Simply key in the feet, inches, and fractional

14

Page 25

Getting Started

inches where each value is separated by a space and the fraction is

entered using a forward slash (/). For example, to enter 3 feet, 6 and

3/32 inches, you would key in 3 6 3/32. Once the cursor leaves that

field, the distance will automatically be con verted to the appropriate

decimal distance.

If working with distances under 1 foot, it is acceptable to exclude the

feet value; for example "8 5/64" would be interpreted as 8 and 5/64

inches. Likewise, if entering a fractional distance under an inch, you

would only enter the fractional inch.

The following details should be considere d when using the above

method to enter fractional inches:

1. When the job is configured for International Feet or US Surve y

Feet, it is assumed that the distance entered is in the same units

as the job is configured for.

2. If the job is configured for meters, it is assumed that the

distances entered are in International Feet and will be converted

to meters when the cursor leaves the current field. (You cannot

use this method to enter a metric distance in fractional format.)

3. If a fractional inch is entered that cannot be evenly divided by

1/64 inch, it will automatically be converted to the nearest 64

th

inch. This conversion would be negligible for survey data and

unlikely to occur.

An alternate method to using this shortcut is to tap the

Quick Pick

button while the cursor is in a distance field that you want to change

and select AU Conversion. Enter the appropriate feet, inches and

fractional inches and tap Use . See the Reference manual for more

information on the AU Conversion screen.

15

Page 26

User’s Manual

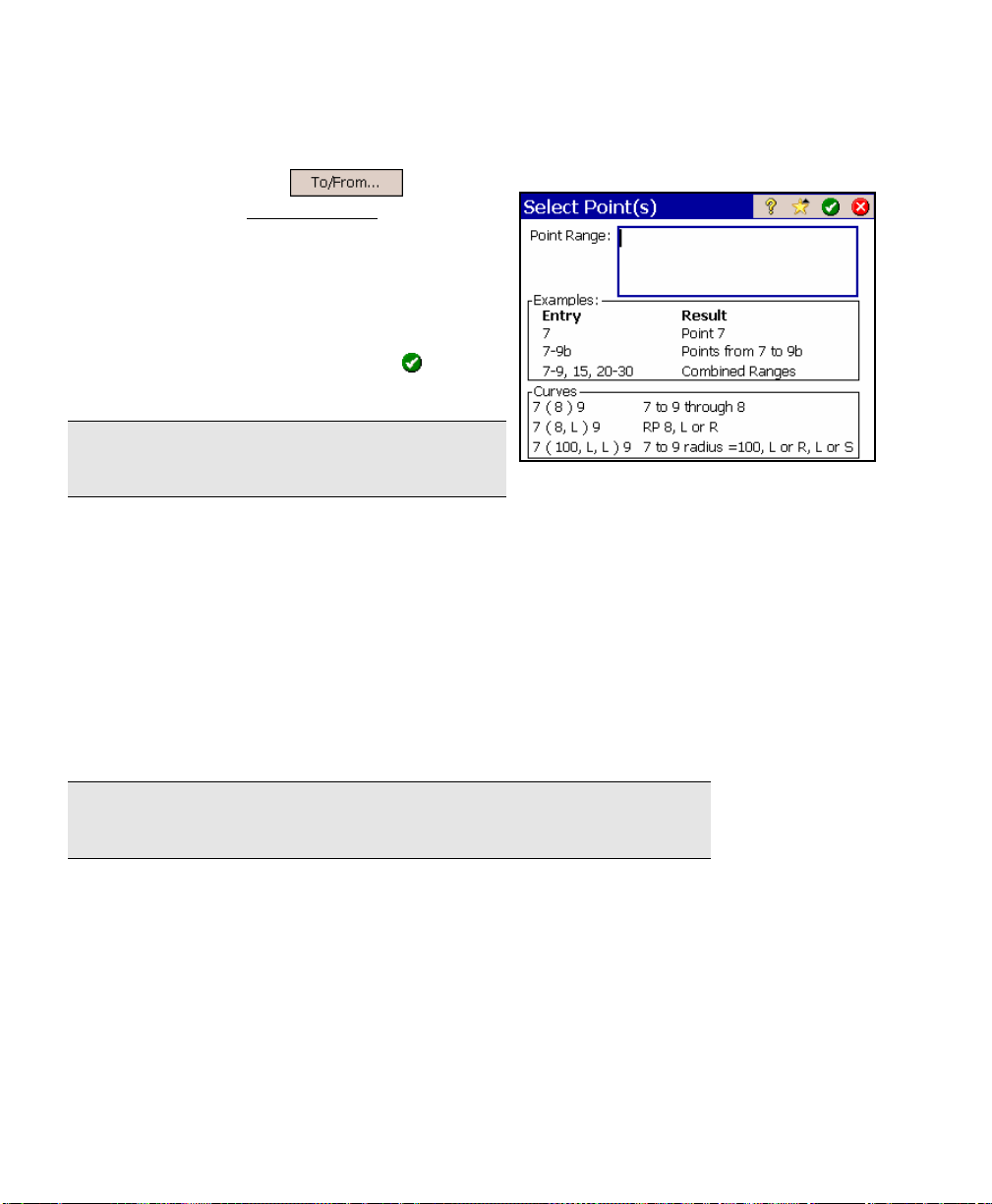

Point List Editor

Many screens contain a button,

which accesses the Select Point(s)

allows you to enter a simple list of points or a

list of points that describe a line that can

contain curves.

Examples of how to enter different lists of

points are displayed in the lower portion of the

screen. Once the list is entered, tap

return to the previous screen.

Note: Spaces in point lists are ignored. They

are only used in the examples for clarity.

The examples for entering the three possible curve types are

explained in detail as follows:

• 7 ( 8 ) 9

The first example, defines a curve that passes through Points

7, 8 and 9, respectively.

screen that

to

• 7 ( 8, L ) 9

The second example defines a curve where Point 8 is the

radius point and the curve begins to the Left (from the point

of view of the radius point), turning from Point 7 to Point 9.

Note: When defining a curve with a radius point, the other two points

must be the same distance from the radius point for a solution.

• 7 ( 100, L, L ) 9

The third example describes a curve with a radius of 100,

using the same units as the job, that begins at Point 7,

turning to the Left (from the point of view of the radius point),

creating a Large arc (> 180°), and ending at Point 9.

16

Page 27

Getting Started

Entering Distances in Other Units

When a distance is entered in a particular field, it is normally entered

using the same units that are configured for the current job, but

distances can also be entered that are expressed in other distance

units.

When entering a distance that is expressed in units that do not match

those configured for the job, you simply append the entered distance

with the abbreviation for the type of units entered. For example, if

the distance units for your current job were set to International Feet

and you wanted to enter a distance in meters, you would simply

append the distance value with an m or M for meters. As soon as the

cursor is moved to another field, the meters that were entered will be

converted to feet.

The abbreviations can be entered in lower case or upper case

characters. They can also be entered directly after the distance

value, or separated with a space. The following abbreviations can be

appended to an entered distance:

• International Feet: f or ft or ift

• US Survey Feet: usf or usft

• Inches: i or in

• Meters: m

• Centimeters: cm

• Millimeters: mm

• Chains: c or ch

17

Page 28

User’s Manual

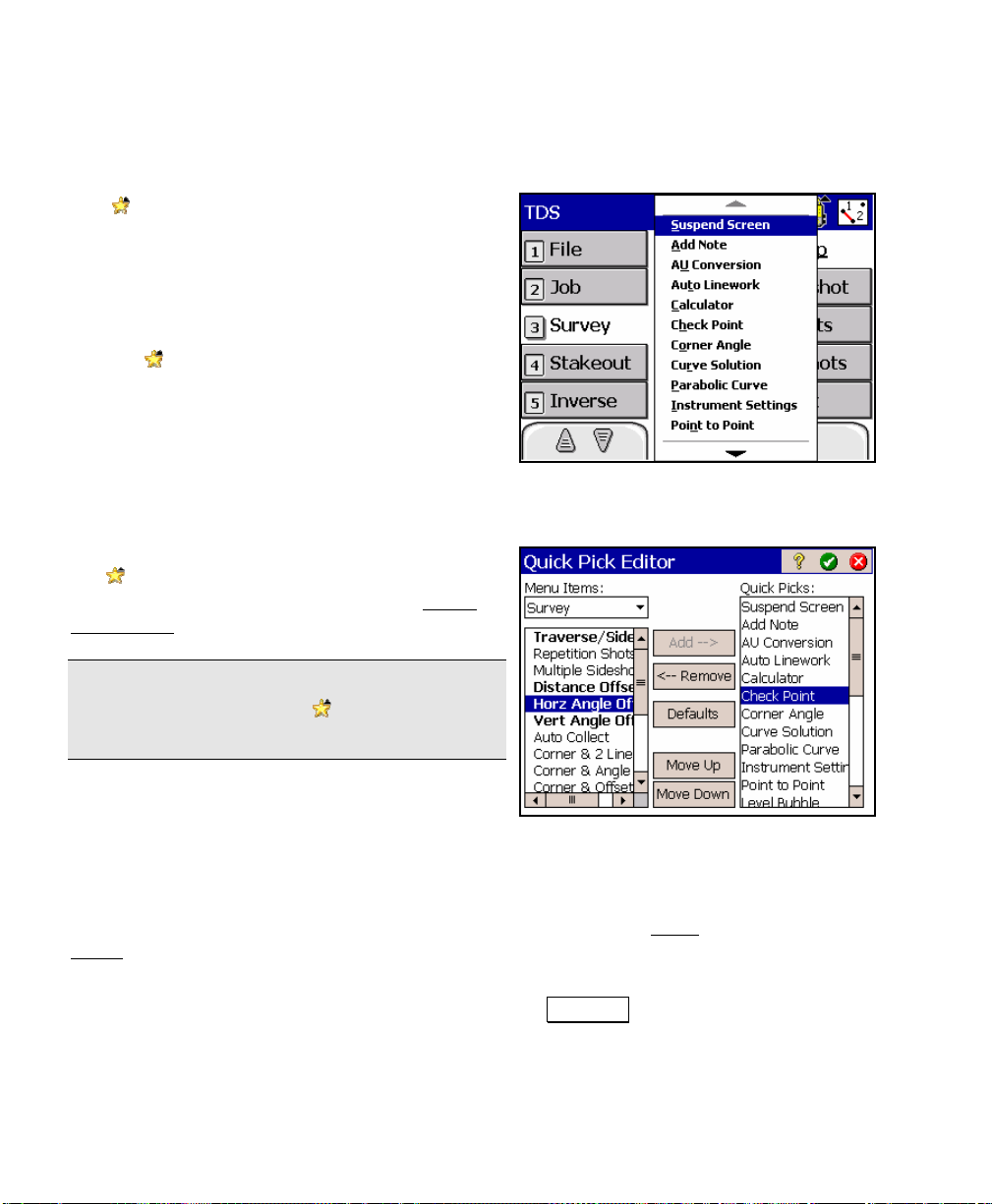

Quick Pick

The button is called the Quick Pick button.

This button is used to quickly access any of

several commonly-used routines. The list of

routines available from the Quick Pick button

can be customized and sorted in any order.

To access a screen with the Quick Pick button,

first tap

Customizing the Quick Pick List

If you want to customize the Quick Pick list,

tap

and tap Edit Quick Pick. This opens the Quick

Pick Editor.

and then tap the desired routine.

and then scroll to the bottom of the list

Tip: You can quickly get to the bottom of the

Quick Pick list by tapping then pressing the

up-arrow hardware button once.

The current Quick Pick list is displayed in the

right column and the routines that can be

added to the list are displayed in the left column, where the routines

that are already in the Quick Pick list are shown in bold.

To add a routine, first select the menu item from the Menu Item

dropdown list where that routine is normally accessed from the Main

Menu. (Not all routines can be added to the Quick Pick list. If a

routine is not listed, it cannot be added.)

Select the routine from the left column then tap th e Add --> button

to add it to the Quick Pick list on the right.

18

Page 29

Getting Started

The new routine will initially be placed at the bottom of the list. To

move it elsewhere in the list, select it and tap the Move Up or

Move Down buttons. (Any other routines in the Quick Pick list can

also be repositioned in this way.)

To remove a routine from the Quick Pick list, select it and tap the

<-- Remove button.

Tapping the Defaults button will revert the custom list back to the

default list. Since any changes will be lost, a prompt will first ask if

you are sure.

Smart Targets

Survey Pro has the ability to create and store custom configurations

for any number of prisms or other target types. These are called

Smart Targets.

Smart Targets are useful when working with multiple prisms on the

same job, particularly when the prisms have different characteristics

such as rod height and/or offset because the user can quickly switch

between different Smart Targets before taking a shot.

Smart Targets also provide a way to quickly switch between taking a

shot at a prism and taking a shot at a reflectorless target. The total

station EDM configuration is switched for you automatically.

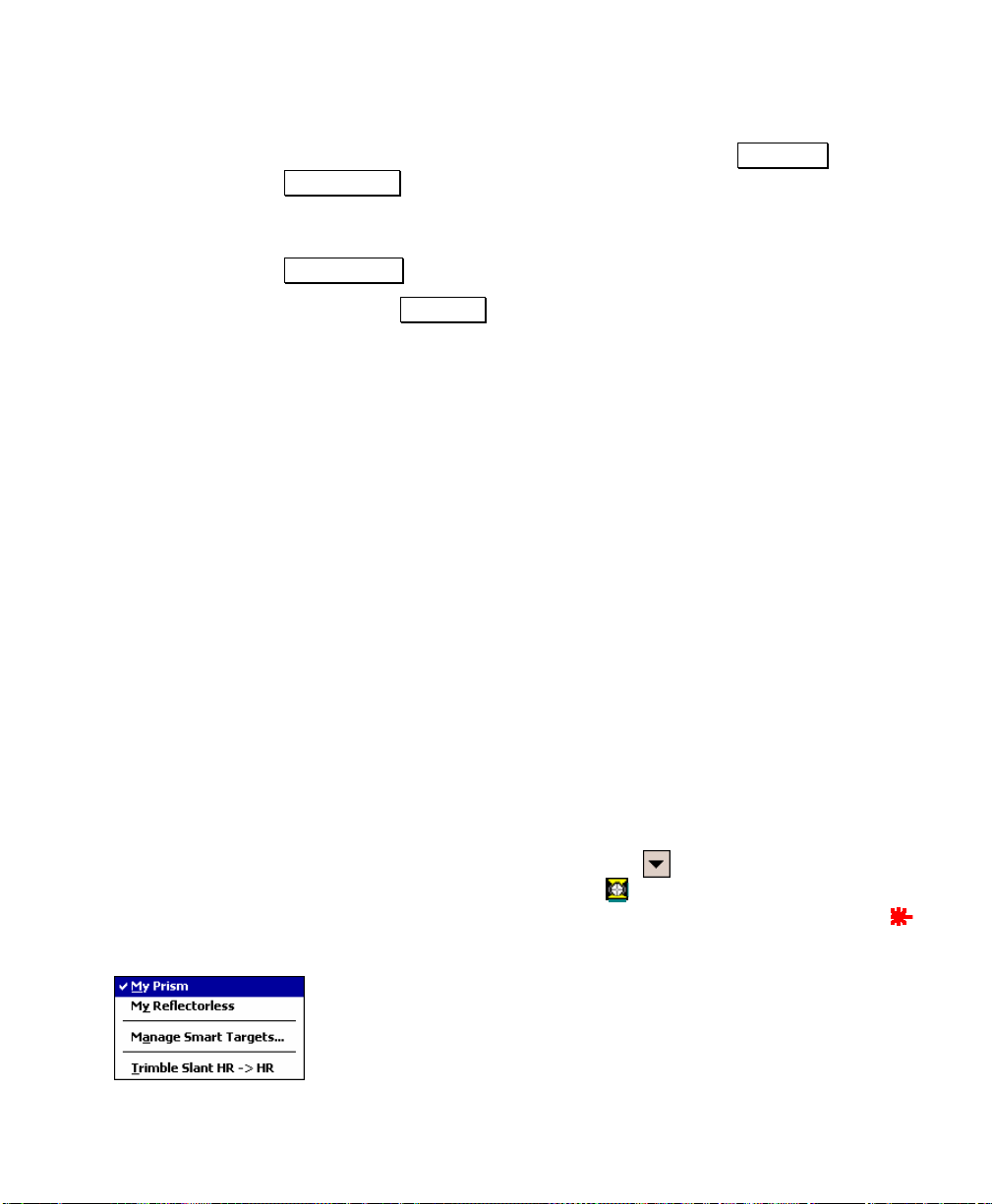

Selecting Smart Targets

You can quickly select any existing Smart Target from a screen that

has an HR field. Tap the power button

HR field that you want to shoot. A

power button indicates a prism target type is currently selected. A

icon indicates a reflectorless target type is currently selected

All the available Smart Targets will be displayed in the upper

portion of the drop-down list. The Smart Targets listed will

depend on if you are selecting a Smart Target for your foresight

or your backsight.

Simply tap the Smart Target that you want to use from the drop-

corresponding with the

icon displayed next to the

19

Page 30

User’s Manual

down list. The preset configuration for the selec ted Smart Target will

be automatically set.

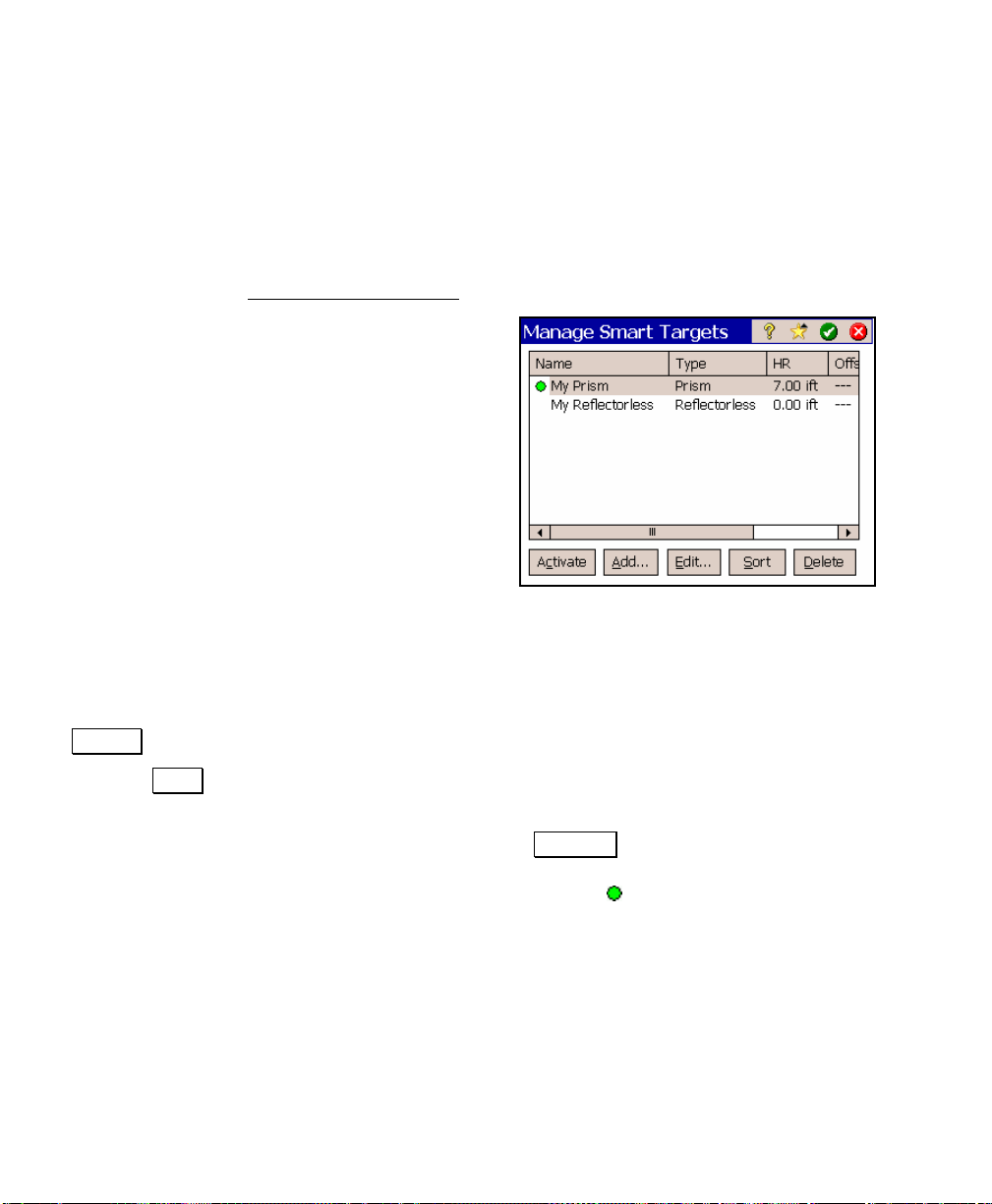

Manage Smart Targets

Select Manage Smart Targets from the same drop-down list described

above to access the Manage Smart Targets

can create a new custom Smart Target or edit

any existing Smart Target.

Survey Pro includes two foresight Smart

Targets called My Prism and My Reflectorless,

respectively and one backsight Smart Target

called My Backsight Prism. These can be edited

or deleted, but at least one prism and one

reflectorless foresight Smart Target and at

least one prism backsight Smart Target must

exist at all times. Because of this, for example,

you would not be able to delete My Backsight

Prism unless another Smart Target with a

prism target type for your backsight was available. Similarly, you

would not be able to change My Reflectorless to a prism target type

unless you already had another foresight Smart Target configured

with a reflectorless target type.

screen. From here you

To delete an existing Smart Target, tap it to select it and then tap

Delete .

Tapping Sort will sort the list of Smart Targets alphabetically.

You can also activate a Smart Target from this screen by tapping the

desired Smart Target to select it and then tapping Activate ,

although it’s faster to activate Smart Targets using the shortcut

described above. The active Smart Target is shown with a

next to it.

20

symbol

Page 31

Getting Started

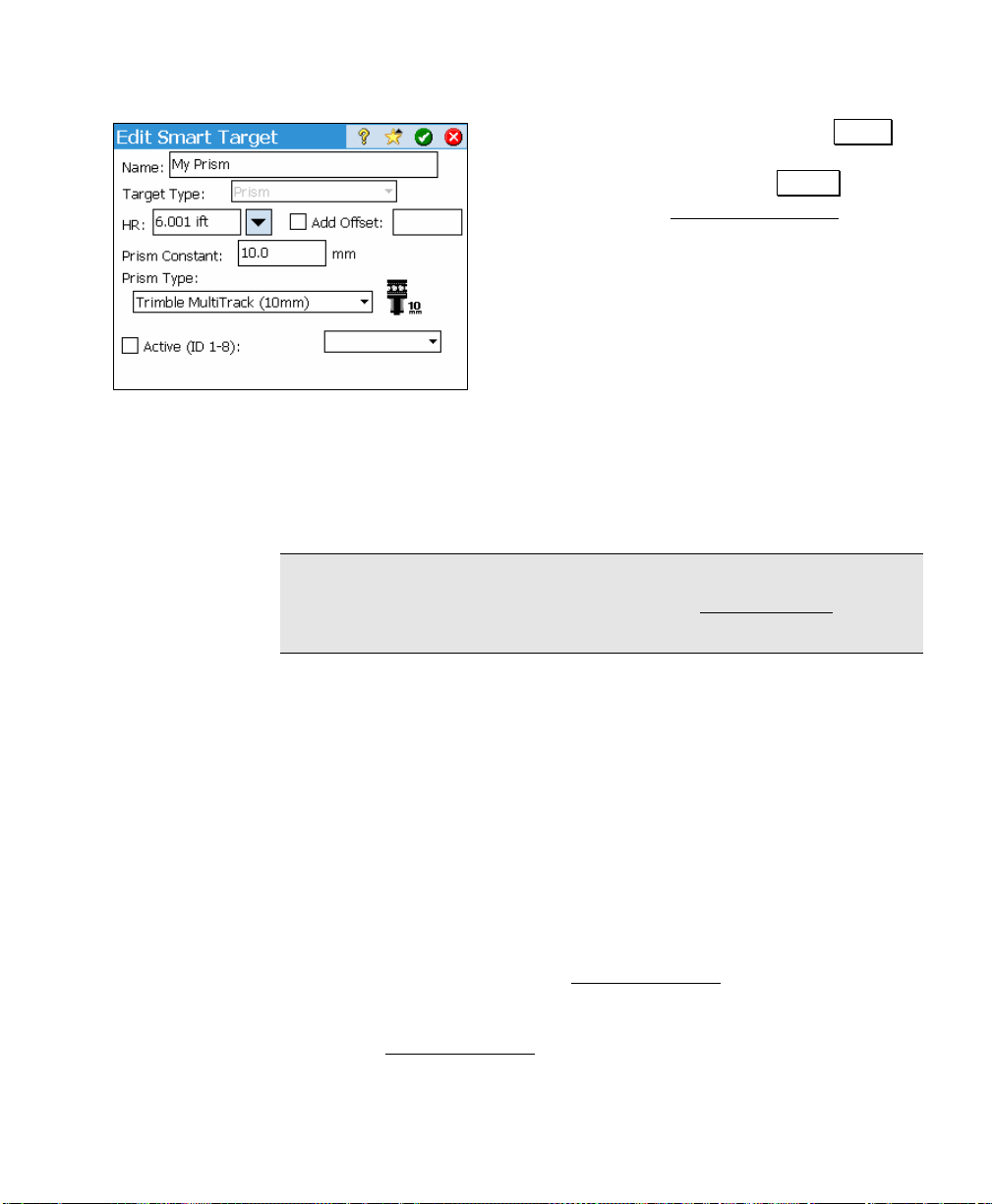

To create a new Smart Target tap the Add…

button. To edit an existing target, tap it from

the list to select it and then tap Edit… . Either

option will open the Edit Smart Target screen.

The Smart Target Name you provide will be

shown in the drop-down list when you switch

between Smart Targets.

The Target Type field determines how the EDM

will be configured on the total station when

taking shots to the Smart Target. It can be

Prism when using a standard prism,

Reflectorless to perform distance measurements without a prism, Long

Range Prism, which increases the output power of the EDM for

shooting prisms at long distances, or On Gun, which uses the EDM

settings configured on the total station (Leic a only). Not all target

types are supported by all total station.

Note: If using a Trimble S6/VX, there are special smart targ et

settings available, which are described under Smart Targets in the

Reference Manual.

The HR field will be the default rod height whene ver this Smart

Target is selected. Updating the HR from any screen that has an

editable HR field while a Smart Target is selected will also save that

new value here, making it the new default HR for the current Smart

Target.

If the Add Offset to HR is checked, the offset entered in the

corresponding field will then be added to the rod height you provide.

(A negative value would subtract the offset from the HR.) This is

useful for people who use a device that always elevates their rod by a

fixed distance, but still want to use the rod height measurement

displayed on the rod for simplicity.

For example, if you were in the Backsight Setup

screen and selected a

foresight Smart Target with a default HR of 5 feet and an HR offset

value of 1 foot, you would see 5.00 ift displayed in the foresight HR

field of the Backsight Setup

screen, as well as every other editable

foresight HR field, but you would see 5.0+1.0 ift in every output -only

21

Page 32

User’s Manual

HR field showing the HR entered plus the offset. (The raw data file

will also clearly note when a rod height offset is being applied.)

The Prism Constant field should contain the prism constant for the

prism associated with this Smart Target as long as a prism constant

is not also set in the total station. If a prism constant is set in Survey

Pro and on the total station, it will be applied twice resulting in

incorrect distance measurements for every shot.

If you are using a robotic total station that supports prisms that

output a target ID, the Use Target ID field will be available where you

can specify the target ID for the Smart Target.

If Use For Search is available and selected, the total station will only

look for the Target ID when it is searching for the targ et. Once the

target is found, it will track the prism, but it is possible for the total

station to start tracking a different reflector that comes into view. If

Use Always is selected, the total station will continuously monitor the

Target ID and only track the prism with the specified Target ID.

Tap

to close the Edit Smart Targets screen and save any changes.

Map View

from the command bar, or from various screens

Many screens provide access to a map view. The map view is a

graphical representation of the objects in the current job.

Map View without basemaps Map View with basemaps

22

Page 33

Getting Started

There are different map views depending on from where the map

view is accessed and they can display slightly different information

such as a vertical profile.

The main map view is accessed from the Main Menu by tapping the

button at the bottom of the screen in the command bar. If you are

using basemaps, it is from this map view where the basemaps are

managed.

All other map views are accessed by tapping the

button from a

variety of screens.

A bar is shown at the bottom of every map view that indicates the

scale.

The buttons along the left edge of the screen allo w you to change

what is displayed in the map view.

Tip: You can pan around your map by dragging your stylus across the

screen.

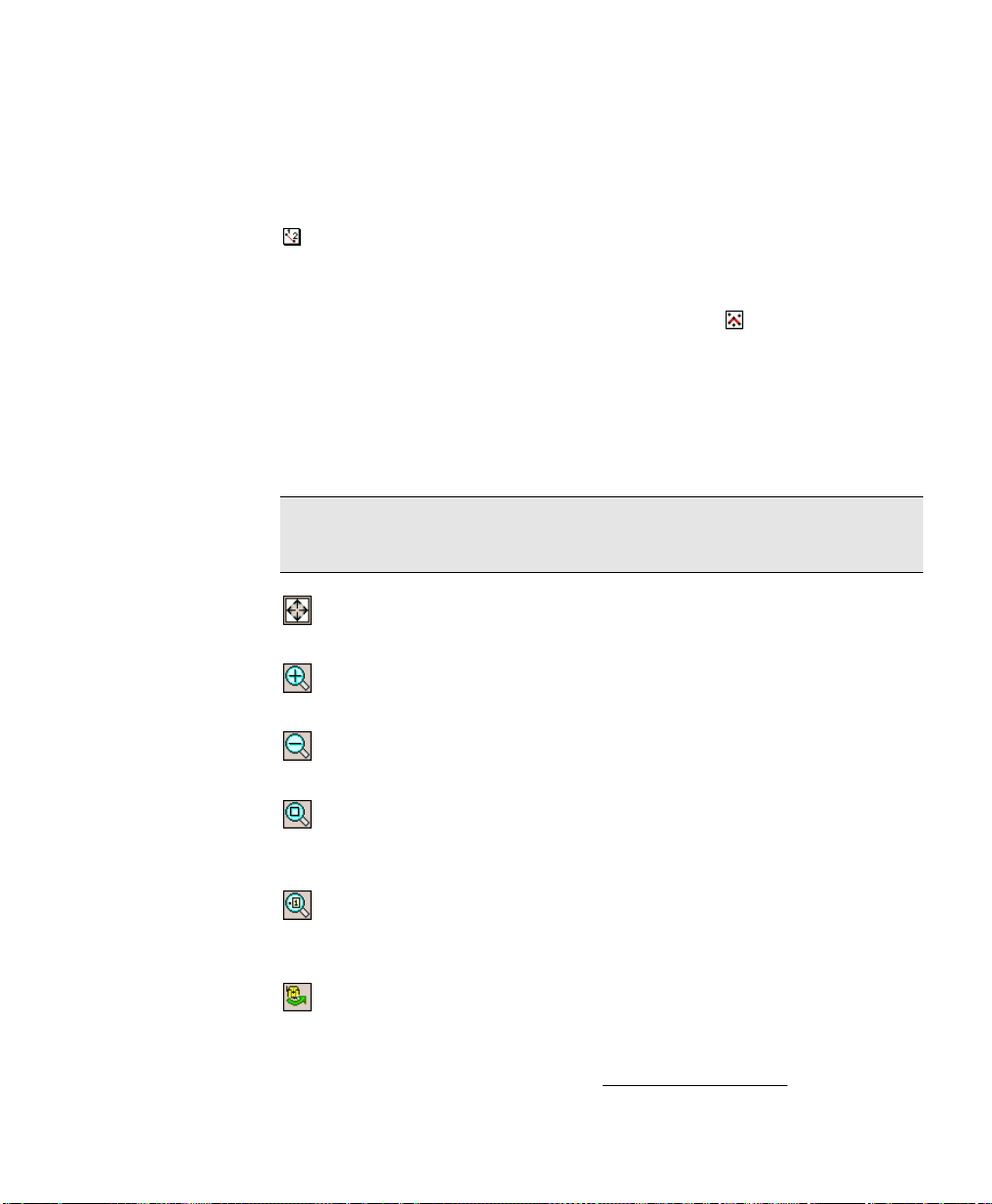

Zoom Extents Button: will change the scale of the screen so that

all the points in the current job will fit on the screen.

Zoom In Button: will zoom the current screen in by

approximately 25%.

Zoom Out Button: will zoom the current screen out by

approximately 25%.

Zoom Window Button: Allows you to drag a box across the

screen. When your finger or stylus leaves the screen, the map wil l

zoom to the box that was drawn.

Zoom To Point Button: Prompts you for a point name and then

the map view will be centered to the specified point with the point

label displayed in red.

Turn To Point Button: Tap this button and then tap a point in

the map view to automatically turn the total station to the selected

point. This is only available when a robotic total station is selected

and Remote Control is active in the Instrument Settings

.

23

Page 34

User’s Manual

Increase Vertical Scale: is only available when viewing a

vertical profile. Each time it is tapped, the vert ical scale of the view

is increased.

Decrease Vertical Scale: is only available when viewing a

vertical profile. Each time it is tapped, the vert ical scale of the view

is decreased.

Zoom Preview Button: will display only the points that are

currently in use (only available from certain map view screens).

Map Display Options: Accesses the Map Display Options screen,

described below.

Manage Basemaps: Accesses the Manage Basemaps screen,

described below (only available from the main map view, access ed

from the command bar button in Main Menu).

Basemaps

Basemaps can be used in jobs to more accurately display local objects

and terrain in the map view to give the surveyor a better idea of

where they are in relation to local land features.

There are two general types of basemaps – raster images and CAD

drawings. Raster images are usually created from photographs and

can accurately display the local terrain with great detail. CAD

drawings are created from CAD software and will typic ally display

points, roads, boundaries and any other objects that can be drawn

with lines.

Basemap Files

Survey Pro supports basemap files from AutoCAD, GeoTiff, and TDS.

Since basemap files can be large in size, the following points should

be considered when managing basemap files:

24

Page 35

Getting Started

• Before you can use a basemap in

Survey Pro, you need to copy the

appropriate basemap files from a PC to

the same directory where your current

job is located. If the basemap files are

stored in a different directory and then

added to the current job, the files will

be copied to the job’s directory.

• If you use the Save As routine and save

the current job to a new directory, any

basemaps associated with that job will

be copied to the new location.

Manage Basemaps

Once the basemap files are stored on the data collec tor, they must be

added to the current job before they can be viewed in the map view.

1. To add basemaps, open the Main Map View by tapping the

button in the command bar from the Main Menu.

2. From the main Map View

button to open the Manage Basemaps

screen shown here.

3. Tap the Add… button. This will open a

new screen where you can select the

basemap that you want to add to the

current job.

4. Once a basemap is added, it will appear in

the list in the Manage Basemaps

5. Repeat Steps 3 and 4 to add any additional

basemaps.

, tap the

screen.

25

Page 36

User’s Manual

Basemaps are drawn to the screen in the

reverse order that they are listed in the

Manage Basemaps

screen, where the first

basemap in the list is the last one drawn,

and thus, will be drawn "on top" of any

other basemaps. This is important to

remember if any basemaps overlap since if

a raster basemap were drawn on top of

another basemap, it would cover any

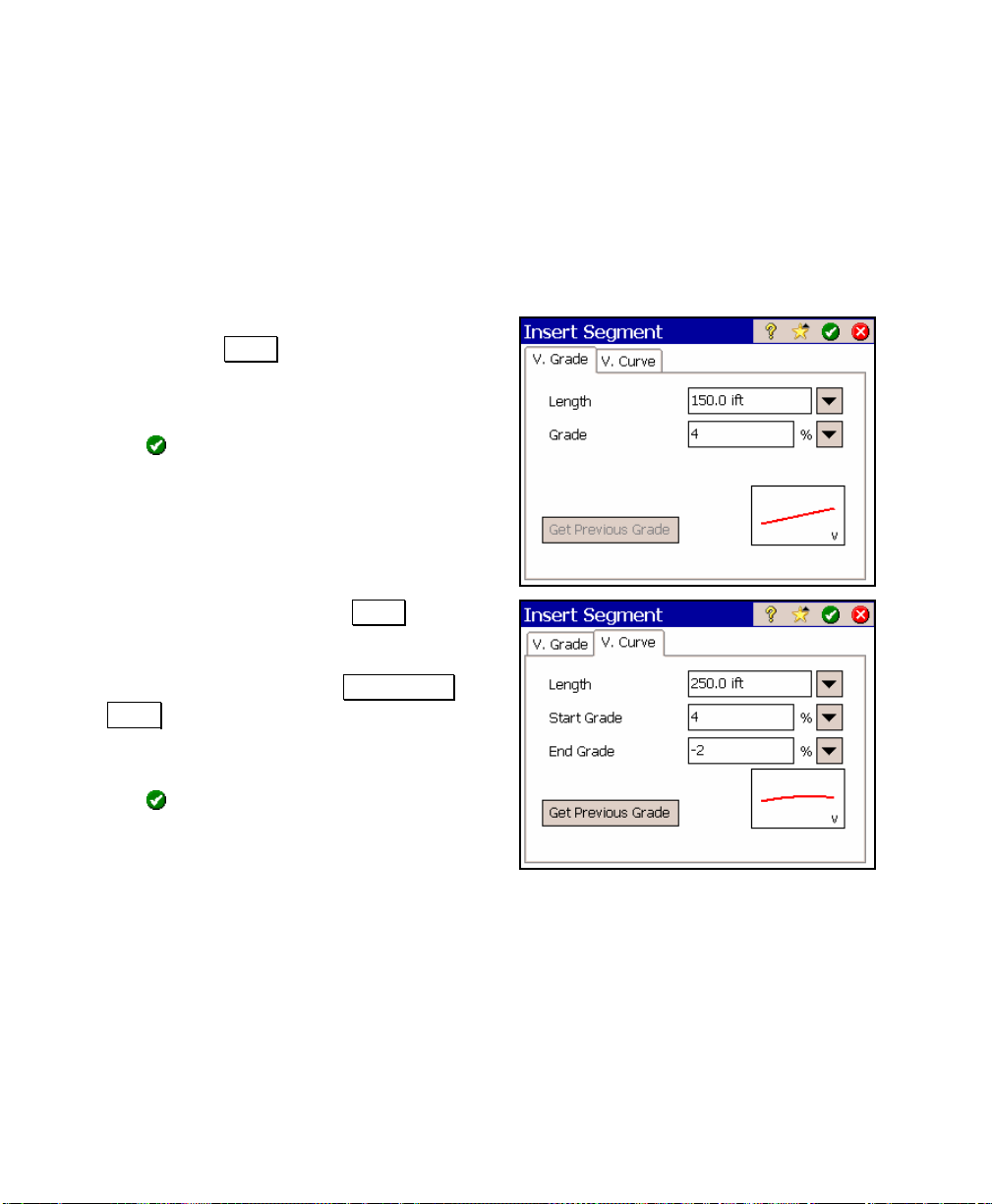

basemaps below it.

The list shown contains a vector basemap,

tds.dxf that occupies the same area as the

other two basemaps, which are raster

basemaps. The vector basemap is at the

top of the list so the points and lines it

contains will be drawn last and appear on

top of the two raster basemaps.

6. To change the order of the basemaps in

the list, select a basemap and tap the

Move Up or Move Down buttons to

move it up or down in the list,

respectively.

7. To remove any basemap from the list,

select it and tap Remove . This will

remove the basemap from the list and

un-associate it from the current job.

(This will not delete the corresponding

basemap file.)

Raster basemap drawn first.

Vector basemap drawn last.

26

Resulting map view with both basemaps in

view.

Page 37

Getting Started

8. The colors of the objects in vector basemaps

can be modified by selecting the basemap

and then tapping Edit… to open the Edit

Basemap screen.

The Settings Screen

The Settings screen is used to control all of the settings available for

your total station, data collector, current job, and Survey Pro

software.

Most of the settings remain unchanged unless you deliberately

change them, meaning the default settings are whatever they were

set to last. For example, if you create a new job where you change the

direction units from azimuths to bearings and then create another

new job, the default direction units for the new job will be bearings.

Survey Pro behaves in this way since most people use the same

settings for a majority of their jobs. This way, once the settings are

set, they become the default settings for all new jobs and current jobs.

Some settings are considered critical and are therefore stored within

the job. The following settings are stored within a job and will

override the corresponding settings in the Settings

opened:

• Scale Factor – Surveying Settings Card

• Earth Curvature On or Off – Surveying Settings Card

• Units for Survey Data (distances) – Units Settings Card

• North or South Azimuth – Units Settings Card

• Angle Units – Units Settings Card

screen when it is

27

Page 38

User’s Manual

• GPS setup information such as localization, mapping plane,

etc. (Requires GPS Module)

The Settings

independent screens where each individual

screen contains different types of settings.

There are two ways to navigate to the various

screens. The first method is to tap the

button to drop down the list of available

screens and then tap on the desired screen

from the list to open it. The second method is

to tap the buttons to the side of the screen title,

which will open the previous or next screen

respectively. For example in the screen shown,

you could tap

(General Settings

Settings) screen. Repeatedly tapping either of these buttons will

cycle through all the available screens.

Consult the Reference Manual for an explanation of each field on

every Settings

If using a Bluetooth total station, refer to the Bluetooth section on

Page 294.

screen actually consists of several

to open the previous

) screen, or tap to open the next (Units

screen.

File Management and ForeSight DXM

Survey Pro uses a variety of files to store data and inform ation

about your project. The files include t h e main data file, the .JOB file,

and the raw data file, the .RAW file, and several other supplementary

files that Survey Pro can use for additional information. To help

manage this data and to supplement Survey Pro capabilities, TDS

has an office product called ForeSight DXM.

ForeSight DXM is a complete data management tool that works

directly with Survey Pro data files. ForeSight DXM can make any

project easier to manage and makes doing every day tasks, such as

downloading, quick and easy. ForeSight DXM has a variety of

28

Page 39

Getting Started

analysis tools, geodetic tools including projection setups, and the

capability to convert TDS data files into many other formats,

including LandXML, for use in CAD.

ForeSight DXM makes the field-to-office and the office-to-field

process seamless and easy. If you don’t already own a copy of

ForeSight DXM, contact your TDS Dealer for more information. You

can also download a full-featured demonstration copy of ForeSight

DXM from the TDS Web site at www.tdsway.com

.

Job Files

Every job that is used with TDS Survey Pro actually consists of at

least two separate files; a job file and a raw data file. Each file

performs a different role within the software.

A job file can be created in the Data collector, or on a PC using TDS

ForeSight DXM (or other PC software) and then transferred to the

Data collector. It is a binary file that has a file name that is the same

as the job name, followed by a *.JOB extension. A job file is similar to

the older TDS-format coordinate file, except in addition t o stori ng

point names and their associated coordinates, a job file also contains

all of the line work as well.

When you specify points to use for any reason within Survey Pro, the

software will read the coordinates for the spec ified points from the job

file. Whenever you store a new point within Surv ey Pro, the point is

added to this file.

A job file can be edited on the Survey Pro when using the Edit Points

screen. Since a job file is binary, it requires special soft ware for

editing on a PC, such as TDS Survey Link. It can also be converted to

or from an ASCII file using Survey Link. (Refer to the Surve y L ink

documentation for this procedure.)

When a job file is converted to an ASCII file, the resulting file is

simply a list of points and coordinates. Each line consists of a point

name, northing or latitude, easting or longitude, elevation or elliptical

height, and a note where each value is separated by a comma.

29

Page 40

User’s Manual

Raw Data Files

A raw data file is an ASCII text file that is automatically generated

whenever a new job is created on Survey Pro and cannot be created

using any other method. It has the same file name as the current job

file (the job name), followed by the *.RAW extension.

A raw data file is essentially a log of everythin g that occurred in the

field. All activity that can create or modify a point is written to a raw

data file. Survey Pro never "reads" from the raw data file – it only

writes to the file. Since a raw data file stores all of the activity that

takes place in the field, it can be used to regenerate the original job

file if the job file was somehow lost. This process requires the TDS

Survey Link software.

Since a raw data file is considered a legal document, it cannot be

edited using any TDS software other than appending a note to it

using the View Raw Data

invalidate all of its contents and is not supported in any way by TDS.

When viewing a raw data file on a PC using a simple text editor or on

Survey Pro using the View Raw Data

unaltered, which can appear somewhat cryptic. When viewin g the file

from within Survey Link, the codes are automatically translated on

the screen to a format that is easier to understand.

screen. Editing a raw data file would

screen, the file is shown

30

Page 41

Getting Started

Control Files

The current job can be configured to access the points from another

job stored on the data collector. When the current job is using p oints

from another job, that other job is called a Control File and the points

in the control file are called Control Points. (Any non-point objects in

a control file are always ignored.)

A control file can be selected from the New Job wizard when creating

a new job, or the File Import Control screen can be used to select a

control file for an existing job, or to manage the current control file.

See the Reference Manual for more information on these screens.

There are two methods for accessing control points: imported control

points and external control points. Each method has advantages and

disadvantages, which are explained below.

Import Control File

When a control file is imported, the control points are copied into the

current job and stored on a special layer called CONTROL.

Importing control points provides improved RAW data consistency

since each control point is written to the raw data file as a store point.

This can significantly help when regenerating points from RAW data

and generating reports in the office.

Importing control points may not be the best method when using very

large control files, while collecting relatively small sets of points since

the imported control points can make the current job very large with

too many points to easily manage.

Importing control points is also not recommended when you want to

switch between different control files from the curren t j ob.

31

Page 42

User’s Manual

External Control File

When using an external control file, the points in the control fi le are

simply linked to the current job and do not become a permanent part

of the current job. Because of this, an external control file can later

be unlinked, or cleared from the current job.

Some users prefer to keep a set of known points in a separate c ontrol

file when repeatedly working on new jobs in the same general area.

That way when they return to the job site, they can create a new job,

but select the external control file to easily have access to the known

control points.

Once an external control file is selected, the control points can be

used in the same way as the job’s points with the following

exceptions:

• An external control file has read only attributes. This means

that the points in the control file cannot be modified or

deleted; they can only be read. For example, you can select a

control point to use as an occupy point during data collection

or as a design point during stake out, but you could not use a

control point for a foresight where you intend to overwrite the

existing coordinates with new coordinates. You would a lso be

unable to modify a control point from the Edit Points

screen.

• Since the points in an external control file are shar ed with the

points in the current job, you cannot open an external control

file if any of the point names used in it are also used in the

current job. If you attempt to do so, a dialog will tell you that

a duplicate point name was encountered and the control file

will not be opened.

32

Page 43

Getting Started

Description Files

A Description File is used to automate the task of entering

descriptions for points that are stored in a job. They are especially

useful when the same descriptions are frequently used in the same

job.

A description file is a text file containing a list of the descriptions that

you will want to use with a particular job. The file itself is usually

created on a PC, using any ASCII text editor such as Notepad, which

is included with Microsoft Windows. It is then saved using any file

name and the .txt extension and then transferred to the Data

Collector.

It is important to realize that when you use a more sophisticated

application, such as a word processor to create a description file, you

must be careful how the file is saved. By default, a word processor

will store additional non-ASCII data in a file making it incompatible

as a description file. However this can be avoided if you use the File >

Save As… routine from your word processor and choose a Text Only

format as the type of document to save. For more information on

creating a text file using a word processor, refer to your word

processor’s documentation.

Description files can be created in two different formats; one includes

codes and the other does not. The chosen format determines how

descriptions are entered. Each format is described below.

Description Files without Codes

A description file that does not contain codes is

simply a list of the descriptions that you will want to

use in a job. The content of a sample description file,

without codes, is shown here.

The following rules apply to description files without

codes:

• Each line in the file contains a separate description.

• A description can be up to 16 characters in length (including

spaces).

33

Page 44

User’s Manual

• A description can contain any characters included on a

keyboard.

• Descriptions do not need to be arranged in alphabetical order.

(Survey Pro does that for you.)

• Descriptions are not case sensitive.

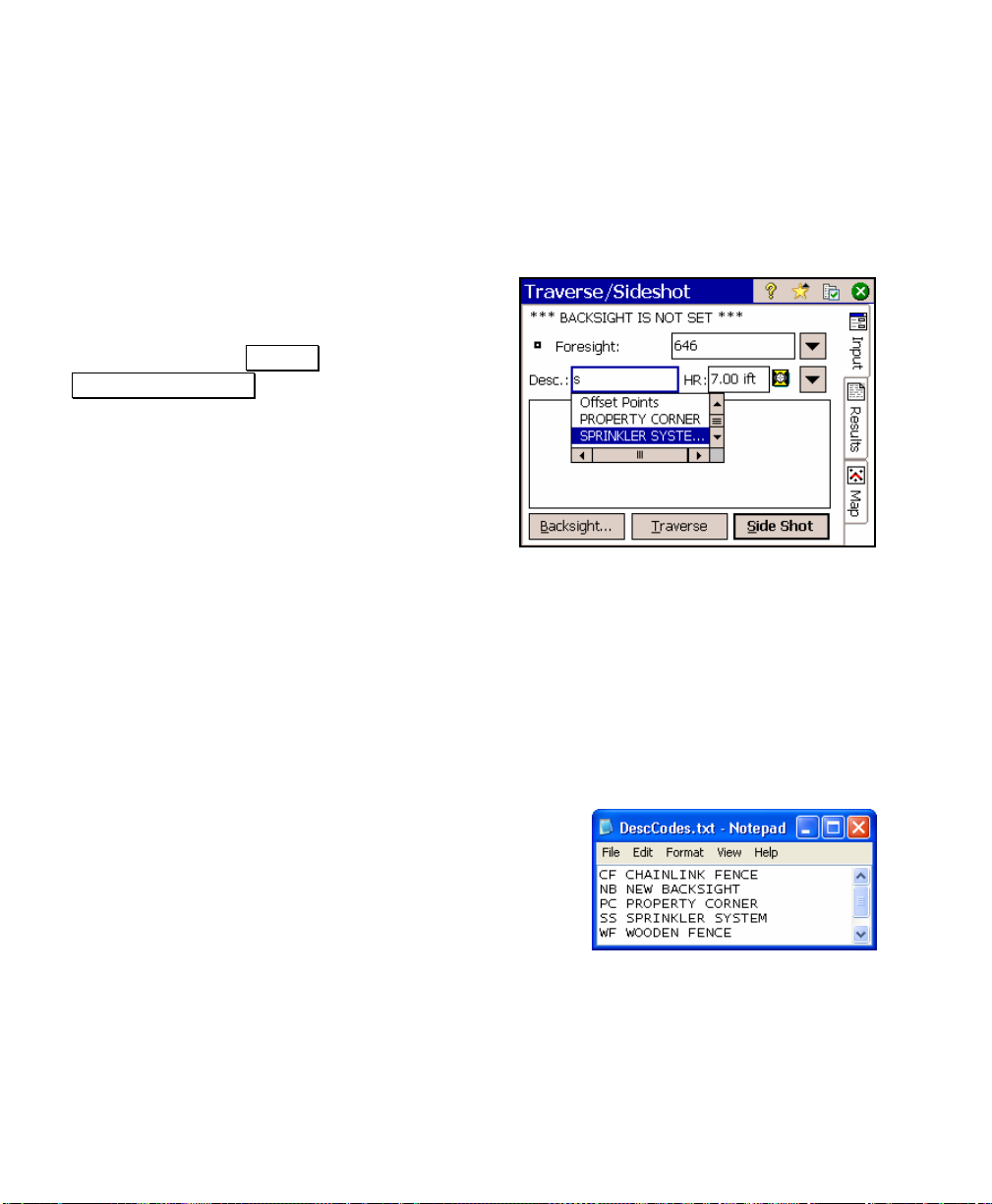

To use a description from a description file,

simply start typing that description in any

Description field. (You can experiment with

descriptions in the .Survey ,

Traverse / Sideshot screen.) Once you start

typing a description, a dropdown list will

appear displaying all of the descriptions in the

descriptor file along with all the descriptors

that have been used in the current job in

alphabetical order. If the first letter(s) that

you typed match the first letters of a

description in the descriptor file, that

description will automatically be selected in the dropdown list. Once

it is selected, you can have that description replace what you have

typed by pressing [Enter] on the keypad. You can also use the arrow

keys to scroll through the dropdown list to make an alternate

selection.

Description Files with Codes

A description file that uses codes is similar to those

without codes, except a code precedes each description

in the file. A sample description file with codes is

shown here.

The following rules apply to description files that use

codes:

• Each line in a description file begins with a code, followed by

a single space, and then the description.

• A description code can consist of up to seven characters with

no spaces.

34

Page 45

Getting Started

• Description codes are case sensitive.

• The description is limited to 16 characters.

• Descriptions can include any character included on a

keyboard.

To use a description from a description file with codes simply type the

code associated with the desired description in any Description field.

As soon as soon as the cursor moves out of the Description field, the

code is replaced with the corresponding description. For example, if

you typed PC in a description field while using the description file

shown above, PC would be replaced with PROPERTY CORNER once

the cursor was moved to another field.

You can combine a description with any other text , or combine two

descriptions by using an ampersand (&). For example, entering

NB&PC would result in a description of NEW BACKSIGHT

PROPERTY CORNER. This method also works when spaces are

included with an ampersand. For example, entering NB&PC would

have the same result as entering NB & PC.

Opening a Description File

Once a description file is created and stored in the data collector, it is

activated with the following steps:

1. Select .Job , Settings from the Main Menu

2. Select the Files tab and tap the Browse button in the Description

File section of the screen.

3. All of the files with a .txt extension will be displayed. Select the

file that you want to use and tap Open .

4. If the description file contains codes, check the This File Uses

Codes checkbox.

.

35

Page 46

User’s Manual

Feature Codes

As explained above, a description or descriptor codes can be used to

help describe a point prior to storing it, but this can be a limited

solution for describing certain points.

Survey Pro also allows you to describe any object using feature codes.

Feature codes can be used to describe objects quickly and in more

detail than a standard text description, particularly when data is

collected for several points that fit into the same category. For

example, if the locations for all the utility poles in an area were being

collected, a single feature code could be used to separately describe

the condition of each utility pole.

When describing an object using feature codes, a selection is made

from any number of main categories called features. Once a

particular feature is selected, any number of descriptions can be

made from sub-categories to the select ed feature called attributes.

In general, a feature describes what an object is and attributes are

used to describe the details of that object.